Page 1

EDS94ARNExxxx

13279702

Ä.<ö#ä

L-force Drives

Software Manual

9400

E94AxRNxxxx

9400 regenerative power supply module

Parameter setting

L

Page 2

9400 regenerative power supply module | Parameter setting

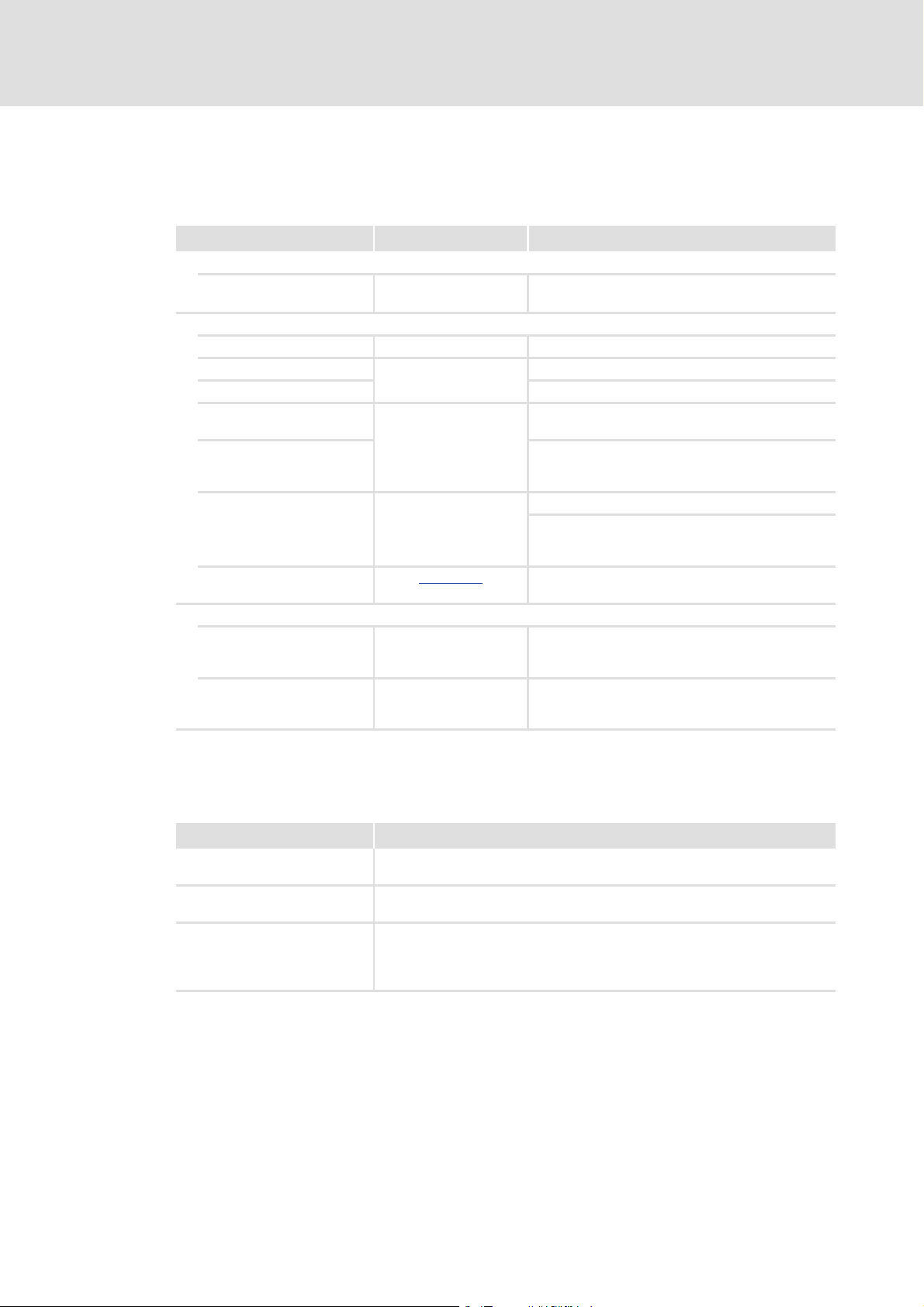

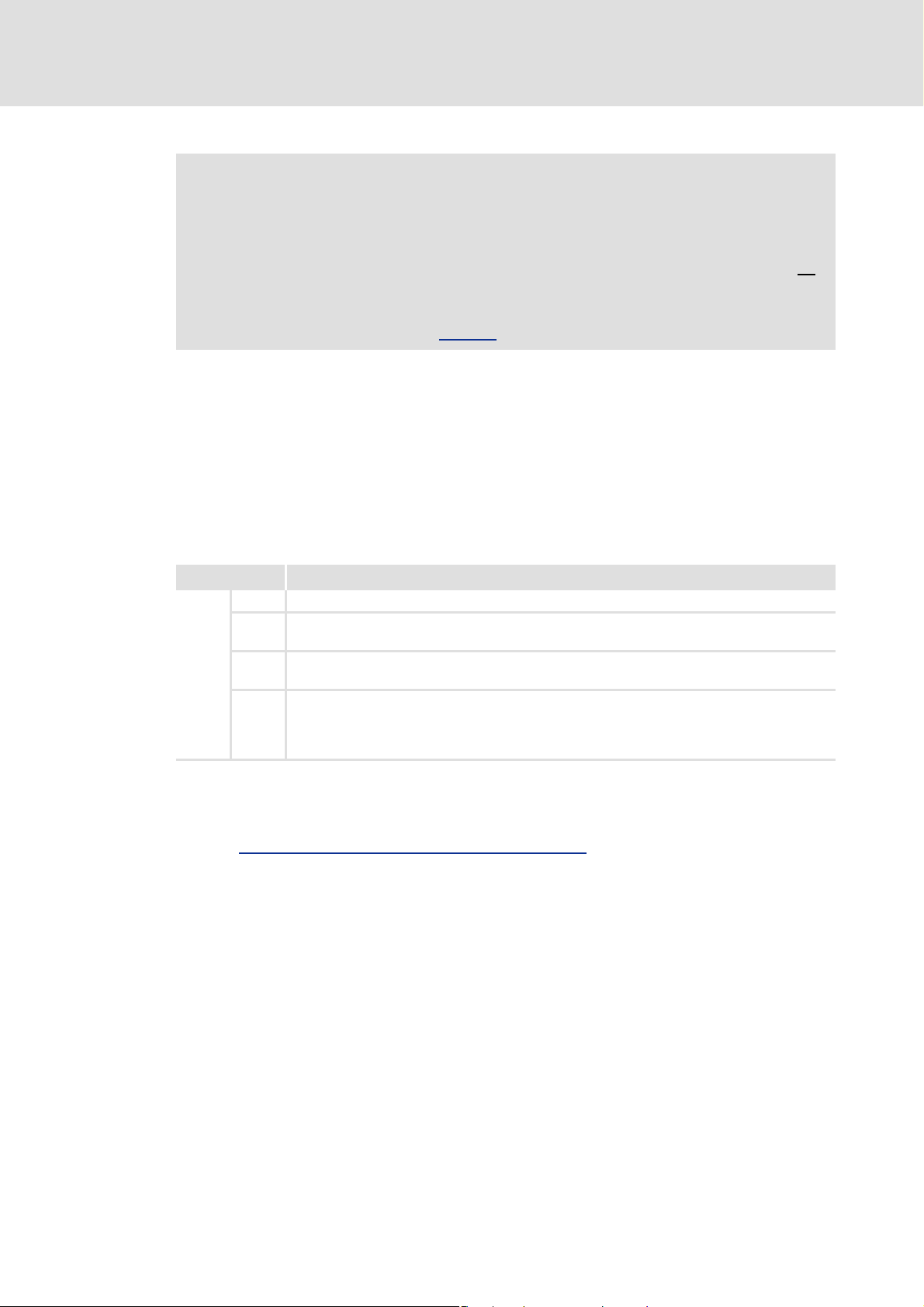

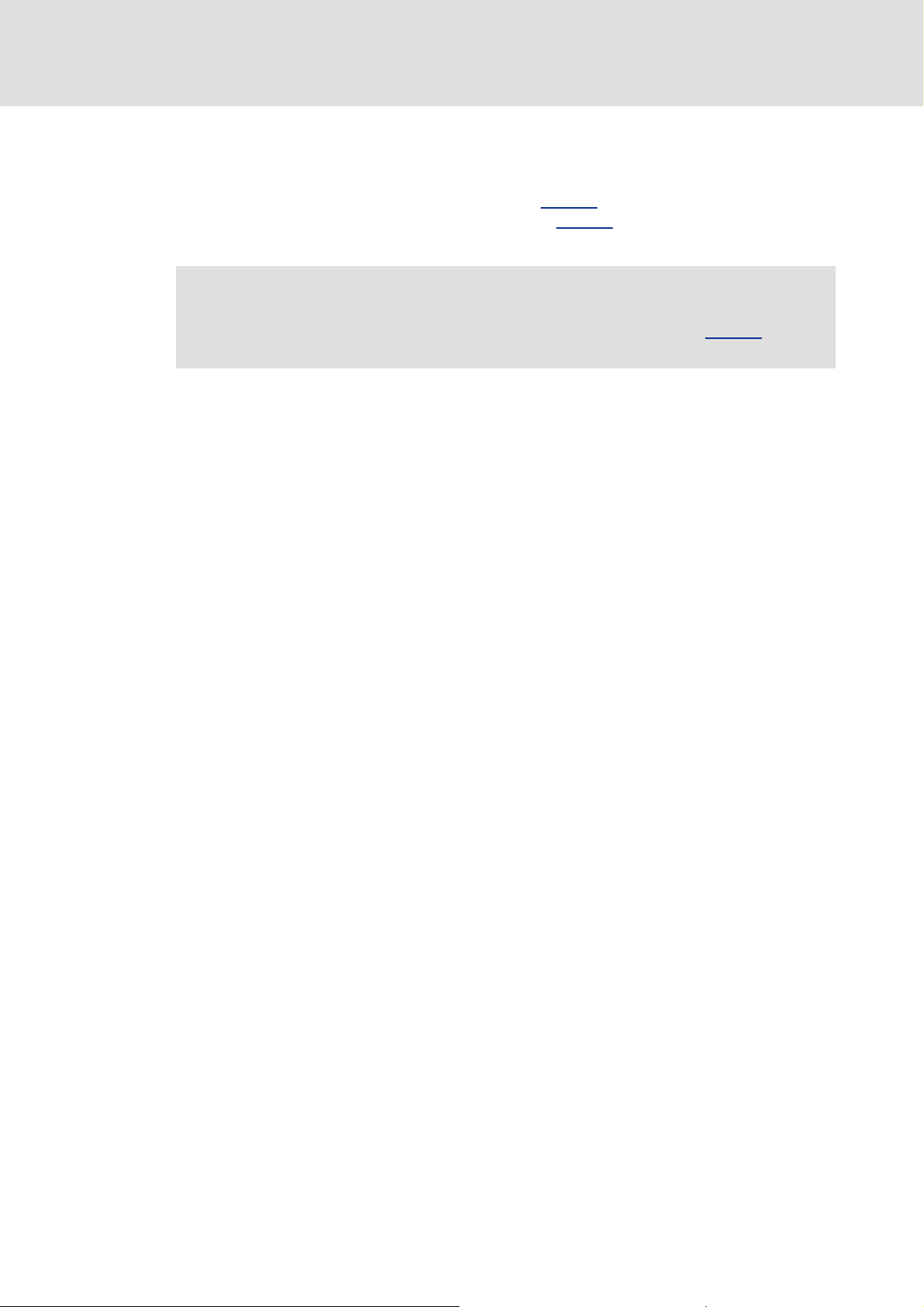

Overview of technical documentation for 9400 Servo Drives

Overview of technical documentation for 9400 Servo Drives

Project planning, selecting & ordering Legend:

9400 Hardware Manual Printed documentation

Catalogue / electronic catalogue (DSC - Drive Solution Catalogue) Online documentation

(PDF/Engineer online help)

Mounting & wiring Abbreviations used:

MA for controller BA Operating Instructions

MA for regenerative power supply module KHB Communication Manual

MA for communication module MA Mounting Instructions

MA for extension module SW Software Manual

MA for safety module

MA for accessories

MA for remote maintenance components

Parameter setting

BA for keypad

SW for Lenze »Engineer« software

SW for controller (9400 HighLine/9400 PLC)

SW for regenerative power supply module This documentation

KHB for communication module

SW for extension module

SW for safety module

SW for Lenze technology application

SW for 9400 function library

Configuring & programming

SW for Lenze »L-force Engineer« software

SW for Lenze »PLC Designer« software

SW for controller (9400 HighLine/9400 PLC)

KHB for communication module

SW for extension module

SW for safety module

SW for Lenze technology application

SW for 9400 function library

Commissioning the drive/device

SW for controller

SW for regenerative power supply module This documentation

Chapter "Commissioning

Chapter "Oscilloscope

Chapter "Diagnostics & fault analysis

Remote Maintenance Manual

Establishing the networking

KHB for communication medium used

" ( 12)

" ( 170)

" ( 187)

2 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 3

9400 regenerative power supply module | Parameter setting

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Conventions used

1.2 Terminology used

1.3 Definition of notes used

2 Commissioning

2.1 Short setup

2.1.1 Example circuit

2.1.2 Commissioning with the keypad

2.1.3 Commissioning with the Engineer

2.1.4 Controlling the regenerative power supply module via terminals

2.2 Device replacement

2.3 Filter replacement

3 Regenerative power supply module application

3.1 Parameterising the brake chopper/brake resistor

3.1.1 Setting the voltage threshold for braking operation

3.1.2 Setting the brake chopper mode

3.1.3 Monitoring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.3.1 Overcurrent protection

3.1.3.2 Ixt utilisation of brake transistor

3.1.3.3 I2t utilisation of brake resistor

3.1.3.4 DC-bus overvoltage

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Signal configuration

3.2.1 Device and line interface

3.2.2 Output ports

3.3 Assignment of the I/O terminals

4 Device interface

4.1 Device commands

4.1.1 Load Lenze setting

4.1.2 Load start parameters

4.1.3 Load route data from the ENP

4.1.4 Activate application

4.1.5 Save selected application

4.1.6 Save start parameters

4.1.7 Delete logbook

4.1.8 Archive log file

4.1.9 Start application

4.1.10 Stop application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

EDS94ARNExxxx EN 2.3 - 06/2014 L 3

Page 4

9400 regenerative power supply module | Parameter setting

Contents

4.1.11 Reset program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.1.12 Delete program

4.1.13 Restart program

4.1.14 Reset runtime measurement

4.1.15 Inhibit controller

4.1.16 Enable controller

4.1.17 Reset error

4.1.18 Reset max DC power mot.

4.1.19 Reset max DC power reg.

4.1.20 Reset max. line power reg.

4.1.21 Reset transmitted energy

4.1.22 Reset regenerated energy

4.1.23 CAN on-board: Reset node

4.1.24 CAN module: Reset node

4.1.25 CAN on-board: Pred.Connect.Set

4.1.26 CAN module: Pred.Connect.Set

4.1.27 CAN on-board: Identify node

4.1.28 CAN module: Identify node

4.1.29 Unbind/bind Ethernet module MXI1

4.1.30 Unbind/bind Ethernet module MXI2

4.1.31 Activate parameter sets 1 ... 4

4.1.32 Archive parameter sets 1 ... 4

4.1.33 Format file system

4.1.34 Restore file system

4.1.35 Prepare firmware update

4.1.36 Restart controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.2 Device states

4.2.1 State "Initialisation active"

4.2.2 State "Device is ready to switch on"

4.2.3 State "Device is switched on"

4.2.4 State "Operation"

4.2.5 State "Warning active"

4.2.6 State "Warning locked active"

4.2.7 State "Trouble active"

4.2.8 State "Fault active"

4.2.9 State "System fault active"

4.3 Automatic restart after power-on/trouble/fault

4.4 Monitoring the device utilisation

4.5 Display of peak power

4.6 Display of output and regenerated energy

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 5

9400 regenerative power supply module | Parameter setting

Contents

5 I/O terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.1 Overview

5.2 Analog inputs

5.2.1 Terminal assignment/electrical data

5.2.2 Parameter setting

5.2.3 Reconfiguring analog input 1 into current input

5.3 Analog outputs

5.3.1 Terminal assignment/electrical data

5.3.2 Parameter setting

5.4 Digital inputs

5.4.1 Terminal assignment/electrical data

5.4.2 Parameter setting

5.5 Digital outputs

5.5.1 Terminal assignment/electrical data

5.5.2 Parameter setting

5.6 "State bus" monitoring function

6 "CAN on board" system bus

6.1 General information

6.1.1 General data and operating conditions

6.1.2 Supported protocols

6.1.3 Communication time

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.2 Possible settings via DIP switches

6.2.1 Setting the node address

6.2.2 Setting the baud rate

6.3 LED status displays for the system bus

6.4 Structure of the CAN data telegram

6.4.1 Identifier

6.4.2 User data

6.5 Communication phases/network management

6.5.1 State transitions

6.5.2 Network management telegram (NMT)

6.5.3 Parameterising a device to act as a CAN master

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . 110

EDS94ARNExxxx EN 2.3 - 06/2014 L 5

Page 6

9400 regenerative power supply module | Parameter setting

Contents

6.6 Process data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.6.1 Process data object identifiers

6.6.2 Transmission type

6.6.3 Masking of TPDOs for event control

6.6.4 Data reception monitoring of RPDOs

6.6.5 Synchronisation of PDOs via sync telegram

6.6.5.1 Parameter setting

6.6.5.2 Effect of C01130 on the sync phase position

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . 118

6.7 Parameter data transfer

6.7.1 Parameter data object identifiers

6.7.2 User data

6.7.2.1 Command

6.7.2.2 Addressing by means of index and subindex

6.7.2.3 Data 1 ... data 4

6.7.2.4 Error messages

6.7.3 Parameter data telegram examples

6.7.3.1 Read parameters

6.7.3.2 Write parameters

6.7.3.3 Read block parameters

6.8 Diagnostics

6.9 Monitoring

6.9.1 Node guarding protocol

6.9.2 Heartbeat protocol

6.9.3 Emergency telegram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

6.9.1.1 Telegram structure

6.9.1.2 Parameter setting

6.9.1.3 Commissioning example

6.9.2.1 Telegram structure

6.9.2.2 Parameter setting

6.9.2.3 Commissioning example

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

. . . . . . . . . . . . . . . . . . . . 124

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

6.10 Implemented CANopen objects

6 L EDS94ARNExxxx EN 2.3 - 06/2014

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Page 7

9400 regenerative power supply module | Parameter setting

Contents

7 Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

7.1 Technical data

7.2 Function description

7.3 User interface

7.3.1 Oscilloscope toolbar

7.3.2 Oscillograph

7.3.3 Vertical settings

7.3.4 Status bar

7.3.5 Trigger/cursor settings

7.3.6 Horizontal settings

7.3.7 Recording settings

7.4 Operation

7.4.1 Selecting the variables to be recorded

7.4.2 Selecting the recording time/sample rate

7.4.3 Selecting the trigger condition

7.4.4 Starting recording

7.4.5 Adjusting the representation

7.4.6 Reading individual measured values

7.5 Data records

7.5.1 Saving/exporting a data record

7.5.2 Loading/importing a data record

7.5.3 Deleting a data record in the project

7.5.4 Overlay function

7.5.5 Copying a data record to the clipboard

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

7.6 Internal variables (oscilloscope signals)

8 Diagnostics & fault analysis

8.1 LED status displays

8.1.1 LED status displays for the device state

8.2 Drive diagnostics with the »Engineer«

8.3 Device diagnostics via keypad/bus system

8.4 Logbook

8.4.1 Functional description

8.4.2 Filtering logbook entries

8.4.3 Reading out logbook entries

8.4.4 Exporting logbook entries to a file

8.5 Monitoring

8.5.1 Setting the error response

8.5.2 Warning thresholds

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

EDS94ARNExxxx EN 2.3 - 06/2014 L 7

Page 8

9400 regenerative power supply module | Parameter setting

Contents

8.6 Error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

8.6.1 Structure of the error number (bit coding)

8.6.1.1 Response

8.6.1.2 Instance ID

8.6.1.3 Module ID

8.6.1.4 Error ID

8.6.1.5 Example for the bit coding of the error number

8.6.2 Resetting an error message

8.6.3 Short overview (A-Z)

8.6.4 Cause & possible remedies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

. . . . . . . . . . . . . . . . . . 201

9 Internal interfaces

9.1 LS_AnalogInput - analog inputs

9.2 LS_AnalogOutput - analog outputs

9.3 LS_DigitalInput - digital inputs

9.4 LS_DigitalOutput - digital outputs

9.5 LS_DriveInterface - device interface

9.6 LS_LineInterface - line interface

9.7 LS_SyncInput - status information for the sync telegram

10 Parameter reference

10.1 Structure of the parameter descriptions

10.1.1 Data type

10.1.2 Parameters with read-only access

10.1.3 Parameters with write access

10.1.4 Parameter attributes

10.1.5 Abbreviations used in parameter & selection texts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

. . . . . . . . . . . . . . . . . . . . . . . . . . 264

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

10.1.3.1 Parameters with setting range

10.1.3.2 Parameters with selection list

10.1.3.3 Parameters with bit-coded setting

10.1.3.4 Parameters with subcodes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

. . . . . . . . . . . . . . . . . . . . . . . . 271

10.2 Parameter list

10.3 Table of attributes

11 Index

8 L EDS94ARNExxxx EN 2.3 - 06/2014

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Your opinion is important to us

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

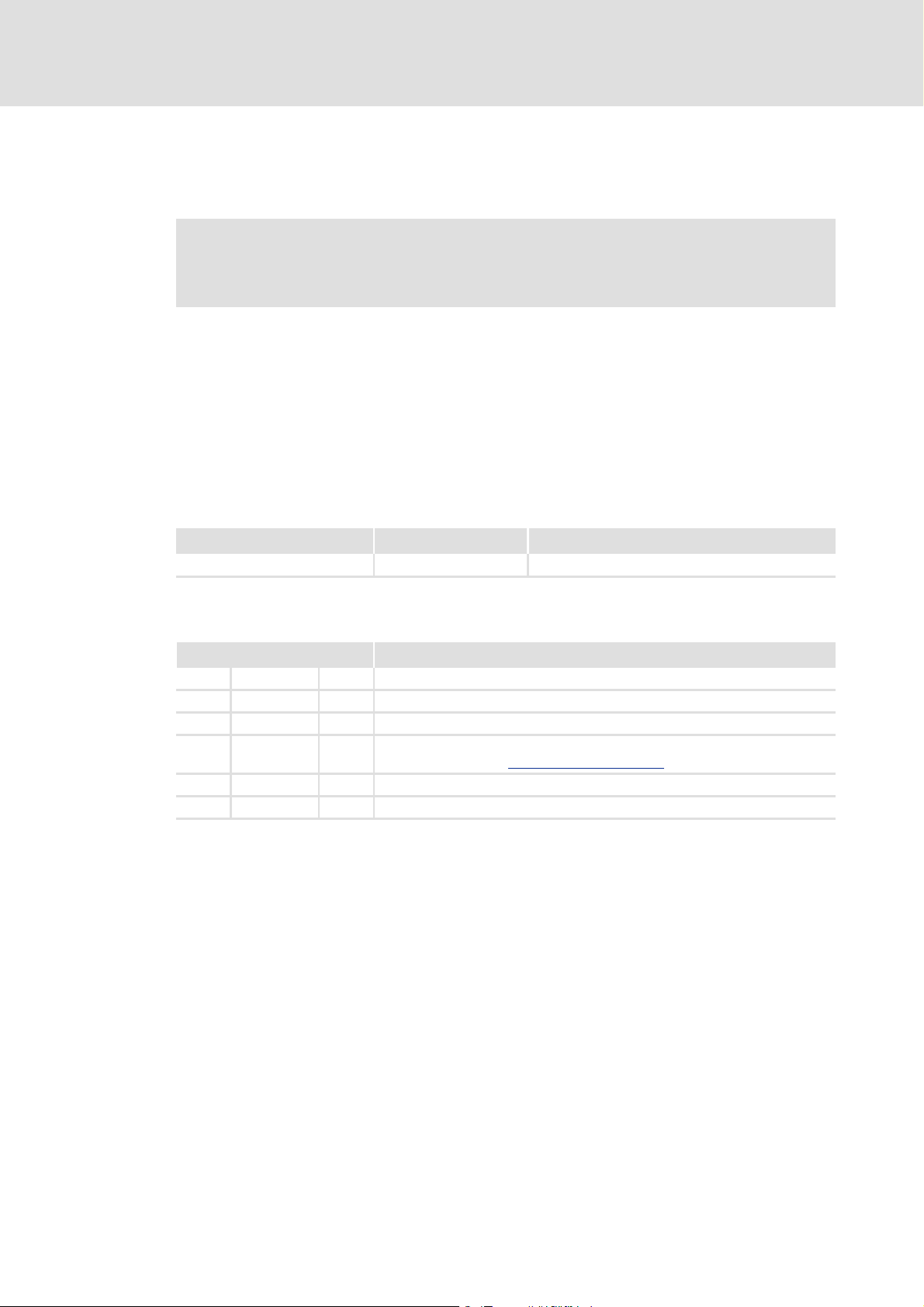

Page 9

9400 regenerative power supply module | Parameter setting

1 About this documentation

This documentation contains information about the regenerative power supply module.

Please read the Mounting Instructions supplied with the regenerative power

supply module before you start working!

The Mounting Instructions contain safety information which must be observed!

Target group

This documentation is directed at all persons who parameterise and diagnose the

regenerative power supply module by means of the L-force »Engineer« software and the

keypad.

Information on the validity

The information provided in this documentation is valid for the following standard

devices:

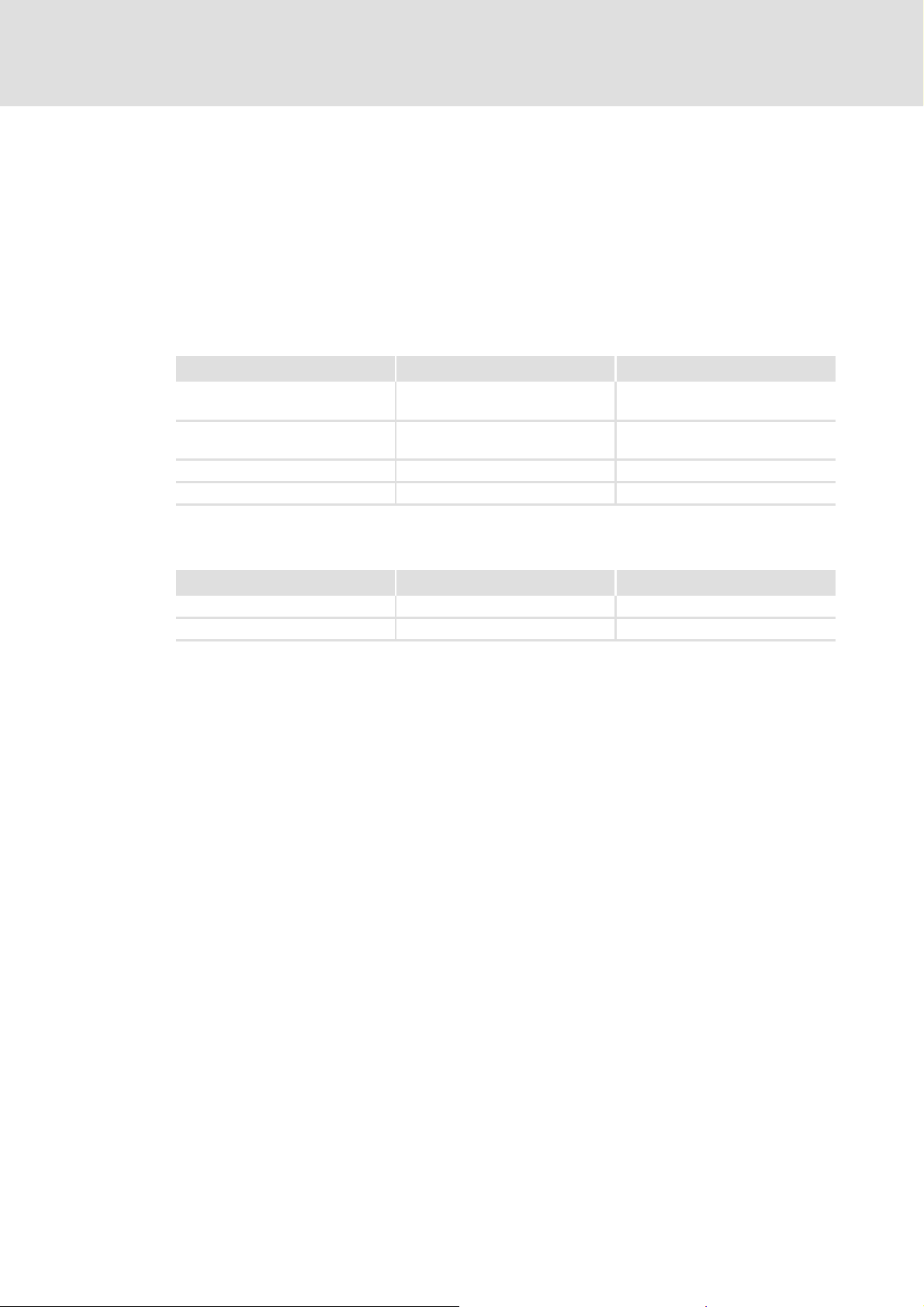

About this documentation

Product series Type designation From software version

Servo Drives 9400 E94AxRNxxxx 1.0

Document history

Version Description

2.3 06/2014 TD05 Error corrections

2.2 03/2010 TD05 Error corrections

2.1 01/2009 TD05 Error corrections

2.0 11/2008 TD05 • Extended by new functions for regenerative power supply module V2

•New main chapter: "CAN on board" system bus

1.1 07/2008 TD05 Error corrections

1.0 04/2008 TD05 First edition

EDS94ARNExxxx EN 2.3 - 06/2014 L 9

Page 10

9400 regenerative power supply module | Parameter setting

About this documentation

Conventions used

1.1 Conventions used

This documentation uses the following conventions to distinguish between different types

of information:

Type of information Writing Examples/notes

Numbers

Decimal separator Point Generally the decimal point is used.

For example: 1234.56

Text

Program name » « The Lenze PC software »Engineer«...

Window Italics The Message window... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element Bold The OK button... / The Copy command... / The

Sequence of menu

commands

Shortcut <Bold> Use <F1> to open the online Help.

Hyperlink Underlined

Symbols

Page reference ( 10) Optically highlighted reference to another page. Is

Step-by-step instructions

Properties tab...

If the execution of a function requires several

commands, the individual commands are separated

by an arrow: Select File

If a command requires a combination of keys, a "+" is

placed between the key symbols:

Use <Shift>+<ESC> to...

A hyperlink is an optically highlighted reference

which is activated with a mouse click.

activated via mouse-click in this online

documentation.

Step-by-step instructions are indicated by a

pictograph.

Open to...

1.2 Terminology used

Term Meaning

»Engineer« Lenze software which supports you throughout the whole machine life cycle -

Code "Container" for one or several parameters used for parameter setting or

Subcode If a code contains several parameters, the individual parameters are stored

from planning to maintenance.

monitoring of the regenerative power supply module.

under "subcodes".

This documentation uses a slash "/" as a separator between code and subcode

(e.g. "C00118/3").

10 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 11

9400 regenerative power supply module | Parameter setting

1.3 Definition of notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

About this documentation

Definition of notes used

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to another documentation

EDS94ARNExxxx EN 2.3 - 06/2014 L 11

Page 12

9400 regenerative power supply module | Parameter setting

Commissioning

2 Commissioning

This chapter describes three different commissioning scenarios:

A. Short setup

– Target: Adapting the regenerative power supply module to the electromechanics

and the control system.

B. Device replacement

– Target: Replacing a regenerative power supply module which has failed in a running

system by a replacement device using the "old" memory module.

C. Filter replacement

– Target: Replacing a filter which has failed in a running system.

( 13)

( 20)

( 20)

12 L EDS94ARNExxxx EN 2.3 - 06/2014

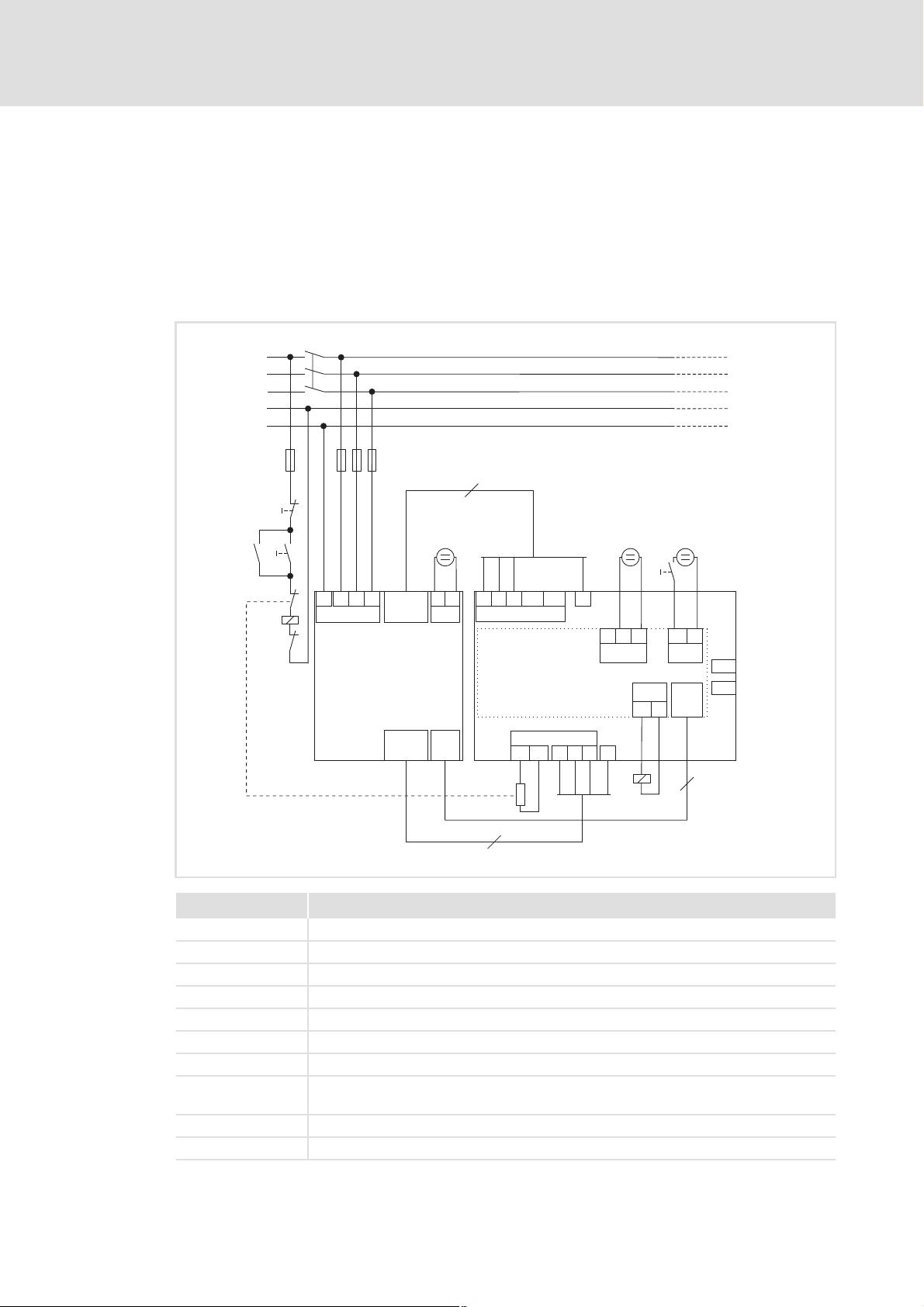

Page 13

9400 regenerative power supply module | Parameter setting

L3

N

PE

L1

L2

F1...F3

F4

K1

K1

K2

K1

L1 L2

L3

E94ARNE0xx4

X111

-UG

O

I

RFR

+UG

Rb2

Rb1

R

B

R

B

L1 L2

L3

X112

X5

GI

RFR

J

. . .

+

-

X8

+

+

+

E94AZPP0364

X2

GE24E

+

-

SB

+

-

GE

24E

X323

X324

15

4

4

E94AZMR0xx4xDB

L1 L2

L3

X109

X110

L1.2

L2.2

L3.2

L1.1

L2.1

L3.1

X321

X322

X320

X4

GODO2

K2

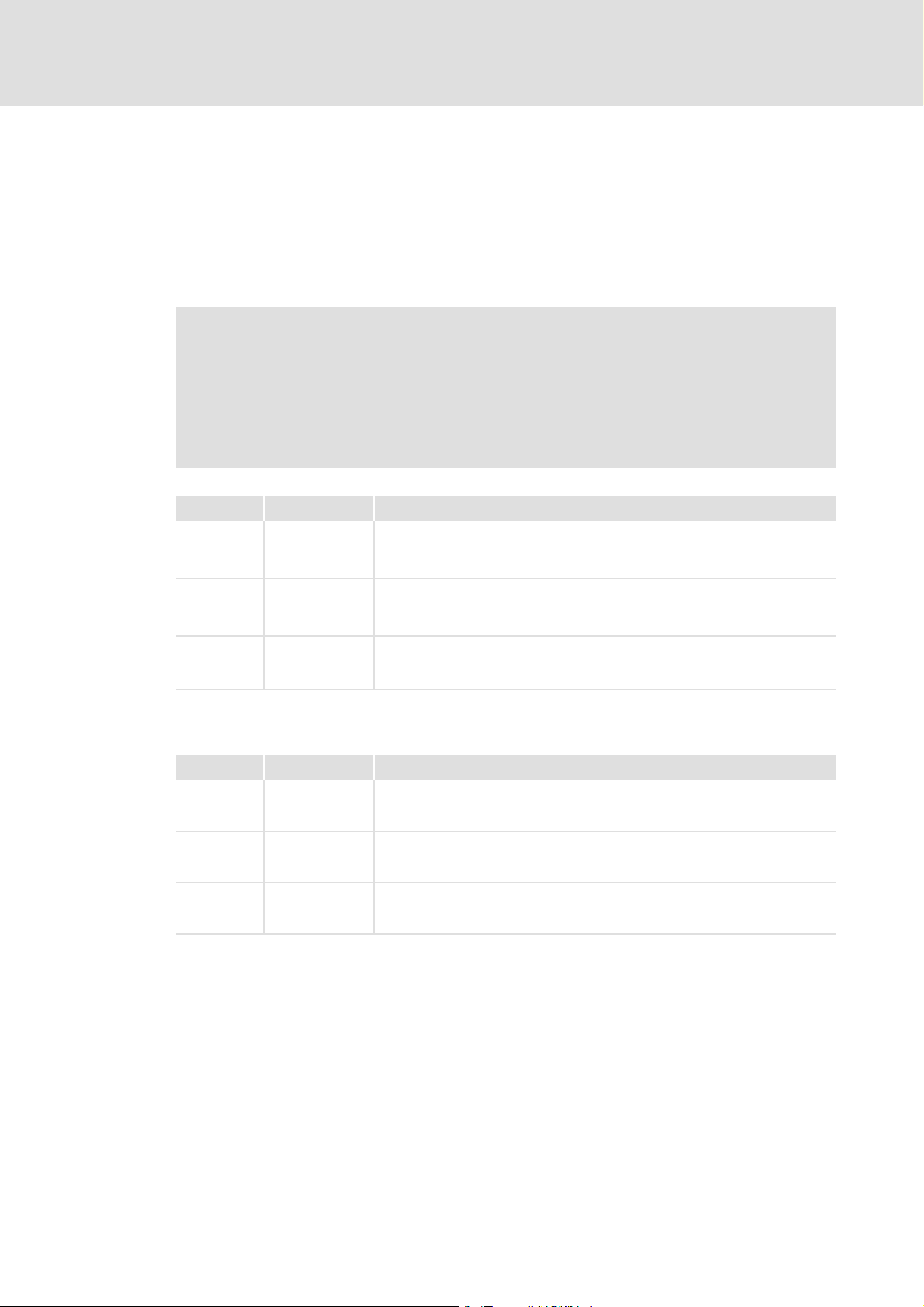

2.1 Short setup

The short setup described in this chapter serves to adapt the regenerative power supply

module to the electromechanics and the control system. The short setup can be carried out

with the keypad or the Lenze PC software »Engineer«.

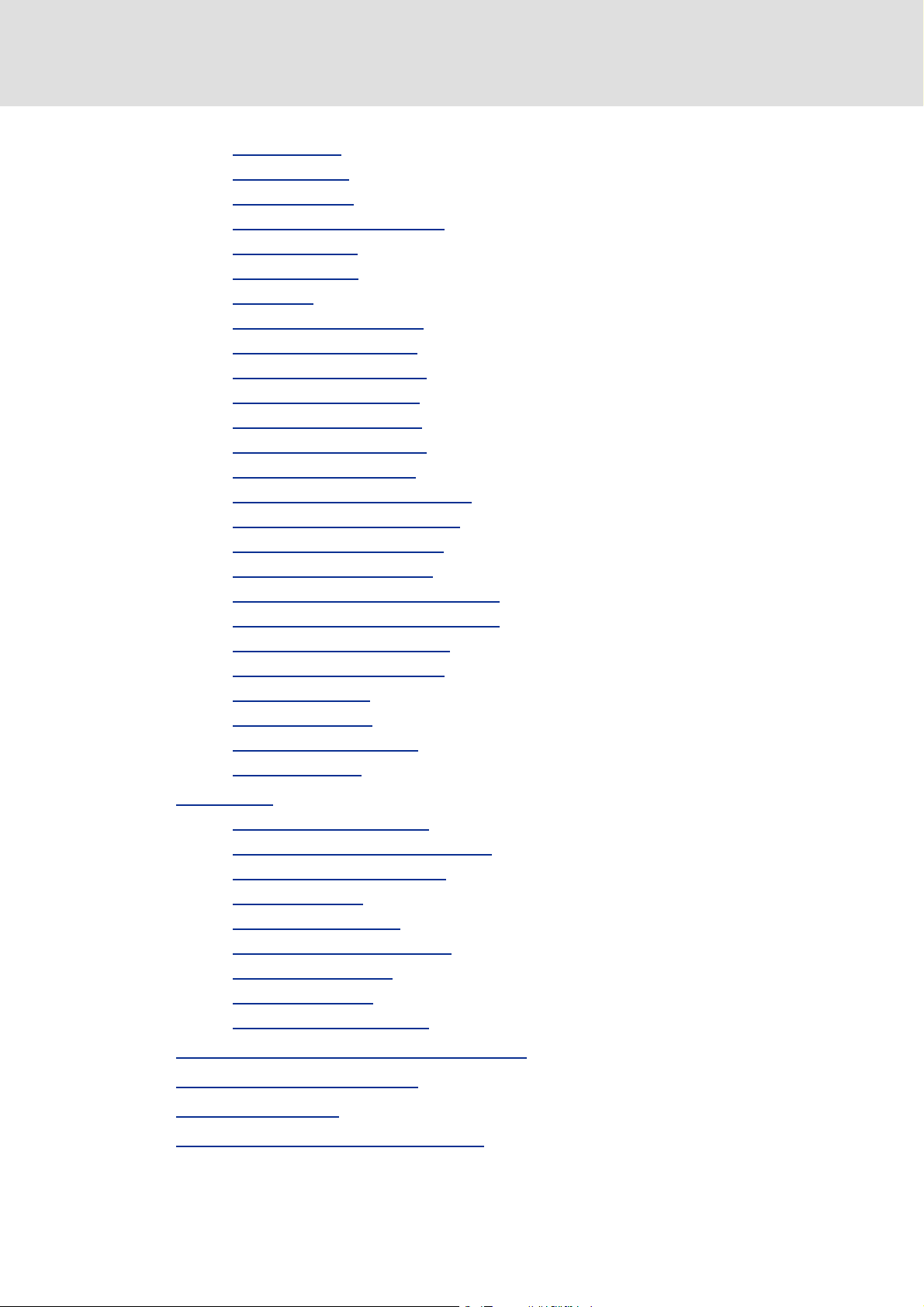

2.1.1 Example circuit

Commissioning

Short setup

94PSPVR01

Name Component

E94ARNE0xx4 Regenerative power supply module

E94AZPP0364 Installation backplane of regenerative power supply module

E94AZMR0... Mains filter

F1 ... F4 Fuses

RFR Controller enable (only for regenerative feedback)

K1 Mains contactor

RB Brake resistor

24-V voltage source for the control electronics

24-V voltage source for the digital inputs in accordance with IEC 61131-2

From version 02.00: Overtemperature disconnection (DO2 load: max. 50 mA)

EDS94ARNExxxx EN 2.3 - 06/2014 L 13

(safely separated power supply unit (SELV/PELV), in accordance with IEC 61131-2)

Page 14

9400 regenerative power supply module | Parameter setting

Commissioning

Short setup

2.1.2 Commissioning with the keypad

1. Switch on 24-V supply of the regenerative power supply module.

– With the first switch-on of the regenerative power supply module, the filter data are

automatically read out of the electronic filter nameplate (ENP) and temporarily

saved in the regenerative power supply module.

2. If the mains voltage is not 400/415 V, adapt the Lenze setting in C00173

– Note: A change of the setting in C00173

utilisation! In the chapter "Rated data" of the Hardware Manual, the device types

and their permissible device utilisation at different mains voltages and switching

frequencies are specified.

3. Carry out optional parameter setting:

– Parameterising the brake chopper/brake resistor

– Signal configuration

4. Save the parameter set (C00002

– By saving the parameter set, certain data such as the filter data are permanently

available in the regenerative power supply module and do not need to be read again

from the electronic filter nameplate at the next switch-on. This shortens the

initialisation time correspondingly.

5. Switch on mains voltage the DC bus is charged.

6. Deactivate controller inhibit via controller enable terminal (RFR) regenerative

feedback is enabled.

7. Controlling the regenerative power supply module via terminals

( 30)

= "11: Save start parameters").

also has an impact on the permissible device

( 22)

. ( 19)

accordingly.

14 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 15

9400 regenerative power supply module | Parameter setting

2.1.3 Commissioning with the Engineer

For commissioning with the Lenze PC software »Engineer« you need:

A PC with the following system requirements:

– Processor with at least 1.4 GHz

– At least 512 MB RAM and 650 MB of free hard disk space

– Operating system Microsoft® Windows® 2000 (service pack 2 or higher) or

Windows® XP

A connection to the regenerative power supply module, e. g. via the diagnostic adapter

offered by Lenze.

Commissioning

Short setup

Note!

Please observe the documentation for the diagnostic adapter!

For communication with the regenerative power supply module, at least the

control electronics of the regenerative power supply module must be supplied

with 24-V low voltage via the connector X2; detailed information on this can be

found in the Mounting Instructions for the regenerative power supply module.

Stop!

If you alter parameters in the »Engineer« while an online connection to the

regenerative power supply module is established, the changes are directly

accepted in the regenerative power supply module!

Tip!

An online connection can also be established via optional interfaces which are

provided by corresponding communication modules in the module receptacles

MXI1/MXI2 of the regenerative power supply module.

Detailed information about the different interfaces can be found in the

corresponding Communication Manuals.

EDS94ARNExxxx EN 2.3 - 06/2014 L 15

Page 16

9400 regenerative power supply module | Parameter setting

Commissioning

Short setup

How to carry out the commissioning with the »Engineer«:

1. Start the »Engineer«.

2. Select the procedure in the Start-up wizard.

• For instance, select the option "Select component from catalog".

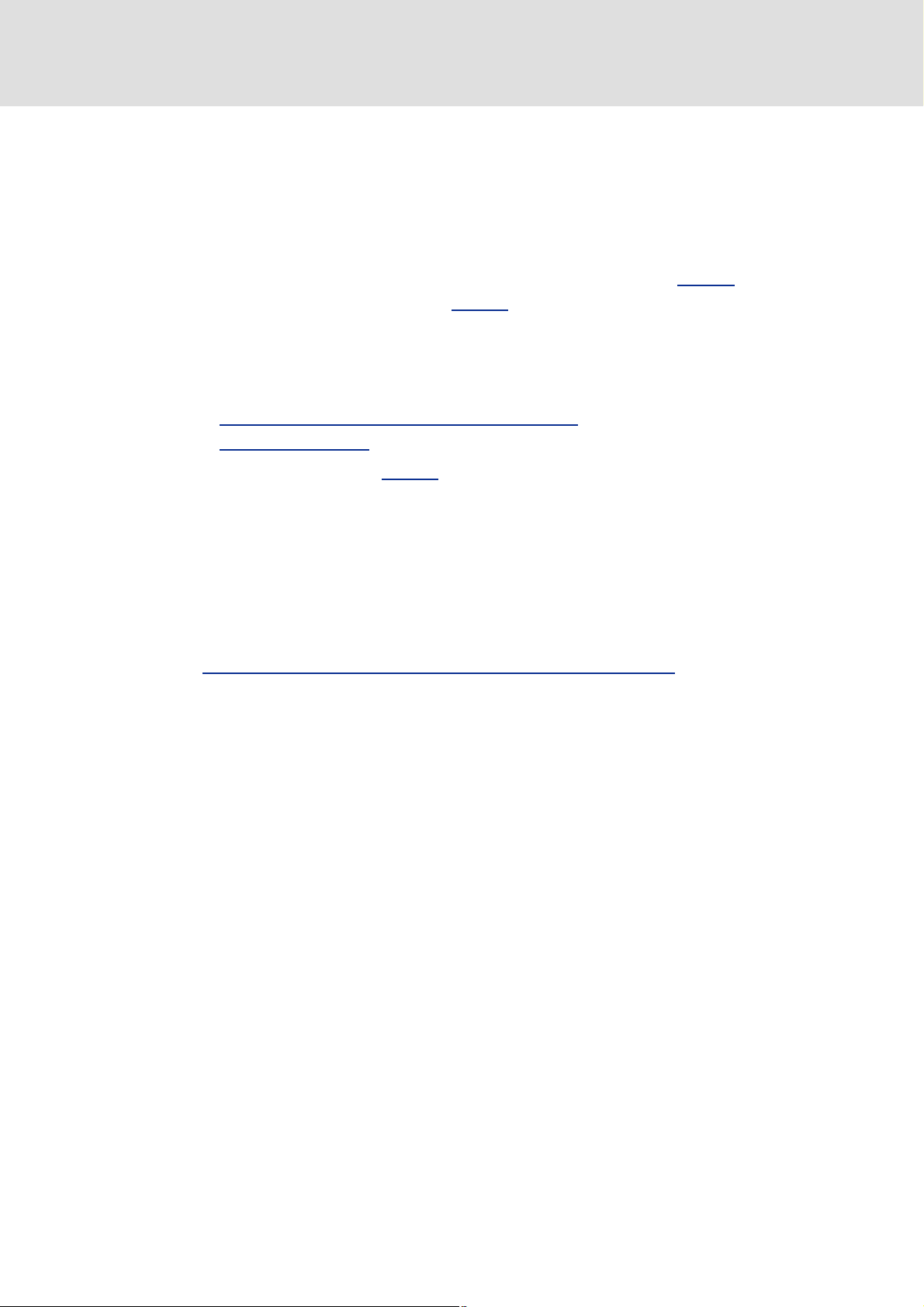

3. Add the corresponding components from the catalog to the project:

• Regenerative power supply module

• Available device modules

• Regenerative power supply module application

Project view example in the »Engineer«:

4. Select the regenerative power supply module in the Project view.

5. Change to the Application parameters tab in the Workspace.

6. If the mains voltage is not 400/415 V, adapt the Lenze setting accordingly in the

Mains voltage list field.

Note: A change of the setting in C00173

device utilisation! In the chapter "Rated data" of the Hardware Manual, the device

types and their permissible device utilisation at different mains voltages and

switching frequencies are specified.

16 L EDS94ARNExxxx EN 2.3 - 06/2014

also has an impact on the permissible

Page 17

9400 regenerative power supply module | Parameter setting

Commissioning

Short setup

7. Carry out optional parameter setting:

• Parameterising the brake chopper/brake resistor

• Signal configuration

• Establish network/communication.

8. Switch on 24-V supply of the regenerative power supply module.

• With the first switch-on of the regenerative power supply module, the filter

data are automatically read out of the electronic filter nameplate (ENP) and

temporarily saved in the regenerative power supply module.

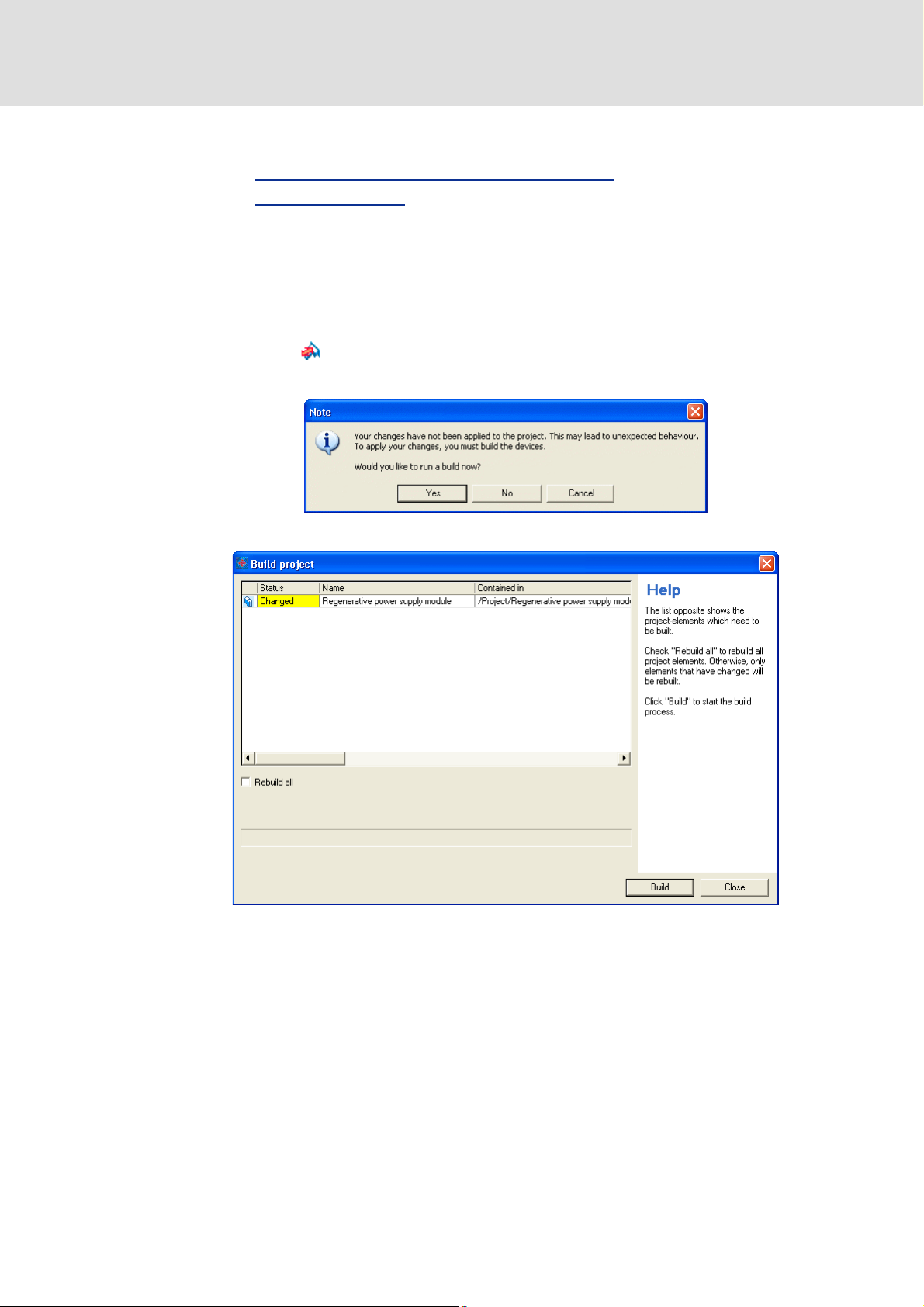

9. Click the icon.

10. Confirm the following note with Yes to accept the changes on the project:

( 30)

( 22)

The Build project dialog box is displayed:

11. Click Build to build the project.

• After the project has been built successfully, a corresponding note is displayed.

EDS94ARNExxxx EN 2.3 - 06/2014 L 17

Page 18

9400 regenerative power supply module | Parameter setting

Commissioning

Short setup

12. Confirm the note that the project has been built successfully with OK.

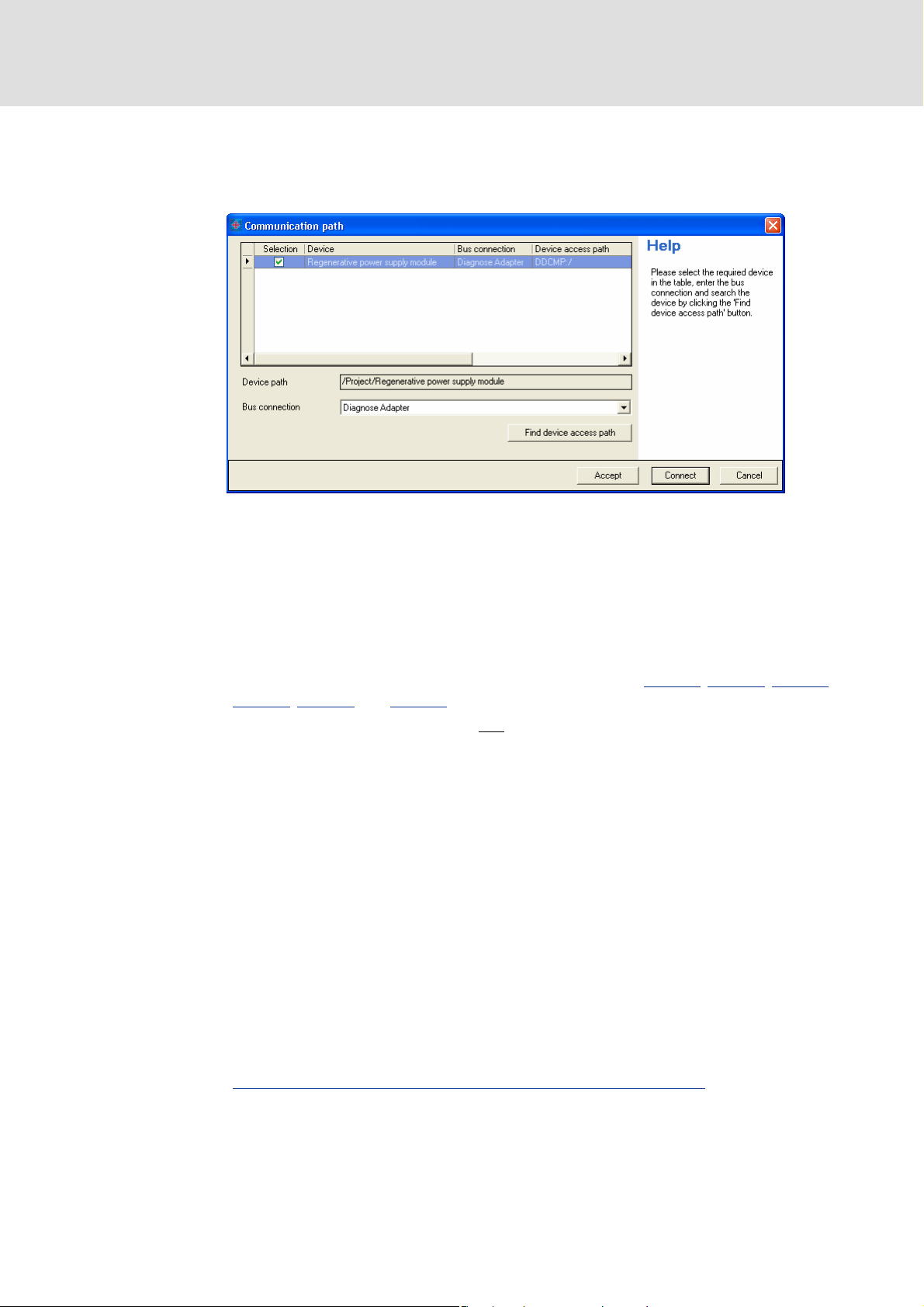

If no communication path has been configured for the regenerative power supply

module yet, the Communication path dialog box is displayed:

13. Set the bus connection (e. g. "Diagnostic adapter") to the regenerative power

supply module in the Communication path dialog box.

14. Click Connect to establish the online connection to the regenerative power supply

module.

• After the connection has been established successfully, the Transfer to device

dialog box is displayed.

Note: The following parameters are set automatically in the regenerative power

supply module via the electronic filter nameplate (ENP): C00070

C00076

• »Engineer« versions ≥ V2.9 do not

• If an older »Engineer« version is used, these parameters have to be saved prior

15. Click Start in the Transfer to device dialog box.

16. Confirm the query on whether the device is to be inhibited and the application is

to be stopped with Yes.

• Then the transmission is started.

17. After the transmission has been carried out successfully, confirm the query on

whether the application is to be started with Yes.

, C00084 and C00085.

overwrite these parameters during a

parameter download.

to a parameter download and then reset manually to the saved values.

, C00071, C00075,

18. Also confirm the query on whether the device is to be enabled with Yes.

19. Switch on mains voltage the DC bus is charged.

20. Deactivate controller inhibit via controller enable terminal (RFR) regenerative

feedback is enabled.

21. Controlling the regenerative power supply module via terminals

18 L EDS94ARNExxxx EN 2.3 - 06/2014

.

Page 19

9400 regenerative power supply module | Parameter setting

Note!

The regenerative power supply module still remains inhibited via the controller

enable terminal (RFR) if this terminal is set to LOW level.

Commissioning

Short setup

Please note that the regenerative power supply module will only be enabled if all

sources for controller inhibit are reset!

• The sources or trip elements that are active for controller inhibit are displayed

in a bit-coded manner in C00158

2.1.4 Controlling the regenerative power supply module via terminals

If the regenerative power supply module is enabled, the application can be controlled via

the digital inputs and/or MotionBus (if it is integrated in a network).

Terminal assignment of digital inputs

Terminal Assignment (Lenze setting)

X5 RFR Controller enable

DI1 Inhibit regenerative feedback

• Function also possible via bit 01 of control word 1.

DI2 Activate brake chopper

• Function also possible via bit 02 of control word 1.

DI3 Reset (acknowledge) error

• A pending error message can be reset (acknowledged) by a LOW-HIGH edge if the cause of

the error message has been eliminated.

• Function also possible via bit 07 of control word 1.

.

Tip!

Detailed information on device applications can be found in the chapter

"Regenerative power supply module application

". ( 21)

EDS94ARNExxxx EN 2.3 - 06/2014 L 19

Page 20

9400 regenerative power supply module | Parameter setting

Commissioning

Device replacement

2.2 Device replacement

Scenario: The regenerative power supply module in a running system has failed.

Note!

For the procedure described below we assume that the memory module and

possibly available extension modules in the regenerative power supply module

and the filter are not affected by the failure and all parameters have been stored

with mains failure protection.

Worksteps

Replacement of the regenerative power supply module:

1. Replace regenerative power supply module.

See Mounting Instructions for the regenerative power supply module!

2. Insert memory module of the regenerative power supply module that has failed into the replacement

device.

3. If further extension modules are plugged into the failed regenerative power supply module, they must

also be inserted into the replacement device.

Further steps are not required since all required data are stored on the memory module.

2.3 Filter replacement

Scenario: The filter in a running system has failed.

Note!

In the procedure described below we assume that the regenerative power

supply module is not affected by the failure.

Worksteps

Replacement of the filter:

1. Replace filter.

For a filter with an electronic nameplate (ENP):

2. Restart regenerative power supply module with connected filter to read out the filter data from the

3. Execute device command C00002

For a filter without an electronic nameplate (ENP):

See Mounting Instructions for the regenerative power supply module!

electronic nameplate.

• Restart the device either by switching the voltage supply off and on again, or via the device

command C00002

Note:

The filter is operated with the filter data from the memory module.

= "11000: Restart regenerative power supply module".

= "11: Save start parameters".

20 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 21

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

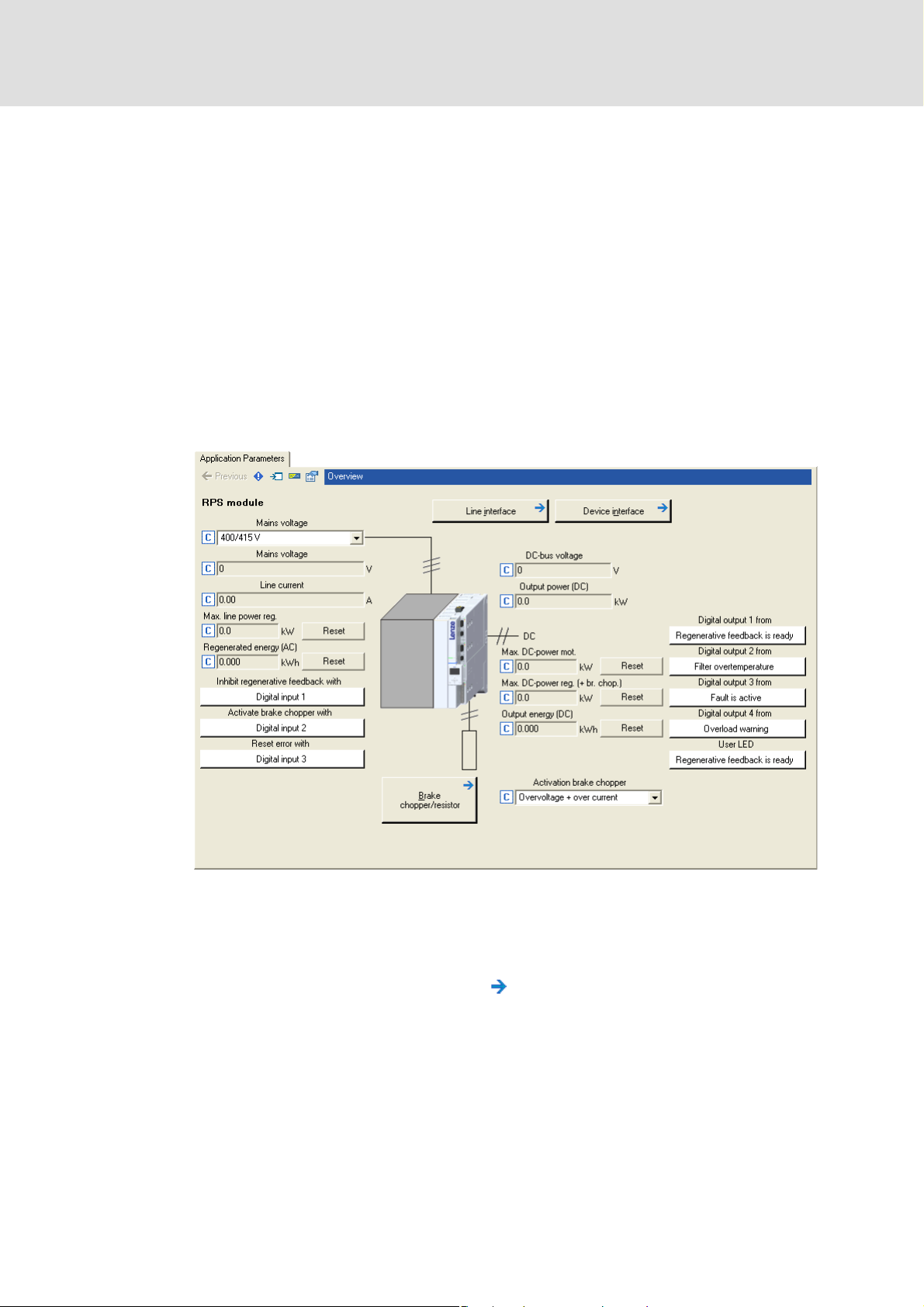

3 Regenerative power supply module application

This chapter provides you with information on the "Regenerative power supply module"

application by which the regenerative power supply module can be controlled via digital

inputs and input ports. Status information is provided to other applications via digital

outputs and output ports.

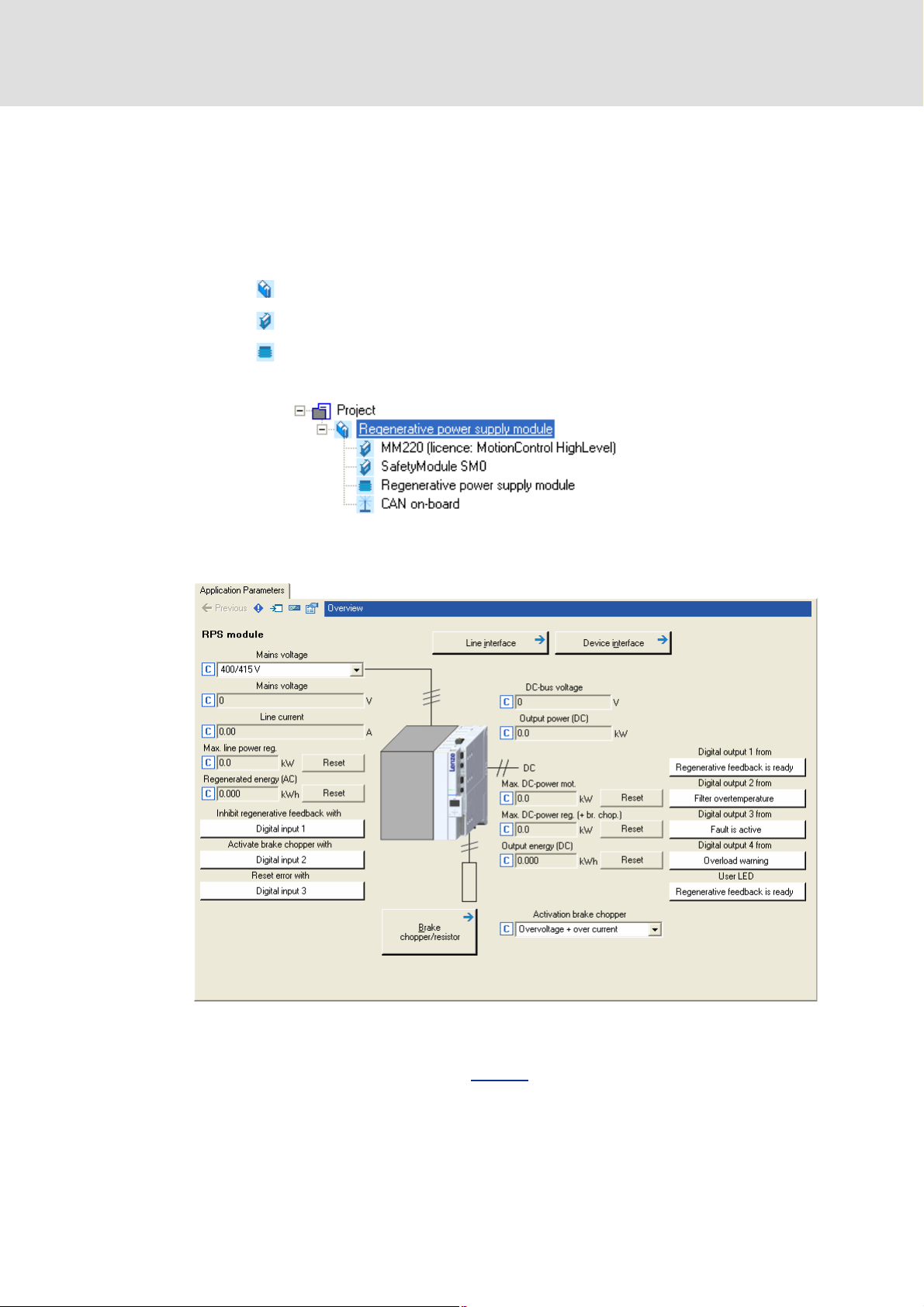

How to get to the parameterisation dialog of the application:

1. Select the regenerative power supply module in the Project view of the »Engineer«.

2. Change to the Application parameters tab in the Workspace.

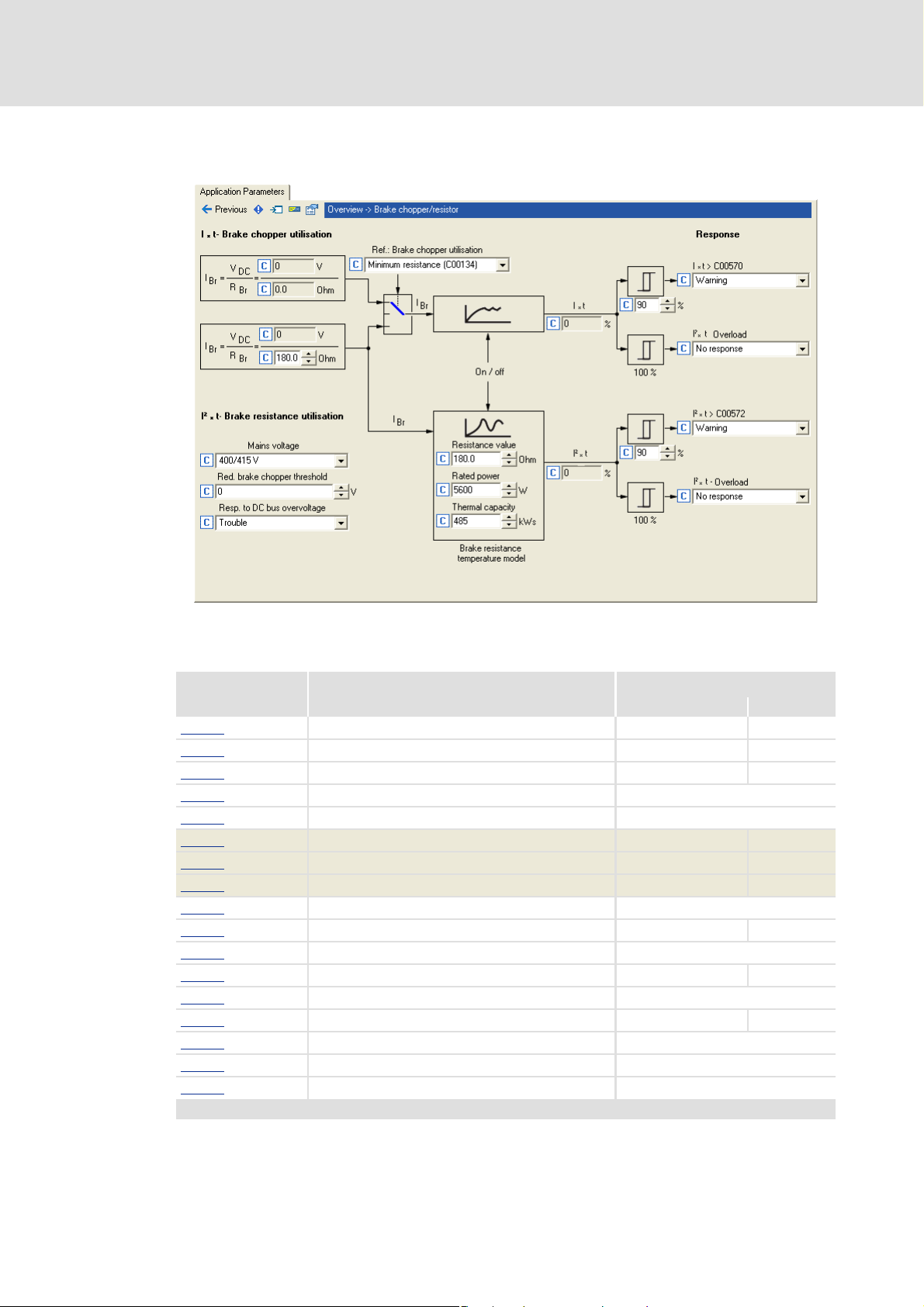

Parameterisation dialog in the »Engineer«

The white buttons show the assignment of the control inputs and status outputs of the

application.

– The assignment is defined by the "Regenerative power supply module" application

and can, if required, be reconfigured by clicking the corresponding button.

If you click the button marked with the icon, you get to the parameterisation dialog

for the brake chopper/brake resistor, which is one level beneath.

EDS94ARNExxxx EN 2.3 - 06/2014 L 21

Page 22

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

3.1 Parameterising the brake chopper/brake resistor

The regenerative power supply module is equipped with an integrated brake transistor.

The required brake resistor has to be connected externally (see mounting instructions/

hardware manual).

The rated values for the brake transistor are listed in the Hardware Manual, chapter

"Rated data".

Stop!

If the connected brake resistor has a lower resistance than the parameterised

brake resistor, the brake transistor may be damaged!

The brake resistor can be thermally overloaded. Carry out protective measures

suitable for the system, e.g.:

• Parameterisation of an error response in C00574

parameterised error message in the application or machine control. I2t

utilisation of brake resistor ( 27)

• External wiring using the temperature contact on the brake resistor (e.g.

interruption of the supply via mains contactor and activation of the

mechanical brakes).

and evaluation of the

22 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 23

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

The brake chopper/brake resistor can be parameterised in the »Engineer» on the

Application parameters tab, dialog level Overview Brake chopper/resistor:

Short overview: Parameters for braking operation

Parameter Information Lenze setting

Value Unit

C00129 Brake resistor value 180.0 Ohm

C00130

C00131

C00132

C00133

C00134 Minimum brake resistance - Ohm

C00137 Brake transistor utilisation - %

C00138 Brake resistor utilisation - %

C00173

C00181

C00569

C00570

C00571

C00572

C00573

C00574

C00600

Highlighted in grey = display parameter

Rated power of brake resistor 5600 W

Therm. capacity brake resistor 485 kWs

Activation brake chopper At overvoltage and overcurrent

Ref: Brake chopper utilisation Minimum resistance (C00134)

Mains voltage 400/415 V

Red. brake chopper threshold 0 V

Resp. brake trans. ixt > C00570 Warning

Warning thres. brake transistor 90 %

Resp. brake resist. i2t > C00572 Warning

Warning thres. brake resistor 90 %

Resp. to overload brake trans. No response

Resp. to overtemp. brake resist. No response

Resp. to DC bus overvoltage Trouble

EDS94ARNExxxx EN 2.3 - 06/2014 L 23

Page 24

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

3.1.1 Setting the voltage threshold for braking operation

The voltage threshold for braking operation is set via C00173

(reduced brake chopper threshold). When the brake chopper threshold is exceeded in the

DC bus, the brake chopper is switched on.

Mains voltage selected in C00173 Effective brake chopper threshold

230 V 390 V - value in C00181

400/415 V 725 V - value in C00181

460/480 V 765 V - value in C00181

500 V 790 V - value in C00181

3.1.2 Setting the brake chopper mode

For software versions below V2.0, the following applies:

The regenerative power supply module only feeds back to the mains and activates the

brake chopper if the inverter-side current reaches the maximum device current. If the

current is below the maximum device current and the DC-bus voltage is below the brake

chopper threshold, the brake chopper is not activated.

From software version V2.0 onwards, the following applies:

C00132

can be used to set the conditions for brake chopper activation:

(mains voltage) and C00181

(0 ... 100 V)

(0 ... 100 V)

(0 ... 100 V)

(0 ... 100 V)

Only at overvoltage:

The brake chopper is only activated if the DC-bus voltage has reached the brake

chopper threshold. This setting corresponds to the behaviour of the 9400 controller.

At overvoltage and overcurrent (Lenze setting):

This setting corresponds to the behaviour of regenerative power supply modules with

software versions below V2.0.

At overvoltage and overcurrent and overload:

With this setting, the brake chopper is used for energy consumption if a device

utilisation of 90 % is reached during feedback operation.

– The "normal" voltage thresholds for braking operation still apply. Setting the

voltage threshold for braking operation ( 24)

– To protect the brake chopper against damage, monitoring of the Ixt utilisation is still

active. Ixt utilisation of brake transistor

( 26)

24 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 25

9400 regenerative power supply module | Parameter setting

3.1.3 Monitoring

3.1.3.1 Overcurrent protection

The brake chopper hardware is monitored for overcurrent (short circuit or earth fault).

Note!

Monitoring for overcurrent can only be activated if a real brake current flows. A

test in idle state (without a brake resistor connected) is not possible.

If the monitoring function responds:

– The brake chopper is switched off immediately.

– The "Fault" response that is set fixedly is activated.

– The "Brake transistor: overcurrent" error message is entered in the logbook of the

regenerative power supply module.

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

Note!

The error can only be acknowledged after 2 seconds at the earliest to resume the

braking operation.

Tip!

In addition to the overcurrent protection, the regenerative power supply module is

provided with two more monitoring modes for braking operation, which are active

even if no brake resistor is connected (testing mode for checking the parameter

setting):

Ixt utilisation of brake transistor

I2t utilisation of brake resistor

( 26)

( 27)

EDS94ARNExxxx EN 2.3 - 06/2014 L 25

Page 26

9400 regenerative power supply module | Parameter setting

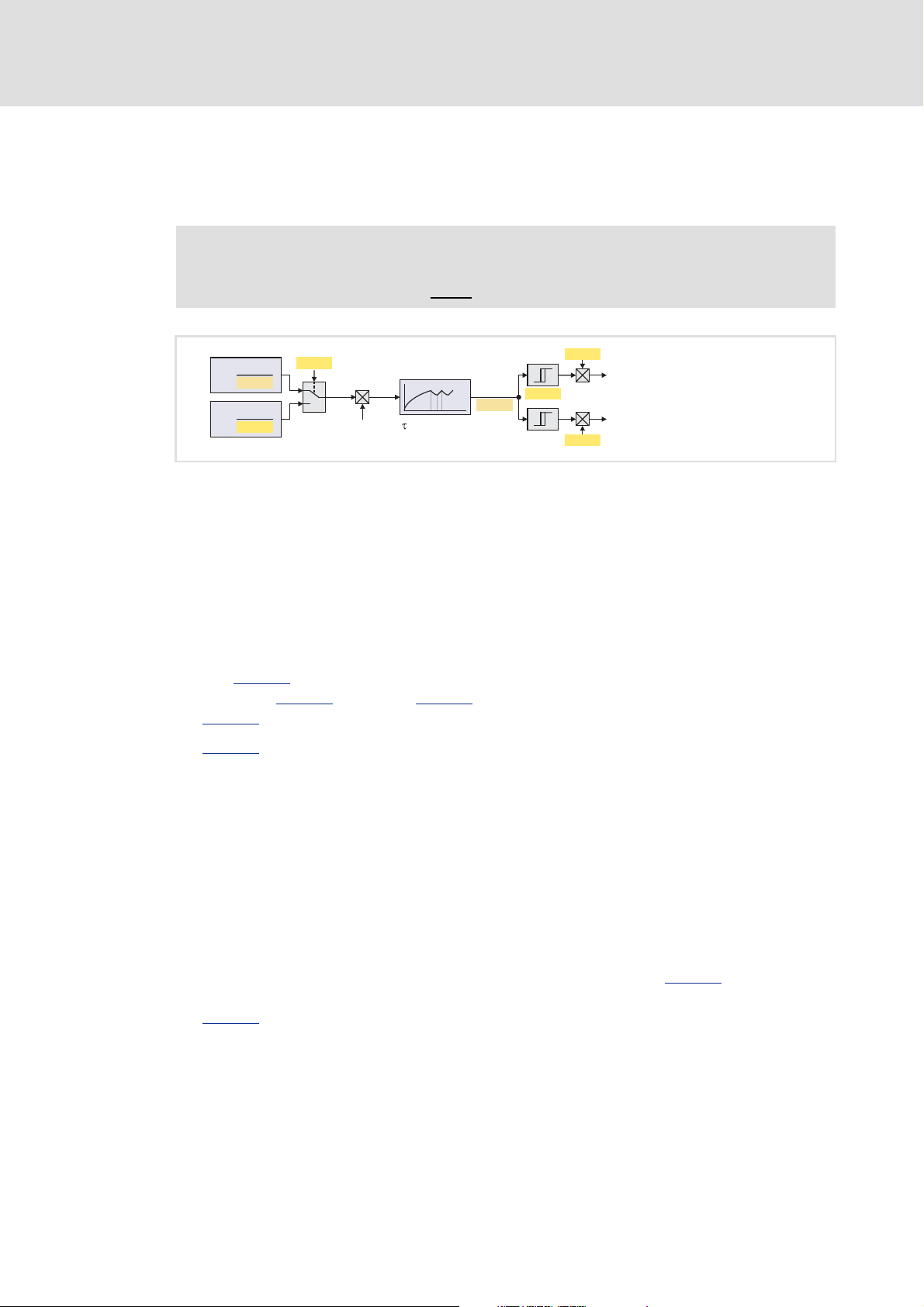

Ixt

C00137

1

0

C00134

C00129

C00133

T=0

Off

T=1

On

100 %

C00570

C00569

C00573

Logbook entry "Brake chopper: Ixt > C00570"

Logbook entry " "Brake chopper: Ixt overload

U

DC_act

U

DC_act

I=

Br

I=

Br

I

Br

= f(duty cycle, R )

Br

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

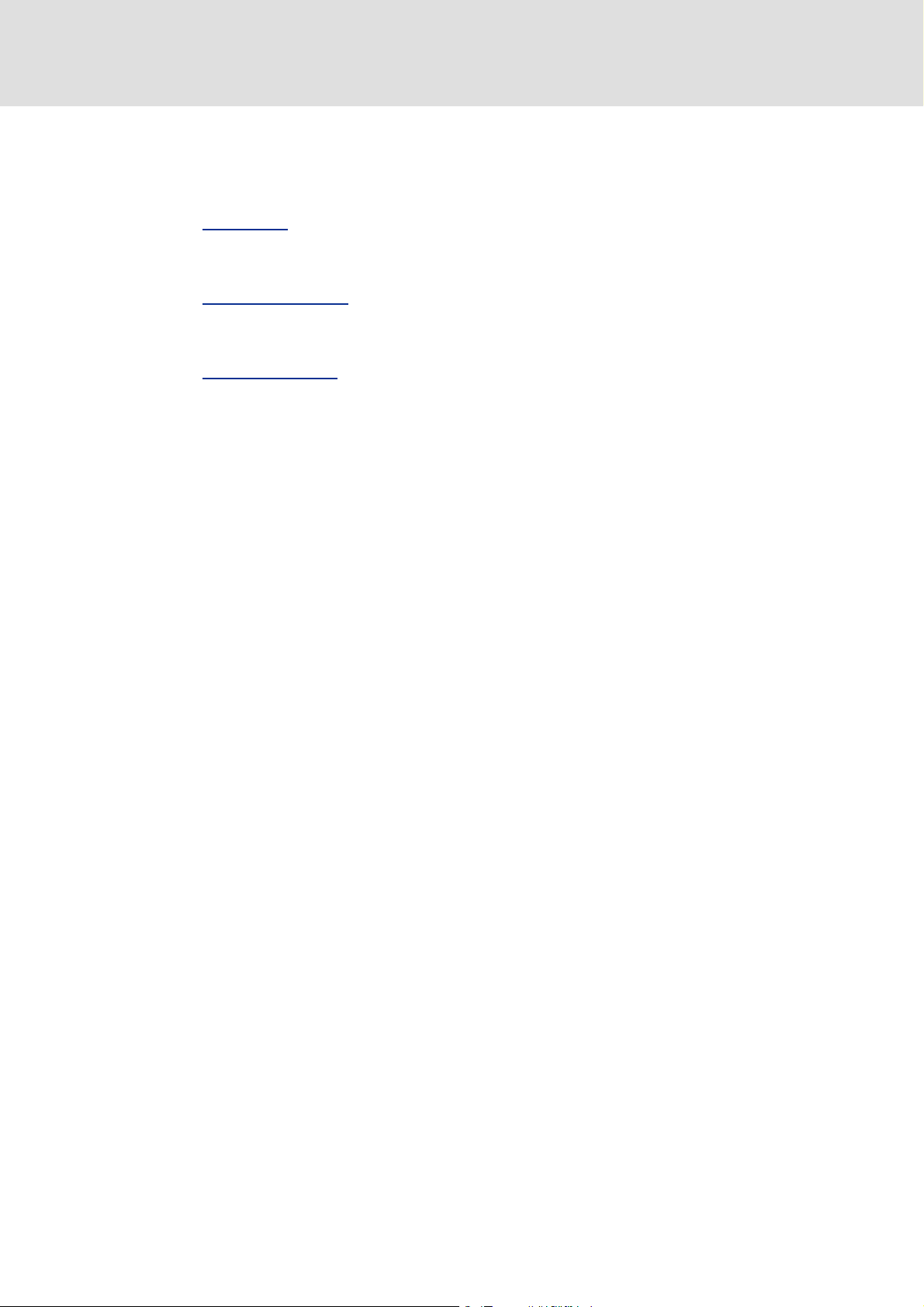

3.1.3.2 Ixt utilisation of brake transistor

The regenerative power supply module monitors the Ixt utilisation of the internal brake

transistor.

Note!

The braking operation will never be switched off by this monitoring function.

[3-1] Signal flow of Ixt utilisation - brake chopper

The monitoring function is based on a mathematical model which calculates the

braking current from the current DC-bus voltage and the brake resistance

parameterised.

– Hence, the monitoring function can respond even if no brake resistor is connected

and can therefore also be used for a testing mode to check the parameterisation.

The calculation considers the thermal utilisation of the brake transistor by a

correspondingly adapted time constant.

Use C00133

setting in C00173

C00129

C00137

to select whether the minimum brake resistance depending on the mains

(display in C00134), or the brake resistance value parameterised in

is to be used as a reference for calculating the utilisation.

displays the calculated utilisation of the brake transistor in [%].

– A 100 % utilisation corresponds to the continuous braking power which is provided

by the brake chopper at a DC-bus voltage of 790 V (or 390 V at a mains voltage of

230 V).

– The maximum braking power (assuming that the utilisation starts at 0 %) can be

provided for a period depending on the device.

– The calculated utilisation is also provided as the oscilloscope signal

Common.dnIxtBrakeChopper to check the braking operation while the system is

running

30

(scaling: 2

≡ 100 %).

If the utilisation exceeds the advance warning threshold set in C00570

, the message

"Brake chopper: Ixt > C00570" is entered into the logbook and the response set in

C00569

26 L EDS94ARNExxxx EN 2.3 - 06/2014

(default setting: "Warning") is activated.

Page 27

9400 regenerative power supply module | Parameter setting

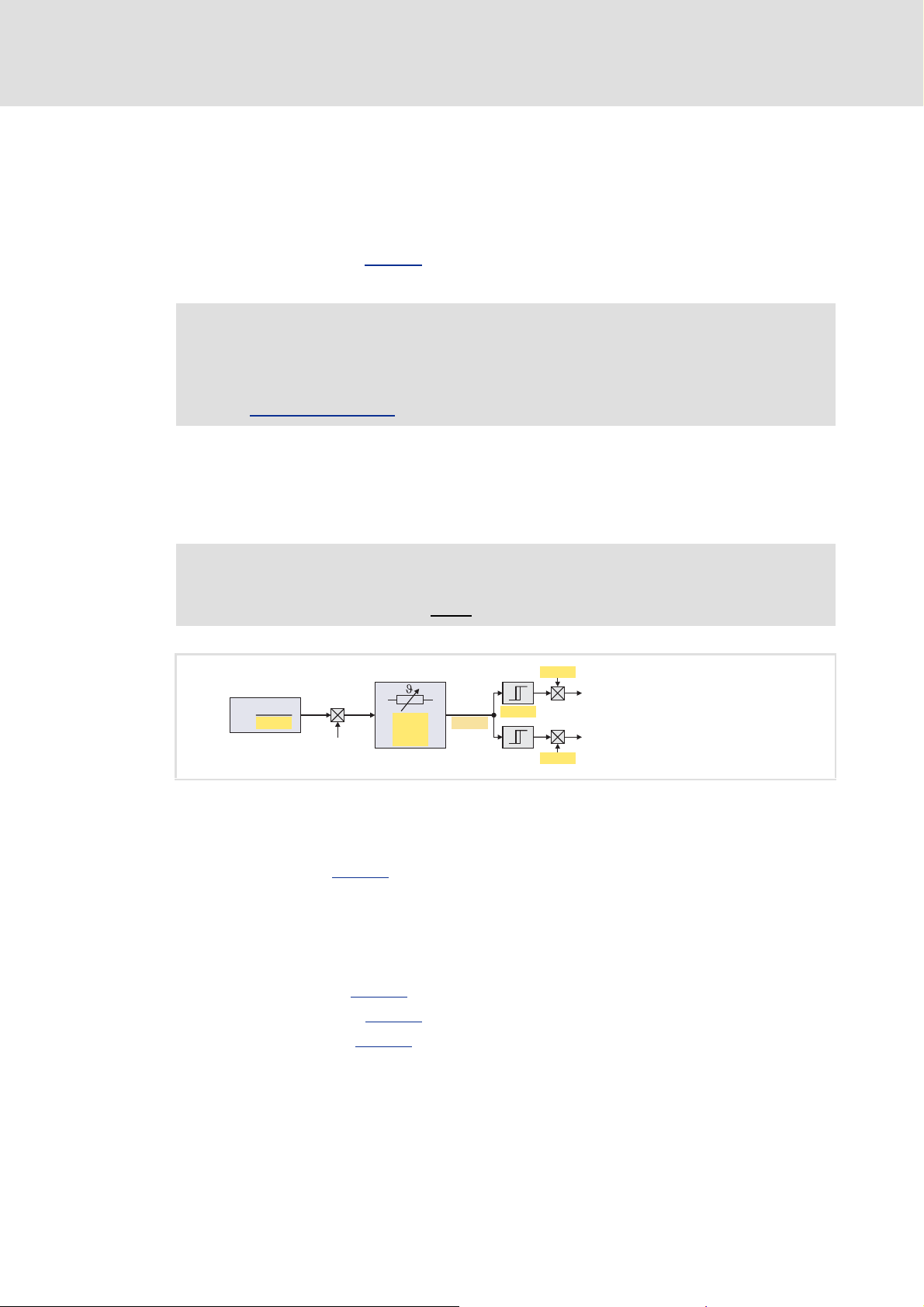

I2t

C00138

C00129

T=0

Off

T=1

On

100 %

C00572

C00571

C00574

C00129

C00130

C00131

Logbook entry " "Brake resistor: I2t > C00572

Logbook entry " "Brake resistor: I2t overload

U

DC_act

Temperature model

I=

Br

I

Br

When the utilisation reaches the limit value (100 %):

– The activation of the brake chopper is reset to the permanently permissible pulse-

no-pulse ratio (taking into account the parameterised brake resistance). (The brake

chopper is activated with 4 kHz, which means that it can be switched on/off at

minimum intervals of 250 μs.)

– The response set in C00573

corresponding effects on the state machine and the inverter.

Note!

If the DC-bus voltage exceeds the overvoltage threshold due to a too high

braking energy, the monitoring function for overvoltage in the DC bus responds.

DC-bus overvoltage

3.1.3.3 I2t utilisation of brake resistor

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

(default setting: "No response") is activated with the

( 29)

The regenerative power supply module is provided with a monitoring function for the I

utilisation of the brake resistor which is proportional to the converted braking power.

Note!

The braking operation will never be switched off by this monitoring function.

[3-2] Signal flow - I2t utilisation - brake resistor

The monitoring function is based on a mathematical model which calculates the

braking current from the current DC-bus voltage and the brake resistance

parameterised in C00129

– Hence, the monitoring function can respond even if no brake resistor is connected

and can therefore also be used for a testing mode to check the parameterisation.

.

2

t-

The calculation considers the thermal utilisation of the brake resistor based on the

following parameters:

– Resistance value (C00129

– Continuous power (C00130

– Thermal capacity (C00131

EDS94ARNExxxx EN 2.3 - 06/2014 L 27

)

)

)

Page 28

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

C00138 displays the calculated utilisation of the brake resistor in [%].

– A 100 % utilisation corresponds to the continuous power of the brake resistor

resulting at the maximum permissible temperature limit of the brake resistor.

– The calculated utilisation is also provided as the oscilloscope signal

Common.dnI2tBrakeResistor to check the braking operation while the system is

running

(scaling: 2

30

≡ 100 %).

If the utilisation exceeds the advance warning threshold set in C00572

"Brake resistor: I2t > C00572" is entered into the logbook and the response set in

C00571

When the utilisation reaches the limit value (100 %):

– The response set in C00574

– The activation of the brake chopper is reset to the permanently permissible pulse-

(default setting: "Warning") is activated.

(default setting: "No response") is activated with the

corresponding effects on the state machine and the inverter.

no-pulse ratio (taking into account the parameterised brake resistance). (The brake

chopper is activated with 4 kHz, which means that it can be switched on/off at

minimum intervals of 250 μs.)

, the message

Stop!

The brake resistor can be thermally overloaded. Carry out protective measures

suitable for the system, e.g.:

• Parameterisation of an error response in C00574

parameterised error message in the application or machine control.

• External wiring using the temperature contact on the brake resistor (e.g.

interruption of the supply via mains contactor and activation of the

mechanical brakes).

and evaluation of the

Note!

If the system is dimensioned correctly, this monitoring function should not

respond. If individual rated data of the connected brake resistor are not known,

they must be determined "empirically".

From software version V2.0 onwards, C00571

the error response "Brake chopper is inhibited".

• If this error response occurs, the brake chopper is inhibited without providing

feedback to the device control. Instead, feedback is provided via the

LI_bChopperOffByTrouble output of the LS_LineInterface

• If the corresponding trigger threshold is fallen below by 5 %, the pulse inhibit

of the brake chopper is deactivated again and the status signal

LI_bChopperOffByTrouble is reset to FALSE.

and C00574 additionally provide

system block.

28 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 29

9400 regenerative power supply module | Parameter setting

3.1.3.4 DC-bus overvoltage

If the braking energy is too high and the DC-bus voltage therefore exceeds the overvoltage

threshold which results from the mains setting in C00173

error message is output and the response set in C00600

"Trouble").

Note!

For hoist applications the "Fault" response should be selected in C00600 (in

combination with an emergency stop via mechanical brakes).

Regenerative power supply module application

Parameterising the brake chopper/brake resistor

, the "Overvoltage in the DC bus"

is activated (default setting:

EDS94ARNExxxx EN 2.3 - 06/2014 L 29

Page 30

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Signal configuration

3.2 Signal configuration

3.2.1 Device and line interface

If required, the default signal configuration of the control and setpoint inputs of the device

and line interface can be easily reconfigured by parameterising the multiplexer

parameters assigned.

Device interface

Signal (Lenze setting) Control input Signal configuration

DIGIN 1 Set controller inhibit

(inhibit regenerative feedback)

Control word 1 bit 01 Set controller inhibit

(inhibit regenerative feedback)

DIGIN 3 Reset error 1 C03130/3

Control word 1 bit 07 Reset error 2 C03130/4

C03130/1

C03130/2

Line interface

Signal (Lenze setting) Control input Signal configuration

DIGIN 2 Activate brake chopper C03190/1

Control word 1 bit 02 Activate brake chopper C03190/2

30 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 31

3.2.2 Output ports

If required, the default signal configuration of the output ports can be easily reconfigured

by parameterising the multiplexer parameters assigned.

Output port "LPortAxisOut1"

The output port LPortAxisOut1 is intended for the connection to a following axis.

Signal (Lenze setting) Output port Signal configuration

Axis status word

• Application-specific signals can be added.

Setpoints for horizontal communication

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Signal configuration

FALSE Axis status word bit 00 C03120/1

FALSE Axis status word bit 01 C03120/2

FALSE Axis status word bit 02 C03120/3

FALSE Axis status word bit 03 C03120/4

FALSE Axis status word bit 04 C03120/5

FALSE Axis status word bit 05 C03120/6

FALSE Axis status word bit 06 C03120/7

FALSE Axis status word bit 07 C03120/8

FALSE Axis status word bit 08 C03120/9

FALSE Axis status word bit 09 C03120/10

FALSE Axis status word bit 10 C03120/11

FALSE Axis status word bit 11 C03120/12

FALSE Axis status word bit 12 C03120/13

FALSE Axis status word bit 13 C03120/14

FALSE Axis status word bit 14 C03120/15

FALSE Axis status word bit 15 C03120/16

0 % Axis port out 1 (16 bits) C03124/1

0 % Axis port out 2 (32 bits) C03124/2

EDS94ARNExxxx EN 2.3 - 06/2014 L 31

Page 32

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Signal configuration

Output port "LPortStatus1"

The output port LPortStatus1 is intended for the connection to a higher-level control

system.

Signal (Lenze setting) Output port Signal configuration

Status word 1

FALSE Status word 1 bit 00 C03121/1

FALSE Status word 1 bit 01 C03121/2

FALSE Status word 1 bit 02 C03121/3

FALSE Status word 1 bit 03 C03121/4

FALSE Status word 1 bit 04 C03121/5

FALSE Status word 1 bit 05 C03121/6

FALSE Status word 1 bit 06 C03121/7

FALSE Status word 1 bit 07 C03121/8

FALSE Status word 1 bit 08 C03121/9

FALSE Status word 1 bit 09 C03121/10

FALSE Status word 1 bit 10 C03121/11

FALSE Status word 1 bit 11 C03121/12

FALSE Status word 1 bit 12 C03121/13

FALSE Status word 1 bit 13 C03121/14

FALSE Status word 1 bit 14 C03121/15

FALSE Status word 1 bit 15 C03121/16

Output port "LPortStatus2"

The output port LPortStatus2 is intended for the connection to a higher-level control

system.

Signal (Lenze setting) Output port Signal configuration

Status word 2

FALSE Status word 2 bit 00 C03122/1

FALSE Status word 2 bit 01 C03122/2

FALSE Status word 2 bit 02 C03122/3

FALSE Status word 2 bit 03 C03122/4

FALSE Status word 2 bit 04 C03122/5

FALSE Status word 2 bit 05 C03122/6

FALSE Status word 2 bit 06 C03122/7

FALSE Status word 2 bit 07 C03122/8

FALSE Status word 2 bit 08 C03122/9

FALSE Status word 2 bit 09 C03122/10

FALSE Status word 2 bit 10 C03122/11

FALSE Status word 2 bit 11 C03122/12

FALSE Status word 2 bit 12 C03122/13

FALSE Status word 2 bit 13 C03122/14

FALSE Status word 2 bit 14 C03122/15

FALSE Status word 2 bit 15 C03122/16

32 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 33

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Signal configuration

Output port "LPortStatus2"

The output port LPortStatus2 is intended for the connection to a higher-level control

system.

Signal (Lenze setting) Output port Signal configuration

Status word 2

FALSE Status word 2 bit 00 C03122/1

FALSE Status word 2 bit 01 C03122/2

FALSE Status word 2 bit 02 C03122/3

FALSE Status word 2 bit 03 C03122/4

FALSE Status word 2 bit 04 C03122/5

FALSE Status word 2 bit 05 C03122/6

FALSE Status word 2 bit 06 C03122/7

FALSE Status word 2 bit 07 C03122/8

FALSE Status word 2 bit 08 C03122/9

FALSE Status word 2 bit 09 C03122/10

FALSE Status word 2 bit 10 C03122/11

FALSE Status word 2 bit 11 C03122/12

FALSE Status word 2 bit 12 C03122/13

FALSE Status word 2 bit 13 C03122/14

FALSE Status word 2 bit 14 C03122/15

FALSE Status word 2 bit 15 C03122/16

EDS94ARNExxxx EN 2.3 - 06/2014 L 33

Page 34

9400 regenerative power supply module | Parameter setting

Regenerative power supply module application

Assignment of the I/O terminals

3.3 Assignment of the I/O terminals

In the following tables the Lenze assignment of the I/O terminals for the "Regenerative

power supply module" application is listed.

If required, the default signal configuration can be easily reconfigured via the

parameterisation dialog on the Application parameters tab, or via parameterisation of

the multiplexer parameters assigned.

Digital inputs

Terminal Assignment (Lenze setting)

X5 RFR Controller enable

DI1 Inhibit regenerative feedback

• Function also possible via bit 01 of control word 1.

DI2 Activate brake chopper

• Function also possible via bit 02 of control word 1.

DI3 Reset (acknowledge) error

• A pending error message can be reset (acknowledged) by a LOW-HIGH edge if the cause of

the error message has been eliminated.

• Function also possible via bit 07 of control word 1.

DI4 -

DI5 -

DI6 -

DI7 -

DI8 -

Digital outputs

Terminal Signal (Lenze setting) Signal configuration

X4 DO1 "Ready for regenerative feedback" state

• Mains voltage is applied.

• Charging of DC bus is completed.

• There is no short circuit or earth fault.

• There is no device overload, i.e. the device utilisation (C00064

below the warning threshold set in C00123

DO2 "Filter overtemperature" state C03100/2

DO3 "Fault active - acknowledgement required" state

• A monitoring function with the "Fault" response has been triggered

and the regenerative power supply module is in the "Fault active"

device state.

DO4 "Warning active" state

• A filter overload or device overload warning has occurred or another

monitoring function with the "Warning" error response has been

triggered and the regenerative power supply module is in the

"Warning active" device state.

.

) is

C03100/1

C03100/3

C03100/4

34 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 35

9400 regenerative power supply module | Parameter setting

Note!

"Ready for regenerative feedback" status message via digital output DO1:

• If one of the conditions listed in the table for digital output DO1 is not met

anymore, the digital output DO1 is reset to LOW level.

Conditions for returning to the "ready for regenerative feedback" state:

• If a mains failure has been detected, the mains voltage has to be applied for

at least two complete periods after mains recovery, before the digital output

DO1 is reset to HIGH level.

• If a short circuit or earth fault has occurred, the device is ready for operation

again after approx. 2 s, i.e. after this time the digital output DO1 is

automatically reset to HIGH level.

• The device utilisation evaluation has a hysteresis of 5 %. This means that the

device utilisation (C00064

output DO1 is reset to HIGH level.

Regenerative power supply module application

Assignment of the I/O terminals

) must drop to < (C00123 - 5 %) before the digital

Display elements

User LED Signal (Lenze setting) Signal configuration

"Ready for regenerative feedback" state

• See description for digital output DO1.

C03100/5

State bus

Terminal Signal (Lenze setting) Signal configuration

X2 SB FALSE C03100/6

Analog outputs

Terminal Signal (Lenze setting) Signal configuration

X3 AO1 0 % C03110/1

AO2 0 % C03110/2

Related topics:

Analog outputs

( 92)

Digital inputs

Digital outputs

"State bus" monitoring function

LED status displays for the device state

EDS94ARNExxxx EN 2.3 - 06/2014 L 35

( 94)

( 95)

( 96)

( 188)

Page 36

9400 regenerative power supply module | Parameter setting

Device interface

4 Device interface

This chapter will provide you with information on the device interface via which you can

query the states of the regenerative power supply module and set it to specific states.

How to get to the parameterisation dialog of the device interface:

1. Select the regenerative power supply module in the Project view of the »Engineer«.

2. Change to the Application parameters tab in the Workspace.

3. Click the Device interface button in the Overview dialog box.

Parameterisation dialog in the »Engineer«

The white buttons display the configuration of the device interface inputs.

LS_DriveInterface - device interface

– The assignment is defined by the technology application selected and can, if

required, be reconfigured by clicking the corresponding button.

If you click a button marked with the icon, you get one level deeper in the

corresponding parameterisation dialog.

( 259)

36 L EDS94ARNExxxx EN 2.3 - 06/2014

Page 37

9400 regenerative power supply module | Parameter setting

4.1 Device commands

The following subchapters describe the device commands of the regenerative power

supply module, which are available in C00002

or via the »Engineer« when an online connection has been established.

Note!

Before switching off the supply voltage after a device command has been

executed, check via the status display in C00003

been executed successfully!

Device interface

Device commands