Page 1

GHB 13.0001−EN

.88$

Ä.88$ä

Hardware Manual

E931Ex

Servo inverters for extra−low voltages

Page 2

Please read these instructions before you start working!

Follow the enclosed safety instructions.

Page 3

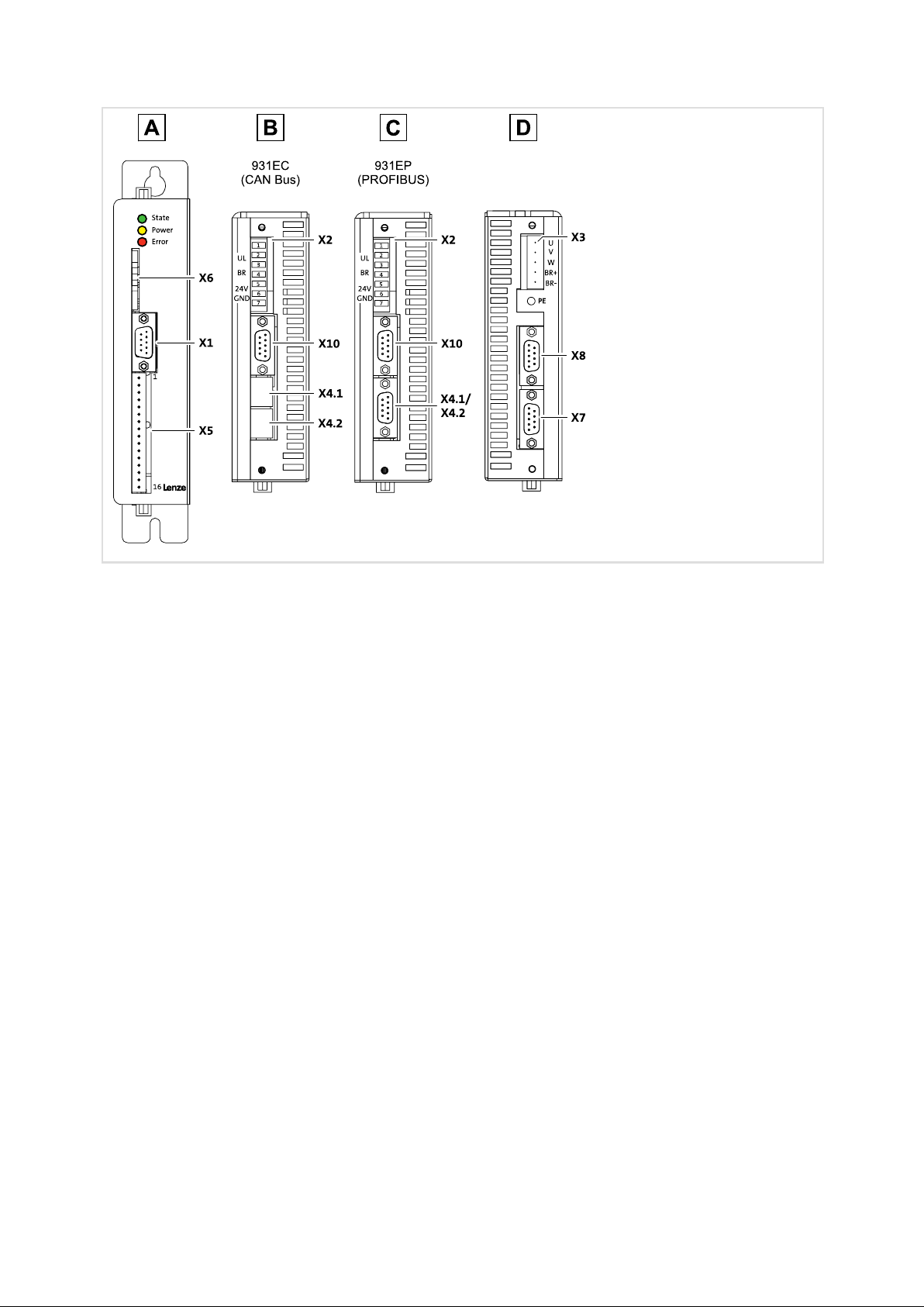

Overview

931E−002.iso

Page 4

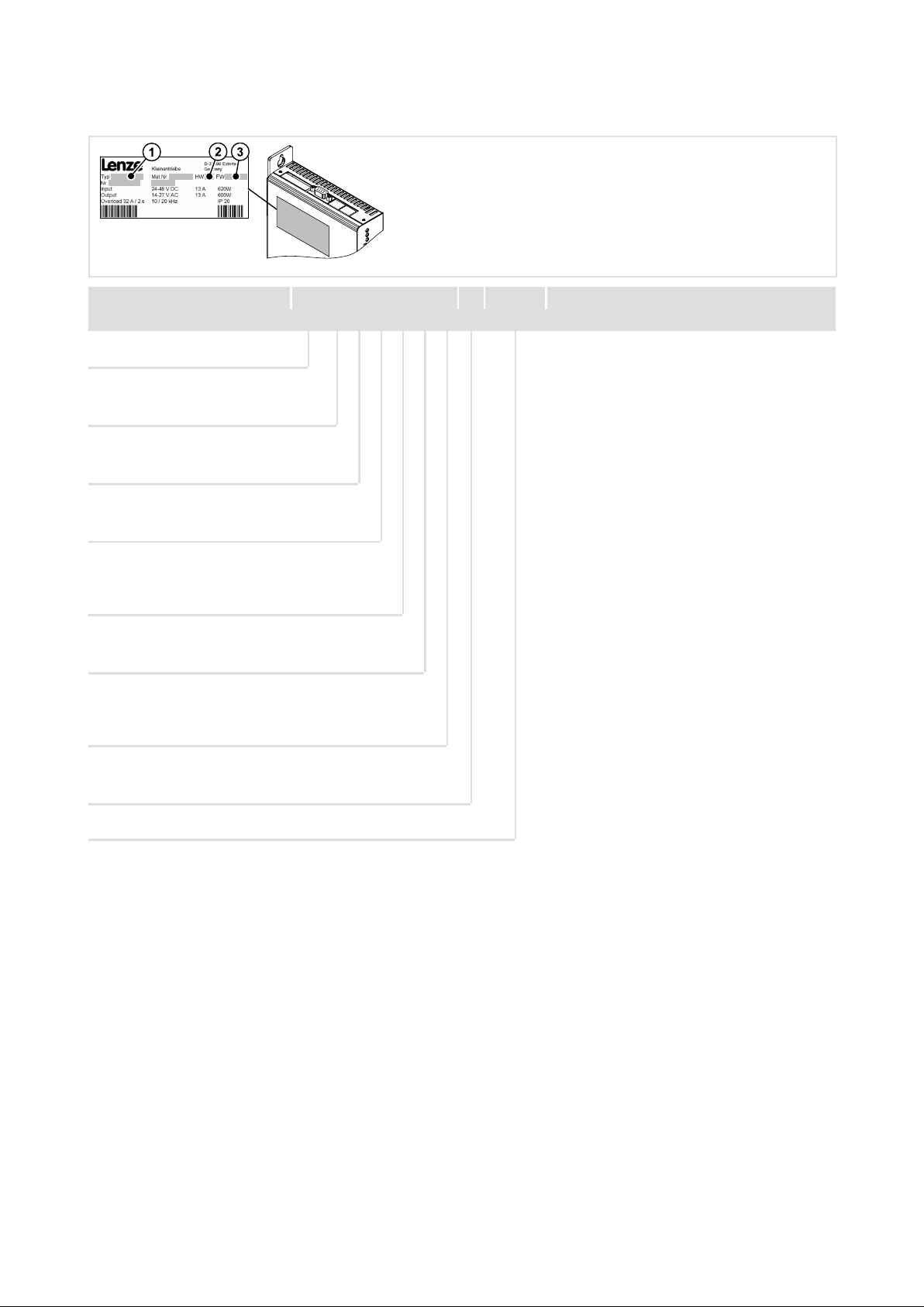

This documentation is valid for ...

931 ... servo inverters as of nameplate data:

93 1 E x K 1 0 2.0 3.2

Product range

930

Size/power range

1 = up to 600 W

Design

E = built−in unit for IP 20 control cabinet

931E_008

Communication

C =

CAN bus integrated

P =

PROFIBUS integrated

Voltage class

K = design for low voltage

Options

1 = with digital inputs and outputs

with analog inputs and outputs

Installation

0 = installation in control cabinet

Hardware version

Software version

4

GHB 13.0001−EN EN 3.0

Page 5

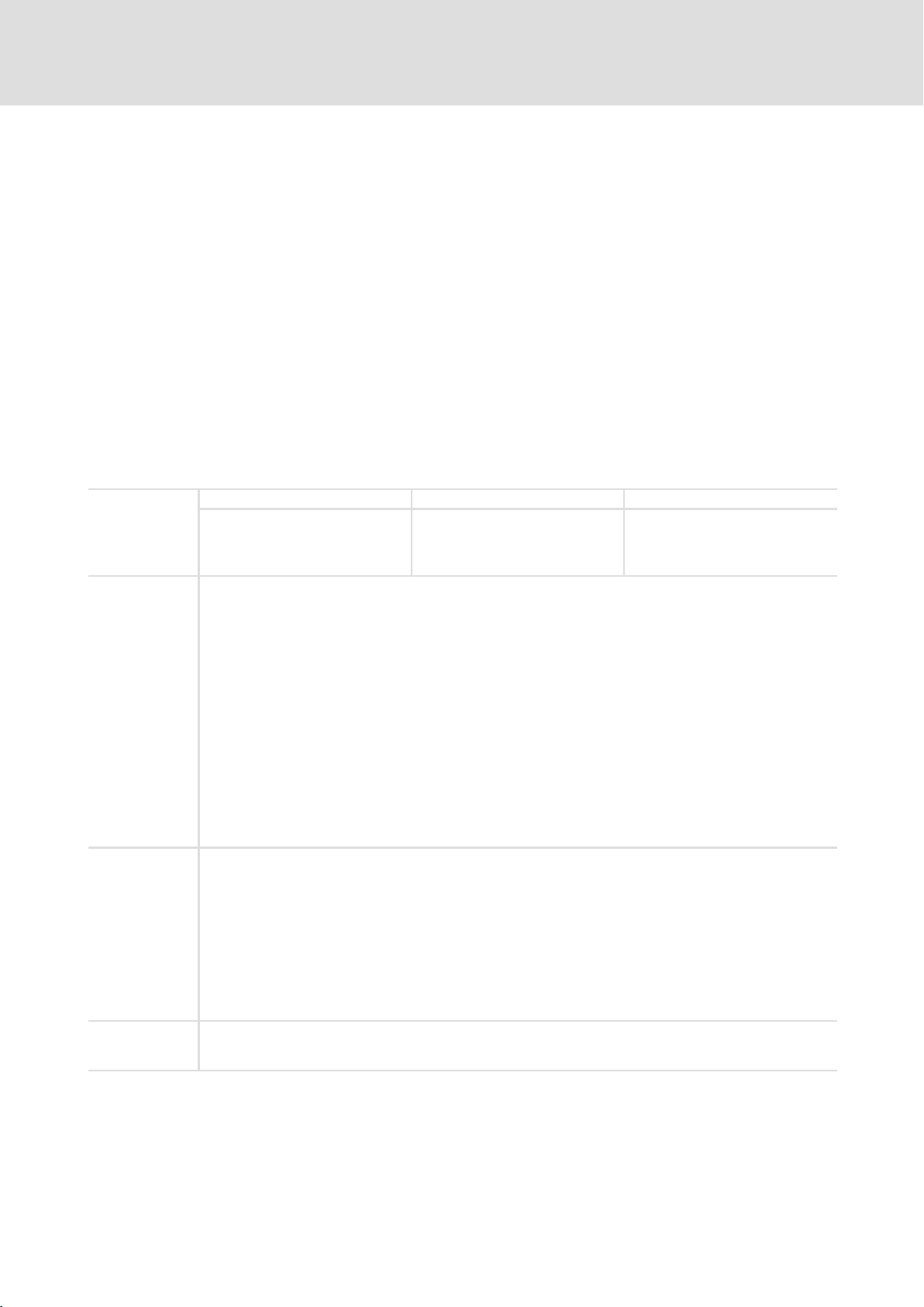

Key for the overview

View from the front

Pos. Description

X1 RS232

X5 Digital inputs and outputs / analog inputs and outputs

X6 Slot for multimedia memory card

931EC ˘ View from above

Pos. Description

X2 Voltage supply

X4.1

X4.2

X10 Digital frequency interface

931EP ˘ View from above

Pos. Description

X2 Voltage supply

X4.1/X4.2 PROFIBUS interface

X10 Digital frequency interface

View from below

Pos. Description

X3 Motor connection

X7 Resolver input

X8 SinCos encoder input

CAN interfaces

LED Colour State Note

State Green

Power Yellow

Error Red

Green

Yellow

Red

1)

Detailed description of the blink codes: 40

on The control is correctly supplied by a 24 V control voltage, the drive is ready for operation.

blinking Data is written on or read from the memory card.

off No voltage

on The power section is enabled, the motor is supplied with voltage. The drive works with the set

control.

off The drive does not work, the output stage is inactive.

off No fault

blinking Internal drive error

After the cause of the error has been eliminated, you have to acknowledge the error message:

l Either by using the parameterisation software, or via an edge at DIN9 (controller enable).

l If no error is active anymore, the LED goes out.

on l The drive is in the initialisation phase after the control voltage has been switched on.

l A new firmware is being installed.

Note!

The light−emitting diode "Error" constantly blinks if a fault is active:

ƒ It only displays one fault at a time.

ƒ If several faults are active at the same time, the fault that occured first is displayed.

1)

GHB 13.0001−EN EN 3.0

5

Page 6

What is new, what has changed ?

Material No. Version Description

.88$ 3.0 12/2007 TD35 Advanced by the 931EP (PROFIBUS) device variant

13058894 2.0 08/2005 TD09 Complete revision for the series

− 1.0 03/2003 LKA Preliminary version

0Fig. 0Tab. 0

Tip!

Current documentation and software updates concerning Lenze products can be found on

the Internet in the "Services & Downloads" area under

http://www.Lenze.com

© 2007 Lenze GmbH & Co KG Kleinantriebe, Hans−Lenze−Straße 1, D−32699 Extertal

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze GmbH &

Co KG Kleinantriebe.

All information given in this documentation has been selected carefully and complies with the hardware and software described.

Nevertheless, discrepancies cannot be ruled out. We do not take any responsibility or liability for any damage that may occur.

Necessary corrections will be included in subsequent editions.

6

GHB 13.0001−EN EN 3.0

Page 7

Contents i

1 Preface and general information 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Terminology used 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Scope of supply 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Legal regulations 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety and application notes for Lenze controllers 11 . . . . . . . . . . . . . . . . . .

2.2 Residual hazards 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Definition of notes used 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Technical data 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 General data and operating conditions 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Rated data 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Communication 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Controller with CAN bus 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Controller with PROFIBUS 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important notes 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Dimensions 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Mounting clearance 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Installation according to EMC (installation of a CE−typical drive system) 21 . . . . . . .

5.3 Voltage supply 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Motor connection 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Control terminals 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Feedback connection 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Resolver at X7 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 SinCos encoder at X8 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Communication 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Connection of digital frequency coupling at X10 29 . . . . . . . . . . . . . . . . . . .

5.7.2 Connection of CAN bus at X4.1 and X4.2 30 . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.3 Connection of PROFIBUS 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.4 Connection of RS232 serial interface to X1 31 . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Initial switch−on 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GHB 13.0001−EN EN 3.0

7

Page 8

Contentsi

7 Troubleshooting and fault elimination 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Status of the drive 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Error message 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Accessories 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 System cables and plugs 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Power supply units 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Memory cards 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Motors for 931E servo inverters 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 General data and operating conditions 44 . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Rated data 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Mechanical data 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Index 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

GHB 13.0001−EN EN 3.0

Page 9

Preface and general information

1 Preface and general information

1.1 About this Manual

Target group

This manual addresses to all persons designing, mounting, commissioning and setting the

servo inverters of the 931 series.

Together with the catalogue, it presents the project documents for the mechanical

engineer and the system engineer.

Contents

The manual complements the mounting instructions included in the scope of supply:

ƒ The features and functions are described in detail.

ƒ It provides detailed information on the possible applications.

1

About this Manual

ƒ The parameter setting is clarified by examples.

ƒ In case of doubt, the supplied mounting instructions always apply.

Finding information

ƒ Via the contents and index, you quickly find the information regarding a specific

problem.

ƒ Descriptions and data with regard to other Lenze products can be gathered from the

respective catalogues, Operating Instructions, and Manuals.

ƒ You can request Lenze documentation from your responsible Lenze sales partner, or

download it from the Internet as a PDF file.

1.2 Terminology used

Term In the following text used for

Controller 931E servo inverter

Device 931E servo inverter

Drive 931E servo inverter with connected motor

SDC »Small Drive Control« parameterisation software

GHB 13.0001−EN EN 3.0

9

Page 10

1

Preface and general information

Scope of supply

1.3 Scope of supply

ƒ 931E servo inverter

ƒ Mounting instructions

After receipt of the delivery, check immediately whether the items delivered match the

accompanying documents. Lenze does not accept any liability for deficiencies claimed at

a later date.

Claim

ƒ visible transport damage immediately to the forwarder.

ƒ visible deficiencies / incompleteness immediately to your Lenze representative.

1.4 Legal regulations

Labelling

Application as

directed

Liability l The information, data, and notes in these instructions met the state of the art at the time of printing.

Warranty l Terms of warranty: see Sales and Delivery Conditions of Lenze GmbH & Co KG Kleinantriebe.

Nameplate CE identification Manufacturer

Lenze drive controllers are

definitely identified by the

contents of the nameplate.

931E servo inverters

l must only be operated under the operating conditions prescribed in these Instructions.

l are components

– for open and closed loop control of variable speed drives with synchronous motors.

– for installation in a machine

– for assembly with other components to form a machine.

l are electric units for the installation into control cabinets or similar closed electrical operating areas.

l comply with the requirements of the Low−Voltage Directive.

l are not machines for the purpose of the Machinery Directive.

l are not to be used as domestic appliances, but only for industrial purposes.

Drive systems with 931E servo inverters

l comply with the EMC Directive if they are installed according to the guidelines of CE−typical drive systems.

l can be used

– for operation on public and non−public mains

– for operation in industrial premises.

l The user is responsible for the compliance of his application with the EC Directives.

Any other use shall be deemed as inappropriate!

Claims on modifications referring to controllers which have already been supplied cannot be derived from

the information, illustrations, and descriptions.

l The specifications, processes, and circuitry described in these Instructions are for guidance only and must

be adapted to your own specific application. Lenze does not take responsibility for the suitability of the

process and circuit proposals.

l Lenze does not accept any liability for damage and operating interference caused by:

– disregarding the Operating Instructions

– unauthorised modifications to the drive controllers

– operating errors

– improper working on and with the drive controllers

l Warranty claims must be made to Lenze immediately after detecting the deficiency or fault.

l The warranty is void in all cases where liability claims cannot be made.

In compliance with the EC

Low−Voltage Directive

Lenze GmbH & Co KG

Kleinantriebe

Postfach 10 13 52

D−31763 Hameln

10

GHB 13.0001−EN EN 3.0

Page 11

Safety instructions

General safety and application notes for Lenze controllers

2 Safety instructions

2.1 General safety and application notes for Lenze controllers

(in accordance with Low−Voltage Directive 2006/95/EC)

For your pesonal safety

During operation, Lenze controllers (frequency inverters, servo inverters, DC speed

controllers) and their corresponding components can be live, moving and rotating

according to their degree of protection. Surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, incorrect installation or

operation creates the risk of severe injury to persons or damage to material assets.

Additional information can be obtained from the documentation.

High amounts of energy are released in the controller. Thus, it is required to always wear

a personal protective equipment (body protection, headgear, eye protection, ear

protection, hand guard).

2

All operations concerning transport, installation, and commissioning as well as servicing

must be carried out by qualified, skilled personnel only (IEC 364 and CENELEC HD 384 or

DIN VDE 0100 and IEC−Report 664 or DIN VDE 0110. National regulations for the

prevention of accidents must be observed.).

According to this basic safety information, skilled personnel are persons who are familiar

with the installation, mounting, commissioning, and operation of the product and who

have the necessary qualifications for their occupation.

Application as directed

Drive controllers are components designed for the installation in electrical systems or

machinery. They must not be used as household appliances. They are intended exclusively

professional and commercial purposes according to EN 61000−3−2.

When installing the controllers into machines, commissioning (i.e. starting of operation as

directed) is prohibited until it is certain that the machine complies with the regulations of

EC Directive 98/37/EC (Machinery Directive). EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is

compliance with EMC Directive (89/336/EEC).

The controllers meet the requirements of the Low-Voltage Directive 2006/95/EC.

The technical data and information on the connection conditions can be obtained from the

nameplate and the documentation. They must be followed in any case.

Warning: Drive controllers are products with restricted availability according to

EN 61800−3. These products can cause radio interferences in residential areas. In this case,

special measures are required.

Transport, storage

Please observe the notes on transport, storage and appropriate handling.

Observe the climatic conditions according to the technical data.

GHB 13.0001−EN EN 3.0

11

Page 12

2

Safety instructions

General safety and application notes for Lenze controllers

Installation

The controllers must be installed and cooled according to the instructions given in the

corresponding documentation.

Ensure proper handling and avoid mechanical stress. Do not bend any component and do

not change any insulation distance during transport or handling. Do not touch any

electronic component or contact.

Controllers contain electrostatically sensitive components which can easily be damaged

by inappropriate handling. Do not damage or destroy any electrical component since doing

so might endanger your health!

Electrical connection

When working on live controllers, the valid regulations for the prevention of accidents (e.g.

VBG 4) must be observed.

The electrical installation must be carried out according to the appropriate regulations

(e.g. cable cross/sections, fuses, PE connection). Additional information can be obtained

from the documentation.

The documentation contains information concerning installation in compliance with EMC

(shielding, earthing, filter arrangement, and cable installation). These notes must also be

observed for CE−marked controllers. The manufacturer of the system or machine is

responsible for ensuring compliance with the limit values demanded by the EMC

legislation. The controllers must be installed in housings (e.g. control cabinets) to comply

with the limit values for radio interferences valid at the site of installation. The housings

must enable an EMC−compliant installation. Make sure in particular that e.g. the control

cabinet doors have a circumferential metal connection to the housing. Reduce housing

openings and cutouts to a minimum.

Operation

If necessary, systems including controllers must be equipped with additional monitoring

and protection devices according to the valid safety regulations (e.g. law on technical

equipment, regulations for the prevention of accidents). You are allowed to adapt the

controllers to your application. Please observe the corresponding information given in the

documentation.

After the controller has been disconnected from the voltage supply, all live components

and power connections must not be touched immediately because capacitors can still be

charged.

All protection covers and doors must be kept shut during operation.

Maintenance and servicing

The controllers do not require any maintenance if the prescribed conditions of operation

are observed.

If the ambient air is polluted, the cooling surfaces of the controller may contaminate, or the

air vents of the controller may be blocked. Therefore, the cooling surfaces and air vents

must be cleaned periodically under these operating conditions. Do not use sharp or

pointed tools for this purpose!

Waste disposal

Recycle metal and plastic materials. Assembled PCBs must be disposed of professionally.

The product−specific safety and application notes given in these instructions must be

observed!

12

GHB 13.0001−EN EN 3.0

Page 13

Safety instructions

Residual hazards

2

2.2 Residual hazards

Protection of persons

After power−off, the power terminals UL, BR and GND still carry hazardous voltages for at

least 3 minutes!

ƒ Before working on the controller, check that no voltage is applied to the power

terminals.

ƒ Always protect the power terminals against contact.

The discharge current to ground (PE) is > 3.5 mA, according to EN 50178.

ƒ If a fixed installation is required, design the PE conductor with a cable cross−section

of at least 1.5 mm

Make sure that cables are installed correctly, and that bolted connections and plug

connections are faultless.

Due to the high currents with regard to low−voltage applications, current−carrying parts

can be strongly heated.

Device protection

ƒ Connect or disconnect all pluggable terminals in a deenergised state only!

2

or use a design with double PE conductor.

ƒ A cyclic connection and disconnection of the supply voltage can overload and

destroy the input current limitation of the drive controller:

– When effecting a cyclic switching of the supply voltage over a longer period, the

period between two switch−on processes at least has to be one minute!

Motor protection

Drive systems can reach dangerous overspeeds (e.g. setting of high field frequencies for

motors and machines which are not qualified for this purpose):

ƒ The controllers do not offer any protection against these operating conditions. Use

additional components for this.

Protection of the machine/system

A missing or incorrect resolver adjustment can bring about undefined control states. The

perfect operation is no longer guaranteed.

GHB 13.0001−EN EN 3.0

13

Page 14

2

Safety instructions

Definition of notes used

2.3 Definition of notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property damage

if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

14

GHB 13.0001−EN EN 3.0

Page 15

General data and operating conditions

3 Technical data

3.1 General data and operating conditions

Conformity CE 2006/95/EC Low-Voltage Directive

Regulations EN 61800−3 Interference level B

Climatic conditions Air humidity max. 90 % without condensation

Cooling Passively via housing surface and rear panel

Admissible temperature range

Transport −25 °C... +70 °C

Storage −25 °C... +70 °C

Operation 0 °C ... +50 °C above +40 °C, reduce the power by 20 W/°C

Permissible installation height 0 ... 1000 m amsl above 1000 m amsl, reduce the rated output

Mounting position Vertical

Installation clearances

above/below ³ 100 mm

sidewise Directly alignable

Monitoring Overvoltage / undervoltage in the DC bus, overcurrent or short

circuit of the output stage, motor temperature and output stage

temperature, I

Type of protection IP 20

Inputs 6 digital inputs, 2 analog inputs

(adjustable via software)

Outputs 2 digital outputs, 2 analog outputs

(adjustable via software)

Memory cards Multimedia card

Technical data

current by 5 %/1000 m

2x

t−monitoring of the motor, encoder monitoring

3

GHB 13.0001−EN EN 3.0

15

Page 16

3

Technical data

Rated data

3.2 Rated data

Supply voltage

Rated voltage 24V DC 48V DC

Permissible range 19.2 V DC − 0 % ... 57.6 V DC + 0 %

Supply current at rated power approx. 13 A

Max. supply current 35 A

Rated power 310 W 620 W

Efficiency up to 95 %

PWM frequency (switchable) 10 kHz 20 kHz 10 kHz 20 kHz

Rated output current 0 ... 13 A

Output surge current for 2 s 32 A

Rated output voltage 0 ... 14 V

Output frequency 0 ... 200 Hz

Control voltage

Control current min. 0.25 A (control section only)

Brake chopper switching threshold

On approx. 63 V DC

Off approx. 60 V DC

Overvoltage monitoring switching threshold approx. 70 V DC

Internal brake resistor

Resistance R 17 W

Permanent power P

Peak power P

External brake resistor

Resistance R > 5 W

Permanent power P

Motor holding brake 24 V / 1 A

Positioning range ± 219 revolutions

Savable positions 64

Scanning times of the control loops

Current controller 100 ms

Speed controller 200 ms

Position controller 400 ms

1)

Observe minimum voltage of the brake!

1)

pulse

eff

eff

N

N

0 ... 10 A

max. 1.5 A (all outputs connected)

eff

25 A

eff

eff

24 V DC ±20 %

200 W for 50 ms

10 ... 600 W

10 W

0 ... 13 A

32 A

eff

eff

0 ... 27 V

0 ... 10 A

25 A

eff

eff

eff

16

GHB 13.0001−EN EN 3.0

Page 17

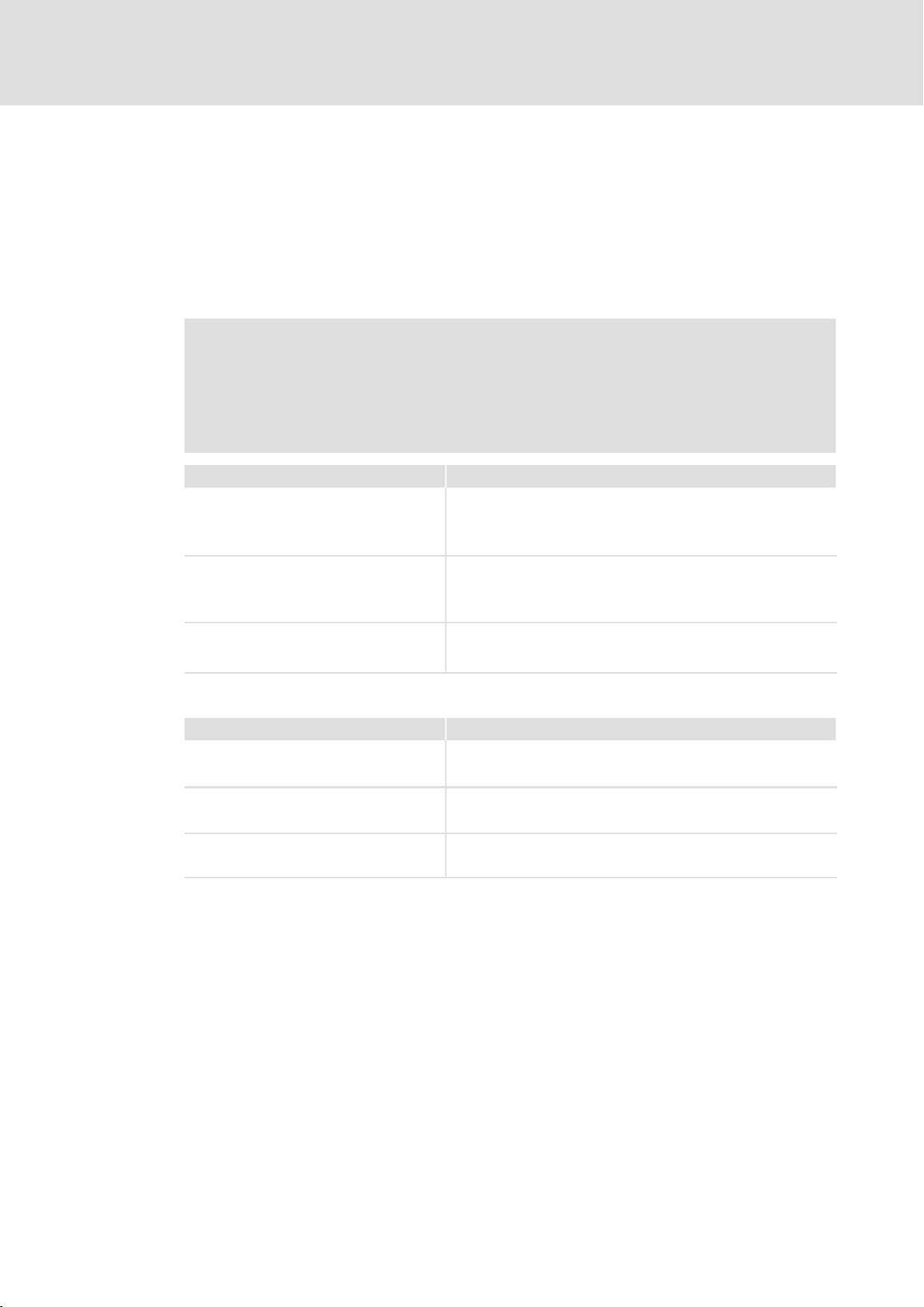

3.3 Communication

3.3.1 Controller with CAN bus

Area Values

Communication profile DS 301, DSP 402

Communication medium RS232

Network topology Without repeater: line / with repeaters: line or tree

CAN node Slave

Baud rate (in kbps) 10, 20, 50, 100, 125, 250, 500

Maximum cable length per bus

segment

Bus connection RJ45

3.3.2 Controller with PROFIBUS

Area Values

Communication profile

(DIN 19245 part 1 and part 3)

Communication medium RS485

Drive profile PROFIdrive

Network topology Without repeater: line / with repeaters: line or tree

PROFIBUS−DP station Slave

Baud rate [kbps] 9.6 ... 12000

Maximum cable length per bus

segment

Bus connection X4.1, X4.2 9−pin Sub−D socket

Technical data

Communication

Controller with CAN bus

1200 m (dependent on baud rate and cable type used)

PROFIBUS−DP−V0

1200 m (dependent on the baud rate and cable type used)

3

GHB 13.0001−EN EN 3.0

17

Page 18

4

Mechanical installation

Important notes

4 Mechanical installation

4.1 Important notes

ƒ Use the controllers as built−in units only!

ƒ In case of contaminated cooling air (dust, lints, greases, aggressive gases):

– Take suitable preventive measures, e.g. separate air duct, installation of filters,

regular cleaning, etc.

Stop!

Do not install drives on top of each other in the control cabinet!

ƒ Observe installation clearances!

– You can install several controllers next to each other without free space in a

control cabinet.

– Ensure unimpeded ventilation of cooling air and outlet of exhaust air!

– Allow a free space of 100 mm at the top and at the bottom.

– If possible, the rear panel of the drive controller should be provided with a good

thermal connection to the control cabinet wall.

– In case of high load and a bad heat dissipation, the drive controller reduces the

drive power, or possibly switches off.

ƒ Do not exceed the range of the ambient operation temperature specified in the

Technical Data.

ƒ In case of permanent oscillation or agitation:

– Check whether shock absorbers are necessary.

Possible mounting positions:

Vertically on the control cabinet rear panel with mains terminals at the top.

18

GHB 13.0001−EN EN 3.0

Page 19

4.2 Dimensions

Mechanical installation

Dimensions

4

Fig. 1 Drive dimensions

4.3 Mounting clearance

Fig. 2 Installation clearances

931E−006.iso

931E−007.iso

GHB 13.0001−EN EN 3.0

19

Page 20

5

Electrical installation

Important notes

5 Electrical installation

5.1 Important notes

Stop!

The drive controller contains electrostatically sensitive components.

The personnel must be free of electrostatic charge when carrying out assembly

and service operations.

Danger!

ƒ The connection of all pluggable terminals has to be effected in a

deenergised state.

ƒ Connecting and disconnecting the voltage supply (X2) due to the charging

processes of the DC bus capacitor may cause traces of burning on the

plug−in connection, and may result in a destruction of the internal electronic

circuit.

ƒ A false polarity of the DC supply can bring about the destruction of the

drive. Before switching the drive on, ensure that the polarity of the

DC supply is correct.

Note!

The following requirements have to be met with regard to the trouble−free

operation:

ƒ An installation according to EMC.

ƒ The shield of the motor cable has to be applied to PE potential on a

preferably large surface in order to prevent negative effects.

ƒ The resolver cable, encoder cable, and the motor cable may have a

maximum length of 15 m!

ƒ The feeding power supply units have to be sufficiently dimensioned. The

power supply units have to be protected against overcurrent by means of

appropriate input fuses.

20

GHB 13.0001−EN EN 3.0

Page 21

Electrical installation

Installation according to EMC (installation of a CE−typical drive system)

5.2 Installation according to EMC (installation of a CE−typical drive system)

Important notes

The electromagnetic compatibility of a machine depends on the type of installation and on

the care that is taken. Special attention should be paid to:

ƒ Assembly

ƒ Shielding

ƒ Grounding

For diverging installations, the conformity to the EMC Directive requires a check of the

machine or system regarding the EMC limit values. This, for instance, applies to the use of

unshielded cables.

The compliance of the machine application with the EMC Directive is in the responsibility

of the user.

ƒ If you observe the following measures, you can assume that the machine will

operate without any EMC problems caused by the drive system, and that compliance

with the EMC Directive and the EMC law is achieved.

5

ƒ If devices which do not comply with the CE requirements concerning noise

immunity EN 50082−2 are operated close to the controller, these devices may be

electromagnetically disturbed by the controllers.

Design

Contact drive controller extensively to the grounded mounting plate:

ƒ Mounting plates with conductive surfaces (zinc−coated, stainless steel) allow

permanent contact.

ƒ Painted plates are not suitable for installation in accordance with EMC.

ƒ If you use several mounting plates, connect them extensively to one another in a

conductive manner (e. g. by using copper strips).

Shielding

ƒ Connect the shield of the motor cable on the drive controller to the shield

connection of the drive controller.

ƒ Extensively connect the shield in the terminal box on the motor or on the motor

housing to PE:

– Metal glands at the motor terminal box ensure an extensive connection of the

shield and the motor housing.

Earthing

Ground all metallically conductive components (controller, motor filter) using suitable

cables connected to a central earthing point (PE bar).

Maintain the minimum cross−sections prescribed in the safety regulations:

ƒ With regard to EMC, however, not the cable cross−section is important, but the

GHB 13.0001−EN EN 3.0

surface of the cable and the contact with a cross−section as large as possible, i.e.

large surface.

21

Page 22

5

Electrical installation

Installation according to EMC (installation of a CE−typical drive system)

Principle circuit diagram

Note!

The described terminal assignment complies with the delivery status. You can

alter the terminal assignment via the operating software.

( Software Manual 931 E)

1/PE AC 230 V

L1

N

PE

F1 F2

K10 K11

~~

==

24 ... 48 V DC

GND

24VDC

470

470

PES

560

560

S1

S2

S3

S4

S5

S6

ZZZ

PES PES

RB

1UL2UL3BR4

X2

X5

PES

1

2

3

4

5

6

7

PES

PES

8

9

10

11

12

13

14

15

16

X3

+AIN 0

-AIN 0

+AIN 1

-AIN 1

+AMON 0

+AMON 1

GND

DIN 4

DIN 5

DIN 6

DIN 7

DIN 8

DIN 9

DOUT 0

DOUT 1

DOUT 2

5

-BR

24V524V6GND7GND

931E

4

+BR

W

X4.1

X4.2

X7

X8

X10

7

1

2V3

U

PE

PE

KTY

R

M

3~

PE

22

Fig. 3 Basic circuit diagram: installation according to EMC

F1, F2 primary−side fusing of the power supply units, consider the rules of conductor protection

RB external brake resistor

PES large−surface connection of the shield to PE

minimum wiring required for operation

S1 = reversal of rotation direction

S2 = jog value selection

S3 = quick stop

S4 = limit switch 1

S5 = limit switch 2

S6 = controller enable

931E_009

GHB 13.0001−EN EN 3.0

Page 23

5.3 Voltage supply

The drive controller requires two voltage supplies on X2 for the operation:

ƒ the control voltage (24 V DC) for the supply of the internal processors as well as of

the digital outputs, and − if available − the holding brake.

ƒ the supply voltage of the power unit with 24 V or 48 V DC

Both voltages have the same reference potential in the drive controller. They are not

isolated. The connections for the control voltage and the supply voltage of the power unit

are equipped with polarity protection and are additionally secured by means of a fuse or

by a polyswitch in the drive.

Note!

In principle, it is recommended to use 2 separate DC power supply units for the

control voltage (24 V DC) and the supply voltage (24 V DC ... 48 V DC). If the

power unit is also operated with 24 V DC, you can use a common 24 V DC

power supply unit under the following conditions:

ƒ The 24 V DC power supply unit has to be highly dynamic and robust and has

to provide the required current without voltage dip even with regard to

quick changes in current (e. g. 30 A within 0.5 ms). In this respect, also the

behaviour of further loads integrated in the DC supply system has to be

taken into consideration (e. g. a further drive controller). Furthermore, the

power supply unit has to be sufficiently dimensioned with regard to the

maximum current.

ƒ With regard to longer DC supply cables, a backup capacitor has to be

switched between UL and GND, in order to stabilise the supply voltage. You

can easily check the stability of the supply voltage by means of the

oscilloscope integrated in the parameterisation software.

Electrical installation

Voltage supply

5

GHB 13.0001−EN EN 3.0

23

Page 24

5

Electrical installation

Voltage supply

Stop!

The maximum permissible current loading of the terminal strip X2 is 16 A per

terminal. If required, the supply voltage has to be connected in parallel!

X2 supply voltage

Pin No. Designation Value Specification

1

2 As 1, loop through of the supply to further drives

3 BR Connection external brake resistor against UL

4

5 As 4, loop through of the supply to further drives

6

7 As 6, loop through of the GND potential to further drives

Terminal data

Cable [mm2] [AWG] [Nm] [lb−in]

Flexible

With wire end

ferrule

UL 24 ... 48 V

24 V +24 V / 1.5 A

GND 0 V

Max. conductor cross−section Tightening torque Screw drive

7mm

DC−bus voltage output stage

Control voltage for control section, DOUT0, DOUT1, DOUT2 and holding

brake, max. 1.5 A

Common reference potential for the DC−bus voltage and control voltage

2.5 12 0.5 ... 0.6 4.4 ... 5.3 Slot 0.6 x 3.5

External brake resistors

Stop!

The drive controller does not monitor the temperature of the external resistor.

For this purpose, additional safety measures are to be considered!

The drive controller is provided with an integrated brake resistor which is designed for a

permanent power of 10 W or for a pulse power of 200 W for 50 ms.

If higher permanent or pulse powers are required, you can connect an additional external

brake resistor to the integrated brake chopper.

If the switching threshold of the brake chopper is exceeded, both resistors are energised.

Parameter Value

Switching threshold brake chopper on Approx. 63 V

Switching threshold brake chopper off Approx. 60 V

Resistance, external > 5 W

Rated power 10 W ... 600 W

24

GHB 13.0001−EN EN 3.0

Page 25

Electrical installation

Motor connection

5

5.4 Motor connection

ƒ For trouble−free operation, we recommend to use Lenze standard cables.

ƒ Ensure a proper shielding of the motor and feedback cable to avoid interferences.

X3 motor connection

Pin No. Designation Specification

1U

2 V 0 V ... 13 A

3 W 0 Hz ... 200 Hz

4 BR+

5 BR− 0 V

Terminal data

Cable [mm2] [AWG] [Nm] [lb−in]

Flexible

With wire end

ferrule

Stop!

The brake is supplied by the control voltage at X2. In order to ensure the

trouble−free operation of the brake, the control voltage has to be in the

tolerance range of the brake used!

Motor phases

Fundamental wave in case of

overload for 2 s up to 32 A

Brake

Max. conductor cross−section Tightening torque Screw drive

7mm

2.5 12 0.5 ... 0.6 4.4 ... 5.3 Slot 0.6 x 3.5

eff

approx. 0 V ... 27 V

eff

24V DC

eff

GHB 13.0001−EN EN 3.0

25

Page 26

5

Electrical installation

Control terminals

5.5 Control terminals

The digital and analog inputs and outputs are placed in the plug X5. The digital and analog

inputs and outputs have the same reference potential.

X5 inputs and outputs

Pin No. Signal

1 +AIN0 (DIN0) Analog input 0

2

3

4

5

6 +AMON1

7 GND Reference potential for pin 1 ... 6, pin 8 ... 16

8 DIN4 Digital input 4 Rated voltage +24V DC

9 DIN5 Digital input 5 Voltage range 0 ... +30 V DC

10 DIN6 Digital input 6 HIGH signal > +8 V DC

11

12 DIN8 Digital input 8 Input impedance > 4.7 kW

13 DIN9 Digital input 9

14

15

16

−AIN0 (DIN1) DIN1

+AIN1 (DIN2) Analog input 1

−AIN1 (DIN3) DIN3 Limiting frequency ~ 1 kHz

+AMON0

DIN7 Digital input 7 LOW signal < +4 V DC

DOUT0 Digital output 0

DOUT1 Digital output 1

DOUT2 Digital output 2 Switching delay

Function

Lenze Alternatively

adjustable via

SDC

DIN0

differential

(speed setpoint, current

setpoint)

DIN2

differential

Analog monitors

output of internal quantities (current, speed,

etc.)

(controller enable / delete error)

(ready for operation)

Specification

Input voltage −10 V ... +10 V

Overvoltage protection −30 V ... +30 V

Input impedance > 20 kW

Resolution

Offset error < ± 50 mV

Gain error

Output signal 0 V ... 10 V,

Switching delay

(LOW−HIGH transmission)

Output voltage 0 V / 24 V

LOW signal 0 ... 4 V DC

HIGH signal 18 V ... 30 V

Output current max. 10 mA

Load impedance

(LOW−HIGH transmission)

12 Bit

< 5 %

max. 2 mA

< 1 ms

> 2.2 kW

< 1 ms

26

Terminal data

Max. conductor cross−section Tightening torque Screw drive

Cable [mm2] [AWG] [Nm] [lb−in]

Flexible

With wire end

ferrule

7mm

2.5 12 0.5 ... 0.6 4.4 ... 5.3 Slot 0.6 x 3.5

GHB 13.0001−EN EN 3.0

Page 27

Electrical installation

Feedback connection

Resolver at X7

5

5.6 Feedback connection

5.6.1 Resolver at X7

ƒ You can connect a resolver to X7 in order to record the speed and position.

ƒ Use Lenze system cables in order to provide for a trouble−free operation.

ƒ Self−prepared cables have to be provided as follows:

– Only use cables with cores that are twisted in pairs and shielded, featuring the

specified cable cross−sections.

– Apply the shield to both sides.

Features

Features Values

Connection on the drive controller 9−pole Sub−D socket

Monitoring Monitoring of the resolver and resolver cable with regard to open

Positioning resolution 16 bit

Encoder detection resolution 12 Bit

Connectable resolvers 2−pole, U = 10 V, f = 10 kHz

Ratio 0.3 (standard) or 0.5 (as of hardware version 1.1)

Carrier frequency 8 ... 10 Nm

Permissible exciting voltage 7 V

Impedance of the excitation (at

10 kHz)

Impedance of the stator (at 10 kHz) ³ (500 + j1000) W

circuit

... 12 V

eff

eff

³ (30 + j150) W

Connection plan

<15m

X7

+REF

-REF

+COS

-COS

+SIN

-SIN

KTY

+KTY

-KTY

Fig. 4 Resolver connection

Cores twisted in pairs

Assignment of the 9−pin Sub−D socket (X7) at the controller

Pin 1 2 3 4 5 6 7 8 9

Signal +REF −REF GND +COS −COS +SIN −SIN +KTY −KTY

2

0.5 mm

(AWG 20) ˘ 0.14 mm2 (AWG 26)

1

2

3

4

5

6

7

8

9

931E−005.cdr

GHB 13.0001−EN EN 3.0

27

Page 28

5

Electrical installation

Feedback connection

SinCos encoder at X8

5.6.2 SinCos encoder at X8

ƒ You can connect a SinCos encoder with serial communication (single turn or multi

turn) to X8.

ƒ Use Lenze system cables in order to provide for a trouble−free operation.

ƒ Self−prepared cables have to be provided as follows:

– Only use cables with cores that are twisted in pairs and shielded, featuring the

specified cable cross−sections.

– Apply the shield to both sides.

Features

Field Values

Connection on the drive controller 9−pole Sub−D socket

Input frequency: Max. 100 kHz

Current consumption per channel: 6 mA

Supply of the incremental encoder l Via X8/4 (VCC, DC 5 V), X8/5 (GND)

Encoder with number of increments 128 − 1024 periods / revolution

Angular resolution l Interpolation min. 10 Bit

Recommended encoders Sick−Stegmann SKS / SKM36

l Max. current consumption at X8/4: 200 mA

l Speed measurement 20 Bit

l Positioning 16 Bit

l Angular error < 2’

Connection plan

<15m

B

B

A

A

V

CC

GND

Z

KTY

Z

+KTY

-KTY

Fig. 5 Connection of incremental encoder with TTL level

Signals for CW rotation

Cores twisted in pairs

Assignment of 9−pin Sub−D socket (X8) at the controller

Pin 1

2 3 4 5 6 7 8 9

Signal B A A V

2

0.14 mm

(AWG 26) 1 mm

X8

1

2

3

4

A

5

A

6

B

7

B

8

Z

Z

9

GND (−KTY) Z Z +KTY B

CC

2

(AWG 18) 0.14 mm

2

(AWG 26)

931E−004.cdr

28

GHB 13.0001−EN EN 3.0

Page 29

Connection of digital frequency coupling at X10

5.7 Communication

ƒ In order to provide for a perfect operation, we recommend the use of Lenze system

cables. ( 42)

ƒ Check the plug connections of the bus cables with regard to a tight fit.

5.7.1 Connection of digital frequency coupling at X10

ƒ Master frequency features:

– Angular resolution / number of increments max. 12 bits / 1024 increments

switchable to 512 / 256 / 128 / 64 and 32 increments

– Track signals A, B, Z in accordance with RS422 standard

– Output impedance R

Output X10 Input X10

l Output frequency: 0 ... 500 kHz

l Current capacity per channel: max 20mA.

l Two−track with inverse 5 V signals (RS422) and zero

track

l In case of a parallel connection maximally three

slave drives can be connected

l By LOW level, PIN 8 (enable) indicates the

initialisation of the master drive (e. g. when the

mains has been switched off in the meantime). This

enables the slave drive to monitor the master.

= 120 W

a,diff

Technical data master frequency

l Input frequency:

l Max. 5 mA

l Two−track with inverse signals and zero track

Electrical installation

Communication

– 0 ... 500 kHz for TTL level

– With regard to incremental encoders with HTL

level, also operable without reversed signals

5

Connection plan

<15m

X10 X10

AA

1

BB

2

ZZ

3

GND GND

4

5

A

6

B B

7

8

Z Z

GND GND

9

Fig. 6 Connection of digital frequency input and digital frequency output (X10)

X10 Slave drive Signals with CW rotation

X10 Master drive

Assignment of 9−pin Sub−D socket (X10) at the controller for digital frequency coupling

Pin 1 2 3 4 5 6 7 8 9

Signal A B Z GND n. c. A B Z GND

0.14 mm

(AWG 26)

1

2

3

4

5

A

6

7

8

9

A

A

B

B

Z

Z

931E−003.cdr

Cores twisted in pairs

2

0.5 mm

(AWG 20)

2

0.14 mm

(AWG 26)

2

0.5 mm

(AWG 20)

2

0.14 mm

(AWG 26)

2

GHB 13.0001−EN EN 3.0

29

Page 30

5

Electrical installation

Communication

Connection of CAN bus at X4.1 and X4.2

5.7.2 Connection of CAN bus at X4.1 and X4.2

Features

ƒ Parameter presettings

ƒ Data exchange from controller to controller

ƒ Connection of operator and input devices

ƒ Connection of external controls and control systems

ƒ Baud rate 125, 250, 500 kBaud

Stop!

For the termination of the bus system, an external 120 W terminating resistor is

required.

Connection plan

X4.1 / X4.2

Fig. 7 Connection of CAN bus (X4.1, X4.2)

Pin no. Meaning Comment

1 CAN−HIGH CAN−HIGH (high is dominant)

2 CAN−LOW CAN−LOW (low is dominant)

3 CAN−GND CAN ground

4 Reserved

5 Reserved

6 CAN−SHLD CAN shield (hardware version 1.1 and higher)

7 CAN−GND CAN ground

8 Reserved

Tip!

An RJ45 bus terminating connector is available for the 931E drive controllers.

Please contact Lenze.

931E−001.iso

30

GHB 13.0001−EN EN 3.0

Page 31

Electrical installation

Communication

Connection of PROFIBUS

5

5.7.3 Connection of PROFIBUS

Assignment of Sub−D socket

The controller is connected to the PROFIBUS via the 9−pin Sub−D socket X4.1/X4.2.

View Pin Designation Explanation

1 − −

2 − −

9

6

5

1

3 RxD/TxD−P Data line B (received/transmitted data plus)

4 RTS Request to send

(received/transmitted data, no differential signal)

5 M5V2 Data reference potential (ground to 5V)

6 P5V2 5 V DC / 30 mA (bus termination)

7 − −

8 RxD/TxD−N Data line A (received/transmitted data minus)

9 − −

5.7.4 Connection of RS232 serial interface to X1

The serial interface is designed as a 9−pole Sub−D−plug. The signal levels comply with the

RS232 specification.

X1 RS232

Pin No. Designation Value

1 n. c. Not assigned

2 R x D 0 V / 10 V

3 T x D 0 V / 10 V

4 n. c. Not assigned

5 GND

6

7

8

9

n. c. Not assigned

GHB 13.0001−EN EN 3.0

31

Page 32

6

Commissioning

Before switching on

6 Commissioning

6.1 Before switching on

Stop!

Avoid injury to persons and damage to material assets during commissioning!

ƒ Necessarily observe the switch−on sequence.

ƒ During the resolver adjustment, the drive has to be able to rotate freely

without load!

Tip!

For faults during commissioning, see chapter Troubleshooting and fault

elimination. ( 38)

Before the first commissioning and before commissioning after longer downtimes, check:

Check Checked

Have all necessary electrical connections been established?

Are there no short circuits and earth faults?

Are all plug connections fixed?

Are all plugs secured with the bolted connections specified for this purpose?

Are all bolted connections tightened?

Are control voltage and power supply connected with the right polarity?

Are the output voltages of the power supply units set correctly?

+24 V DC for the control

+24V DC or +48 V DC for the power supply

Is the shield of the motor cable and that of the feedback cable correctly applied?

Are the correct signals assigned to the digital inputs and outputs?

Are at least DIN9 (controller enable), DIN6 (start positioning) assigned?

If limit switches are connected, are they connected to DIN7 and DIN8?

If you use the analog inputs for the setpoint selection or for torque limitation

Are the correct signals assigned to the analog inputs?

Is the voltage for the analog inputs settled in the permissible range

0 ... 10 V?

32

GHB 13.0001−EN EN 3.0

Page 33

6.2 Initial switch−on

Note!

The described terminal assignment complies with the delivery status. You can

alter the terminal assignment via the operating software.

( Software Manual 931 E)

Tip!

The windows to the individual menu items in the »Small Drive Control (SDC)«

parameterisation software remain open after you have entered and adopted

changes.

Close the windows when you have edited a menu item, so that the monitor

operations remain clearly visible.

Commissioning

Initial switch−on

6

When carrying out initial commissioning, some basic settings have to be effected before

the drive can be started.

GHB 13.0001−EN EN 3.0

33

Page 34

6

Commissioning

Initial switch−on

Basic settings:

1. Connect the serial interface on the drive controller and on the PC to a null modem

cable.

2. Switch on the control voltage, but not yet the power supply!

– If the green LED (state) is blinking, the voltage is in the permissible range.

3. Start the »Small Drive Control (SDC)« parameterisation software.

– If you are not able to effect a connection between the PC and the drive controller,

check the setting of the serial interface on the PC (see Software Manual).

– If communication is defective, a message is displayed on the user interface.

4. Select the item "Select as commissioned" in the window "Initial commissioning".

– Ignore the error messages which are displayed due to the power supply that is not

yet existent.

5. Select the connected motor in the "Parameters Drive parameters Motor data"

menu.

– If you select a motor from the integrated motor data base, you do not have to

enter the motor parameters manually.

– If you do not find the connected motor in the motor data base, you have to enter

the motor parameters manually. The data can be gathered from the nameplate of

the motor.

6. Select and parameterise the connected encoder system in the "Parameters Drive

parameters Resolver settings" menu.

7. Select the operating mode "Speed control" in the window "Commands".

8. Assign the setpoint sources in the "Operating mode Setpoint selection..." menu:

– analog speed setpoint (±10 V DC) via AIN0

931E_013

34

GHB 13.0001−EN EN 3.0

Page 35

Commissioning

Initial switch−on

9. Parameterise the analog terminals in the "Parameters I/Os... Analog inputs"

menu:

– Here you assign the setpoint quantity to the voltage level.

– By means of the offset, you can adjust the potentiometer.

– By means of the slide control "safe null", you can define a range where the motor

is safely stopped.

6

931E_012

GHB 13.0001−EN EN 3.0

35

Page 36

6

Commissioning

Initial switch−on

10. Parameterise the digital terminals in the "Parameters I/Os... Digital inputs"

menu.

– Terminal assignment see connection example. ( 22)

– The analog inputs may not be configured as digital inputs. Therefore, in the

"Parameters IOs Digital inputs" menu, check whether the selection

"Interprete AINs as DINs" is not set! Otherwise you are not able to evaluate the

analog setpoint.

– The function of the digital inputs can be displayed under the menu item "Function

overview". Check the right function here.

– The 931E Software Manual decribes how you configure analog inputs as digital

inputs.

11. Set the threshold for the undervoltage recognition in the "Parameters Drive

parameters DC bus monitoring" menu.

– Adjust the threshold according to the application and the supply voltage (e. g. 16 V

for 24 V DC power supply).

The basic settings are now completed.

Now you calibrate the feedback system and the controller parameters.

931E_011

36

GHB 13.0001−EN EN 3.0

Page 37

Commissioning

Initial switch−on

Calibrating the feedback system and the controller parameters:

12. Make sure that the controller is inhibited!

– DIN9 = LOW

13. Switch on the power supply.

14. Check whether error messages are pending.

– First of all, eliminate and acknowledge the errors, or alter the error tracking

system.

15. Make sure that the drive can rotate without load!

16. Select the resolver adjustment in the "Parameters Drive parameters Resolver

settings" menu.

– Caution: the motor shaft rotates during the adjustment!

17. Parameterise the controller in the "Parameters Controller parameters Speed

controller menu.

6

Note!

If you have selected a Lenze servo motor from the motor data base, the current

controller parameters are already optimised.

If required, the parameters have to be slightly adapted to your application.

18. Use the icon "Save parameters" in the menu bar, in order to save the settings in the

EEPROM of the drive controller in a powerfail−proof manner.

The settings are completed.

You can now start the drive.

Starting the drive:

19. Set a speed setpoint on AIN0.

20. Enable controller.

– DIN9 = HIGH

21. The drive now operates in speed−controlled operation.

22. If you want to change the direction of rotation during operation:

– Change in potential on AIN0

– HIGH signal on DIN4

Detailed information can be found in the 931E Software Manual.

GHB 13.0001−EN EN 3.0

37

Page 38

7

Troubleshooting and fault elimination

Status of the drive

7 Troubleshooting and fault elimination

7.1 Status of the drive

The current operating status of the drive controller is displayed by 3 light−emitting diodes.

Thus, a quick diagnostics is possible. Details with regard to diagnostics information are

supplied by the parameterisation software.

LED Colour State Note

State Green

Power Yellow

Error Red

Green

Yellow

Red

on The control is correctly supplied by a 24 V control voltage, the drive is ready for operation.

blinking Data is written on or read from the memory card.

off No voltage

on The power section is enabled, the motor is supplied with voltage. The drive works with the set

off The drive does not work, the output stage is inactive.

off No fault

blinking Internal drive error

on l The drive is in the initialisation phase after the control voltage has been switched on.

1)

Detailed description of the blink codes: 40

control.

1)

After the cause of the error has been eliminated, you have to acknowledge the error message:

l Either by using the parameterisation software, or via an edge at DIN9 (controller enable).

l If no error is active anymore, the LED goes out.

l A new firmware is being installed.

Note!

The light−emitting diode "Error" constantly blinks if a fault is active:

ƒ It only displays one fault at a time.

ƒ If several faults are active at the same time, the fault that occured first is

displayed.

38

GHB 13.0001−EN EN 3.0

Page 39

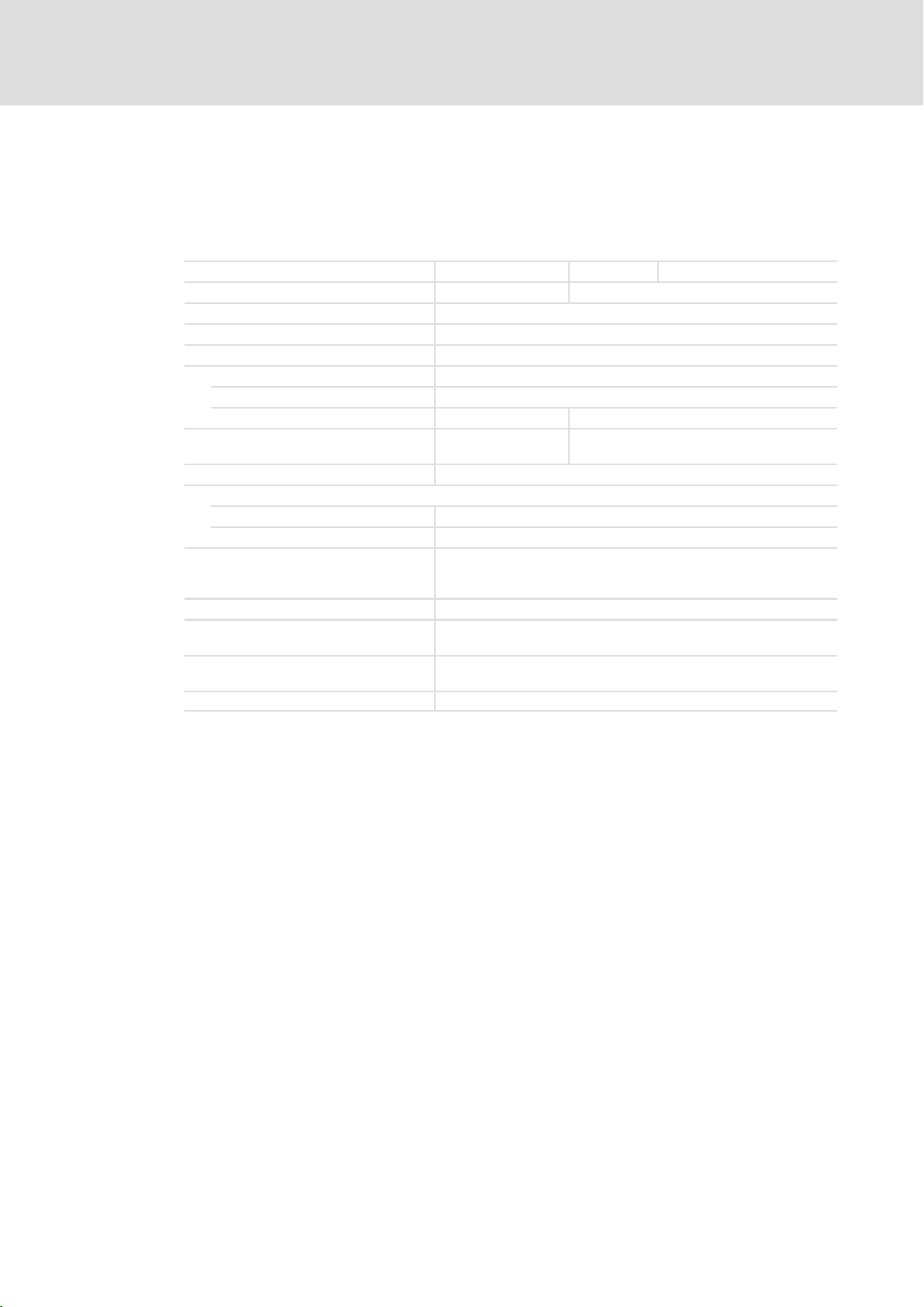

7.2 Error message

Various monitoring functions protect the drive against impermissible operating

conditions. If a monitoring function is activated, a response corresponding to the

protection of the drive is actuated. The following things are monitored:

ƒ Temperature of the output stage

ƒ Motor temperature

ƒ I2t monitoring of the motor

ƒ Overcurrent / short circuit of the output stage

ƒ DC−bus voltage (under− and overvoltage)

ƒ Following error with regard to position control

ƒ Error with regard to the reference run

ƒ Error with regard to the angle encoder system

Troubleshooting and fault elimination

Error message

7

ƒ Communication error

ƒ Initialisation error

ƒ Check sum error of the parameters

Some responses to failures can be set within the SDC parameterisation software. Possible

responses are:

Reaction Meaning Reaction of the drive

A Immediate disconnection of the

output stage

h Emergency stop The motor is braked to zero speed at the current limit. If there

W Warning The controller keeps operating, the output stage remains

O Off The warning signal is inhibited − no response.

The motor coasts.

is a motor holding brake, it is applied. The output stage

switches off.

switched on. The warning signal can be read out via the CAN

bus or via the serial RS232 interface.

Used symbols:

Symbol Meaning

þ Default setting

¨ Response parameterisable in SDC

− Selection not possible

GHB 13.0001−EN EN 3.0

39

Page 40

7

Troubleshooting and fault elimination

Error message

Red LED is

blinking

15x þ − − − Parameter set

10x þ ¨ ¨ ¨ I2t error l Adjust the i2t time of the motor.

9x þ ¨ ¨ ¨ Following error position

8x þ − − − Resolver or SINCOS

7x þ − − − Overvoltage in the DC

Reaction

A h W O

Cause Remedy

inconsistent

control

encoder error; as the case

may be, definite

recognition only possible

after approx. ½ motor

revolution

bus > 70 V

Check parameter set of the drive by means

of the parameterisation software ( 931E

Software Manual).

( 931E Software Manual)

l Effect resolver adjustment. ( 931E

Software Manual)

l Check set motor data. ( 931E

Software Manual)

l Optimise controller setting. ( 931E

Software Manual)

l Adjust travel profile (e. g. adjust

acceleration ramps).

l Reduce load torque of the motor.

l Optimise controller setting to improve

the running precision. ( 931E

Software Manual)

l Adjust travel pofile (e. g. reduce

acceleration and braking ramps.

( 931E Software Manual)

l Amplify following error

window/increase switch−in delay.

( 931E Software Manual)

l Check correct fit of the resolver plug.

l Check resolver cable with regard to

cable breakage, short circuit.

l Check PIN assignment of the resolver

cable plug.

l Parameterise encoder correctly.

( 931E Software Manual)

l Check whether power supply unit

operates correctly, and whether the

supply voltage of the power unit is

settled in the permissible range

(19.2 V DC ... 57.6 V DC).

l Decrease the steepness of the braking

ramp. (931E Software Manual)

l Connect external brake resistor to X2.

l Check whether other drives connected

to the DC supply of the power unit have

caused this overvoltage.

40

GHB 13.0001−EN EN 3.0

Page 41

Troubleshooting and fault elimination

Error message

RemedyCauseReactionRed LED is

Red LED is

blinking

blinking

6x þ − − − Overcurrent / short

5x þ − − − System error Switch off and then reconnect control

4x þ ¨ − − Overtemperature drive

3x þ ¨ ¨ ¨ Overtemperature motor l Check whether the motor cooling via

2x þ ¨ ¨ ¨ Undervoltage in the DC

1x ¨ ¨ þ ¨ MMC not connected l Check setting of multimedia card

OWhA

circuit

controller

bus

RemedyCause

Check motor cable and motor phases with

regard to a short circuit of the phases or

the drive

voltage. If the error re−occurs, send in the

drive.

l Check correct mounting in the control

cabinet:

– Heatsink has to fit extensively to the

housing of the control cabinet.

– Are further heat sources mounted

near the drive controller, bringing

about an increased ambient

temperature of the inverter?

l Check whether the ventilation slots of

the drive controller are soiled or

blocked. If required, clean.

l Optimise controller settings (bad

settings result in an unnecessary

heating). ( 931E Software Manual)

l Check resolver adjustment. ( 931E

Software Manual)

l Reduce load torque of the motor.

the motor housing is prevented by

deposits, etc.(if required, cleaning of the

motor).

l Are there further heat sources near the

motor, bringing about an additional

increase in the predominant ambient

temperature, and thus contributing to a

diminution of the dissipation of lost

heat?

l Check controller settings, bad settings

result in an unnecessary heating.

( 931E Software Manual)

l Reduce load torque of the motor.

l Check setting of the thermal sensor.

l Check resolver cable or encoder cable

with regard to open circuit.

l Check resolver adjustment. ( 931E

Software Manual)

l Check DC−bus voltage, if required,

adjust undervoltage trigger level.

( 931E Software Manual)

(MMC).

l Connect MMC.

l Change setting of the error tracking

system by means of the

parameterisation software.

7

GHB 13.0001−EN EN 3.0

41

Page 42

8

Accessories

System cables and plugs

8 Accessories

8.1 System cables and plugs

Connector plugs

Set connector plugs Use Rated current /

X3 Motor connection 16 A / 2.5 mm

x2 Voltage supply 16 A / 2.5 mm

X5 Inputs and outputs 1 A / 1.5 mm

max. cross−section

Motor connection system cables

Motor − servo inverter

Connection on the servo

inverter

X3 (U, V, W, PE)

Resolver feedback

Connection on the servo

inverter

X7

Sub−D plug, 9−pole

Absolute value encoder feedback

Connection on the servo

inverter

X8

Sub−D socket, 9−pole

Length [m] Connection on the motor Order number

2.5

5

Length [m] Connection on the motor Order number

2.5

5 13011242

Length [m] Motor connection side Order number

2.5

5 13041363

6−pole socket

M23 socket, 12−pole

M23 socket, 12−pole

Order number

2

2

2

13041955

13009636

13011101

13009635

13041367

42

Communication system cables

CAN system cable

CAN input Length [m] CAN output Order number

X4.1

RJ 45 plug

Serial null modem connection RS232

Connection on the servo

inverter

x1

Sub−D socket, 9−pole

3 X4.2

RJ 45 plug

Length [m] Connection on the PC Order number

1.8 Sub−D socket, 9−pole 492232

492234

GHB 13.0001−EN EN 3.0

Page 43

8.2 Power supply units

Technical data of the power supply units

Secondary side Primary side Order number

DC 24 V

(DC 2.5 ... 28.5 V)

DC 24 V

(DC 2.5 ... 28.5 V)

DC 48 V

(DC 40 ... 56 V)

5A

10 A Approx. 2.34 A (AC 120 V)

20 A Approx. 4.76 A (AC 120 V)

5A

10 A Approx. 3 × 0.63 A

20 A Approx. 3 × 1.1 A

5A AC 85 V − 0 % ... 264 V + 0 %

10 A

20 A Approx. 3 × 2.3 A

AC 85 V − 0 % ... 264 V + 0 %

45 Hz − 0 % ... 65 Hz + 0 %

3 AC 320 V − 0 % ... 575 V + 0 %

45 Hz − 0 % ... 65 Hz + 0 %

45 Hz − 0 % ... 65 Hz + 0 %

3 AC 320 V − 0 % ... 575 V + 0 %

45 Hz − 0 % ... 65 Hz + 0 %

Accessories

Power supply units

Approx. 1.6 A (AC 120 V)

Approx. 0.84 A (AC 230 V)

Approx. 1.2 A (AC 230 V)

Approx. 2.3 A (AC 230 V)

Approx. 3 × 0.36 A

(AC 400 V)

Approx. 3 × 0.34 A

(AC 480 V)

(AC 400 V)

Approx. 3 × 0.57 A

(AC 480 V)

(AC 400 V)

Approx. 3 × 1.0 A

(AC 480 V)

Approx. 2.2 A (AC 120 V)

Approx. 1.2 A (AC 230 V)

Approx. 3 × 1.2 A

(AC 400 V)

Approx. 3 × 1.0 A

(AC 480 V)

(AC 400 V)

Approx. 3 × 1.9 A

(AC 480 V)

8

EZV1200−000

EZV2400−000

EZV4800−000

EZV1200−001

EZV2400−001

EZV4800−001

EZV2400−002

EZV4800−002

EZV9600−000

8.3 Memory cards

Memory cards (on request)

Format Capacity Order number

MMC (multimedia card) 64 MB 13041516

GHB 13.0001−EN EN 3.0

43

Page 44

8

Accessories

Motors for 931E servo inverters

General data and operating conditions

8.4 Motors for 931E servo inverters

Further information on motors and gearboxes can be gathered from the

respective catalogue.

8.4.1 General data and operating conditions

Design Smooth, round

Design B14 flange in accordance with DIN 42948 and IEC 72; form C

Cooling Naturally ventilated

Insulation material class F

Winding insulation Max. voltage amplitude 1500 V; du/dt < 5 kV/ms

Permissible temperature ranges

Operation −20 °C ... + 40 °C

Type of protection IP54 in accordance with DIN EN60034−5

Connection System connector

Temperature monitoring KTY 110

Speed feedback Pancake resolver (size 15)

Absolute value encoder

8.4.2 Rated data

Motor type

SDSGS 035−22 SDSGS 035−22 SDSGS 047−22

Rated power [W] 140 140 210

Rated torque [Nm] 0.45 0.45 0.8

Rated current [A] 9.5 4.0 6.2

Rated voltage [V] 13 30 30

Rated frequency [Hz] 100 100 83

Rated speed [min−1] 3000 3000 2500

Power factor 1 1 1

Maximum speed, mechanical [min−1] 6000 6000 6000

Continuous standstill torque [Nm] 0.55 0.55 1

Continuous standstill current [A] 10.4 4.4 6.7

Maximum continuous standstill torque for 2 s [Nm] 1.0 2.9 4/5

Operating mode S1 S1 S1

Moment of inertia [kgcm2] 0.293 0.293 0.444

44

GHB 13.0001−EN EN 3.0

Page 45

Accessories

Motors for 931E servo inverters

Mechanical data

8.4.3 Mechanical data

Motor type

SDSGS 035−22 SDSGS 035−22 SDSGS 047−22

Weight [kg] 2.2 2.2 3

Flange IEC IEC56 B14 C80 IEC56 B14 C80 IEC56 B14 C80

Shaft end IEC 72 9 x 20 9 x 20 11 x 20

Locating bearing at the output end 6000 6000 6000

Floating bearing 6000 6000 6000

Max. radial force Fr top of pivot

Max. radial force Fr middle of pivot

Max. axial force F

*)

a

*)

Forces determined for bearing service−life of 20000h

*)

*)

[N] 250 250 300

[N] 260 260 350

[N] 200 200 250

Fr

8

Fa

l/2

l

Fig. 8 Points of application of the radial (Fr) and axial force (Fa)

GHB 13.0001−EN EN 3.0

45

Page 46

Index9

9 Index

A

Application as directed, 10

B

Baud rate, 17

C

Cable length, per bus segment, 17

Commissioning, 32

− Initial switch−on, 33

Communication profile, 17

Connection incremental encoder, at X8, 28

Connection plan, 27 , 28 , 29 , 30

Control terminals, 26

Controller

− Application as directed, 10

− Labelling, 10

D

Definition of notes used, 14

Definitions, 9

Device protection, 13

Drive profile, 17

Liability, 10

M

Manufacturer, 10

Mechanical installation, 18

Motor protection, 13

Mounting clearance, 19

N

Nameplate, 4

Network topology, 17

Notes, definition, 14

O

Operating conditions, 44

Overspeeds, 13

P

PROFIBUS, 31

PROFIBUS−DP function module,

communication medium, 17

Protection of persons, 13

E

E82ZAFPC00x, baud rate, 17

Electrical installation, 20

Error message, 39

G

General data, 44

I

Incremental encoder, connection at X8, 28

Initial switch−on, 33

Installation, PROFIBUS, 31

Installation, electrical, 20

Installation, mechanical, 18

L

Labelling, controller, 10

Legal regulations, 10

R

Rated data, 44 , 45

Residual hazards, 13

Resolver, Connecting, 27

S

Safety instructions, 11

− Definition, 14

− Structure, 14

Switch on, initial, 33

T

Technical data, 15

Troubleshooting and fault elimination, 38

Type code, 4

W

Warranty, 10

Waste disposal, 12

46

GHB 13.0001−EN EN 3.0

Page 47

Lenze GmbH & Co KG Kleinantriebe

Hans−Lenze−Straße 1

D−32699 Extertal

Germany

(

( Service

Ê Service

E−Mail Lenze@Lenze.de

Internet www.Lenze.com

+49(0)515482−0

0080002446877 (24 h helpline)

+49(0)515482−1112

GHB 13.0001−EN

EN 3.0

© 12/2007

TD35

10987654321

Loading...

Loading...