Page 1

Inverter

8400

Inverter Drives 8400 protec · Drive-based safety _ _ _ _ _ _ _ _ _ _

E84Dxxxxx...

Software manual EN

Ä.A+0ä

13321015

L

Page 2

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 5

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.4 Terms and abbreviations used in drive-based safety _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.5 Notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

2Introduction _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

2.1 Functional range of the functional safety (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

2.2 Function mode of safety engineering _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.3 Connection to the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2.3.1 "LS_SMInterface" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

2.3.1.1 Status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

2.3.1.2 I/O-Status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

2.3.1.3 Control information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

2.3.1.4 Transferring the control information to the application _ _ _ _ _ _ _ _ _ _ _ 14

2.3.1.5 Interconnection examples _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

2.4 Parameter setting and configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

2.5 Diagnostics & error management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

3 Safe configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

3.1 Change parameter settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

3.2 Import/export parameter settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

3.3 Plausibility check _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

3.4 General parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

3.4.1 Setting of the safety address _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

3.5 Safety functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.5.1 Stop functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.5.1.1 Prioritisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.5.1.2 Restart behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

3.5.1.3 Emergency stop function (SSE) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

3.5.1.4 Safe torque off (STO) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

3.5.1.5 Safe stop 1 (SS1) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

3.5.2 Operation mode selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

3.5.2.1 Operation mode selector (OMS) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

3.5.2.2 Enable switch (ES) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

3.6 Safety bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

3.6.1 PROFIsafe connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

3.6.1.1 PROFIsafe output data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

3.6.1.2 PROFIsafe input data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

4 Safety option 20 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

5 Safety option 30 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

5.1 Safe inputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

6 Safe parameter transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

6.1 Send safe data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.2 Read safe data from device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

6.3 Write parameter set into file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

6.4 Read parameter set out of file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

6.5 General reset of device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

6.6 Password management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

2 Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

7.1 Parameter list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

7.2 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 3

Page 4

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

The manual contains the complete information on the application as directed of the decentralised

controllers 8400

protec with drive-based safety (safety option 20 and 30).

Please read the mounting instructions supplied with the controller before you start

working!

The mounting instructions contain safety instructions that must be observed!

Target group

This manual is intended for all persons who want to parameterise, configure, and diagnose the

integrated safety systems in controllers of the 8400

engineering software.

Validity

The information given in this manual applies to 8400 protec controllers with the following

nameplate data:

protec series with the L-force »Engineer«

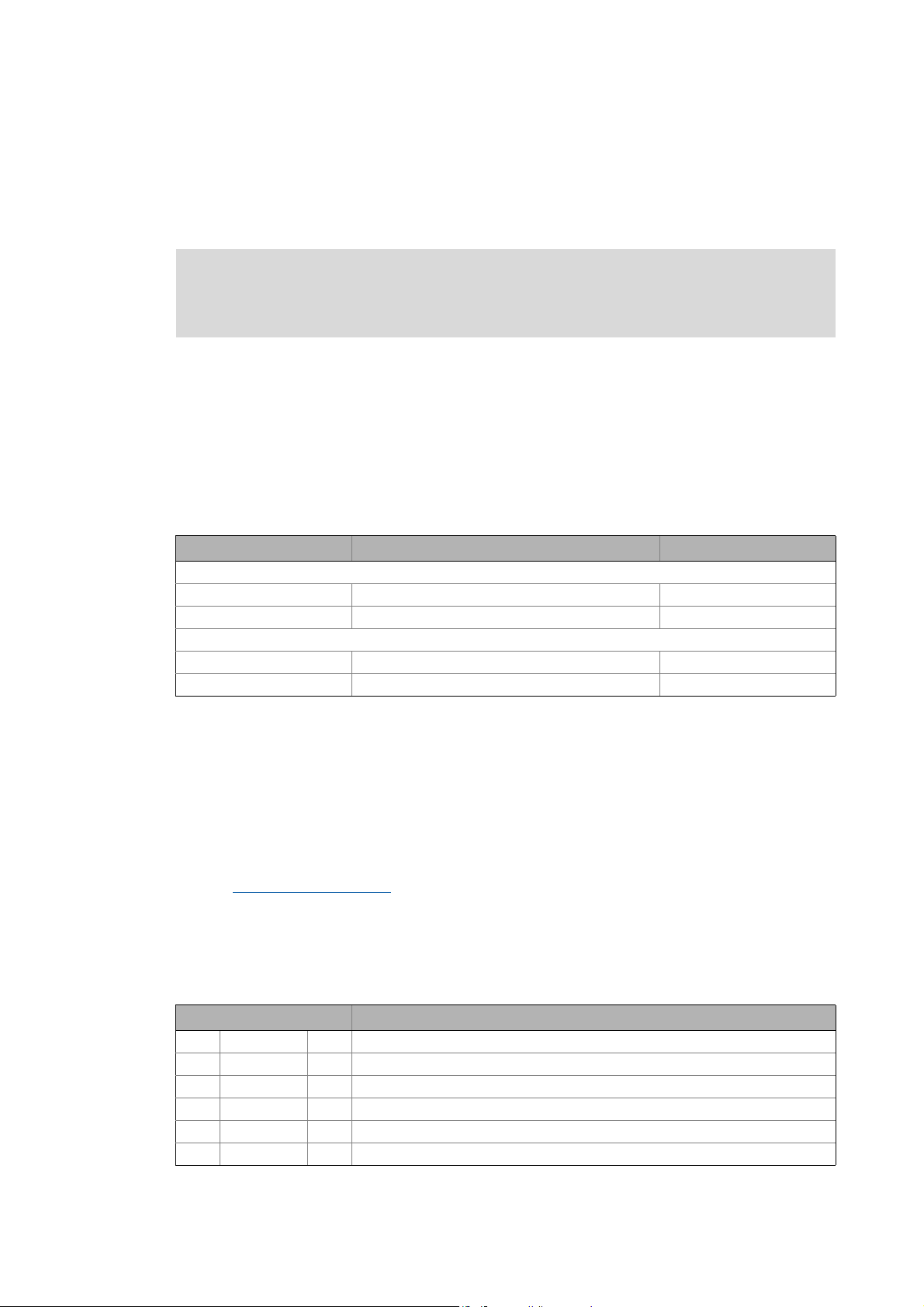

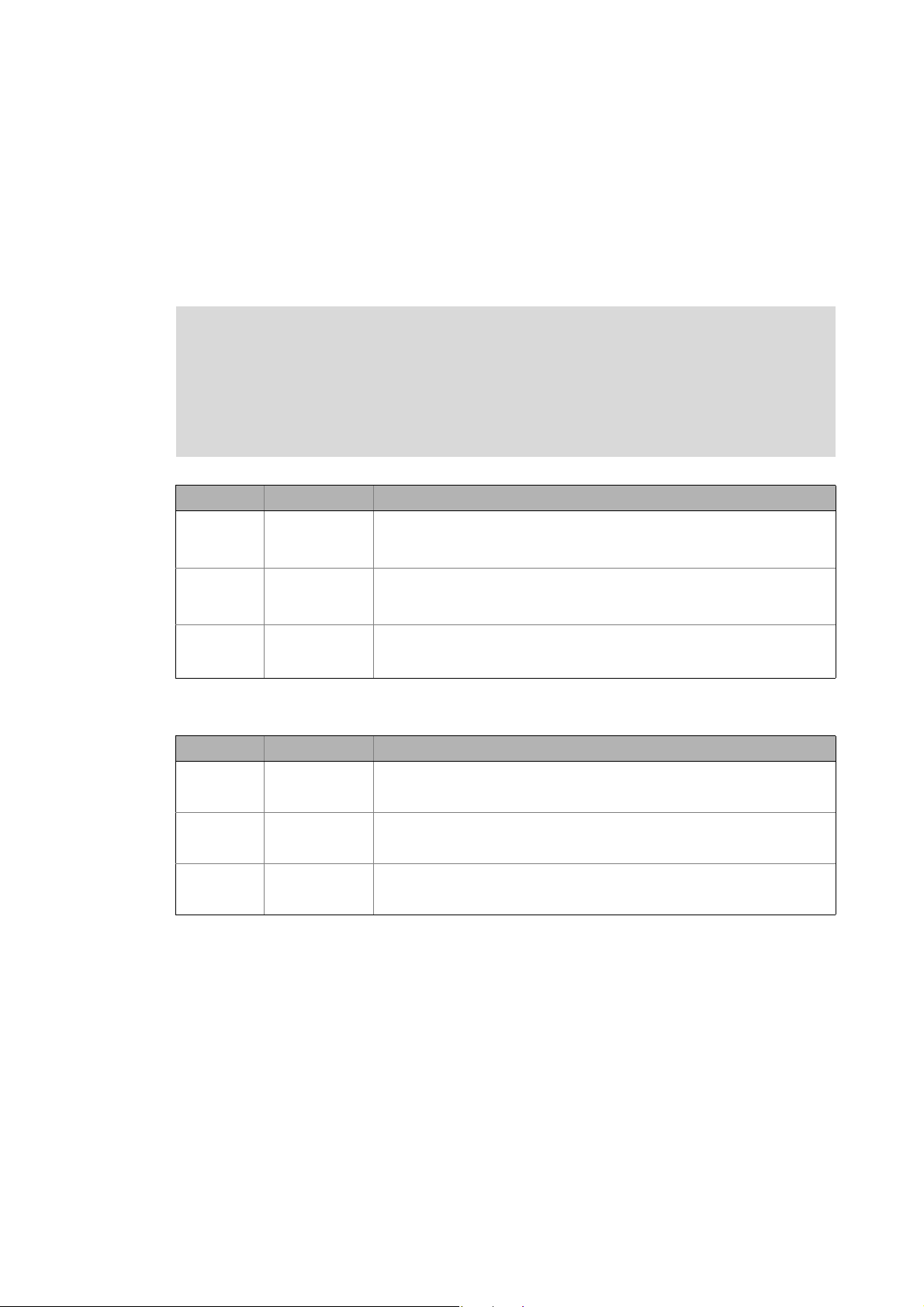

Product series Type designation From software version

8400 protec StateLine

with safety option 20 E84DSWTxxxxxxN0xxx-xKxxS 01.00

with safety option 30 E84DSWTxxxxxxN0xxx-xLxxS 01.00

8400 protec HighLine

Screenshots/application examples

All screenshots provided in this documentation are application examples. Depending on the

software version of the controller and the version of the installed »Engineer« software, the

screenshots in this documentation may differ from the representation in the »Engineer«.

with safety option 20 E84DHWTxxxxxxN0xxx-xKxxS 01.00

with safety option 30 E84DHWTxxxxxxN0xxx-xLxxS 01.00

Tip!

Information and tools for Lenze products are provided in the download area at

http://www.Lenze.com

1.1 Document history

Download

Version Description

2.4 05/2013 TD05 Corrections

2.3 01/2013 TD05 Converted to new layout

2.2 02/2010 TD14 Corrections

2.1 11/2009 TD14 Corrections

2.0 09/2009 TD14 Corrections and extension by safety option SO20

1.0 05/2009 TD14 First edition

4

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 5

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This manual uses the following conventions to distinguish between different types of information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separators Point The decimal point is generally used.

For example: 1234.56

Text

Version information Blue text colour Information that is only valid for or from a certain software

Program name » « The Lenze »Engineer« PC software ...

Window italics The Message window ... / The Options dialog box...

Variable name By setting bEnable to TRUE...

Control element bold The OK button... / The Copy command... / The Properties

Sequence of menu

commands

Shortcut <bold> Press <F1> to open the online help.

Hyperlink Underlined

Icons

Page reference ( 5) Optically highlighted reference to another page. In this

Step-by-step instructions

version of the controller is marked accordingly in this

manual.

Example: This function extension is available from software

version V3.0!

tab... / The Name input field...

If the execution of a function requires several commands,

the individual commands are separated by an arrow: Select

Open to...

File

If a command requires a combination of keys, a "+" is placed

between the key symbols:

Use <Shift>+<ESC> to...

Optically highlighted reference to another topic. In this

documentation activated by mouse-click.

documentation activated by mouse-click.

Step-by-step instructions are indicated by a pictograph.

Information that is only valid for or as from a certain software version of the controller are marked

accordingly in this manual.

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 5

Page 6

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

»Engineer« Lenze PC software which supports you in "engineering" (parameterisation,

Application block Block for a technology application (e.g. actuating drive - speed)

Code Parameter used for controller parameterisation or monitoring.

Display codes Parameter that displays the current status or value of a system block input/

FB Editor Function block editor

Function block General designation of a function block for free interconnection (only

Lenze setting This setting is the default factory setting of the device.

Port block Block for implementing the process data transfer via a fieldbus

Subcode If a code contains several parameters, these are stored in the "subcodes".

System block System blocks provide interfaces to basic functions and to the hardware of

diagnostics and configuration) throughout the whole life cycle, i.e. from

planning to maintenance of the commissioned machine.

A technology application is a drive solution based on the experience and

know-how of Lenze in which function blocks interconnected to a signal flow

form the basis for implementing typical drive tasks.

The term is usually called "index".

output.

Graphical interconnection tool which is provided for FB interconnections in

the »Engineer« on the FB editor tab and by means of which the applications

integrated in the drive can also be reconfigured and extended by individual

functions.

HighLine).

A function block can be compared with an integrated circuit that contains a

certain control logic and delivers one or several values when being executed.

• Each function block has a unique identifier (the instance name) and a

processing number which defines the position at which the function

block is calculated during the task cycle.

This Manual uses a slash "/" as a separator between code and subcode

(e.g. "C00118/3").

The term is usually called "subindex".

the controller in the FB editor of the »Engineer« (e.g. to the digital inputs).

6

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 7

1 About this documentation

1.4 Terms and abbreviations used in drive-based safety

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Terms and abbreviations used in drive-based safety

Abbreviation Meaning

24O 24-V voltage supply for non-safe feedback

OFF state Signal state of the sensors when they are activated or respond

DO Non-safe feedback output

ON state Signal state of the sensors in normal operation

F-PLC Safety PLC

GSE File with device-specific data for establishing the PROFIBUS communication

GSDML File with device-specific data for establishing the PROFINET communication

Cat. Category according to EN 954-1 (valid until 30 November 2009)

Optocoupler supply Supply of optocouplers to control the driver

OSSD Output Signal Switching Device, tested signal output

PELV Protective extra low voltage

PL Performance Level according to EN ISO 13849-1

PM P/N switching signal paths

PP P/P switching signal paths

PS PROFIsafe

PWM Pulse width modulation

S bus Safety bus

SD-In Safe input (Safe Digital Input)

SD-Out Safe output (Safe Digital Output)

SELV Safety extra low voltage

SIA, SIB Safe input, channel A or channel B

SIL Safety Integrity Level according to IEC 61508

SO integrated safety option

Abbreviation Safety function

AIE Error acknowledgement (Acknowledge in Error)

AIS Restart acknowledgement (Acknowledge in Stop)

ES Safe enable switch (Enable Switch)

OMS Operation mode selector

SS1 Safe stop 1

SSE Emergency stop (Safe Stop Emergency)

STO Safe torque off

Formerly: Safe standstill

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 7

Page 8

1 About this documentation

1.5 Notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.5 Notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another documentation

8

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 9

2Introduction

2.1 Functional range of the functional safety (short overview)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Introduction

The safety concept of the decentralised frequency inverters 8400 protec provide three safety

options depending on the device version.

Safety option 10 (SO10):

• The drive-based safety implemented in the inverter permits to connect external safety

components, e.g. passive sensors. Active sensors with self-testing signals can be directly

connected without using further components.

Safety option 20 (SO20):

• The drive is switched off safely by a higher-level safety PLC via PROFIsafe/PROFINET.

Safety option 30 (SO30):

• The safe disconnection can both be carried out by a higher-level safety PLC via PROFIsafe/

PROFINET and through the connection of active or passive sensors.

Note!

Safety options 20 and 30 can be parameterised via the »Engineer«.

The motion functions are continued to be executed by the controller. The drive-based

safety monitors the safe compliance with the limit values. When the limit values are

exceeded, the drive-based safety starts the control functions according to EN 60204-1

directly in the controller.

The safety functions are suitable for applications according to IEC 61508 to SIL 3 and

achieve the performance level (PL) e according to EN ISO 13849-1.

The requirements of the EN 954-1 standard which was valid until 30 November 2009 are

fulfilled for safety option 10 to control category 4 and for safety option 20 and 30 to

control category 3.

Detailed information on technical data and electrical installation can be found in the

mounting instructions for the 8400 protec.

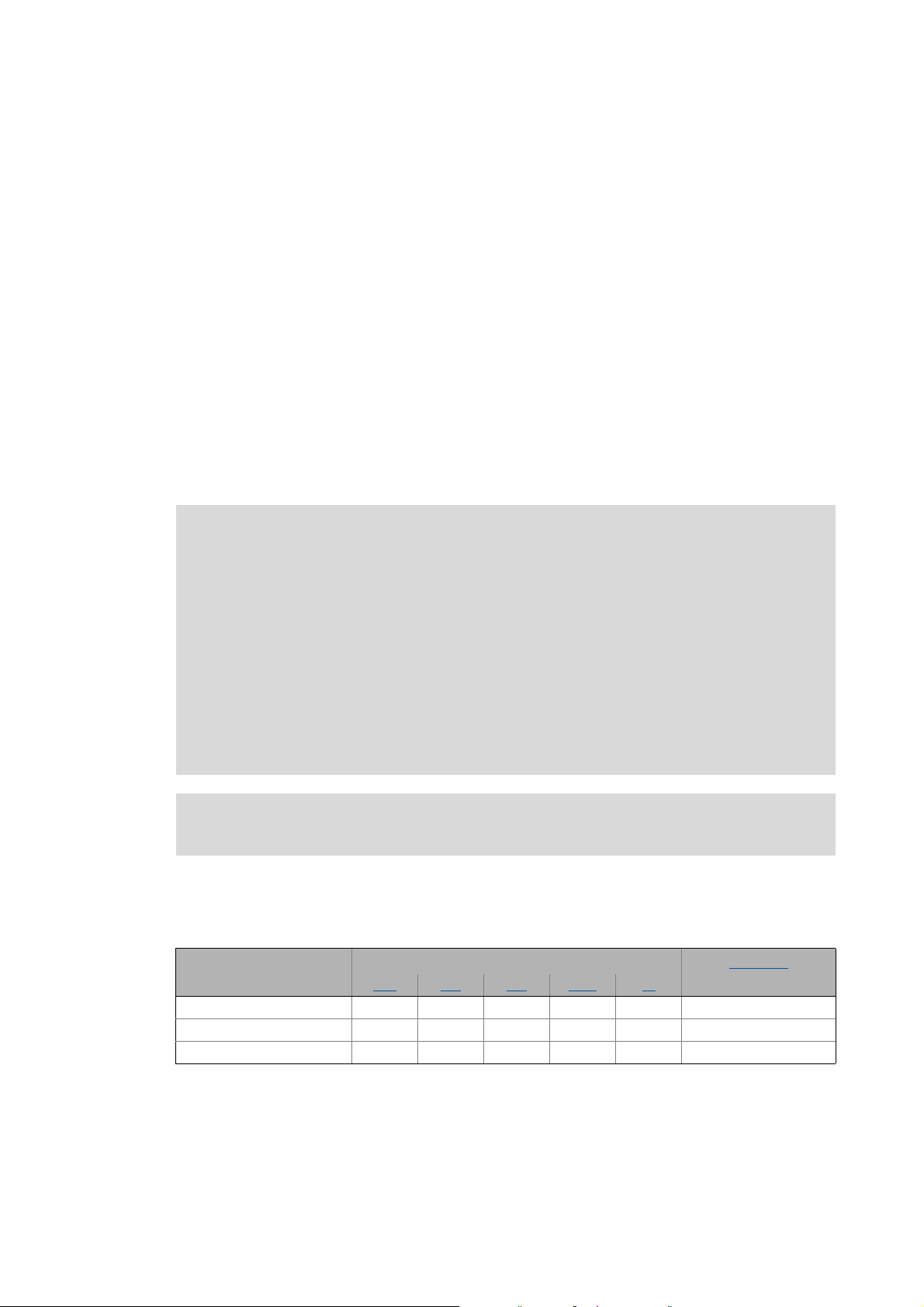

2.1 Functional range of the functional safety (short overview)

Safety option Safety function Safety bus

STO SS1 SSE OMS ES

Safety option 10

Safety option 20

Safety option 30

PROFINET

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 9

Page 10

2Introduction

M

SO

PWM

µC

PC

3x

3x

Xx

2.2 Function mode of safety engineering

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

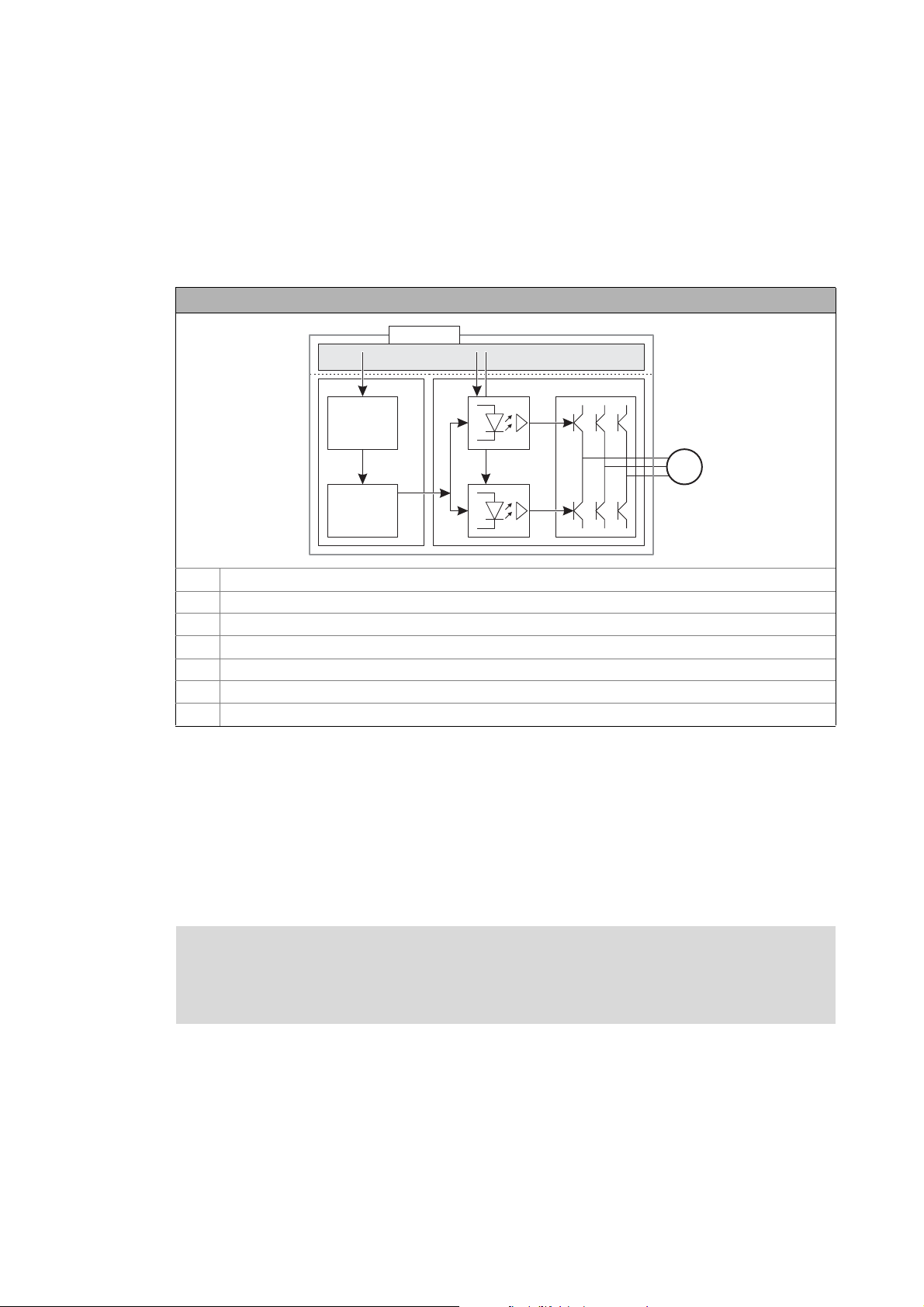

2.2 Function mode of safety engineering

Disconnecting paths

The transmission of the pulse width modulation is safely (dis-)connected by the drive-based safety.

Hence the drivers do not create a rotating field. The motor is safely switched to torqueless operation

(STO).

Disconnecting paths of the drive-based safety

SO Safety option

xx Control terminals of the safety option 10 and 30 (M12 circular connector)

C Control section

μC Microcontroller

PWM Pulse width modulation

PPower section

M Motor

Safety status

When the controller is switched off by the safety system, it is changed to the "Safe torque off active"

status

• "Drive is torque-free" is entered in the logbook.

• C00155 (Bit 10 = 1) displays "Safe torque off active".

Fail-safe status

Note!

If internal errors of the safety system are detected, the motor is safely switched to

torqueless operation (fail-safe state).

10

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 11

2Introduction

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3 Connection to the application

When a safety function is requested, the safety technology activates the corresponding safe

monitoring function. The only standstill function executed directly is the "safe torque off" (STO)

function. All other safety functions require a controller action which is safely monitored.

Note!

The execution of the corresponding action (e.g. braking, braking to standstill, holding

the standstill position) requires an appropriate application interconnection which must

be provided by the operator!

"LS_SMInterface" system block

The LS_SMInterface system block in the function block editor of the »Engineer« serves to transmit

the control and status information from the safety system to the application. ( 12)

Basic procedure

1. Activation of the safety function (e.g. SS1 - safe stop 1).

• Monitoring starts.

2. Via a control word, the safety system transmits the information to the controller that the safety

function has been activated.

3. The application evaluates the control word and starts the required motion sequence (e.g.

braking).

Internal communication

The drive-based safety system and the standard device communicate via an internal interface.

Note!

If the communication to the controller is interrupted, e.g. by switching off the controller,

the safety system responds with the following actions:

• Error stop with STO is activated.

• Error message "Warning" is transmitted.

• The LED "S-Error" on the front of the controller is on.

The required error acknowledgement (AIE) is possible via the safety bus and with SO30

via the error acknowledgement input (plug X62).

Further information can be found in chapter "Diagnostics & error management

" ( 20).

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 11

Page 12

2Introduction

Z6WDWH

Z,26WDWH

Z&RQWURO

E3RZHU6WDJH(QDEOH

Z0RGXOH,'

/6B60,QWHUIDFH

6DIHW\

RSWLRQ

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

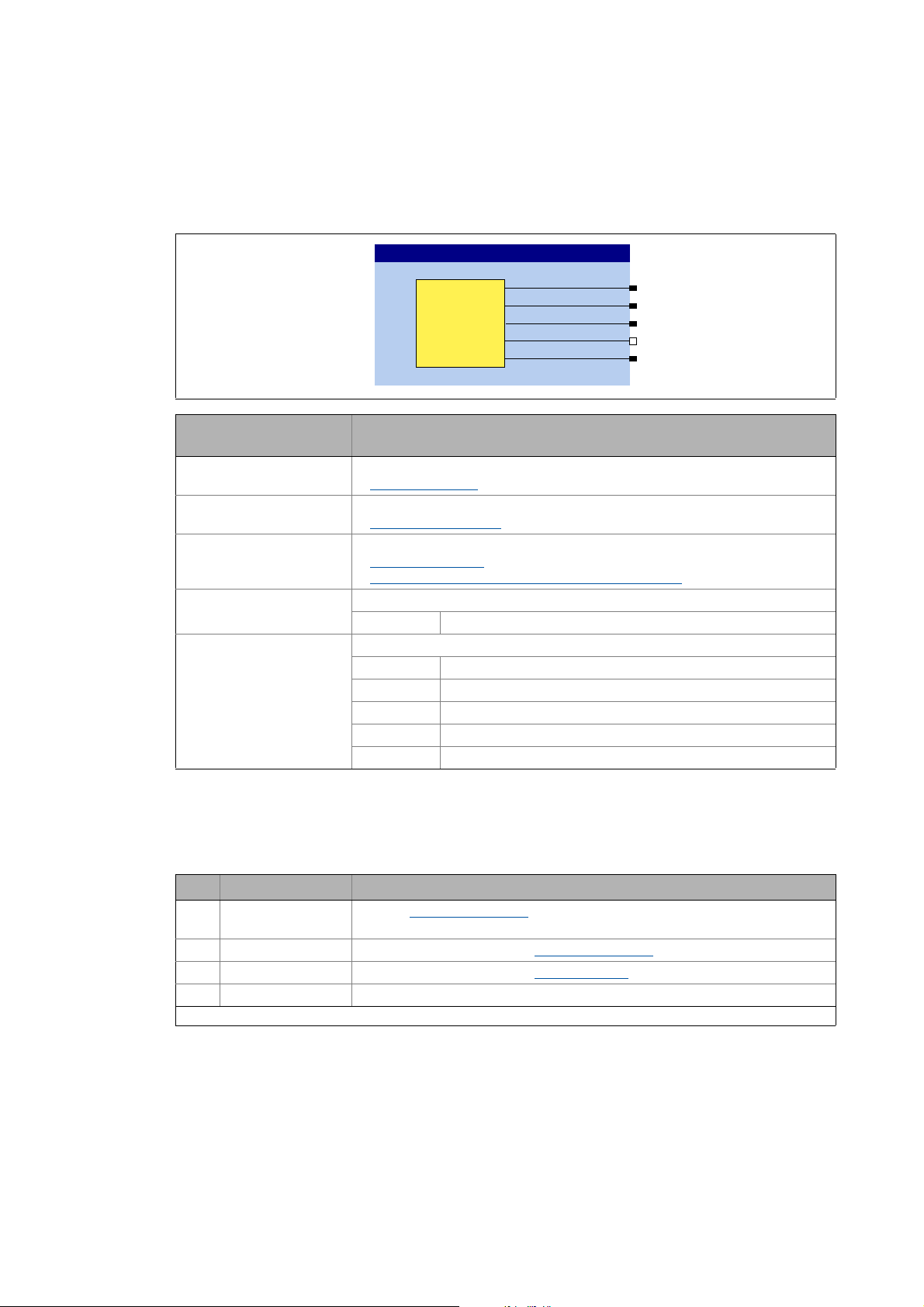

2.3.1 "LS_SMInterface" system block

The system block LS_SMInterface is the interface to the integrated safety system in the function

block editor of the »Engineer«.

Output

wState

wIOState

wControl

bPowerStageEnable

wModuleID

2.3.1.1 Status information

The drive-based safety system transmits information about the status of the requested or active

safety functions with the bit coded status signal wState.

Data type

WORD

WORD

WORD

BOOL

WORD

Value/meaning

Bit coded status information of the drive-based safety

Status information

Bit coded I/O information of the drive-based safety

I/O-Status information

Bit coded control information of the drive-based safety

Control information

Transferring the control information to the application

Status signal "Inverter enable"

TRUE Inverter is enabled by the safety system.

ID of the safety system in the controller

0 No safety system available

1 Safety option 10 (SO10):

2 Reserved

3 Safety option 20 (SO20):

4 Safety option 30 (SO30):

( 12)

( 13)

( 13)

( 14)

12

Bit Name Meaning

0STO Function Safe torque off (STO)

3 EC_STO Error stop category 0: Function Safe torque off (STO)

4 EC_SS1 Error stop category 1: Function Safe stop 1 (SS1)

14 Error active Drive-based safety system in error status (trouble or warning).

Unlisted bits are reserved for future extensions!

[2-1] Bit coding of the status signal wState

is active.

• The drive is safely switched to torqueless operation.

is active.

is active.

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 13

2Introduction

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3.1.2 I/O-Status information

The bit-coded wIOState status signal serves to transfer the status the safe inputs and the safe

output:

Bit Name Meaning

0 SD-In1 Sensor input 1 in ON state.

1 SD-In2 Sensor input 1 in ON state.

5 AIS Restart is acknowledged via terminal (negative edge: 10).

6 AIE Error is acknowledged via terminal (negative edge: 10).

8 PS_AIS Restart is acknowledged via safety bus (positive edge: 01).

9 PS_AIE Error is acknowledged via safety bus (positive edge: 01).

Unlisted bits are reserved for future extensions!

[2-2] Bit coding of the wIOState status signal

2.3.1.3 Control information

The bit coded wControl control signal serves to transfer information about requested or active

safety functions. The application in the controller must evaluate the control signal and carry out the

corresponding action.

• It is possible to request/activate several safety functions at the same time.

Bit Name Meaning

0SS1 active Safe stop 1 (SS1)

2ES active Enable switch (ES)

3OMS Operation mode selector (OMS)

4SSE active Emergency stop function (SSE)

• Depending on the parameterisation of the emergency stop function, bit 1 (SS1

active) or bit 0 of the status signal SMI_wState (STO active) is set after the

function has ended.

5 OMS active Special operation is active.

Unlisted bits are reserved for future extensions!

[2-3] Bit coding of the wControl control signal

is active.

function for motion functions in special operations is active.

function for special operations is requested.

is active.

Note!

The application in the controller must evaluate the control signal wControl and carry out

the corresponding action. The execution of the corresponding action (e.g. braking to

standstill) requires an appropriate application interconnection which must be provided

by the operator!

See the following subchapter "Transferring the control information to the application".

( 14)

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 13

Page 14

2Introduction

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

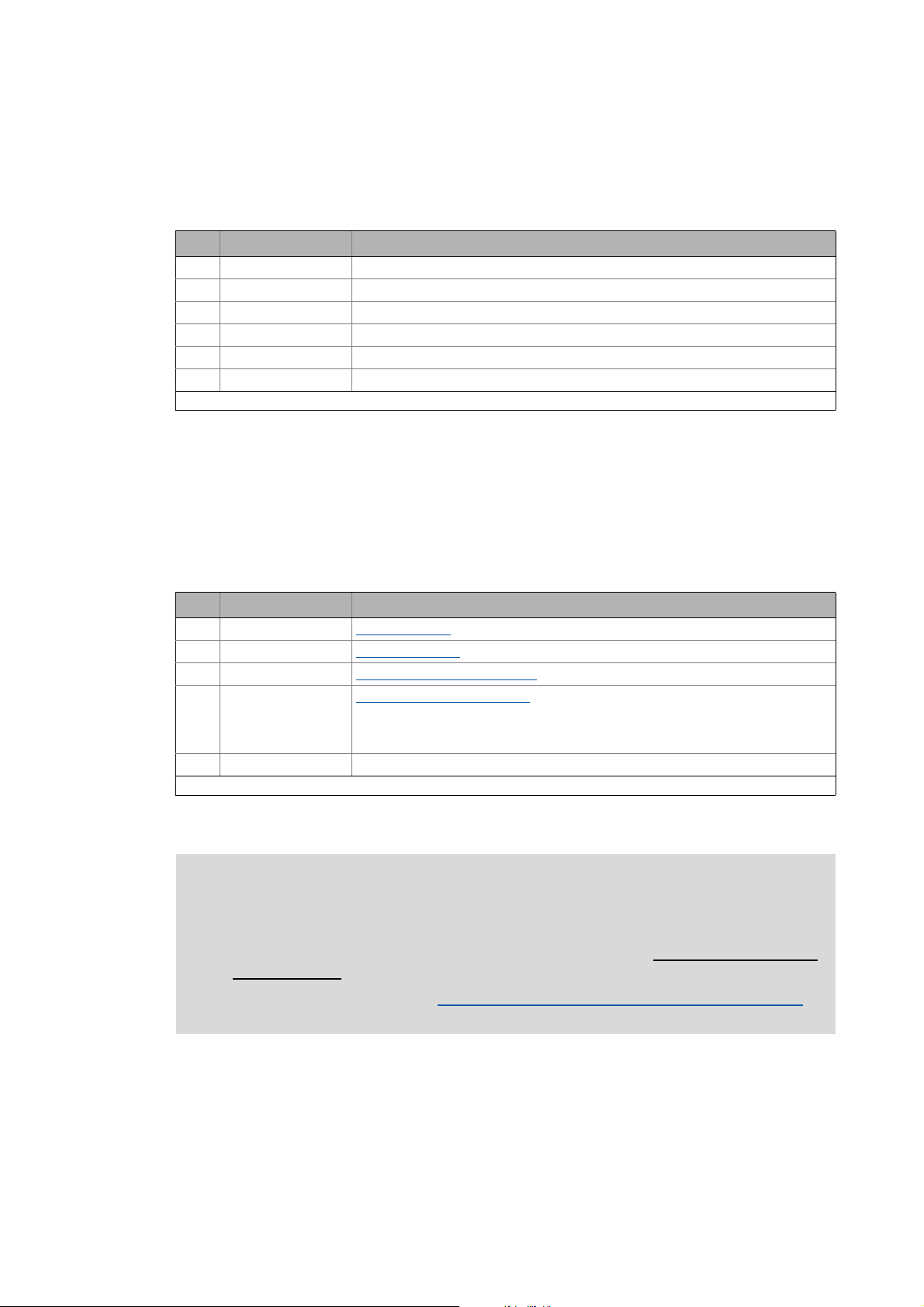

2.3.1.4 Transferring the control information to the application

In the simplest case, you only have to go to the I/O level in the FB editor and connect the wControl

output of the LS_SMInterface system block with the wSMControl input of the application block:

On the application level, the wSMControl input is connected with the motion control kernel. The

motion control kernel evaluates the transmitted control information and activates the required

motion sequence (e.g. braking).

Note!

At present, the motion control kernel only evaluates bit 0 (SS1). When this safety

function is requested, the drive will be decelerated to standstill along the stop ramp set

in C02610/3.

Additional functions are in preparation.

14

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 15

2Introduction

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

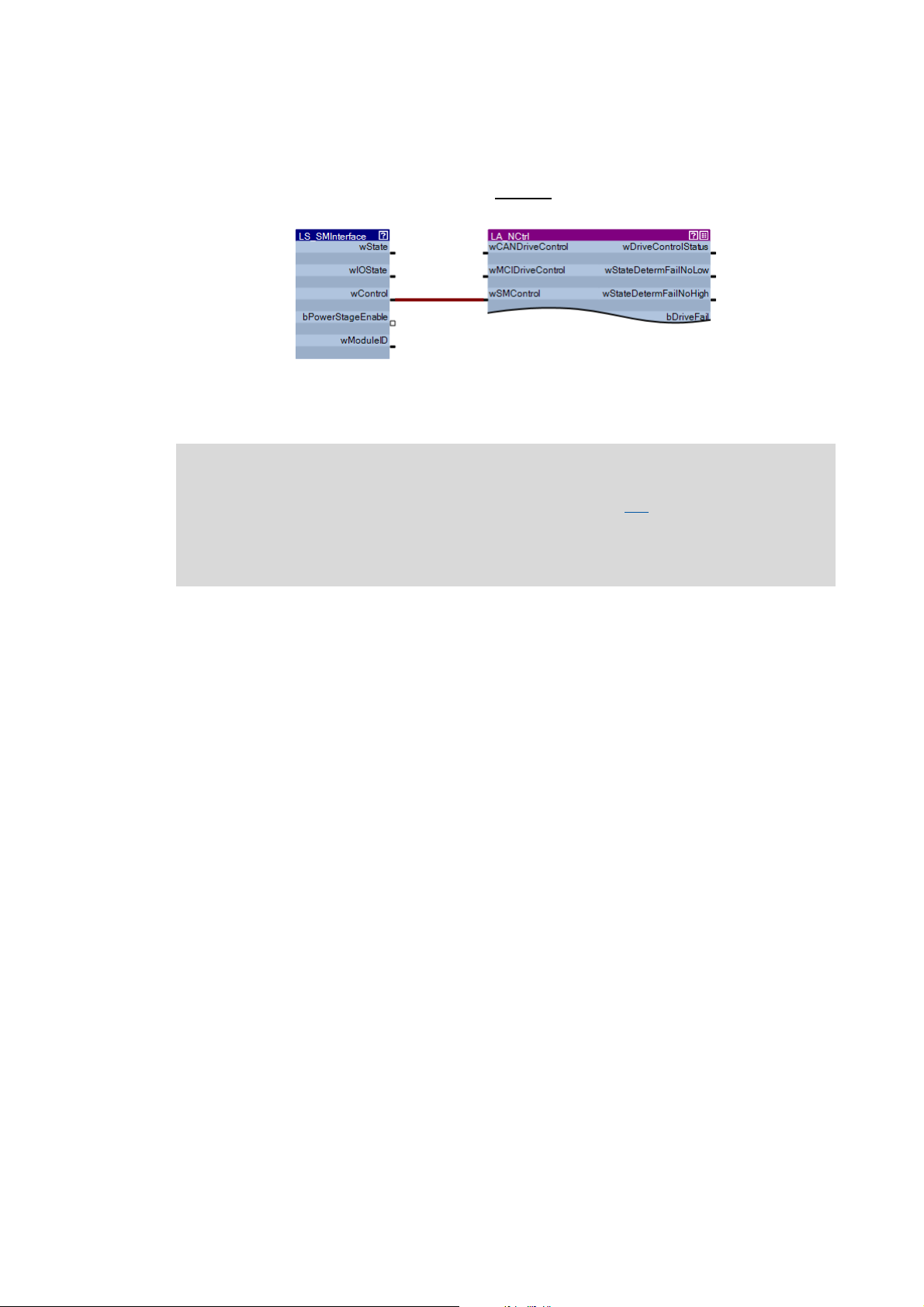

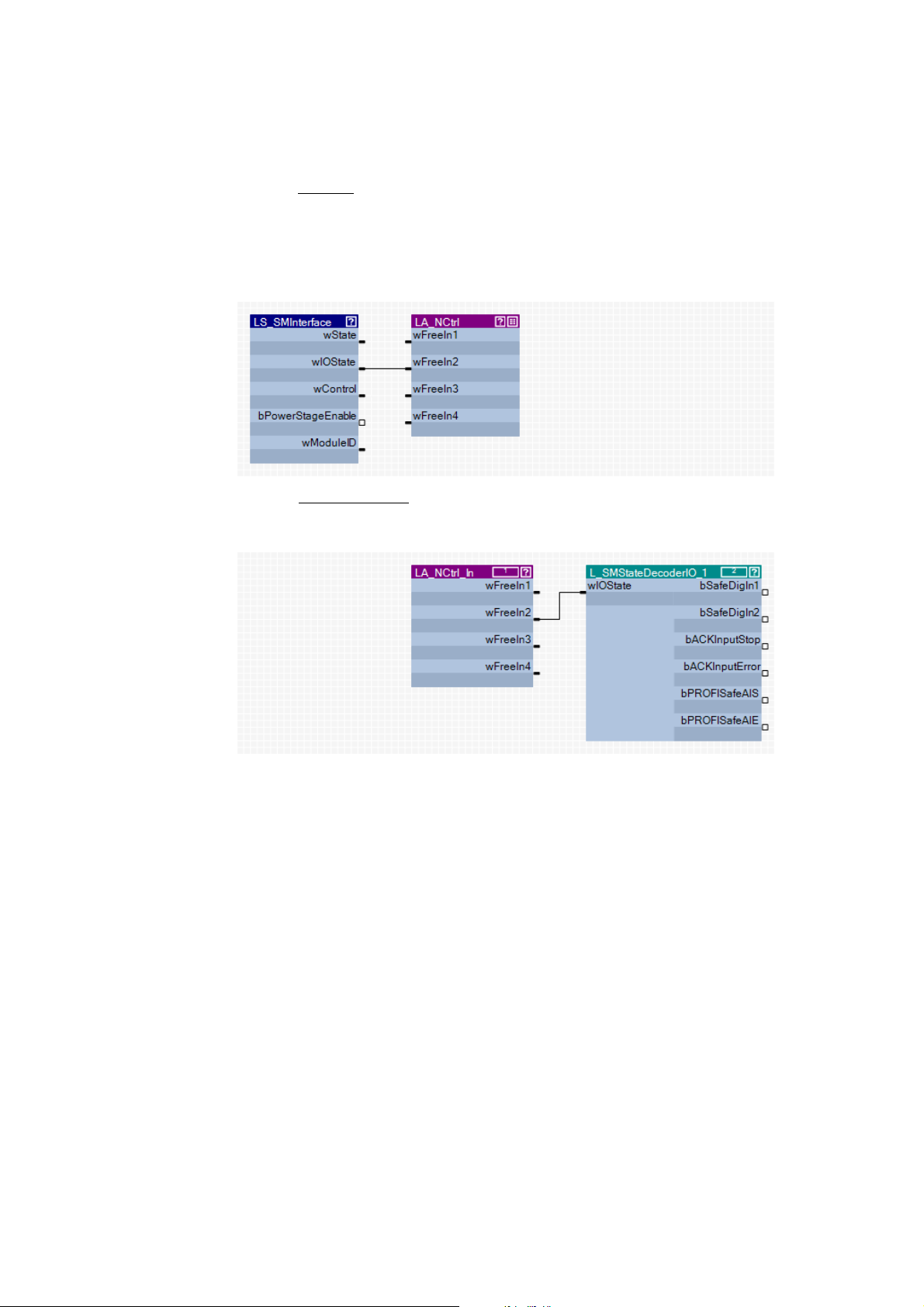

2.3.1.5 Interconnection examples

... for decoding the status and control information of the drive-based safety system into single

boolean signals.

How to decode the status information into single boolean status signals:

1. Go to the I/O level

system block with one of the free inputs wFreeIn1 ... wFreeIn4 of the application block.

• In the following example, the wState output is connected with the free wFreeIn1 input

of the LA_NCtrl application block on the I/O level.

• For a better overview, all other connections of the LA_NCtrl application block are not

shown here.

in the FB editor and connect the wState output of the LS_SMInterface

2. Go to the application level

input of the L_SMStateDecoder_1 function block.

•The free inputs wFreeIn1 ... wFreeIn4 are outputs on the application level.

The L_SMStateDecoder_1 function block decodes the status signal assigned to the wState

input into single boolean status signals for further use in the FB interconnection.

and connect the selected free input wFreeIn with the wState

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 15

Page 16

2Introduction

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

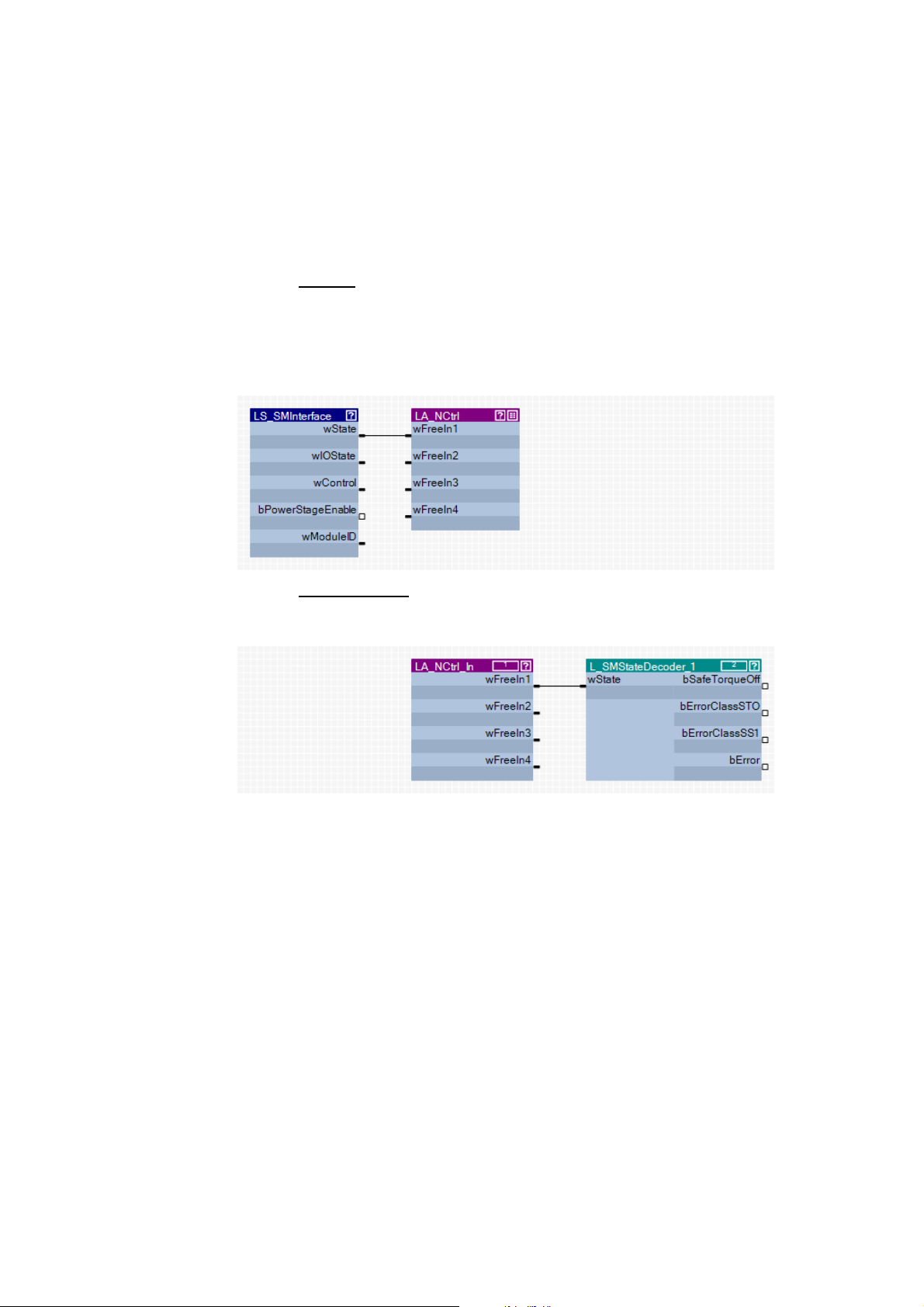

How to decode the I/O status information into single boolean status signals:

1. Go to the I/O level

system block with one of the free inputs wFreeIn1 ... wFreeIn4 of the application block.

• In the following example, the wIOState output is connected with the free wFreeIn2 input

of the LA_NCtrl application block on the I/O level.

• For a better overview, all other connections of the LA_NCtrl application block are not

shown here.

2. Go to the application level

input of the L_SMStateDecoderIO_1 function block.

•The free inputs wFreeIn1 ... wFreeIn4 are outputs on the application level.

in the FB editor and connect the wIOState output of the LS_SMInterface

and connect the selected free input wFreeIn with the wIOState

The L_SMStateDecoderIO_1 function block decodes the status signal assigned to the

wIOState input into single boolean status signals for further use in the FB interconnection.

16

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 17

2Introduction

2.3 Connection to the application

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

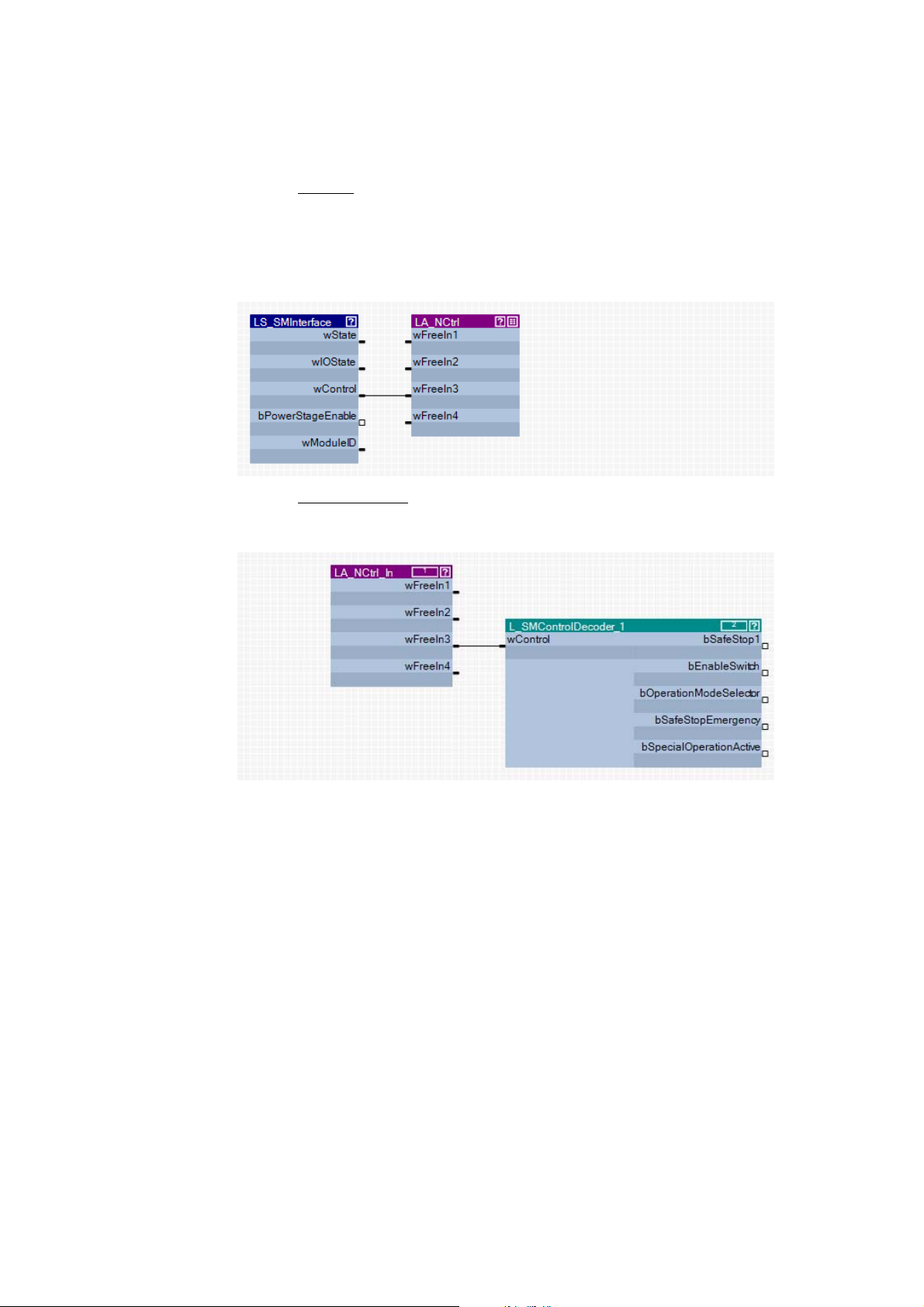

How to decode the control information into single boolean control signals:

1. Go to the I/O level

system block with one of the free inputs wFreeIn1 ... wFreeIn4 of the application block.

• In the following example, the wControl output is connected with the free wFreeIn3 input

of the LA_NCtrl application block on the I/O level.

• For a better overview, all other connections of the LA_NCtrl application block are not

shown here.

2. Go to the application level

on this level, with the wControl input of the L_SMControlDecoder_1 function block.

•The free inputs wFreeIn1 ... wFreeIn4 are outputs on the application level.

in the FB editor and connect the wControl output of the LS_SMInterface

and connect the selected free input wFreeIn, which is an output

The L_SMControlDecoder_1 function block decodes the control signal assigned to the

wControl input into single boolean control signals for further use in the FB interconnection.

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 17

Page 18

2Introduction

2.4 Parameter setting and configuration

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

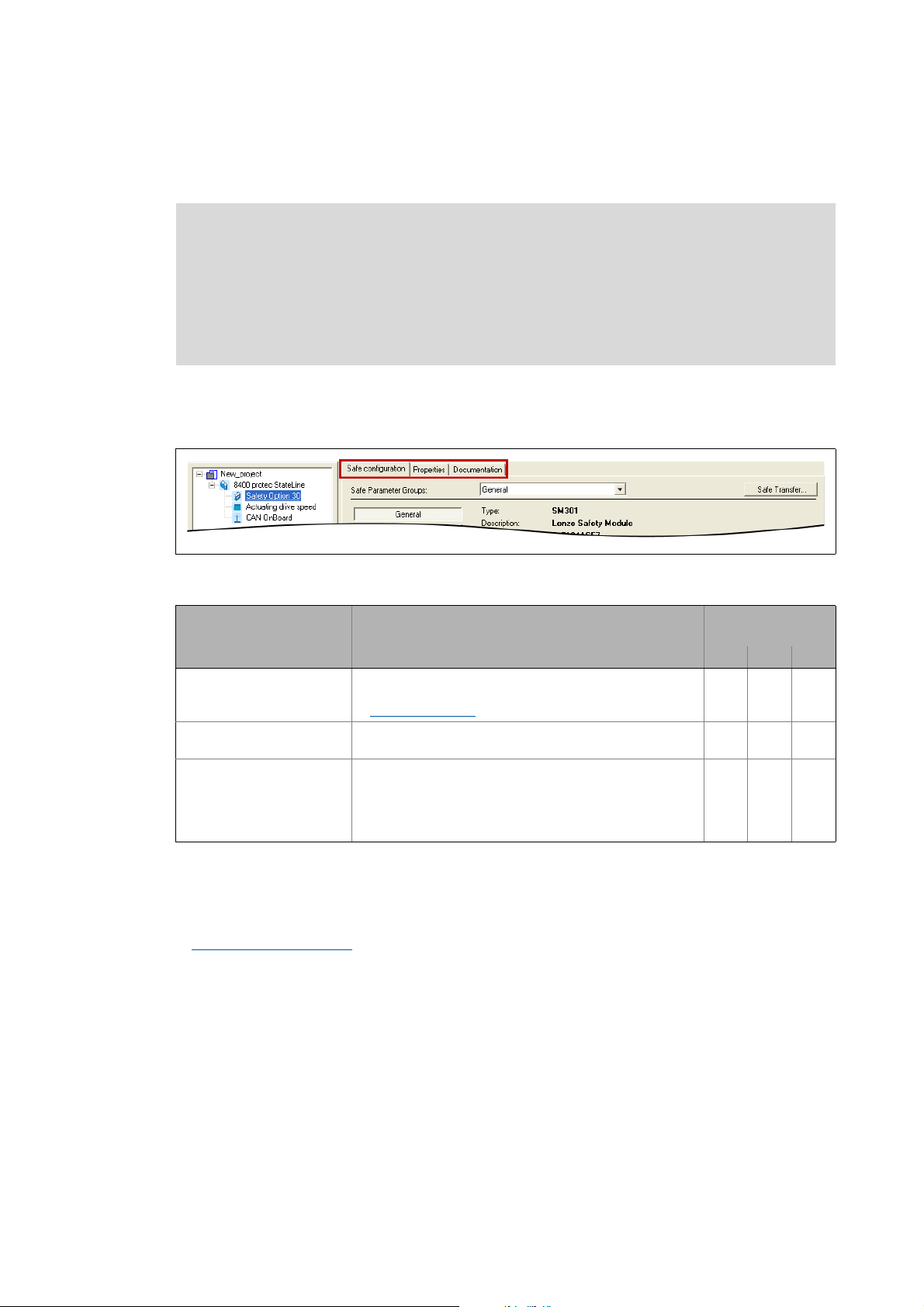

2.4 Parameter setting and configuration

Note!

Safety-relevant parameters can only be transmitted to the drive-based safety system via

safe parameter setting with the »Engineer«.

The parameter set is stored in the memory module and in the drive-based safety system

with a unique module ID, which must correspond to the effective safety address in the

drive-based safety system.

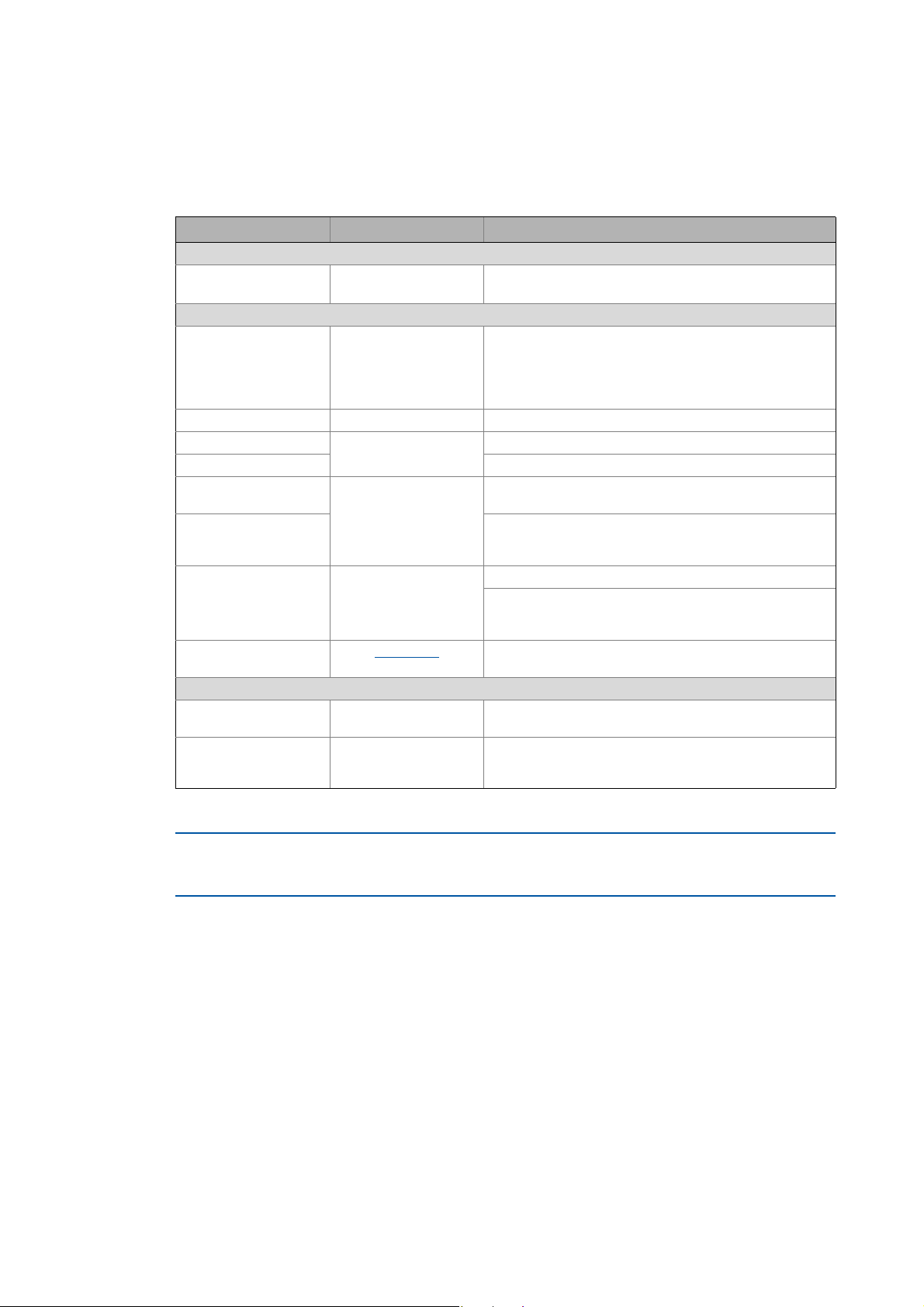

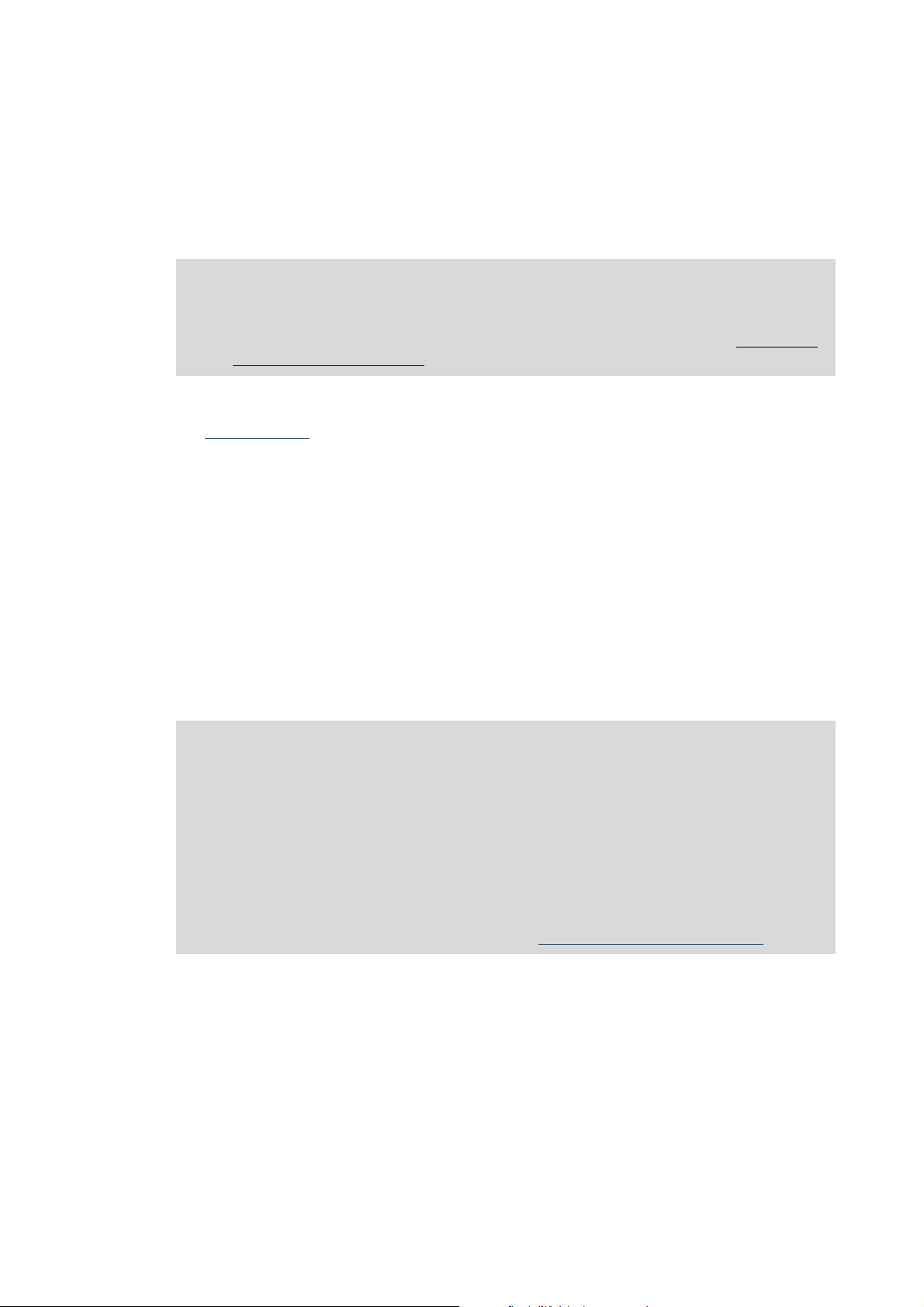

If you select the safety option in the project view of the »Engineer«, different tabs for the safety

system are available in the workspace. The following illustration shows the tabs for safety

option

30:

[2-1] Tabs of the integrated safety system (here as an example for safety option 30)

Tab Information available for

Safe configuration This tab serves to make the safe configuration of the drive-

Features This tab displays general information on the safety system,

Documentation This tab serves to add notes and electronic documents to the

Safe parameter transfer

By clicking Safe Transfer on the Safe configuration tab, the Safe Transfer dialog box opens which

provides the function for a safe parameter transfer.

Safe parameter transfer ( 44)

based safety.

Safe configuration

e.g. product name, version, etc.

drive-based safety system.

• Detailed information on adding documentations can be

found in the »Engineer« documentation in chapter

"Project structure".

( 22)

safety soption

10 20 30

18

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 19

2Introduction

2.4 Parameter setting and configuration

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Service status

If you request the "Send safe data to device" function in the Safe Transfer dialog box via the Send

button, the drive-based safety system changes to the "Service status" which is required for a safe

parameter setting.

Send safe data ( 45)

The service status means:

• The standard stop is active and the drive is safely switched to torqueless operation (STO).

• With safety option 30, the safe inputs are evaluated as OFF state.

• The communication via safety bus is - if possible - active, but passivated.

Note!

• The service status is also active if the parameter set in the memory module does not

correspond to the parameter set in the drive-based safety system during the

initialisation.

• The service status can be exited by reinitialising the drive-based safety system, i.e. the

communication via the safety bus is interrupted.

Supported interfaces for a safe parameter setting

A safe parameter setting with the »Engineer« is supported via the following interfaces:

• Diagnostic interface X70

• CANopen system bus interface

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 19

Page 20

2Introduction

',

',

','2

','2

',

',

5'<

(55

96

%UDNH

%865'<

%86(55

/LQN

/LQN

66WDWH

6(UURU

6$FNQZ

6(QDEOH

'59

6WDWXV &RP 6DIHW\ ,2 ,2

2.5 Diagnostics & error management

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

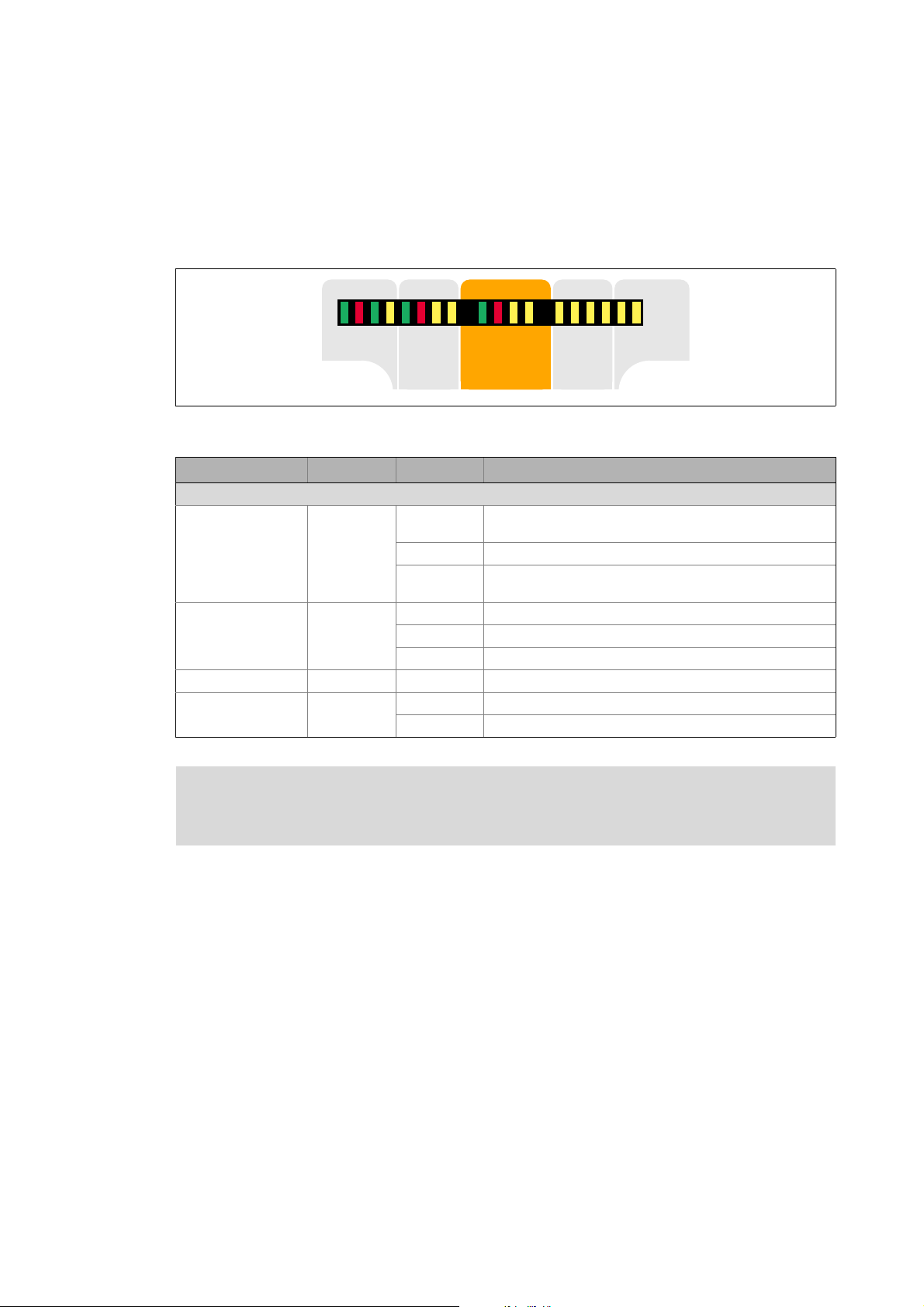

2.5 Diagnostics & error management

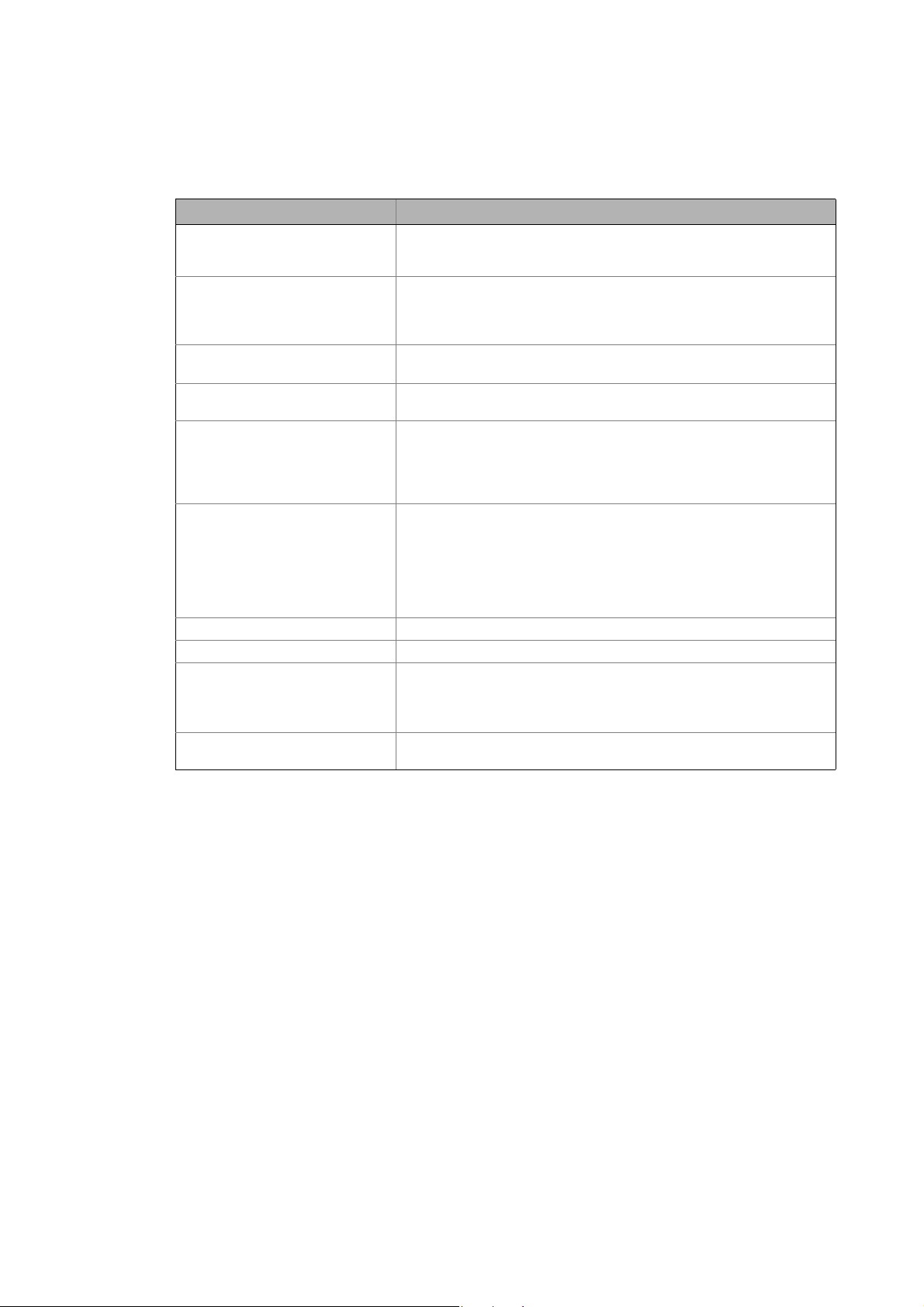

LED display

In the "Safety" field in the middle of the LED display on the front of the controller you will get

information on the status of the drive-based safety system:

[2-2] LED display on the front of the controller

Labelling Colour Status Description

LED status displays for the integrated safety system

S-State green off Communication between standard device and safety system

blinking Integrated safety system is in the service status

on Communication between standard device and safety system

S-Error red off Error-free operation

blinking Integrated safety system is not accepted by standard device

S-Acknw yellow on Parameter set acceptance must be acknowledged

S-Enable yellow blinking Safety function active (non-safe display)

on Warning/fault/error

on Controller enabled

is not possible

has been established

Note!

The status of safety option 10 is only indicated via the "S-Enable" LED display.

20

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 21

2Introduction

2.5 Diagnostics & error management

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

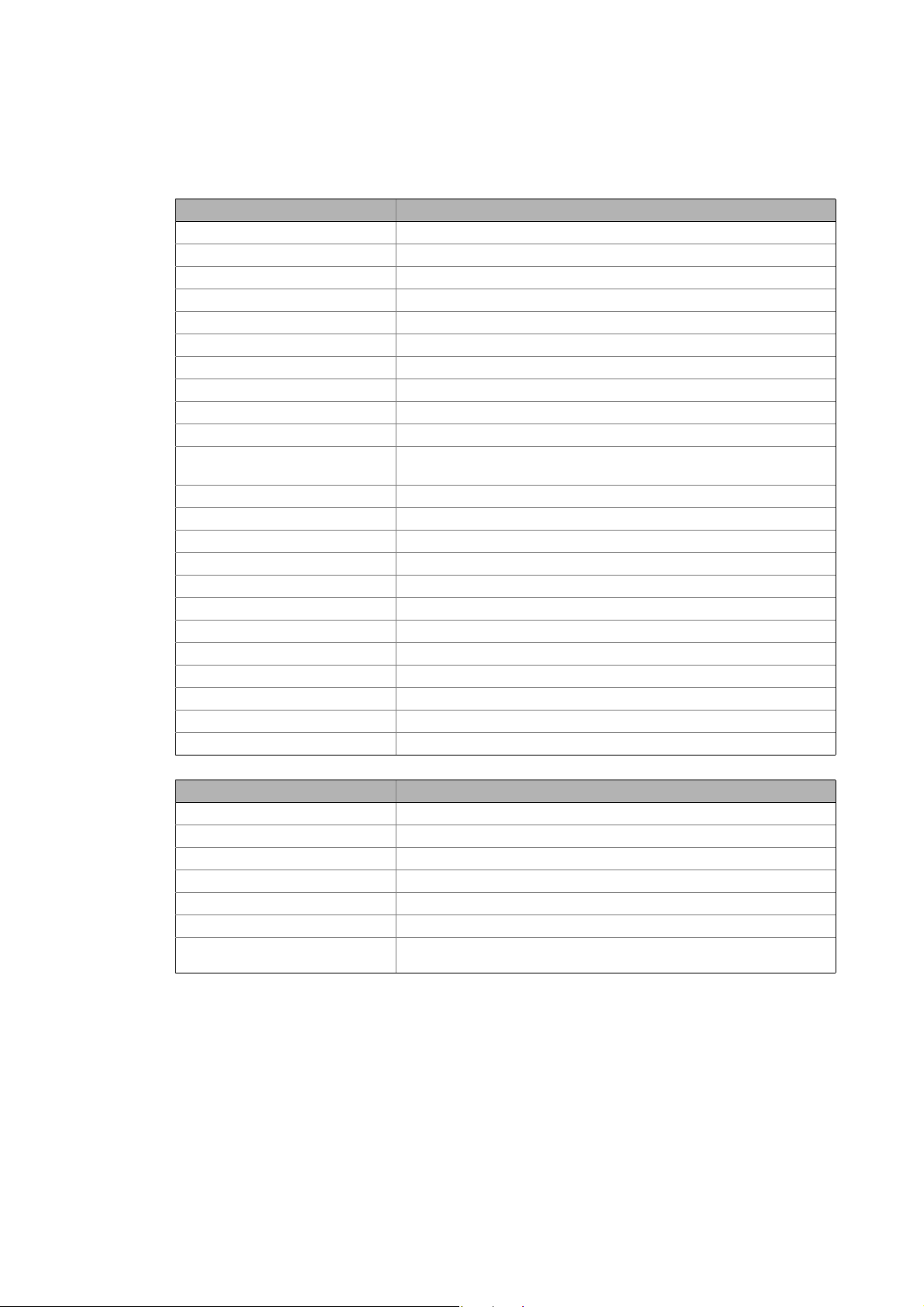

Error states

Detected errors or maloperation of the drive are assigned to error states with definite responses.

The response can be co-ordinated with the complete drive via the error states.

Features Error status

System error Fault Warning

Event Fatal internal error Error Monitoring function

LED "S_Error" On On On

State of the drive-based

safety system

The control category

according to EN 954-1...

Response The motor is immediately

Acknowledgement after

event has been

eliminated

Lockout (CPU stopped) Error status Normal operation

... has been abandoned ... has not been abandoned

safely switched to torqueless

operation via

•STO

• Switching off and then on

again of the 24-V supply at

the safety module

The motor is immediately safely switched to torqueless

operation via

•STO

or shutdown via

• SS1 (parameterisable)

• Error acknowledgement (AIE) plug X62 (positive

signal pulse with a signal duration of 0.3 ... 10 s)

• Error acknowledgement (AIE) via safety bus (bit

"PS_AIE")

• Switching off and then on again of the 24-V supply

at the safety module

Note!

If the system error still occurs after switching the supply voltage, please contact the

Lenze service!

Error in PROFIsafe communication

When PROFIsafe is used as safety bus:

• If errors occur in the PROFIsafe communication, the data are passivated by the PROFIsafe driver.

• After the PROFIsafe communication is reinitialised, the drive reenabled if no standstill function

has been selected.

• Events which cause an error status are sent as a diagnostic telegram via the safety bus.

Logbook

The logbook function integrated in the controller records important events in the system in

chronological order, including error states of the drive-based safety system.

Tip!

When an online connection has been established, the logbook can be displayed in the

»Engineer« via the Logbook button on the Diagnostic tab for the controller.

Detailed information on the logbook can be found in the Online Help for the controller.

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 21

Page 22

3 Safe configuration

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Safe configuration

The drive-based safety system can be safely configured in the »Engineer« on the Safe configuration

tab for the SM301 safety module

[3-1] Example: Safe configuration tab for safety option 30

The parameters of the drive-based safety system are divided into different groups according to their

functions.

• A group is selected via the Parameter groups list field.

• Some parameter groups are divided into functional subgroups for a better overview which can

be selected via the buttons on the left.

• General parameters

• Safe inputs

(Safe inputs SD-In1 and SD-In2 are only available in connection with the safety option 30.)

• Stop functions

• Operation mode selection

• Safety bus

• In the parameter list all parameters of the parameter group/subgroup selected are displayed.

•The Value field serves to change the corresponding parameter value.

Change parameter settings

•The context menu (right mouse button) provides functions for the import/export of the

parameter settings.

Import/export parameter settings

( 42)

( 33)

( 25)

( 27)

( 31)

( 23)

( 24)

Tip!

If you put the mouse pointer over a parameter, further information on the parameter will

be displayed in a pop-up window.

If you select the entry "All parameters" in the Parameter groups list field, all parameters of

the drive-based safety system are displayed on the tab.

The FilePrint command in the »Engineer« menu bar serves to print all parameter settings

of the drive-based safety system for the purpose of documentation.

22 Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 23

3 Safe configuration

3.1 Change parameter settings

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.1 Change parameter settings

Note!

Changed parameters of the drive-based safety system are not transmitted automatically

to the device, even if an online connection has been established!

The parameter set for the drive-based safety system is only safely transmitted when

clicking the Send button in the Safe transfer dialog box!

Send safe data

How to change a parameter setting:

1. Select the parameter to be changed from the list.

2. Enter the new value into the Value column or select it from the defined options.

• Invalid or impermissible values are displayed in "red" in the input field.

• A selection from the list field may cause a deactivation of parameters which are now

irrelevant due to the selection (marked by a grey background colour).

3. Press <Return key> or click into another box to accept the changed value.

• By pressing the <Esc> key you can cancel the entry.

( 45)

Tip!

The parameter settings of the drive-based safety system can also be displayed in the

»Engineer« parameter list (tab All parameters category Safety option) and on the keypad.

Changes, however, are only possible via the Safe configuration tab!

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 23

Page 24

3 Safe configuration

3.2 Import/export parameter settings

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.2 Import/export parameter settings

For transmitting/copying the parameter settings of the drive-based safety system to other

controllers of the 8400 protec series with an identical safety option, the import/export functions

can be used which are available in the parameter list via the Context menu (right mouse button).

Command in the context menu Information

Import... Import all parameter settings from the file.

Export... Export all parameter settings to the file.

Unlocking Unlock imported parameter settings.

• After the "Import" function has been executed, the imported parameter

settings are protected from change by the user. Only an explicit unlocking

enables a change again.

Import group... Import parameter settings of a group from a file.

• Only possible when selecting a parameter group.

Export group... Export parameter settings of a group to a file.

• Only possible when selecting a parameter group.

Unlock group Unlock imported parameter settings of a group.

• After the "Import group" function has been executed, the imported

parameter settings are protected from change by the user. Only an

explicit unlocking enables a change again.

24

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 25

3 Safe configuration

3.3 Plausibility check

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Plausibility check

Before transmitting the parameter set to the drive-based safety system, a plausibility check always

takes place.

Note!

Only a plausible parameter set can be transmitted to the drive-based safety system

using the "Send safe data" function!

With the Plausibility check... command in the Context menu (right mouse button) of the parameter

list you can start the plausibility check manually, to check the changes made in the parameter

settings with regard to plausibility.

• After the plausibility check a status message indicates whether the plausibility check was

successful.

• If the plausibility check failed, the status message contains the parameters with implausible

settings.

Tip!

C15016

3.4 General parameters

Short overview of "General" parameter group:

Parameter Information Lenze setting

-Module ID 1

C15111

Module ID

Unique identification (1 ... 65534) for the safe device.

Safety address

The safety address serves as a unique identification of the drive-based safety system in systems

with several drives.

Setting of the safety address

displays the parameter set version of the drive-based safety system.

Safety address 0

( 26)

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 25

Page 26

3 Safe configuration

3.4 General parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.4.1 Setting of the safety address

The safety address can be set via the "Safety address" parameter (C15111).

Setting via parameter setting

• Via the parameter "safety address" (C15111

Effective safety address

The effective safety address is the result of the setting via parameter setting.

• The effective safety address must match the module ID assigned in the safe parameter set.

• If "PROFIsafe" has been selected as safety bus, the effective safety address is accepted

simultaneously as the PROFIsafe target address. This address must match the corresponding

configuration of the safety PLC.

) addresses in the range of 0 ... 65534 can be set.

Tip!

C15112

displays the effective safety address.

26

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 27

3 Safe configuration

3.5 Safety functions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5 Safety functions

3.5.1 Stop functions

The stop functions are divided according to the tripping reason:

• Standard stop (simple stop)

• Tripping by a safe input with the parameterised functions STO

• Tripping by activating the bits STO or SS1 via the safety bus.

• In special operation (OMS

switch (ES

•Emergency stop

• Tripping by a safe input with the parameterised function SSE

• Tripping by activating the bit SSE via the safety bus.

• STO

function".

• In special operation (OMS

• Error stop

• Tripping as response to an error.

• In special operation (OMS

).

or SS1 can be set as the function to be executed via the parameter "SSE: Emergency stop

) the standard stop can be avoided by confirming it with the enable

) the emergency stop cannot be avoided.

) the error stop cannot be avoided.

, SS1.

.

Short overview of "Safety functions Safe stop" parameter group:

Parameter Information Lenze setting

C15205 SSE: Emergency stop function STO

C15300/1 Restart behaviour - STO, SS1 Acknowledged restart

C15305

3.5.1.1 Prioritisation

Stop functions with priority influence the process of already started subordinated functions.

1. Safe torque off (STO)

• The STO function has the highest priority and thus takes priority over all other functions.

Functions already started (e.g. SS1) are cancelled and the drive is switched off.

2. Safe stop 1 (SS1)

• Considering the stop time for SS1, the drive is switched to torque-free operation.

3. Monitoring functions

• The monitoring functions have the same priorities. They can be executed at the same time.

Value Unit

SS1: Stop time 0 ms

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 27

Page 28

3 Safe configuration

3.5 Safety functions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5.1.2 Restart behaviour

The restart behaviour of the drive after a stop function has been executed can be set via the

following parameters:

•"Restart behaviour - STO, SS1" (C15300/1

)

Danger!

If the request for the safety function is cancelled, the drive can restart automatically.

In case of an automatic restart, you have to provide external measures which ensure

that the drive only restarts after a confirmation (EN 60204).

Restart behaviour in case of setting "Acknowledged restart"

• After a standard stop the restart must be acknowledged (AIS) via terminal or safety bus.

• After an error stop, the error must be acknowledged first (AIE), before the restart is

acknowledged with AIS.

Acknowledgement via terminal via safety bus

AIS (Positive signal pulse with a signal duration

AIE (Positive signal pulse with a signal duration

Note!

The restart behaviour after an emergency stop corresponds to the restart behaviour

parameterised for the STO/SS1 stop function.

Restart behaviour in case of setting "Automatic restart"

The higher-level control must ensure that the drive only restarts after an acknowledgement. The

stop status of the drive is reported to the higher-level control via bit STO.

of 0.3 ... 10 s

of 0.3 ... 10 s)

PROFIsafe bit "PS_AIS"

Safety bus

PROFIsafe bit "PS_AIE"

Safety bus

( 33)

( 33)

28

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 29

3 Safe configuration

n

t

0

STO

3.5 Safety functions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5.1.3 Emergency stop function (SSE)

Safe Stop Emergency / SSE

Description The emergency stop function starts STO or SS1, depending on the setting of the "emergency stop

Parameter C15205 SSE: Emergency stop function

Activation How to activate the function:

function" parameter.

• In special operation the emergency stop cannot be avoided.

• Connect the emergency stop buttons, which must not be overruled by a special operation, to

the emergency stop function. For this purpose, parameterise the safe input as "emergency

stop" (C15031

• A data telegram with a corresponding content is sent to the controller via the safety bus.

Safety bus

• "OFF state" at a safe input which has been assigned to the function by parameter setting.

Safe inputs

).

• Selection of the function to be performed (STO

( 33)

( 42)

or SS1).

3.5.1.4 Safe torque off (STO)

Safe torque off / STO (corresponds to a "Stop 0" according to EN 60204)

Description By using this function the power supply for the motor is safely interrupted immediately. The

Priority Priority function: none

Function

Parameter Function sequence and error response have no adjustable parameters.

Activation How to activate the function:

motor cannot generate a torque and thus no dangerous motions of the drive.

• Additional measures are required against movements caused by external forces, e.g.

mechanical brakes.

• The restart behaviour can be set. Restart behaviour

Subordinated function: SS1

• A data telegram with a corresponding content is sent to the controller via the safety bus.

Safety bus

• "OFF state" at a safe input which has been assigned to the function by parameter setting.

Safe inputs

• As response to the error stop request.

• As response to the emergency stop request.

( 33)

( 42)

( 28)

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 29

Page 30

3 Safe configuration

n

t

0

SS1

STO

STO

3.5 Safety functions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5.1.5 Safe stop 1 (SS1)

Safe stop 1 / SS1 (corresponds to a "Stop1" according to EN 60204)

Description The drive-based safety system monitors whether the drive has reached the set tolerance margin

Priority Priority function: STO

Function

(n=0) within the parameterised stopping time and, after the stopping time has elapsed,

switches the drive to torque-free operation via the safety function STO

• The drive must be braked to standstill through the application!

• The speed is calculated from the standard device.

• Without an encoder, the function evaluates the speed status n=0 of the controller. In this

case the stopping time monitored by the drive-based safety system must be 0.5 s longer than

the stopping time parameterised on the controller.

• Additional measures are required against movements caused by external forces, e.g.

mechanical brakes. The application time of a brake must be considered when determining

the stopping time.

• A restart is only possible after the stopping time has elapsed completely. Restart behaviour

( 28)

.

Parameter C15305 SS1, SS2: Stop time

Activation How to activate the function:

Normal

behaviour

Error behaviour If standstill could not be reached when the stopping time has elapsed, an error message is

C15310

• A data telegram with a corresponding content is sent to the controller via the safety bus.

Safety bus

• "OFF state" at a safe input which has been assigned to the function by parameter setting.

Safe inputs

• As response to the error stop request.

• As response to the emergency stop request.

When the stopping time has elapsed, a standard stop is started.

• The power supply for the motor is safely interrupted immediately (STO

generate a torque and thus no dangerous movements of the drive.

generated and an error stop is started.

• The power supply for the motor is safely interrupted immediately (STO

generate a torque and thus no dangerous movements of the drive.

SOS: Speed window (n=0)

( 33)

( 42)

). The motor cannot

). The motor cannot

30

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 31

3 Safe configuration

Normal operation

Acknowledge (AIS)

for restart

Special operation

Stop function

Enable switch (ES)

Motion function

Activate OMS

Deactivate OMS

0

1

2

3.5 Safety functions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5.2 Operation mode selection

Short overview of "Safety functions Operation mode selection" parameter group:

Parameter Information Lenze setting

Value Unit

C15200 OMS: Stop function STO

C15201

3.5.2.1 Operation mode selector (OMS)

Operation Mode Selector / OMS

Description This function serves to switch between normal operation and "special operation" of the drive.

OMS: Motion function Free traversing

The special operation enables the overriding of a standard stop (STO and SS1 ) by release

through an enable switch. Enable switch (ES)

( 32)

Conditions • A safe input must be parameterised and interconnected as an operation mode selector. You

Function

Parameter C15200 OMS: Stop function

Requesting the

special operation

Deactivating the

special operation

Error behaviour • The emergency stop function can be triggered in both operating modes.

can only connect and parameterise one operation mode selector. The OMS bit of the safety

bus must be deactivated. (C15113

• The special operation can also be selected via the safety bus with the OMS bit unless a safety

input is set as an operation mode selector.

• The plausibility check rejects ambiguous settings until you have parameterised them

correctly.

Basic status of normal operation

If special operation is requested, the stop function parameterised for special operation

or SS1) is activated.

(STO

A release through the enable switch enables the motion function ( free traversing)

parameterised for the special operation.

C15201

How to request the special operation:

• " ON state " at a safe in put to which the "op eration mod e select or" function ha s be en assigned

by parameter setting. Safe inputs

• Only if no safe input is used, the function can be activated via the safety bus by sending a data

telegram with a corresponding content to the controller.

A change-over from special operation to normal operation is only possible when the drive is at

standstill (stop function STO

• For a restart, the restart must be acknowledged (AIS) via terminal or safety bus.

• The automatic restart is not permitted. If the "Automatic restart" is parameterised, this must

be prevented by special measures, e.g. programming in the master control.

OMS: Motion function

• The "Free traversing" setting must be suitable for the application!

or SS1 active).

).

( 42)

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 31

Page 32

3 Safe configuration

3.5 Safety functions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5.2.2 Enable switch (ES)

Enable Switch / ES

Description Enable Switch / ES

This function enables overriding of the standard stop functions STO

operation.

A release via the enable switch activates the parameterised motion function during special

Conditions • A safe input must be parameterised and interconnected as an enable switch. You can only

Activation How to activate the function:

operation and the drive can be traversed.

The stopping times assigned to the stop functions are directly deactivated/stopped.

connect and parameterise one enable switch. The ES bit of the safety bus must be

deactivated (C15113

• The confirmation can also be selected via the safety bus using the ES bit unless a safe input

is set as an enable switch.

• The special operation must be activated. Operation mode selector (OMS)

• The plausibility check rejects ambiguous settings until you have parameterised them

correctly.

• "ON state" at a safe input to which the "enable switch" function has been assigned by

parameter setting. Safe inputs

• Only if no safe input is used, the function can be activated via the safety bus by sending a data

telegram with a corresponding content to the controller.

).

( 42)

and SS1 during special

( 31)

32

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 33

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.6 Safety bus

The drive-based safety system provides parameterisable interfaces for standardised safety bus

systems. By selecting the bus system, the corresponding parameters are made available.

Short overview of "Safety bus" parameter group:

Parameter Information Lenze setting

C15100

C15113

Unlisted bits are reserved for future extensions!

S bus: Configuration No safety bus

S bus: Filter control data (bit-coded):

Bit 0 STO

Bit 1 SS1

Bit 9 ES Passing through

Bit 11 OMS

Bit 16 PS_AIS

Bit 17 PS_AIE Passing through

Bit 23 SSE

Passing through

Passing through

Passing through

Passing through

Passing through

S bus: Configuration

Selection of the safety bus system used. Communication modes that are currently being supported:

• Operation without safety bus

• Operation with PROFIsafe protocol

S bus: Filter control data

Unused functions in the control data of the safety bus must be set to "Inhibit" via this parameter.

Then, these functions cannot be activated anymore via the safety bus independently of the

transmitted control data.

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 33

Page 34

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.6.1 PROFIsafe connection

Conditions

The safety options 20 and 30 support the transmission of safe information via the PROFIsafe

protocol according to the specification "PROFIsafe -Profile for Safety Technology", version 2.0, of the

PROFIBUS Nutzerorganisation (PNO). The controller transmits the PROFIsafe information to the

drive-based safety system for safe evaluation.

PROFIsafe connection Setting "S bus: Configuration" (C15100)

PROFINET PROFIsafe/PROFINET

Note!

The operation with PROFIsafe via PROFINET is only permissible in accordance with the

specification "PROFIsafe-Profile for Safety Technology", version 2.0.

Addressing

In order that a data telegram reaches the correct device, a unique PROFIsafe target address is

required. If "PROFIsafe" has been selected as safety bus, the safety address is accepted

simultaneously as the PROFIsafe target address. This address must match the corresponding

configuration of the safety PLC.

Setting of the safety address

PROFIsafe frame

( 26)

Note!

The PROFIsafe data is sent in the second slot of a PROFINET data telegram. This must be

observed for the hardware configuration of the safety PLC!

PROFINET data telegram

Header PROFIsafe data Data Trailer

Slot 2 Slot 1

34

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 35

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

PROFIsafe data

In the PROFIsafe data, one bit each is used to control a certain safety function.

• The structure of the PROFIsafe message is described in the PROFIsafe profile.

• The length of the PROFIsafe message is 8 bytes (fix).

PROFIsafe message - V1 mode

Bit offset

Byte offset 7 6 5 4 3 2 1 0

0

1

2

3

4 Control byte or status byte

5Consecutive number

6CRC2

7

(Signature originating from PROFIsafe process data and PROFIsafe parameters)

(PROFIsafe output data/PROFIsafe input data)

PROFIsafe process data

PROFIsafe message - V2 mode

Bit offset

Byte offset 7 6 5 4 3 2 1 0

0

1

2

3

4 Control byte or status byte

5CRC2

6

7

(Signature originating from PROFIsafe process data, PROFIsafe parameters

(PROFIsafe output data/PROFIsafe input data)

PROFIsafe process data

and the consecutive number)

• In the following subchapters, the meaning of the PROFIsafe process data is separately described

for PROFIsafe output data and PROFIsafe input data.

Tip!

For detailed information about the PROFIsafe message, please see the PROFINET

communication manual.

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 35

Page 36

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.6.1.1 PROFIsafe output data

The PROFIsafe output data (control data) is transmitted from the control to the drive-based safety

system.

Bit Name Value Meaning

0 STO 0 The STO function is activated.

1 SS1 0 The SS1 function is activated.

9ES 1 Confirmation is active:

During special operation motion functions are possible.

11 OMS 0 Normal operation

1 Special operation

16 PS_AIS 01Activate restart acknowledgement.

The bit must be set for at least one PROFIsafe cycle.

17 PS_AIE 01 Activation of error acknowledgement.

The bit must be set for at least one PROFIsafe cycle.

23 SSE 0 The SSE function is activated.

Unlisted bits are reserved for future extensions and must be transmitted with "0"!

Control byte

For the PROFIsafe V1 mode only the indicated bits of the PROFIsafe control byte are supported:

Assignment Bit

Byte 7 6 5 4 3 2 1 0

4 - - - activate_FV - - - -

[3-1] Structure of the PROFIsafe control byte in V1 mode

Bit coding of control byte

Bit Name Value Meaning

4 activate_FV 1 The PROFIsafe output data is passivated.

- 0 Reserved for future extensions.

[3-2] Detailed specification of the control byte in V1 mode

For the PROFIsafe V2 mode only the indicated bits of the PROFIsafe control byte are supported:

Assignment Bit

Byte 7 6 5 4 3 2 1 0

4 - - Toggle_h activate_FV - R_cons_nr - -

[3-3] Structure of the PROFIsafe control byte in V2 mode

Bit coding of control byte

Bit Name Value Meaning

2 R_cons_nr 1 Reset of the consecutive number.

4 activate_FV 1 The PROFIsafe output data is passivated.

5 Toggle_h 1/0 Change increases the consecutive number.

- 0 Reserved for future extensions.

[3-4] Detailed specification of the control byte in V2 mode

36

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 37

3 Safe configuration

11

00

0

11

1

a

a

i

i

120

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Control data filter

Unused functions in the control data of the safety bus must be set to "Inhibit" via the parameter

"S bus: Control data filter" (C15113

safety bus independently of the transmitted control data.

[3-2] Function example - filter

From version 1.2 of the drive-based safety system, the filtered control data is displayed in the

parameter "S bus: Control data display" (C15115

). Then, these functions cannot be activated anymore via the

Control data, incoming

(0 = active, 1 = inactive)

Control data filter

(Selection in the »Engineer«: a = "pass through", i = "inhibit")

Effective control data

(0 = active, 1 = inactive)

):

Parameter | Name:

C15115 | S bus: display control data

Display of the safety bus control data after being filtered via C15113

Value is bit-coded: Information

(From version 1.2 of the drive-based safety system)

Bit 0 STO Safe torque off

Bit 1 SS1 Safe stop 1

Bit 9 ES Safe enable switch

Bit 11 OMS Safe operation mode selector

Bit 16 PS_AIS Restart acknowledgement via safety bus

Bit 17 PS_AIE Error acknowledgement via safety bus

Bit 23 SSE Emergency stop function

Read access Write access CINH PLC-STOP No transfer

Data type: BITFIELD_32

Index: 9460

= 24F4

d

h

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 37

Page 38

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.6.1.2 PROFIsafe input data

The PROFIsafe input data (status information) is transmitted from the drive-based safety system to

the control system.

Bit Name Value Meaning

0 STO active 1 The STO function is active and the drive is safely switched to

1 SS1 active 1 The SS1 function is active.

9 ES active 1 ES function is active during special operation: Motion function

0 ES function is not active during special operation: Stop function

11 OMS 0 Normal operation is requested.

23 SSE active 1 The SSE function is active.

24 SD-In1 1 Sensor at I1A and I1B: Channels A and B are in ON state.

25 SD-In2 1 Sensor at I2A and I2B: Channels A and B are in ON state.

29 OMS active 1 The OMS function is active: Special operation.

31 Error active 1 Error status is active (fault or warning).

Unlisted bits are reserved for future extensions and must be transmitted with "0"!

0 The OMS function is not active: Normal operation.

torque-free operation.

• This bit is also set by SS1 after the stopping time has elapsed.

• At the end of the function the bit 0 (STO active) is set.

• When the emergency stop function STO is parameterised, bit 0

(STO active) is set as well.

• When the emergency stop function SS1 is parameterised, first

bit 1 (SS1 active) is set and at the end of the function bit 0 (STO

active) is set.

• In contrast to bit 11 (OMS), this bit remains set until the special

operation is cancelled and the change-over to normal operation

has taken place via the stop function.

[3-5] Detailed specification of the PROFIsafe input data

38

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 39

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Status byte

For the PROFIsafe V1 mode, only the given bits of the PROFIsafe status byte are supported:

Assignment Bit

Byte 7 6 5 4 3 2 1 0

4 - - - FV_activated COM-Failure WD-Timeout COM-Failure CRC - -

[3-6] Structure of the PROFIsafe status byte in V1 mode

Bit coding of status byte

Bit Name Meaning

2 COM-Failure CRC Status is active after communication error.

3 COM-Failure WD-Timeout Status is active after time-out.

4 FV_activated The PROFIsafe input data are passivated.

- Reserved for future extensions.

[3-7] Detailed specification of the status byte in V1 mode

For the PROFIsafe V2 mode, only the given bits of the PROFIsafe status byte are supported:

Assignment Bit

Byte 7 6 5 4 3 2 1 0

4 - cons_nr_R Toggle_d FV_activated WD-Timeout CE_CRC - -

[3-8] Structure of the PROFIsafe status byte in V2 mode

Bit coding of status byte

Bit Name Meaning

2 CE-CRC Status is active after communication error.

3 WD-Timeout Status is active after time-out.

4 FV_activated The PROFIsafe input data are passivated.

5 Toggle_d Change shows an increase of the consecutive number.

6 cons_nr_R Consecutive number has been reset.

- Reserved for future extensions.

[3-9] Detailed specification of the control byte in V2 mode

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 39

Page 40

3 Safe configuration

3.6 Safety bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

PROFIsafe parameter

These PROFIsafe parameters and contents are supported:

PROFIsafe parameter

Name Description Valid contents

F_Source_Add PROFIsafe source address of the safety PLC 0x01 ... 0xFFFE

F_Dest_Add PROFIsafe target address of the safety system

DIP switch:

F_WD_Time PROFIsafe monitoring time of the safety system 110 ... 65535 ms

F_Check_SeqNr Check of the sequence no. in CRC

V1 mode:

V2 mode:0not relevant

F_Check_iPar Check of the iParameters CRC3 in CRC 0

F_SIL Supported SIL (Safety Integrity Level)

F_CRC_Length Length of CRC

V1-mode/2-byte-CRC:

V2-mode/3-byte-CRC:10

F_Block_ID Identification of the parameter type 0

F_Par_Version Version of the safety layer

V1 mode:

V2 mode:01

F_Par_CRC cyclic CRC is calculated

[3-10] Supported PROFIsafe parameters

Code:

SIL1:

SIL2:

SIL3:

0x01 ... 0x03FF

0x01 ... 0xFFFE

0

1

2

Diagnostic messages

Faulty configurations of the PROFIsafe parameters are reported to the safety PLC with a diagnostic

telegram (communication manual PROFINET).

Diagnostic information

Error number Description

64 The set PROFIsafe target address does not comply with the F_Dest_Add parameter.

65 The F_Dest_Add parameter has the invalid value 0x0000 or 0xFFFF

66 The F_Source_Add parameter has the invalid value 0x0000 or 0xFFFF.

67 The F_WD_Time parameter has the invalid value 0 ms.

68 The F_SIL parameter does not have the valid value 0 ... 2.

69 The F_CRC_Length parameter does not have the valid value 1.

70 The version of the PROFIsafe parameter set is wrong.

71 CRC1 error

GSDML file

All information on the configuration of the PROFINET system is contained in the GSDML file. Thus,

the integration is easy and user-friendly.

40

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 41

4 Safety option 20

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Safety option 20

The safety option 20 is exclusively controlled via PROFIsafe/PROFINET.

Information on the PROFIsafe connection can be found in the chapter "Safety bus". ( 33)

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05 41

Page 42

5 Safety option 30

5.1 Safe inputs

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Safety option 30

The safety option 30 provides interfaces for connecting active or passive sensors.

In the following chapter, the safe configuration of the safe inputs is explained.

5.1 Safe inputs

General information

The following applies to the connection of safety sensors:

• Sensor type and function can be parameterised.

• A local evaluation is carried out if a corresponding parameter setting has been made.

• If a safety bus is activated, the sensor signals are sent as status information to the master

control.

• Deactivated sensor inputs must not be connected. The status of a non-connected input is in the

OFF state.

• If a signal is detected at a deactivated sensor input during initialisation, the drive remains

inhibited (STO

).

• Faulty inputs are evaluated as OFF state.

Note!

Make sure that an internal contact function test is carried out at the safe inputs:

• Safe input in the ON state

• A LOW level at one channel

monitoring starts simultaneously.

• A LOW level must be detected at both channels

otherwise a discrepancy error will be reported.

• To be able to confirm the discrepancy error, a LOW level must be detected before at

both channels

• Safe input in the OFF state

• A HIGH level at one channel

• A HIGH level must be detected at both channels

otherwise a discrepancy error will be reported.

• To be able to confirm the discrepancy error, a HIGH level must be detected before

at both channels

.

.

puts the input in the OFF state. The discrepancy

within the discrepancy time,

starts the discrepancy monitoring.

within the discrepancy time,

Tip!

Detailed information on the contact function test, the connection of passive/active sensors

and example circuits can be found in the manual for the drive-based safety system.

42

Lenze · 8400 protec · Drive-based safety · Software Manual · DMS 2.4 EN · 05/2013 · TD05

Page 43

5 Safety option 30

5.1 Safe inputs

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Short overview of "Safe inputs" parameter group:

Parameter Information Lenze setting

Value Unit

C15030/1...2 SD-In1...2 sensor type Input is deactivated

C15031/1...2

C15032/1...2

C15033/1...2 SD-In1...2 discrepancy time 10 ms

C15034/1...2

Sensor type/sensor function

Sensor type and function can be parameterised.

SD-In1...2 sensor function Free assignment

SD-In1...2 free assignment STO

SD-In1...2 input delay 0 ms

Note!