Page 1

EDS84AVHCxx

efesotomasyon.com - Lenze

13316436

Ä.@aEä

L-force Drives

Software Manual

8400

E84AVHCxxxxx

8400 Inverter Drives HighLine C

L

Page 2

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

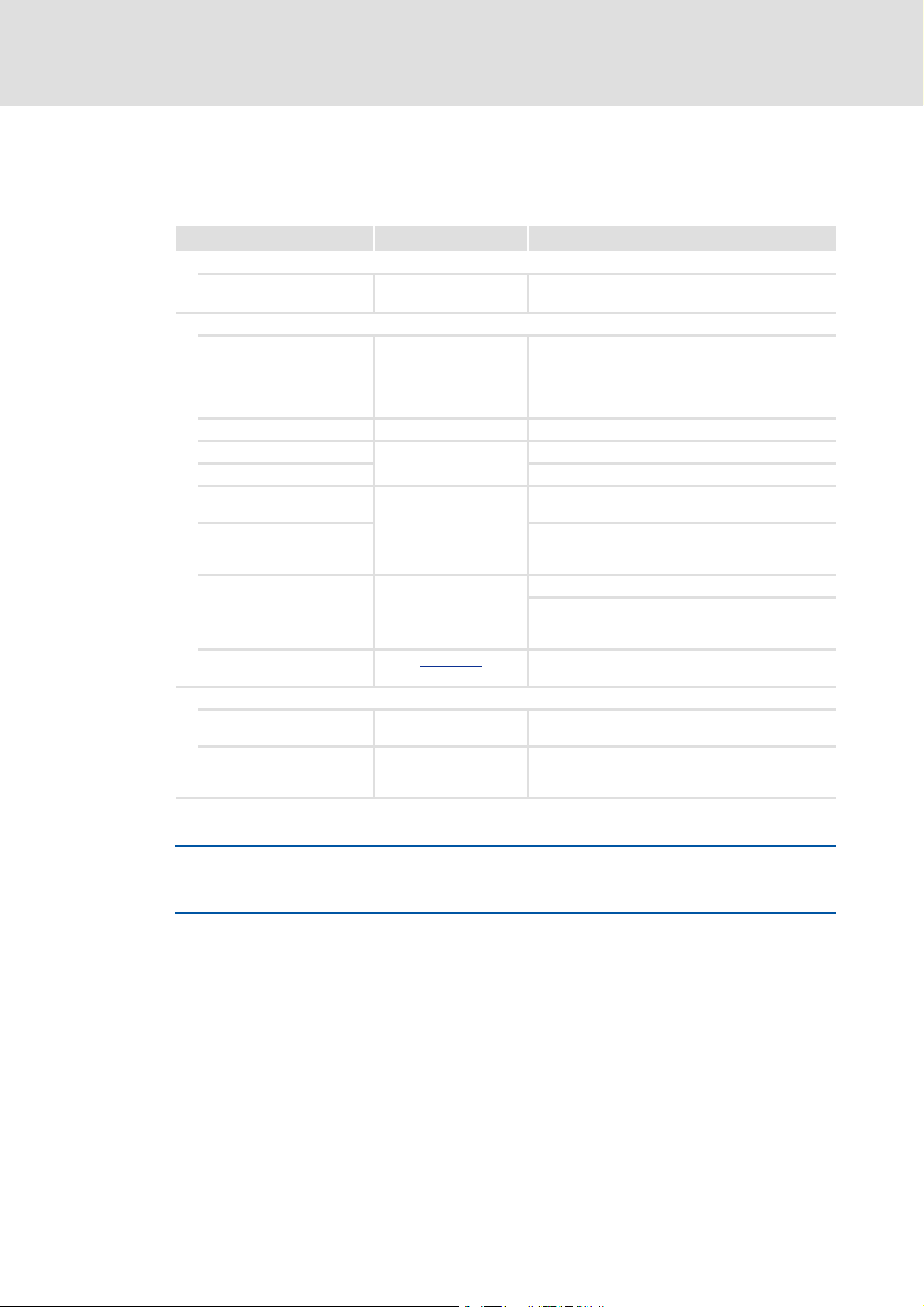

Overview of technical documentation for Inverter Drives 8400

Overview of technical documentation for Inverter Drives 8400

Project planning, selection & ordering Legend:

8400 hardware manual Printed documentation

Catalogue Online documentation

(PDF/Engineer online help)

Mounting & wiring Abbreviations used:

MA 8400 BaseLine/StateLine/HighLine BA Operating Instructions

MA for the communication module KHB Communication manual

MA for the extension module MA Mounting instructions

MA for the safety module SW Software Manual

MA for the accessories

Parameterisation

BA keypad

SW 8400 BaseLine

SW 8400 StateLine

SW 8400 HighLine Í This documentation

KHB for the communication module

Drive commissioning

SW 8400BaseLine/StateLine/HighLine

chapter "Commissioning"

chapter "Diagnostics & error management"

Remote maintenance manual

Establishing networks

KHB for the communication medium used

2 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 3

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.1 Document history

1.2 Conventions used

1.3 Terminology used

1.4 Definition of the notes used

2 Introduction: Parameterising the controller

2.1 General notes on parameters

2.2 Handling the memory module

2.3 Handling the keypad

3 Commissioning

3.1 Guide

3.1.1 Before commissioning

3.1.2 Trouble during commissioning

3.2 Safety instructions with regard to commissioning

3.2.1 General safety instructions

3.2.2 Safety instructions with regard to motor operation

3.3 Quick commissioning

3.3.1 Keypad control

3.3.2 Terminal control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . 36

3.4 Commissioning the "Actuating drive speed" TA using the keypad

3.5 Commissioning the "Actuating drive speed" TA using the »Engineer«

3.6 Commissioning the "Table positioning" TA using the »Engineer«

3.7 Commissioning the "Switch-off positioning" TA using »Engineer«

4 Device control (DCTRL)

4.1 Controller commands

4.1.1 Load Lenze setting

4.1.2 Load all parameter sets

4.1.3 Save all parameter sets

4.1.4 Enable/Inhibit controller

4.1.5 Activate/Deactivate quick stop

4.1.6 Reset error

4.1.7 Delete logbook

4.1.8 Identify motor parameter

4.1.9 CAN reset node

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . 60

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 3

Page 4

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

4.2 Device states. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.2.1 FirmwareUpdate

4.2.2 Init

4.2.3 MotorIdent

4.2.4 SafeTorqueOff

4.2.5 ReadyToSwitchON

4.2.6 SwitchedON

4.2.7 OperationEnabled

4.2.8 Warning

4.2.9 TroubleQSP

4.2.10 Trouble

4.2.11 Fault

4.2.12 SystemFault

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4.3 Automatic restart after mains connection/fault...

4.4 Synchronisation of the internal time base of the controller

4.5 Internal interfaces | "LS_DriveInterface" system block

4.5.1 wCANControl/wMCIControl control words

4.5.2 wDeviceStatusWord status word

5 Motor control (MCTRL)

5.1 Motor selection/Motor data

5.1.1 Selecting a motor from the motor catalogue in the »Engineer«

5.1.2 Automatic motor data identification

5.2 Selecting the operating mode

5.2.1 Selection help

5.3 Defining current and speed limits

5.4 V/f characteristic control (VFCplus)

5.4.1 Basic settings

5.4.1.1 Defining the V/f characteristic shape

5.4.1.2 Defining current limits (Imax controller)

5.4.2 Optimise control behaviour

5.4.2.1 Adapting the V/f base frequency

5.4.2.2 Adapting the Vmin boost

5.4.2.3 Optimising the Imax controller

5.4.2.4 Torque limitation

5.4.2.5 Defining a user-defined V/f characteristic

5.4.3 Remedies for undesired drive behaviour

5.4.4 Signal flow

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

. . . . . . . . . . . . . . . . . . . . . . 123

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 5

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

5.5 V/f control (VFCplus + encoder) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

5.5.1 Basic settings

5.5.1.1 Parameterising the slip regulator

5.5.2 Signal flow

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.6 Sensorless vector control (SLVC)

5.6.1 Types of control

5.6.1.1 Speed control with torque limitation

5.6.1.2 Torque control with speed limitation

5.6.2 Basic settings

5.6.3 Optimise control behaviour

5.6.3.1 Optimising the starting performance after a controller enable

5.6.3.2 Optimising the setting of the speed controller

5.6.3.3 Optimising dynamic performance and field weakening behaviour

5.6.3.4 Optimise response to setpoint changes and determine mass inertia

5.6.4 Remedies for undesired drive behaviour

5.6.5 Signal flow

5.7 Servo control (SC)

5.7.1 Types of control

5.7.1.1 Speed control with torque limitation

5.7.1.2 Torque control with speed limitation

5.7.2 Basic settings

5.7.2.1 Parameterising the encoder/feedback system

5.7.3 Optimise control behaviour

5.7.3.1 Optimise current controller

5.7.3.2 Optimise speed controller

5.7.3.3 Optimise response to setpoint changes and determine mass inertia

5.7.3.4 Setting the current setpoint filter (band-stop filter)

5.7.3.5 Adapting the max. acceleration change (jerk limitation)

5.7.3.6 Optimising the behaviour in the field weakening range

5.7.4 Signal flow

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . 137

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

. . . 139

. . . . . . . . . . . . . . . . . . . 140

141

142

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . 150

. . . . . . . . . . . . . . . . . . . 152

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

158

. . . . . . . . . . . . . . 160

. . . . . . . . . 161

. . . . . . . . . . 162

5.8 Parameterisable additional functions

5.8.1 Selection of switching frequency

5.8.2 Flying restart function

5.8.3 DC-injection braking

5.8.4 Slip compensation

5.8.5 Oscillation damping

5.8.6 Phase sequence reversal for correcting misconnected UVW motor phases

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

5.8.3.1 Manual DC-injection braking (DCB)

5.8.3.2 Automatic DC-injection braking (Auto-DCB)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

. . . . . . . . . . . . . . . . . . . . . 175

. . 181

Page 6

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

5.9 Encoder/feedback system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

5.9.1 Parameterising digital inputs as encoder inputs

5.9.2 Encoder evaluation procedure

5.9.3 Encoder with HTL level at DI1/DI2

5.9.4 Encoder with HTL level at DI6/DI7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

. . . . . . . . . . . . . . . . . . . . . . . . . . . 185

5.10 Braking operation/braking energy management

5.10.1 Setting the voltage source for braking operation

5.10.2 Selecting the response to an increase of the DC-bus voltage

5.10.3 Avoiding thermal overload of the brake resistor

5.11 Monitoring

5.11.1 Device overload monitoring (Ixt)

5.11.2 Motor load monitoring (I2xt)

5.11.3 Motor temperature monitoring (PTC)

5.11.4 Brake resistor monitoring (I2xt)

5.11.5 Motor phase failure monitoring

5.11.6 Mains phase failure monitoring

5.11.7 Maximum current monitoring

5.11.8 Maximum torque monitoring

5.11.9 Encoder open-circuit monitoring

5.12 Internal interfaces | system block "LS_MotorInterface"

5.13 Internal status signals | system block "LS_DeviceMonitor"

6 I/O terminals

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

. . . . . . . . . . . . . . . . . . . . . . . . . . 192

. . . . . . . . . . . . . . . 193

5.10.2.1 Inverter motor brake

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

. . . . . . . . . . . . . . . . . . . . . . . . . . . 196

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

. . . . . . . . . . . . . . . . . . . . . . . . . 214

6.1 Digital input terminals

6.1.1 Change function assignment

6.1.1.1 Using DI1(6) and DI2(7) as digital inputs

6.1.1.2 Using DI1(6) and DI2(7) as frequency inputs

6.1.1.3 Using DI1(6) as counting input

6.1.2 Internal interfaces | System block "LS_DigitalInput"

6.2 Digital output terminals

6.2.1 Internal interface | System block "LS_DigitalOutput"

6.3 Analog terminals

6.3.1 Parameterising analog input

6.3.1.1 Signal adaptation by means of characteristic

6.3.2 Parameterising analog output

6.3.3 Internal interfaces | System block "LS_AnalogInput"

6.3.4 Internal interfaces | System block "LS_AnalogOutput"

6.4 Configuring exception handling of the output terminals

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

. . . . . . . . . . . . . . . . . . . . . . . . 220

. . . . . . . . . . . . . . . . . . . . . 221

. . . . . . . . . . . . . . . . . . . . . . . 229

. . . . . . . . . . . . . . . . . . . . . . . 233

. . . . . . . . . . . . . . . . . . . . 239

. . . . . . . . . . . . . . . . . . . . . . . 242

. . . . . . . . . . . . . . . . . . . . . 243

. . . . . . . . . . . . . . . . . . . . . . . . . . 244

6 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 7

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

6.5 User-defined terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

6.5.1 Source-destination principle

6.5.2 Changing the terminal assignment with the keypad

6.5.3 Changing the terminal assignment with the »Engineer«

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

. . . . . . . . . . . . . . . . . . . . . . . 247

. . . . . . . . . . . . . . . . . . . 249

6.6 Electrical data

7 Technology applications

7.1 General information

7.1.1 Purpose of the technology applications

7.1.2 Application cases for a technology application

7.1.3 Basic software structure

7.2 Overview of available technology applications

7.3 Selection of the technology application and the control mode

7.4 TA "Actuating drive speed"

7.4.1 Basic signal flow

7.4.2 Internal interfaces | application block "LA_NCtrl"

7.4.2.1 Control words wCANDriveControl/wMCIDriveControl

7.4.3 Terminal assignment of the control modes

7.4.3.1 Terminals 0

7.4.3.2 Terminals 2

7.4.3.3 Terminals 11

7.4.3.4 Terminal 16

7.4.3.5 Keypad

7.4.3.6 PC

7.4.3.7 CAN

7.4.3.8 MCI

7.4.4 Setting parameters (short overview)

7.4.5 Configuration parameters (short overview)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

. . . . . . . . . . . . . . . . . . . . . 261

. . . . . . . . . . . . . . . . . . . . . . . . . . 265

. . . . . . . . . . . 273

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 7

Page 8

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

7.5 TA "Table positioning" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

7.5.1 Basic signal flow

7.5.1.1 Possibilites for the position selection

7.5.2 Internal interfaces | Application block "LA_TabPos"

7.5.2.1 Control words wCANDriveControl/wMCIDriveControl

7.5.3 Terminal assignment of the control modes

7.5.3.1 Terminals 0

7.5.3.2 Terminals 2

7.5.3.3 Terminals 11

7.5.3.4 Terminal 16

7.5.3.5 Keypad

7.5.3.6 PC

7.5.3.7 CAN

7.5.3.8 MCI

7.5.4 Setting parameters (short overview)

7.5.5 Configuration parameters (short overview)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

. . . . . . . . . . . . . . . . . . . . . . . . 295

. . . . . . . . . . . 304

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

7.6 TA "Switch-off positioning"

7.6.1 Basic signal flow

7.6.2 Internal interfaces | application block "LA_SwitchPos"

7.6.2.1 Truth table for activating the pre-switch off

7.6.3 Terminal assignment of the control modes

7.6.4 Setting parameters (short overview)

7.6.5 Configuration parameters (short overview)

7.7 "GeneralPurpose" functions

7.7.1 Analog switch

7.7.2 Arithmetic

7.7.3 Multiplication/Division

7.7.4 Binary delay element

7.7.5 Binary logic

7.7.6 Analog comparison

7.6.2.2 Control words wCANDriveControl/wMCIDriveControl

7.6.3.1 Terminals 0

7.6.3.2 Terminals 2

7.6.3.3 Terminals 11

7.6.3.4 Terminal 16

7.6.3.5 Keypad

7.6.3.6 PC

7.6.3.7 CAN

7.6.3.8 MCI

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

. . . . . . . . . . . . . . . . . . . . . 328

. . . . . . . . . . . . . . . . . . . . . 335

. . . . . . . . . . . 336

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

8 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 9

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

7.7.7 Binary signal monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

7.7.8 Analog signal monitor

7.7.9 D-FlipFlop

7.7.10 Counter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

8 Basic drive functions (MCK)

8.1 Basic signal flow

8.2 Internal interfaces | System block "LS_MotionControlKernel"

8.2.1 MCK control word

8.2.2 MCK status word

8.2.3 Interface to safety system

8.3 MCKInterface

8.3.1 Control inputs | "L_MckCtrlInterface" function block

8.3.2 Status outputs | FB "L_MckStateInterface"

8.4 Basic settings

8.4.1 Machine parameters

8.4.2 Min/Max speed

8.4.3 Limit position monitoring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

8.3.1.1 Alternative functions for control bit "PosExecute"

8.3.1.2 Operating mode change with profile number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

8.4.1.1 Gearbox ratio

8.4.1.2 Feed constant

8.4.3.1 Software limit positions

8.4.3.2 Hardware limit switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

. . . . . . . . . . . . . . . . . . . . . . 364

. . . . . . . . . . . . . . . . . . . . . . . 376

. . . . . . . . . . . . . . . 381

. . . . . . . . . . . . . . . . . . . 382

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

8.5 Speed follower

8.5.1 Parameter setting

8.5.1.1 Functional settings

8.5.2 Requesting the operating mode

8.5.3 Setpoint selection

8.6 Homing

8.6.1 Parameter setting

8.6.2 Requesting the operating mode

8.6.3 Carrying out homing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

8.6.1.1 Referencing mode

8.6.1.2 Home position & home value offset

8.6.1.3 Traversing a sequence profile after completion of homing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

. . . . . . . 404

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 9

Page 10

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

8.7 Manual jog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

8.7.1 Parameter setting

8.7.1.1 Functional settings

8.7.1.2 Smooth start and quick stop of the drive

8.7.1.3 Second speed

8.7.2 Requesting the operating mode

8.7.3 Executing manual jogging

8.7.3.1 Manual jog to limit position

8.7.3.2 Retracting of an operated limit switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

. . . . . . . . . . . . . . . . . . . . . . . . 409

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

. . . . . . . . . . . . . . . . . . . . . . . . . . 413

8.8 Positioning

8.8.1 Possible motion profiles

8.8.2 Parameter setting

8.8.3 Requesting the operating mode

8.8.4 Carrying out positioning

8.9 Stop

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

8.9.1 Parameter setting

8.9.2 Requesting the operating mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

8.8.2.1 Functional settings

8.8.2.2 Profile entry

8.8.2.3 Positioning modes

8.8.2.4 S-ramp time for jerk limitation

8.8.2.5 Following error monitoring

8.8.4.1 Stipulation of the profile to be executed

8.8.4.2 Starting/cancelling a traversing task

8.8.4.3 Override of the parameterised positioning mode

8.8.4.4 Position teaching

8.8.4.5 "Position target reached" status

8.8.4.6 "Transient phenomenon active" status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 418

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

. . . . . . . . . . . . . . . . . . . . . . . . 424

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

. . . . . . . . . . . . . . . . 426

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

. . . . . . . . . . . . . . . . . . . . . . . . . . 429

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

8.10 Position follower

8.10.1 Parameter setting

8.10.2 Requesting the operating mode

8.10.3 Setpoint selection

8.11 Override

8.11.1 Speed override

8.11.2 Acceleration override

8.11.3 S-ramp smoothing override

10 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

8.10.1.1 Functional settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

Page 11

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

8.12 Holding brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

8.12.1 Internal interfaces

8.12.2 Parameter setting

8.12.2.1 Operating mode

8.12.2.2 Functional settings

8.12.2.3 Time response of the brake (time diagram)

8.12.2.4 Switching thresholds

8.12.2.5 Applying and releasing time

8.12.2.6 Ramp times for approaching the setpoint speed

8.12.2.7 Motor magnetising time (only with asynchronous motor)

8.12.2.8 Actual value monitoring

8.12.3 Process when brake is released

8.12.4 Process when brake is closed

8.12.5 Response to pulse inhibit

8.12.6 Torque precontrol during starting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 442

. . . . . . . . . . . . . . . . . . . . . . 443

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

. . . . . . . . . . . . . . . . . 447

. . . . . . . . 448

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

9 Diagnostics & error management

9.1 Basics on error handling in the controller

9.2 LED status displays

9.2.1 LED status displays of the device state

9.3 Drive diagnostics with the »Engineer«

9.4 Drive diagnostics via keypad/bus system

9.5 Logbook

9.5.1 Functional description

9.5.2 Filtering logbook entries

9.5.3 Reading out logbook entries

9.5.4 Exporting logbook entries to a file

9.6 Monitoring

9.6.1 Monitoring configuration

9.6.2 Setting the error response

9.6.3 AutoFailReset function

9.7 Maloperation of the drive

9.8 Operation without mains supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 460

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 462

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 470

9.9 Error messages of the operating system

9.9.1 Structure of the error number (bit coding)

9.9.2 Reset of error message

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

9.9.1.1 Error type

9.9.1.2 Error subject area

9.9.1.3 Error ID

9.9.1.4 Example for bit coding of the error number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

. . . . . . . . . . . . . . . . . . . . . 473

Page 12

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

9.9.3 Short overview (A-Z) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

9.9.4 Cause & possible remedies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

9.10 System block "LS_SetError_1"

9.11 System block "LS_SetError_2"

10 System bus "CAN on board"

10.1 General information

10.1.1 General data and application conditions

10.1.2 Supported protocols

10.1.3 Communication time

10.2 Possible settings via DIP switch

10.2.1 Activating the bus terminating resistor

10.2.2 Setting the baud rate

10.2.3 Setting the node address

10.3 LED status displays for the system bus

10.4 Going online via system bus (CAN on board)

10.5 Structure of the CAN data telegram

10.5.1 Identifier

10.5.2 User data

10.6 Communication phases/network management

10.6.1 Status transitions

10.6.2 Network management telegram (NMT)

10.6.3 Parameterising the controller as CAN master

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 496

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 502

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 503

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 507

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 511

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 512

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 513

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 515

10.7 Process data transfer

10.7.1 Available process data objects

10.7.1.1 RPDO1 | Port block "LP_CanIn1"

10.7.1.2 RPDO2 | Port block "LP_CanIn2"

10.7.1.3 RPDO3 | Port block "LP_CanIn3"

10.7.1.4 TPDO1 | Port block "LP_CanOut1"

10.7.1.5 TPDO2 | Port block "LP_CanOut2"

10.7.1.6 TPDO3 | Port block "LP_CanOut3"

10.7.2 Identifiers of the process data objects

10.7.3 Transmission type

10.7.4 PDO synchronisation via sync telegram

10.7.5 Monitoring of the RPDOs for data reception

10.7.6 Configuring exception handling of the CAN PDOs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 516

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 517

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 525

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 519

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 520

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 522

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 523

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 524

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 528

. . . . . . . . . . . . . . . . . . . . . . . . . 528

12 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 13

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

10.8 Parameter data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 530

10.8.1 Identifiers of the parameter data objects

10.8.2 User data

10.8.2.1 Command

10.8.2.2 Addressing by means of index and subindex

10.8.2.3 Data 1 ... Data 4

10.8.2.4 Error messages

10.8.3 Parameter data telegram examples

10.8.3.1 Read parameters

10.8.3.2 Write parameters

10.8.3.3 Read block parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 532

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 535

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 537

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 538

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 539

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

. . . . . . . . . . . . . . . . . . . . 533

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 537

10.9 Monitoring

10.9.1 Integrated error detection

10.9.2 Heartbeat protocol

10.9.3 Emergency telegram

10.10 Implemented CANopen objects

10.11 Internal interfaces | System block "LS_CANManagement"

11 Fieldbus interface

11.1 Process data transfer

11.2 Control mode "MCI"

11.2.1 Port block "LP_MciIn"

11.2.2 Port block "LP_MciOut"

12 Parameter reference

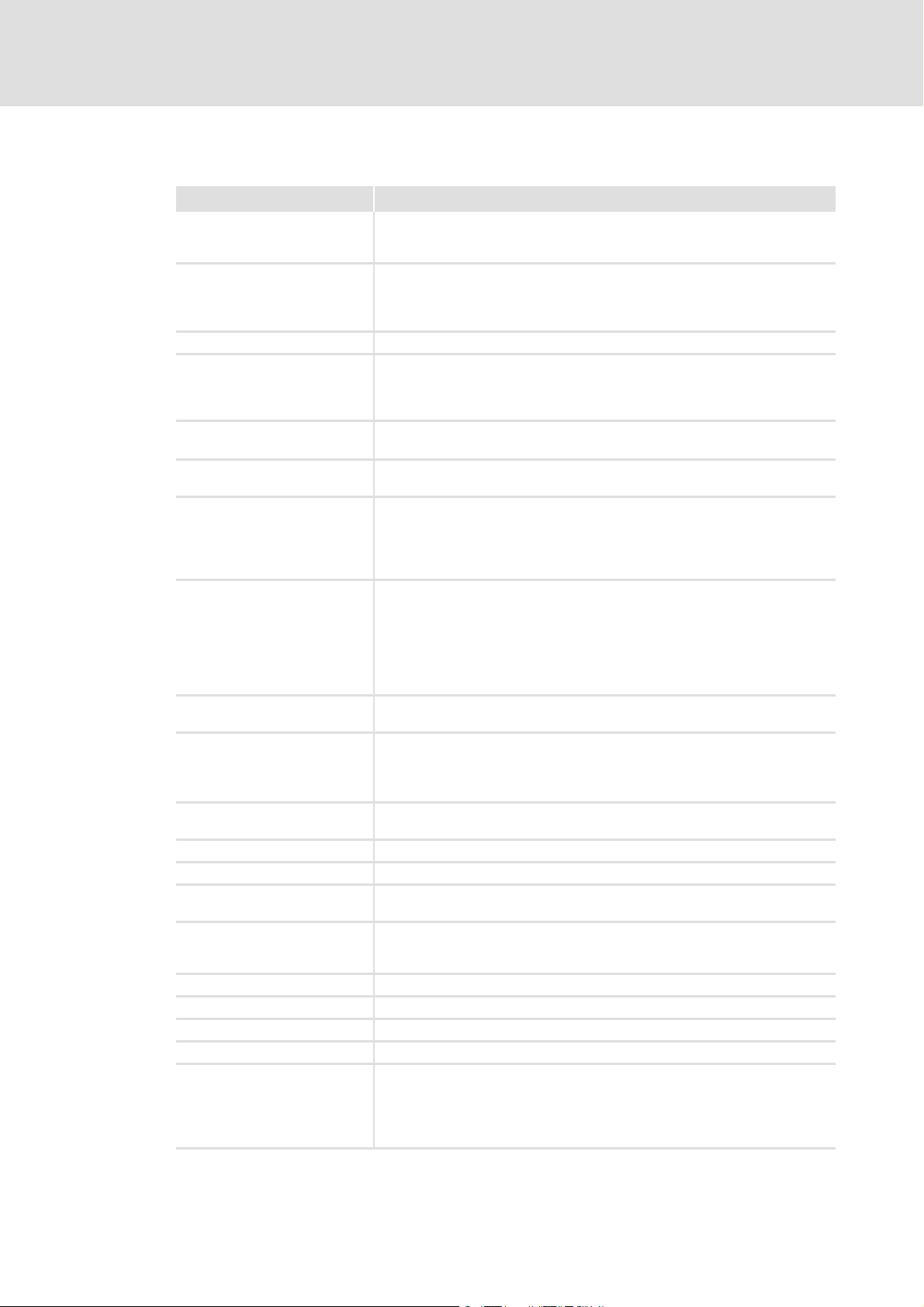

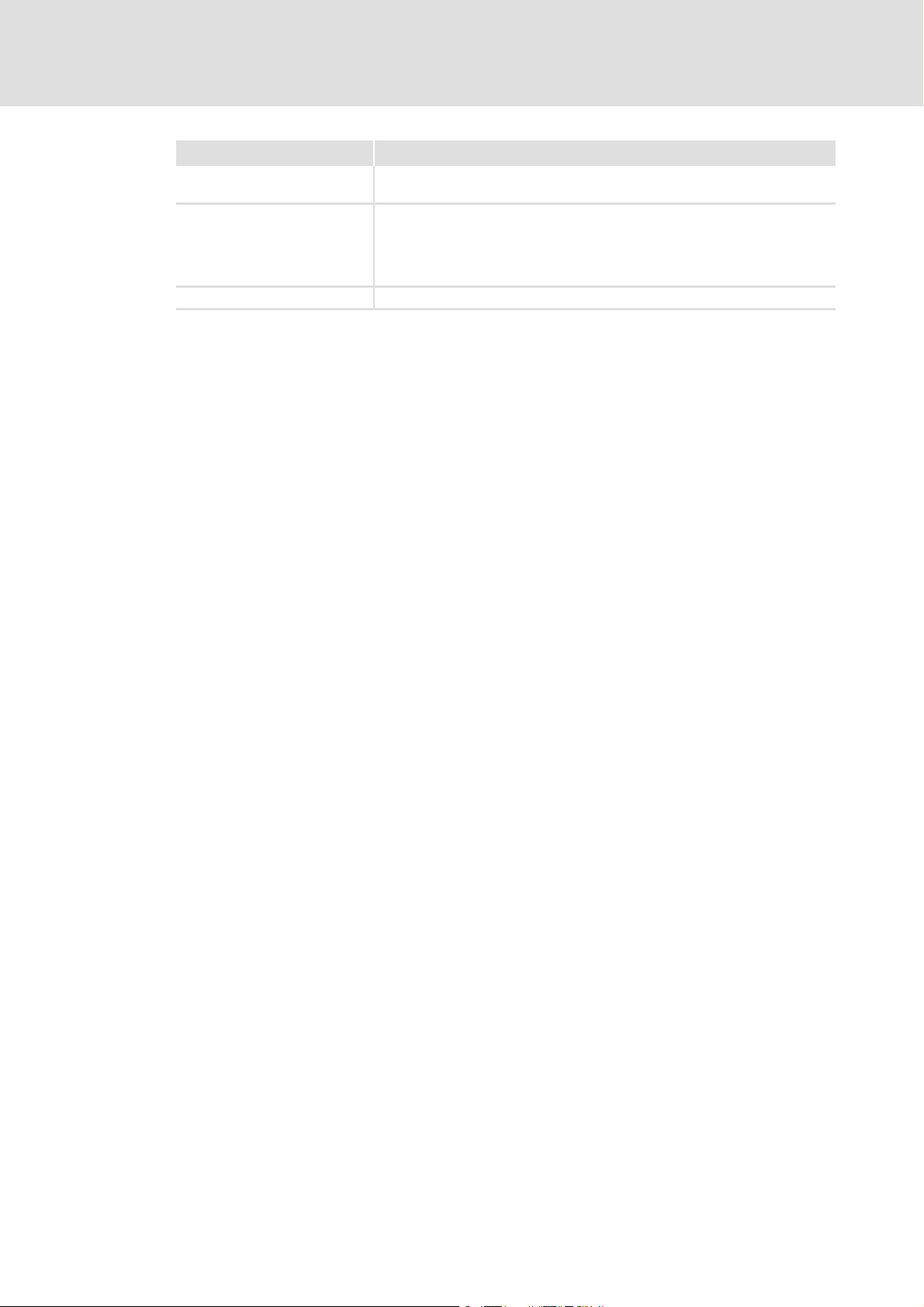

12.1 Structure of the parameter descriptions

12.1.1 Data type

12.1.2 Parameters with read-only access

12.1.3 Parameters with write access

12.1.4 Parameter attributes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 542

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543

10.9.2.1 Telegram structure

10.9.2.2 Parameter setting

10.9.2.3 Commissioning example

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 547

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 572

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 576

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 578

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

12.1.3.1 Parameters with setting range

12.1.3.2 Parameters with selection list

12.1.3.3 Parameters with bit-coded setting

12.1.3.4 Parameters with subcodes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 548

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 577

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 579

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 580

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 581

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

. . . . . . . . . . . . . . . . . . . . . . . . . 571

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 581

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 581

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 582

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 583

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 13

Page 14

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

12.2 Parameter list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 585

12.2.1 Selection lists for connection parameters

12.2.1.1 Selection list - analog signals

12.2.1.2 Selection list - digital signals

12.2.1.3 Selection list - angle signals

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 797

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 797

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 808

12.3 Table of attributes

13 Working with the FB Editor

13.1 Basics

13.1.1 Basic components of a drive solution

13.1.2 Conventions used for input/output identifiers

13.1.3 Scaling of physical units

13.2 User interface

13.2.1 Toolbar

13.2.2 Search function

13.2.3 Level selection

13.2.4 Editor view/overview

13.2.5 Context menu

13.2.6 Status bar

13.2.7 Overview window

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 820

13.1.1.1 What is a function block?

13.1.1.2 Parameterisable function blocks

13.1.1.3 What is a system block?

13.1.1.4 What is a port block?

13.1.1.5 What is an application block?

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 827

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 809

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 820

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 821

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 822

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 823

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 823

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 824

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 824

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 825

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 826

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 828

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 829

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 830

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 832

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 833

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 833

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 834

13.3 Using the FB Editor as "Viewer"

13.3.1 Following connections of inputs and outputs

13.3.2 Keyboard commands for navigation

13.3.3 Change online display format

13.4 Reconfiguring the predefined interconnection

13.4.1 Inserting/Deleting objects

13.4.1.1 Inserting a function block

13.4.1.2 Inserting a system block

13.4.1.3 Inserting a port block

13.4.1.4 Inserting a comment

13.4.1.5 Deleting objects that are no longer required

13.4.2 Changing connector visibilities

13.4.3 Arranging objects in the drawing area

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 836

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 838

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 839

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 841

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 842

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 844

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 846

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 848

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 851

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 837

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 841

. . . . . . . . . . . . . . . . . . . . . 850

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 852

14 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 15

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

13.4.4 Creating/deleting connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 853

13.4.4.1 Creating a connection using the connection line

13.4.4.2 Creating a connection using port identifiers

13.4.4.3 Creating a connection via connection dialog

13.4.4.4 Deleting connections that are no longer required

13.4.5 Changing the processing order

13.4.6 Copying interconnection elements (across all devices)

13.4.6.1 Insert options for copied elements

13.4.7 Resetting changed interconnection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 859

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 863

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 864

. . . . . . . . . . . . . . . . . 855

. . . . . . . . . . . . . . . . . . . . . 856

. . . . . . . . . . . . . . . . . . . . . 857

. . . . . . . . . . . . . . . . 858

. . . . . . . . . . . . . . . . . . . . . 861

13.5 Adjusting online and offline interconnection

13.6 Printing the interconnection

13.7 Comparing interconnections

13.8 Copying an interconnection

13.9 Exporting/Importing an interconnection

14 Function library

14.1 Function blocks

14.1.1 L_Absolute_1

14.1.2 L_Absolute_2

14.1.3 L_AddSub_1

14.1.4 L_AnalogSwitch_1

14.1.5 L_AnalogSwitch_2

14.1.6 L_AnalogSwitch_3

14.1.7 L_AnalogSwitch_4

14.1.8 L_AnalogSwitch_5

14.1.9 L_And_1

14.1.10 L_And_2

14.1.11 L_And_3

14.1.12 L_And5_1

14.1.13 L_And5_2

14.1.14 L_Arithmetik_1

14.1.15 L_Arithmetik_2

14.1.16 L_Arithmetik_3

14.1.17 L_Arithmetik_4

14.1.18 L_Arithmetik_5

14.1.19 L_ArithmetikPhi_1

14.1.20 L_ArithmetikPhi_2

14.1.21 L_ArithmetikPhi_3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 872

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 872

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 876

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 876

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 877

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 883

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 884

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 885

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 886

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 887

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 866

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 867

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 870

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 878

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 879

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 880

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 881

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 882

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 888

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 889

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 890

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 891

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 892

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 893

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 894

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 895

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 865

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 871

Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010 L 15

Page 16

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

14.1.22 L_Compare_1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 896

14.1.22.1 Function 1: nIn1 = nIn2

14.1.22.2 Function 2: nIn1 > nIn2

14.1.22.3 Function 3: nIn1 < nIn2

14.1.22.4 Function 4: |nIn1| = |nIn2|

14.1.22.5 Function 5: |nIn1| > |nIn2|

14.1.22.6 Function 6: |nIn1| < |nIn2|

14.1.23 L_Compare_2

14.1.24 L_Compare_3

14.1.25 L_Compare_4

14.1.26 L_Compare_5

14.1.27 L_ComparePhi_1

14.1.27.1 Function 1: dnIn1 = dnIn2

14.1.27.2 Function 2: dnIn1 > dnIn2

14.1.27.3 Function 3: dnIn1 < dnIn2

14.1.27.4 Function 4: |dnIn1| = |dnIn2|

14.1.27.5 Function 5: |dnIn1| > |dnIn2|

14.1.27.6 Function 6: |dnIn1| < |dnIn2|

14.1.28 L_ComparePhi_2

14.1.29 L_ComparePhi_3

14.1.30 L_ComparePhi_4

14.1.31 L_ComparePhi_5

14.1.32 L_ConvBitsToWord_1

14.1.33 L_ConvBitsToWord_2

14.1.34 L_ConvBitsToWord_3

14.1.35 L_ConvDIntToWords_1

14.1.36 L_ConvDIntToWords_2

14.1.37 L_ConvDIntToWords_3

14.1.38 L_ConvUnitsToIncr_1

14.1.39 L_ConvUnitsToIncr_2

14.1.40 L_ConvUnitsToIncr_3

14.1.41 L_ConvW_1

14.1.42 L_ConvW_2

14.1.43 L_ConvW_3

14.1.44 L_ConvW_4

14.1.45 L_ConvWordsToDInt_1

14.1.46 L_ConvWordsToDInt_2

14.1.47 L_ConvWordsToDInt_3

14.1.48 L_ConvWordToBits_1

14.1.49 L_ConvWordToBits_2

14.1.50 L_ConvWordToBits_3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 901

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 902

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 903

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 904

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 905

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 910

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 911

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 912

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 913

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 914

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 915

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 916

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 917

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 918

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 919

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 920

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 921

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 922

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 923

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 925

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 926

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 927

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 928

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 929

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 930

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 931

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 932

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 933

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 897

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 898

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 899

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 900

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 900

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 900

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 906

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 907

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 908

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 909

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 909

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 909

16 L Firmware ≤ 05.00 - DMS 4.2 EN - 02/2010

Page 17

8400 HighLine | Parameter setting & configuration

efesotomasyon.com - Lenze

Contents

14.1.51 L_Counter_1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 934

14.1.52 L_Counter_2

14.1.53 L_Counter_3

14.1.54 L_Curve_1

14.1.54.1 Function 2: nOut_a = f(x)

14.1.54.2 Function 3: nOut_a = f(table)

14.1.55 L_DFlipFlop_1

14.1.56 L_DFlipFlop_2

14.1.57 L_DigitalDelay_1

14.1.58 L_DigitalDelay_2

14.1.59 L_DigitalDelay_3

14.1.60 L_DigitalLogic_1

14.1.61 L_DigitalLogic_2

14.1.62 L_DigitalLogic5_1

14.1.63 L_DigitalLogic5_2

14.1.64 L_DT1_1

14.1.65 L_FixSet_a_1

14.1.66 L_FixSet_w_1

14.1.67 L_FixSet_w_2

14.1.68 L_GainOffset_1

14.1.69 L_GainOffset_2

14.1.70 L_GainOffset_3

14.1.71 L_GainOffsetP_1

14.1.72 L_GainOffsetP_2

14.1.73 L_GainOffsetP_3

14.1.74 L_GainOffsetPhiP_1

14.1.75 L_GainOffsetPhiP_2

14.1.76 L_Interpolator_1

14.1.76.1 Signal interpolation

14.1.76.2 Signal monitoring

14.1.77 L_JogCtrlExtension_1

14.1.78 L_Limit_1

14.1.79 L_Limit_2

14.1.80 L_LimitPhi_1

14.1.81 L_LimitPhi_2

14.1.82 L_LimitPhi_3

14.1.83 L_MPot_1

14.1.83.1 Activate & control motor potentiometer

14.1.83.2 Deactivate motor potentiometer

14.1.84 L_MulDiv_1

14.1.85 L_MulDiv_2

14.1.86 L_Mux_1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 936

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 938

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 940

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 941

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 942

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 945

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 946

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 947

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 949

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 950

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 951

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 953

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 955

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 957

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 959

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 960

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 961

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 962

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 963

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 964

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 965

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 966

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 967

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 968

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 969

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 970