Page 1

Supplementary instructions

Supplementary instructions

OPTIFLEX 2200 C

OPTIFLEX 2200 C

OPTIFLEX 2200 COPTIFLEX 2200 C

Supplementary instructions Supplementary instructions

2-wire / Guided Radar (TDR) Level Meter

Description of PROFIBUS PA interface

Description of PROFIBUS PA interface

Description of PROFIBUS PA interfaceDescription of PROFIBUS PA interface

The documentation is only complete when it is used in combination with the relevant

documentation of the level meter.

© KROHNE 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-AD

Page 2

CONTENTS

OPTIFLEX 2200 C

1 Safety instructions 3

1.1 Installation........................................................................................................................ 3

1.2 Scope of the document..................................................................................................... 3

1.3 Scope of delivery............................................................................................................... 3

2 PROFIBUS PA 4

2.1 Software history ............................................................................................................... 4

2.2 Device description ............................................................................................................ 4

2.3 Function blocks and the PROFIBUS PA Profile ............................................................... 4

2.4 Technical data................................................................................................................... 5

3 Electrical connection 6

3.1 Topology of a PROFIBUS PA network .............................................................................. 6

3.2 Electrical connection for signal converter....................................................................... 7

4 Commissioning / Operation 8

4.1 Hardware settings ............................................................................................................ 8

4.2 GSD files ......................................................................................................................... 10

4.3 Ident. Number ................................................................................................................ 10

4.4 Configuration of cyclic data transfer.............................................................................. 11

4.5 Cyclic data....................................................................................................................... 12

4.5.1 Input data .............................................................................................................................. 12

4.6 Diagnosis ........................................................................................................................ 17

5 Notes 21

2

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-AD

Page 3

OPTIFLEX 2200 C

1.1 Installation

Install the GSD files in your system. If it is necessary to use the process control system to change

the settings of the device, install the DD files. If it is necessary to use PACTware™ to change the

settings of the device, install PACTware™ and the DTM PROFIBUS PA files.

The software, files and installation instructions are given on the DVD-ROM supplied with the

device. You can download the latest version of PACTware™ and the DTM PROFIBUS PA from our

website. For more data, refer to the “readme.txt” files.

1.2 Scope of the document

These instructions are supplementary to the standard product documentation of the signal

converter. The details described herein, in particular the safety information, are valid and shall

be adhered to. The present supplementary instructions provide additional information for the

device when it is connected to a PROFIBUS network.

INFORMATION!

The information in this document only contains the data applicable to the PROFIBUS module.

The technical data in the signal converter Handbook is valid in its current version, provided that it

is not rendered invalid or replaced by these supplementary instructions.

SAFETY INSTRUCTIONS 1

1.3 Scope of delivery

A device for PROFIBUS communication is supplied with:

Supplementary instructions for the PROFIBUS PA interface (this document)

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

3

Page 4

2 PROFIBUS PA

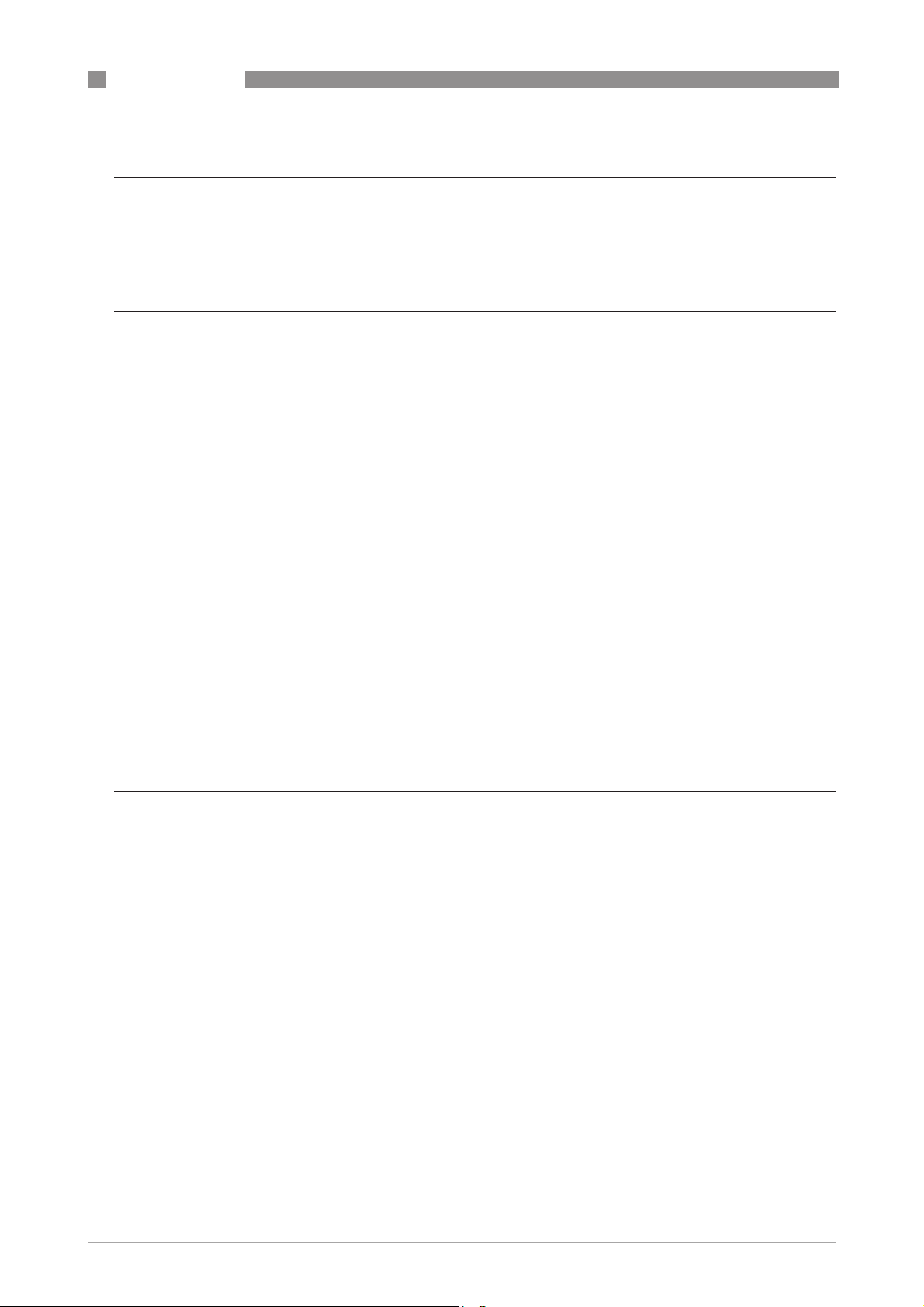

2.1 Software history

Issued Signal converter Application program System integration

OPTIFLEX 2200 C

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

08/13 PROFIBUS PA

module Ident.

No

0x4550

(4001858601c)

V2.42.0.42 Simatic

2.2 Device description

This device is a 2-wire level transmitter that uses TDR (Time Domain Reflectometry) / Guided

Radar technology. It measures the distance of liquids, liquid gases, pastes, powders, slurries

and granular products.

The level transmitter has an MBP (Manchester-coded, bus-powered) interface to connect the

device to a PROFIBUS PA network, when equipped with the appropriate options.

The level transmitter is approved for use in potentially explosive atmospheres when equipped

with the appropriate options.

PCS7

or

other SPS of

other

manufact.

Laptop / PC PDM

HW Config

or

other

Software of

other SPS

manufact.

(≥ 6.0 SP5)DD(Ident.-No.)

Pactware DTM ≥ 1.0.0

GSD (device

specific)

GSD (profile

specific)

KR014550.GSD OPTIFLEX 2200

PA1397.GSD AI 1 (Phy MBP)

2.3 Function blocks and the PROFIBUS PA Profile

The Analog Input Function Block agrees with PROFIBUS PA Profile 3.02. The Analog Input

Function Block is the data interface to a process control system (a PLC, ...). The control system

(cyclic communication services) can read or write input and output data.

INFORMATION!

The PROFIBUS PA Profile 3.02 has a standard set of parameters and functions available for

PROFIBUS devices used in process control. The PROFIBUS device is a function block application

in which parameters and functions are grouped into different blocks.

The device has these blocks:

Block Usage

1 Physical Block (PB) contains identification and diagnosis parameters of the device

1 Level Transducer Block (TB-Level) contains parameters and functions to control the level

4 Analog Input Function Blocks (AI-FB) contains parameters and functions to control the measuring

measurement

output; provides the measuring value(s)

4

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 5

OPTIFLEX 2200 C

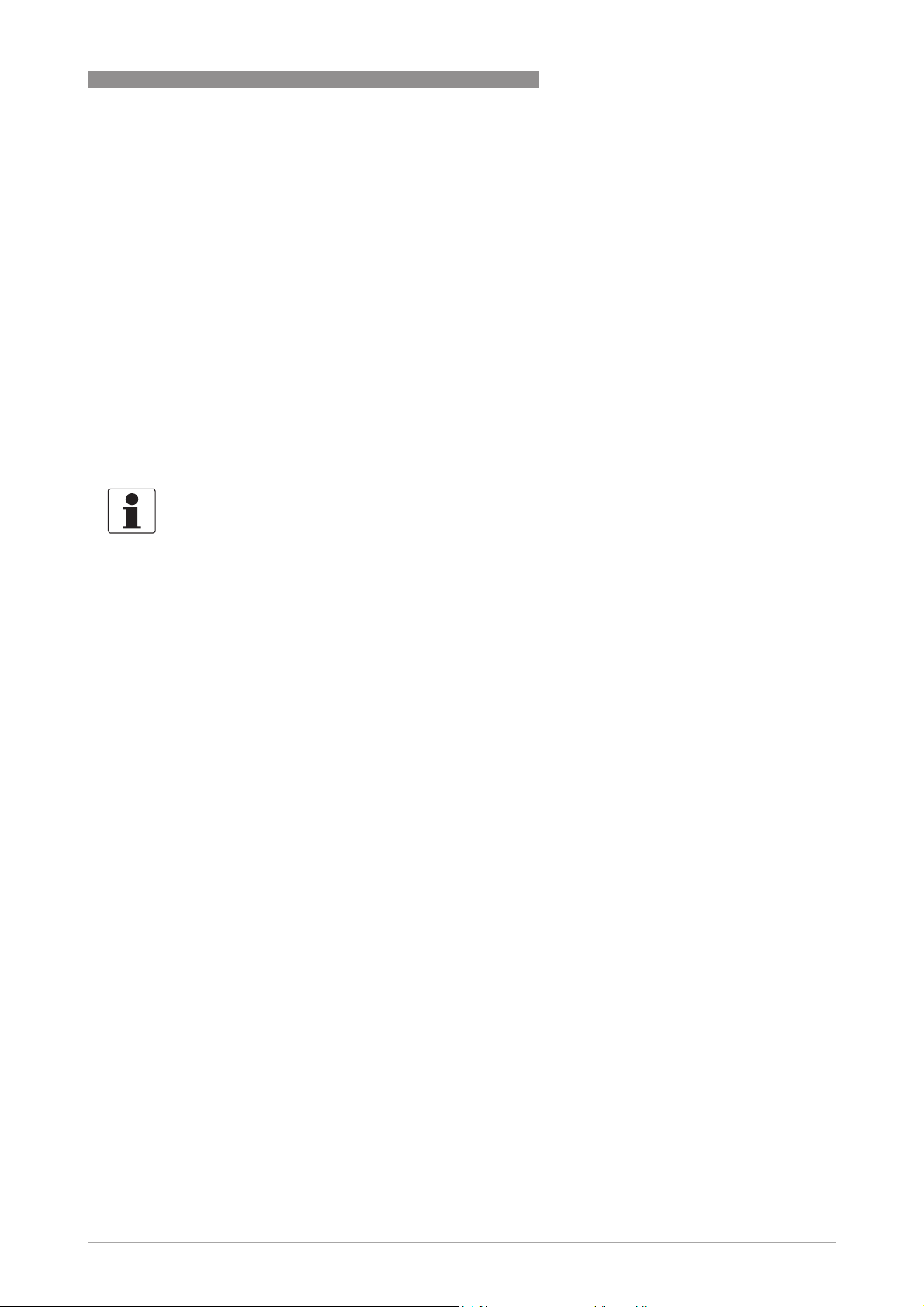

The device has 4 slots. The Analog Input Function Blocks use slot 1 (as a virtual module). The

user cannot change this setting. But the user can change the measurement name and unit for

each Function Block. Refer to the table that follows:

INFORMATION!

If it is necessary to change the measurement name, change the channel parameter in the acyclic

PROFIBUS services.

PROFIBUS PA 2

Slot Module

type

1 AI-FB Level (default setting) mm 1

1 Default measurement unit

The calibration units are used as default units.

2.4 Technical data

Hardware

Type PROFIBUS MBP interface. This interface agrees with IEC 61158-2 (bit rate

Device power supply 9...32 V - bus powered; no additional power supply required

Polarity sensitivity No

Base current 14 mA

FDE Yes. The Fault Disconnection Electronics (FDE) operates independently.

Max. error current 20.5 mA

Start current after 10 ms Lower than base current

Measurement name Unit

Distance mm 1

Conversion L 1

Conversion Distance L 1

31.25 kbit/s);

voltage mode (MBP = Manchester-Coded, Bus-Powered)

Software

Supported GSD KR014550.GSD

PA139700.GSD

Device profile PROFIBUS PA Profile V3.02; conformance class B, compact

Address setting Default: 126

Hardware DIP switch: 0…125

PROFIBUS service Set_Slave_Add: 0...125

Factory_Reset=2712: 126

Write protection Password and/or hardware switch

SAPs 2 × MS1 SAPs – acyclic interface to PLC

3 × MS2 SAPs – the number of MS2 Service Access Points is usually equal to

the maximum number of master class 2 tools

Function blocks 1 Physical Block

1 Level Transducer Block

4 Analog Input Function Blocks

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

5

Page 6

3 ELECTRICAL CONNECTION

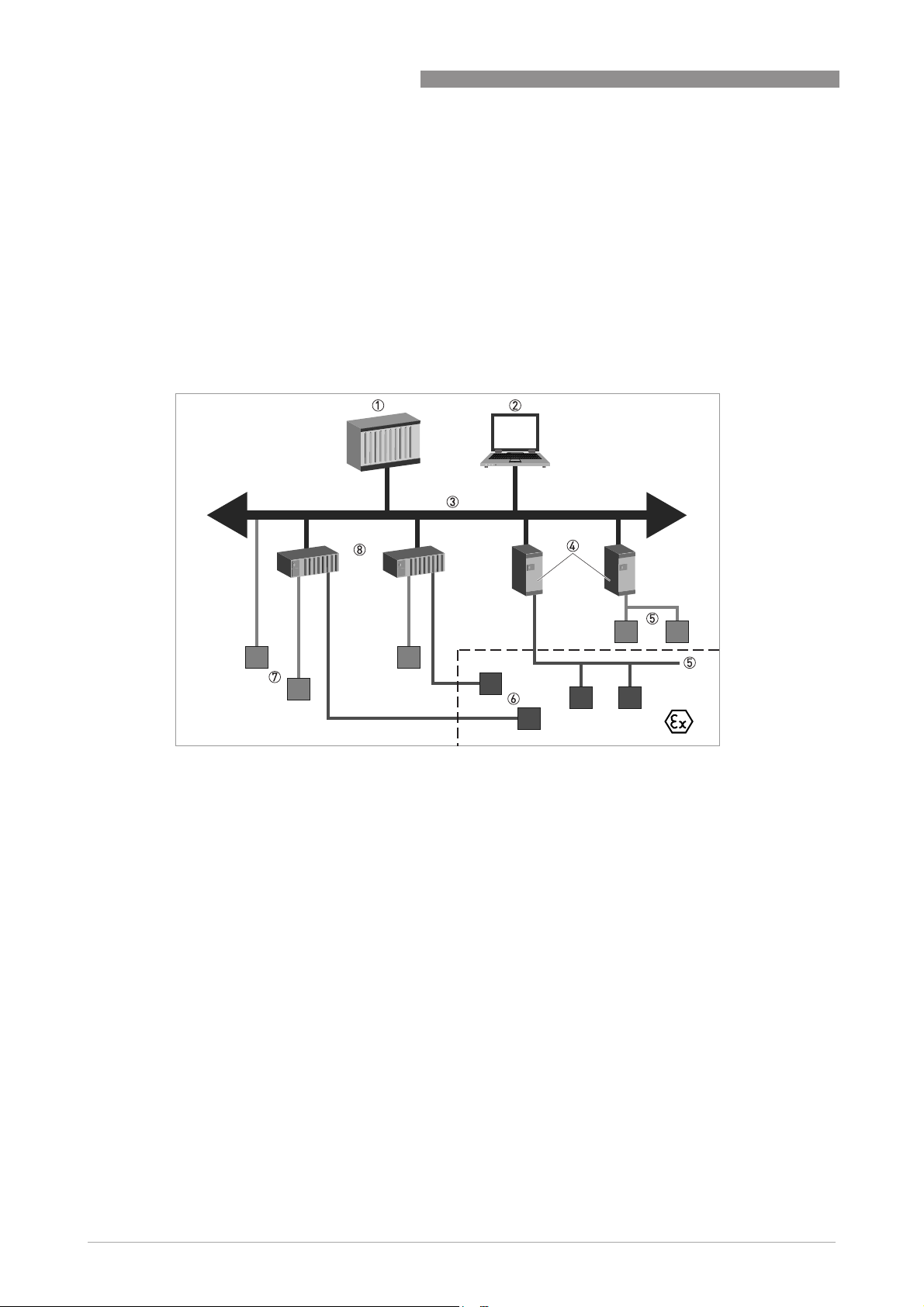

3.1 Topology of a PROFIBUS PA network

The following diagram shows a typical network configuration with PROFIBUS PA devices in

hazardous and non-hazardous areas, as well as the connection of conventional non-PROFIBUS

devices (e.g. with 4 … 20 mA signals) to a PROFIBUS network.

The PROFIBUS PA segment is connected to a segment coupler which, among other things,

provides the conversion to the PROFIBUS DP bus line. In addition it provides the power supply for

bus–powered PROFIBUS PA devices. Refer to the instruction manual of the segment coupler

concerning the DP bus parameters, e.g. the supported baud rates.

OPTIFLEX 2200 C

Figure 3-1: PROFIBUS PA network

1 Control system (PLC); class 1 master

2 Engineering or operation control tool; class 2 master

3 PROFIBUS DP network with max. 12 Mbit/s

4 PROFIBUS PA segment coupler DP / PA

5 PROFIBUS PA network with 31.25 kbit/s

6 HART

7 More devices with 4…20 mA

8 Analogue I/O module

®

device

Refer also to the PROFIBUS PA User and Installation Guideline (Version 2.2, February 2003 PNO

Order No. 2.092).

6

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 7

OPTIFLEX 2200 C

ELECTRICAL CONNECTION 3

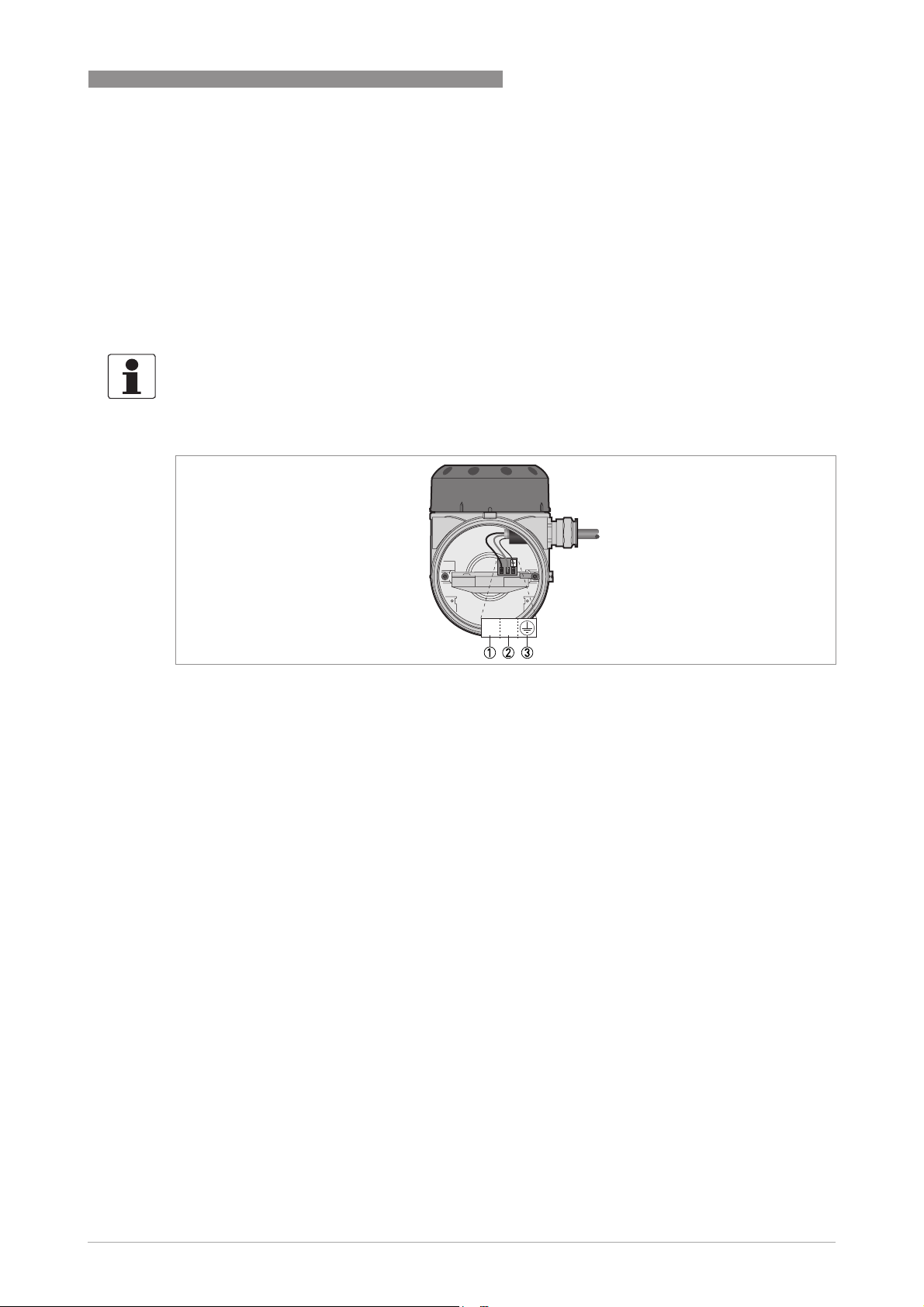

3.2 Electrical connection for signal converter

Bus cable - Shielding and grounding

The statements of the FISCO model only apply if the used bus cable meets the required

specifications.

In order to ensure optimum electromagnetic compatibility of systems it is important that the

system components, and in particular the bus cables, are shielded. These shields must have as

few gaps as possible.

INFORMATION!

The PROFIBUS PA interface of the signal converter will operate only if the power supply is

connected/available. The device terminal is not sensitive to electrical polarity.

Figure 3-2: Electrical installation: terminals

1 Power supply / communication terminal

2 Power supply / communication terminal

3 Grounding terminal

Use the shortest possible length of shield wire to connect the electrical cable to the functional

earth (FE) terminal.

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

7

Page 8

4 COMMISSIONING / OPERATION

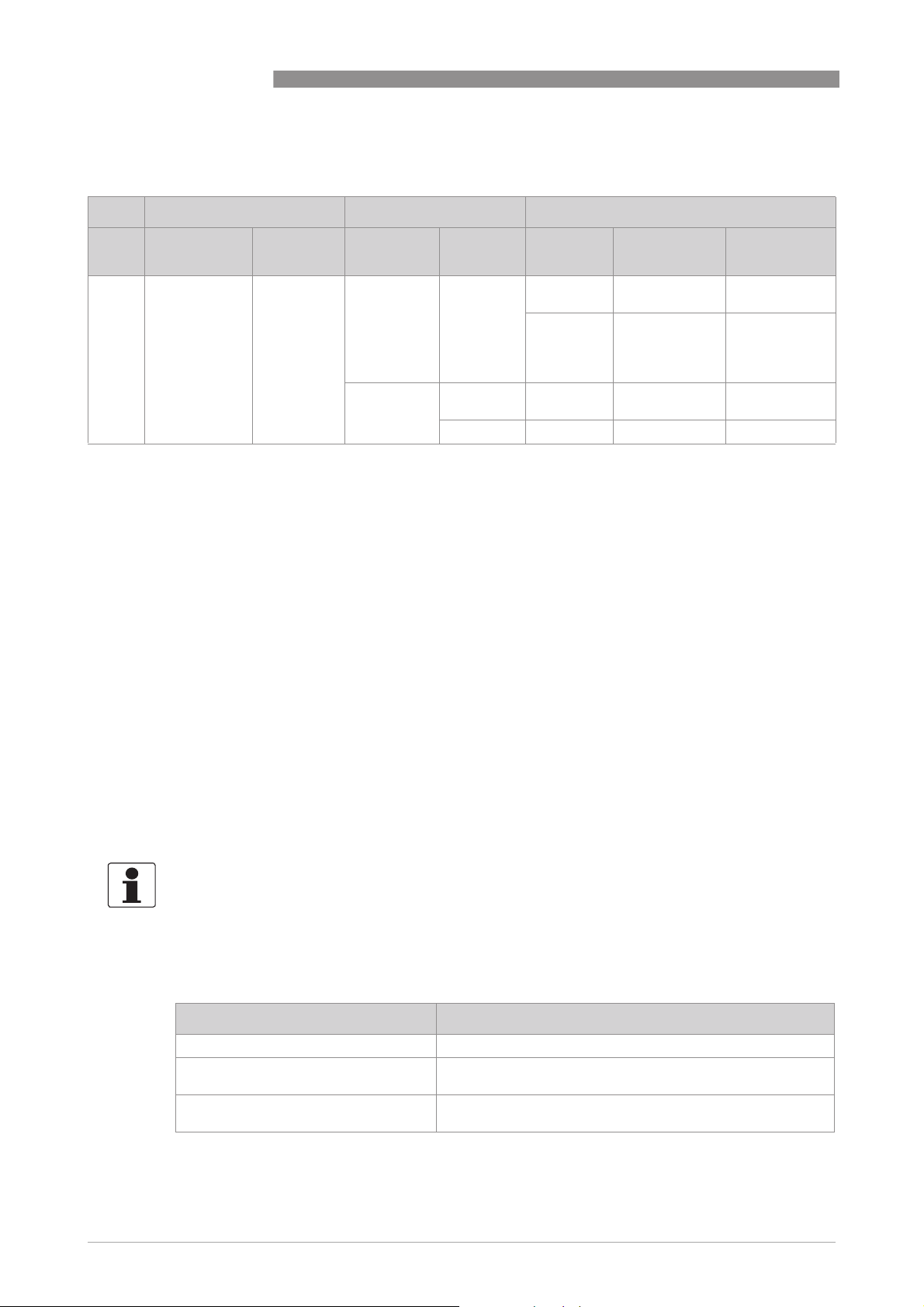

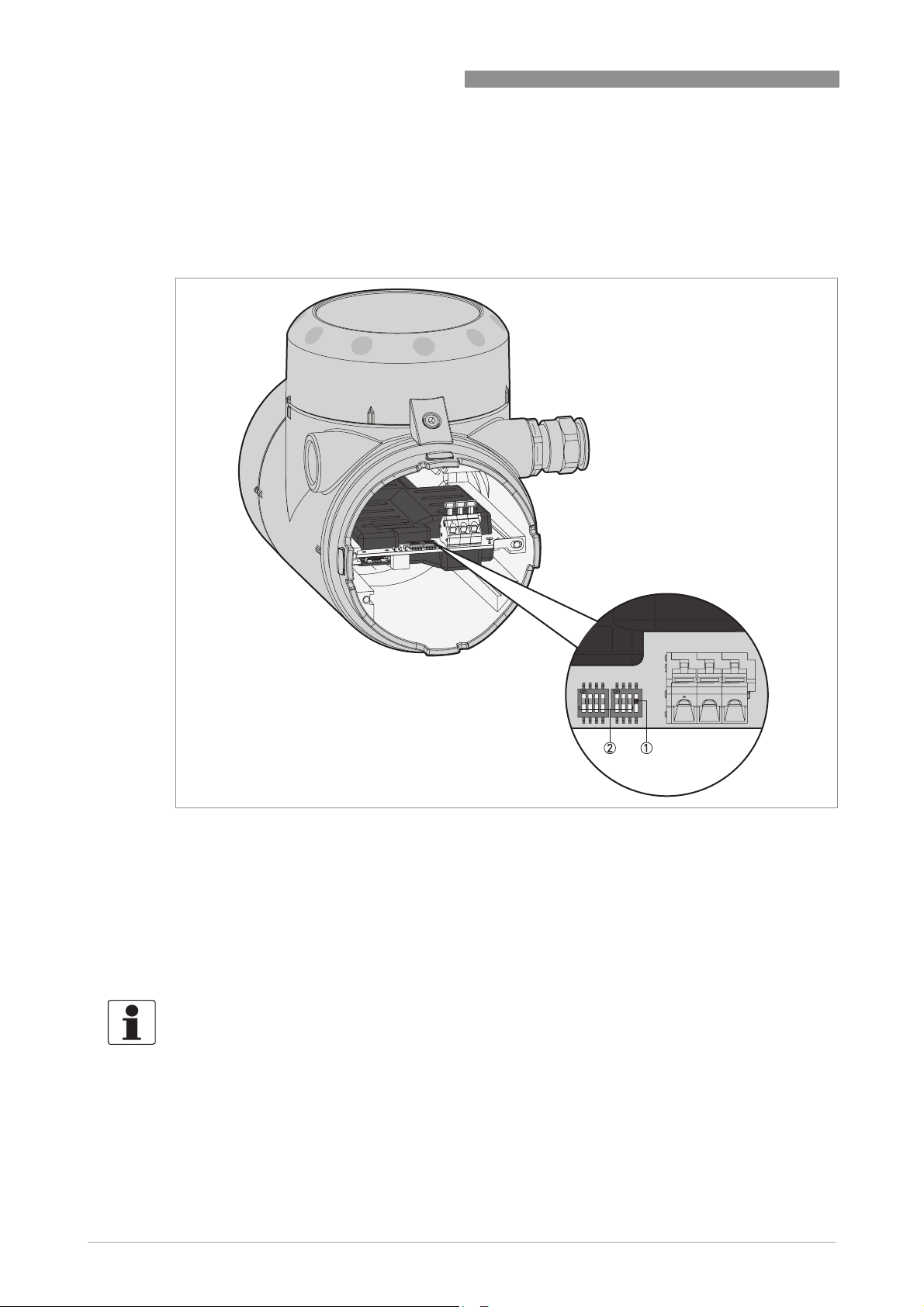

4.1 Hardware settings

There is a DIP switch block with 8 switches on the level transmitter module to set the PROFIBUS

device address and prevent changes to the station address from the network.

OPTIFLEX 2200 C

Figure 4-1: How to use the DIP switches to change the station address

1 Hardware DIP switch

OFF: The user can set the station address with the network bus

ON: The user can set the address of the device with the 7 other DIP swtiches (item 2). You cannot use the network bus

or the local display to change the station address.

2 7 "Station Address" DIP switches. Each DIP switch is a bit position (bits 0...6). Bit 0 is on the left side of the switch

block.The base 10 value of each bit is given in the table that follows. This data is used to calculate the "Station Address"

number.

OFF: binary number "0".

ON: binary number "1".

INFORMATION!

If the Hardware DIP switch is set to "ON", the hardware is locked and you cannot use the network

bus to change the station address.

8

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 9

OPTIFLEX 2200 C

Station address: DIP switch positions

Function Bit DIP switch positions

Hardware 1 7 OFF ON

Station address 6 + 0 + 64

1 If this DIP switch is set to "ON", you cannot use the network bus to change the station address

The station address is calculated by adding the "ON" values of each switch on the DIP switch

block. The default setting for each switch is “OFF”.

COMMISSIONING / OPERATION 4

Value ("OFF") Value ("ON")

5 + 0 + 32

4 + 0 + 16

3 + 0 + 8

2 + 0 + 4

1 + 0 + 2

0 + 0 + 1

Station address

• If the "Station Address" DIP switches are set to a correct station address (≤125), the device

uses this address. The Set_Slave_Add service is not used. Automatic Ident. Number

adaptation is not possible via Set_Slave_Add service in this case. Physical block parameter

FACTORY_RESET code 2712 (reset station address to its default value) is rejected.

• If the "Station Address" DIP switches are set to an incorrect address (>125), the device

ignores this setting. The Set_Slave_Add service and the Physical block parameter

FACTORY_RESET code 2712 (reset station address to its default value) are used. If

No_add_Cfg flag is set to "ON", the device will continue to use FACTORY_RESET code 2712.

• If the "Station Address" DIP switches are changed from an incorrect address to a correct

address, the device uses the address set on the DIP switch block.

• If the "Station Address" DIP switches are changed from a correct address to an incorrect

address, the device will use the default address 126. The flag No_Add_Chg will be set back to

"OFF".

INFORMATION!

You can also use the local display (menu item 2.6.1 ADDRESS) to set the Station Address to a

new value. You can change the value when the Hardware DIP switch is "OFF". If the Hardware

DIP switch is "ON", you can see the Station Address on the local display screen but you cannot

change the value.

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

9

Page 10

4 COMMISSIONING / OPERATION

4.2 GSD files

The GSD file contains information that will be needed for configuration of the PROFIBUS DP

communication network. Supplementary files (e.g. ___.bmp and ___.dib) contain icons which will

represent the PROFIBUS devices in the view of the bus configuration system/master system. The

files must be loaded into the configuration program before you connect the device to the

network. Follow the instructions in the manual of the host supplier when installing GSD file and

supplementary files.

The GSD files of all KROHNE devices with PROFIBUS PA interface are available at the KROHNE

internet site for download.

INFORMATION!

If it is supported by the host configuration tool the device entry for the level meter will be located

within the slave family

“

PROFIBUS PA”.

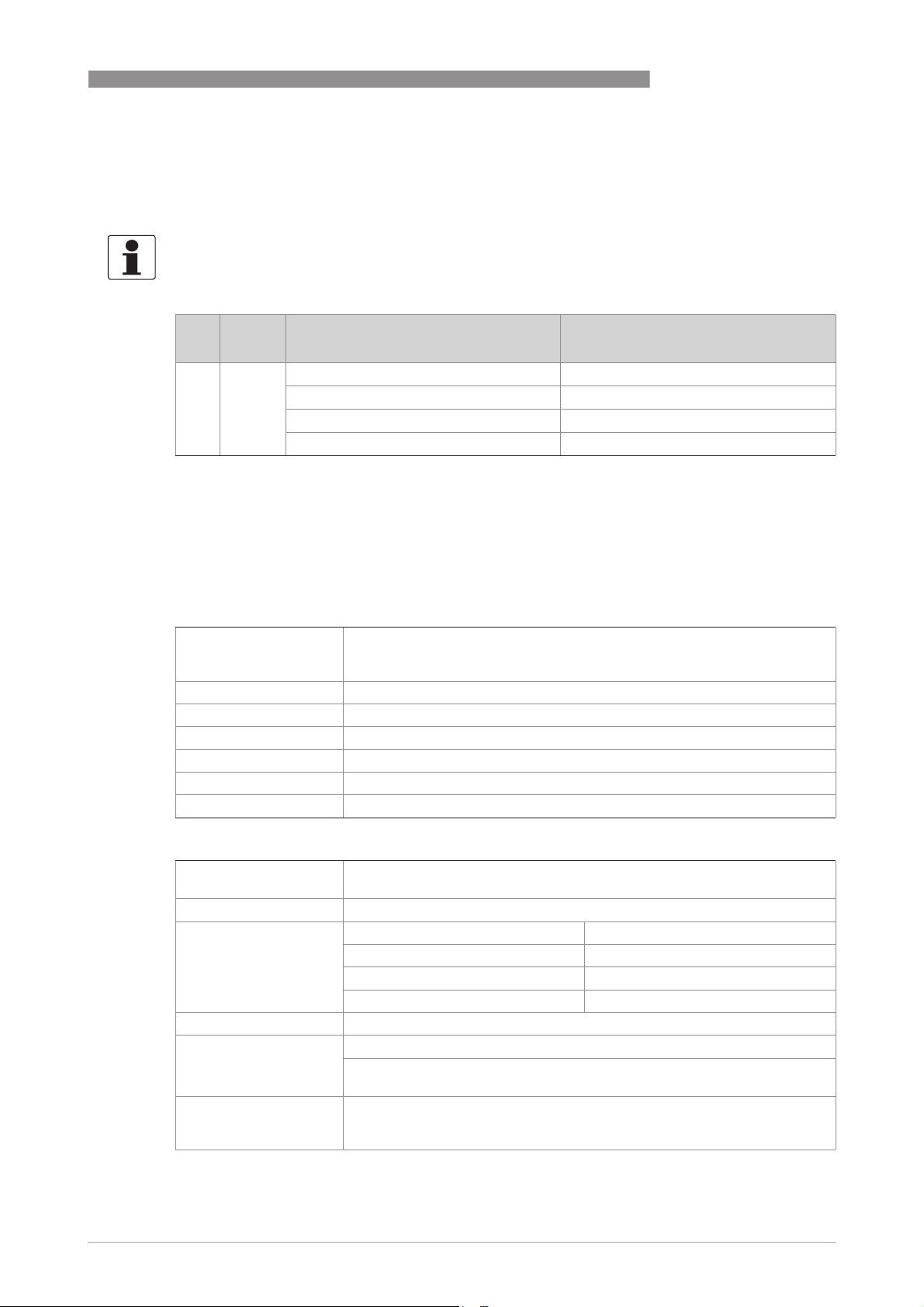

4.3 Ident. Number

Manufacturer specific Ident. Number (4550hex)

Manufacturer specific Ident. Number (4550hex)

Manufacturer specific Ident. Number (4550hex)Manufacturer specific Ident. Number (4550hex)

This setting gives a complete set of operations that can be run on the device. All Functions

Blocks (4 AI-FB) are used for cyclic data transfer. Device-specific diagnosis data is transferred in

addition to the Profile diagnosis.

OPTIFLEX 2200 C

Cyclic layout:

Slot Function Block Valid GSD Modules

1 AI-FB Empty Module

It is necessary to use GSD file KR014550.GSD in this mode. It is possible to use this file for all

types of PROFIBUS DP/PA segment couplers.

AI: Out

INFORMATION!

If a different GSD file is used in the PROFIBUS master system, it is not possibe to transfer cyclic

data.

10

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 11

OPTIFLEX 2200 C

Profile specific Ident. Number (9700hex)

Profile specific Ident. Number (9700hex)

Profile specific Ident. Number (9700hex)Profile specific Ident. Number (9700hex)

The 4 AI-FB are available only for cyclic data transfer. Cyclic PROFIBUS services cannot supply

device-specific diagnosis data. This operational condition can make devices from different

suppliers operate better together. The system will only use functions that are available to all

PROFIBUS PA level transmitters. It is not necessary to change the settings of the control system

to transfer data.

Cyclic layout:

Slot Function Block Valid GSD Modules

COMMISSIONING / OPERATION 4

1 AI-FB Analog Input (AI) short

It is necessary to use GSD file PA139700.GSD in this mode. This file is supplied by PROFIBUS

International (refer to www.profibus.com). It is possible to use this file for all types of PROFIBUS

DP/PA segment couplers. If this file is used, “Condensed Status” is not available.

INFORMATION!

If a different GSD file is used in the PROFIBUS master system, it is not possibe to transfer cyclic

data.

4.4 Configuration of cyclic data transfer

During network configuration the user has to select which function block input/output data shall

be transferred between the PROFIBUS master and the PROFIBUS slave. The GSD file described

above contains several types of modules for this purpose. During configuration a module has to

be assigned to each slot of the device in order to select which data has to be transferred for the

corresponding function blocks. The cyclic layout (see section Ident. Number selector) shows

which module types are valid for each slot. The order of transmission of the data always remains

the same. If an “Empty Module” is assigned to a slot no data will be sent for the corresponding

function block and all function block data following this empty module will move up one position.

Analog Input (AI) long

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

11

Page 12

4 COMMISSIONING / OPERATION

4.5 Cyclic data

In a PROFIBUS network cyclic data is described from the point of view of the master. Therefore

input data is transferred from the slave to the master while output data is transferred from the

master to the slave.

4.5.1 Input data

Input data is transferred from the level transmitter to the master for the measuring value. If

input data transfer is configured, 5 bytes are transferred for the corresponding slot:

• 4 byte float value (Float Format according to IEEE Standard 754 Short Real Number)

• 1 byte status value

Float value

Float value

Float valueFloat value

The example that follows shows the format of the float value according to IEEE Standard 754

Short Real Number:

OPTIFLEX 2200 C

Float format

Byte n Byte n+1

Bit7 Bit6 Bit7 Bit6

7

6

5

4

3

2

1

0

VZ

2

2

2

2

2

2

2

2

Exponent Mantissa

Byte n+2 Byte n+3

Bit7 Bit7

-82-92-102-112-122-132-142-152-162-172-182-192-202-212-222-23

2

Mantissa Mantissa

Example (binary): 40 F0 00 00 (hex) = 0100 0000 1111 0000 0000 0000 0000 0000

Formula:

Formula:

Formula:Formula:

VZ

(Exponent – 127)

value = (-1)

value = (-1)

0

* 2

* 2

(129 – 127)

* (1 + Mantissa)

* (1 + 2-1 + 2-2 + 2-3)

value = 1 * 4 * (1 + 0.5 + 0.25 + 0.125)

value = 7.5

-12-22-32-42-52-62-7

2

12

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 13

OPTIFLEX 2200 C

Status value

Status value

Status valueStatus value

The PROFIBUS interface of the level transmitter supports the PROFIBUS-PA Profile Version

3.02. In this Profile the Condensed Status and Diagnosis has replaced by default the Classic

Status and Diagnosis of the PROFIBUS-PA Profile Version 3.0. The Condensed Status and

Diagnosis has been created to make diagnostic events more obvious and to allow predictive and

preventive maintenance. Nevertheless Classic Status and Diagnosis is still available for the level

transmitter. It is implemented for backwards compatibility to "older" devices or PLC systems

which do not support Condensed Status and Diagnosis.

The device may be switched between "Condensed Status and Diagnosis" and "Classic Status and

Diagnosis"

• automatically during start-up of the cyclic data transfer by setting the parameter PRM_COND

within the Set_Prm service data.

• using an engineering tool (e.g. DD/DTM) to write the parameter COND_STATUS_DIAG (slot 0,

index 43).

Coding for both parameters is:

• 0: Classic Status

• 1: Condensed Status (factory setting)

COMMISSIONING / OPERATION 4

INFORMATION!

The parameter COND_STATUS_DIAG cannot be modified directly if cyclic data transfer is active.

Nevertheless it is reset to the factory setting if a reset to default data is requested by an

engineering tool.

The coding of the status value depends on the active status and diagnosis mode. It is described in

the following tables.

Condensed Status

Condensed Status

Condensed StatusCondensed Status

The Condensed Status codes have been defined to allow easier decoding of the information

provided by the PROFIBUS devices. The coding is shown in the following table:

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

262

5

4

2

232

2

1

0

2

2

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

13

Page 14

4 COMMISSIONING / OPERATION

Status = bad

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

0 0 0 0 0 0 0 0 = non-specific (not provided by the device)

0 0 1 0 0 0 1 1 = passivated (diagnostic alerts inhibited)

0 0 1 0 0 1 x x = maintenance alarm, more diagnosis available

0 0 1 0 1 0 x x = process related, no maintenance

0 0 1 1 1 1 x x = function check / local override; value not usable

Status = uncertain

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

0 1 0 0 1 0 x x = substitute set

0 1 0 0 1 1 1 1 = initial value

0 1 1 0 1 0 x x = maintenance demanded

0 1 1 1 0 0 1 1 = simulated value, start

0 1 1 1 0 1 1 1 = simulated value, end

0 1 1 1 1 0 x x = process related, no maintenance

262

262

5

4

2

5

4

2

232

232

2

1

2

2

1

2

OPTIFLEX 2200 C

0

2

0

2

Status = good (Non Cascade)

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

1 0 0 0 0 0 x x = ok

1 0 0 0 0 1 x x = update event

1 0 0 0 1 0 x x = advisory alarm

1 0 0 0 1 1 x x = critical alarm

1 0 1 0 0 0 x x = initiate fail safe (not provided by the level

1 0 1 0 0 1 x x = maintenance required

1 0 1 0 1 0 x x = maintenance demanded

1 0 1 1 1 1 x x = function check

262

5

4

2

232

2

1

0

2

2

transmitter)

14

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 15

OPTIFLEX 2200 C

Status = Limits

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

Good (Non Cascade):Good (Non Cascade):

• Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

Good (Cascade):Good (Cascade):

• Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

Uncertain:Uncertain:

(function block outputs value has been frozen, A/D converter is saturated or out of range, ...)

• Bad:

Bad: function block output value is bad - do not use it for process control!

Bad:Bad:

262

COMMISSIONING / OPERATION 4

5

4

2

232

2

1

0

2

2

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.

Classic Status

Classic Status

Classic StatusClassic Status

The Classic Status is implemented to provide compatibility to systems which are not configured

for Condensed Status. The coding is shown in the following table:

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

262

5

4

2

232

2

1

0

2

2

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

15

Page 16

4 COMMISSIONING / OPERATION

Status = bad

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

0 0 0 0 0 0 = non-specific

0 0 0 0 0 1 = configuration error

0 0 0 0 1 0 = not connected

0 0 0 0 1 1 = device failure

0 0 0 1 0 0 = sensor failure

0 0 0 1 0 1 = no communication (last usable value)

0 0 0 1 1 0 = no communication (no usable value)

0 0 0 1 1 1 = out of service

Status = uncertain

Quality Quality substatus Limits

262

5

4

2

232

2

1

2

OPTIFLEX 2200 C

0

2

Gr Gr QS QS QS QS Qu Qu

7

2

262

5

4

2

232

2

1

0

2

2

0 1 0 0 0 0 = non-specific

0 1 0 0 0 1 = last usable value

0 1 0 0 1 0 = substitute-set

0 1 0 0 1 1 = initial value

0 1 0 1 0 0 = sensor conversion not accurate

0 1 0 1 0 1 = engineering unit violation (unit not in the valid set)

0 1 0 1 1 0 = sub-normal

0 1 0 1 1 1 = configuration error

0 1 1 0 0 0 = simulated value

Status = good (Non Cascade)

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

1 0 0 0 0 0 = ok

1 0 0 0 0 1 = update event

1 0 0 0 1 0 = active advisory alarm

1 0 0 0 1 1 = active critical alarm

1 0 0 1 0 0 = unacknowledged update event

1 0 0 1 0 1 = unacknowledged advisory alarm

1 0 0 1 1 0 = unacknowledged critical alarm

1 0 1 0 0 0 = initiate fail safe

1 0 1 0 0 1 = maintenance required

262

5

4

2

232

2

1

0

2

2

16

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 17

OPTIFLEX 2200 C

Status = Limits

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

2

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

Good (Non Cascade):Good (Non Cascade):

• Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

Good (Cascade):Good (Cascade):

• Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

Uncertain:Uncertain:

(function block outputs value has been frozen, A/D converter is saturated or out of range, ...)

• Bad:

Bad: function block output value is bad - do not use it for process control!

Bad:Bad:

262

COMMISSIONING / OPERATION 4

5

4

2

232

2

1

0

2

2

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.

4.6 Diagnosis

The device does internal self-tests. The results are given as detailed diagnosis data that agrees

with PROFIBUS PA Profile 3.02. You can set device parameters to see the diagnosis data and you

can also use an engineering tool (DD/DTM, ...) to read it. Cyclic services transfer diagnosis data

to the control system (PLC, ...).

Diagnosis is bitwise coded. Thus it is possible to report more than one indication simultaneously.

The GSD file contains a text for each diagnosis bit to show a text message in the control system.

The references are specified in the UNIT_DIAG_BIT(i) entries. They show which bit is set to

indicate a special diagnosis event.

The quantity and content of diagnosis data depends on the device settings. The active Ident.

Number and the selected status and diagnosis mode will have an effect diagnosis propagation.

The tables that follow show the diagnosis events which are reported for different settings. The

bit number is equal to the count in the GSD file. It gives the position in the device-related

diagnostic field of the Slave_Diag service.

Diagnosis to control system in case of

• Manufacturer specific Ident. Number (4550hex)

• Profile specific Ident. Number (9700hex)

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

17

Page 18

4 COMMISSIONING / OPERATION

Bit Number

supported

Description

Correction action

OPTIFLEX 2200 C

16 yes Error appears -

17 yes Error disappears -

1

24

Hardware failure electronics Restart the device. If the error occurs again: send the device back

to the manufacturer with an indication of the error.

1

27

Electronic temperature too low Electronic temperature below -40°C. Comply with the application

limits with regard to temperature of the medium and ambient

temperature. If the process conditions are within the specified

limits: send the device back to the manufacturer with an

indication of the error.

Electronic temperature too high Electronic temperature above +85°C. Comply with the application

limits with regard to temperature of the medium and ambient

temperature. If the process conditions are within the specified

limits: send the device back to the manufacturer with an

indication of the error.

1

28

Memory error Reset the device to Factory/Default settings. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

1

29

Measurement failure Check process conditions (Flow/Level, Temperature). If the

process conditions are within the specified limits: send the device

back to the manufacturer with an indication of the error.

1

34

Configuration invalid Reset the device to Factory/Default settings. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

35 yes Restart Device is restarted because of power-up or warmstart request. In

case of unexpected restart: send the device back to the

manufacturer with an indication of the error.

36 yes Coldstart Device is reset to its Factory/Default settings because of a user

request or exchange of the basic module (serial number is

changed). Recover user specific parameter settings.

37 yes Maintenance required Linearization or temperature compensation is not operating

correct. See for detailed failure message or send the device back

to the manufacturer with an indication of the error.

39 yes Ident_Number violation Ident. Number Selector was modified while cyclic data transfer

was active. To clear this message perform one of the following

actions:

• Reset Ident. Number Selector to its former setting

• Stop cyclic data transfer

• Restart the device

2

40

42

43

55 yes Extension available Refer to detailed diagnosis in bits 56 to 103.

56

57

Maintenance alarm Check detailed diagnosis. Restart the device. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

2

Function check Simulation is active. Disable simulation to clear this message.

2

Invalid process condition Check process conditions (Flow/Level, Temperature). If the

process conditions are within the specified limits: send the device

back to the manufacturer with an indication of the error.

3

Converter EEPROM Error Replace the signal converter.For more data, refer to the

handbook.

3

Converter RAM Error Replace the signal converter.For more data, refer to the

handbook.

18

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 19

OPTIFLEX 2200 C

Bit Number

supported

Description

3

58

59

60

61

63

64

65

66

67

68

72

73

75

76

Converter ROM Error Replace the signal converter.For more data, refer to the

3

Sensor EEPROM Error Replace the signal converter.For more data, refer to the

3

Sensor RAM Error Replace the signal converter.For more data, refer to the

3

Sensor ROM Error Replace the signal converter.For more data, refer to the

3

Oscillator Frequency Failure Replace the signal converter.For more data, refer to the

3

Converter Voltage Error Replace the signal converter.For more data, refer to the

3

Sensor Voltage Error Do a check of the power supply at the device terminals. Make sure

3

Internal Communication Error De-energize the device. Make sure that the signal cable engages

3

Temperature Out of Range Error Measure the ambient temperature. De-energize the device until

3

Sensor not compatible Go to menu 1.1.0 IDENT. in Configuration mode. Record the

3

Reference Lost Error Speak to your supplier to make sure that the electronics are still

3

Level Lost Error Measure the level of the contents in the tank using another

3

Overfill Error Remove some of the product until the level is below the blocking

3

No Probe detected Error Replace the signal converter.For more data, refer to the

COMMISSIONING / OPERATION 4

Correction action

handbook.

handbook.

handbook.

handbook.

handbook.

handbook.

that voltage values are in the specified limits in menu item 2.2.2

DIAGNOSTIC (Configuration mode / Supervisor menu). If the

voltage is correct, replace the signal converter. For more data on

how to replace the signal converter, refer to the handbook.

in the terminal and the screw connection is tight. Energize the

device. If the problem continues, replace the signal converter. For

more data, refer to the handbook.

the ambient temperature is back in the given range. If the

temperature does not stay in the correct range, make sure that

there is insulation around the signal converter. If this error

occurs 2 times, replace the device.

version numbers of the device software given in menu items 1.1.2,

1.1.3 and 1.1.4. Give this data to the supplier.

functioning correctly. Make sure that your installation has ESD

protection. For more data, refer to the handbook.

method of measurement. If the tank is empty (the level is below

the end of the probe), then fill the tank until product level is in the

measurement range. If the tank is full (the level is in the blocking

distance), then remove the contents from the tank until the level

is back in the measuring range. If the product was lost and the

tank is neither full nor empty, wait for the device to find the level

again.

If the device has to measure a product with εr≥1.6, refer to MEAS.

AMP. (Measured Pulse Amplitude, menu item 2.5.6) and then

adjust MEAS. THRESH. (measurement threshold, menu item

2.5.7). If the product has a low dielectric constant (εr<1.6) and the

device is in TBF mode, refer to PROBE END AMP (probe end pulse

amplitude, menu item 2.5.8) and then adjust PROBE END TH.

(probe end threshold, menu item 2.5.9). For more data, refer to

the handbook.

Make sure that the signal converter is correctly attached the

probe. For more data, refer to the handbook.

distance.

handbook.

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

19

Page 20

4 COMMISSIONING / OPERATION

Bit Number

supported

80

Description

3

Flange Lost Warning Risk of device failure. Replace electronics module or contact the

Correction action

OPTIFLEX 2200 C

supplier.

3

82

Snapshot Invalid Do a check of the device, tank and the process.

Do a new snapshot recording. If necessary, contact the supplier.

3

84

Reference Position Outside Range Risk of device failure. Replace electronics module or contact the

supplier.

3

85

Audio Signal Offset Outside Range Risk of device failure. Replace electronics module or contact the

supplier.

3

86

Temperature Below -35°C Measure the ambient temperature. De-energize the device until

the ambient temperature is back in the given range. If the

temperature does not stay in the correct range, make sure that

there is insulation around the signal converter.

3

87

Temperature Above +75°C Measure the ambient temperature. De-energize the device until

the ambient temperature is back in the given range. If the

temperature does not stay in the correct range, make sure that

there is insulation around the signal converter.

3

90

Temperature out of range warning Measure the ambient temperature. De-energize the device until

the ambient temperature is back in the given range. If the

temperature does not stay in the correct range, make sure that

there is insulation around the signal converter.

3

93

Local Operation The device is in configuration mode. A supervisor has used the

LCD display of the device to enter a menu. Use the LCD display to

go back to normal mode.

3

100

No OF2200C Connection De-energize the device. Make sure that the signal cable engages

in the terminal and the screw connection is tight. Energize the

device. If the problem continues, replace the signal converter. For

more data, refer to the handbook.

1 Indication is supported if Classic Diagnosis is active only.

2 Indication is supported if Condensed Diagnosis is active only.

3 Indication is supported in cyclic diagnosis only if Ident. Number 4550 hex is active. Nevertheless this information is always available via

acyclic access (e.g. by using DD / DTM) for all Ident. Numbers supported.

20

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 21

OPTIFLEX 2200 C

NOTES 5

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

21

Page 22

5 NOTES

OPTIFLEX 2200 C

22

www.krohne.com 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Page 23

OPTIFLEX 2200 C

NOTES 5

www.krohne.com10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

23

Page 24

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

© KROHNE 10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-AD - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...