Page 1

Technical Datasheet

Technical Datasheet

OPTIWAVE 1010

OPTIWAVE 1010

OPTIWAVE 1010OPTIWAVE 1010

Technical DatasheetTechnical Datasheet

Radar (FMCW) Level Transmitter for bypass chambers

and magnetic level indicators (BM 26 Advanced)

•

Device welded to a bypass chamber with an optional IP68 level indicator (BM 26

Advanced) – for the continuous measurement of clean liquids

•

Device is configured and ready to use before it leaves the factory

•

Measuring distance up to 8 m / 26.2 ft

© KROHNE 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 2

CONTENTS

OPTIWAVE 1010

1 Product features 3

1.1 The FMCW radar level transmitter for bypass chambers ............................................... 3

1.2 Overview............................................................................................................................ 4

1.3 Measuring principle.......................................................................................................... 6

2 Technical data 7

2.1 Technical data................................................................................................................... 7

2.2 Measuring accuracy ....................................................................................................... 11

2.3 Minimum power supply voltage ..................................................................................... 13

2.4 Dimensions and weights ................................................................................................ 14

3 Installation 16

3.1 Pre-installation requirements ....................................................................................... 16

3.2 Pressure and temperature ranges ................................................................................ 16

3.3 Recommended mounting position ................................................................................. 19

3.4 Mounting restrictions ..................................................................................................... 19

4 Electrical connections 20

4.1 Electrical installation: 2-wire, loop-powered ................................................................ 20

4.2 Electrical connection for current output ....................................................................... 20

4.2.1 Non-Ex devices ..................................................................................................................... 20

4.2.2 Devices for hazardous locations........................................................................................... 21

4.3 Networks ........................................................................................................................ 21

4.3.1 General information.............................................................................................................. 21

4.3.2 Point-to-point connection..................................................................................................... 21

4.3.3 Multi-drop networks ............................................................................................................. 22

5 Order information 23

5.1 Order code ...................................................................................................................... 23

5.2 Accessories..................................................................................................................... 25

6 Notes 26

2

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 3

OPTIWAVE 1010

PRODUCT FEATURES

1.1 The FMCW radar level transmitter for bypass chambers

The OPTIWAVE 1010 is a non-contact FMCW radar welded to a bypass chamber with an optional

IP68 level indicator (BM 26 Advanced). It continuously measures the distance and level of clean

liquids.

1

1 OPTIWAVE 1010 radar level transmitter

2 Welded connection (matching element)

3 BM 26 Advanced magnetic level indicator (MLI) or bypass chamber

4 Standard aluminium housing

5 Aluminium housing with distance piece

6 Stainless steel housing

Highlights

• 2-wire, loop-powered, HART®, 6 GHz Radar (FMCW) Level Transmitter for clean liquids

• Welded to a bypass chamber or BM 26 Advanced MLI

• Device is configured and ready to use before it leaves the factory

• Adjustments possible using HART® communication / DTM / DDs

• ±5mm/ 0.2¨ accuracy

• Measuring distance up to 8 m / 26.2 ft

• Metaglas® or Metapeek seal (dual process seal system)

• Max. process conditions +150°C / +302°F and 40 barg / 580 psig

• No minimum dielectric constant when using a float

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

3

Page 4

1

PRODUCT FEATURES

Industries

• Chemical market

• Power

• Water & Wastewater

• Automotive

• HVACR (heating, ventilation, air conditioning and refrigeration)

Applications

• Raw material storage

• Water hammer arresters

• Liquefied gas

• Hydraulic oil

• Cooling water and steam condensates

1.2 Overview

Standard aluminium housing

OPTIWAVE 1010

• Max. process connection temperature:

+100°C / +212°F

• Max. process pressure: 16 barg / 232 psig

• Metapeek process seal

4

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 5

OPTIWAVE 1010

Aluminium housing with distance piece

PRODUCT FEATURES

• Max. process connection temperature:

+150°C / +302°F

• Max. process pressure: 40 barg / 580 psig

• Metaglas® process seal

1

Stainless steel housing

• Max. process connection temperature:

+120°C / +248°F

• Max. process pressure: 40 barg / 580 psig

• Metaglas® process seal

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

5

Page 6

1

PRODUCT FEATURES

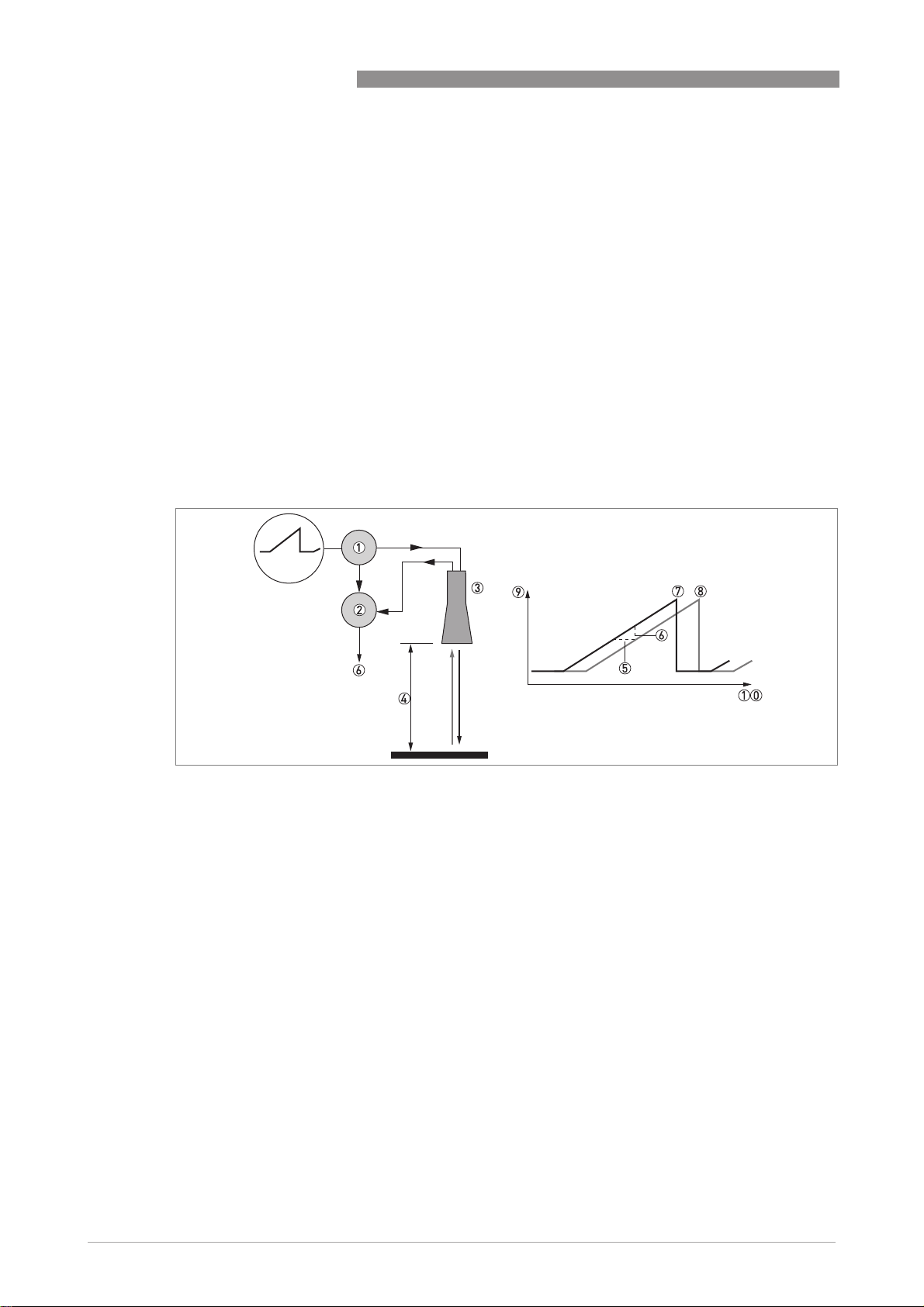

1.3 Measuring principle

A radar signal is emitted via an antenna, reflected from the product surface and received after a

time t. The radar principle used is FMCW (Frequency Modulated Continuous Wave).

The FMCW-radar transmits a high frequency signal whose frequency increases linearly during

the measurement phase (called the frequency sweep). The signal is emitted, reflected on the

measuring surface and received with a time delay, t. Delay time, t=2d/c, where d is the distance

to the product surface and c is the speed of light in the gas above the product.

For further signal processing the difference Δf is calculated from the actual transmitted

frequency and the received frequency. The difference is directly proportional to the distance. A

large frequency difference corresponds to a large distance and vice versa. The frequency

difference Δf is transformed via a Fourier transformation (FFT) into a frequency spectrum and

then the distance is calculated from the spectrum. The level results from the difference between

the maximum distance and the measured distance.

OPTIWAVE 1010

Figure 1-1: Measuring principle of FMCW radar

1 Transmitter

2 Mixer

3 Antenna

4 Distance to product surface, where change in frequency is proportional to distance

5 Differential time delay, Δt

6 Differential frequency, Δf

7 Frequency transmitted

8 Frequency received

9 Frequency

10 Time

6

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 7

OPTIWAVE 1010

TECHNICAL DATA

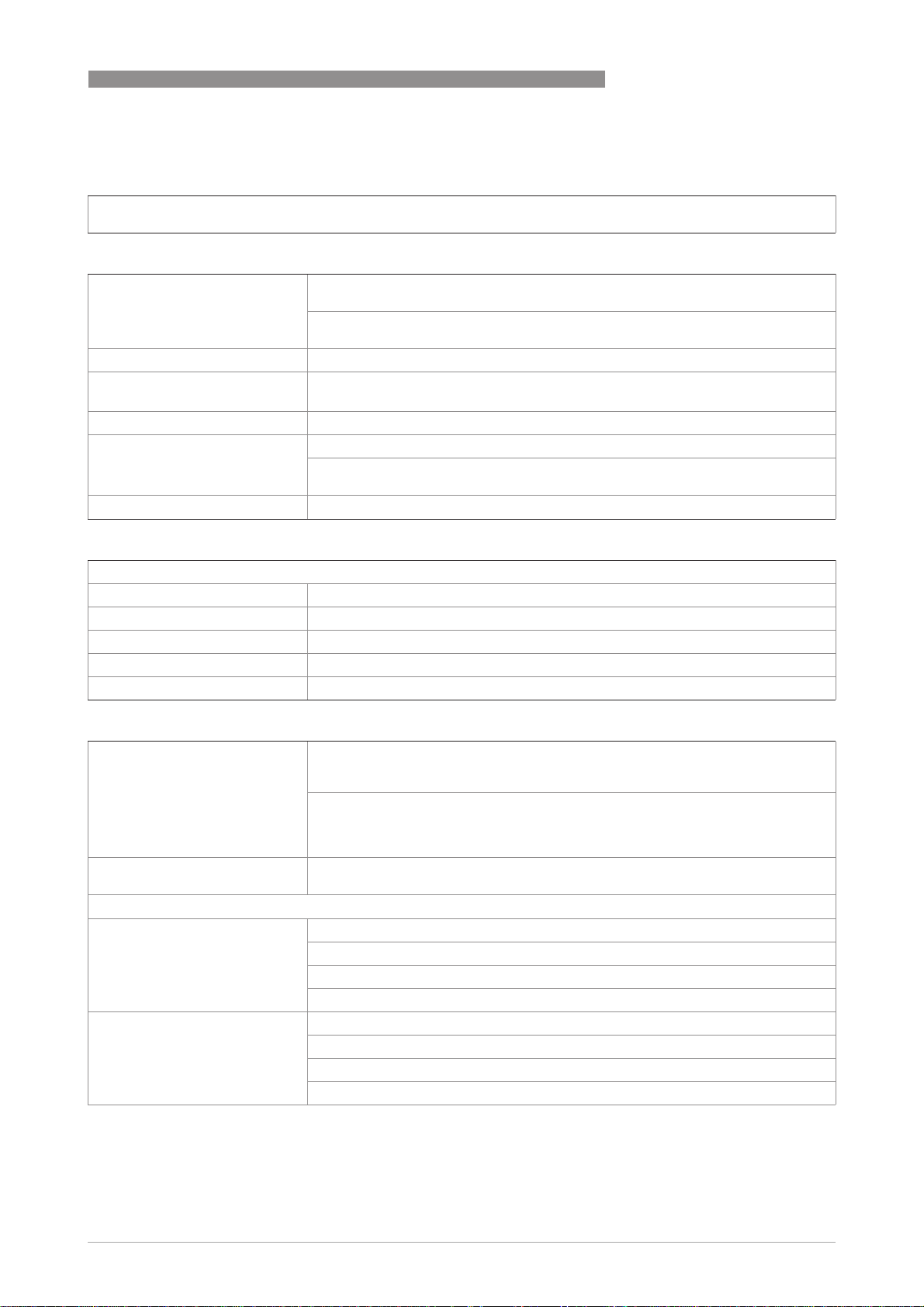

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle 2-wire loop-powered level transmitter; C-band (6 GHz) FMCW radar

Application range Level indication of liquids in applications up to 40 barg / 580 psig

Primary measured value Distance to the surface of the liquid (or the top of the float, if the liquid has a low

Secondary measured value Level of the liquid in the bypass chamber

Design

Construction The measurement system consists of a bypass chamber, a signal converter and an

Measuring range 0.3...5.6 m / 0.98...18.4 ft (max. 8 m / 26.2 ft)

Top dead zone Minimum value: 300 mm / 11.8¨ from the matching element

User interface

User interface

User interfaceUser interface

User interface PACTware™

dielectric constant)

optional float

2

Measuring accuracy

Repeatability ±2mm/ ±0.08¨

Accuracy Standard: ±10 mm / ±0.4¨ without calibration or with a 2-point calibration

Influence of temperature on the

bypass chamber

Reference conditions acc. to DIN EN 61298-1

Reference conditions acc. to DIN EN 61298-1

Reference conditions acc. to DIN EN 61298-1Reference conditions acc. to DIN EN 61298-1

Temperature +18...+30°C / +64...+86°F

Pressure 860...1060 mbara / 12.5...15.4 psia

Relative air humidity 45...75%

Target A special float with a target is installed in the bypass chamber and used to calibrate

Option: ±5mm/ ±0.2¨ with a 5-point calibration¨

0.01 mm/1 m of distance/°C (relative to +25°C) /

0.000216¨/1 ft of distance/°F (relative to +77°F)

the device

1

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature -40…+85°C/ -40…+185°F

Storage temperature -40…+85°C/ -40…+185°F

Ex: see supplementary operating instructions or approval certificates

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

7

Page 8

2

TECHNICAL DATA

OPTIWAVE 1010

Process temperature Standard aluminium version with Metapeek process seal:

Pressure

Pressure

PressurePressure

Process pressure Standard (with Metapeek):

Other conditions

Other conditions

Other conditionsOther conditions

Minimum dielectric constant (εr) Not applicable. If εr <3, a float with a target is used.

Ingress protection IEC 60529: IP66/67

Maximum rate of change 10 m/min / 32.8 ft/min

Measurement update rate Typically 2 measurement cycles/s

Standard aluminium version with Metapeek process seal:

Standard aluminium version with Metapeek process seal:Standard aluminium version with Metapeek process seal:

with a Kalrez® 6375 gasket: -20...+100°C / -4...+212°F

with a FKM/FPM gasket: -40...+100°C / -40...+212°F

with a EPDM gasket: -40...+100°C / -40...+212°F

Aluminium version with distance piece and Metaglas

Aluminium version with distance piece and Metaglas® process seal:

Aluminium version with distance piece and MetaglasAluminium version with distance piece and Metaglas

with a Kalrez® 6375 gasket: -20...+150°C / -4...+302°F

with a FKM/FPM gasket: -40...+150°C / -40...+302°F

with a EPDM gasket: -40...+150°C / -40...+302°F

Stainless steel version with Metaglas

Stainless steel version with Metaglas® process seal:

Stainless steel version with MetaglasStainless steel version with Metaglas

with a Kalrez® 6375 gasket: -20...+120°C / -4...+248°F

with a FKM/FPM gasket: -40...+120°C / -40...+248°F

with a EPDM gasket: -40...+120°C / -40...+248°F

The process connection temperature must agree with the temperature limits of the

gasket material.

Ex: see supplementary operating instructions or approval certificates

Standard (with Metapeek): -1…16 barg / -14.5…232 psig

Standard (with Metapeek):Standard (with Metapeek):

With Metaglas

With Metaglas®:::: -1…40 barg / -14.5…580 psig

With MetaglasWith Metaglas

process seal:

process seal: process seal:

2

3

3

process seal:

process seal: process seal:

Installation conditions

Dimensions and weights For dimensions and weights data, refer to

the technical data sheet for the BM 26 Basic / Advanced.

Dimensions and weights

on page 14 and

Materials

Housing Standard: Polyester-coated aluminium

Option: Stainless steel (1.4408 / 316)

Wetted materials Standard: Stainless steel (1.4404 / 316L) bypass chamber / magnetic level indicator

Process seal Standard Aluminium: Metapeek process seal with O-ring

Cable gland Standard: none

Weather protection (option) Stainless steel (1.4404 / 316L)

with a PEEK cone in the matching element and a FKM/FPM, EPDM or Kalrez® 6375

O-ring

Aluminium version with distance piece: Metaglas® process seal with O-ring

Stainless steel version: Metaglas® process seal with O-ring

Options: Plastic (Non-Ex: black, Ex ia-approved: blue); nickel-plated brass;

stainless steel

8

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 9

OPTIWAVE 1010

TECHNICAL DATA

Process connections

The device is welded to the top of the bypass chamber of the magnetic level indicator. For more data about the process

connections of the magnetic level indicator, refer to the technical data sheet for the BM 26 Basic / Advanced.

Electrical connections

Power supply Non-Ex, Ex db- and Ex tb-approved devices

Maximum current 22 mA

Current output load RL [Ω] ≤ ((U

Cable entry Standard: M20×1.5; Option: ½ NPT

Cable gland Standard: none

Cable entry capacity (terminal) 0.5…2.5 mm²

Non-Ex, Ex db- and Ex tb-approved devices

Non-Ex, Ex db- and Ex tb-approved devicesNon-Ex, Ex db- and Ex tb-approved devices

14.5…32 VDC; min./max. value for an output of 22 mA at the terminals

Ex ia-approved devices

Ex ia-approved devices

Ex ia-approved devicesEx ia-approved devices

14.5…30 VDC; min./max. value for an output of 22 mA at the terminals

-14.5 V)/22 mA). For more data, refer to

voltage

Options: M20×1.5 (cable diameter: 6...10 mm / 0.2...0.39¨); others are available on

request

ext

on page 13.

Minimum power supply

2

Input and output

Current output / HART

Current output / HART®

Current output / HARTCurrent output / HART

Output signal 4…20 mA HART® or 3.8…20.5 mA acc. to NAMUR NE 43

Resolution ±3 µA

Analog temperature drift Typically 50 ppm/K (150 ppm/K maximum)

Digital temperature drift Typically ±5mm/ 0.2¨ – max. 15 mm / 0.59¨ for the full temperature range

Error signal High: 22 mA; Low: 3.6 mA acc. to NAMUR NE 43

4

Approvals and certification

CE The device meets the essential requirements of the EU Directives. The

Vibration resistance EN 60068-2-6 / IEC 61298-3

Explosion protection

Explosion protection

Explosion protectionExplosion protection

ATEX (Ex ia or Ex db or Ex tb)

KIWA 15ATEX0022 X

IECEx (Ex ia or Ex db or Ex tb)

IECEx KIW 15.0012 X

manufacturer certifies successful testing of the product by applying the CE

marking.

For more data about the EU Directives and European Standards related to this

device, refer to the EU Declaration of Conformity. You can find this documentation

on the DVD-ROM supplied with the device or it can be downloaded free of charge

from the website (Download Center).

10-82.2 Hz: 0.15 mm; 82.2-1000 Hz: 20 m/s²

II 1/2 G Ex ia IIC Tx Ga/Gb;

II 2 D Ex ia IIIC T120°C Db (stainless steel housing only);

II 1/2 G Ex db IIC T6...T4 Ga/Gb (stainless steel housing only);

II 2 D Ex tb IIIC T120°C Db (stainless steel housing only)

Ex ia IIC Tx Ga/Gb;

Ex ia IIIC T120°C Db (stainless steel housing only);

Ex db IIC T6...T4 Ga/Gb (stainless steel housing only);

Ex tb IIIC T120°C Db (stainless steel housing only)

5

5

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

9

Page 10

2

TECHNICAL DATA

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

EMC Electromagnetic Compatibility (EMC) directive

Radio approvals EU

LVD Essential requirements of Low-Voltage (LVD) directive

NAMUR NAMUR NE 43 Standardization of the Signal Level for the Failure Information of

Construction code Option: NACE MR0175 / ISO 15156; NACE MR0103

1 For more data, refer to the "Measuring accuracy" section in this chapter

2 Kalrez® is a registered trademark of DuPont Performance Elastomers L.L.C. The process connection temperature must agree with

the temperature limits of the gasket material.

3 Metaglas® is a registered trademark of Herberts Industrieglas, GMBH & Co., KG. The process connection temperature must agree

with the temperature limits of the gasket material.

4 HART® is a registered trademark of the HART Communication Foundation

5 Tx = T6...T4 (without a distance piece) or T6...T3 (with a distance piece)

EU

EUEU

Radio Equipment directive

FCC Rules

FCC Rules

FCC RulesFCC Rules

Part 15

Industry Canada

Industry Canada

Industry CanadaIndustry Canada

License-exempt RSS-210

Digital Transmitters

NAMUR NE 53 Software and Hardware of Field Devices and Signal Processing

Devices with Digital Electronics

NAMUR NE 107 Self-Monitoring and Diagnosis of Field Devices

OPTIWAVE 1010

10

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 11

OPTIWAVE 1010

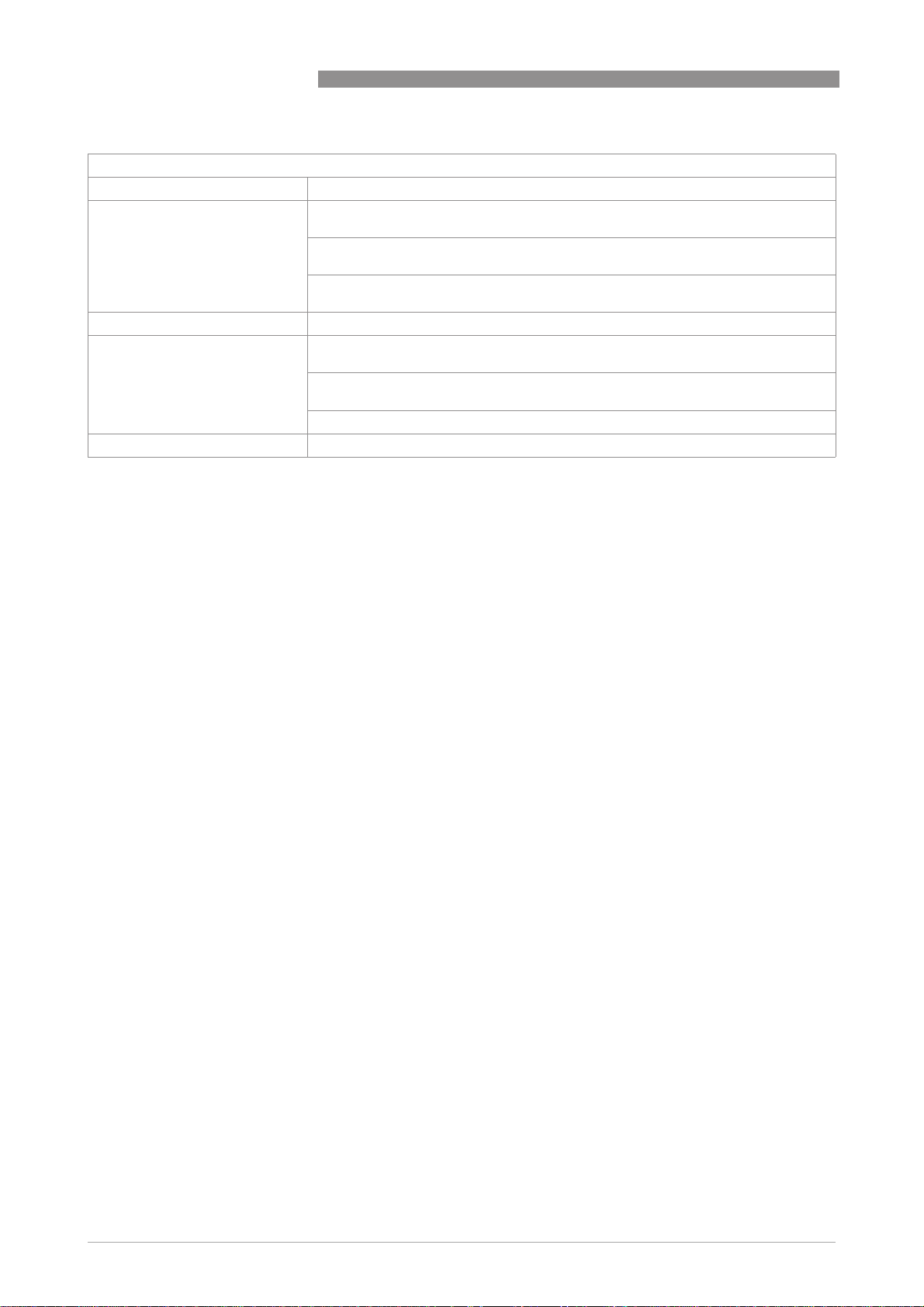

2.2 Measuring accuracy

Use these graphs to find the measuring accuracy for a given distance from the transmitter.

Measuring accuracy without calibration or after 2-point calibration (with a 2-point

calibration certificate)

TECHNICAL DATA

2

Figure 2-1: Measuring accuracy / distance from the process connections of the bypass chamber, in mm

X: Distance from the top process connection [mm]

Y: Accuracy [+yy mm / -yy mm]

1: 200 mm

2: Float offset. Refer to the "Basic parameters" menu in the DTM for the float offset value.

Figure 2-2: Measuring accuracy / distance from the process connections of the bypass chamber, in inches

X: Distance from the top process connection [inches]

Y: Accuracy [+yy¨ / -yy¨]

1: 7.9¨

2: Float offset. Refer to the "Basic parameters" menu in the DTM for the float offset value.

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

11

Page 12

2

TECHNICAL DATA

Measuring accuracy after 5-point calibration (with a 5-point calibration certificate)

Figure 2-3: Measuring accuracy / distance from the process connections of the bypass chamber, in mm

X: Distance from the top process connection [mm]

Y: Accuracy [+yy mm / -yy mm]

1: 200 mm

2: Float offset. Refer to the "Basic parameters" menu in the DTM for the float offset value.

3: 200 mm

OPTIWAVE 1010

12

Figure 2-4: Measuring accuracy / distance from the process connections of the bypass chamber, in inches

X: Distance from the top process connection [inches]

Y: Accuracy [+yy¨ / -yy¨]

1: 7.9¨

2: Float offset. Refer to the "Basic parameters" menu in the DTM for the float offset value.

3: 7.9¨

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 13

OPTIWAVE 1010

2.3 Minimum power supply voltage

Use these graphs to find the minimum power supply voltage for a given current output load.

Non-Ex devices or devices with a Hazardous Location approval (Ex db / Ex tb)

TECHNICAL DATA

2

Figure 2-5: Minimum power supply voltage for an output of 22 mA at the terminal (Non-Ex devices or devices with a

Hazardous Location approval (Ex db / Ex tb))

X: Power supply U [VDC]

Y: Current output load R

L

[Ω]

Devices with a Hazardous Location approval (Ex ia)

Figure 2-6: Minimum power supply voltage for an output of 22 mA at the terminal (devices with a Hazardous Location

approval (Ex ia))

X: Power supply U [VDC]

Y: Current output load R

L

[Ω]

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

13

Page 14

2

TECHNICAL DATA

2.4 Dimensions and weights

Device versions

Figure 2-7: Device versions

1 Non-Ex or Ex ia-approved device (aluminium housing – standard version)

2 Non-Ex or Ex ia-approved device (aluminium housing – with distance piece)

3 Non-Ex, Ex ia- Ex db- or Ex tb-approved device (stainless steel housing)

Device versions: Dimensions in mm and inches

OPTIWAVE 1010

Dimensions Device versions

Aluminium:

non-Ex or Ex ia-approved

(standard)

non-Ex or Ex ia-approved

Aluminium:

(with distance piece)

Stainless steel:

non-Ex, Ex ia, Ex db or

Ex tb-approved

[mm] [inches] [mm] [inches] [mm] [inches]

aaaa 98 3.86 98 3.86 99.5 3.92

bbbb 178 7.01 278 10.94 189 7.44

cccc 138 5.43 138 5.43 133 5.24

dddd 153 6.02 253 9.96 164 6.46

eeee 14 0.55 14 0.55 14 0.55

ffff 42.4 1.67 42.4 1.67 42.4 1.67

gggg 90 3.54 90 3.54 90 3.54

hhhh 64.5 2.54 164 6.47 60 2.36

14

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 15

OPTIWAVE 1010

Weather protection

Figure 2-8: Device versions with the weather protection option

1 Non-Ex or Ex ia-approved device (aluminium housing – standard version)

2 Non-Ex or Ex ia-approved device (aluminium housing – with distance piece)

3 Non-Ex, Ex ia- Ex db- or Ex tb-approved device (stainless steel housing)

Devices with weather protection: Dimensions in mm and inches

Dimensions Devices with weather protection

TECHNICAL DATA

2

Aluminium:

non-Ex or Ex ia-approved

(standard)

non-Ex or Ex ia-approved

Aluminium:

(with distance piece)

Stainless steel:

non-Ex, Ex ia, Ex db or

Ex tb-approved

[mm] [inches] [mm] [inches] [mm] [inches]

aaaa 154 6.06 154 6.06 154 6.06

bbbb 119 4.69 119 4.69 98 3.86

cccc 136 5.35 136 5.35 118 4.65

dddd 183 7.20 272 10.71 186 7.32

Weights

Type of device Weights

Aluminium Stainless steel

without weather

protection

[kg] [lb] [kg] [lb] [kg] [lb] [kg] [lb]

Non-Ex / intrinsically-safe (Ex ia)

Non-Ex / intrinsically-safe (Ex ia)

Non-Ex / intrinsically-safe (Ex ia)Non-Ex / intrinsically-safe (Ex ia)

Standard 2.54 5.61 3.87 8.53 — — — —

With distance piece 3.52 7.76 4.85 10.69 — — — —

with weather

protection

without weather

protection

with weather

protection

Non-Ex / intrinsically-safe (Ex ia) / Explosion proof (Ex db) / Protected by enclosure (Ex tb)

Non-Ex / intrinsically-safe (Ex ia) / Explosion proof (Ex db) / Protected by enclosure (Ex tb)

Non-Ex / intrinsically-safe (Ex ia) / Explosion proof (Ex db) / Protected by enclosure (Ex tb)Non-Ex / intrinsically-safe (Ex ia) / Explosion proof (Ex db) / Protected by enclosure (Ex tb)

Standard — — — — 3.85 8.49 5.18 11.42

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

15

Page 16

3

INSTALLATION

3.1 Pre-installation requirements

Obey the precautions that follow to make sure that the device is correctly installed.

• Make sure that there is sufficient space on all sides.

• Protect the signal converter from direct sunlight.

• Do not subject the signal converter to heavy vibrations.

3.2 Pressure and temperature ranges

OPTIWAVE 1010

If the ambient temperature is more than +70

°

C / +158°F, there is a risk of injury if you touch the

device. Use a protective cover or metallic grid to prevent injury.

Figure 3-1: Pressure and temperature ranges

1 Bypass chamber temperature

Non-Ex devices: Depends on the device versions and the seal material. Refer to the table that follows.

Ex devices: see supplementary operating instructions

2 Ambient temperature

Non-Ex devices: -40...+85°C / -40...+185°F

Ex devices: see supplementary operating instructions

3 Process pressure

Depends on the type of seal and process connection. Refer to the table that follows.

16

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 17

OPTIWAVE 1010

Aluminium housing for non-Ex and Ex ia-approved devices

INSTALLATION

3

Version Seal Distance piece Bypass chamber

Process pressure

temperature

[°C] [°F] [barg] [psig]

Metapeek FKM/FPM with

Metapeek

Kalrez® 6375

with Metapeek

EPDM with

Metapeek

Metaglas®

and

distance

piece

FKM/FPM with

Metaglas®

Kalrez® 6375

with Metaglas®

EPDM with

Metaglas®

without -40...+100 -40...+212 -1...16 -14.5...232

without -20...+100 -4...+212

without -40...+100 -40...+212

with -40...+150 -40...+302 -1...40 -14.5...580

with -20...+150 -4...+302

with -40...+150 -40...+302

Stainless steel housing for non-Ex , Ex ia-, Ex db- and Ex tb-approved devices

Version Seal Distance piece Bypass chamber

temperature

[°C] [°F] [barg] [psig]

Metaglas® FKM/FPM with

Metaglas®

Kalrez® 6375

with Metaglas®

EPDM with

Metaglas®

without -40...+120 -40...+248 -1...40 -14.5...580

without -20...+120 -4...+248

without -40...+120 -40...+248

Process pressure

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

17

Page 18

3

INSTALLATION

Ambient temperature / process temperature, in °C

Figure 3-2: Ambient temperature / process temperature, in °C

OPTIWAVE 1010

Ambient temperature / process temperature, in °F

Figure 3-3: Ambient temperature / process temperature, in °F

1 Maximum ambient temperature, °C

2 Maximum process temperature, °C

3 Maximum ambient temperature, °F

4 Maximum process temperature, °F

5 Device with aluminium housing

6 Device with stainless steel housing

7 Device with aluminium housing and distance piece

18

The maximum ambient temperature for non-Ex devices is +85°C / +185°F. The process

connection temperature must agree with the temperature limits of the gasket material.

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 19

OPTIWAVE 1010

3.3 Recommended mounting position

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

Make sure that the cable glands are aligned with the process connections of the bypass

chamber.

INSTALLATION

3

Figure 3-4: Recommended mounting position

1 Internal tube diameter. Min. ... Max.: 38...56 mm / 1.50...2.20¨

2 Float offset (the distance between the surface of the liquid and the radar target on top of the float).

Min. ... Max.: 0...200 mm / 0...7.87¨.

3 Distance to top process connection (bypass chamber) = minimum distance (refer to the "basic parameters" menu in

the DTM)

4 Distance to bottom process connection (bypass chamber) = maximum distance (refer to the "basic parameters" menu

in the DTM)

3.4 Mounting restrictions

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

If the device uses a float to measure the level of the liquid, slowly pressurize the bypass

chamber. A float can damage the PEEK cone of the radar level transmitter at the top of the

bypass chamber.

If there are parasitic signals, the device will not measure correctly. Parasitic signals are caused

by sudden changes in bypass chamber diameter in the path of the radar beam.

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

19

Page 20

4

ELECTRICAL CONNECTIONS

4.1 Electrical installation: 2-wire, loop-powered

Figure 4-1: Terminals for electrical installation

1 Grounding terminal in the housing (if the electrical cable is shielded)

2 Current output terminal – polarity insensitive

3 Current output terminal – polarity insensitive

4 External ground connection

OPTIWAVE 1010

Electrical power to the output terminal energizes the device. The output terminal is also used for

®

HART

communication.

4.2 Electrical connection for current output

4.2.1 Non-Ex devices

Figure 4-2: Electrical connections for non-Ex devices

1 Power supply

2 Resistor for HART® communication

3 Optional connection to the grounding terminal

4 Output: 14.5...32 VDC for an output of 22 mA at the terminal

5 Device

20

Electrical polarity has no effect on device operation.

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 21

OPTIWAVE 1010

4.2.2 Devices for hazardous locations

For electrical data for device operation in hazardous locations, refer to the related certificates of

compliance and supplementary instructions (ATEX, IECEx etc.). You can find this documentation

on the DVD-ROM delivered with the device or it can be downloaded free of charge from the

website (Download Center).

4.3 Networks

4.3.1 General information

The device uses the HART® communication protocol. This protocol agrees with the HART®

Communication Foundation standard. The device can be connected point-to-point. It can also

operate in a network with a device address from 1 to 63.

The device output is factory-set to communicate point-to-point. To change the communication

mode from point-to-point

4.3.2 Point-to-point connection

point-to-point to multi-drop

point-to-pointpoint-to-point

multi-drop, refer to "HART" in the handbook.

multi-dropmulti-drop

ELECTRICAL CONNECTIONS

4

Figure 4-3: Point-to-point connection (non-Ex)

1 Address of the device (0 for point-to-point connection)

2 4...20 mA + HART®

3 Resistor for HART® communication

4 Power supply

5 HART® converter

6 HART® communication software

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

21

Page 22

4

ELECTRICAL CONNECTIONS

4.3.3 Multi-drop networks

OPTIWAVE 1010

Figure 4-4: Multi-drop network (non-Ex)

1 Address of the device (each device must have a different address in multidrop networks)

2 4mA + HART®

3 Resistor for HART® communication

4 Power supply

5 HART® converter

6 HART® communication software

22

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 23

OPTIWAVE 1010

5.1 Order code

The measuring system has 2 parts:

• The OPTIWAVE 1010 radar (FMCW) level transmitter. Give the order code – refer to the table

that follows.

• The BM26 Advanced (magnetic level indicator (MLI) or bypass chamber). Give the order code

– refer to the table for the Advanced version (with OPTIWAVE 1010)

Basic/Advanced technical data sheet

Make a selection from each column to get the full order code. The characters of the order code

highlighted in light grey describe the standard.

ORDER INFORMATION

Advanced version (with OPTIWAVE 1010) in the BM26

Advanced version (with OPTIWAVE 1010)Advanced version (with OPTIWAVE 1010)

5

VF01 4 OPTIWAVE 1010 6 GHz Radar (FMCW) Level Transmitter for bypass chambers and magnetic level indicators

VF01

VF01 4 Order code (complete this code on the pages that follow)

VF01VF01

OPTIWAVE 1010 6 GHz Radar (FMCW) Level Transmitter for bypass chambers and magnetic level indicators

OPTIWAVE 1010 6 GHz Radar (FMCW) Level Transmitter for bypass chambers and magnetic level indicators OPTIWAVE 1010 6 GHz Radar (FMCW) Level Transmitter for bypass chambers and magnetic level indicators

(BM 26 ADVANCED)

(BM 26 ADVANCED)

(BM 26 ADVANCED)(BM 26 ADVANCED)

Converter version (Housing material

Converter version (Housing material – protection class)

Converter version (Housing material Converter version (Housing material

1 OPTIWAVE 1010: Compact version (Aluminium – IP66 / IP67)

2 OPTIWAVE 1010: Compact version (Stainless steel – IP66 / IP67)

3 OPTIWAVE 1010: Compact version (Aluminium – IP66/67) with distance piece for electronic spare parts

only

Approval

Approval

ApprovalApproval

0 Without

1 ATEX II 1/2 G Ex ia IIC Tx Ga/Gb + II 2 D Ex ia IIIC T120°C

2 ATEX II 1/2 G Ex db IIC T6…T4 Ga/Gb + II 2 D Ex tb IIIC T120°C Db

6 IECEx Ex ia IIC Tx Ga/Gb + Ex ia IIIC T120°C Db

7 IECEx Ex db IIC T6…T4 Ga/Gb + Ex tb IIIC T120°C Db

1

Other approval

Other approval

Other approvalOther approval

0 Without

B EAC Russia

C EAC Belarus

K EAC Kazakhstan

Order code (complete this code on the pages that follow)

Order code (complete this code on the pages that follow)Order code (complete this code on the pages that follow)

6

6

6

protection class)

protection class) protection class)

4

2

3

5

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

23

Page 24

5

ORDER INFORMATION

Process seal

Process seal – Temperature / Pressure / Material / Remarks (material to be checked by the

Process seal Process seal

customer)

customer)

customer)customer)

0 Without

1 -40°C...+100°C (-40°F…+212°F) / -1…16 barg (-14.5…232 psig) / FKM/FPM / aluminium

housing and Metapeek process seal

2 -40°C...+100°C (-40°F…+212°F) / -1…16 barg (-14.5…232 psig) / EPDM / aluminium housing

and Metapeek process seal

3 -20°C...+100°C (-4°F…+212°F) / -1…16 barg (-14.5…232 psig) / Kalrez® 6375 / aluminium

housing and Metapeek process seal

5 -40°C...+150°C (-40°F…+302°F) / -1...40 barg (-14.5…580 psig) / FKM/FPM / aluminium

housing, Metaglas® process seal and distance piece

6 -40°C...+150°C (-40°F…+302°F) / -1...40 barg (-14.5…580 psig) / EPDM / aluminium housing,

Metaglas® process seal and distance piece

7 -20°C...+150°C (-4°F…+302°F) / -1...40 barg (-14.5…580 psig) / Kalrez® 6375 / aluminium

housing, Metaglas® process seal and distance piece

A -40°C...+120°C (-40°F…+248°F) / -1...40 barg (-14.5…580 psig) / FKM/FPM / stainless steel

housing and Metaglas® process seal

B -40°C...+120°C (-40°F…+248°F) / -1...40 barg (-14.5…580 psig) / EPDM / stainless steel

housing and Metaglas® process seal

C -20°C...+120°C (-4°F…+248°F) / -1...40 barg (-14.5…580 psig) / Kalrez® 6375 / stainless steel

housing and Metaglas® process seal

Antenna: Matching element / Material

Antenna: Matching element / Material

Antenna: Matching element / MaterialAntenna: Matching element / Material

0 Without

1 Metallic Horn for tube Ø42.4 × 2 / 316L

0 0 0 0 Output

VF01

VF01 4 0 0 0 0 1 0 0 0 0 Order code (complete this code on the

VF01VF01

Temperature / Pressure / Material / Remarks (material to be checked by the

Temperature / Pressure / Material / Remarks (material to be checked by the Temperature / Pressure / Material / Remarks (material to be checked by the

Output

OutputOutput

1 2-wire / 4...20mA passive HART

Cable entry / Cable gland

Cable entry / Cable gland

Cable entry / Cable glandCable entry / Cable gland

1 M20×1.5 / Without

2 M20×1.5 / Plastic

3 M20×1.5 / Nickel-plated brass

4 M20×1.5 / Stainless steel

A ½ NPT (nickel-plated brass) / Without

B ½NPT (stainless steel) / Without

Housing (Orientation / Display / Weather protection)

Housing (Orientation / Display / Weather protection)

Housing (Orientation / Display / Weather protection)Housing (Orientation / Display / Weather protection)

A Vertical / Without / Without

D Vertical / Without / With

0 Version

Version

VersionVersion

0 KROHNE (RAL 9006 / RAL 5005)

6 KROHNE USA (FCC)

A KMIC L (for liquid applications)

0 0 0 Calibration certificate

Calibration certificate

Calibration certificateCalibration certificate

0 Without

1 Calibration certificate 2 factory default

points

2 Calibration certificate 5 factory default

points for accuracy ±5mm (±0.2¨)

Order code (complete this code on the

Order code (complete this code on the Order code (complete this code on the

pages that follow)

pages that follow)

pages that follow)pages that follow)

OPTIWAVE 1010

24

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 25

OPTIWAVE 1010

VF01

VF01 4 0 0 0 0 1 0 0 0 0 Order code

VF01VF01

1 For more data, refer to the Technical data section (Approvals and certification)

2 The dust approval is only applicable to the stainless steel housing. The bypass chamber or BM 26 Advanced must be approved for ATEX

applications.

3 For the stainless steel housing only. The bypass chamber or BM 26 Advanced must be approved for ATEX applications.

4 The dust approval is only applicable to the stainless steel housing.

5 For the stainless steel housing only

6 Pending

ORDER INFORMATION

TAG Number

TAG Number

TAG NumberTAG Number

0 Without

2 Tag No. on stainless steel plate

(18 characters max.)

Other constructions

Other constructions

Other constructionsOther constructions

0 Without

1 NACE design

(MR 0175 / MR 0103 / ISO 15156)

Order code

Order codeOrder code

5

5.2 Accessories

We supply accessories for this device. When you send an order for accessories, please give the

reference numbers that follow:

Figure 5-1: Accessories

1 Viator RS232 / HART converter

2 Viator USB / HART converter

3 316L stainless steel weather protection

Item Description Quantity Part reference

1 Viator RS232 / HART converter 1 XF50020600

2 Viator USB / HART converter 1 XF50020700

3 316L stainless steel weather protection 1 XF50050800

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

25

Page 26

6

NOTES

OPTIWAVE 1010

26

www.krohne.com 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

Page 27

OPTIWAVE 1010

NOTES

6

www.krohne.com10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en

27

Page 28

K

K

K

KROHNE – Process instrumentation and measurement solutions

•

Flow

•

Level

•

Temperature

•

Pressure

•

Process Analysis

•

Services

© KROHNE 10/2016 - 4004263503 - TD OPTIWAVE 1010 R03 en - Subject to change without notice.

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.: +49 203 301 0

Fax: +49 203 301 10389

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...