Page 1

OPTITEMP TRA-CXX

OPTITEMP TRA-CXX

OPTITEMP TRA-CXXOPTITEMP TRA-CXX

Industrial compact sensors

Handbook

Handbook

HandbookHandbook

© KROHNE 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

OPTITEMP TRA-CXX

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2014 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 3

OPTITEMP TRA-CXX

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Approvals and certifications............................................................................................. 5

1.2.1 CE ............................................................................................................................................ 5

1.3 Safety instructions from the manufacturer ..................................................................... 5

1.3.1 Copyright and data protection ................................................................................................ 5

1.3.2 Disclaimer ............................................................................................................................... 6

1.3.3 Product liability and warranty ................................................................................................ 7

1.3.4 Information concerning the documentation........................................................................... 7

1.3.5 Warnings and symbols used................................................................................................... 8

1.4 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 Device description .......................................................................................................... 10

2.2.1 Design of the compact sensors ............................................................................................10

2.2.2 Types of electrical connections ............................................................................................ 11

2.2.3 Types of temperature transmitters ...................................................................................... 12

2.2.4 Housing ................................................................................................................................. 13

2.2.5 Thermowells ......................................................................................................................... 13

2.3 Process connections and areas of application .............................................................. 14

2.3.1 Threaded sensor ................................................................................................................... 14

2.3.2 Flange sensor ....................................................................................................................... 14

2.4 Overview of available versions ....................................................................................... 15

2.5 Nameplate ...................................................................................................................... 16

3 Installation 17

3.1 General notes on installation ......................................................................................... 17

3.2 Storage ........................................................................................................................... 17

3.3 Transport ........................................................................................................................ 17

3.4 Proper installation.......................................................................................................... 17

3.4.1 Possible installations............................................................................................................ 18

3.4.2 Other installation requirements........................................................................................... 19

3.5 Load limits ...................................................................................................................... 20

3.5.1 Vibration load ........................................................................................................................ 20

3.5.2 Temperature load ................................................................................................................. 20

3.6 Installation notes on the individual device classes........................................................ 22

3.6.1 Threaded compact sensor .................................................................................................... 22

3.6.2 Flange sensor ....................................................................................................................... 23

4 Electrical connections 24

4.1 Safety instructions.......................................................................................................... 24

4.2 Electrical connection of M12 connector......................................................................... 25

4.3 Electrical connection of Valve EN 175301-803 connector ............................................. 26

4.4 Grounding ....................................................................................................................... 27

4.5 Protection category ........................................................................................................27

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

3

Page 4

CONTENTS

OPTITEMP TRA-CXX

4.6 Power supply .................................................................................................................. 27

5 Operation 28

5.1 Start-up........................................................................................................................... 28

5.2 Normal operation ...........................................................................................................28

5.3 Faults and damage: reason and remedies .................................................................... 28

6 Service 30

6.1 Cleaning and maintenance............................................................................................. 30

6.2 Availability of services .................................................................................................... 30

6.3 Returning the device to the manufacturer..................................................................... 30

6.3.1 General information.............................................................................................................. 30

6.3.2 Form (for copying) to accompany a returned device............................................................ 31

6.4 Disposal .......................................................................................................................... 31

7 Technical data 32

7.1 Measuring principle........................................................................................................32

7.1.1 Resistance temperature sensor ........................................................................................... 32

7.2 Technical data tables ..................................................................................................... 33

7.3 Dimensions ..................................................................................................................... 36

7.3.1 Compact sensors .................................................................................................................. 36

7.4 Measuring accuracy ....................................................................................................... 39

7.5 Process connections ...................................................................................................... 39

7.6 Sensor response time .................................................................................................... 40

8 Appendix 41

8.1 Technical legislation in effect ........................................................................................ 41

9 Notes 42

4

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 5

OPTITEMP TRA-CXX

1.1 Intended use

CAUTION!

Responsibility for the use of the measurement devices with regard to suitability, intended use

and corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

The compact sensors are used to measure the temperature of gases, liquids, vapour and solids

in industrial applications with limited installation space. The devices are particularly suited to

the measurement of

• liquids with low viscosity

• water and chemicals with low corrosiveness

1.2 Approvals and certifications

SAFETY INSTRUCTIONS 1

1.2.1 CE

Article 1, section 2.1.4 of the Pressure Equipment Directive 97/23/EC does not apply to compact

thermometers. For this reason, neither a conformity assessment nor a CE marking is possible.

The EC directives applicable to temperature transmitters are contained in transmitter part of

this documentation.

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

5

Page 6

1 SAFETY INSTRUCTIONS

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

OPTITEMP TRA-CXX

6

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 7

OPTITEMP TRA-CXX

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTITEMP TRA-CXX

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 9

OPTITEMP TRA-CXX

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

The manufacturer delivers all industrial temperature sensors with the relevant technical

documentation. The following table illustrates which sensor is delivered with which

documentation (HB = Handbook):

Scope of order HB for temperature sensors HB for transmitters

DEVICE DESCRIPTION 2

Compact sensor without

transmitter

Compact sensor with built in

transmitter

Compact sensor with rail mount

transmitter

X -

X -

X X

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

9

Page 10

2 DEVICE DESCRIPTION

2.2 Device description

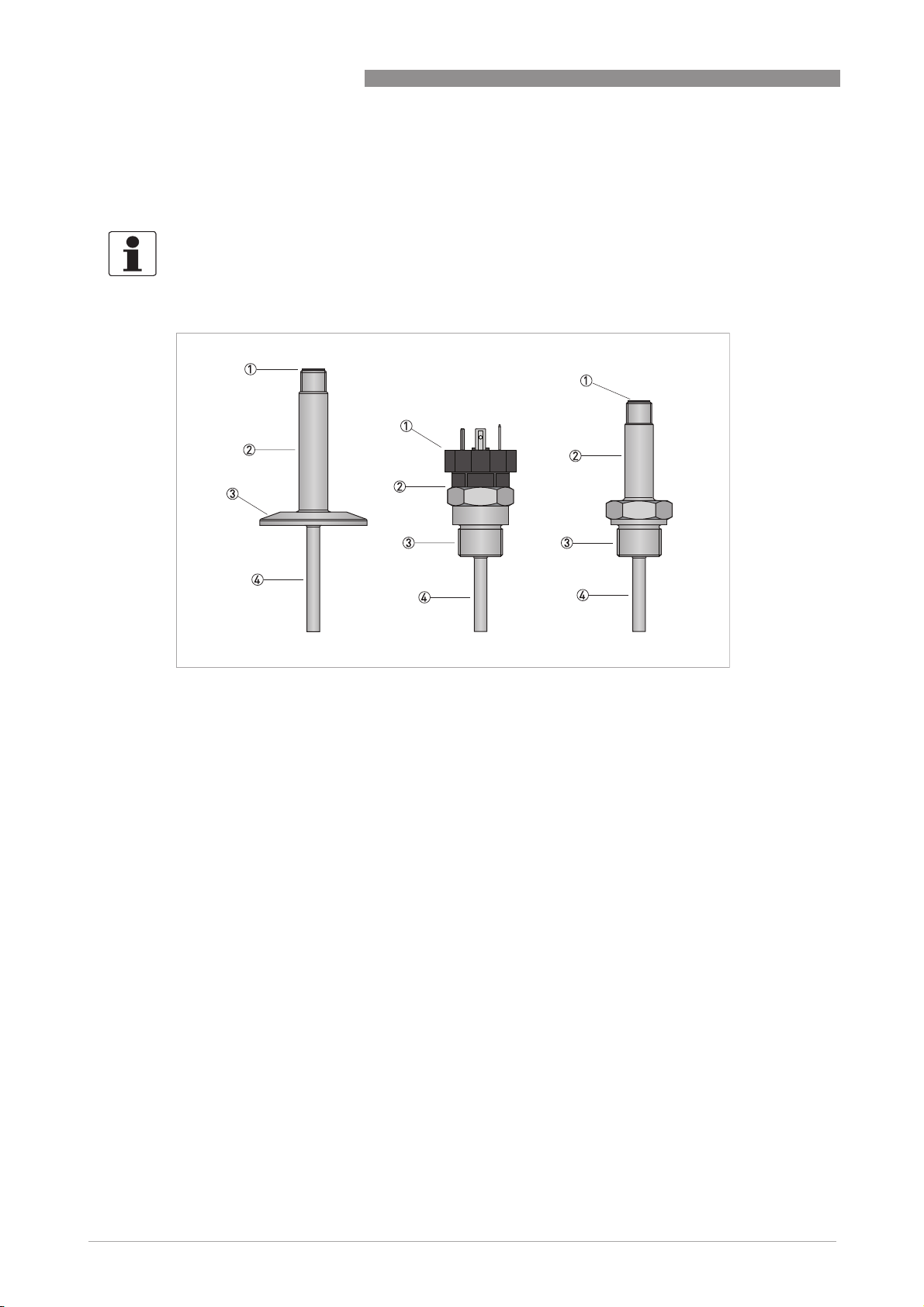

2.2.1 Design of the compact sensors

INFORMATION!

In this documentation, the term "compact sensor" refers to all temperature assemblies

featuring with/without built-in transmitter.

OPTITEMP TRA-CXX

Figure 2-1: Design of all compact sensors

1 Electrical connection

2 Housing

3 Process connection

4 Thermowell

OPTITEMP compact sensors consist of a measuring probe with a process connection and a neck

tube with an electrical connection at the end. The sensors are avaiable with a built in

transmitter.

The transmitter linearizes to measured value to a 4… 20mA output and has a built in failure

mode, loop.

10

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 11

OPTITEMP TRA-CXX

2.2.2 Types of electrical connections

Electrical connections protects the temperature transmitter from environmental effects

(e. g. dirt or dust). They are available as:

• M12 connector

• Valve EN 175301-803 connector

Electrical connections available

M12 connector

M12 connector Valve EN 175301-803 connector

M12 connectorM12 connector

DEVICE DESCRIPTION 2

Valve EN 175301-803 connector

Valve EN 175301-803 connectorValve EN 175301-803 connector

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

11

Page 12

2 DEVICE DESCRIPTION

2.2.3 Types of temperature transmitters

Electrical temperature assemblies have just one, weak, interference-prone output signal. If this

signal has to travel a great distance or if a standard signal of 4...20 mA is required, use of a

temperature transmitter is recommended:

INFORMATION!

The manufacturer cannot make any general statement as to the distance from which the use of a

temperature transmitter is necessary as it depends on the specific interference associated with

the installation site. The operator alone is responsible for this decision.

There are two types of temperature transmitters:

• Built-in transmitter: Located in the housing of the temperature assembly

• Rail-mounted transmitter: Located in the control cabinet or field housing, recognisable by

the "R" in the product name (e. g. TT 50 R); they are usually used when the temperature in the

connection head does not allow for the use of a head-mounted transmitter

Built in transmitters

Built in transmitters

Built in transmittersBuilt in transmitters

OPTITEMP TRA-CXX

The built-in transmitters convert the temperature sensor's small signal into a standardised

output signal of 4...20 mA, not susceptible to interference. Which built in transmitter that is used

depends on the choice of the sensor.

The temperature range is set at factory:

• 0... +100°C / +32... +212°F

• -50... +150°C / -58... +302°F

Other temperature ranges are available on request.

Rail mounted transmitters

Rail mounted transmitters

Rail mounted transmittersRail mounted transmitters

You can parameterise almost any temperature transmitter using a PC and a computer program.

The only exceptions are the TT 10 R and TT 11 R versions, whose measuring ranges must be set

using solder bridges. The following temperature transmitters are currently available:

Available rail mounted transmitters

TT 10 R (analogue, 4...20 mA)

TT 11 R (analogue 3-wire transmitter, output: 0...10 VDC)

TT 30 R (digital, 4...20 mA)

TT 31 R (digital, 4...20 mA, 1- & 2-channel)

TT 32 R (digital 4-wire, outputs: 0/4...20 mA, 0/1...5 VDC, 0/2...10 VDC)

TT 40 R (digital, 4...20 mA, precise)

12

TT 50 R (digital, 4...20 mA, HART®)

TT 51 R (digital, 4...20 mA, HART®, SIL2, precise)

TT 60 R (digital, Profibus-PA)

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 13

OPTITEMP TRA-CXX

INFORMATION!

Consult the relevant transmitter handbook for more detailed information on the rail mountesd

temperature transmitters.

2.2.4 Housing

The housing connects the process connection (i.e. screw socket or flange) to the electrical

contact. Its function is to thermally decouple the connection and transmitter so the ambient

temperature doesn't exceed the permissible limits.

The materials of the housing and the thermowell are identical.

2.2.5 Thermowells

The thermowell is designed to prevent external loads (e. g. static pressure, flowing and

aggressive media) from damaging the sensor element. As a rule, the thermowell is made of the

same material as the system in which the measuring is done. The thermowell is built up from

multiple part and welded together.

DEVICE DESCRIPTION 2

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

13

Page 14

2 DEVICE DESCRIPTION

2.3 Process connections and areas of application

2.3.1 Threaded sensor

The gas tight threaded process connection is suitable for general applications with none or low

pressure. Can be mounted on pipes or tanks like in the chemical industry and into a solid part as

in the equipment industry. Depending on the application there are several types of threads and

standards to consider.

2.3.2 Flange sensor

The ISO 2852 Stainless steel clamp is a pipe coupling for the food and beverage industry. It is an

international standard defining a non-permanent hygienic piping interconnect method. Mainly

used in the food processing industry and with dairy farm equipment. The connection is built up

with a flange on the instrument and a counter flange in the pipe or tank. Between the flanges a

polymer sealing gasket fitting is placed. An enclosing clamp covers the outer circumference of

the flange to squeeze the two flanges together and with help of the gasket make a tight and solid

connection.

This clamp connection makes it easy to connect and disconnect without any special tools,

suitable for processes where continues cleaning is required like the food and beverage industry.

Companies that supply products according to the specifications of ISO 2852 do not necessarily

mention the ISO standard as such, instead referring to the equipment by terms common in the

relevant industries or applications like Tri-clamp or S-clamp.

OPTITEMP TRA-CXX

14

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 15

OPTITEMP TRA-CXX

2.4 Overview of available versions

INFORMATION!

The beginning of the product name refers to the type of sensor in the temperature assembly:

•

TRA: Sensor with Pt100, RTD

•

C: Compact series

TRA-C10

TRA-C10 TRA-C20

TRA-C10TRA-C10

TRA-C20 TRA-C30

TRA-C20TRA-C20

DEVICE DESCRIPTION 2

TRA-C30

TRA-C30TRA-C30

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

15

Page 16

2 DEVICE DESCRIPTION

2.5 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

The nameplate is located on the housing, it measures 42.4 mm x 8.5 mm / 1.67" x 0.33":

OPTITEMP TRA-CXX

TRA-CXX

Figure 2-2: Sample nameplate

1 Type of compact sensor

2 Production Order

3 Part number

4 Individual serial number

5 Manufacturer

6 Production site

7 Manufacturer's website

8 Range

9 Output

10 Note that the handbook is available for download from the manufacturer's website

11 CE Marking

12 WEEE Marking

PN: XXXXXXXXXX

SN: Nyyww.XXXXXX

PO: XXXXXXXXX

Range: XXXXXXXXXX

Output: XXXXXXXXXXX

Malmö, SWEDEN

www.krohne.com

INFORMATION!

For a customer-specific TAG No., the manufacturer can print out a separate label if required.

16

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 17

OPTITEMP TRA-CXX

3.1 General notes on installation

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

INSTALLATION 3

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

3.2 Storage

CAUTION!

Always store industrial temperature assemblies in a dry place protected from dust. The

permissible range for storage temperatures is -40...+70

3.3 Transport

CAUTION!

Always transport industrial temperature assemblies in their original packaging. Do not expose

the devices to moisture or vibration during transport. The information that applies to storage

also applies to transport.

3.4 Proper installation

CAUTION!

Take the following points into consideration prior to installing the temperature assembly:

•

The dimensions of the thermowell (length, diameter, wall thickness, type of tip) comply with

the requirements of the measuring point. The mechanical load as a result of flowing media,

vibration and resonances is the focus here. In addition, incorrect dimensions can lead to

measurement errors.

•

The thermowell is sufficiently resistant to chemically aggressive media (refer to the generally

accessible corrosion tables). Otherwise, corrosion may occur or the medium may penetrate

into the thermowell. When in doubt, select a thermowell made from the same material as

your system.

°

C / -40...+176°F.

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

17

Page 18

3 INSTALLATION

3.4.1 Possible installations

Installations include the parameters "installation site", "installation angle" and "insertion

length". Depending on the space available and the diameter of the pipe, three installations are

recommended for pipes with flowing product:

• Small pipe diameter: Installation directly against the direction of flow in a bend in the

pipe (1).

• Small pipe diameter: Installation diagonally against the direction of flow, if a bend in the pipe

is available (2).

• Large pipe diameter: Vertical installation, if flow-induced periodic vortex shedding does not

cause the thermometer to vibrate in its resonance frequency (3).

OPTITEMP TRA-CXX

Figure 3-1: Recommended installations

18

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 19

OPTITEMP TRA-CXX

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insertPermitted insertion length of the thermowell or measuring insert

The "insertion length" of the thermowell or measuring insert refers to the distance from the seal

of the process connection (for G threads) or the bottom of the flange (for flange thermometers)

to the tip of the thermowell or sheath. This length determines how far the sensor projects into

the measured medium.

To avoid measurement errors, ensure that the insertion length ("b" in the drawing below) meets

the following requirement:

• Tubes with Ø < 300 mm / 11.8": thermowell tip should project past the middle of the pipe is

possible, if the flow velocity of the product allows it.

INSTALLATION 3

Figure 3-2: Permitted insertion length

3.4.2 Other installation requirements

DANGER!

When a seal is damaged or incorrect, the medium may leak out, causing material damage or

bodily harm! It is the sole responsibility of the operator to select the right seal.

• A well-insulated pipeline or tank around the measuring point reduces the heat transfer and

the distorting influence of the ambient temperature.

• To avoid measurement errors caused by poor heat transfer, the measuring insert must

always be in contact with the bottom of the thermowell (this is normally guaranteed by filling

the thermowell with heat conducted compound).

• Choosing the right gasket for the process connection depends on the process conditions; the

manufacturer can thus only give the general recommendation that the gasket must comply

with the individual requirements of the measuring point (e.g. pressure, temperature,

chemically aggressive media, hygienic requirements).

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

19

Page 20

3 INSTALLATION

3.5 Load limits

The load limits of compact sensors depend on several factors:

• Dimensions and design of the measuring tip (especially the insertion length and diameter)

• Tip material

• Mechanical conditions the tip is subject to due to the measured medium (pressure,

temperature, flow velocity, viscosity, density)

• Sealable pressure of the process connection

• Vibration load

INFORMATION!

The "sealable pressure" is the maximum pressure the process connection can seal against.

The sheer number of factors at play illustrates the difficulty in making universally valid

statements about the load limits. For further information, please contact the manufacturer.

OPTITEMP TRA-CXX

3.5.1 Vibration load

CAUTION!

Permanently operating the sensor tip in its natural resonance can quickly damage or destroy the

temperature assembly! So, prior to installation, ensure that this does not happen and select a

sensor tip with a different length, a different diameter or another material if necessary.

All industrial temperature assemblies that feature an insert and neck tube and are attached to

the process connection have two components that can vibrate: the insert and the neck tube with

the neck tube. That is why the terms "insert resonance" and "neck tube resonance" are

commonly heard.

An insert surrounded by the measured medium is a body behind which vortices periodically are

released ("Kármán vortex street"). If the frequency of the vortex detachment is equal to the

resonance frequency of the thermowell, it starts to vibrate. If this happens for a short period of

time, such as when starting up the system and the frequency of the vortex detachment passes

through the resonance range of the thermowell, there is generally no damage is caused. The

opposite is true, however, if the vibrations remain permanently in the resonance range.

3.5.2 Temperature load

The temperature of the measured medium and the thermal dissipation via thermowell and neck

tube also cause the connection to heat up. After some time, the interior of the neck tube and any

existing transmitter heat up to the temperature of the neck tube.

This occurs in thermometers with and without neck tubes. A neck tube, however, causes thermal

decoupling and can prevent the connection or temperature transmitter from overheating at high

process temperatures.

20

CAUTION!

When the temperature is too high, the connection and the components found in the neck tube

(e. g. temperature transmitter) can be damaged or destroyed! It is your responsibility as the

operator to ensure that the connection and transmitter does not get too hot. If this does happen,

select another installation site or a longer neck tube.

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 21

OPTITEMP TRA-CXX

CAUTION!

Sometimes even a neck tube cannot prevent the maximum permissible temperature in the

transmitter or electrical connection from being exceeded! It does cause extensive thermal

decoupling of the connection but you still have to always take into consideration the installation

situation as well as the ambient and process temperatures!

INFORMATION!

For more information regarding the maximum allowable temperatures, please refer to the

"Technical Data" section.

INSTALLATION 3

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

21

Page 22

3 INSTALLATION

3.6 Installation notes on the individual device classes

3.6.1 Threaded compact sensor

A threaded compact sensor can be installed two different ways:

• Screwed in directly: Pipes with a wall thickness ≥ 20 mm / 0.8" make it possible to drill a hole

and cut a thread.

• Screw into threaded sleeves: Pipes with a wall thickness < 20 mm / 0.8" require a sleeve to be

welded in; these are not included in delivery but make up part of the accessories range.

OPTITEMP TRA-CXX

Figure 3-3: Compact sensor for direct screw-in

1 Housing

2 Threading into application's wall

3 Thermowell

CAUTION!

You, the user, are responsible for selecting a suitable sealing material for the process

connection, not the manufacturer! When installing the seals to the process connection, always

ensure a good fit!

CAUTION!

Sometimes even a neck tube cannot prevent the maximum permissible temperature in the

connection head from being exceeded! It does cause extensive thermal decoupling of the

connection head but you still have to always take into consideration the installation situation as

well as the ambient and process temperatures!

22

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 23

OPTITEMP TRA-CXX

3.6.2 Flange sensor

The compact flange sensor can be installed using a ISO 2852 DN25/38 clamp, for example, as

shown in the following drawing:

INSTALLATION 3

Figure 3-4: Installing a compact sensor with a ISO 2852 DN25/38 clamp

1 Housing

2 ISO 2852 DN25/38 clamp

3 Application wall

CAUTION!

You, the user, are responsible for selecting a suitable sealing material for the process

connection, not the manufacturer! When installing the seals to the process connection, always

ensure a good fit!

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

23

Page 24

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

OPTITEMP TRA-CXX

24

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 25

OPTITEMP TRA-CXX

ELECTRICAL CONNECTIONS 4

4.2 Electrical connection of M12 connector

Electrical connection with transmitter

Electrical connection with transmitter

Electrical connection with transmitterElectrical connection with transmitter

1

2

43

-

+

1 Out

2 M12-connector front view

3 R

Load

Electrical connection without transmitter

Electrical connection without transmitter

Electrical connection without transmitterElectrical connection without transmitter

423

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

25

Page 26

4 ELECTRICAL CONNECTIONS

4.3 Electrical connection of Valve EN 175301-803 connector

Electrical connection with transmitter

Electrical connection with transmitter

Electrical connection with transmitterElectrical connection with transmitter

1

3

2

-

+

OPTITEMP TRA-CXX

1 I

Out

2 Grounding not connected

3 R

Load

Electrical connection without transmitter

Electrical connection without transmitter

Electrical connection without transmitterElectrical connection without transmitter

312

26

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 27

OPTITEMP TRA-CXX

4.4 Grounding

DANGER!

The thermowells on the industrial temperature assemblies are grounded via the process

connection. No additional grounding is required.

4.5 Protection category

The IP protection category of an compact sensors depends on connection contact. When the

cable contact is connected properly the compact sensors TRA-C10 and TRA-C30 are available in

class IP67 and TRA-C20 in class IP65.

4.6 Power supply

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

ELECTRICAL CONNECTIONS 4

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

27

Page 28

5 OPERATION

5.1 Start-up

CAUTION!

Double check the following things prior to starting up an industrial compact sensor in order to

avoid measuring errors as well as damage to or the destruction of the compact sensor:

•

Ensure that the thermowells have been properly installed according to the manufacturer's

instructions.

•

Ensure that the process connection has been successfully tested for leaks.

•

Ensure that the measuring insert has been properly electrically connected according to the

manufacturer's instructions (refer to measuring insert handbook).

5.2 Normal operation

WARNING!

Never touch the thermowell, neck tube or connection in operation without protective gloves!

These components can become very hot during operation and cause burns.

5.3 Faults and damage: reason and remedies

OPTITEMP TRA-CXX

INFORMATION!

The most probable cause of a fault is the sensor element itself and its electronic components.

The following issues come into question here:

•

Short circuit or open circuit

•

Insulation resistance too low

In addition, the following faults and damage may occur:

Liquid on the process connection

A damaged or incorrect seal can lead to a leak at the process connection. Should this occur,

replace the seal and ensure that the new one meets the individual requirements of the

measuring point (pressure, temperature, chemically aggressive media). It is the sole

responsibility of the operator of the device to select the right seal.

28

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 29

OPTITEMP TRA-CXX

Temperature indication too high or too low

When reference measurements result in an incorrect temperature indication, three causes

come into question:

• Severe heat transfer caused by too short insertion length of thermowell: the compact sensor

indicates a temperature that is too low when it is above the ambient temperature and one that

is too high when it is below the ambient temperature.

• Severe heat transfer via the process connection, the pipeline or the tank wall due to a lack of

insulation.

• Incorrect thermowell dimensions (diameter, wall thickness).

To keep the heat transfer to a minimum, either increase the insertion length of the compact

sensor or improve the insulation of the measuring point.

Damage to the thermowell and penetrating liquid

If the thermowell is not sufficiently resistant to chemically aggressive media, corrosion may

occur and the measured medium may penetrate. In case of doubt, choose a thermowell made of

the same material as the pipe or tank in which the medium is located.

OPERATION 5

Breaks or tears

It is possible for breaks or tears to occur due to the force of the media flowing against the

thermowell. It is also possible for vibrations in the resonance range to damage or destroy the

thermowell. Superimposition of the two causes or a combination of insufficient mechanical and

chemical resistance is also possible. The following are starting points for troubleshooting:

• Selection of a thermowell with different dimensions

• Change in neck tube length at critical head resonances

• Selection of a different installation site

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

29

Page 30

6 SERVICE

6.1 Cleaning and maintenance

As a rule, the temperature assemblies require no cleaning or maintenance. However,

depending on the conditions of use and the thermal and mechanical load, they can age. This is

true of both measuring inserts with Pt100 RTDs and measuring inserts with thermocouples.

As a result of the ageing process, the characteristics ("characteristic curve") can change. That

means that the relationship between the electrical resistance (measuring insert with Pt100 RTD)

or the thermovoltage (measuring insert with thermocouple) and the temperature changes. In

this case, calibration shows whether any deviations in measurement values are still within

permissible tolerances.

6.2 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

OPTITEMP TRA-CXX

6.3 Returning the device to the manufacturer

6.3.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

30

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 31

OPTITEMP TRA-CXX

6.3.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 6

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

6.4 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

31

Page 32

7 TECHNICAL DATA

7.1 Measuring principle

All of the temperature assemblies described here belong to the class known as "contact

temperature assemblies". Unlike "radiation temperature assemblies", these temperature

assemblies come into direct contact with the medium whose temperature they are to measure.

The type of measuring principle depends on the sensor that you combine with the transmitter.

Two different sensor types are available for transmitters, RTD and thermocouple. The RTD's

measuring principle are used in the compact sensors and described in the following subsection.

7.1.1 Resistance temperature sensor

The measuring insert with a temperature-sensitive sensor made from a platinum RTD, whose

value at 0°C / +32°F is 100 Ω. That is where the name "Pt100" comes from.

It is generally valid that the electric resistance of metals increases according to a mathematical

function as the temperature rises. This effect is taken advantage of by resistance temperature

sensors to measure temperature. The "Pt100" temperature sensors features a measuring

resistance with defined characteristics, standardised in IEC 60751. The same is true for the

tolerances. The average temperature coefficient of a Pt100 is 3.85 x 10

0...+100°C / +32...+212°F.

OPTITEMP TRA-CXX

-3K-1

in the range from

During operation, a constant current I (≤ 1 mA) flows through the Pt100 RTD, which brings about

a voltage drop U. The resistance R is calculated using Ohm's Law (R=U/I). As the voltage drop U

at 0°C / +32°F is 100 mV, the resulting resistance of the Pt100 temperature assembly is

100 Ω (100 mV / 1 mA = 100 Ω).

Figure 7-1: Pt100 resistance temperature sensor in 4-wire connection at 0°C / +32°F, schematic.

1 Pt100 RTD

2 Voltage meter

3 Current source

32

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 33

OPTITEMP TRA-CXX

7.2 Technical data tables

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Application range Measuring the temperature of gases, liquids, vapours and solid

Measuring principle Contact sensor

Measured value Temperature

Design

Modular design Industrial temperature sensors consist of several components which,

TECHNICAL DATA 7

bodies in industrial processes. The devices are particularly suited to

liquids with low viscosity, water and chemicals with low

corrosiveness as well as saturated steam and superheated steam.

together, form a thermometer assembly:

• Thermowell

• Housing

• Electrical connection

• Transmitter (built in or rail mounted )

Signal converter Built-in analog transmitter, OPTITEMP OEM 201

Sensor Pt100 RTD as thin layer (TF), class A with a characteristic according

Surface roughness(only valid for

TRA-C10)

Measuring range Refer to "Operating conditions".

Analogue or digital temperature transmitter in the TT family as railmount transmitter.

to DIN EN 60751.

Ra 0.8, Ra <0.8 electropolished available on request

Measuring accuracy

Reference conditions Ambient temperature: +23°C / +73.4°F (fluctuations due to air

Maximum measuring error More detailed information in the subsection "Measurement Error"

Long term stability for built-in

transmitter

Influence of ambient for bulit in

transmitter

Response time for built in

transmitter

pressure and density have no impact on measuring accuracy).

(also in the "Technical data" section). The maximum measurement

error also depends on the type of sensor:

• Sensor element with Pt100 RTD: measurement error in accordance

with tolerance class A, according to DIN EN 60751.

±0.1% of span per year

Max. of ±0.01°C or ±0.01% of span per °C

Max. of ±0.01°F or ±0.006% of span per °F

< 10 ms

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

33

Page 34

7 TECHNICAL DATA

Operating conditions

Load limits The load limits depend on several factors (e.g. dimensions, design

Temperature

Temperature

TemperatureTemperature

Process temperature Maximum -50...+200°C / -50...+392°F, depending on design and

Pre-configured temperature

ranges

Ambient temperature Maximum -40...+85°C / -40...+185°F, depending on media

Storage temperature -40...+70°C / -40...+158°F at 40...60% relative humidity.

Other conditions

Other conditions

Other conditionsOther conditions

Protection categories Following protection categories can be provided if the connection

Shock resistance: Acc. to IEC60068-2-31, test Ec

Vibrations resistance: Acc. to IEC60068-2-6, test Fc, 10-2000Hz, 4g

OPTITEMP TRA-CXX

and material of thermowell). The compact sensor TRA-C10 can

handle pressure up to 16 bar / 232 psia while TRA-C20 and TRA-C30

can handle pressures up to 40 bar / 580 psia. This applies only if the

sensor is mounted properly.

material.

-50...+150°C / -58...+302°F or 0...+100°C / 32... +212°F

(Other ranges available on request)

temperature, sensor design and material.

cable is properly connected:

OPTITEMP TRA-C10, TRA-C30: IP67

OPTITEMP TRA-C20: IP65

Installation conditions

Insertion angle 90° to the flow, directly against or diagonally against the flow.

Insertion length Recommendable: 10...15 x thermowell diameter for gas,

5...10 x thermowell diameter for liquids (short insertion lengths may

impair measuring accuracy).

Materials

Thermowells (including process

connection)

The metal materials of the thermowells, neck tubes, flanges and

threads as process connections are always identical:

Standard:

Standard:

Standard:Standard:

1.4404 / AISI 316 L (X2CrNiMo 17-12-2)

Process connections

Threaded thermometer Gastight thread acc. to ISO 228/1: G½, other sizes on request.

Attachment using welding sleeves. Starting at a wall thickness of

20 mm / 0.8", it is possible to screw in directly with thread in the pipe

Flange thermometer Acc. to ISO 2852: DN25/38, other sizes on request.

34

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 35

OPTITEMP TRA-CXX

Electrical connections

Power supply Only necessary when using a temperature transmitter and depends

Power consumption Only when using a temperature transmitter, typically 550 mW.

Electrical connection M12-connector (for TRA-C10 and TRA-C30) or Valve EN 175301-803

Current output

Current output

Current outputCurrent output

Output range Exists only when using a temperature transmitter, 4...20 mA

Error signal Sensor break: Upscale (>=21,0 mA)

Load Relevant only when using a temperature transmitter (typically

Other electrical characteristics

Other electrical characteristics

Other electrical characteristicsOther electrical characteristics

Galvanic isolation Relevant only when using a temperature external transmitter (see

Time constant More detailed information can be found in the subsection "Response

TECHNICAL DATA 7

on transmitter type, typically 24 VDC.

7.5...32VDC for the built-in transmitter.

(for TRA-C20)

Sensor short-circuit: Downscale (<=3,6 mA)

250 Ω).

transmitter handbook).

times" of the section "Technical data".

Approvals and certificates

Electromagnetic compatibility For bulit in transmitter EN 61326-1

CE The device fulfils the statutory requirements of the EC directives. The

ESD, Radiated EM-field: Criteria A,

Surge: max 3% of span during disturbance influence

Burst and Conducted RF: max 1% of span during disturbance

influence

For external transmitter, refer to handbook for used temperature

transmitter.

Manufacturer certifies that these requirements have been met by

applying the CE marking.

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

35

Page 36

7 TECHNICAL DATA

7.3 Dimensions

7.3.1 Compact sensors

The dimensions for the compact sensors given in this subsection are standard measurements.

Upon request the manufacturer can supply devices with other dimensions.

OPTITEMP TRA-C10

OPTITEMP TRA-CXX

c

a

b

Figure 7-2: Dimensions of OPTITEMP TRA-C10

d

e

TRA-C10

"a" (insertion

length)

"b" (thermowell

diameter)

"c" (housing

length)

"d" (housing

diameter)

"e" (flange

diameter)

[mm] ["] [mm] ["] [mm] ["] [mm] ["] [mm] ["]

50 1.97 6 0.24 73 2.87 13.5 0.53 50.5 1.99

100 3.94 6 0.24 73 2.87 13.5 0.53 50.5 1.99

50 1.97 6 0.24 88 3.46 13.5 0.53 50.5 1.99

100 3.94 6 0.24 88 3.46 13.5 0.53 50.5 1.99

36

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 37

OPTITEMP TRA-CXX

OPTITEMP TRA-C20

TECHNICAL DATA 7

c

a

Figure 7-3: Dimensions of OPTITEMP TRA-C20

d

b

TRA-C20

"a" (insertion length) "b" (thermowell

diameter)

"c" (housing length) "d" (thread

dimension)

[mm] ["] [mm] ["] [mm] ["] [mm] ["]

50 1.97 6 0.24 35.5 1.40 G1/2" G1/2"

100 3.94 6 0.24 35.5 1.40 G1/2" G1/2"

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

37

Page 38

7 TECHNICAL DATA

OPTITEMP TRA-C30

OPTITEMP TRA-CXX

c

a

b

Figure 7-4: Dimensions of OPTITEMP TRA-C30

d

e

TRA-C30

"a" (insertion

length)

"b" (thermowell

diameter)

"c" (housing

length)

"d" (housing

diameter)

"e" (thread

dimension)

[mm] ["] [mm] ["] [mm] ["] [mm] ["] [mm] ["]

50 1.97 6 0.24 56 2.2 13.5 0.53 G1/2" G1/2"

100 3.94 6 0.24 56 2.2 13.5 0.53 G1/2" G1/2"

50 1.97 6 0.24 72 2.83 13.5 0.53 G1/2" G1/2"

100 3.94 6 0.24 72 2.83 13.5 0.53 G1/2" G1/2"

38

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 39

OPTITEMP TRA-CXX

7.4 Measuring accuracy

The measuring accuracy depends largely on the following factors:

• The type of the measuring sensor (type of circuit, measuring range).

• The correct dimensions (diameter, wall thickness) and insertion length of the thermowell for

good thermal coupling to the process temperature (insufficient insertion depth often results

in measurement errors).

• The type of temperature transmitter used.

INFORMATION!

Please consult the appropriate handbook for further information regarding the accuracy of the

external temperature transmitters.

With the exception of the TT 60 R version, all of the temperature transmitters generate an

analogue output signal. For this reason, the following table indicates the measuring accuracy of

most of the transmitters as a percentage of the measuring range. The measuring accuracy of the

RTD sensor without transmitter is class A according to IEC 60751.

TECHNICAL DATA 7

Temperature transmitter

Type of temperature transmitter Accuracy (% of the measuring range or °K)

Built-in transmitter OPTITEMP OEM 201 (analogue,

4...20 mA)

TT 10 R (analogue, 4...20 mA) ± 0.15%

TT 11 R (analogue 3-wire transmitter, output:

0...10 VDC)

TT 30 R (digital, 4...20 mA) ± 0.10%

TT 31 R (digital, 4...20 mA, 1- & 2-channel) ± 0.10%

TT 32 R (digital 4-wire, outputs: 0/4...20 mA,

0/1...5 VDC, 0/2...10 VDC)

TT 40 R (digital, 4...20 mA, precise) ± 0.05%

TT 50 R (digital, 4...20 mA, HART®)

TT 51 R (digital, 4...20 mA, HART®, SIL2, precise)

TT 60 R (digital, Profibus-PA) ± 0.10°K

7.5 Process connections

Threaded compact sensor

Process connection Ø of thermowell (material 1.4404 / 316 L)

± 0.15%

± 0.15%

± 0.10%

± 0.10%

± 0.05%

[mm] ["]

Thread G½" 6 0.24

Flange compact sensor

Process connection Ø of thermowell (material 1.4404 / 316 L)

[mm] ["]

ISO 2852 Clamp DN25/38 6 0.24

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

39

Page 40

7 TECHNICAL DATA

7.6 Sensor response time

Sensor response times are generally indicated as "50% time" (t05) and "90% time" (t09). "50%

time" refers to the time needed for a temperature sensor signal to achieve 50% of its end value

in the face of erratic temperature changes (this applies analogously to "90% time").

INFORMATION!

You can find more information about response times in VDI 3522.

Compact sensor with thermowell, with measuring element Pt100 RTD

Ø of thermowell Water with 0.4 m/s or 1.31 ft/s

[mm] ["] t05[s] t09[s]

6 0.24 3.2 9.0

Water flows against the compact sensor at 0.4 m/s

or 1.31 ft/s

OPTITEMP TRA-CXX

The transmitter response time is <10 ms.

40

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 41

OPTITEMP TRA-CXX

8.1 Technical legislation in effect

Standard Title

VDE/VDI 3511 Technical temperature measurements

VDI/VDE 3522 Response time of contact temperature assemblies.

IEC 60751 Industrial platinum resistance thermometers and platinum temperature

sensors.

APPENDIX 8

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

41

Page 42

9 NOTES

OPTITEMP TRA-CXX

42

www.krohne.com 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Page 43

OPTITEMP TRA-CXX

NOTES 9

www.krohne.com02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

43

Page 44

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Straße 5

47058 Duisburg (Germany)

Tel.:+49 203 301 0

Fax:+49 203 301 103 89

info@krohne.com

© KROHNE 02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...