KROHNE OPTISYS SLM 2100 Handbook

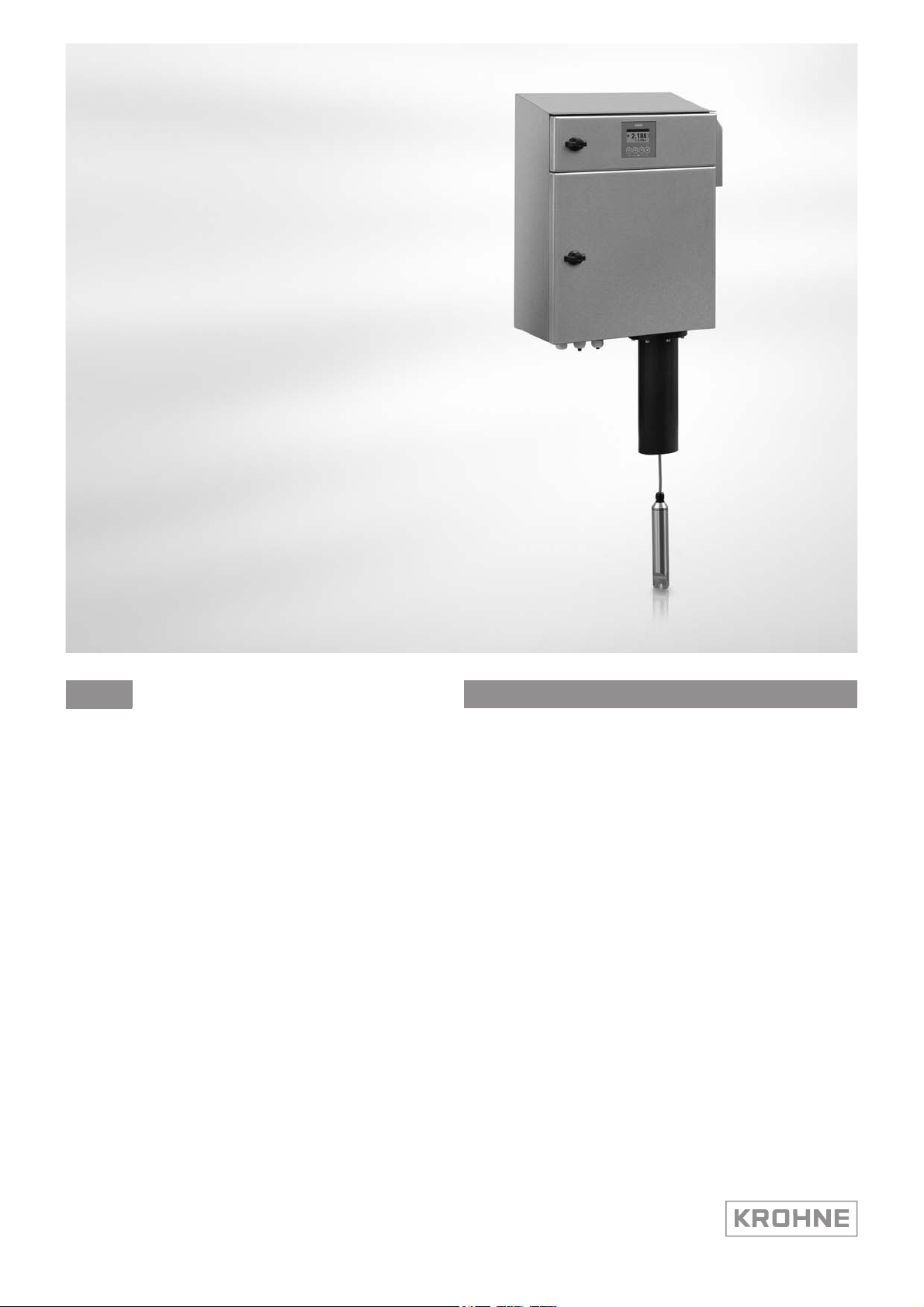

OPTISYS SLM 2100

OPTISYS SLM 2100

OPTISYS SLM 2100OPTISYS SLM 2100

Sludge level meter

Electronic Revision:

1.0.1

Original handbook

Handbook

Handbook

HandbookHandbook

© KROHNE 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

:

IMPRINT

:::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2017 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

CONTENTS

1 Safety instructions 6

1.1 Software history ............................................................................................................... 6

1.2 Intended use ..................................................................................................................... 7

1.3 Certifications .................................................................................................................... 7

1.4 Safety instructions from the manufacturer ..................................................................... 8

1.4.1 Copyright and data protection ................................................................................................ 8

1.4.2 Disclaimer ............................................................................................................................... 8

1.4.3 Product liability and warranty ................................................................................................ 9

1.4.4 Information concerning the documentation........................................................................... 9

1.4.5 Warnings and symbols used................................................................................................. 10

1.5 Safety instructions for the operator............................................................................... 10

2 Device description 11

2.1 Scope of delivery............................................................................................................. 11

2.2 Device description .......................................................................................................... 12

2.3 Nameplate ...................................................................................................................... 14

3 Installation 15

3.1 General notes on installation ......................................................................................... 15

3.2 Storage and transport .................................................................................................... 15

3.3 Typical measuring point ................................................................................................. 16

3.4 Installation order............................................................................................................ 17

3.4.1 Mounting of the sludge level meter...................................................................................... 18

3.5 Installing the cleaning unit (optional) ............................................................................ 24

3.5.1 Installation of the water hose to cleaning unit..................................................................... 25

4 Electrical connections 27

4.1 Safety instructions.......................................................................................................... 27

4.2 Used abbreviations .........................................................................................................27

4.3 Description of electrical symbols................................................................................... 28

4.4 Important device-specific notes on electrical connection............................................. 29

4.5 Overview of cable connections ....................................................................................... 30

4.6 Overview of the terminal compartment ......................................................................... 31

4.7 Connecting the power supply......................................................................................... 32

4.8 Description and properties of the output and the input ................................................ 34

4.8.1 Current output ...................................................................................................................... 34

4.8.2 Control input (active)............................................................................................................. 35

4.9 Connection of output and input ...................................................................................... 36

4.9.1 Important notes..................................................................................................................... 36

4.9.2 Current output ...................................................................................................................... 37

4.9.3 Electrical connection of control inputs................................................................................. 38

4.10 Description and properties of the relays ..................................................................... 40

4.10.1 Connection of the relays ..................................................................................................... 41

4.11 Protection category ...................................................................................................... 42

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

3

CONTENTS

OPTISYS SLM 2100

5 Operation 43

5.1 Start-up and general remarks for configuration........................................................... 43

5.2 Switching on the power .................................................................................................. 44

5.3 Operating elements........................................................................................................ 45

5.4 Measuring page .............................................................................................................. 46

5.4.1 Navigating through the menus .............................................................................................47

5.5 Menu mode structure..................................................................................................... 51

5.6 Function tables ............................................................................................................... 52

5.6.1 Menu A, quick setup.............................................................................................................. 52

5.6.2 Menu B, test .......................................................................................................................... 52

5.6.3 Menu C, setup ....................................................................................................................... 53

5.7 Functions in detail .......................................................................................................... 58

5.7.1 Definition of positions and zones.......................................................................................... 59

5.7.2 Initial configuration in extended settings ............................................................................. 60

5.7.3 Measuring function ............................................................................................................... 61

5.7.4 Assignment of current outputs............................................................................................. 62

5.7.5 Measuring mode ................................................................................................................... 62

5.7.6 Definition of fluff and blanket concentration........................................................................ 63

5.7.7 Definition of settings in zone tracking mode........................................................................ 63

5.7.8 Rake guard / trigger input .................................................................................................... 64

5.7.9 Timer / start signal ............................................................................................................... 64

5.7.10 Maintenance switch ............................................................................................................ 64

5.7.11 Calibration........................................................................................................................... 65

5.7.12 Reference point calibration ................................................................................................ 68

5.7.13 Passwords........................................................................................................................... 68

5.7.14 Timeout function ................................................................................................................. 68

5.8 Status messages and diagnostic information................................................................ 69

5.8.1 Error category "Device failure" (bold "F") ............................................................................ 70

5.8.2 Error category "Application error" ( "F", not bold) .............................................................. 71

5.8.3 Error category "Information" (I) ........................................................................................... 71

5.8.4 Error category "Out of specification" (S) .............................................................................. 71

6 Service 72

6.1 Manual initiation of a measurement .............................................................................. 72

6.2 Maintenance ................................................................................................................... 72

6.2.1 Cleaning unit (optional)......................................................................................................... 74

6.3 Spare parts availability...................................................................................................75

6.4 Availability of services .................................................................................................... 75

6.5 Returning the device to the manufacturer..................................................................... 75

6.5.1 General information.............................................................................................................. 75

6.5.2 Form (for copying) to accompany a returned device............................................................ 76

6.6 Disposal .......................................................................................................................... 76

7 Technical data 77

7.1 Measuring principle........................................................................................................77

7.2 Technical data................................................................................................................. 78

7.3 Dimensions ..................................................................................................................... 81

4

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

CONTENTS

8 Notes 85

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

5

1

SAFETY INSTRUCTIONS

1.1 Software history

The "Electronic Revision" (ER) is consulted to document the revision status of electronic

equipment according to NE 53 for all devices. It is easy to see from the ER whether

troubleshooting or larger changes in the electronic equipment have taken place and how that

has affected the compatibility.

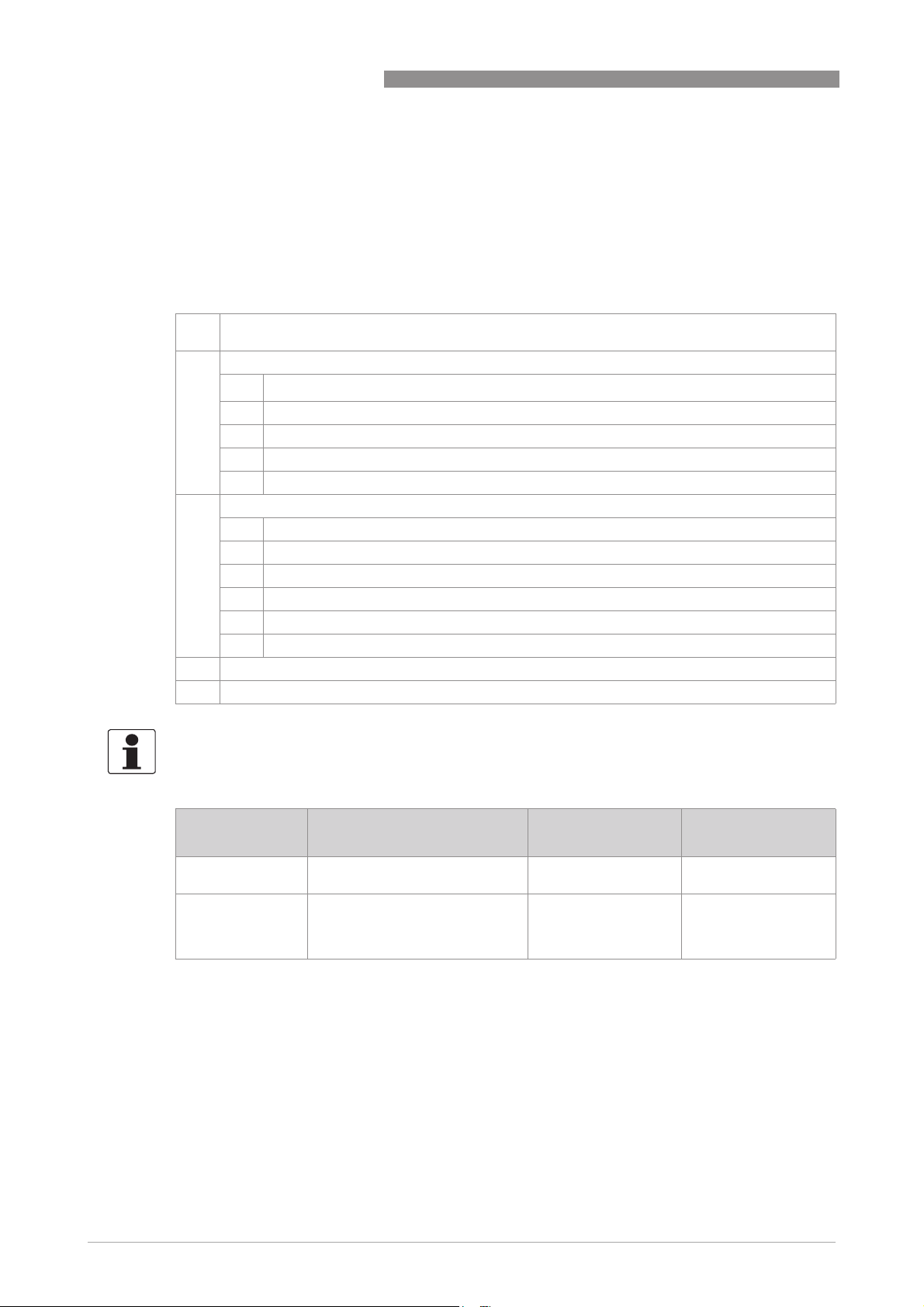

Changes and effect on compatibility

1 Downwards compatible changes and fault repair with no effect on operation (e.g. spelling

mistakes on display)

2-_ Downwards compatible hardware and/or software change of interfaces:

HART

®

H

P PROFIBUS

F Foundation Fieldbus

M Modbus

X all interfaces

3-_ Downwards compatible hardware and/or software change of inputs and outputs:

I Current output

F, P Frequency / pulse output

S Status output

C Control input

CI Current input

X all inputs and outputs

4 Downwards compatible changes with new functions

5 Incompatible changes, i.e. electronic equipment must be changed.

OPTISYS SLM 2100

INFORMATION!

In the table below, "x" is a placeholder for possible multi-digit alphanumeric combinations,

depending on the available version.

Release date Electronic revision Changes and

Documentation

compatibility

04/2013 ER 1.0.0 - MA OPTISYS SLM 2100

XX/2015 ER 1.0.1 4 MA OPTISYS SLM 2100

R02 en

R03 en

MA OPTISYS SLM 2100

R04 en

6

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

1.2 Intended use

The OPTISYS SLM 2100 sludge level meter is primarily designed for use in water and waste

water treatment plants. There it determines the sedimentation profile in clarifiers and sludge

thickeners and detects sludge blanket or fluff level. For this it measures the suspended solids

concentration and height of the sensor above ground as the sensor is lowered into the basin or

tank.

However, the design of the OPTISYS SLM 2100 makes it possible to use it in other applications

where reliable monitoring of interface or stratification in suspensions is necessary.

The OPTISYS SLM 2100 shall not be used in hazardous areas, which e.g. require Ex approvals. It

could ignite gases. Additionally, due to the sensors material, the meter shall not be used in

applications with a high concentration of salt (e.g. seawater). The device has been constructed

for indoor and outdoor use below the maximum altitude of 2000 m / 6562 ft.

By observing the operation instructions, national standards, safety requirements and accident

prevention regulations the residual risk is reduced to an acceptable level.

SAFETY INSTRUCTIONS

1

1.3 Certifications

CE marking

The device meets the essential requirements of the EU directives. The CE marking indicates the

conformity of the product with the union legislation applying to the product and providing for CE

marking.

For full information of the EU directives and standards and the approved certifications, please

refer to the EU declaration on the KROHNE website

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

7

1

SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

OPTISYS SLM 2100

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

8

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

SAFETY INSTRUCTIONS

1

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

9

1

SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTISYS SLM 2100

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

10

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION

2

Figure 2-1: Scope of delivery

1 Sludge level meter (optional with cleaning unit and spray shield)

2 Key for cable drum lock and key for electronic compartment lock

3 Mounting accessories

4 Documentation

Optional accessories

Optional accessories

Optional accessoriesOptional accessories

• Mounting frame

• Rod steel U-bolts for round handrail

• Cleaning unit

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

11

2

DEVICE DESCRIPTION

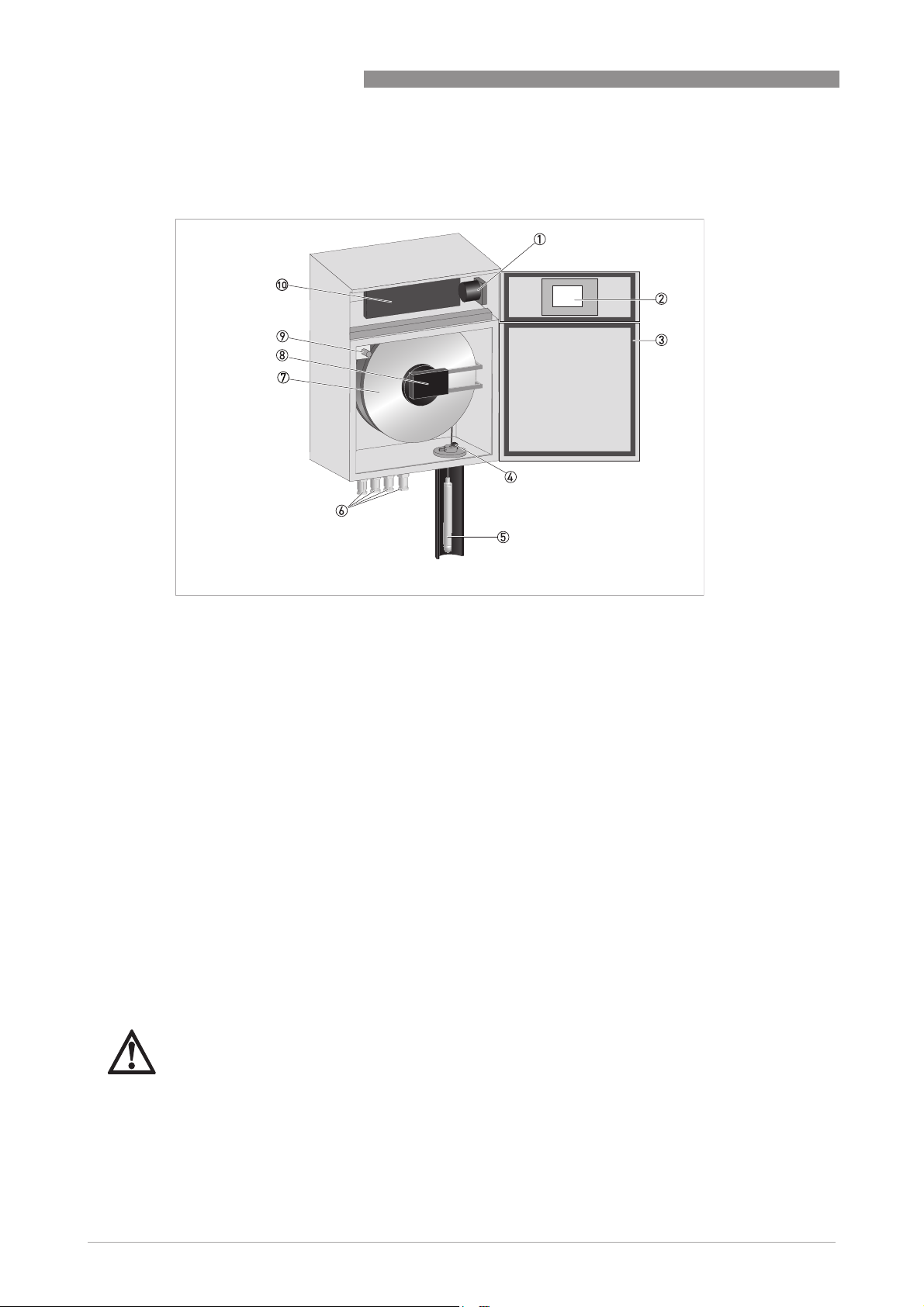

2.2 Device description

OPTISYS SLM 2100

Figure 2-2: Device description of OPTISYS SLM 2100

1 Fan

2 Electronic compartment door with display

3 Cable drum compartment door

4 Guide roller and zero point reference switch

5 Sensor

6 4 x cable feedthrough M20

7 Cable drum with heating unit at the back

8 Pickup and axle board with optical interface

9 Safety switch

10 Main electronics and connectors

Main electronics unit

The main electronic unit is located in a separate compartment above the cable drum, which can

be accessed via a separate door with a key lock. It contains the mainboard and fan assembly. The

mainboard bears the main processor and all electrical connectors. It also controls all

mechanical and electrical events in the device and communicates with sensor, display and

keyboard. It additionally contains the current outputs and control inputs.

Fan assembly

The position of the fan is on the top right side of the enclosure. In combination with the heater

the instrument maintains suitable temperature conditions inside the enclosure of the meter.

DANGER!

The rotating fan blades can be accessed, when the electronic compartment door is open and

there is a risk of injury when rotating fan is touched.

12

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

Display and keyboard

Display and keyboard are located in the front door of the electronics compartment. Display and

keyboard are based on the GDC (general device concept), which means a common HMI (human

machine interface) to all KROHNE GDC instruments is provided. The keyboard consists of four

membrane keys and the display is a LCD graphic display with a resolution of 128 x 64 Pixel.

Cable drum assembly and heater unit

The cable drum helps to move the sensor up and down in the basin. It is mounted directly on the

motor shaft of a synchronous motor, hidden behind the drum mounting plate. The cable drum

always moves with a very constant speed. Since the diameter of the cable roll in the drum varies,

the speed of the sensor varies. That is why the sensor moves slower during the end of the

sampling. Due to the roll design, shortening of cable or movement of the metal sleeve on the

sensor cable is prohibited. This will lead to different diameter of the cable roll and finally

resulting in wrong results in the height/depth measurements. The heater unit is located behind

the drum mounting plate. In combination with the fan the instrument maintains suitable

temperature conditions inside the enclosure of the meter.

Guide roller and zero point reference switch

The guide roller helps to keep the cable in place during the measuring process. A stable height

measurement is reached by zero point reference switch. The inductive proximity switch reacts

on the metal sleeve on the sensor cable and calibrates the home position. Each time when

leaving the menu the device performs a zero point calibration. In addition a regular calibration

during the process can be performed time based via the setup.

DEVICE DESCRIPTION

2

Sensor

The sensor used in the OPTISYS SLM 2100 is a suspended solid sensor. The sensor contains a

near-infrared light source and a receiver in an angle of 180°. Both are positioned in such a way

that the emitted near-infrared light has to pass through the liquid before reaching the receiver.

The suspended solids in the liquid absorb the emitted light leading to a lower intensity at the

detector. The light loss is proportional to the suspended solid content.

Pickup board & axle board

The pickup board is mounted on a spring loaded lever arm and transfers power and

communication signals to the cable drum.

The axle board on the cable drum is powered contactless ("inductively") by the pickup board. It

communicates with the main electronics unit via the pickup board and with the sensor via an

optical interface.

Cable feedthroughs

The 4 M20 cable feedthroughs are for the connection of power, signal and control cables. Only

three cable feedthroughs can be used, if the optional cleaning unit is installed.

Safety switch

The safety switch located on the top left corner of the cable drum compartment is a protective

device, which de-energizes the motor when the front door is opened in order to avoid danger due

to moving parts inside the meter.

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

13

2

DEVICE DESCRIPTION

Cleaning unit (optional)

The cleaning unit, mounted under the device, consists of a valve and a spraying system to keep

the sensor and cable free of deposits ensuring low maintenance efforts of OPTISYS SLM 2100.

The cleaning unit uses water which can be supplied either by an external water source (process

water) or by water from the clear water phase. The latter can be performed by an external pump

which is controlled by the OPTISYS SLM 2100.

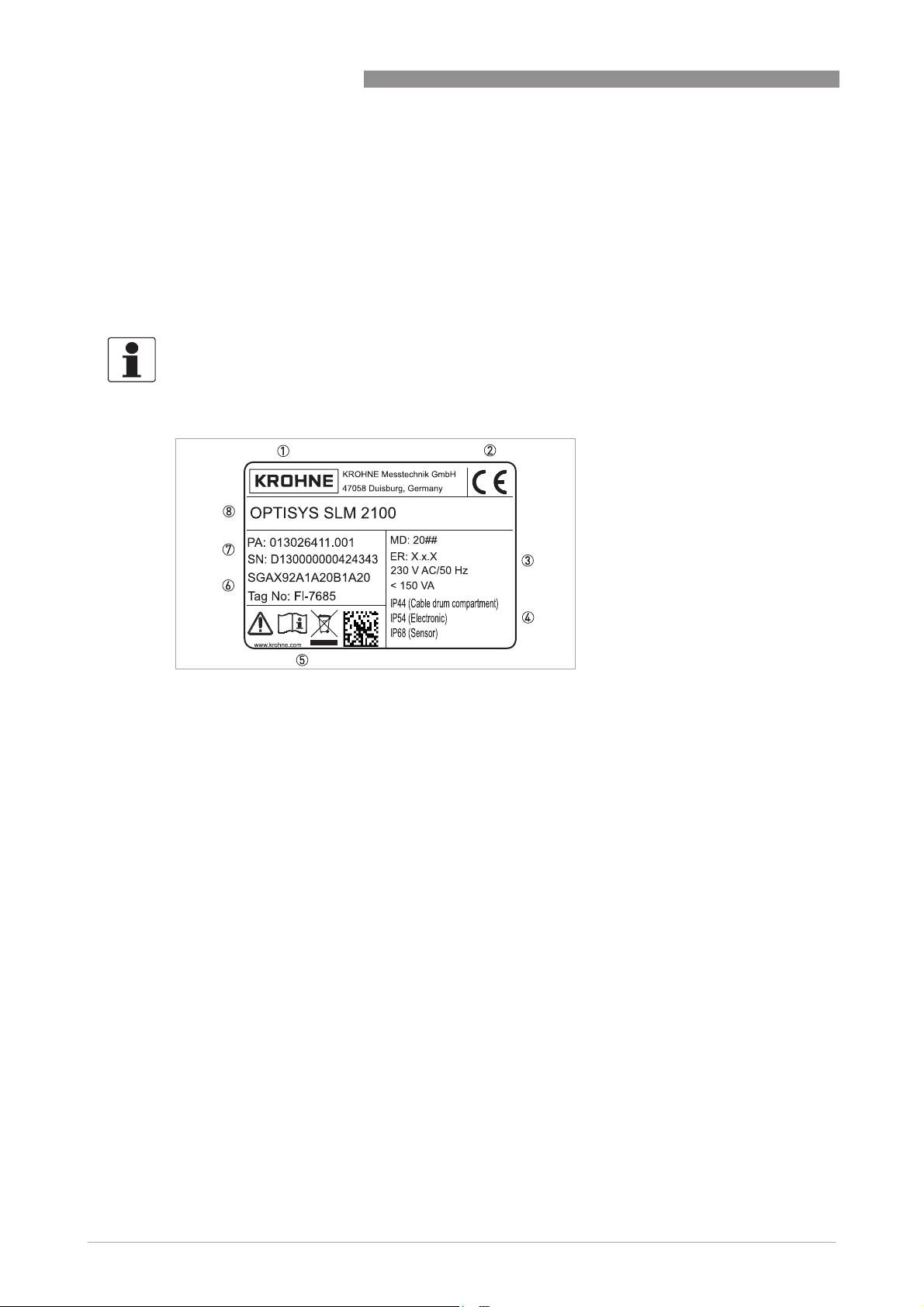

2.3 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISYS SLM 2100

Figure 2-3: Example of a nameplate

1 Manufacturer

2 CE marking

3 Manufacturing year,

Electronic revision,

Power supply data

4 Protection categories

5 Observe the operation and installation instruction,

Electronic / electric device waste marking,

Data matrix code

6 Order code / TAG no.

7 Production order / Serial number

8 Device name

14

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

INFORMATION!

The display should be mounted in a height of 1.5...1.8 m / 4.9...5.9 ft to prevent ergonomic

hazards.

INFORMATION!

During work on the device above the basin the personnel have to be protected by personal safety

equipment.

INSTALLATION

3

3.2 Storage and transport

• Store and transport the device in a dry, dust-free environment.

• Store and transport the device in an environment with a temperature between -20...+60°C/

-4...+140°F.

• The original packing is designed to protect the equipment. It has to be used if the device is

transported or sent back to the manufacturer including the sensor fixation inside the device,

to prevent damage of the sensor.

INFORMATION!

Due to the weight above 20 kg / 44.1 lbs please lift and carry the device only with two persons or

use appropriate lifting equipment and if the surfaces of the device are wet, please use gloves for

lifting.

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

15

3

INSTALLATION

3.3 Typical measuring point

OPTISYS SLM 2100

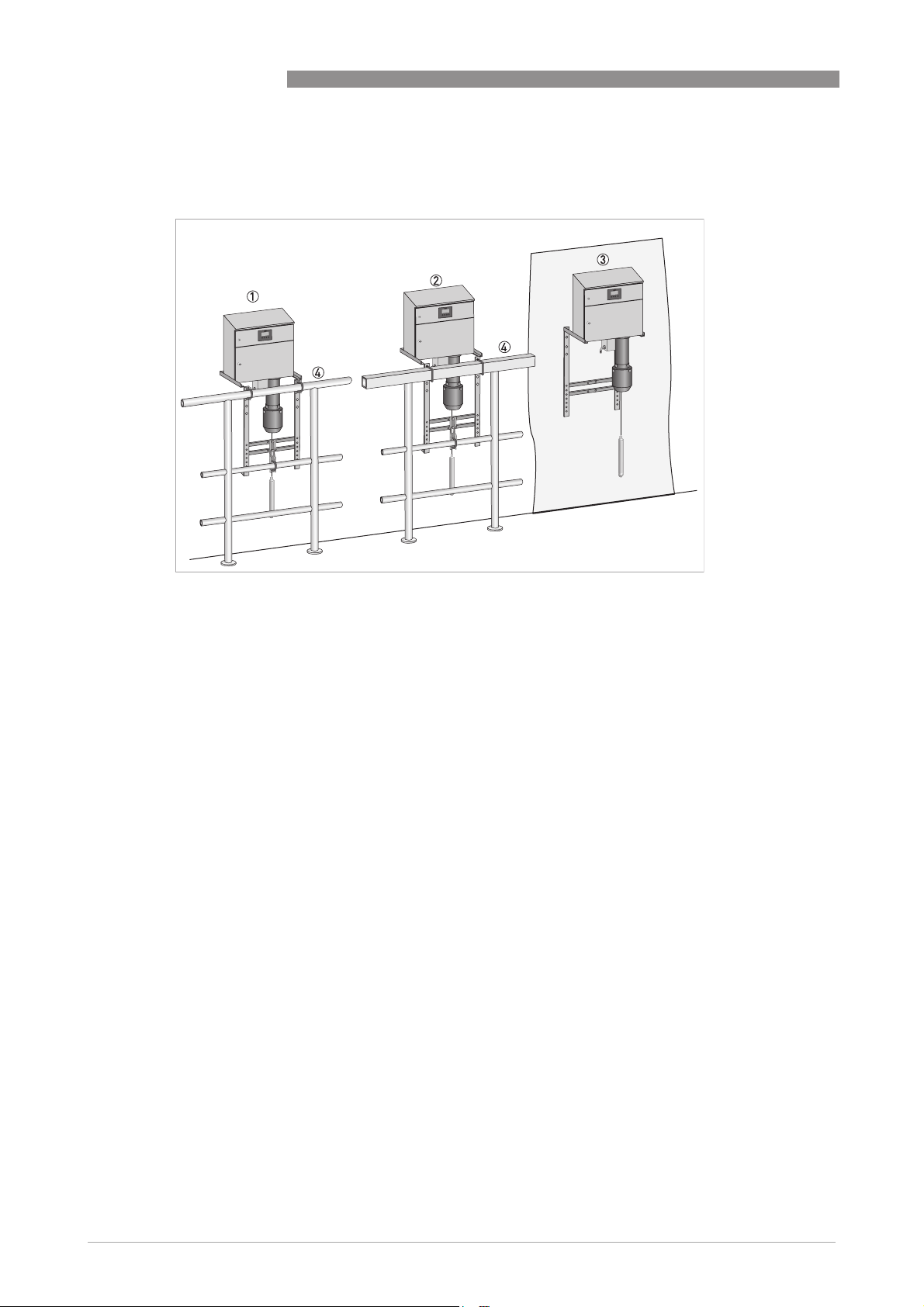

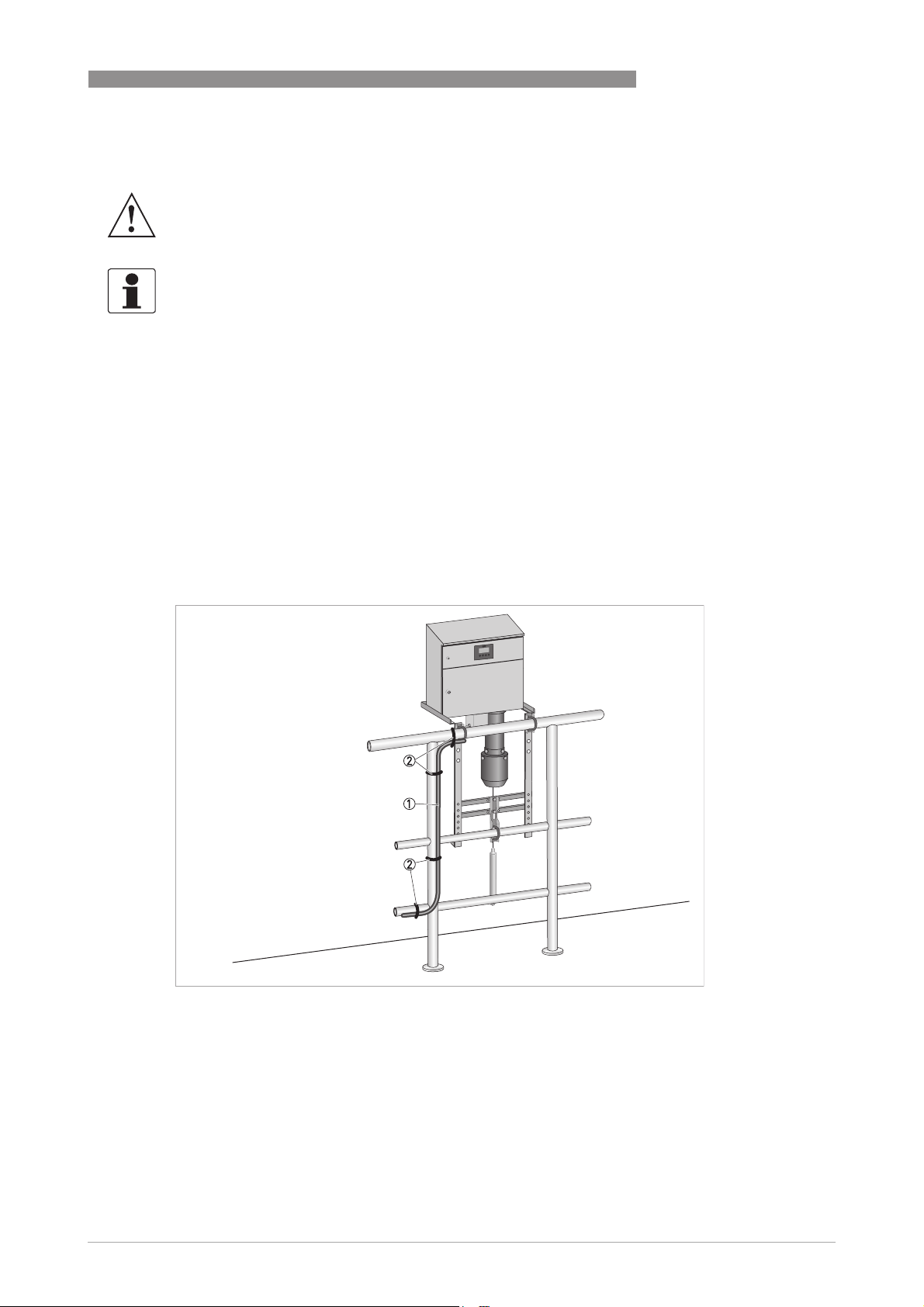

Figure 3-1: Example of typical measuring points

1 OPTISYS SLM 2100 with brackets for round handrail on horizontal post

2 OPTISYS SLM 2100 with brackets for rectangular handrail (not included of scope of delivery)

3 OPTISYS SLM 2100 mounted on a wall

4 Handrail

16

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

3.4 Installation order

DANGER!

Do not install the sludge level meter in hazardous areas, it can ignite explosive gases!

DANGER!

Do not cover or obstruct the ventilation. It can lead to overheating of the device.

INFORMATION!

The device must not be heated by radiated heat (e.g. exposure to the sun) to a electronics

housing surface temperature above the maximum permissible ambient temperature. If it is

necessary to prevent damage from heat sources, a heat protection (e.g. sun shade) has to be

installed.

INFORMATION!

The operator is responsible for providing, securing and the possibility of switching off the supply

voltage.

INSTALLATION

3

INFORMATION!

The external electrical main switch (red / yellow) of the device has to be located close to the

device and easily accessible. An internal main switch is not available.

INFORMATION!

The device should be located at save installation site in order to prevent the danger of falling in

the water basin. Furthermore, there should be enough space in front of the device ensuring an

easy access.

To install the measuring system in the best way, follow the steps described below.

Steps to install the meter

1 Mounting of the sludge level meter

(for detailed information refer to

2 Installing the cleaning unit (optional)

(for detailed information refer to

3 Connecting the power supply

(for detailed information refer to

4 Connection of the current outputs

(for detailed information refer to

5 Connecting the rake guard switch / external trigger or maintenance switch - if required

(for detailed information refer to

6 Configuration of the sludge level meter

(for detailed information refer to

7 Calibration of the sludge level meter

(for detailed information refer to

Mounting of the sludge level meter

Cleaning unit (optional)

on page 74)

Connecting the power supply

Current output

on page 37).

Electrical connection of control inputs

Functions in detail

Calibration

on page 65).

on page 58).

on page 18).

on page 32).

on page 38).

INFORMATION!

For decommissioning of the device please repeat the steps above in reverse order from 5 to 1.

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

17

3

INSTALLATION

3.4.1 Mounting of the sludge level meter

INFORMATION!

To ensure proper assembly, please use only the mounting material provided with the meter.

INFORMATION!

All bolts, nuts and washers should be greased to prevent cold welding and ensure simple

disassemble after use.

INFORMATION!

Please ask a second person to help with this procedure.

Due to many different applications and installation points of sludge level meter a standardised

mounting is often not applicable. To overcome the problem of the local conditions three different

opportunities exist to order the mounting of the sludge meter.

Available mounting possibilities

Available mounting possibilities

Available mounting possibilitiesAvailable mounting possibilities

OPTISYS SLM 2100

INFORMATION!

Ensure that the handrail is suitable for the weight of the mounting frame and the device

(standard: 26.5 kg / 58.4 lbs, with cleaning unit: 31kg / 68.3 lbs); otherwise support the handrail

with additional material. The operator is responsible for safe installation, especially against the

fall in the sedimentation basin.

18

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

Direct mounting without frame

Direct mounting without frame

Direct mounting without frameDirect mounting without frame

The sludge meter can be mounted directly on the wall. The sludge level meter has 4 M6 threads

on the back and on the bottom of the instrument. If the threads on the bottom are used, ensure

that there is enough space for sensor, cable feedthroughs and the cleaning unit. For further

information refer to

• Mount the meter using the 4 M6 screws

Dimensions

on page 81.

INSTALLATION

3

Figure 3-2: Mounting on wall

1 4 x M6 screws

2 Wall

3 OPTISYS SLM 2100

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

19

3

INSTALLATION

Mounting frame

Mounting frame

Mounting frameMounting frame

The mounting frame can be used for round or rectangular handrails. For rectangular handrails

suitable rectangular brackets should be selected which are not part of the scope of delivery. Use

at least 3 fixation points as described in the installation of round handrails. For further

information refer to

Mounting frame with brackets with round handrail (vertical or horizontal)

Mounting frame with brackets with round handrail (vertical or horizontal)

Mounting frame with brackets with round handrail (vertical or horizontal)Mounting frame with brackets with round handrail (vertical or horizontal)

This option allows installing the sludge level meter on many round handrails. The rod steel Ubolts cover handrails between diameters of 33...60.3 mm / 1.3...2.37 inch. Two round rod steel Ubolts fixate the mounting frame on the upper handrail. A further rod steel U-bolt stabilises the

sludge level meter by fixation to a horizontal or vertical bar.

Mounting on round handrail with horizontal bar

Mounting on round handrail with horizontal bar

Mounting on round handrail with horizontal barMounting on round handrail with horizontal bar

Dimensions

OPTISYS SLM 2100

on page 81.

20

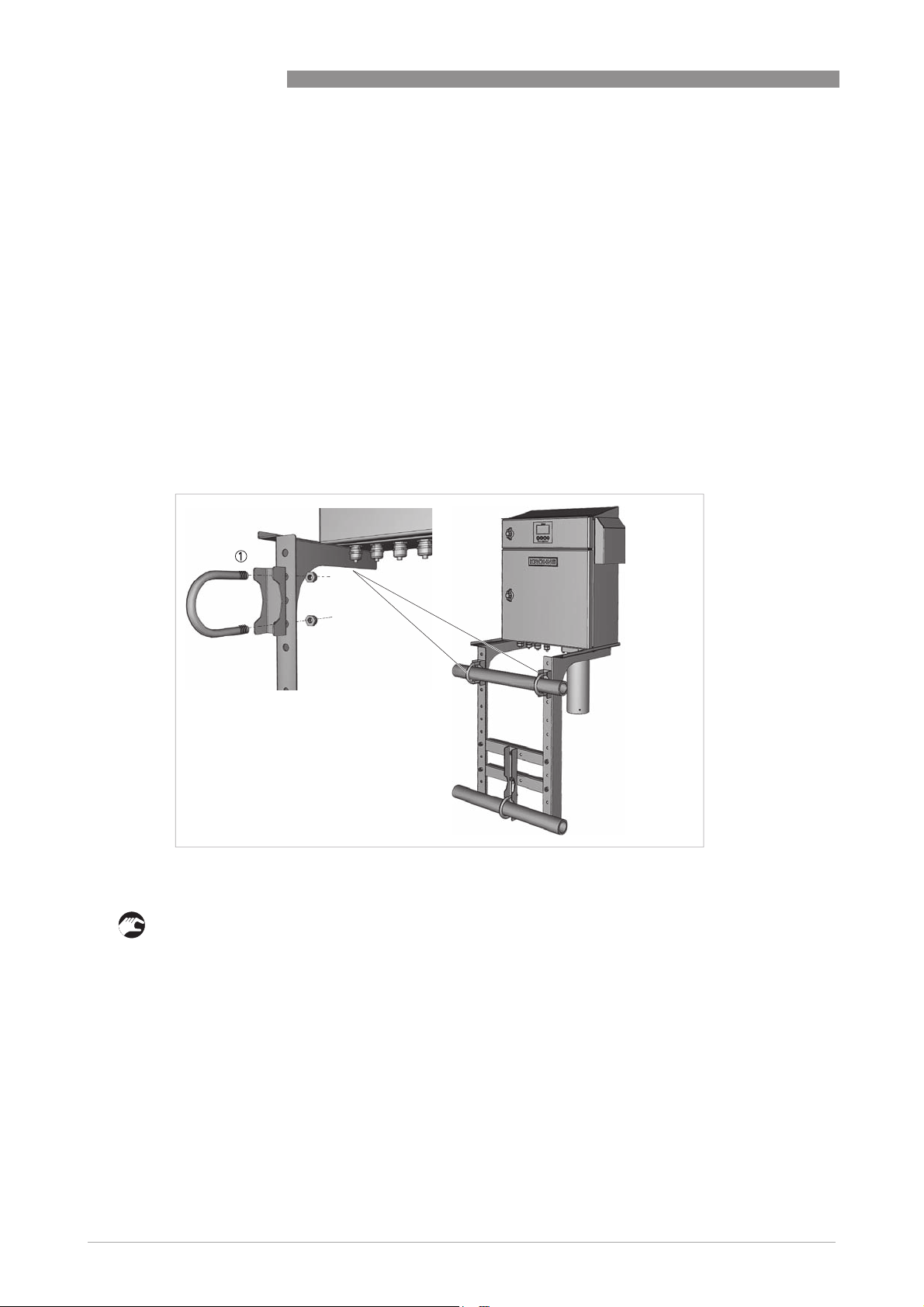

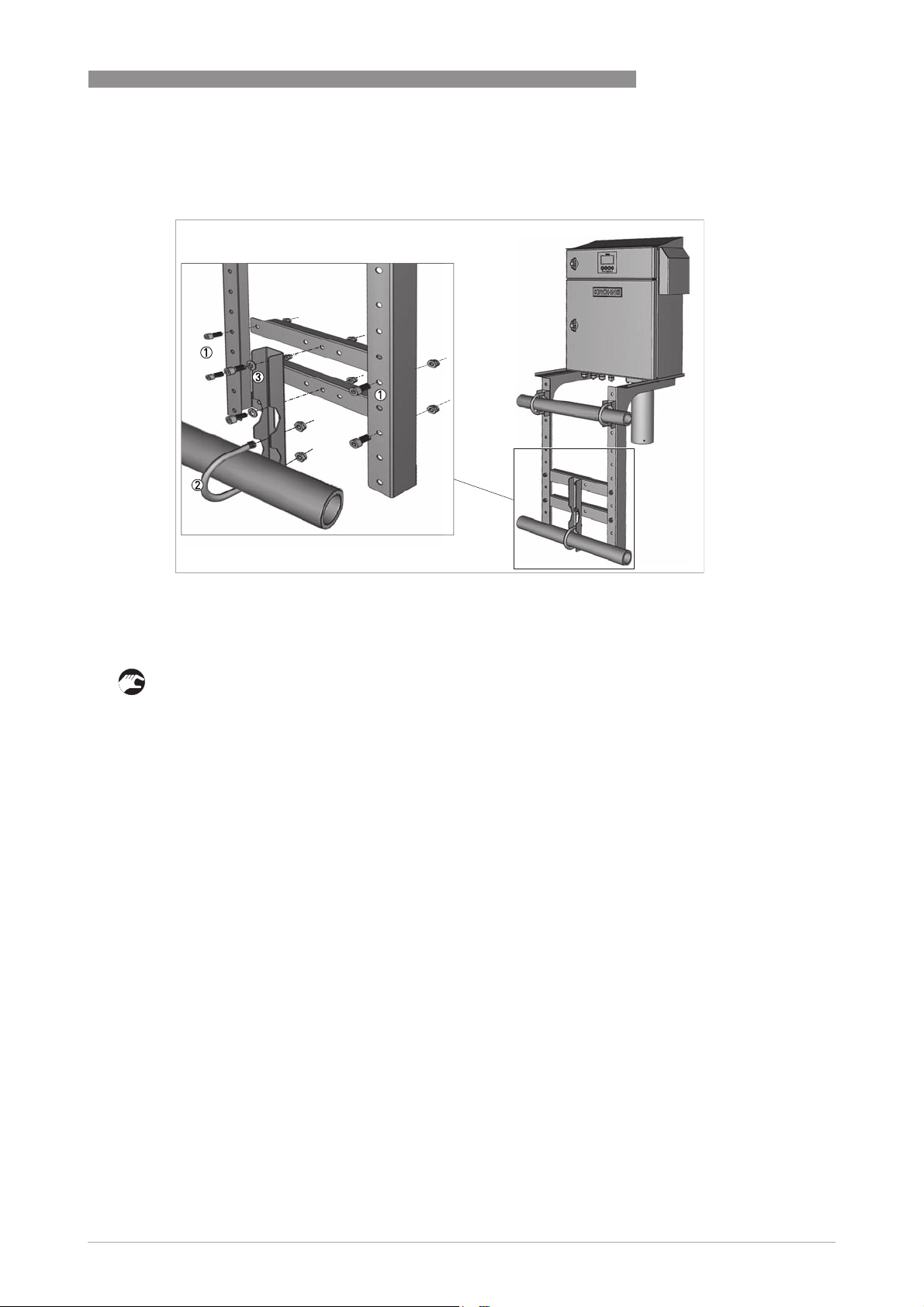

Figure 3-3: Mounting of upper handrail

1 Rod steel U-bolts

• Mount the frame using the rod steel U-bolts (M10) and nuts 1 in a position that the frame is

above the handrail.

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

Mounting on lower round handrail with horizontal bar

Mounting on lower round handrail with horizontal bar

Mounting on lower round handrail with horizontal barMounting on lower round handrail with horizontal bar

INSTALLATION

3

Figure 3-4: Mounting of lower handrail (horizontal)

1 Screws and nuts

2 Rod steel U-bolt

3 Adapter for lower handrail

• Find suitable and stable positions of the lower crossbars.

• Fix crossbars with screws (M8 x 20), nuts and washers 1.

• On both crossbars mount the adaption plate 3.

• Mount the rod steel U-bolt (M10) 2 to the horizontal pole with washers.

• Use the slot holes to adjust the respective height.

• Adjust the position of all brackets.

• Tighten all screws.

• Position the meter on the frame and tighten it with M6 screws.

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

21

3

INSTALLATION

Mounting on lower round handrail with vertical bar

Mounting on lower round handrail with vertical bar

Mounting on lower round handrail with vertical barMounting on lower round handrail with vertical bar

OPTISYS SLM 2100

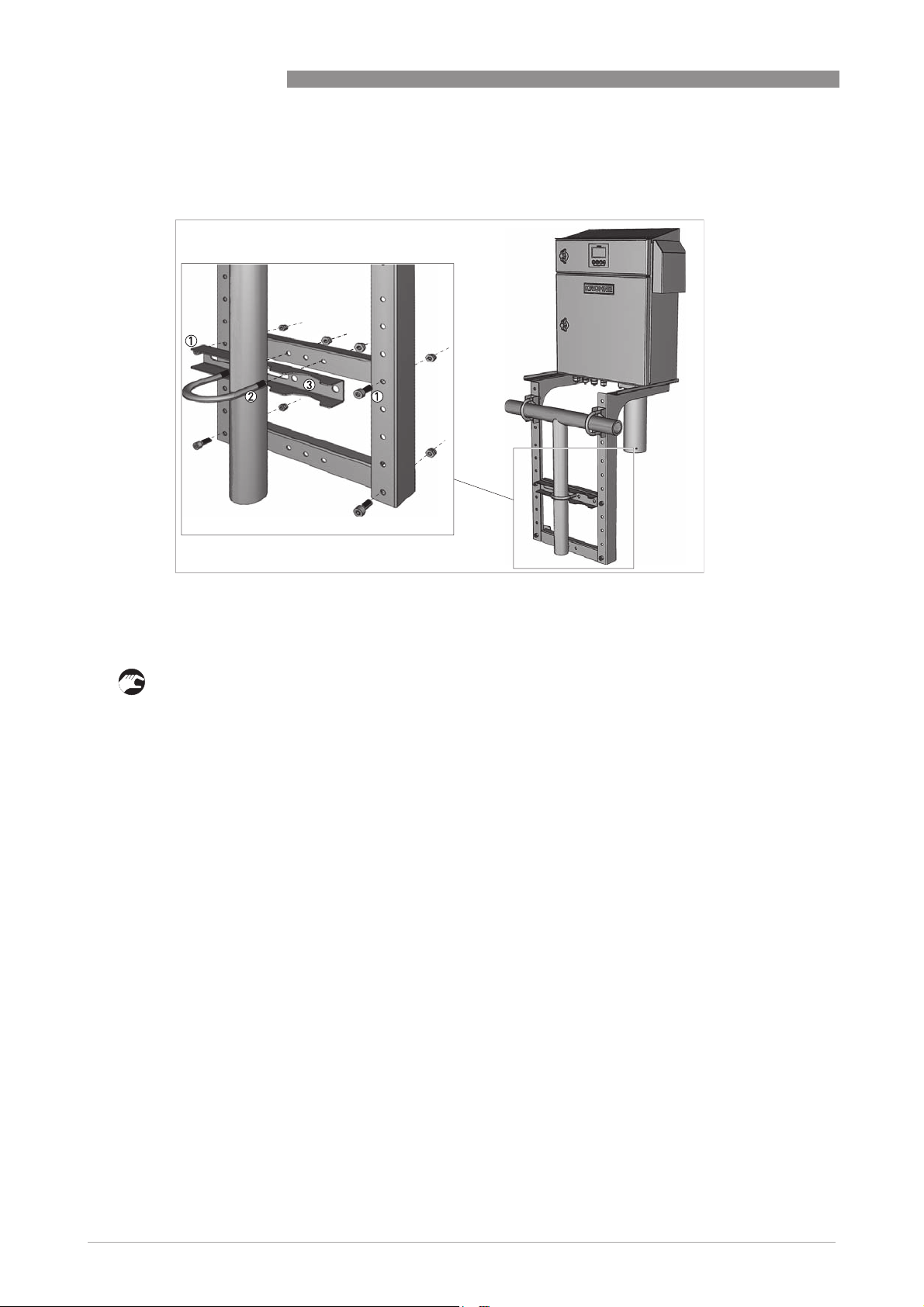

Figure 3-5: Mounting of lower handrail (vertical)

1 Screws and nuts

2 Rod steel U-bolt

3 Adapter for lower handrail

• Find suitable and stable positions of the lower crossbars.

• Fix crossbars with screws and nuts 1.

• On one crossbar mount the adaption plate 3.

• Mount the rod steel U-bolt 2 to the vertical pole.

• Adjust the position of all brackets.

• Tighten all screws.

• Position the meter on the frame and tighten it with M6 screws.

22

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

Fixing the meter

Fixing the meter

Fixing the meterFixing the meter

INSTALLATION

3

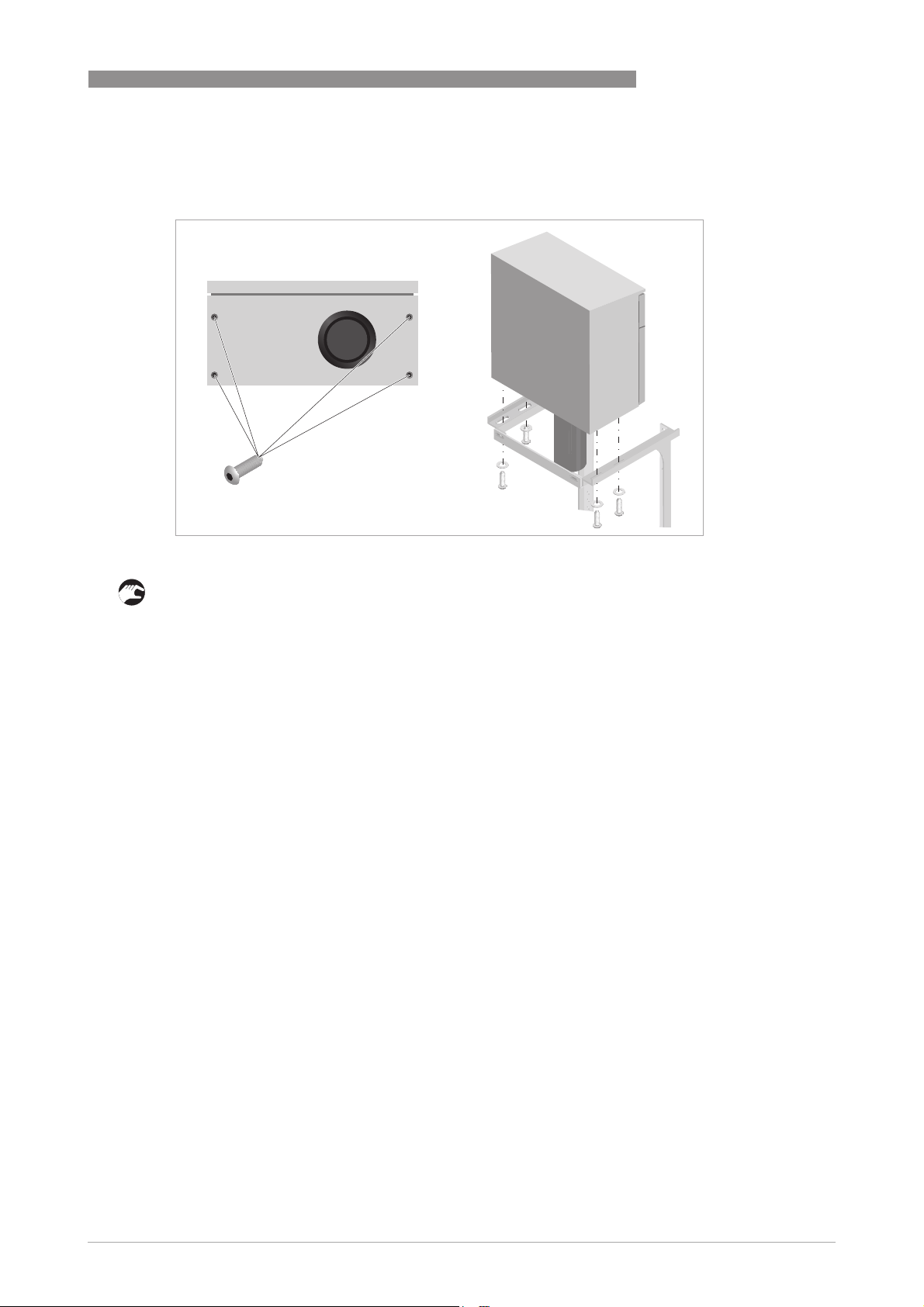

Figure 3-6: Mounting device on handrail

• Fix the meter to the upper part of the mounting frame using screws (M6 x 16) and washers

according to the drawing above.

• Please make sure that the meter is mounted in such a height that display and keyboard are at

eye level.

• Remove the sensor transportation protection to prevent blocking of the sensor.

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

23

3

INSTALLATION

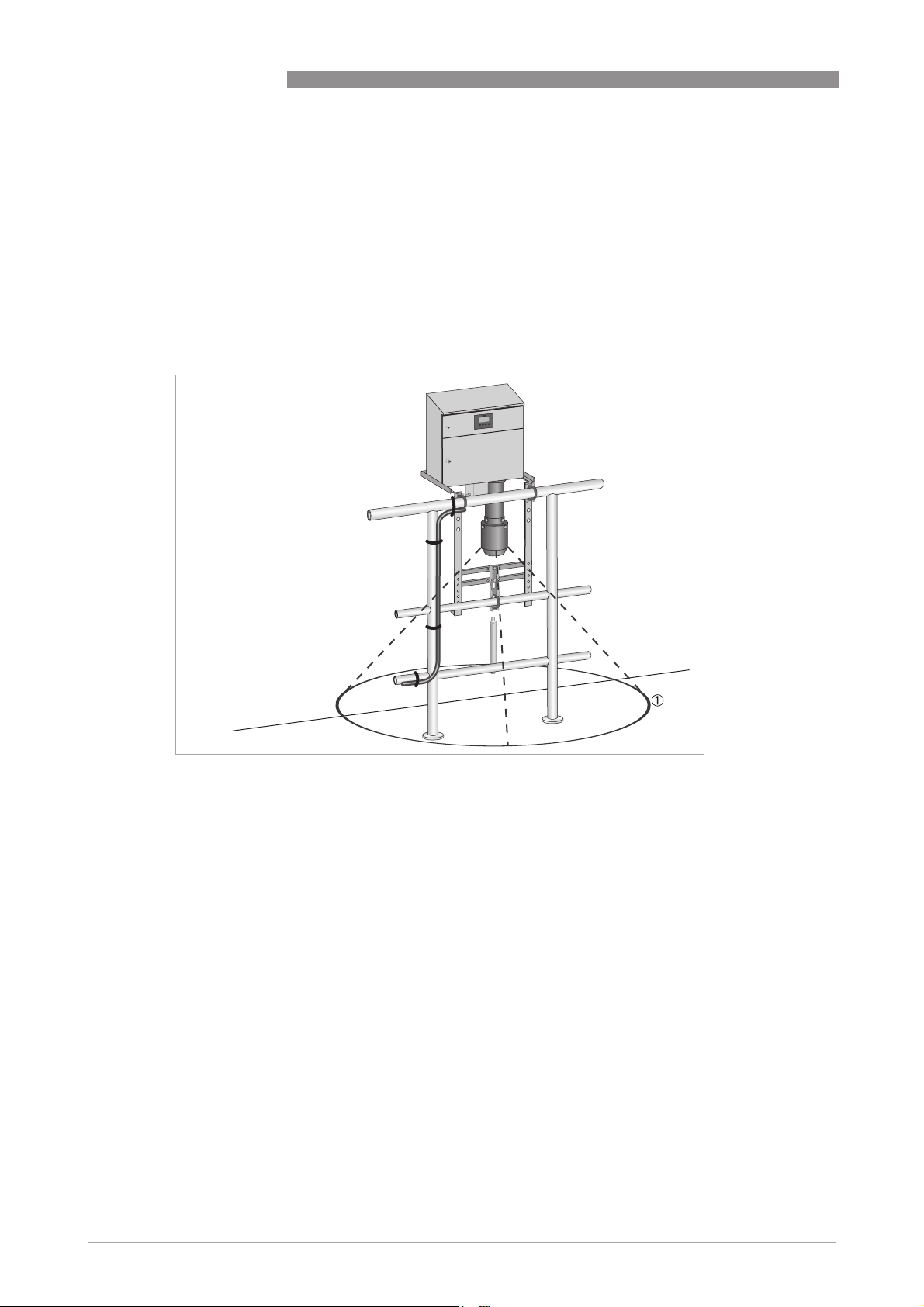

3.5 Installing the cleaning unit (optional)

The cleaning unit, mounted under the device, consists of a valve and a spraying system to keep

the sensor and cable free of deposits ensuring low maintenance efforts of the device. The

cleaning unit is mounted and electrically connected to the device by the manufacturer with

exception of the spray shield and the water connection.

If installing a device containing a cleaning unit, keep a safety area around the sensor garage free

from electrical device or water sensitive parts, as outlined in the following drawing.

OPTISYS SLM 2100

Figure 3-7: Safety area

1 Radius: 2 m / 78.74"

The cleaning unit can be supplied with water by 2 options:

• External water supply by hose with drinking or process water.

• Water supplied by pumped clear water of the sedimentation basin. For further information

refer to

Description and properties of the relays

on page 40.

24

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

3.5.1 Installation of the water hose to cleaning unit

WARNING!

The maximum allowed water pressure should not exceed 6 bar / 87 psi.

INFORMATION!

An external separation switch of the water supply has to be located close to the device and easily

accessible.

A 3/4" male connector (Whitworth EN 10226) with metric thread provides the mounting junction

for the water hose adapter.

When installing the water hose adapter on the connector, carefully fix the nut of the fitting. The

electric valve inside the cleaning system housing may be twisted, which may cause water

leakage.

When installing the device, make sure the water hose is adequately fixed as outlined. Mount the

water hose in such a way that the weight of it is not carried by the hose adapter. When fixing the

hose also take into account that it must be avoided that it moves when the system is switched

on/off.

INSTALLATION

3

Figure 3-8: Fixing points water hose

1 Water hose

2 Fixing points

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

25

3

INSTALLATION

Mounting sprayshield

Mounting sprayshield

Mounting sprayshieldMounting sprayshield

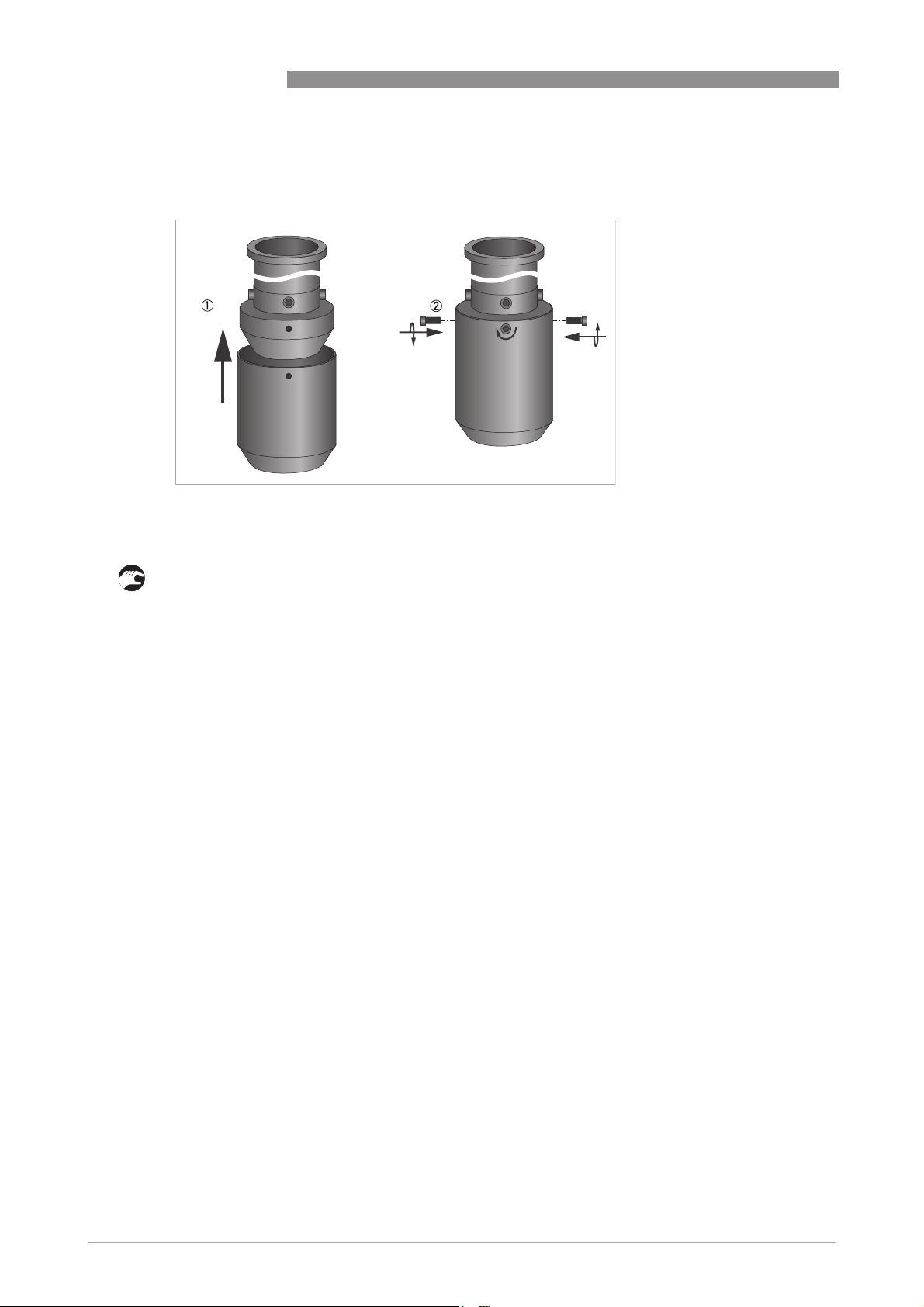

Figure 3-9: Mounting sprayshield

1 Push the sprayshield above the cleaning unit. Please be aware that the holes are align to each other.

2 Insert the 4 M6 screws.

OPTISYS SLM 2100

• The sprayshield has to be mounted by the operator using 4 M6 screws to the cleaning unit as

described in this drawing.

26

www.krohne.com 01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

OPTISYS SLM 2100

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

WARNING!

Before performing any work on the device switch off the power and make sure that it cannot be

switched on accidently.

ELECTRICAL CONNECTIONS

4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

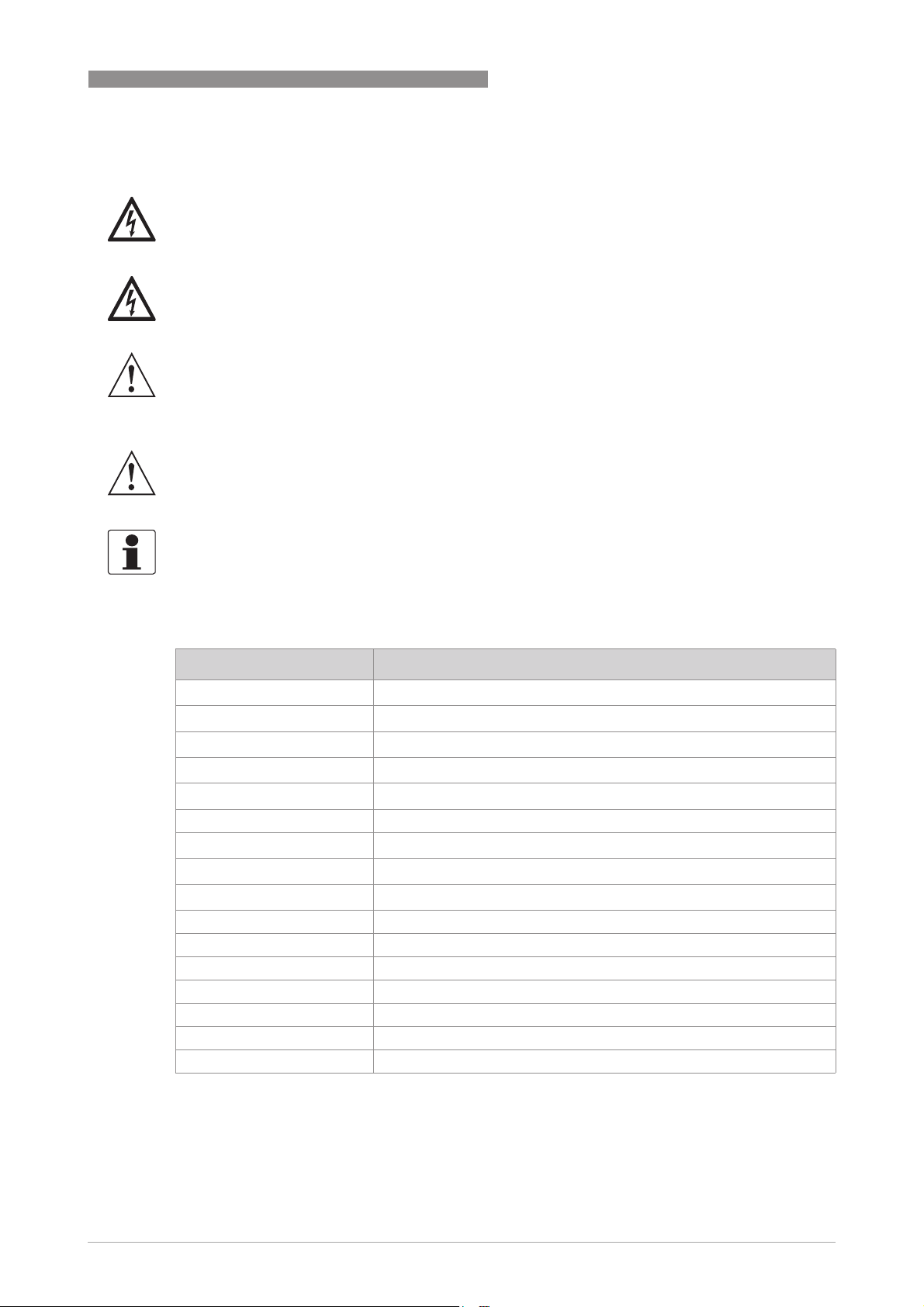

4.2 Used abbreviations

Abbreviation Description

CI

a

I

a

I

max

I

nom

R

L

P Power

U

int, nom

U

ext

U

o

VAC Alternating current (AC) voltage

CI Control input

PCS Process control system

NO Switch (normally open)

NC Switch (normally closed)

LED Light-emitting diode

K Relay

Control input active

Current output active

Maximum current

Nominal current

Load resistance

Nominal internal voltage

External voltage

Terminal voltage

www.krohne.com01/2017 - 4002737304 - MA OPTISYS SLM 2100 R04 en

27

Loading...

Loading...