Page 1

Quick Start

Quick Start

OPTISONIC 3400

OPTISONIC 3400

OPTISONIC 3400OPTISONIC 3400

Quick StartQuick Start

Multi purpose, all-round, ultrasonic flowmeter for

liquids in all industrial processes

ER 2.2.7_

© KROHNE 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 2

CONTENTS

OPTISONIC 3400

1 Safety instructions 4

2 Installation 5

2.1 Scope of delivery............................................................................................................... 5

2.2 Device description ............................................................................................................ 6

2.3 Nameplates ...................................................................................................................... 7

2.3.1 Example of nameplate for the compact version .................................................................... 7

2.3.2 Nameplate for the measuring sensor (field version)............................................................. 8

2.3.3 Examples of nameplates on the signal converter (field version) .......................................... 8

2.4 Storage ........................................................................................................................... 10

2.5 Transport ........................................................................................................................ 10

2.6 Pre-installation requirements ....................................................................................... 11

2.7 General requirements .................................................................................................... 11

2.7.1 Vibration ................................................................................................................................ 11

2.8 Installation conditions ....................................................................................................12

2.8.1 Inlet and outlet...................................................................................................................... 12

2.8.2 Bends in 2 or 3 dimensions................................................................................................... 12

2.8.3 T-section ............................................................................................................................... 12

2.9 Bends .............................................................................................................................. 13

2.10 Open feed or discharge ................................................................................................ 13

2.11 Position of pump........................................................................................................... 14

2.12 Control valve ................................................................................................................. 14

2.13 Down going pipeline over 5 m /16 ft length ................................................................. 15

2.14 Insulation ...................................................................................................................... 15

2.15 Mounting ....................................................................................................................... 16

2.16 Flange deviation............................................................................................................ 16

2.17 Mounting position .........................................................................................................16

2.18 Mounting the field housing, remote version ................................................................ 17

2.18.1 Pipe mounting ..................................................................................................................... 17

2.18.2 Turning the display of the field housing version ................................................................ 18

3 Electrical connections 19

3.1 Safety instructions.......................................................................................................... 19

3.2 Signal cable (remote versions only)............................................................................... 19

3.3 Power supply .................................................................................................................. 21

3.4 Laying electrical cables correctly .................................................................................. 22

3.5 Inputs and outputs, overview ......................................................................................... 23

3.5.1 Combinations of the inputs/outputs (I/Os) ........................................................................... 23

3.5.2 Description of the CG number .............................................................................................. 24

3.5.3 Fixed, non-alterable input/output versions.......................................................................... 25

3.5.4 Alterable input/output versions............................................................................................ 26

4 Technical data 27

4.1 Dimensions and weights ................................................................................................ 27

4.2 Variants........................................................................................................................... 27

4.3 Standard flow sensor ..................................................................................................... 28

4.4 Variant flow sensor; XXT - High Viscosity and Cryogenic (SS) versions........................ 34

2

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 3

OPTISONIC 3400

CONTENTS

4.5 Signal converter housing ............................................................................................... 40

5 Notes 41

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

3

Page 4

1

SAFETY INSTRUCTIONS

Warnings and symbols used

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

OPTISONIC 3400

HANDLING

• This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

Safety instructions for the operator

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

LEGAL NOTICE!

The responsibility as to the suitability and intended use of this device rests solely with the user.

The supplier assumes no responsibility in the event of improper use by the customer. Improper

installation and operation may lead to loss of warranty. In addition, the "Terms and Conditions of

Sale" apply which form the basis of the purchase contract.

INFORMATION!

•

Further information can be found on the supplied CD-ROM in the manual, on the data sheet,

in special manuals, certificates and on the manufacturer's website.

•

If you need to return the device to the manufacturer or supplier, please fill out the form

contained on the CD-ROM and send it with the device. Unfortunately, the manufacturer

cannot repair or inspect the device without the completed form.

4

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 5

OPTISONIC 3400

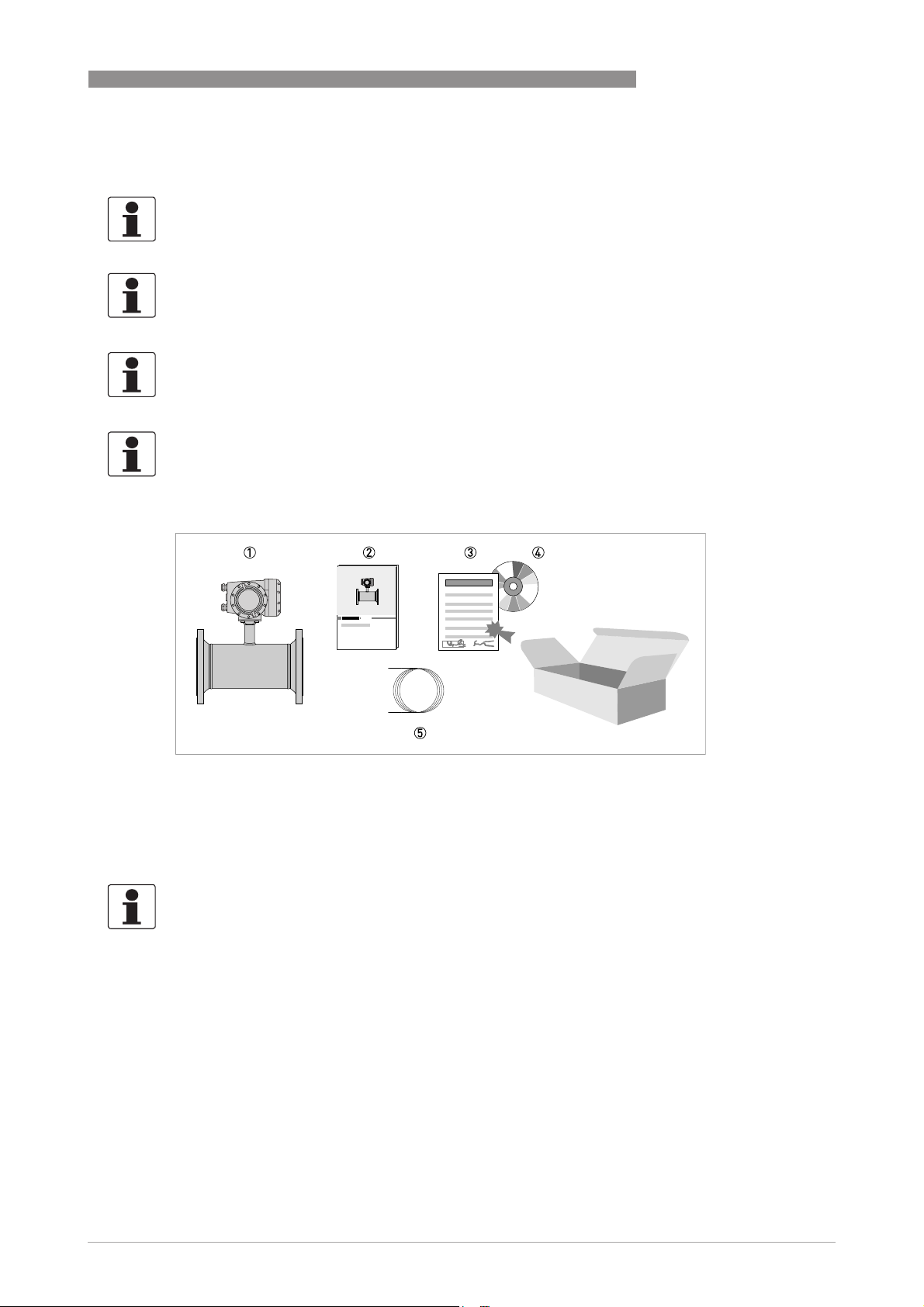

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

The field device will arrive in two cartons. One carton contains the converter and one carton

contains the sensor.

INFORMATION!

Make sure to combine the sensor and the converter correctly, so they match by the devices

serial number.

INSTALLATION

2

Figure 2-1: Scope of delivery - compact version

1 Ordered flowmeter

2 Product documentation

3 Factory calibration certificate

4 CD-ROM with product documentation in available languages

5 Signal cable (remote versions only)

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

5

Page 6

2

INSTALLATION

2.2 Device description

This ultrasonic flowmeter is designed for the continuous measurement of actual volume flow,

mass flow, flow speed, velocity of sound, gain, SNR and diagnosis value.

Exclusively for measuring conductive and / or non-conductive fluids in closed, completely filled

pipeline circuits.

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

The following versions are available:

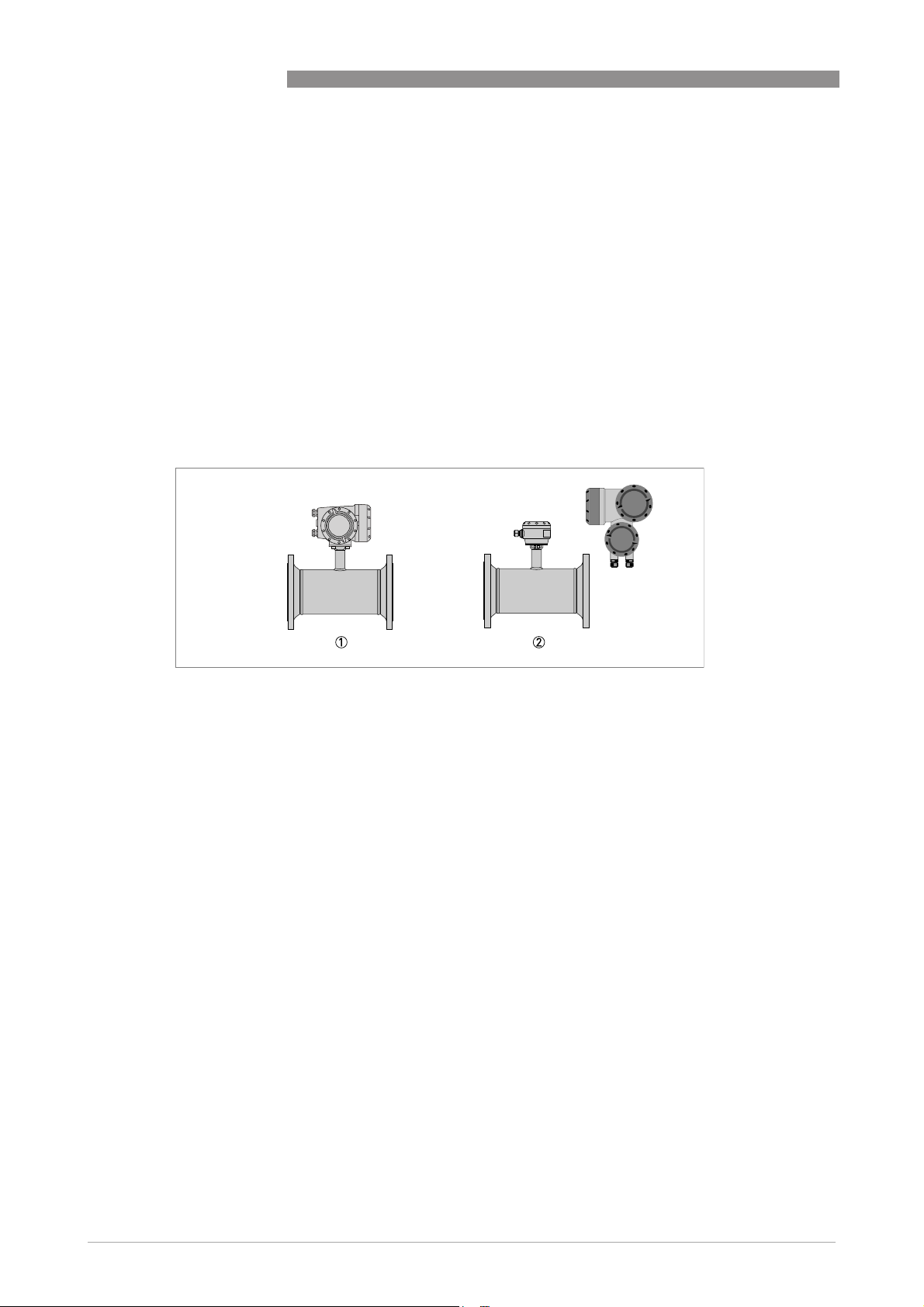

• Compact version (the signal converter is mounted directly on the measuring sensor)

• Remote version (electrical connection to the measuring sensor via signal cable)

OPTISONIC 3400

1 Compact version

2 Remote version

6

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 7

OPTISONIC 3400

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

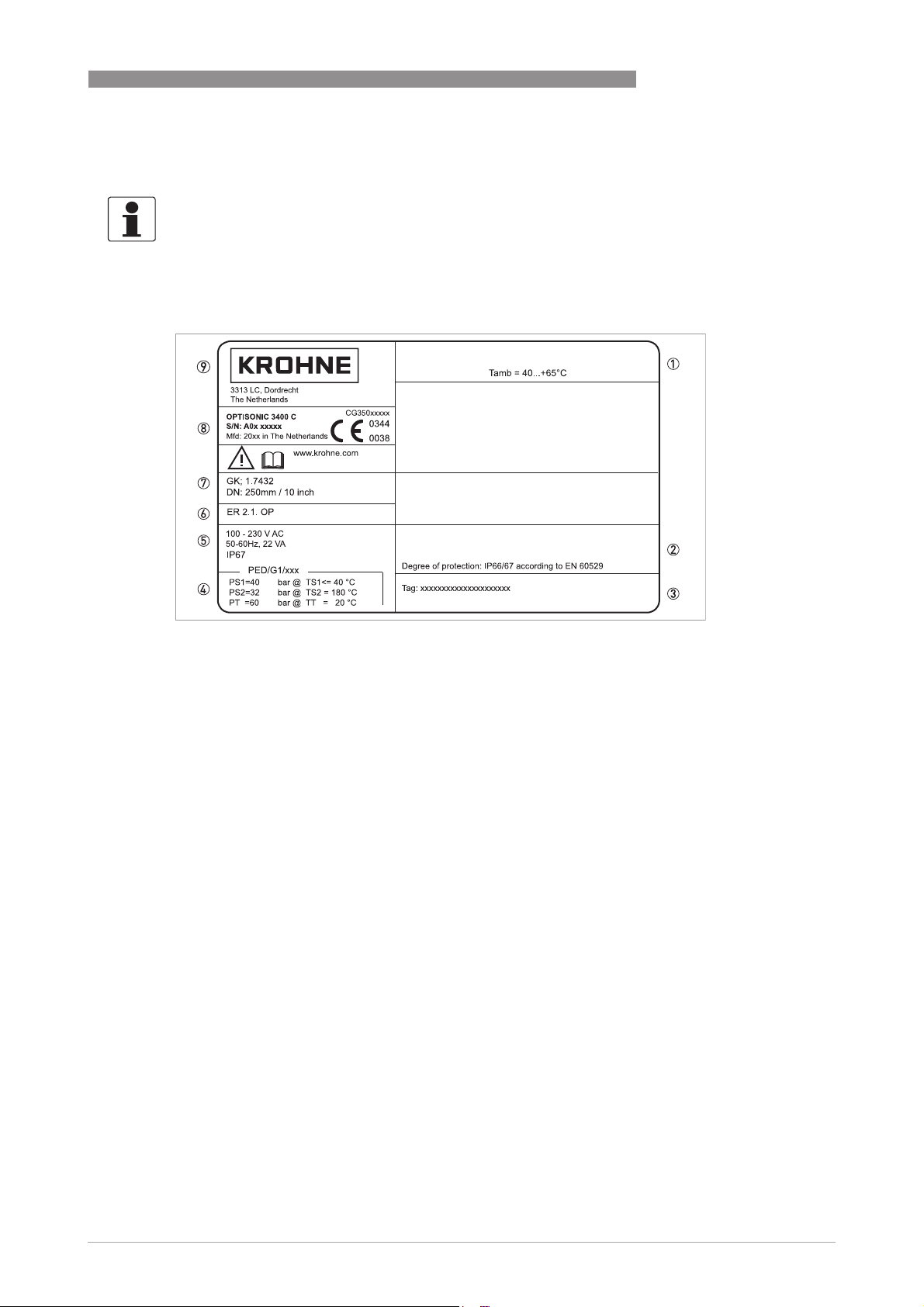

2.3.1 Example of nameplate for the compact version

INSTALLATION

2

Figure 2-2: Example of nameplate for the compact version

1 Ambient temperature

2 Protection class

3 Tag number

4 PED data, type I / II / II or SEP

5 Mains supply data

6 Electronic revision number

7 Calibration data

8 Type designation of the flowmeter and CE sign with number(s) of notified body / bodies

9 Name and address of the manufacturer

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

7

Page 8

2

INSTALLATION

2.3.2 Nameplate for the measuring sensor (field version)

Examples for measuring sensor versions in Standard version.

1. Ambient temperature

2. Protection class

3. Tag number

4. PED data, type I / II / II or SEP

5. Calibration data

6. Type designation of the flowmeter and CE sign with number(s) of notified body / bodies

7. Name and address of the manufacturer

OPTISONIC 3400

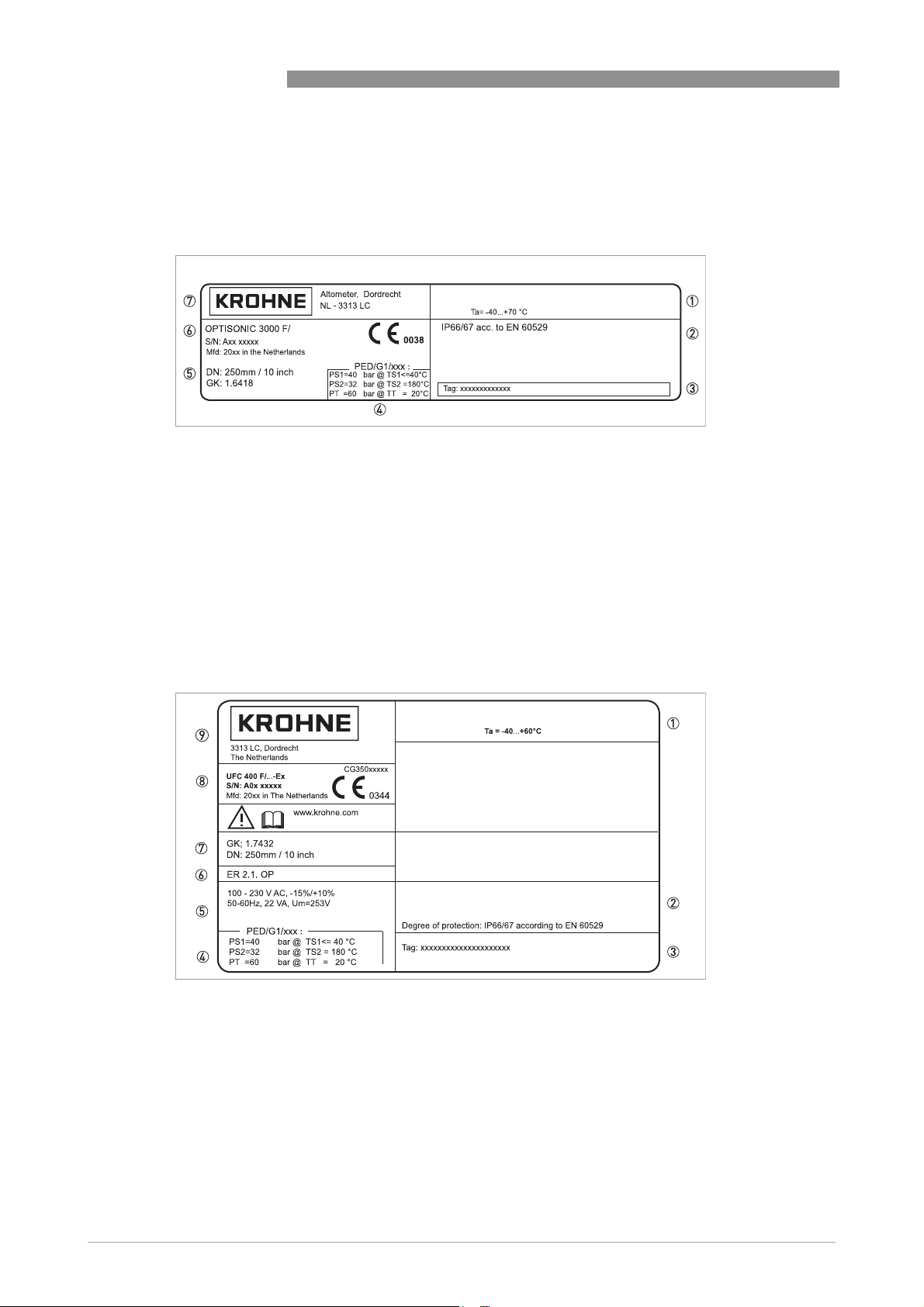

2.3.3 Examples of nameplates on the signal converter (field version)

Figure 2-3: Examples of nameplates on the signal converter (field version)

1 Ambient temperature

2 Protection class

3 Tag number

4 PED data, type I / II / II or SEP

5 Mains supply data

6 Electronics revision numbers

7 Calibration data

8 Type designation of the flowmeter and CE sign with number(s) of notified body / bodies

9 Name and address of the manufacturer

8

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 9

OPTISONIC 3400

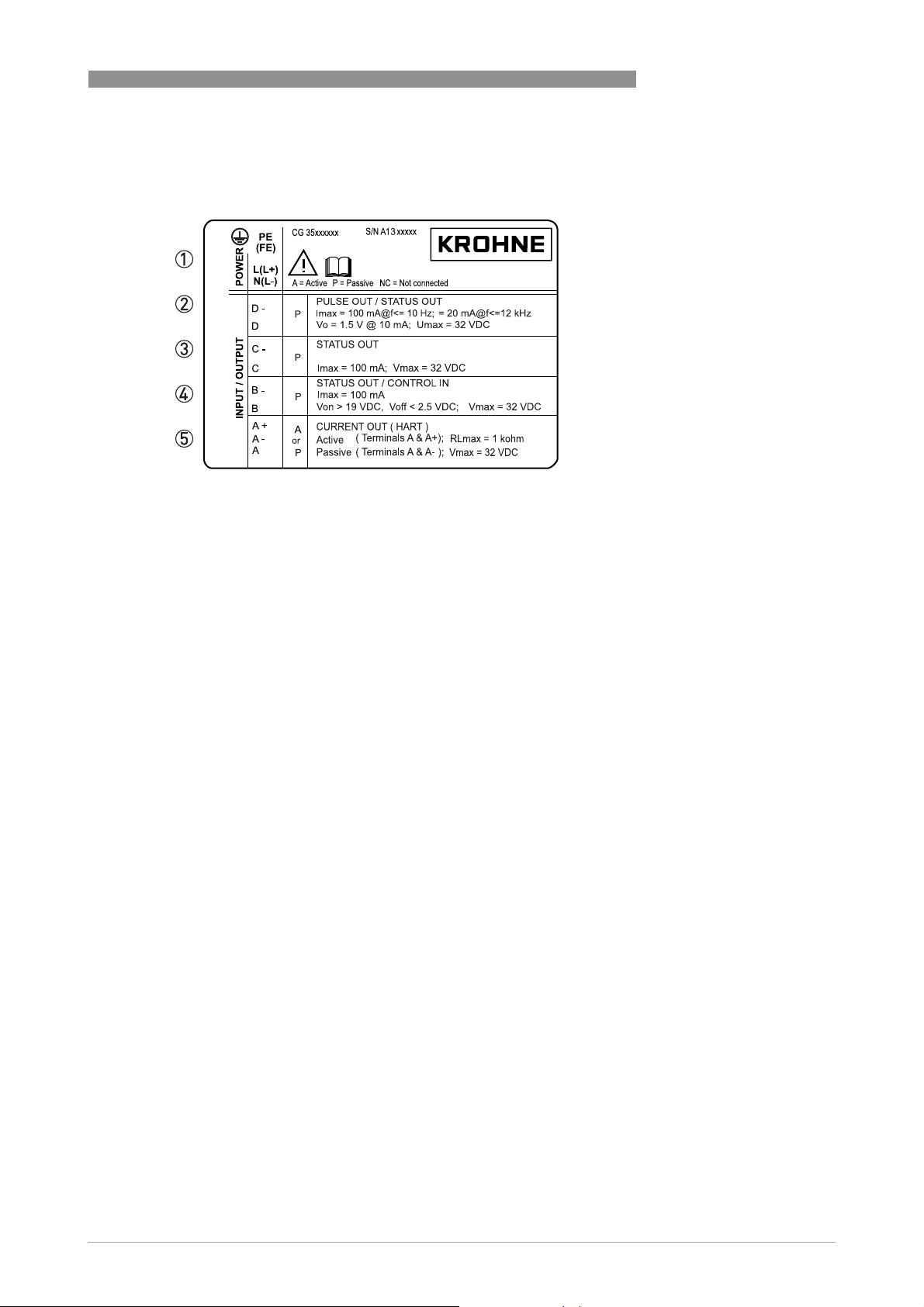

Electrical connection data of inputs/outputs (example of basic version)

Electrical connection data of inputs/outputs (example of basic version)

Electrical connection data of inputs/outputs (example of basic version)Electrical connection data of inputs/outputs (example of basic version)

1 Power supply (AC: L and N, DC: L+ and L-, PE for ≥ 24V AC, FE for ≤ 24 VAC and DC)

2 Connection data of connection terminal D/D-

3 Connection data of connection terminal C/C-

4 Connection data of connection terminal B/B-

5 Connection data of connection terminal A/A-, A+ only operable in basic version

INSTALLATION

2

• A = active mode; the signal converter supplies the power for connection of the subsequent

devices

• P = passive mode; external power supply required for operation of the subsequent devices

• N/C = connection terminals not connected

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

9

Page 10

2

INSTALLATION

2.4 Storage

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store the device in its original packaging.

• Storage temperature: -50...+70°C / -58...+158°F

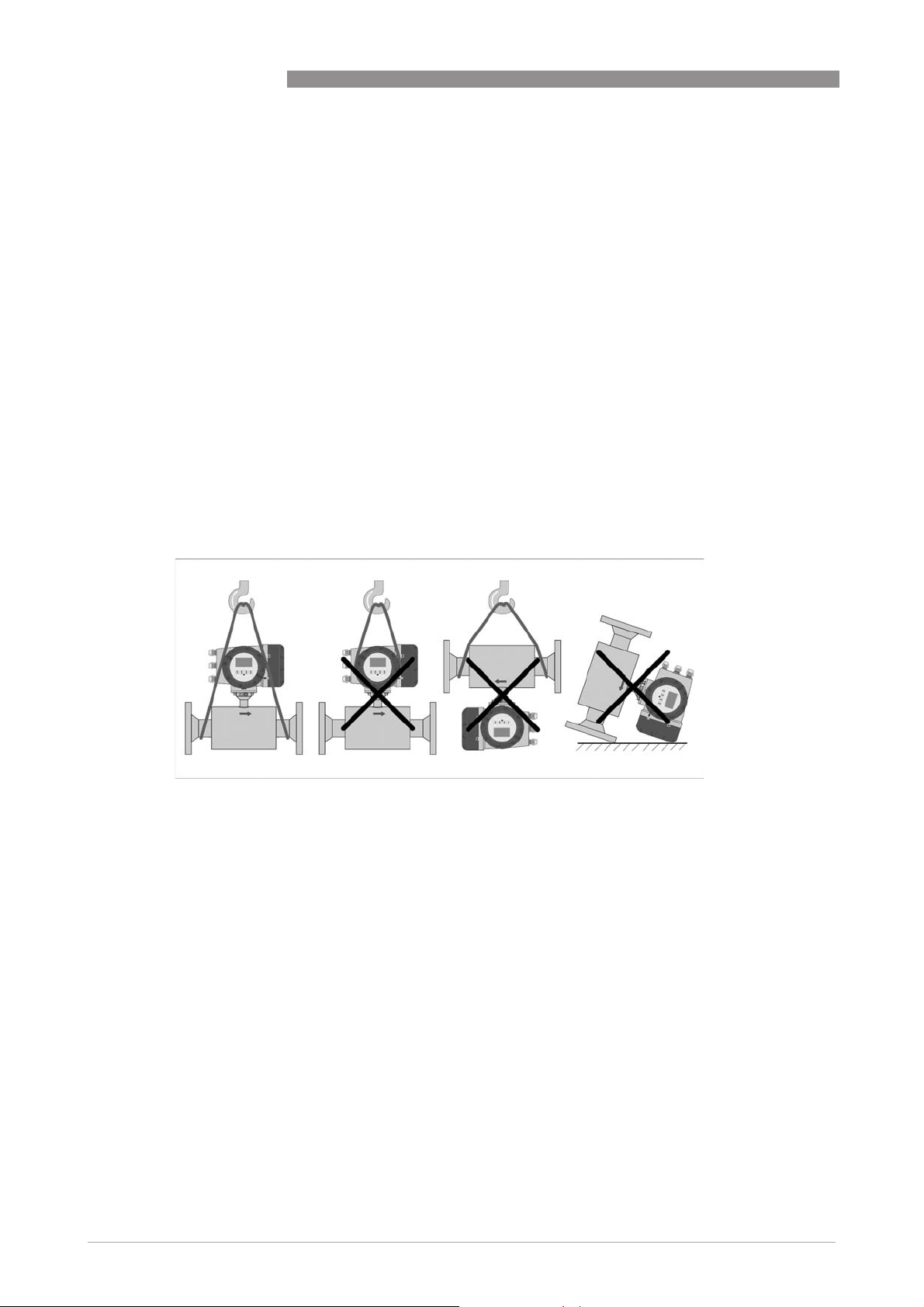

2.5 Transport

Signal converter

• Do not lift the signal converter by the cable glands.

Measuring sensor

• Do not lift the measuring sensor by the connection box.

• Use hoisting belts only.

• To transport flange devices, use lifting straps. Wrap these around both process connections.

OPTISONIC 3400

Figure 2-4: Transport

10

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 11

OPTISONIC 3400

2.6 Pre-installation requirements

INFORMATION!

To assure a quick, safe and uncomplicated installation, we kindly request you to make provisions

as stated below.

Make sure that you have all necessary tools available:

• Allen key (4 mm)

• Small screwdriver

• Wrench for cable glands

• Wrench for pipe mounting bracket (remote version only) see; on page 17

• Torque wrench for installing flowmeter in pipeline

2.7 General requirements

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibration. The flowmeters are tested for a

vibration level in accordance with IEC 68-2-6.

INSTALLATION

2

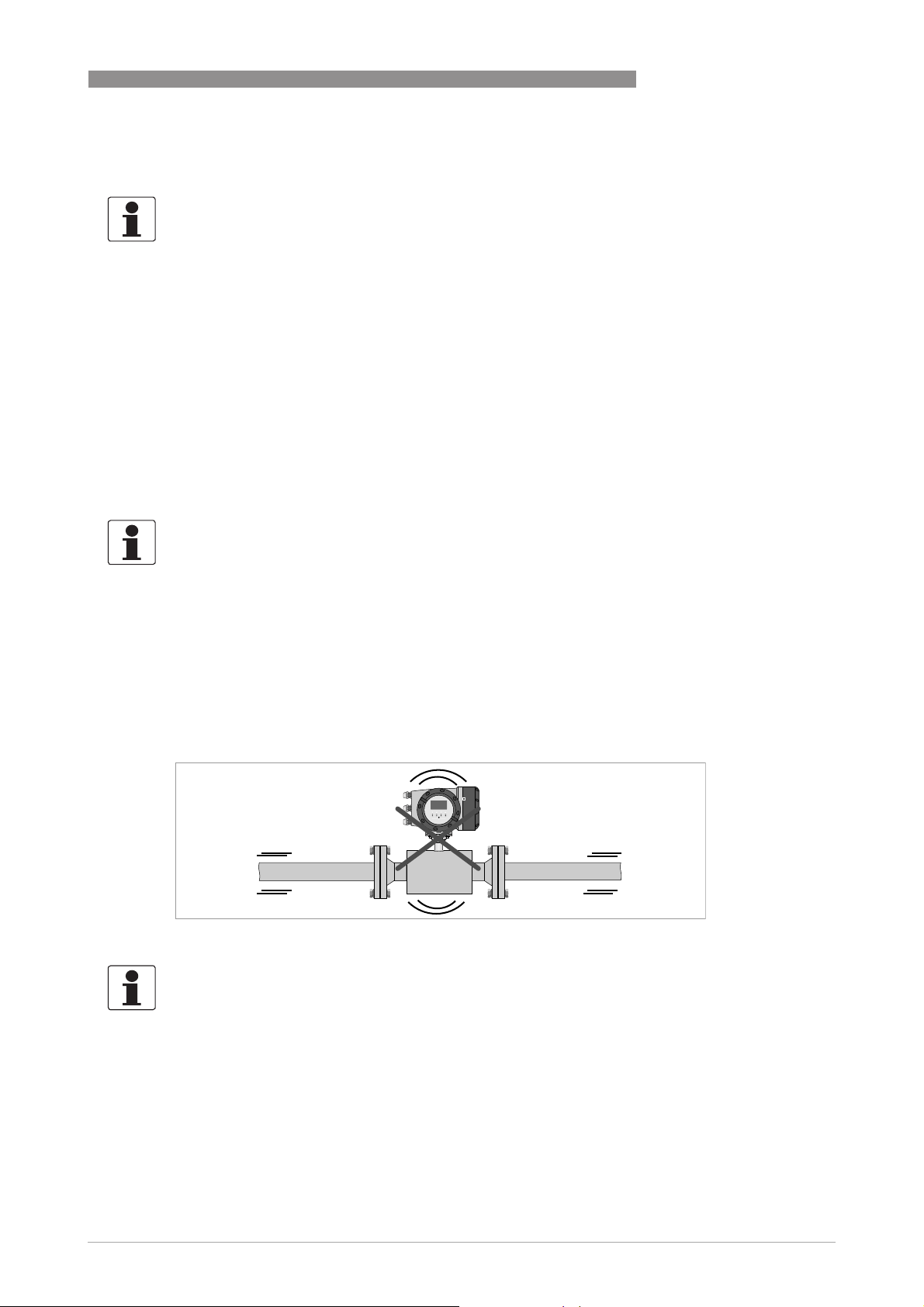

2.7.1 Vibration

Figure 2-5: Avoid vibrations

INFORMATION!

In case of expected vibrations, please install a field version.

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

11

Page 12

2

INSTALLATION

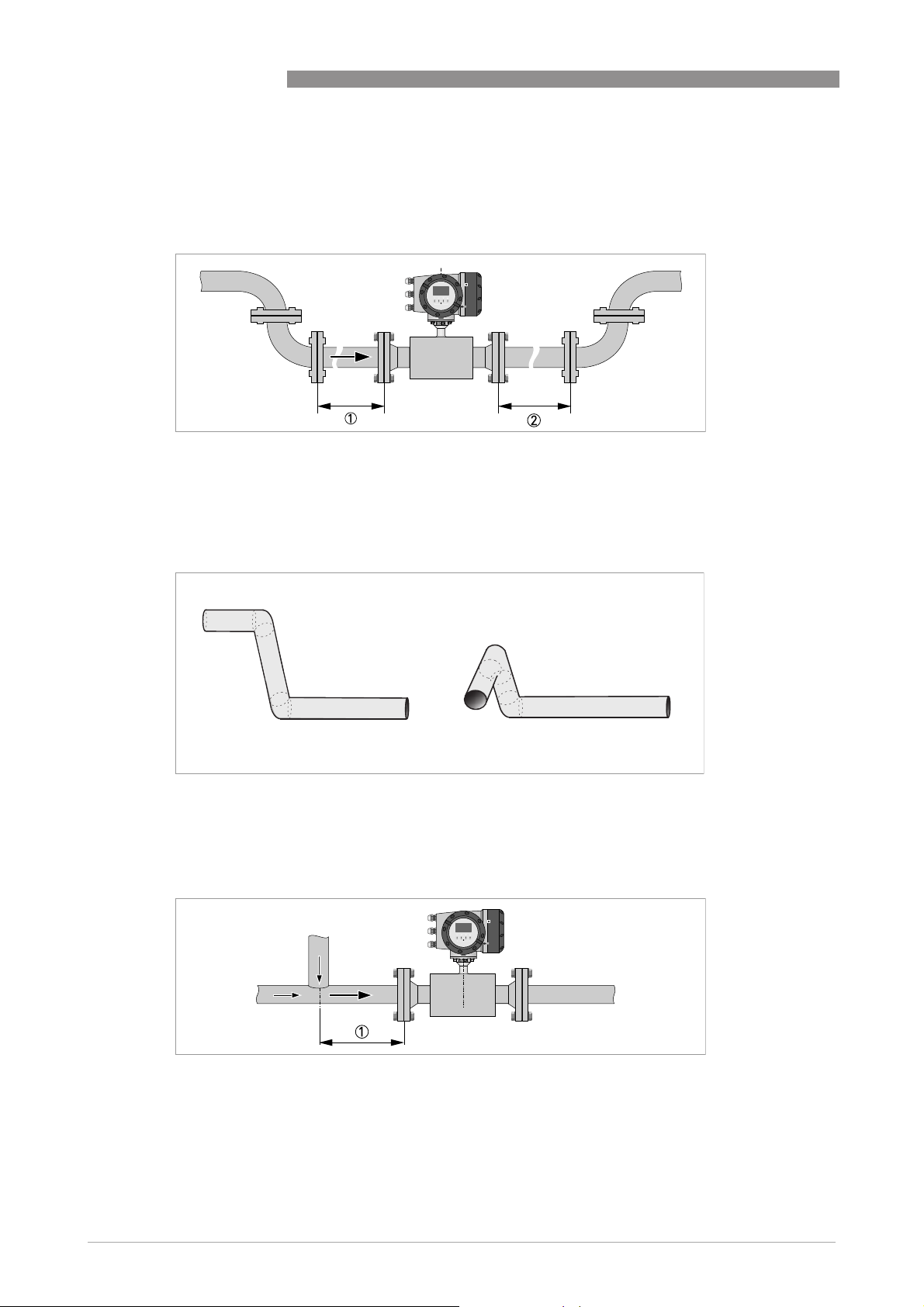

2.8 Installation conditions

2.8.1 Inlet and outlet

Figure 2-6: Recommended inlet and oulet

1 Refer to chapter "Bends in 2 or 3 dimensions"

2 ≥ 3 DN

2.8.2 Bends in 2 or 3 dimensions

OPTISONIC 3400

Figure 2-7: 2 and 3 dimensional bends, in front of flowmeter

1 Bends in 2 dimensions: ≥ 5 DN; bends in 3 dimensions: ≥ 10 DN

2.8.3 T-section

Figure 2-8: Distance behind a T-section

1 ≥ 5 DN

12

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 13

OPTISONIC 3400

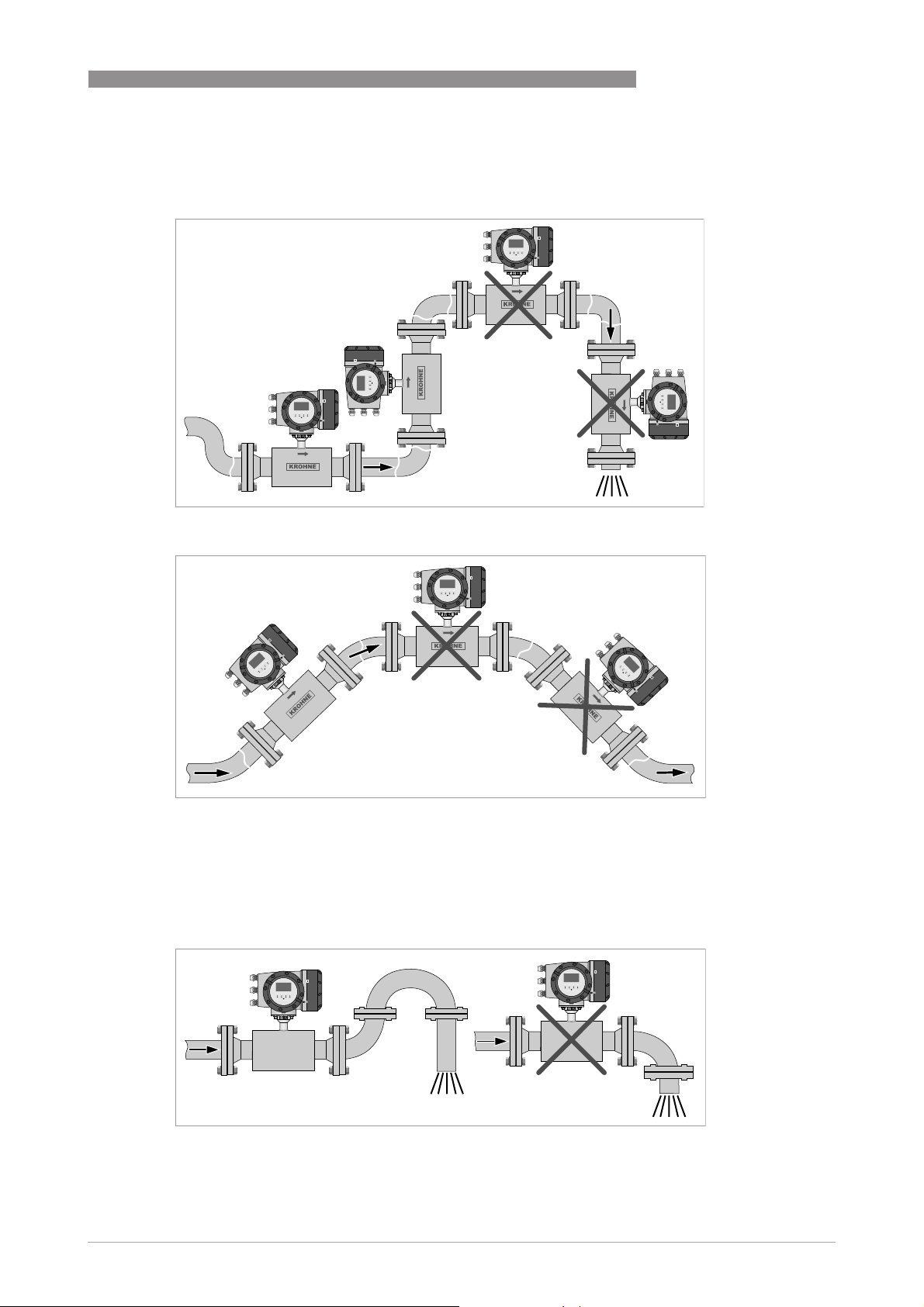

2.9 Bends

Figure 2-9: Installation in bending pipes

INSTALLATION

2

Figure 2-10: Installation in bending pipes

2.10 Open feed or discharge

Figure 2-11: Open discharge

Install meter on a lowered section of the pipe to ensure a full pipe condition through the meter.

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

13

Page 14

2

INSTALLATION

2.11 Position of pump

CAUTION!

Never install flowmeter at a pump suction side in order to avoid cavitation or flashing in the

flowmeter.

Figure 2-12: Position of pump

1 ≥ 15 DN

OPTISONIC 3400

2.12 Control valve

Figure 2-13: Installation in front of a control valve

1 ≥ 20 DN

14

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 15

OPTISONIC 3400

2.13 Down going pipeline over 5 m /16 ft length

Install air vent downstream of the flowmeter to prevent vacuum. Although this will not harm the

meter, it may cause gases to come out of solution (cavitate) and interfere with proper

measurements.

INSTALLATION

2

Figure 2-14: Down going pipeline over 5 m / 16 ft length

1 ≥ 5 m / 16 ft

2 Install air vent

2.14 Insulation

Figure 2-15: Insulation

1 Connection box

2 Insulation area

WARNING!

The flow sensor can be insulated completely, except for the connection box.

(Ex: maximum temperature, refer to Ex supplement)

For devices used in hazardous area, additional maximum temperature and insulation

precautions apply. Please refer to the Ex documentation!

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

15

Page 16

2

INSTALLATION

2.15 Mounting

2.16 Flange deviation

CAUTION!

Max. permissible misalignment of pipe flange faces: M

accoording ASME B16.5 Individual flanges. See Appendix 12 ; Flange face aligment of the

General Piping Requirements DEP 31.38.01.11-GEN

0.5 degree,

max

OPTISONIC 3400

Figure 2-16: Flange deviation

1 M

max

2.17 Mounting position

Figure 2-17: Horizontal and vertical mounting

16

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 17

OPTISONIC 3400

2.18 Mounting the field housing, remote version

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

2.18.1 Pipe mounting

Figure 2-18: Pipe mounting of the field housing

INSTALLATION

2

1 Fix the signal converter to the pipe.

2 Fasten the signal converter using standard U-bolts and washers.

3 Tighten the nuts.

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

17

Page 18

2

INSTALLATION

2.18.2 Turning the display of the field housing version

OPTISONIC 3400

Figure 2-19: Turning the display of the field housing version

The display of the field housing version can be turned in 90° increments.

1 Unscrew the cover from the display and operation control unit.

2 Using a suitable tool, pull out the two metal puller devices to the left and right of the display.

3 Pull out the display between the two metal puller devices and rotate it to the required position.

4 Slide the display and then the metal puller devices back into the housing.

5 Re-fit the cover and tighten it by hand.

CAUTION!

The ribbon cable of the display must not be folded or twisted repeatedly.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

18

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 19

OPTISONIC 3400

3.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS

3

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Signal cable (remote versions only)

The flow sensor is connected to the signal converter via one signal cable, with 6 (labeled) inner

coax cables for the connection of three acoustic paths.

Figure 3-1: Construction of field version

1 Signal converter

2 Open connection box

3 Tool for releasing connectors

4 Marking on cable

5 Insert cable(s) into terminal compartment

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

19

Page 20

3

ELECTRICAL CONNECTIONS

CAUTION!

To ensure smooth functioning, always use the signal cable(s) included in the delivery.

OPTISONIC 3400

Figure 3-2: Clamp the cables on the shielding bush

1 Cables

2 Cable glands

3 Grounding clamps

4 Cable with metal shielding bush

Electrical connection - Standard version

Figure 3-3: Connect the cables in the connection box of the flow sensor

20

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 21

OPTISONIC 3400

Connection of flow sensor type Cryogenic and XXT

Figure 3-4: Connect the cables in the connection box of the flow sensor

INFORMATION!

Connect the cable on connector with similar numeral marking

ELECTRICAL CONNECTIONS

3

3.3 Power supply

WARNING!

When this device is intended for permanent connection to the mains.

It is required (for example for service) to mount an external switch or circuit breaker near the

device for disconnection from the mains. It shall be easily reachable by the operator and marked

as the disconnecting the device for this equipment.

The switch or circuit breaker and wiring has to be suitable for the application and shall also be in

accordance with the local (safety) requirements of the (building) installation

(e.g. IEC 60947-1 / -3)

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

INFORMATION!

The power terminals in the terminal compartments are equipped with additional hinged lids to

prevent accidental contact.

1 100...230 VAC (-15% / +10%), 22 VA

2 24 VDC (-55% / +30%), 12 W

3 24 VAC/DC (AC: -15% / +10%; DC: -25% / +30%), 22 VA or 12 W

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

21

Page 22

3

ELECTRICAL CONNECTIONS

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

100...230 VAC (tolerance range: -15% / +10%)

• Note the power supply voltage and frequency (50...60 Hz) on the nameplate.

• The protective ground terminal PE

clamp terminal in the terminal compartment of the signal converter

INFORMATION!

240 VAC+5% is included in the tolerance range.

24 VDC (tolerance range: -55% / +30%)

24 VAC/DC (tolerance ranges: AC: -15% / +10%; DC: -25% / +30%)

• Note the data on the nameplate!

• For measurement process reasons, a functional ground FE

separate U-clamp terminal in the terminal compartment of the signal converter.

• When connecting to functional extra-low voltages, provide a facility for protective separation

(PELV) (acc. to VDE 0100 / VDE 0106 and/or IEC 364 / IEC 536 or relevant national

regulations).

OPTISONIC 3400

PE of the power supply must be connected to the separate U-

PEPE

FE must be connected to the

FEFE

INFORMATION!

For 24 VDC, 12 VDC-10% is included in the tolerance range.

3.4 Laying electrical cables correctly

Figure 3-5: Protect housing from dust and water

1 Lay the cable in a loop just before the housing.

2 Tighten the screw connection of the cable entry securely.

3 Never mount the housing with the cable entries facing upwards.

4 Seal cable entries that are not needed with a plug.

22

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 23

OPTISONIC 3400

3.5 Inputs and outputs, overview

3.5.1 Combinations of the inputs/outputs (I/Os)

This signal converter is available with various input/output combinations.

Basic version

• Has 1 current output, 1 pulse output and 2 status outputs / limit switches.

• The pulse output can be set as status output/limit switch and one of the status outputs as a

control input.

Ex i version

• Depending on the task, the device can be configured with various output modules.

• Current outputs can be active or passive.

• Optionally available also with Foundation Fieldbus and Profibus PA

Modular version

• Depending on the task, the device can be configured with various output modules.

ELECTRICAL CONNECTIONS

3

Bus systems

• The device allows intrinsically safe and non intrinsically safe bus interfaces in combination

with additional modules.

• For connection and operation of bus systems, please note the separate documentation.

Ex option

• For hazardous areas, all of the input/output variants for the housing designs C and F with

terminal compartment in the Ex d (pressure-resistant casing) or Ex e (increased safety)

versions can be delivered.

• Please refer to the separate instructions for connection and operation of the Ex-devices.

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

23

Page 24

3

ELECTRICAL CONNECTIONS

3.5.2 Description of the CG number

Figure 3-6: Marking (CG number) of the electronics module and input/output variants

1 ID number:5

2 ID number: 0 = standard

3 Power supply option

4 Display (language versions)

5 Input/output version (I/O)

6 1st optional module for connection terminal A

7 2nd optional module for connection terminal B

The last 3 digits of the CG number (5, 6 and 7) indicate the assignment of the terminal

connections. Please refer to the following examples.

Examples for CG number

OPTISONIC 3400

CG 350 x1 100 100...230 VAC & standard display; basic I/O: Ia or Ip & Sp/Cp & Sp & Pp/S

p

CG 350 x1 7FK 100...230 VAC & standard display; modular I/O: Ia & PN/SN and optional module PN/SN & C

CG 350 x1 4EB 24 VDC & standard display; modular I/O: Ia & Pa/Sa and optional module Pp/Sp & I

p

Description of abbreviations and CG identifier for possible optional modules

on terminals A and B

Abbreviation Identifier for CG No. Description

I

a

I

p

Pa / S

a

Pp / S

p

PN / S

N

C

a

C

p

C

N

- 8 No additional module installed

- 0 No further module possible

A Active current output

B Passive current output

C Active pulse output, frequency output, status output or limit switch

(changeable)

E Passive pulse output, frequency output, status output or limit switch

(changeable)

F Passive pulse output, frequency output, status output or limit switch acc.

to NAMUR (changeable)

G Active control input

K Passive control input

H Active control input to NAMUR

Signal converter monitors cable breaks and short circuits acc. to

EN 60947-5-6. Errors indicated on LC display. Error messages possible

via status output.

N

24

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 25

OPTISONIC 3400

3.5.3 Fixed, non-alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Connection terminal A+ is only operable in the basic input/output version.

CG-No. Connection terminals

A+ A A- B B- C C- D D-

Basic in-/output (I/O) (Standard)

1 0 0

Ip + HART® passive

Sp / Cp passive

1

ELECTRICAL CONNECTIONS

2

Sp passive Pp / Sp passive

2

3

Ia + HART® active

1

Ex-i in-/outputs (Option)

2 0 0

3 0 0

2 1 0 Ia active PN / SNNAMUR

passive

C

p

3 1 0 Ia active PN / SNNAMUR

passive

C

p

2 2 0 Ip passive PN / SNNAMUR

Cp passive

3 2 0 Ip passive PN / SNNAMUR

passive

C

p

1 Function changed by reconnecting

2 Changeable

2

2

2

2

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

PN / SN NAMUR

PN / SN NAMUR

PN / SN NAMUR

PN / SN NAMUR

PN / SNNAMUR

PN / SNNAMUR

2

2

2

2

2

2

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

25

Page 26

3

ELECTRICAL CONNECTIONS

3.5.4 Alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Term. = (connection) terminal

CG no. Connection terminals

A+ A A- B B- C C- D D-

Modular IOs (option)

4 _ _ max. 2 optional modules for term. A + B

8 _ _ max. 2 optional modules for term. A + B

6 _ _ max. 2 optional modules for term. A + B

B _ _ max. 2 optional modules for term. A + B

7 _ _ max. 2 optional modules for term. A + B

C _ _ max. 2 optional modules for term. A + B

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

OPTISONIC 3400

Pa / Sa active

Pa / Sa active

Pp / Sp passive

Pp / Sp passive

PN / SN NAMUR

PN / SN NAMUR

1

1

1

1

1

1

PROFIBUS PA/DP

D _ _ max. 2 optional modules for term. A + B PA+ (2) PA- (2) PA+ (1) PA- (1)

F _ _ max. 2 optional modules for term. A + B PA+ (2) PA- (2) PA+ (1) PA- (1)

FOUNDATION Fieldbus (option)

E _ _ max. 2 optional modules for term. A + B V/D+ (2) V/D- (2) V/D+ (1) V/D- (1)

Modbus (option)

G _ _

2

1 changeable

2 not activated bus terminator

max. 2 optional modules for term. A + B CommonSign. B

(D1)

Sign. A

(D0)

26

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 27

OPTISONIC 3400

4.1 Dimensions and weights

Remote version

Remote version a = 88 mm / 3.5"

Remote versionRemote version

Compact version

Compact version a = 155 mm / 6.1"

Compact versionCompact version

TECHNICAL DATA

b = 139 mm / 5.5"

c = 106 mm / 4.2"

Total height = H + a

b = 230 mm / 9.1"

c = 260 mm / 10.2"

Total height = H + a

1

2

1

2

4

1 The value may vary depending on the used cable glands.

2 The value depends on version

4.2 Variants

Standard version and

Standard version and

Standard version and Standard version and

Extended temperature -

Extended temperature -

Extended temperature - Extended temperature High Viscosity -

High Viscosity -

High Viscosity - High Viscosity -

Cryogenic versions;

Cryogenic versions;

Cryogenic versions;Cryogenic versions;

≤ DN300 / 12"

DN300 / 12"

DN300 / 12" DN300 / 12"

Standard version;

Standard version;

Standard version;Standard version;

≥ DN350 / 14"

DN350 / 14"

DN350 / 14" DN350 / 14"

Extended temperature -

Extended temperature -

Extended temperature - Extended temperature High Viscosity -

High Viscosity -

High Viscosity - High Viscosity -

Cryogenic version;

Cryogenic version;

Cryogenic version; Cryogenic version;

≥ DN350 / 14"

DN350 / 14"

DN350 / 14" DN350 / 14"

DIN: L= 250...500 mm /

9.8"...19.7"

ANSI: L= 250...500 mm /

9.8"...19.7"

* for Cryo - HV - XXT

versions;

ANSI: L= 250...550 mm /

9.8"...21.7"

DIN: L= 500..600 mm /

19.7"...23.6"

ANSI: L= 700...800 mm /

27.6"...31.5"

DIN: L= 500...750 mm /

19.7"...29.5"

ANSI: L= 700...850 mm /

27.6"...33.5"

For all dimensions and options; see tables on next pages (tables not final)

Note; the cCSA versions ( DN25...65 / 1...2.5") are manufactured with a heavy duty neck (SS)

which is 3.6 mm / 0.14 inch higher.

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

27

Page 28

4

TECHNICAL DATA

4.3 Standard flow sensor

The following dimensions are applicable for the OPTISONIC 3400 in compact and remote

versions;

EN1092-1; Standard variant - PN40

OPTISONIC 3400

Nominal

Dimensions [mm], Approx weight

size

DN L H W Di CS Di SS CS SS

25 250 155 115 27 27 8 8

32 260 156 140 35 35 9 10

40 270 173 150 39 41 11 14

50 300 193 165 53 53 14 17

65 300 203 185 63 63 18 19

80 300 238 200 78 81 17 18

100 350 268 235 102 104 24 24

125 350 297 270 127 130 30 29

150 400 326 300 154 158 37 37

200 400 427 375 207 207 63 63

250 500 492 450 260 260 100 100

300 500 547 515 308 308 140 140

EN1092-1; Standard variant - PN25

Nominal

size

Dimensions [mm] Approximate weight

[kg]

[kg]

28

DN L H W Di CS Di SS CS SS

100 350 268 235 102 104 24 23

125 350 297 270 127 130 30 29

150 400 326 300 154 158 37 37

200 400 419 360 207 207 61 61

250 450 479 425 255 255 80 80

300 500 532 485 305 305 102 102

350 500 539 555 330 330 126 126

400 600 596 620 379 379 172 167

450 700 654 670 441 441 199 199

500 700 707 730 488 488 252 252

600 800 817 845 588 588 335 355

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 29

OPTISONIC 3400

EN1092-1; Standard variant - PN16

TECHNICAL DATA

4

Nominal

Dimensions [mm] Approximate weight

size

DN L H W Di CS Di SS CS SS

100 350 261 220 102 104 20 19

125 350 287 250 127 130 20 20

150 350 319 285 154 158 30 29

200 400 409 340 207 207 51 47

250 400 469 405 255 255 64 64

300 500 520 460 305 305 84 84

EN1092-1; Standard variant - PN10

Nominal

size

DN L H W Di CS Di SS CS SS

200 400 409 340 207 207 48 48

250 400 464 395 255 255 55 55

300 500 512 445 305 305 71 71

350 500 517 505 341 341 69 69

400 600 572 565 388 388 90 90

450 600 623 615 441 441 97 101

500 600 674 670 487 487 118 118

600 600 779 780 585 585 157 157

Dimensions [mm] Approximate weight

[kg]

[kg]

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

29

Page 30

4

TECHNICAL DATA

ASME 150 lb Standard variant

OPTISONIC 3400

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] kg] [lb] [kg]

1 9,8 250 6,0 152 4,3 108 1,1 27 20 9 22 10

1¼ 10,2 260 6,3 161 4,6 117 1,4 35 22 10 22 10

1½ 10,6 270 6,9 174 5,0 127 1,5 1 39 1 26 12 26 12

2 11,8 300 7,4 187 6,0 152 2,1 53 33 15 35 16

2½ 11,8 300 8,7 221 7,0 178 2,5 63 42 19 44 20

3 13,8 350 9,2 233 7,5 191 3,1 78 44 20 44 20

4 13,8 350 10,4 265 9,0 229 4,0 102 57 26 60 27

5 13,8 350 11,4 289 10,0 254 5,0 128 71 32 73 33

6 15,7 400 12,4 316 11,0 279 6,1 154 88 40 90 41

8 15,7 400 16,1 408 13,5 343 8,0 203 110 50 108 49

10 19,7 500 18,5 470 16,0 406 10,0 255 161 73 150 68

12 19,7 500 20,9 531 19,0 483 12,0 305 214 97 209 95

14 27,6 700 20,9 531 21,0 533 13,3 337 260 118 249 113

16 31,5 800 23,2 589 23,5 597 15,3 388 342 155 315 143

18 31,5 800 25,0 635 25,0 635 17,2 438 406 184 348 158

20 31,5 800 27,2 692 27,5 699 19,3 489 489 222 448 203

24 31,5 800 31,5 801 32,0 813 23,0 1 584 1 761 345 591 268

28 35,4 900 35,8 909 36,5 927 27,1 1 687 1 1052 477 - 32 39,4 1000 40,4 1027 41,8 1061 30,8 1 783 1 1598 725 - 36 43,3 1100 39,5 1004 46,0 1168 34,8 1 884 1 2006 910 - 40 47,2 1200 48,9 1243 50,8 1289 38,6 1 980 1 2621 1189 - -

1 Inner Diameter SS differs from CS, consult KROHNE for more information

30

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 31

OPTISONIC 3400

ASME 300 lb Standard variant

TECHNICAL DATA

4

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

1 9,8 250 6,3 160 4,9 124 1,1 27 22 10 24 11

1¼ 10,2 260 6,6 169 5,3 133 1,4 35 22 10 22 10

1½ 10,6 270 6,9 175 6,1 155 1,6 41 31 14 31 14

2 11,8 300 7,6 194 6,5 165 2,1 53 35 16 37 17

2½ 11,8 300 9,0 227 7,5 191 2,5 63 44 20 44 20

3 13,8 350 9,6 243 8,3 210 3,1 78 53 24 55 25

4 15,7 400 10,9 278 10,0 254 4,0 102 79 36 82 37

5 15,7 400 11,9 301 11,0 279 5,0 128 97 44 99 45

6 17,7 450 13,2 335 12,5 318 6,1 154 128 58 130 59

8 17,7 450 16,8 427 15,0 381 8,0 203 190 86 179 81

10 19,7 500 19,2 489 17,5 445 9.7 1 248 1 280 127 256 116

12 23,6 600 21,4 544 20,5 521 11.8 1 299 1 421 191 388 176

14 27,6 700 22,0 560 23,0 584 13.1 1 333 1 489 222 467 212

16 31,5 800 24,3 617 25,5 648 15,0 381 688 312 642 291

18 31,5 800 26,5 674 28,0 711 16,5 1 419 1 882 400 811 368

20 31,5 800 28,8 731 30,5 775 18,4 1 467 1 1065 483 955 433

24 31,5 800 33,5 852 36,0 914 22,1 1 560 1 1537 697 1413 641

1 Inner Diameter SS differs from CS, consult KROHNE for more information

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

31

Page 32

4

TECHNICAL DATA

ASME 600 lb Standard variant

OPTISONIC 3400

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

1 10,6 270 6,3 160 4,9 124 1,1 27 24 11 24 11

1¼ 10,6 270 6,6 169 5,3 133 1,4 35 24 11 24 11

1½ 11,4 290 7,4 189 6,1 155 1,5 1 39 1 33 15 33 15

2 13,0 330 7,6 194 6,5 165 2,1 53 40 18 40 18

2½ 13,0 330 9,0 227 7,5 191 2,5 63 51 23 51 23

3 15,7 400 9,6 243 8,3 210 2,9 74 62 28 64 29

4 15,7 400 11,3 287 10,8 273 3,6 1 92 1 110 50 108 49

5 19,7 500 12,9 327 13,0 330 4,8 122 172 78 174 79

6 19,7 500 13,9 354 14,0 356 5,5 1 140 1 223 101 216 98

8 19,7 500 17,6 446 16,5 419 7,6 194 298 135 302 137

10 23,6 600 20,5 521 20,0 508 9,6 243 527 239 487 221

12 23,6 600 23,0 583 22,0 559 11,4 289 628 285 586 266

14 27,6 700 22,4 569 23,8 603 12,1 1 308 1 767 348 714 324

16 31,5 800 25,0 636 27,0 686 13,9 1 354 1 1093 496 1010 458

18 31,5 800 27,2 690 29,3 743 15,7 1 398 1 1338 607 1210 549

20 35,4 900 29,5 750 32,0 813 17,4 1 443 1 1757 797 1601 726

24 35,4 900 34,0 865 37,0 940 20,9 1 532 1 2480 1125 2238 1015

1 Inner Diameter SS differs from CS, consult KROHNE for more information

32

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 33

OPTISONIC 3400

ASME 900 lb Standard variant

TECHNICAL DATA

4

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

1 11,8 300 7,2 183 5,9 149 1,1 27 2 2 24 11

1½ 11,8 300 7,8 198 7,0 178 1,6 41 2 2 33 15

2 14,6 370 9,0 230 8,5 216 2,1 53 2 2 64 29

3 17,7 450 10,7 271 9,5 241 2,6 1 67 1 93 42 95 43

4 17,7 450 12,1 309 11,5 292 3,4 1 87 1 143 65 137 62

6 23,6 600 14,9 379 15,0 381 5,2 1 132 1 309 140 306 139

8 31,5 800 19,3 490 18,5 470 7,0 1 178 1 562 255 540 245

10 31,5 800 22,6 574 21,5 546 9,1 1 230 1 772 350 750 340

12 35,4 900 24,6 625 24,0 610 10,8 1 273 1 1080 490 1025 465

14 35,4 900 23,2 589 25,2 641 11,8 1 300 1 1213 550 1146 520

16 39,4 1000 25,4 646 27,7 705 13,6 1 344 1 1565 710 1433 650

18 39,4 1000 28,0 712 31,0 787 15,3 1 387 1 2050 930 1940 880

20 43,3 1100 30,4 773 33,8 857 17,0 1 432 1 2624 1190 2535 1150

24 51,2 1300 36,1 916 41,0 1041 20,4 1 518 1 4718 2140 4475 2030

1 Inner Diameter SS differs from CS

2 Consult KROHNE for more information

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

33

Page 34

4

TECHNICAL DATA

OPTISONIC 3400

4.4 Variant flow sensor; XXT - High Viscosity and Cryogenic (SS) versions.

The following dimensions are applicable for the OPTISONIC 3400 in compact and remote

versions;

EN1092-1; Extended temperature - High Viscosity and Cryogenic (SS) version - PN40

Nominal

size

Dimensions [mm] Approx weight

[kg]

DN L H W Di CS Di SS CS SS

25 250 155 115 27 27 8 8

32 260 156 140 35 35 10 10

40 270 173 150 39 41 11 13

50 300 193 165 53 53 15 16

65 300 203 185 63 63 19 19

80 350 238 200 81 81 17 18

100 350 268 235 104 104 24 23

125 350 297 270 130 130 30 29

150 400 326 300 158 158 37 36

200 500 427 375 207 207 69 69

250 550 492 450 260 260 101 101

300 550 547 515 308 308 137 137

EN1092-1; Extended temperature - High Viscosity and Cryogenic (SS) version - PN25

Nominal

size

Dimensions [mm] Approximate weight

[kg]

34

DN L H W Di CS Di SS CS SS

100 350 268 235 104 104 29 29

125 350 297 270 130 130 29 29

150 400 326 300 158 158 38 38

200 500 419 360 207 207 61 61

250 550 479 425 260 259 82 82

300 550 532 485 308 308 108 108

350 600 594 555 338 338 148 148

400 650 652 620 389 389 186 186

450 700 702 670 439 439 223 223

500 750 752 730 488 488 290 290

600 800 857 845 586 586 362 362

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 35

OPTISONIC 3400

EN1092-1; Extended temperature - High Viscosity and Cryogenic (SS) version - PN16

TECHNICAL DATA

4

Nominal

size

Dimensions [mm] Approximate weight

[kg]

DN L H W Di CS Di SS CS SS

100 350 261 220 104 104 23 23

125 350 287 250 130 130 29 29

150 350 319 285 158 158 38 38

200 450 409 340 207 207 49 49

250 500 469 405 260 260 67 68

300 500 520 460 310 310 82 82

EN1092-1; Extended temperature - High Viscosity and Cryogenic (SS) version - PN10

Nominal

size

DN L H W Di CS Di SS CS SS

200 450 409 340 207 207 50 50

250 500 512 445 260 260 66 66

300 500 512 445 310 310 75 75

350 500 559 505 342 342 91 91

400 600 594 565 393 393 114 114

450 600 674 615 443 443 130 130

500 650 722 670 494 494 151 151

600 700 824 780 594 594 195 195

700 750 929 895 694 3 280 3

800 900 1039 1015 794 3 380 3

900 900 1137 1115 889 3 469 3

1000 1000 1247 1230 991 3 595 3

3 TBD - Consult KROHNE for more information

Dimensions [mm] Approximate weight

[kg]

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

35

Page 36

4

TECHNICAL DATA

ASME 150 lb - Extended temperature - High Viscosity and Cryogenic versions

OPTISONIC 3400

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

1 9,8 250 6,0 152 4,3 108 1,1 27 20 9 20 9

1¼ 10,2 260 6,3 161 4,6 117 1,4 35 24 11 22 10

1½ 10,6 270 6,9 174 5,0 127 1,6 41 26 12 24 11

2 11,8 300 7,4 187 6,0 152 2,1 53 33 15 33 15

2½ 11,8 300 8,7 221 7,0 178 2,5 63 42 19 42 19

3 13,8 350 9,2 233 7,5 191 3,1 78 44 20 44 20

4 13,8 350 10,4 265 9,0 229 4,0 102 57 26 57 26

5 13,8 350 11,4 289 10,0 254 5,0 128 71 32 71 32

6 15,7 400 12,4 316 11,0 279 6,1 154 88 40 88 40

8 17,7 450 16,1 408 13,5 343 8,0 203 119 54 115 52

10 21,7 550 18,5 470 16,0 406 10,0 255 168 76 159 72

12 21,7 550 20,9 531 19,0 483 12,0 305 216 99 216 99

14 27,6 700 20,9 531 21,0 533 13,3 337 311 141 298 135

16 31,5 800 23,2 589 23,5 597 15,3 388 399 181 373 169

18 31,5 800 25,0 635 25,0 635 17,2 438 470 213 414 188

20 31,5 800 27,2 692 27,5 699 19,3 489 560 254 518 235

24 33,5 850 31,5 801 32,0 813 23,3 591 869 394 692 314

28 35,4 900 37,2 945 36,5 927 27,1 1 687 1 1052 527 - 32 37,4 950 41,8 1062 41,8 1061 30,8 1 783 1 1598 769 - 36 41,3 1050 45,8 1163 46,0 1168 34,8 1 884 1 2006 963 - 40 43,3 1100 50,2 1276 50,8 1289 38,6 1 980 1 2621 1225 - -

1 Inner Diameter SS differs from CS, consult KROHNE for more information

36

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 37

OPTISONIC 3400

ASME 300 lb - Extended temperature - High Viscosity and Cryogenic versions.

TECHNICAL DATA

4

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

1 9,8 250 6,3 160 4,9 124 1,1 27 22 10 22 10

1¼ 10,2 260 6,6 169 5,3 133 1,4 35 24 11 22 10

1½ 10,6 270 6,9 175 6,1 155 1,6 41 31 14 29 13

2 11,8 300 7,6 194 6,5 165 2,1 53 35 16 35 16

2½ 11,8 300 9,0 227 7,5 191 2,5 63 44 20 44 20

3 13,8 350 9,6 243 8,3 210 3,1 78 53 24 53 24

4 15,7 400 10,9 278 10,0 254 4,0 102 79 36 79 36

5 15,7 400 11,9 301 11,0 279 5,0 128 97 44 97 44

6 17,7 450 13,2 335 12,5 318 6,1 154 128 58 128 58

8 19,7 500 16,8 427 15,0 381 8,0 1 203 1 203 92 187 85

10 21,7 550 19,2 489 17,5 445 9.7 1 248 1 288 135 265 120

12 23,6 600 21,4 544 20,5 521 11.8 1 299 1 428 194 392 178

14 27,6 700 24,0 609 23,0 584 13.1 1 333 1 536 243 518 235

16 31,5 800 26,2 665 25,5 648 15,0 381 699 317 697 316

18 31,5 800 28,4 722 28,0 711 16,5 1 419 1 941 427 871 395

20 31,5 800 30,5 774 30,5 775 18,4 1 467 1 1131 513 1023 464

24 33,5 850 34,8 884 36,0 914 22,1 1 560 1 1658 752 1530 694

1 Inner Diameter SS differs from CS, consult KROHNE for more information

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

37

Page 38

4

TECHNICAL DATA

ASME 600 lb - Extended temperature - High Viscosity and Cryogenic versions.

OPTISONIC 3400

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

1 10,6 270 6,3 160 4,9 124 1,1 27 24 11 24 11

1¼ 10,6 270 6,6 169 5,3 133 1,4 35 24 11 24 11

1½ 11,4 290 7,4 189 6,1 155 1,5 1 39 1 33 15 33 15

2 13,0 330 7,6 194 6,5 165 2,1 53 40 18 40 18

2½ 13,0 330 9,0 227 7,5 191 2,5 63 51 23 51 23

3 15,7 400 9,6 243 8,3 210 2,9 74 62 28 62 28

4 15,7 400 11,3 287 10,8 273 3,6 1 92 1 110 50 108 49

5 19,7 500 12,9 327 13,0 330 4,8 122 172 78 172 78

6 19,7 500 13,9 354 14,0 356 5,5 1 140 1 223 101 216 98

8 21,7 550 17,6 446 16,5 419 7,6 194 320 145 313 142

10 25,6 650 20,5 521 20,0 508 9,3 1 236 1 536 243 503 228

12 27,6 700 23,0 583 22,0 559 11,1 1 281 1 679 308 631 286

14 29,5 750 24,3 618 23,8 603 12,1 1 308 1 842 382 789 358

16 31,5 800 26,9 684 27,0 686 13,9 1 354 1 1155 524 1074 487

18 33,5 850 29,1 738 29,3 743 15,7 1 398 1 1442 654 1307 593

20 35,4 900 31,2 793 32,0 813 17,4 1 443 1 1832 831 1682 763

24 37,4 950 35,3 896 37,0 940 20,9 1 532 1 2630 1193 2383 1081

1 Inner Diameter SS differs from, consult KROHNE for more information

38

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 39

OPTISONIC 3400

ASME 900 lb - Extended temperature, High Viscosity and *Cryogenic versions.

TECHNICAL DATA

4

Nom.

size

Dimensions Inner diameter

[Di]

Approximate weight

L H W CS / SS 1 CS SS

[inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [lb] [kg] [lb] [kg]

3 17,7 450 10,7 271 9,5 241 2,6 1 67 1 93 42 93 42

4 17,7 450 12,1 309 11,5 292 3,4 1 87 1 143 65 141 64

6 23,6 600 14,9 379 15,0 381 5,2 1 132 1 309 140 304 138

8 31,5 800 18,6 472 18,5 470 7,0 1 178 1 540 245 503 228

10 31,5 800 21,6 550 21,5 546 8,5 1 216 1 809 367 756 343

12 35,4 900 24,0 609 24,0 610 10,1 1 257 1 1129 512 994 451

14 35,4 900 25,1 637 25,2 641 11,2 1 284 1 1303 591 1162 527

16 39,4 1000 27,3 694 27,7 705 13,1 1 333 1 1627 738 1517 688

18 39,4 1000 29,9 760 31,0 787 14,9 1 378 1 2112 958 2022 917

20 39,4 1000 32,6 828 33,8 857 16,5 1 419 1 2599 1179 2399 1088

24 51,2 1300 37,6 955 41,0 1041 19,9 1 505 1 4830 2191 4482 2033

1 Inner Diameter SS differs from CS, consult KROHNE for more information

*Cryogenic and XXT versions not available for 8"...24"

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

39

Page 40

4

TECHNICAL DATA

4.5 Signal converter housing

OPTISONIC 3400

1 Compact housing (C)

2 Field housing (F)

Dimensions and weights in mm and kg

Version Dimensions [mm] Weight

a b c d e g h

C 202 120 155 260 137 - - 4.2

F 202 120 155 - - 295.8 277 5.7

[kg]

Dimensions and weights in inch and lb

Version Dimensions [inch] Weight

a b c d e g h

C 7.75 4.75 6.10 10.20 5.40 - - 9.30

F 7.75 4.75 6.10 - - 11.60 10.90 12.60

[lb]

40

www.krohne.com 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

Page 41

OPTISONIC 3400

NOTES

5

www.krohne.com02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en

41

Page 42

KROHNE product overview

•

Electromagnetic flowmeters

•

Variable area flowmeters

•

Ultrasonic flowmeters

•

Mass flowmeters

•

Vortex flowmeters

•

Flow controllers

•

Level meters

•

Temperature assemblies

•

Pressure transmitters

•

Analysis products

•

Products and systems for the oil & gas industry

•

Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 203 301 0

Fax:+49 203 301 103 89

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 02/2015 - QS OPTISONIC 3400 - 4002741204-R04 en - Subject to change without notice.

www.krohne.com

Loading...

Loading...