Page 1

Corrosion Guide Rev 1.05 Jan 2006

OPTIMASS

•• 11000000 SSeerriieess TTwwiinn SSttrraaiigghhtt TTuubbee CCoorriioolliiss MMaassss FFlloowwmmeetteerr

•• 33000000 SSeerriieess SSiinnggllee ZZ TTuubbee CCoorriioolliiss MMaassss FFllo

owwmmeetteerr

•• 77000000 SSeerriieess SSiinnggllee SSttrraaiigghhtt TTuubbee CCoorriioolliiss MMaassss FFlloowwmmeetteerr

•• 88000000//99000000 SSeerriieess TTwwiinn UU TTuubbee CCoorri

ioolliiss MMaassss FFlloowwmmeetteerr

DDIISSCCLLAAIIMMEERR::

KROHNE does not represent or warrant the accuracy of the information included in this guide for end user applications. The data presented is based on

published data and field experience. However, only the end-user is aware of the specific chemical makeup of their process and must therefore accept the

ultimate responsibility for the suitability of the wetted parts for the process. Responsibility as to suitability and intended use of our instruments rests solely

with the end user!

Corrosion & Abrasion Guidelines for Coriolis Meters

Page 2

2

Corrosion Guide Rev 1.05 Jan 2006

Contents:

1 Corrosion of Wetted Parts

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Material Compatibility . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Material Information . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.1 What is Stainless Steel? . . . . . . . . . . . . . . . .4

1.4 NACE Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.5 Galvanic Corrosion with Titanium . . . . . . . . . . . . . . . .4

1.6 Problem Applications . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.7 Using Material Compatibility Tables . . . . . . . . . . . . . .5

2 Abrasion Guidelines

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.2 Protecting Flanges with Transition Pieces . . . . . . . . .14

2.3 Managing Fluid Velocity . . . . . . . . . . . . . . . . . . . . . . .14

2.4 Titanium as the standard material . . . . . . . . . . . . . . . .14

2.5 Conditioning the fluid flow . . . . . . . . . . . . . . . . . . . . . .15

2.6 Installation of the Flow Meter . . . . . . . . . . . . . . . . . . .15

2.7 Inclusion of air or gas in the fluid . . . . . . . . . . . . . . . .15

2.8 Consider installing the meter in a by-pass . . . . . . . . .15

2.9 Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3 Environmental Protection

3.1 Housing Specifications . . . . . . . . . . . . . . . . . . . . . . . .16

Page 3

Corrosion Guide Rev 1.05 Jan 2006

3

Element Typical Specification

C 0.013 0.035 Max

Mn 1.6 2.0 Max

P 0.028 0.045 Max

S 0.009 0.030 Max

Si 0.38 1.0 Max

Cr 16.84 16.0...18.0

Ni 11. 2 6 10.0...15.0

Mo 2.12 2.0...3.0

Fe Balance Balance

Specifications for SS316L

Element Typical Specification

Al 3.0 2.5...3.5

V 2.5 2.0...3.0

Fe 0.13 0.25 Max

C 0.05 0.08 Max

Ti Balance Balance

Specifications for Titanium Gr9

Stainless Steel

318L

7000 series

All wetted parts: UNS S31803 to

ASTM A789, A790, A479 and A240

(also known as DUPLEX Stainless

Steel SAF2205).

This 318L stainless steel is NACE

approved.

ALL hygienic and aseptic process

connections: 316L UNS 31603 or

equivalent (also NACE approved).

Hastelloy C22

7000 series

All wetted parts: UNS NO6022 to

ASTM B619, B622, B626, B574

and B575

This HC-22 is NACE approved.

Titanium

7000 series

Measuring tube: UNS R56320 to

ASTM B338 titanium grade 9

Flange raised faces: UNS R50400

to ASTM B348 and B265 titanium

grade 2.

Titanium grade 9 is not NACE

approved.

Stainless Steel

316L

3000, 8000 / 9000

series

All wetted parts: 316L UNS 31603

or equivalent.

316L is NACE Approved.

Hastelloy C22

3000, 8000 / 9000

series

All wetted parts: UNS NO6022 to

ASTM B622, B626, B564, B574

and B575.

Hastelloy C22 is NACE approved.

1. Corrosion Of Wetted Parts

1.1 Introduction:

General corrosion guidelines for process vessels,

pipework and parts (such as thermo-wells or MID

flowmeter earthing rings) cannot be applied to Coriolis

mass flowmeters, since they refer to the bulk removal

of material from comparatively thick walled components, and they also tend not to address specific

localised corrosion mechanisms.

Greater care must be taken in the case of mass

flowmeters, since the tube wall thicknesses are in the

region of 0.2 … 2mm (depending on meter size), so

the removal of even a small amount of material can

cause a measurement problem or a meter tube

mechanical failure.

Additionally, localised corrosion effects such as pitting

or stress corrosion cracking can occur even without

corrosion of the overall tube. If severe enough, these

effects may cause a meter tube mechanical failure.

For these reasons you will find that many fluids will be

shown as unsuitable in this guide for use with mass

flowmeters when compared to more general corrosion

guidelines.

1.2 Material Compatibility

1.3 Material information

The Optimass meter range can be supplied with wetted parts (measuring tubes and connections) in the following materials:

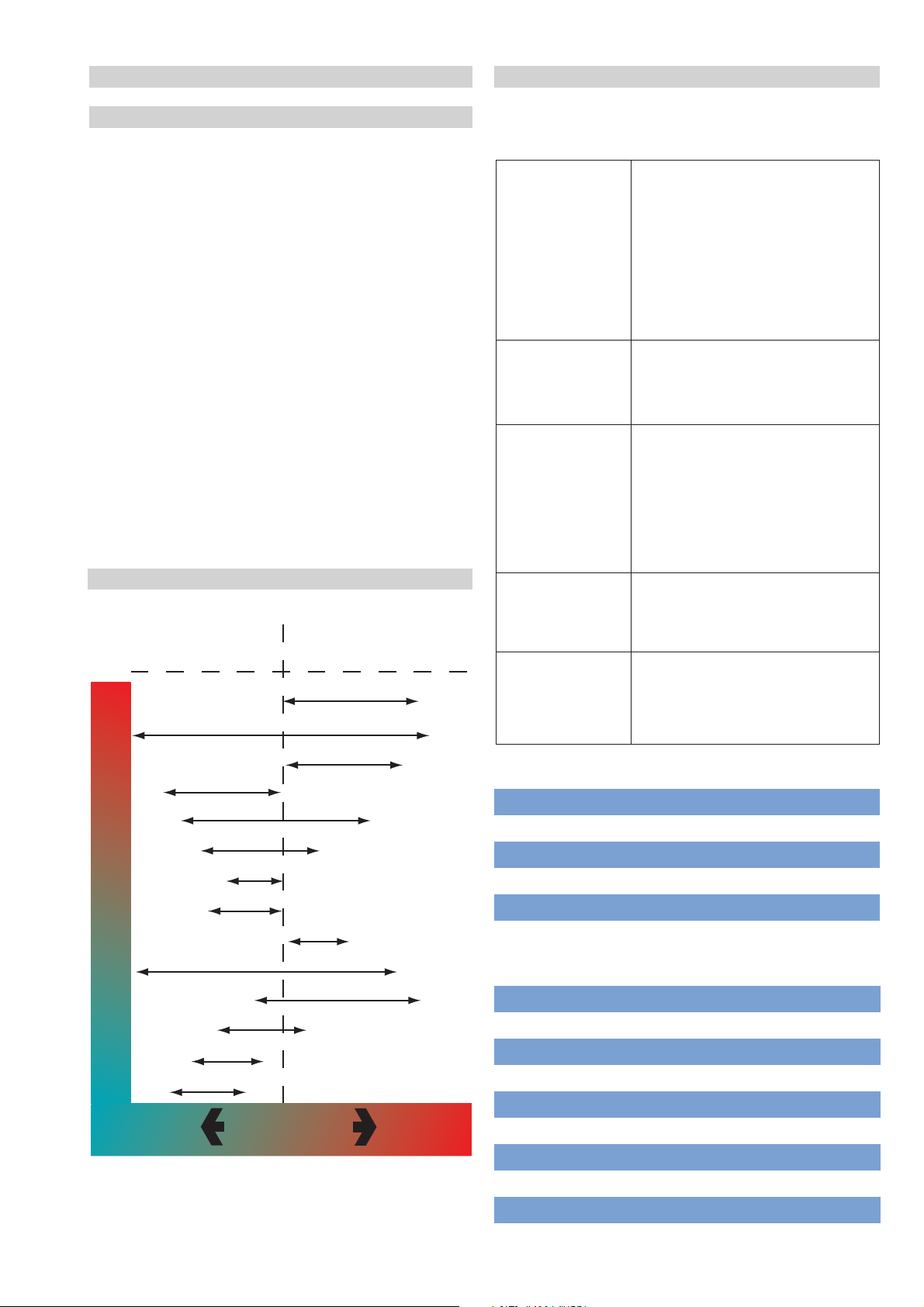

Oxidising

environment

Tantalum

Chlorides

Titanium

C-276

C-4

Ni-Cr-Mo Alloy

No 20 Alloy (Stainless)

Inconel

316 Stainless

Reducing

environment

Zirconium

Ni-Mo Alloy

C-22

Monel

Monel

304 Stainless

Non Chlorides

Oxidizing

Acids

Increasing

aggressivness

Reducing

Agents

Page 4

4

Corrosion Guide Rev 1.05 Jan 2006

Element Typical Specification

C 0.02 0.030 Max

Mn 0.70 2.0 Max

P 0.025 0.030 Max

S 0.001 0.020 Max

Si 0.40 1.0 Max

Cr 22.4 21.0...23.0

Ni 5.8 4.5...6.5

Mo 3.3 2.5...3.5

N 0.16 0.08...0.2

Fe Balance Balance

Specifications for SS318L

Element Typical Specification

Cr 21.6 20.00...22.5

Mo 13.7 12.5...14.5

W 2.9 2.5...3.5

Fe 4.7 2.0...6.0

Co 1.1 2.5 Max

Mn 0.3 0.5 Max

V 0.13 0.35 Max

Ni Balance Balance

Specifications for Hasteloy C22

Please be aware that 318L is a “shorthand” expression

KRONHE have adopted for the material to aid our customers’ understanding that the material is a low carbon

stainless steel of a speciifc composition, in the same

way that 316L is used as “shorthand” for UNS S31603.

318L is more expensive to use than 316L, but we need

to consider the technical benefits that it brings. 318L

has a much higher tensile strength compared to 316L.

We use this property in our meter to manage the stress

caused by lengthening of the tube under thermal

expansion. If we used 316L, the tube would deform

well below the +100

0

C maximum we specify for 318L.

The corrosion resistance of 318L is equal to 316L. The

standard surface roughness is similar and it can be polished to the same fine surface finish of <0.5 um Ra for

hygienic and aseptic applications. 318L is extensively

used worldwide, where customers utilise the higher tensile strength to reduce wall thickness (and so the cost

and weight) of process plant and piping. This means that

there should be no reluctance from our customers in

accepting this material.

KROHNE is the only company to offer a stainless steel

straight tube mass flowmeter.

1.4 NACE Information

National Association of Chemical Engineers (NACE standard MR0175-2000) is a material requirements standard

relating to the general problems of Sulphide Stress

Cracking (SSC) of metals directed towards sour environments.

1.5 Galvanic Corrosion with Titanium

This can occur when a titanium tube meter is placed in

contact with other metals, for instance in a steel

pipeline. As titanium is a “noble” metal, the other material will normally corrode in preference to the titanium.

In the case of stainless steel pipelines, titanium is very

close in the galvanic table therefore galvanic corrosion

is unlikely to be a problem and no precautions are necessary.

If carbon steel pipelines are used, galvanic corrosion of

the carbon steel may occur with certain acids. This corrosion process causes small amounts of hydrogen gas

to be liberated at the wetted metal-to-metal contact

area. This hydrogen gas may then cause embrittlement

in the titanium. This can be avoided by electrically insulating the Optimass from the pipeline using insulating

gaskets, bolt sleeves and washers.

Of course the use of an alternative tube material e.g.

Hastelloy C-22 will prevent the problem entirely.

1.3.1 What is 318L Stainless steel?

Many customers have asked “what is the 318L stainless

steel that you use in the Optimass 7000 single straight

tube meter, and why do you use this material instead of

316L”? Measuring instruments are more normally manufactured with wetted parts from 316L stainless steel,

which is a 100% austenic structure steel, with composition 18% .Chrome, 8% Nickel, 2.5% Molybdenum, with

the balance Iron.

318L is a 50% austenitic / 50% ferritic structure steel

(typically known as "duplex"), with (typical) composition

22% Chrome, 5% Nickel, 3% Molybdenum, with the balance Iron.

This material is defined under the following international codes:

•

UNS S31803

•

ASTM A789, A790, A479, A420

•

DIN 1.4462

Page 5

Corrosion Guide Rev 1.05 Jan 2006

5

Remember in all cases KROHNE cannot accept

responsibility for the final choice of material. The ultimate responsibility lies with the end user. We can only

advise based on our experience!

Explanation of data tables

1. Key to symbols used

Symbol Meaning

Suitable, with a corrosion rate less than

0.05 mm (0.002”) per year

X Unsuitable, due to higher corrosion rate

nd No data is currently available

1.6 Problem Applications

Hydrochloric acid (HCl):

This acid normally contains fluoride and chloride impurities that will promote stress corrosion cracking in all

tube materials. This effect will always cause a meter

failure even if there is no bulk removal of tube material.

For this reason we do not recommend Optimass

meters for any HCl application.

Instead look to alternative instrument technologies such

as capacitive MID (Capaflux) or variable area flowmeters (H250 PTFE).

Methanol:

“Pure” methanol (> 98% purity) tends to cause the

removal of the protective oxide layer on a titanium

measuring tube thus promoting corrosion. Titanium

therefore cannot be used. Stainless steel or Hastelloy

C-22 are suitable alternatives for these applications.

Methanol with a minimum 2%, or greater, water content

does not exhibit this tendency and can be freely used

with all tube materials.

Oxygen gas:

There is a risk of ignition where an oxygen rich (> 35%

O

2

) gas mixture is used with a titanium measuring

tube.Always offer stainless steel as an

alternative.Remember also that the “degreasing” option

for wetted parts should also be offered for use with oxygen gas applications.

Passivation of meters

A “passivation fluid” is normally composed of a mixture

of nitric acid (HNO

3

) and hydrofluoric acid (HF) and is

used to ‘passivate’ (clean) stainless steel pipework in

high purity systems, typically found in the pharmaceutical industry. The process removes weld discoloration,

dirt, grease, metal particles, etc.

The nitric acid has negligible corrosive effect, but

hydrofluoric acid is very aggressive even at levels less

than 0.5% for all wetted tube materials. It is recommended that any meter is removed and replaced with

spool pieces during the passivation process. This is

due to the relatively thin wall of mass flow meter tubes;

the customer’s pipework being relatively thick is tolerant to a small loss of material.

1.7 Using Material Compatibility Tables.

Identify the chemical to be used either by name or by

the Formula.

Check that you know the concentration of the chemical

and that it is within the concentrations listed in column

3.

Identify the best material for the application and then

check that this is acceptable for the customer.

2. Where a temperature is given, this signifies suitability only up to this point (e.g. 212/100 denotes

up to 212

o

F or 100oC). Where no temperature is

given, this signifies suitability up to the lower of

either the boiling point of the product, or the

maximum operating temperature of the Optimass

flowmeter concerned.

The first temperature given is always in Fahrenheit

and the second in Centigrade/Celsius.

3. Always check the relevant technical data sheet

for the maximum operating temperature of the

meter series and wetted material.

4. For the purposes of corrosion resistance, stainless steel grades 316L and 318L can be considered as both being the same.

Page 6

6

Corrosion Guide Rev 1.05 Jan 2006

Fluid Chem. Formula Concentration

Stainless Steel

Max

oF/o

C

Hastelloy C-22

Max

oF/o

C

Titanium

Max

oF/o

C

Acetaldehyde CH3CHO 100% 200/93 200/93 300/149

Acetate CH3CO2CH3 100% 400/204 400/204 400/204

Acetic Acid CH3COOH 20% 400/204 300/149 260/127

Acetic Acid CH3COOH 50% 160/71 210/99 260/127

Acetic Acid CH3COOH 80% 160/71 210/99 260/127

Acetic Acid CH3COOH 95% X 200/93 210/99

Acetic Acid CH3COOH 100% X 200/93 200/93

Acetone CH3COCH3 100% 400/204 140/60 200/93

Acetyl Chloride CH3COCI 100% 70/21 99/37 220/105

Acetylene CH2 100% 400/204 220/105 79/26

Adipic Acid (CH2)5(COOH)2 100% 50/10 200/93 428/220

Air

Aluminium Chloride AlCl3 10% X 220/105 200/93

Aluminium Chloride AlCl3 40% X 220/105 X

Aluminium Chloride AlCl3 100% X 158/70 X

Aluminium Fluoride AlCl3 20% X X X

Aluminium Nitrate AlNO3 100% 302/150 X 208/98

Aluminium Sulphate Al2SO4 6.50% X 285/140 220/105

Aluminium Sulphate Al2SO4 40% X 285/140 220/105

Aluminium Sulphate Al2SO4 100% X nd 200/93

Ammonia (anhydrous) dry NH3 always 100% 248/120 248/120 77/25

Ammonia (aqueous) NH3 + water 30% 158/70 158/70 X

Ammonia (aqueous) NH3 + water 50% 86/30 302/150 X

Ammonium Acetate NH4CH3COO 15% 220/105 220/105 77/25

Ammonium Acetate NH4CH3COO 55% 170/77 nd nd

Ammonium Bicarbonate NH4HCO3 50% X nd 212/100

Ammonium Carbonate (NH4)2CO3 50% X X

Ammonium Chlorate (NH4)ClO3 30% nd nd 122/50

Ammonium Chloride NH4Cl 40% X 221/105 221/105

Ammonium Fluoride NH4F 25% X 170/77 nd

Ammonium Hydroxide NH4OH 45% X X 170/77

Ammonium Nitrate NH4NO3 28% 280/137 80/27

Ammonium Oxalate (NH4)C2O4 10% X 75/24 75/24

Ammonium Perchlorate NH4ClO4 20% 170/77 X 285/140

Ammonium Phosphate (NH4)3PO4 10% X 140/60 248/120

Ammonium Phosphate (NH4)3PO4 100% X 140/60 140/60

Ammonium Sulphate (NH4)2SO4 10% X 220/104 248/120

Ammonium Sulphate (NH4)2SO4 100% X X 248/120

Aniline C6H6NH2 100% 509/265 248/120 230/110

Aniline hydro chloride C6H5NH2xHCl 25% X nd 212/100

Aqua Regia HCl / H2SO4 100% X X X

Argon Ar 100%

Barium Carbonate BaCO3 100% X X 77/25

Barium Chloride BaCl2 25% X 158/70 122/50

Barium Hydroxide Ba(OH)2 10% 225/107 225/107 77/25

Barium Nitrate Ba(NO3)2 20% 150/65 X 77/25

Benzene C6H6 100% X X 240/116

Benzoic Acid C6H5COOH 10% X 180/82 248/120

Benzoic Acid C6H5COOH 100% X 180/82 248/120

Benzyl Chloride C7H7Cl 100% X X 140/60

Boric Acid BH3 10% X 320/160 320/160

Boric Acid BH3 100% nd nd 77/25

Bromine Liquid Br 100% X X X

Butyric Acid CH3(CH2)2COOH 100% X 260/127 225/107

Calcium Carbonate CaCO3 100%

Calcium Chloride CaCl2 75% X 221/105 O 221/105

Calcium Chloride CaCl2 100% X 392/200 X

= Compatible

X = Not Compatible nd = No Data Available

Page 7

7

Corrosion Guide Rev 1.05 Jan 2006

Fluid Chem. Formula Concentration

Stainless Steel

Max oF/oC

Hastelloy C-22

Max oF/oC

Titanium

Max oF/oC

Calcium Hydroxide Ca(OH)2 50% X 212/100 171/77

Calcium Hypochlorite Ca(Ocl)2 15% X 122/50 221/105

Calcium Hypochlorite Ca(Ocl)2 95% X X 221/105

Calcium Sulphate CaSO4 10% nd X nd

Calcium Sulphate CaSO4 100% X nd 140/60

Calcium Hypochlorite CaCl2+6H2O 15% X 122/50 221/105

Calcium Hypochlorite CaCl2+6H2O 95% X X 221/105

Carbon Tetrachloride

(anhydrous)

dry CCl4 100% 140/60 140/60 248/120

Carbonic Acid Saturated X

Chlorine (anhydrous) dry Cl2 any X X X

Chlorine (aqueous) Cl2 + water any X X X

Chloroacetic Acid CH2CICOOH 85% X X 221/105

Chloroform CHCl3 100% 80/27 80/21 221/105

Chlorosulphonic Acid HCISO3 100% X 185/85 X

Chromic Acid H8CrO5 25% X 167/75 221/105

Chromic Acid H8CrO5 50% X 75/24 221/105

Chromic Acid H8CrO5 100% X X 221/105

Citric Acid C6H8O7 25% X 221/105 212/100

Citric Acid C6H8O7 60% X 221/105 X

Copper Nitrate Cu(NO3)2 100% 280/138 X 77/25

Copper Sulphate CuSO4 100% X X 221/105

Cupric Chloride CuCl2 any X X X

Cupric Cyanide CuCN 100% X X 77/25

Cuprous Chloride CuCl 55% nd nd 194/90

Dichloroacetic Acid CHCl2COOH any nd nd X

Diethyl Phthalate C12H14O4 100% 221/105 nd 221/105

Ethyl Alcohol (Ethanol) C2H5OH 100% 221/105 221/105 221/105

Ethylene gas C2H4 100%

Ethylene dichloride

(anhydrous)

dry C2H2Cl2 100% X 221/105 221/105

Ethyl Acetate CH3 COOC2H5 100% 320/160 320/160 221/105

Ferric Chloride FeCl3 100% X X 248/120

Ferric Hydroxide Fe(OH)3 6% 70/21 80/27 68/20

Ferric Hydroxide Fe(OH)3 100% 70/21 80/27 nd

Ferric Sulphate Fe2(SO4)3 15% 221/105 104/40 221/105

Ferric Sulphate Fe2(SO4)3 35% X 104/40 221/105

Ferric Sulphate Fe2(SO4)3 100% X X 221/105

Ferrous Sulphate FeSO4 100% X X 248/120

Fluoboric Acid HBF4 30% 80/27 200/93 X

Fluorine (anhydrous) dry F any X X X

Fluosilicic Acid H2SiF6 any X X X

Formaldehyde CH2O 100% 221/105 X 221/105

Formic Acid (aerated) HCOO4 50% X 221/105 221/105

Formic Acid (non-aerated) HCOO4 85% X 221/105 X

Heptane C6H12 100% 221/105 221/105 221/105

Hydrazine (NH2)2 100%

Hydrobromic Acid HBO3 100% X 140/60 X

Hydrochloric Acid HCL + water any X X X

Hydrofluoric Acid HF + water any X X X

Hydrogen gas H

Hydrogen Chloride gas HCL any X X X

Hydrogen Cyanide NCN 100% 88/31 88/31 88/31

Hydrogen Fluoride gas HF any X X X

Hydrogen Peroxide H2O2 50% 194/90 194/90 X

Hydrogen Peroxide H2O2 90% 118/48 118/48 X

Iodine Liquid I2 100% X

77/25

= Compatible

X = Not Compatible nd = No Data Available

Page 8

8

Corrosion Guide Rev 1.05 Jan 2006

Fluid Chem. Formula Concentration

Stainless Steel

Max oF/oC

Hastelloy C-22

Max oF/oC

Titanium

Max oF/oC

Lactic Acid CH3CHOHCOOH 25% 122/50 122/50 122/50

Lithium Chloride LiCl 50% X 212/100 212/100

Magnesium Chloride MgCl2 50% X 280/138 248/120

Magnesium Hydroxide Mg(OH)2 100% 212/100 212/100 167/75

Magnesium Sulphate MgSO4 50% nd 200/93 200/93

Maleic Acid CH2(COOH)2 100% X 176/80 248/120

Manganese Chloride MnCl2 45% X 212/100 212/100

Mercuric Chloride HgCl2 10% X X 266/130

Mercuric Cyanide Hg(CN)2 10% 95/35 X 95/35

Methanol + > 2% H2O C2H4OH 98%

Methanol + > 50ppm H20 C2H40H 99.99%

X

Methanol pure C2H40H 100%

X

Methyl Ethyl Ketone CH3CH2COCH3 100% 200/93 200/93 200/93

Methyl Methacrylate C5H8O2 100%

Methylene Chloride CH2Cl2 100% X X 239/115

Mono Sodium

Orthophosphate in water

NaPO3 200 millimoles nd nd 86/30

Monochloacetic Acid CH2ClCOOH 100% nd nd

N-Butyric Acid CH3(CH2)2COOH 100% X 212/100 212/100

Nickel Chloride NiCl2 100% X 194/90 194/90

Nickel Nitrate Ni(NO3)2 50% X

77/25

Nickel Sulphamate 50%

Nitric Acid HNO3 100% “red fuming” 75/24 75/24 140/60

Nitric Acid HNO3 70% 75/24 75/24 140/ 60

Nitric Acid HNO3 50% 100/38 75/24 140/ 60

Nitric Acid HNO3 40% 125/52 75/24 140/ 60

Nitric Acid HNO3 30% 130/66 75/24 140/ 60

Nitric Acid HNO3 20% 176/80 130/66 140/ 60

Oxalic Acid (COOH)2 100% X 212/100 X

Oxygen rich gas mixture O2 > 35%

X

“Passivation” fluid Mixture HNO3 + HF X X X

Pentane C5H10 100% X

Perchloric Acid HClO4 any X 212/100 nd

Phenol C6H5OH 95% 131/55

X

Phosphoric Acid H3PO4 100% X X X

Phosphoric Acid H3PO4 98% X 77/25 X

Phosphoric Acid H3PO4 20% X 77/25 77/25

Phosphoric Acid H3PO4 5% 77/25 77/25 77/25

Potassium Bromide KBr 100% X X

Potassium Bromide KBr 30% X 95/35

Potassium Chloride KCI 99% X

Potassium Hydroxide KOH 40% 170/77 170/77 170/77

Potassium Iodide KI 75% 212/100 212/100 212/100

Potassium Nitrate KNO3 100% X 212/100 240/115

Potassium Permanganate KMnO4 100% X

Potassium Sulphate K2SO4 25% 212/100 X 240/115

Propanol (Propyl Alcohol) C3H6OH 100%

Seawater (Brine) C3H6OH 100% X

Silver Nitrate AgNO3 70% 85/30 85/30 212/70

Sodium Bisulphate NaHSO4 20% X X 85/30

Sodium Carbonate Na2CO3 100% 212/100 212/100 212/100

Sodium Chlorate NaCIO3 100% X 302/150 302/150

Sodium Chloride NaCI 100% X 212/100 212/100

Sodium Cyanide NaCN 50% 77/25 nd 266/130

Sodium Dichromate Na2Cr 100% X 80/27 77/25

Sodium Formate HCOONa 50% 131/55 131/55 nd

= Compatible

X = Not Compatible nd = No Data Available

Page 9

9

Corrosion Guide Rev 1.05 Jan 2006

Fluid Chem. Formula Concentration

Stainless Steel

Max

oF/o

C

Hastelloy C-22

Max

oF/o

C

Titanium

Max

oF/o

C

Sodium Hydroxide NaOH 45% X 104/40 131/55

Sodium Hydroxide NaOH 75% X 104/40 X

Sodium Hypochlorite NaOCl any X X X

Sodium Iodide NaI 65% X nd 212/100

Sodium Nitrate NaNO3 60% 233/112 233/112 248/120

Sodium Nitrate NaNO3 100% X X 248/120

Sodium Nitrite NaNO2 50% 212/100 212/100 266/130

Sodium Peroxide (Na)2O2 15% 212/100 X X

Sodium Phosphate NaPO4 15% X 212/100 212/100

Sodium Silicate Na2SiO3 100% 212/100 212/100 212/100

Sodium Sulphate Na2SO4 20% 212/100 212/100 X

Sodium Sulphide Na2S 50% X 212/100 X

Sodium Sulphite NaSO3 25% 212/100 212/100 212/100

Sodium Sulphite NaSO3 50% nd nd 212/100

Stannic Chloride SnCl2 any X X X

Stearic Acid CH2(CH2)16COOH 100%

212/100 X

Succinic Acid (CH2 COOH)2 50% X X

Sulphamic Acid NH2 SO2 OH any X nd X

Sulphur (molten) S 100%

Sulphuric Acid H2SO4

10%velocity

< 3 m/s

100/38 100/38 X

Sulphuric Acid H2SO4

25%velocity

< 3 m/s

75/24 100/38 X

Sulphuric Acid H2SO4

40%velocity

< 3 m/s

X 100/38 X

Sulphuric Acid H2SO4

55%velocity

< 3 m/s

X 86/30 X

Sulphurous Acid H2SO3 10% X X 175/80

Tannic Acid C76H52O46 95% 212/100 X 212/100

Tartaric Acid (CHOHCOOH) 2 50% 212/100 X 122/50

Terephthalic Acid C8H6O4 77%

Tetrachlorethane C2H2Cl4 100% X 160/71 160/71

Tetrachlorethylene

(Perchloroethylene)

Cl2C:CCl2 100% X 285/140 X

Thionyl Chloride SO2Cl2 100% X nd 104/40

Toluene C6H5CH3 100%

Trichlorethane C2H3Cl3 100% X X 77/25

Tricloroacetic Acid CCl3COOH 50% X 212/100 nd

Trisodium Phosphate (Na)3PO4 90% X

nd

Urea (NH2)2CO 100% 194/90 194/90 194/90

Zinc Chloride ZnCL2 75% X

212/100

Zinc Chloride ZnCL2 100% X

X

Zinc Sulphate ZnSO4 35% X 212/100 212/100

= Compatible

X = Not Compatible nd = No Data Available

Page 10

10

Corrosion Guide Rev 1.05 Jan 2006

Chem. Formula Fluid Concentration

Stainless Steel

Max oF/oC

Hastelloy C-22

Max oF/oC

Titanium

Max oF/oC

Air

Carbonic Acid Saturated X

Nickel Sulphamate 50%

(CH2 COOH)2 Succinic Acid 50% X X

(CH2)5(COOH)2 Adipic Acid 100% 50/10 200/93 428/220

(CHOHCOOH) 2 Tartaric Acid 50% 212/100 X 122/50

(COOH)2 Oxalic Acid 100% X 212/100 X

(Na)2O2 Sodium Peroxide 15% 212/100 X X

(Na)3PO4 Trisodium Phosphate 90% X

nd

(NH2)2 Hydrazine 100%

(NH2)2CO Urea 100% 194/90 194/90 194/90

(NH4)2CO3 Ammonium Carbonate 50% X X

(NH4)2SO4 Ammonium Sulphate 10% X 220/104 248/120

(NH4)2SO4 Ammonium Sulphate 100% X X 248/120

(NH4)3PO4 Ammonium Phosphate 10% X 140/60 248/120

(NH4)3PO4 Ammonium Phosphate 100% X 140/60 140/60

(NH4)C2O4 Ammonium Oxalate 10% X 75/24 75/24

(NH4)ClO3 Ammonium Chlorate 30% nd nd 122/50

AgNO3 Silver Nitrate 70% 85/30 85/30 212/70

Al2SO4 Aluminium Sulphate 6.50% X 285/140 220/105

Al2SO4 Aluminium Sulphate 40% X 285/140 220/105

Al2SO4 Aluminium Sulphate 100% X nd 200/93

AlCl3 Aluminium Chloride 10% X 220 /105 200/93

AlCl3 Aluminium Chloride 40% X 220 / 105 X

AlCl3 Aluminium Chloride 100% X 158/70 X

AlCl3 Aluminium Fluoride 20% X X X

AlNO3 Aluminium Nitrate 100% 302/150 X 208/98

Ar Argon 100%

Ba(NO3)2 Barium Nitrate 20% 150/65 X 77/25

Ba(OH)2 Barium Hydroxide 10% 225/107 225/107 77/25

BaCl2 Barium Chloride 25% X 158/70 122/50

BaCO3 Barium Carbonate 100% X X 77/25

BH3 Boric Acid 10% X 320/160 320/160

BH3 Boric Acid 100% nd nd 77/25

Br Bromine Liquid 100% X X X

C12H14O4 Diethyl Phthalate 100% 221/105 nd 221/105

C2H2Cl2 dry

Ethylene dichloride

(anhydrous)

100% X 221/105 221/105

C2H2Cl4 Tetrachlorethane 100% X 160/71 160/71

C2H3Cl3 Trichlorethane 100% X X 77/25

C2H4 Ethylene gas 100%

C2H40H Methanol + > 50ppm H20 99.99%

X

C2H40H Methanol pure 100%

X

2H4OH Methanol + > 2% H2O 98%

C2H5OH Ethyl Alcohol (Ethanol) 100% 221/105 221/105 221/105

C3H6OH Propanol (Propyl Alcohol) 100%

C3H6OH Seawater (Brine) 100% X

C5H10 Pentane 100% X

C5H8O2 Methyl Methacrylate 100%

C6H12 Heptane 100% 221/105 221/105 221/105

C6H5CH3 Toluene 100%

C6H5COOH Benzoic Acid 10% X 180/82 248/120

C6H5COOH Benzoic Acid 100% X 180/82 248/120

C6H5NH2xHCl Aniline hydro chloride 25% X nd 212/100

C6H5OH Phenol 95% 131/55

X

C6H6 Benzene 100% X X 240/116

C6H6NH2 Aniline 100% 509/265 248/120 230/110

= Compatible

X = Not Compatible nd = No Data Available

Page 11

11

Corrosion Guide Rev 1.05 Jan 2006

Chem. Formula Fluid Concentration

Stainless Steel

Max oF/oC

Hastelloy C-22

Max oF/oC

Titanium

Max oF/oC

C6H8O7 Citric Acid 25% X 221/105 212/100

C6H8O7 Citric Acid 60% X 221/105 X

C76H52O46 Tannic Acid 95% 212/100 X 212/100

C7H7Cl Benzyl Chloride 100% X X 140/60

C8H6O4 Terephthalic Acid 77%

Ca(Ocl)2 Calcium Hypochlorite 15% X 122/50 221/105

Ca(Ocl)2 Calcium Hypochlorite 95% X X 221/105

Ca(OH)2 Calcium Hydroxide 50% X 212/100 171/77

CaCl2 Calcium Chloride 75% X 221/105 221/105

CaCl2 Calcium Chloride 100% X 392/200 X

CaCl2+6H2O Calcium Hypochlorite 15% X 122/50 221/105

CaCl2+6H2O Calcium Hypochlorite 95% X X 221/105

CaCO3 Calcium Carbonate 100%

CaSO4 Calcium Sulphate 10% nd X nd

CaSO4 Calcium Sulphate 100% X nd 140/60

CCl3COOH Tricloroacetic Acid 50% X 212/100 nd

CCl4 dry

Carbon Tetrachloride

(anhydrous)

100% 140/60 140/60 248/120

CH2 Acetylene 100% 400/204 220/105 79/26

CH2(CH2)16COOH Stearic Acid 100%

212/100 X

CH2(COOH)2 Maleic Acid 100% X 176/80 248/120

CH2CICOOH Chloroacetic Acid 85% X X 221/105

CH2Cl2 Methylene Chloride 100% X X 239/115

CH2ClCOOH Monochloacetic Acid 100% nd nd

CH2O Formaldehyde 100% 221/105 X 221/105

CH3 COOC2H5 Ethyl Acetate 100% 320/160 320/160 221/105

CH3(CH2)2COOH Butyric Acid 100% X 260/127 225/107

CH3(CH2)2COOH N-Butyric Acid 100% X 212/100 212/100

CH3CH2COCH3 Methyl Ethyl Ketone 100% 200/93 200/93 200/93

CH3CHO Acetaldehyde 100% 200/93 200/93 300/149

CH3CHOHCOOH Lactic Acid 25% 122/50 122/50 122/50

CH3CO2CH3 Acetate 100% 400/204 400/204 400/204

CH3COCH3 Acetone 100% 400/204 140/60 200/93

CH3COCI Acetyl Chloride 100% 70/21 99/37 220/105

CH3COOH Acetic Acid 20% 400/204 300/149 260/127

CH3COOH Acetic Acid 50% 160/71 210/99 260/127

CH3COOH Acetic Acid 80% 160/71 210/99 260/127

CH3COOH Acetic Acid 95% X 200/93 210/99

CH3COOH Acetic Acid 100% X 200/93 200/93

CHCl2COOH Dichloroacetic Acid any nd nd X

CHCl3 Chloroform 100% 80/27 80/21 221/105

Cl2 + water Chlorine (aqueous) any X X X

Cl2 dry Chlorine (anhydrous) any X X X

Cl2C:CCl2

Tetrachlorethylene

(Perchloroethylene)

100% X 285/140 X

Cu(NO3)2 Copper Nitrate 100% 280/138 X 77/25

CuCl Cuprous Chloride 55% nd nd 194/90

CuCl2 Cupric Chloride any X X X

CuCN Cupric Cyanide 100% X X 77/25

CuSO4 Copper Sulphate 100% X X 221/105

F dry Fluorine (anhydrous) any X X X

Fe(OH)3 Ferric Hydroxide 6% 70/21 80/27 68/20

Fe(OH)3 Ferric Hydroxide 100% 70/21 80/27 nd

Fe2(SO4)3 Ferric Sulphate 15% 221/105 104/40 221/105

Fe2(SO4)3 Ferric Sulphate 35% X 104/40 221/105

Fe2(SO4)3 Ferric Sulphate 100% X X 221/105

= Compatible

X = Not Compatible nd = No Data Available

Page 12

12

Corrosion Guide Rev 1.05 Jan 2006

Chem. Formula Fluid Concentration

Stainless Steel

Max oF/oC

Hastelloy C-22

Max oF/oC

Titanium

Max oF/oC

FeCl3 Ferric Chloride 100% X X 248/120

FeSO4 Ferrous Sulphate 100% X X 248/120

H Hydrogen gas

H2O2 Hydrogen Peroxide 50% 194/90 194/90 X

H2O2 Hydrogen Peroxide 90% 118/48 118/48 X

H2SiF6 Fluosilicic Acid any X X X

H2SO3 Sulphurous Acid 10% X X 175/80

H2SO4 Sulphuric Acid

10%

velocity < 3 m/s

100/38 100/38 X

H2SO4 Sulphuric Acid

25%

velocity < 3 m/s

75/24 100/38 X

H2SO4 Sulphuric Acid

40%

velocity < 3 m/s

X 100/38 X

H2SO4 Sulphuric Acid

55%

velocity < 3 m/s

X 86/30 X

H3PO4 Phosphoric Acid 100% X X X

H3PO4 Phosphoric Acid 98% X 77/25 X

H3PO4 Phosphoric Acid 20% X 77/25 77/25

H3PO4 Phosphoric Acid 5% 77/25 77/25 77/25

H8CrO5 Chromic Acid 25% X 167/75 221/105

H8CrO5 Chromic Acid 50% X 75/24 221/105

H8CrO5 Chromic Acid 100% X X 221/105

HBF4 Fluoboric Acid 30% 80/27 200/93 X

HBO3 Hydrobromic Acid 100% X 140/60 X

HCISO3 Chlorosulphonic Acid 100% X 185/85 X

HCL Hydrogen Chloride gas any X X X

HCl / H2SO4 Aqua Regia 100% X X X

HCL + water Hydrochloric Acid any X X X

HClO4 Perchloric Acid any X 212/100 nd

HCOO4 Formic Acid (aerated) 50% X 221/105 221/105

HCOO4 Formic Acid (non-aerated) 85% X 221/105 X

HCOONa Sodium Formate 50% 131/55 131/55 nd

HF Hydrogen Fluoride gas any X X X

HF + water Hydrofluoric Acid any X X X

Hg(CN)2 Mercuric Cyanide 10% 95/35 X 95/35

HgCl2 Mercuric Chloride 10% X X 266/130

HNO3 Nitric Acid 100% “red fuming” 75/24 75/24 X

HNO3 Nitric Acid 75% 75/24 75/24 140/ 60

HNO3 Nitric Acid 70% 75/24 75/24 140/ 60

HNO3 Nitric Acid 50% 100/38 75/24 140/ 60

HNO3 Nitric Acid 40% 125/52 75/24 140/ 60

HNO3 Nitric Acid 30% 130/66 75/24 140/ 60

HNO3 Nitric Acid 20% 176/80 130/66 140/ 60

HNO3 + HF Mixture “Passivation” fluid X X X

I2 Iodine Liquid 100% X

77/25

K2SO4 Potassium Sulphate 25% 212/100 X 240/115

KBr Potassium Bromide 100% X X

KBr Potassium Bromide 30% X 95/35

KCI Potassium Chloride 99% X

KI Potassium Iodide 75% 212/100 212/100 212/100

KMnO4 Potassium Permanganate 100% X

KNO3 Potassium Nitrate 100% X 212/100 240/115

KOH Potassium Hydroxide 40% 170/77 170/77 170/77

LiCl Lithium Chloride 50% X 212/100 212/100

Mg(OH)2 Magnesium Hydroxide 100% 212/100 212/100 67/75

MgCl2 Magnesium Chloride 50% X 280/138 248/120

MgSO4 Magnesium Sulphate 50% nd 200/93 200/93

MnCl2 Manganese Chloride 45% X 212/100 212/100

Na2CO3 Sodium Carbonate 100% 212/100 212/100 212/100

= Compatible

X = Not Compatible nd = No Data Available

Page 13

13

Corrosion Guide Rev 1.05 Jan 2006

Chem. Formula Fluid Concentration

Stainless Steel

Max oF/oC

Hastelloy C-22

Max oF/oC

Titanium

Max oF/oC

Sodium Dichromate 100% X 80/27 77/25

Na2S Sodium Sulphide 50% X 212/100 X

Na2SiO3 Sodium Silicate 100% 212/100 212/100 212/100

Na2SO4 Sodium Sulphate 20% 212/100 212/100 X

NaCI Sodium Chloride 100% X 212/100 212/100

NaCIO3 Sodium Chlorate 100% X 302/150 302/150

NaCN Sodium Cyanide 50% 77/25 nd 266/130

NaHSO4 Sodium Bisulphate 20% X X 85/30

NaI Sodium Iodide 65% X nd 212/100

NaNO2 Sodium Nitrite 50% 212/100 212/100 266/130

NaNO3 Sodium Nitrate 60% 233/112 233/112 248/120

NaNO3 Sodium Nitrate 100% X X 248/120

NaOCl Sodium Hypochlorite any X X X

NaOH Sodium Hydroxide 45% X 0/40 0/55

NaOH Sodium Hydroxide 75% X 0/40 X

NaPO3

Mono Sodium

Orthophosphate in water

200 millimoles nd nd O86/30

NaPO4 Sodium Phosphate 15% X 212/100 212/100

NaSO3 Sodium Sulphite 25% 212/100 212/100 212/100

NaSO3 Sodium Sulphite 50% nd nd 212/100

NCN Hydrogen Cyanide 100% 88/31 88/31 88/31

NH2 SO2 OH Sulphamic Acid any X nd X

NH3 + water Ammonia (aqueous) 30% 158/70 158/70 X

NH3 + water Ammonia (aqueous) 50% 86/30 302/150 X

NH3 dry Ammonia (anhydrous) always 100% 248/120 248/120 77/25

NH4CH3COO Ammonium Acetate 15% 220/105 220/105 77/25

NH4CH3COO Ammonium Acetate 55% 170/77 nd nd

NH4Cl Ammonium Chloride 40% X 221/105 221/105

NH4ClO4 Ammonium Perchlorate 20% 170/77 X 285/140

NH4F Ammonium Fluoride 25% X 170/77 nd

NH4HCO3 Ammonium Bicarbonate 50% X nd 212/100

NH4NO3 Ammonium Nitrate 28% 280/137 80/27

NH4OH Ammonium Hydroxide 45% X X 170/77

Ni(NO3)2 Nickel Nitrate 50% X

77/25

NiCl2 Nickel Chloride 100% X 194/90 194/90

O2 Oxygen rich gas mixture > 35%

X

S Sulphur (molten) 100%

SnCl2 Stannic Chloride any X X X

SO2Cl2 Thionyl Chloride 100% X nd 104/40

ZnCL2 Zinc Chloride 75% X

212/100

ZnCL2 Zinc Chloride 100% X

X

ZnSO4 Zinc Sulphate 35% X 212/100 212/100

= Compatible

X = Not Compatible nd = No Data Available

If you do not find the required fluid in the table, please contact your nearest sales office.

Page 14

14

Corrosion Guide Rev 1.05 Jan 2006

Flow

Flange Bolt

Centralising

Sleeves

Gaskets

Transition

Piece

Pipe Work

Flow Meter

Flange Bolt

Typical Transition Piece Application

2. Abrasion Guidelines & information.

2.1 Introduction

For almost 10 years, the Krohne Corimass G Class

and Optimass 7000 series Coriolis mass flow meters

have been successfully used on abrasive fluids such as

slurries (mineral and metal mining) as wella as sand &

water mixtures.

In these applications, a single straight measuring tube

will always offer clear advantages over other designs

with tube geometries that suffer erosion and premature

failure of flow dividers and bends in the abrasive fluid

stream. Notwithstanding this, even a meter with a single straight tube will suffer some erosion unless simple

precautions are taken.

Other specific problems with abrasive fluids are typified

by their tendency to separate out with the heavier particles falling to the bottom of the pipeline and the carrier

fluid flowing above in a stratified flow.

The purpose of this application guidance is to highlight

potential problems so that they can be mitigated

against during the planning and installation of the

meter.

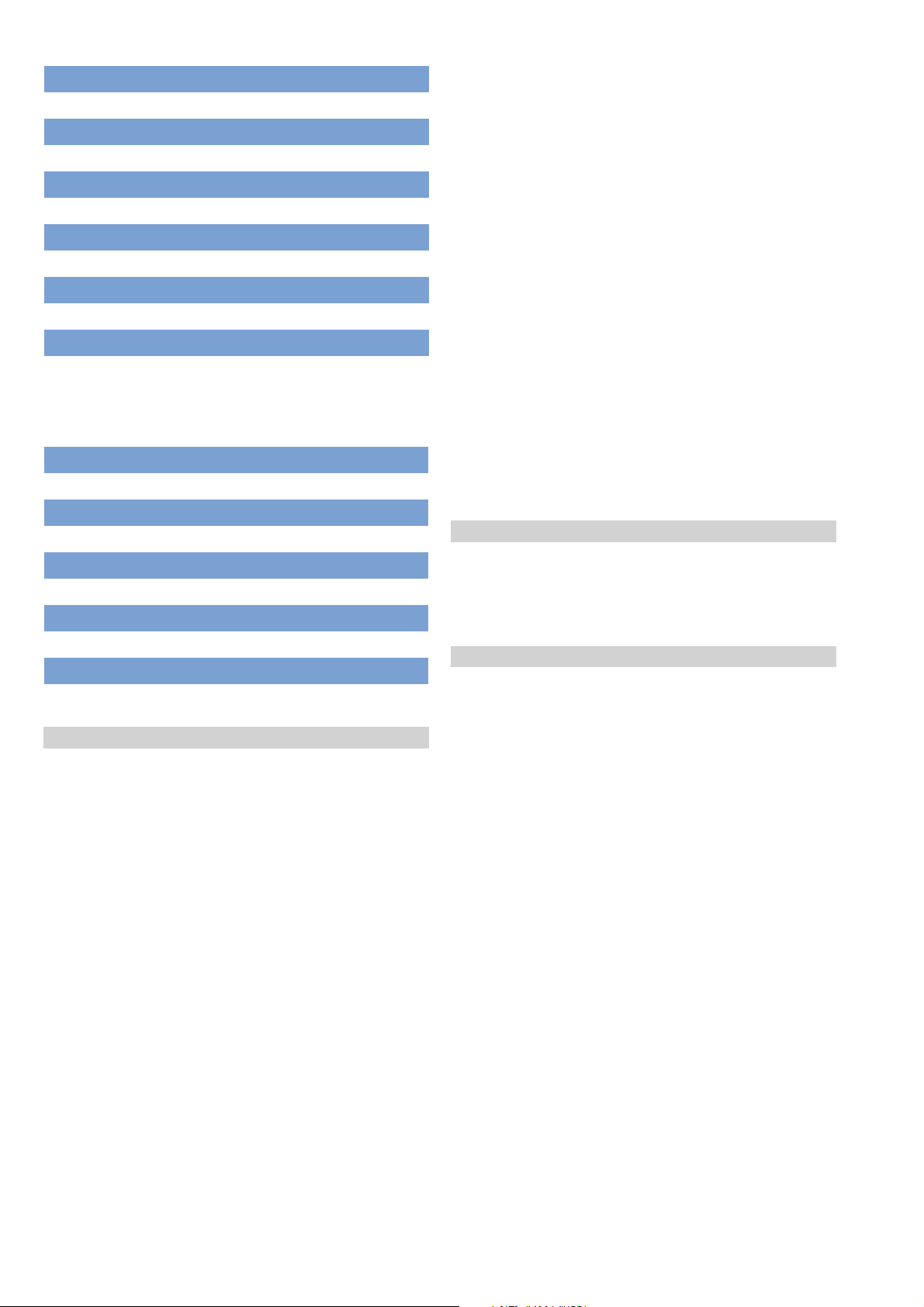

2.2 Protecting Flanges with Transition Pieces

Since the meter measuring tube will typically have a

different internal diameter than the process pipework, a

“step change” will occur where the flanges are connected. This edge presents a very obvious erosion point

and after a period, the weld between the flange raised

face and measuring tube could fail causing a leak path.

Transition pieces are stainless steel (although Hastelloy

can be used) discs that are sandwiched between the

two flanges, secured by through bolts and centred by

rubber sleeves around the bolts.

The taper on the internal diameter of the disc is manufactured to correct the difference between the meter

and process pipe, thus providing a gradual transition

for the abrasive fluid into the meter.

They must be considered as “sacrificial wear parts”,

and should be removed periodically for inspection of

the internal taper dimension and replacement if necessary.

Prices for these parts are available from Krohne.

2.3 Managing fluid velocity

There are two considerations here based on the fluid

flow rate and density:

Maximum velocity

To prevent excessive erosion this should be never be

more that 4 m/sec (12 ft/sec).

Minimum velocity

So the particles and carrier are homogeneous mixed

this should be at least 1 m/s (3 ft/sec).

The Optimass sizing software will assist you in calculating these limits. For abrasive slurries always size

according to these velocity limits, and not lowest measuring error which tends towards a smaller meter size

and hence a higher velocity.

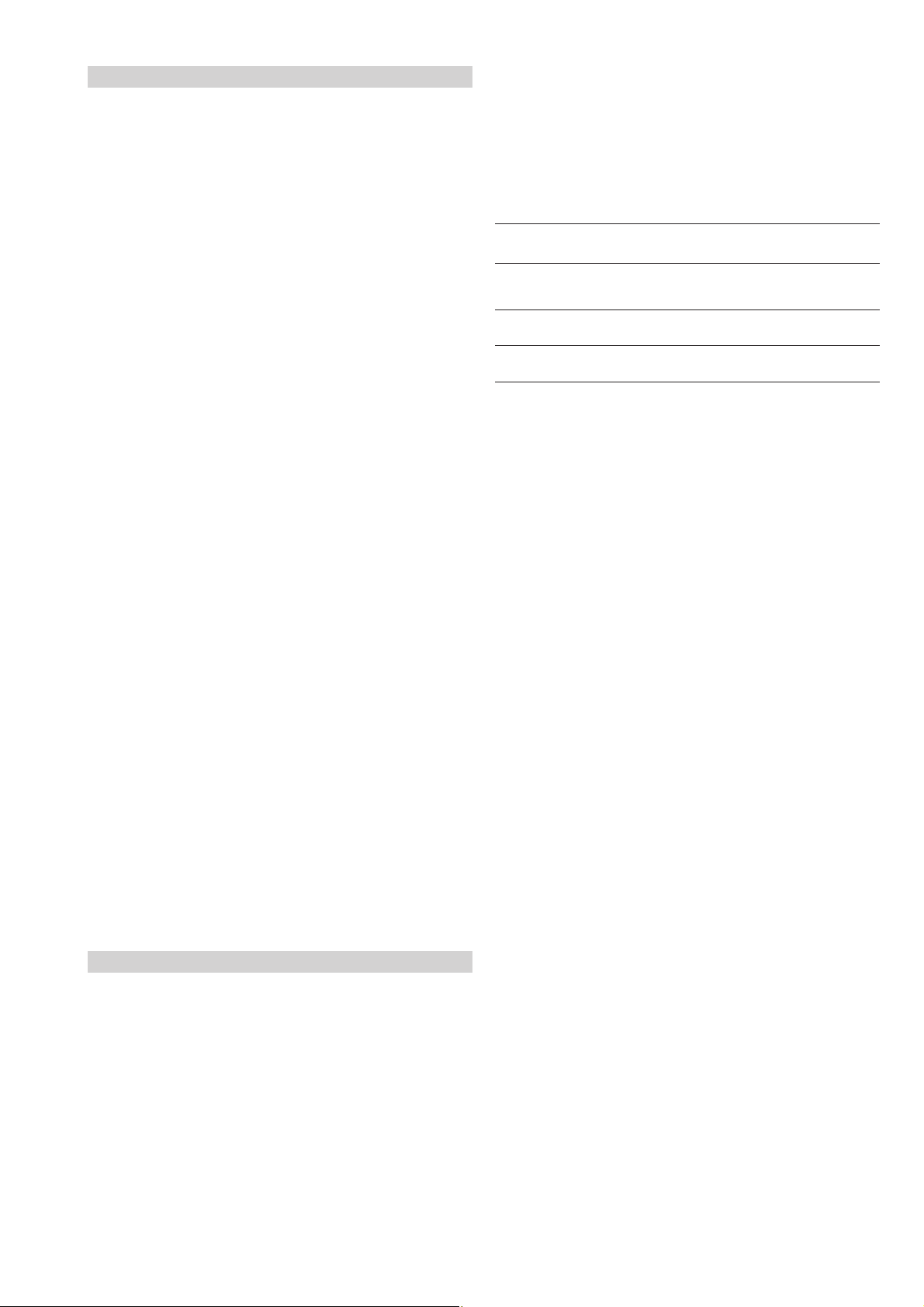

2.4 Titanium as the standard material

Titanium should always be used as the standard material for measuring tubes. This is because size-for-size,

a titanium measuring tube has a greater wall thickness

than either stainless steel or Hastelloy. Simply put, this

tube has more material to erode before failure, so

extending the working lifetime of the meter.

Optimass Sizing Software Screen Shot

Page 15

15

Corrosion Guide Rev 1.05 Jan 2006

Meter

size

Material Outside dia.

Wall

Thickness

Internal

dia.

40

T 38.10 ± 0.13 0.91 ± 0.09 36.28

H 38.10 ± 0.1 0.71 ± 0.07 36.68

S 38.10 ± 0.13 0.71 ± 0.07 36.68

50

T 50.80 ± 0.15 1.24 ± 0.01 48.32

H 50.80 ± 0.15 1.00 ± 0.01 48.80

S 48.26 ± 0.13 1.00 ± 0.01 46.26

80

T 73.00 ± 0.254 2.10 ± 0.02 68.80

H 73.03 ± 0.254 1.04 ± 0.01 70.95

S 73.00 ± 0.13 1.40 ± 0.01 70.20

All dimensions in mm

It should be noted that the exception to this is when

stainless steel or Hastelloy are required for fluid compatibility (corrosion resistance).

2.5 Conditioning of the fluid flow profile

(as it enters the meter)

Firstly remember that a Coriolis mass flow meter directly measures mass flow and density of the fluid. It does

not measure velocity, so from a measuring principle

standpoint there is no need for flow profile conditioning.

However with an abrasive fluid, there is the requirement to condition the flow so that the abrasive particles

enter the meter parallel to the tube wall. This minimises

the probability that any given abrasive particle will

strike the tube wall and remove (erode) the tube material.

If the flow is “tumbling” or “swirling” as it enters the

meter, there is a risk that erosion will occur at the specific point where the particles preferentially impact onto

the tube wall, so causing premature failure. These

problems are always associated with using a pipework

bend or elbow very close to the meter inlet.

Therefore we recommend a straight length of inlet

process pipe equal to at least 10, or preferably 20 x

pipe internal diameters.

2.6 Installation of the flow meter

In order to keep the heavy abrasive particles evenly

dispersed in the carrier fluid as a homogenous mixture

that is required for correct meter operation, we would

recommend a vertical meter installation. Otherwise

there is the tendency, especially at lower flow velocities, for the fluid to separate out and become stratified.

Further, a flow direction vertically upwards is normally

preferred to ensure that meter is always full of liquid,

and does not “siphon” empty.

2.7 Inclusion of air or gas in the fluid

High density fluids such as mineral slurries typically

require a high drive energy due to their tendency

towards being inhomogeneously mixed.

Entrained air or gas will cause a further increase in the

required energy to drive (vibrate) the tube system. If

the inclusion is too great then the meter will not operate

correctly. This problem is particularly pronounced on

larger sized meters (T 50 & T 80), which typically are

used for abrasive fluid applications in order to reduce

the fluid velocity to acceptable levels.

So we would recommend that all efforts be made to

prevent the inclusion of air or gas in the fluid as part of

the process design, since from our experience once

entrained in the fluid it is virtually impossible to remove

prior to the metering point

2.8 Consider installing the meter in a by-pass

If the application is for density measurement only, then

often a more cost-effective solution is to install a smaller sized meter (although size 25 is smallest recommended) in a by-pass line off the main pipeline.

2.9 Conclusions

We are confident that if the seven steps above are followed correctly, then the probability of application related problems are greatly reduced and the operating lifetime of the meter greatly increased.

3. Environmental Protection

The materials exposed to the environment as standard

are:

MFM x050 Ex

MFM x051 Ex

MFM xo50 Ex

MFM x051 Ex

MFC 050 Ex

MFC 051 Ex

•

304L Stainless Steel for the sensor body with optional

316LStainless Steel for offshore

applications.

•

Electronics housing is die cast

aluminium, powder coated.

•

The aluminium has a low copper

content (see specification table).

All above housings will be powder coated in silver and

All covers (screw-on type) will be painted in blue RAL

5005

MFC 300C

MFC 300F

MFC 300W

•

304L Stainless Steel for the sensor body with optional

316LStainless Steel for offshore

applications.

•

Electronics housing in Stainless

Steel 316L.

Page 16

16

Corrosion Guide Rev 1.05 Jan 2006

Alloy type Si Fe Cu Mn Mg Cr Ni Zn Ti Pb

ADC 1

AlSi12Fe

11.0...13.0 1.3 1.0 0.3 0.3 - 0.5 0.5 - -

ADC 3

AlSi9Mg0,5Fe

9.0...10.0 3 1.0 0.3 0.4...0.6 - 0.5 0.5 - -

AlSi10Mg [Fe] 9.0...11.0 1.0 0.1 0.55 0.20...0.50 - 0.15 0.15 0.20 0.15

ALZn10Si8Mg 8.5...9.3 0.4 0.02 0.4 0.3...0.5 - - 9.0...10.0 0.1 -

For aggressive coastal or off shore based environments, KROHNE can provide an optional salt water resistant

coating. (see specifications below)

This is not in the standard price list. Please contact Product Management in Wellingborough, UK.

3.1 Housing Specifications

The MFC 050 and MFC 051 Range of Converters are available with KD(W) housings

KD Housing

This housing is prepared for long term applications in coastal and offshore environments.

KDW

The “W” suffix denotes the same specification as the standard KD housing but with the following additions:

•

Ingress protection IP 67

•

Special surface finish to:

•

Aluminium housing

•

Chromatized with (Henkel) Alodine 1200 S

•

Coated with Brillux 5910 Polyester powder

•

All outside threads have stainless steel inlays

•

Blue (RAL 5005) housing colour

•

1000 h spray test with sodium chloride solutions to:

•

DIN 50021:1988

•

ISO 1456:1974

•

ASTM B 117:1973

The MFC 300 Range of Converters are available with a SS 316L Housing

ADC 1

AlSi12Fe

ADC 3

AlSi9Mg0,5Fe

AlSi10Mg [Fe] ALZn10Si8Mg SS 316L

MFC050

MFC 051

MFC050 Ex

MFC051 Ex

MFC 300

MFC 300 Ex

Page 17

17

Corrosion Guide Rev 1.05 Jan 2006

Sources of information:

ATI Wah Chung, Albany Oregon, Technical Data Sheet: TitAly-052

Haynes International, Kokomo, Indiana, USA

Sandvick AB, SE-811 81 Sandviken, Sweden

Page 18

18

Corrosion Guide Rev 1.05 Jan 2006

Australia

KROHNE Australia Pty Ltd

Quantum Business Park

10/287 Victoria Rd

Rydalmere NSW 2116

TEL.: +61 2 8846 1700

FAX: +61 2 8846 1755

e-mail: krohne@krohne.com.au

Austria

KROHNE Austria Ges.m.b.H.

Modecenterstraße 14

A-1030 Wien

TEL.: +43(0)1/203 45 32

FAX: +43(0)1/203 47 78

e-mail: info@krohne.at

Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

TEL.: +32(0)2-4 66 00 10

FAX: +32(0)2-4 66 08 00

e-mail: krohne@krohne.be

Brazil

KROHNE Conaut

Controles Automaticos Ltda.

Estrada Louis Pasteur, 230 C.P. 56

06835 - 080 EMBU - SP

TEL.: +55(0)11-4785-2700

FAX: +55(0)11-4785-2768

e-mail: conaut@conaut.com.br

China

KROHNE Measurement Instruments

(Shanghai) Co. Ltd.

9th Floor, Xujiahui International Building

1033 Zhaojiabang Road

Shanghai 200030

P. R. China

TEL.: +86 21 6487 9611

FAX: +86 21 6438 7110

e-mail: info@krohne-asia.com

CIS

Kanex KROHNE Engineering AG

Business-Centre Planeta, Office 403

Marxistskaja-Street 3

109147 Moscow/Russia

TEL.: +7(0)095-9117 165

FAX: +7(0)095-9117 231

e-mail: krohne@dol.ru

Czech Republic

KROHNE CZ, spol. s r.o.

Sobìšická 156

63800 Brno

TEL.: +420 545 532 111

FAX: +420 545 220 093

e-mail: brno@krohne.cz

France

KROHNE S.A.S.

Les Ors

BP 98

F-26103 ROMANS Cedex

TEL.: +33(0)4-75 05 44 00

FAX: +33(0)4-75 05 00 48

e-mail: info@krohne.fr

Germany

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Str.

D-47058 Duisburg

TEL.: +49(0)203-301-0

FAX: +49(0)203-301-10 389

e-mail: info@krohne.de

India

KROHNE Marshall Ltd.

A-34/35, M.I.D.C.

Industrial Area, H-Block,

Pimpri Poona 411018

TEL.: +91(0)202-7442020

FAX: +91(0)202-7442020

e-mail: pcu@vsnl.net

Iran

KROHNE Liaison Office

North Sohrevardi Ave.

26, Sarmad St., Apt. #9

Tehran 15539

TEL.: ++98-21-874-5973

FAX: ++98-21-850-1268

e-mail: krohne@krohneiran.com

Italy

KROHNE Italia Srl.

Via V. Monti 75

I-20145 Milano

TEL.: +39(0)2-4 30 06 61

FAX: +39(0)2-43 00 66 66

e-mail: info@krohne.it

Korea

KROHNE Korea

Room 508 Miwon Bldg

43 Yoido-Dong

Youngdeungpo-Ku

Seoul, Korea

TEL.: 00-82-2-780-1743

FAX: 00-82-2-780-1749

e-mail: krohnekorea@krohnekorea.com

Netherlands

KROHNE Altometer

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306300

FAX: +31(0)78-6306390

e-mail: postmaster@krohne-altometer.nl

Netherlands

KROHNE Nederland B.V.

Kerkeplaat 14

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306200

FAX: +31(0)78-6306405

Service Direkt: +31(0)78-6306222

e-mail: info@krohne.nl

Norway

KROHNE Norway A.S.

Ekholtveien 114

NO-1526 Moss

P.O. Box 2178, NO-1521 Moss

TEL.: +47(0)69-264860

FAX: +47(0)69-267333

e-mail: postmaster@krohne.no

Internet: www.krohne.no

Singapore

Tokyo Keiso - KROHNE Singapore Pte. Ltd.

14, International Business Park,

Jurong East

Chiyoda Building #01-01/02

Singapore 609922

Singapore

TEL.: ++65-65-67-4548

FAX: ++65-65-67-9874

South Africa

KROHNE Pty. Ltd.

163 New Road

Halfway House Ext. 13

Midrand

TEL.: +27(0)11-315-2685

FAX: +27(0)11-805-0531

e-mail: midrand@krohne.co.za

Spain

I.I. KROHNE Iberia, S.r.L.

Poligono Industrial Nilo

Calle Brasil, n°. 5

E-28806 Alcalá de Henares-Madrid

TEL.: +34(0)91-8 83 21 52

FAX: +34(0)91-8 83 48 54

e-mail: krohne@krohne.es

Switzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

TEL.: +41(0)61-638 30 30

FAX: +41(0)61-638 30 40

e-mail: info@krohne.ch

United Kingdom

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough,

Northants NN8 6AE, UK

TEL.: +44(0)19 33-408 500

FAX: +44(0)19 33-408 501

e-mail: info@krohne.co.uk

USA

KROHNE Inc.

7 Dearborn Road

Peabody, MA 01960

TEL.: +1-978 535-6060

FAX: +1-978 535 -1720

e-mail: info@krohne.com

Other Representatives

Algeria

Argentina

Belarus

Cameroon

Canada

Chile

Colombia

Croatia

Denmark

Ecuador

Egypt

Finland

Gabon

Ghana

Greece

Hong Kong

Hungary

Indonesia

Ivory Coast

Iran

Ireland

Israel

Japan

Jordan

Other Countries

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Str.

D-47058 Duisburg

TEL.: +49(0)203-301-0

FAX: +49(0)203-301-389

e-mail: export@krohne.de

Kuwait

Libya

Lithuania

Malaysia

Morocco

Mauritius

Mexico

New Zealand

Peru

Poland

Portugal

Romania

Saudi Arabia

Senegal

Slovakia

Slovenia

Sweden

Taiwan

Thailand

Turkey

Tunisia

Venezuela

Yugoslavia

Subject to change without notice

Loading...

Loading...