Page 1

Handbook

Handbook

OPTIMASS 6000

OPTIMASS 6000

OPTIMASS 6000OPTIMASS 6000

HandbookHandbook

Sensor for mass flow

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 2

:

IMPRINT

:::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2018 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 3

OPTIMASS 6000

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 CE certification ................................................................................................................. 5

1.3 Associated documents ..................................................................................................... 5

1.4 Insulation case.................................................................................................................. 6

1.5 Pressure Equipment Directive (PED)............................................................................... 6

1.6 Dirty gas............................................................................................................................ 7

1.7 Safety instructions from the manufacturer ..................................................................... 7

1.7.1 Copyright and data protection ................................................................................................ 7

1.7.2 Disclaimer ............................................................................................................................... 8

1.7.3 Product liability and warranty ................................................................................................ 8

1.7.4 Information concerning the documentation........................................................................... 8

1.7.5 Warnings and symbols used................................................................................................... 9

1.8 Safety instructions for the operator................................................................................. 9

2 Device description 10

2.1 Scope of delivery............................................................................................................. 10

2.1.1 Meters with hygienic connections ........................................................................................ 11

2.2 Nameplates .................................................................................................................... 11

2.3 Dual Seal........................................................................................................................ 11

2.4 Temperature differential and thermal shock ................................................................ 13

2.5 Functional safety (SIL capable converter) ..................................................................... 14

3 Installation 15

3.1 General notes on installation ......................................................................................... 15

3.2 Storage ........................................................................................................................... 15

3.3 Handling.......................................................................................................................... 16

3.4 Installation conditions ....................................................................................................17

3.4.1 Supporting the meter............................................................................................................ 17

3.4.2 Mounting the meter .............................................................................................................. 18

3.4.3 Self draining.......................................................................................................................... 19

3.4.4 Gas / liquid build up .............................................................................................................. 19

3.4.5 Side mounting .......................................................................................................................20

3.4.6 Cross talk .............................................................................................................................. 20

3.4.7 Flange connections............................................................................................................... 21

3.4.8 Maximum pipework forces (end loadings) ........................................................................... 21

3.4.9 Pipework reducers................................................................................................................ 22

3.4.10 Flexible connections ........................................................................................................... 22

3.4.11 Hygienic installations.......................................................................................................... 23

3.4.12 Heating and insulation ........................................................................................................ 24

3.4.13 Purge ports ......................................................................................................................... 25

3.4.14 Burst discs .......................................................................................................................... 25

3.4.15 Zero calibration................................................................................................................... 26

3.4.16 Sunshades........................................................................................................................... 26

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

3

Page 4

CONTENTS

OPTIMASS 6000

4 Electrical connections 27

4.1 Safety instructions.......................................................................................................... 27

4.2 Electrical and I/O connections ....................................................................................... 27

5 Service 28

5.1 Spare parts availability...................................................................................................28

5.2 Availability of services .................................................................................................... 28

5.3 Returning the device to the manufacturer..................................................................... 28

5.3.1 General information.............................................................................................................. 28

5.3.2 Form (for copying) to accompany a returned device............................................................ 29

5.4 Disposal .......................................................................................................................... 29

6 Technical data 30

6.1 Measuring principle (twin tube) ..................................................................................... 30

6.2 Technical data................................................................................................................. 32

6.3 Guidelines for maximum operating pressure................................................................ 40

6.4 Dimensions and weights ................................................................................................ 46

6.4.1 Flanged versions................................................................................................................... 46

6.4.2 NAMUR dimensions .............................................................................................................. 57

6.4.3 Hygienic versions .................................................................................................................. 58

6.4.4 Heating jacket version .......................................................................................................... 61

6.4.5 Purge port option .................................................................................................................. 63

6.4.6 Burst discs ............................................................................................................................ 64

6.4.7 Burst disc option ................................................................................................................... 64

7 Notes 65

4

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 5

OPTIMASS 6000

1.1 Intended use

This mass flowmeter is designed for the direct measurement of mass flow rate, product density

and product temperature. Indirectly, it also enables the measurement of parameters like total

mass, concentration of dissolved substances and the volume flow. For use in hazardous areas,

special codes and regulations are also applicable and these are specified in a separate

documentation.

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in

industrial environment. There may be potential difficulties in ensuring electromagnetic

compatibility in other environments, due to conducted as well as radiated disturbances.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

SAFETY INSTRUCTIONS

1

1.2 CE certification

CE marking

This device conforms with the most recent and up to date versions of the following:

• EMC Directive

• ATEX Directive

• Low Voltage Directive

• Pressure Equipment Directive

• RoHS

• Measuring Instrument Directive

The manufacturer declares conformity and the device carries the CE mark.

1.3 Associated documents

This handbook should be read in conjunction with relevant documents in relation to:

• hazardous areas

• communications

• concentration

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

5

Page 6

1

SAFETY INSTRUCTIONS

• corrosion

1.4 Insulation case

On meters fitted with an insulation case, the case will be filled with one of the following

materials:

Cryogenic meters

Cryogenic meters (-200°C...+40°C / -364°F...+104°F)

Cryogenic metersCryogenic meters

Block grade EPS 1112A (Polystyrene) containing flame retardant additive (FRA)

Standard meters

Standard meters (-70°C...+230°C / -94°F...+446°F)

Standard metersStandard meters

Glass mineral wool

High temperature meters

High temperature meters (-50°C...+400°C / -58°F...+752°F)

High temperature metersHigh temperature meters

Silicon dioxide based mineral wool

Do not open the insulation case. Some, or all, of the above materials can cause:

OPTIMASS 6000

• skin irritation

• throat and lung irritation

• eye irritation

Install the meter so that water cannot get into the insulation case. Water will damage the

insulation material and reduce performance.

1.5 Pressure Equipment Directive (PED)

LEGAL NOTICE!

The Pressure Equipment Directive places legal requirements on both the manufacturer and the

end user. Please read this section carefully!

To ensure the PED integrity of the meter, you MUST check that the serial numbers on the

converter nameplate and the sensor nameplate are the same.

To comply with the requirements of the Pressure Equipment Directive (PED) the manufacturer

provides all the relevant technical data in the technical data section of this handbook. Secondary

pressure containment is NOT supplied on this meter.

6

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 7

OPTIMASS 6000

Tube failure

Where the meter is being used to measure high pressure gasses and / or gasses kept as liquids

by high pressure and / or where there is a risk of tube failure because of the use of corrosive or

erosive fluids, frequent pressure and / or thermal cycling, seismic or other shock loading, the

burst disc option MUST be purchased. For more information, please contact your nearest

representative.

DANGER!

If it is suspected that the primary measuring tube has failed, de-pressurise the meter and

remove it from service as soon as it is safe to do so.

1.6 Dirty gas

Dirty gas is gas that carries sand or other solid particles. Dirty gas causes excessive wear to the

primary measuring tube that can eventually result in complete tube failure. In some situations

tube failure where gas is being measured, can be very dangerous.

DANGER!

If the meter is being used to measure gas and there is a risk that the gas might be dirty, you

must fit a filter upstream of the meter to catch solid particles.

SAFETY INSTRUCTIONS

1

1.7 Safety instructions from the manufacturer

1.7.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

7

Page 8

1

SAFETY INSTRUCTIONS

1.7.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

1.7.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

OPTIMASS 6000

1.7.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

8

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 9

OPTIMASS 6000

1.7.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS

1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i

RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.8 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

9

Page 10

2

DEVICE DESCRIPTION

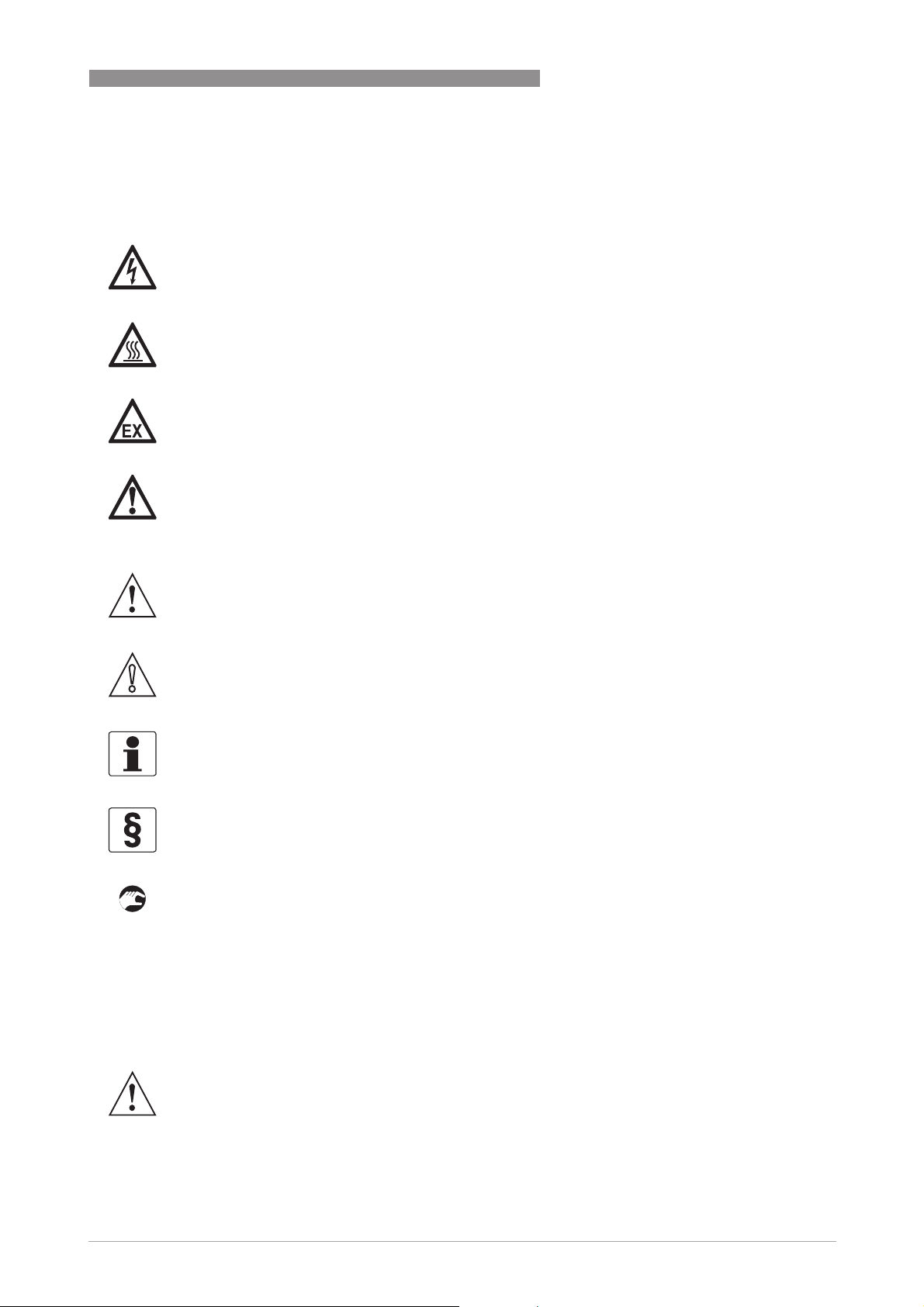

2.1 Scope of delivery

Compact version

1 Mass flowmeter.

2 Carton.

3 Documentation.

4 2.5 mm hex head tool.

5 CD-ROM and calibration certificate.

OPTIMASS 6000

Remote version

1 Mass flowmeter.

2 Converter. This will be either: field (as shown), wall or rack.

3 Carton.

4 2.5 mm hex head tool.

5 CD-ROM and calibration certificate.

6 Documentation.

If any items are missing, please contact the manufacturer.

If your meter has flange connections, the flange specification is stamped on the outer edge of the

flange. Check that the specification on the flange is the same as your order.

10

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 11

OPTIMASS 6000

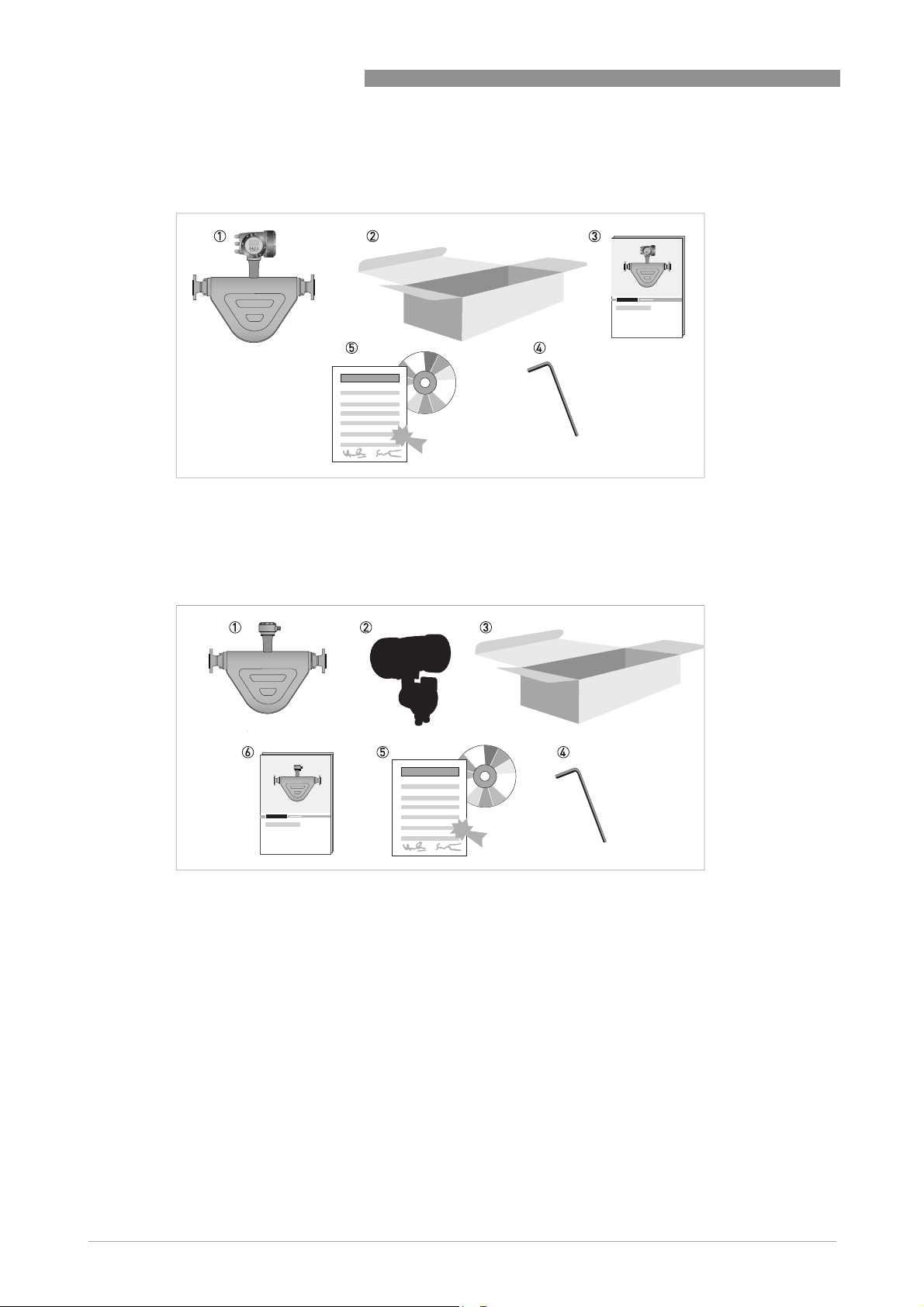

2.1.1 Meters with hygienic connections

1 Fully welded - the O-rings between the meter and the process pipework are not supplied as standard but can be or-

dered.

2 DIN 11864-2 Form A - the O-rings between the Form A and Form B parts of the connection are not supplied as standard

but can be ordered.

3 The 11864-2 Form B is not supplied as part of this connection but it can be ordered.

Inspect the condition of all seals between the meter and the process line (including seals

supplied as part of the hygienic adapter) at regular intervals and replace them as necessary.

DEVICE DESCRIPTION

2

The time between inspections must be based on the seal material and the process conditions.

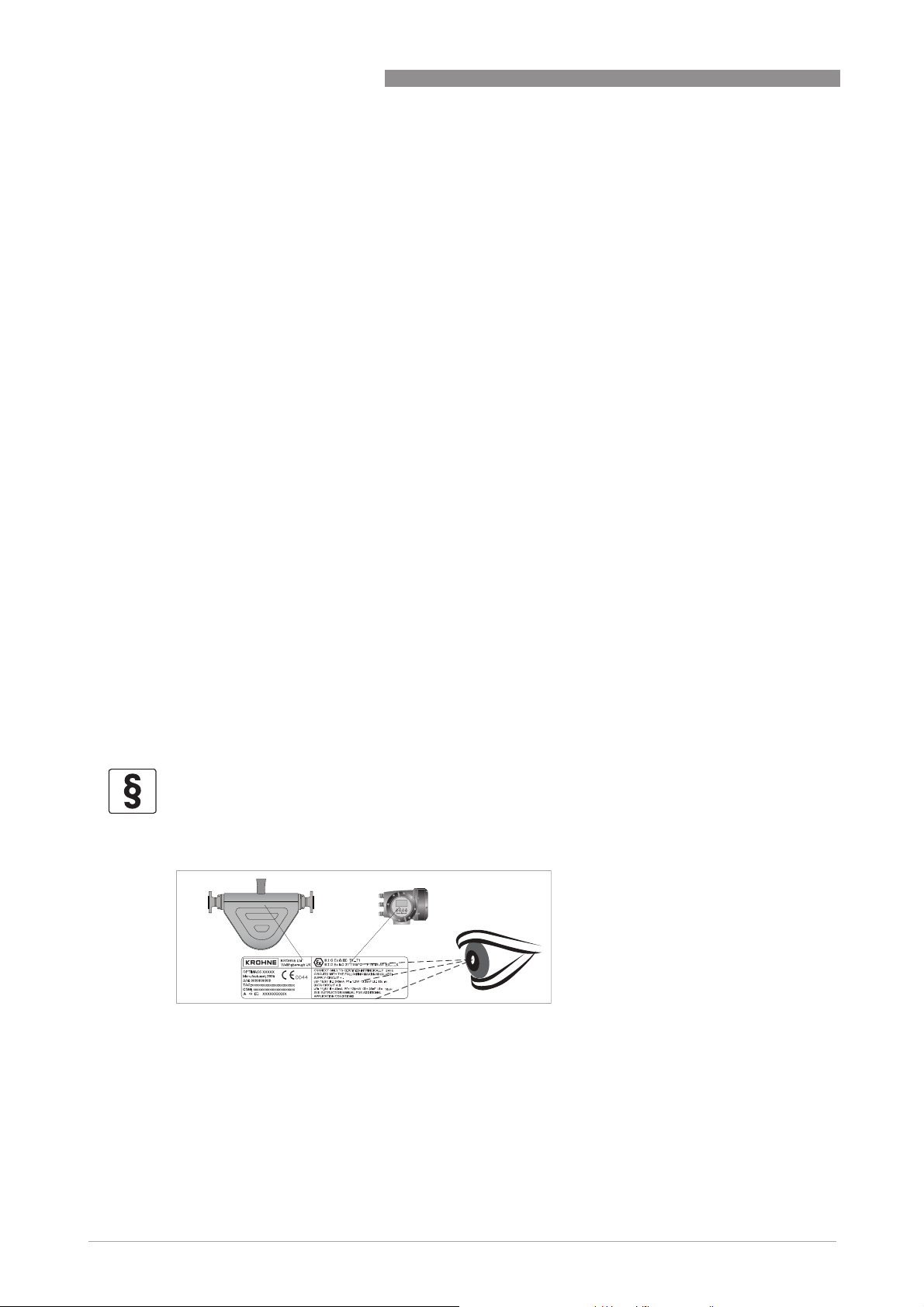

2.2 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.3 Dual Seal

To comply with the requirements of ANSI/ISA -12.27.01-2011 “Requirements for process Sealing

Between electrical systems and Flammable or Combustible process Fluids” a secondary seal is

incorporated into all OPTIMASS / GAS products. If the primary seal fails, the secondary seal will

prevent escaping fluid reaching the electronic compartment.

Pressures and / or temperatures are limited by tube, temperature, connection and Ex limits.

Check the meter nameplates and relevant documentation for full details. On all meters

operating on gas measurement, the casing of the meter is fitted with a burst disc. If the primary

seal (tube) fails leakage will occur from the burst disc. Install the meter so that the burst disc is

pointing away from personnel.

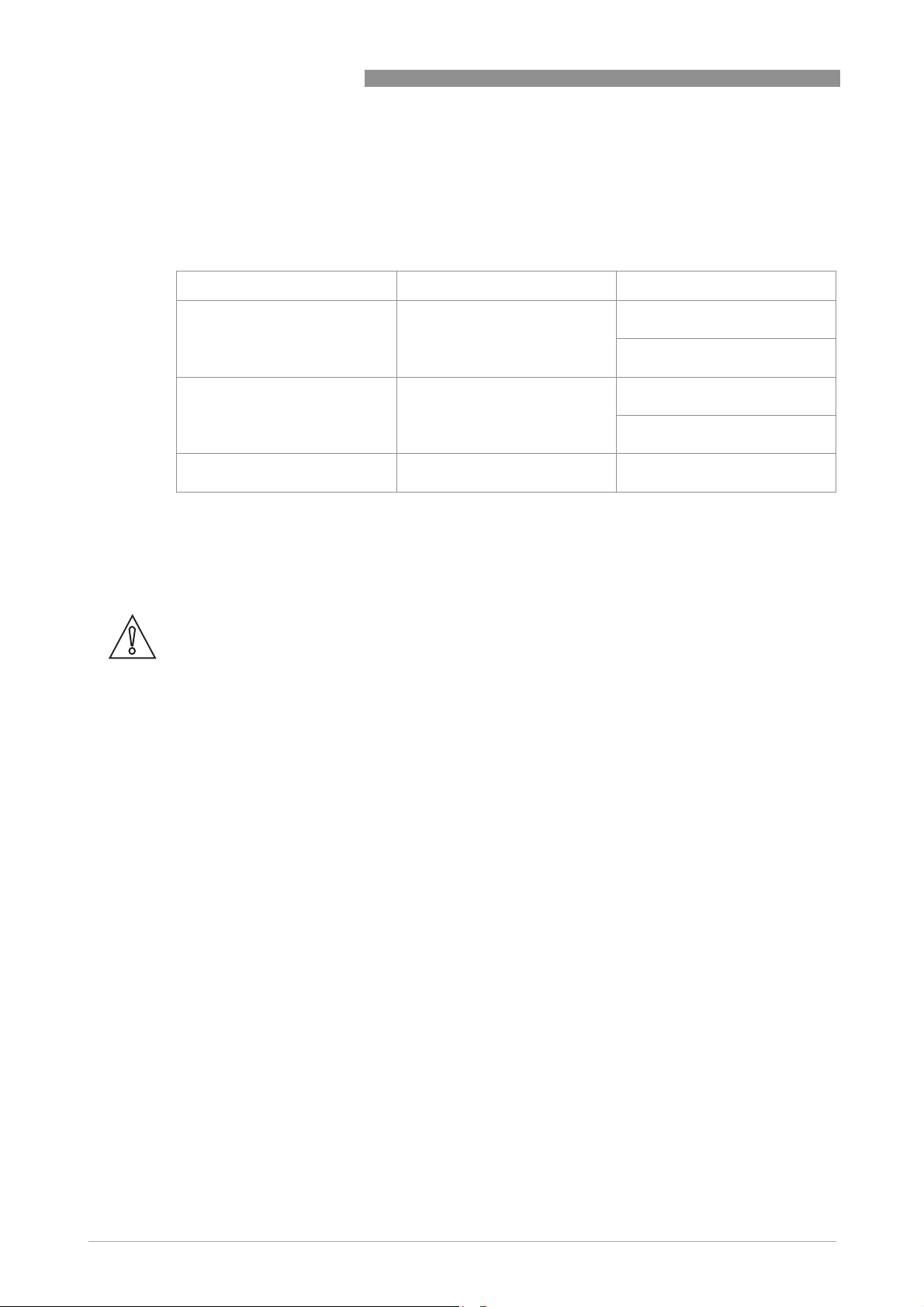

Liquids

Liquids (Example model code: OPTIMASS 6000F S50 - LIQUID)

LiquidsLiquids

Pressure and temperature data:

Pressure and temperature data:

Pressure and temperature data:Pressure and temperature data:

OPTIMASS 6000 / 6000F / 6400C-200°C...+230°C and 100...10000 kPa (Stainless Steel)

OPTIMASS 6000 / 6000F / 6400C-50°C...+230°C and 100...20000 kPa (Hastelloy® / duplex)

OPTIMASS 6000 / 6000F- HT -50°C...+400°C and 100...10000 kPa

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

11

Page 12

2

DEVICE DESCRIPTION

If the primary seal fails, the casing of the meter will fill with liquid and the meter will stop

working. The meter will notify the operator by displaying the status message "Sensor: Sensor

signal low" on the converter or PLC display. This is an indication that the primary seal (tube) has

failed and the status of the meter should be checked.

As soon as it is safe to do so, de-pressurise the process line and remove the meter. Please

contact customer service for servicing or replacement of the meter.

INFORMATION!

At high pressures, process fluid may also leak from the meter casing. This is also an indicatioin

that the primary seal has failed.

Meter status:

Meter status:

Meter status:Meter status:

The meter will also display the mesage "Sensor: Sensor signal low" if the measuring tubes are

not completely filled with fluid. For example, if the meter is drained or re/filled. To check the

status of the meter, drain and re/fill with fluid and note the converter or PLC display. See the

relevant section of the converter handbook for a list of status messages and diagnostics

information.

OPTIMASS 6000

If the meter continues to display the message: "Sensor: Sensor signal low" you MUST assume

that the primary seal (tubes) has failed and the appropriate action MUST be taken.

Gases

Gases (Example model code: OPTIMASS 6000F S50 - GAS)

GasesGases

Pressure / temperature data:

Pressure / temperature data:

Pressure / temperature data:Pressure / temperature data:

OPTIMASS 6000 / 6000F / 6400C -200°C...+230°C and 500... 10000 kPa (Stainless Steel)

OPTIMASS 6000 / 6000F / 6400C-50°C...+230°C and 500...20000 kPa (Hastelloy® / duplex)

OPTIMASS 6000F- HT -50°C...+400°C and 500...10000 kPa

Pressures and/or temperatures may be further limited by tube, temperature, connection and Ex

limits. Consult the meter nameplate and relevant documentation for full details.

On all meters operating on gas measurement the casing of the meter is fitted with a burst disc. If

the primary seal (tube/s) fails leakage will occur from the burst disc. Install the meter so that the

burst disc is pointing away from personnel.

Regular maintenance of the burst disc:

Regular maintenance of the burst disc:

Regular maintenance of the burst disc:Regular maintenance of the burst disc:

Carry out regular maintenance checks on burst discs for leakage and/or blockages. On all

OPTIMASS meters, the primary seal is considered to be the measuring tube of the meter. The

materials of construction of the measuring tube/s are described within the relevant sections of

this handbook and the customer’s product and any other fluid flowing through the tube must be

compatible with the material of construction. If failure of the primary seal is suspected then the

process line should be de-pressurised and the meter removed as soon as it is safe to do so.

Please contact customer service for servicing or replacement of the meter.

12

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 13

OPTIMASS 6000

2.4 Temperature differential and thermal shock

Temperature differential

Temperature differential

Temperature differentialTemperature differential

The maximum difference between ambient temperature and process (operating) temperatures

are:

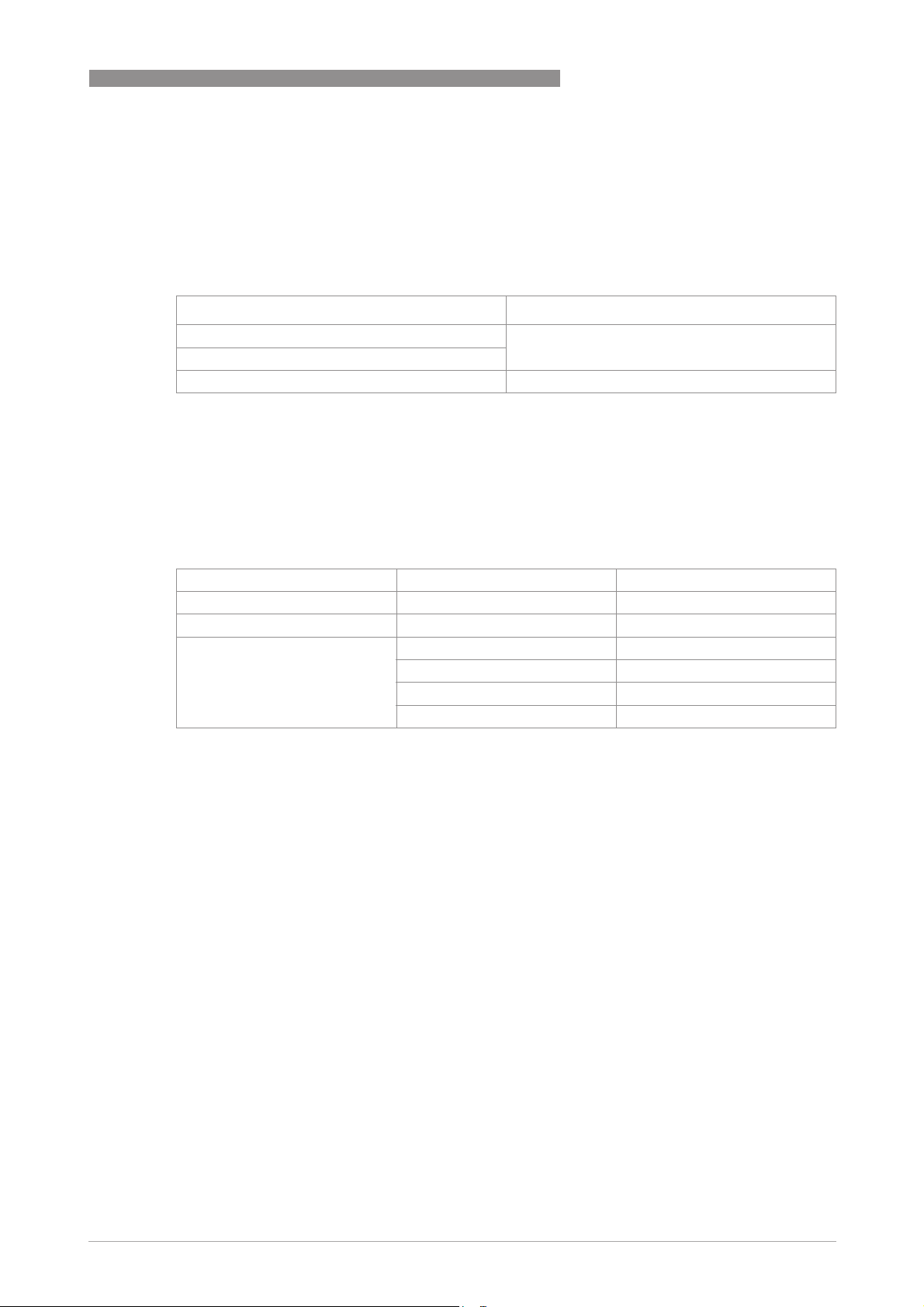

Meter temperature range Maximum temperature differential

-200°C...+40°C / -328°F...+104°F 210°C / 410°F

-70°C...+230°C / -94°F...+446°F

-50°C...+400°C / -58°F...+752°F 380°C / 716°F

Thermal shock

Thermal shock

Thermal shockThermal shock

Thermal shock occurs when there is a sudden and extreme change (shift) in process

temperature. Continual shocking (cycles) reduces the life span of the meter depending on the

temperature shift. Please refer to the table below for the maximum temperature shift and the

number of times (cycles) that the meter can be shocked at that temperature.

DEVICE DESCRIPTION

2

Meter size Max temperature shift Cycles

08...100 100°C / 212°F 3500

150...200 100°C / 212°F 2000

250 -100°C / -148°F 2000

+100°C / +212°F 400

+80 / +176°F 800

+50 / +122°F 1500

Thermal shocking below these temperature shifts will increase the life span of the meter. For

more information, please contact your nearest representative.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

13

Page 14

2

DEVICE DESCRIPTION

Maximum temperature rate rise

Maximum temperature rate rise

Maximum temperature rate riseMaximum temperature rate rise

If the change in temperature (rate rise) is greater than 100°C / 212°F, the temperature rise must

be over a period of time. Calculate the time required for the whole temperature rise using the

table below.

Meter size Temperature rate rise Example

08...50 6°C / 10.8°F per minute 20°C...230°C / 68°F...446°F = 70

80...200 3°C / 5.4°F per minute 20°C...230°C / 68°F...446°F = 70

250 3°C / 5.4°F per minute

1 Up to 230°C / 446°F

1

OPTIMASS 6000

minutes

20°C...400°C / 68°F...752°F = 80

minutes

minutes

20°C...400°C / 68°F...752°F = 140

minutes

20°C...230°C / 68°F...446°F = 70

minutes

These limits will provide a minimum calculated life span for the meter of 2000 cycles for meter

sizes 08...200 and 1000 cycles for meter size 250. Temperature rises below 100°C / 212°F, or

temperature rises over a longer period of time, will increase the life span of the meter.

CAUTION!

Operation outside these limits may result in shifts in density and mass flow calibration. Repeated

shocking and / or rapid heating, may also result in premature failure of the meter. However,

higher thermal shocks and / or an increased number of cycles are possible at lower working

pressures. For more information, please contact your nearest representative.

2.5 Functional safety (SIL capable converter)

The meter can be used to measure mass, volume and density at SIL 2 (single channel

architecture) and SIL 3 (multi-channel architecture with redundancy).

For more information please refer to the Safety manual.

14

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 15

OPTIMASS 6000

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry and dust-free location.

• Avoid direct exposure to the sun.

• Store the device in its original packing.

• Do not allow the ambient temperature to fall below -50°C / -58°F or rise above +85°C /

+185°F. (-40°C / -40°F and +70°C / +158°F. where a SIL capable converter has been supplied)

INSTALLATION

3

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

15

Page 16

3

INSTALLATION

3.3 Handling

OPTIMASS 6000

16

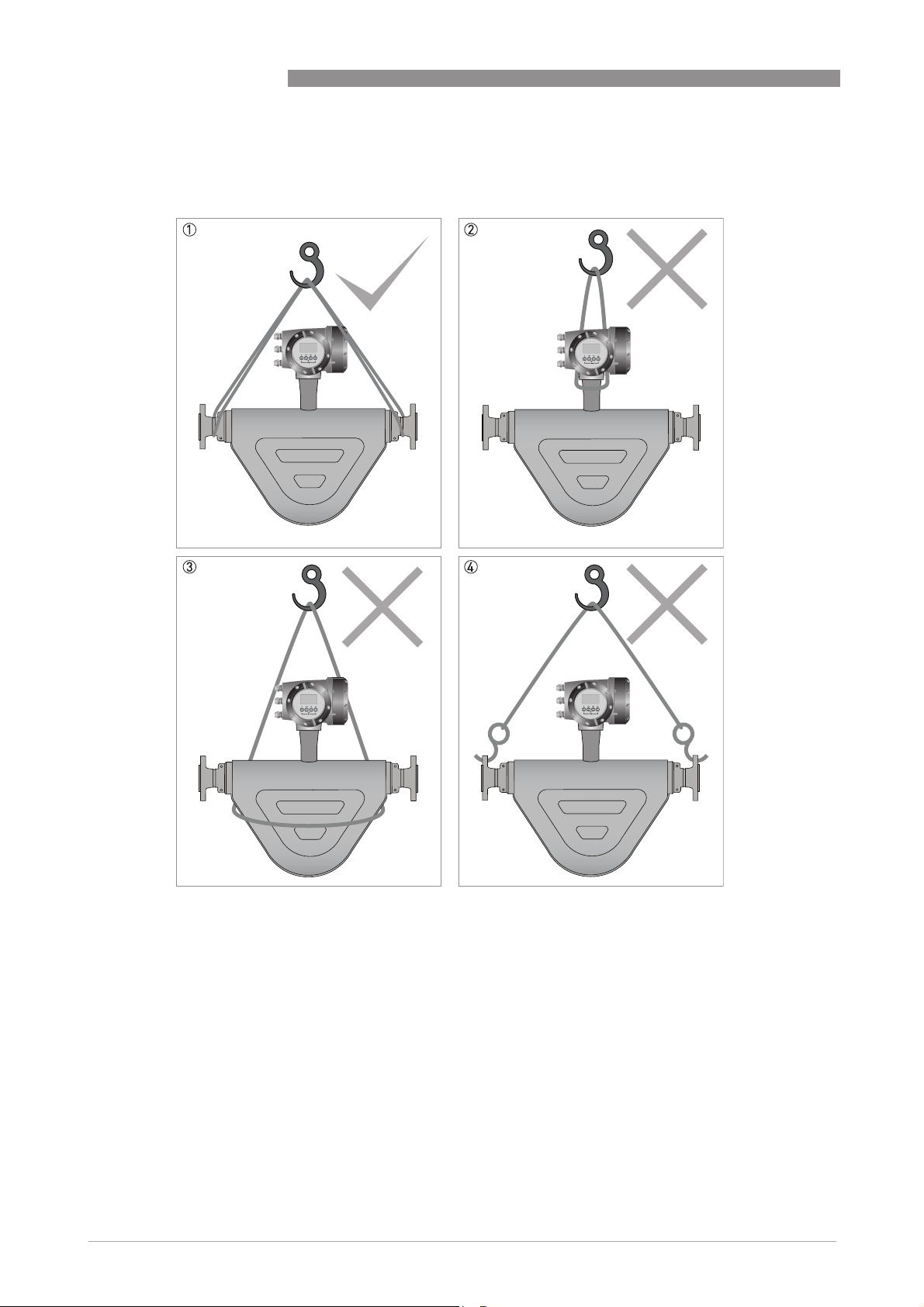

1 Use a well maintained sling to lift the meter by the spigots.

2 DO NOT lift the meter by the converter housing or the electronics stem.

3 DO NOT lift the meter by the meter body.

4 DO NOT lift the meter using the flange bolt holes.

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 17

OPTIMASS 6000

3.4 Installation conditions

3.4.1 Supporting the meter

INSTALLATION

3

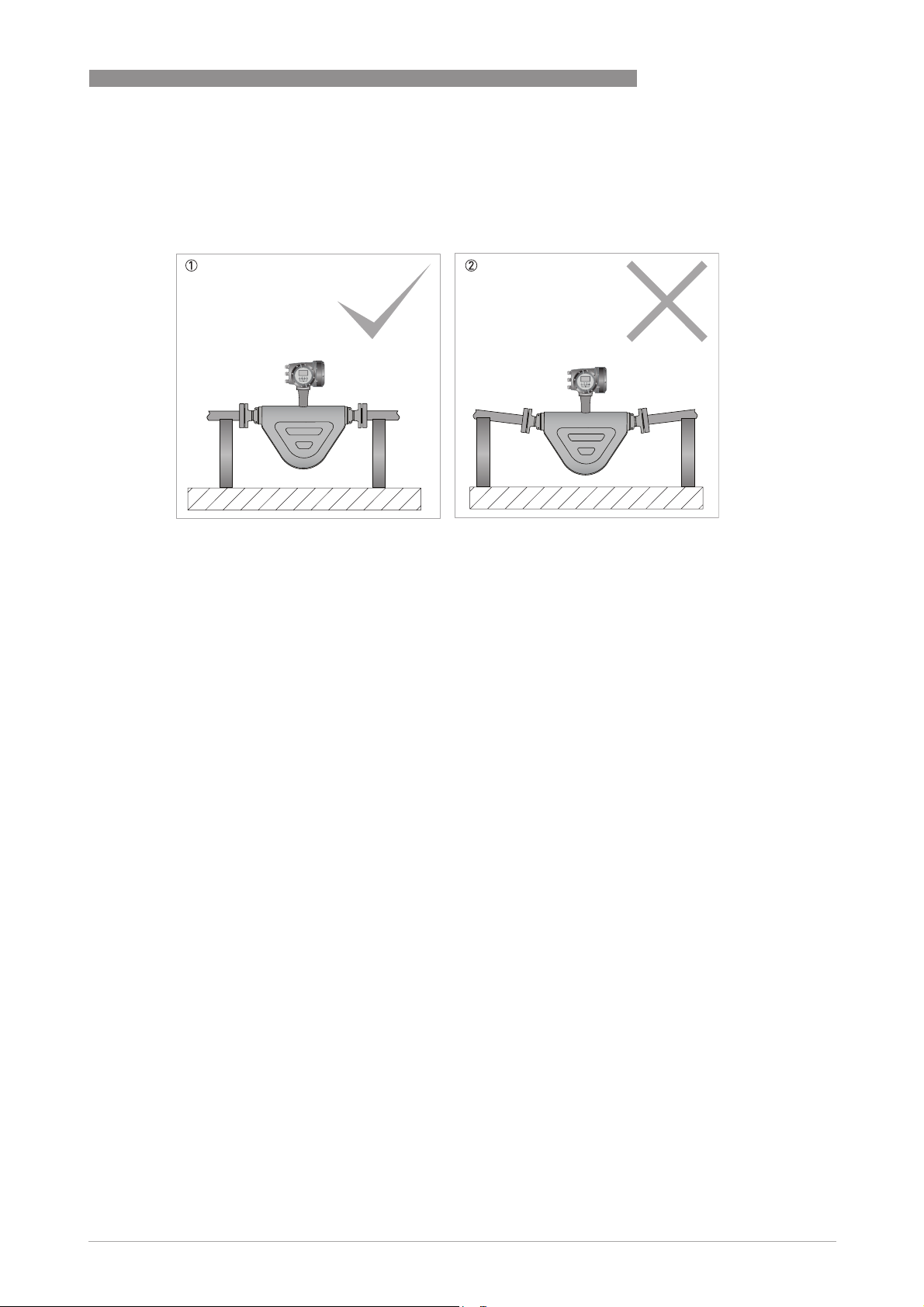

1 Support the weight of the meter on the process pipework.

2 DO NOT leave a long pipe run between the meter and the support. This can cause damage to the meter, especially on

larger meter sizes.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

17

Page 18

3

INSTALLATION

3.4.2 Mounting the meter

Mounting positions

OPTIMASS 6000

18

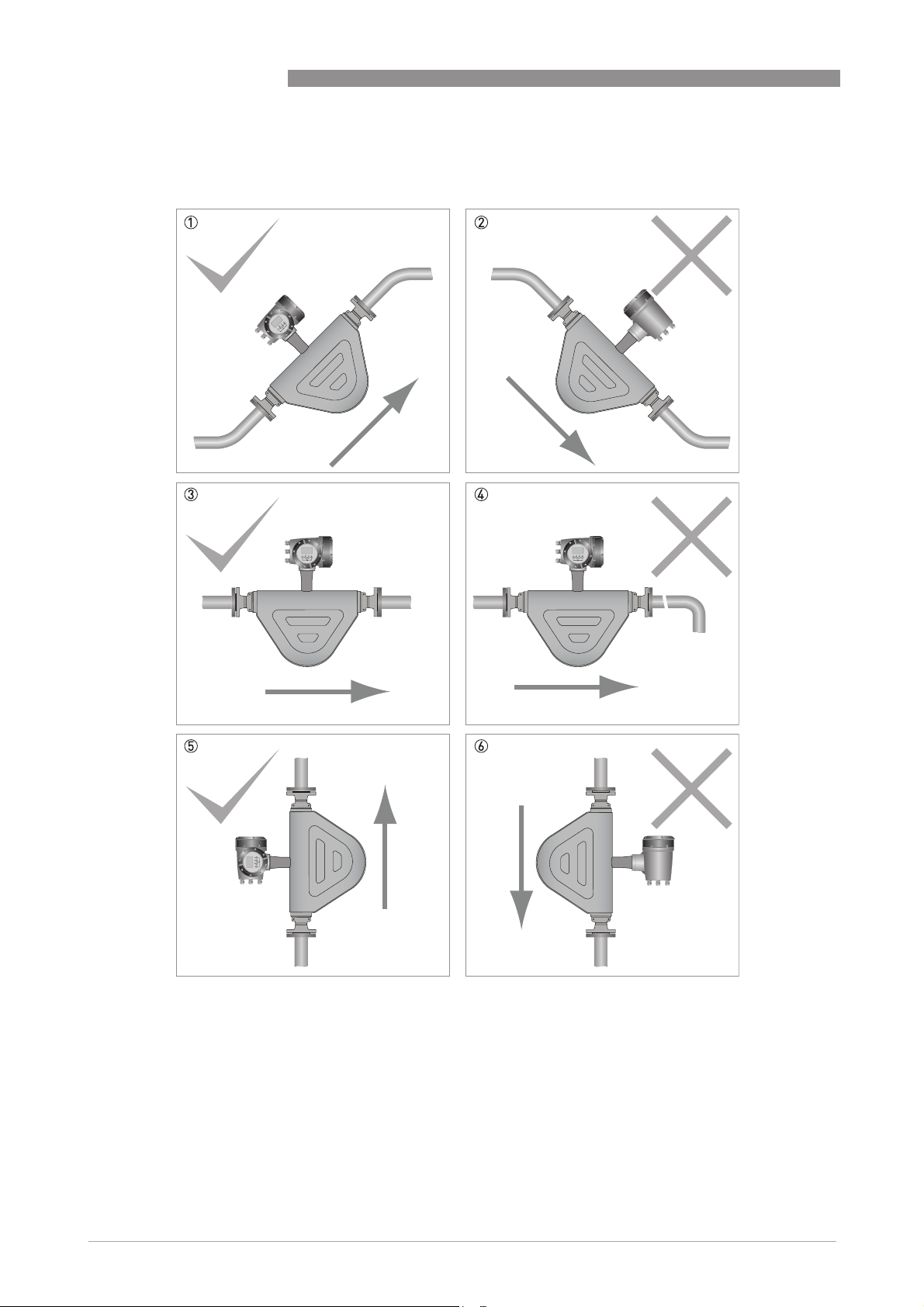

1 The meter can be mounted at an angle but it is recommended that the flow is uphill.

2 Avoid mounting the meter with the flow running downhill because it can cause siphoning. If the meter has to be mount-

ed with the flow running downhill, install an orifice plate or control valve downstream of the meter to maintain backpressure.

3 Horizontal mounting with flow running left to right.

4 Avoid mounting meter with long vertical runs after the meter as it can cause cavitation. Where the installation includes

a vertical run after the meter, install an orifice plate or control valve downstream to maintain backpressure.

5 The meter can be mounted vertically but it is recommended that the flow is uphill.

6 Avoid mounting the meter vertically with the flow running downhill. This can cause siphoning. If the meter has to be

installed this way, install an orifice plate or control valve downstream to maintain backpressure.

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 19

OPTIMASS 6000

3.4.3 Self draining

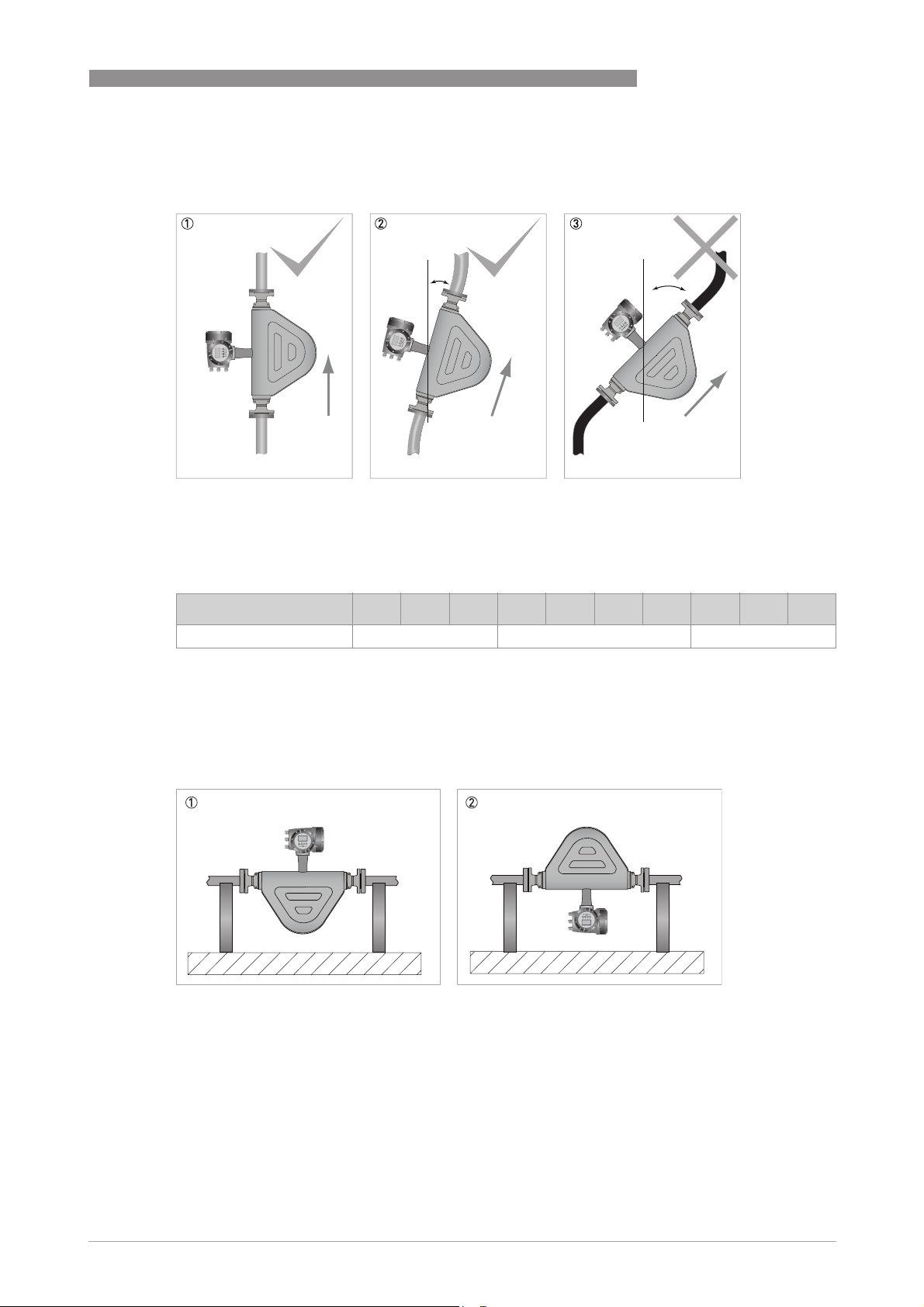

1 If the meter needs to be self draining, install the meter vertically.

2 If conditions prevent vertical installation, the meter can be installed at an angle, as shown. The table below gives the

maximum angle according to meter size.

3 If the meter is installed at an angle greater than shown in the table, the meter will not be self draining.

INSTALLATION

3

Maximum angle (according to meter size)

Meter size 08 10 15 25 50 80 100 150 200 250

Maximum angle 15° 20° 20°

3.4.4 Gas / liquid build up

In certain applications, the design of the meter can cause either gas or liquid to build up in the

measuring tube.

1 Where liquids are being measured, mount the meter as shown. This will prevent gas building up in the measuring tube,

when there is no flow.

2 Where gases are being measured, mount the meter as shown. This will prevent liquids building up in the measuring

tube, when there is no flow.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

19

Page 20

3

INSTALLATION

3.4.5 Side mounting

The meter can be installed with the converter (or remote junction box) on the side of the meter

so that the measuring tubes are sitting one above the other. Avoid this method of installation

where there is a two phase process flow, or where the process fluid contains gas. If this situation

cannot be avoided, please contact the manufacturer for advice.

OPTIMASS 6000

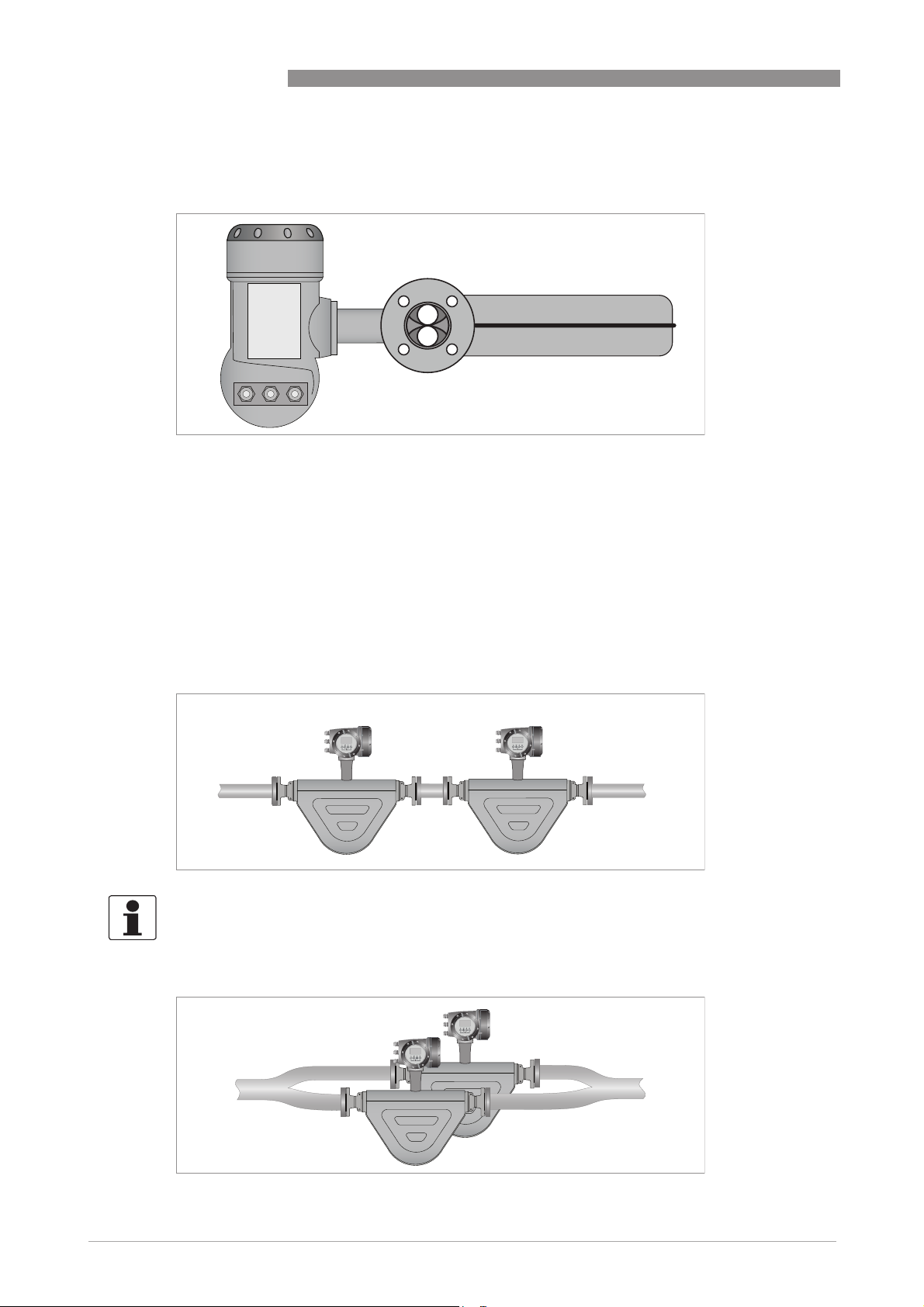

3.4.6 Cross talk

Where more than one meter is being installed, a very high level of immunity to cross talk means

that the meters can be mounted within close proximity to each other. The meters can be

mounted either in series or parallel, as shown.

INFORMATION!

Where the meters are installed in series, it is strongly recommended that the process pipe

diameter remains constant. For more information, please contact the manufacturer.

20

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 21

OPTIMASS 6000

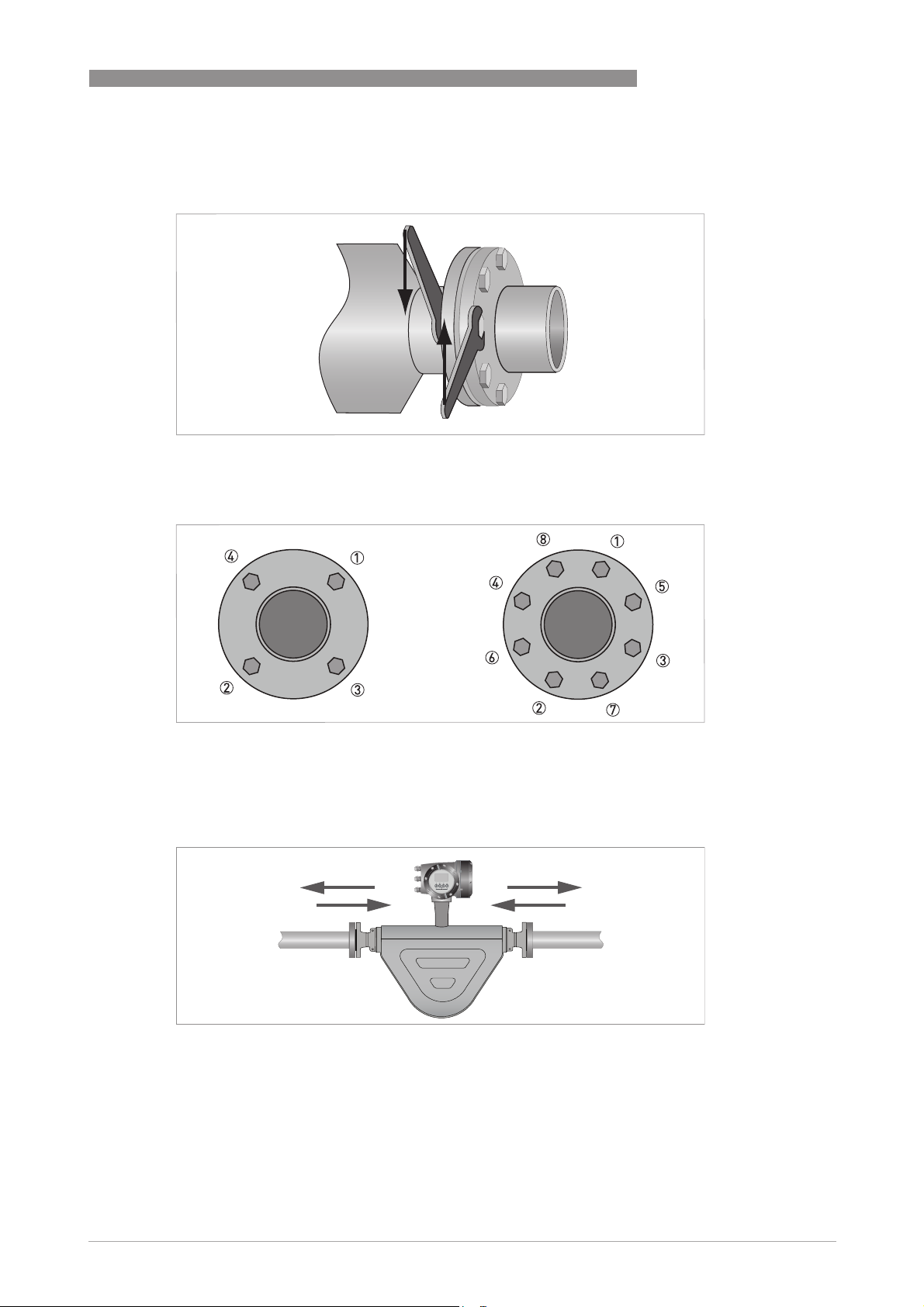

3.4.7 Flange connections

Tighten the flange bolts evenly and in turn.

INSTALLATION

3

Use a regular pattern to tighten the bolts evenly

3.4.8 Maximum pipework forces (end loadings)

Mass flowmeters have a maximum level of force (negative or positive) that can be applied to the

ends of the meter. Refer to the table below for permitted forces.

Please refer to the table in the technical data section of this Handbook for the maximum end

loadings.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

21

Page 22

3

INSTALLATION

3.4.9 Pipework reducers

Always avoid extreme step changes in pipe size. Use pipework reducers, where there is a large

difference between pipework size and meter flanges.

3.4.10 Flexible connections

OPTIMASS 6000

Flexible connections can be used but because of the high flow rates associated with large

diameter meters, it is recommended that flexible connections are not used on meters larger

than size 80.

22

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 23

OPTIMASS 6000

3.4.11 Hygienic installations

Mounting the meter for hygienic applications

1 Install the meter vertically to allow self draining.

2 DO NOT install the meter horizontally.

INSTALLATION

3

Where the meter has been approved by the sanitary requirements of the European Hygienic

Engineering and Design Group, you MUST give consideration to:

• Installation - install the meter at an angle to allow self-draining (see illustration).

• Cleaning fluids - cleaning fluids should flow uphill with a velocity rate greater than

1.5 m/s / 5ft/s. If the process flow is downhill, install a flow restrictor downstream of the

meter. This will make sure that the meter is completely filled with the cleaning fluid.

• Process connections and seals MUST be in accordance with EHEDG documentation.

The manufacturer also recommends that you refer to EHEDG (www.ehedg.org) document

number 8 "HYGIENIC EQUIPMENT DESIGN CRITERIA".

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

23

Page 24

3

INSTALLATION

3.4.12 Heating and insulation

Insulation

Insulation

InsulationInsulation

The meter can be insulated to a maximum depth as shown (A). Do not insulate above this depth

as this will cause the electronics to overheat.

Insulation

OPTIMASS 6000

S08 S10 S15 S25 S50 S80 S100 S150 S200 S250

Dimension A [mm] 100 100 100 100 100 100 100 100 100 100

Dimension A [inches] 3.9 3.9 3.9 3.9 3.9 3.9 3.9 3.9 3.9 3.9

Factory fitted heating jacket

Factory fitted heating jacket

Factory fitted heating jacketFactory fitted heating jacket

If the meter has been ordered with a heating jacket, it will be supplied with DN15 PN40 to EN

1092-1 or 1/2¨ ASME150 flange connections.

24

Figure 3-1: The loop inside the heating jacket, carries the heating medium.

Connecting / using the heating jacket

• Use rigid or reinforced flexible hoses to connect the heating jacket to the heat source.

• The heating jacket / loop material is SS316.

• Suitable heating mediums are steam or hot oil. Avoid the use of heating mediums that can

cause crevice corrosion in Stainless Steel.

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 25

OPTIMASS 6000

• Where liquid is being used, set up the pipe configuration so that air can be vented from the

system.

• Where steam is being used, set up the pipe configuration so that condensation can be drained

off.

• Gradually heat the jacket to working temperature before flowing the process fluid through

the meter.

CAUTION!

The design of the heating jacket is such that NO end load pressure (negative or positive) can be

applied. The manufacturer recommends that (where possible) flexible hoses are used to connect

to the heat source.

CAUTION!

The maximum heating pressure and temperature for heating jackets is 10 barg at

°

C / 145 psig at 446°F or 5 barg at 400°C / 72.5 psig at 752°F

230

3.4.13 Purge ports

If the meter has been ordered with a purge port, it will be supplied with NPT female connections

which are clearly marked. The connections are sealed with NPT plugs and PTFE tape.

INSTALLATION

3

CAUTION!

DO NOT remove these plugs.

The meter is factory sealed with a dry nitrogen gas fill and if moisture is allowed to enter the

meter casing it will cause damage. The plugs should only be removed to purge the meter casing

in the event that the primary measuring tube fails.

If it is suspected that the primary measuring tube has failed, de-pressurise the meter and

remove it from service, as soon as it is safe to do so.

3.4.14 Burst discs

If the meter has been ordered with a burst disc, it will be supplied with the disc fitted. The failure

pressure of the disc is 10 barg at +20°C / 145 psig at +68°F.

CAUTION!

The fitted burst disc will be suitable for the flow rates and process conditions specified on the

original order. If the process conditions alter in any way, it is recommended that you contact the

manufacturer for advice regarding suitability.

If the process product is hazardous (in any way) it is recommended that an exhaust tube is

connected to the NPT male thread of the burst disc and the pipe routed so that the process

product can be discharged to a safe area. Use a tube with a diameter large enough AND routed in

such a way, so that pressure cannot build up in the meter case.

INFORMATION!

For gas applications, the burst disc must be specified at the time of ordering.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

25

Page 26

3

INSTALLATION

3.4.15 Zero calibration

The procedure for zero calibration is contained in the converter handbook. However, the

following information should be considered when installing the meter.

Zero calibration

OPTIMASS 6000

1 Where the meter has been installed vertically, install shut-off valves either side of the meter to assist with zero cali-

bration.

2 If the process flow cannot be stopped, install a bypass section for zero calibration.

3.4.16 Sunshades

The meter MUST be protected from strong sunlight.

1 Horizontal installation

2 Vertical installation

26

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 27

OPTIMASS 6000

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS

4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Electrical and I/O connections

For information regarding electrical and I/O connections, please refer to the handbook for the

relevant signal converter.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

27

Page 28

5

SERVICE

5.1 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

5.2 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

5.3 Returning the device to the manufacturer

OPTIMASS 6000

5.3.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

WARNING!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of the personnel, the manufacturer may only handle, test and repair returned devices

that have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

WARNING!

If the device has been operated with toxic, caustic, radioactive, flammable or water-endangering

products, you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that it is safe to handle and stating the

product used.

28

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 29

OPTIMASS 6000

5.3.2 Form (for copying) to accompany a returned device

CAUTION!

To avoid any risk for our service personnel, this form has to be accessible from outside of the

packaging with the returned device.

Company: Address:

Department: Name:

Tel. no.: Fax no. and/or Email address:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

This medium is: radioactive

water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such substances.

We have flushed out and neutralized all cavities in the device.

SERVICE

5

We hereby confirm that there is no risk to persons or the environment through any residual media contained in the

device when it is returned.

Date: Signature:

Stamp:

5.4 Disposal

LEGAL NOTICE!

Disposal must be carried out in accordance with legislation applicable in your country.

Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:

Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:

Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:Separate collection of WEEE (Waste Electrical and Electronic Equipment) in the European Union:

According to the directive 2012/19/EU, the monitoring and control instruments marked with the

WEEE symbol and reaching their end-of-life must not be disposed of with other waste

The user must dispose of the WEEE to a designated collection point for the recycling of WEEE or

send them back to our local organisation or authorised representative.

must not be disposed of with other waste.

must not be disposed of with other wastemust not be disposed of with other waste

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

29

Page 30

6

TECHNICAL DATA

6.1 Measuring principle (twin tube)

Meter from the side, showing tube layout

OPTIMASS 6000

1 Measuring tubes

2 Drive coil

3 Sensor 1

4 Sensor 2

Static meter not energised and with no flow

1 Measuring tubes

2 Drive coil

3 Sensor 1

4 Sensor 2

A Coriolis twin tube mass flowmeter consists of two measuring tubes 1 a drive coil 2 and two

sensors (3 and 4) that are positioned either side of the drive coil.

30

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 31

OPTIMASS 6000

Energised meter

1 Measuring tubes

2 Direction of oscilation

3 Sine wave

When the meter is energised, the drive coil vibrates the measuring tubes causing them to

oscillate and produce a sine wave 3. The sine wave is monitored by the two sensors.

Energised meter with process flow

TECHNICAL DATA

6

1 Process flow

2 Sine wave

3 Phase shift

When a fluid or gas passes through the tubes, the coriolis effect causes a phase shift in the sine

wave that is detected by the two sensors. This phase shift is directly proportional to the mass

flow.

Density measurement is made by evaluation of the frequency of vibration and temperature

measurement is made using a Pt500 sensor.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

31

Page 32

6

TECHNICAL DATA

OPTIMASS 6000

6.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle Coriolis mass flow

Application range Mass flow and density measurement of fluids, gases and solids

Measured values Mass, density, temperature

Calculated values Volume, referred density, concentration, velocity

Sensor model range

Sensor model range

Sensor model rangeSensor model range

Stainless Steel 316L 08...250 Compact / remote 100 barg @ 20°C / 1450 psig @ 68°F, temp. range

Hastelloy® 08...80

Duplex Stainless Steel 100...200 Compact / remote 200 barg @ 20°C / 2900 psig @ 68°F, temp. range

-70°C...+230°C / -94°F...+446°F

Remote only 100 barg @ 20°C / 1450 psig @ 68°F, temp. range

-50°C...+400°C / -58°F...+752°F

Compact / remote 100 barg @ 20°C / 1450 psig @ 68°F, temp. range

-200°C...+40°C / -364°F...+104°F

Compact / remote 200 barg @ 20°C / 2900 psig @ 68°F, temp. range

-70°C...+400°C / -58°F...+752°F

Compact / remote 200 barg @ 20°C / 2900 psig @ 68°F, temp. range

-50°C...+400°C / -58°F...+752°F

Remote only 200 barg @ 20°C / 2900 psig @ 68°F, temp. range

-196°C...+40°C / -364°F...+104°F

-50°C...+230°C / -58°F...+446°F

Design

Basic System consists of a measuring sensor and a converter to process the

Features Fully welded maintenance free sensor with twin V-shaped measuring tube

Variants

Variants

VariantsVariants

Compact version Integral converter

Remote version Available with a field version of the converter

output signal

Performance specification

Reference conditions

Reference conditions

Reference conditionsReference conditions

Calibration fluid Water

Calibration temperature +20°C / +68°F (± 5°C)

Calibration pressure 1...6 barg / 14.5...87 psig

Calibration rig Accreditation satisfies the requirements of BS EN ISO / IEC 17025

Mass flow (standard)

Mass flow (standard)

Mass flow (standard)Mass flow (standard)

Liquid flow rate ≥ zero stability × 1000

Base accuracy ±0.1% of actual measured flow rate

Repeatability Better than 0.05% of measured flow rate

32

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 33

OPTIMASS 6000

Liquid flow rate < zero stability × 1000

Base accuracy ±zero stability (see zero stability below)

Repeatability Better than zero stability × 0.5

Gas Better than 0.35% plus zero stability

Repeatability Better than 0.2% plus zero stability

Mass flow (optional)

Mass flow (optional)

Mass flow (optional)Mass flow (optional)

Liquid flow rate ≥ zero stability × 2000

Base accuracy 0.05% of measured flow rate

Repeatability Better than 0.025% of measured flow rate

Liquid flow rate < zero stability × 2000

Base accuracy ±zero stability

Repeatability Better than zero stability × 0.5

Zero stability

Zero stability

Zero stabilityZero stability

Meter size Standard temperature High temperature

08 < 0.03 kg/h < 0.48 kg/h

10 < 0.06 kg/h < 0.096 kg/h

15 < 0.19 kg/h < 0.304 kg/h

25 < 0.95 kg/h < 1.52 kg/h

50 < 1.75 kg/h < 2.80 kg/h

80 < 3.90 kg/h < 6.24 kg/h

100 < 8.75 kg/h < 14.00 kg/h

150 < 16.00 kg/h < 25.60 kg/h

200 < 27.50 kg/h < 44.00 kg/h

250 < 50.00 kg/h < 80.00 kg/h

Effect on sensor zero point caused by a deviation in process temperature from zero calibration temperature

Effect on sensor zero point caused by a deviation in process temperature from zero calibration temperature

Effect on sensor zero point caused by a deviation in process temperature from zero calibration temperatureEffect on sensor zero point caused by a deviation in process temperature from zero calibration temperature

Standard temperature range

All materials sizes 08...10 0.0010% of nominal flow per 1°C / 0.00056% of nominal flow per 1°F

All materials sizes 15...250 0.00075% of nominal flow per 1°C / 0.00042% of nominal flow per 1°F

High temperature range

All materials sizes 08...250 0.008% of nominal flow per 1°C / 0.0044% of nominal flow per 1°F

Pressure effect on mass flow rate

Pressure effect on mass flow rate

Pressure effect on mass flow ratePressure effect on mass flow rate

All materials sizes 08...50 -0.005% of reading per 1 barg / -0.00034 % per 1 psig

All materials sizes 80...100 -0.0055% of reading per 1 barg / -0.00038 % per 1 psig

All materials sizes 150...250 -0.008% of reading per 1 barg / -0.00055 % per 1 psig

Density

Density

DensityDensity

Measuring range

Base accuracy

Repeatability / on site calibration

Process temperature effect of deviation from calibration temperature

Process temperature effect of deviation from calibration temperature

Process temperature effect of deviation from calibration temperatureProcess temperature effect of deviation from calibration temperature

All materials / meter sizes Better than 0.015 g/l per 1°C / 0.0083 g/l per 1°F

100...3000 kg/m3 / 6...187 lb/ft

±1 kg/m3 / ±0.06 lb/ft

±0.3 kg/m3 / ±0.015 lb/ft

3

3

3

TECHNICAL DATA

6

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

33

Page 34

6

TECHNICAL DATA

OPTIMASS 6000

Pressure effect on density of deviation from calibration pressure (based on reference density = 1000 kg/m

Pressure effect on density of deviation from calibration pressure (based on reference density = 1000 kg/m

Pressure effect on density of deviation from calibration pressure (based on reference density = 1000 kg/mPressure effect on density of deviation from calibration pressure (based on reference density = 1000 kg/m

All materials size 08

All materials sizes 10…15

All materials sizes 25…80

All materials sizes 100…150

Volume flow

Volume flow

Volume flowVolume flow

Measurement error and repeatability calculations satisfy the requirements of BS ISO 10790 (most recent and up to date

version)

Temperature

Temperature

TemperatureTemperature

Measurement error ± 0.5°C ± 0.5% of reading / ±0.9°F ± 0.5% of reading

+0.038 kg/m3 per bar

+0.026 kg/m3 per bar

+0.017 kg/m3 per bar

+0.011 kg/m3 per bar

3333

)

Operating conditions

Nominal flow rates

Nominal flow rates (1 barg / 14.5 psig pressure drop)

Nominal flow ratesNominal flow rates

08 600 kg/h / 22 lb/min

10 1200 kg/h / 44 lb/min

15 3800 kg/h / 139 lb/min

25 19000 kg/h / 698 lb/min

50 35000 kg/h / 1286 lb/min

80 78000 kg/h / 2866 lb/min

100 175000 kg/h / 6430 lb/min

150 320000 kg/h / 11758 lb/min

200 550000 kg/h / 20209 lb/min

250 1000000 kg/h / 36743 lb/min

Assumes operating density 1000 kg/m3 / 62.4 lb/ft

For Hastelloy® meters, assume a pressure drop of 1.15 barg

Maximum flow rates

Maximum flow rates

Maximum flow ratesMaximum flow rates

All meters 150% of nominal flow rate

3

Environmental

Ambient temperature

Ambient temperature

Ambient temperatureAmbient temperature

Compact meter Standard converter SIL capable converter

Aluminium converter -40...+65°C / -40…+149°F -40...+55°C / -40…+131°F

Stainless Steel converter -40...+60°C / -40…+131°F -40...+55°C / -40…+131°F

Remote meter Standard converter SIL capable converter

Standard temperature range -40...+65°C / -40…+149°F -40...+55°C / -40…+131°F

Cryogenic temperature range -20...+65°C / -4…+149°F -40...+55°C / -40…+131°F

Hazardous Area versions Refer to temperature limits

Protection category (Acc. toEN 60529 IP 67, NEMA 4X

Vibration (acc IEC 60068-2-6)

Process temperatures

Process temperatures

Process temperaturesProcess temperatures

Standard temperature range (flange

connections)

Safe area -70…+230°C / -94…+446°F -70...+150°C / -94...+302°F

Hazardous area -50…+230°C / -58…+446°F -50°C...+150°C / -58...+302°F

34

10-150-10 Hz with 0.15 mm for 10...60 Hz, 20 m/s2 for 60…150 Hz

Extended stem Short stem

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 35

OPTIMASS 6000

High temperature range -50…+400°C / -58…+752°F N/A

Cryogenic temperature range -200…+40°C / -328…+104°F -200…+40°C / -328…+104°F

Standard temperature range (hygienic

connections)

Safe area -70…+150°C / -94…+302°F -70…+150°C / -94…+302°F

Hazardous area -50…+150°C / -58…+302°F -50…+150°C / -58…+302°F

Nominal pressure at 20

Nominal pressure at 20° C / 68

Nominal pressure at 20Nominal pressure at 20

Measuring tube

Measuring tube SS 316 / 316L Hastelloy® C22 / S31803

Measuring tubeMeasuring tube

FM / PED -1…100 barg / -14.5…1450 psig -1…200 barg / -14.5…2900 psig

CRN / ASME B31.3 -1…100 barg / -14.5…1450 psig Pending

Outer casing burst pressure

Outer casing burst pressure

Outer casing burst pressureOuter casing burst pressure

08 ≈ 100 barg

10

15

25

50 ≈ 70 barg

80

100 ≈ 10 barg

150

200

250

If the process temperature is higher than 20°C / 68°F, the burst pressure will be lower. For more information please

contact the manufacturer.

Fluid properties

Fluid properties

Fluid propertiesFluid properties

Permissible physical condition Liquids, gases, slurries

Permissible gas content (volume) Contact manufacturer for information.

Permissible solid content (volume) Contact manufacturer for information.

Installation conditions

Installation conditions

Installation conditionsInstallation conditions

Inlet / outlet runs None required

C / 68°FFFF

C / 68C / 68

1

Extended stem Short stem

TECHNICAL DATA

6

Materials

Stainless Steel (316 / 316L) meter

Stainless Steel (316 / 316L) meter

Stainless Steel (316 / 316L) meterStainless Steel (316 / 316L) meter

Measuring tubes / Flanges Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Spigots Stainless Steel CF3M (1.4409)

Bridge AISI 316 / 316L (1.4401 / 1.4404) dual certified

Outer casing Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Stainless Steel (S31803) meter

Stainless Steel (S31803) meter

Stainless Steel (S31803) meterStainless Steel (S31803) meter

Measuring tubes / Flanges Stainless Steel UNS 31803 (1.4462)

Spigots Stainless Steel J92205 (1.4470)

Bridge AISI 316 / 316L (1.4401 / 1.4404) dual certified

Outer casing Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Hastelloy

Hastelloy® C22 meter

HastelloyHastelloy

Measuring tubes / raised face Hastelloy® C22

(Backing) flanges Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Bridge Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Outer casing Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

C22 meter

C22 meter C22 meter

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

35

Page 36

6

TECHNICAL DATA

Heating jacket version

Heating jacket version

Heating jacket versionHeating jacket version

Heating loop and insulation jacket Stainless Steel AISI 316 (1.4401)

All versions

All versions

All versionsAll versions

Junction box (remote version) Die-cast Aluminium (polyurethane coating)

Optional Stainless Steel 316 (1.4401)

OPTIMASS 6000

Process connections

Flange

Flange

FlangeFlange

DIN DN10…300 / PN16…160

ASME ½...12" / ASME 150…1500

JIS 10A...300A / 10...20K (10K maximum allowable temperature 300°C / 572°F)

Hygienic

Hygienic

HygienicHygienic

Tri-clover ¾...4"

Tri-clamp DIN 32676 DN15..100

Tri-clamp ISO 2852 1...4"

DIN 11864-2 Form A DN15...100

Male thread DIN 11851 DN15...100

Male thread SMS 25...100 mm / 1...4"

Electrical connections

Electrical connections For full details, including: power supply, power consumption etc., see

I/O For full details of I/O options, including data streams and protocols, see

technical data for the relevant signal converter.

technical data for the relevant signal converter.

Approvals

CE The device fulfils the statutory requirements of the CE directive. The

CRN acc to: ASME B31.3 (most recent and up to date version)

NACE MR0175 / ISO 15156 ("Sulphide Stress Corrosion Cracking Resistant Metallic

Custody transfer Measuring Instruments Directive (MID) MI 002 and MI 005 (most recent and

Functional safety SIL2 / SIL3 (acc to: IEC 61508)

ATEX (most recent and up to date version)

ATEX (most recent and up to date version)

ATEX (most recent and up to date version)ATEX (most recent and up to date version)

OPTIMASS 6400C non Ex i signal outputs

OPTIMASS 6400C non Ex i signal outputs

OPTIMASS 6400C non Ex i signal outputsOPTIMASS 6400C non Ex i signal outputs

Ex d connection compartment II 1/2 G Ex db ia IIC T6...T1 Ga/Gb

Ex e connection compartment II 1/2 G Ex db eb ia IIC T6...T1 Ga/Gb

manufacturer certifies that these requirements have been met by applying

the CE mark.

Materials for Oil Field Equipment") and MR0103 ("Materials Resistant to

Sulfide Stress Cracking in Corrosive Petroleum Refining Environments")

(most recent and up to date versions)

up to date version)

OIML R117-1

OIML R137

Compliant with API and AGA

II 2 D Ex tb IIIC T270°C Db

II 2 D Ex tb IIIC T270°C Db

36

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 37

OPTIMASS 6000

OPTIMASS 6400C Ex i signal outputs

OPTIMASS 6400C Ex i signal outputs

OPTIMASS 6400C Ex i signal outputsOPTIMASS 6400C Ex i signal outputs

Ex d connection compartment II 1/2(1) G Ex db ia [ia Ga] IIC T6...T1 Ga/Gb

II 2(1) D Ex tb [ia Da] IIIC T270°C Db

Ex e connection compartment II 1/2(1) G Ex db eb ia [ia Ga] IIC T6...T1 Ga/Gb

II 2(1) D Ex tb [ia Da] IIIC T270°C Db

OPTIMASS 6000 / 6000F

OPTIMASS 6000 / 6000F II 1 G Ex ia IIC T6...T1 Ga

OPTIMASS 6000 / 6000FOPTIMASS 6000 / 6000F

II 1 D Ex ia IIIC T270°C Da

II 1 D Ex ia IIIC T440°C Da

1 For information only. Secondary pressure containment is NOT supplied on this meter

TECHNICAL DATA

ATEX temperature limits

OPTIMASS 6000 / 6000F with or without heating jacket / insulation

Ambient temp. T

-40...40 -50...40 T6 T80

-40...55 -50...40 T6 T80

-40...65 -50...40 T6 T80

Cryogenic version

Cryogenic version

Cryogenic versionCryogenic version

-20...65 -200...40 T6-T1 T80

OPTIMASS 6400C with aluminium converter housing, with or without heating jacket / insulation

-40...40 -50...40 T6 T80

-40...50 -50...40 T6 T80

-40...65 -50...65 T4-T1 T105

Cryogenic version

Cryogenic version

Cryogenic versionCryogenic version

-40...65 -200...40 T6-T1 T80

OPTIMASS 6400C with SS converter housing, with or without heating jacket / insulation

-40...40 -50...40 T6 T80

-40...50 -50...40 T6 T80

-40...60 -50...60 T4-T1 T100

Cryogenic version

Cryogenic version

Cryogenic versionCryogenic version

-25...+60 -200...40 T6-T1 T80

°C Medium temp. Tm °C Temp. class Max. Surface temp. °C

amb

-50...150 T3 T190

-50...230 T2-T1 T270

-50...150 T3 T190

-50...230 T2-T1 T270

-50...150 T3 T190

-50...230 T2-T1 T270

-50...150 T3 T190

-50...230 T2-T1 T270

-50...150 T3 T190

-50...230 T2-T1 T270

-50...150 T3 T190

-50...230 T2-T1 T270

-50...150 T3 T190

-50...230 T2-T1 T270

6

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

37

Page 38

6

TECHNICAL DATA

High temperature versions

High temperature versions

High temperature versionsHigh temperature versions

OPTIMASS 6000F - HT with aluminium junction box, heating jacket and insulation

-40...40 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...55 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...60 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...65 -50...350 T1 T390

OPTIMASS 6000F - HT with SS junction box, heating jacket and insulation

-40...40 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...50 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...55 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...60 -50...350 T1 T390

OPTIMASS 6000F - HT with aluminium or SS junction box, insulation but no heating jacket

-40...40 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...55 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

-40...65 -50...40 T6 T80

-50...230 T2 T270

-50...400 T1 T440

OPTIMASS 6000

38

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 39

OPTIMASS 6000

Maximum end loadings (Stainless Steel 316 / 316L)

TECHNICAL DATA

6

S08 /

S15 S25 S50 S80 S100 S150 S200 S250

S10

Flanges

Flanges

FlangesFlanges

20°C 40 barg 15 kN 25 kN 38 kN 48 kN 99 kN 130 kN 250 kN 300 kN 350 kN

100 barg 12 kN 17 kN 19 kN 15 kN 20 kN 100 kN 120 kN 150 kN 200 kN

230°C 32 barg 7 kN 12 kN 18 kN 25 kN 45 kN 60 kN 50 kN 100 kN 150 kN

60 barg 5 kN 20 kN

400°C 27.4 barg 5 kN 6 kN 10 kN 12 kN 20 kN 50 kN 80 kN 100 kN 150 kN

40 barg 4 kN 5 kN 20 kN

Hygienic (all connections)

Hygienic (all connections)

Hygienic (all connections)Hygienic (all connections)

150°C 10 barg 5 kN 9 kN 12 kN 12 kN 18 kN 21 kN N/A N/A N/A

140°C 40 barg 3 kN 5 kN 5 kN N/A N/A N/A N/A N/A N/A

25 barg N/A N/A N/A 9 kN N/A N/A N/A N/A N/A

16 barg N/A N/A N/A N/A 12 kN 12 kN N/A N/A N/A

Heating jacket connections

Heating jacket connections

Heating jacket connectionsHeating jacket connections

1

1 All temperature and pressure ranges

0 kN 0 kN 0 kN 0 kN 0 kN 0 kN 0 kN 0 kN 0 kN

Maximum end loadings (Hastelloy® and Stainless Steel UNS S31803)

H08 /

H10

H15 H25 H50 H80 D100 D150 D200

Flanges (not including CRN)

Flanges (not including CRN)

Flanges (not including CRN)Flanges (not including CRN)

20°C 200 barg 12 kN 17 kN 19 kN 15 kN 20 kN 100 kN 120 kN

230°C 145 barg 5 kN 20 kN

Flanges (CRN regions)

Flanges (CRN regions)

Flanges (CRN regions)Flanges (CRN regions)

20°C 200 barg

230°C 145 barg

Heating jacket connections

Heating jacket connections

Heating jacket connectionsHeating jacket connections

3

1 D200 limited to 180 barg at 20°C

2 D100 and D150 limited to 120 barg at 230°C. D200 limited to 110 barg at 230°C

3 All temperature and pressure ranges

1

2

12 kN 17 kN 19 kN 15 kN 20 kN 60 kN 30 kN 10 kN

5 kN 20 kN

0 kN 0 kN 0 kN 0 kN 0 kN 0 kN 0 kN 0 kN

• DN08...50 (axial) loads have been calculated, based on 316L schedule 40 process pipework,

where un-radiographed butt welds have been used in pipe joints.

• DN80...250 (axial) loads have been calculated, based on 316L schedule 80 process pipework,

where un-radiographed butt welds have been used in pipe joints.

• The loads shown are the maximum permitted static load. If loads are cycling (between

tension and compression) these loads should be reduced. For advice, consult the

manufacturer.

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

39

Page 40

6

TECHNICAL DATA

6.3 Guidelines for maximum operating pressure

Always make sure that the meter is used within its operating limits.

Pressure / temperature de-rating (metric) for meters with SS 316 measuring tubes.

Pressure / temperature de-rating (metric) for meters with SS 316 measuring tubes.

Pressure / temperature de-rating (metric) for meters with SS 316 measuring tubes. Pressure / temperature de-rating (metric) for meters with SS 316 measuring tubes.

Standard temperature range.

Standard temperature range.

Standard temperature range.Standard temperature range.

OPTIMASS 6000

Figure 6-1: Measuring tube PED certification

X temperature [°C]

Y pressure [barg]

Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes.

Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes.

Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes. Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes.

Standard temperature range.

Standard temperature range.

Standard temperature range.Standard temperature range.

40

Figure 6-2: Measuring Tube PED certification

X temperature [°F]

Y pressure [psig]

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 41

OPTIMASS 6000

Pressure / temperature de-rating (metric) for meters with SS 316 and Hastelloy

Pressure / temperature de-rating (metric) for meters with SS 316 and Hastelloy®C22,

Pressure / temperature de-rating (metric) for meters with SS 316 and HastelloyPressure / temperature de-rating (metric) for meters with SS 316 and Hastelloy

PED certified measuring tubes. High temperature range.

PED certified measuring tubes. High temperature range.

PED certified measuring tubes. High temperature range.PED certified measuring tubes. High temperature range.

TECHNICAL DATA

C22,

C22, C22,

6

X temperature [°C]

Y pressure [barg]

1 Hastelloy® C22 08...80

2 Stainless Steel 316 08...250

Pressure / temperature de-rating (imperial) for meters with SS 316 and Hastelloy

Pressure / temperature de-rating (imperial) for meters with SS 316 and Hastelloy®

Pressure / temperature de-rating (imperial) for meters with SS 316 and HastelloyPressure / temperature de-rating (imperial) for meters with SS 316 and Hastelloy

C22, PED certified measuring tubes. High temperature range.

C22, PED certified measuring tubes. High temperature range.

C22, PED certified measuring tubes. High temperature range.C22, PED certified measuring tubes. High temperature range.

X temperature [°F]

Y pressure [psig]

1 Hastelloy® C22 08...80

2 Stainless Steel 316 08...250

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

41

Page 42

6

TECHNICAL DATA

Pressure / temperature de-rating (metric) for meters with SS 31803 and Hastelloy

Pressure / temperature de-rating (metric) for meters with SS 31803 and Hastelloy®

Pressure / temperature de-rating (metric) for meters with SS 31803 and HastelloyPressure / temperature de-rating (metric) for meters with SS 31803 and Hastelloy

C22, PED certified measuring tubes. Standard temperature range

C22, PED certified measuring tubes. Standard temperature range

C22, PED certified measuring tubes. Standard temperature rangeC22, PED certified measuring tubes. Standard temperature range

OPTIMASS 6000

X temperature [°C]

Y pressure [barg]

1 PED / CRN H08...80

2 CRN D100...150

3 CRN D200

Pressure / temperature de-rating (imperial) for meters with SS 31803 and Hastelloy

Pressure / temperature de-rating (imperial) for meters with SS 31803 and Hastelloy®

Pressure / temperature de-rating (imperial) for meters with SS 31803 and HastelloyPressure / temperature de-rating (imperial) for meters with SS 31803 and Hastelloy

C22, PED certified measuring tubes. Standard temperature range.

C22, PED certified measuring tubes. Standard temperature range.

C22, PED certified measuring tubes. Standard temperature range.C22, PED certified measuring tubes. Standard temperature range.

42

X temperature [°F]

Y pressure [psig]

1 PED / CRN H08...80

2 CRN D100...150

3 CRN D200

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 43

OPTIMASS 6000

Pressure / temperature de-rating (metric) for meters with SS 316, PED certified

Pressure / temperature de-rating (metric) for meters with SS 316, PED certified

Pressure / temperature de-rating (metric) for meters with SS 316, PED certified Pressure / temperature de-rating (metric) for meters with SS 316, PED certified

measuring tubes. Cryogenic temperature range.

measuring tubes. Cryogenic temperature range.

measuring tubes. Cryogenic temperature range.measuring tubes. Cryogenic temperature range.

TECHNICAL DATA

6

X temperature [°C]

Y pressure [barg]

Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes

Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes

Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes Pressure / temperature de-rating (imperial) for meters with SS 316 measuring tubes

PED certified. Cryogenic temperature range.

PED certified. Cryogenic temperature range.

PED certified. Cryogenic temperature range.PED certified. Cryogenic temperature range.

X temperature [°F]

Y pressure [psig]

www.krohne.com09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

43

Page 44

6

TECHNICAL DATA

Pressure / temperature de-rating (metric) for meters with Hastelloy

Pressure / temperature de-rating (metric) for meters with Hastelloy®C22, PED

Pressure / temperature de-rating (metric) for meters with HastelloyPressure / temperature de-rating (metric) for meters with Hastelloy

certified measuring tubes. Cryogenic temperature range.

certified measuring tubes. Cryogenic temperature range.

certified measuring tubes. Cryogenic temperature range.certified measuring tubes. Cryogenic temperature range.

OPTIMASS 6000

C22, PED

C22, PED C22, PED

X temperature [°C]

Y pressure [barg]

Pressure / temperature de-rating (imperial) for meters with Hastelloy

Pressure / temperature de-rating (imperial) for meters with Hastelloy® C22, PED

Pressure / temperature de-rating (imperial) for meters with HastelloyPressure / temperature de-rating (imperial) for meters with Hastelloy

certified measuring tubes. Cryogenic temperature range.

certified measuring tubes. Cryogenic temperature range.

certified measuring tubes. Cryogenic temperature range.certified measuring tubes. Cryogenic temperature range.

X temperature [°F]

Y pressure [psig]

C22, PED

C22, PED C22, PED

44

Flanges

• DIN flange ratings are based on EN 1092-1 2007 table G.4.1 material group 14EO

• ASME flange ratings are based on ASME B16.5 2003 table 2 material group 2.2

• JIS flange ratings are based on JIS 2220: 2001 table 1 division 1 material group 022a

• JIS 10K flanges are limited to a maximum temperature of 300°C / 572°F

www.krohne.com 09/2018 - 4001894006 - MA OPTIMASS 6000 R06 en

Page 45

OPTIMASS 6000

Pressure / temperature de-rating (metric) for meters with hygienic connections.

Pressure / temperature de-rating (metric) for meters with hygienic connections.

Pressure / temperature de-rating (metric) for meters with hygienic connections.Pressure / temperature de-rating (metric) for meters with hygienic connections.

X temperature [°C]

Y pressure [barg]

1 SMS 1...1½", DIN 11851 DN10...40

2 SMS 2", Tri-clamp DN10...40, DIN 11864-2 DN10...40, DIN 11851 DN50...65

3 SMS 3", Tri-clamp DN50...65, DIN11864-2, DIN11864-2 DN50...100, DN11851 DN80...100

4 SMS 4", Tri-clamp DN80...100

TECHNICAL DATA

6

Pressure / temperature de-rating (imperial) for meters with hygienic connections.

Pressure / temperature de-rating (imperial) for meters with hygienic connections.

Pressure / temperature de-rating (imperial) for meters with hygienic connections.Pressure / temperature de-rating (imperial) for meters with hygienic connections.

X temperature [°F]

Y pressure [psig]

1 SMS 1...1½", DIN 11851 DN10...40

2 SMS 2", Tri-clamp DN10...40, DIN 11864-2 DN10...40, DIN 11851 DN50...65

3 SMS 3", Tri-clamp DN50...65, DIN11864-2, DIN11864-2 DN50...100, DN11851 DN80...100

4 SMS 4", Tri-clamp DN80...100

Notes

• The maximum operating pressure will be either the flange / hygienic connection rating or the

measuring tube rating, WHICHEVER IS THE LOWER!

• For hygienic applications above 10 bar, connection sizes DN25…100 / 1…4” are limited to the

measurement of liquid at the pressures shown in the above table.

• The maximum pressure for steam cleaning is 10 bar / 145 psi.

WHICHEVER IS THE LOWER!

WHICHEVER IS THE LOWER!WHICHEVER IS THE LOWER!