Page 1

Handbook

Handbook

OPTIGAS 4010C

OPTIGAS 4010C

OPTIGAS 4010COPTIGAS 4010C

HandbookHandbook

Sensor for gas dispenser applications

Software revision:

V2.3.xx

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2014 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 3

OPTIGAS 4010C

CONTENTS

1 Safety instructions 4

1.1 Intended use ..................................................................................................................... 4

1.2 Associated documents ..................................................................................................... 4

1.3 Dirty gas............................................................................................................................ 4

1.4 Safety instructions from the manufacturer ..................................................................... 4

1.4.1 Copyright and data protection ................................................................................................ 4

1.4.2 Disclaimer ............................................................................................................................... 5

1.4.3 Product liability and warranty ................................................................................................ 5

1.4.4 Information concerning the documentation........................................................................... 5

1.4.5 Warnings and symbols used................................................................................................... 6

1.5 Safety instructions for the operator................................................................................. 6

2 Device description 7

2.1 Scope of delivery............................................................................................................... 7

2.2 Device description ............................................................................................................ 7

3 Installation 8

3.1 Storage ............................................................................................................................. 8

3.2 General notes on installation ........................................................................................... 9

3.3 Mounting restrictions ....................................................................................................... 9

3.3.1 General installation principles ...............................................................................................9

3.3.2 Flow direction........................................................................................................................ 11

4 Electrical connections 12

4.1 Safety instructions.......................................................................................................... 12

4.2 Electrical and I/O connections ....................................................................................... 12

5 Service 13

5.1 Spare parts availability...................................................................................................13

5.2 Availability of services .................................................................................................... 13

5.3 Fault finding.................................................................................................................... 13

5.4 Returning the device to the manufacturer..................................................................... 14

5.4.1 General information.............................................................................................................. 14

5.4.2 Form (for copying) to accompany a returned device............................................................ 15

5.5 Disposal .......................................................................................................................... 15

6 Technical data 16

6.1 Measuring principle........................................................................................................16

6.2 Technical data................................................................................................................. 18

6.3 Dimensions and weights ................................................................................................ 20

7 Notes 21

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

3

Page 4

1 SAFETY INSTRUCTIONS

1.1 Intended use

This flowmeter has been specifically designed for measuring Compressed Natural Gas (CNG) in

retail dispensers.

1.2 Associated documents

This handbook should be read in conjunction with relevant documents in relation to:

• hazardous areas

• communications

• concentration

• corrosion

1.3 Dirty gas

Dirty gas is gas that carries sand or other solid particles. Dirty gas causes excessive wear to the

primary measuring tube that can eventually result in complete tube failure. In some situations

tube failure where gas is being measured, can be very dangerous.

OPTIGAS 4010C

DANGER!

If the meter is being used to measure gas and there is a risk that the gas might be dirty, you

must fit a filter upstream of the meter to catch solid particles.

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

4

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 5

OPTIGAS 4010C

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

SAFETY INSTRUCTIONS 1

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTIGAS 4010C

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

6

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 7

OPTIGAS 4010C

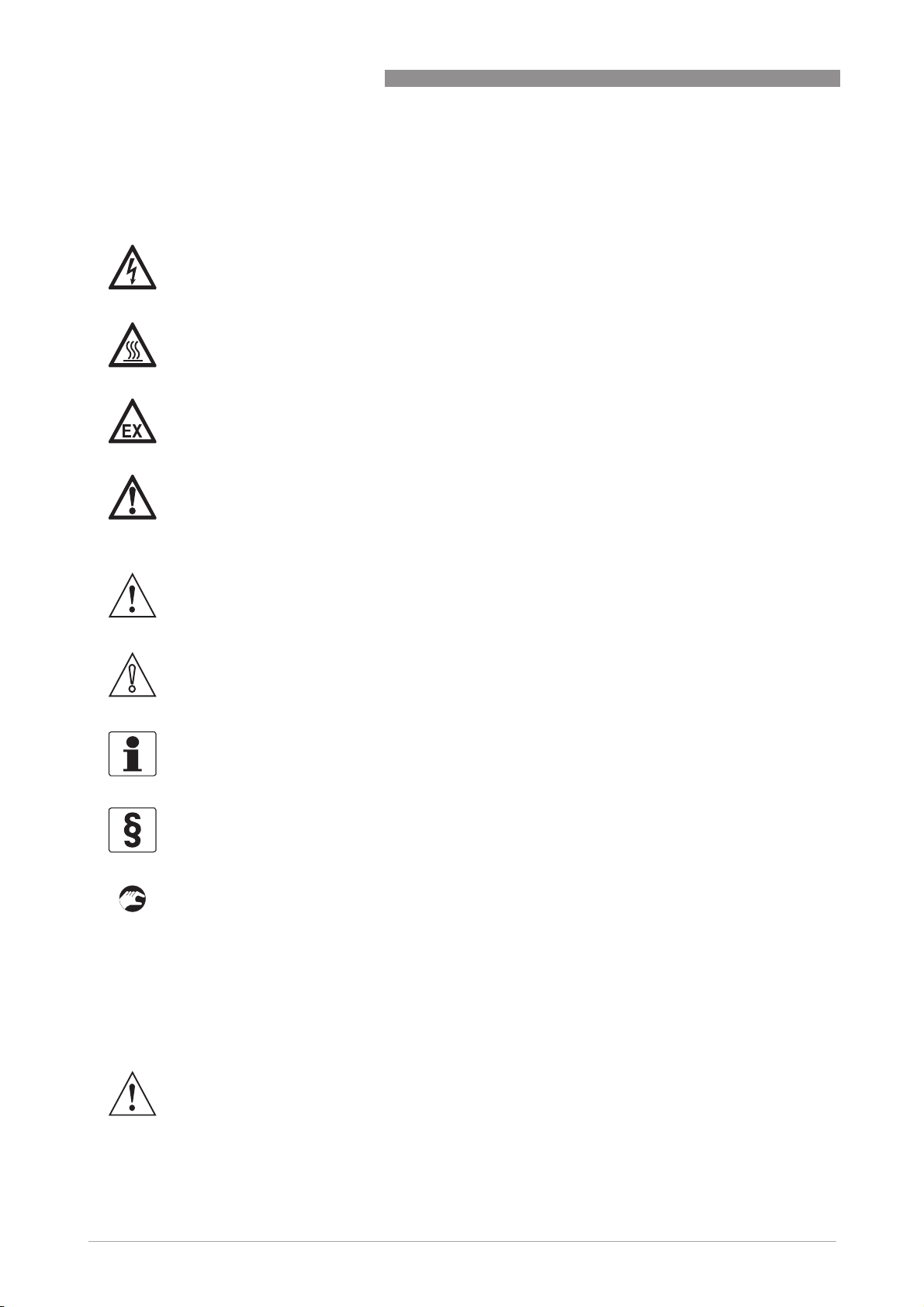

2.1 Scope of delivery

1 Mass flowmeter.

2 Carton.

3 Documentation.

4 CD-ROM and calibration certificate.

DEVICE DESCRIPTION 2

If any items are missing, please contact the manufacturer.

2.2 Device description

This device has been designed for the mass measurement of Compressed Natural Gas (CNG) in

CNG dispensers.

With excellent repeatability and low flow stability, the device is supplied ready to install and

operate. The operating data is factory set according to the order specification but can be changed

with the use of Toolbox.

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

7

Page 8

3 INSTALLATION

3.1 Storage

• Store the device in a dry and dust-free location.

• Avoid direct exposure to the sun.

• Store the device in its original packing.

• Do not allow the ambient temperature to fall below -50°C / -58°F or rise above +85°C /

+185°F.

OPTIGAS 4010C

8

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 9

OPTIGAS 4010C

3.2 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.3 Mounting restrictions

3.3.1 General installation principles

INSTALLATION 3

There are no special installation requirements but you should note the following

points:

• Support the weight of the meter as close to the meter body as possible.

• Mount the meter in such a way to avoid the build up of liquid in the measuring tube.

• Straight runs either side of the meter are not required.

• The use of reducers and other fittings at flanges, including flexible hoses, is allowed but you

should take care to avoid cavitation.

• Avoid extreme pipe size reductions.

• Meters are not affected by crosstalk and can be mounted in series or in parallel.

• Avoid mounting the meter at the lowest point in the pipeline where liquid can collect.

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

9

Page 10

3 INSTALLATION

Mounting positions

OPTIGAS 4010C

10

1 Avoid mounting the meter with the flow running uphill because it can cause liquid to build up on the supply side of the

meter.

2 Mount the meter with the flow running downhill. This will allow any build up of liquid to drain from the meter.

3 Avoid mounting the meter with the connection box above the meter. This can cause liquid to collect in the measuring

tubes at their lowest point in the meter.

4 Mount the meter with the junction box underneath the meter. This will prevent liquid from collecting in the measuring

tubes.

5 The meter can be mounted vertically but DO NOT mount it so that the flow is uphill. This can cause fluid to build up on

the supply side of the meter.

6 If you are mounting the meter vertically, mount it so that the flow is downhill. This will allow any build up of fluid to

drain from the meter.

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 11

OPTIGAS 4010C

3.3.2 Flow direction

With the orientation of the meter as shown in the illustration, the factory set flow direction is left

to right.

If the meter has been intalled with the process flow running from right to left, the flow direction

can be changed through the supplied software Toolbox

INSTALLATION 3

Toolbox. Please see the START-UP

ToolboxToolbox

START-UP section.

START-UPSTART-UP

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

11

Page 12

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

OPTIGAS 4010C

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Electrical and I/O connections

For information regarding electrical and I/O connections, please refer to the handbook for the

relevant signal converter.

12

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 13

OPTIGAS 4010C

5.1 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

5.2 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

5.3 Fault finding

SERVICE 5

The status of the meter and possible problems, can be checked using the diagnostic functions

available in the Toolbox software supplied with the meter, or Modbus RS485 communication.

There are no serviceable components in the meter. If the Toolbox diagnostics show a fault, the

meter should be replaced.

The following diagnostic functions are available (please refer to the relevant converter Handbook

for register values):

Temperature:

Temperature:

Temperature:Temperature:

This displays the temperature in either °C or °F. The temperature shown should be stable and

the same as the actual process temperature.

Frequency:

Frequency:

Frequency:Frequency:

This displays the vibration frequency of the measuring tubes and should be stable to the first

decimal point. For example, the display might show 230.1xxx Hz. Variations in the first digit after

the decimal point indicates a fluctuation in gas density. This fluctuation can be caused by

changes in pressure / temperature or moisture in the gas.

Drive energy:

Drive energy:

Drive energy:Drive energy:

The typical value of the drive energy for gas with no moisture content is: 1...5%.

Sensor A and B:

Sensor A and B:

Sensor A and B:Sensor A and B:

The display should show values for sensors A and B of 80% and should be within 2% of each

other.

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

13

Page 14

5 SERVICE

5.4 Returning the device to the manufacturer

5.4.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

OPTIGAS 4010C

14

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 15

OPTIGAS 4010C

5.4.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 5

This medium is: radioactive

water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

5.5 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

15

Page 16

6 TECHNICAL DATA

6.1 Measuring principle

Meter from the side, showing tube layout

1

OPTIGAS 4010C

3

2

1 Measuring tubes

2 Drive coil

3 Sensor 1

4 Sensor 2

Static meter not energised and with no flow

4

16

1 Measuring tubes

2 Drive coil

3 Sensor 1

4 Sensor 2

A Coriolis twin-tube mass flowmeter consists of two measuring tubes (1) a drive coil (2) and

two sensors (3 and 4) that are positioned either side of the drive coil.

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 17

OPTIGAS 4010C

Energised meter

1 Measuring tubes

2 Direction of oscilation

3 Sine wave

When the meter is energised, the drive coil vibrates the measuring tubes causing them to

oscillate and produce a sine wave (3). The sine wave is monitored by the two sensors.

Energised meter with process flow

TECHNICAL DATA 6

1 Process flow

2 Sine wave

3 Phase shift

When a fluid or gas passes through the tubes, the Coriolis effect causes a phase shift in the sine

wave that is detected by the two sensors. This phase shift is directly proportional to the mass

flow.

Temperature measurement is made using a Pt500 sensor.

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

17

Page 18

6 TECHNICAL DATA

OPTIGAS 4010C

6.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Coriolis mass flow

Application range Measurement of Compressed Natural Gas (CNG)

Measured values Mass, standard or normal volume, temperature (volume & density for liquids

Design

Basic System consists of a measuring sensor with integral MFC010 converter to

Features Fully welded maintenance- free sensor with twin U-shaped measuring tube

only)

process the output signal.

Application conditions

Fluid Compressed Natural Gas (CNG) with operating pressure typically > 100 barg

Flow range capacity 1...70 kg/min / 2.2...155 lbs/min

Accuracy ±0.5% of total batch (where minimum actual flow rate is 1 kg/min / 2.2

Repeatability ±0.3% of actual flow rate + zero stability (for a batch size > 1 kg . 2.2lbs)

Zero stability ±0.015% of flow range capacity

Pressure rating

Pressure rating

Pressure ratingPressure rating

Static 350 barg / 5076 psig

Cycling 300 barg / 4351 psig

Process fluid temperature -40...+93°C / -40…+200°F

Ambient temperature -40...+55°C / -40…+131°F

/ 1450 psig

lbs/min)

Mechanical

Process connections ¾" NPT female (adaptor options are available)

Materials

Materials

MaterialsMaterials

Measuring tube Stainless Steel 316L (1.4404)

Outer casing

Sensor electronics housing

Junction box Die cast Aluminium (polyurethane coating)

Electrical

Power supply 12 VDC via Ex approved barrier (11.4...12.6 VDC)

Programming Via Modbus. 1

Outputs Modbus RTU over RS485

Diagnostics

18

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 19

OPTIGAS 4010C

TECHNICAL DATA 6

Interface cable 2 x screened twisted pairs with a minimum 20 AWG conductors. Total C ≤

Cable glands M20 X 1.5 Stainless Steel suitable for cable diameter 6.5...9.5 mm

50nF, total L ≤ 200µH

Approvals

Custody transfer PTB type approval 5.411 / 04.15

Vibration IEC 60068-2-6

ATEX (acc. 94/9/EC)

ATEX (acc. 94/9/EC)

ATEX (acc. 94/9/EC)ATEX (acc. 94/9/EC)

OPTIGAS 4010C without heating jacket / insulation

OPTIGAS 4010C without heating jacket / insulation

OPTIGAS 4010C without heating jacket / insulationOPTIGAS 4010C without heating jacket / insulation

II 1/2 G Ex ib IIC T4...T1 Ga/Gb

II 2 D Ex ib IIIC T210°C Db

Ex ib IIC T4...T1 Ga/Gb

Ex ib IIIC T210°C Db

IECEx

IECEx

IECExIECEx

Ex ib IIC T6...T1 Ga/Gb

Ex ib IIIC T4*** °C Db

NEPSI

NEPSI

NEPSINEPSI

OPTIGAS 4010C

OPTIGAS 4010C

OPTIGAS 4010COPTIGAS 4010C

Ex ib IIC T4...T1 Ga/Gb

1 Toolbox software is available from the manufacturer but it requires a compatible Modbus to PC adapter with approved barrier. Please

call for more information.

ATEX (acc. 94/9/EC) temperature limits

Ambient temp.

Tamb °C

OPTIGAS 4010C without heating jacket /

insulation

-40...+65 60 T4 T130

Max. medium

temp. Tm °C

125 T3 T195

140 T2 - T21 T210

Temp. class Max. surface

temp. °C

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

19

Page 20

6 TECHNICAL DATA

6.3 Dimensions and weights

OPTIGAS 4010C

[mm] [inches]

A 359 ±2 14.1 ±0.08

B 97 3.8

C 162 6.4

D 194 7.6

E 50 1.97

20

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 21

OPTIGAS 4010C

NOTES 7

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

21

Page 22

7 NOTES

OPTIGAS 4010C

22

www.krohne.com 07/2014 - 4002962702 - MA OPTIGAS R02 en

Page 23

OPTIGAS 4010C

NOTES 7

www.krohne.com07/2014 - 4002962702 - MA OPTIGAS R02 en

23

Page 24

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature assemblies

• Pressure transmitters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 203 301 0

Fax:+49 203 301 103 89

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 07/2014 - 4002962702 - MA OPTIGAS R02 en - Subject to change without notice.

www.krohne.com

Loading...

Loading...