Technical Datasheet

Technical Datasheet

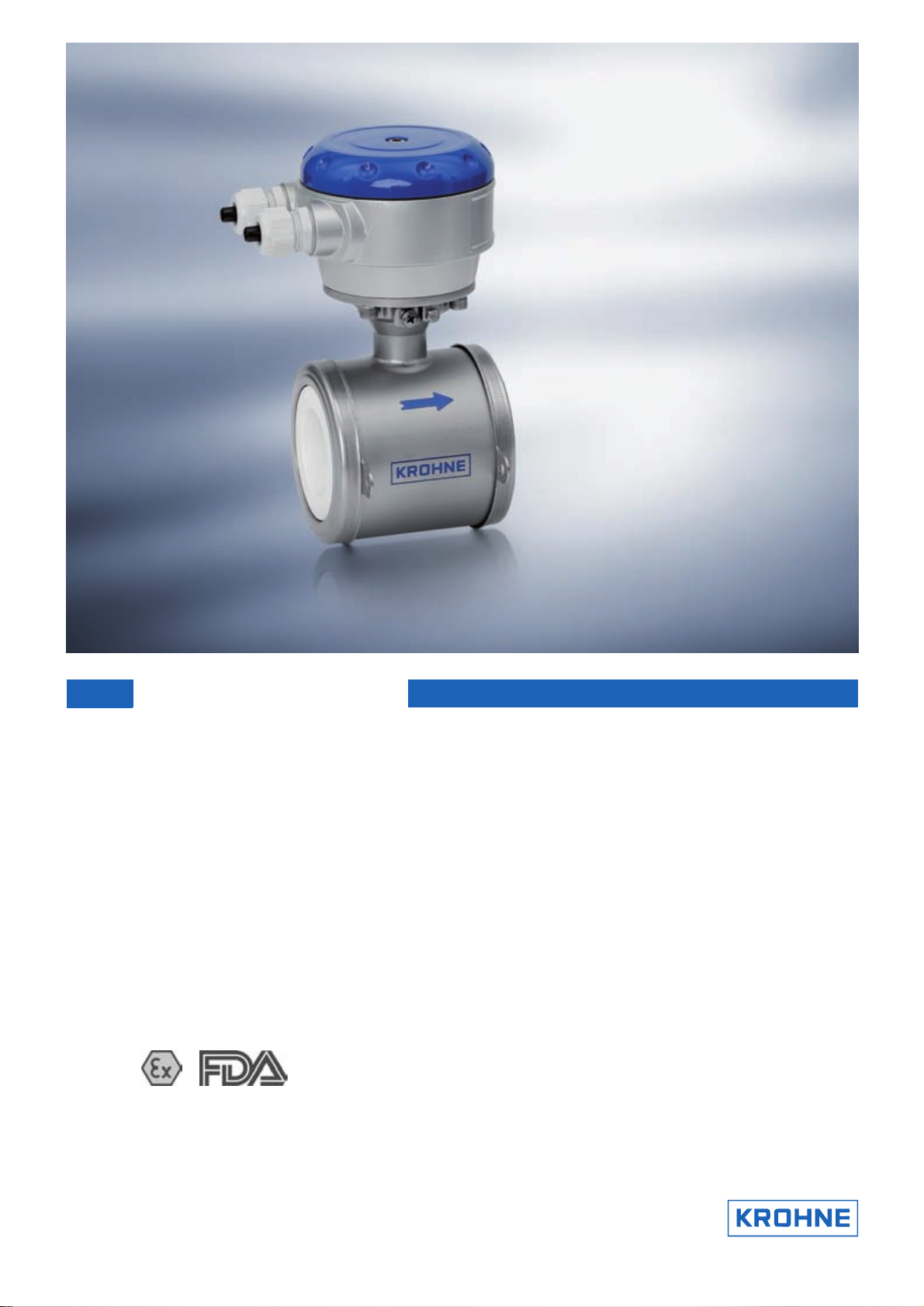

OPTIFLUX 5000

OPTIFLUX 5000

OPTIFLUX 5000OPTIFLUX 5000

Technical DatasheetTechnical Datasheet

Electromagnetic flowmeter in sandwich version

• Exceptional long-term stability and accuracy

• For highly aggressive and abrasive fluids

• Fully vacuum-resistant with high-tech ceramics liner

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

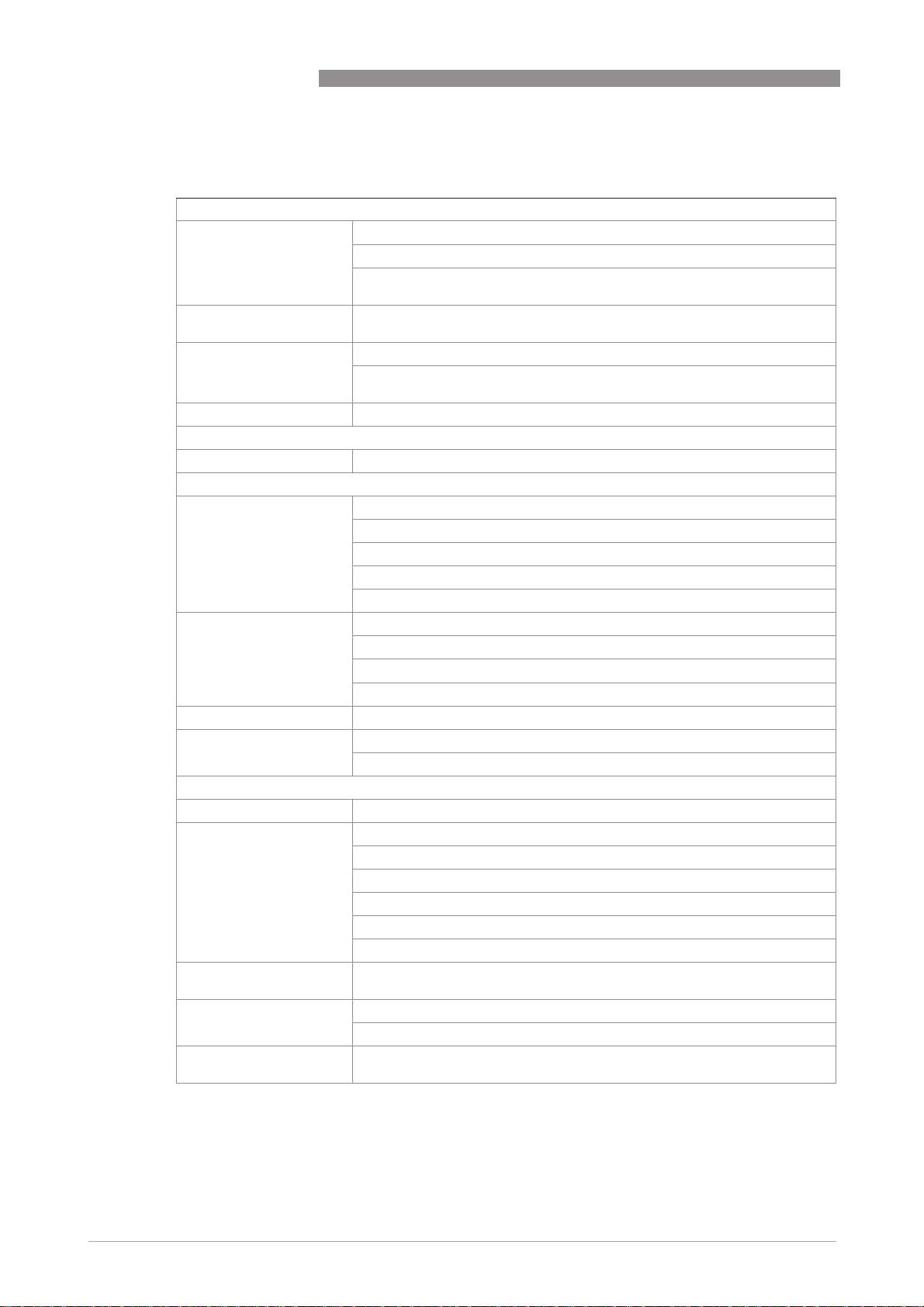

CONTENTS

OPTIFLUX 5000

1 Product features 3

1.1 Solution with high-tech ceramics .................................................................................... 3

1.2 Options and variants......................................................................................................... 5

1.3 Measuring principle.......................................................................................................... 6

2 Technical data 7

2.1 Technical data................................................................................................................... 7

2.2 Measuring accuracy ....................................................................................................... 12

2.3 Dimensions and weights ................................................................................................ 13

3 Installation 16

3.1 Notes on installation ......................................................................................................16

3.2 Intended use ................................................................................................................... 16

3.3 Installation conditions ....................................................................................................16

3.3.1 Inlet and outlet...................................................................................................................... 16

3.3.2 Mounting position.................................................................................................................. 16

3.3.3 Flange deviation.................................................................................................................... 17

3.3.4 T-section ............................................................................................................................... 17

3.3.5 Vibration ................................................................................................................................ 17

3.3.6 Magnetic field........................................................................................................................ 18

3.3.7 Bends .................................................................................................................................... 18

3.3.8 Open discharge ..................................................................................................................... 19

3.3.9 Control valve ......................................................................................................................... 19

3.3.10 Air venting ........................................................................................................................... 19

3.3.11 Pump ................................................................................................................................... 20

4 Electrical connections 21

4.1 Safety instructions.......................................................................................................... 21

4.2 Grounding ....................................................................................................................... 21

4.3 Virtual reference for IFC 300 (C, W and F version) ........................................................ 22

5 Notes 23

2

www.krohne.com 10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

OPTIFLUX 5000

1.1 Solution with high-tech ceramics

The OPTIFLUX 5000

OPTIFLUX 5000 is one of the most accurate flowmeters available in the market today. This is

OPTIFLUX 5000OPTIFLUX 5000

the result of a special tube design with conical parts, optimizing the flow profile. Leading

metrological institutes use the OPTIFLUX 5000

high-end signal converter IFC 300.

OPTIFLUX 5000 as their master meter in combination with the

OPTIFLUX 5000OPTIFLUX 5000

PRODUCT FEATURES 1

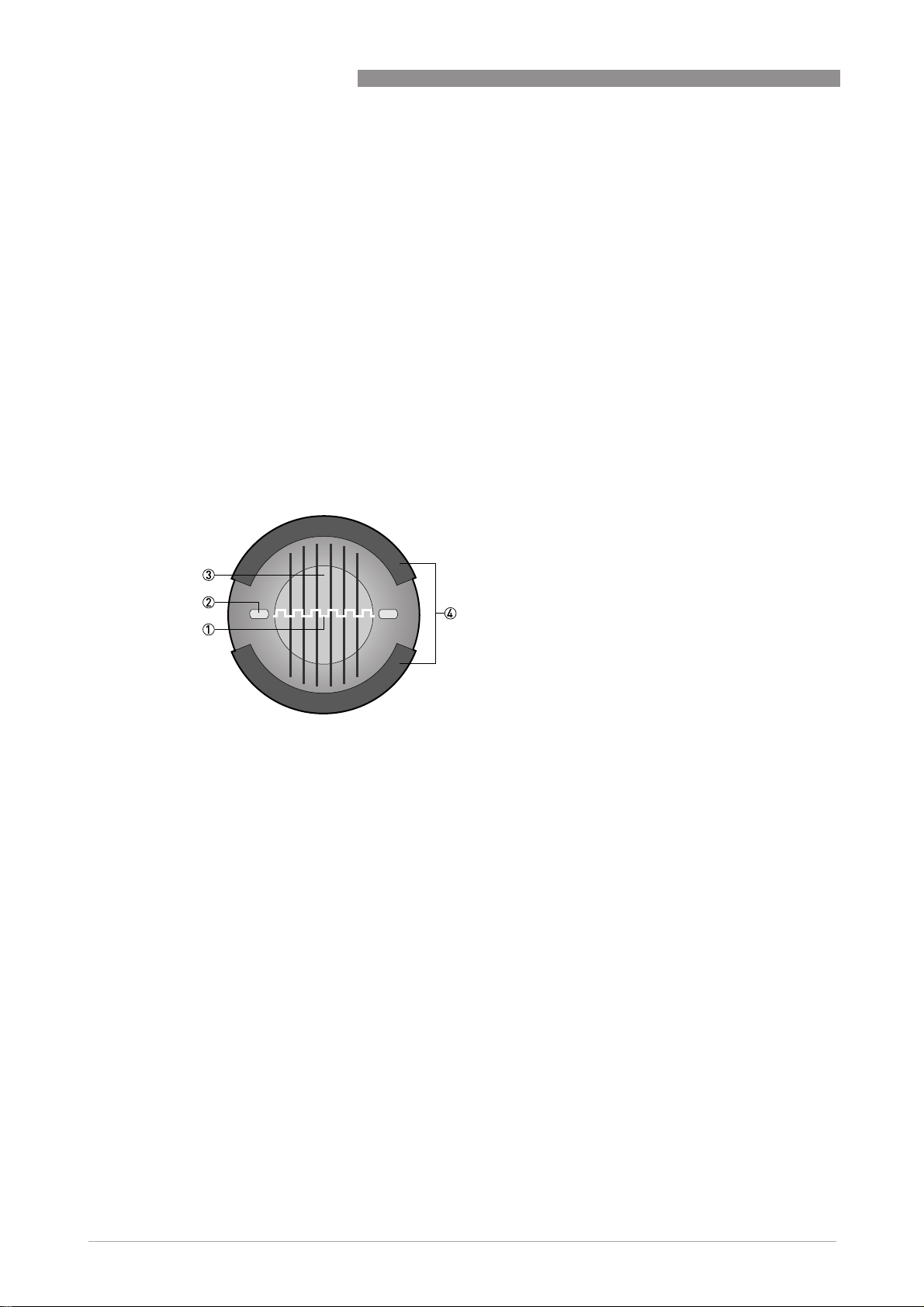

1 Sandwich design

2 Ceramic liner

3 Cermet electrodes

www.krohne.com10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

3

1 PRODUCT FEATURES

Highlights

• Excellent long-term stability and accuracy

• Unique flow tube

• Fused in-place Cermet or platinum electrodes

• Transfer standard of international metrological authorities

• For most aggressive and abrasive fluids

• Fully vacuum-resistant

• High-tech ceramics liner

• Insensitive against temperature shocks

Industries

• Chemical

• Paper & Pulp

• (Waste) water

• Minerals & Mining

• Food & beverage

• Machinery

OPTIFLUX 5000

Applications

• Master transfer meter

• Precise volumetric dosing of additives

• Chemical injection

• For acids, alkaline, paste, slurries and many other aggressive media even with high solid

contents

4

www.krohne.com 10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

OPTIFLUX 5000

1.2 Options and variants

PRODUCT FEATURES 1

The OPTIFLUX 5000 is available in a

diameter range of DN2.5 up to DN100

and is configurable with the IFC 100 and

the IFC 300 signal converter. It is also

optionally suitable in hazardous areas.

Grounding rings are available in high

grade alloy's. The installation of the

OPTIFLUX 5000 SW can be further

eased by choosing for the virtual

reference. Grounding rings can then be

omitted. This can only combined with

the IFC 300 signal converter.

www.krohne.com10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

5

1 PRODUCT FEATURES

1.3 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils. Inside of

the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flow meter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalising, recording and output processing.

OPTIFLUX 5000

1 Induced voltage (proportional to flow velocity)

2 Electrodes

3 Magnetic field

4 Field coils

6

www.krohne.com 10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

OPTIFLUX 5000

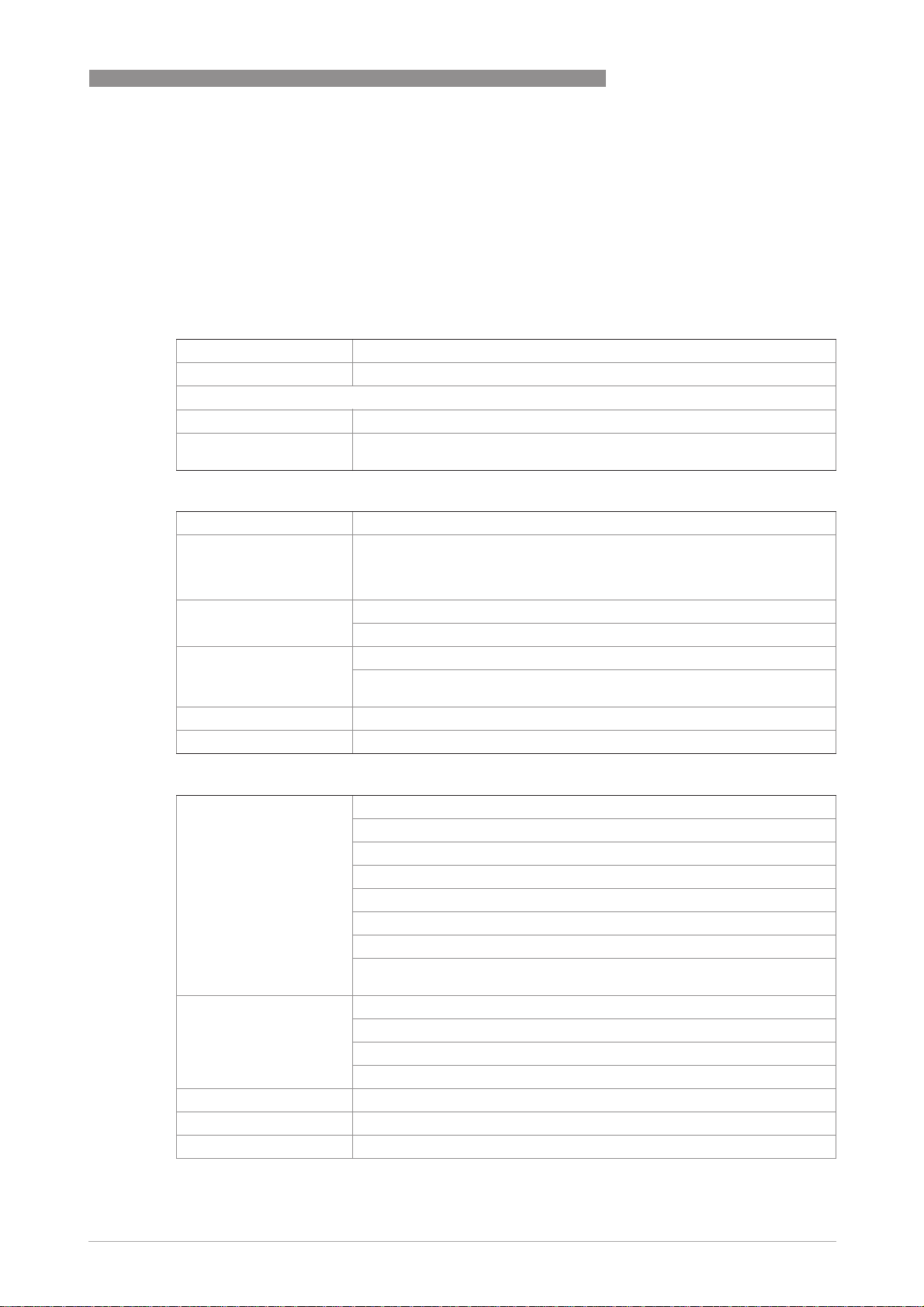

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Faraday's law

Application range Electrically conductive fluids

Measured value

Measured value

Measured valueMeasured value

Primary measured value Flow velocity

Secondary measured

value

Design

Features Sandwich version with optimized flow tube

Modular construction The measurement system consists of a flow sensor and a signal converter.

Compact version With IFC 100 converter: OPTIFLUX 5100 C

Remote version In wall (W) mount version with IFC 100 converter: OPTIFLUX 5100 W

Nominal diameter DN2.5...100 / 1/10...4"

Measurement range -12...+12 m/s / -40...+40 ft/s

TECHNICAL DATA 2

Volume flow, mass flow, electrical conductivity, coil temperature

It is available as compact and as separate version. More information about

the signal converter can be found in the documentation of the signal

converter.

With IFC 300 converter: OPTIFLUX 5300 C

In field (F), wall (W) or rack (R) mount version with IFC 300 converter:

OPTIFLUX 5300 F, W or R

Measuring accuracy

Reference conditions Medium: water

Temperature: 20°C / 68°F

Inlet section: 10 DN

Outlet section: 5 DN

Flow velocity: > 1 m/s / > 3 ft/s

Operating pressure: 1 bar / 14.5 psig

Valve closing time variation: < 1 ms

Wet calibrated on EN 17025 accredited calibration rig by direct volume

comparison.

Maximum measuring

error

Repeatability ±0.1% of MV, minimum 1 mm/s

Long term stability ±0.1% of MV

Special calibration On request

Related to volume flow (MV = Measured Value).

These values are related to the pulse / frequency output.

The additional typical measuring deviation for the current output is ±10 μA.

For detailed information refer to

Measuring accuracy

on page 12.

www.krohne.com10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

7

2 TECHNICAL DATA

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Compact version: -40...+140°C / -40... +284°F

Maximum temperature

change (shock)

Ambient temperature -40…+65°C / -40…+149°F

Storage temperature -50…+70°C / -58…+158°F

Pressure

Pressure

PressurePressure

Ambient Atmospheric

Nominal flange pressure

EN 1092-1 Standard:

ASME B16.5 Standard:

Vacuum load 0 mbar / 0 psi

Pressure ranges for

secondary containment

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Physical condition Liquids

Electrical conductivity Non water:

Permissible gas content

(volume)

Permissible solid content

(volume)

Recommended flow

velocity

OPTIFLUX 5000

Remote version: -40...+180°C / -40...+356°F

For Ex versions different temperature ranges are applicable. Please see the

relevant Ex documentation for details.

120°C / 248°F

For Ex versions different temperature ranges are applicable. Please see the

relevant Ex documentation for details.

Standard:

Standard:Standard:

DN100: PN 16

DN2.5...80: PN 40

Option:

Option:

Option:Option:

DN100: PN 25

Standard:

Standard:Standard:

1/10...4": 150 lb

Option:

Option:

Option:Option:

1/10...4": 300 lb

Pressure resistant up to 40 bar / 580 psi

Burst pressure up to approx. 160 bar / 2320 psi

Non water:

Non water:Non water:

DN25...100: ≥ 1 μS/cm

DN4...15: ≥ 5 μS/cm

DN2.5: ≥ 10 μS/cm

Demineralised cold water:

Demineralised cold water:

Demineralised cold water:Demineralised cold water:

DN2.5...100: ≥ 20 μS/cm

≤ 5%

IFC 100: ≤ 10%

IFC 300: ≤ 70%

-12...+12 m/s / -40...+40 ft/s

8

www.krohne.com 10/2011 - 4000525402 - TD OPTIFLUX 5000 SW R05 en

Loading...

Loading...