KROHNE OPTIFLUX 4000 Specifications

Technical Datasheet

Technical Datasheet

OPTIFLUX 4000

OPTIFLUX 4000

OPTIFLUX 4000OPTIFLUX 4000

Technical DatasheetTechnical Datasheet

Electromagnetic flow sensor

•

Robust, fully welded construction for industrial process applications

•

For demanding applications including corrosive, abrasive and high pressure

•

Engineered constructions for customer specific solutions

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

CONTENTS

OPTIFLUX 4000

1 Product features 3

1.1 The all-round solution for process industries................................................................. 3

1.2 Options.............................................................................................................................. 5

1.3 Measuring principle.......................................................................................................... 7

2 Technical data 8

2.1 Technical data................................................................................................................... 8

2.2 Legal metrology.............................................................................................................. 16

2.2.1 OIML R49 ............................................................................................................................... 16

2.2.2 MID Annex III (MI-001)........................................................................................................... 18

2.2.3 Verification to MI-001 & OIML 49.......................................................................................... 20

2.2.4 OIML R117 ............................................................................................................................. 21

2.2.5 MI-005 ................................................................................................................................... 21

2.3 Measurement accuracy.................................................................................................. 22

2.4 Dimensions and weights ................................................................................................ 24

2.5 Pressure derating........................................................................................................... 29

2.6 Vacuum load ................................................................................................................... 31

3 Installation 32

3.1 Intended use ................................................................................................................... 32

3.2 General notes on installation ......................................................................................... 32

3.2.1 Vibration ................................................................................................................................ 32

3.2.2 Magnetic field........................................................................................................................ 32

3.3 Installation conditions ....................................................................................................33

3.3.1 Inlet and outlet...................................................................................................................... 33

3.3.2 Bends in 2 or 3 dimensions................................................................................................... 33

3.3.3 T-section ............................................................................................................................... 34

3.3.4 Bends .................................................................................................................................... 34

3.3.5 Open feed or discharge......................................................................................................... 35

3.3.6 Flange deviation.................................................................................................................... 35

3.3.7 Pump ..................................................................................................................................... 35

3.3.8 Control valve ......................................................................................................................... 36

3.3.9 Air venting and vacuum forces ............................................................................................. 36

3.3.10 Mounting position................................................................................................................ 37

3.4 Mounting......................................................................................................................... 38

3.4.1 Torques and pressures......................................................................................................... 38

4 Electrical connections 41

4.1 Safety instructions.......................................................................................................... 41

4.2 Grounding ....................................................................................................................... 41

4.3 Virtual reference for IFC 300 (C, W and F version) ....................................................... 43

4.4 Connection diagrams ..................................................................................................... 43

2

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

OPTIFLUX 4000

1.1 The all-round solution for process industries

The OPTIFLUX 4000

OPTIFLUX 4000 design meets the demands of a very wide range of applications in industries

OPTIFLUX 4000OPTIFLUX 4000

including the chemical, pulp & paper, water and wastewater, minerals and mining, iron, steel

and metals, pharmaceuticals and oil & gas industry.

The OPTIFLUX 4000 has a field proven and unsurpassed lifetime. This is assured by the fully

welded construction, full bore pipe construction, absence of moving parts and wear resistant

liner materials. Even for demanding applications in harsh environments or with aggressive and

abrasive media the OPTIFLUX 4000 can offer a solution.

Examples include water injection under high pressures (2500 lbs), sub-sea installations, slurries

with very high solids contents, alkaline solutions and acids, up to chemical dosing, bleaching,

colouring, and black liquor in the paper industry. If required, a solution beyond our standard

scope can be engineered. KROHNE has in-house specialized know-how on constructions,

welding and exotic materials.

For custody transfer applications, OPTIFLUX 4000 has a wide range of certifications including

OIML R49 & R117, MI-001, MI-004 & MI-005.

PRODUCT FEATURES

1

1 Robust fully welded construction

2 Diameter range: DN2.5...DN3000

3 PFA, PTFE, ETFE, PU, hard rubber and soft rubber liners

4 Hastelloy, titanium, tantalum, stainless steel, platinum and low noise electrodes

www.krohne.com08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

3

1

PRODUCT FEATURES

Highlights

• Trusted and accepted flow sensor for all process applications

• Proven in use and unsurpassed lifetime

• Large installed base – more than 400.000 units - in virtually any industry

• All welded rugged construction, to extend lifetime of equipment

• Good corrosion, erosion / abrasion resistance

• Wide choice of materials for housing & flanges including SS, Duplex, 6Mo

• Flexibility in sizes including installation lengths, special constructions, special inner

diameters and inner thicknesses

• Corrosion resistant and leak tight electrodes. Specials (materials, retractable or pointed) on

demand

• External coatings for offshore or subsoil installation. Optional paint specifications acc. to ISO

12944 – protective coating

• Reliable measurement under very demanding conditions:

including high temperatures up to 180°C / 356°F, pressures up to 2500 bar, high solids

contents (up to 70%)

• Bi-directional flow metering

• Wide range of approvals for hazardous areas

• Compliant with requirements for custody transfer OIML R49 & R117, MI-001, MI-004 &

0,005

• No grounding rings with virtual reference option on IFC 300

• Extensive diagnostic capabilities

OPTIFLUX 4000

Industries

• Chemicals

• Pulp & Paper

• Minerals & Mining

• Oil & gas

• Iron, Steel & Metals

• Water and wastewater

• Pharmaceuticals

Applications

• For clean liquids

• For slurries and pastes with high solids content

• For abrasive and aggressive products

4

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

OPTIFLUX 4000

1.2 Options

The solution for any industry

PRODUCT FEATURES

From standard to customized

From standard to customized

From standard to customizedFrom standard to customized

For easy ordering the standard range of the

OPTIFLUX 4000 covers all popular sizes, materials

and coatings. Process connections are available in

EN 1092-1 (up to PN40), ASME B16.5 (up to 2500 lbs),

JIS (20K) and AWWA (class D).

But KROHNE does not stop here. Our extensive

engineering department is dedicated to provide

solutions for all specifications not covered by our

standard range. Requests for special sizes, flange

connections, pressure ratings, building lengths, and

materials, will always get a serious review.

Whenever possible we will engineer a flow meter

that fits your application.

1

Easy installation

Easy installation

Easy installationEasy installation

Fitting the OPTIFLUX 4000 is easy with the flanged

design and standard ISO insertion lengths. To

further ease the operation, the OPTIFLUX 4000 can

be installed without filters and straighteners. Even

grounding rings are not required with the patented

"Virtual Reference"

"Virtual Reference" option on the IFC 300 converter.

"Virtual Reference""Virtual Reference"

IP68

IP68

IP68IP68

Installation in measurement chambers subject to

(constant) flooding is possible with the IP68 rated

version. The chambers can even be completely

surpassed if the IP68 version is combined with our

special subsoil coating, allowing the OPTIFLUX 4000

to be installed directly in the ground.

www.krohne.com08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

5

1

PRODUCT FEATURES

OPTIFLUX 4000

Custody transfer

Custody transfer

Custody transferCustody transfer

In combination with the IFC 300 converter the

OPTIFLUX 4000 is suitable for custody transfer

applications. It meets the requirements of OIML R49

and can be verified according to Annex MI-001 of the

Measuring Instruments Directive (MID) for cold

water and to OIML R117 and MID Annex MI-005 for

liquids other than water.

Explosion safety

Explosion safety

Explosion safetyExplosion safety

In combination with the IFC 100 or IFC 300 signal

converter, the OPTIFLUX 4000 has received a wide

range of approvals for hazardous areas, including

ATEX, CSA, FM, IEC and NEPSI.

6

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

OPTIFLUX 4000

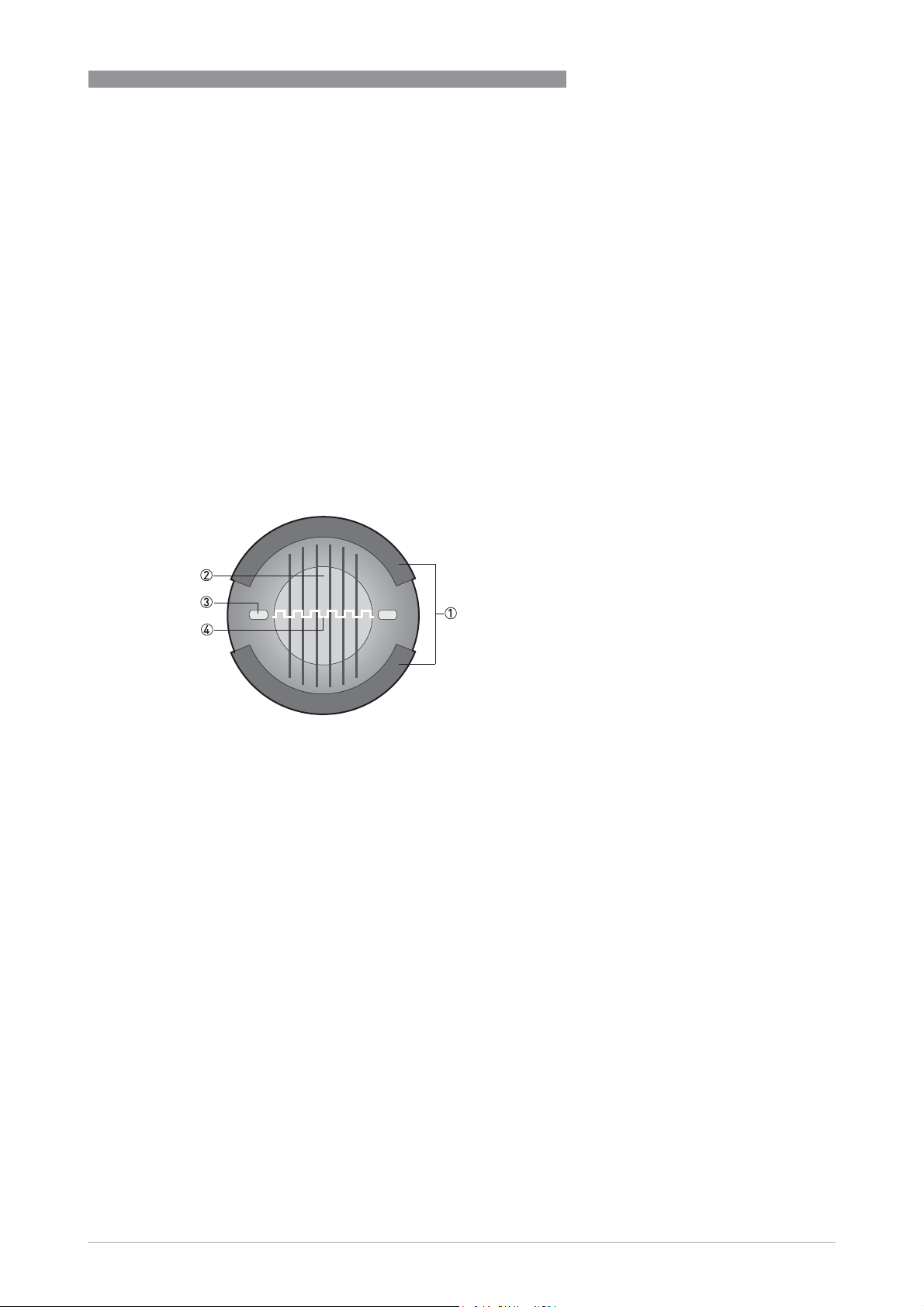

1.3 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils.

Inside of the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flowmeter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate Q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalizing, recording and output processing.

PRODUCT FEATURES

1

Figure 1-1: Measuring principle

1 Field coils

2 Magnetic field

3 Electrodes

4 Induced voltage (proportional to flow velocity)

www.krohne.com08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

7

2

TECHNICAL DATA

OPTIFLUX 4000

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

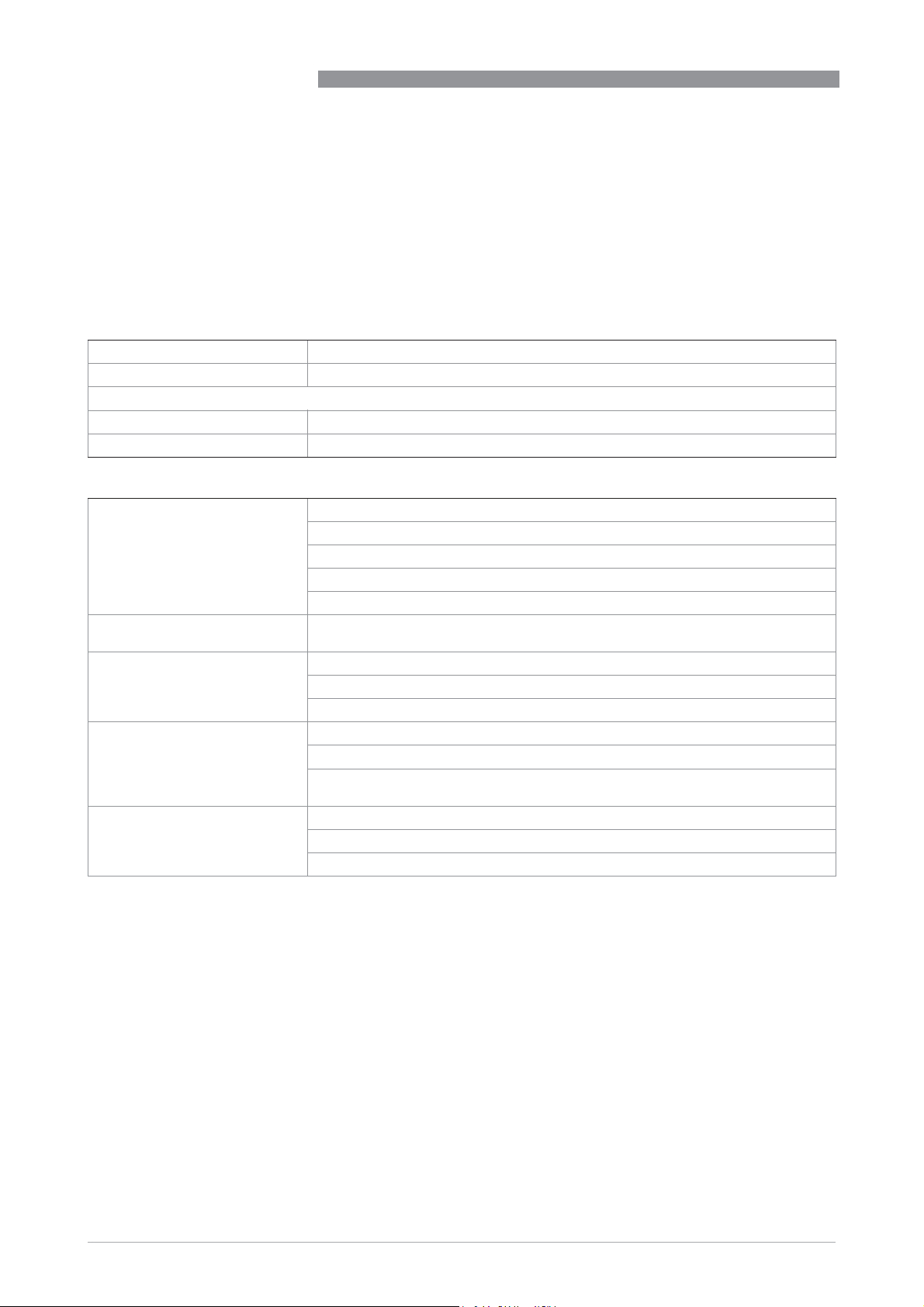

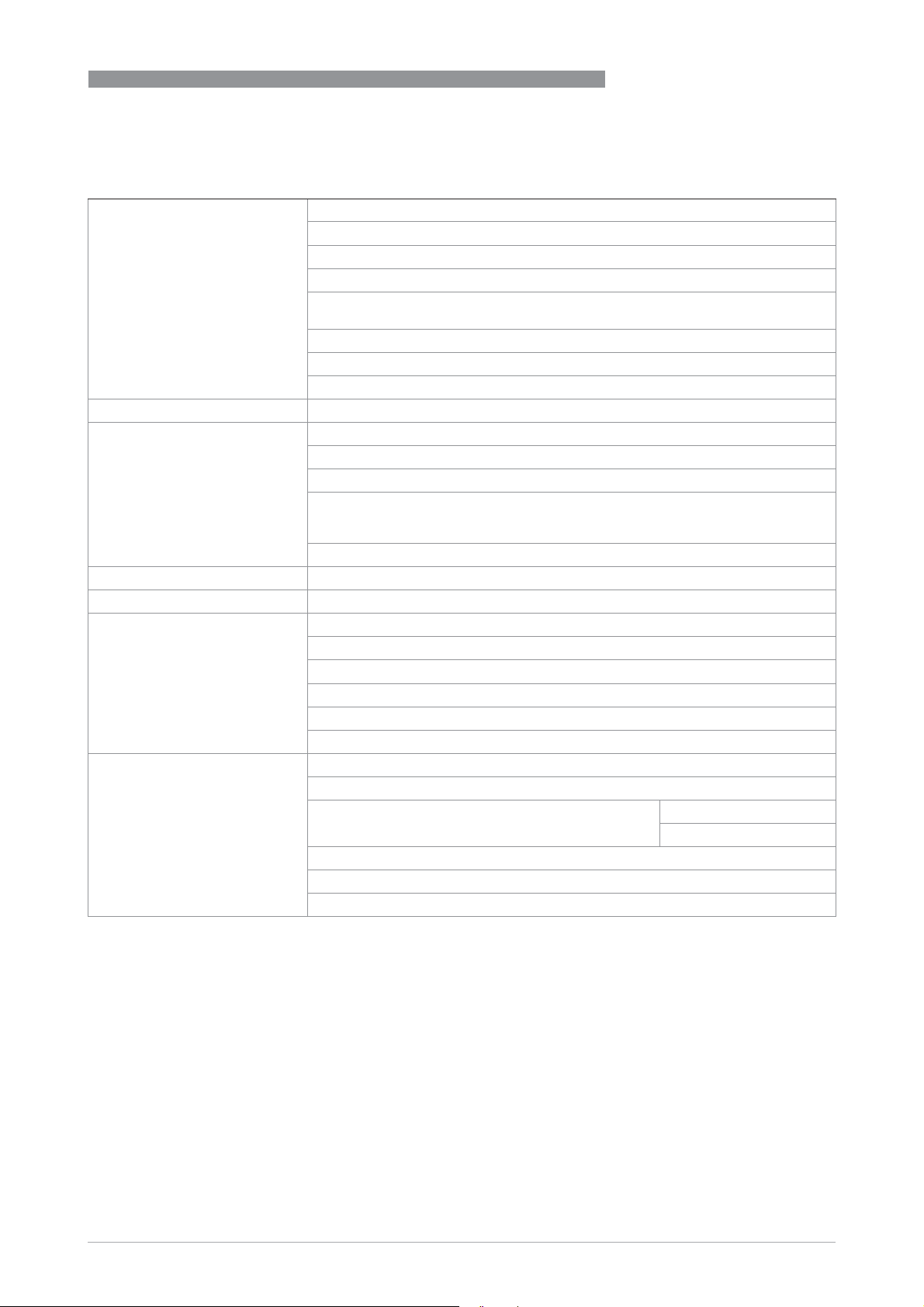

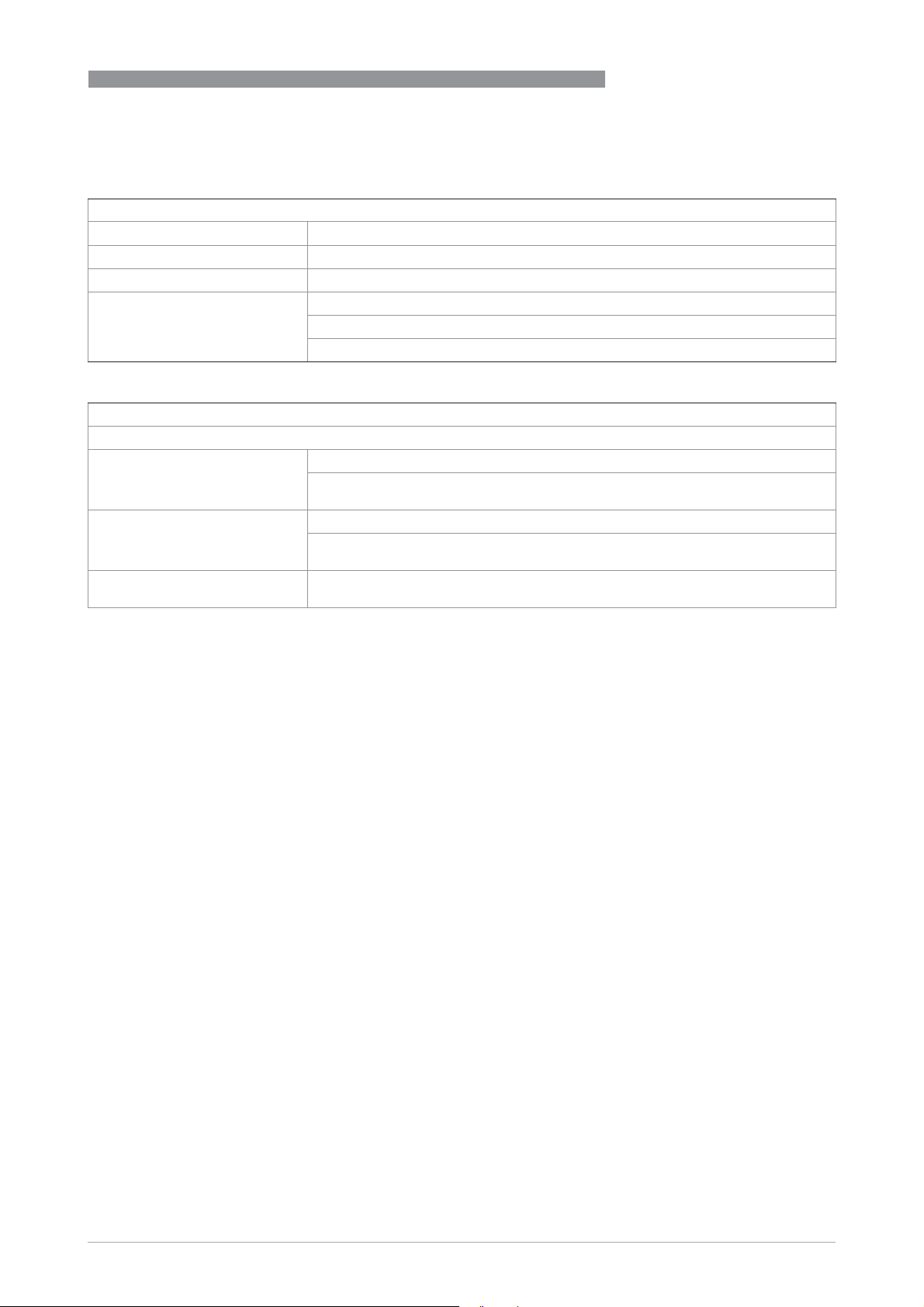

Measuring system

Measuring principle Faraday's law

Application range Electrically conductive fluids

Measured value

Measured value

Measured valueMeasured value

Primary measured value Flow velocity

Secondary measured value Volume flow

Design

Features Fully welded maintenance-free flow sensor.

Flange version with full bore flow tube.

Standard as well as higher pressure ratings.

Broad range of nominal sizes.

Industry specific insertion lengths.

Modular construction The measurement system consists of a flow sensor and a signal converter. It is

Compact version With signal converter IFC 050: OPTIFLUX 4050 C

Remote version In wall (W) mount version with signal converter IFC 050: OPTIFLUX 4050 W

Nominal diameter With signal converter IFC 050: DN2.5... 1200 / 1/10...48"

available as compact and as separate version.

With signal converter IFC 100: OPTIFLUX 4100 C

With signal converter IFC 300: OPTIFLUX 4300 C

In wall (W) mount version with signal converter IFC 100: OPTIFLUX 4100 W

In field (F), wall (W) or rack (R) mount version with signal converter IFC 300:

OPTIFLUX 4300 F, W or R

With signal converter IFC 100: DN2.5...1200 / 1/10...48"

With signal converter IFC 300: DN2.5...3000 / 1/10...120"

8

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

OPTIFLUX 4000

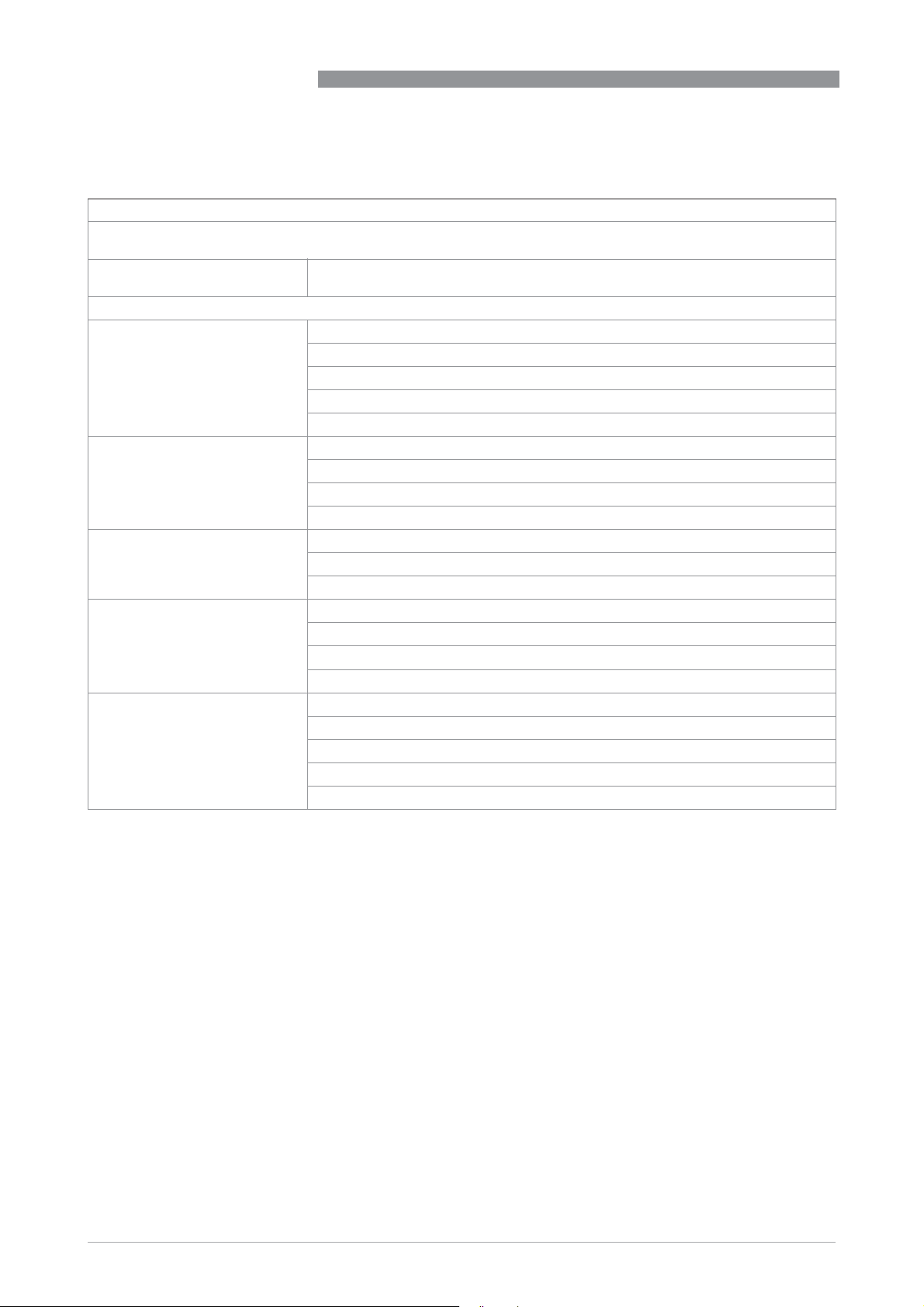

Measuring accuracy

Maximum measuring error Depending on signal converter and DN size.

IFC 050: down to 0.5% of the measured value ± 1 mm/s

IFC 100: down to 0.3% of the measured value ± 1 mm/s

IFC 300: down to 0.2% of the measured value ± 1 mm/s

Optionally: optimised accuracy for IFC050 and IFC100. For more details on

optimised accuracy, see the concerning signal converter documentation.

The additional typical measuring deviation for the current output is ±10 PA.

The maximum measuring error depends on the installation conditions.

For detailed information refer to

Repeatability ± 0.1% of MV, minimum 1 mm/s

Calibration / Verification Standard:

Long term stability ± 0.1% of MV

Special calibration On request.

MID Annex III (MI-001)

(Directive 204/2/E8)

OIML R49 Certificate of conformity to OIML R49

Standard:

Standard:Standard:

2 point calibration by direct volume comparison.

Optional:

Optional:

Optional:Optional:

Verification to Measurement Instrument Directive (MID), Annex III (MI-001).

Standard: Verification at Ratio (Q3/Q1) = 80, Q3 t 2 m/s

Optional: Verification at Ratio (Q3/Q1) > 80 on request

(Only in combination with signal converter IFC 300)

EC-Type examination certificate to MID Annex III (MI-001)

EC-Type examination certificate to MID Annex III (MI-001)

EC-Type examination certificate to MID Annex III (MI-001)EC-Type examination certificate to MID Annex III (MI-001)

(Only in combination with signal converter IFC 300)

Diameter range: DN25...1600

Forward and reverse (bi-directional) flow

Liquid temperature range: +0.1°C / +50°C

For detailed information refer to

Certificate of conformity to OIML R49

Certificate of conformity to OIML R49Certificate of conformity to OIML R49

(Only in combination with signal converter IFC 300)

Diameter range Class 1: DN80...500

Forward and reverse (bi-directional) flow

Liquid temperature range: +0.1°C / 50°C

For detailed information refer to

Measurement accuracy

Legal metrology

Legal metrology

TECHNICAL DATA

on page 22.

on page 16.

Class 2: DN25...50

on page 16.

2

www.krohne.com08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

9

2

TECHNICAL DATA

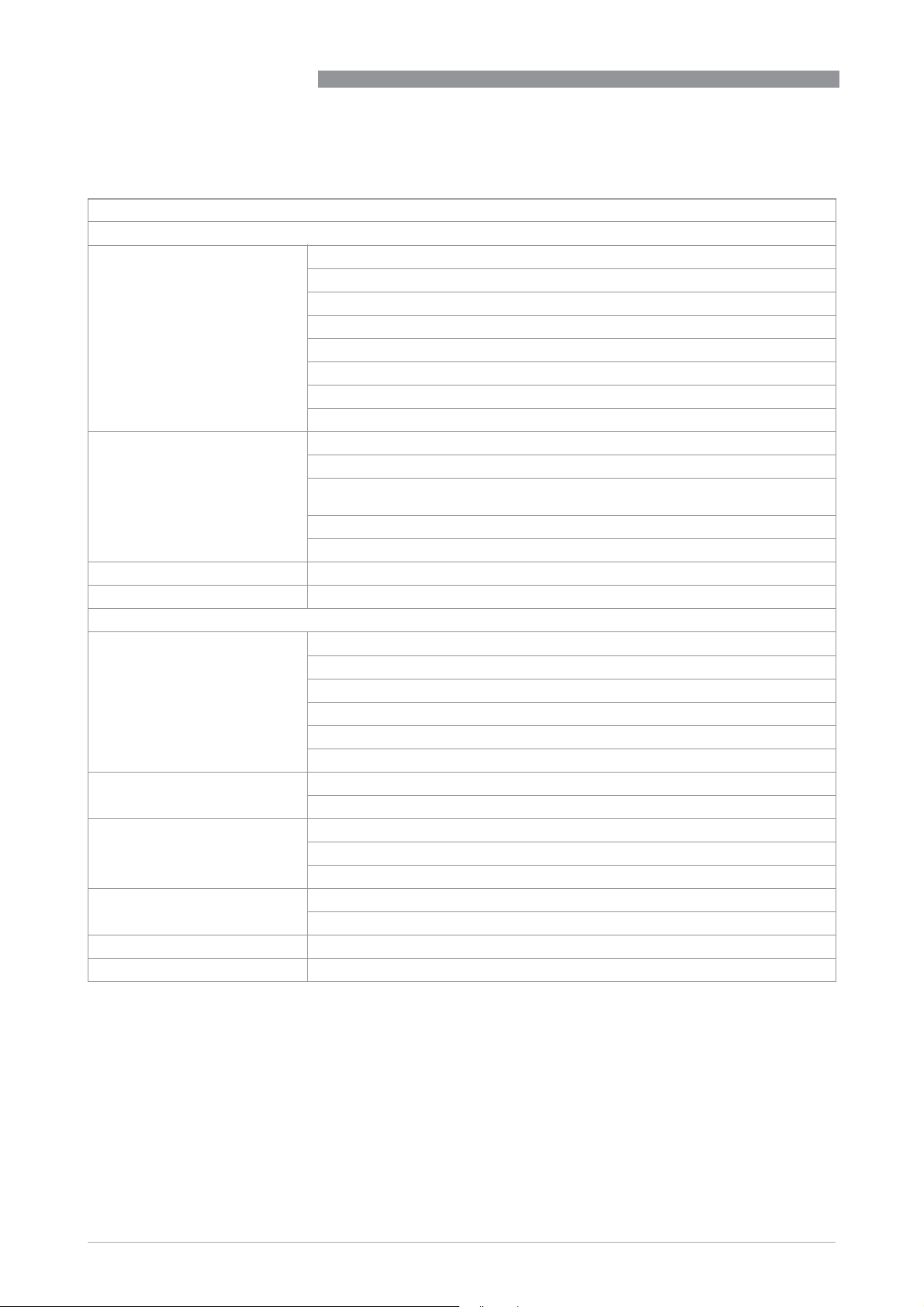

Operating conditions

Temperature

Temperature

TemperatureTemperature

For Ex versions different temperatures are valid. Please check the relevant Ex documentation for details.

Process temperature PTFE / PFA: -40...+180°C / -40...+356°F for remote versions

PTFE / PFA: -40...+140°C /-40...+284°F for IFC 300 compact versions

PTFE / PFA: -40...+120°C /-40...+248°F for IFC 050 and IFC100 compact versions

ETFE: -40...+120°C / -40...+248°F

Hard rubber: -5...+80°C / 23...+176°F

Soft rubber: -5...+60°C / 23...+140°F

PU: -5...+65°C / 23...+149°F

For more information about temperatures see the temperature table in the manual.

Ambient temperature Standard

Storage temperature -50…+70°C/ -58…+158°F

Measuring range -12...+12 m/s / -40...+40 ft/s

Pressure

Pressure

PressurePressure

EN 1092-1 DN2200...3000: PN2.5

ASME B16.5 1/10...40": 150 lb RF

JIS DN50...1000 / 2..40": 10 K

AWWA DN700...1800 / 28...72" class D

Vacuum load For detailed information refer to

Pressure loss Negligible

Standard (with aluminum signal converter housing):

StandardStandard

-40…+65°C/ -40…+149°F

Protect electronics against self-heating with ambient temperatures above +55°C /

+131°F.

Option

Option (with stainless steel signal converter housing):

OptionOption

-40...+55°C/ -40…+130°F

DN1200...2000: PN6

DN200...1000: PN10

DN65 and DN100...150: PN16

DN2.5...50 and DN80: PN40

Other pressures on request.

Other pressures on request.

DN2.5...40 / 1/10...1½" : 20 K

Other pressures on request.

Other pressures on request.

Vacuum load

on page 31.

OPTIFLUX 4000

10

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

OPTIFLUX 4000

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Physical condition Electrically conductive liquids

Electrical conductivity Water: t 20 PS/cm

Standard: t 1 PS/cm

Permissible gas content (volume) IFC 050: d 3%

IFC 100: d 5%

IFC 300: d 5%

Permissible solid content

(volume)

IFC 050: d 10%

IFC 100: d 10%

IFC 300: d 70%

Installation conditions

Installation Assure that the flow sensor is always fully filled.

For detailed information refer to

Flow direction Forward and reverse.

Arrow on flow sensor indicates positive flow direction.

Inlet run t 5 DN

Outlet run t 2 DN

Dimensions and weights For detailed information refer to

Installation

Dimensions and weights

TECHNICAL DATA

on page 32.

on page 24.

2

www.krohne.com08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

11

2

TECHNICAL DATA

OPTIFLUX 4000

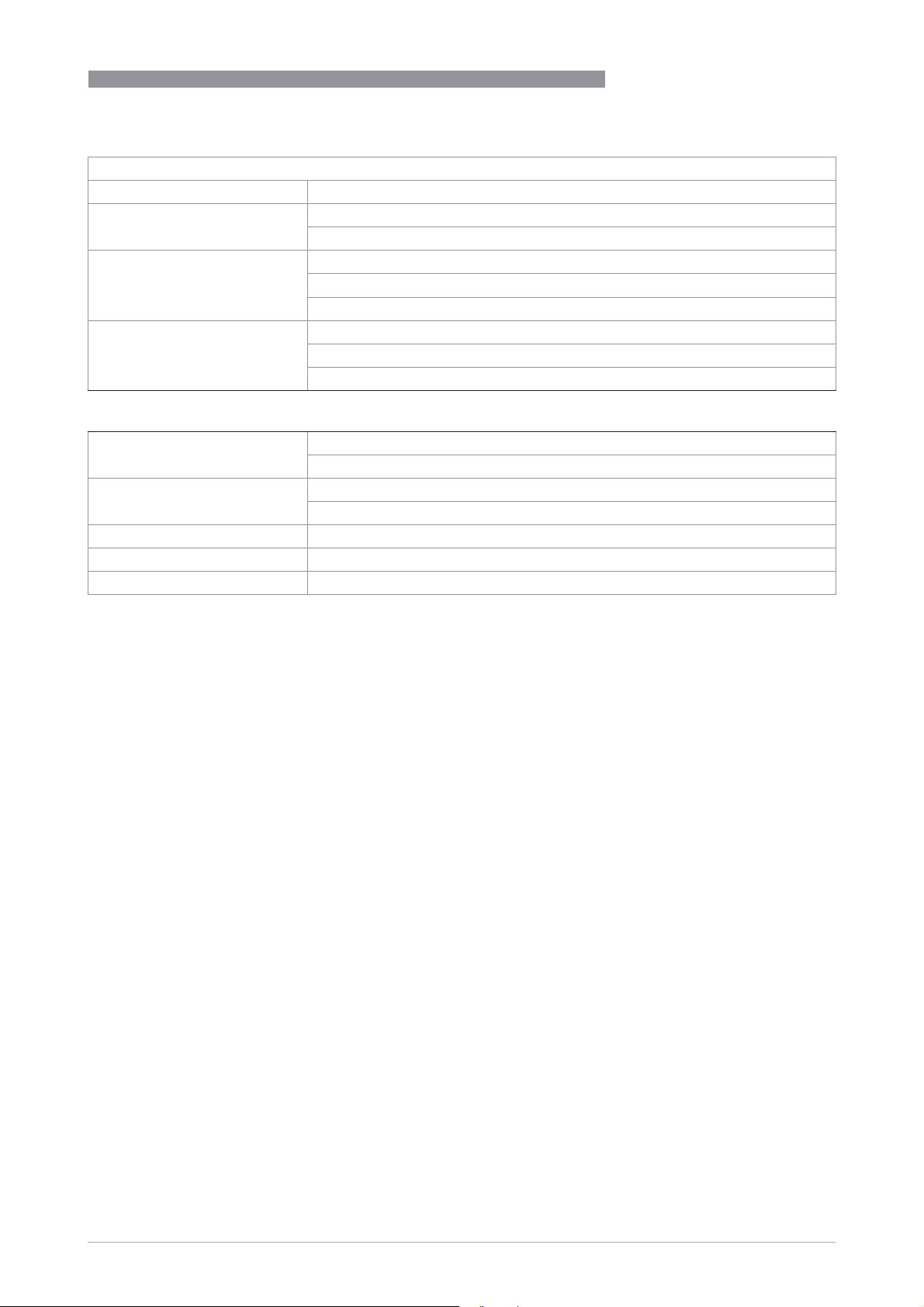

Materials

Flow sensor housing DN2.5...15 / 1/10...½": stainless steel 1.4408

DN20 / ¾": GTW-S 30

DN25...3000 / 1...120": sheet steel

Other materials on request.

Measuring tube Austenitic stainless steel

Flanges Standard: carbon steel

Other materials on request.

Liner Standard

Protective coating On exterior of the meter: flanges, housing, signal converter (compact version) and /

Connection box Only for remote versions

Measuring electrodes

Grounding rings Standard :

Standard

StandardStandard

DN2.5...15 / 1/10...½": PFA

DN20 ¾": PTFE

DN25...150 / 1...6": PFA

DN200...1800 / 8...72": ETFE

Option

Option

OptionOption

DN25...600 / 1...24": PTFE

DN200...1800 / 8...72": PU

DN200...3000 / 8...120": Hard rubber (Ex only)

DN50...600 / 2...24": Soft rubber

Other materials on request.

or connection box (field version)

Standard coating

Option: off shore coating

Standard: die-cast aluminum

Option: stainless steel

Standard: Hastelloy® C

Option: platinum, stainless steel, titanium, tantalum, low noise

Option: conductive rubber (only in combination with soft rubber liner)

Other materials on request.

Standard : stainless steel

Standard :Standard :

Reference electrode (optional)

12

Option:

Option: Hastelloy® C, titanium, tantalum

Option:Option:

Grounding rings can be omitted with virtual reference option for the signal

converter IFC 300.

Standard: Hastelloy® C

Option: platinum, stainless steel, titanium, tantalum, low noise

Other materials on request.

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

OPTIFLUX 4000

TECHNICAL DATA

Process connections

Flange

Flange

FlangeFlange

EN 1092-1 DN2.5...3000 in PN2.5...40

ASME 1/10...120" in 150...2500 lb RF

JIS DN2.5...1000 in JIS 10...20 K

Design of gasket surface EN 1092-1, ASME, JIS; RF

AWWA: FF

Other sizes or pressure ratings on request.

Electrical connections

For full detail refer to the relevant documentation of the signal converter.

Signal cable

Signal cable (remote versions only)

Signal cableSignal cable

Type A (DS) In combination with the signal converter IFC 050, IFC 100 and IFC 300

Type B (BTS) Only in combination with the signal converter IFC 300

I/O For full details of I/O options, including data streams and protocols, see technical

In combination with the signal converter IFC 050, IFC 100 and IFC 300

In combination with the signal converter IFC 050, IFC 100 and IFC 300In combination with the signal converter IFC 050, IFC 100 and IFC 300

Standard cable, double shielded.

Max. length: 600 m / 1968 ft (dep. on electrical conductivity and flow sensor).

Only in combination with the signal converter IFC 300

Only in combination with the signal converter IFC 300Only in combination with the signal converter IFC 300

Optional cable, triple shielded.

Max. length: 600 m / 1968 ft (dep. on electrical conductivity and flow sensor).

datasheet of the relevant signal converter.

2

www.krohne.com08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

13

2

TECHNICAL DATA

OPTIFLUX 4000

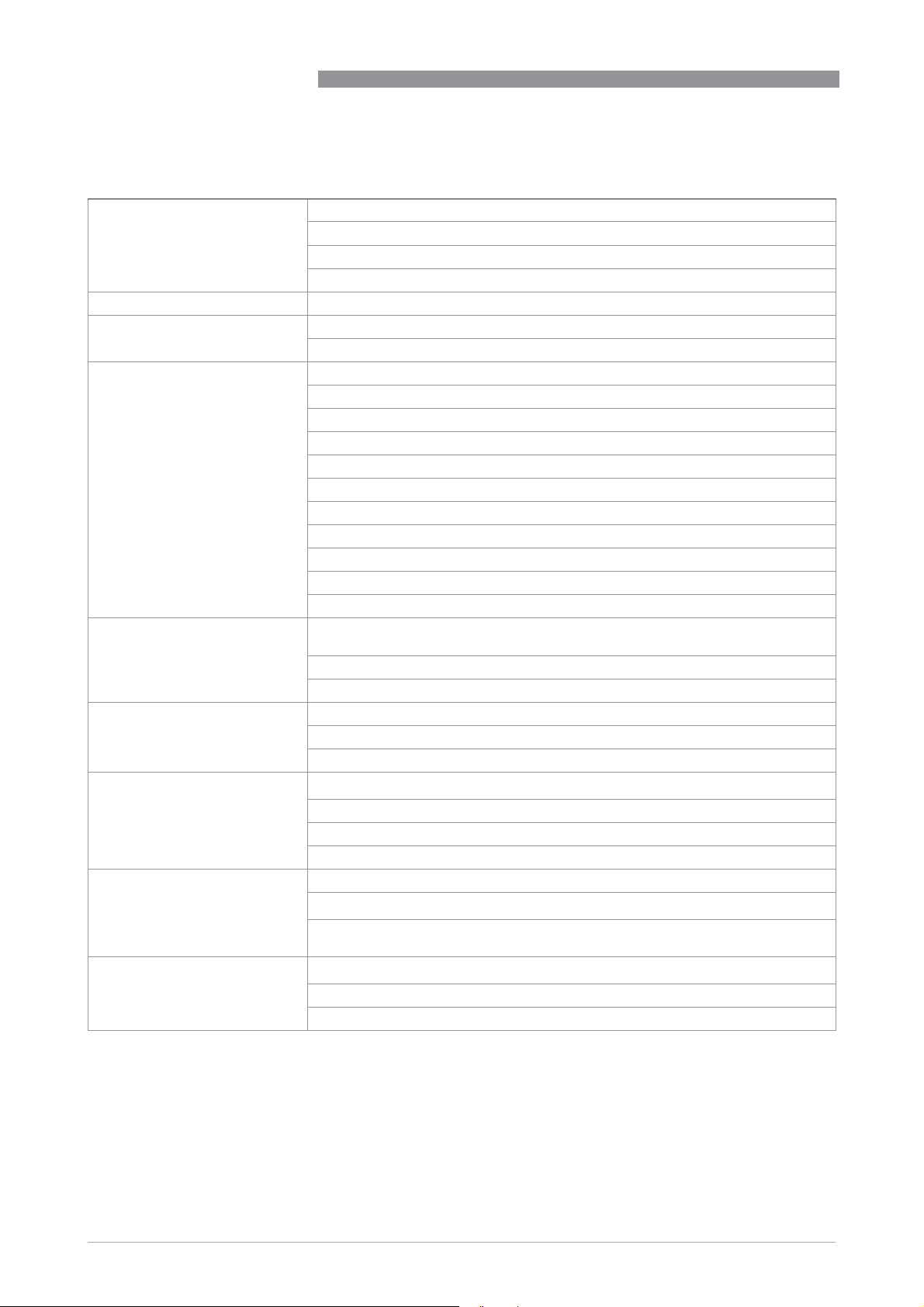

Approvals and certificates

CE

CE

CECE

This device fulfils the statutory requirements of the EU directives. The manufacturer certifies successful testing of the

product by applying the CE mark.

For full information of the EU directive & standards and the approved certifications;

please refer to the (8 'eclaration RI&RQIRUPLW\or the website of the manufacturer.

Hazardous areas

Hazardous areas

Hazardous areasHazardous areas

ATEX Please check the relevant Ex documentation for details.

Compact version with signal converter IFC 050 C :

Compact version with signal converter IFC 050 C : II 2 GD

Compact version with signal converter IFC 050 C :Compact version with signal converter IFC 050 C :

Compact version with signal converter IFC 100 C:

Compact version with signal converter IFC 100 C: II 2 GD

Compact version with signal converter IFC 100 C:Compact version with signal converter IFC 100 C:

Compact version with signal converter IFC 300 C:

Compact version with signal converter IFC 300 C: II 2 GD or II 2(1) GD

Compact version with signal converter IFC 300 C:Compact version with signal converter IFC 300 C:

Remote version:

Remote version:II 2 GD

Remote version:Remote version:

FM In combination with signal converter IFC 300:

CSA In combination with signal converter IFC 300:

IECEx Compact version with signal converter IFC 100:

NEPSI GYJ05234 / GYJ05237

In combination with signal converter IFC 300:

In combination with signal converter IFC 300:In combination with signal converter IFC 300:

Class I, Div 2, groups A, B, C and D

Class II, Div 2, groups F and G

Class III, Div 2, groups F and G

In combination with signal converter IFC 300:

In combination with signal converter IFC 300:In combination with signal converter IFC 300:

Class I, Div 2, groups A, B, C and D

Class II, Div 2, groups F and G

IFC 100:

IFC 100:IFC 100:

IIC T4

Compact version with signal converter IFC 300:

IIC T6...T3

Ex me ia IIC T6...T3

Ex de ia IIC T6...T3

Ex qe ia IIC T6...T3

Ex e ia IIC T6...T3

IFC 300:

IFC 300:IFC 300:

14

www.krohne.com 08/2017 - 4000525105 - TD OPTIFLUX 4000 R08 en

Loading...

Loading...