KROHNE OPTIFLUX 4000 Quick Start Guide

Quick Start

Quick Start

OPTIFLUX 4000

OPTIFLUX 4000

OPTIFLUX 4000OPTIFLUX 4000

Quick StartQuick Start

Electromagnetic flow sensor

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

CONTENTS

OPTIFLUX 4000

1 Safety instructions 3

2 Installation 4

2.1 Scope of delivery............................................................................................................... 4

2.2 Device description ............................................................................................................ 5

2.3 Nameplate ........................................................................................................................ 6

2.4 Storage ............................................................................................................................. 7

2.5 Transport .......................................................................................................................... 7

2.6 Pre-installation requirements ......................................................................................... 7

2.7 General requirements...................................................................................................... 8

2.7.1 Vibration .................................................................................................................................. 8

2.7.2 Magnetic field.......................................................................................................................... 8

2.8 Installation conditions ...................................................................................................... 9

2.8.1 Inlet and outlet........................................................................................................................ 9

2.8.2 Bends in 2 or 3 dimensions..................................................................................................... 9

2.8.3 T-section ............................................................................................................................... 10

2.8.4 Bends .................................................................................................................................... 10

2.8.5 Open feed or discharge......................................................................................................... 11

2.8.6 Flange deviation.................................................................................................................... 11

2.8.7 Pump ..................................................................................................................................... 11

2.8.8 Control valve ......................................................................................................................... 12

2.8.9 Air venting and vacuum forces ............................................................................................. 12

2.8.10 Mounting position................................................................................................................ 13

2.9 Mounting......................................................................................................................... 14

2.9.1 Torques and pressures......................................................................................................... 14

2.9.2 Temperatures ....................................................................................................................... 17

3 Electrical connections 18

3.1 Safety instructions.......................................................................................................... 18

3.2 Grounding ....................................................................................................................... 18

3.3 Virtual reference for IFC 300 (C, W and F version) ....................................................... 20

3.4 Connection diagrams ..................................................................................................... 20

4 Technical data 21

4.1 Dimensions and weights ................................................................................................ 21

4.2 Vacuum load ................................................................................................................... 26

5 Notes 27

2

www.krohne.com 09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

OPTIFLUX 4000

Warnings and symbols used

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

SAFETY INSTRUCTIONS

1

HANDLING

• This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i

RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

Safety instructions for the operator

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

LEGAL NOTICE!

The responsibility as to the suitability and intended use of this device rests solely with the user.

The supplier assumes no responsibility in the event of improper use by the customer. Improper

installation and operation may lead to loss of warranty. In addition, the "Terms and Conditions of

Sale" apply which form the basis of the purchase contract.

INFORMATION!

•

Further information can be found on the supplied CD-ROM in the manual, on the data sheet,

in special manuals, certificates and on the manufacturer's website.

•

If you need to return the device to the manufacturer or supplier, please fill out the form

contained on the CD-ROM and send it with the device. Unfortunately, the manufacturer

cannot repair or inspect the device without the completed form.

www.krohne.com09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

3

2

INSTALLATION

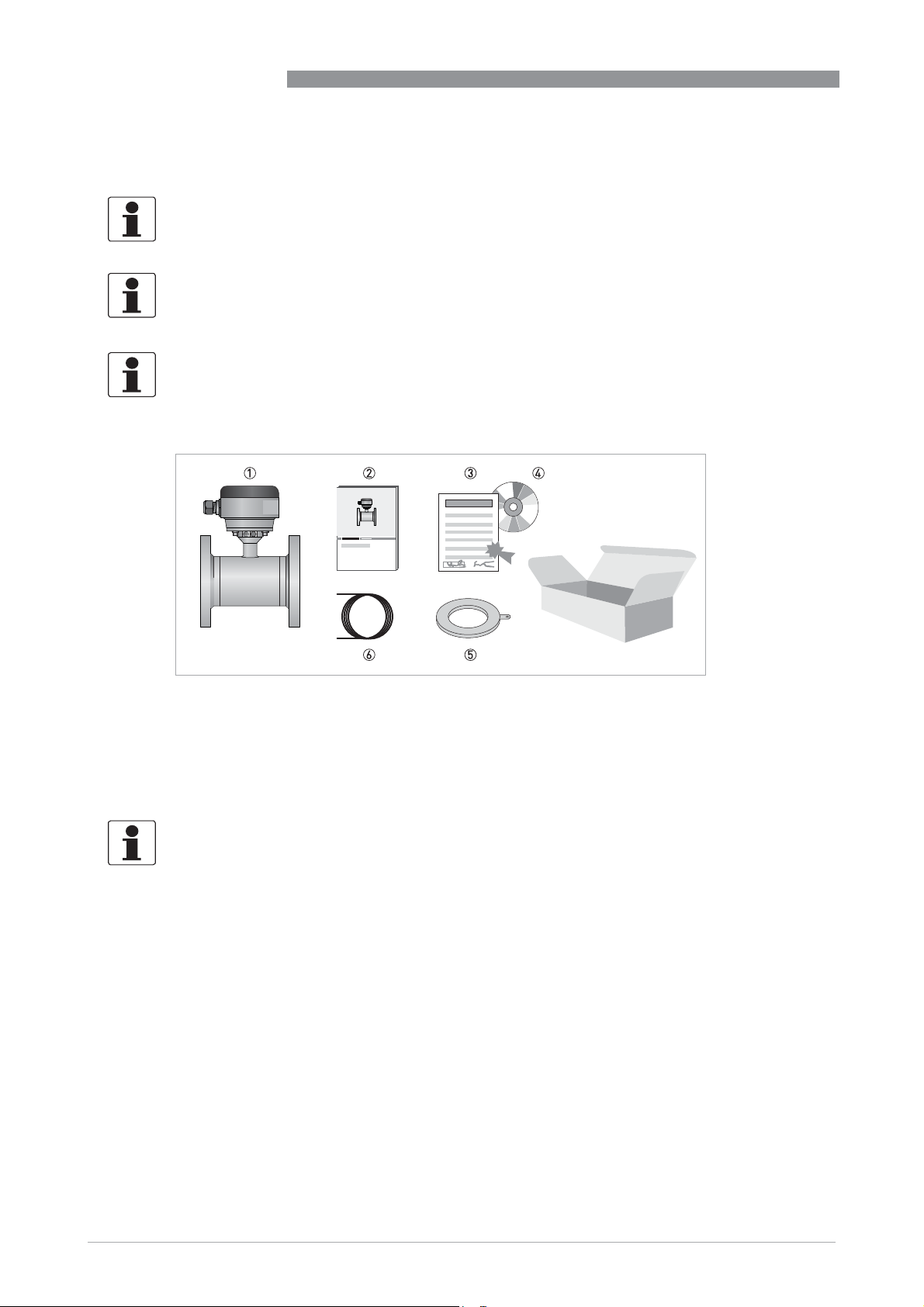

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

The remote version will arrive in two cartons. One carton contains the converter and one carton

contains the sensor.

OPTIFLUX 4000

Figure 2-1: Scope of delivery

1 Ordered flowmeter

2 Product documentation

3 Factory calibration report

4 CD-ROM with product documentation in available languages

5 Grounding rings (optional)

6 Signal cable (remote versions only)

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

4

www.krohne.com 09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

OPTIFLUX 4000

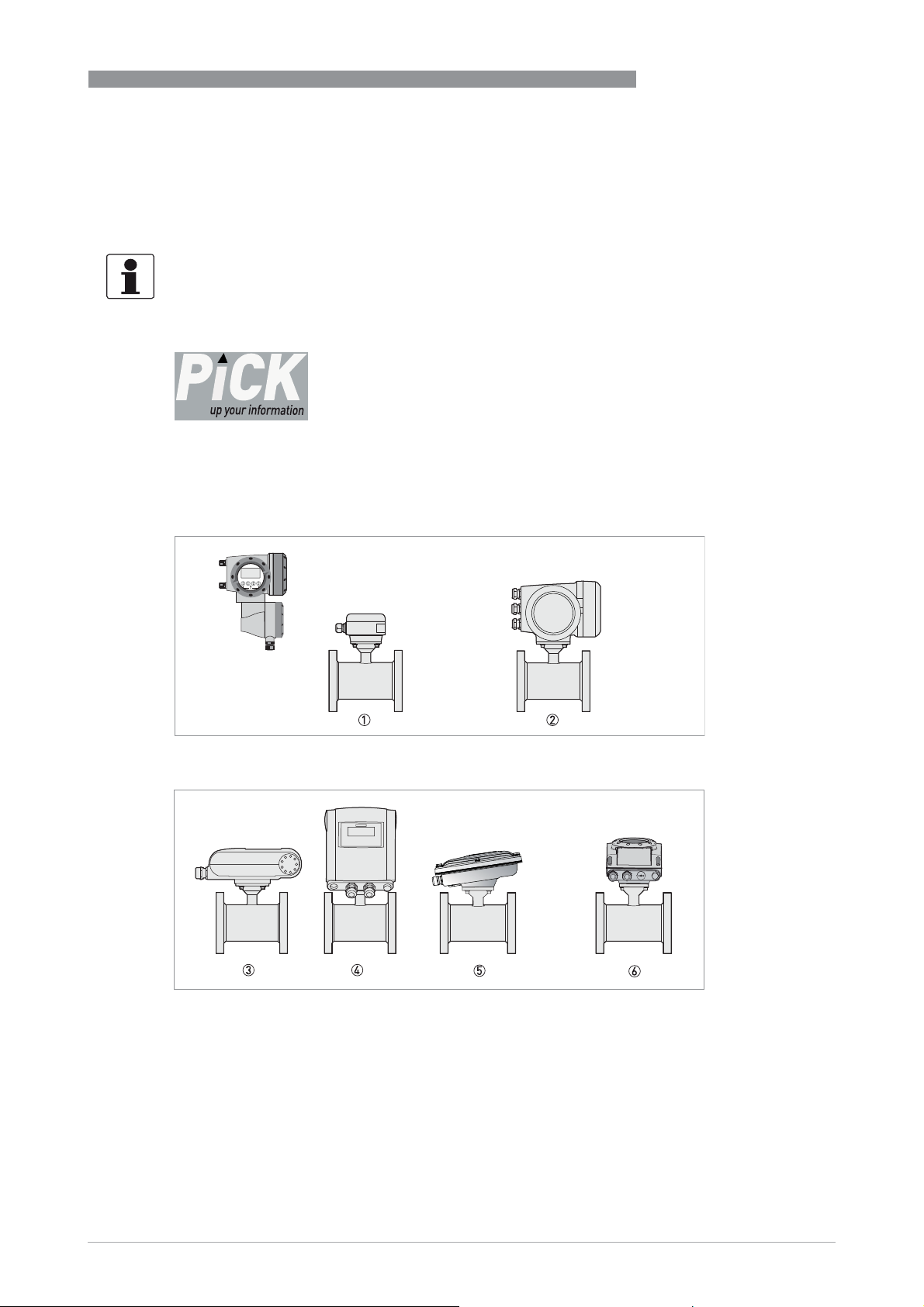

2.2 Device description

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

INFORMATION!

Product specific information and extensive product specification is available using PICK, the

Product Information Center KROHNE web-tool.

PICK can be found via the service menu button on the KROHNE.com website.

The following versions are available:

á Compact version (the signal converter is mounted directly on the flow sensor)

á Remote version (a measuring sensor with connection box and a separate signal converter)

INSTALLATION

2

Figure 2-2: Device versions

1 Remote version

2 Compact version with signal converter IFC 300

3 Compact version with signal converter IFC 100 (0°)

4 Compact version with signal converter IFC 100 (45°)

5 Compact version with signal converter IFC 100 (10°) Stainless steel

6 Compact version with signal converter IFC 050 (10°)

www.krohne.com09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

5

2

INSTALLATION

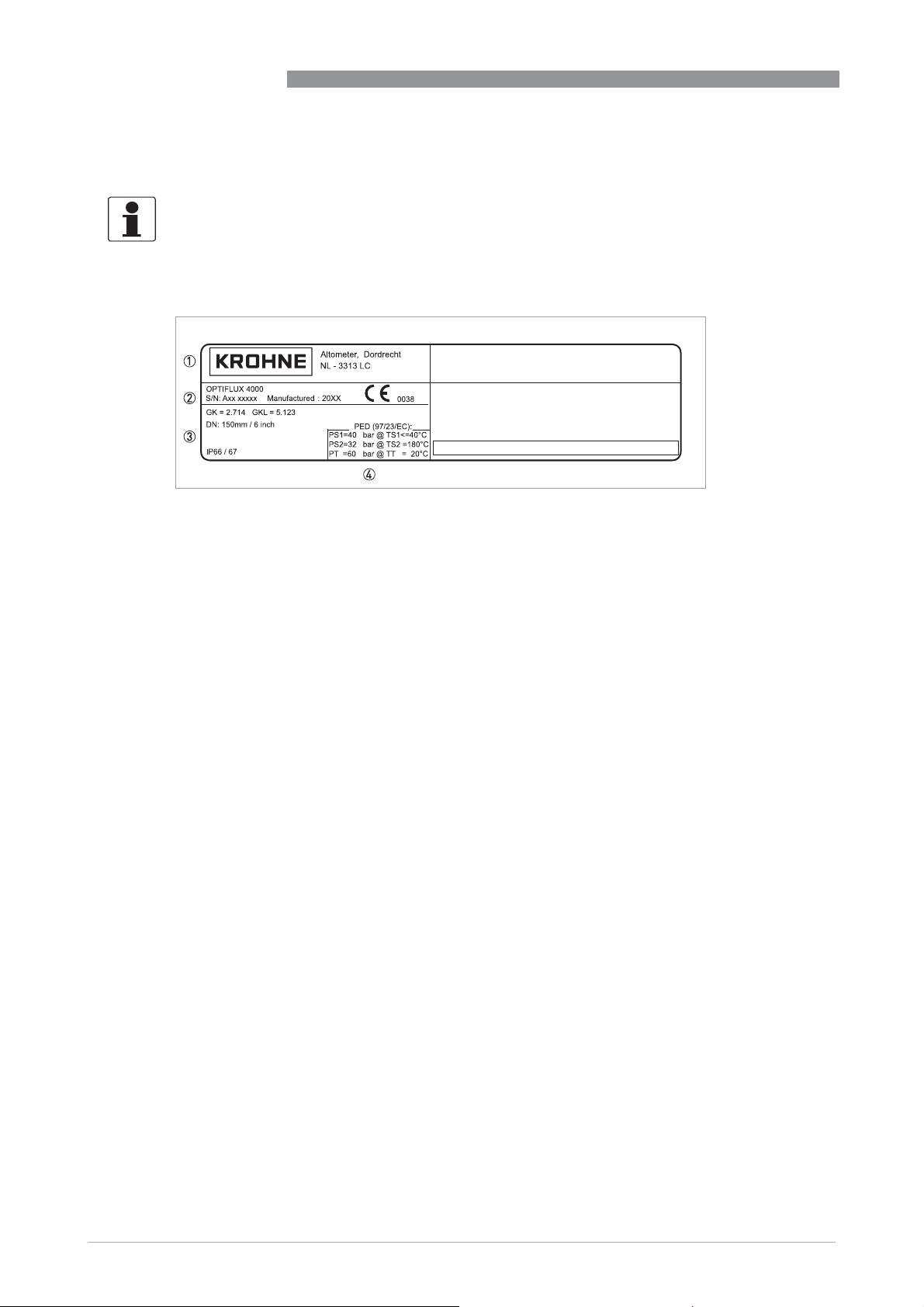

2.3 Nameplate

INFORMATION!

Check the device nameplate to ensure that the device is delivered according to your order.

Additional information (a.o correct supply voltage), can be found in the documentation of the

signal converter.

1 Name and address of the manufacturer

2 Type designation of the flowmeter and CE sign with number(s) of notified body / bodies

3 Calibration data

4 PED data

OPTIFLUX 4000

6

www.krohne.com 09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

OPTIFLUX 4000

2.4 Storage

• Store the device in a dry and dust-free location.

• Avoid lasting direct exposure to the sun.

• Store the device in its original packaging.

• Storage temperature: -50...+70°C / -58...+158°F

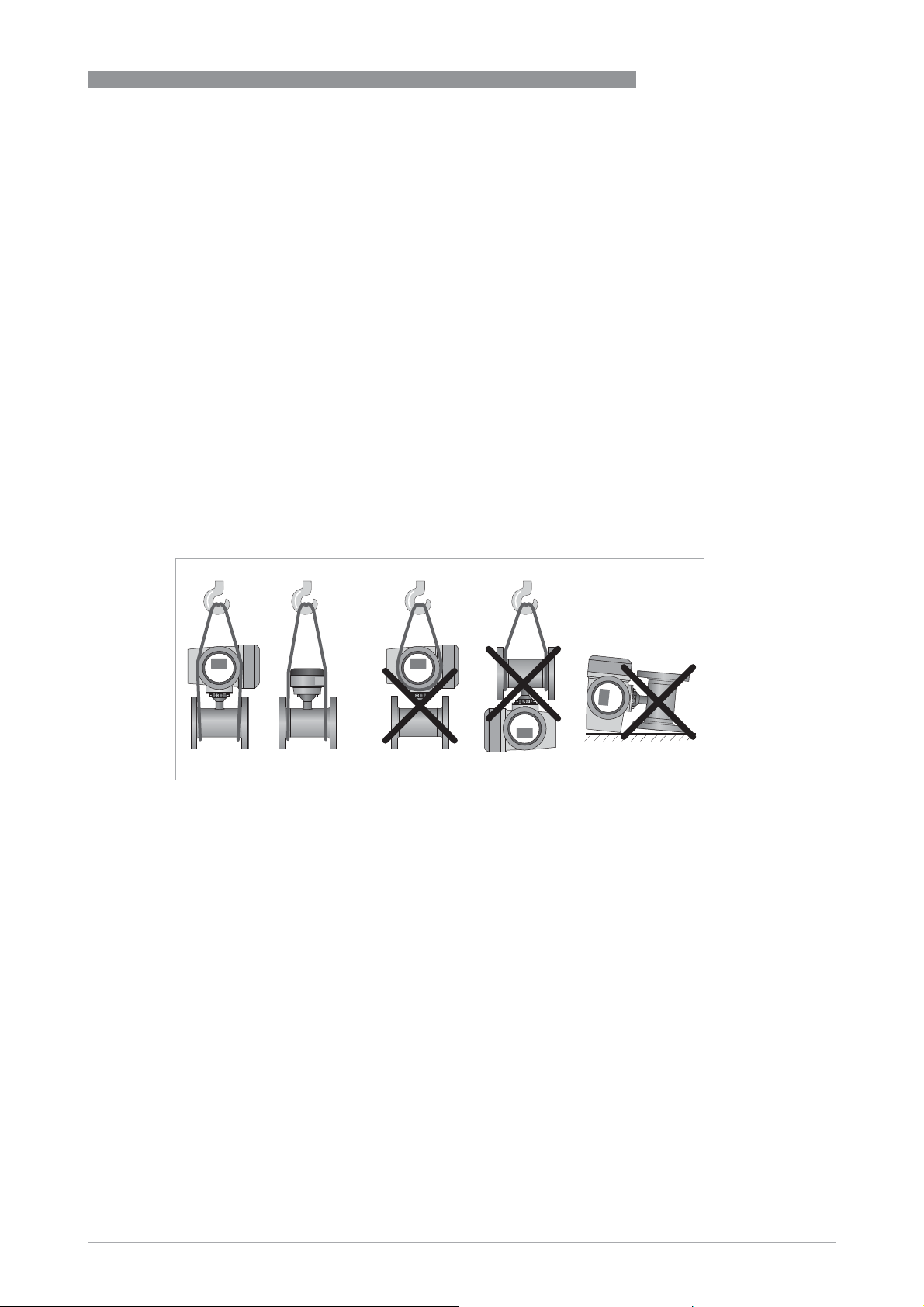

2.5 Transport

Signal converter

• No special requirements.

Compact version

• Do not lift the device by the signal converter housing.

• Do not use lifting chains.

• To transport flange devices, use lifting straps. Wrap these around both process connections.

INSTALLATION

2

Figure 2-3: Transport

2.6 Pre-installation requirements

Make sure that you have all necessary tools available:

• Allen key (4 mm)

• Small screwdriver

• Wrench for cable glands

• Wrench for wall mounting bracket (remote version only)

• Torque wrench for installing flowmeter in pipeline

www.krohne.com09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

7

2

INSTALLATION

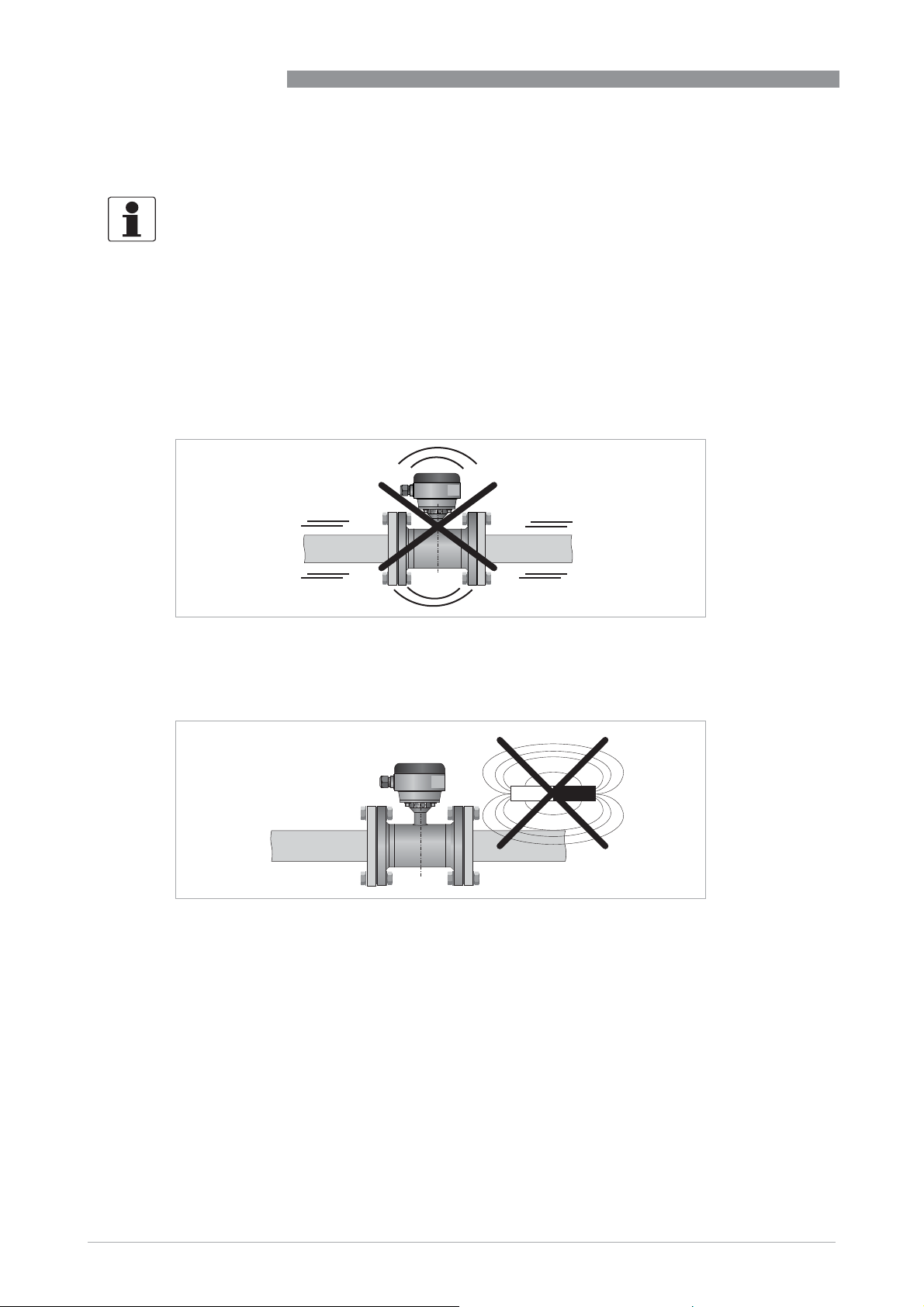

2.7 General requirements

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibration. The flowmeters are tested for a

vibration level in accordance with IEC 68-2-64.

2.7.1 Vibration

OPTIFLUX 4000

Figure 2-4: Avoid vibrations

2.7.2 Magnetic field

Figure 2-5: Avoid magnetic fields

8

www.krohne.com 09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

OPTIFLUX 4000

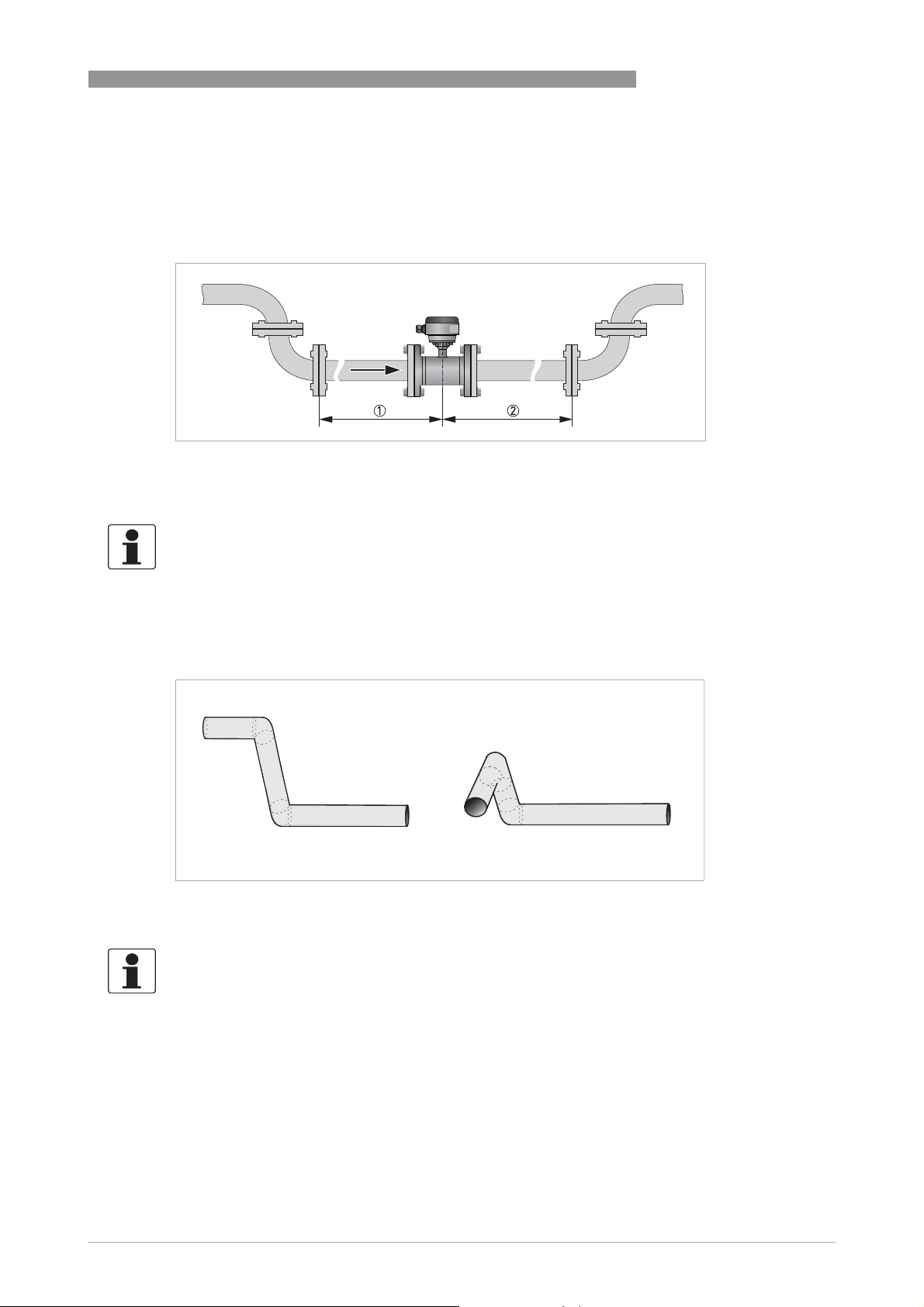

2.8 Installation conditions

2.8.1 Inlet and outlet

Figure 2-6: Recommended inlet and outlet

1 Refer to chapter "Bends in 2 or 3 dimensions"

2 t 2 DN

INSTALLATION

2

INFORMATION!

Sensors of type VN02 up to DN10:

The inlet and outlet sections are enclosed inside the sensor.

2.8.2 Bends in 2 or 3 dimensions

Figure 2-7: Inlet when using 2 and/or 3 dimensional bends upstream of the flowmeter

Inlet length: using bends in 2 dimensions: t 5 DN; when having bends in 3 dimensions: t 10 DN

INFORMATION!

2 Dimensional bends occur in a vertical plane only, while 3 Dimensional bends occur in both

vertical and

and horizontal plane.

andand

www.krohne.com09/2017 - 4003872403 - QS OPTIFLUX 4000 R06 en

9

Loading...

Loading...