KROHNE OPTIFLEX 1300 C Specifications

Technical Datasheet

Technical Datasheet

OPTIFLEX 1300 C

OPTIFLEX 1300 C

OPTIFLEX 1300 COPTIFLEX 1300 C

Technical DatasheetTechnical Datasheet

Guided Radar (TDR) Level Transmitter for heavy-duty

and interface applications

•

Universal device that can measure level of liquids, pastes, granulates, powders,

and liquid interface

•

Easy to install: on-site calibration is not needed

•

Operates up to 300 bar / 4350 psi

© KROHNE 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

CONTENTS

OPTIFLEX 1300 C

1 Product features 3

1.1 The superior TDR solution ............................................................................................... 3

1.2 Applications ...................................................................................................................... 5

1.3 Application table for probe selection ............................................................................... 8

1.4 Measuring principle.......................................................................................................... 9

2 Technical data 12

2.1 Technical data................................................................................................................. 12

2.2 Pressure/temperature table for probe selection .......................................................... 18

2.3 Guidelines for maximum operating pressure (CRN certification) ................................ 19

2.4 Measurement limits ....................................................................................................... 23

2.5 Dimensions and weights ................................................................................................ 26

3 Installation 40

3.1 Intended use ................................................................................................................... 40

3.2 Pre-installation requirements ....................................................................................... 40

3.3 How to prepare the tank before you install the device.................................................. 41

3.3.1 General information for nozzles........................................................................................... 41

3.3.2 Installation requirements for concrete roofs....................................................................... 43

3.3.3 Recommendations for pits and tanks made of non-conductive materials.......................... 43

3.4 Installation recommendations for liquids...................................................................... 44

3.4.1 General requirements .......................................................................................................... 44

3.4.2 Standpipes............................................................................................................................. 45

3.5 Installation recommendations for solids....................................................................... 49

3.5.1 Nozzles on conical silos........................................................................................................ 49

3.5.2 Traction loads on the probe.................................................................................................. 50

4 Electrical connections 51

4.1 Electrical installation: outputs 1 and 2 .......................................................................... 51

4.1.1 Non-Ex devices ..................................................................................................................... 51

4.1.2 Devices for hazardous locations........................................................................................... 52

4.2 Protection category ........................................................................................................52

4.3 Networks ........................................................................................................................ 53

4.3.1 General information.............................................................................................................. 53

4.3.2 Point-to-point networks ....................................................................................................... 53

4.3.3 Multi-drop networks ............................................................................................................. 54

5 Order information 55

5.1 Order code ...................................................................................................................... 55

6 Notes 66

2

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

1.1 The superior TDR solution

This device is a Guided Radar (TDR) Level Transmitter for measuring distance, level, interface,

level and interface, volume and mass. It has higher signal dynamics and a sharper pulse than

conventional TDR devices and therefore better reproducibility and accuracy. A variant with a

remote converter can be mounted up to 14.5 m / 47.6 ft from the probe. The device can operate

at very low and very high process temperatures as long as the process connection temperature

limits are observed.

PRODUCT FEATURES

1

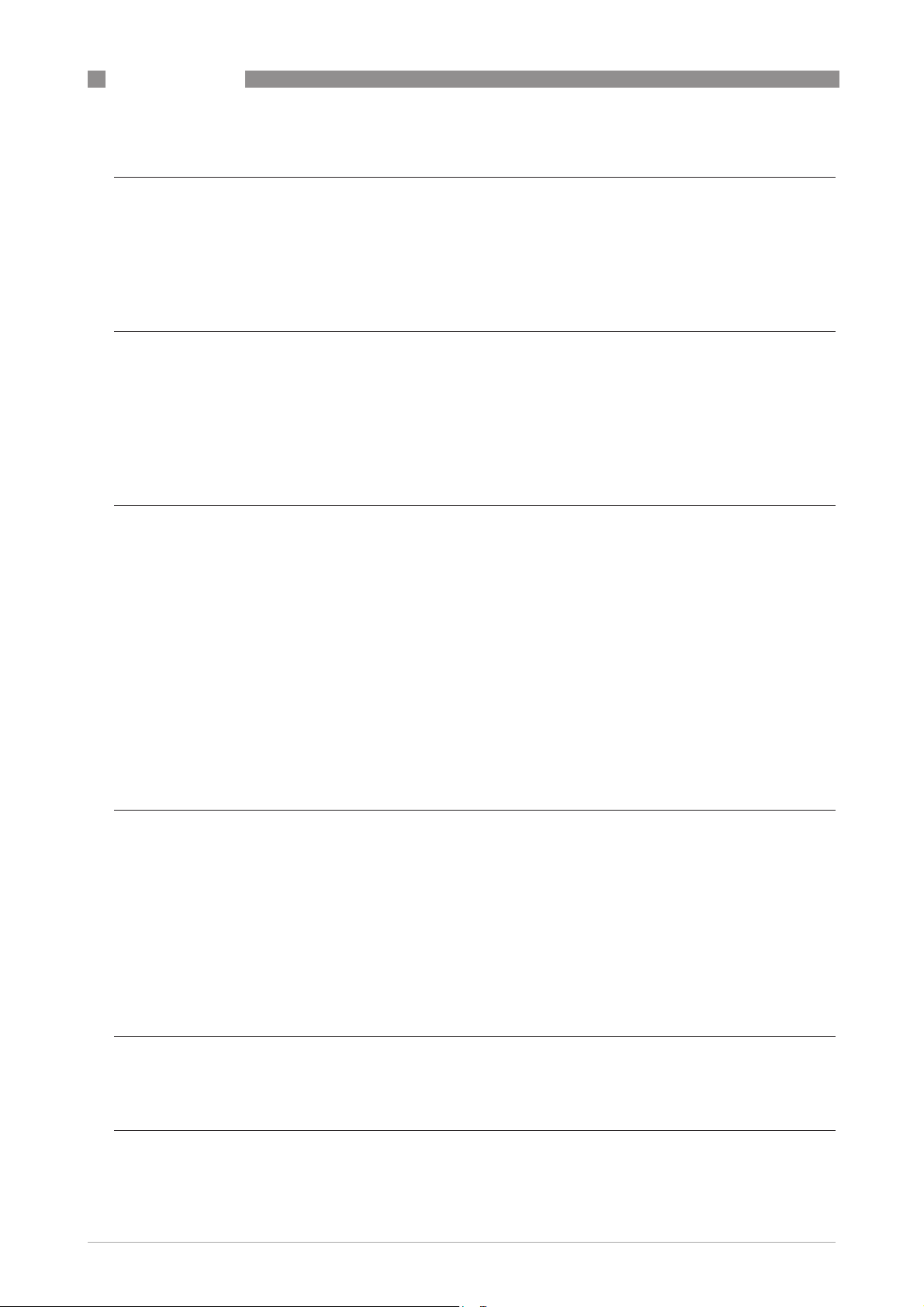

1 Touch screen with 4-button operation

2 2-wire level meter

3 Converter is rotatable and removable under process conditions

4 5 different types of probes suitable for a wide range of media

5 Optional ESD protection (30 kV) or Metaglas® dual process sealing system for dangerous products

6 Same converter for Ex and non-Ex

7 Large graphical display

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

3

1

PRODUCT FEATURES

Highlights

• Displays level and interface

• PACTware and DTMs included as standard

• Optional second current output – used for displaying interface measurements, for example

• High-pressure and high-temperature versions

• Optimal process safety (with Metaglas® dual process sealing system for dangerous products)

• Display in 9 languages: even in Chinese, Japanese and Russian

• Available in stainless steel and HASTELLOY® C-22®. Other materials are available on

request: monel, tantalum, titanium, duplex etc.

• Angled single cable and rod probes are available on request for installation in tanks which

contain obstructions

Industries

• Chemicals & Petrochemicals

• Oil & Gas

• Minerals & Mining

• Wastewater

• Pulp & Paper

• Food & Beverages

• Pharmaceutical

• Energy

OPTIFLEX 1300 C

Applications

• Blending tanks

• Distillation tanks

• Process tanks

• Separator

• Solid silos (inventory)

• Storage tanks

4

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

1.2 Applications

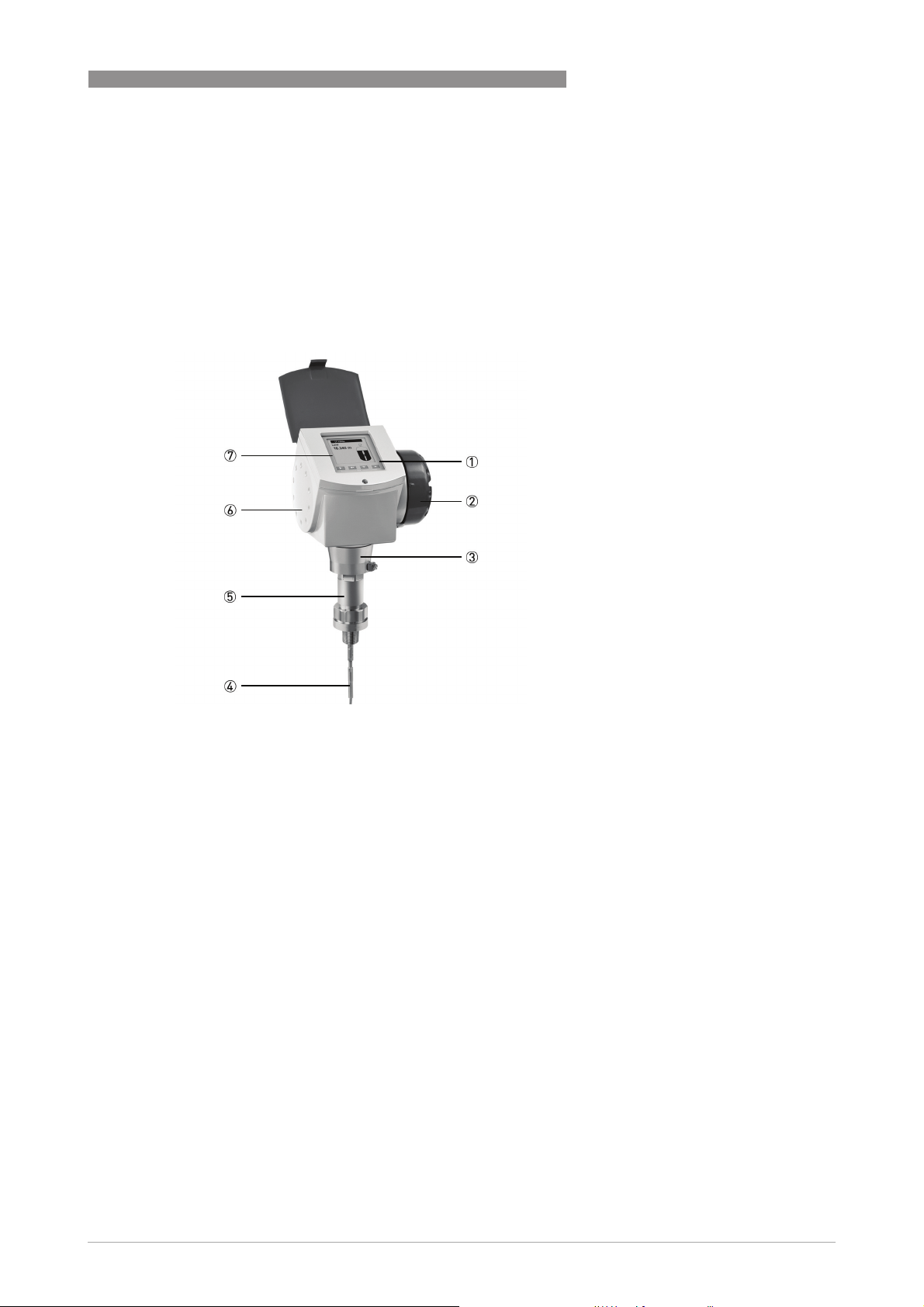

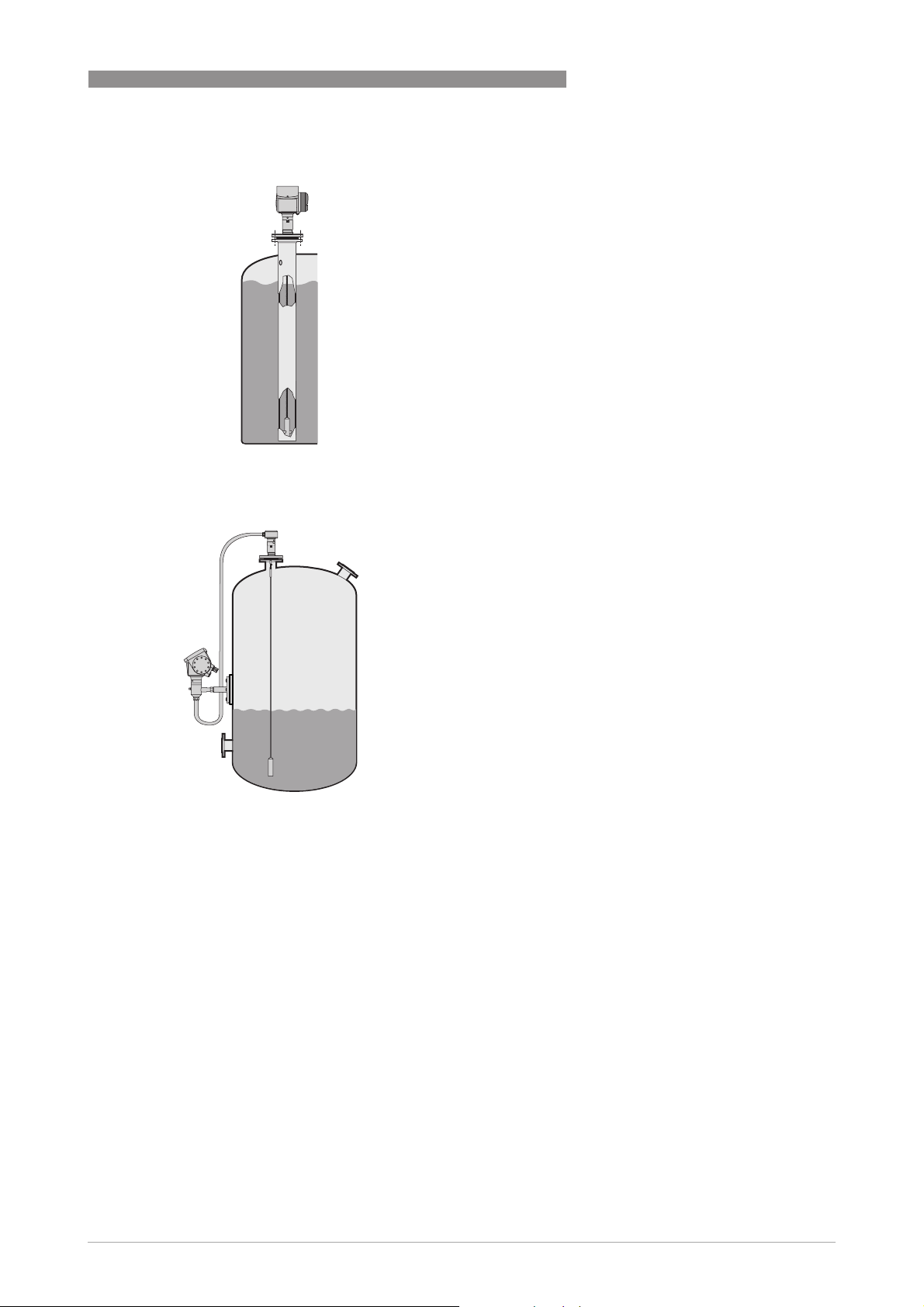

1. Level measurement of liquids

PRODUCT FEATURES

The level transmitter can measure the level of a

wide range of liquid products on a large variety of

installations within the stated pressure and

temperature range, including LPG and LNG. It does

not require calibration or commissioning when

installed. A Metaglas® option is also available for

dangerous products and ensures that no leakage is

possible.

A number of probe end attachments are available.

For example, the user can fix the end of cable probes

to heating coils: the heat prevents deposits building

up on the probe.

1

2. Interface measurement of liquids

The level transmitter can measure interface with or

without an air gap. It can also measure level and

interface simultaneously. It has an optional second

analogue output.

The coaxial probe of the level transmitter has a top

dead zone of only 35 mm / 1.4¨: this makes it ideal

for tracking full tank or ballast interface.

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

5

1

PRODUCT FEATURES

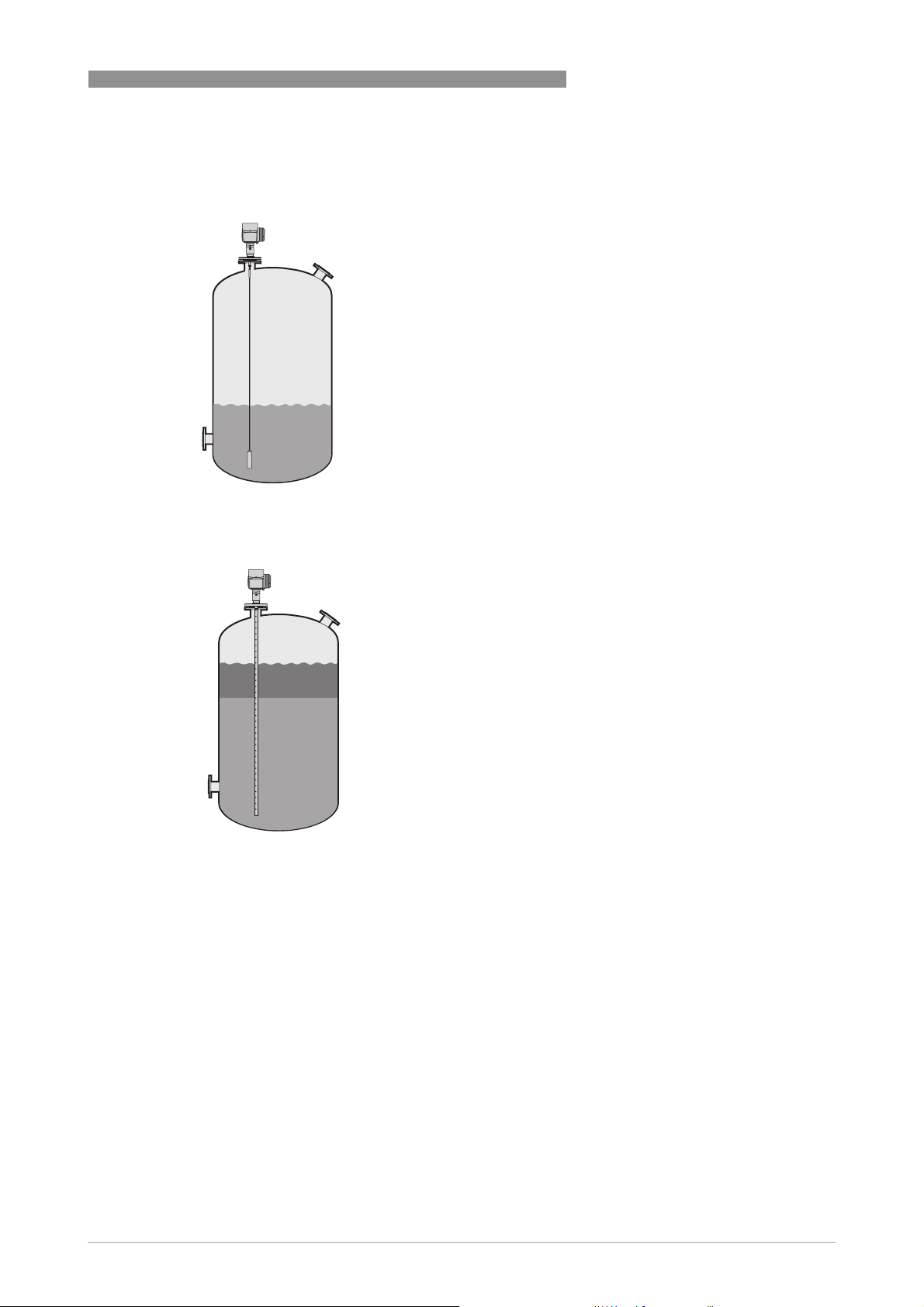

3. Level measurement of solids

4. Measurement of liquids in a bypass chamber

OPTIFLEX 1300 C

The level transmitter has a strengthened Ø8 mm /

0.3¨ single cable probe for measuring powders and

granulates in silos up to 35 m / 115 ft high.

The Ø4 mm / 0.15¨ single cable probe is used for

small silos. An ESD protection (30 kV) option is also

available.

If a product has a very low dielectric constant

(ε

<1.6), the level transmitter automatically

r

switches to TBF (Tank Bottom Following) mode and

keeps operating.

The level transmitter can measure accurately in

agitated conditions and in the presence of foam. If

the tank is full of obstructions such as agitators and

reinforcements, we recommend installing the level

transmitter in a bypass chamber. This solution is

available from KROHNE under the name BM 26 F.

Please refer to the BM 26 F documentation for

further information.

6

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

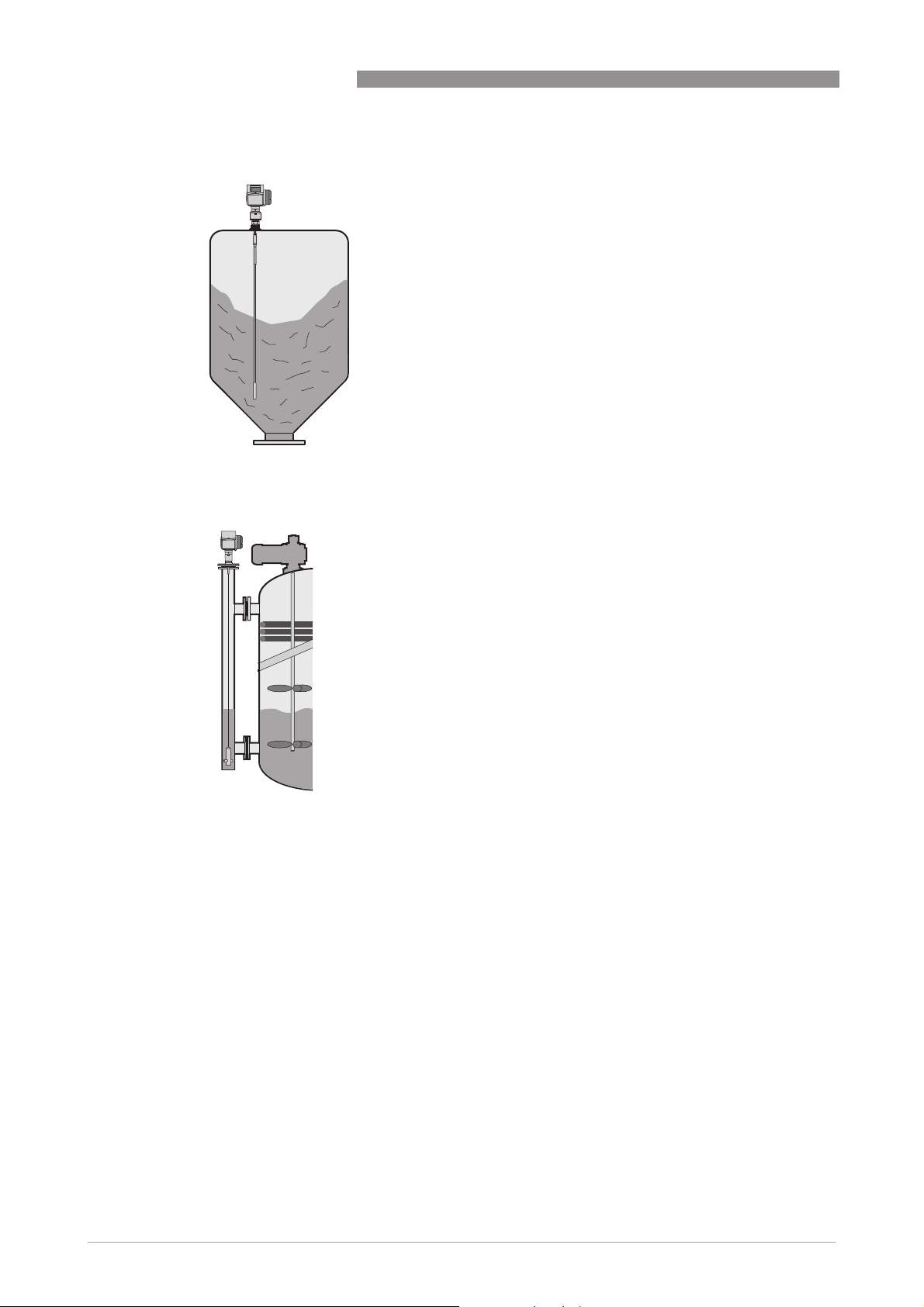

5. Measurement of liquids in a still well

6. Remote display on high or inaccessible tanks

PRODUCT FEATURES

You can also install the level transmitter in a still

well if there are vortices, agitators or other

obstructions in the tank. It is also suitable for tanks

with floating roofs. The level transmitter's setup

wizard allows you to quickly configure your device to

suit specific types of installations and get the best

possible performance from it.

1

If it is difficult or impossible to read the level

transmitter's integrated display at the top of the

tank, we recommend the remote display variant. It is

provided with a cable up to 14.5 m / 47.6 ft long and a

bracket for mounting in an accessible position.

If there is vibration in the installation, we also

recommend that you attach the remote converter to

a wall or another safe object that is not attached to

the installation.

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

7

1

PRODUCT FEATURES

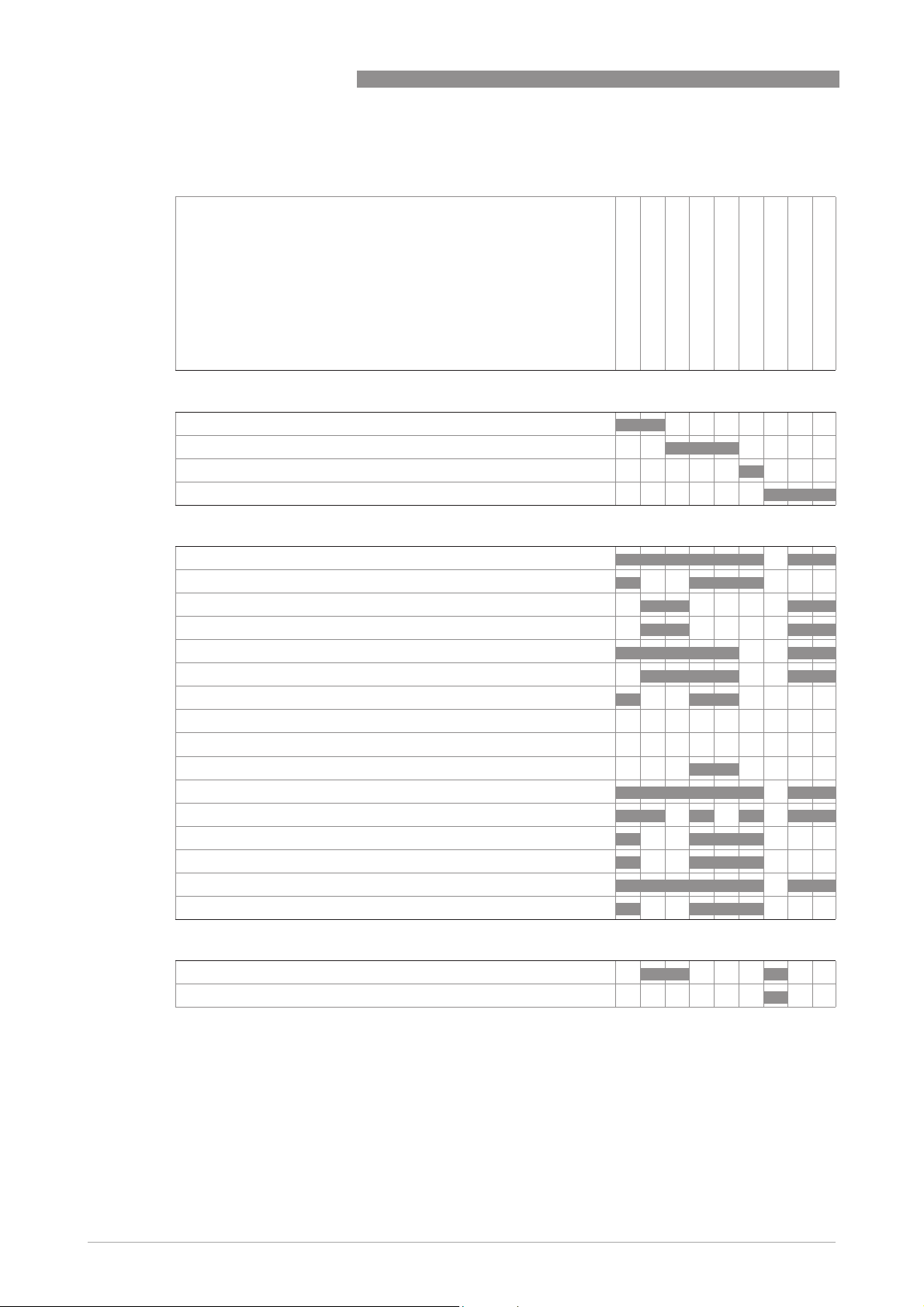

1.3 Application table for probe selection

Maximum probe length, L

4m/ 13ft

6m/ 20ft

8m/ 26ft

35 m / 115 ft

Double rod

OPTIFLEX 1300 C

Single rod

Single rod (segmented)

Coaxial

Coaxial (segmented)

Double cable

Single cable Ø8 mm / 0.32¨

Single cable Ø4 mm / 0.16¨

Single cable Ø2 mm / 0.08¨

Liquids

Liquid application

LPG, LNG

Highly viscous liquids

Highly crystallising liquids

Highly corrosive liquids

Foam

Agitated liquids

High-pressure applications

High-temperature applications

Spray in tank

Storage tanks

Installation in bypass chamber

Small diameter nozzles

Long nozzles

Stilling wells

Interface measurement

Solids

Powders

Granules, <5 mm / 0.1¨

1 1

2 2 2 2 2

3 3 3 3 3 3 3 4

5

1 1 1 1

6 6

7

7

J standard J optional U on request

1 Install the device in a stilling well or a bypass chamber

2 Use this probe with an anchor fitting. For more data, refer to the handbook.

3 Max. pressure is 100 bar / 1450 psig. Refer to the pressure-temperature table for probe selection.

4 Optional. Max. pressure is 300 bar / 4350 psig. Refer to the pressure-temperature table for probe selection.

5 Optional. Max. temperature is 300°C/ 570°F. Refer to the pressure-temperature table for probe selection.

6 Max. length is 20 m / 65.5 ft, more on request

7 Max. length is 10 m / 33 ft, more on request

8

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

1.4 Measuring principle

This Guided Radar (TDR) level meter has been developed from a proven technology called Time

Domain Reflectometry (TDR).

The device transmits low-intensity electromagnetic pulses of approximately half a nanosecond

width along a rigid or flexible conductor. These pulses move at the speed of light. When the

pulses reach the surface of the product to be measured, the pulses are reflected with an

intensity that depends on the dielectric constant, ε

dielectric constant and reflects the pulse back to the meter converter at 80% of its original

intensity).

The device measures the time from when the pulse is emitted to when it is received: half of this

time is equivalent to the distance from the reference point of the device (the flange facing) to the

surface of the product. The time value is converted into an output current of 4...20 mA and/or a

digital signal.

Dust, foam, vapor, agitated surfaces, boiling surfaces, changes in pressure, changes in

temperature and changes in density do not have an effect on device performance.

PRODUCT FEATURES

, of the product (for example, water has a high

r

1

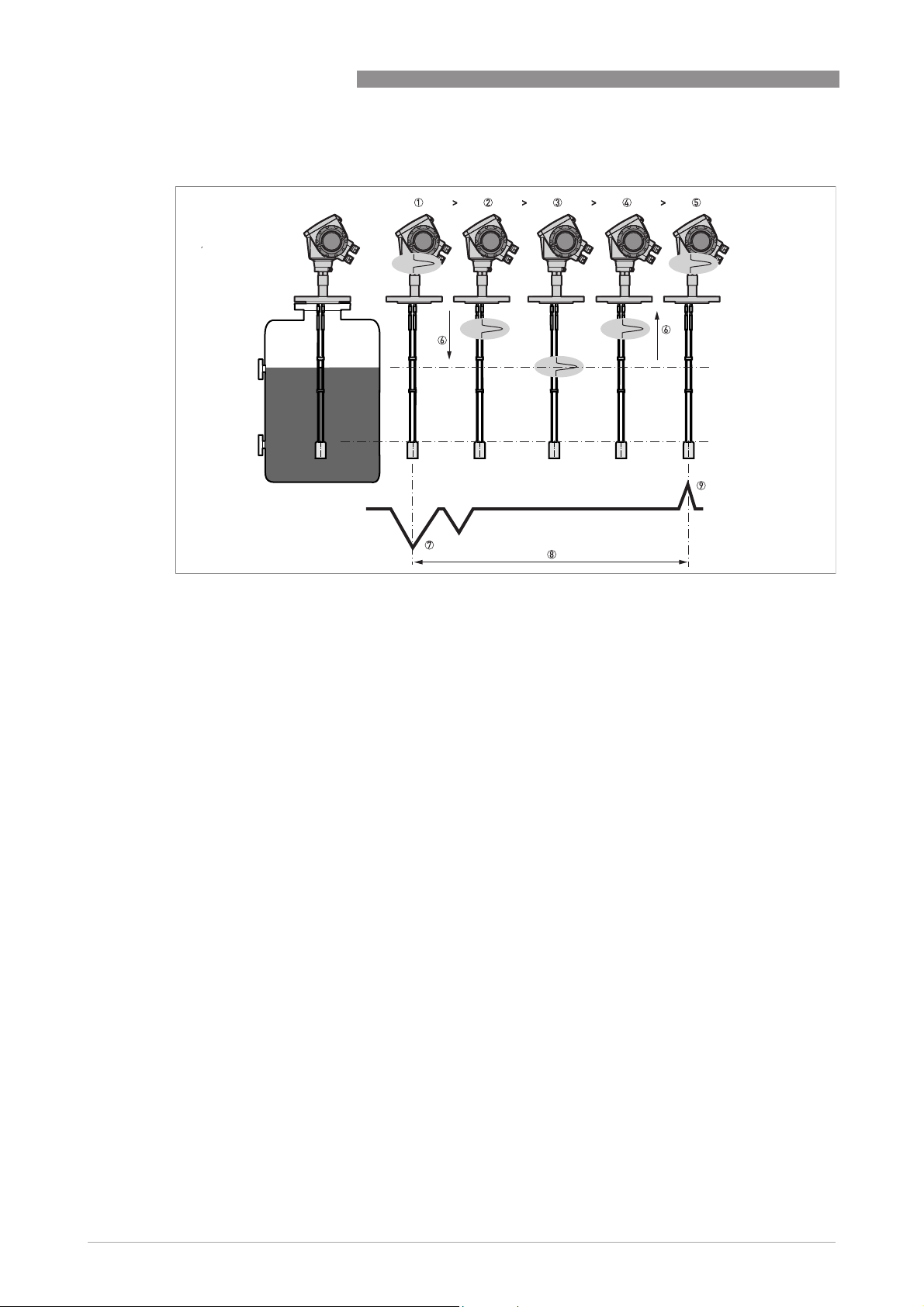

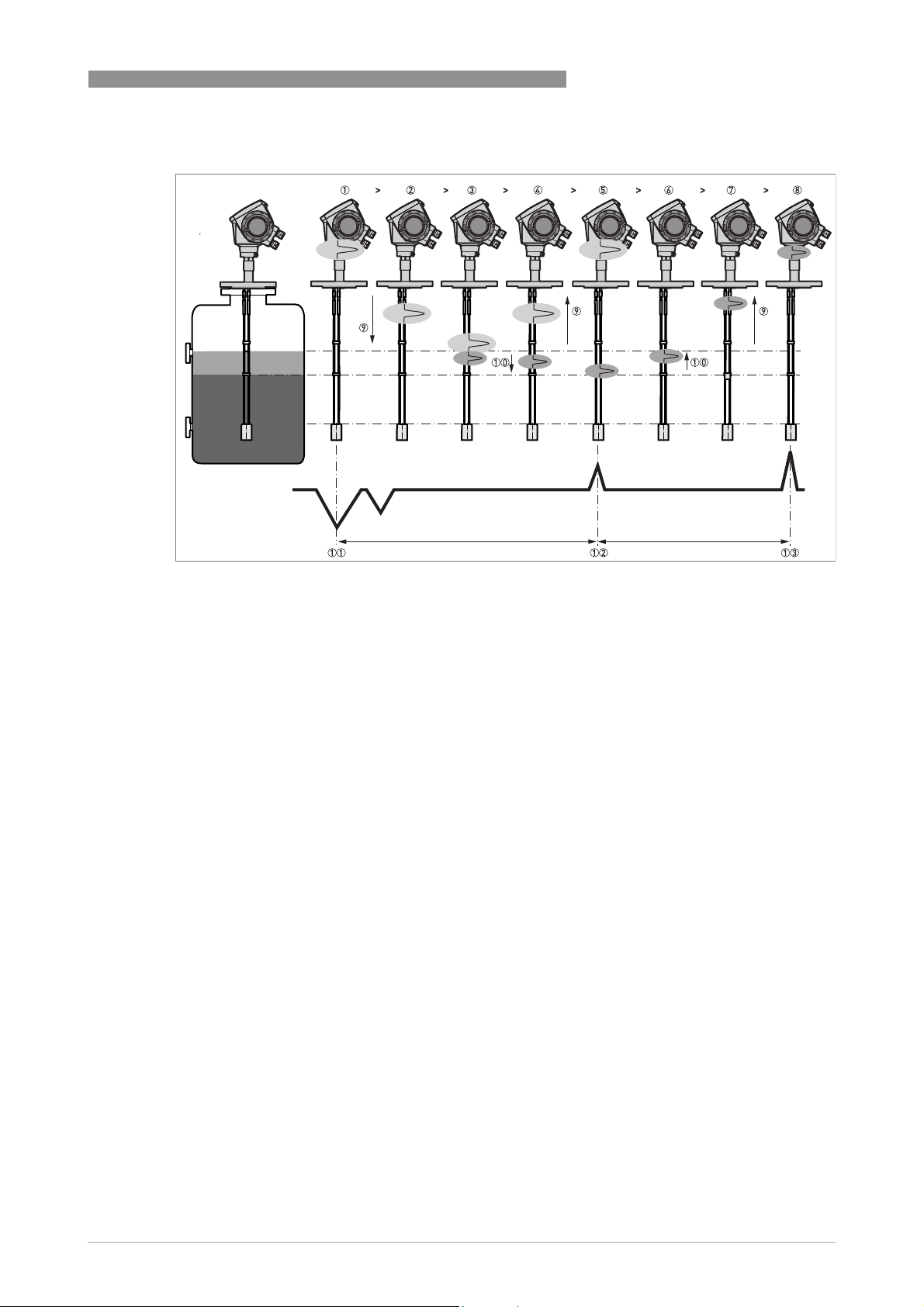

The illustration that follows shows a snapshot of what a user would see on an oscilloscope, if the

level of one product is measured.

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

9

1

PRODUCT FEATURES

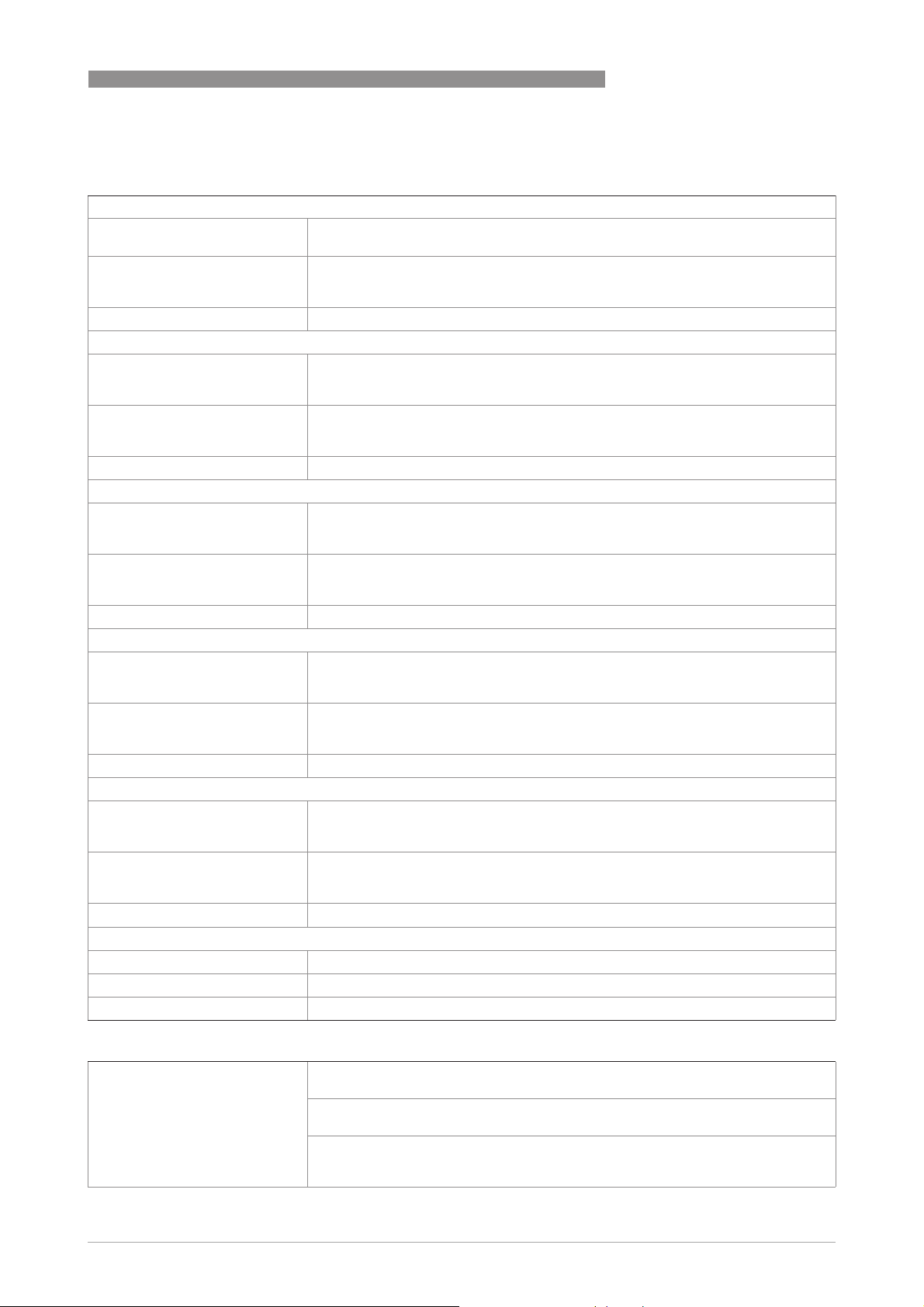

Level measurement principle (direct mode)

OPTIFLEX 1300 C

Figure 1-1: Level measurement principle

1 Time 0: The electromagnetic (EM) pulse is transmitted by the converter

2 Time 1: The pulse goes down the probe at the speed of light in air, V1

3 Time 2: The pulse is reflected

4 Time 3: The pulse goes up the probe at speed, V1

5 Time 4: The converter receives the pulse and records the signal

6 The EM pulse moves at speed, V1

7 Transmitted EM pulse

8 Half of this time is equivalent to the distance from the reference point of the device (the flange facing) to the surface

of the product

9 Received EM pulse

The illustration that follows shows a snapshot of what a user would see on an oscilloscope, if the

level and/or interface of products are measured.

Interface measurement:

Interface measurement: The dielectric constant of the top liquid must be less than the dielectric

Interface measurement:Interface measurement:

constant of the bottom liquid. If not, or if there is too small a difference, the device may not

measure correctly.

10

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

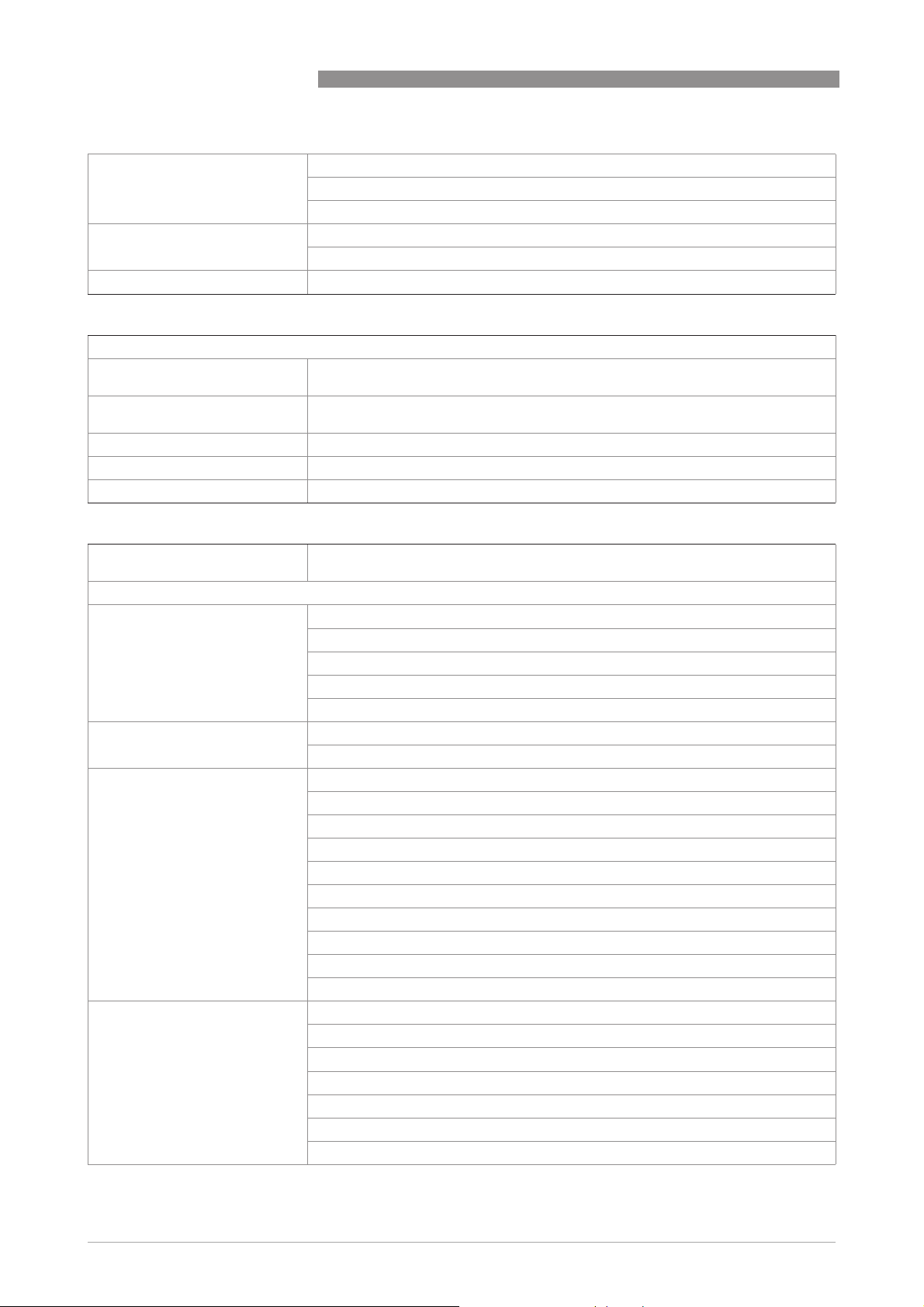

Level and interface measurement principle (direct measurement)

PRODUCT FEATURES

1

Figure 1-2: Level and interface measurement principle (2 liquids in the tank)

1 Time 0: The electromagnetic (EM) pulse is transmitted by the converter

2 Time 1: The pulse goes down the probe at the speed of light in air, V1

3 Time 2: Part of the pulse is reflected at the surface of the top liquid, the remaining pulse goes down the probe

4 Time 3: Part of the pulse goes up the probe at speed, V1. The remaining pulse goes down the probe at the speed of

light in the top product, V2

5 Time 4: The converter receives part of the pulse and records the signal. The remaining pulse is reflected at the inter-

face of the 2 liquids

6 Time 5: The remaining pulse is goes up the probe at speed, V2

7 Time 6: The remaining pulse goes up the probe at speed, V1

8 Time 7: The converter receives the remaining pulse and records the signal

9 The EM pulse moves at speed, V1

10 The EM pulse moves at speed, V2

11 Transmitted EM pulse

12 Received EM pulse (distance to the top liquid)

13 Received EM pulse (distance to the interface of 2 liquids)

If products have a very low dielectric constant (εr<1.6), only a small part of the EM pulse is

reflected at the surface of the product. Most of the pulse is reflected at the probe end. TBF (tank

bottom following) mode is used to measure the distance to the product surface.

TBF mode (indirect measurement) compares:

• The time for the pulse to go to the probe end and go back to the converter when the tank is

empty.

• The time for the pulse to go to the probe end and go back to the converter when the tank is

full or partially filled.

The level of the product in the tank can be calculated from the time difference.

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

11

2

TECHNICAL DATA

OPTIFLEX 1300 C

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle 2-wire loop-powered level transmitter; Time Domain Reflectometry (TDR)

Application range Level measurement of liquids, pastes, slurries, powders and granulates

Primary measured value Time between the emitted and received signal

Secondary measured value Distance, level, volume, mass and/or interface

Design

Construction The measurement system consists of a measuring sensor (probe) and a signal

Options Integrated LCD display with sun cover (-20…+60°C/ -4…+140°F);

Accessories Weather protection

Max. measuring range Double rod Ø8 mm / 0.32¨: 4 m / 13 ft

Tolerance, probe length ±0.5%

Dead zone This depends on the type of probe. For more data, refer to

converter which is available in a compact or remote version

if the ambient temperature is not in these limits, the display switches off

2nd current output

ESD protection (max. 30 kV)

Metaglas® (dual process sealing system for dangerous products (ammonia,

chlorine, ...))

Remote housing connected to the probe via a flexible conduit

Standard lengths: 2 m / 6.6 ft, 4.5 m / 14.8 ft, 9.5 m / 31.2 ft and 14.5 m / 47.6 ft

Probe end types (not for rod and coaxial probes)

Probe end types (not for rod and coaxial probes)

Probe end types (not for rod and coaxial probes)Probe end types (not for rod and coaxial probes)

Standard: Counterweights (refer to counterweight dimensions in "Technical data:

Dimensions and weights")

Options: Turnbuckle, chuck, threaded end, crimped end, open end

Discs (low-pressure flanges) with bolt hole dimensions and positions that agree

with DN80...200 in PN06 or 3¨...8¨ in 150 lb for devices with the G 1½ threaded

connection. Max. pressure: 1 barg / 14.5 psig at +20°C / +68°F.

Single rod Ø8 mm / 0.32¨: 4 m / 13 ft

Single rod Ø8 mm / 0.32¨ (segmented): 6 m / 20 ft

Coaxial Ø22 mm / 0.87¨: 6 m / 20 ft

Coaxial Ø22 mm / 0.87¨ (segmented): 6 m / 20 ft

Double cable Ø4 mm / 0.16¨: 8 m / 26 ft

Single cable Ø2 mm / 0.08¨: 35 m / 115 ft (for liquids only)

Single cable Ø4 mm / 0.16¨: 35 m / 115 ft (an angled probe is available on request

for installations with very low ceilings or objects in the tank that prevent installation

on top of the tank)

Single cable Ø8 mm / 0.32¨: 35 m / 115 ft (for solids only)

1

Measurement limits

page 23.

on

12

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

Display and User interface

Display and User interface

Display and User interfaceDisplay and User interface

Display LCD display

9 lines, 160×160 pixels in 8-step grayscale with 4-button keypad

Interface languages English, German, French, Italian, Spanish, Portuguese, Japanese, Simplified

Chinese and Russian

TECHNICAL DATA

Accuracy

Resolution 1mm/ 0.04¨

Repeatability ±1mm/ ±0.04¨

Accuracy (in direct mode) Liquids:

Accuracy (in TBF mode) ±20 mm / ±0.8¨ (εr constant)

Minimum layer (interface) 50 mm / 2¨

Reference conditions acc. to EN 60770

Reference conditions acc. to EN 60770

Reference conditions acc. to EN 60770Reference conditions acc. to EN 60770

Temperature +20°C ±5°C / +68°F ±10°F

Pressure 1013 mbara ±20 mbar / 14.69 psia ±0.29 psi

Relative air humidity 60% ±15%

Liquids:

Liquids:Liquids:

±3mm/ ±0.12¨, when distance <10m/ 33ft;

±0.03% of measured distance, when distance > 10 m / 33 ft

Powders:

Powders:

Powders:Powders:

±20 mm / ±0.8¨

Interface:

Interface:

Interface:Interface:

±10 mm / ±0.4¨ (εr constant)

2

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature -40…+80°C/ -40…+176°F

Storage temperature -40…+85°C/ -40…+185°F

Process connection temperature Standard

Pressure

Pressure

PressurePressure

Operating pressure Single cable Ø8 mm / 0.32

Ex: see supplementary operating instructions or approval certificates

Standard

StandardStandard

-50…+200°C/ -58…+392°F (according to the temperature limits of the gasket

material. Refer to "Material" in this table.)

Ex: see supplementary operating instructions or approval certificates

High-Temperature (HT) and High-Temperature / High-Pressure (HT/HP) versions

High-Temperature (HT) and High-Temperature / High-Pressure (HT/HP) versions

High-Temperature (HT) and High-Temperature / High-Pressure (HT/HP) versions High-Temperature (HT) and High-Temperature / High-Pressure (HT/HP) versions

with FKM/FPM and Kalrez

with FKM/FPM and Kalrez® 6375 gaskets

with FKM/FPM and Kalrezwith FKM/FPM and Kalrez

+300°C / +572°F (single cable Ø2 mm / 0.08¨ probe only)

Ex: see supplementary operating instructions or approval certificates

HT and HT/HP versions with EPDM gaskets

HT and HT/HP versions with EPDM gaskets

HT and HT/HP versions with EPDM gasketsHT and HT/HP versions with EPDM gaskets

+250°C / +482°F (single cable Ø2 mm / 0.08¨ probe only)

Ex: see supplementary operating instructions or approval certificates

Single cable Ø8 mm / 0.32¨ probe

Single cable Ø8 mm / 0.32Single cable Ø8 mm / 0.32

-1…40 barg / -14.5…580 psig

subject to process connection temperature and probe type used

High-Pressure (HP) version

High-Pressure (HP) version

High-Pressure (HP) versionHigh-Pressure (HP) version

max. 300 barg / 4350 psig (single cable Ø2 mm / 0.08¨ probe only)

subject to process connection temperature and probe type used

All other probe types

All other probe types

All other probe typesAll other probe types

-1…100 barg / -14.5…1450 psig

subject to process connection temperature and probe type used

6375 gaskets

6375 gaskets6375 gaskets

probe

probe probe

2

2

2

2

2

2

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

13

2

TECHNICAL DATA

Other conditions

Other conditions

Other conditionsOther conditions

Dielectric constant (εr) Level in direct mode:

Vibration resistance IEC 60068-2-6 and EN 50178 (10...57 Hz: 0.075 mm / 57...150 Hz:1g)

Protection category IP 66/67 equivalent to NEMA 4X (housing) and 6P (probe)

Level in direct mode:

Level in direct mode:Level in direct mode:

≥1.4 for coaxial probe; ≥1.6 for single and double probes

Interface in direct mode:

Interface in direct mode:

Interface in direct mode:Interface in direct mode:

εr(interface) >> εr(level)²

Level in TBF mode:

Level in TBF mode:

Level in TBF mode:Level in TBF mode:

≥1.1

OPTIFLEX 1300 C

Installation conditions

Process connection size Refer to "Installation: How to prepare the tank before you install the device" and

Process connection position Make sure that there are not any obstructions directly below the process

Dimensions and weights Refer to "Technical data: Dimensions and weights"

"Technical data: Measurement limits"

connection for the device.

Material

Housing Standard: Polyester-coated aluminium

Option: Stainless steel (1.4404 / 316L)

Single rod (single-piece) Standard: Stainless steel (1.4404 / 316L)

Option: Stainless steel (1.4404 / 316L) in a PVDF protective sheath, HASTELLOY®

C-22® (2.4602)

On request: Stainless steel (1.4404 / 316L) in a PVC or PP protective sheath

On request: Monel; Tantalum; Titanium; Duplex

Single rod (segmented) Standard: Stainless steel (1.4404 / 316L)

Double rod Standard: Stainless steel (1.4404 / 316L)

Option: HASTELLOY® C-22® (2.4602)

On request: Monel; Tantalum; Titanium; Duplex

Coaxial (single-piece) Standard: Stainless steel (1.4404 / 316L)

Option: HASTELLOY® C-22® (2.4602)

Coaxial (segmented) Standard: Stainless steel (1.4404 / 316L)

Single cable Standard: Stainless steel (1.4401 / 316)

Option: HASTELLOY® C-22® (2.4602)

– only for the Ø2 mm / 0.08¨ single cable probe

On request: FEP-coated stainless steel (-20...+150°C / -4...+302°F)

– only for the Ø4 mm / 0.16¨ single cable probe

Double cable Stainless steel (1.4401 / 316)

Process fitting Standard: Stainless steel (1.4404 / 316L)

Option: HASTELLOY® C-22® (2.4602)

On request: Monel; Tantalum; Titanium; Duplex

Gaskets FKM/FPM (-40…+200°C/ -40…+392°F); Kalrez® 6375 (-20…+200°C/ -4…+392°F);

Weather protection (Option) Stainless steel (1.4301 / 304)

Protective sheath

(On request for single rod only)

Conduit for remote housing

(Option)

EPDM (-50...+150°C / -58...+302°F) – all probes except single cable Ø8 mm / 0.32¨

PP (-40…+90°C/ -40…+194°F); PVC (-15…+80°C/ +5…+176°F);

PVDF (-40…+150°C/ -40…+302°F)

Zinc-coated steel in a PVC sheath (-40...+105°C / -40...+221°F)

4

3

5

14

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

TECHNICAL DATA

Process connections

Thread

Thread

ThreadThread

Single cable Ø2 mm / 0.08¨ G ½ (ISO 228); ½ NPT (ASME B1.20.1); ½ NPTF (ASME B1.20.3 – for the HT/HP

Single cable Ø8 mm / 0.32¨

Double cable Ø4 mm / 0.16¨

Double rod Ø8 mm / 0.32¨

All other probes G ¾…1½ (ISO 228); ¾…1½ NPT (ASME B1.20.1)

Flange versions for double rod and double cable probes

Flange versions for double rod and double cable probes

Flange versions for double rod and double cable probesFlange versions for double rod and double cable probes

EN 1092-1 DN50...80 in PN40 (Type B1), DN100…200 in PN16 or PN40 (Type B1), DN50...150 in

ASME B16.5 2¨…8¨ in 150 lb, 2¨...6¨ in 300 lb RF, 2¨...4¨ in 600 lb RF; 3¨...4¨ 900 lb RF, 2¨ in 900 lb

JIS B2220 50…100A in 10K; others on request

Flange versions for single cable Ø8 mm / 0.32

Flange versions for single cable Ø8 mm / 0.32¨ cable probes

Flange versions for single cable Ø8 mm / 0.32Flange versions for single cable Ø8 mm / 0.32

EN 1092-1 DN40...80 in PN40 (Type B1), DN100…200 in PN16 or PN40 (Type B1), DN40…150 in

ASME B16.5 1½¨…8¨ in 150 lb, 1½¨...6¨ in 300 lb RF, 1½¨ ...4¨ in 600 lb RF; 3¨...4¨ 900 lb RF,

JIS B2220 40…100A in 10K; others on request

Flange versions for single cable Ø2 mm / 0.08

Flange versions for single cable Ø2 mm / 0.08¨ probe

Flange versions for single cable Ø2 mm / 0.08Flange versions for single cable Ø2 mm / 0.08

EN 1092-1 DN25...80 in PN40 (Type B1), DN100…200 in PN16 or PN40 (Type B1), DN40…150 in

ASME B16.5 1¨…8¨ in 150 lb RF, 1½¨...6¨ in 300 lb RF, 1¨...4¨ in 600 lb RF, 3¨...4¨ in 900 lb RF,

JIS B2220 40…100A in 10K; others on request

Flange versions for other probes

Flange versions for other probes

Flange versions for other probesFlange versions for other probes

EN 1092-1 DN25...80 in PN40 (Type B1), DN100…200 in PN16 or PN40 (Type B1), DN25…150 in

ASME B16.5 1¨…8¨ in 150 lb RF, 1½¨...6¨ in 300 lb RF, 1¨...4¨ in 600 lb RF, 3¨...4¨ in 900 lb RF,

JIS B2220 40…100A in 10K; others on request

Other options for single and double rod probes

Other options for single and double rod probes

Other options for single and double rod probesOther options for single and double rod probes

SMS Available on request

Tri-clamp Available on request

Others Others on request

version)

G1½ (ISO 228); 1½ NPT (ASME B1.20.1)

PN63 or PN100 (Type B1); others on request

Optional flange facing: Types C, D, E and F

or 1500 lb RJ; others on request

Optional flange facing: RJ (Ring Joint)

cable probes

cable probes cable probes

PN63 or PN100 (Type B1); others on request

Optional flange facing: Types C, D, E and F

1½¨...2¨ in 900 lb or 1500 lb RJ; others on request

Optional flange facing: RJ (Ring Joint)

probe

probe probe

PN63 or PN100 (Type B1); others on request

Optional flange facing: Types C, D, E and F

1¨...2¨ in 900 lb or 1500 lb RJ, 1¨ in 2500 lb RJ; others on request

Optional flange facing: RJ (Ring Joint)

PN63 or PN100 (Type B1); others on request

Optional flange facing: Types C, D, E and F

1¨...2¨ in 900 lb or 1500 lb RJ; others on request

Optional flange facing: RJ (Ring Joint)

2

Electrical connections

Power supply Terminals output 1

Terminals output 1 – Non-Ex / Ex i:

Terminals output 1 Terminals output 1

14…30 VDC; min./max. value for an output of 22 mA at the terminal

Terminals output 1

Terminals output 1 – Ex d:

Terminals output 1 Terminals output 1

20…36 VDC; min./max. value for an output of 22 mA at the terminal

Terminals output 2

Terminals output 2 – Non-Ex / Ex i / Ex d:

Terminals output 2 Terminals output 2

10…30 VDC; min/max. value for an output of 22 mA at the terminal (additional

power supply needed – output only)

Non-Ex / Ex i:

Non-Ex / Ex i: Non-Ex / Ex i:

Ex d:

Ex d: Ex d:

Non-Ex / Ex i / Ex d:

Non-Ex / Ex i / Ex d: Non-Ex / Ex i / Ex d:

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

15

2

TECHNICAL DATA

Cable entry M20×1.5; ½ NPT

G ½ (not for FM- and CSA-approved devices. Not for stainless steel housings.)

Stainless steel housings: M20×1.5

Cable gland Standard: none

Options: M20×1.5; others are available on request

Cable entry capacity (terminal) 0.5…1.5 mm²

Input and output

Current output

Current output

Current outputCurrent output

Output signal

(Output 1)

Output signal

(Output 2 – optional)

Resolution ±3 µA

Temperature drift Typically 50 ppm/K

Error signal High: 22 mA; Low: 3.6 mA acc. to NAMUR NE 43

4…20 mA HART® or 3.8…20.5 mA acc. to NAMUR NE 43

4…20 mA (no HART® signal) or 3.8…20.5 mA acc. to NAMUR NE 43 (optional)

OPTIFLEX 1300 C

6

Approvals and certification

CE This device fulfils the statutory requirements of the EC directives. The

Explosion protection

Explosion protection

Explosion protectionExplosion protection

ATEX

KEMA 04ATEX1218 X

IECEx

IECEx KEM 06.0024X

FM – Dual Seal-approved NEC 500

CSA – Dual Seal-approved CEC Section 18 (Zone ratings)

manufacturer certifies successful testing of the product by applying the CE mark.

II 1 G, 1/2 G, 2 G Ex ia IIC T6...T2 Ga or Ex ia IIC T6...T2 Ga/Gb or Ex ia IIC T6....T2 Gb;

II 1 D, 1/2 D, 2 D Ex ia IIIC T95°C Da or Ex ia IIIC T95°C Da/Db or Ex ia IIIC T95°C Db;

II 1/2 G, 2 G Ex ia/d IIC T6..T2 Ga/Gb or Ex d ia IIC T6...T2 Gb;

II 1/2 D, 2 D Ex ia tb IIIC T95°C Da/Db or Ex ia tb IIIC T95°C Db;

II 3 G Ex nA II T6…T2 X

Ex ia IIC T6...T2 Ga; Ex ia IIIC T95°C Da;

Ex ia/d IIC T6...T2 Ga/Gb; Ex ia tb IIIC T95°C Da/Db

NEC 500

NEC 500NEC 500

XP-IS / Cl. I / Div. 1 / Gr. ABCD / T6-T1;

DIP / Cl. II, III / Div. 1 / Gr. EFG / T6-T1;

IS / Cl. I, II, III / Div. 1 / Gr. ABCDEFG / T6-T1;

NI / Cl. I / Div. 2 / Gr. ABCD / T6-T1

NEC 505

NEC 505

NEC 505NEC 505

Cl. I / Zone 0 / AEx d[ia] / IIC / T6-T1;

Cl. I / Zone 0 / AEx ia / IIC / T6-T1;

Cl. I / Zone 2 / AEx nA[ia] / IIC / T6-T1

Hazardous (Classified) Locations, indoor/outdoor Type 4X and 6P, IP66, Dual Seal

CEC Section 18 (Zone ratings)

CEC Section 18 (Zone ratings)CEC Section 18 (Zone ratings)

Cl. I, Zone 1, Ex d, IIC (Probe: Zone 0) T6;

Cl. I, Zone 0, Ex ia, IIC T6;

Cl. I, Zone 2, Ex nA, IIC T6

CEC Section 18 and Annex J (Division ratings)

CEC Section 18 and Annex J (Division ratings)

CEC Section 18 and Annex J (Division ratings)CEC Section 18 and Annex J (Division ratings)

XP-IS, Cl. I, Div. 2, Gr. ABCD; Cl. II, Div. 2, Gr. FG; Cl. III, Div. 2 T6;

IS, Cl. I, Div. 1, Gr. ABCD; Cl. II, Gr. FG; Cl. III T6

16

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

TECHNICAL DATA

2

NEPSI

GYJ111195/96

DNV / INMETRO

DNV 12.0042 X

KGS

11-GA4BO-0327X

11-GA4BO-0328X

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

EMC Electromagnetic Compatibility Directive 2004/108/EC in conjunction with

NAMUR NAMUR NE 21 Electromagnetic Compatibility (EMC) of Industrial Process and

WHG

Z-65.16-460

CRN This certification is for all Canadian provinces and territories. For more data, refer

Construction code On request: NACE MR0175 / ISO 15156; NACE MR0103

1 Metaglas® is a registered trademark of Herberts Industrieglas, GMBH & Co., KG

2 Refer to the Pressure/Temperature table for probe selection

3 This option is not available for FM- or CSA-approved devices

4 HASTELLOY® is a registered trademark of Haynes International, Inc.

5 Kalrez® is a registered trademark of DuPont Performance Elastomers L.L.C.

6 HART® is a registered trademark of the HART Communication Foundation

Ex d ia IIC T2~T6 DIP A21/A20 TA T70°C~T95°C IP6X;

Ex ia IIC T2~T6 DIP A21/A20 TA T70°C~T95°C IP6X

Ex ia IIC T6…T2 Ga; Ex ia IIIC T70°C...T95°C Da IP6X;

Ex d [ia Ga] IIC T6…T2 Ga/Gb; Ex tb [ia Da] IIIC T70°C...T95°C Db IP6X

Ex ia IIC T6~T2; Ex iaD 20 IP6X T70°C~T95°C;

Ex d[ia] IIC T6~T2; Ex tD[iaD] A21/20 IP6X T70°C~T95°C

EN 61326-1 (2013). The device agrees with this standard if:

– the device has a coaxial probe or

– the device has a single / double probe that is installed in a metallic tank.

Laboratory Control Equipment

NAMUR NE 43 Standardization of the Signal Level for the Failure Information of

Digital Transmitters

In conformity with the German Federal Water Act, §9

to the website.

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

17

2

TECHNICAL DATA

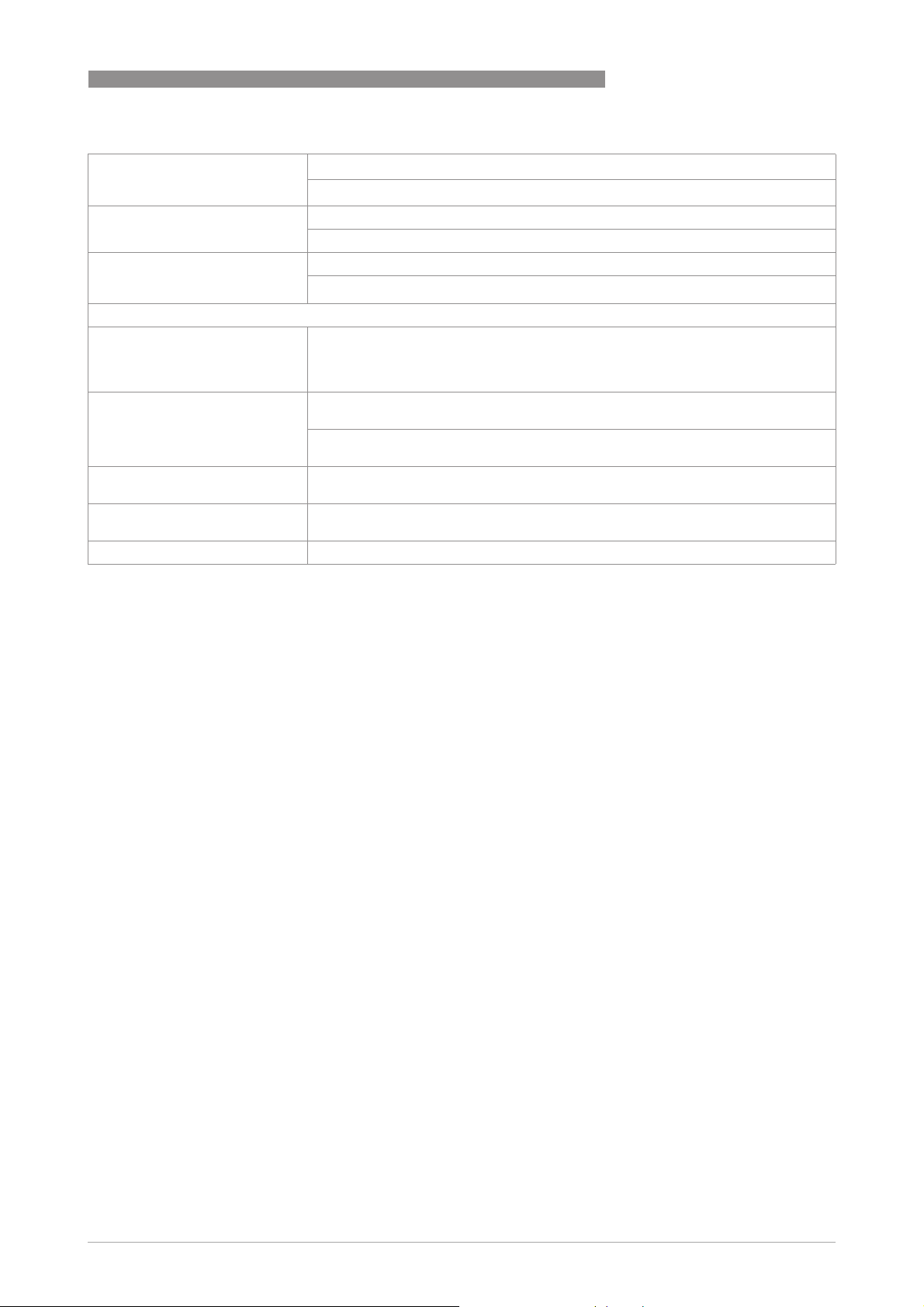

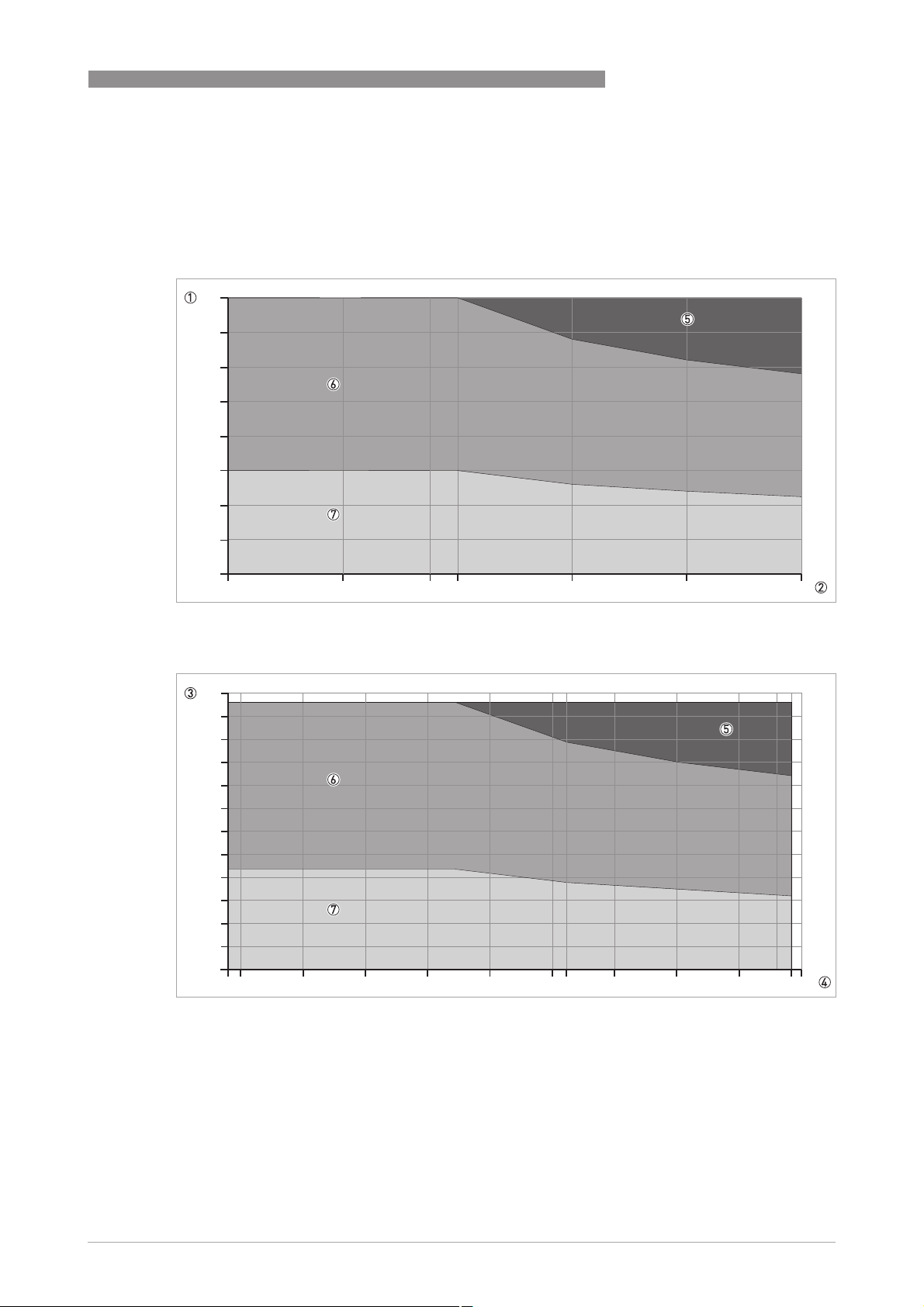

2.2 Pressure/temperature table for probe selection

Make sure that the transmitters are used within their operating limits.

300

280

100

60

40

OPTIFLEX 1300 C

0

-50

Figure 2-1: Pressure/temperature table for probe selection in °C and barg

4350

4060

1450

870

580

0

-58

Figure 2-2: Pressure/temperature table for probe selection in °F and psig

1 Process pressure, P

2 Process connection temperature, T [°C]

3 Process pressure, P

4 Process connection temperature, T [°F]

5 All probes

6 All probes. This does not include the Ø8 mm / 0.32¨ single cable probe.

7 High-Pressure (HP) version of the Ø2 mm / 0.08¨ single cable probe

8 High-Temperature/High-Pressure (HT/HP) version of the Ø2 mm / 0.08¨ single cable probe

9 High-Temperature (HT) version of the Ø2 mm / 0.08¨ single cable probe

[barg]

s

[psig]

s

0

0

50 100

120

210 300 390 480 570

150 200 250 300

18

The minimum and maximum process connection temperature and the minimum and maximum

process pressure also depends on the gasket material selected. Refer to "Technical data" on

page 12

.

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

TECHNICAL DATA

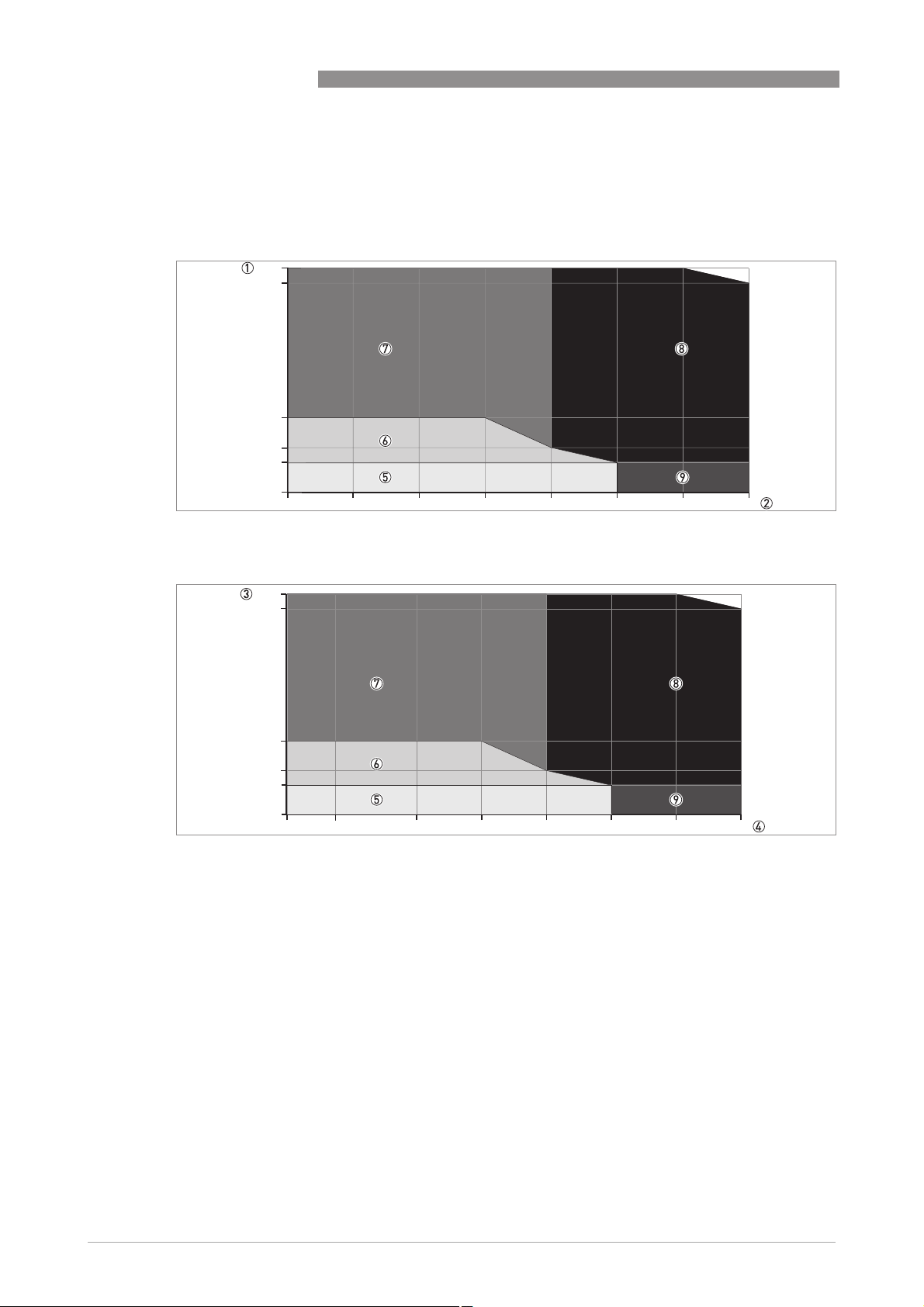

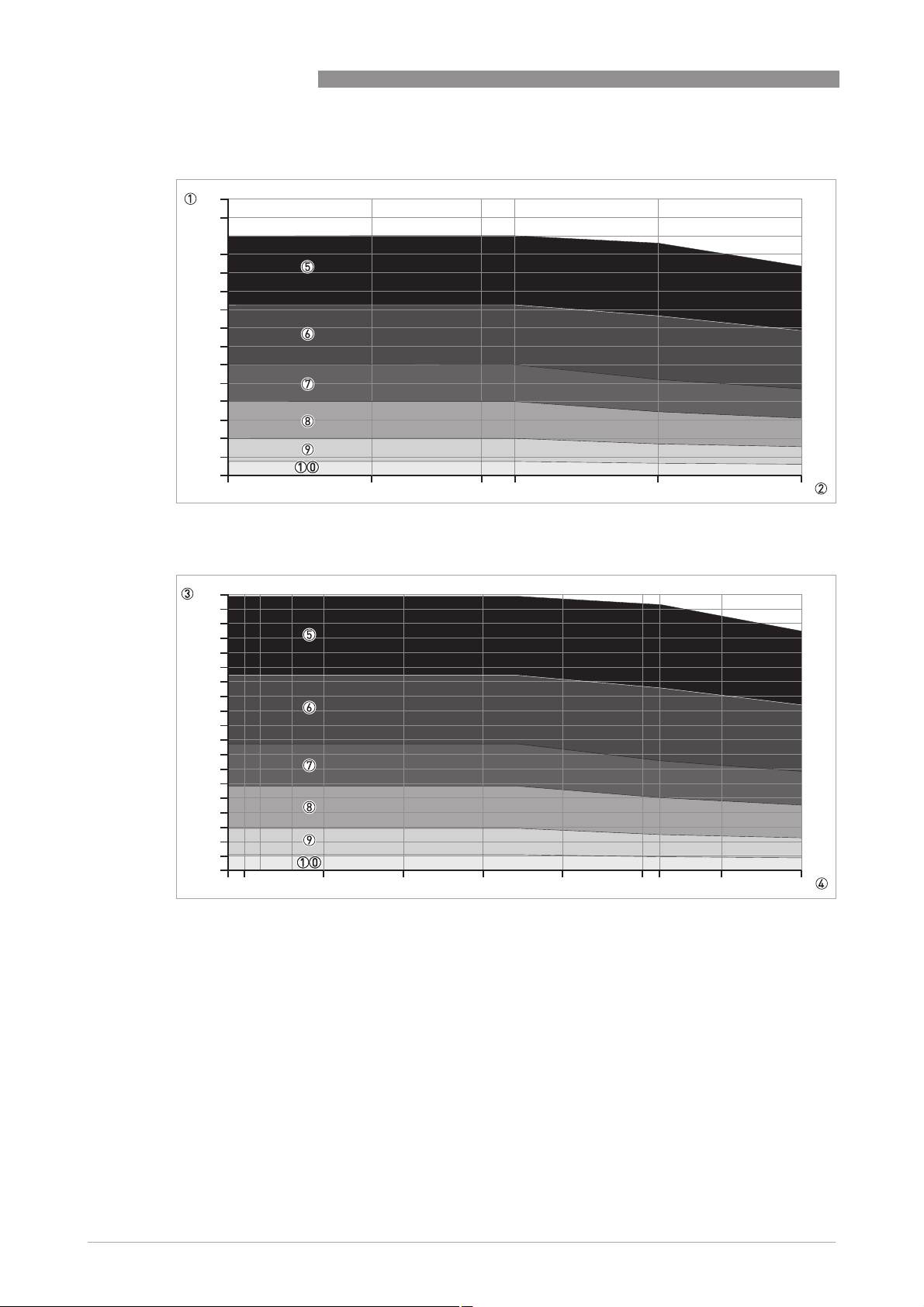

2.3 Guidelines for maximum operating pressure (CRN certification)

Make sure that the devices are used within their operating limits. CRN certification is necessary

for all devices that are installed on a pressure vessel and used in Canada.

40

35

30

25

20

15

10

2

5

0

-50 0 50 100 150 200

Figure 2-3: Pressure / temperature de-rating (ASME B16.5), Ø8 mm single cable probe, in °C and barg

600

550

500

450

400

350

300

250

200

150

100

50

0

-60

-50

0 50 100 150 200

38

212 250

300 350

392 400

Figure 2-4: Pressure / temperature de-rating (ASME B16.5), Ø0.3¨ single cable probe, in °F and psig

1 p [barg]

2 T [°C]

3 p [psig]

4 T [°F]

5 Threaded connection, NPT (ASME B1.20.1).

6 Flange connection, Class 300 and Class 600. Threaded connection, NPT (ASME B1.20.1).

7 Flange connection, Class 150

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

19

2

TECHNICAL DATA

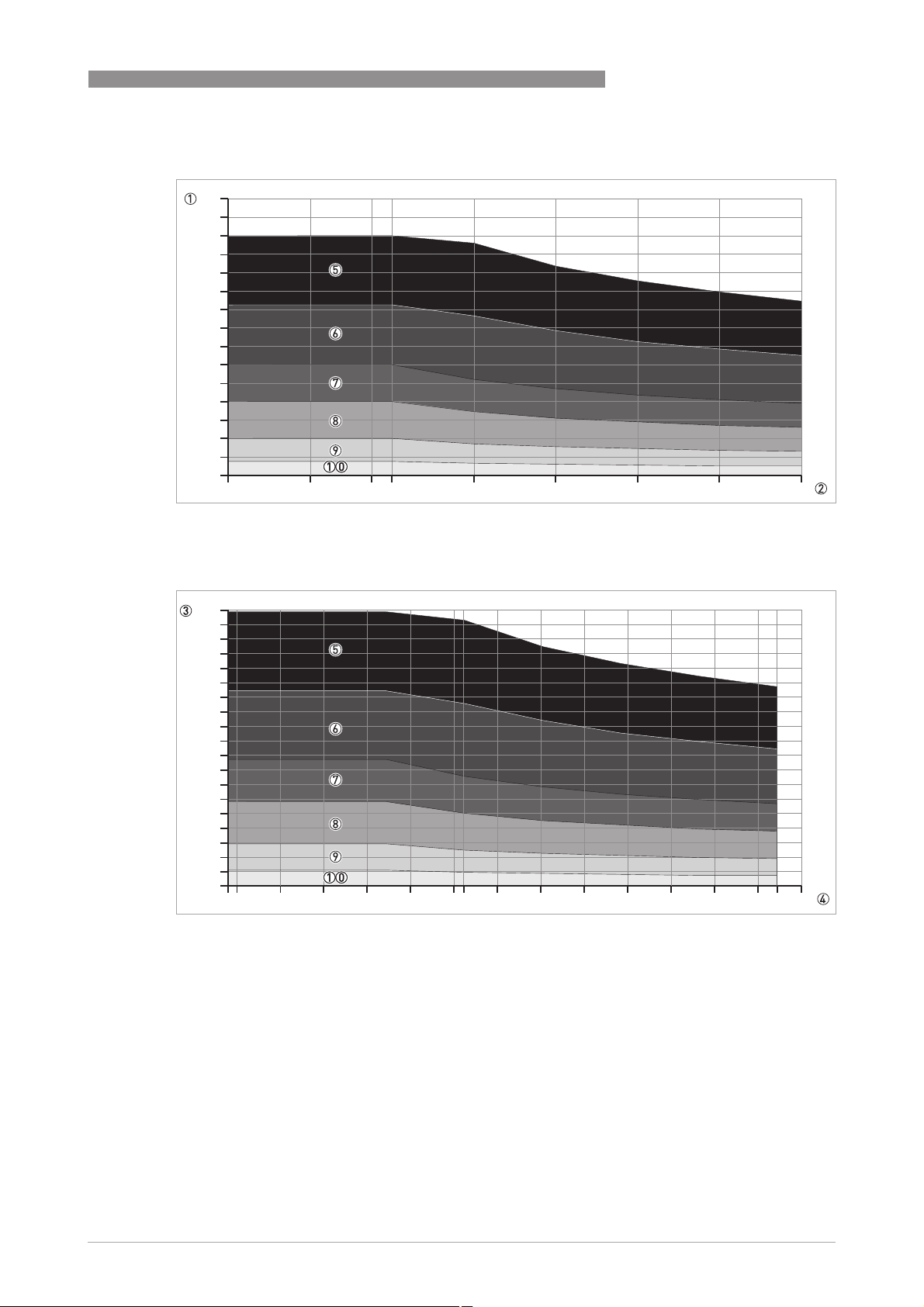

300

280

260

240

220

200

180

160

140

120

100

80

60

40

20

0

-50 0

Figure 2-5: Pressure / temperature de-rating (ASME B16.5), Ø2 mm single cable probe (HP version), in °C and barg

OPTIFLEX 1300 C

50 100 150

38

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

0

-60 -50 0 50 100 150 200 212 250 300

Figure 2-6: Pressure / temperature de-rating (ASME B16.5), Ø0.08¨ single cable probe (HP version), in °F and psig

1 p [barg]

2 T [°C]

3 p [psig]

4 T [°F]

5 Flange connection, Class 2500: RJ flange facing only. Threaded connection, NPTF (ASME B1.20.3).

6 Flange connection, Class 1500: RJ flange facing only

7 Flange connection, Class 900: LT, LG, ST, SG and RJ flange facings only

8 Flange connection, Class 600

9 Flange connection, Class 300

10 Flange connection, Class 150

20

www.krohne.com 07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

OPTIFLEX 1300 C

300

280

260

240

220

200

180

160

140

120

100

Figure 2-7: Pressure / temperature de-rating (ASME B16.5), Ø2 mm single cable probe (HT and HT/HP versions), in °C

and barg

TECHNICAL DATA

80

60

40

20

0

-50 0 50 100 150 200 250 300

38

2

3800

3600

3400

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

0

-60-50 0 50 100 150 200 212 250 300 350 400 450 500 550 572 600

Figure 2-8: Pressure / temperature de-rating (ASME B16.5), Ø0.08¨ single cable probe (HT and HT/HP versions), in °F

and psig

1 p [barg]

2 T [°C]

3 p [psig]

4 T [°F]

5 Flange connection, Class 2500: RJ flange facing only. Threaded connection, NPTF (ASME B1.20.3).

6 Flange connection, Class 1500: RJ flange facing only

7 Flange connection, Class 900: LT, LG, ST, SG and RJ flange facings only

8 Flange connection, Class 600

9 Flange connection, Class 300

10 Flange connection, Class 150

www.krohne.com07/2015 - 4000112208 - TD OPTIFLEX 1300 R13 en

21

Loading...

Loading...