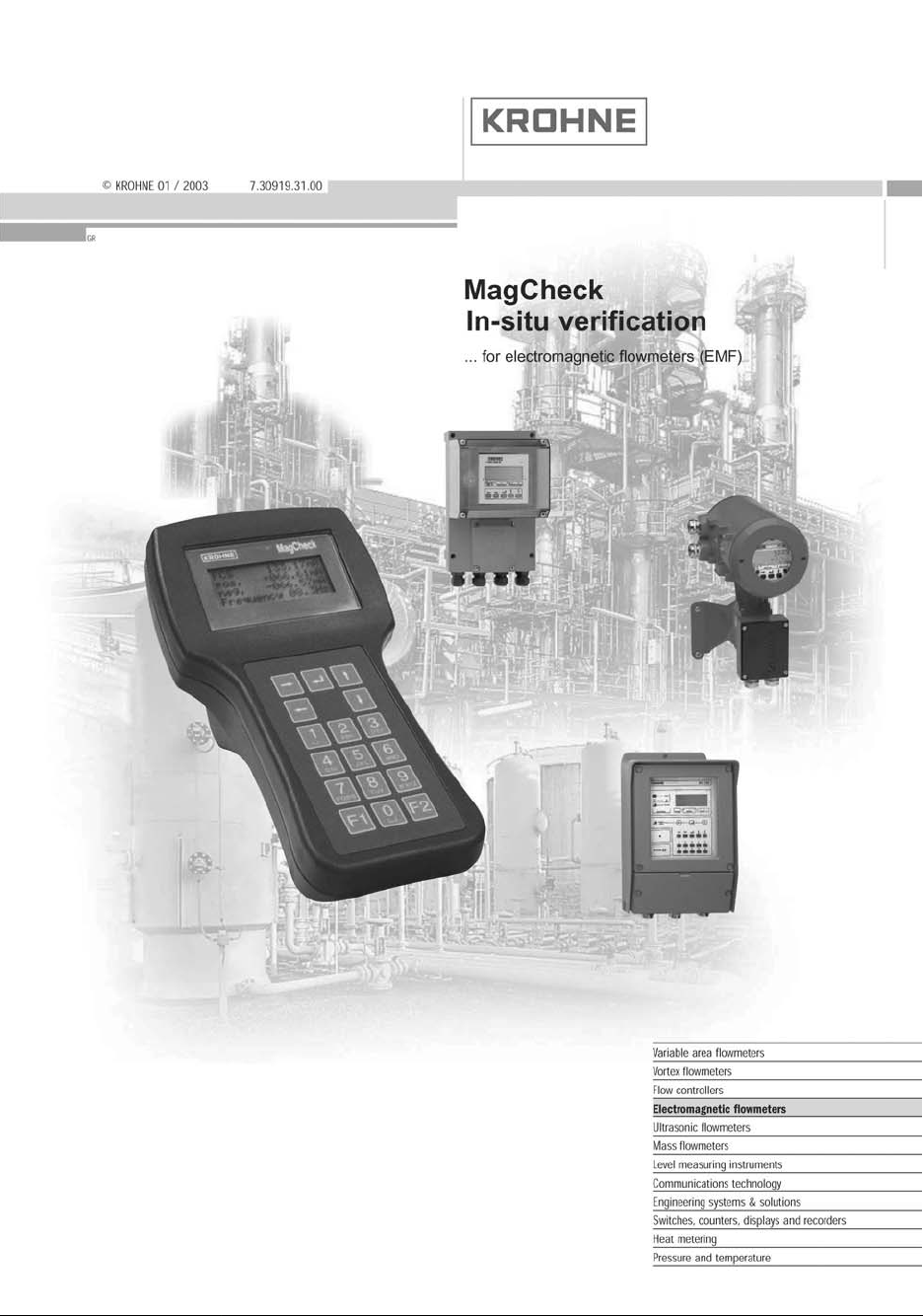

Page 1

Page 2

General advice on safety

Use of MagCheck on converters, which are not listed as may cause damage to these converters, to

MagCheck and, in case of connection to hazardous area versions of these converters damage to

protective elements. As a result safety risks in later operation of these converters cannot be

excluded.

Product liability and warranty

Responsibility for suitability and intended use of this instrument rests solely with the user. Improper

installation and operation may lead to loss of warranty. In addition, the general conditions of sale

are applicable and are the basis for the purchase contract.

If the instrument needs to be returned to KROHNE, please note the information given in the service

part of these instructions.

Items included with supply

A rugged suitcase containing:

• MagCheck

• Operating and installation instructions (hard copy)

• CD with MagCheck PC program, operating and installation instructions, Excel spreadsheets for

data processing

• IFC 010 connecting cable

• IFC 020 connecting cable

• IFC 090 connecting cable

• IFC 110 connecting cable

• PC RS 232 connecting cable

• Power supply adapter 100..230V to 15 V DC

• Power plug adapter for different plug standards

2 MagCheck

Page 3

Table of contents

General advice on safety 3

Product liability and warranty 3

Items included with supply 3

1 MagCheck introduction 4

1.1 Introduction 4

1.2 MagCheck as automatic verificator for KROHNE IMoCom converters 4

1.3 MagCheck as manual signal calibrator 5

2 Connecting and operating MagCheck 6

2.1 Preparation 6

2.2 Connecting cables 6

2.3 Connection diagrams 7

2.4 User interfaces 9

2.5 Starting phase 9

2.6 How to operate the menu 10

3 Description of MagCheck menu functions 12

3.1 Menu structure 12

3.2 Automatic verification with KROHNE IMoCom converters 13

3.3 MagCheck as manual flow signal calibrator 14

3.4 MagCheck Menu functions for manual calibration test 17

4 Using MagCheck with a PC 21

4.1 System specifications 21

4.2 Installation PC software 21

4.3 Settings of MagCheck PC software 21

4.4 Connecting MagCheck to PC 22

4.5 Downloading and storing MagCheck verification data onto PC 22

4.6 Exporting and importing verification files from / to floppy or hard disk 23

4.7 Trend analysis 24

5 Interpretation of verification results 26

5.1 Accuracy data ADC, field current, mA or frequency output 26

5.2 Coil resistance 26

5.3 Electrode resistance with full pipe 26

5.4 Electrode resistance with empty pipe 27

5.5 Coil insulation 28

5.6 Limitations of accuracy statement 28

6 Service and recalibration 29

6.1 Recalibration 29

6.2 Software 29

6.3 Spare parts 29

Appendix 1 29

MagCheck 3

Page 4

1 MagCheck introduction

1.1 Introduction

MagCheck is an all-round portable testing and verification device for KROHNE electromagnetic

flowmeters, enabling a complete functionality and accuracy verification of the EMF without taking

the meter out of the pipeline nor interrupting the process. MagCheck measures autonomously and

can be used on KROHNE EMF-converters (not on Ex-converters!). MagCheck can be employed

either as an automatic verification instrument or as a manual flow signal calibrator, depending on

the converter type.

MagCheck is used for precise analysis and verification of magnetic flowmeters. Precision of these

meters is not only a function of accuracy of electric data, but also depends on the mechanical

installation of flowhead and converter. Faulty installation, both mechanical or electrical, may not be

detected by MagCheck.

Use of MagCheck on converters, which are not listed as compatible may cause

damage to these converters, to MagCheck and in case of connection to hazardous

area versions of these converters damage to protective elements!

MagCheck can and must NOT be used on:

• TIV 50, TIV 60

• K300, F200

• SC150

• ALTOFLUX 2W, IFC 040

• IFC 090i

• TIDALFLUX*

• CAPAFLUX, IFC 090 K / CAP

• NB 900 Power Booster

• Any Ex Zone 1/div 1 versions (hazardous area versions) of

ALTOFLUX 2W, IFC 040; SC80A / AS, SC100A / AS;

IFC 080, IFC 200, IFC 200 E; IFC 090, IFC 090i; IFC 110;

IFC 210 Ex versions!

*) Verification of the conventional electromagnetic flowmeter part of TIDALFLUX IFM 4110 PF is

possible after disabling the level input to IFC 110 PF. This will allow for a statement of flow velocity

measurement part, not of total the performance of TIDALFLUX.

1.2 MagCheck as automatic verificator for KROHNE IMoCom converters

MagCheck is able to perform a fully automatic verification on magnetic flowmeters in combination

with these converters. In this mode accuracy of the converter and all electric data of the primary

head are verified which are vital for their function and accuracy. During the fully automatic test run

the display will indicate all measured data. MagCheck reads and stores all settings of the IMoCom

converter and all measured data of up to 70 meters.

MagCheck can verify KROHNE electromagnetic flowmeters with following IMoCom signal

converters:

• IFC 010

• IFC 020

• IFC 090 Non-Ex versions

Data may be downloaded onto a PC (Microsoft Windows 95, 98, 2000, NT) using the KROHNE

MagCheck PC-program. After downloading data into the PC the related memory areas in the

MagCheck are cleared and can be used for further measurements. The KROHNE MagCheck PCprogram evaluates the downloaded data. If all data are within their limits, the program will create a

final certificate confirming the meter operates with an accuracy deviation of less then 1% related to

reference conditions. If the evaluation shows data exceeding their limits, the certificate will state,

that the meter is not working properly.

• IFC 110 Non-Ex and non TIDALFLUX-versions only

• IFC 210 Non-Ex versions

4 MagCheck

Page 5

1.3 MagCheck as manual signal calibrator

MagCheck replaces KROHNE Simulators GS8 / GS8A. With its integrated microprocessor,

calibrated mA-meter and frequency meter MagCheck allows for verifying the accuracy of converters

without the need for any further instruments like calculators, mA- and frequency meters.

MagCheck generates precise adjustable flow signals. The flow signal can be set in steps of 0.1% of

full scale. These very precise flow signals will be fed into the signal inputs of the converter. The

output signals (mA, frequency) are indicated on the MagCheck display. In this manual flow signal

calibrator mode no data will be stored in MagCheck. The measured/indicated data must be noted

and evaluated manually (see Appendix 1).

With non-IMoCom converters: In the flow signal calibrator mode with these previous converters data

as meter size (DN), GK, full scale setting must be entered into MagCheck manually.

MagCheck may be used

as flow signal calibrator for

following KROHNE

electromagnetic flowmeter

signal converters:

With IMoCom converters MagCheck loads data as meter size (DN), GK, full scale setting, current

and pulse output settings automatically down from IMoCom converter through the IMoCom

interface.

• T900

• SC100A, SC 100AS Non-Ex versions only!

• SC80A, SC 80AS Non-Ex versions only!

• AQUAFLUX 070

• IFC 080 Non-Ex versions only!

• IFC 200E, IFC 200. Non-Ex versions only!

• and all IMoCom converters as listed under 1.2

MagCheck 5

Page 6

2 Connecting and operating MagCheck

2.1 Preparation

2.1.1 Initial preparations

Make sure that there is sufficient memory space left for new verifications. Connect MagCheck to a

power outlet via its power adapter. MagCheck will start searching for the IMoCom interface. Stop

this by pressing F1. Enter Menu 1.1. test MID. Press arrow →. MagCheck will indicate (example):

1.1 test MID

no connection

inputs: 69/70

In this case only one set of data (one verification) can be stored additionally. Download existing

data into the PC to clear more memory space (refer to chapter 5) if necessary. Take print-outs of

the Excel spreadsheets (Refer to Appendix 1) and results of earlier verifications/ tests on related

meters with you.

2.1.2 Document flowmeter data

Read and note all totalisers and counter values before and after verification and document the

following (you may note these in the dedicated Excel spreadsheets, refer to chapter 7):

2.1.3 Disconnecting cables

Prior to connecting MagCheck to the magnetic flowmeter, signal-, field-, output cables of the

flowmeter must be disconnected by pulling the connectors. All flowmeter outputs are interrupted,

related process instrumentation will see open inputs. As a result the meter will not indicate the

actual flow during the verification the meter.

Before changing any connections act according all process related safety and

information rules existing in your organisation! Disable all alarms and take all

controls to manual, which are dependent on the flowmeter outputs!

2.2 Connecting cables

MagCheck is supplied with connection cables for IFC 010, IFC 020, IFC 090, IFC 110 F and a

RS 232 cable (25 pole to 9 pole connector) for connecting MagCheck to PC (download of

verification data) and a 100..230 Volt AC power supply, that is only used during download of

verification data from MagCheck into PC. There is no need to unscrew any terminal screw with

these cables. For manual calibration tests on older Non-IMoCom converters special cables can be

supplied on request.

The 25-pin connector must be plugged into the MagCheck. Its securing screws must be fid to avoid

contact failures during verification runs, e.g. due to accidental mechanical stress on the cable (see

connection diagrams)

The following connections to the signal converter must be established:

• IMoCom (for tests on IMoCom converters only as listed under 1.2.)

• Electrode signal

• Field current

• Outputs (mA and pulse)

Connection to flow head (flow tube) only is necessary for automatic verification with IMoCom

converters, not for use of MagCheck as precision flow signal calibrator for converter verifications.

The following connections to the flow head must be established±

• Electrode signal

• Field coil connection

6 MagCheck

Page 7

During verification and test of converters as listed above, MagCheck does not need

any external power supply or batteries. MagCheck takes all its power from the field

current of these signal converters. The external power supply supplied with

MagCheck is only needed during download of verification data into a PC.

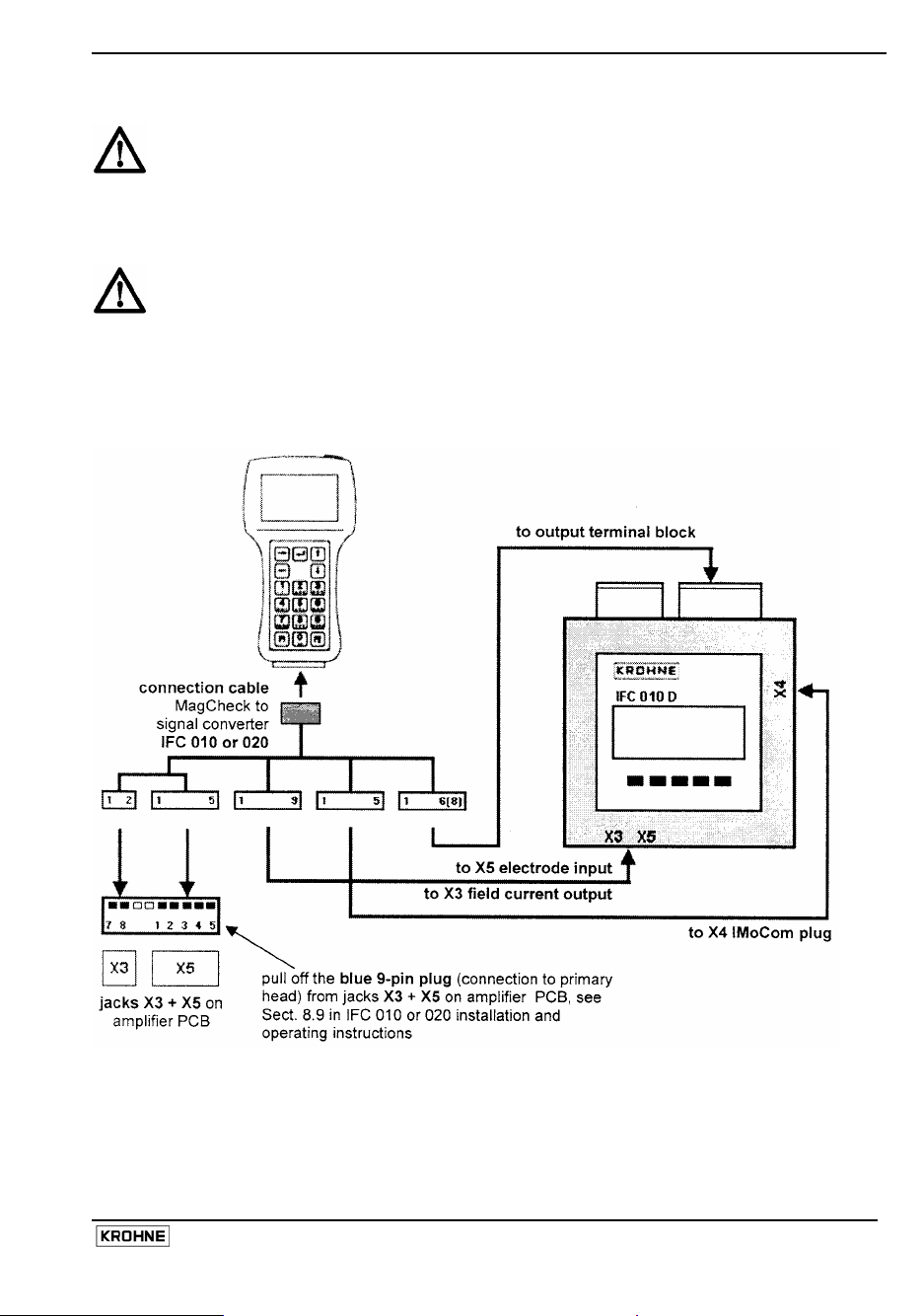

2.3 Connection diagrams

For use of MagCheck as precision flow signal calibrator for detailed manual

verification of converters Connections to flow head (field coils and electrodes) are

not needed.

Please note!

In the drawing of IFC 010 manual in Sect. 7.5 the jacks X1 and X4 were named wrong:

X1 must be X3 and X4 must be X5!

Connection MagCheck IFC 010 or IFC 020

MagCheck 7

Page 8

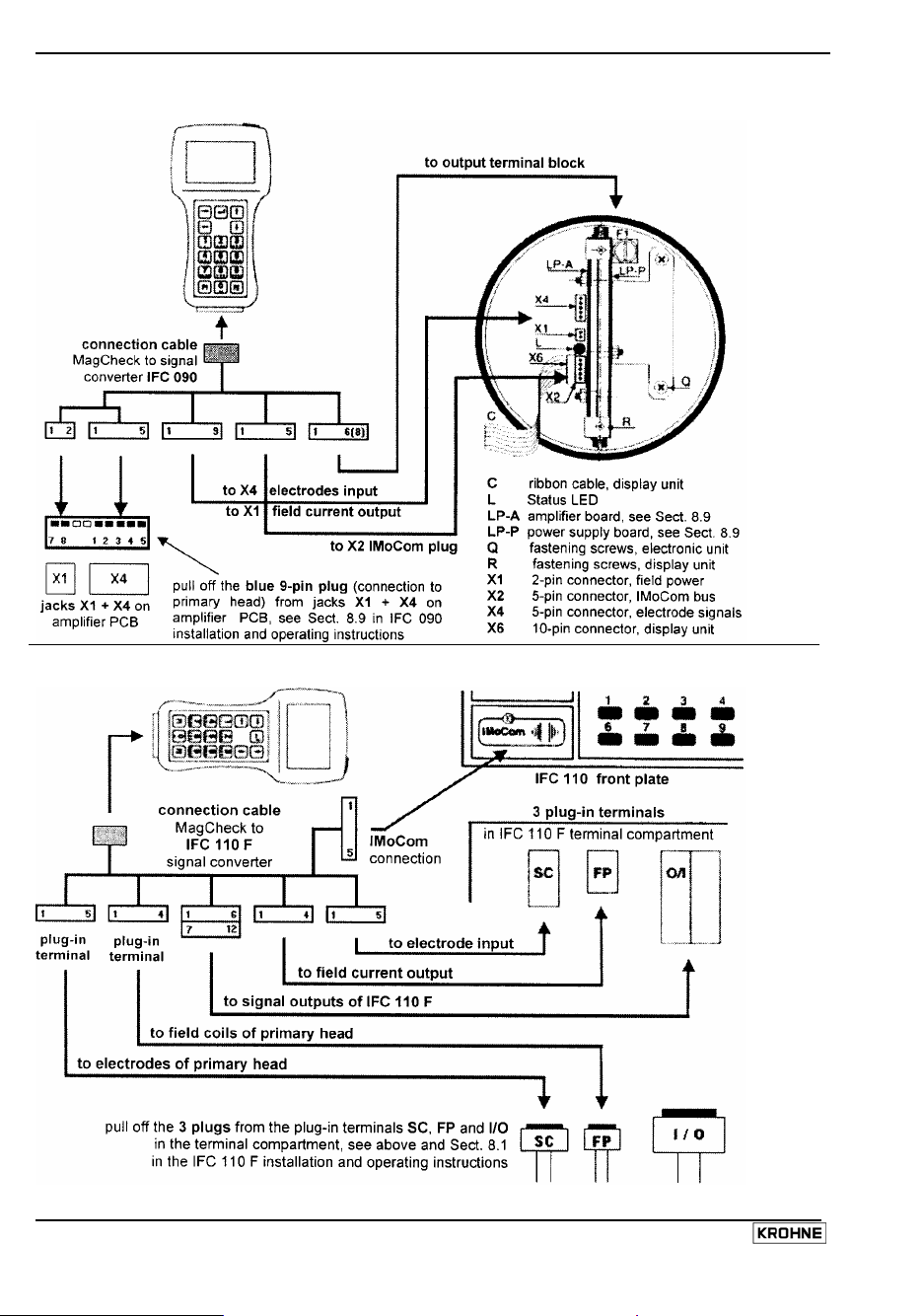

Connection MagCheck IFC 090

Connection MagCheck IFC 110 F

8 MagCheck

Page 9

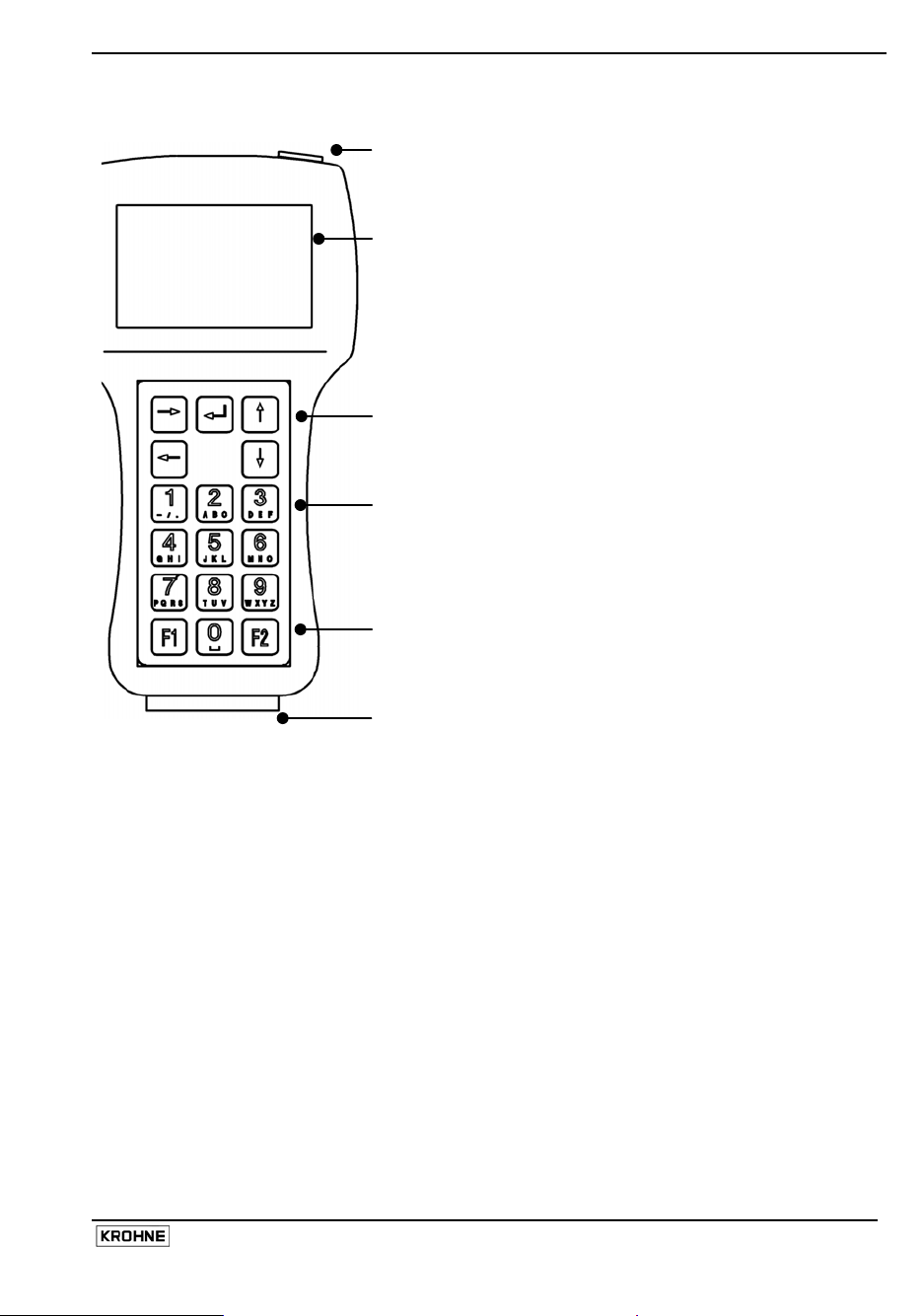

2.4 User interfaces

Connector for external power supply

(necessary only for download of verification data into PC)

Display

4 rows, 16 digits each

Backlit with external power supply

Arrow keys

• Entering into a menu (→)

• Stepping from digit to digit (→ ←)

• Increasing or reducing values (↑ ↓)

• Confirmation of entered data (↵)

• Stepping to the next (sub-)menu (↵)

• Returning to the main menu (↵)

Alpha-numerical keys

• Entering values,

• menu number

• Texts

F1 key

• start of MagCheck without IMoCom connection

F2 key

• For encoded access to MagCheck Service Menu only, no

function for verification

25-pole connector for

• converter verification cables

• PC-data transfer cable

2.5 Starting phase

After connection to converter and after power supply of the converter has been switched on

MagCheck will start a self test, checking all its EEPROM data for their validity. After it will signal

"OK" (in case of an error it will indicate "ERROR"), for approximately 5 seconds.

2.5.1 With IMoCom converters (IMoCom interface connected)

Next step is automatic start of communication with the IMoCom Bus of the IFC. After indicating :

"Test of communication", MagCheck locks in onto the IMoCom Bus of the IFC. It will read the

settings of the IFC and start to simulate a 100% signal.

2.5.2 With Non-IMoCom Converters or IMoCom-interface not connected

If there is no communication MagCheck will ask you to press "F1". and will stay in Menu 1.0 until

settings are entered (see below). All meter parameters data in menu 1.2 must be entered

manually.

If energy (field current level) received by MagCheck is too low, MagCheck display will flicker and

MagCheck will not start. This can be caused by:

• poor connection or defective cable / connector connecting field current to MagCheck

• a defective field current supply of the converter

• You have connected to an IFC040 converter

MagCheck 9

Page 10

←

↑

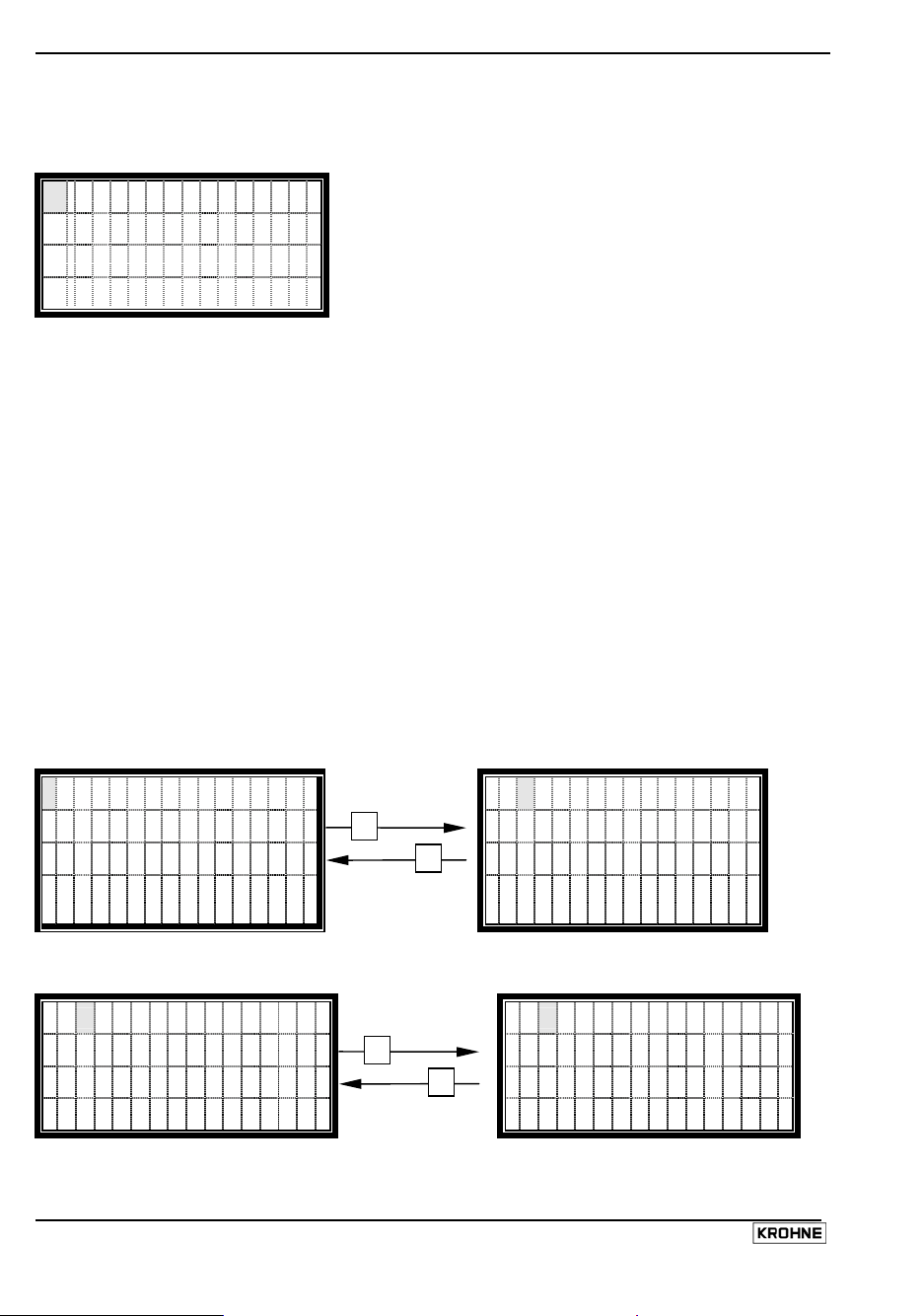

2.6 How to operate the menu

2.6.1 Display in main menu

There are three main menus indicated with x.0.

1 . 0 o p e r a t i o N

I Mo C o m - B u s ) (

f i e l d c u r r e n T + -

Menu line

Indication line

Status line for IMoCom connection

Status line for field current

In the main menu display, the two last lines represent status lines.

The IMoCom-Bus status line displays the actual status of the IMoCom connection as follows:

() Two moving brackets IMoCom present, IMoCom data transfer operating

() Two static brackets IMoCom present, no data transmission window present

no No IMoCom connected

The field current status line displays the actual status of the field current as follows:

+ - Plus, minus Correct (field current is switching from positive to negative current and vice

versa)

+ Plus Positive DC or pulsating DC (defective converter, negative half wave

missing)

- Minus Negative DC or pulsating DC (defective converter, positive half wave

missing)

No indication No current (defective converter, no field current)

The indication lines are used to show error messages.

2.6.2 Selecting menus and changing data

Moving the cursor

Cursor position is indicated by grey blinking background

1 . 0 o p e r a t i o n

I M o C o m - B u s ( )

f i e l d c u r r e n t + -

Cursor to the right

→

Cursor to the left

1. 1 t e s t MI D

I M o C o m - B u s ) (

fi el d cur r ent + -

Changing the numbers

Alternatively the corresponding numerical key can be used

3 z e r o s e t

1 .

I M o C o m - B u s ) (

f i e l d c u r r e n t + -

Increase number

↓

Decrease number

1. 4 si mul at i o n

I M o C o m - B u s ( )

f i e l d c u r r e n t + -

10 MagCheck

Page 11

↑

←

↵

Changing the Texts (Units)

When changing the units, the values are converted automatically

f u l l s c a l e

0 2 48 . 0

m 3 / h r

Selecting the next

text

↓

Selecting the

previous text

Changing from text (Unit) to numbers

f u l l s c a l e

068. 8 9

l / s

f u l l s c a l e

0 2 4 8 . 0

m 3 / h r

To numbers

→

To text

f u l l s c a l e

0

248. 0

m 3l / h r

Changing to submenus

3 .

1 l a n g u a g e

I M O C o m - B u s )

f i e l d c u r r e n t +

To submenu

→

(

- Back to main menu

l a n g u a g e

Engl i sh ( G B )

Fr ench ( F )

Ge r m a n ( D )

2.6.3 Initial settings of MagCheck

The only necessary initial setting is selection of the user language. Connect MagCheck to an IFC

XX0 or connect to a power outlet using its power adapter. In the latter case

• Press F1 to stop MagCheck’s search for an IMoCom interface

• Select Menu 3.1

• Press button → and select language English, German or French by the ↑↓ buttons

• Confirm selection by ↵

MagCheck 11

Page 12

3 Description of MagCheck menu functions

3.1 Menu structure

The menu of MagCheck has the following functional parts.

Menu Text Description

1.0 Operation Operation menu, main menu

1.1 Test MID Automatic verification menu for electromagnetic flowmeters

with IMoCom- converters

..1.2 – 1.8 Menu for manual calibration test of converters

1.2 Parameter Calibration test menu, entering meter data

→ Diameter

→ Full scale

→ Primary constant

→ FCS nominal

1.3 Zero set Zero setting

1.4 Simulation Generation of flow signals, adjustable in 0.1%-steps of full

1.5 Curr. output Display of true value (IMoCom converters only) and actual

1.6 Pulse output Display of true value (IMoCom converters only) and actual

1.7 Field current Indication of field current, displaying

1.8 Hardw. Info Display of:

1.9 Reset Reset menu (On IMoCom converters only)

2.0 Test Information menu

2.1 Device Info Display of MagCheck Serial number, software version and

3.0 Install Installation menu (main menu)

3.1 Language Language setting. English, French, German

3.2 Data transf. Data transfer menu from MagCheck to PC

DN 2.5 – 3000 mm/0.1 – 120 inch

Full scale value for flow Q=100%

(available display values: m3/hr, Liter/hr, USGal/min, l/s)

See EMF tag plate

Nominal field current value

scale value

value

value

• Positive current

• Negative current

• Sum of positive and negative current

• Field frequency

• Software ID of the respective modules

• Actual status information

(IMoCom converters only)

calibration date

12 MagCheck

Page 13

3.2 Automatic verification with KROHNE IMoCom converters

3.2.1 How to start verification

Menu Explanation Display Details

1.0 Operation

1.1

Test MID

Next screen 1.1 Test MID Starts automatic verification of flowmeter with

KROHNE IMoCom. All data will be verified and

stored in MagCheck.

Next screen

inputs xx/70: Number of stored verification files (e.g.

11/70), not transferred to the PC before. A total of

70 files can be stored. In this example 59

verifications can be made before memory is full.

date Enter actual date (DD/MM/YY). This will allow PC

program to correctly assort verifications in trend

analysis. Attention: No plausibility check! Check

carefully!

tag number All signs on the MagCheck keyboard may be used

for entering the tag number. Method is the same

as typing an SMS on a cell phone.

Entered Tag Number will be used as identifier at

download into PC. You may use up to 16

characters.

Next screen measurement Test conditions must be defined

(Select acc.

to test /

process

conditions

using ↑↓.

This will

allow

MagCheck to

select the

correct

verification

program)

pipe full

pipe empty

no pipe

filled with liquid

Electrode resistance will be tested via liquid.

With empty pipe the measured electrode

resistance will not comply with full pipe specs.

Result: Error statement in verification certificate

empty, clean, dry pipe

Electrodes will be tested for insulation. With a full,

wet or contaminated pipe, the measured electrode

resistance will not comply with empty pipe

specifications. Result: Error Message in

verification certificate

Converter verification only

No verification of flow tube.

Process

Enter type, other data

liquid

Next screen name user Enter name of MagCheck operator

(Select by

↑↓)

start? Select "back" or "yes"

back Will allow you to step back and check and correct

all data as entered above.

yes

Selecting yes and pressing ↵ will start automatic

verification run.

→

→

↵

↵

↵

↵

↵

MagCheck 13

Page 14

3.2.2 Explanation of the automatic verification run (verified data)

Converter data Data indicated and stored

Measurement of the field current Calibrated and actual value [mA]

Measurement of field frequency Act frequency [Hz]

ADC linearity and accuracy test at 25% of full scale 1)

ADC linearity and accuracy test at 50% of full scale 1)

ADC linearity and accuracy test at 75% of full scale 1)

Output of input amplifier and

analogue to digital converter: True

and act. value [% of full scale]

ADC linearity and accuracy test at 100 % of full scale 1)

Testing of the 1st calibration point P04 for current output 2)

Calibrated and actual value [mA]

Testing of the 2nd calibration point P20 for current output 2)

Testing of the 1st pulse output with f = 500 Hz 3) True and actual value [Hz] for

f100% = 1000Hz

If flowhead is tested as well

Measurement of field coil resistance Coil resistance (Ohms)

Measurement of resistance of electrode 1 4)

Measurement of resistance of electrode 2 4)

Measurement of isolation resistance of field coils

Resistance values are measured.

Display of subsequent voltage

levels and resistance values

Following the measurement, the measured data are stored in the MagCheck.

1) ADC test verifies accuracy of input amplifier and analogue to digital conversion of flow signal

During this test the GK of the converter is temporarily set to factory test conditions GK = 2.500.

At end of verification the GK will be reprogrammed automatically by MagCheck to original data.

2) mA output tests verify compliance of mA output with factory calibration settings

Time constant T settings via IMoCom is reduced by MagCheck to allow for sufficiently fast

settling of mA output and pulse output. At the end of the verification, the time constant will be

reprogrammed automatically by MagCheck to original data.

3) For test of frequency / pulse output setting of this output will be temporarily programmed by

MagCheck to 1000 Hz at full scale flow. At end of verification frequency / pulse output will be

reprogrammed automatically by MagCheck to original data.

4) If mode "Empty pipe" has been selected under MagCheck Function 1.1 electrode insulation

data are measured, displayed and stored.

In case of power interruption during flow meter verification e.g. by interruption of wiring, field current

supply etc. the setting of GK, pulse output and time constant must be checked and eventually

reprogrammed manually. Such an interruption is indicated by MagCheck after its restart with the

warning message: Last meter not re-programmed.

3.3 MagCheck as manual flow signal calibrator

3.3.1 Menu for manual calibration with IMoCom connection to IMoCom converters

MagCheck IMoCom connector must be connected to the IMoCom connector of the converter.

Note down all data settings and readings in a paper print of the Excel spreadsheet

“MagCheck_Verification_Listing.XLS” (see Appendix 1). After transfer of these data into this file,

error calculations and a protocol will be created automatically. Main menus must be selected

manually.

14 MagCheck

Page 15

Menu Explanation Display Details, recommended actions

1.2

Parameter

1.3

Zero set

1.4

Simulation

Menu for meter data.

With MagCheck

connected to IMoCom,

MagCheck will

automatically read

these data from the

converter.

Shows actual zero

setting as stored in

IMoCom converter.

Verifies calibration and

linearity of ADC, current

(1.5), pulse output (1.6)

by a precision flow

signal in 0.1% steps of

Full scale (see 1.2)

1.2 Parameter

Diameter Note the value displayed.

Full scale Q100% Note the values displayed.

Primary constant

Note the value displayed.

GK Value

FCS nominal Note the value displayed.

1.3 Zero set

Zero value

(units as full scale)

No changes possible.

Read and note.

1.4 Simulation

True value

(% + physical

units)

Actual value

Enter desired flow value (%).

Note % setting carefully.

Note true value [%].

Note act. value [%].

(% + physical.

units)

Act. value is ADC

value.

1.5

Current

output

1.6

Pulse output

1.7

Field current

1.8

Hardw. info

Shows current output at

flow as entered under

1.4

Shows pulse output at

flow as entered under

1.4

Shows field current

peak to peak (FCS),

pos., neg.

Shows software

versions + status

information according

to Function 2.2 of

IMoCom converters

1.5 Current output

True value [mA]

Actual value [mA]

1.6 Pulse output

True value [Hz]

Actual value [Hz]

1.7 Field current

True value [mA]

Actual value [mA]

1.8 hardw. Info

ADC

X.XXXXXX

Texts as

"Warning"

YYYYYYYYYY

Next module

X.XXXXX.XX

Note true value [mA].

Note act. value [mA].

Note true value [Hz].

Note act. value [Hz].

Note true value [mA].

Note act. value [mA].

Note data.

Eventual warning relates to

status info (numbers in 4th row)

(default no warning

0000000000).

Continue to step through by ↵

until last device has been shown.

Texts as

"Warning"

YYYYYYYYYY

1.9

Reset

Resets MagCheck and

re-starts

communication to

IMoCom converter

1.9 Reset New start, if you suspect a

system hang-up.

no

yes

Select using ↑↓.

On "yes + ↵" system will re-start

and return to Menu 1.9. All data

entered manually will be

replaced by default settings.

3.3.2 Menu for manual calibration of converters without IMoCom connection

Note down all set and measured data in a copy of “MagCheck_Converter_Cal_Prot.XLS” (see

Appendix 1). Main menus must be selected manually. Connect MagCheck and press F1.

MagCheck 15

→

↵

↵

↵

↵

→

↵

→

↵

→

↵

→

↵

→

↵

→

↵

↵

→

Page 16

Menu Explanation Display Details, recommended actions

1.2

Parameter

MagCheck starts

with KROHNE

standard

converter default

settings

Actual

parameters

listed right acc.

to meter setting

must be entered

manually acc. to

flow meter type

plate.

1.2 Parameter Menu for entering meter data.

Diameter DN 2.5 – 3000 mm / 0.1 – 120 inch Select

using ↑↓.

Full scale

Select physical unit using ↑↓.

(m3/hr, Liter/hr, USGal/min, l/s)

Enter full scale value for Q100% acc. type

plate or actual setting. In case of data

outside of meter range max / min values

are shown.

Primary

constant

FCS nominal

Enter GK / GKL acc. type plate. Take care,

no plausibility check.

Enter nominal field current [mA]:

IFC 010 125

IFC 020, 090, 110, 210: 250

SC80, IFC 080, 200 125

T900 000

1.3

Zero set

Allows

MagCheck zero

adjustment

1.3 Zero set

Default

000.000

For standard tests use default.

For precision tests follow 3.4.2.

Physical unit as

set under 1.2

1.4

Simulation

Verifies

calibration and

linearity of ADC,

current (1.5),

1.4 Simulation

True value

in % + phys.

units)

Enter desired flow value (%).in 0.1% steps

Read converter display, note % and

flowrate.

pulse output

(1.6) by a

precision flow

signal of Full

scale as under

1.2

1.5

Current

output

Shows current

output value at

flow rate (%) as

entered under

1.5 Current

output

Actual value

[mA]

Read, note mA values.

1.4

1.6

Pulse output

Shows pulse

output value at

flow rate (%) as

entered under

1.6 Pulse

output

Actual value

[Hz]

Read, note indicated pulse [Hz] rate.

1.4

1.7

Field current

Shows field

current peak to

peak (FCS),

1.7 Field

current

Act. value [mA] Note act. values [mA].

pos., neg.

1.8

• In this operation mode menus 1.8 and 1.9 have no function.

Hardw. info

1.9

Reset

→

↵

→

↵

↵

↵

→

→

↵

→

↵

→

↵

→

↵

16 MagCheck

Page 17

3.4 MagCheck Menu functions for manual calibration test

With IMoCom converters and IMoCom connected to MagCheck, MagCheck reads all parameters

(as under Function 1.2 and 1.3 of the converter). So accuracy data of the converters will be tested

under original setting conditions. If test shall be done using deviating parameters IMoCom

connection must be disconnected, MagCheck must be restarted (e.g. by shortly pulling cable

connector off and plugging in again. Descriptions below, how to enter data into Function 1.2 and 1.3

mainly refer to non-IMoCom converters.

3.4.1 Function 1.2 Parameters

Select with keys ↑ and ↓. Go to subfunction ,,Full scale value” with key → or ←.

Full scale value Q

For test under conditions as installed, enter the actual setting of full scale Q100% as shown on type

plate of the converter or in the documentation of this site. If different full scale values are entered

into the converter and into the MagCheck mark the maximum and minimum flow velocity limits for

full scale settings.

Min- /max-values of Q100%: The maximum and minimum full scale values are subject to nominal

diameter (DN) and the flow velocity (v). These limits are given in KROHNE documentation, e.g.

Installation and Operating Instructions of related converters. If these should not be accessible, the

minimum and maximum flow rates dependant on meter size with metric units may be calculated in

m3/hr as:

%100

min

1

%00

max

All IMoCom converters and AQF 070, SC80A, SC80 AS, IFC 200, IFC 200E, SC100A , SC100AS:

V100%

:0.3 m/s and V100%

min

Change to subfunction ,,Primary constant” with key ↵.

Primary constant GK

Enter Primary Constant GK / GKL acc. to type plate of signal converter or flowhead. Limits: 1.000 to

9.999.

Go to subfunction „FCS nominal” with key ↵.

Field Current Supply nominal

Enter nominal field current [mA]:

IFC 010 125

IFC 020, 090, 110, 210, SC 100 250

SC80, IFC 080, AQF 070, IFC 200 125

T900 000

Back to menu 1.2 Parameter by pressing ↵.

3.4.2 Function 1.3 Zero set

Press → key.

Enter the zero point: Minimal zero point: -10% of the full scale value; Maximal zero point: +10% of

the full scale value, e.g. Full scale is 100 m3/h. Minimum zero point is -10m3/h and maximum zero

MagCheck 17

100%

π

]hr/m[Q

=

4

π

]hr/m[Q

=

4

23

23

:12 m/s. For T900: V100%

max

[]

%100

min

%100

max

[]

10006.3s/mv]mm[DN

÷×××

10006.3s/mv]mm[DN

÷×××

:0.5 m/s and V100%

min

:9.999 m/s

max

Page 18

point is +10m3/h.

With Non-IMoCom converters zero must be entered manually. Set function 1.3 Zero set to 000.000

with unit acc. setting of converter. To find a correct zero setting for the calibration test, step to Menu

1.4 Simulation. Set simulation value to 000.0%. Read indication from converter display. If indication

is too noisy, increase time constant of converter to 10s.. 30s. Wait 10 time constants, until indication

is stable. Read indication on converter display, enter read value with inverted sign into menu

Function 1.3 Zero Set.

Example:

Indication is -0.13 m3/hr.

Enter + 0.13 m3/hr (select sign by using ↑↓) into Function 1.3 Zero Set.

Back to menu 1.3 Zero setting by pressing ↵.

3.4.3 Function 1.4 Simulation

Press → key.

Entering a value here will simulate flow by creating a precise calibrated flow signal as input signal

for the converter. The outputs of the converter follow this calibrated flow signal level.

The simulated flow value may be set between –999.9% and +999.9% of the full scale as set or read

under "Function 1.2 Full Scale Value". For normal tests, setting shall be within ± 100.0%.

If the maximum signal level of MagCheck is exceeded, the warning "error message: simulation

parameters, check" is shown on the MagCheck display.

Back to menu 1.4 Simulation by pressing ↵.

3.4.4 Function 1.5 Curr. Output

Press → key.

Display according to setting of Function 1.4 Simulation.

Example: Function 1.4 Simulation value set to 50.0%, Converter settings I0% = 4 mA, I100%= 20

mA).

Display Function 1.5:

MagCheck Display Head Line Current output

No IMoCom connection to converter Act. 11.998 mA

True 12.000 mA With IMoCom-converter and IMoCom

connection from MagCheck to converter

Act. 11.998 mA

Back to menu 1.5 Field current by pressing ↵.

3.4.5 Function 1.6 Pulse output

Press → key.

Display of the measured output frequency from the pulse output in pulses/second.

Example: Function 1.4 Simulation value set to 50.0%, f100%= 800 Pulses / second)

Display Function 1.6.

MagCheck Display Indication Headline: Pulse output

No IMoCom connection Act. 399,8 Hz

With IMoCom-converter and IMoCom

connection from MagCheck to converter

True 400,0 Hz

Act. 399,8 Hz

18 MagCheck

Page 19

Attention: With low pulse frequency settings MagCheck will change to measuring pulse period.

Example: Full Scale of converter Q

is 100 m3/hour, Pulse Rate of converter is set to 1

100%

pulse/m3. Accordingly the converter will send 1 pulse every 36 seconds, if Function 1.4 Simulation

has been set to 100%.

With setting of Function 1.4 Simulation to 10% it will last very long until a value can be indicated.

In such cases it will be better to increase pulse rate setting of the converter by a factor of 10, 100 or

to 1000 Hz for this test. Make sure to restore the original settings after completion of the test!

Back to menu 1.6 Pulse output by pressing ↵.

3.4.6 Function 1.7 Field Current

Press → key.

Display of the measured field current (all values in mA):

FCS = peak to peak field current

pos. = the positive half wave

neg: = the negative half wave

Frequency = actual value of field frequency

Back to menu 1.7 Field current by pressing ↵.

3.4.7 Function 1.8 Hardw. info

Press → key.

This menu may be used on IMoCom Converters only after IMoCom connection has been

established. Hardware Information and Status Information acc to menu 2.2 of IFC 010, 020, 090,

110 are shown.

Display of Software I.D.-no. and status message of the connected module: In this menu, an 8position software number and a 10-position status code are stored. These status codes enable a

quick and simple diagnosis of your flow meter. The number of modules indicated depends on the

number of modules present in the flow meter. Should one module report a fatal error or a warning,

this will be shown in the fourth line of the display.

Change to next status report by pressing ↵.

Back to menu 1.8 Hardware Info by pressing ↵.

3.4.8 Function 1.9 Reset

Reset Function with IMoCom converters only! Press → key.

In some cases, it can be useful to perform a restart of a device. To perform a restart, the “Reset”function can be chosen in this menu. Only possible with IMoCom-connection between MagCheck

and IFC. Should a restart be performed without the MagCheck connected to the mains supply, the

MagCheck will also be restarted and the main menu will be shown again

3.4.9 Function 2.1 Device Info

Press → key.

Following information is displayed:

Device Info

SN (Serial Number): XXXXXXXX

SV (Software Version): XX.XXX.XXX.X

CalDate (calibration Date): XX.XX.XX

Back to menu 2.1 Software by pressing ↵.

MagCheck 19

Page 20

3.4.10 Function 3.1 Language

Press → key.

Select language of MagCheck display texts: English (GB), French (F) or German (D). The selected

language appears in flashing text.

• Select with ↑ and ↓

• Confirm with ↵ (Data change accept)

• Select choice with ↑ and ↓, confirm with ↵

• Back to menu 3.1 Language by pressing ↵

3.4.11 Function 3.2 Data transfer from MagCheck to the PC

Connect MagCheck to PC. The external power supply must be connected to MagCheck. The 25-pin

PC connector of the RS 232 cable (supplied with MagCheck) must be connected to the MagCheck

connector, the 9-pole connector to RS232 COM port of the PC COM port. On the PC, the

MagCheck PC program must be active. During transfer of the data from MagCheck to PC, the

message “Data transfer” is shown on the MagCheck display.

Press → key.

The display will show, that MagCheck is now ready for data transfer. Data Transfer to the PC will

be started by clicking "Read verification data from MagCheck" on the PC screen.

Back to menu 3.2 Data transfer by pressing ↵.

After data transfer the according memory areas in the MagCheck will be released for

overwriting by new files, this means all downloaded data are erased from

MagCheck.

20 MagCheck

Page 21

4 Using MagCheck with a PC

4.1 System specifications

To be able to install the MagCheck system on to your PC, the following specifications apply:

• MS Windows

• MS Windows

®

-PC

®

95, 98, 2000, NT, XP

• > 32 MB memory, >32 MB free space on hard disk,

• CD-ROM drive

• Free Com Port: RS 232

• Mouse, keyboard, monitor, printer

4.2 Installation PC software

Insert the CD into the CD drive of your PC and

follow the instructions of the Set-up-program.

During installation you will be asked for a

password. To work without password leave the

field blank and click ok. There is no way to

recover a lost password. After installation and

clicking on the MagCheck icon on the desktop

the main screen of the MagCheck main menu

will appear:

4.3 Settings of MagCheck PC software

4.3.1 Selection of the PC program language

Enter Menu Extra. Select Language, select:

English, Français, Deutsch or Nederlands. After

selection the program must be closed and

restarted.

4.3.2 Selection of the MagCheck Com-Port for download of verification data

Enter Menu Extra. Select "Serial port."

MagCheck PC- program checks the port of your computer and offers an appropriate selection.

Confirm.

MagCheck 21

Page 22

4.4 Connecting MagCheck to PC

• The 25-pin PC connector of the RS 232 cable

(supplied with MagCheck) must be

connected to the MagCheck connector, the

9-pole connector to RS232 COM port of the

PC COM port as configured above.

• The external power supply must be

connected to MagCheck.

• Any power adapter used with MagCheck

must meet safe separation regulations (IEC

950, SELV, safe electrical low voltage

regulations)

• The power supply adapter (FRIWO 7238/15)

supplied by KROHNE has been certified for

safe separation under office ambient

conditions (dry rooms).

Do not use this power supply

adapter in wet environments. Risk of

personal hazards!

4.5 Downloading and storing MagCheck verification data onto PC

• Start MagCheck PC-program. Connect MagCheck to PC.

• MagCheck will start searching for communication to an IMoCom interface. Press F1.

• Select MagCheck Menu 3.2. After pressing arrow → MagCheck will indicate "Ready for data

transfer".

• Click on MagCheck PC main menu, button: "Read flowmeter verification files from MagCheck".

• MagCheck PC program will ask : "Number of new flowmeter verification files: X (e.g. 1-70). Do

you want to download these flowmeter files?"

• Click "OK" and the following screen appears:

• If the meter has been verified for the first

time, select the lower radio button

("..flowmeter not known.."). Enter a file

name under which the flowmeter data will

be stored. Recommended e.g.: Customer

Company (abbrev) + Location +Tagname,

e.g. WaterSWW_Kingsville_FIC107

• If the related flowmeter has been verified

before and the actual verification data

should be added to its history, select the

upper radio button and select the correct

device identification from the pull-down

menu, to which this new verification file

should be added. The downloaded data

will now become part of the selected

meter history!

• With the button "Cancel..." data sets may

be excluded from download.

• Button "Abort reading...." will stop

downloading of verification data.

Verification files which not have been downloaded will remain in MagCheck memory.

22 MagCheck

Page 23

4.6 Exporting and importing verification files from / to floppy or hard disk

4.6.1 Menu “File”

File format of all verification export- and importfiles is *.MCK.

For exporting verification files which have been

downloaded from MagCheck into PC select

menu File, Export.

4.6.2 Exporting MagCheck verification files

After clicking on "Export..." a screen appears,

which allows selecting a directory where to store

the export file and entering a file name.

The upper pull-down list “Store in:” allows for

selecting an appropriate directory for storing the

export file. The lower box allows for entering an

appropriate file name (e.g.

MagCh_Date_All_UserComp.MCK).

The list below shows all verification data files

stored in file MagCheck.MCK in the MagCheck

data base. Deselect files which should not be

exported by clicking on the marker field. Click on

OK, the marked data sets will be exported to the

file.

4.6.3 Importing MagCheck verification files

Select: Menu File, Import. Select drive /

directory, *.MCK file, Click on "Open". Window

"Load MagCheck Import-and export file" (see

right) will open. Selected data sets will be

imported in to the meter data bank of the

MagCheck program.

If one of these flowmeter data sets already exists

in the MagCheck PC data bank, a warning will

appear. If the existing flowmeter data set is to be

replaced by the import file, click "yes".

MagCheck 23

Page 24

4.7 Trend analysis

The trend analysis shows all

measured data in detail. Its

graphic presentation of all data

and the related error limits

allows for easy checking of

stability, drifts of all measured

parameters.

Click on tab "Measurement

results" on MagCheck PC

program main screen.

Select meter to be shown on

pull-down list "Device

identification"

(example: FT-1)

Tab "Info" will show a listing of

meter data incl. order number,

converter number and all

settings as read by MagCheck.

Pull-down lists will allow selection of a sequence of meter verifications in the meter history.

As an example the following view shows meter FT-1, parameter "ADC 100%" for verifications 3 to 6

out of a sequence 1 to 7. Any other parameter may be presented in the same way.

Numerical data for the related parameter are shown at the right side. Dotted lines indicate the error

limits for the related parameter. These limit data are listed just above the diagram, too.

In case of the first verification (no history) or selection of one verification only (e.g. from "Parameter

6" to "Parameter 6" results are shown as numerical values.

24 MagCheck

Page 25

4.7.1 Information "Flowmeter has been changed..."

This information will appear if, compared to the first verification, one of the following parameters has

been changed: GK, nominal diameter , Full scale, I0%, I100%, settings of pulse output.

4.7.2 Printing the Trend Analysis

Open the specific flowmeter file.

On Main Menu Bar select "File", "Print", "Page

setup". Adjust page settings.

Select: "File", "Print", "Trend analysis”.

4.7.3 Trend Analysis Print selection menu

This menu allows for selection of:

• the device

• the parameter sequence to be printed

• print preview on the monitor,

• printing as Adobe Acrobat-Reader .PDF-file,

which may be stored or sent by e-mail

• or print on any printer connected to the PC.

4.7.4 Printing verification certificates

On Main Menu Bar select: "File", "Print", "Page

setup". Adjust page settings.

Select : "File", "Print", "Certificate".

This menu allows for selection of the device, the parameter set (verification) to be printed, print

preview on the monitor, printing as Adobe Acrobat-Reader *.PDF-file, which may be stored, sent by

e-mail or printed on any printer connected to the PC.

MagCheck 25

Page 26

5 Interpretation of verification results

Check in the trend analysis which parameters are exceeding their limits. Most common causes are

outlined below.

5.1 Accuracy data ADC, field current, mA or frequency output

ADC is the primary signal processing. It includes input instrumentation amplifier and analogue to

digital conversion of the flow signal voltage. Accuracy of ADC and field current directly influence

accuracy of any output of the electromagnetic flowmeter. If accuracy of ADC, mA or frequency

output, or field current is wrong: exchange converter electronics.

5.2 Coil resistance

Coil resistance value is dependent of coil temperature during verification. Coil temperature again is

dependent on ambient temperature and on medium temperature in the flow tube of the magnetic

flowmeter. Temperature coefficient is 0.4% per °C (0.2% per °F). Two failure modes can be

detected:

• Resistance is zero or far below plausible value: Check cabling, connectors, terminals to field

coils on short circuits.

• Resistance is high: Check cabling, connectors, terminals to field coils on interruptions or poor

contact.

Check connectors / connections below the terminal board. If these are ok and coil resistance

remains infinite or zero, interruption or short-circuit of an internal connection is possible (but

extremely rare). In that case, the flowhead must be exchanged.

5.3 Electrode resistance with full pipe

In general: Electrode resistance with full pipe depends on conductivity (σ) of the liquid. Conductivity

depends on liquid type, concentration, temperature. Change of electrode resistance between two

verifications only is significant as long as precisely the same liquid with same concentration and

temperature will flow through the flowmeter without creating any deposits. Electrode resistance

values may be estimated from electrode diameter “d” and conductivity (σ) according to following

formula:

[]

=Ω

kR

Electrode

This formula may be used for approximate plausibility checks if the results of electrode resistance

measurements are outside of the measuring range of MagCheck. The results of this formula may

show a deviation to true value of electrode resistance as indicated by the tolerance data.

Electrode resistance with full pipe very high: Check cabling to electrodes (signal cable, connector in

remote flowhead connection box) on interruption. Remove meter from line, clean electrodes and

grounding rings.

Asymmetric electrode resistance: Differences in electrode 1- and 2 resistance values by more than

±50% may be caused by:

• Heavy coating (contamination) on one of the electrodes (Countermeasure: Clean electrodes)

• Beginning short circuit of one electrode, e.g. by contamination with highly conductive matter

(Action: Clean electrodes and liner carefully) or by electrode leakage.

Electrode leakage and conductive deposits can be confirmed by verification with empty pipe.

Select “Pipe Empty” in Menu 1.1.

26 MagCheck

1000

[] [ ]

×

/

cmScmd

µσ

100% / 50%:Tol.

+−

Page 27

5.4 Electrode resistance with empty pipe

Low resistance of electrodes with empty pipe may influence accuracy. This may be caused by

humidity on terminal boards in converter and flowhead, defective signal cables at separate meters or

electrode leakage. With empty, clean and dry pipe the electrode resistance must be > 10 MOhms.

The MagCheck limit of > 6 MOhms considers minor insulation degradation on signal cable and

lining.

• Check converter signal cable connectors, flowhead

terminals and PC-board. Clean, dry?

• Bottom side of PC-board in flowhead connection box

and connector. Clean and dry thoroughly!

Disconnect signal wires at flowhead terminals 2, 3.

• Do not disconnect cable shield terminals 1, GND

• Make sure that open cable ends are clean, dry and do

not contact each other or any flow meter part.

• Repeat verification. MagCheck result now:

↓ OK?

• Cable is ok. Investigate flowhead connection box:

Terminals and PC-board clean, dry?

(also: check bottom side and connector)

• Clean and dry thoroughly! Assemble again.

• Disconnect all cables to converter

• Do insulation test on flowhead terminals:

• Terminal 2 to 1 or GND (≤ 100 VDC).

• Terminal 3 to 1 or GND (≤ 100 VDC).

↓ OK?

Resistance electrodes with empty pipe OK

Signal cable

→ NOT OK?

defective,

low insulation

Exchange!

Take meter out.

Clean liner.

Remove deposits.

→ NOT OK?

Dry liner.

Repeat insulation

tests on terminals

← ←

2, 3 to 1 / GND

↓ ↓

OK?

Test coil insulation as below/

Contact KROHNE.

→ NOT

OK?

↓

MagCheck 27

Page 28

5.5 Coil insulation

Coil insulation is a vital parameter for accurate function of a magnetic flowmeter. Causes for poor

insulation may be found in wet or defective field current cable, wet or dirty terminals and connectors

or liquid entrained in the meter body. What to do if result "Coil insulation" is "NOT OK":

• Check converter field current cable connectors,

flowhead terminals and PC-board. Clean, dry?

• Bottom side of PC-board and connector in flowhead

connection box. Clean and dry thoroughly!

Disconnect field current wires at flowhead terminals

7,8.

• Do not disconnect cable shield terminals 1, GND

• Make sure that open cable ends are clean, dry and do

not contact each other or any flow meter part.

• Repeat verification. Does MagCheck indicate

→ NOT OK?

Field current cable

defective,

low insulation

Exchange!

insulation > 10 MOhm? Now?

↓ OK?

• Cable is ok. Investigate flowhead connection box:

Terminals and PC-board clean, dry?

(also Bottom side and connector). Clean and dry

thoroughly! Re-assemble the cable connections.

→ NOT OK? Contact KROHNE

• Disconnect all cables to converter

• Do an insulation test (≤ 100 VDC) on flowhead

terminals 7 or 8 to 1 or GND > 10 MOhm?

Field coil insulation OK

↓ OK?

5.6 Limitations of accuracy statement

MagCheck is verifying all vital electrical data of the flowmeter and converter. The verification result

does not include factors as: deposits in flowtube, installation not according to installation rules,

gases in the liquid.

28 MagCheck

Page 29

6 Service and recalibration

6.1 Recalibration

MagCheck must be recalibrated annually. The calibration menu is indicated in Function 2.1 Device

Info.

For recalibration and/or repair please contact your local KROHNE representative.

6.2 Software

If there are any problems regarding the MagCheck software, please have the following information

ready and contact your local KROHNE representative.

• System: Microsoft Windows

®

98 / 2000 / NT4 / XP

• Type of processor

• Com port in use

• Type of flowhead (A-number)

• Type of signal converter (serial number)

• Description of error(s)

• MagCheck Export file (*.MCK) with statement, which device looks wrong

• Trend analysis (Adobe Acrobat reader *.PDFfile)

6.3 Spare parts

The following spare parts are available for MagCheck:

Spare part BaaN ordering number

MagCheck (in suitcase) complete replacement! XN00121100

Power supply adapter 100..230V to 15 V DC with plug adapter for

XN00121200

different plug standards

IFC 010 connecting cable XN00121300

IFC 020 connecting cable XN00121400

IFC 090 connecting cable XN00121500

IFC 110 connecting cable XN00121600

PC RS 232 connecting cable XN00121900

MagCheck CD (incl. MagCheck PC program, installation and operating

XN00122000

instructions, Excel spreadsheets for data processing)

Installation and operating instructions UK English (printed) XN00122100

Installation and operating instructions German (printed) XN00122200

Installation and operating instructions French (printed) XN00122300

Appendix 1

MS Excel spreadsheets, available on the KROHNE MagCheck CD, allow for easier documentation

and evaluation of manual and automatic verifications of flowmeters. Keep printouts ready for use on

site.

MagCheck 29

Page 30

Documentation of automatic verification files

To make sure that verification files are documented and can be correlated to customer or tag

number even years after first evaluation, use the Excel spreadsheet

MagCheck_Verification_Listing.XLS. Take some print-outs with you whenever you leave for

verifications and document local situation and file names immediately on site. This will enable you

to add verification files adequately to previous taken verification data and to create a clear history.

30 MagCheck

Page 31

Documentation of data of manual converter calibration test

Data and readings in menu 1.2 to 1.7 during manual calibration test may be noted in a print-out of

spreadsheet MagCheck_Manual _Test_Report.XLS. These data may be easily transferred into the

Excel spreadsheet, which automatically calculates errors.

MagCheck 31

Page 32

Australia

KROHNE Australia Pty Ltd.

Unit 19 No.9, Hudson Ave.

Castle Hill 2154, NSW

TEL.: +61(0)2-98948711

FAX: +61(0)2-98994855

e-mail: krohne@krohne.com.au

Austria

KROHNE Ges.m.b.H.Austria

Modecenterstraße 14

A-1030 Wien

TEL.: +43(0)1-2 03 45 32

FAX: +43(0)1-2 03 47 78

e-mail: info@krohne.at

Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

TEL.: +32(0)2-4 66 00 10

FAX: +32(0)2-4 66 08 00

e-mail: krohne@krohne.be

Brazil

KROHNE Conaut

Controles Automaticos Ltda.

Estrada Das Águas Espraiadas, 230 C.P. 56

06835 - 080 EMBU - SP

TEL.: +55(0)11-4785-2700

FAX: +55(0)11-4785-2768

e-mail: conaut@conaut.com.br

China

KROHNE Measurement Instruments Co. Ltd.

Room 7E, Yi Dian Mansion

746 Zhao Jia Bang Road

Shanghai 200030

TEL.: +86(0)21-64677163

FAX: +86(0)21-64677166

Cellphone: +86(0)139 1885890

e-mail: ksh@ihw.com.cn

CIS

Kanex KROHNE Engineering AG

Business-Centre Planeta, Office 403

ul. Marxistskaja 3

109147 Moscow/Russia

TEL.: +7(0)095-9117165

FAX: +7(0)095-9117231

e-mail: krohne@dol.ru

Czech Republic

KROHNE CZ, spol. s r.o.

Sobe˘s˘ická 156

CZ-63800 Brno

TEL.: +420(0)5-45 53 21 11

FAX: +420(0)5-45 522 00 93

e-mail: brno@krohne.cz

Algeria

Argentina

Bulgaria

Camaroon

Canada

Chile

Columbia

Croatia

Denmark

Ecuador

Egypt

Finland

French Antilles

Greece

Guinea

Hong Kong

Hungary

Indonesia

Ivory Coast

Iran

Ireland

Israel

Japan

Jordan

Kuwait

Marocco

Mauritius

Mexico

New Zealand

Pakistan

Poland

Portugal

Saudi Arabia

Senegal

Singapore

Slovakia

Slovenia

Sweden

Taiwan

Thailand

Turkey

Tunesia

Venezuela

Yugoslavia

France

KROHNE S.A.

Usine des Ors

B.P. 98

F-26 103 Romans Cedex

TEL.: +33(0)4-75 05 44 00

FAX: +33(0)4-75 05 00 48

e-mail: info@krohne.fr

Germany

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Straße

D-47058 Duisburg

TEL.: +49(0)203-301-0

FAX: +49(0)203-301 389

e-mail: krohne@krohne.de

India

KROHNE Marshall Ltd.

A-34/35, M.I.D.C.

Industrial Area, H-Block,

Pimpri Poona 411018

TEL.: +91(0)20-744 20 20

FAX: +91(0)20 -744 20 40

e-mail: pcu@vsnl.net

Italy

KROHNE Italia Srl.

Via V. Monti 75

I-20145 Milano

TEL.: +39(0)2-4 30 06 61

FAX: +39(0)2-43 00 66 66

e-mail: krohne@krohne.it

Korea

Hankuk KROHNE

2 F, 599-1

Banghwa-2-Dong

Kangseo-Ku

Seoul

TEL.: +82(0)2665-85 23-4

FAX: +82(0)2665-85 25

e-mail: flowtech@unitel.co.kr

Netherlands

KROHNE Altometer

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306300

FAX: +31(0)78-6306390

e-mail: postmaster@krohne-altometer.nl

KROHNE Nederland B.V.

Kerkeplaat 12

NL-3313 LC Dordrecht

TEL.: +31(0)78-6306200

FAX: +31(0)78-6306405

Service Direkt: +31(0)78-6306222

e-mail: info@krohne.nl

Norway

Krohne Instrumentation A.S.

Ekholtveien 114

NO-1526 Moss

P.O. Box 2178, NO-1521 Moss

TEL.: +47(0)69-264860

FAX: +47(0)69-267333

e-mail: postmaster@krohne.no

Internet: www.krohne.no

South Africa

KROHNE Pty.Ltd.

163 New Road

Halfway House Ext. 13

Midrand

TEL.: +27(0)11-315-2685

FAX: +27(0)11-805-0531

e-mail: midrand@krohne.co.za

Spain

I.I. KROHNE Iberia, S.r.L.

Poligono Industrial Nilo

Calle Brasil, n°. 5

E-28806 Alcalá de Henares-Madrid

TEL.: +34(0)91-8 83 21 52

FAX: +34(0)91-8 83 48 54

e-mail: krohne@krohne.es

Switzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

TEL.: +41(0)61-638 30 30

FAX: +41(0)61-638 30 40

e-mail: info@krohne.ch

United Kingdom

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough,

Northants NN8 6AE, UK

TEL.: +44(0)19 33-408 500

FAX: +44(0)19 33-408 501

e-mail: info@krohne.co.uk

USA

KROHNE Inc.

7 Dearborn Road

Peabody, MA 01960

TEL.: +1-978 535-60 60

FAX: +1-978 535 -17 20

e-mail: krohne@krohne.com

Overseas Representatives

Other Countries:

KROHNE Messtechnik

GmbH & Co. KG

Ludwig-Krohne-Str.

D-47058 Duisburg

TEL.: +49(0)203-301 309

FAX: +49(0)203-301 389

e-mail: export@krohne.de

Subject to change without notice

Loading...

Loading...