Page 1

Handbook

Handbook

OPTISENS MAC 100

OPTISENS MAC 100

OPTISENS MAC 100OPTISENS MAC 100

HandbookHandbook

Multiparameter signal converter

Electronic Revision: ER 1.0.0

The documentation is only complete when used in combination with the relevant

documentation for the sensor.

© KROHNE 04/2011 - MA OPTISENS MAC 100 R01 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2011 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 3

OPTISENS MAC 100

CONTENTS

1 Safety instructions 6

1.1 Software history ............................................................................................................... 6

1.2 Intended use ..................................................................................................................... 7

1.3 Certifications .................................................................................................................... 7

1.4 Safety instructions from the manufacturer ..................................................................... 8

1.4.1 Copyright and data protection ................................................................................................ 8

1.4.2 Disclaimer ............................................................................................................................... 8

1.4.3 Product liability and warranty ................................................................................................ 9

1.4.4 Information concerning the documentation........................................................................... 9

1.4.5 Warnings and symbols used................................................................................................. 10

1.5 Safety instructions for the operator............................................................................... 11

2 Device description 12

2.1 Scope of delivery............................................................................................................. 12

2.2 Device description .......................................................................................................... 13

2.3 Sensor input combinations............................................................................................. 15

2.4 Nameplate ...................................................................................................................... 16

3 Installation 17

3.1 Notes on installation ......................................................................................................17

3.2 Storage and transport .................................................................................................... 17

3.3 Wall mounting ................................................................................................................ 17

4 Electrical connections 20

4.1 Safety instructions.......................................................................................................... 20

4.2 Used abbreviations .........................................................................................................20

4.3 Important device-specific notes on electrical connection............................................. 21

4.4 Opening the converter housing ...................................................................................... 22

4.5 Overview of the terminal compartment ......................................................................... 22

4.6 Connecting the signal cables ......................................................................................... 23

4.7 Connecting the power supply......................................................................................... 23

4.8 Description and properties of the outputs and the input............................................... 25

4.8.1 Current output ...................................................................................................................... 25

4.8.2 Relay outputs ........................................................................................................................ 25

4.8.3 Control input (passive) .......................................................................................................... 26

4.9 Connection diagrams of the outputs and the input ....................................................... 27

4.9.1 Important notes..................................................................................................................... 27

4.9.2 Description of electrical symbols ......................................................................................... 27

4.9.3 Block diagram....................................................................................................................... 28

4.9.4 Current output (active).......................................................................................................... 28

4.9.5 Relay outputs ........................................................................................................................ 29

4.9.6 Control input ......................................................................................................................... 29

4.10 Electrical connection of the outputs and the input...................................................... 30

4.10.1 Connecting the current outputs..........................................................................................30

4.10.2 Connecting the relay outputs.............................................................................................. 31

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

3

Page 4

CONTENTS

OPTISENS MAC 100

5 Start-up 34

5.1 Switching on the power .................................................................................................. 34

6 Operation 36

6.1 Operating elements........................................................................................................ 36

6.2 Measuring mode.............................................................................................................37

6.2.1 First measuring page............................................................................................................ 37

6.2.2 Second measuring page ....................................................................................................... 39

6.2.3 Status page ........................................................................................................................... 40

6.2.4 Trend diagram....................................................................................................................... 41

6.3 Menu mode ..................................................................................................................... 41

6.3.1 Navigating through the menus .............................................................................................42

6.3.2 Menu "quick setup"............................................................................................................... 46

6.4 Menu mode structure..................................................................................................... 47

6.5 Function tables ............................................................................................................... 50

6.5.1 Menu A, quick setup.............................................................................................................. 50

6.5.2 Menu B, test .......................................................................................................................... 52

6.5.3 Menu C, setup ....................................................................................................................... 54

6.5.4 Menu D, service..................................................................................................................... 59

6.6 Functions in detail .......................................................................................................... 60

6.6.1 Manual hold........................................................................................................................... 60

6.6.2 Simulation of measured values ............................................................................................60

6.6.3 Status log and calibration log ............................................................................................... 61

6.6.4 Error current of current output............................................................................................ 62

6.6.5 Overflow sign and exponential format.................................................................................. 63

6.6.6 Save settings .........................................................................................................................65

6.6.7 Load settings......................................................................................................................... 65

6.6.8 Passwords............................................................................................................................. 66

6.7 Status messages and diagnostic information................................................................ 66

6.7.1 Error category "Device failure" (bold "F")............................................................................ 68

6.7.2 Error category "Application error" ( "F", not bold) .............................................................. 69

6.7.3 Error category "Out of specification" (S) .............................................................................. 69

6.7.4 Error category "Check request" or "Run check" (C) ............................................................ 70

6.7.5 Error category "Information" (I) ........................................................................................... 70

6.8 Timeout function............................................................................................................. 71

7 Service 72

7.1 Maintenance and repair ................................................................................................. 72

7.2 Spare parts availability...................................................................................................72

7.3 Availability of services .................................................................................................... 72

7.4 Returning the device to the manufacturer..................................................................... 73

7.4.1 General information.............................................................................................................. 73

7.4.2 Form (for copying) to accompany a returned device............................................................ 74

7.5 Disposal .......................................................................................................................... 74

4

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 5

OPTISENS MAC 100

CONTENTS

8 Technical data 75

8.1 Measuring principle........................................................................................................75

8.2 Technical data table .......................................................................................................75

8.3 Dimensions and weight .................................................................................................. 79

8.3.1 Housing ................................................................................................................................. 79

8.3.2 Mounting plate ...................................................................................................................... 80

9 Notes 81

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.1 Software history

The "Electronic Revision" (ER) is consulted to document the revision status of electronic

equipment according to NE 53 for all GDC devices. It is easy to see from the ER whether

troubleshooting or larger changes in the electronic equipment have taken place and how that

has affected the compatibility.

Changes and effect on compatibility

1 Downwards compatible changes and fault repair with no effect on operation (e.g. spelling

mistakes on display)

2-_ Downwards compatible hardware and/or software change of interfaces:

HART

®

H

P PROFIBUS

F Foundation Fieldbus

M Modbus

X all interfaces

3-_ Downwards compatible hardware and/or software change of inputs and outputs:

I Current output

F, P Frequency / pulse output

S Status output

C Control input

CI Current input

X all inputs and outputs

4 Downwards compatible changes with new functions

5 Incompatible changes, i.e. electronic equipment must be changed.

OPTISENS MAC 100

INFORMATION!

In the table below, "x" is a placeholder for possible multi-digit alphanumeric combinations,

depending on the available version.

Release date Electronic Revision Changes and

Documentation

compatibility

2007-12-11 ER 1.0.0 - MA MAC 100 R01

6

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 7

OPTISENS MAC 100

1.2 Intended use

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

WARNING!

If the device is not used according to the operating conditions (refer to chapter "Technical data"),

the intended protection could be affected.

In combination with the different sensors of the OPTISENS 1000 series the MAC 100 measures

analytical parameters in water and waste water applications.

1.3 Certifications

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

SAFETY INSTRUCTIONS 1

CE marking

The device fulfils the statutory requirements of the following EC directives:

• Low Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

as well as

• EN 61010

• EMC specification acc. to EN 61326/A1

• NAMUR recommendations NE 21 and NE 43

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

OPTISENS MAC 100

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

8

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 9

OPTISENS MAC 100

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

9

Page 10

1 SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTISENS MAC 100

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

10

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 11

OPTISENS MAC 100

1.5 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

SAFETY INSTRUCTIONS 1

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

11

Page 12

2 DEVICE DESCRIPTION

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISENS MAC 100

1 Signal converter

2 Product documentation

12

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 13

OPTISENS MAC 100

2.2 Device description

1 Display

2 Operation keys

3 Cable glands

DEVICE DESCRIPTION 2

The signal converter is able to measure different parameters in liquids and fluids which are

common in the water and waste water industry. It has three freely programmable current

outputs and optionally three mechanical relays which can be configured as alarm or status

relays or limit switches.

The manufacturer offers the device as a one channel version and a version with two channels.

The last one possesses two sensor inputs for using sensors with different measuring principles

as they are:

• Amperometric measurements (disinfection parameters, dissolved oxygen)

• Potentiometric measurements (pH / ORP)

• Conductive measurements (conductive / inductive)

When ordering the one channel version, only the interface "Pos.A" is populated. In the version

with two channels the interfaces "Pos.A" and "Pos.B" are populated (for further information

refer to

Overview of the terminal compartment

on page 22):

INFORMATION!

•

The configuration of the signal converter (i.e. the number and type of sensor inputs) has to be

set in the factory and cannot be changed later.

•

The number and type of sensor inputs is specified via the order code and visible on the

nameplate.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

13

Page 14

2 DEVICE DESCRIPTION

The manufacturer offers the signal converter as a wall mount version only. Each device has a

passive control input that can signal an external "out of specification error" (e.g. that there is no

flow). Additionally the control input can help to set the analog outputs (current outputs and limit

switches) to "zero" or to "manual hold" (e.g. for maintenance). For further details about the

control input please refer to

The type and design of the cable glands depend on the version of the converter. The following

types and designs are available (the drawings show the device from the bottom side):

Cable glands (1 channel)

Control input (passive)

OPTISENS MAC 100

on page 26.

1 Power (M20)

2 Current output or relay output (M20)

3 Current outputs or temperature sensor (M20)

4 Sensor input (M20)

5 Possibility to connect a functional earth (only relevant for version with 24 V, which is in preparation)

Cable glands (2 channel, separate temperature sensor)

1 Power (M20)

2 Current output or relay output (M20)

3 Current outputs or temperature sensor (M20)

4 Sensor input for sensor A and B (double PG two times 5 mm / 0.20" screwed connection)

5 Possibility to connect a functional earth (only relevant for version with 24 V, which is in preparation)

14

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 15

OPTISENS MAC 100

Cable glands (2 channel, integrated temperature sensor)

1 Power (M20)

2 Current output or relay output (M20)

3 Current outputs (M20)

4 Sensor input for sensor A and B (double PG two times 8 mm / 0.31" screwed connection)

5 Possibility to connect a functional earth (only relevant for version with 24 V, which is in preparation)

2.3 Sensor input combinations

The following combinations of sensor inputs are possible:

DEVICE DESCRIPTION 2

Sensor type Measured

parameter

Measuring

principle

Signal converter

Input A Input B

PAS 1000 pH pH value Potentiometric X X

PAS 1000 ORP ORP value Potentiometric X X

AAS 1000 Cl

AAS 1000 ClO

AAS 1000 H2O

AAS 1000 O

AAS 1000 DO 1 Dissolved oxygen Amperometric X X

CAS 1000 1 Conductivity /

IAS 1000 1 Conductivity Inductive X X

1 In preparation

2

2

1 Ozone Amperometric X -

3

Free chlorine Amperometric X -

1 Chlorine dioxide Amperometric X -

1 Hydrogen peroxide Amperometric X -

2

specific resistance

Conductive (2pole)

X X

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

15

Page 16

2 DEVICE DESCRIPTION

2.4 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

1 Manufacturer

2 CE marking

3 Power supply data

4 Tag number of the order

5 Sensor type input B

6 Sensor type input A

7 Article code

8 Serial number

9 Device name and order code

OPTISENS MAC 100

16

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 17

OPTISENS MAC 100

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage and transport

• Store and transport the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store and transport the device in its original packing.

• Storage temperature: -40...+70°C / -40...+158°F

INSTALLATION 3

3.3 Wall mounting

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

CAUTION!

Always note the following items to ensure a proper and safe installation:

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibration.

•

Use assembly materials and tools in compliance with the applicable occupational health and

safety directives (assembly materials and tools are not part of the scope of delivery).

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

17

Page 18

3 INSTALLATION

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

The mounting plate is fixed at the back side of the device in the delivery condition. The following

drawings illustrate the proper mounting:

Wall mounting with plugs

OPTISENS MAC 100

• Note the drawing above and mark all drill holes with the help of a pen, e.g. a felt pen (1).

• Fasten the device securely to the wall with the help of plugs, screws and the mounting

plate (2).

18

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 19

OPTISENS MAC 100

Wall mounting of multiple devices

INSTALLATION 3

[mm] ["]

a Ø6.5 Ø0.26

b 87.2 3.4

c 241 9.5

d 310 12.2

e 257 10.1

For further information about the dimensions of the mounting plate refer to

page 80.

Mounting plate

on

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

19

Page 20

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISENS MAC 100

4.2 Used abbreviations

Abbreviation Description

C

p

I

a

I

max

I

nom

R

L

R plus number (e.g. R1) Relay contact

P Power

U

ext

U

ext, max

U

int, nom

Control input passive

Current output active

Maximum current

Nominal current

Load resistance

External voltage source

Maximum voltage of the external voltage source

Nominal internal voltage

20

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 21

OPTISENS MAC 100

ELECTRICAL CONNECTIONS 4

4.3 Important device-specific notes on electrical connection

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries!

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

When installing and wiring the device, note the safety regulations of the current state of the art.

Also note the following items to avoid fatal injuries, destruction or damage of the device or

measuring errors:

•

De-energise the cables of the power supply before you start any installation works.

•

Always install input and control cables divided from each other and from high voltage current

cables.

•

Assure that all cables of the inputs and current outputs are shielded. Connect the shieldings

only to one side, e.g. to the device.

•

When using relays, note that with inductive loads the interference must be suppressed.

•

Assure that all electrical connection works are compliant with the VDE 0100 directive

"Regulations for electrical power installations with line voltages up to 1000 V" or equivalent

national regulations.

•

Use suitable cable glands for the various electrical cables and suitable connecting cables for

the field of application. The outer diameter of the connecting cables has to fit to the cable

glands.

•

The nominal voltage of the connecting cable has to fit to the operating voltage of the device.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

21

Page 22

4 ELECTRICAL CONNECTIONS

4.4 Opening the converter housing

INFORMATION!

Clean and grease all threads each time you open the housing. Use only resin-free and acid-free

grease. Before closing the cover, ensure that the housing gasket is properly fitted, clean and

undamaged.

All installation works on the electrical connections require to open the converter housing:

• Loose the four screws (1) with a crosstip screwdriver.

• Lift the housing at the top and bottom at the same time (2).

• Slide the housing cover backward (3).

i The housing cover is guided and held by the inside hinge; you have access to the terminal

compartment now (see 4 in the previous drawing and next section).

OPTISENS MAC 100

4.5 Overview of the terminal compartment

1 Cover of power supply terminal

2 Cover of relay outputs terminal

3 Current output terminal

4 Shield terminal

5 Terminals for sensor input A

6 Terminals for sensor input B

7 Possibility to connect a functional earth (only relevant for 24 V version, which is in preparation)

8 Cable glands

8

22

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 23

OPTISENS MAC 100

4.6 Connecting the signal cables

INFORMATION!

The cable glands installed by the manufacturer are designed for a cable diameter of 8 to 13 mm.

If you are using cables with a larger diameter, you must replace the manufacturer's cable glands

with suitable ones.

For all information concerning the signal cables of the used sensor(s) and their connection refer

to the relevant sensor handbook(s).

4.7 Connecting the power supply

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries!

ELECTRICAL CONNECTIONS 4

CAUTION!

When connecting the power supply, always note the safety regulations of the current state of the

art. To avoid fatal injuries, destruction or damage of the device or measuring errors, also note

the following items:

•

De-energise the cables of the power supply before you start any installation works!

•

Always keep the housing of the device well closed if you do not perform any installation

works. The function of the housing is to protect the electronic equipment from dust and

moisture.

•

Assure that there is a fuse protection for the infeed power circuit (I

≤ 16 A) and a

nom

disconnecting device (switch, circuit breaker) to isolate the signal converter.

•

Check the nameplate and assure that the power supply meets the voltage and frequency of

the device. You can operate the device in the range of 100...230 VAC and 8 VA with a tolerance

of -15/+10% while 240 VAC +5% is included in the tolerance range (a version with a power

supply of 24 VAC/DC is in preparation). A power supply outside these specifications may

destroy the device!

•

Assure that the protective earth conductor (PE) is longer than the L- and N-conductor.

INFORMATION!

The manufacturer has designed all creepage distances and clearances according to VDE 0110

and IEC 664 for pollution degree 2. The power supply circuits fulfil the overvoltage category III

and the output circuits fulfil the overvoltage category II.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

23

Page 24

4 ELECTRICAL CONNECTIONS

Before you start to connect the power supply cables, note the following drawing with the function

of the terminals:

1 L1...L3 (live)

2 Neutral

3 Protective Earth (PE)

Afterwards connect the power supply cables accordingly:

OPTISENS MAC 100

CAUTION!

The manufacturer strongly recommends to use a slotted screwdriver with a tip of 3.5 x 0.5 mm /

0.14 x 0.02" to push down the lever! Otherwise you could damage the lever.

• De-energise the power supply cables with the help of a disconnecting device (switch, circuit

breaker)!

• Open the converter housing ( refer to

Opening the converter housing

on page 22).

• Remove the cover of the power supply terminal (1) by pressing it down and pulling forwards

at the same time (2 and 3), be careful and do not disrupt the retaining band (it prevents the

cover from getting lost)!

• Use a slotted screwdriver with a tip of 3.5 x 0.5 mm / 0.14 x 0.02" to push down the lever,

connect the wires to the terminals and pull up the levers again (4 and 5).

• Refasten the cover of the power supply terminal, close the converter housing and tighten all

screws of the housing.

24

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 25

OPTISENS MAC 100

ELECTRICAL CONNECTIONS 4

4.8 Description and properties of the outputs and the input

4.8.1 Current output

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

INFORMATION!

For further information refer to the connection diagrams and the technical data table.

• All outputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Output data: measuring results of the sensor inputs A and B inclusive temperature.

• Active mode: output range 0(4)...20 mA, load resistance R

U

int, nom

• Self-monitoring: interruption or load resistance too high in the current output loop.

• Error signalling possible via alarm relays, error indication on LC display.

• Current value error detection can be adjusted.

=15VDC.

≤ 550 Ω at I

L

max

≤ 22 mA,

4.8.2 Relay outputs

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

INFORMATION!

For further information refer to the diagrams on page 28

data table

The device has three electro-mechanical relays that can work as alarm relays or limit switches

(electronic relays are in preparation):

• The relay contacts are electrically isolated from each other and from all other circuits.

• The output stages of the status outputs / limit switches behave like relay contacts.

• Possible conditions: NO (normally open) or NC (normally closed).

• Contact ratings:

- Relays for low voltages: U ≤ 30 VDC, I ≤ 1 A, resistive load (PELV / SELV) or U ≤ 50 VAC,

I ≤ 4 A, resistive load (PELV / SELV)

- Relays for high voltages: U = 100...230 VAC, I ≤ 4 A, max. 1000 VA resistive load

• The contact circuits have to be either PELV / SELV circuits or hazardous voltage circuits.

on page 75

and

on page 29

.

as well as the technical

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

25

Page 26

4 ELECTRICAL CONNECTIONS

4.8.3 Control input (passive)

CAUTION!

Pay attention to the maximum voltage and current values which can be applied to the control

input! Applying power outside the allowed range can destroy or damage the device!

INFORMATION!

The factory default is a disabled control input!

The passive control input can trigger different events in the converter from outside. It is engaged

via applying a voltage of U

properties in detail are the following:

• Passive, not polarity sensitive

• Condition "off": U

• Condition "on": U

• U

• I

• I

ext, max

nom

nom

≤ 32 VDC

=6.5mA with U

=8.2mA with U

off

on

> 8 VDC and disengaged via applying a voltage of U

on

≤ 2.5 VDC with I

≥ 8VDC with I

=24VDC

ext

=32VDC

ext

nom

nom

=0.4mA

= 2.8 mA

OPTISENS MAC 100

<2.5VDC. The

off

For instance the control input can work together with a flow monitor that monitors the sample

flow and gives a signal if the flow drops below a certain threshold. If in this case the control input

has the setting "flow control", it triggers an "out of specification error" (this errors indicates that

the measured value cannot be trusted anymore). For more information refer to

"Out of specification" (S)

on page 69.

Error category

There are other purposes for the usage of the control input. For detailed information refer to the

function C3.5 and especially C3.5.1 in the corresponding function table.

26

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 27

OPTISENS MAC 100

ELECTRICAL CONNECTIONS 4

4.9 Connection diagrams of the outputs and the input

4.9.1 Important notes

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

INFORMATION!

•

All groups are electrically isolated from each other and from all other input and output

circuits.

•

Depending on the version, the inputs/outputs must be connected passively or actively or acc.

to NAMUR EN 60947-5-6 (refer to the sticker in the cover of the terminal compartment for

information about the I/O version and inputs/outputs of your device).

•

Passive operating mode: an external power supply is necessary to operate (activation) the

subsequent devices (U

•

Active operating mode: the signal converter supplies the power for operation (activation) of

the subsequent devices, observe max. operating data.

•

Terminals that are not used must not have any conductive connection to other electrically

conductive parts.

ext

).

4.9.2 Description of electrical symbols

Symbol Description

mA meter, 0...20 mA or 4...20 mA and other, RL is the internal resistance of the

measuring point including the cable resistance

DC voltage source (U

DC voltage source (U

diagrams

Internal DC voltage source

Controlled internal power source in the device

Button, NO contact or similar

), external power supply, any connection polarity

ext

), observe connection polarity according to connection

ext

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

27

Page 28

4 ELECTRICAL CONNECTIONS

4.9.3 Block diagram

OPTISENS MAC 100

1 Power supply (100...230 VAC)

2 Control input (non-polarised), 8...32 VDC

3 Sensor input B, refer to sensor handbook (the terminals P, U and X show an example with a NTC resistor)

4 Sensor input A, refer to sensor handbook (the terminals P, U and X show an example with a Pt100/1000 resistor)

5 Current outputs A and B

6 Current output C, HART (in preparation)

7 Relay outputs R1, R2 and R3

4.9.4 Current output (active)

CAUTION!

To avoid damage or destruction of the device always note the following items:

•

Observe the connection polarity!

•

Note the properties of the current output, further information on page 28

Connection diagram of current output (active)

.

28

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 29

OPTISENS MAC 100

4.9.5 Relay outputs

CAUTION!

To avoid damage or destruction of the device always note the properties of the relay outputs,

further information on page 25

Example: different conditions of a relay output

1 Normal operation: device in operation and no current error message, indicator lamp off, relay contact open.

2 Alarm condition: error message occurs, indicator lamp on, device de-energised or with malfunction, relay contact

closed.

4.9.6 Control input

CAUTION!

To avoid damage or destruction of the device always note the properties of the control input,

further information on page 26

ELECTRICAL CONNECTIONS 4

.

.

1 Signal

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

29

Page 30

4 ELECTRICAL CONNECTIONS

4.10 Electrical connection of the outputs and the input

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

OPTISENS MAC 100

• Open the housing cover ( refer to

• Push the prepared cables through the cable entries and connect the necessary conductors.

• Connect the shield.

• Tighten the screw connection of the cable entry securely.

• Seal all cable entries that are not needed with a plug.

• Close the housing cover.

INFORMATION!

Ensure that the housing gasket is properly fitted, clean and undamaged.

4.10.1 Connecting the current outputs

CAUTION!

Use the correct cable gland, refer to the following drawing and to the section

"device description" in the manual.refer to the device description on page 30

Opening the converter housing

on page 22).

.

30

• Conduct the cables with prefabricated shielding through the correct cable glands (1 and 2).

• Insert the cable into the terminal (3).

• To remove the cable push the lever down with a suitable tool (4) and pull the cable out of the

terminal (5).

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 31

OPTISENS MAC 100

4.10.2 Connecting the relay outputs

DANGER!

To avoid dangerous voltages, the switching voltage for the relay contacts must fulfill one of the

following conditions: it must either originate from the same network as the signal converter

power supply including pre-fuse and separator (see Section 4.6) or come from a SELV or PELV

network. When installing, always comply with the prevailing national and international

regulations and standards.

CAUTION!

If you want to switch inductive loads (even relays or protection coils), you always have to dejam

them! Otherwise there may occur interferences with the measuring signal. Also note the

following items:

•

If you use DC voltage, dejam the relay coil with a free-wheeling diode; refer to the following

table and the following drawing "Interference suppression"!

•

If dejamming is not possible, you have to assure that the relay contact is protected by a RC

protection circuit! Also refer to the following table.

•

If you use potential-free relay outputs, assure that a suitable shut-off device and a pre-fuse is

installed in the feed line on site.

•

When switching inductive loads, the manufacturer recommends a protective circuit to avoid

unnecessarily high contact burn on the relay contact!

ELECTRICAL CONNECTIONS 4

INFORMATION!

In delivery condition, the relay contacts are also suitable for low signal currents (from

approx. 1 mA). Please note that the gold plating burns off during the switching operation when

larger currents are used (from approx. 100 mA). Afterwards, the relays can no longer reliably

switch small currents!

AC voltage: required capacitors and resistances for dejamming

Current up to Capacitor Resistor

60 mA 10 nF / 260 V 390 Ω / 2 W

70 mA 47 nF / 260 V 22 Ω / 2 W

150 mA 100 nF / 260 V 47 Ω / 2 W

1.0 A 220 nF / 260 V 47 Ω / 2 W

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

31

Page 32

4 ELECTRICAL CONNECTIONS

Interference suppression (A = AC, B = DC)

1 Resistor, R = 47...390 Ω, see table before

2 Capacitor, C = 10...220 nF, see table before (e.g. Siemens MKC B 81 921)

3 Relay coil

4 Free-wheeling diode

5 Relay coil

Required cable properties

• Maximum wire cross section: 1.5 mm2/ 0.06 square inch

• Minimum stripping length for wires: 8 mm / 0.31"

Note the following procedure, remove the cover and connect the cables accordingly:

OPTISENS MAC 100

Step 1: removing the cover

CAUTION!

The screw under the cover (5) is not to be used as a cable connection. Do not loosen or remove

the cover or the screw!

• Start to remove the internal cover of the relay outputs (1) by pressing it down (2).

• Pull the cover forward (3), then upward out of the clip and remove it (2 and 4).

• Remove the cover of the earth terminal by pulling it upward 5.

i You see the 10-pin terminal block which is fitted with a connected bridge.

32

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 33

OPTISENS MAC 100

Step 2: connecting the cables

• Connect the cables to the single relay terminals (1) as described in the previous drawing (2),

note the required cable properties!

• If you want to release a cable from the relay terminals, first unlock the locking device (3) with

a suitable tool and pull out the cable (4).

ELECTRICAL CONNECTIONS 4

INFORMATION!

If a switching voltage is applied to connection "C" (6 in the previous drawing), relay contacts R1,

R2 and R3 are supplied in parallel with the help of the link plug (5). This allows the voltage

switched from the relays to be passed on. You can remove the bridge if this supply is not needed.

• After you have connected all cables, refasten the cover of the relay outputs.

• Close the converter housing and tighten all screws of the housing.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

33

Page 34

5 START-UP

5.1 Switching on the power

DANGER!

To avoid fatal injuries as well as destruction or damage of the device assure a correct installation

before switching on the power. This includes:

•

The device is mechanically safe, mounting and power connection comply with the regulations.

•

The electrical terminal compartments must be secured, i.e. the housing has to be closed and

the screws have to be tightened.

•

The electrical operating data of the power supply comply with the requirements of the device.

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

INFORMATION!

The manufacturer delivers the device preconfigured and ready for operation with the sensor

specified in the customer's order. Though due to the physics of the measurement, the operator

has to perform an onsite calibration or an adjustment to the relevant sensor and to the

environmental conditions at the initial start-up. For more details refer to the manual of the

relevant sensor!

OPTISENS MAC 100

• Switch on the power with the help of a disconnecting device (switch, circuit breaker).

i The device performs a self test; afterwards it begins to measure immediately if a sensor is

connected and the display shows the current value(s).

Example: current value (1 channel device)

The previous drawing shows the measured value of sensor input A in the upper line and the

temperature reading in the lower line.

34

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 35

OPTISENS MAC 100

INFORMATION!

Note that the display can only show a temperature reading if a temperature sensor is attached! If

this is not the case, the information "-10

Example: current value (2 channel device)

°

C / +14°F" appears in the last line.

START-UP 5

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

35

Page 36

6 OPERATION

6.1 Operating elements

The operation elements consist of the four operation keys below the display. In the texts of this

documentation each operation key has a specific symbol:

Operating key Symbol in text

OPTISENS MAC 100

The function of a key depends on the mode of the device and on the menu level:

Key Measuring mode Menu mode

Main menu

level

> Switch from measuring mode to

menu mode; press key for

2.5 seconds (display shows "keep

key pressed" and countdown) and

release it after further

2.5 seconds (display shows

"release key now" and

countdown)

^ Reset of the display controller 1 Return to

↑ or ↓ Switch between measuring pages Select menu,

Esc: > + ↑ No function No function Return to main

1 This function allows checks with respect to custody transfer; it can be used in few situations, e.g. if the display is dis-

turbed.

Access to

displayed menu,

then 1st

submenu is

displayed

measuring mode

(prompt appears

whether the data

should be saved)

moving up or

down

Sub-menu or

function level

Access to

displayed submenu or function

Return to next

higher level or

sublevel, data

are saved

Select sub-menu

or function,

moving up or

down

menu level, data

not saved

Parameter and

data level

Numerical

values: move

cursor one

position to the

right

Return to submenu or

function, data

are saved

Change

parameter/data

marked by the

cursor, move the

decimal point

Return to next

higher level, data

not saved

36

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 37

OPTISENS MAC 100

INFORMATION!

•

Always push the keys at right angles to the front. Touching them from the side can cause

incorrect operation!

•

Each time you press a key, an "X" flashes in the upper right corner of the display.

•

After 5 minutes of inactivity, there is an automatic return to the measuring mode. In this case

the device does not save previously changed data!

6.2 Measuring mode

The measuring mode consists of four different measuring pages. You can scroll through them

and choose the desired one by pressing the keys ↑ or ↓.

INFORMATION!

•

The following sections show the measuring pages in the default status. You can change their

appearance in the menu mode.

•

After starting-up the device always shows the first measuring page. If you choose another

measuring page with the help of ↑ or ↓, the display shows this page continuously.

•

The converter is not able to detect the exhaustion of the connected electrodes!

OPERATION 6

6.2.1 First measuring page

After switching on the power, the display always shows the first measuring page. In the default

status there is no difference between the first measuring page of the one channel version and

the two channel version. Right beside all measuring results you see the corresponding unit at

the end of the line. Only if there is no unit available it is left out (this is only the case with the

diagnosis values).

INFORMATION!

Diagnosis values are all values which do not belong to the measured values of the sensor

inputs A and B (e.g. error messages). Also note the following items:

•

If there is enough space and the type of measuring result is not clear when looking at the

figure(s) and unit, there is also a short description (in the following named "label") at the

beginning of the lines.

•

The labels can appear on the first measuring page as well on the second measuring page.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

37

Page 38

6 OPERATION

Possible labels

Sens A: Measured value of process input A

Sens B: Measured value of process input B

off Indicating that a value is currently not available

lin: Linearity value

FB1: ... FB8: Different function blocks of Profibus (in

Al1: ... Al3:, Int1 ... Int2, PID Different functions for Foundation Fieldbus (in

IIn A or IIn B: Source of the value is the sensor connected to the

The following drawing shows an example of the first measuring page in the default setting:

OPTISENS MAC 100

Label Description

preparation)

preparation)

current input A or B

Pressing ↑ will bring you to the second measuring page. Pressing ↓ will bring you to the trend

diagram.

38

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 39

OPTISENS MAC 100

6.2.2 Second measuring page

The second measuring page is the only one with a different appearance in the default status

depending on the device version:

Version with 1 channel

INFORMATION!

The bargraph in the middle line of the previous display shows the complete measuring range as

percent designation (on the left side the minimum, on the right side the maximum). The bar

indicates the current status.

OPERATION 6

Version with 2 channels

Pressing ↑ will bring you to the status page. Pressing ↓ will bring you to the first measuring

page.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

39

Page 40

6 OPERATION

6.2.3 Status page

The software groups all status messages in a predefined order of importance. The following

drawing shows an example of a display with different status messages:

In front of each message there is a letter indicating the category of a message. Furthermore

there is a message explaining the error category in front of each group of messages (in the

previous drawing this is the message "application error"). The following table lists all categories

and represents their defined order of importance.

OPTISENS MAC 100

Letter Category Consequence Example

FFFF Error in device A measurement is not possible. Note:

F Application

error

S Out of

specification

C Check in

progress

I Information Informational character, no direct

the "F"

"F" is bold to make a difference from

"F""F"

the normal "F" for all application errors!

A measurement is not possible! Over range, value constant

A measurement is possible but with

uncertain accuracy!

A test function is active, the displayed

value is not the true value!

impact on the measuring results.

One CPU is not present.

because of limitation.

Low flow (i.e. there is not

enough flow on the sensor tip

to produce a stable signal).

Manual hold function is active

(i.e. all outputs are frozen).^^

Power fail

Also regard the following characteristics of the status messages:

• Each status message must not exceed one line; a single screen can contain up to four

messages.

• If there are more messages present, the other messages appear on separate and alternating

screens.

• The total number of displayed messages is limited to 16; the current software contains more

than 70 status messages, the total number of completely different messages is 104 by

principle.

• You can reset all error messages with the help of the submenu "A5 reset errors" within the

main menu "A quick setup".

40

For further information about the status messages refer to

information

on page 66. Pressing ↑ will bring you to the trend diagram. Pressing ↓ will bring you

to the second measuring page.

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Status messages and diagnostic

Page 41

OPTISENS MAC 100

6.2.4 Trend diagram

This screen shows the first value of the first measuring page as a trend plot. You can select the

limits and values in the corresponding menu (5.9.4.3, C5.3.1 meas. page / C5.4 2. meas. page).

The scale of the Y-axis is in percent units related to the limits selected for first value of the first

measuring page. On the left side of the display you always see the actual upper and lower values

of the scale. The range of the Y-axis can be fixed or automatic (see function table of C5.5).

The X-axis represents the time. You can select the range which appears in the lower right corner

of the screen. Every dot on the screen is an average over the corresponding time. The following

drawing is an example of the trend diagram:

OPERATION 6

INFORMATION!

Be aware that just the curve is stored, you have no further access to the values. All values

beyond the time limit are deleted. Furthermore the trend diagram is deleted after any warm

start (e.g. by changing a parameter).

Pressing ↑ will bring you to the first measuring page. Pressing ↓ will bring you to the status

page.

6.3 Menu mode

The menu mode consists of four main menus with a couple of different sub-levels. Altogether

there are the following levels:

• Main menu level

• First and second sub-menu level

• Parameter level

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

41

Page 42

6 OPERATION

6.3.1 Navigating through the menus

To switch from the measuring mode to the menu mode you have to execute the following steps:

• Press > for at least 2.5 seconds (meanwhile the display shows the text "keep key pressed" and

a time counting back).

• After 2.5 seconds release the pressed key (you have to do this within the next 2.5 seconds

during which the display shows the text "release key now" and a time counting back).

i You are in the main menu level of the menu mode. The display always looks as follows:

Display in main menu level

OPTISENS MAC 100

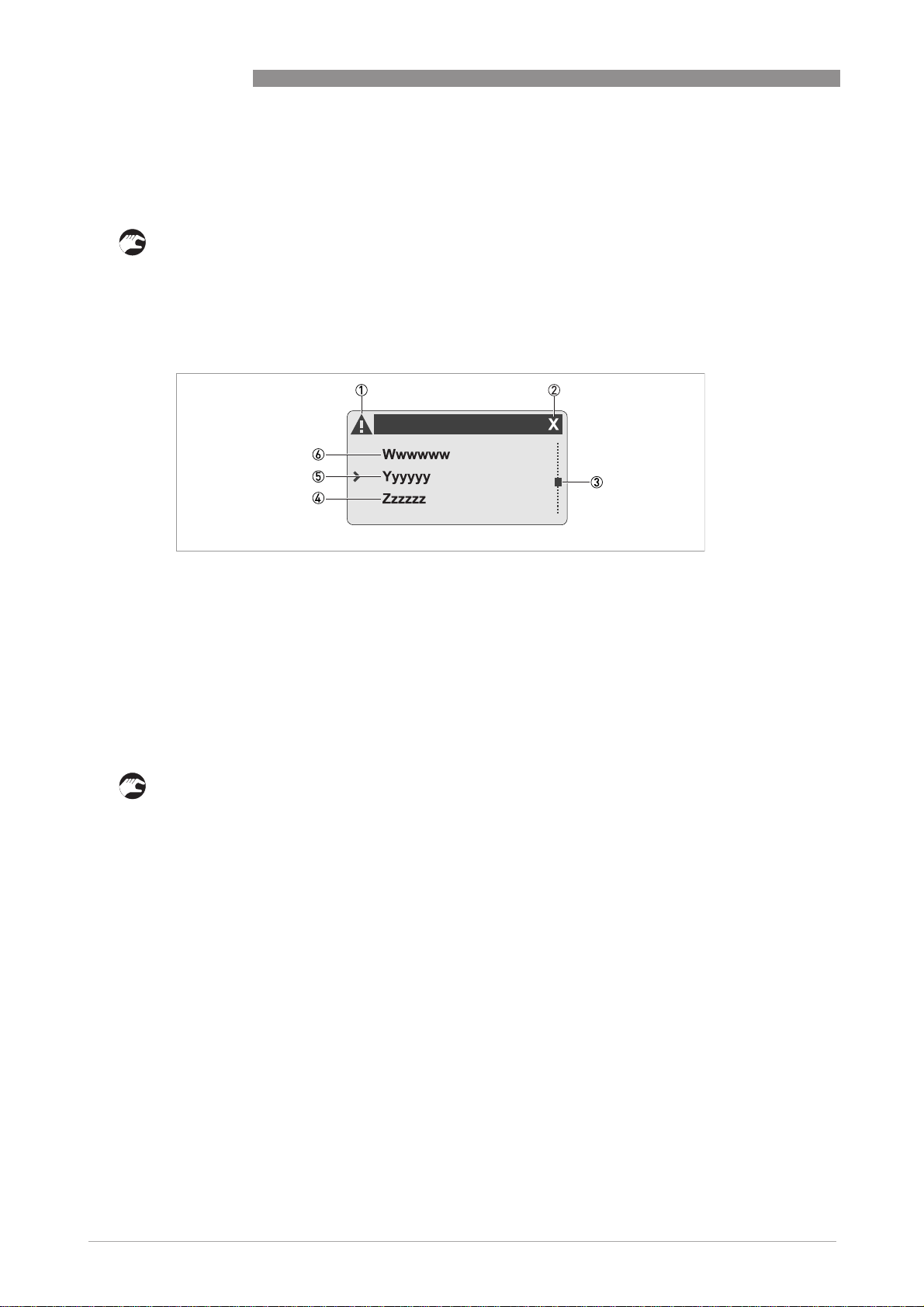

Figure 6-1:

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Menu code of selected menu item (see table of menu structure or function tables)

3 Indicates position within the current item list

4 Next menu item, reachable by pressing ↑ (if "- - -" appears in this line, this signalises the end of the list)

5 Selected menu item in bold characters

6 Previous menu item, reachable by pressing ↓ (if "- - -" appears in this line, this signalises the beginning of the list)

The main menu mode consists of the main menus "quick setup", "test", "setup" and "service".

You can either leave the main menu level and return to the measuring mode or choose and enter

a main menu:

• Press ^ to return to the measuring mode (in this case a prompt appears and asks if you want

to save the changed data; choose "Yes" or "No" with the help of ↓ or ↑ and confirm by

pressing ^).

• If you do not want to leave the main menu level, press > to enter the first main menu

("quick setup") or choose another main menu with the help of ↑ or ↓ and enter it by

pressing >.

i You are in the submenu level. The display always looks like the drawing on the following

page.

42

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 43

OPTISENS MAC 100

Display in submenu level

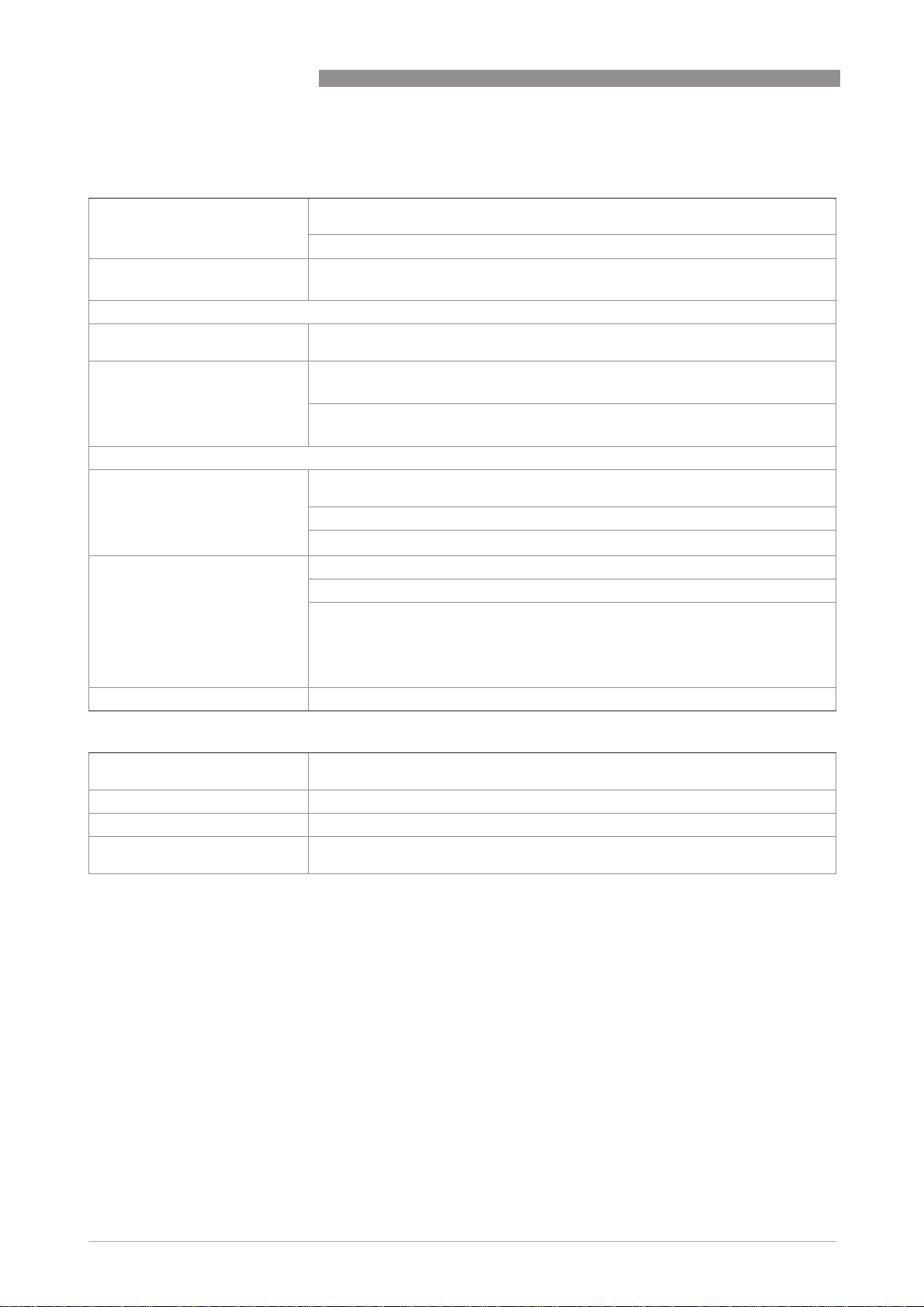

Figure 6-2:

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Superior main menu

3 Menu code of selected menu item (see table of menu structure or function tables); up to two figures can appear right

beside the character indicating the main menu (one if you are on the first submenu level and two on the second submenu level)

4 Indicates position within the current item list

5 Previous menu item, reachable by pressing ↓ (if "- - -" appears in this line, this signalises the beginning of the list)

6 Currently setting of the chosen menu item in bold character (here 7)

7 Selected menu item, in bold characters

8 Next menu item, reachable by pressing ↑ (if "- - -" appears in this line, this signalises the end of the list)

OPERATION 6

The submenu level consists of the first and second submenu level. The principle of choosing a

menu item is always the same:

• Press > to enter the first menu item or choose another menu item with the help of ↑ or ↓ and

enter it by pressing >.

i You navigate through the tree structure of the submenu level, finally you always reach the

parameter or data level.

• If you want to return to the main menu level without saving the input, press > and ↑ at the

same time.

• If you want to return to the main menu level and save your input, press ^ one or more times

depending on the level you are (pressing ^ results in moving one level upwards until you

reach the main menu level).

INFORMATION!

Like the lowest menu level (i.e. the parameter or data level) some submenus also offer the

possibility to make adjustments. The procedure is similar to the procedure on the parameter

level, see next page.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

43

Page 44

6 OPERATION

On the parameter level you see a list with one or more parameters or data. You can scroll

through this list using ↑ or ↓:

INFORMATION!

In this list all parameters or data which have been changed (i.e. they deviate from the default

setting) have a hook at the right end of their line(see position number 4 in the following

drawing).

Display with list of parameters or data

Figure 6-3:

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Superior submenu or subsequent submenu

3 Menu code of selected parameter (see table of menu structure or function tables)

4 Denotes the change of a parameter (this marking allows to simply and quickly identify all data which differ from the

default setting when browsing through the list)

5 Instead of the check mark there can also appear a lock symbol at this position; it indicates a parameter that cannot be

changed, because of the parameter lock on the front.

6 Indicates position within the current item list

7 Previous menu item, reachable by pressing ↓ (if "- - -" appears in this line, this signalises the beginning of the list)

8 Currently setting of the chosen menu item, also in bold character (here 7)

9 Selected menu item, in bold characters

10 Next menu item, reachable by pressing ↑ (if "- - -" appears in this line, this signalises the end of the list)

OPTISENS MAC 100

44

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 45

OPTISENS MAC 100

On the parameter or data level you have the possibility to change the decimal point, numbers,

units or settings. Before that you have to choose the desired parameter or data and open to edit

it:

• Press > to open and edit the first list item or choose another item with the help of ↑ or ↓ and

press >.

i You are in the parameter edit mode now. All changeable values are highlighted and shown

reverse (if nothing is shown reverse, you are in the read-only view and you cannot change

the setting).

• Use ↑ or ↓ to change the highlighted area; if there are numerical values or a decimal point to

be changed, you can move the cursor with > to the desired position and change its value with

the help of ↑ or ↓.

• If you want to return to the parameter or data list and save your input, press ^; afterward you

can press ^ one or more times to return to the main menu.

• If you want to return to the next higher level without saving the input, press > and ↑ to the

same time.

Display with parameter or data ready to edit

OPERATION 6

Figure 6-4:

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Superior submenu or subsequent submenu

3 Menu code of selected parameter (see table of menu structure or function tables)

4 Symbol denotes that there is a factory setting

5 Symbol denotes that there is a permissible value range

6 Permissible value range (for numerical values)

7 Currently set value, unit or function that you can change (always appears with highlighted background)

8 Current selected parameter

9 Factory setting of parameter (non-alterable)

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

45

Page 46

6 OPERATION

Some parameters allow to select and move the decimal point. If you do so and the point reaches

the right (left) end of the related number, further pressing the key ↑ (↓) changes the format to

exponential. In the following example the exponential syntax means 54000 x 10

suppressed to save space. The exponent is increased (decreased) by a factor of three every time

you press the key ↑ (↓). The change of the exponent to zero resets the exponential syntax to the

normal presentation.

Decimal point and exponential format in the parameter edit mode

OPTISENS MAC 100

3

, where the 10 is

6.3.2 Menu "quick setup"

The menu structure consists of four main menus. The first one is the main menu "quick setup",

which groups the most important functions of the other main menus. In this way you have the

possibility to configure the signal converter quickly.

46

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 47

OPTISENS MAC 100

6.4 Menu mode structure

INFORMATION!

The following table just presents an overview. When programming the device, always consult the

function tables additionally as they contain further information!

OPERATION 6

Measuring

mode

3 or 4

pages,

scrolling

with ↓ or ↑

Main menu Submenu Parameter

>2.5s^A quick setup

>2.5s^B test

A quick setup >^A1 language >^For further

A quick setupA quick setup

A2 Tag

A3 manual hold

A4 set clock

A5 reset errors

A6 analog

outputs

A9...A11: calibration menus for process input A;

existence of the single sub-menus depends on the

hardware setting and the used sensor (e.g. if you use a

pH sensor then only the menu A8 with the name "pH

cal." appears); refer to sensor manual for further

information.

A12...A16: calibration sub-menus for process input B,

existence also depending on the hardware setting and

the used sensor.

↓↑ ↓↑ ↓↑ ↓↑

B test >^B1 Simulation

B testB test

↓↑ ↓↑ ↓↑ ↓↑

Process Input A>^

B2 Simulation

Process Input B

>^A6.1 measurement

A6.2 unit

A6.3 range

A6.4 time constant

B1.1...B1.7: simulation menus

for process input A; existence of

the single sub-menus depends

on the hardware setting and the

used sensor, refer to sensor

manual for further information.

B2.1...B2.7: simulation menus

for process input B; existence of

the single sub-menus depends

on the hardware setting and the

used sensor, refer to sensor

manual for further information.

information

see function

tables.

>^For further

information

see function

tables.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

47

Page 48

6 OPERATION

OPTISENS MAC 100

Measuring

mode

3 or 4

pages,

scrolling

with ↓ or ↑

Main menu Submenu Parameter

>2.5s^B test

>2.5s^C setup

B test >^B3 simulation IO >^B3.1 - / current output A >^For further

B testB test

B3.2 - / current output B

B3.3 - / current output C

B3.4 - / control input D

B3.5 - / status output R1 or limit

switch R1

B3.6 - / status output R2 or limit

switch R2

B3.7 - / status output R3 or limit

switch R3

B4 actual values B4.1...B4.8: menus which show

B5 logbooks B5.1 status log

B6 information B6.1 C number

↓↑ ↓↑ ↓↑ ↓↑

C setup >^C1 process input A>^C1.1...C1.18: menus for the

C setupC setup

C2 process input

B

↓↑ ↓↑ ↓↑ ↓↑

the corresponding actual

reading; existence of the single

sub-menus depends on the

hardware setting and the used

sensor; refer to sensor manual

for further information.

B5.2 calibration log

B6.2 process input A

B6.3 process input B

B6.4 SW.REV. MS

B6.5 SW.REV. UIS

B6 Electronic Revision ER

setup of the corresponding

process input; existence of the

single sub-menus depends on

the hardware setting and the

used sensor; refer to sensor

manual for further information.

C2.1...C2.17: menus for the

setup of the corresponding

process input; existence of the

single sub-menus depends on

the hardware setting and the

used sensor; refer to sensor

manual for further information.

information

see function

tables.

>

^

48

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 49

OPTISENS MAC 100

OPERATION 6

Measuring

mode

3 or 4

pages,

scrolling

with ↓ or ↑

Main menu Submenu Parameter

>2.5s^C setup

D service:

D service: This menu is password protected and contains functions to be used by service personnel only.

D service:D service:

C setup >^C3 I/O >^C3.1 hardware >^For further

C setupC setup

C3.2 current output A

C3.3 current output B

C3.4 current output C

C3.5 control input D

C3.6 status output R1 or limit

switch R1

C3.7 status output R2 or limit

switch R2

C3.8 status output R3 or limit

switch R3

C4 I/O HART (in preparation)

C5 device >^C5.1 device info

C5.2 display

C5.3 1.meas.page

C5.4 2.meas.page

C5.5 graphic page

C5.6 special functions

C5.7 units

↓↑ ↓↑ ↓↑ ↓↑

information

see function

tables.

www.krohne.com04/2011 - MA OPTISENS MAC 100 R01 en

49

Page 50

6 OPERATION

OPTISENS MAC 100

6.5 Function tables

6.5.1 Menu A, quick setup

INFORMATION!

Note that the appearance of some sub-menus depends on the hardware setting and the used

sensor(s). E.g. if you use a pH sensor then only the menu A8 with the name "process input A

pH calibration" appears.

A1, language

Language selection (depends on the region for which the converter has been ordered). Available languages: German,

English.

A2, tag

Measuring point identifier (Tag no.), helps to identify the device in a plant, appears in the LC display header in the

normal measuring mode (up to 8 digits).

A3, manual hold

Manual shift into the simulation mode for maintenance; device aborts measuring and holds all analog measurements

from the process inputs. Options: On (enter the simulation mode) / Off (enter the normal measuring mode again.)

A4, set clock

Manual setting of date and time.

A5, reset errors

This functions allows to reset all errors that are not reset automatically (e.g. power fail or counter overflow). You can

answer the question "reset?" with the following options: no (exit without reset) / yes (reset and exit the function).

50

www.krohne.com 04/2011 - MA OPTISENS MAC 100 R01 en

Page 51

OPTISENS MAC 100

OPERATION 6

A6, analog outputs

Level Designation / function Settings / descriptions

Depending on the hardware setting this menu is applicable to the current outputs A/B/C, the limit switches R1/R2/R3

and the first line of the first measuring page.

A6.1

A6.1 measurement Value used for driving the current output C. You can answer the question

A6.1A6.1

A6.2

A6.2 unit Unit for the current output range, the class of the unit depends on the

A6.2A6.2

A6.3

A6.3 range Range of the main current output C of the device. You can answer the

A6.3A6.3

"use all outputs?" with the following options: no (exits the function using the

value only of current output C) / yes (exits the function copying the value to

all analog outputs).

measurement used at this current output (for further information refer to

function C5.7 "Units").

question "use at all output?" with the following options: no (exits the function