Komatsu PC800-8, PC850-8 Service Manual

CONTENTS

Specifications...................................................................................................................... |

1 |

||

Precautions for Field Assembly .......................................................................................... |

2 |

||

Assembling Procedures, Applicable Equipment and Schedule .......................................... |

3 |

||

Kit Layout Diagram ............................................................................................................. |

4 |

||

Transportation..................................................................................................................... |

5 |

||

List of Tools for Field Assembling....................................................................................... |

11 |

||

Tightening Torque............................................................................................................... |

12 |

||

Coating Materials................................................................................................................ |

16 |

||

A. Assembly of Base Machine ............................................................................................ |

19 |

||

A- 1. |

Installation of Left and Right Track Frames ........................................................... |

20 |

|

A- |

2. |

Installation of Travel Pipe ...................................................................................... |

24 |

A- 3. |

Installation of Top Guard ....................................................................................... |

27 |

|

A- |

4. |

Installation of Radiator Cover ................................................................................ |

28 |

A- |

5. |

Installation of Rearview Mirror ............................................................................... |

29 |

A- |

6. |

Installation of Left Side Step .................................................................................. |

33 |

A- |

7. |

Installation of Handrail ........................................................................................... |

34 |

A- |

8. |

Installation of Handrail (With top guard) ................................................................ |

35 |

A- |

9. |

Installation of Muffler Tail Tube.............................................................................. |

37 |

A-10. Sticking Sheet to Counterweight ........................................................................... |

38 |

||

A-11. Installation of Counterweight ................................................................................. |

39 |

||

A-12. Installation of ORBCOMM Antenna (if equipped).................................................. |

40 |

||

A-13. Installation of Step Light ........................................................................................ |

41 |

||

A-14. Air Bleeding of Travel Motor .................................................................................. |

43 |

||

A-15. Installation of Travel Piping Cover......................................................................... |

44 |

||

A-16. Testing Track Shoe Tension.................................................................................. |

46 |

||

A-17. Check Fuel, Coolant and Oil Levels ...................................................................... |

49 |

||

A-18. Parts to be Touched up after Field Assembly........................................................ |

52 |

||

B. Assembling of Work Equipment of Backhoe .................................................................. |

53 |

||

B- 1. |

Assembly of Arm Cylinder ..................................................................................... |

54 |

|

B- 2. |

Connection of Arm Cylinder Hoses........................................................................ |

55 |

|

B- 3. |

Installation of Boom Cylinder Foot......................................................................... |

57 |

|

B- 4. |

Relieving Remaining Pressure from Hydraulic Circuit ........................................... |

58 |

|

B- 5. |

Installation of Boom Cylinder Hoses...................................................................... |

59 |

|

B- 6. |

Assembly of Boom Assembly ................................................................................ |

60 |

|

B- 7. |

Hose Connection of Arm and Bucket Circuits........................................................ |

61 |

|

B- 8. |

Installation of Quick Return Hose .......................................................................... |

62 |

|

B- 9. |

Installation of Boom Cylinder ................................................................................. |

63 |

|

B-10. Installation of Arm Assembly ................................................................................. |

64 |

||

B-11. Installation of Hose between Boom and Bucket Cylinder...................................... |

66 |

||

B-12. Installation of Bucket Assembly............................................................................. |

67 |

||

B-13. Lubrication Piping to Work Equipment .................................................................. |

68 |

||

B-14. Air Bleeding from Cylinder..................................................................................... |

69 |

||

B-15. Wiring of Work Equipment..................................................................................... |

70 |

||

B-16. Greasing after Assembling Work Equipment......................................................... |

71 |

||

M. Procedure for Inspection and Maintenance after Completion of Assembly ................... |

73 |

||

M- 1. Inspection of Oil Level in Hydraulic Tank and Refill .............................................. |

74 |

||

M- 2. Replacement of Return Filter (Standard Filter to Flushing Filter).......................... |

76 |

||

M- 3. Flushing of Hydraulic Circuit ................................................................................. |

79 |

||

M- 4. Error Code............................................................................................................. |

81 |

||

C. Assembling of Work Equipment of Loading Shovel..................................................... |

83 |

C- 1. Releasing residual pressure in hydraulic circuit .................................................. |

84 |

C- 2. Pulling out boom foot pin and boom cylinder foot pin ......................................... |

85 |

C- 3. Installation of boom and arm assembly............................................................... |

86 |

C- 4. Installation of flushing piping between chassis and boom .................................. |

87 |

C- 5. Installation of flushing piping for boom cylinder and arm cylinder....................... |

88 |

C- 6. Installation of flushing piping for bucket cylinder................................................. |

89 |

C- 7. Installation of flushing piping for bottom dump cylinder ...................................... |

90 |

C- 8. Installation of boom cylinder................................................................................ |

92 |

C- 9. Installation of boom cylinder foot......................................................................... |

93 |

C-10. Installation of boom cylinder hoses..................................................................... |

94 |

C-11. Installation of boom cylinder rod pin ................................................................... |

95 |

C-12. Installation of arm cylinder hoses........................................................................ |

96 |

C-13. Installation of bucket cylinder.............................................................................. |

97 |

C-14. Installation of bucket cylinder hose ..................................................................... |

98 |

C-15. Installation of connecting hoses between chassis and boom top ....................... |

99 |

C-16. Installation of bottom dump cylinder hoses......................................................... |

100 |

C-17. Installation of bucket assembly ........................................................................... |

101 |

C-18. Installation of working lamps............................................................................... |

103 |

C-19. Installation of work equipment grease piping...................................................... |

104 |

C-20. Greasing after assembling of work equipment.................................................... |

105 |

C-21. Bleeding air from work equipment circuit ............................................................ |

106 |

C-22. Checking oil level in hydraulic tank and adding oil.............................................. |

107 |

C-23. Replacement of Return Filter (Standard Filter to Flushing Filter) ....................... |

108 |

C-24. Flushing of Hydraulic Circuit ............................................................................... |

111 |

Field Assembly Inspection Report (Backhoe) |

|

Field Assembly Inspection Report (Loading Shovel) |

|

SPECIFICATIONS

Machine model |

PC800-8 |

PC800LC-8 |

PC800SE-8 |

PC850-8 |

PC850SE-8 |

||

|

|

|

|

|

|

|

|

Weight of machine |

kg |

75,000 |

77,200 |

|

76,000 |

79,500 |

79,100 |

|

|

|

|

|

|

|

|

Bucket capacity |

m3 |

3.1 |

3.1 |

|

4.0 |

3.4 |

4.3 |

Engine model |

– |

|

|

|

SAA6D140E-5 |

|

|

|

|

|

|

|

|

||

Flywheel horsepower |

kW/rpm {HP/rpm} |

|

|

363/1,800 {486/1,800} |

|

||

|

|

|

|

|

|

|

|

Min. ground clearance |

mm |

|

|

840 |

|

|

|

|

|

|

|

|

|

|

|

Travel speed (Low/High) |

km/h |

|

|

2.8/4.2 |

|

|

|

|

|

|

|

|

|

|

|

Swing speed |

rpm |

|

|

6.8 |

|

|

|

|

|

|

|

|

|

|

|

PC800-8

aThe figures in ( ) show the value when the track width is reduced.

PC850-8

aThe figures in ( ) show the value when the track width is reduced.

1

PRECAUTIONS FOR FIELD ASSEMBLY

1.Selection of workplace

1)When selecting a workplace, consider the following items so that you can load and unload the machine.

•Width

•Hardness

•Flatness

•Access road, place for turn

2)Do not work in a place where dust, rainwater, etc. may enter the hydraulic circuit during assembling work.

3)Do not assemble while a strong wind is blowing or it is raining.

2.Preparation and check of slings and tools

1)Check each sling and tool thoroughly. When using wood blocks, etc., check that their inside is not rotten or broken.

3.Check of actual work

1)Apply the parking brakes of the trailer and crane truck securely and put chocks under their wheels.

2)Before starting the work lower the temperature and pressure of the engine oil, hydraulic oil, cooling water, etc.

3)When starting the engine, make an arranged sign such as sounding of the horn and check that the work equipment control lever and travel lever are in neutral and the fuel control dial (or fuel control lever) is at the low idling position.

4)When using the crane, balance the load.

5)Allow only the persons concerned into the workplace.

4.Before starting the work, read this manual thoroughly and keep the precautions in your mind.

The numbers in circles in the illustrations correspond to the numbers in ( ) in the text. (For example q (1))

5.The supervisor shall write down the precautions for each work process and explain them to the workers.

6.Hold a meeting every morning to check today's work plan and safe work.

2

3

Days

Assembly unit

Crane

Air compressor

Worker

Base machine

q Left track frame w Right track frame e Axle assembly

(Two)

45t 45t

0.49 -- 0.69 MPa (5 -- 7 kg/cm2)

15 m3/min

Leader + 3 mechanics

Start of assembling

· Meeting with all workers

Backhoe

|

|

Loading shovel- |

|

|

type excavator |

r Upper structure |

t Counterweight |

|

y Platform group |

|

|

|

|

|

|

· Inspection of oil |

u Assembling of work |

|

level and coolant level |

equipment |

35t

·Inspection of oil level and coolant level

·Air bleeding from work equipment cylinder

·Flushing of hydraulic circuit

·Adjustment of track tension

·Performance test

Divisions 4 |

AND EQUIPMENT APPLICABLE |

PROCEDURES, ASSEMBLING |

|

SCHEDULE |

|

Completion of Installation of unit assembly to body |

Completion of body |

· Completion of general |

|

assembling |

assembling |

||

|

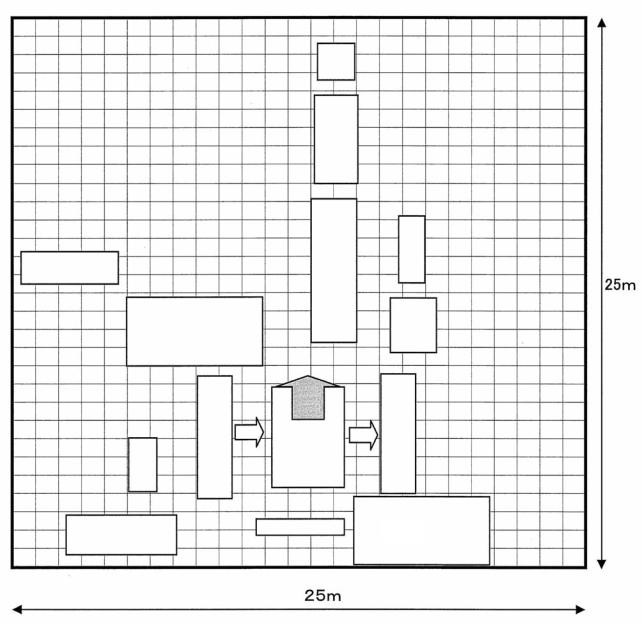

KIT LAYOUT DIAGRAM

•The dimensions given below are the minimum dimensions needed.

•The kit dimensions in the diagram are outline dimensions.

•When selecting a place, see precautions for “FIELD ASSEMBLING”.

Tools, facility

45t crane

Left deck |

Crawler frame |

Motor cover · handrails

Bucket |

|

Arm link |

|

|

cylinder |

Boom |

Arm |

|

|

|

Boom |

|

cylinder |

Foreword |

|

|

frame |

Revolving |

Crawler |

|

|

frame |

|

Counterweight |

45t crane |

|

4

TRANSPORTATION

Packing Style for Transportation

These machines can be divided into three or four kits for transportation. Please ask us or our service shop for transportation.

t 4-kit Transportation

t Packing Style of Each Kit (Sizes in drawing are given in millimeters.)

•Upper structure (single piece of cab)

|

a |

Cab convex portion (air intake for air conditioner) |

3,219 |

|

|

|

|

|

|

Full width |

b |

Door hinge |

3,204 |

|

|

|

|

||

c |

Lock used when the door is opened |

3,262 |

||

(mm) |

||||

|

|

|

||

|

d |

Stopper used when the door is opened |

3,287 |

|

|

|

|

|

|

|

e |

Handrail |

3,220 |

|

|

|

|

|

5

•Upper structure without head guard

Unit: mm

|

Equipped |

|

Not equipped |

||

|

with cab |

|

with cab |

||

Overall height |

H1: 2,840 |

|

H2: 2,840 |

||

(mm) |

|

||||

|

|

|

|

|

|

|

a |

|

3,204 |

|

|

Overall width |

b |

|

3,220 |

|

|

c |

|

3,262 |

*3,195 |

||

(mm) |

|

||||

d |

|

3,219 |

|

|

|

|

|

|

|

||

|

e |

|

3,287 |

|

|

Weight (kg) |

|

25,620 |

25,080 |

||

* Revolving frame

• Upper structure with head guard

Unit: mm |

|

|

|

|

|

|

|

|

|

|

|

Equipped |

|

Not equipped |

|

||

|

|

|

with cab |

|

with cab |

|

||

|

Overall height |

|

H1: 2,910 |

|

H2: 2,840 |

|

||

|

(mm) |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

3,204 |

|

|

|

|

Overall width |

|

b |

|

3,220 |

|

|

|

|

|

c |

|

3,262 |

*3,195 |

|

||

|

(mm) |

|

|

|

||||

|

|

d |

|

3,219 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

e |

|

3,287 |

|

|

|

|

Weight (kg) |

|

|

25,770 |

25,180 |

|

||

Fix the upper structure on the truck by means of chain block. |

* Revolving frame |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Undercarriage

Unit: mm

Model |

PC800-8 |

PC850-8 |

PC800LC-8 |

|

PC800SE-8 |

PC850SE-8 |

|||

|

|

|

|

|

Quantity |

2 |

2 |

2 |

|

|

|

|

|

|

Weight (kg) |

21,500 |

22,000 |

23,600 |

|

(10,750×2) |

(11,000×2) |

(11,800×2) |

||

|

||||

|

|

|

|

6

•Work equipment

(1) Boom

|

|

|

|

|

|

|

|

Model |

PC800-8 |

PC800SE-8 |

PC850-8 |

PC850SE-8 |

|

|

PC800LC-8 |

|

||||

|

A (mm) |

8,505 |

7,405 |

8,345 |

7,405 |

|

|

|

|

|

|

|

|

|

B (mm) |

2,705 |

2,560 |

2,695 |

2,560 |

|

|

|

|

|

|

|

|

|

C (mm) |

4,387 |

4,104 |

4,295 |

4,104 |

|

|

|

|

|

|

|

|

|

D (mm) |

1,218 |

1,098 |

1,210 |

1,098 |

|

|

|

|

|

|

|

|

|

Overall |

1,500 |

1,500 |

1,500 |

1,500 |

|

|

width (mm) |

|

||||

|

|

|

|

|

|

|

|

Weight |

7,510 |

6,950 |

7,770 |

6,950 |

|

|

(kg) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2) Arm

|

|

|

|

|

|

|

|

Model |

PC800-8 |

PC800SE-8 |

PC850-8 |

PC850SE-8 |

|

|

PC800LC-8 |

|

||||

|

A (mm) |

5,105 |

4,075 |

4,800 |

4,075 |

|

|

|

|

|

|

|

|

|

B (mm) |

1,324 |

1,696 |

1,410 |

1,696 |

|

|

|

|

|

|

|

|

|

C (mm) |

2,459 |

2,237 |

2,478 |

2,237 |

|

|

|

|

|

|

|

|

|

D (mm) |

577 |

709 |

648 |

709 |

|

|

|

|

|

|

|

|

|

Overall |

749 |

753 |

749 |

753 |

|

|

width (mm) |

|

||||

|

|

|

|

|

|

|

|

Weight |

3,970 |

4,880 |

4,485 |

4,880 |

|

|

(kg) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(3) Bucket

|

|

|

|

|

|

|

|

Model |

PC800-8 |

PC800SE-8 |

PC850-8 |

PC850SE-8 |

|

|

PC800LC-8 |

|

||||

|

A (mm) |

2,365 |

2,200 |

2,390 |

2,200 |

|

|

|

|

|

|

|

|

|

B (mm) |

1,850 |

1,950 |

1,880 |

1,950 |

|

|

|

|

|

|

|

|

|

C (mm) |

1,052 |

889 |

1,118 |

889 |

|

|

|

|

|

|

|

|

|

D (mm) |

646 |

714 |

599 |

714 |

|

|

|

|

|

|

|

|

|

Overall |

1,845 |

2,105 |

1,870 |

2,255 |

|

|

width (mm) |

|

||||

|

|

|

|

|

|

|

|

Weight |

2,960 |

3,420 |

3,840 |

4,245 |

|

|

(kg) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

(4) Boom cylinder (for all models)

Weight: 1,550 kg (775 kg × 2 pcs)

(5) Arm cylinder

|

|

|

|

|

|

|

PC800-8 |

PC800SE-8 |

|

|

Model |

PC850-8 |

|

|

|

PC800LC-8 |

|

||

|

|

PC850SE-8 |

|

|

|

|

|

|

|

|

Quantity |

1 |

2 |

|

|

|

|

|

|

|

A (mm) |

3,500 |

2,595 |

|

|

|

|

|

|

|

B (mm) |

1,885 |

1,391 |

|

|

|

|

|

|

|

Weight |

870 |

986 (493 × 2) |

|

|

(kg) |

|

||

|

|

|

|

|

|

|

|

|

|

•Others

(1) Counterweight

Unit: mm

Model |

PC800-8 |

PC850-8 |

PC800LC-8 |

|

PC800SE-8 |

PC850SE-8 |

(If equipped) |

||

|

||||

|

|

|

|

|

A (mm) |

451 |

451 |

451 |

|

|

|

|

|

|

B (mm) |

1,689 |

1,689 |

1,689 |

|

|

|

|

|

|

C (mm) |

684 |

684 |

684 |

|

|

|

|

|

|

Weight |

9,740 |

11,890 |

13,600 |

|

(kg) |

||||

|

|

|

8

(2) Top guard (PC850-8, PC850SE-8 only)

Unit: mm

Weight: 55 kg

(3) Catwalk (1) (for all models)

Unit: mm

Weight: 49 kg

(4) Catwalk (2) (for all models)

Unit: mm

Weight: 31 kg

9

(5) Radiator duct (for all models)

Unit: mm

Weight: 81 kg

(6) Travel motor cover (for all models)

Weight: 115 kg × 2

10

LIST OF TOOLS FOR FIELD ASSEMBLING

No. |

|

Tool names |

Specifications |

Q’ty. |

Remarks |

|

1 |

Equipment |

Engine compressor |

Komatsu, 0.69 MPa {7.0kg/cm2} Class |

1 |

|

|

4 |

Stepladder |

5 -stepped- 1500 mm |

2 |

|

||

2 |

|

Crane truck |

441 kN {45 ton}, 245 kN {25 ton} |

1 each |

|

|

3 |

|

Grease pump |

Air type |

1 |

Work equipment lubrication |

|

|

|

|

|

|

|

|

5 |

|

Impact wrench |

KW10P (for M10) |

1 |

|

|

6 |

|

|

KW12PI (For M12) |

1 |

|

|

7 |

|

|

KW20P (For M16) |

1 |

|

|

8 |

|

|

KW45FS (Spline) |

1 |

For counterweight |

|

9 |

|

Socket for KW45FS |

Spline × 65 mm |

1 |

For counterweight |

|

10 |

|

Air hose |

50 m |

1 |

For impact wrench |

|

11 |

|

16-time wrench |

4413 Nm {450 kgm} |

1 |

For counterweight |

|

12 |

|

Socket for 16-time wrench |

T38.1 × 65 mm |

1 |

For counterweight |

|

13 |

|

|

T38.1 × 55 mm |

1 |

For track frame |

|

14 |

|

|

T38.1 × 50 mm |

1 |

For track frame |

|

15 |

|

4-time wrench |

25.4, 19 |

1 |

|

|

16 |

Tool |

Socket for 4-time wrench |

T25.4 × 50 mm |

1 |

|

|

17 |

|

T25.4 × 55 mm |

1 |

|

||

18 |

|

Torque wrench |

412 Nm {42 kgm} – T25.4 mm |

1 |

For 16-time wrench |

|

19 |

|

|

834 Nm {85 kgm} – T25.4 mm |

1 |

For 4-time wrench |

|

20 |

|

|

4118 Nm {420 kgm} – T38.1 mm |

1 |

For counterweight and track frame |

|

21 |

|

Standard tool |

Socket, spanner, wrench |

2 set |

|

|

22 |

|

Sledge hammer |

10 P |

1 |

|

|

23 |

|

Bar |

1 m |

2 |

|

|

24 |

|

Hydraulic jack |

490 kN {50 ton} (stroke 170) |

2 |

Revolving frame pedestal |

|

25 |

|

|

196 kN {20 ton} |

1 |

When tightening track frame |

|

|

|

connecting bolts. |

||||

|

|

|

|

|

||

26 |

|

Waste oil pan |

Large, small |

2 each |

When connecting travel and |

|

|

|

|

|

|

work equipment piping |

|

27 |

|

Wooden block |

300 × 400 mm |

4 |

Revolving frame pedestal |

|

28 |

|

Wire |

ø10 × 3 m |

2 |

For catwalk |

|

29 |

|

|

ø20 × 5 m |

2 |

For boom, arm and bucket |

|

30 |

|

|

ø25 × 5 m |

4 |

For revolving frame and track frame |

|

31 |

|

|

ø30 × 5 m |

2 |

For counterweight |

|

32 |

tool |

Shackle |

SD30 |

3 |

|

|

33 |

|

SC18 |

4 |

|

||

34 |

Lifting |

Nylon sling |

50 mm wide × 3 m |

2 |

For boom cylinder and arm cylinder |

|

35 |

Pin |

ø50 × 5 m |

2 |

Track frame |

||

|

||||||

36 |

|

Lever block |

14.7 – 29.4 kN {1.5 – 3 ton} |

2 |

|

|

37 |

|

Eyebolt |

M16 |

2 |

|

|

38 |

|

|

M12 |

2 |

|

|

39 |

|

Detergent liquid |

Brake cleaner |

10 |

|

|

40 |

|

Hydraulic oil |

EO-10 |

300 l |

|

|

41 |

andOil grease |

Grease |

G2-LI |

20 kg |

Work equipment lubrication |

|

42 |

Repair paint |

Natural yellow |

5 |

|

||

|

|

|||||

43 |

|

|

Black gray |

5 |

|

|

44 |

|

Waste cloth |

Bundle |

20 kg |

|

11

TIGHTENING TORQUE

Remove the plugging parts (flanges, heads, caps, and O-rings) of the work equipment piping and undercarriage piping, oil stopper plugs of the greasing piping, cylinder fixing jigs, and oil stopper plugs of the tap holes of the loose-supply items which were used for transportation and keep them carefully so that they can be used again for the next transportation.

Tighten the bolts to the torque shown in the following table, unless otherwise specified.

1.Tightening torque of bolts

When tightening the bolts with an impact wrench/spanner, apply Table 1.

Tighten the bolts according to Table 1 as a rule. When this rule is applied, the tightening torque is not shown in the drawing.

Table 1

|

|

|

|

Unit: Nm {kgm} |

Nominal size of thread |

Width across flats |

|

Tightening torque |

|

pitch |

|

|

|

|

b (mm) |

Target |

|

Range |

|

a (mm) |

|

|||

6 1 |

10 |

12 |

|

8.8 - 14.7 |

{1.2} |

|

{0.9 - 1.5} |

||

|

|

|

||

8 1.25 |

13 |

25 |

|

14.7 - 34 |

{2.5} |

|

{1.5 - 3.5} |

||

|

|

|

||

10 1.5 |

17 |

54 |

|

34 - 74 |

{5.5} |

|

{3.5 - 7.5} |

||

|

|

|

||

12 1.75 |

19 |

89 |

|

54 - 123 |

{9} |

|

{5.5 - 12.5} |

||

|

|

|

||

14 2 |

22 |

137 |

|

84 - 196 |

{14} |

|

{8.5 - 20} |

||

|

|

|

||

16 2 |

24 |

230 |

|

147 - 309 |

{23.5} |

|

{15 - 31.5} |

||

|

|

|

||

18 2.5 |

27 |

315 |

|

201 - 427 |

{32} |

|

{20.5 - 43.5} |

||

|

|

|

||

20 2.5 |

30 |

460 |

|

319 - 608 |

{47} |

|

{32.5 - 62} |

||

|

|

|

||

22 2.5 |

32 |

650 |

|

471 - 829 |

{66.5} |

|

{48 - 84.5} |

||

|

|

|

||

24 3 |

36 |

810 |

|

588 - 1030 |

{82.5} |

|

{60 - 105} |

||

|

|

|

||

27 3 |

41 |

1180 |

|

883 - 1470 |

{120} |

|

{90 - 150} |

||

|

|

|

||

30 3 |

46 |

1520 |

|

1130 - 1910 |

{155} |

|

{115195} |

||

|

|

|

||

33 3 |

50 |

1960 |

|

1470 - 2450 |

{200} |

|

{150 - 250} |

||

|

|

|

||

36 3 |

55 |

2450 |

|

1860 - 3040 |

{250} |

|

{190 - 310} |

||

|

|

|

||

39 3 |

60 |

2940 |

|

2260 - 3630 |

{300} |

|

{230 - 370} |

||

|

|

|

||

12

When tightening the bolts with a torque wrench, apply Table 2.

Apply Table 2 when the proper tightening torque range is particularly narrow.

Table 2

|

|

|

|

|

|

Unit: Nm {kgm} |

Nominal size of thread |

Width across flats |

|

|

Tightening torque |

|

|

pitch |

|

|

|

|

|

|

b (mm) |

Target |

|

Range |

|||

a (mm) |

|

|||||

6 1 |

10 |

13.2 |

|

11.8 |

- 14.7 |

|

{1.35} |

|

{1.2 - 1.5} |

||||

|

|

|

||||

8 1.25 |

13 |

31 |

|

27 |

- 34 |

|

{3.2} |

|

{2.8 - 3.5} |

||||

|

|

|

||||

10 1.5 |

17 |

66 |

|

59 |

- 74 |

|

{6.7} |

|

{6.0 - 7.5} |

||||

|

|

|

||||

12 1.75 |

19 |

113 |

|

98 - 123 |

||

{11.5} |

|

{10.0 - 12.5} |

||||

|

|

|

||||

14 2 |

22 |

172 |

|

153 |

- 190 |

|

{17.5} |

|

{15.5 - 19.5} |

||||

|

|

|

||||

16 2 |

24 |

260 |

|

235 |

- 285 |

|

{26.5} |

|

{23.5 - 29.5} |

||||

|

|

|

||||

18 2.5 |

27 |

360 |

|

320 |

- 400 |

|

{37.0} |

|

{33.0 - 41.0} |

||||

|

|

|

||||

20 2.5 |

30 |

510 |

|

455 |

- 565 |

|

{52.3} |

|

{46.5 - 58.0} |

||||

|

|

|

||||

22 2.5 |

32 |

688 |

|

610 |

- 765 |

|

{70.3} |

|

{62.5 - 78.0} |

||||

|

|

|

||||

24 3 |

36 |

883 |

|

785 |

- 980 |

|

{90.0} |

|

{80.0 - 100.0} |

||||

|

|

|

||||

27 3 |

41 |

1295 |

|

1150 |

- 1440 |

|

{132.5} |

|

{118.0 - 147.0} |

||||

|

|

|

||||

30 3 |

46 |

1720 |

|

1520 |

- 1910 |

|

{175.0} |

|

{155.0- 195.0} |

||||

|

|

|

||||

33 3 |

50 |

2210 |

|

1960 |

- 2450 |

|

{225.0} |

|

{200.0 - 250.0} |

||||

|

|

|

||||

36 3 |

55 |

2750 |

|

2450 |

- 3040 |

|

{280.0} |

|

{250.0 - 310.0} |

||||

|

|

|

||||

39 3 |

60 |

3280 |

|

2890 |

- 3630 |

|

{335.0} |

|

{295.0 - 370.0} |

||||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13

2.Tightening torque of pipe threads

Tighten taper male pipe threads of nominal sizes of R1/8 - R1 and Rc1/8 - Rc1 and parallel female pipe threads of nominal size of Rp1/8 - Rp1 (coated with adhesive) according to the following standard.

If tightening torque is specified particularly, however, do not apply the following standard.

2-1. If the material of male threads is SS400, FC, or SGP, apply Table 1.

Table 1

Unit: Nm {kgm}

Material of female thread |

Steel |

Cast iron |

Light alloy |

||||

Nominal size |

|||||||

|

|

|

|

|

|

||

1 / 8 |

3.9 |

- 6.9 |

2.9 |

- 5.9 |

2.0 |

- 3.9 |

|

{0.4 - 0.7} |

{0.3 - 0.6} |

{0.2 - 0.4} |

|||||

|

|||||||

1 / 4 |

5.9 - 11.8 |

4.9 |

- 9.8 |

3.9 - 7.8 |

|||

{0.6 - 1.2} |

{0.5 - 1.0} |

{0.4 - 0.8} |

|||||

|

|||||||

3 / 8 |

16.7 - 26.5 |

13.7 |

- 21.6 |

9.8 - 16.7 |

|||

{1.7 - 2.7} |

{1.4 - 2.2} |

{1.0 - 1.7} |

|||||

|

|||||||

1 / 2 |

32.3 - 52.9 |

26.5 |

- 43.1 |

19.6 - 32.3 |

|||

{3.3 - 5.4} |

{2.7 - 4.4} |

{2.0 - 3.3} |

|||||

|

|||||||

3 / 4 |

51.0 - 85.3 |

42.1 |

- 70.6 |

31.4 - 52.9 |

|||

{5.2 - 8.7} |

{4.3 - 7.2} |

{3.2 - 5.4} |

|||||

|

|||||||

1 |

86.2 - 173.5 |

72.5 - 146.0 |

54.9 - 111.7 |

||||

{8.8 - 17.7} |

{7.4 - 14.9} |

{5.6 - 11.4} |

|||||

|

|||||||

2-2. If the material of male threads is S43C, apply Table 2.

Table 2

Unit: Nm {kgm}

Material of female thread |

Steel |

Cast iron |

Light alloy |

||

Nominal size |

|||||

|

|

|

|

||

1 / 8 |

16.7 |

- 29.4 |

9.8 - 19.6 |

6.9 - 14.7 |

|

{1.7 - 3.0} |

{1.0 - 2.0} |

{0.7 - 1.5} |

|||

|

|||||

1 / 4 |

19.6 |

- 44.1 |

16.7 - 37.2 |

12.7 - 28.4 |

|

{2.0 - 4.5} |

{1.7 - 3.8} |

{1.3 - 2.9} |

|||

|

|||||

3 / 8 |

44.1 |

- 93.1 |

37.2 - 77.4 |

27.4 - 58.8 |

|

{4.5 - 9.5} |

{3.8 - 7.9} |

{2.8 - 6.0} |

|||

|

|||||

1 / 2 |

98.0 - 188.2 |

83.3 - 157.8 |

60.8 - 115.6 |

||

{10.0 - 19.2} |

{8.5 - 16.1} |

{6.2 - 11.8} |

|||

|

|||||

3 / 4 |

170.5 - 316.5 |

141.1 - 247.0 |

105.8 - 186.2 |

||

{17.4 - 32.3} |

{14.4 - 25.2} |

{10.8 - 19.0} |

|||

|

|||||

1 |

367.5 - 612.5 |

309.7 - 514.5 |

235.2 - 392.0 |

||

{37.5 - 62.5} |

{31.6 - 52.5} |

{24.0 - 40.0} |

|||

|

|||||

14

3. Tightening torque of hoses (with taper/face seal)

Unit: Nm {kgm}

Nominaldiameter |

Width across |

|

|

|

Tightening torque |

|

|

of hose |

flatse. |

|

Range |

|

Target |

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

02 |

19 |

35 - 63 |

{3.5 - 6.5} |

|

44 |

{4.5} |

|

|

|

|

|

|

|

|

|

03 |

22 |

54 - 93 |

{5.5 - 9.5} |

|

74 |

{7.5} |

|

|

|

|

|

|

|

|

|

24 |

59 - 98 {6.0 - 10.0} |

|

78 |

{8.0} |

|||

|

|

||||||

|

|

|

|

|

|

|

|

04 |

27 |

84 |

- 132 |

{8.5 - 13.5} |

|

103 |

{10.5} |

|

|

|

|

|

|

|

|

05 |

32 |

128 |

- 186 |

{13.0 - 19.0} |

|

157 |

{16.0} |

|

|

|

|

|

|

|

|

06 |

36 |

177 |

- 245 |

{18.0 - 25.0} |

|

216 |

{22.0} |

|

|

|

|

|

|

|

|

{10} |

41 |

177 |

- 245 {18.0 - 25.0} |

|

216 |

{22.0} |

|

|

|

|

|

|

|

|

|

{12} |

46 |

197 |

- 294 {20.0 - 30.0} |

|

245 |

{25.0} |

|

|

|

|

|

|

|

|

|

{14} |

55 |

246 |

- 343 {25.0 - 35.0} |

|

294 |

{30.0} |

|

|

|

|

|

|

|

|

|

When connecting hoses, take care not to twist them.

15

COATING MATERIALS

a The recommended coating materials such as adhesives, gasket sealants and greases used for disassembly and assembly are listed below.

a For coating materials not listed below, use the equivalent of products shown in this list.

Category |

Komatsu code |

Part No. |

Q'ty |

Container |

|

Main applications, features |

|

|

|

|

|

|

|

|

LT-1A |

790-129-9030 |

150 g |

Tube |

• Used to prevent rubber gaskets, rub- |

|

|

|

ber cushions, and cock plug from |

||||

|

|

|

|

|

|

coming out. |

|

|

|

|

|

• Used in places requiring an immedi- |

|

|

|

|

20 g |

Polyethylene |

|

ately effective, strong adhesive. |

|

LT-1B |

790-129-9050 |

|

Used for plastics (except polyethyl- |

||

|

(2 pcs.) |

container |

|

ene, polyprophylene, tetrafluoroeth- |

||

|

|

|

|

|||

|

|

|

|

|

|

lene and vinyl chloride), rubber, |

|

|

|

|

|

|

metal and non-metal. |

|

|

|

|

Polyethylene |

• |

Features: Resistance to heat and |

|

LT-2 |

09940-00030 |

50 g |

|

chemicals |

|

|

container |

• |

Used for anti-loosening and sealant |

|||

|

|

|

|

|||

|

|

|

|

|

|

purpose for bolts and plugs. |

|

|

790-129-9060 |

Adhesive: |

|

• |

Used as adhesive or sealant for met- |

|

|

1 kg |

|

|

al, glass and plastic. |

|

|

LT-3 |

(Set of adhesive |

Hardening |

Can |

|

|

|

and hardening |

|

|

|||

|

|

agent: |

|

|

|

|

|

|

agent) |

|

|

|

|

Adhesives |

|

500 g |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

LT-4 |

790-129-9040 |

250 g |

Polyethylene |

• |

Used as sealant for machined holes. |

|

container |

|

|

|||

|

|

|

|

|

|

|

|

Holtz |

790-126-9120 |

75 g |

Tube |

• |

Used as heat-resisting sealant for re- |

|

MH 705 |

|

pairing engine. |

|||

|

|

|

|

|

|

|

|

Three bond |

|

|

Polyethylene |

• Quick hardening type adhesive |

|

|

790-129-9140 |

50 g |

• |

Cure time: within 5 sec. to 3 min. |

||

|

1735 |

container |

• |

Used mainly for adhesion of metals, |

||

|

|

|

||||

|

|

|

|

|

|

rubbers, plastics and woods. |

|

|

|

|

|

• Quick hardening type adhesive |

|

|

Aron-alpha |

|

|

Polyethylene |

• Quick cure type (max. strength after |

|

|

790-129-9130 |

2 g |

|

30 minutes) |

||

|

201 |

container |

|

|||

|

|

|

• Used mainly for adhesion of rubbers, |

|||

|

|

|

|

|

||

|

|

|

|

|

|

plastics and metals. |

|

Loctite |

|

|

Polyethylene |

• Resistance to heat, chemicals |

|

|

79A-129-9110 |

50 cc |

• |

Used at joint portions subject to high |

||

|

648-50 |

container |

||||

|

|

|

|

temperatures. |

||

|

|

|

|

|

|

|

|

LG-1 |

790-129-9010 |

200 g |

Tube |

• Used as adhesive or sealant for gas- |

|

|

|

kets and packing of power train case, |

||||

|

|

|

|

|

|

etc. |

|

|

|

|

|

• Used as sealant for various threads, |

|

|

LG-5 |

790-129-9080 |

1 kg |

Can |

|

pipe joints, flanges. |

|

• |

Used as sealant for tapered plugs, |

||||

|

|

|

|

|

||

|

|

|

|

|

|

elbows, nipples of hydraulic piping. |

|

|

|

|

|

• |

Features: Silicon based, resistance |

|

|

|

|

|

• |

to heat, cold |

|

LG-6 |

790-129-9020 |

200 g |

Tube |

Used as sealant for flange surface, |

|

|

|

tread. |

||||

|

|

|

|

|

• |

|

Gasket |

|

|

|

|

Used as sealant for oil pan, final |

|

|

|

|

|

|

drive case, etc. |

|

sealant |

|

|

|

|

|

|

|

|

|

|

• Features: Silicon based, quick hard- |

||

|

LG-7 |

790-129-9070 |

1 kg |

Tube |

• |

ening type |

|

Used as sealant for flywheel hous- |

|||||

|

|

|

|

|

|

ing, intake manifold, oil pan, thermo- |

|

|

|

|

|

|

stat housing, etc. |

|

Three bond |

790-129-9090 |

100 g |

Tube |

• |

Used as heat-resisting sealant for re- |

|

1211 |

|

pairing engine. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

• |

Features: Silicone type, heat resist- |

|

Three bond |

|

|

|

|

ant, vibration resistant, and impact |

|

419-15-18131 |

100 g |

Tube |

|

resistant sealing material |

|

|

1207B |

|

||||

|

|

|

|

• Used as sealing material for transfer |

||

|

|

|

|

|

||

|

|

|

|

|

|

case |

16

Category |

Komatsu code |

Part No. |

Q'ty |

Container |

|

|

Main applications, features |

|

|

|

|

|

|

|

|||

|

LM-G |

09940-00051 |

60 g |

Can |

• Used as lubricant for sliding portion |

|||

|

|

(to prevent from squeaking). |

||||||

Molybdenum |

|

|

|

|

|

|||

|

|

|

|

• Used to prevent seizure or scuffling |

||||

disulphide |

LM-P |

09940-00040 |

200 g |

Tube |

|

of the thread when press fitting or |

||

lubricant |

|

shrink fitting. |

||||||

|

|

|

|

|

• Used as lubricant for linkage, bear- |

|||

|

|

|

|

|

|

ings, etc. |

||

|

|

SYG2-400LI |

|

|

• |

General purpose type |

||

|

G2-LI |

SYG2-350LI |

Various |

Various |

|

|

|

|

|

SYG2-400LI-A |

|

|

|

|

|||

|

|

SYG2-160LI |

|

|

|

|

|

|

|

|

SYGA-160CNLI |

|

|

|

|

|

|

|

|

SYG2-400CA |

|

|

• Used for normal temperature, light |

|||

|

G2-CA |

SYG2-350CA |

Various |

Various |

|

load bearing at places in contact |

||

|

SYG2-400CA-A |

|

with water or steam. |

|||||

|

|

SYG2-160CA |

|

|

|

|

|

|

|

|

SYGA-160CNCA |

|

|

|

|

|

|

|

Molybdenum |

SYG2-400M |

400 g × 10 |

Bellows type |

• Used for heavy load portion |

|||

|

disulphide |

|

|

|

|

|||

Grease |

SYG2-400M-A |

400 g × 20 |

Bellows type |

|

|

|

|

|

grease |

|

|

|

|

||||

|

LM-G (G2-M) |

SYGA-16CNM |

16 kg |

Can |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Hyper White |

|

|

|

• Seizure resistance and heat resist- |

|||

|

SYG2-400T-A |

|

|

|

ance higher than molybdenum di- |

|||

|

Grease G2-T |

|

|

|

||||

|

SYG2-16CNT |

400 g |

Bellows type |

|

sulfide grease |

|||

|

G0-T (*) |

|

||||||

|

SYG0-400T-A (*) |

16 kg |

Can |

• |

Since this grease is white, it does |

|||

|

*: For use in cold |

|||||||

|

SYG0-16CNT (*) |

|

|

|

not stand out against machine |

|||

|

district |

|

|

|

||||

|

|

|

|

|

body. |

|

||

|

|

|

|

|

|

|

||

|

Biogrease G2B |

SYG2-400B |

|

|

• |

Since this grease is decomposed |

||

|

G2-BT (*) |

400 g |

Bellows type |

|

by bacteria in short period, it has |

|||

|

*: For high |

SYGA-16CNB |

|

less effects on microorganisms, |

||||

|

temperature |

SYG2-400BT (*) |

16 kg |

Can |

|

animals, and plants. |

||

|

and large load |

SYGA-16CNBT (*) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUNSTAR |

|

20 ml |

Glass |

|

|

• |

Used as primer for cab side |

|

PAINT PRIMER |

|

|

|

|

(Expiration date: 4 months) |

||

|

580 SUPER |

|

|

container |

|

|

|

|

Primer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUNSTAR |

|

20 ml |

Glass |

|

|

• Used as primer for glass side |

||

|

|

|

|

|||||

|

GLASS PRIMER |

|

|

|

|

(Expiration date: 4 months) |

||

|

580 SUPER |

417-926-3910 |

|

container |

|

|

|

|

|

|

|

glass |

|

|

|||

|

SUNSTAR |

|

|

|

• |

"S" is used for high-tempera- |

||

|

PENGUINE |

|

|

|

cab |

|

ture season (April - October) |

|

|

|

320 ml |

Polyethylene |

|

and "W" for low-temperature |

|||

|

SEAL 580 |

|

|

|||||

|

SUPER "S" or |

|

|

container |

for |

|

season (November - April) as |

|

Adhesive |

|

|

|

|

adhesive for glass. |

|||

"W" |

|

|

|

|

||||

|

|

|

|

Adhesive |

|

(Expiration date: 4 months) |

||

|

|

|

|

|

|

|||

|

Sika Japan, |

20Y-54-39850 |

310 ml |

Polyethylene |

• Used as adhesive for glass. |

|||

|

Sikaflex 256HV |

container |

|

(Expiration date: 6 months) |

||||

|

|

|

|

|

|

|

||

|

SUNSTAR |

417-926-3920 |

320 ml |

Polyethylene |

• |

Used to seal joints of glass |

||

|

|

|

||||||

|

PENGUINE |

|

|

|

parts. |

|||

Caulking |

SEAL No. 2505 |

|

|

container |

|

|

|

(Expiration date: 4 months) |

|

|

|

|

|

|

|

|

|

material |

SEKISUI |

20Y-54-55130 |

333 ml |

Polyethylene |

|

|

• Used to seal front window. |

|

|

SILICONE |

|

|

|

(Expiration date: 6 months) |

|||

|

SEALANT |

|

|

container |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17

A. ASSEMBLY OF BASE MACHINE

19

Assembly procedure |

Installation of Left and Right Track Frames (1/4) |

|

|

||

A-1 |

||

|

||

|

|

•Before transportation, the Upper Structure (also called the “Revolving Frame Assembly”) was rotated 90° from its original position. Start the engine and return the Upper Structure to its original position by slowly rotating it 90° as follows.

•Lift the Upper Structure by two cranes and position it on the Track Frames as shown.

Weight of Upper Structure: 25,800 kg

Slowly rotate 90°

Fitting the wire at counterweight portion (Example):

Set the wire safely and securely.

Wooden block |

|

|

|

||

|

|

|

|||

|

|

|

|

Stopper |

|

|

|

Use a shackle for |

|

||

|

|

|

|

|

|

|

|

secure connection. |

|

|

|

|

|

|

|

|

|

Precautions |

|

Necessary tools |

|

Necessary equipment |

|

|

|

|

|

|

|

Never enter under the lifted Upper Structure. |

|

Name |

Q’ty |

Name |

Q’ty |

|

|

|

|

|

|

|

ø 25 × 5000 wire |

4 |

45 ton crane |

1 |

|

|

|

|

|

|

|

|

SD30 shackle |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others |

|

|

|

|

20

Assembly procedure |

Installation of Left and Right Track Frames (2/4) |

|

|

||

A-1 |

||

|

||

|

|

•Lower the Upper Structure by two cranes and install it on the Track Frames as shown.

Mount the M36 × 3 bolts and tighten them with 250 to 310 kgm torque.

Mount the M33 × 3 bolts Right track frame and tighten them with

200 to 250 kgm torque.

Left track frame

No. |

Loose-supply items |

Q’ty |

1 |

209-09-11310 |

8 |

2 |

209-30-61120 |

8 |

3 |

209-09-51110 |

8 |

4 |

209-30-71121 |

2 |

5 |

01643-33690 |

8 |

6 |

209-30-11330 |

8 |

7 |

209-09-51110 |

32 |

8 |

209-30-61120 |

32 |

Precautions |

|

Necessary tools |

|

Necessary equipment |

|

|

|

|

|

|

|

|

|

Name |

Q’ty |

Name |

Q’ty |

|

|

|

|

|

|

|

4 time wrench |

1 |

45 ton crane |

2 |

|

|

|

|

|

|

|

|

Torque wrench (100 kg) |

1 |

|

|

|

|

|

|

|

|

|

|

Socket (25.4 Sq. × 55 mm) |

1 |

|

|

|

|

|

|

|

|

|

|

Torque wrench (4,200 kg) |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others |

|

|

|

|

21

Assembly procedure |

Installation of Left and Right Track Frames (3/4) |

|

|

||

A-1 |

||

|

||

|

|

•Secure two points of the center frame of the track by placing a hydraulic jack and a 300 × 400 mm wooden block at each point. Make sure that these points do not interfere with the upper structure rotation.

•Lift the Track Frame Assembly and install it on the Center Frame.

Weight of a single side of Track Frame

Assembly: 11,000 kg

Precautions |

|

Necessary tools |

|

Necessary equipment |

|

|

|

|

|

|

|

|

|

Name |

Q’ty |

Name |

Q’ty |

|

|

|

|

|

|

|

Hydraulic jack (50 ton) |

2 |

45 ton crane |

1 |

|

|

|

|

|

|

|

|

Wooden block (300 × 400 mm) |

2 |

|

|

|

|

|

|

|

|

|

|

Wire (ø30 mm, 5000 mm long) |

2 |

|

|

|

|

|

|

|

|

|

|

Pin (ø50 mm, 500 mm) |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others |

|

|

|

|

22

Assembly procedure |

Installation of Left and Right Track Frames (4/4) |

|

|

||

A-1 |

||

|

||

|

|

Thickness of 100 mm

Wooden block

a When tightening bolts, raise the track with a hydraulic jack as shown above so as to get sufficient space for tightening.

Precautions |

|

Necessary tools |

|

Necessary equipment |

|

|

|

|

|

|

|

Do not remove the shoes before assembling |

|

Name |

Q’ty |

Name |

Q’ty |

|

|

|

|

|

|

(so as to maintain the tightening torques of |

4 time wrench |

1 |

|

|

|

the shoe bolts). |

|

|

|

|

|

Torque wrench (100 kg) |

1 |

|

|

||

|

|

|

|||

|

|

|

|

|

|

|

Socket (25.4 Sq. × 55 mm) |

1 |

|

|

|

|

|

|

|

|

|

|

Torque wrench (4,200 kg) |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others |

|

|

|

|

23

Assembly procedure |

Installation of Travel Pipe (1/3) |

|

|

||

A-2 |

||

|

||

|

|

Fig. 1

L.H. R.H.

Fig. 2

|

|

|

|

|

No. |

|

Parts already installed to body |

Q’ty |

|

|

|

|

|

|

1 |

|

209-64-12131 |

2 |

|

|

|

|

|

|

2 |

|

209-64-12141 |

2 |

|

|

|

|

|

|

3 |

|

209-62-42610 |

2 |

|

|

|

|

|

|

4 |

|

209-62-42520 |

1 |

|

|

|

|

|

|

5 |

|

209-62-42510 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

|

Loose-supply items |

Q’ty |

|

|

|

|

|

|

6 |

|

07000-13032 |

4 |

|

|

|

|

|

|

|

|

|

|

|

Precautions |

|

Necessary tools |

|

|

|

Necessary equipment |

|||

|

|

|

|

|

|

|

|

|

|

• Before removing the oil stopper of each |

|

Name |

Q’ty |

|

|

|

Name |

|

Q’ty |

|

|

|

|

|

|

|

|

|

|

hose, turn the bolt slowly to release the |

Width across flats 32 spanner |

2 |

|

|

|

|

|

|

|

internal pressure. |

|

|

|

|

|

|

|

|

|

Width across flats 24 spanner |

2 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Width across flats 22 spanner |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

KW12P impact |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L150 extension |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M17 socket |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others |

|

|

|

|

|

|

|

|

24

Assembly procedure |

Installation of Travel Pipe (2/3) |

|

|

||

A-2 |

||

|

||

|

|

L.H. R.H.

Fig. 3

|

|

|

|

No. |

|

Parts already installed to body |

|

Q’ty |

|

|

|

|

|

1 |

|

209-64-12131 |

|

2 |

|

|

|

|

|

2 |

|

209-64-12141 |

|

2 |

|

|

|

|

|

3 |

|

209-62-42610 |

|

2 |

|

|

|

|

|

4 |

|

209-62-42520 |

|

1 |

|

|

|

|

|

5 |

|

209-62-42510 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

|

Loose-supply items |

|

Q’ty |

|

|

|

|

|

6 |

|

07000-13032 |

|

4 |

|

|

|

|

|

|

|

|

|

|

|

Precautions |

Necessary tools |

|

|

|

Necessary equipment |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Name |

Q’ty |

|

|

|

Name |

|

Q’ty |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others

25

Assembly procedure |

Installation of Travel Pipe (3/3) |

|

|

||

A-2 |

||

|

||

|

|

(1)Arrange the pilot hoses (4) (L.H.), (5) (R.H.) for selecting machine speed and the drain hoses (3) (Figs 1,2 and 3)

(2)Arrange the main hoses (1) and (2) on the travel motor side (Figs 1,2 and 3). Use new O-rings (6) out of the loose-supply items and use split flange, bolt and washer out of the travel motor parts.

|

|

|

|

No. |

|

Parts already installed to body |

|

Q’ty |

|

|

|

|

|

1 |

|

209-64-12131 |

|

2 |

|

|

|

|

|

2 |

|

209-64-12141 |

|

2 |

|

|

|

|

|

3 |

|

209-62-42610 |

|

2 |

|

|

|

|

|

4 |

|

209-62-42520 |

|

1 |

|

|

|

|

|

5 |

|

209-62-42510 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

|

Loose-supply items |

|

Q’ty |

|

|

|

|

|

6 |

|

07000-13032 |

|

4 |

|

|

|

|

|

|

|

|

|

|

|

Precautions |

Necessary tools |

|

|

|

Necessary equipment |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Name |

Q’ty |

|

|

|

Name |

|

Q’ty |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others

26

Assembly procedure |

Installation of Top Guard |

|

|

||

A-3 |

||

|

||

|

|

|

. |

|

|

|

|

|

No. |

|

Loose-supply items |

|

Q’ty |

|

|

|

|

|

|

1 |

|

209-954-4211 |

|

1 |

|

|

|

|

|

|

2 |

|

195-Z11-2970 |

|

6 |

|

|

|

|

|

|

3 |

|

01011-81220 |

|

2 |

|

|

|

|

|

|

4 |

|

01643-31232 |

|

4 |

|

|

|

|

|

|

5 |

|

130-43-64260 |

|

6 |

|

|

|

|

|

|

6 |

|

01024-81280 |

|

2 |

|

|

|

|

|

|

7 |

|

01024-81295 |

|

2 |

|

|

|

|

|

|

8 |

|

01024-01220 |

|

2 |

|

|

|

|

|

|

9 |

|

20Y-954-4220 |

|

2 |

|

|

|

|

|

|

10 |

|

20Y-954-4240 |

|

2 |

|

|

|

|

|

|

11 |

|

20Y-954-4230 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Precautions |

Necessary tools |

|

|

|

Necessary equipment |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Name |

Q’ty |

|

|

|

Name |

|

Q’ty |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Others

27

Loading...

Loading...