komatsu PC800SE-8, PC800, PC800-8 SPECIFICATIONS

STANDARD EQUIPMENT

STANDARD EQUIPMENT

ENGINE AND RELATED ITEMS:

●Air cleaner, double element, dry

●Variable speed cooling fan, with fan guard

●Engine, Komatsu SAA6D140E-5

ELECTRICAL SYSTEM:

●Alternator, 50 amp, 24 V

●Batteries, 170 Ah, 2 x 12 V

●Starting motors, 11kW

●Working lights-2 boom, 2 cab top front, 1 cab bottom

●Step light with timer

●Auto decelerator

UNDERCARRIAGE:

●610 mm 24'' double grouser

●8 track/3 carrier rollers (each side)

●Hydraulic track adjusters (each side)

●Variable track gauge

●Sealed track

GUARDS AND COVERS:

HYDRAULIC CONTROLS:

●Fully hydraulic, with Electronic Open-Center Load-Sensing (EOLSS) and engine speed sensing (pump and engine mutual control system)

●Two axial piston motors for swing with single-stage relief valve

●One axial piston motor per track for travel with counter balance valve

●Two variable capacity piston pumps

●Two control valves, 5+4 spools (boom, arm, bucket, swing, and travel)

●Control levers, wrist control levers for arm, boom, bucket, and swing with PPC system

●Control levers and pedals for steering and travel with PPC system

●Oil cooler

●In-line filter

●Heavy lift mode system

●Shockless boom control

●Swing priority selection system

●Two-mode setting for boom

● Dust-proof net for radiator and oil cooler |

DRIVE AND BRAKE SYSTEM: |

|

● Brakes, hydraulic lock travel brakes, oil disc parking |

||

● Pump/engine room partition cover |

||

● Travel motor guards |

● Hydrostatic two travel speed system with planetary triple reduction |

|

OPERATOR ENVIRONMENT: |

final drive |

|

|

●Damper mount, all-weather, sound-suppressed cab with tinted safety glass windows, lockable door, intermittent window wiper and washer, floormat, cigarette lighter and ashtray

●Multi-function color monitor, electronically-controlled throttle dials, electric service meter, gauges (coolant temperature, hydraulic oil temperature and fuel level), caution lights (electric charge, engine oil pressure, and air cleaner clogging), indicator lights (engine preheating and swing lock light) level check lights (coolant, engine oil, and hydraulic oil level), self-diagnostic system with trouble data memory

●Seat, fully adjustable with suspension

●Cab with pull-up type front window

●Rear view mirror (R,H)

OTHER STANDARD EQUIPMENT:

●Automatic swing holding brake

●Counterweight, 9800 kg 21,610 lb

●Horn, electric

●Marks and plates, English

●Paint, Komatsu standard

●Large handrails

●One-touch engine oil drainage

●PM tune-up service connector

●Remote greasing for radiator fan drive

●Travel alarm

●Rear reflector

●Anti-slip plates

●Corrosion resistor

OPTIONAL EQUIPMENT

OPTIONAL EQUIPMENT

● Additional track guard |

● Cab front guard (ISO 10262 level 2) |

● Provision for fast fuel fill |

● Air suspension seat |

● Cab with fixed front window |

● Radio AM/FM |

● Alternator, 75 Amp, 24 V |

● Catwalk |

● Rain visor |

● Arms (Backhoe): |

● Coolant heater |

● Rear view mirror (L,H) |

PC800-8: |

● Counterweight 11850 kg 26,120 lb |

● Seat belt 78 mm 3'', 50 mm 2'' |

—3600 mm 11'10'' arm assembly |

● Double flange track roller |

● Shoes: |

—4600 mm 15'1'' arm assembly |

● 12V electric supply |

—710 mm 28'' double grouser |

—5600 mm 18'4'' arm assembly |

● Fire extinguisher |

—810 mm 32'' double grouser |

PC800SE-8: |

● Full length track guard |

—910 mm 36'' double grouser |

—2945 mm 9'8'' SE arm assembly |

● General tool kit |

—1010 mm 40'' double grouser |

● Auto air conditioner |

● Grease gun, electric pump with indicator |

● Spare parts for first service |

● Automatic greasing |

● High cab mount |

● Strengthened revolving frame underguard |

● Booms (Backhoe): |

● Interconnected horn and warning light |

● Sun visor |

PC800-8: |

● Large-capacity batteries |

● Track frame undercover (center) |

—8200 mm 26'11'' boom assembly |

● Loading shovel attachments |

● Vandalism protection locks |

PC800SE-8: |

● Lower wiper |

● Working lights 2 (on cab) |

—7100 mm 23'4'' boom assembly |

● OPG top guard |

|

www.Komatsu.com |

|

Printed in Japan 200810 IP.As(05) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CEN00072-01 |

|

|

|

Materials and specifications are subject to change without notice. |

|||

|

|

|

|

|

|

|

is a trademark of Komatsu Ltd. Japan. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HORSEPOWER

Gross:370 kW 496 HP @ 1800 rpm

Net:363 kW 487 HP @ 1800 rpm

OPERATING WEIGHT Backhoe:74200–77810 kg

163,580–171,540 lb

Loading shovel:77000 kg

169,750 lb

PC800/800SE-8 BACKHOE

PC800-8 LOADING SHOVEL

PC

800

|

YDRAULICH |

Photo may include optional equipment. |

XCAVATORE |

|

|

|

|

|

|

PC800-8 H Y D R A U L I C E X C A V A T O R

WALK-AROUND

Productivity Features

●High Work Equipment Speed

Increased arm dumping and bucket dumping speed realize efficient loading operation.

●Heavy Lift Mode

The heavy lift mode increases lifting force by 10%.

●Large Digging Force

High operation efficiency with large digging force for severe applications.

●Two-mode Setting for Boom

Switch selection allows either powerful digging or smooth boom operation.

●Twin Swing Motor System provides excellent swing performance, even on slopes.

●Large Drawbar Pull and Steering Force provide excellent mobility.

●Swing Priority Mode

The swing priority mode improves efficiency for loading dump trucks at 90˚ or 180˚.

●Shockless Boom

Switch selection reduces chassis vibration after sudden stops.

See page 5.

Easy Maintenance

●Easy Cleaning of Cooling Unit

Fan reverse-rotation function facilitates clogged radiator cleaning.

●Centralized Arrangement of Engine Checkpoints

●Anti-slip Plates for improved foot traction

●Large Handrail, Step and Catwalk provide easy access to the engine and hydraulic equipment.

● Increased Fuel Tank Capacity

See page 10.

PC800-80

HYDRAULIC EXCAVATOR

HORSEPOWER

Ecology and Economy Features

●Komatsu SAA6D140E-5 Engine is Tier 3 Emissions Certified.

•World’s first cooled EGR system with bypass-assist type electronically controlled venturi

•Offers high power and low fuel consumption, while conforming to Tier 3 emission certified.

•Reduces NOx emission approximately 40%.

•Equipped with an electronically controlled variable speed fan.

Gross:370 kW 496 HP @ 1800 rpm Net:363 kW 487 HP @ 1800 rpm

OPERATING WEIGHT

Backhoe 74200 – 77810 kg

163,580 – 171,540 lb

Loading shovel 77000 kg

169,750 lb

●Economy Mode Four-level Setting

Enables operator to select the appropriate Economy mode level to match production requirement with lowest fuel consumption.

●Reduction of Ambient Noise

Meets the EU stage 2 noise regulations.

•Electronically controlled variable speed fan drive

•Large hybrid fan

•Glasswool-furnished low-noise muffler and noise reducing cover around the muffler

See page 4.

Excellent Reliability and Durability

●KMAX Bucket Teeth offer superior penetration and longterm sharpness.

●Fuel Pre-filter with water separator equipped as standard.

●O-ring Face Seals, which have excellent sealing performance, are used for the hydraulic hoses.

●High-pressure In-line Filtration

The cool-running hydraulic system is protected with the most extensive filtration system available, including a high pressure in-line filter for each main pump.

2

● Highly Reliable Electronic Devices

Exclusively designed electronic devices have

passed severe testing.

• Controllers • Sensors • Connectors

• Heat resistant wiring • Circuit breaker

●Boom Foot Hoses are arranged under the boom foot, improving hose life and safety.

See page 6.

Working Environment

●Large Comfortable Cab

•Low noise and vibration with cab damper mounting

•Large-capacity air conditioner (optional)

•Pressurized cab prevents external dust from entering

•OPG top guard level 2 (by ISO 10262 standard) capable with optional bolt-on top guard.

See pages 8, 9.

Photo may include optional equipment.

Advanced Monitor Features

•Machine condition can be checked with Equipment Management Monitoring System (EMMS). See page 11.

•Two working modes combine with heavy lift mode for maximum productivity. See page 5.

3

|

PC800-8 H Y D R A U L I C E X C A V A T O R |

HYDRAULIC EXCAVATOR |

PC800-80 |

|

|

||

|

|

|

|

PRODUCTIVITY & ECOLOGY FEATURES

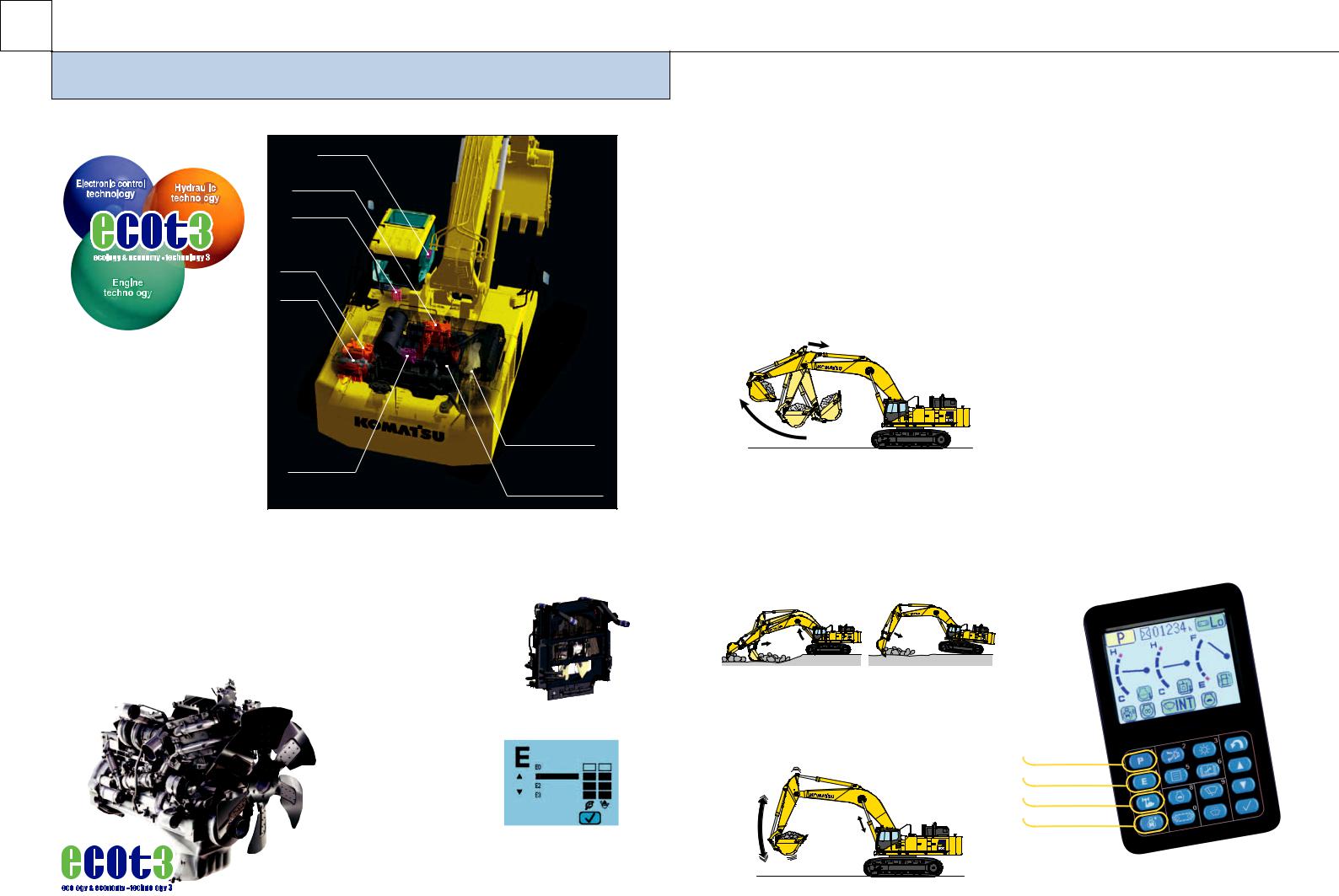

Komatsu Technology

Komatsu develops and produces all major components, such as engines, electronics and hydraulic components, in house.

With this “Komatsu Technology,” and adding customer feedback, Komatsu is achieving great advancements in technology.

To achieve both high levels of productivity and economical performance, Komatsu has developed the main components with a total control system.

The result is a new generation of high performance and environment friendly excavators.

LCD color monitor

Hydraulic control valve

Hydraulic system controller

Main pump

Pump for fan

Electronic control unit for engine

Electronically controlled variable speed fan

Engine

Heavy duty HPCR (High Pressure Common Rail) system Electronically controlled cooled EGR system

Environment-friendly Clean Engine Mounted

Komatsu SAA6D140E-5 engine is Tier 3 and EU stage 3A emissions certified.

The SAA6D140E-5 engine adopts the world’s first cooled EGR system with electronically controlled bypass-assist type venturi. NOx emission is reduced 40%, while maintaining high power and low fuel consumption.

|

|

|

This is an image photo: may |

|

|

||

4 |

|

|

differ from the actual engine. |

|

|

|

Electronically Controlled Variable Speed Fan Contributes to Low Fuel Consumption and Low Noise

The electronic control system sets the rotational speed of the cooling fan according to the coolant, hydraulic oil, and ambient temperature; effectively uses the engine output to prevent wasteful fuel consumption; and reduces noise during low-speed fan rotation.

Lower and Economical Fuel

Consumption Using

Economy Mode

Enables operator to set the Eco mode to up to four levels according to working conditions so that production requirement is

achieved at lowest possible fuel consumption.

Reduction of Ambient Noise (optional)

Reduced noise by adoption of an electronically controlled variable speed fan drive, large hybrid fan, low-noise muffler and cover with glasswool, to meet EU stage 2 noise regulations.

Large Digging Force

Thanks to the high engine output and an excellent hydraulic system, this machine demonstrates powerful digging force.

Maximum arm crowd force (ISO):

250 kN 25.5 ton

Maximum bucket digging force (ISO):

333 kN 34.0 ton

Work Equipment Speed Increased

An arm quick return circuit is provided for arm dumping. This returns a portion of oil flow directly to the hydraulic tank at arm dumping to reduce the hydraulic pressure loss. Combined with increased bucket dumping speed, faster loading work is realized.

Large Drawbar Pull and Steering Force

Since the machine has a large drawbar pull and a high steering force, it demonstrates excellent mobility even when it is being used on inclined sites.

Two-mode Setting for Boom

Smooth mode provides easy operation for gathering blasted rock and scraping operations. When maximum digging force is needed, switch to power mode for more effective excavating.

|

Boom raise |

Smooth |

Power |

mode |

mode |

Shockless Boom Control

The PC800-8 boom circuit features a shockless valve (double-check slow return valve) to automatically reduces the amount of vibration present when operating the boom. Operator fatigue is reduced (which can improve safety and productivity), and spillage caused by vibration is minimized.

Extend and retract

Working Mode Selection

Power and Economy Mode

The PC800-8 excavator is equipped with two working modes. Each mode is designed to match engine speed, pump flow, and system pressure to the current application, giving the operator flexibility to match equipment performance to the job at hand.

Working Mode |

Application |

Advantage |

|

|

|

|

|

P |

Power |

● Maximum production/power |

|

Mode |

● Fast cycle time |

||

|

|||

|

|

|

|

E |

Economy |

● Good cycle time |

|

(E0,E1,E2,E3) |

Mode |

● Good fuel economy |

|

|

|

|

Heavy Lift Mode

Gives the operator 10% more lifting force on the boom when needed for handling rock or heavy lifting applications.

Swing Priority Setting

The swing priority setting allows the operator to use the same easy motion for 180˚ loading as 90˚ loading operations. By altering the oil flow, this setting allows you to select either boom or swing as the priority for increased production.

Selection |

|

Result |

|

|

|

|

|

|

|

|

|

ON |

|

Oil flow to the swing motor is increased. |

|

|

180˚loading operations are most efficient. |

|

|

|

|

|

|

OFF |

|

Oil flow to the boom is increased. |

|

|

90˚loading operations are most efficient. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Mode

Economy Mode

Heavy Lift Mode

Swing Priority Mode

5

Loading...

Loading...