komatsu PC200LC-8, PC200-8 SPECIFICATIONS

STANDARD EQUIPMENT

STANDARD EQUIPMENT

● Alternator, 35 Ampere, 24 V |

● Engine, Komatsu SAA6D107E-1 |

● Track guiding guard, center section |

● Anti-slip plates |

● Engine overheat prevention system |

● Track roller |

● Auto-decel |

● Fan guard structure |

—PC200-8, 7 each side |

● Automatic engine warm-up system |

● Hydraulic track adjusters (each side) |

—PC200LC-8, 9 each side |

● Batteries, 110 Ah/2 x 12 V |

● Multi-function color monitor |

● Track shoe |

● Boom holding valve |

● Power maximizing system |

—PC200-8, 600 mm 24" triple grouser |

● Cab, OPG top guard level 2 capable with |

● PPC hydraulic control system |

—PC200LC-8, 700 mm 28" triple grouser |

optional bolt-on top guard |

● Radiator and oil cooler dust proof net |

● Travel alarm |

● Counterweight |

● Rear reflector |

● Working light, 2 (boom and RH) |

● Dry type air cleaner, double element |

● Rearview mirrors (RH, LH, rear, sidewise) |

● Working mode selection system |

● Electric horn |

● Starting motor, 4.5 kW/24 V x 1 |

|

● EMMS monitoring system |

● Suction fan |

|

OPTIONAL EQUIPMENT

OPTIONAL EQUIPMENT

● Additional filter system for poor-quality fuel |

● Cab accessories |

● Service valve |

● Air conditioner with defroster |

—Rain visor |

● Shoes, triple grouser |

● Alternator, 60 Ampere, 24 V |

—Sun visor |

—PC200-8: 500 mm 20", |

● Arms |

● Cab front guard |

700 mm 28", 800 mm 31.5" |

—2925 mm 9'7" arm assembly |

—Full height guard |

—PC200LC-8: 600 mm 24", |

—2410 mm 7'11" arm assembly |

—Half height guard |

800 mm 31.5", 900 mm 35.5" |

—1840 mm 6'0" arm assembly |

● Heater with defroster |

● Track frame undercover |

● Batteries, large capacity |

● Long lubricating intervals for work equip- |

● Track roller guards (full length) |

● Bolt-on top guard, [Operator Protective |

ment bushing (500 hours) |

● Working lights |

Guards level 2] |

● Rear view monitoring system |

—2 on cab |

● Boom, 5700 mm 18'8" |

● Seat belt, retractable |

—1 on counterweight |

|

● Seat, suspension |

|

SPECIAL PURPOSE BUCKET

SPECIAL PURPOSE BUCKET

• Ditch cleaning bucket |

• Slope finishing bucket for scraping |

—Capacity |

slopes of banks |

SAE heaped 0.80 m3 1.05 yd3 |

—Capacity |

CECE heaped 0.70 m3 0.92 yd3 |

SAE heaped 0.40 m3 0.52 yd3 |

Width 1800 mm 70.9" |

CECE heaped 0.35 m3 0.46 yd3 |

• Trapezoidal bucket is ideal for digging |

Width 2000 mm 78.7" |

ditches and for drainage works |

|

—Capacity |

|

SAE heaped 0.7 m3 0.92 yd3 |

|

CECE heaped 0.5 m3 0.65 yd3 |

|

•Ripper bucket for hard and rock ground —Capacity

SAE heaped 0.62 m3 0.81 yd3 CECE heaped 0.56 m3 0.73 yd3 Width 990 mm 39.0"

•Single-shank ripper and three-shank ripper are recommended for rock-digging and crushing, hard soil digging, pavement removal works, etc.

www.Komatsu.com |

|

|

|

Printed in Japan 200905 IP.As(10) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CEN00049-06 |

Materials and specifications are subject to change without notice. |

|

|

|

is a trademark of Komatsu Ltd. Japan. |

|

|

|

|

|

|

FLYWHEEL HORSEPOWER

Gross: 116 kW 155 HP @ 2000 rpm

Net: 110 kW 148 HP @ 2000 rpm

OPERATING WEIGHT PC200-8: 19400– 20010 kg

42,770– 44,110 lb

PC200LC-8: 20630– 21460 kg

45,480– 47,310 lb

PC200-8 PC200LC-8

PC

200

|

YDRAULICH |

Photo may include optional equipment. |

XCAVATORE |

|

|

|

|

|

|

|

PC200-8 H Y D R A U L I C E X C A V A T O R |

HYDRAULIC EXCAVATOR |

PC200-8 0 |

|

|

||

|

|

|

|

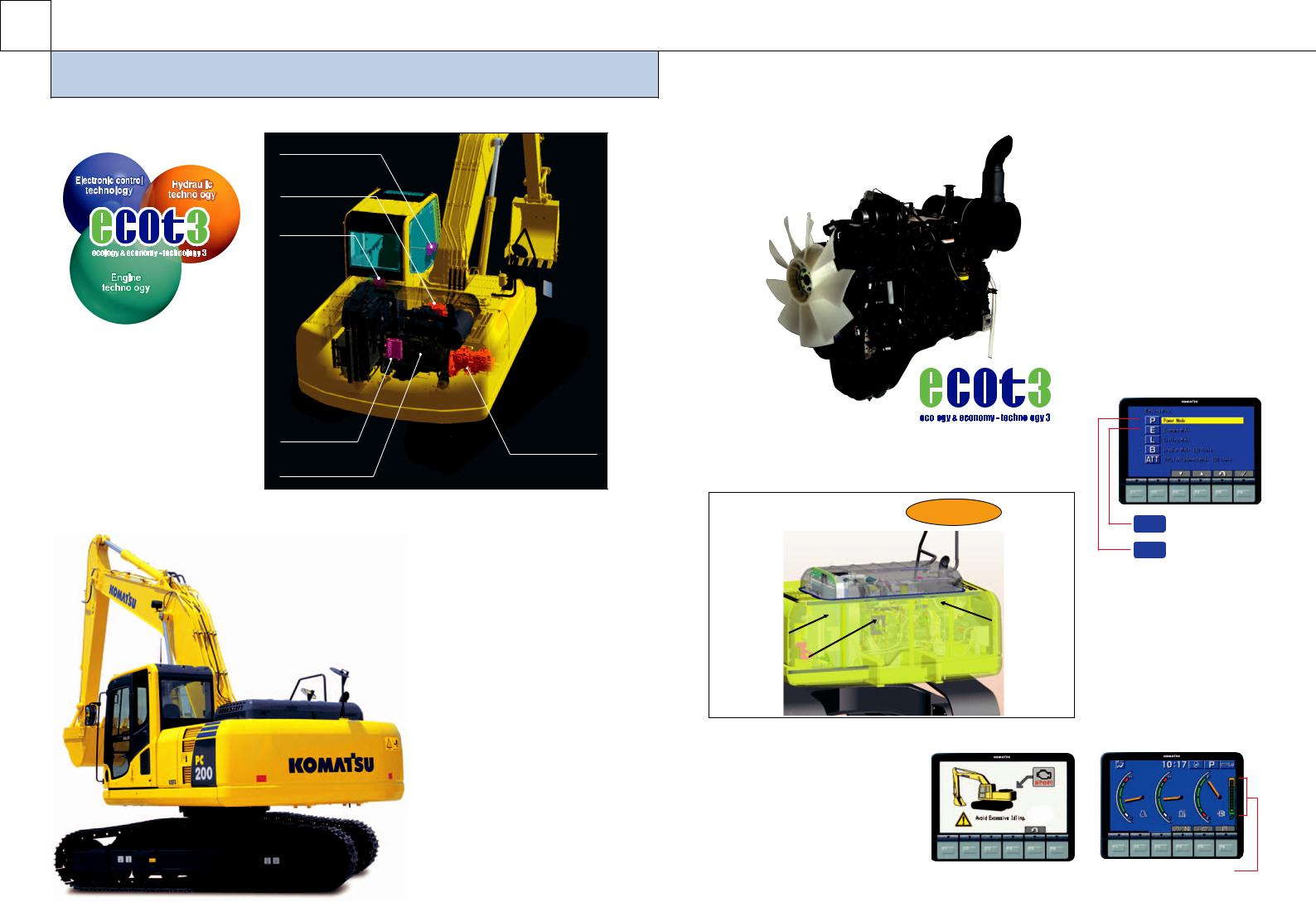

WALK-AROUND

Ecology and Economy Features

●Low fuel consumption by total control of the engine, hydraulic

and electronic system.

Reduces fuel consumption by approx. 10%. (Compared with the PC200-7)

● Low emission engine

A powerful, turbocharged and air-to-air aftercooled Komatsu SAA6D107E-1 provides 110 kW 148 HP. This engine meets EPA Tier 3 and EU Stage 3A emissions certified, without sacrificing power or machine productivity.

•Economy mode improves fuel consumption.

•Eco-gauge for energy-saving operations

•Extended idling caution for fuel conservation

●Low operation noise

The dynamic noise is lowered by 2 dB compared with the PC200-7, realizing a low noise operation.

See page 4 and 5.

Safety Design

•Cab dedicated to hydraulic excavator for protecting the operator in the event of a roll over accident.

•Anti-slip plates for safe work on machine

•Safety enhancement with large side-view, sidewise, and rear mirrors added.

•Rear view monitoring system for easy checking behind the machine (optional)

•OPG top guard level 2 capable with optional bolt-on top guard. See page 7.

Large TFT LCD monitor

•Easy-to-see and use 7" large multi-function color monitor

•Can be displayed in 12 languages for global support.

TFT : Thin Film Transistor

LCD : Liquid Crystal Display

See page 8.

2

HORSEPOWER

Large Comfortable Cab

•Low-noise cab, similar to passenger car

•Low vibration with cab damper mounting

•Highly pressurized cab with optional air conditioner

•Operator seat and console with armrest that enables operations in the appropriate operational posture.

See pages 6.

Gross: 116 kW 155 HP @ 2000 rpm Net: 110 kW 148 HP @ 2000 rpm

OPERATING WEIGHT PC200-8: 19400 – 20010 kg

42,770 – 44,110 lb

PC200LC-8: 20630 – 21460 kg

45,480 – 47,310 lb

BUCKET CAPACITY

0.50– 1.17 m3

0.65– 1.53 yd3

Easy Maintenance

•Long replacement interval of engine oil, engine oil filter, and hydraulic filter

•Remote mounted engine oil filter and fuel drain valve for easy access

•Equipped with the fuel pre-filter as standard (with water separator)

•Side-by-side cooling concept enables individual cooling modules to be serviced.

•Equipped with the EMMS monitoring system

See page 9.

Photo may include optional equipment.

3

|

PC200-8 H Y D R A U L I C E X C A V A T O R |

HYDRAULIC EXCAVATOR |

PC200-8 0 |

|

|

||

|

|

|

|

ECOLOGY & ECONOMY FEATURES

Komatsu Technology

Komatsu develops and produces all major components, such as engines, electronics and hydraulic components, in house.

With this “Komatsu Technology,” and adding customer feedback, Komatsu is achieving great advancements in technology.

To achieve both high levels of productivity and economical performance, Komatsu has developed the main components with a total control system. The result is a new generation of high performance and environment-friendly excavators.

Seven-inch TFT liquid crystal display

Hydraulic control valve Flow divide/merge control with EPC

Hydraulic system controller

Electronic control unit for engine

Engine

Heavy duty HPCR (High Pressure Common Rail) system

Main pump

Two pump independent control

Low Fuel Consumption

The newly-developed Komatsu SAA6D107E-1 [ecot3] engine enables NOx emissions to be significantly reduced with the accurate multi-staged fuel injection by the engine controller. It improves total engine durability using the high-pressure fuel injection system developed specifically for construction machinery. This excavator significantly reduces hourly fuel consumption using the highly-efficient matching techniques of the engine and hydraulic unit and also provides features that promote energy-saving operations such as the E mode and Eco-gauge.

Fuel consumption |

10% reduced |

|

|

|

|

Compared with the PC200-7 at P mode and 100% working efficiency.

Fuel consumption varies depending on job conditions.

4

Low Emission Engine |

Working Modes Selectable |

||

Komatsu SAA6D107E-1 meets EPA, Tier 3 and EU Stage |

Two established work modes are fur- |

||

3A emissions certified and reduced NOx emission by 29% |

ther improved. |

||

compared with the |

P mode – Power or work priority mode |

||

PC200-7. |

|||

has low fuel consumption, but fast |

|||

|

|

||

|

|

equipment speed and maximum pro- |

|

|

|

duction and power are maintained. |

|

|

|

E mode – Economy or fuel priority |

|

|

|

mode further reduces fuel consumption, |

|

|

|

but maintains the P-mode-like working |

|

|

|

equipment speed for light duty work. |

|

|

|

You can select Power or Economy |

|

|

|

modes using a one-touch operation on |

|

|

|

the monitor panel depending on work- |

|

|

|

loads. |

|

|

|

|

|

|

|

|

|

Low Operation Noise

Enables a low noise operation using the low-noise engine and methods to cut noise at source.

Dynamic noise 2 dB reduced

(Compared with the PC200-7)

Reduced fan speed |

Low-noise muffler |

|

|

Large capacity radiator |

Optimal arrangement |

|

|

Electronically controlled |

of sound absorbing |

common rail type engine |

materials |

•Multi-staged injection

•Highly rigid cylinder block

Idling Caution

To prevent unnecessary fuel consumption, an idling caution is displayed on the monitor, if the engine idles for 5 minutes or more.

E |

Fuel priority |

E mode |

|

P |

Work priority |

P mode |

Eco-gauge that Assists Energysaving Operations

Equipped with the Eco-gauge that can be recognized at a glance on the right of the multi-function color monitor for envi- ronment-friendly energy-saving operations. Allows focus on operation in the green range with reduced CO2 emissions and efficient fuel consumption.

Eco-gauge

5

Loading...

Loading...