Komatsu PC138USLC, PC138US Maintenance Manual

TEN00189-01

HYDRAULIC EXCAVATOR

PC138US

PC138USLC

-8 -8

SERIAL NUMBERS |

PC138US- |

20001 |

and up |

|

PC138USLC20001 |

||||

|

|

|||

NOTICE

Komatsu has Operation & Maintenance Manuals written in some other languages. if a foreign language manual is necessary, contact your local distributor for availability.

WARNING

Unsafe Use of this machine may cause serious injury or Death.Operators and maintenance personnel must read this manual before operating or maintaining this machine. This manual should be kept near the machine for reference and periodically reviewed by all personnel

who will come into contact with it .

Downloaded from www.Manualslib.com manuals search engine

1 - 1

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

FOREWORD |

|

|

FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and effectively. The precautions in this manual must be followed at all times when performing operation and maintenance. Most accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of machines. Accidents can be prevented by knowing beforehand conditions that may cause a hazard when performing operation and maintenance.

WARNING

Before beginning operation or maintenance, operators and maintenance personnel must always observe the following points.

Read this manual thoroughly and understand its contents fully.

Read this manual thoroughly and understand its contents fully.

Read the safety messages and safety labels given in this manual carefully so that they should be understood fully.

Keep this manual at the storage location for the Operation and Maintenance Manual given below so that all personnel involved in working on the machine can consult it periodically.

In case this manual should be lost or damaged, immediately contact Komatsu or your Komatsu distributor to obtain a new copy. When you sell the machine, make sure that this manual should be provided to the new owner together with the machine.

In this manual, measurements are expressed in international standard units (SI). For the reference purpose, weight units used in the past are also displayed in ( ).

Storage location for the Operation and Maintenance Manual:

Magazine box at rear of cab

1 - 2

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

FOREWORD |

|

|

1 - 3

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

FOREWORD |

|

|

1 - 4

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

SAFETY INFORMATION |

|

|

SAFETY INFORMATION

To enable you to use this machine safely, safety precautions and labels are given in this manual and affixed to the machine to give explanations of situations involving potential hazards and of the methods of avoiding such situations.

Signal words

The following signal words are used to inform you that there is a potential hazardous situation that may lead to personal injury or damage.

In this manual and on machine labels, the following signal words are used to express the potential level of hazard.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. This word is used also to alert against unsafe practices that may cause property damage.

Example of safety message using signal word

WARNING

When standing up from the operator's seat, always place the lock lever in the LOCK position.

If you accidentally touch the control levers when they are not locked, this may cause a serious injury or death.

Other signal words

In addition to the above, the following signal words are used to indicate precautions that should be followed to protect the machine or to give information that is useful to know.

This word is used for precautions that must be taken to avoid actions which could shorten the life of the machine.

This word is used for information that is useful to know.

1 - 5

Downloaded from www.Manualslib.com manuals search engine

SAFETY INFORMATION |

FOREWORD |

|

|

Safety labels

Safety labels

Safety labels are affixed to the machine to inform the operator or maintenance worker on the spot when carrying out operation or maintenance of the machine that may involve hazard.

This machine uses "Safety labels using words" and "Safety labels using pictograms" to indicate safety procedures.

Example of safety label using words

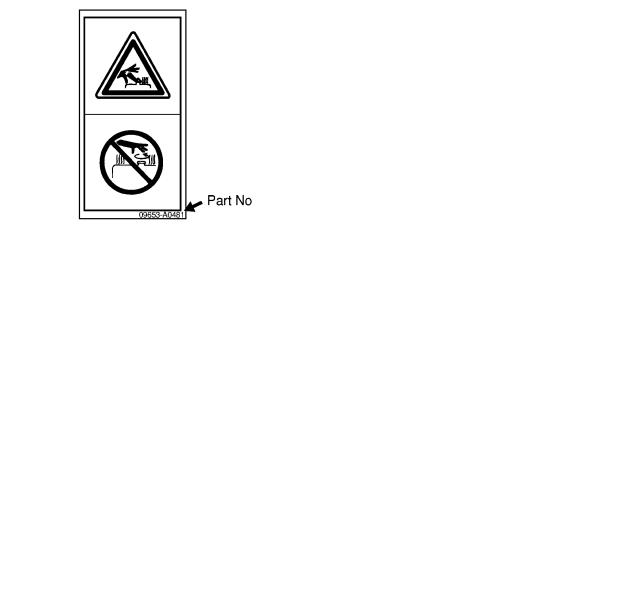

Safety labels using pictogram

Safety pictograms use a picture to express a level of hazardous condition equivalent to the signal word. These safety pictograms use pictures in order to let the operator or maintenance worker understand the level and type of hazardous condition at all times. Safety pictograms show the type of hazardous condition at the top or left side, and the method of avoiding the hazardous condition at the bottom or right side. In addition, the type of hazardous condition is displayed inside a triangle and the method of avoiding the hazardous condition is shown inside a circle.

Komatsu cannot predict every circumstance that might involve a potential hazard in operation and maintenance. Therefore, the safety messages in this manual and on the machine may not include all possible safety precautions. If any procedures or actions not specifically recommended or allowed in this manual are used, it is your responsibility to take the necessary steps to ensure safety.

In no event should you engage in prohibited uses or actions described in this manual.

The explanations, values, and illustrations in this manual were prepared based on the latest information available at that time. Continuing improvements in the design of this machine can lead to changes in detail which may not be reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available information of your machine or for questions regarding information in this manual.

The numbers in circles in the illustrations correspond to the numbers in ( ) in the text. (For example: 1 J (1))

1 - 6

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

INTRODUCTION |

|

|

INTRODUCTION

This Komatsu machine is designed to be used mainly for the following work:

Digging work

Digging work

Leveling work

Leveling work

Ditching work

Ditching work

Loading work

Loading work

Demolition work

Demolition work

See the section "RECOMMENDED APPLICATIONS (PAGE 3-168)" for further details.

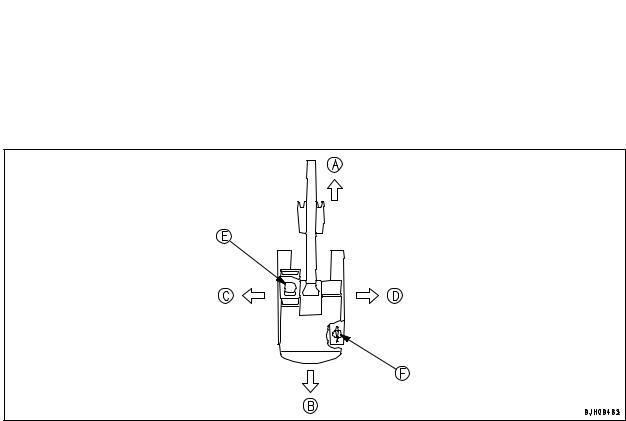

DIRECTIONS OF MACHINE

(A) |

Front |

(E) |

Operator's seat |

(B) |

Rear |

(F) |

Sprocket |

(C)Left

(D)Right

In this manual, the terms front, rear, left, and right refer to the travel direction as seen from the operator's seat when the operator's seat is facing the front and the sprocket is at the rear of the machine.

BREAKING-IN THE NEW MACHINE

NOTICE

Your Komatsu machine has been thoroughly adjusted and tested before shipment from the factory. However, operating the machine under full load before breaking the machine in can adversely affect the performance and shorten the machine life.

Be sure to break in the machine for the initial 100 hours (as indicated on the service meter).

Make sure that you fully understand the content of this manual, and pay careful attention to the following points when breaking in the machine.

Run the engine at idle for 15 seconds after starting it. During this time, do not operate the control levers or fuel control dial.

Run the engine at idle for 15 seconds after starting it. During this time, do not operate the control levers or fuel control dial.

Idle the engine for 5 minutes after starting it up.

Idle the engine for 5 minutes after starting it up.

Avoid operation with heavy loads or at high speeds.

Avoid operation with heavy loads or at high speeds.

Immediately after starting the engine, avoid sudden starts, sudden acceleration, unnecessary sudden stops, and sudden changes in direction.

Immediately after starting the engine, avoid sudden starts, sudden acceleration, unnecessary sudden stops, and sudden changes in direction.

1 - 7

Downloaded from www.Manualslib.com manuals search engine

PRODUCT INFORMATION |

FOREWORD |

|

|

PRODUCT INFORMATION

When requesting service or ordering replacement parts, please inform your Komatsu distributor of the following items.

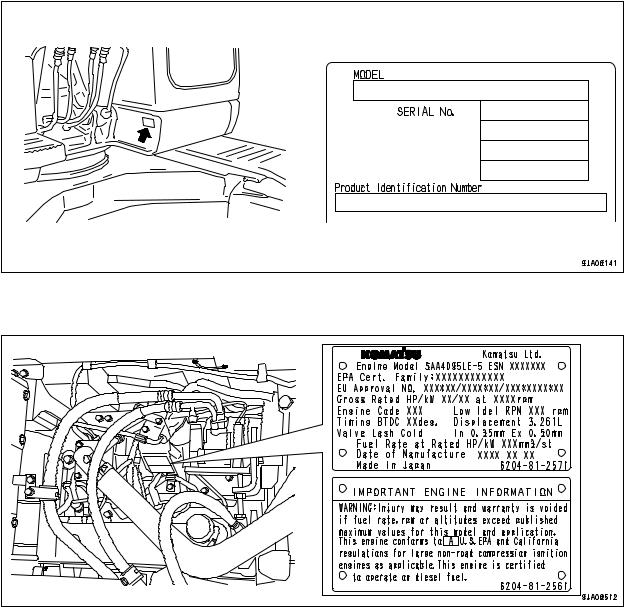

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

On the bottom right of the operator's cab

The design of the nameplate differs according to the territory.

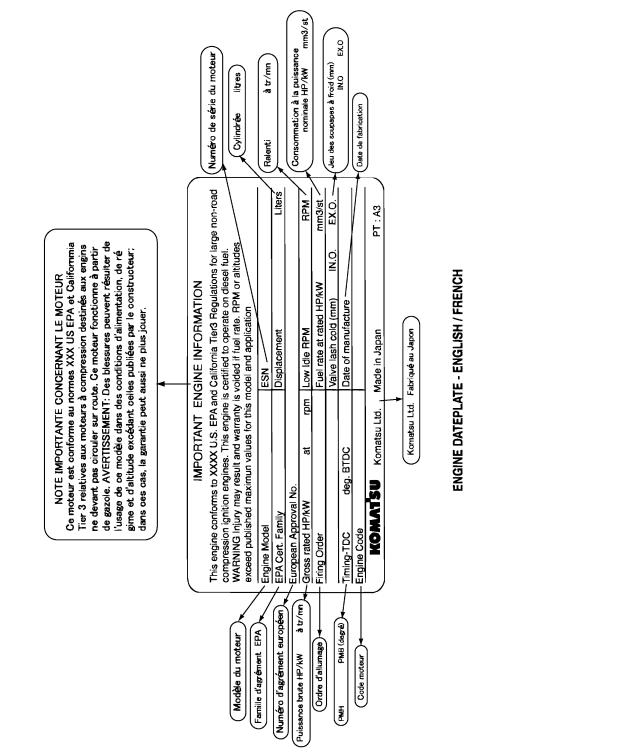

EPA REGULATIONS, ENGINE NUMBER PLATE

This is on the fuel main filter bracket.

EPA: Environmental Protection Agency, U.S.A.

1 - 8

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

PRODUCT INFORMATION |

|

|

SERVICE METER LOCATION

On top of the machine monitor

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

Machine serial No.

Engine serial No.

Product identification number (PIN)

Distributor name

Address

Service Personnel

Phone/Fax

1 - 9

Downloaded from www.Manualslib.com manuals search engine

CONTENTS FOREWORD

CONTENTS

FOREWORD |

1- |

1 |

FOREWORD |

1- |

2 |

SAFETY INFORMATION |

1- |

5 |

INTRODUCTION |

1- |

7 |

DIRECTIONS OF MACHINE |

1- |

7 |

BREAKING-IN THE NEW MACHINE |

1- |

7 |

PRODUCT INFORMATION |

1- |

8 |

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE |

1- |

8 |

EPA REGULATIONS, ENGINE NUMBER PLATE |

1- |

8 |

SERVICE METER LOCATION |

1- |

9 |

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR |

1- |

9 |

SAFETY |

2- |

1 |

SAFETY |

2- |

2 |

SAFETY LABELS |

2- |

4 |

LOCATION OF SAFETY LABELS |

2- |

5 |

SAFETY LABELS |

2- |

6 |

GENERAL PRECAUTIONS |

2- 13 |

|

SAFETY MACHINE OPERATION |

2- 22 |

|

STARTING ENGINE |

2- 22 |

|

OPERATION |

2- 24 |

|

TRANSPORTATION |

2- 30 |

|

BATTERY |

2- 31 |

|

TOWING |

2- 33 |

|

LIFTING OBJECTS WITH BUCKET |

2- 34 |

|

SAFETY MAINTENANCE INFORMATION |

2- 35 |

|

OPERATION |

3- |

1 |

MACHINE VIEW ILLUSTRATIONS |

3- |

2 |

OVERALL MACHINE VIEW |

3- |

2 |

CONTROLS AND GAUGES |

3- |

3 |

DETAILED CONTROLS AND GAUGES |

3- |

5 |

MONITORING SYSTEM |

3- |

5 |

SWITCHES |

3- 68 |

|

CONTROL LEVERS AND PEDALS |

3- 73 |

|

SUN ROOF |

3- 77 |

|

WINDSHIELD |

3- 77 |

|

SLIDING DOOR |

3- 83 |

|

EMERGENCY ESCAPE HAMMER |

3- 84 |

|

CAP WITH LOCK |

3- 85 |

|

ENGINE HOOD |

3- 86 |

|

CAB REAR COVER |

3- 87 |

|

PUMP ROOM DOOR, BATTERY ROOM DOOR |

3- 88 |

|

DOOR AT FRONT OF TOOL BOX |

3- 89 |

|

AIR CONDITIONER CONTROLS |

3- 90 |

|

RADIO |

3-103 |

|

FUSE |

3-108 |

|

FUSIBLE LINK |

3-109 |

|

AUXILIARY ELECTRIC POWER |

3-110 |

|

CONTROLLERS |

3-111 |

|

OPERATION MANUAL STORAGE |

3-112 |

|

1 - 10

Downloaded from www.Manualslib.com manuals search engine

FOREWORD |

CONTENTS |

|

|

|

|

TOOL BOX |

3-112 |

|

GREASE PUMP HOLDER |

3-112 |

|

CUP HOLDER |

3-112 |

|

ASHTRAY |

3-113 |

|

FIRE EXTINGUISHER |

3-113 |

|

MACHINE OPERATIONS AND CONTROLS |

3-114 |

|

BEFORE STARTING ENGINE |

3-114 |

|

STARTING ENGINE |

3-133 |

|

AFTER STARTING ENGINE |

3-138 |

|

STOPPING THE ENGINE |

3-149 |

|

MACHINE OPERATION |

3-150 |

|

STEERING THE MACHINE |

3-154 |

|

SWINGING |

3-156 |

|

WORK EQUIPMENT CONTROLS AND OPERATIONS |

3-157 |

|

WORKING MODE |

3-159 |

|

PROHIBITED OPERATIONS |

3-160 |

|

GENERAL OPERATION INFORMATION |

3-162 |

|

TRAVELING ON SLOPES |

3-165 |

|

ESCAPE FROM MUD |

3-167 |

|

RECOMMENDED APPLICATIONS |

3-168 |

|

BUCKET REPLACEMENT AND INVERSION |

3-170 |

|

PARKING MACHINE |

3-173 |

|

MACHINE INSPECTION AFTER DAILY WORK |

3-174 |

|

LOCKING |

3-175 |

|

ROAD LINERS |

3-176 |

|

TRANSPORTATION |

3-178 |

|

TRANSPORTATION PROCEDURE |

3-178 |

|

LOADING AND UNLOADING WITH TRAILER |

3-179 |

|

LIFTING MACHINE |

3-186 |

|

COLD WEATHER OPERATION |

3-188 |

|

COLD WEATHER OPERATION INFORMATION |

3-188 |

|

AFTER DAILY WORK COMPLETION |

3-189 |

|

AFTER COLD WEATHER SEASON |

3-190 |

|

LONG TERM STORAGE |

3-191 |

|

BEFORE STORAGE |

3-191 |

|

DURING STORAGE |

3-192 |

|

AFTER STORAGE |

3-192 |

|

STARTING MACHINE AFTER LONG-TERM STORAGE |

3-192 |

|

TROUBLES AND ACTIONS |

3-193 |

|

RUNNING OUT OF FUEL |

3-193 |

|

PHENOMENA THAT ARE NOT FAILURES |

3-193 |

|

TOWING THE MACHINE |

3-194 |

|

LIGHTWEIGHT TOWING HOOK |

3-195 |

|

SEVERE JOB CONDITION |

3-195 |

|

DISCHARGED BATTERY |

3-196 |

|

OTHER TROUBLE |

3-201 |

|

MAINTENANCE |

4- |

1 |

MAINTENANCE INFORMATION |

4- |

2 |

OUTLINE OF SERVICE |

4- |

4 |

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC |

4- |

4 |

|

1 - 11 |

|

Downloaded from www.Manualslib.com manuals search engine

CONTENTS |

FOREWORD |

|

|

|

|

ELECTRIC SYSTEM MAINTENANCE |

4- |

7 |

WEAR PARTS |

4- |

8 |

WEAR PARTS LIST |

4- |

8 |

RECOMMENDED FUEL, COOLANT, AND LUBRICANT |

4- |

9 |

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE |

4- 10 |

|

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN |

|

|

KOMATSU GENUINE OIL |

4- 11 |

|

TIGHTENING TORQUE SPECIFICATIONS |

4- 12 |

|

TIGHTENING TORQUE LIST |

4- 12 |

|

SAFETY CRITICAL PARTS |

4- 13 |

|

SAFETY CRITICAL PARTS LIST |

4- 13 |

|

MAINTENANCE SCHEDULE |

4- 14 |

|

MAINTENANCE SCHEDULE CHART |

4- 14 |

|

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER |

4- 16 |

|

MAINTENANCE PROCEDURE |

4- 17 |

|

WHEN REQUIRED |

4- 17 |

|

CHECK BEFORE STARTING |

4- 46 |

|

EVERY 100 HOURS MAINTENANCE |

4- 47 |

|

EVERY 250 HOURS MAINTENANCE |

4- 49 |

|

EVERY 500 HOURS MAINTENANCE |

4- 56 |

|

EVERY 1000 HOURS MAINTENANCE |

4- 65 |

|

EVERY 2000 HOURS MAINTENANCE |

4- 71 |

|

EVERY 4000 HOURS MAINTENANCE |

4- 75 |

|

EVERY 5000 HOURS MAINTENANCE |

4- 77 |

|

EVERY 8000 HOURS MAINTENANCE |

4- 79 |

|

SPECIFICATIONS |

5- |

1 |

SPECIFICATIONS |

5- |

2 |

ATTACHMENTS AND OPTIONS |

6- |

1 |

ATTACHMENTS AND OPTIONS - GENERAL INFORMATION |

6- |

2 |

SAFETY FIRST |

6- |

2 |

ATTACHMENT INSTALLATION |

6- |

3 |

BUCKET WITH HOOK |

6- |

4 |

HOOK CONDITION |

6- |

4 |

PROHIBITED OPERATIONS |

6- |

4 |

MACHINE READY FOR ATTACHMENT |

6- |

5 |

LOCATIONS |

6- |

5 |

HYDRAULIC CIRCUIT |

6- |

8 |

ATTACHMENT REMOVAL AND INSTALLATION |

6- |

9 |

ATTACHMENT OPERATIONS |

6- 13 |

|

LONG TERM STORAGE |

6- 17 |

|

SPECIFICATIONS |

6- 17 |

|

ATTACHMENT GUIDE |

6- 18 |

|

ATTACHMENT COMBINATIONS |

6- 19 |

|

TRACK SHOES SELECTION |

6- 20 |

|

RECOMMENDED ATTACHMENT OPERATIONS |

6- 21 |

|

HYDRAULIC BREAKER |

6- 21 |

|

HANDLING MACHINES EQUIPPED WITH KOMTRAX |

6- 26 |

|

BASIC PRECAUTIONS |

6- 26 |

|

INDEX |

7- |

1 |

1 - 12

Downloaded from www.Manualslib.com manuals search engine

2 - 1

Downloaded from www.Manualslib.com manuals search engine

SAFETY SAFETY

SAFETY

SAFETY LABELS |

2- |

4 |

LOCATION OF SAFETY LABELS |

2- |

5 |

SAFETY LABELS |

2- |

6 |

SAFETY INFORMATION |

|

|

Safety rules |

2- |

13 |

If problems are found |

2- |

13 |

Working wear and personal protective items |

2- |

13 |

Fire extinguisher and first aid kit |

2- |

13 |

Safety equipment |

2- 13 |

|

Keep machine clean |

2- 14 |

|

Keep operator's compartment clean |

2- 14 |

|

Leaving operator's seat with lock |

2- |

14 |

Handrails and steps |

2- |

15 |

Precautions when working in high place |

2- |

15 |

Mounting and dismounting |

2- 15 |

|

No persons on attachments |

2- 15 |

|

Do not get caught in articulated portion |

2- |

16 |

Burn prevention |

2- |

16 |

Fire prevention and explosion prevention |

2- |

17 |

Action if fire occurs |

2- |

17 |

Windshield washer fluid |

2- |

18 |

Falling objects, flying objects and intruding objects prevention |

2- |

18 |

Attachment installation |

2- |

18 |

Attachment combinations |

2- 18 |

|

Cab window glasses |

2- 18 |

|

Unauthorized modifications |

2- |

19 |

Safety at jobsite |

2- |

19 |

Working on loose ground |

2- 19 |

|

Distance to high voltage cables |

2- |

19 |

Ensure good visibility |

2- |

20 |

Ventilation for enclosed area |

2- |

20 |

Signalman's signal and signs |

2- |

21 |

Emergency exit from operator's cab |

2- |

21 |

Asbestos dust hazard prevention |

2- |

21 |

2 - 2

Downloaded from www.Manualslib.com manuals search engine

SAFETY |

SAFETY |

|

|

|

|

SAFETY MACHINE OPERATION |

2- 22 |

|

STARTING ENGINE |

2- 22 |

|

Checks before starting engine |

2- |

22 |

Safety rules for starting engine |

2- |

23 |

Starting engine in cold weather |

2- |

23 |

OPERATION |

2- 24 |

|

Checks before operation |

2- |

24 |

Safety rules for changing machine directions |

2- |

24 |

Safety rules for traveling |

2- |

25 |

Traveling on slopes |

2- |

26 |

Operations on slopes |

2- |

27 |

Prohibited operations |

2- |

27 |

Operations on snow |

2- 29 |

|

Parking machine |

2- 29 |

|

TRANSPORTATION |

2- 30 |

|

Loading and unloading |

2- 30 |

|

Shipping the machine |

2- 30 |

|

BATTERY |

2- 31 |

|

Battery hazard prevention |

2- |

31 |

Starting engine with booster cables |

2- |

32 |

TOWING |

2- 33 |

|

Safety rules for towing |

2- |

33 |

LIFTING OBJECTS WITH BUCKET |

2- 34 |

|

Safety rules for lifting objects |

2- |

34 |

SAFETY MAINTENANCE INFORMATION |

2- 35 |

|

Warning Tag |

2- 35 |

|

Keep Work Place Clean and Tidy |

2- 35 |

|

Appoint Leader when Working with Others |

2- 35 |

|

Stop Engine Before Carrying Out Maintenance |

2- 36 |

|

Two Workers for Maintenance when Engine is Running |

2- 37 |

|

Proper Tools |

2- |

37 |

Accumulator, Gas spring |

2- |

38 |

Personnel |

2- 38 |

|

Attachments |

2- 38 |

|

Work Under the Machine |

2- 38 |

|

Noise |

2- 38 |

|

When Using Hammer |

2- 39 |

|

Welding Works |

2- 39 |

|

Removing Battery Terminals |

2- 39 |

|

Safety First when Using High-pressure Grease to Adjust Track Tension |

2- |

39 |

Do Not Disassemble Recoil Springs |

2- 39 |

|

Safety Rules for High-pressure Oil |

2- |

40 |

Precaution for High Fuel Pressure |

2- |

40 |

Safety Handling High-pressure Hoses |

2- 40 |

|

Precaution for High Voltage |

2- |

40 |

Waste Materials |

2- |

41 |

Air Conditioner Maintenance |

2- |

41 |

Compressed Air |

2- 41 |

|

Periodic Replacement of Safety Critical Parts |

2- |

41 |

|

|

2 - 3 |

Downloaded from www.Manualslib.com manuals search engine

SAFETY LABELS |

SAFETY |

|

|

SAFETY LABELS

The following warning signs and safety labels are used on this machine.

Be sure that you fully understand the correct position and content of labels.

Be sure that you fully understand the correct position and content of labels.

To ensure that the content of labels can be read properly, be sure that they are in the correct place and always keep them clean. When cleaning them, do not use organic solvents or gasoline. These may cause the labels to peel off.

There are also other labels in addition to the warning signs and safety labels. Handle those labels in the same way.

If the labels are damaged, lost, or cannot be read properly, replace them with new ones. For details of the part numbers for the labels, see this manual or the actual label, and place an order with Komatsu distributor.

2 - 4

Downloaded from www.Manualslib.com manuals search engine

SAFETY |

SAFETY LABELS |

|

|

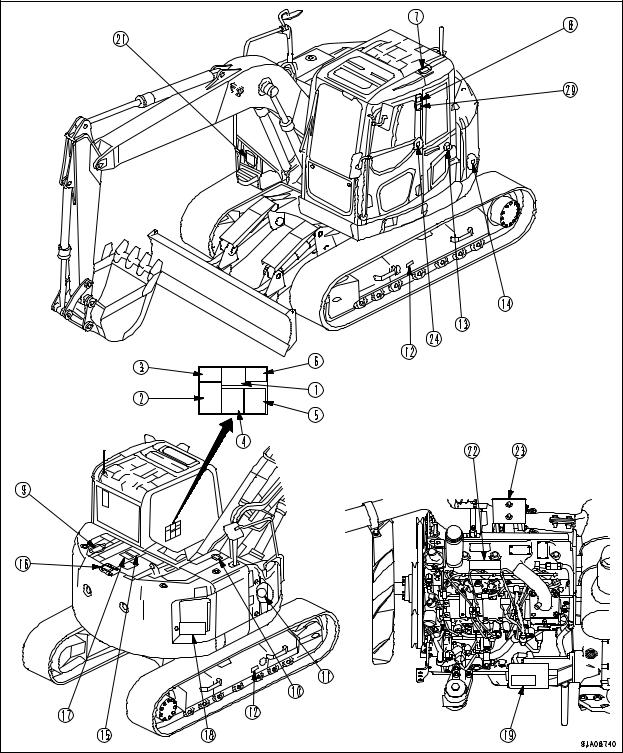

LOCATION OF SAFETY LABELS

2 - 5 |

Downloaded from www.Manualslib.com manuals search engine

SAFETY LABELS |

SAFETY |

|

|

SAFETY LABELS

(1)Caution before operating or maintaining machine (09651-03001)

(2) Caution before operating (09802-03000)

(3) Caution for leaving operator's seat (09654-03001)

2 - 6

Downloaded from www.Manualslib.com manuals search engine

SAFETY |

SAFETY LABELS |

|

|

(4) Caution for going close to electric cables (09801-03001)

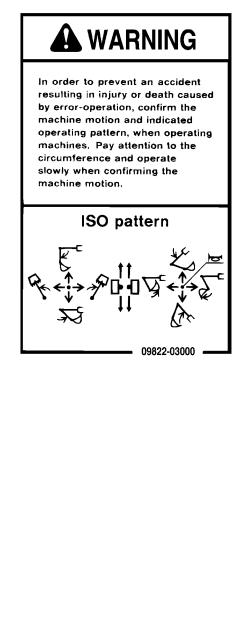

(5)Caution for operating pattern (09822-03000) Standard machine

2 - 7

Downloaded from www.Manualslib.com manuals search engine

SAFETY LABELS |

SAFETY |

|

|

(6)Caution when opening or closing front window (09839-03000)

(7) Caution when stowing front window (09803-03000)

(8) Caution when window comes out or breaks (20U-98-21910)

(9) Caution with high-temperature coolant (09668-03001)

2 - 8

Downloaded from www.Manualslib.com manuals search engine

SAFETY |

SAFETY LABELS |

|

|

(10) Caution with high-temperature hydraulic oil (09653-03001)

(11)Caution when handling accumulator (09659-53000)

(12)Caution when adjusting track tension (09657-03003)

(13) Caution when handling cable (09808-03000)

(14) Caution when handling battery (09664-30082)

2 - 9

Downloaded from www.Manualslib.com manuals search engine

SAFETY LABELS |

SAFETY |

|

|

(15)Stop rotation during inspection and maintenance (09667-03001)

(16) Caution against falling (09805-03000)

(17) Caution against falling (09805-13000)

(18) Prohibition to enter swing range (09133-23000)

(19) Jump start prohibited (09842-A0481)

This safety label is fixed to the engine starting motor.

2 - 10

Downloaded from www.Manualslib.com manuals search engine

SAFETY

(20)Caution for control pattern (21W-98-44220) Machine equipped with control pattern selector valve

(21)Caution when changing control pattern (22M-98-11180) Machine equipped with control pattern selector valve

(22) Caution for high-pressure fuel (6217-71-9331)

Downloaded from www.Manualslib.com manuals search engine

SAFETY LABELS

2 - 11

SAFETY LABELS |

SAFETY |

|

|

(23) Caution for high temperature (09817-A0753)

(24) Caution when swinging or traveling in reverse

The safety labels, (1) through (6) are a single seal. In replacement, place an order for it with Part No. 22U-00-21290.

2 - 12

Downloaded from www.Manualslib.com manuals search engine

SAFETY GENERAL PRECAUTIONS

GENERAL PRECAUTIONS

SAFETY RULES

Only trained and authorized personnel can operate and maintain the machine.

Only trained and authorized personnel can operate and maintain the machine.

Follow all safety rules, precautions and instructions when operating or performing maintenance on the machine.

Follow all safety rules, precautions and instructions when operating or performing maintenance on the machine.

If you are under the influence of alcohol or medication, your ability to safely operate or repair your machine may be severly impaired putting yourself and everyone else on your jobsite in danger.

If you are under the influence of alcohol or medication, your ability to safely operate or repair your machine may be severly impaired putting yourself and everyone else on your jobsite in danger.

When working with another operator or with a person on worksite traffic duty, be sure that all personnel understand all hand signals that are to be used.

When working with another operator or with a person on worksite traffic duty, be sure that all personnel understand all hand signals that are to be used.

IF PROBLEMS ARE FOUND

If you find any problems in the machine during operation or maintenance (noise, vibration, smell, incorrect gauges, smoke, oil leakage, etc., or any abnormal display on the warning devices or monitor), report to the person in charge and have the necessary action taken. Do not operate the machine until the problem has been corrected.

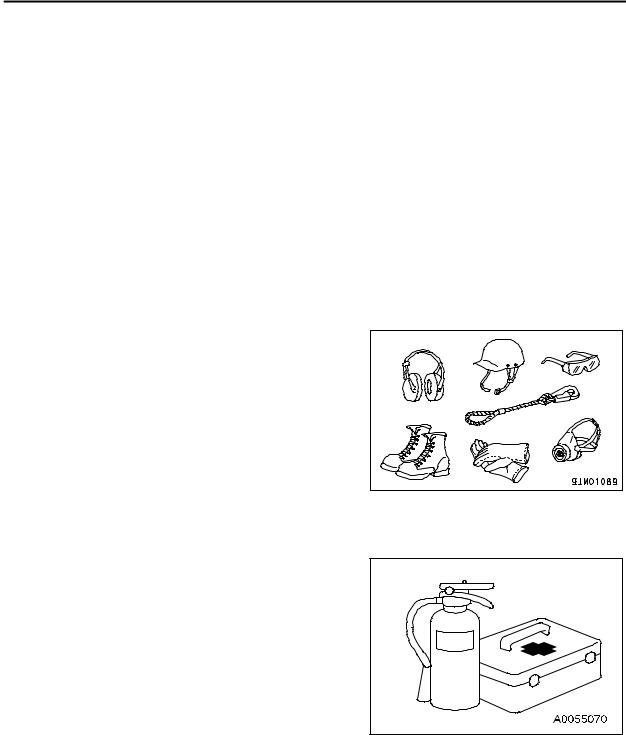

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS

Do not wear loose clothing and accessories. There is a hazard that they may catch on control levers or other protruding parts.

Do not wear loose clothing and accessories. There is a hazard that they may catch on control levers or other protruding parts.

If you have long hair and it hangs out from your hard hat, there is a hazard that it may get caught up in the machine, so tie your hair up and be careful not to let it get caught.

If you have long hair and it hangs out from your hard hat, there is a hazard that it may get caught up in the machine, so tie your hair up and be careful not to let it get caught.

Always wear a hard hat and safety shoes. If the nature of the work requires it, wear safety glasses, mask, gloves, ear plugs, and safety belt when operating or maintaining the machine.

Always wear a hard hat and safety shoes. If the nature of the work requires it, wear safety glasses, mask, gloves, ear plugs, and safety belt when operating or maintaining the machine.

Check that all protective equipment functions properly before using it.

Check that all protective equipment functions properly before using it.

FIRE EXTINGUISHER AND FIRST AID KIT

Always follow the precautions below to prepare for action if any injury or fire should occur.

Be sure that fire extinguishers have been provided and read the labels to ensure that you know how to use them in emergencies.

Be sure that fire extinguishers have been provided and read the labels to ensure that you know how to use them in emergencies.

Carry out periodic inspection and maintenance to ensure that the fire extinguisher can always be used.

Carry out periodic inspection and maintenance to ensure that the fire extinguisher can always be used.

Provide a first aid kit in the storage point. Carry out periodic checks and add to the contents if necessary.

Provide a first aid kit in the storage point. Carry out periodic checks and add to the contents if necessary.

SAFETY EQUIPMENT

Be sure that all guards and covers are in their proper position. Have guards and covers repaired immediately if they are damaged.

Be sure that all guards and covers are in their proper position. Have guards and covers repaired immediately if they are damaged.

Understand the method of use of safety features and use them properly.

Understand the method of use of safety features and use them properly.

Never remove any safety features. Always keep them in good operating condition.

Never remove any safety features. Always keep them in good operating condition.

2 - 13

Downloaded from www.Manualslib.com manuals search engine

GENERAL PRECAUTIONS |

SAFETY |

|

|

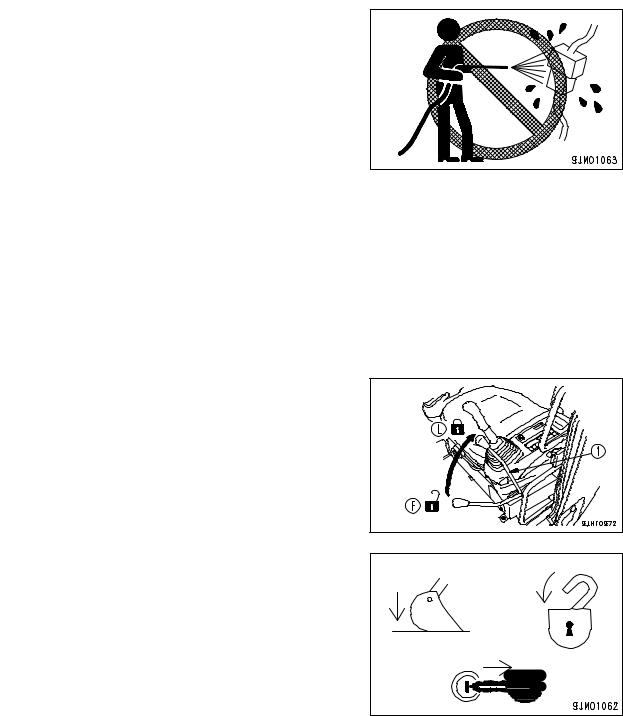

KEEP MACHINE CLEAN

If water gets into the electrical system, there is a hazard that it will cause malfunctions or misoperation. Do not use water or steam to wash the electrical system (sensors, connectors).

If water gets into the electrical system, there is a hazard that it will cause malfunctions or misoperation. Do not use water or steam to wash the electrical system (sensors, connectors).

If inspection and maintenance is carried out when the machine is still dirty with mud or oil, there is a hazard that you will slip and fall, or that dirt or mud will get into your eyes. Always keep the machine clean.

If inspection and maintenance is carried out when the machine is still dirty with mud or oil, there is a hazard that you will slip and fall, or that dirt or mud will get into your eyes. Always keep the machine clean.

KEEP OPERATOR'S COMPARTMENT CLEAN

When entering the operator's compartment, always remove all mud and oil from the soles of your shoes.

When entering the operator's compartment, always remove all mud and oil from the soles of your shoes.

If you operate the pedal with mud or oil affixed to your shoes, your foot may slip and this may cause a serious accident.

Do not leave parts or tools lying around the operator's compartment.

Do not leave parts or tools lying around the operator's compartment.

Do not stick suction pads to the window glass. Suction pads act as a lens and may cause fire.

Do not stick suction pads to the window glass. Suction pads act as a lens and may cause fire.

Do not use cellular telephones inside the operator's compartment when driving or operating the machine.

Do not use cellular telephones inside the operator's compartment when driving or operating the machine.  Never bring any dangerous objects such as flammable or explosive items into the operator's compartment.

Never bring any dangerous objects such as flammable or explosive items into the operator's compartment.

LEAVING OPERATOR'S SEAT WITH LOCK

Before standing up from the operator's seat (such as when opening or closing the front window or roof window, or when removing or installing the bottom window, or when adjusting the operator's seat), always lower the work equipment completely to the ground, set lock lever (1) securely to the LOCK position (L), then stop the engine. If you accidentally touch the control levers or control pedals when they are not locked, there is a hazard that the machine may suddenly move and cause serious injury or property damage.

Before standing up from the operator's seat (such as when opening or closing the front window or roof window, or when removing or installing the bottom window, or when adjusting the operator's seat), always lower the work equipment completely to the ground, set lock lever (1) securely to the LOCK position (L), then stop the engine. If you accidentally touch the control levers or control pedals when they are not locked, there is a hazard that the machine may suddenly move and cause serious injury or property damage.

When leaving the machine, always lower the work equipment completely to the ground, set lock lever (1) securely to the LOCK position (L), then stop the engine. Use the key to lock all the equipment. Always remove the key, take it with you, and keep it in the specified place.

When leaving the machine, always lower the work equipment completely to the ground, set lock lever (1) securely to the LOCK position (L), then stop the engine. Use the key to lock all the equipment. Always remove the key, take it with you, and keep it in the specified place.

2 - 14

Downloaded from www.Manualslib.com manuals search engine

SAFETY |

GENERAL PRECAUTIONS |

|

|

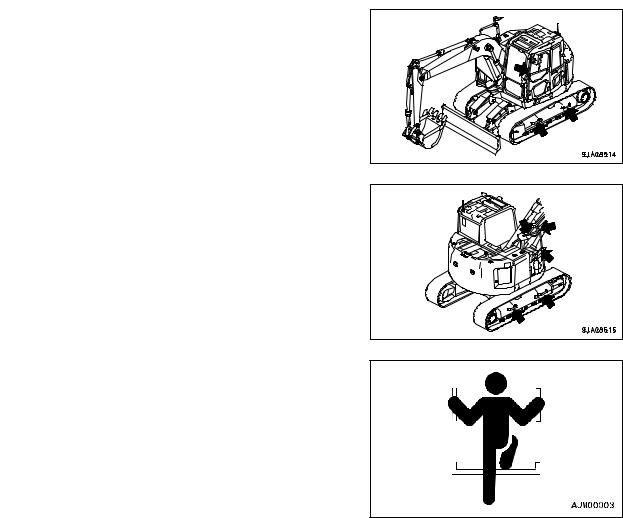

HANDRAILS AND STEPS

To prevent personal injury caused by slipping or falling off the machine, always do as follows.

Use the handrails and steps marked by arrows in the diagram on

Use the handrails and steps marked by arrows in the diagram on

the right when getting on or off the machine.

To ensure safety, always face the machine and maintain three-point contact (both feet and one hand, or both hands and one foot) with the handrails and steps (including the track shoe) to ensure that you support yourself.

To ensure safety, always face the machine and maintain three-point contact (both feet and one hand, or both hands and one foot) with the handrails and steps (including the track shoe) to ensure that you support yourself.

Do not grip the control levers, or lock lever when getting on or off the machine.

Do not grip the control levers, or lock lever when getting on or off the machine.

Never climb on the engine hood or covers where there are no non-slip pads.

Never climb on the engine hood or covers where there are no non-slip pads.

Before getting on or off the machine, check the handrails and steps (including the track shoe). If there is any oil, grease, or

Before getting on or off the machine, check the handrails and steps (including the track shoe). If there is any oil, grease, or

mud on the handrails or steps (including the track shoe), wipe it off immediately. Always keep these parts clean. Repair any damage and tighten any loose bolts.

Do not get on or off the machine while holding tools in your hand.

Do not get on or off the machine while holding tools in your hand.

PRECAUTIONS WHEN WORKING IN HIGH PLACES

When working at high places, use a step ladder or other stand to ensure that the work can be carried out safely.

MOUNTING AND DISMOUNTING

Never jump on or off the machine. Never get on or off a moving machine.

Never jump on or off the machine. Never get on or off a moving machine.

If the machine starts to move when there is no operator on the machine, do not jump on to the machine and try to stop it.

If the machine starts to move when there is no operator on the machine, do not jump on to the machine and try to stop it.

NO PERSONS ON ATTACHMENTS

Never let anyone ride on the work equipment, or other attachments. There is a hazard of falling and suffering serious injury.

2 - 15

Downloaded from www.Manualslib.com manuals search engine

GENERAL PRECAUTIONS |

SAFETY |

|

|

DO NOT GET CAUGHT IN ARTICULATED PORTION

The clearance around the work equipment will change according to the movement of the link. If you get caught, this may lead to serious personal injury. Do not allow anyone to approach any rotating or telescoping part.

BURN PREVENTION

Hot coolant

To prevent burns from hot water or steam spurting out when checking or draining the coolant, wait for the water to cool to a temperature where it is possible to touch the radiator cap by hand before starting the operation. Even when the coolant has cooled down, loosen the cap slowly to relieve the pressure inside the radiator before removing the cap.

To prevent burns from hot water or steam spurting out when checking or draining the coolant, wait for the water to cool to a temperature where it is possible to touch the radiator cap by hand before starting the operation. Even when the coolant has cooled down, loosen the cap slowly to relieve the pressure inside the radiator before removing the cap.

Hot oil

To prevent burns from hot oil spurting out when checking or draining the oil, wait for the oil to cool to a temperature where it is possible to touch the cap or plug by hand before starting the operation. Even when the oil has cooled down, loosen the cap or plug slowly to relieve the internal pressure before removing the cap or plug.

2 - 16

Downloaded from www.Manualslib.com manuals search engine

SAFETY |

GENERAL PRECAUTIONS |

|

|

FIRE PREVENTION AND EXPLOSION PREVENTION

Fire caused by fuel or oil

Fire caused by fuel or oil

Fuel, oil, antifreeze, and window washer liquid are particularly flammable and can be hazardous. To prevent fire, always observe the following:

Do not smoke or use any flame near fuel or oil.

Do not smoke or use any flame near fuel or oil.

Stop the engine before refueling.

Do not leave the machine while adding fuel or oil.

Tighten all fuel and oil caps securely.

Do not spill fuel on overheated surfaces or on parts of the electrical system.

Use well-ventilated areas for adding or storing oil and fuel.

Keep oil and fuel in the determined place and do not allow unauthorized persons to enter.

After adding fuel or oil, wipe up any spilled fuel or oil.

When carrying out grinding or welding work on the chassis, move any flammable materials to a safe place before starting.

When washing parts with oil, use a non-flammable oil. Diesel

oil and gasoline may catch fire, so do not use them.

Put greasy rags and other flammable materials into a safe

container to maintain safety at the work place.

Do not weld or use a cutting torch to cut any pipes or tubes that contain flammable liquids.

Fire caused by accumulation of flammable material.

Fire caused by accumulation of flammable material.

Remove any dry leaves, chips, pieces of paper, dust, or any other flammable materials accumulated or affixed around the engine, exhaust manifold, muffler, or battery, or inside the undercovers.

Fire coming from electric wiring

Fire coming from electric wiring

Short circuits in the electrical system can cause fire.

Always keep electric wiring connections clean and securely tightened.

Check the wiring every day for looseness or damage. Tighten any loose connectors or wiring clamps. Repair or replace any damaged wiring.

Fire coming from hydraulic line

Fire coming from hydraulic line

Check that all the hose and tube clamps, guards, and cushions are securely fixed in position.

If they are loose, they may vibrate during operation and rub against other parts. This may lead to damage to the hoses, and cause high-pressure oil to spurt out, leading to fire damage or serious injury.

Explosion caused by lighting equipment

Explosion caused by lighting equipment

When checking fuel, oil, battery electrolyte, window washer fluid, or coolant, always use lighting with anti-explosion specifications. If such lighting equipment is not used, there is danger of explosion that may cause serious injury.

When taking the electrical power for the lighting from the machine itself, follow the instructions in this manual.

ACTION IF FIRE OCCURS

If a fire occurs, escape from the machine as follows.

Turn the start switch OFF to stop the engine.

Turn the start switch OFF to stop the engine.

Use the handrails and steps to get off the machine.

Use the handrails and steps to get off the machine.

2 - 17

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...