Keyence XG-X Camera

Using Cameras with a

PLC

Troubleshooting Case Study

Programmable Controller

KV-8000

Series

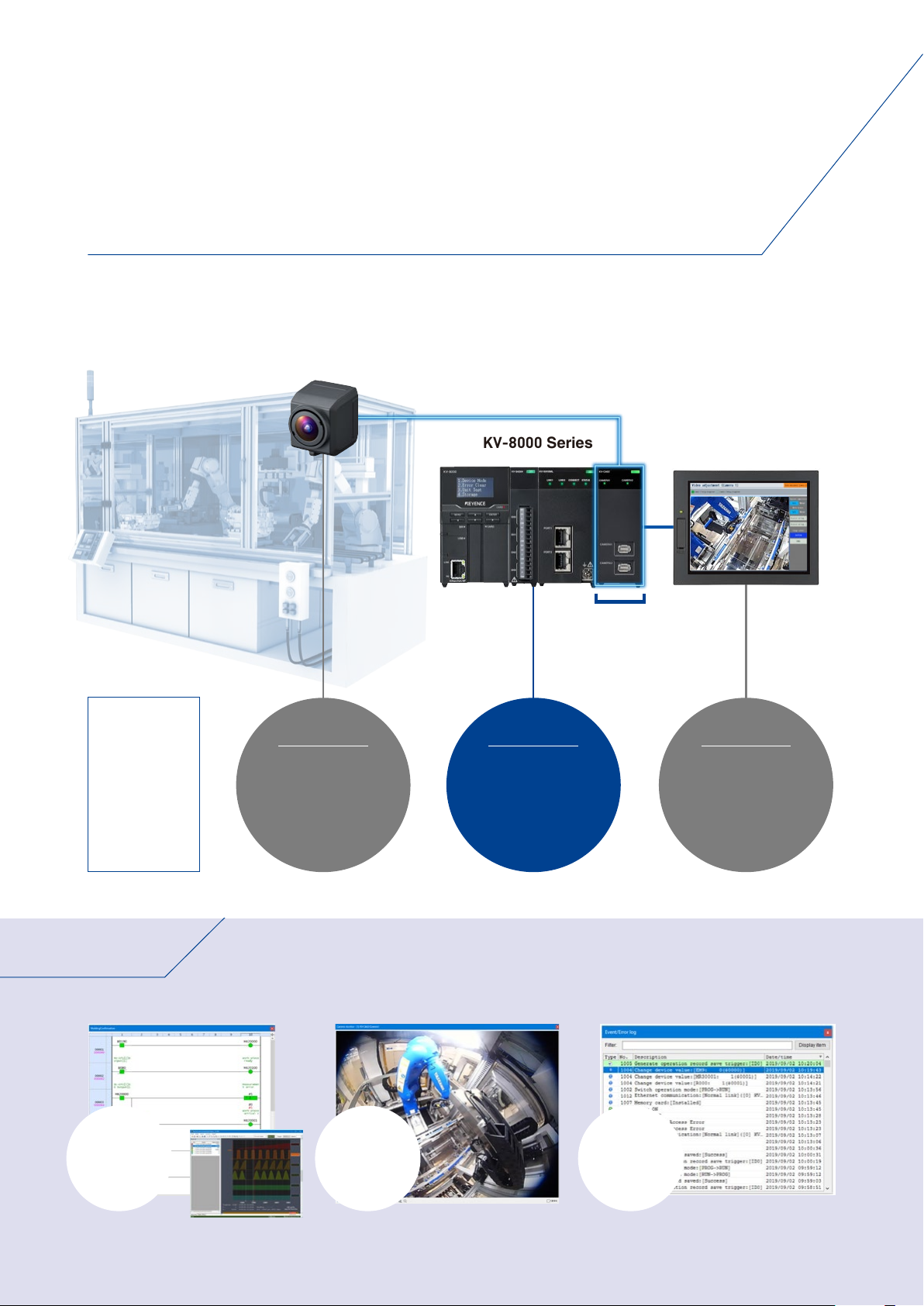

Troubleshooting with equipment

PLCs

Using the Machine Operation Recorder function while

controlling equipment

Equipment problems are recorded (with the Machine Operation Recorder function) at the same time as

equipment is controlled.

The camera video before and after a problem occurs, all the devices of the PLC for each scan, and the

operation history of the operator are all recorded.

Camera

Device roles

Camera

Video capturing

KV-8000

Equipment

Series

KV-8000

Series

control

Machine

Operation

Recorder

Camera

input

Series

VT5

VT5

Series

Equipment operations

and parameter

settings

Real-time

monitoring of the

camera video

Equipment

PLC

2

Details that can be recorded with the Machine Operation Recorder

function

Ladder operations, camera video, and the operation history can all be linked and played back.

Equipment

PLC ladder/

signals

The behaviour of all devices can

be checked each scan.

Camera

video

Mechanical, target, and human

movements are recorded with two types

of cameras.

HMI

operation

history

The operation history from the HMI and

the inputs from the host PC are recorded.

Troubleshooting with PLCs added

to existing installations

Using the Machine Operation Recorder function with it added to

existing equipment

Equipment problems are recorded (with the Machine Operation Recorder function) by acquiring signals from

an existing equipment PLC in a program-less manner.

The camera video before and after a problem occurs and specific devices at each communication cycle are

recorded.

Camera

Device roles

Camera

Video capturing

Existing equipment

Existing

equipment PLC

Equipment control

PLC KV-8000

PLC link

KV-8000

Series

PLC link with an

existing

equipment PLC

Machine

Operation

Recorder

* The KV-XLE02 or KV-XL202/

XL402 is required.

Series

Camera

input

*

PLC added to an

existing installation

Signals from

an existing

equipment

PLC

Linked devices can be checked at each

communication cycle.

Details that can be recorded with the

Machine Operation Recorder function

Changes to specific devices and the camera video

can be linked and played back.

Camera

video

Mechanical, target, and human movements

are recorded with two types of cameras.

Linked playback even when

added to an existing

installation

Linked playback of waveforms and video

3

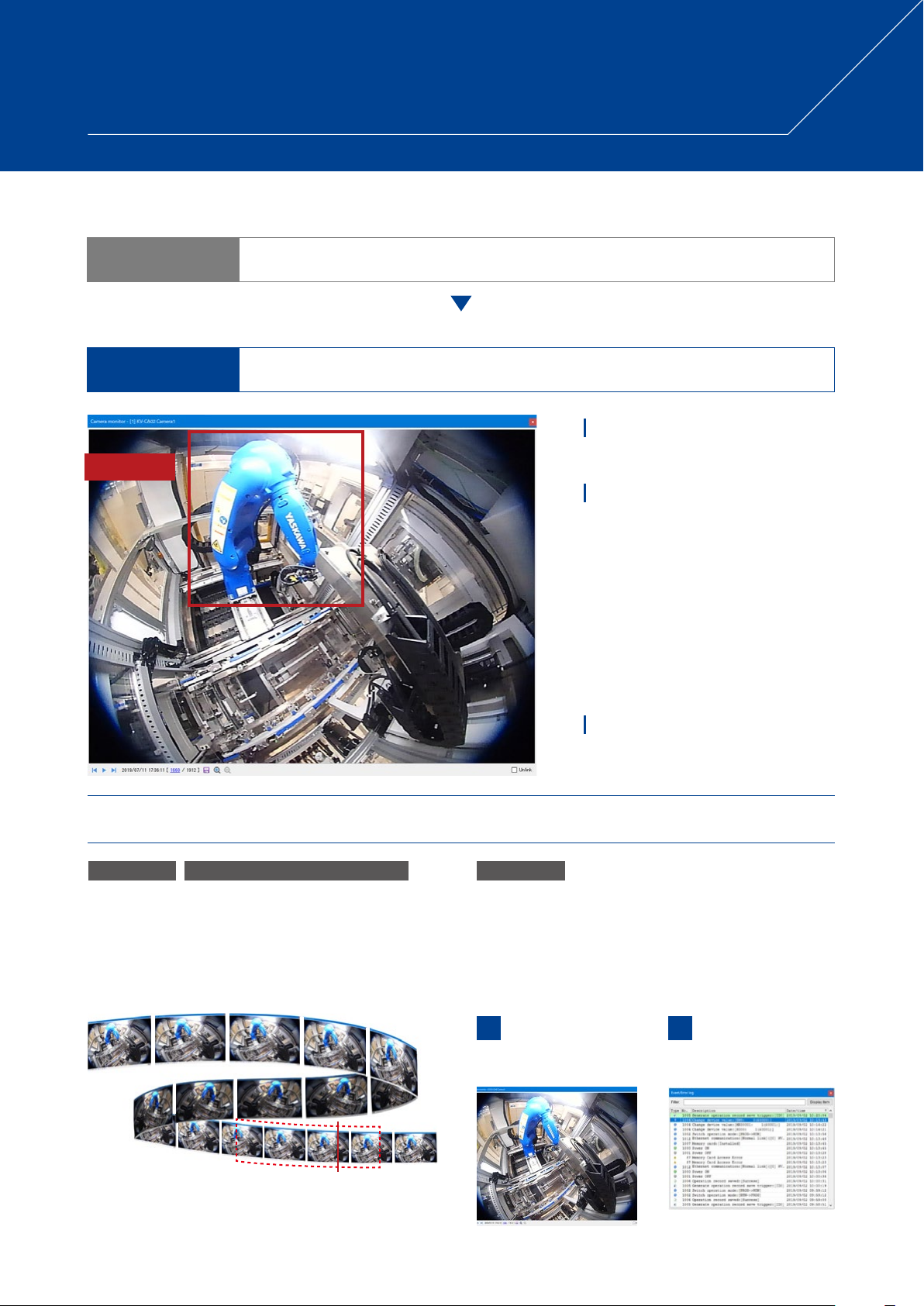

Case

1

Robot path

Conventional

KV-8000

Robots

It is difficult to isolate the causes of problems in processes that use robots.

Solved with the Machine

Operation Recorder function

The behaviour of the robot is recorded, enabling quick identification of the

cause.

Image capturing target

Robot behaviour (path)

Installation results

• Because video of the problem

occurring is recorded, the issue can

be identified immediately even in

situations where operators are not

close to the machine, such as with

unmanned lines.

• The cause—be it the robot, the

operator, or something else—can be

isolated in the initial response to the

problem.

Troubleshooting details

Just the data before and after the

occurrence of a problem is recorded.

The KV-8000 can automatically record just the data before

and after the occurrence of a problem. This makes it

possible to immediately understand the situation by

eliminating the hassle of searching for the scenes to view.

Problem

Automatic recording just before and after the problem

Eliminating the hassle of searching for the scenes to view makes it

possible to understand the situation in the minimal amount of time.

Used camera

Wide field and high-resolution camera

KV-CA1W

EquipmentEquipment Added to existing installation

Judgement is fast during the initial

response to isolate the cause.

The operation history of the operator is retained and is

synchronised with the robot behaviour. This makes it

possible to accurately and quickly isolate the cause

during the initial response to the problem.

Use the camera to

1

check the operation

of the robot.

Isolate the mechanical cause. Isolate the human cause.

Use events to check

2

the operation

history.

4

Loading...

Loading...