Page 1

Fixed Mount 2D Code Reader

Important

Point

Reference

300GB

Table of Contents

General Precautions..........................................................................2

Safety Information for SR-750 Series................................................2

SR-750 Series

User's Manual Rev.4.0

Read this manual together with the SR-750 Series Additional Functions Manual.

Read this manual before use.

Keep this manual in a safe place for future reference.

Symbols

This user's manual uses the following symbols that alert you to important

messages. Be sure to read these messages carefully.

It indicates a hazardous situation which, if not avoided, will result

DANGER

in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

WARNING

result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

CAUTION

result in minor or moderate injury.

It indicates a situation which, if not avoided, could result in

NOTICE

product damage as well as property damage.

Cautions as to operation that is always performed are shown.

Cautions as to operation that can be easily performed incorrectly

are shown.

Matters that will help the user improve understanding of the text and

useful information are shown.

The items and pages to be referred to in this document are shown.

Introduction

This instruction manual describes the connection/wiring procedure, setting

instructions, and precautions for using the "SR-750 Series 2D Code Reader".

Please read this manual thoroughly before using the SR-750 Series to ensure

optimum performance. Keep this manual handy for quick future reference.

1-1 Checking the Package Contents ....................................................... 3

1-2 Part Names and Functions ................................................................ 3

1-3 System Configuration and Setup Flow .............................................. 4

2-1 Connecting the Power Source ........................................................... 6

2-2 Connecting the Control Cable and Wiring ......................................... 6

2-3 Connecting the Ethernet Cable ......................................................... 8

3-1 Using the SR-750 Series ................................................................... 9

3-2 Quick Calibration ............................................................................. 10

3-3 Alternate Function ........................................................................... 11

3-4 Test Mode........................................................................................ 12

3-5 Preset/Verification Function.............................................................14

3-6 Multi-I/O Function ............................................................................ 14

3-7 Image Saving Function.................................................................... 16

3-8 Silent Mode...................................................................................... 18

3-9 SR-600 Compatible Output Mode ...................................................19

3-10 Batch Setting Code.......................................................................... 20

3-11 Code quality verification function..................................................... 20

3-12 Duplicate reading prevention interval reset.....................................24

3-13 Edit data function/Edit image file name function..............................24

4-1 Reading Operations......................................................................... 26

4-2 Timing Mode.................................................................................... 26

4-3 Data Transmission Timing ............................................................... 27

4-4 Read Mode ...................................................................................... 28

5-1 Installing, Starting, and Shutting Down............................................30

5-2 Screen Layout .................................................................................33

5-3 AutoID Network Navigator Operation Flow...................................... 34

5-4 Details of Settings View ................................................................... 34

5-5 Sending/Receiving Configuration.................................................... 49

5-6 Saving/Reading a Configuration File...............................................49

5-7 Quick Setup Code ........................................................................... 50

5-8 Terminal........................................................................................... 50

5-9 LiveView .......................................................................................... 51

5-10 ImageView....................................................................................... 52

5-11 FileView ........................................................................................... 53

5-12 Installation Guide ............................................................................. 53

5-13 Export Reader Configuration ........................................................... 54

5-14 Report Generator Function..............................................................55

5-15 Creating Reports for the SR-750 Series.......................................... 56

6-1 Before Mounting the SR-750 Series................................................60

6-2 Mounting the SR-750 Series ........................................................... 60

6-3 Adjusting the Mounting Position ...................................................... 61

6-4 Confirming the Reading Stability ..................................................... 61

7-1 Communication of the SR-750 Series ............................................. 63

7-2 Data Communication Format........................................................... 63

7-3 RS-232C Communication................................................................67

7-4 Ethernet Communication ................................................................. 68

7-5 Socket Communication.................................................................... 69

7-6 FTP Communication ........................................................................ 69

8-1 Details of Command Communication .............................................. 71

8-2 Operation Commands ..................................................................... 71

8-3 Details of Configuration Commands................................................ 75

9-1 PLC Link .......................................................................................... 85

9-2 Configuration ................................................................................... 85

9-3 Device Assignment.......................................................................... 87

9-4 Reference Program ......................................................................... 90

9-5 PLC Link Error ................................................................................. 91

10-1 Master/Slave function ...................................................................... 92

10-2 Setting procedure ............................................................................92

10-3 Multi drop link mode ........................................................................93

10-4 Multi head mode .............................................................................. 93

1

E SR-750 UM

Page 2

11-1 EtherNet/IP ...................................................................................... 94

WARNING

CAUTION

NOTICE

WARNING

NOTICE

11-2 Cyclic communication...................................................................... 95

11-3 Message Communication..............................................................101

11-4 Reference Program ....................................................................... 105

12-1 PROFINET .................................................................................... 109

12-2 Cyclic communication.................................................................... 109

13-1 Installing MultiMonitor.................................................................... 112

13-2 Using MultiMonitor......................................................................... 113

14-1 Installing FileView.......................................................................... 114

14-2 Using FileView............................................................................... 115

15-1 SR-750 Series Specifications ........................................................ 116

15-2 Dimensions.................................................................................... 117

15-3 SR-750 Series Field of View Size ................................................. 118

15-4 Troubleshooting.............................................................................119

15-5 Checksum Calculation Method...................................................... 121

15-6 ASCII Code List ............................................................................. 121

15-7 Software License ........................................................................... 122

15-8 Precautions on Regulations and Standards..................................122

15-9 Copyright indications ..................................................................... 123

General Precautions

• Do not use this product for the purpose to protect a human

body or a part of human body.

• This product is not intended for use as explosion-proof product.

Do not use this product in a hazardous location and/or

potentially explosive atmosphere.

• Be sure to check that the SR-750 Series performs properly

before starting the work or operation.

• If the SR-750 Series malfunctions, take adequate safety

precautions to prevent various types of damage.

• Do not use the SR-750 Series in a manner not specified herein. It

may result in fire, electric shock or malfunction.

• It should be noted that functions and performances will not be

guaranteed if the SR-750 Series is used in any way not specified

or described in the product specifications or it is modified.

• When the SR-750 Series is used in combination with other

devices, functions and performance may be degraded,

depending on the operating conditions and environment.

Safety Information for SR-750 Series

Safety precautions on Laser product

The SR-750 Series Fixed Mount 2D Code Reader uses a visible semiconductor

laser, with a wavelength of 660 nm, as a Laser pointer for adjusting the reading

position.

Laser Pointer Specifications

Wavelength 660nm

Output 60μW

Pulse duration 200μs

Laser class

* The classification is based on IEC60825-1 standard following the Laser Notice

No. 50 from FDA (CDRH).

• Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

• Do not disassemble this product. The laser radiation emission

from this product is not automatically stopped when it is

disassembled.

Precautions on Class 1 Laser Product

• Do not stare into the direct or specularly reflected beam.

Class 1 Laser Product

(IEC60825-1, FDA(CDRH) Part 1040.10*)

Precautions on Proper Use

• Do not use a voltage other than that described in the

specifications with the SR-750 Series. Doing so may damage to

the unit.

• The SR-750 Series employs 2 power connection methods,

which are 24 V DC supply and supply from PoE power supply

devices. When connecting the SR-750 Series to the power

source, be sure to use one of these methods. Using both power

sources simultaneously may cause damage to the units.

• Be sure to turn off the power to devices attached to the SR-750

Series when you plug in or unplug the cables.

Failure to do so may cause damage to the SR-750 Series.

• Do not disassemble or modify the SR-750 Series. Doing so may

damage to the unit.

• Place cables as far away as possible from high-voltage lines

and power lines. Otherwise, electrical noise can be generated

that may cause product failure or malfunction.

• The SR-750 Series is a precision instrument. Do not impact or

drop the instrument. Pay particular attention when transporting

or installing the unit.

• Do not hold the unit by its cable when carrying. The units may

become damaged if the cables are disconnected or the units

strike each other.

• Do not allow water, oil, dust, or other foreign substances to

stick to the scanner. This may cause read errors.

Use a soft, dry cloth to wipe any substance from the scanner.

(Do not use a cloth dipped in alcohol or other cleaning

substance.)

E SR-750 UM

2

Page 3

1-1 Checking the Package

1

E SR-750-IM

Fixed Mount 2D Code Reader

SR-750 Series

Instruction manual

Read this instruction manual before using the product in order to achieve

maximum performance.

Keep this instruction manual in a safe place after reading it so that it can be

used at any time.

Symbols

The following symbols alert you to important messages. Be sure to read

these messages carefully.

Important

It indicates cautions and limitations that must be followed during operation.

Point

It indicates additional information on proper operation.

Reference

It indicates tips for better understanding or useful information.

indicates the reference pages in this manual or the reference pages in separate manuals.

Safety Information for SR-750 Series

General Precautions

Safety precautions on Laser product

The SR-750 Series Fixed Mount 2D Code Reader uses a visible semiconductor

laser, with a wavelength of 660 nm, as a Laser pointer for adjusting the reading

position.

Laser Pointer Specifications

* The laser classification for FDA(CDRH) is implemented based on

IEC60825-1 in accordance with the requirements of Laser Notice No.50.

Precautions on Proper Use

Precautions on Regulations and Standards

CE Marking

Keyence Corporation has confirmed that this product complies with the

essential requirements of the applicable EC Directive, based on the

following specifications. Be sure to consider the following specifications

when using this product in the Member State of European Union.

zEMC Directive (2004/108/EC)

•Applicable standards EMI : EN61326-1, Class A

EMS: EN61326-1

Remarks:

These specifications do not give any guarantee that the end-product with

this product incorporated complies with the essential requirements of

EMC Directive. The manufacturer of the end-product is solely responsible

for the compliance on the end-product itself according to EMC Directive.

zLow-voltage Directive (2006/95/EC)

•Applicable Standard EN60825-1,

Class 1 Laser Product

EN62471

CSA Certificate

This product complies with the following CSA and UL standards and has

been certified by CSA.

•Applicable standards: CAN/CSA C22.2 No.61010-1

UL61010-1

Be sure to consider the following specifications when using this product as a

product certified by CSA.

•Overvoltage category

•Use this product under pollution degree 3.

•Use this product at the altitude of 2000 m or less.

•Indoor use only.

•When using this product, use the following power supply.

•CSA or UL certified power supply that provides Class 2 output as defined

in the CEC (Canadian Electrical Code) and NFPA79 (NEC: National

Electrical Code), or

•CSA or UL certified power supply that has been evaluated as a Limited

Power Source as defined in CAN/CSA-C22.2 No. 60950-1/UL60950-1.

•Either PoE or 24V power supply shall be used.

•The symbol on the product means "Direct current".

FDA (CDRH) Regulations

This product complies with the following FDA (CDRH) regulations.

•FDA(CDRH) Part 1040.10, Class 1 Laser Product

The laser classification for FDA(CDRH) is implemented based on IEC608251 in accordance with the requirements of Laser Notice No.50.

FCC Regulations

This product complies with the following FCC EMI regulations.

•FCC Part 15 Subpart B, Class A Digital Device

IC (Industry Canada) Regulations

This product complies with the following IC EMI regulations.

•ICES-003, Class A Digital Apparatus

It indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

It indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

It indicates a hazardous situation which, if not avoided, could result in minor

or moderate injury.

It indicates a situation which, if not avoided, could result in product damage

as well as property damage.

•Do not use this product for the purpose to protect a human body or a part

of human body.

•This product is not intended for use as explosion-proof product. Do not

use this product in a hazardous location and/or potentially explosive

atmosphere.

•Be sure to check that the SR-750 Series performs properly before starting

the work or operation.

•If the SR-750 Series malfunctions, take adequate safety precautions to

prevent various types of damage.

•Do not use the SR-750 Series in a manner not specified herein. It may

result in fire, electric shock or malfunction.

•It should be noted that functions and performances will not be guaranteed

if the SR-750 Series is used in any way not specified or described in the

product specifications or it is modified.

•When the SR-750 Series is used in combination with other devices,

functions and performance may be degraded, depending on the operating

conditions and environment.

Wavelength 660nm

Output 60PW

Pulse duration 200Ps

Laser class

Class 1 Laser Product

(IEC60825-1:2007, FDA(CDRH) Part 1040.10*)

•Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

•Do not disassemble this product. The laser radiation emission from this

product is not automatically stopped when it is disassembled.

Precautions on Class 1 Laser Product

•Do not stare into the direct or specularly reflected beam.

96M12458

DANGER

WARNING

CAUTION

NOTICE

WARNING

CAUTION

NOTICE

WARNING

•Do not use a voltage other than that described in the specifications with

the SR-750 Series. Doing so may damage to the unit.

•The SR-750 Series employs 2 power connection methods, which are 24 V

DC supply and supply from PoE power supply devices. When connecting

the SR-750 Series to the power source, be sure to use only one of these

methods. Using both power sources simultaneously may cause damage

to the units.

•Be sure to turn off the power to devices attached to the SR-750 Series

when you plug in or unplug the cables.

Failure to do so may cause damage to the SR-750 Series.

•Do not disassemble or modify the SR-750 Series. Doing so may damage to

the unit.

•Place cables as far away as possible from high-voltage lines and power

lines. Otherwise, electrical noise can be generated that may cause product

failure or malfunction.

•The SR-750 Series is a precision instrument. Do not impact or drop the

instrument. Pay particular attention when transporting or installing the

unit.

•Do not hold the unit by its cable when carrying. The units may become

damaged if the cables are disconnected or the units strike each other.

•Do not allow water, oil, dust, or other foreign substances to stick to the

scanner. This may cause read errors.

Use a soft, dry cloth to wipe any substance from the scanner. (Do not use

a cloth dipped in alcohol or other cleaning substance.)

NOTICE

TEST

TUNE

POW

ERR

NET

IN

STB

OK/NG/

(4) TEST button

(5) TUNE button

(6) POW LED

(7) OK/NG/ERR LED

(8) NET LED

(9) IN LED

(10) Multiple LED indicator

(1) Scanner

(2) Power supply and

control port

(3) Ethernet port

Contents

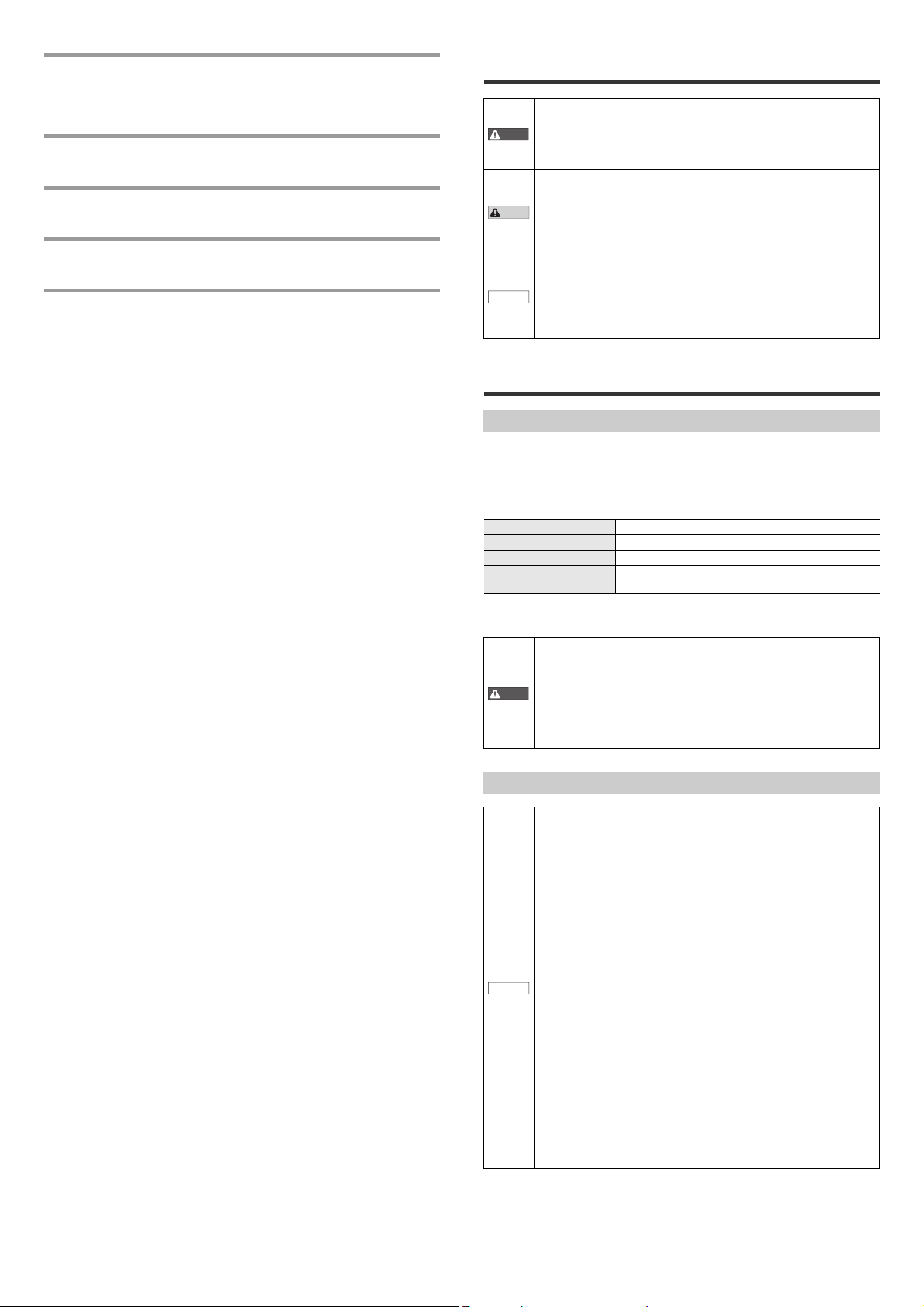

The packages of the SR-750 Series main units and the SR-750 Series

configuration software contain the following components.

Check that you have all the package contents before use.

SR-750 Series (Fixed mount 2D code reader)

Main unit

SR-750/751/750HA SR-752

Mounting screw (M4) x 4 Port cover (Power supply and control port,

Ethernet connection port) x 1 each

Mounting bracket x 1

NFPA79 compliant Ethernet cable

• OP-87359 (2 m cable)

• OP-87360 (5 m cable)

• OP-87361 (10 m cable)

Ethernet assembly plug

• OP-87362

Long distance lens

400 mm lens

• SR-75L4

600 mm lens

• SR-75L6

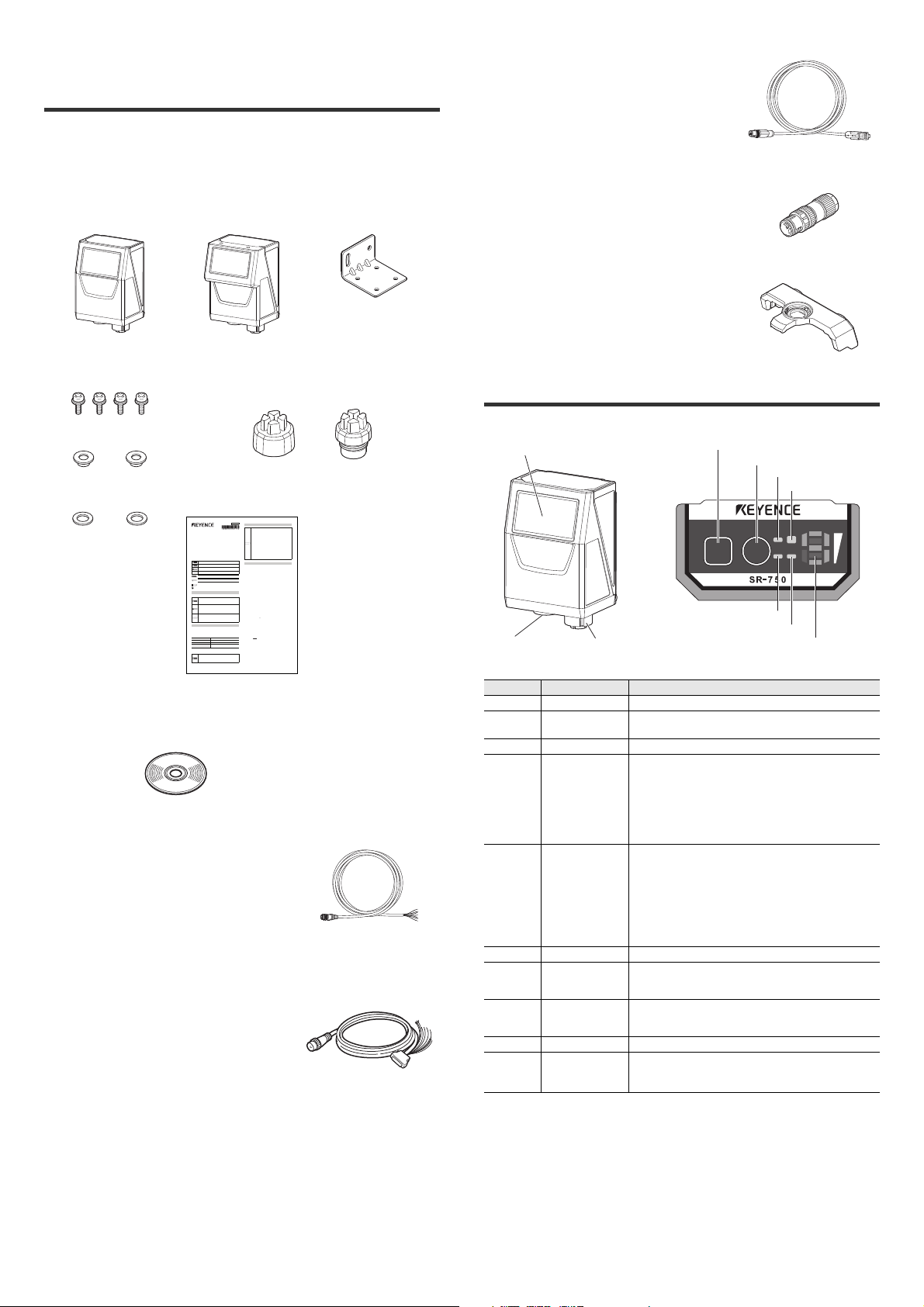

1-2 Part Names and Functions

Insulating spacer x 2

Washer x 2 Instruction Manual

SR-H3W

AutoID Network Navigator

Cable and connector

Control cable (Power supply, I/O, RS-232C)

• OP-87224 (2 m cable)

• OP-87225 (5 m cable)

• OP-87226 (10 m cable)

NFPA79 compliant Control cable

• OP-87353 (2 m cable)

• OP-87354 (5 m cable)

• OP-87355 (10 m cable)

Control cable (NFPA79-compliant) with D-Sub9 pin

(Power supply, I/O, RS-232C)

• OP-87527 (2 m cable)

• OP-87528 (5 m cable)

• OP-87529 (10 m cable)

This section describes the part names and functions of the SR-750 Series.

Number Name Function

(1) Scanner Reads 2D codes and bar codes.

Power supply and

(2)

control port

(3) Ethernet port Connect the Ethernet cable.

(4) TEST button

(5) TUNE button

(6) POW LED When the power is turned ON, the "green" light turns on.

(7) OK/NG/ERR LED

(8) NET LED

(9) IN LED When an input terminal is on, this lights up.

(10)

Multiple LED

indicator

Connect the control cable.

Use this button to perform the following operations:

• Run 1 reading operation.

• Start and stop test mode.

• Run the multi-reading mode.

• Fix the communication settings of RS-232C to the default

values.

• Reset PLC link error.

Use this button to perform the following operations:

• Turn on the laser pointer for reading position adjustment.

• Start parameter tuning.

• Display the number of parameter banks of which the

alternate function is effective.

• Read the quick setup code.

• Reset errors.

• Start Ethernet communication BootP mode connection.

• When OK output is ON, the "green" light turns on.

• When NG output is ON, the "orange" light turns on.

• When ERR output is ON, the "red" light turns on.

• When connected to Ethernet, the "green" light turns on.

• When the Ethernet data is sent/received, the "green" light

turns on.

This displays the operation status including the bank

number upon successful reading, reading stability and

operation mode.

300GB

3

E SR-750 UM

Page 4

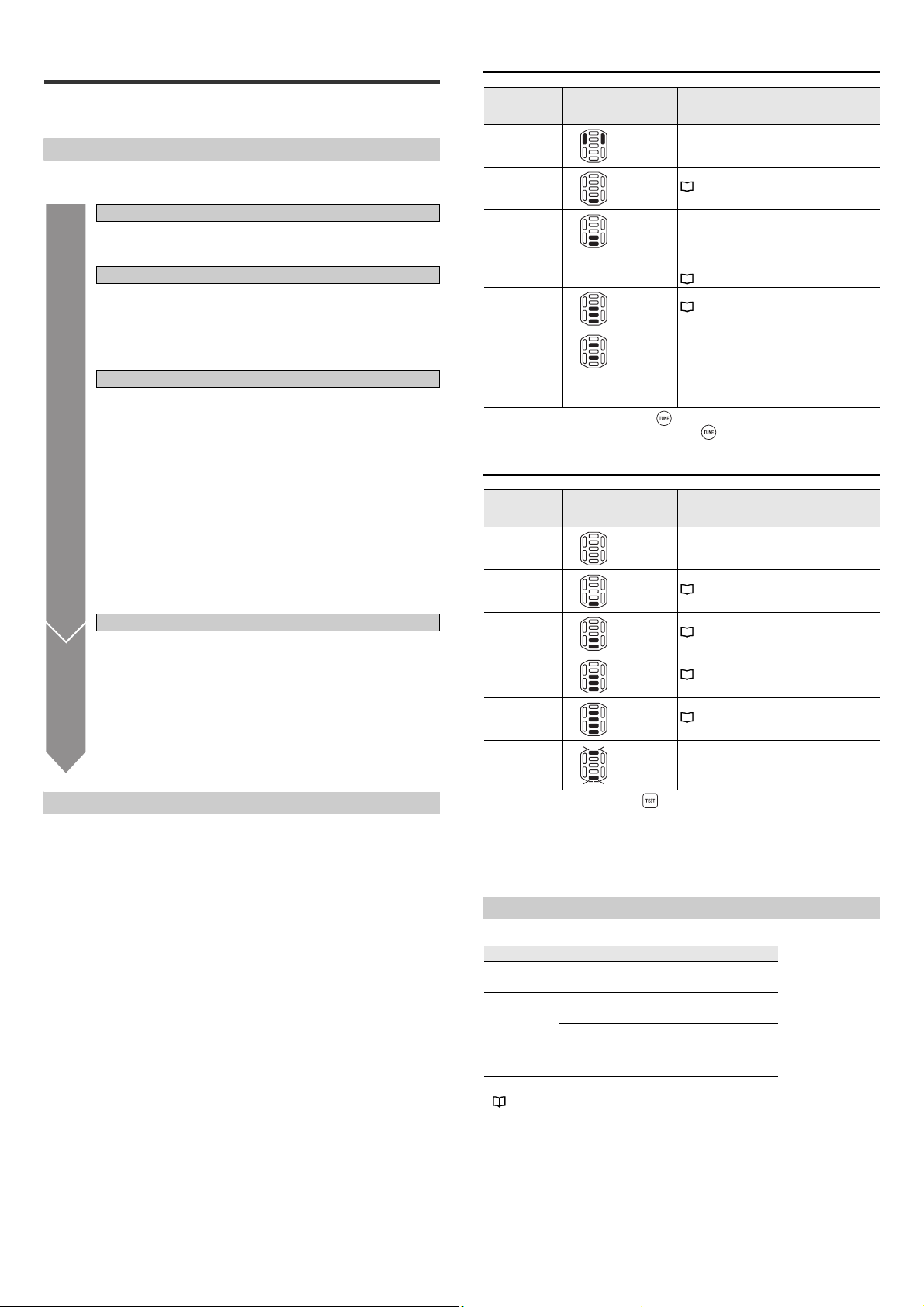

Operation status on the multiple LED indicator

Numeric

value

SR-750 Series Setup PC

Ethernet

AutoID Network

Navigator

Host

PC

PLC

Ethernet

EtherNet/IP

RS-232C

I/O terminal

PROFINET

Run mode

In Run mode, the multiple LED displays a number, letter, or other symbol.

Multiple LED

indicator

Display

content

0 to 10 When reading

P Preset Preset successful

2 points

light up

2 points

flashing

2 points

flashing

L TUNE button lock

NG Saving the read

←→

E

Error code

All LEDs

light up

Operation Meaning

successful

Laser pointer

emission

Set the

communication

parameters of the

RS-232C to the

default state.

Temporary IP

address setting

mode

error image

Error occurred. This shows that an error, such as buffer

At power-on All LEDs light up for 500 ms when the

The parameter bank number is displayed

(1 to 10).

When the parameter bank is 10, the first

digit value and "1" are displayed alternately.

"3-3 Alternate Function (Page 11)"

"3-5 Preset/Verification Function

(Page 14)"

The laser pointer is turned on when the

button is pressed quickly.

Press and hold the button for at least

6 seconds. The LED flashes and the RS232C communication condition returns to

the factory default state.

Press the TUNE button for at least 5

seconds. The LED flashes in the

temporary IP address setting mode.

The button is locked according to the

settings. The laser pointer cannot be turned

on and quick calibration cannot be performed.

The LED lights up while the read error

image is being written into the ROM.

"3-7 Image Saving Function (Page 16)"

over or IP address duplication has

occurred.

E and error code (number) lights up

alternately.

power is turned on.

Other operations

In the quick calibration operation, the multiple LED displays bars, a number, or a

letter.

Action

Quick

calibration

Multiple LED

indicator

Display content Meaning

Bar LEDs light up

in series.

Bar LEDs and

upper 2 points

light up.

This shows the progress of the quick

calibration.

The quick calibration is complete and the

test mode is running. Changing the

position of the code fluctuates the bar

LEDs.

Quick calibration failed

(Data for successful quick calibration was

F

not provided.)

Quick calibration failed

(Data for successful quick calibration was

H

provided.)

Saving complete

d

Error indications on the multiple LED indicator

Display

content

E0, E1

Main unit system error

* Abnormal operation of the main unit. Contact your nearest KEYENCE office.

Configuration file reading error, image save error

E2

* If the operation is not restored even after the main unit is initialized, there may

be problems with the main unit . Contact your nearest KEYENCE office.

E3 PROFINET error

E4 Transmission buffer overflow

E5 IP address duplication error

E6 Main unit system firmware update error

E7 PLC link error

E8 Script error

Description

Quick setup code reading mode

In Quick setup code reading mode, the multiple LED displays a number, alphabet,

etc.

Multiple LED

indicator

←→

C

Display

content

d

F

Meaning

C: Starts reading the quick setup code.

Numeric value: The number "C" of quick setup codes being

read and the numeric value are displayed alternately.

Reading successful or program successful

Reading failed or program failed

Test Mode

In Test mode, the multiple LED displays measurement results.

Multiple LED

status

5 bars lit

4 bars lit

3 bars lit

Reading rate

measurement

(%)

90 to 100 Up to 99 LEVEL 5 Green

70 to 80 100 to 199 LEVEL 4 Green

50 to 60 200 to 299 LEVEL 3 Green

Processing time

(ms)

Position

OK/NG/ERR

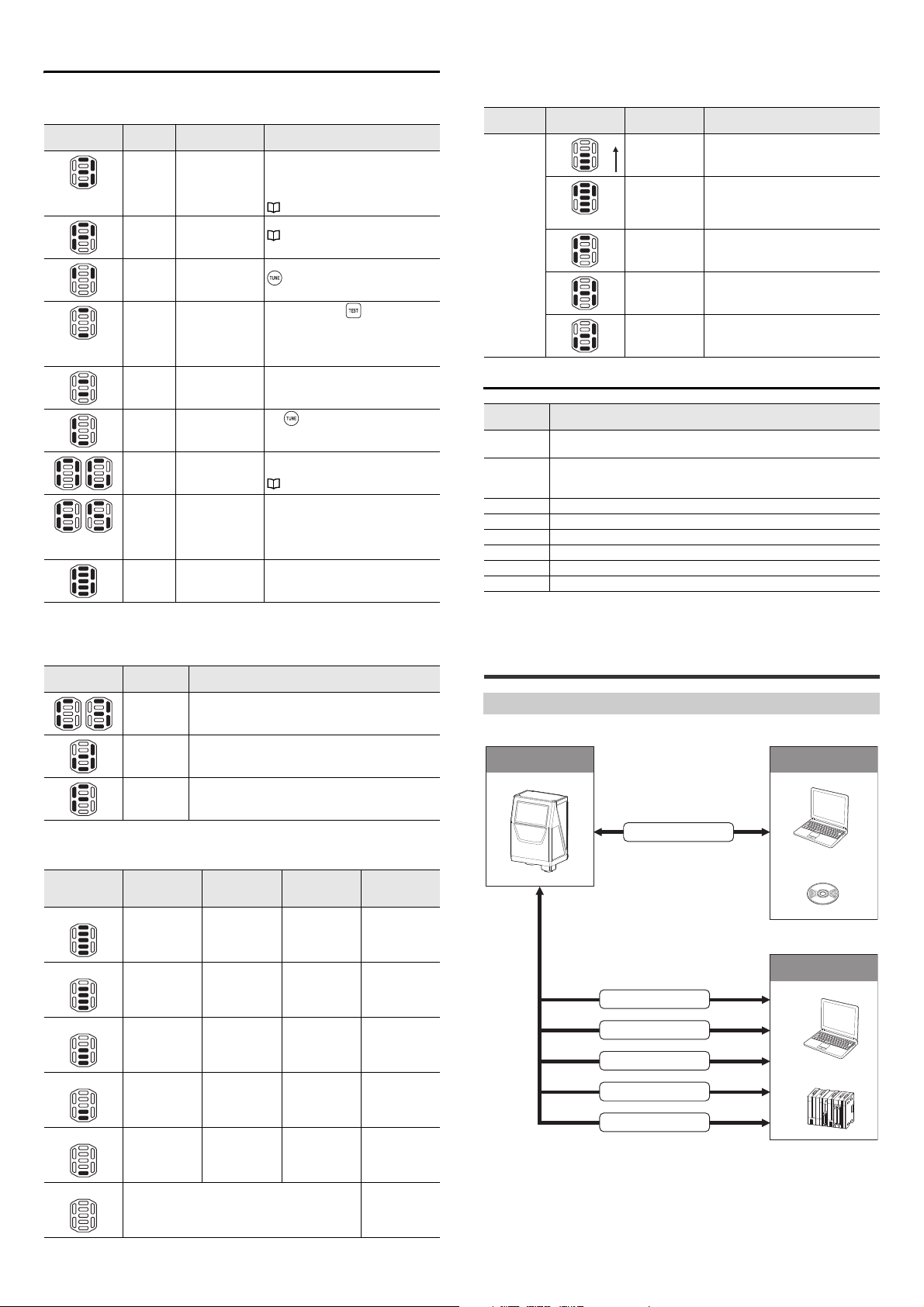

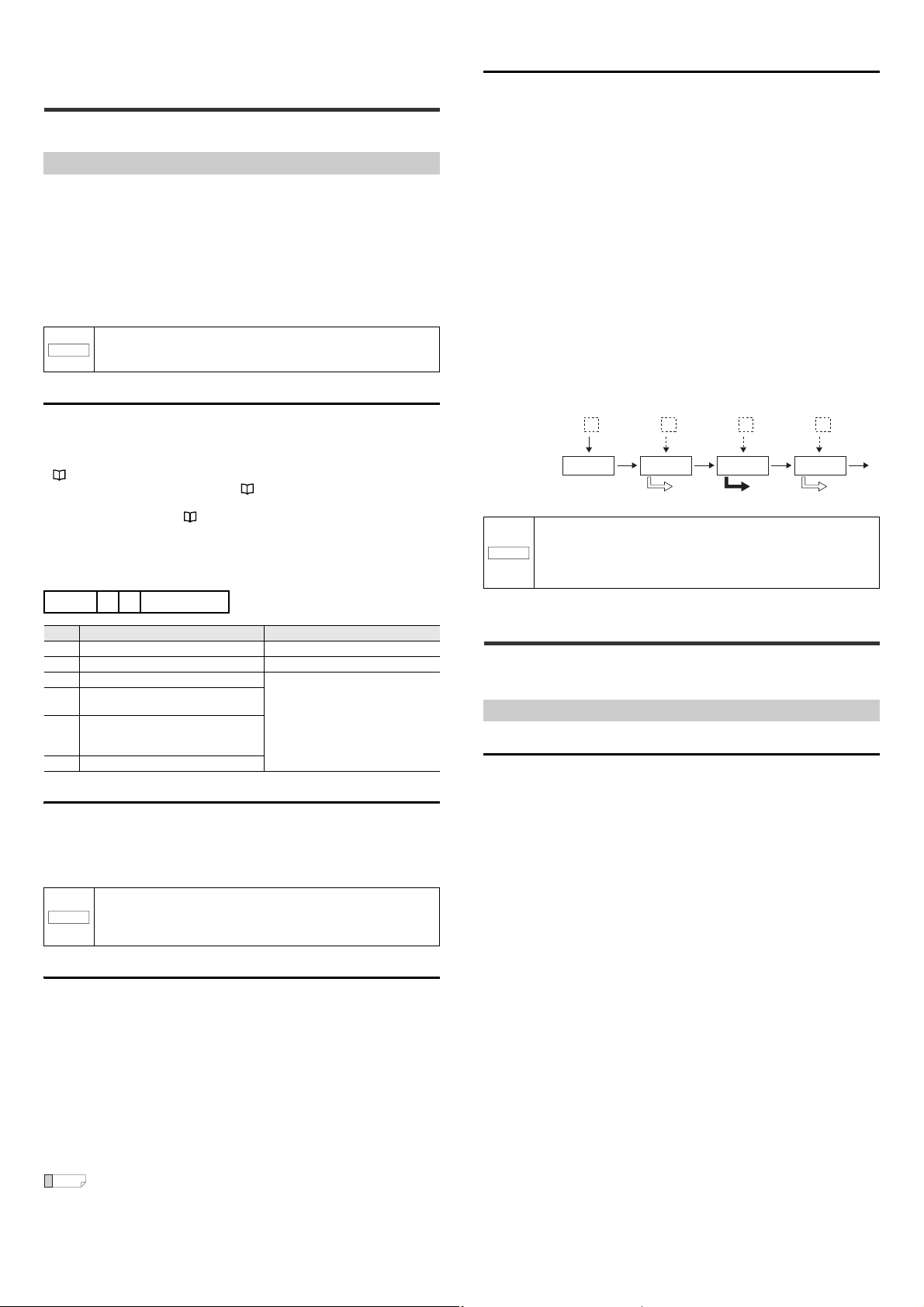

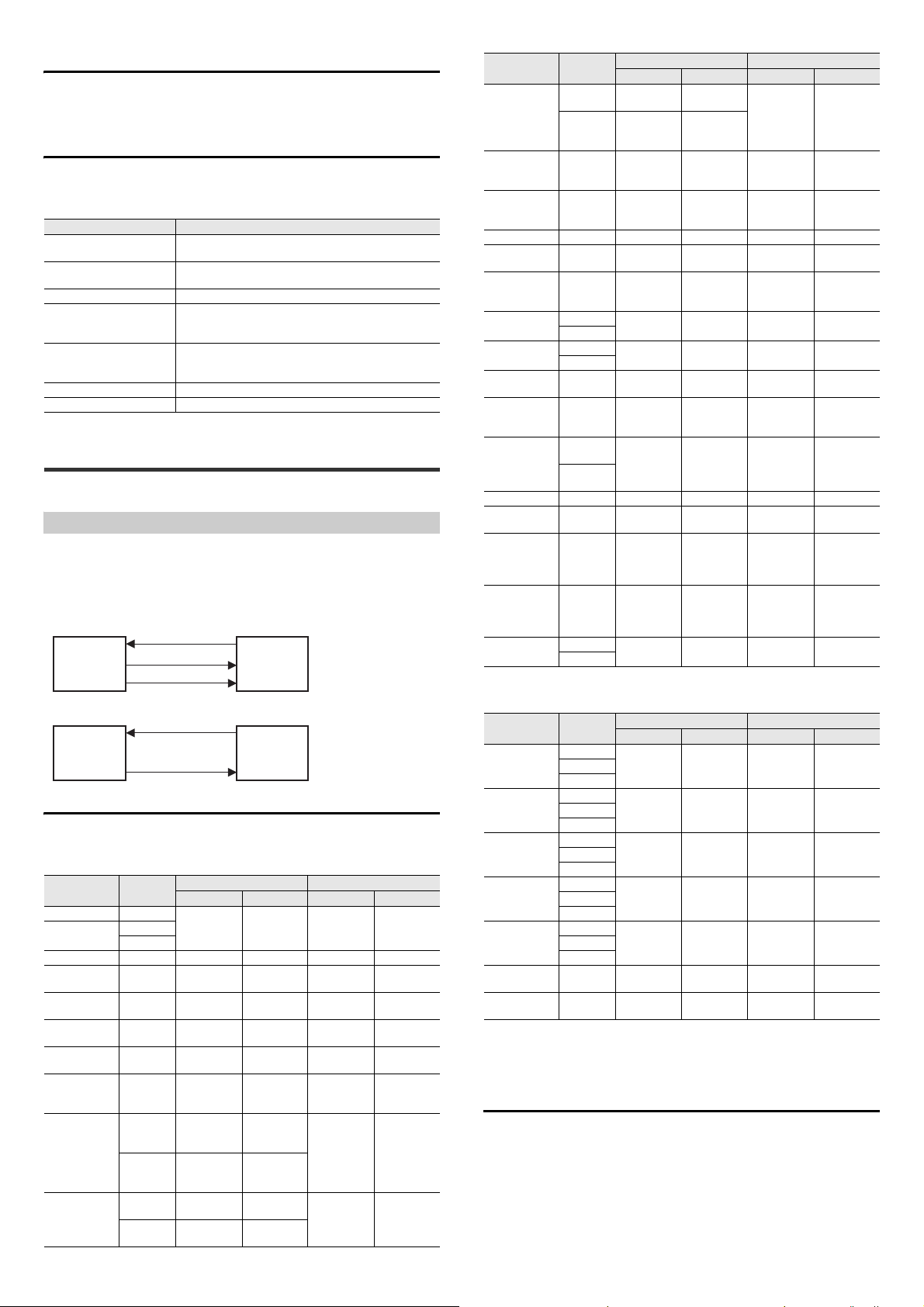

1-3 System Configuration and

Setup Flow

System configuration

The SR-750 Series has the following configuration.

LED

2 bars lit

1 bar lit

0 bars lit

E SR-750 UM

30 to 40 300 to 399 LEVEL 2 Green

10 to 20 400 or more LEVEL 1 Green

Reading error Red

4

Page 5

Setup Flow

After unpacking the package, first check the package contents.

1

Start operation.

Connect the SR-750 Series to a communication unit or a PC.

2

Use the AutoID Network Navigator to configure and send settings to the

SR-750 Series.

3

Install the SR-750 Series according to the location.

4

Adjust the reading conditions and make the operation settings of the SR750 Series.

5

This section describes the flow of the setup procedure required for starting the

operation of the SR-750 Series.

5

E SR-750 UM

Page 6

2-1 Connecting the Power

NOTICE

+24 V

+

24 V DC ±10%

Brown

0 V Blue

SR-750 Series HUB compatible with PoE power supply

Ethernet cable for the

SR-750 Series

NOTICE

NOTICE

Align the notch with the

marking position.

2-2 Connecting the Control

Source

This section describes how to connect the SR-750 Series and the power source.

Power supply to the SR-750 Series

There are 2 methods employed for connecting power source to the SR-750 Series.

• Connect the power supply wire of the control cable to a 24 V DC power supply

device.

• Connect to a PoE (Power over Ethernet) power supply device using the Ethernet

port.

Use only one of the above methods to connect to the power source according to

the usage.

Make sure to use either one of the connection methods for power

supply.

NOTICE

If power is supplied both from the control cable and PoE power

supply device at the same time, the unit may be damaged.

Wiring when supplying 24 V to the control cable

• Use a steady power supply voltage of 24 V DC ±10%.

• Do not use a power supply other than 24 V DC. Otherwise, it

may cause failure.

• Before connecting or disconnecting cables, make sure to turn

off power to the equipment connected to the SR-750 Series.

Otherwise, it may cause the failure of the SR-750 Series.

Connection when supplying power from a PoE device

Use the Ethernet cable for the SR-750 Series for connection. Connect the RJ-45

connector of the Ethernet cable to a device (switching hub, etc.) compatible with

the PoE power supply feature.

Cable and Wiring

Connect the control cable to the SR-750 Series.

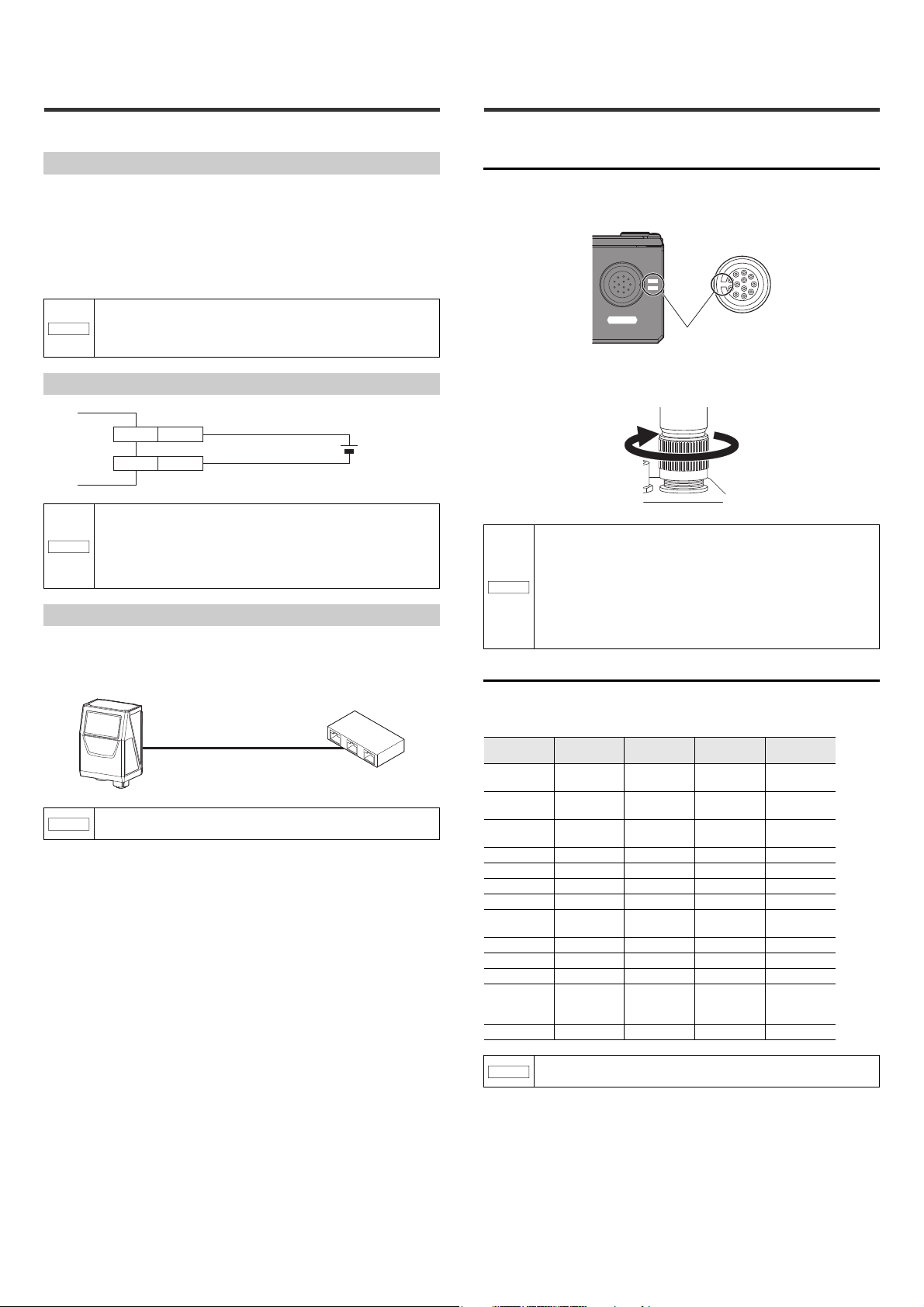

Control cable connection method

1 Align the dent of the cable connector with the marking position next

to the control port.

POWER

2 Tighten the connector screw by turning clockwise. Set the screw

tightening torque to 1.5 - 2.0 N•m.

When connecting the connector, insert it not to lean toward one

side and securely tighten it. Under-tightening can lead to loose

connector due to vibrations, resulting in poor contact.

Insufficient tightening may not meet the requirements of the

protective structure.

* To get a rough idea, after tightening it by hand, retighten it

approximately 90° - 120° using a tool such as pliers.

Do not repeatedly bend the root of the connector of control cable.

Loose connection may result.

Control cable color and the meaning of signal

Be sure to connect with a PoE power supply device compliant

NOTICE

with IEEE802.3af.

The following different color lead wires are drawn out of the control cable. Solder

the lead wire to the connector using the wire attached to the device to be

connected.

Wire color Symbol Description

Brown 24 V

Blue 0 V

Orange RXD

Yellow TXD RS-232C Send Output 28

Purple SGND RS-232C GND – 28

Green IN1 IN1 Input Input 26

Gray IN2 IN2 Input Input 28

White and blue INCOM

Pink OUT1 OUT1 Output Output 28

Aqua blue OUT2 OUT2 Output Output 28

White OUT3 OUT3 Output Output 28

Black OUTCOM

Black tube FG FG – –

Make sure to turn the power off when attaching or removing the

control cable.

+24 V power

supply

Power supply

GND

RS-232C

Receive

Input common

mode voltage

Output

common mode

voltage

Signal

direction

Input 26

–26

Input 28

–28

–28

AWG si ze

E SR-750 UM

6

Page 7

Control cable (NFPA79-compliant) with D-Sub9 pin

D-sub9 pin (Female)

DTE specifications (Terminal definition)

M2.6 screw

54321

9876

Pin No. Symbol Description Signal direction

2 TXD Data Send Output

3 RXD Data Receive Input

5 SGND Signal GND -

Wire color Symbol Description

Green IN1 IN1 Input

Gray IN2 IN2 Input

White and blue INCOM Input common

Pink OUT1 OUT1 Output

Aqua blue OUT2 OUT2 Output

White OUT3 OUT3 Output

Black OUTCOM Output common

1 mm

10 mm

Wire color Symbol Description

Brown 24 V +24 V Power supply

Blue 0 V Power supply GND

Black tube FG FG

6.6 mm

11 m m

4.3 mm

FG Black tube

10kΩ

+

5.6kΩ

Photocoupler isolation

Contact

or

non-contact

Internal circuit

IN1 (Green)

IN2 (Gray)

INCOM

(White and blue)

IN1

(Green)

INCOM

(White and blue)

Brown (red)

Black (white)

Blue (black)

Photoelectric Sensor (NPN)

0002

0001

0000

C

PLC

OUT

COM

(Black)

OUT

1

(Pink)

OUT

2 (Aqua

blue)

OUT

3

(White)

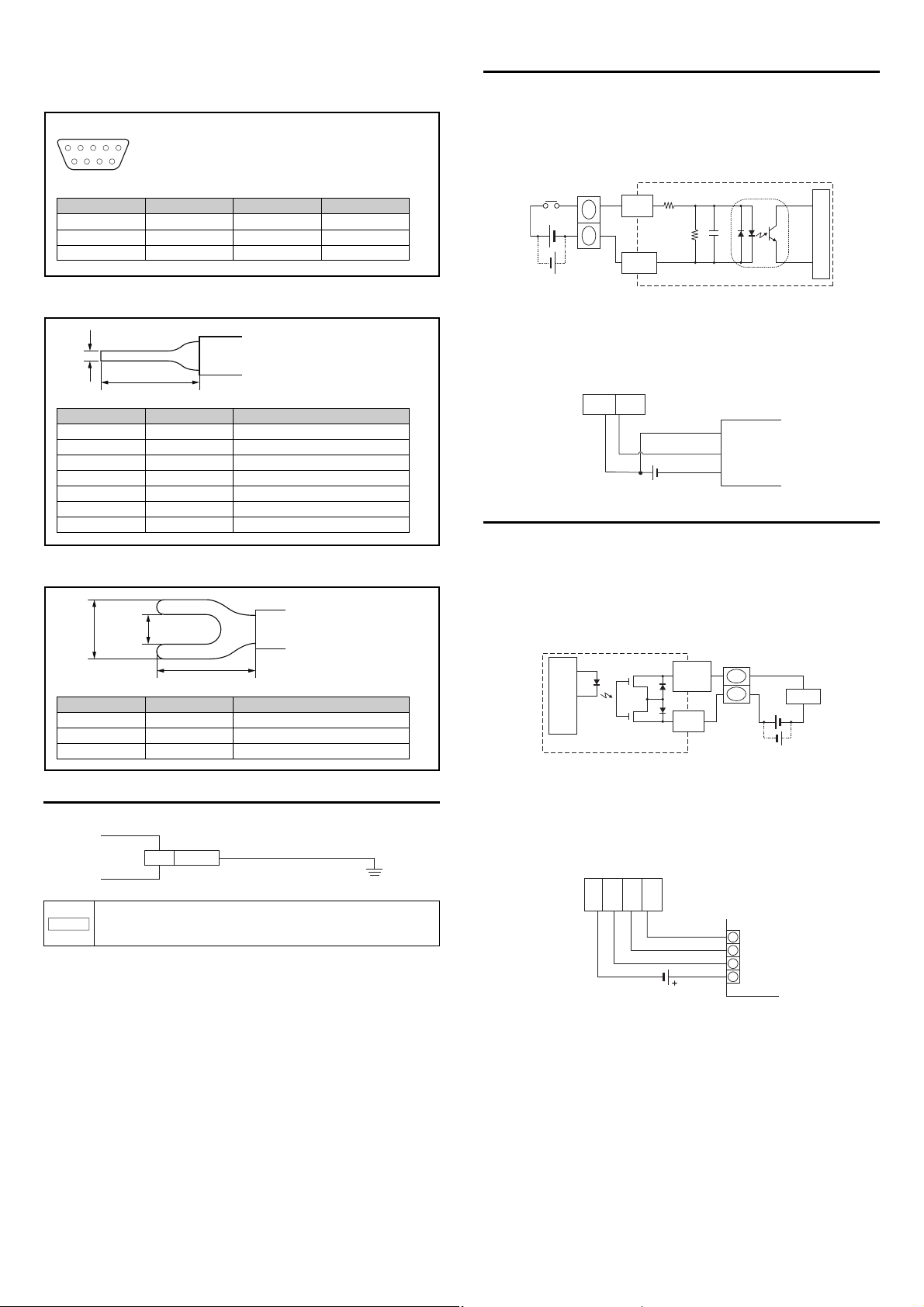

z RS-232C wire

The tip of the RS-232C wire is a D-sub9-pin.

IN1/IN2 wire connection

• The IN1 (timing) input means the input that causes the SR-750 Series to start

reading.

• The IN2 (preset) input means the input that causes the SR-750 Series to register

preset data.

IN1/IN2 inputs operate by voltage inputs.

z Control wire (Input/Output signal wire)

The tip of the control wire is a rod terminal.

z Power wire

The tip of the power wire is a Y-shape terminal.

• Input rating : 15 - 26.4 V DC

• Repetitive peak off-state current : 0.2 mA

Connecting a photoelectric sensor manufactured by

KEYENCE

Connection example when the IN1 terminal is used as the trigger input terminal.

Connecting the OUT1/OUT2/OUT3 wires

• The OUT1 (OK) output is used as an output for successful reading and

verification of OK as a result of checking against the preset data.

• The OUT2 (NG/ERROR) output is used as an output for reading failure and

verification of NG reading as a result of checking against the preset data.

• OUT3 (BUSY) is output any time the trigger input cannot be accepted. For

example, a busy signal will be output at initial start-up, during the key operation,

reading operation, etc.

The output form of each signal is photo MOS relay.

Internal circuit

OUT 1(Pink),

OUT2 (Aqua blue),

OUT3 (White)

OUT COM

(Black)

Load

+

Connecting the FG wire

Be sure to provide Class D ground for the FG wire.

The shield and FG wire of the control cable and the shield of the

Ethernet cable are electrically connected via the main unit case.

NOTICE

Provide them with a common ground.

• Maximum rated load : 30 V DC (1 output maximum 50 mA, 3 outputs

total 100 mA or less)

• Leakage current when OFF : 0.1 mA or less

• Residual voltage when ON : 1 V or less

Connection with KEYENCE PLC (Programmable

controller)

7

E SR-750 UM

Page 8

Wiring the RS-232C signal line

PC SR-750 Series

D-Sub 9 pin

(female)

#4-40 screw

Yel lo w

Orange

Purple

3

5

RD

SD

TxD

SGND

RxD

4SG

Handheld programmer SR-750 Series

Modular

Connector

Yel l ow

Orange

Purple

2

7

3

8

4

5

6

RD

RS

SD

CS

ER

SG

DR

TxD

SGND

RxD

KV-L20V/L20R (Port 1)

KV-N10L

SR-750 Series

D-Sub 9 pin

(female)

#4-40 screw

Yel lo w

Orange

Purple

KV-L20V/L20R (Port 2) SR-750 Series

Yellow

Orange

Purple

2

3

5

8

4

7

1

6

RD

SD

RS

CS

ER

DR

SG

CD

TxD

SGND

RxD

QJ71C24N/-R2 SR-750 Series

D-Sub 9 pin

(male)

M2.6 screw

Yellow

Orange

Purple

SD

RD

RS

CS

SG

TxD

SGND

RxD

2

3

4

5

9

PLC SR-750 S eries

D-Sub 9 pin

(male)

M2.6 screw

Yellow

Orange

Purple

N-R4 SR-750 Series

Round connector

12-pin

(male)

Yel l ow

Orange

Purple

NOTICE

protrusion

positioning pin

connector screw

View from the connector side

protrusion

positioning pin

Rotate the connector screw so that the

protrusion and the positioning pin come

to the above position.

Approx. 4 mm of clearance remains when

inserted fully.

Approx. 4 mm

white mark

protrusion

POWER

ETHERNET

Connect to host devices (PC, PLC, etc.) as illustrated below:

Connection to a PC

2

RxD

TxD

GND(SG)

RTS

CTS

DTR(ER)

DSR(DR)

3

5

7

8

4

6

TxD

RxD

SGND

Connection to the handheld programmer for the

KEYENCE KV Series

Connection to the KV-L21V/L20V/L20R/N10L

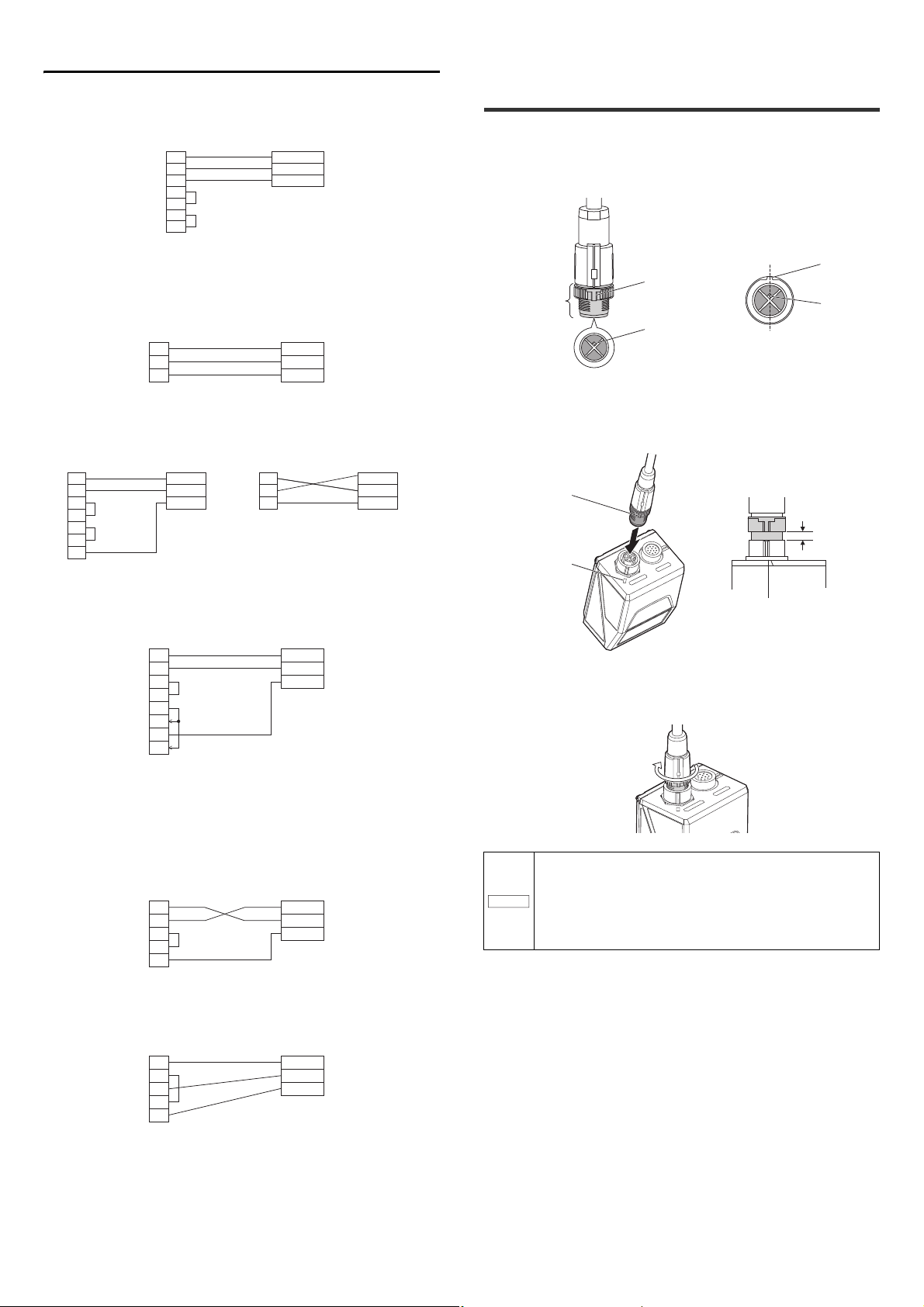

2-3 Connecting the Ethernet

Cable

Connect the Ethernet cable to the SR-750 Series in the following procedure.

1 Preparation of Ethernet cable

First, rotate the connector screw and align the protrusion position with the

positioning pin position in the connector.

2 Connect to the SR-750 main unit

Align the protrusion position of the connector screw with the white mark

position of the SR-750 Series Ethernet port. Then, insert straight to avoid tilting

the connector.

3

SD

5

RD

1

SG

Connection to the QJ71C24N/-R2

Connection to the SYSMAC Series PLC

CJ1W-SCU(-V1)

CS1W-SCU-V1

CS1W-SCB-V1

CP1W-CIF01

TxD

RxD

SGND

POWER

ETHERNET

3 Tighten the connector

Rotate the connector screw in the arrow direction until it stops (approx. 180

degrees) and tighten it.

• When connecting the connector, insert it straight so it does not

tilt. Otherwise, the connector pin may be damaged.

• Tighten the connector screw correctly. If it is not tightened

properly, the connector may become loose due to vibration, etc.

and connection failure may occur.

• Do not repeatedly bend the root of the connector of Ethernet

cable. Loose connection may result.

Wiring with the N-R4 Series

RD

RS

SD

CS

GND

E SR-750 UM

3

4

7

8

12

TxD

RxD

SGND

8

Page 9

3-1 Using the SR-750 Series

Preparations

Start of

Operation

TUNE Button Operation Procedure

This section describes basic uses for performing reading operation using the SR750 Series.

Basic steps

Before using the SR-750 Series, register codes and conduct read test by

performing the following steps:

(1) Read condition setting

Perform the quick calibration on the SR-750 Series.

• 3-2 Quick Calibration

• 5-4 Details of Settings View

(2) Read test

Once the quick tuning is complete, confirm that reading is stable.

Using the test mode of the SR-750 Series, confirm the reading

stability and the read processing time.

• 3-1 Using the SR-750 Series (TEST Button Operation).

• 3-4 Test Mode

• 5-8 Terminal

(3) Determination of operation

Let's consider the usage of the SR-750 Series.

The SR-750 Series has functions that lead to stable operation or

reduction in control man-hours.

Function leading to stable read

• 3-3 Alternate Function

• SR-750 Series Operations

Function leading to reduction in control man-hours

• 3-5 Preset/Verification Function

• 3-6 Multi-I/O Function

• 3-8 Silent Mode

• Edit data function and edit image file name function

• Duplicate reading prevention interval reset

• Master/Slave function

Connection method with a control device

• Connection and Wiring

• SR-750 Series Communication Specifications

(4) Start of Operation

Once the operation procedure and installation conditions have been

determined, you can start the operation.

The SR-750 Series has the functions that are useful for analyzing

read errors, etc. that occur during operation.

• Matching function

• 3-11 Code quality verification function

• 3-7 Image Saving Function

• 7-2 Data Communication Format

• 7-6 FTP Communication

Multiple

Operation

Press once

quickly

(less than 1 s)

Press for 2

seconds

Press for 3

seconds

Press for 4

seconds

Press for 5

seconds

indicator

LED

Lighting Action

The laser pointer emits a laser beam.

(Reading is disabled while the laser pointer is

on.)

Illuminates

Illuminates

Illuminates

Illuminates

Activates the quick calibration function.

1 time

2 times

3 times

3 times

"3-2 Quick Calibration (Page 10)"

The number of parameter banks (0 to 10) for

which the alternate function can be used is

shown on the multiple LED indicator. When the

number of registered parameter banks is 10, "0"

and "1" are displayed alternately.

"3-3 Alternate Function (Page 11)"

Activates the batch setting reading mode.

"3-10 Batch Setting Code (Page 20)"

Activates the temporary IP address setting

mode.

* Only in this mode, the operation does not

finish even if the TUNE button is briefly

pressed once. Assign the temporary IP

address or turn the power on again.

* To quit an action/mode, press the button once briefly.

To quit the quick calibration, hold down the button for at least 2 seconds.

TEST Button Operation Procedure

Multiple

Operation

Press once

quickly

(less than 1 s)

Press for 2

seconds

Press for 3

seconds

Press for 4

seconds

Press for 5

seconds

Press for 6

seconds

indicator

LED

Lighting Action

Illuminates

Illuminates

Illuminates

Illuminates

Illuminates

Illuminates

One reading operation is performed.

Activates the reading rate test mode.

1 time

2 times

3 times

4 times

5 times

"Reading rate test mode" (Page 12)

Activates the tact measurement test mode.

"Read time test mode (Page 13)"

Activates the bar code position test mode.

"Code position measurement test mode"

(Page 13)

Runs the multi 1 read mode.

"4-4 Read Mode (Page 28)"

Sets the communication settings of RS-232C to

the default state temporarily.

SR-750 Main Unit Buttons

The SR-750 Series main unit has 2 buttons for registering and adjusting the

reading operation.

• TUNE button : used for turning on the laser-aimer, starting quick calibration and

• TEST button : used for starting the test mode and changing the RS-232C

According to the operating status of each button, the status is also displayed on the

multiple LED.

This section describes the operation procedure of the 2 buttons.

reading the quick setup code

communication settings to the default condition.

* To quit an operation, press the button once briefly.

* The default state of the RS-232C communication settings is as follows.

• The default settings for the RS-232C communication

Baud rate : 115200 bps Header : None

Data bits : 8 bit Terminator : CR

Parity : Even Stop bit length : 1 bit

Operation of I/O terminals

The default settings of the I/O terminals of the SR-750 Series are as follows:

Terminal Function

Input terminal IN1 Trigger input

Output terminal OUT1 OK

IN2 Preset input

OUT2 NG/ERROR

OUT3 TRG BUSY

LOCK BUSY

MODE BUSY

ERR BUSY

* Functions of each terminal can be changed according to the settings.

"3-6 Multi-I/O Function (Page 14)"

9

E SR-750 UM

Page 10

3-2 Quick Calibration

TEST TUNE

SR-625

POWERR

NET IN

STB

OK/NG/

Focal distance : SR-750H A : 38 mm

SR-750 : 60 mm

SR-751 : 100 mm

SR-752 : 250 mm

Illuminating LEDs

increase upward.

Reading rate

Test result display

Illuminates

Flash alternately

Flash alternately

Parameter bank No.

Indicates whether the

initial settings have

been changed or not.

Green: Not changed.

Red: Changed

Illuminates in green

Illuminates in red

This section describes the Quick Calibration function.

Quick Calibration

The SR-750 Series automatically adjusts parameters for reading the target codes

through the main unit button operation or AutoID Network Navigator and store the

settings in its internal memory.

This function is called "Quick Calibration".

Set the calibration condition by using AutoID Network Navigator or sending the

setting commands.

Setting items of calibration conditions

• Camera settings

Set the brightness adjustment mode, exposure on high speed mode, offset and

dynamic range.

• Tuning options

Set the tuning method, multi read and inverse read.

Quick Calibration Function Operation

The following are the quick calibration methods.

• Using the main unit buttons

• Using the input terminal

• Using AutoID Network Navigator

Each operation method is described.

Activation using the button on the panel

Use the button on the panel of the SR-750 Series to activate the quick calibration.

When the button is held down for 2 seconds in Quick Calibration mode, the

quick calibration is canceled and the SR-750 Series returns to Run mode.

1 Set up the SR-750 Series and prepare the code that is going to be

read.

2 Press the button quickly to start the laser pointer emission and

adjust the reading position.

After the adjustment, press the button quickly to turn off the laser pointer.

* When SR-75L4 or SR-75L6 is attached, the emission of the laser pointer is

not visible.

4 After the calibration, the reading rate measurement is performed

automatically.

Once the calibration finishes successfully, the

SR-750 Series starts the reading rate

measurement.

Check the level of reading stability on the

multiple LED indicator.

If the reading failure continues for a certain period of time, the quick calibration

is performed again.

If the calibration fails, "F" or "H" is displayed

By pressing the button, you can perform the quick calibration again.

• F: Displayed when the quick calibration

failed.

• H: Displayed when the quick calibration was

completed successfully but the reading

failed and another quick calibration was

attempted but failed.

By pressing the button, you can register

the result of the successful calibration.

5 Press the button and select the parameter bank in which to

register the parameters.

Every time the button is pressed, the

parameter bank number changes by one.

When the initial settings have been changed

for the parameter bank being displayed, the

OK/NG/ERROR LED illuminates in red.

When the parameter bank number is 10, "0"

and "1" are displayed alternately.

6 When the parameter bank in which to register the parameters is

determined, press the button to register the parameters.

When the parameters are registered

successfully, the multiple LED indicator

shows "d".

Activation using the input terminal

By assigning "Quick Calibration Operation" to an input terminal, you can use that

terminal to activate the quick calibration.

1 Turn on the input terminal to which the function has been assigned.

The quick calibration starts.

2 "1" is displayed.

Parameter bank 1 is overwritten with the

calibration result and the TUNING OK output

turns on.

When the calibration fails, the OK/NG/ERROR

LED illuminates in red, the ERROR signal is

output, and the calibration operation ends.

3 Press and hold the button for two seconds to perform quick

calibration.

During the quick calibration, the multiple

LED indicator illuminates as shown on the

right.

E SR-750 UM

Point

When the input terminal is used to activate the quick calibration,

the calibration result is automatically written to parameter bank

No. 1.

3 Turn off the input terminal.

10

Page 11

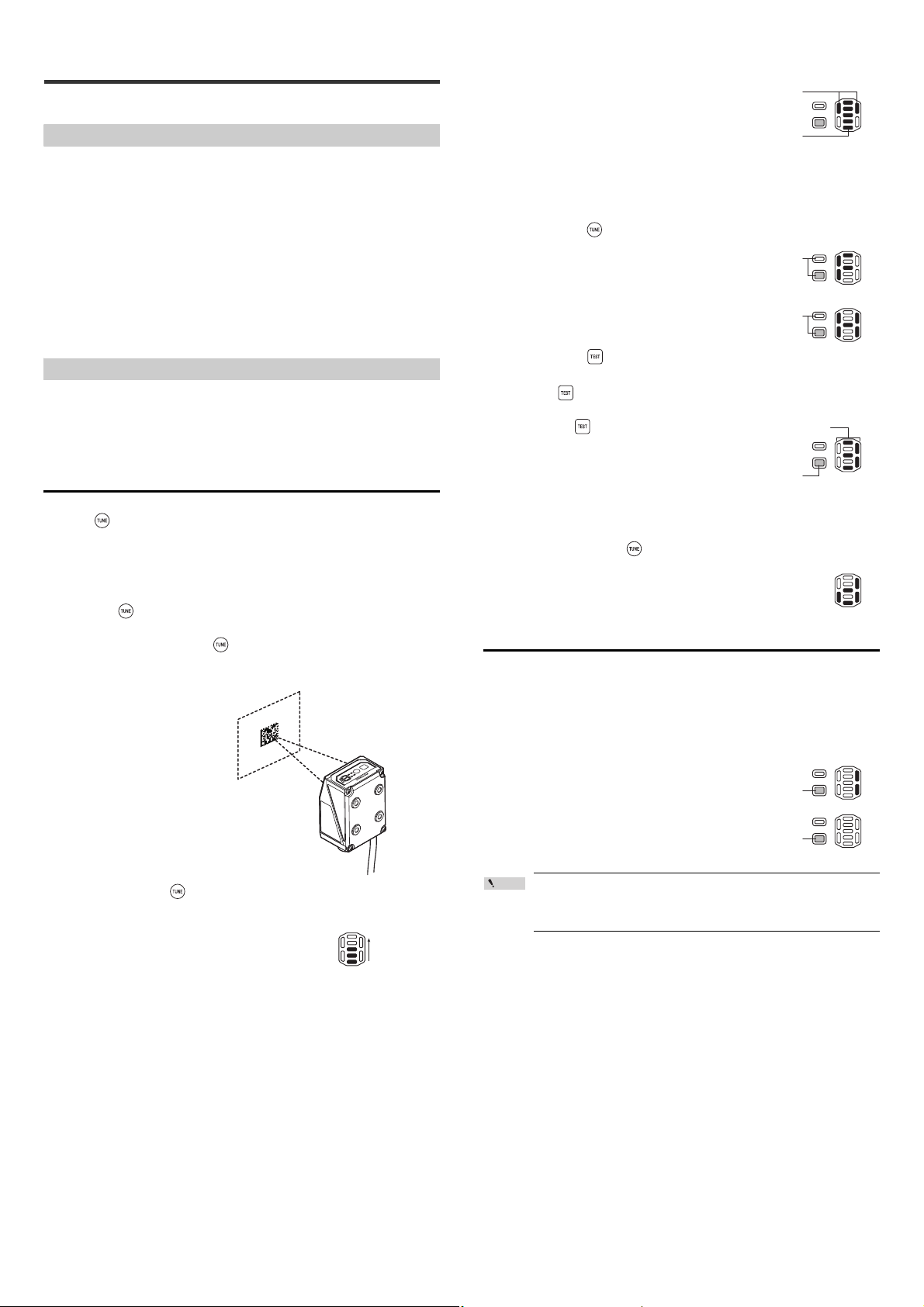

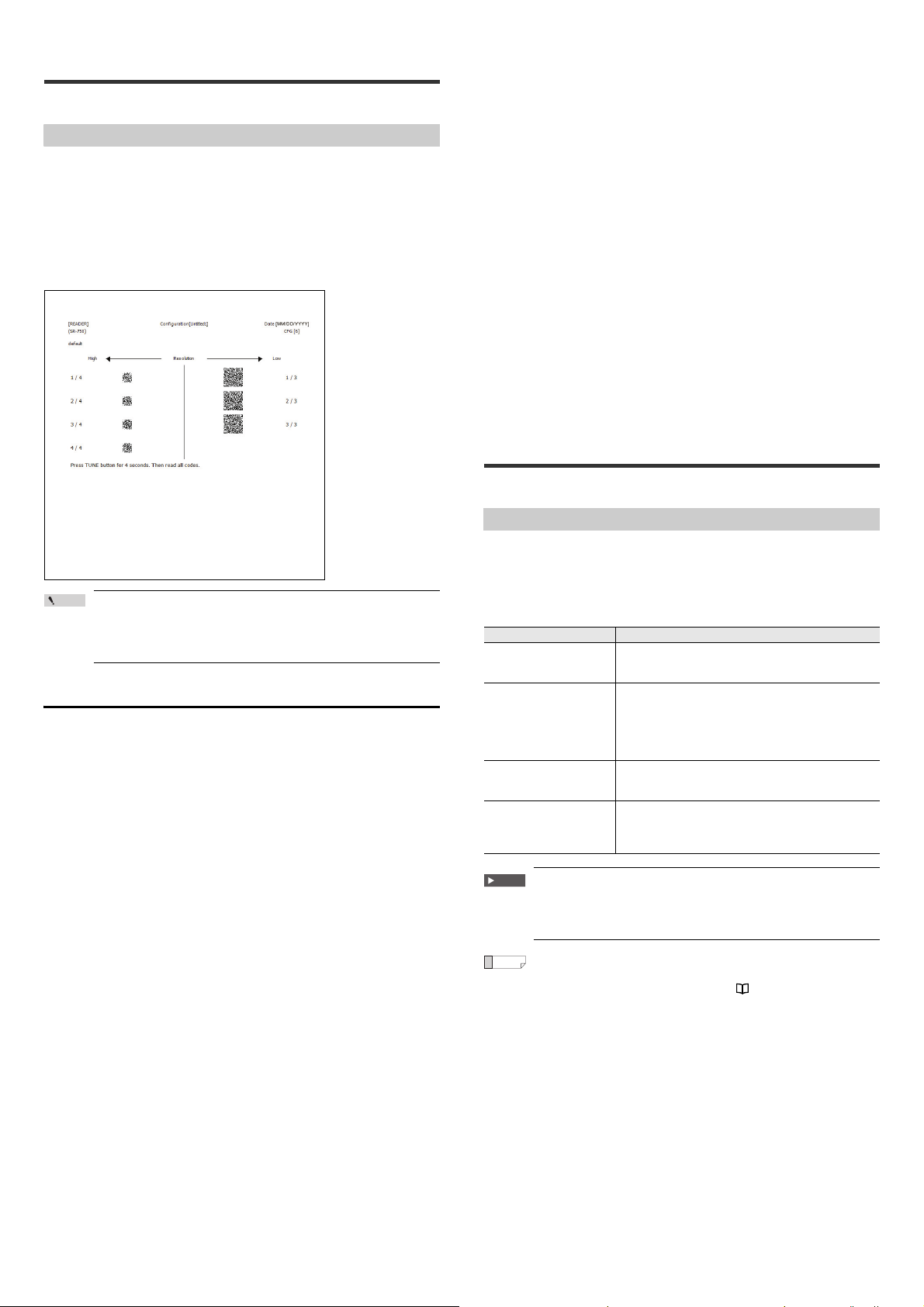

Activation using AutoID Network Navigator

Lights up in green

or blue

Brightness adjustment bar

YES

YES

YES

YES

NO

NO

NO

NO

Reading success

Start reading

Scanning

Decoding

Read error

Select parameter bank

Was re ading

successful?

Level trigger

turned off?

or

One-shot

timeout?

Decode timeout

period remains?

Retry possible?

Quick calibration is performed using AutoID Network Navigator.

Confirming the actual scanned image, you can operate calibration.

1 Connects the SR-750 Series to the AutoID Network Navigator

The following screen will appear when the SR-750 Series is detected.

Confirm that the indicator displayed on the left of the reader name lights up in

green or blue.

2 Click the [Pointer] button.

The laser pointer of the SR-750 Series lights up. Adjust the center of the code

to the position where the laser pointer emitted.

3 Click the [Monitor] button.

Looking at real-time scanned images, you can confirm the code positions.

Adjust the brightness using the "Brightness adjustment bar" on the right.

After the code position is determined, press the "Monitor" button to finish the

setting.

3-3 Alternate Function

This section describes the alternate function.

Alternate Function

The SR-750 Series can perform the reading operation while switching between

multiple parameter banks that are registered for the code being read.

The function that performs reading operation with the most appropriate parameter

while automatically switching the parameter bank - this is called "Alternate

Function".

Even when there are fluctuations in printing conditions or reading distance, since it

operates by switching between multiple parameter banks during a single read

operation, a stable read operation is provided.

By default, read operation is performed using the parameter bank 0 (bank for read

quick setup code).

Parameter banks

The SR-750 Series sets parameters necessary for code recognition such as scan

conditions and filter conditions.

Location where this setting is stored is called a "Parameter Bank".

The SR-750 Series has 10 parameter banks. Multiple optimal parameters can be

registered according to work conditions and printing conditions.

The following settings are stored in the parameter bank.

• Code type............................Set the version of the code to be read, the number of

codes, and the output length limitation function.

• Internal light/External light... Set whether or not to use internal lighting and

external lighting.

• Scan conditions................... Set exposure time, gain, and dynamic range.

• Filter .................................... Set the filter condition to be used.

• Others ................................. Set the alternate, decoding area, algorithm, etc.

4 Click [Calibration] button.

The most appropriate scan condition is automatically set according to the code.

Settings are registered with bank, and the operation finishes.

5 Perform the reading test.

Perform the reading rate test and processing time test, and confirm the reading

stability of the calibration result.

• Reading rate test display screen • Processing time test display screen

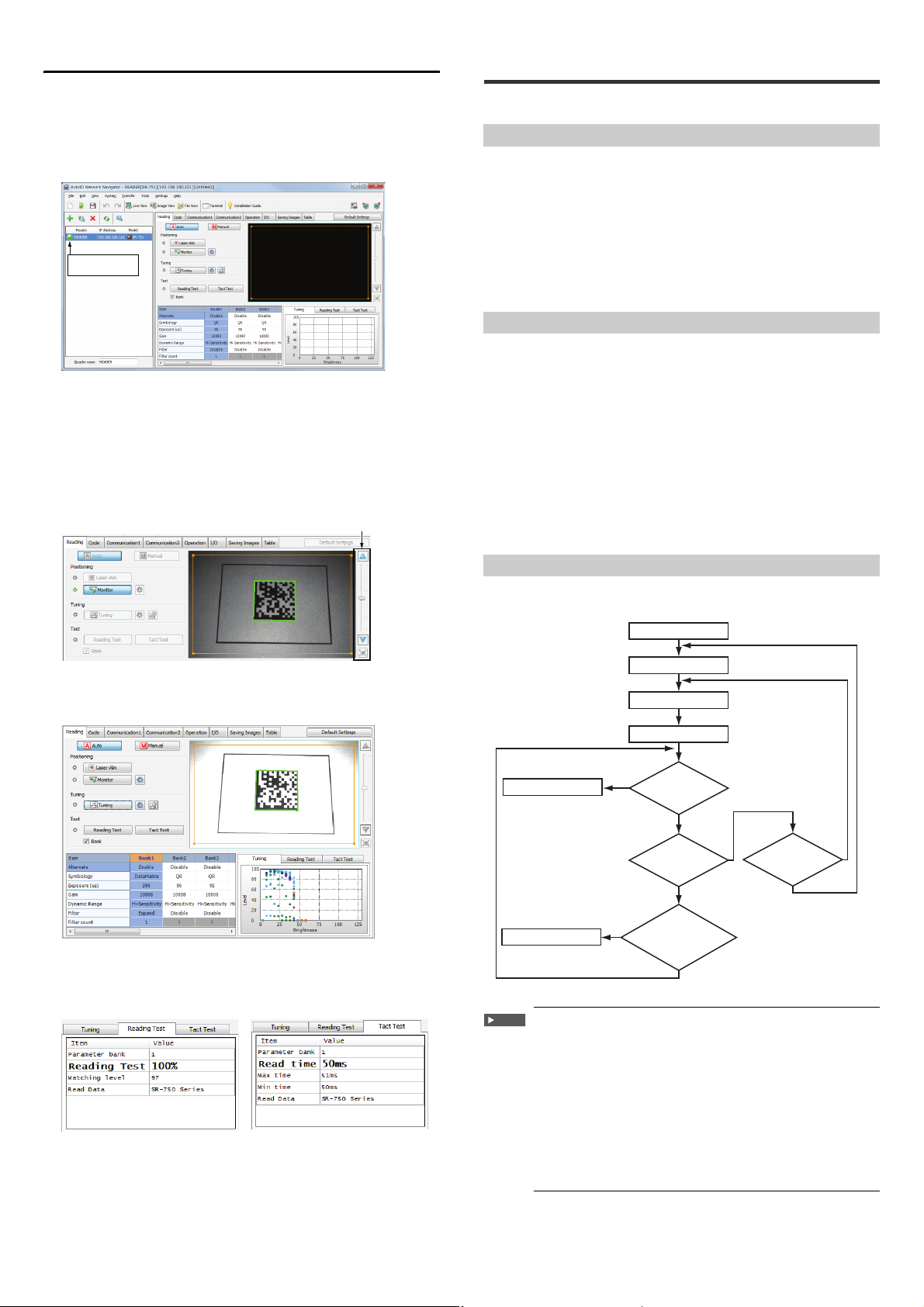

Alternate Function Operations

The following flow chart illustrates operations that occur during the alternate

function:

* Reading starts from the bank set as the "Alternate start bank".

Important

Since the alternate function cycles through the parameter banks

one at a to determine the optimal settings, overall processing time

may increase. (The processing time depends on the decode

timeout period setting.)

The alternate function is turned off by default. The function is

enabled automatically after the Tuning operation has been

performed on any of the parameter banks.

The alternate function is disabled in the following cases:

• When using the read mode in the burst mode

• When the alternate function is turned off for all parameter banks

• When the bank specify trigger input command (LON01 to 10) is

sent to directly specify the parameter bank for reading.

11

E SR-750 UM

Page 12

Bank prioritizing function

Point

Reference

Reading

order

Parameter bank

No.

Reading

order

Parameter bank

No.

1

1

1

3

2

2

2

1

3

3

3

2

4

4

4

4

Reading

Success

Activate the test. Stop the test.

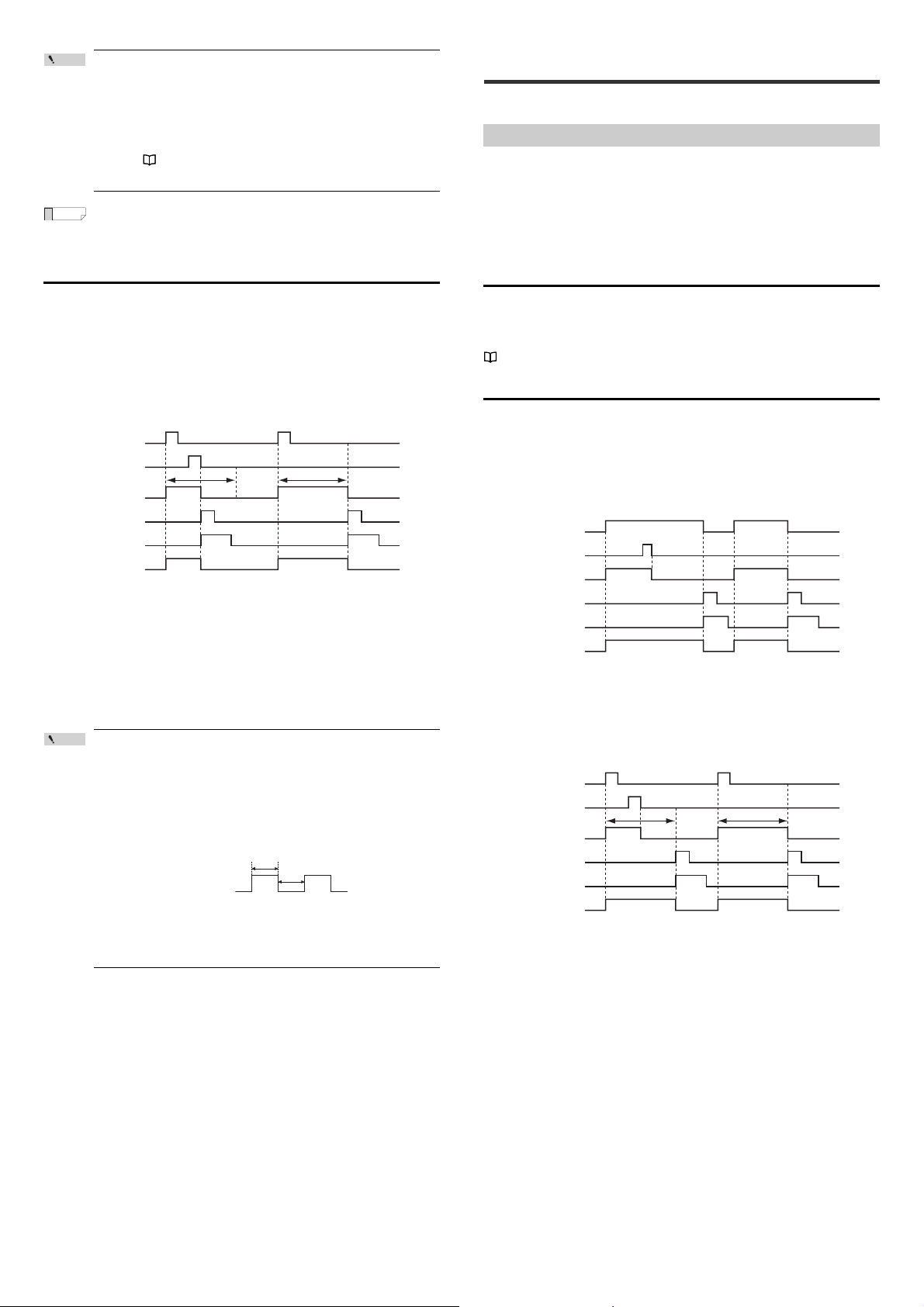

Tes t in g

Test operations

Tes tin g

Test commands

Timing operation

Testing

Tes t i ng

Activate the test. Stop the test.

Timin g ON Timing OFF

When the alternate setting order is set to "Begin with successful bank", the next

reading starts from the parameter bank of the most recent successful reading.

When codes with similar conditions are read in sequence, prioritizing according to

the last successful bank may result in a shorter reading processing time.

Operation of the bank prioritizing function when parameter banks 1 to 4 are

used

The reading order is changed to start reading from the parameter bank of the

previous successful reading.

The bank prioritizing function is effective only in Operation mode.

The reading order is reset to the default setting when one of the

following operations is performed:

• Stopping the power supply

• Entering the test mode

• Entering Setting mode or Test mode

• Changing the alternate setting

Online mode

Online mode is useful for troubleshooting issues during run-time operation.

Online test mode can only be enabled through serial command input.

"8-2 Operation Commands (Page 71)"

To begin the test, turn the timing input on. To end the test and output results, turn

the timing input off.

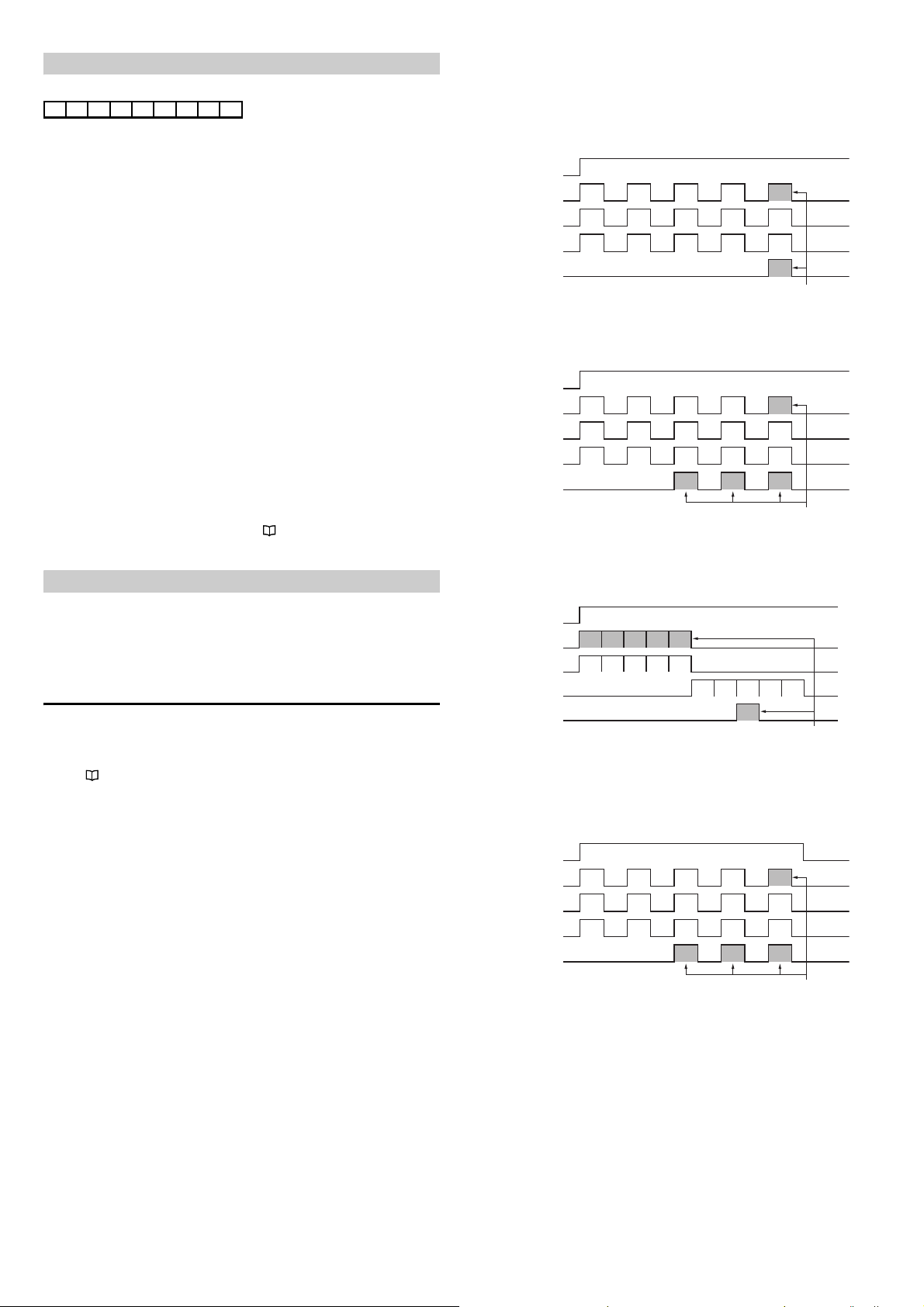

Test Mode Measurement Status

The measurement status of the test mode can be checked on the multiple LED

indicator.

The multiple LED displays the following symbols during test mode.

Multiple LED status

5 bars lit

4 bars lit

Reading rate

(%)

90 to 100 Up to 99 LEVEL5 Green

70 to 80 100 to 199 LEVEL4 Green

Processing

time (ms)

Code position

measurement

OK/NG/

ERROR LED

3-4 Test Mode

This section describes the test mode of the SR-750 Series.

SR-750 Series Test Mode

Function Description

Reading rate test mode Offline Scans codes 10 times and measures the

Offline This test mode checks the number of

Read time test mode Offline This test mode measures the amount of

Offline This test mode measures the amount of time

Code position measurement

test mode

Offline In this test mode, the level that indicates how

For more information about the TEST button operations of the SR-750 Series or

the multiple LED status display, refer to "3-1 Using the SR-750 Series (Page

9)".

•

It is also possible to perform the test mode by specifying a parameter

bank.

"8-2 Operation Commands (Page 71)"

• If no parameter banks have setting values, the test mode is

performed for the parameter bank 0 (bank for read quick setup

code).

reading rate according to the number of times

that the code was read correctly.

successful decodes against the number of

decodes attempted while the trigger input is

turned ON.

decode time that it takes to read a code and

outputs the result every 10 decodings are

performed.

that it takes to read a code and outputs the

result when the trigger input turns OFF.

far the code shifts from the center of the field of

view is measured.

3 bars lit

50 to 60 200 to 299 LEVEL3 Green

2 bars lit

30 to 40 300 to 399 LEVEL2 Green

1 bar lit

10 to 20 400 or more LEVEL1 Green

0 bars lit

Reading error Red

Test Mode Details

This section describes the advanced details of each test mode.

Reading rate test mode

This test mode scans codes and measures the number of successful reads.

The offline mode scans 10 times and outputs the number of successful reads.

The offline test mode outputs the reading rate which is obtained from the number of

decodes against the number of decodes attempted while the trigger input is ON.

The parameter bank switches while scanning, just as when reading with the

alternate function. When reading is successful, the parameter bank used for

reading is fixed and the reading rate is calculated.

When a read error occurs, the test mode switches to another parameter bank and

continues the measurement.

Online and offline modes

Offline mode

Offline mode is useful for fine-tuning the installation position, distance or angle

during initial setup.

Data is continuously output as long as the test is active.

The test result data is output in real time.

E SR-750 UM

12

Page 13

Starting reading rate test mode

Reference

a = Pa rameter bank numbers

(01 to 10)

b = Rea ding rate

(1 to 100)

d = Average b rightness value in co de

region

(0 to 255)

a = Pa rameter bank numbers

(01 to 10)

b = Rea ding rate

(1 to 100)

c = Number of decoding successes/

Number of decoding operations

d = Average b rightness value in co de

region

(0 to 255)

a = Parameter bank No.

(00 to 10)

b = Lat est reading time

c = Maximum read time

(Maximum value of the read

operation from starting the read

time test mode to outputting data)

d = Mi nimum read time

(Maximum value of the read

operation from starting the read

time test mode to outputting data)

* The values for b, c, and d will be

zero suppressed.

a = Parameter bank No.

(00 to 10)

b = Po sition level (0 to 5)

The following procedures can be used to start and stop the reading rate test mode:

• Start: Hold the button for 2 seconds.

Stop: Tap the button once briefly.

• Start: Send the TEST1 (#TEST1) command from the control host.

Stop: Send the QUIT command (#QUIT) from the control host.

• Using AutoID Network Navigator or direct serial commands, assign "TEST" and

"Reading rate test mode" to one of the IN terminals.

Start: Turn the input on

Stop: Turn the input off

Reading rate test mode output data

Offline mode

The offline mode outputs data in the following format every 10 reading operations.

Read data

Online mode

The online mode outputs data in the following format when the trigger input is

turned off.

Read data

:a:b%:d

:a:b%:c:d

Read time test mode output data

Offline mode

The offline mode outputs data in the following format every 10 successful

decodings or every time the decoding fails.

Online mode

The online mode outputs data in the following format when the trigger input is

turned off.

(The format is the same for offline and online modes.)

Read data

Reference

: a : now = b ms : max = c ms : min = d ms

• When starting test mode, the data addition function is inactive.

• When TEST2nn (#TEST2nn) (nn: Parameter bank No.) is sent, the

read time test mode is run for the bank with the specified parameter

bank number.

• When the TEST2nn (#TEST2nn) command is sent or when there is

only 1 parameter bank for reading, the specified decode timeout

period is ignored and read operation is performed with a decode

timeout period of 2550 ms. If it has been determined that the image

cannot be decoded, measurement of the image is stopped without

waiting for the decode timeout period expiration.

Code position measurement test mode

• When starting test mode, the data addition function is inactive.

• When TEST1nn (#TEST1nn) (nn: Parameter bank No.) is sent, the

reading rate test mode is run for the bank with the specified

parameter bank number.

Read time test mode

This test mode measures the amount of time that it takes to read a code and

outputs the result.

The parameter bank switches while scanning, just as when reading with the

alternate function. If reading is successful, the amount of time required from the

start of reading until the completion of reading is measured and output. If the

decoding fails, the read time becomes 0 ms.

Starting read time test mode

The following procedures can be used to start and stop read time test mode:

• Start: Hold the button for 3 seconds.

Stop: Tap the button once briefly to finish.

• Start: Send the TEST2 (#TEST2) command from the control host.

Stop: Send the QUIT command (#QUIT) from the control host to finish.

• Assign "TEST" and "Reading rate test" to one of the IN terminals.

Start: Turn on the input

Stop: Turn off the input

This test mode measures how far the code shifts from the center of the field of

view.

This test mode can be used to perceive the amount of displacement and adjust

both the code position and the SR-750 Series installation location.

Ideal position (LEVEL5) Shifted position (LEVEL1)

The center of the code should coincide with

the center of the field of view.

The code is displaced from the center of the

field of view.

Starting code position measurement test mode

The following procedures can be used to start and stop code position

measurement mode:

• Start: Hold the button for 4 seconds.

Stop: Tap once briefly to finish.

• Start: Send the TEST3 command from the control host.

Stop: Send the QUIT command from the control host.

• Assign "TEST" and "Positioning Test" to one of the IN terminals.

Start: Turn the input on

Stop: Turn the input off

Code position measurement test mode output data

During code position measurement test mode, data of the average of 10 scans (the

fractional portion is dropped) is sent to the computer in the following format after

scanning 10 times:

Read data

:a: level = b

13

• When starting test mode, the data addition function is inactive.

Reference

• The code position measurement test mode does not run in online

mode.

• When TEST3nn (nn: Parameter bank No.) is sent, the code position

test mode is run for the bank with the specified parameter bank

number.

E SR-750 UM

Page 14

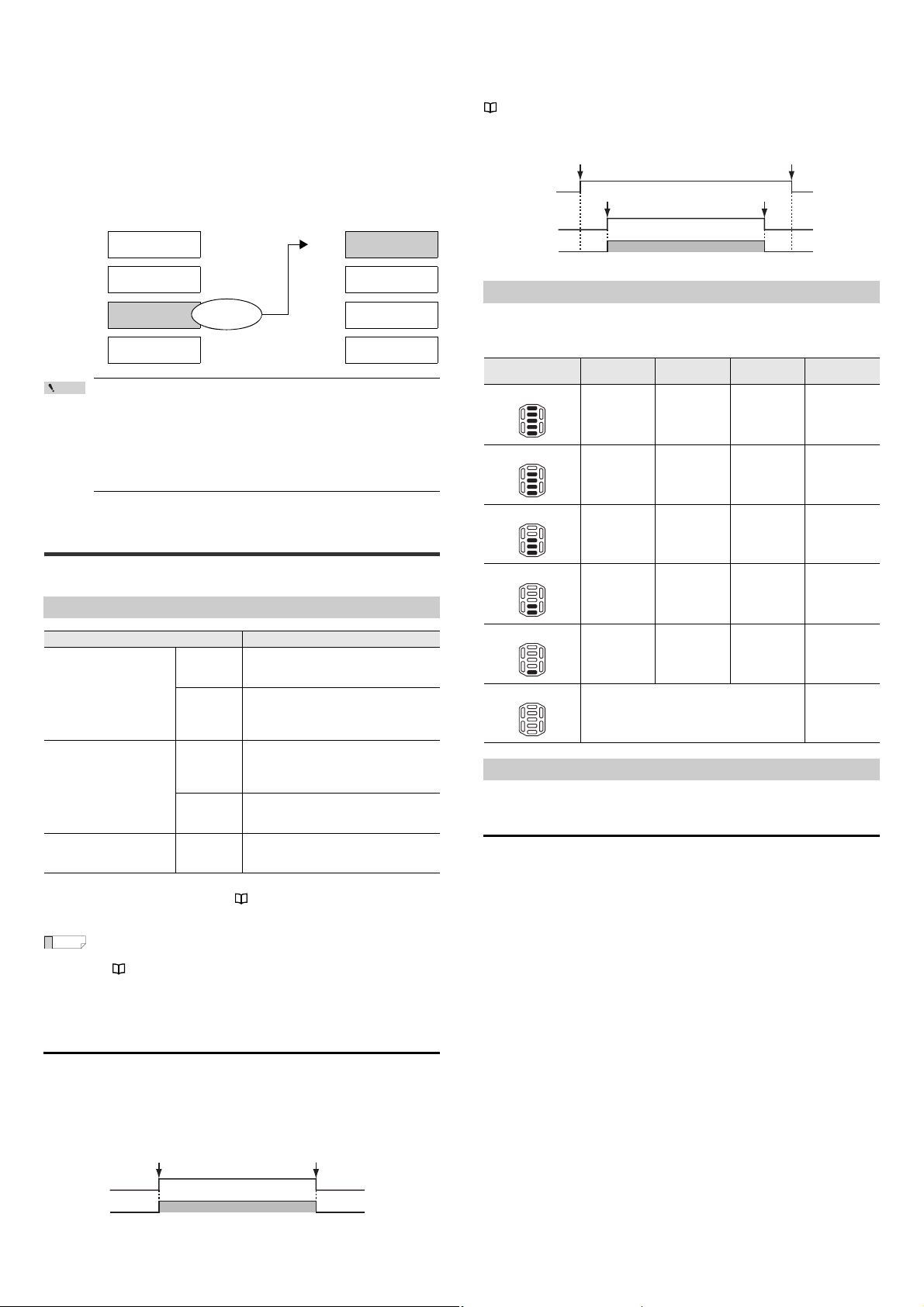

3-5 Preset/Verification

Reference

NOTICE

NOTICE

Data

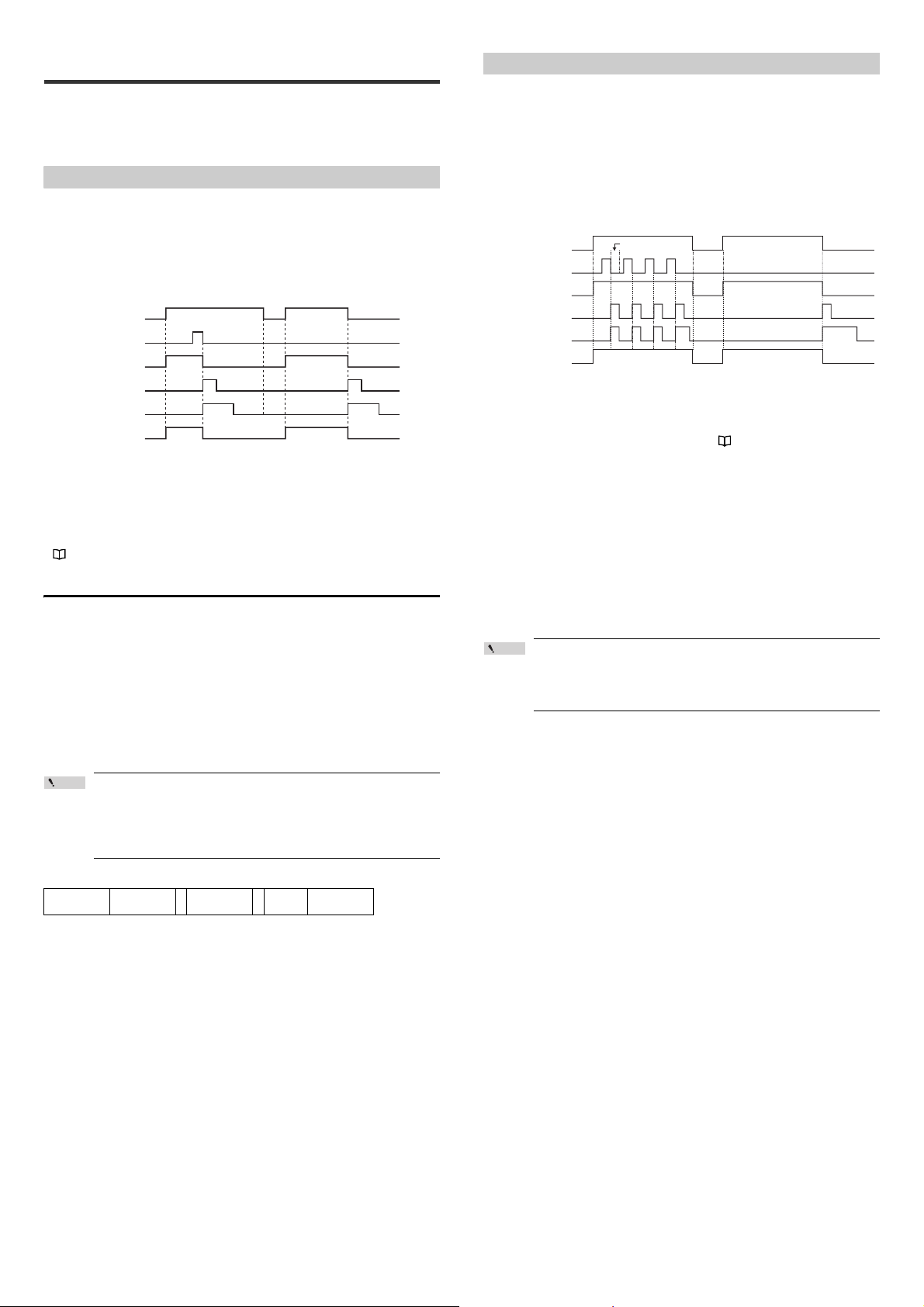

A0 96 B···

First reading

Preset value

98

Preset value

+2

A0 98 B···

Reading + Verification

98

Verification

A0 96 B···

Reading + Verification

00

Verification

Numerical value

+ 2

"Verification

OK"

Numerical value

+ 2

A0 00 B···

Reading + Verification

00

Verification

"Verification

NG"

"Verification

OK"

Function

This section describes the preset/verification function.

Preset/Verification Function

This function allows the SR-750 Series to verify the read code data against the

registered code data (preset data), and output an OK/NG signal to indicate whether

or not they match. This allows the SR-750 Series to perform simple detection of

different codes without a sensor or other devices.

One set of preset data can be stored in the SR-750 Series (maximum 494 digits).

The starting digit (starting position) and range (number of digits) for the verification

can be set in the preset data, so even codes with more than 494 digits can be

verified.

* If the multi 2 read mode or multiple read mode is set, the preset verification

function cannot be used.

The verification starts at the specified starting position on the

preset data and continues for the specified number of digits. Data

cannot be verified at multiple points.

Registering preset data

Use one of the following procedures to register preset data with the SR-750 Series:

• Read a target code by turning on the external input terminal.

* You need to assign the preset data input function to the external input terminal

in advance.

"3-6 Multi-I/O Function (Page 14)"

• Set with the AutoID Network Navigator "5-4 Details of Settings View (Page

34)"

• Set with a setup command "8-3 Details of Configuration Commands (Page

75)"

Output data format for the preset registration result

The following output data format is used when the preset data is registered.

PR nn : Result data nn = Preset registration result (00 to 05)

Sequence Verification Function

This function allows verification of codes including numerical values which change

in series, such as workpiece serial numbers.

When the verification is OK, a value is added to/subtracted from the preset value.

When the verification is NG, neither addition nor subtraction is performed.

When the sequence verification is set, the first data read after the setup or poweron is used as the preset data, and the numerical data for the number of digits set is

verified.

When the PRESET input terminal is turned on during the automatic increment

verification, the current preset value is cleared, and the data to be loaded next is

used as the first load data.

The sequence verification requires the following settings:

• Verification method .........Select "Sequential".

• Starting digit ....................Set the number of digits where the value verification

starts.

• No. of digits ("Length") .... For the numerical verification, the acceptable number

of digits is 1 to 9 digits.

• Increment ........................Enter a value used to add to or subtract from the read

code value. (-9999 to 9999)

The following is the operation example when the starting digit is the third one, two

digits are referenced and an increment of +2 is specified:

The following restrictions are placed on the sequence verification

function:

• The verification results in NG when a value other than a

numerical value is read.

• The preset data cannot be registered through communication.

nn Description Result data

00 Preset registration success Read data

01 Preset read failure Read error data

02 The preset effective digit is specified as 0.

The number of digits of read data is less

03

than the number of digits for preset start.

The preset registration is not possible

04

because the operation mode is set to multi

2 or multiple read.

05 Two or more "!" exist in preset data.

[null]

Output terminal operation

The output terminals perform the following operation:

• Reading successful and matches preset data ............. OK is output

• Reading successful but does not match preset data ... NG is output

• Read error .................................................................... ERROR is output

• Preset data is registered successfully.......................... PRESET OK is output

By default, the PRESET OK output is not assigned to any of the

OUT1 to OUT3 terminals. To connect the PRESET OK output to an

NOTICE

external device, assign the PRESET OK output to an appropriate

OUT terminal.

Functions of "!" and "?" in the preset data (wild cards)

Registering "!" or "?" with the preset data increases the flexibility when comparing

and verifying the code data against the preset data.

"!" .......This character represents an unlimited number of digits and can be used

when any character for any number of digits is OK. If the preset data is "A B

C!", all codes that begin with "ABC" are verified as a match. If the preset

data is "!ABC", all codes that end with "ABC" are verified as a match. A

maximum of 1 "!" can be registered with the preset data.

"?" ......This character represents 1 digit and can be used when any one character

is OK. If the preset data is "A B??5 6", any 2 characters positioned in ?? are

verified as a match. If the preset data has not been registered, "!" is

registered instead. Consequently, OK is output when a barcode is read

successfully and ERROR is output when reading fails, regardless of the

data of the bar code.

By default, the PRESET output is not assigned to any of the OUT1 to

OUT4 terminals. To connect the PRESET OK output to an external

device, you need to assign the PRESET OK output to an appropriate

E SR-750 UM

OUT terminal.

3-6 Multi-I/O Function

You can assign various operating conditions to the I/O terminals of the SR-750

Series. This section describes operations available with the Multi-I/O function.

Function and Operation of the Input Terminals (IN1 and IN2)

Functions assigned to the input terminals

Only 1 of the following functions can be assigned to each of the input terminals IN1

and IN2:

• Trigger input: Use as the input terminal to start/stop reading codes.

• Preset data input: Use as the input terminal to register preset data.

• Start test mode: Use as an input terminal to activate the specified test mode.

(This function cannot be used to start the online test mode.)

• Clear PLC link error: Use as the terminal to clear the PLC link error.

• Tuning operation: Use the terminal to activate the quick calibration function.

• None: Select this option when the terminal is not used as an input terminal.

Use AutoID Network Navigator or setup command to change the setting or assign

the desired function.

* By default, the functions are assigned as follows:

IN1: Trigger input

IN2: Preset input

14

Page 15

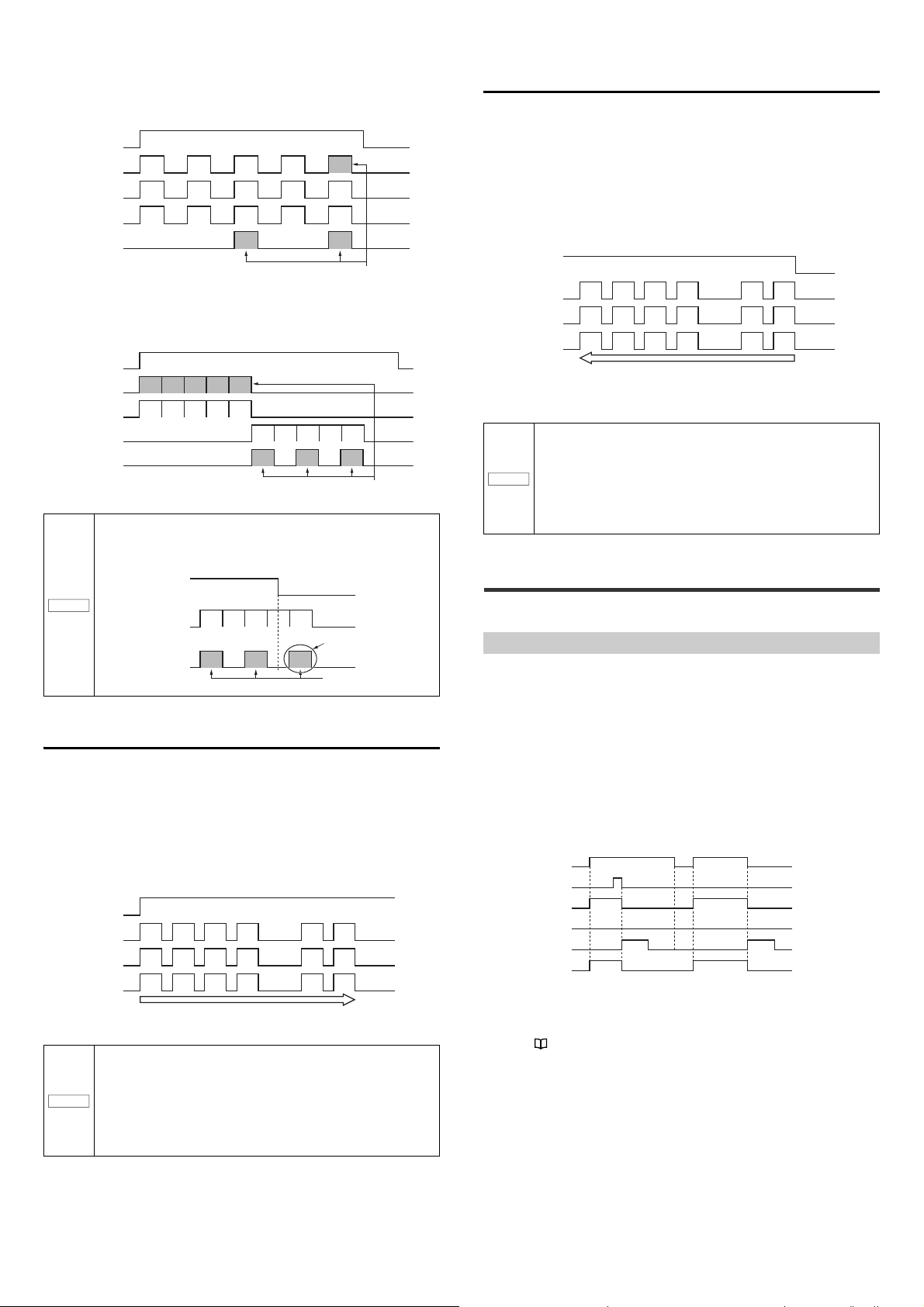

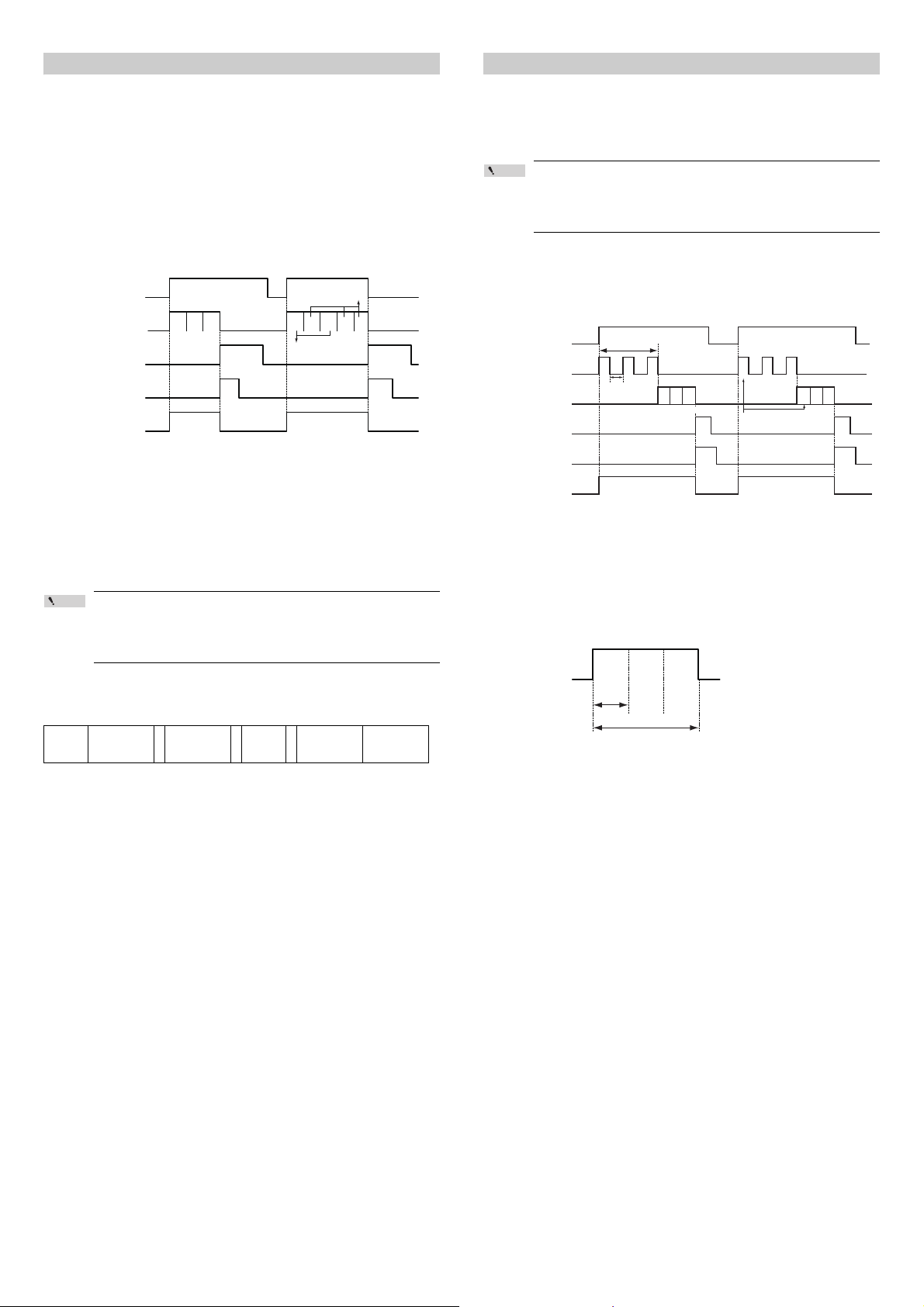

Input terminal status and operation

ON

Timing input

Reading operation

ON

Timing input

Reading operation

Timing input

Reading operation

NOTICE

ON

OK/NG/ERROR

STABLE/UNSTABLE

PRESET OK/TUNING OK

ON

Event occurrence

Period of time set for output ON time

The table below shows the relationship between the status of the input terminal

and the operation of the assigned function.

Function assigned to the

input terminal

Trigger input (TIMING) Start reading. Stop reading.

Preset input (PRESET) Start preset data registration. Finish preset data registration.

Start test mode. (TEST) Activate the test mode. Quit the test mode.

Stop PLC error Stop error ―

Tuning operation (TUNING) Start quick calibration Quit quick calibration

ON OFF

Synchronous IN LED

Users can set the SR-750 Series to illuminate its IN LED when the IN1 or IN2

terminal turns on. When both IN1 and IN2 terminals synchronize with the IN LED,

the LED illuminates based on the OR condition of the terminal status.

(By default, only the IN1 terminal synchronizes with the LED.)

Input polarity setting

The polarity of the input terminal can be selected from "N.O. (normally open)

contact" or "N.C. (normally closed) contact".

(By default, "N.O. contact" is selected.)

The same input polarity is set for IN1 and IN2.

Power-on trigger setting

Normally, the input terminal recognizes the change in the input signal (ON/OFF)

after the SR-750 Series is turned on and its operation stabilizes.

The input terminal does not operate if the input signal turns on before the operation

stabilizes (approximately 500 ms after power on).

If "Power-on trigger" is enabled, the SR-750 Series recognizes the input ON status

during the start-up period, and after the operation stabilizes, it performs the

operation specified for the input signal.

(By default, "Power-on trigger" is disabled.)

Operation of Norm. open and Norm. closed

Norm. open (Normally open)

•Normal

Norm. closed (Normally closed)

•Normal

Function and Operation of the Output Terminals (OUT1, OUT2 and OUT3)

Functions assigned to the output terminals

The following functions can be assigned to the output terminals (OUT1 to OUT3).

You can assign one or more functions to each output terminal.

Result output

This function outputs judgment results according to the SR-750 Series operation.

• OK .................... This signal is output when a bar code is read successfully or

when the comparison/verification against preset data matches.

• NG.................... This signal is output when the comparison/verification against

the preset data does not match.

• ERROR ............ This signal is output when a read error occurs.

• STABLE............ This signal is output when reading is stable ("Matching level

assessment function" or "Code quality verification function" is

enabled and the matching level or Code quality verification result

exceeds the set threshold).

• UNSTABLE ...... This signal is output when reading is unstable ("Matching level

assessment function" or "Code quality verification function" is

enabled and the matching level or Code quality verification result

falls below the set threshold).

• PRESET OK .... This signal is output when the preset data is registered

successfully.

• TUNING OK ..... This signal is output when the calibration is complete.

Operation output

This output function notifies that the SR-750 Series is currently running.

• TRG BUSY.......... During the start-up period, trigger input, preset data

registration, calibration, test mode, or while images are being

sent to FTP, bank numbers are being displayed, live view data

are being sent, monitoring is being performed, while the laser

pointer is on, images are being saved to ROM, the quick setup

codes are being read or being scripted

• LOCK BUSY ....... Forced trigger lock is being applied.

• MODE BUSY....... The quick setup code is being read, during test mode

• ERR BUSY.......... Error occurred (buffer full, setting save error)

External light control output

• EXT. LIGHT......... This signal is output to control external illumination.

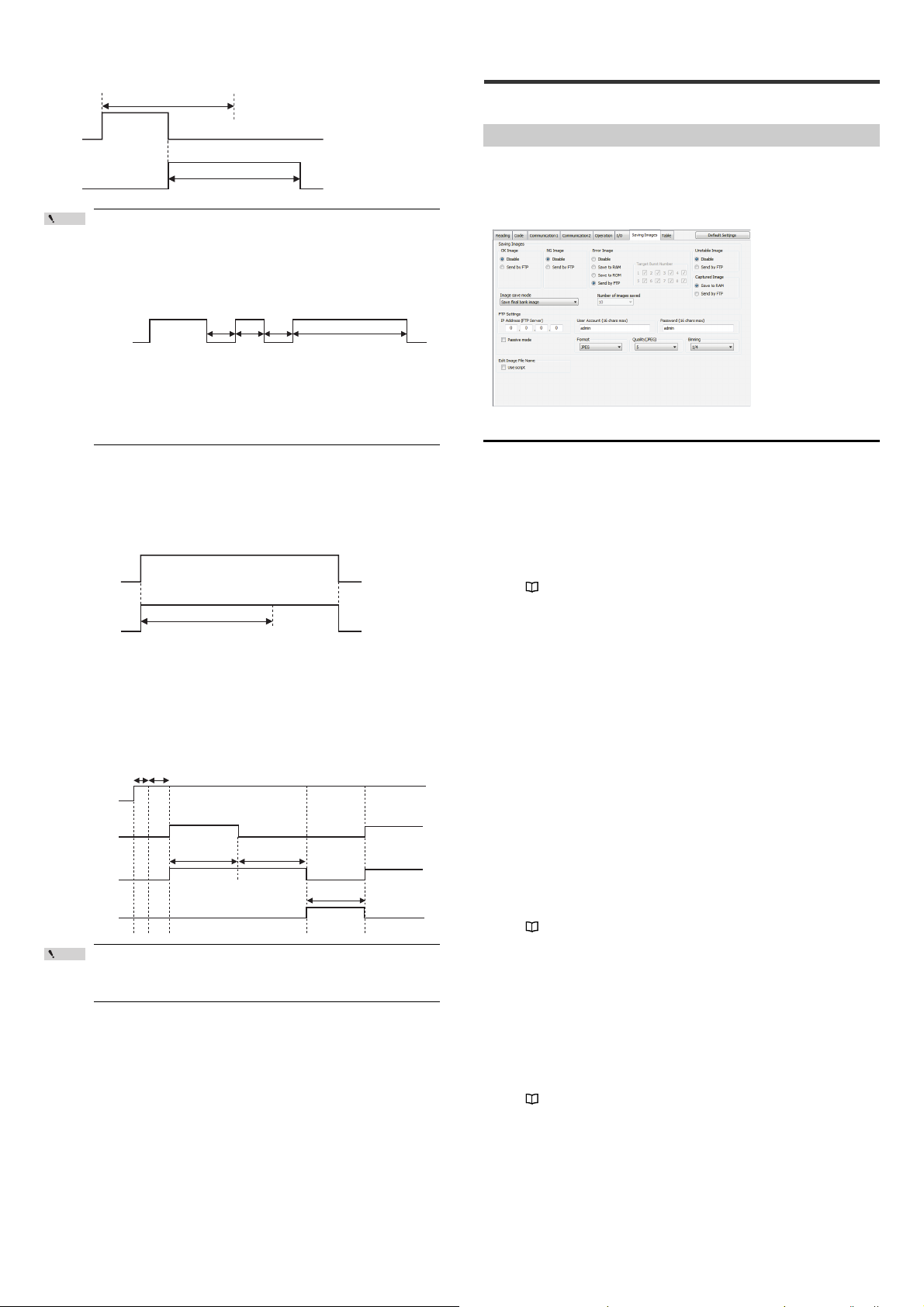

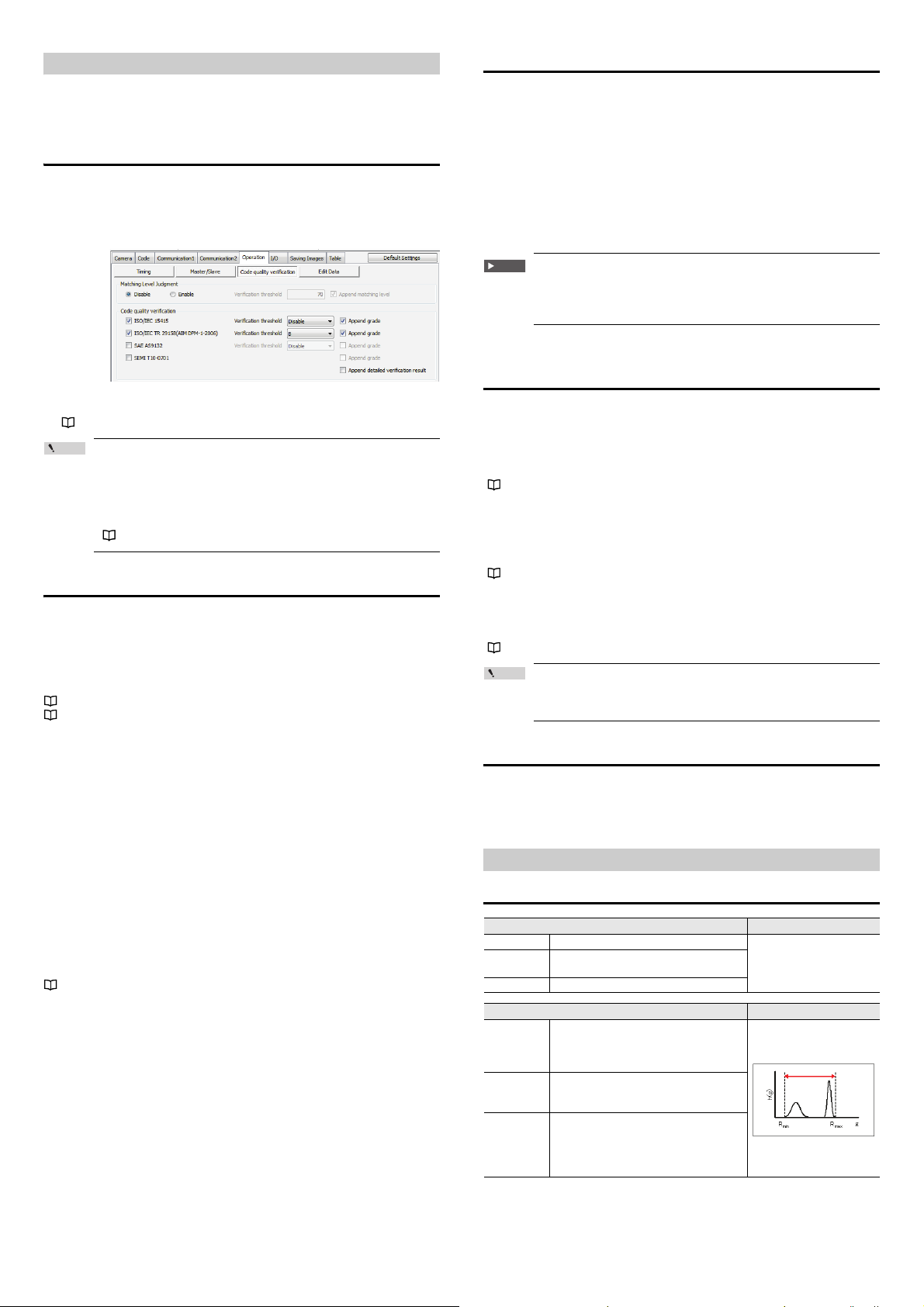

• The result outputs (OK, NG, ERROR, STABLE, UNSTABLE,