Page 1

2D Code Reader (Fixed Type)

SR-600 Series

Instruction Manual

Read this manual before use.

Keep this manual in a safe place for future reference.

Failure to follow instructions may lead to death or serious injury.

DANGER

Failure to follow instructions may lead to injury.

WARNING

96M11490

Operating Precautions

• Do not use a voltage other than 5VDC with the SR-600

Series. Doing so may lead to damage on the unit.

• When using the dedicated communication units (NX-50

Series, N-R2/R4/UB/L1, or DV-90 Series), use a power

supply within the appropriate range for each unit.

• Be sure to turn the power off to devices attached to the

SR-600 series when you plug or unplug the cables.

Failure to do so may cause damage to the SR-600 Series.

• Do not disassemble or modify the SR-600 Series. Doing

so may lead to damage on the unit.

• Keep the cables away from high-tension cables or power

sources. Otherwise, noise could cause malfunctions or

accidents.

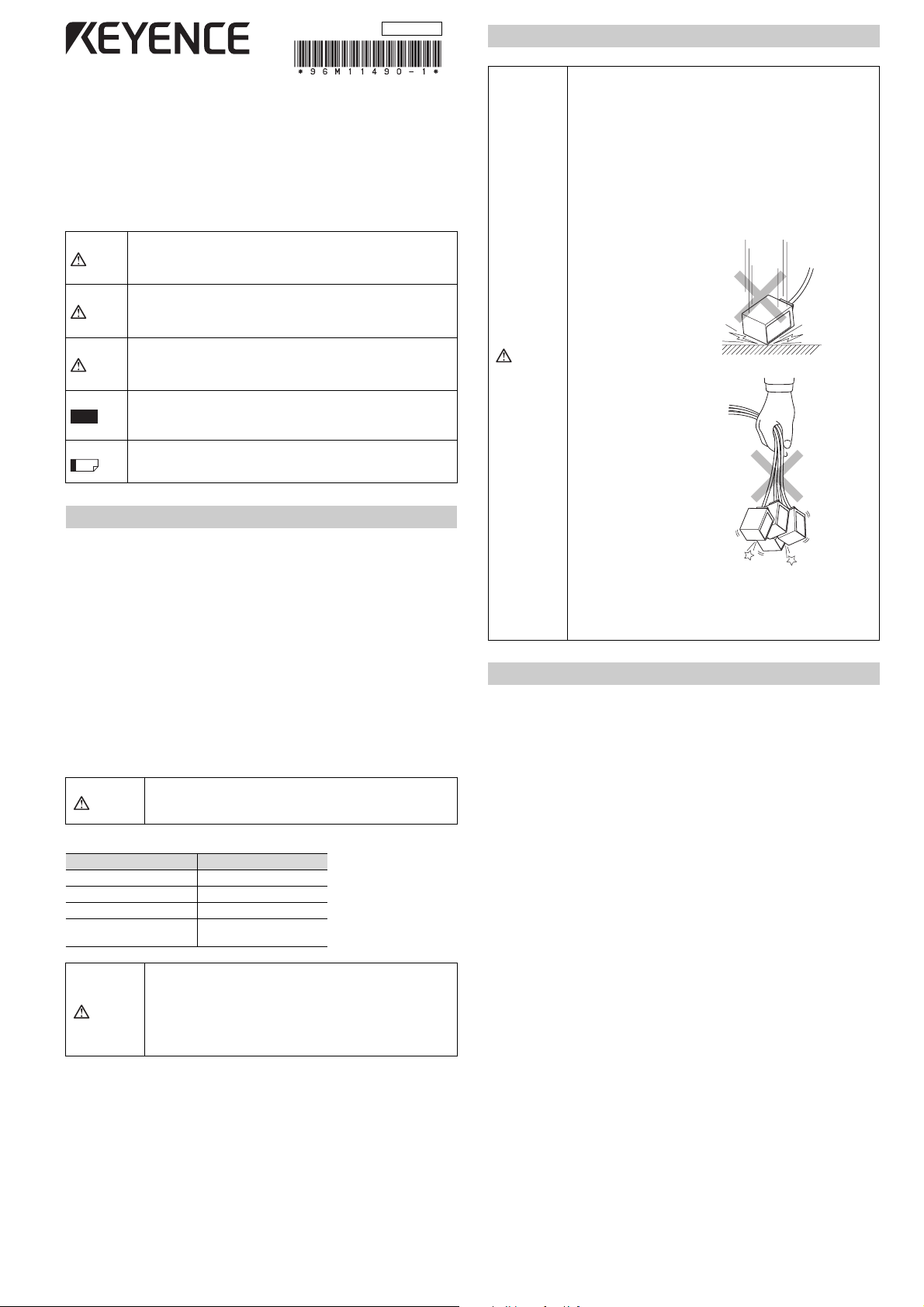

• The SR-600 Series is a

precision instrument. Do

not apply shock to the

instrument or drop it. Be

especially careful when

transporting or installing

the unit.

Failure to follow instructions may lead to product damage or

CAUTION

malfunctions.

Note

Reference

Provides additional information on proper operations that can be

easily mistaken.

Provides advanced and useful information for operation.

Safety Information for SR-600 Series

General cautions

• Take substantial safety measures to avoid any damage in the unlikely event of a

problem occurring.

• KEYENCE cannot guarantee the functionality or performance of units that have been

modified or used with specifications other than those described in this manual.

• When the SR-600 Series is used in combination with other devices, functions and

performance may be degraded, depending on the operating conditions and

surrounding environment.

• Parts of this manual may not be used or duplicated without express permission.

• The contents of his manual are subject to change without notice.

• This product is just intended to detect the object(s). Do not use this product for the

purpose to protect a human body or a part of human body.

• This product is not intended for use as explosion-proof product. Do not use this

product in hazardous location and/or potentially explosive atmosphere.

Safety precautions for laser product

The SR-600 Series uses a visible semiconductor laser, with wavelength of 660 nm, as a

target pointer for adjusting the reading position.

Use of controls or adjustments or performance of

CAUTION

Wavelength 660 nm

Pulse width 200 μs

Laser class

WARNING

procedures other than those specified herein may result in

hazardous radiation exposure.

Laser pointer

Output 90 μW

Class 1 laser product

IEC60825-1

Follow the instructions mentioned in this manual. Otherwise,

injury to the human body (eyes and skin) may result.

Precautions on class 1 laser products

• Do not stare into the beam.

• Do not disassemble this product. Laser emission from

this product is not automatically stopped when it is

disassembled.

CAUTION

• Do not hold the SR-600

Series by its cable. The

units may become

damaged if they strike

each other.

• Do not allow water, oil, dust, or other foreign substances

to stick to the scanner. This may cause read errors. Use a

soft, dry cloth to wipe any substances from the scanner.

(Do not use a cloth dipped in alcohol or other cleaning

substance.)

Regulations and Standards

UL Certifications

The SR-600 Series is an UL/C-UL Listed/Recognized product.

• File No.: E207185, Category: NRAQ/NRAQ7, Applicable standard: UL508

• File No.: E167973, Category: NWGQ2/NWGQ8, Applicable standard: UL60950-1

Be sure to follow the specification below.

• Use a power supply that provides Class 2 output defined in NEPA70

(NEC: National Electrical Code).

• Pollution degree: 2

• Overvoltage category: I

FDA (CDRH) Regulations

The SR-600 Series complies with the following FDA (CDRH) regulations.

Applicable regulations: 21 CFR Part 1040.10, Class 1 Laser Product

The classification is based on IEC60825-1 according to the Laser Notice No. 50 issued

by FDA (CDRH).

CE Marking

The SR-600 Series complies with the essential requirements of EMC Directive and Lowvoltage Directive.

The following harmonized standards are applied.

Applicable standards (EMI): EN55011, Class A

(EMS): EN61000-6-2

(LVD): EN60825-1, Class 1 Laser Product

* We conducted the test on the combination with the SR-600 series and the

communication units (N-R2/UB/R4/L1) to confirm the conformity.

EN55022, Class A

EN61000-6-1

FCC Regulations

The SR-600 Series complies with the following FCC EMI regulations.

• FCC 47 CFR Part 15, Subpart B, Class A, Digital devices

Canada IC (Industry Canada) Regulations

The SR-600 Series complies with the following IC EMI regulations.

• ICES-003, Class A, Digital apparatus

1

E SR-600-IM

Page 2

Checking the Package Contents

Part Names and Functions

Insulating spacer x 2

Washer x 2

Installation screws (M3) x 2

Main unit (SR-600/610/600HA)

Instruction ManualMounting bracket x 1

96M11490

Operating Precautions

•Do not use a voltage other than 5VDC with the SR-600

Series. Doing so may lead to damage on the unit.

2D Code Reader (Fixed Type)

•When using the dedicated communication units (NX-50

Series, N-R2/R4/UB/L1, or DV-90 Series), use a power

supply within the appropriate range for each unit.

SR-600 Series

•Be sure to turn the power off to devices attached to the

SR-600 series when you plug or unplug the cables.

Failure to do so may cause damage to the SR-600 Series.

Instruction Manual

•Do not disassemble or modify the SR-600 Series. Doing

so may lead to damage on the unit.

Read this manual before use.

•Keep the cables away from high-tension cables or power

Keep this manual in a safe place for future reference.

sources. Otherwise, noise could cause malfunctions or

accidents.

•The SR-600 Series is a

precision instrument. Do

Failure to follow instructions may lead to death or serious injury.

DANGER

not apply shock to the

instrument or drop it. Be

especially careful when

transporting or installing

Failure to follow instructions may lead to injury.

WARNING

the unit.

Failure to follow instructions may lead to product damage or

CAUTION

CAUTION

malfunctions.

•Do not hold the SR-600

Series by its cable. The

units may become

Provides additional information on proper operations that can be

Note

damaged if they strike

easily mistaken.

each other.

Provides advanced and useful information for operation.

Reference

Safety Information for SR-600 Series

General cautions

•Take substantial safety measures to avoid any damage in the unlikely event of a

problem occurring.

•Do not allow water, oil, dust, or other foreign substances

•KEYENCE cannot guarantee the functionality or performance of units that have been

to stick to the scanner. This may cause read errors. Use a

modified or used with specifications other than those described in this manual.

soft, dry cloth to wipe any substances from the scanner.

•When the SR-600 Series is used in combination with other devices, functions and

(Do not use a cloth dipped in alcohol or other cleaning

performance may be degraded, depending on the operating conditions and

substance.)

surrounding environment.

•Parts of this manual may not be used or duplicated without express permission.

•The contents of his manual are subject to change without notice.

•This product is just intended to detect the object(s). Do not use this product for the

Regulations and Standards

purpose to protect a human body or a part of human body.

•This product is not intended for use as explosion-proof product. Do not use this

UL Certifications

product in hazardous location and/or potentially explosive atmosphere.

The SR-600 Series is an UL/C-UL Listed/Recognized product.

Safety precautions for laser product

•File No.: E207185, Category: NRAQ/NRAQ7, Applicable standard: UL508

•File No.: E167973, Category: NWGQ2/NWGQ8, Applicable standard: UL60950-1

The SR-600 Series uses a visible semiconductor laser, with wavelength of 660 nm, as a

Be sure to follow the specification below.

target pointer for adjusting the reading position.

•Use a power supply that provides Class 2 output defined in NEPA70

(NEC: National Electrical Code).

Use of controls or adjustments or performance of

•Pollution degree: 2

procedures other than those specified herein may result in

CAUTION

•Overvoltage category: I

hazardous radiation exposure.

FDA (CDRH) Regulations

The SR-600 Series complies with the following FDA (CDRH) regulations.

Laser pointer

Applicable regulations: 21 CFR Part 1040.10, Class 1 Laser Product

Wavelength 660 nm

The classification is based on IEC60825-1 according to the Laser Notice No. 50 issued

Output 90 μW

by FDA (CDRH).

Pulse width 200 μs

Class 1 laser product

CE Marking

Laser class

IEC60825-1

The SR-600 Series complies with the essential requirements of EMC Directive and Lowvoltage Directive.

The following harmonized standards are applied.

Follow the instructions mentioned in this manual. Otherwise,

Applicable standards(EMI): EN55011, Class A

injury to the human body (eyes and skin) may result.

EN55022, Class A

Precautions on class 1 laser products

(EMS): EN61000-6-2

•Do not stare into the beam.

WARNING

•Do not disassemble this product. Laser emission from

this product is not automatically stopped when it is

disassembled.

EN61000-6-1

(LVD): EN60825-1, Class 1 Laser Product

* We conducted the test on the combination with the SR-600 series and the

communication units (N-R2/UB/R4/L1) to confirm the conformity.

FCC Regulations

The SR-600 Series complies with the following FCC EMI regulations.

•FCC 47 CFR Part 15, Subpart B, Class A, Digital devices

Canada IC (Industry Canada) Regulations

The SR-600 Series complies with the following IC EMI regulations.

•ICES-003, Class A, Digital apparatus

1

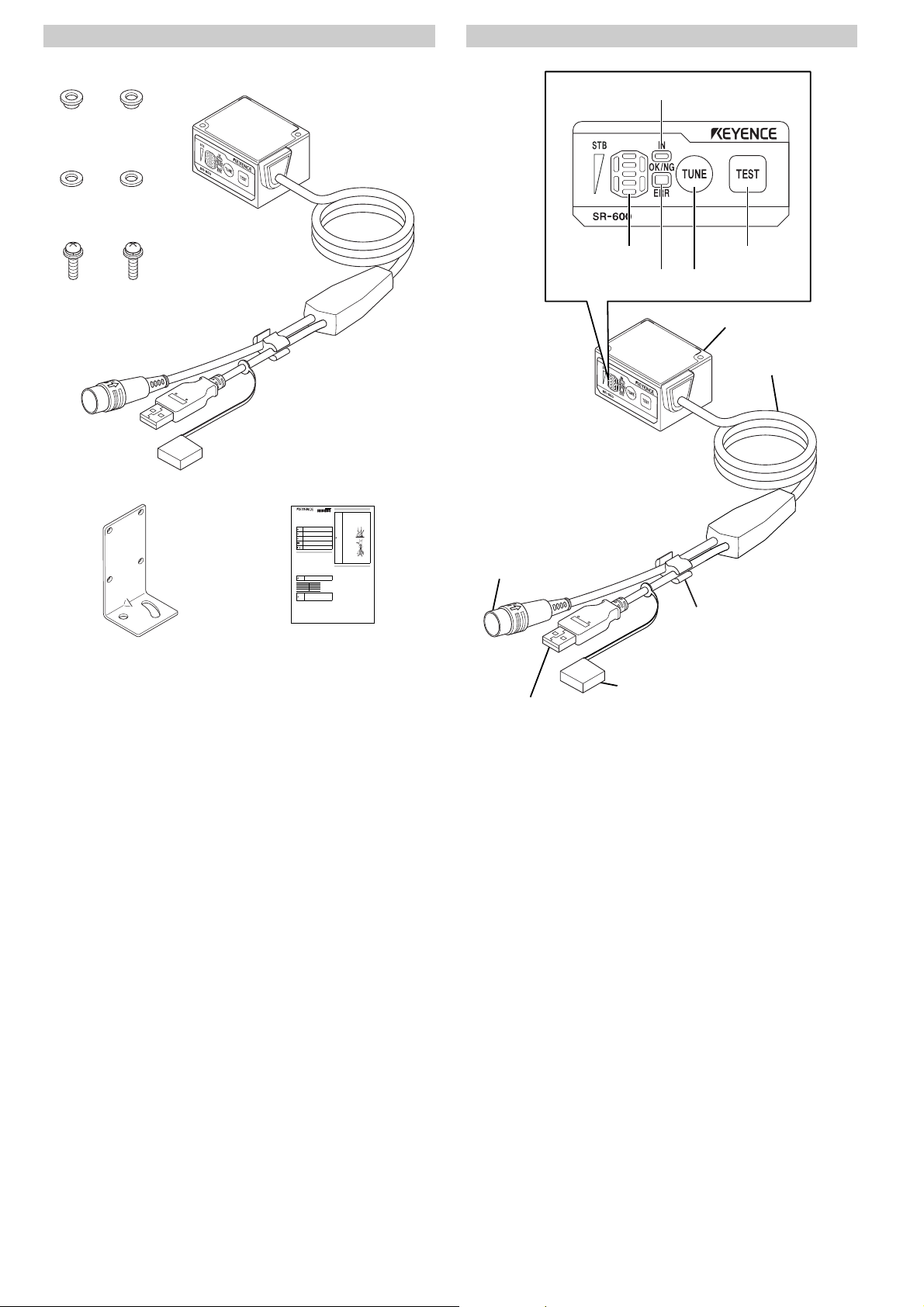

(8) IN LED

(7) Multiple LED

indicator

(9) OK/NG/ERR LED

(11) TEST switch

(10) TUNE switch

(1) Scanner

(2) Cable

(3) Connector

(round connector)

E SR-600-IM

(6) Cable holder

(5) USB connector cap

(4) USB connector

(1) Scanner: Reads 2D codes and barcodes.

(2) Cable: Cable length is 1.8 m.

(3) Connector

(Round connector):

(4) USB Connector: Connects to a PC to change settings with AutoID

(5) USB connector cap: When the USB connector is not in use, place the cap

(6) Cable holder: When the USB connector is not in use, place the

(7) Multiple LED indicator: Displays the operation status including the bank

(8) IN LED: Lights up when an input terminal is on.

(9) OK/NG/ERR LED:

(10) TUNE switch: Use this switch to perform the following operations.

(11) TEST switch: Use this switch to perform the following operations.

Connects to the power supply and communication

unit (N-R2/UB/R4/L1). The connector can be used for

serial communications with external devices.

Navigator. The connector is type A. Cable length is

130 mm from the section where the cable splits.

on the connector to prevent the entry of dust and

contact with surrounding metal objects.

USB cable in the cable holder so that it does not

move around.

number upon successful decoding, reading stability

and operation mode.

(Default settings: Displays the Input terminal 1 state)

• Lights green when a OK signal is output.

• Lights orange when an NG signal is output.

• Lights red when an ERROR signal is output.

Refer to the user manual for more details.

• Turn on the laser pointer for reading position

adjustment

• Display registered parameter banks

(Up to16 banks can be registered.)

• Start parameter tuning

• Read all of the program codes

• Reset errors

Refer to the user manual for more details.

• Start and stop test mode

• Run 1 reading operation

• Run the multi-reading mode

• Fix the communication settings to the default

values when sending and receiving the settings

E SR-600-IM

2

Page 3

Connection and Wiring Method

RP17-13PA-12PC plug (male)

Made by Hirose Electric Co., Ltd.

GND

+5V

12

+

11

5 VDC

Connection to the communication unit

Connect the connector to the communication unit

(N-R2/UB/R4/L1).

Refer to the communication unit instruction manual

for more details.

Connector pin alignment

21

610594

3

8

7

1211

Pin no. Wire color Symbol name Description

1 Transparent OUT1

2GrayOUT2

Output terminal 1

(Default value:

OK output)

Output terminal 2

(Default value:

NG/ERROR output)

3 Purple TxD RS-232C send Output

4 Blue CTS RS-232C send OK Input

5 Lt. blue OUT4

6 Yellow green IN2

Output terminal 4

(Default value:

BUSY output)

Input terminal 2

(Default value:

PRESET input)

7 Brown RxD RS-232C receive Input

8 Pink RTS RS-232C receive OK Output

9OrangeOUT3

10 Yellow IN1

Output terminal 3

(Default value:

ERROR output)

Input terminal 1

(Default value:

TIMING input)

11 Red 5 V 5 V Power –

12 Black GND (SG) Power GND/Signal GND –

* The shielded wire is connected to a signal ground.

It is possible to change the functions of the input terminals and output terminals. Refer

to the user's manual for making these changes.

Connecting the power

Signal

direction

Output

Output

Output

Input

Output

Input

Input terminal 1 and Input terminal 2 wiring

These are non-voltage inputs. Connect relay contacts or NPN open collector outputs.

• The TIMING and PRESET inputs are non-voltage inputs.

10kΩ

Internal circuit

• TIMING (Input terminal 1) is input to initiate the 2D code and barcode reading.

• PRESET (Input terminal 2) is input to preset (register) the 2D code and barcode data

on the SR-600 Series.

DC5V

4.7kΩ

220Ω

IN

GND

6,10

12

With or

without

contacts

Output terminal 1, Output terminal 2, Output terminal 3 and

Output terminal 4 wiring

These are NPN open collector outputs.

4.7kΩ

47kΩ

Internal circuit

* Rated load: 24VDC (30mA) or less

• OK (Output terminal 1) is output for a successful reading when a check against

preset data is successful.

• NG/ERROR output (Output terminal 2) is output for an unsuccessful reading when a

check against preset data fails.

• ERROR (Output terminal 3) is output for an unsuccessful reading.

• BUSY (Output terminal 4) is output when preset data registration has been

completed and internal processing is taking place.

When BUSY is output, TIMING (Input terminal 1) cannot be input.

33V

OUT

GND

1, 2,

5, 9

12

Load

+

RS-232C wiring

Use the following wiring when connecting to a PC or a PLC.

SR-600 Series DOS/V computer

TxD

CTS

RxD

RTS

+5V

3

4

7

8

12

11

Round

connector

12-pin

(male)

+

2

7

3

8

5

4

6

D-sub 9-pin

(female)

#4-40 screw

RxD(RD)

RTS(RS)

TxD(SD)

CTS(CS)

GND(SG)GND

DTR(ER)

DSR(DR)

• Do not use a reverse connection for the power supply.

Doing so may damage the unit.

CAUTION

• Use a stable power supply that is 5 VDC +5%, -10%.

Using a power supply that exceeds this range may

damage the unit.

3

E SR-600-IM

Page 4

Installing the SR-600 Series

Note

Reading distance

15°

Reading distance

20° or more

15° or more

38 mm

(SR-600HA)

60 mm

(SR-600)

100 mm

Included

installation screws

M3 x2

Mounting

bracket

Mounting

bracket

Installation

screw (M4)

Washer

Insulating

spacer

Mounting the SR-600 Series

Install the SR-600 Series as shown below to ensure reading stability.

Installation angle

The scanner of the SR-600 Series should be positioned at an angle of 15° in relation to

the 2D code or barcode surface when carrying out reading.

• Do not position the scanner to face directly at 2D codes or barcodes.

Doing so may cause instability in reading due to mirror reflection.

Using the included mounting bracket

1 Attach the SR-600 Series to the mounting bracket.

Secure the mounting bracket with the included M3 screws.

2 Secure the mounting bracket to the device.

Secure the mounting bracket to the device using the installation screws, purchased

separately, with the included insulating spacers and washers. The installation

screws should be at least 3.7 mm (thickness of the bracket, washer, etc.) + 3 mm

long.

Adjusting the installation position and distance

1 Press the TUNE switch on the SR-600 Series. The laser pointer will emit a laser

beam.

Adjust the installation position and distance so that the laser pointer intersection

point (the center point between the laser pointers for the SR-610) and the center of

the barcode line up.

For the SR-600/600HA

The distance where the left

and right laser beams

intersect is the optimal

reading distance.

Adjust the laser pointer's

intersection point so that it lies

directly in the middle of the 2D

code or the barcode.

For the SR-610

The two laser

pointers

indicate the

reading width.

Adjust the laser

pointers so that

the 2D code or

the barcode

lies directly in

the middle.

CAUTION

• Make sure to attach the included insulating spacers to

prevent excessive noise from the device.

• Reading errors may occur if the insulating spacers are not

attached.

Refer to the user's manual for tuning and confirming reading stability.

• The reading distance and angle differ depending on conditions such as the size and

the print quality of the 2D code or the barcode. Carry out reading tests using the 2D

code or barcode to be used and make adjustments.

E SR-600-IM

4

Page 5

Attaching directly to the device

Note

Installation screws (M3)

Center of scanner

(27.8)

24.33.5

3.5

33

(36.5)

9.3

32

40

18.5

13.2

24

φ

5

Minimum bend R10

3.8

11

2-M3

Depth 4 mm

Cable length 130

Cable length 200

Cable length 1800

Thickness 13

53

21

Secure the SR-600 Series with screws (M3).

The installation screws, purchased separately, should not be any

longer than the length of the plate thickness + 4 mm.

Mounting bracket

* An insulating sheet is affixed to the bottom surface of the mounting bracket. Do

not remove the sheet.

2-(R2.65)

R1.5

R18

7

C1

• Use insulating material when installing the SR-600 Series

CAUTION

to prevent excessive noise from the device.

• Reading errors may occur if the insulating material is not

attached.

Dimensions

Main unit (SR-600/610/600HA)

40°

27.5

5.3

32

3.5

1.5

90°±1.5°

6

0.7

6

3.5

33

60.8

24.3

0.7 0.7

8-(R1.65)

φ

18.5

5.3

2-R1.5

4-3.3

5

E SR-600-IM

Page 6

Specifications

Model

Ty pe

Laser pointer

Light

Supported

code

Minimum

resolution

Reading

Input/output

(typical examples)

Reading

distance

(typical

examples)

Reading view range

RS-232C

SR-600 SR-610 SR-600HA

Short-range Mid-range

Light source Visible semiconductor laser (660 nm)

Output 90μW

Pulse width 200μs

Laser class

Light source High intensity red LED

LED class Class 1 (IEC60825-1)

Barcode

2D Code

Focal distance 60 mm 100 mm 38 mm

Barcode 0.127 mm 0.127 mm

2D Code 0.127 mm 0.25 mm 0.082 mm

Reading time

DataMa trix

QR

Barcode

(focal distance)

Control input 2 non-voltage inputs (IN1, IN2)

Control output

Communication

method

Transmission

speed

Synchronization

method

Data bit

length

Stop bit

length

Parity check None/Even/Odd

USB Full-speed USB 2.0 interface

(IEC60825-1, FDA CDRH Part 1040.10)

Code 39, ITF, Industrial 2of5,

COOP 2of5, NW-7 (Codabar),

Code 128, GS1-128

(EAN-128), GS1-DataBar

(RSS), Code 93, JAN/EAN/

UPC, Trioptic Code 39

QR, MicroQR, DataMatrix, PDF417, MicroPDF,

21 ms (focal distance, QR code 21 x 21)

35 to 95 mm

(Cell size

0.339 mm)

31 to 97 mm

(Cell size

0.339 mm)

29 to 106 mm

(Narrow bar

width

0.339 mm)

42.5 mm x

27.1 mm

4 NPN open collector outputs (OUT1 to OUT4)

Residual voltage 0.8 V or less, leakage current

9600, 19200, 38400, 57600, 115200 bit/s

Class 1

MaxiCode, GS1-Composite

40 to 173 mm

(Cell size

0.508 mm)

35 to 188 mm

(Cell size

0.508 mm)

44 to 205 mm

(Narrow bar

width

0.508 mm)

70.6 mm x

45.0 mm

30 mA max. (24 V or less)

0.1 mA or less

RS-232C standards

Asynchronous

7/8 bits

1/2 bits

High

resolution

-

-

19 to 51 mm

(Cell size

0.254 mm)

17 to 54 mm

(Cell size

0.254 mm)

-

26.6 mm, x

17.0 mm

Model

Ty pe

Enclosure rating IP65

Ambient temperature

Storage temperature

Environment

resistance

Rating

* Use the Limited Power Source defined in UL/IEC60950-1 to comply with UL/

IEC60950-1.

Relative humidity 35 to 95% RH (No condensation)

Ambient luminance

Operating environment Location without dust or corrosive gas

Vibration

Power supply voltage 5 VDC +5%, -10%

Current consumption 630 mA or less

Weight Approx. 160 g (including the cable)

SR-600 SR-610 SR-600HA

C

°

°

High

resolution

C

Short-range Mid-range

0 to +45

-10 to +50

Sunlight: 10,000lx, incandescent lamp

6,000lx, fluorescent lamp: 2,000lx

10 to 55 Hz: double amplitude 1.5 mm in the

X, Y and Z directions. 3 hours respectively.

Warranty

KEYENCE products are strictly factory-inspected. However, in the event of a

failure, contact your nearest KEYENCE office with details of the failure.

1. Warranty period

The warranty period shall be for one year from the date that the product has

been delivered to the location specified by the purchaser.

2. Warranty scope

(1) If a failure attributable to KEYENCE occurs within the above mentioned

warranty period, we will repair the product, free of charge. However, the

following cases shall be excluded from the warranty scope.

• Any failure resulting from improper conditions, improper environments,

improper handling, or improper usage other than described in the

instruction manual, the user’s manual, or the specifications specifically

arranged between the purchaser and KEYENCE.

• Any failure resulting from factors other than a defect of our product,

such as the purchaser’s equipment or the design of the purchaser’s

software.

• Any failure resulting from modifications or repairs carried out by any

person other than KEYENCE staff.

• Any failure that can certainly be prevented when the expendable part(s)

is maintained or replaced correctly as described in the instruction

manual, the user’s manual, etc.

• Any failure caused by a factor that cannot be foreseen at a scientific/

technical level at the time when the product has been shipped from

KEYENCE.

• Any disaster such as fire, earthquake, and flood, or any other external

factor, such as abnormal voltage, for which we are not liable.

(2) The warranty scope is limited to the extent set forth in item (1), and

KEYENCE assumes no liability for any purchaser’s secondary damage

(damage of equipment, loss of opportunities, loss of profits, etc.) or any

other damage resulting from a failure of our product.

3. Product applicability

KEYENCE products are designed and manufactured as general-purpose

products for general industries.

Therefore, our products are not intended for the applications below and are

not applicable to them. If, however, the purchaser consults with us in advance

regarding the employment of our product, understands the specifications,

ratings, and performance of the product on their own responsibility, and takes

necessary safety measures, the product may be applied. In this case, the

warranty scope shall be the same as above.

• Facilities where the product may greatly affect human life or property,

such as nuclear power plants, aviation, railroads, ships, motor vehicles,

or medical equipment

• Public utilities such as electricity, gas, or water services

• Usage outdoors, under similar conditions or in similar environments

E SR-600-IM

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved.

11490E 1110-1 96M11490 Printed in Japan

6

Loading...

Loading...