Kawasaki FX751V, FX801V Owners Manual

ENGLISH

General-purpose Engine

Owner's Manual

Original instructions

SAFETY AWARENESS

Whenever you see the symbols shown below, heed their instructions! Always follow safe operating and maintenance practices.

DANGER

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

NOTE

○○NOTE indicates information that may help or guide you in the operation or service of the vehicle.

READ THIS FIRST

For your safety, read this Owner’s Manual and understand it thoroughly before operating this ENGINE.

DANGER

DANGER

Exhaust gas contains carbon monoxide, a colorless, odorless poisonous gas. Inhaling carbon monoxide can cause serious brain injury or death.

DO NOT run the engine in enclosed areas. Operate only in a well-ventilated area. Gasoline is extremely flammable and can be explosive under certain conditions, creating the potential for serious burns. When refueling, servicing fuel system, draining gasoline and/or adjusting the carburetor:

Stop engine and allow it to cool before refueling. DO NOT smoke.

Make sure the area is well-ventilated and free from any source of flame or sparks, including the pilot light of any appliance.

DO NOT fill the tank so the fuel level rises into the filler neck or level surface of level gauge. If the tank is overfilled, heat may cause the fuel to expand and overflow through the vents in the tank cap.

Wipe off any spilled gasoline immediately.

Engines can become extremely hot during normal operation.

To prevent fire hazard:

Keep the engine at least 1 m (3.3 ft) away from buildings, obstructions and other flammable objects. DO NOT place flammable objects close to the engine.

DO NOT expose combustible materials to the engine exhaust.

DO NOT use the engine on any forest covered, brush covered or grass covered unimproved land unless spark arrester is installed on the muffler.

To avoid getting an electric shock, DO NOT touch spark plugs, plug caps or spark plug leads during engine running.

To avoid a serious burn, DO NOT touch a hot engine or muffler. The engine becomes hot during operation. Before you service or remove parts, stop engine and allow the engine to cool.

DO NOT place hands or feet near moving or rotating parts. Place a protective cover over pulley, V belt or coupling. DO NOT run engine at excessive speeds. This may result in injury.

Always remove the spark plug caps from spark plugs when servicing the engine to prevent accidental starting.

Read warning labels which are on the engine and understand them. If any label is missing, damaged, or worn get a replacement from an authorized Kawasaki engine dealer and install it in the correct position.

EMISSION CONTROL INFORMATION

Fuel Information

THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED REGULAR GRADE GASOLINE ONLY. A minimum of 87 octane of the antiknock index is recommended. The antiknock index is posted on service station pumps in the U.S.A.

Emission Control Information

To protect the environment in which we all live, Kawasaki has incorporated an exhaust emission control system in compliance with applicable regulations of the United States Environmental Protection Agency and the California Air Resources Board. Also, depending on when your engine was produced, it may have an assigned emissions durability period.

* See below for the engine emissions durability period that may apply to your engine.

Exhaust Emission Control System

The exhaust emission control system applied to this engine consists of a carburetor and an ignition system having optimum ignition timing characteristics. The carburetor has been calibrated to provide specific air/fuel mixture characteristics and optimum fuel economy with a suitable air cleaner and exhaust system.

A sealed-type crankcase emission control system is also used to eliminate blow-by gasses. The blow-by gasses are led to a breather chamber through the crankcase and from there to the air cleaner.

Engine Emission Compliance Period |

|

California |

All Other States |

Engines Greater Than or Equal To 225 cc |

Engines Greater Than or Equal To 225 cc |

Durability period - 1 000 hours |

Durability Period - 1 000 hours (Category A) |

*If your engine has an assigned emissions durability period it will be located on the certification label attached to the engine (IMPORTANT ENGINE INFORMATION).

High Altitude Performance Adjustment Information

To improve the EMISSIONS CONTROL PERFORMANCE of engines operated above 1000 meters (3300 feet), Kawasaki requires the following Environmental Protection Agency (EPA) and California Air

Resources Board (CARB) approved modifications. High altitude adjustment requires replacement of carburetor main jets. Installation of these optional parts may be performed by an authorized Kawasaki engine dealer or equally qualified service facility, following repair recommendations specified in the appropriate Kawasaki

Service document or parts catalog.

Operating with the wrong configuration at a given altitude may increase its emissions and decrease fuel efficiency and performance.

NOTE

○○When properly performed, these specified modifications only are not considered to be emissions system

“tampering” and engine performance is generally unchanged as a result.

Maintenance and Warranty

Proper maintenance is necessary to ensure that your engine will continue to have low emission levels. This

Owner’s Manual contains those maintenance recommendations for your engine. Those items identified by the

Periodic Maintenance Chart are necessary to ensure compliance with the applicable standards.

As the owner of the engine, you have the responsibility to make sure that the recommended maintenance is carried out according to the instructions in this Owner’s Manual at your own expense.

The Kawasaki Limited Emission Control System Warranty requires that you return your engine to an authorized Kawasaki engine dealer for remedy under warranty. Please read the warranty carefully, and keep it valid by complying with the owner’s obligations it contains.

Tampering with Emission Control System Prohibited

Federal law and California State law prohibits the following acts or the causing thereof: (1) the removal or rendering inoperative by any person other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any new engine for the purposes of emission control prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the engine after such device or element of design has been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering, do not tamper with the original emission related parts below:

●●Carburetor and their internal parts ●●Spark Plug

●●Magneto system

●●Fuel filter element

●●Air cleaner elements ●●Crankcase ●●Cylinder heads

●●Breather chamber and internal parts ●●Intake pipe and tube

FOREWORD

We wish to thank you for purchasing this Kawasaki engine.

Please read this Owner’s Manual carefully before starting your new engine so that you will be thoroughly familiar with the proper operation of your engine’s control, its features, capabilities and limitations.

Also read the manual of the equipment to which this engine is attached.

To ensure a long, trouble-free life for your engine, give it the proper care and maintenance described in this manual. Always keep this manual at your fingertip so that you can refer to it whenever you need information.

This manual should be considered a permanent part of the engine and should remain with the engine when it is sold.

All rights reserved. No part of this publication may be reproduced without our prior written permission.

This publication includes the latest information available at the time of printing. However, there may be minor differences between the actual product and illustrations and text in this manual.

All products are subject to change without prior notice or obligation.

KAWASAKI HEAVY INDUSTRIES, LTD.

Motorcycle & Engine Company

© 2007 Kawasaki Heavy Industries, Ltd. |

Aug. 2017 (2) (I) |

TABLE OF CONTENTS

GENERAL INFORMATION................................ |

8 |

Location of Safety Related Labels................... |

8 |

Location of Parts.............................................. |

9 |

Engine Serial Number...................................... |

10 |

Tune-up Specifications..................................... |

10 |

Engine Oil Capacity......................................... |

11 |

FUEL AND OIL RECOMMENDATIONS............. |

12 |

Fuel.................................................................. |

12 |

Engine Oil........................................................ |

13 |

PREPARATION.................................................. |

14 |

Fuel.................................................................. |

14 |

Engine Oil........................................................ |

15 |

STARTING.......................................................... |

16 |

Start Engine..................................................... |

16 |

OPERATING....................................................... |

19 |

Warming Up..................................................... |

19 |

Engine Inclination............................................. |

20 |

STOPPING.......................................................... |

21 |

Stopping the Engine......................................... |

21 |

Ordinary Stop................................................ |

21 |

Emergency Stop........................................... |

21 |

ADJUSTMENT.................................................... |

22 |

Separate Choke Type...................................... |

22 |

Throttle Cable Installation, Adjustment......... |

22 |

Choke Cable Installation, Adjustment........... |

22 |

Engine Speed Adjustment................................ |

23 |

MAINTENANCE.................................................. |

24 |

Periodic Maintenance Chart............................. |

24 |

Oil Level Check................................................ |

26 |

Oil Cooler Service............................................ |

26 |

Oil Change....................................................... |

27 |

Oil Filter Change.............................................. |

28 |

Air Cleaner Service.......................................... |

29 |

Air Cleaner.................................................... |

29 |

Primary Element........................................... |

29 |

Secondary Element....................................... |

29 |

Cap (Dust Ejector Valve)............................... |

29 |

Fuel Filter and Fuel Pump Service................... |

31 |

Spark Plug Service.......................................... |

32 |

Cooling System Cleaning................................. |

33 |

STORAGE.......................................................... |

34 |

Engine Storage Procedure............................... |

34 |

TROUBLESHOOTING GUIDE........................... |

36 |

ENVIRONMENTAL PROTECTION.................... |

38 |

SPECIFICATIONS.............................................. |

39 |

WIRING DIAGRAM............................................. |

40 |

Wiring Diagram |

|

(With 12 V - 15 A Charging Coil)...................... |

40 |

8 GENERAL INFORMATION

GENERAL INFORMATION

Location of Safety Related Labels

B |

A |

|

A.Warning Label

B.Engine Maintenance

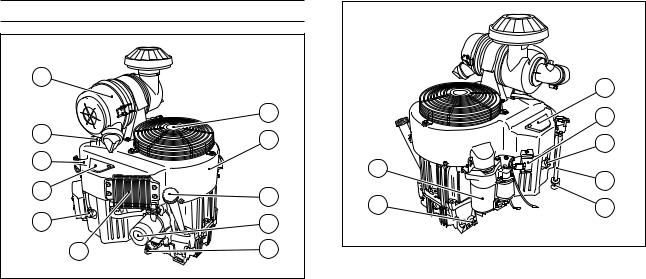

Location of Parts

D |

E |

N |

O |

F |

M

GENERAL INFORMATION 9

|

O |

G |

J |

H |

F |

|

|

I |

K |

|

|

|

A |

C |

L |

|

||

B |

|

|

C |

A. Oil Gauge Filler |

I. Electric Starter |

|

||

|

B. Oil Filter |

J. Voltage Regulator |

|

C. Oil Drain Plug |

K. Fuel Tube |

|

D. Air Cleaner |

L. Fuel Filter |

|

E. Carburetor |

M. Oil Cooler |

|

F. Spark Plug Cap/ |

N. Control Panel |

|

Spark Plug |

O. Cleanout Cover |

|

G. Guard |

(if equipped) |

|

H. Fan Housing |

|

10 GENERAL INFORMATION

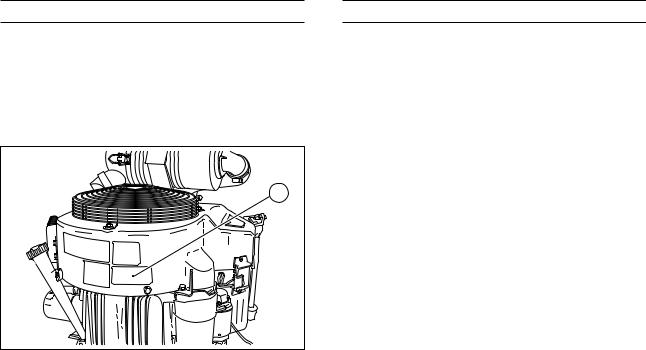

Engine Serial Number

The engine serial number is your only means of identifying your particular engine from others of the same model type.

This engine serial number is needed by an authorized Kawasaki engine dealer or equally qualified service facility when ordering parts.

A |

A. Engine Serial Number

Tune-up Specifications

ITEM |

Specifications |

|

Ignition Timing |

Unadjustable |

|

Spark Plugs: |

NGK BPR4ES |

|

Gap |

0.75 mm (0.030 in) |

|

Low Idle Speed |

1 550 r/min (rpm) |

|

High Idle Speed |

3 600 r/min (rpm) |

|

|

In 0.10 - 0.15 mm |

|

Valve Clearance |

(0.004 - 0.006 in.) |

|

Ex 0.10 - 0.15 mm |

||

|

||

|

(0.004 - 0.006 in.) |

|

Other Specifications |

No other adjustment |

|

needed |

||

|

NOTE

○○High and low idle speeds may vary depending on the equipment on which the engine is used. Refer to the equipment specification.

GENERAL INFORMATION 11

Engine Oil Capacity

Engine Oil Capacity

|

2.1 L (2.2 US·qt) |

FX801V |

[when oil filter is not removed] |

FX751V |

2.3 L (2.4 US·qt) |

|

|

|

[when oil filter is removed] |

|

|

12 FUEL AND OIL RECOMMENDATIONS

FUEL AND OIL RECOMMENDATIONS

Fuel

Use only clean, fresh, unleaded regular grade gasoline.

NOTICE

Do not mix oil with gasoline.

Octane Rating

The octane rating of a gasoline is a measure of its resistance to “knocking”. Using a minimum of 87 octane by the antiknock index is recommended.

The antiknock index is posted on service station pumps in the U.S.A.

NOTE

○○If “knocking” or “pinging” occurs, use a different brand of gasoline or higher octane rating.

○○When not operating your kawasaki engine more than once per month, you can mix a fuel stabilizer with gasoline in the fuel tank. Fuel stabilizer additive could inhibit oxidation of fuel.

Oxygenated Fuel

Oxygenates (either ethanol or MTBE) are added to the gasoline. If you use the oxygenates, be sure it is unleaded and meets the minimum octane rating requirement.

The followings are the EPA approved percentages of fuel oxygenates.

ETHANOL: (Ethyl or Grain Alcohol)

You may use gasoline containing up to 10% ethanol by volume.

MTBE: (Methyl Tertiary Butyl Ether)

You may use gasoline containing up to 15% MTBE by volume.

METHANOL: (Methyl or Wood Alcohol)

You may use gasoline containing up to 5% methanol by volume, as long as it also contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5% methanol by volume may cause starting and/or performance problems. It may also damage metal, rubber, and plastic parts of your fuel system.

FUEL AND OIL RECOMMENDATIONS 13

Engine Oil

The following engine oils are recommended.

API Service Classification: SJ or SL.

Oil Viscosity

Choose the viscosity according to the temperature as follows:

-20ºC |

-10ºC |

0ºC |

10ºC |

20ºC |

30ºC |

40ºC |

|

|

|

|

|

SAE40 |

|

|

|

|

|

SAE30 |

|

|

|

|

|

|

SAE20W-50 |

|

|

|

|

SAE5W-20SAE10W-40 |

|

|

||

|

|

SAE10W-30 |

|

|

||

SAE5W-20 |

|

|

|

|

|

|

-4ºF |

14ºF |

32ºF |

50ºF |

68ºF |

86ºF |

104ºF |

NOTE

○○Although 10W-40 engine oil is the recommended oil for most conditions, the oil viscosity may need to be changed to accommodate atmospheric conditions. Using 20W-50 oil in higher ambient temperatures may reduce oil consumption.

14 PREPARATION

PREPARATION

Fuel

WARNING

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions, creating the potential for serious burns. Turn the ignition switch to “OFF”. Do not smoke.

Make sure the area is well-ventilated and free from any source of flame or sparks; this includes any appliance with a pilot light.

Never fill the tank completely to the top. If the tank is filled completely to the top, heat may cause the fuel to expand and overflow through the vents in the tank cap. After refueling, make sure the tank cap is closed securely. If gasoline is spilled on the fuel tank, wipe it off immediately.

●●Place the engine on level surface before fueling. ●●Remove the fuel tank cap.

●●Slowly pour fuel into the tank through the fuel strainer.

●●Close the tank cap securely.

Engine Oil

Check the engine oil daily before starting the engine otherwise shortage of the engine oil may cause serious damage to the engine such as seizure.

●●Place the engine on level surface. Clean area around the oil gauge before removing it.

●●Remove the oil gauge and wipe it with a clean cloth.

●●Pour the oil slowly to “FULL” mark on the oil gauge.

●●Insert the oil gauge into tube WITHOUT SCREWING IT IN.

●●Remove the oil gauge to check the oil level. The level should be between “ADD” and “FULL” marks.

Do not overfill.

●●Install and tighten the oil gauge.

Engine Oil Capacity

|

2.1 L (2.2 US·qt) |

FX801V |

[when oil filter is not removed] |

FX751V |

2.3 L (2.4 US·qt) |

|

|

|

[when oil filter is removed] |

|

|

PREPARATION 15

B

A.Oil Gauge

B.Tube

NOTICE

The engine is shipped without engine oil.

16 STARTING

STARTING

Start Engine

DANGER

DANGER

Exhaust gas contains carbon monoxide, a colorless, odorless poisonous gas. Inhaling carbon monoxide can cause serious brain injury or death. DO NOT run the engine in enclosed areas. Operate only in a wellventilated area.

WARNING

WARNING

Engine exhaust may ignite combustible materials and cause a fire.

Keep the area around the exhaust outlet clear. Locate the unit so that the exhaust outlet points toward an open area and is located at least one meter (3.3 feet) from any obstructions.

NOTE

○○Be aware of the following in order to start the engine easily in cold weather.

○○Use proper oil for expected temperature (See FUEL AND OIL RECOMMENDATIONS chapter). Use fresh gasoline.

○○Protect the engine or the equipment from direct exposure to weather when not in operation.

○○Before starting the engine, disconnect all possible external loads.

●●Open the fuel valve on the equipment.

●●Put the key into the ignition switch. For Control Panel Switch Type, move the throttle lever on the equipment to its halfway position between “SLOW” speed and “FAST” speed.

Moving the lever away from its low speed end turns ignition on.

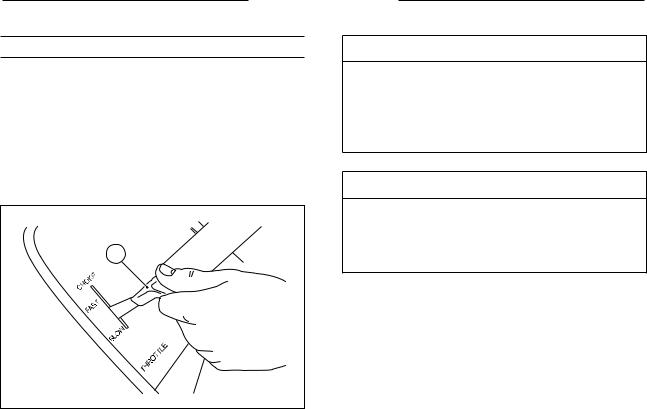

[Separate Choke type]

For a Cold Engine - Place the choke control lever into “CHOKE” position.

●●After starting the engine, gradually return the choke control lever to the fully open position.

ON A

ON A

ON

A. Fuel Valve

STARTING 17

●●Put the key into the ignition switch.

●●Turn the key to the START position on the equipment. Normally the engine will start within 3 seconds.

OFF |

ON |

|

|

|

START |

B

B. Ignition Switch Key

18 STARTING

NOTICE

Do not run the electric starter continuously for more than 5 seconds, otherwise the battery may discharge quickly. If the engine does not start right away, wait 15 seconds and try again.

NOTICE

Whenever you start engine, make sure warning light is not illuminated after engine starts.

If warning light comes on, stop engine immediately and check oil level (If equipped).

OPERATING 19

OPERATING

Warming Up

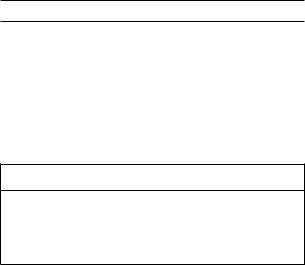

After the engine starts, move the throttle lever on the equipment to halfway between “FAST” and “SLOW”.

To warm up the engine, run it for 3 to 5 minutes with the throttle lever in the same load position (halfway) before putting the equipment under load. Then, move the throttle lever on the equipment to its “FAST” position.

A

NOTICE

Allow engine to warm up sufficiently (3 to 5 minutes at idle) before applying a load. This will allow oil to reach all engine parts, and allow piston clearance to reach design specifications.

NOTICE

While warming up the engine, make sure the warning light (oil pressure) on dash is not on. The warning light must not be illuminated during engine operation (if equipped).

A. Throttle Lever

20 OPERATING

Engine Inclination

This engine will operate continuously at angles up to 25° in any direction.

Refer to the operating instructions of the equipment this engine powers. Because of equipment design or application, there may be more stringent restrictions regarding the angle of operation.

NOTICE

Do not operate this engine continuously at angles exceeding 25° in any direction. Engine damage could result from insufficient lubrication.

STOPPING 21

STOPPING

Stopping the Engine

Ordinary Stop

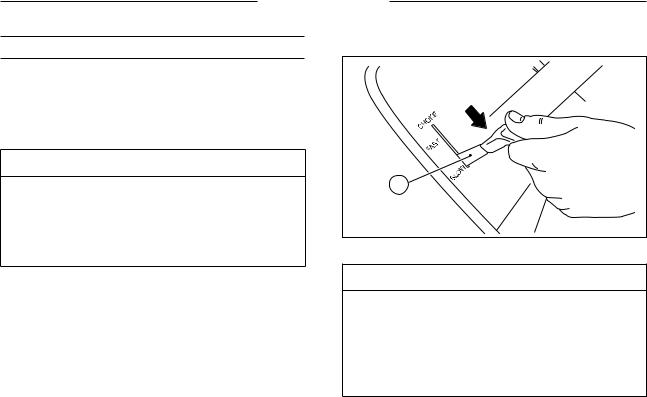

●●Move throttle lever to “SLOW” position.

●●Keep running at the “SLOW” speed for about one minute.

NOTICE

Engine damage can occur from run-on or after-burning if engine is stopped suddenly from high speed loaded operation. Reduce engine speed to idle for one minute before shutting engine off.

●●Turn the ignition switch to “OFF” position.

Emergency Stop

●●Immediately turn the ignition switch to “OFF” position.

●●Close the fuel valve on the equipment.

A |

THROTTLE |

|

A. Throttle Lever

WARNING

WARNING

Leaving the equipment with the key hanging in the ignition can allow operation by someone who does not know how to operate it. It may cause serious accident with injury. Always remove the key from unattended equipment.

22 ADJUSTMENT

ADJUSTMENT

Separate Choke Type

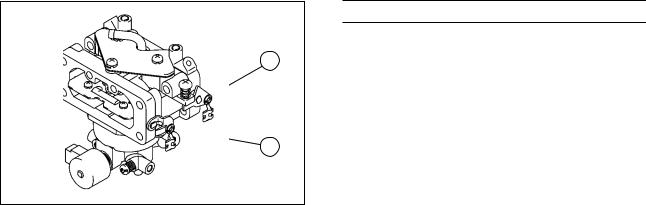

Throttle Cable Installation, Adjustment

●●Link the throttle cable to the speed control lever and loosely clamp the throttle cable outer housing with the cable clamp bolt.

●●Move the throttle lever to “FAST” position.

●●Pull up the outer housing of the throttle cable until the inner wire has almost no slack, and tighten the cable clamp bolt.

●●Move the throttle lever to “SLOW” position. Make sure that the carburetor throttle valve pivot arm is moved smoothly.

Choke Cable Installation, Adjustment

●●Link the choke cable to the choke lever, and loosely clamp the choke cable outer housing with the cable clamp bolt.

●●Move the equipment choke control to “OPEN” position. Make sure that the carburetor choke valve (pivot arm) is fully opened.

●●Pull up the outer housing of the choke cable until the inner wire has almost no slack, and tighten the cable clamp bolt.

●●Move the equipment choke control to “CHOKE” position. Make sure that the carburetor choke valve (pivot arm) is completely closed.

●●Make sure that the choke valve turns from fully close position to fully open position when actuating the equipment choke control.

E |

|

|

I |

F |

J |

|

|

H |

|

|

C |

B |

A |

D |

A. Throttle Cable |

E. |

Pirot Arm |

B. Speed Control Lever |

F. |

Choke Cable |

C.H. Cable Outer Housing |

I. |

Choke Lever |

D.J. Cable Clamp Bolt |

|

|

E

G

E. Throttle Valve Pivot Arm

G. Choke Valve Pivot Arm

ADJUSTMENT 23

Engine Speed Adjustment

NOTE

○○Do not tamper with the governor setting or the carburetor setting to increase the engine speed. Every carburetor is adjusted at the factory and cap or stop plate is installed on each mixture screw.

○○If any adjustment is necessary, see an authorized Kawasaki engine dealer or equally qualified service facility to perform the adjustment.

Loading...

Loading...