ASSEMBLY INSTRUCTIONS

for :

PRO-III & IV

Parts: 80000, 80020, & 90000

®

v _4.1

(916) 638-8703

• 11253- G Trade Center Drive • Rancho Cordova, CA 95742 •

(800) 343-7486

PRO-III & IV

ALL MODELS FOR

TRUCKS WITHOUT SHELLS

G

O

O

P

B

H

L

1010

H

3

C

H

788

A

G

M

K

K

N

G

O

O

P

A

Q

E

4

N

V

R

K

F

P

O

O

G

N

K

1

J

N

F

L

2

1/2", 9/16", & 3/4"

©2011 KARGO MASTER-Pro3&4 _4.1

99

777

A

(4 ea.)

1/2" x 3 1/2"

Hex Bolt

B

(2 ea.)

1/2" x 2 1/4"

Button Head Bolt

S

(6 ea.)

1/2" x 13 x 2 1/2"

Button Head Bolt

(yellow zinc plated, grade 5)

(2 ea.)

T

3/8" x 16 x 2 1/2"

Button Head Bolt

(yellow zinc plated, grade 5)

(2 ea.)

C

3/8" x 2 1/4"

Button Head

(8 ea.)

D

3/8" x 1 3/4"

Button Head

(2 ea.)

E

5/16" x 2 1/4"

Button Head Bolt

(8 ea.)

F

5/16" x 3/4"

Button Head Bolt

(4 ea.)

G

5/16" x 3/4"

Carriage Bolt

H

(14 ea.)

1/2" SAE Flat Washer

(2 ea.)

Q

3/8” T Nut

J

(22 ea.) 3/8" SAE Flat Washer

U

(4 ea.)

3/8" Lock Washer

(yellow zinc plated, grade 5)

R

(6 ea.)

Bed Rail

Clamps

K

(14 ea.) 5/16" Flat Washer

L

(6 ea.)

1/2" Jam Nut

(4 ea.)

P

5/16" x 3/8"

Allen Head Set Screw

N

M

(10 ea.)

3/8" Lock Nut 5/16" Lock Nut

2011 KargoMaster-'Pro 3 & 4' _4.1

(14 ea.)

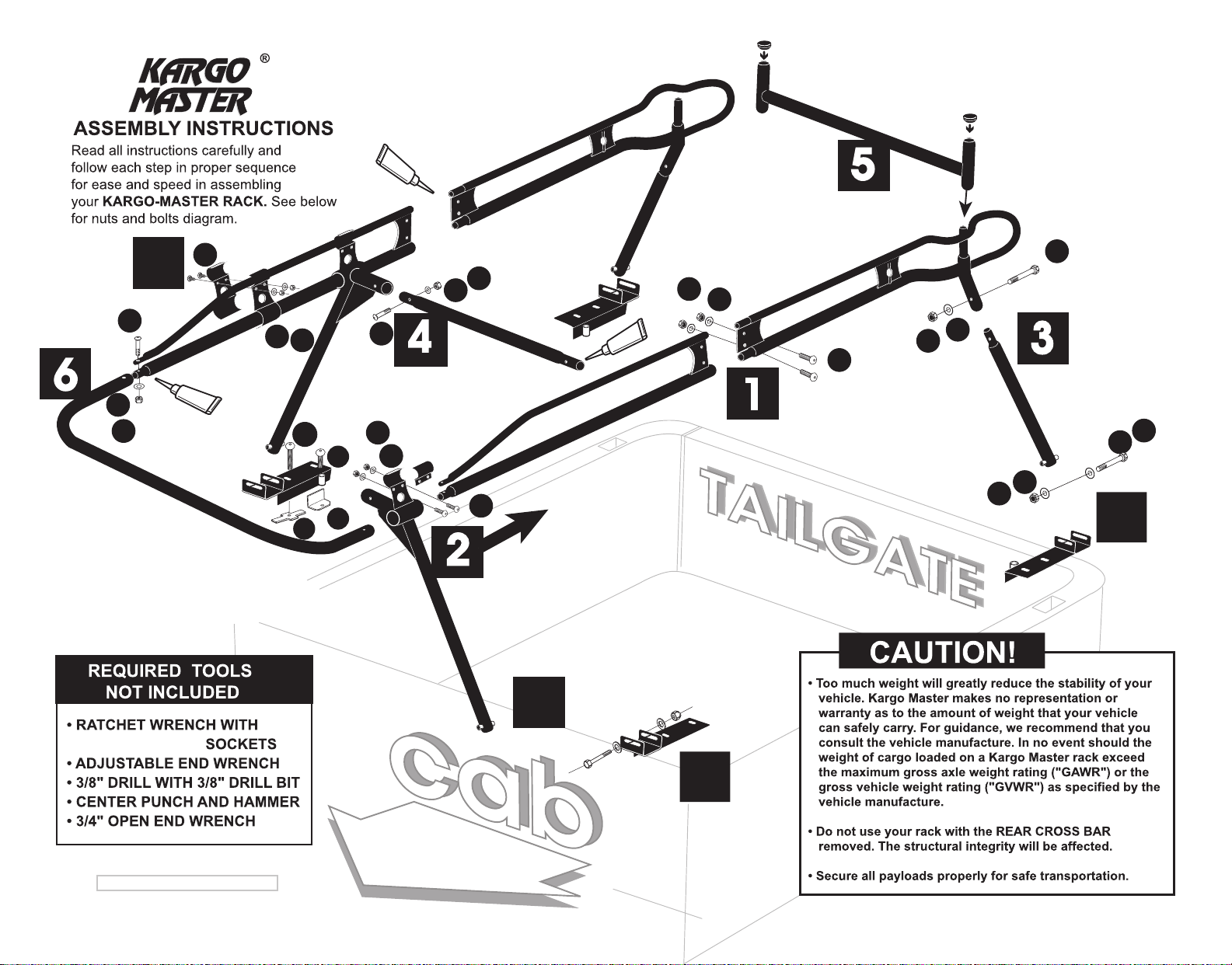

STEP 1

Pro3&4_4.1

#1=

Position FRONT FOOTPLATES on the truck bedrail, as far

forward as possible. Determine which pre-drilled hole (if any) falls over

the stake pocket. If none of the pre-drilled holes fall over the stake

pocket, mark and drill a hole in the foot plate that is approximately over

the center of the stake pocket. Put bolt T through FOOTPLATE and start T Nut Q

as shown. Maneuver

against the bulkhead, and tig

T Nut Q inside the stake pocket, push the FOOTPLATE forward

hten the T nut up against the underside of the

truck bed rail. Secure the rear of the front FOOTPLATE to the bedrail using

Bolt S and Bed Rail Clamp R as shown.

Note: If you prefer to mount the FOOTPLATES by drilling through the truck

bedrail, locate the FOOTPLATES as per above, and attach using included

fasteners D,K & M . We recommend using the pre-drilled hole at the rear

of the FOOTPLA

TES. You will have to locate and drill a second hole in the

FOOTPLATE, get as close to the leg as possible. Be sure you can access the nut.

T

S

TRUCK

CAB

T

-nut

Q

FOOTPLA

(front)

TE

TRUCKs’

Front

Stake

Pocket

Bed Rail Clamp

BEDRAIL

R

STEP 2

Pro3&4_4.1

#1=

Secure the rear of the front FOOTPLATE to the bedrail usingBolt S and Bed

Rail Clamp R as shown.

Note: If you prefer to mount the FOOTPLATES by drilling 3/8" holes through

the truck bedrail, locate the FOOTPLATES as per above, and attach using

included fasteners D, K, & M. We recommend using the pre-drilled hole at

the rear of the FOOTPLATES. You will have to locate and drill a second 3/8"

hole in the FOOTPLATE, as close to the leg as possible (loosely).

Position the REAR FOOTPLATES against the bedrail.

Pro3&4_4.1

GOOP APPLICATION

Apply a healthy air tight bead of goop

around every swaged joint as shown, to

prevent moisture from leaking into and out

of the joint. If this is not done properly, the

inside surface of the tubes can rust and

rusty water can leak out. Maintain this

joint seal throughout the life of your rack.

STEP 3

#1 = Cover entire swedge joints with goop

sealant and join FRONT and REAR side channels

together. There is a RIGHT & LEFT REAR. The

leg cups angle outward. Be sure the connecting

plates overlap, and loosely bolt together with bolts

G, washers K and lock nuts N.

GOOP

Smooth goop at swaged joint & holes

G

O

O

P

N

K

GOOP

Swaged joint & holes

G

STEP 4

#1 = Measure the center to center measurement

between the front and rear footplate saddles.

Final positioning of the front legs will follow.

Bulkhead (front)

Slide the FRONT leg onto the front side channel.

#2 =

There is a RIGHT & a LEFT. Match to the correct side

channel so that both FRONT & REAR legs angle outward.

Position distance to match same as above. Insert the set

screws P, but do not tighten yet.

Loosely attach the top CLAMP with

#3 =

bolts F, washers K, and nuts N.

Tailgate (rear)

STEP 5

#1 =

Cover entire swedge joints with goop

sealant and attach the REAR LEGS with

bolts C, washers J, and nuts M.

N

P

K

F

(RIGHT SIDE SHOWN)

Note: The distance between front & rear

legs will not be longer than the inside

measurements of the bed itself.

M

J

C

G

O

O

P

STEP 6

#1 = Cover entire swedge joints with goop

sealant and insert the CENTER CROSS

BAR into the SIDE RAIL CUPS and attach

with bolts E, washers K and lock nuts N.

STEP 7

E

Pro3&4_4.1

P

O

GO

N

K

#1 = Insert PLASTIC CAPS onto the rear

crossbar uprights, (the tall side of the tube).

Slide the REAR CROSS BAR into the REAR

LEG POSTS at the top, as shown.

STEP 8

#1 = Cover entire swedge joints with

goop sealant and slide FRONT CROSS

BAR onto side rails and bolt together with

bolts B, flat washer H, and jam nut L.

B

H

L

G

O

O

P

STEP 9

#1 = Lift rake onto truck and make

final adjustments and attach front

and rear legs with bolts A, washers

H, and nut L.

Center rack on truck bed.

Pro3&4_4.1

P

Tighten up the bolts on the crossbar and clamp

plates as well as the set screws P.

STEP 10

#1 = Attach the front SUPPORT

UPRIGHT

to bend downward, then...

TIGHTEN DOWN EVERYTHING AND....

where the 1” tube begins

A

H

H

L

N

K

THAT’S IT!

You’re ready to LOAD & GO!

G

STEP 11

Pro3&4_4.1

#1= Tighten down ALL NUTS AND BOLTS, except LEG FOOTPLATES and CENTER CROSS BAR .

DO NOT OVER TIGHTEN ON DOUBLE WALL BED CONSTRUCTION, AS THIS MAY DEFORM THE

SHEET

METAL OF THE PICKUP BED!

C

#2= Center RACK over bed and tighten FRONT

MOUNT BOLTS. On REAR MOUNT BOLTS be sure

LOCK PINS slide IN & OUT smoothly and freely

before tightening the rear BOLTS.

#3= Snug bolts in CENTER CROSS BAR .

J

C

#4= Modern truck beds are made from thin steel with

limited load bearing capacity. Approximately 75% of

the rack load is carried by the front legs. Because the

rack is wider at the bottom than the top, overhead

loads tend to push the bed walls down and apart.

If you expect to carry heavy loads,

we strongly suggest that you purchase

and install OPTIONAL BED SUPPOR

as shown below.

TS

THAT'S IT!

You're ready to

use and enjoy your

KARGO MASTER

TRUCK RACK!

INSIDE BED WALL

8

3"

3/8"

(OPTIONAL

BED SUPPORT)

©2011 KARGO MASTER --'Pro3'_4.1

O

V

E

R

T

U

R

N

F

O

R

C

E

DON'T OVERLOAD YOUR VEHICLE!

LBS.

LBS.

@

@

WEIGHT CARRIED ABOVE THE FLOOR OF THE TRUCK BED (E.G. ON AN OVERHEAD TRUCK RACK)

WILL SIGNIFICANTLY INCREASE THE VEHICLE'S TENDENCY TO OVERTURN. ALWAYS KEEP

HEAVY LOADS EVENLY DISTRIBUTED AND AS LOW AS POSSIBLE. IT IS IMPORTANT TO NOTE THAT

THE KARGO MASTER RACK LOAD BEARING CAPACITY OF 1700 LBS. MAY BE GREATER THAN YOUR

TRUCK'S GAWR OR GVWR CAPACITY, AND IS PROBABLY GREATER THAN THE WEIGHT THAT CAN BE

SAFELY CARRIED OVERHEAD.

100" = 3X lbs.

35" =

X lbs.

For TECHNICAL SUPPORT Call:

1.800.343.7486

HOURS: Monday- Friday 8:00 A.M. to 4:30 P.M. ( PACIFIC )

Loading...

Loading...