Kargo Master 80070 User Manual

ASSEMBLY INSTRUCTIONS

for :

80070 TOP MOUNT

CAMPER SHELL

and TRANSIT CONNECT

RACK

TMCS_3:1

®

(916) 638-8703

• 11261 Trade Center Drive • Rancho Cordova, CA 95742 •

(800) 343-7486

• www.kargomaster.com •

ASSEMBLY INSTRUCTIONS

Read all instructions carefully and follow each

step in proper sequence for ease and speed in

assembling your KARGO-MASTER RACK.

See below for nuts and bolts diagram.

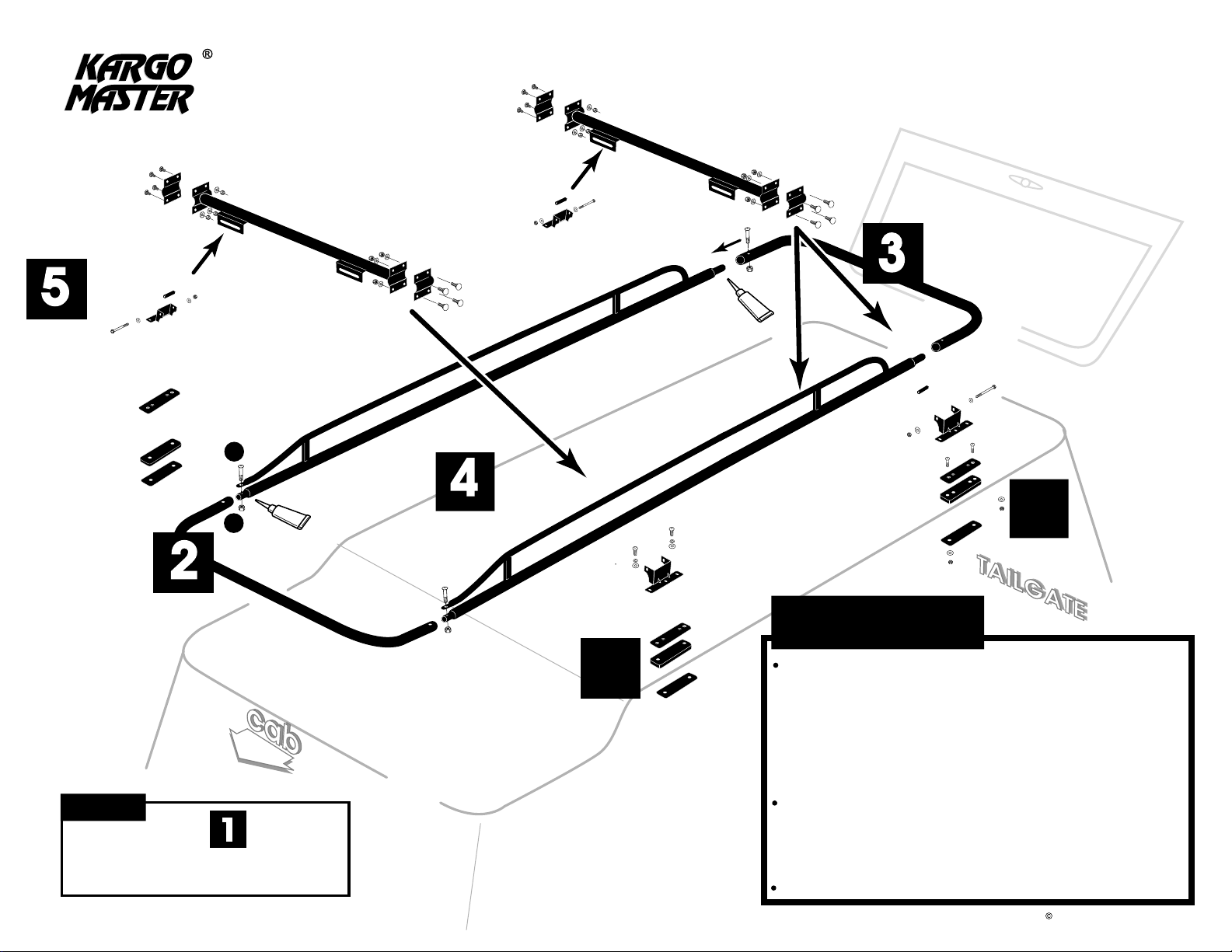

80070 Top Mount

Camper Shell & Transit

Connect Rack

5

2

Camper

G

O

O

P

Transit

B

3

4

G

O

O

P

L

WARNING!

WE RECOMMEND THAT YOU NOT EXCEED 200 LBS. OF EVENLY

88

SPACED CARGO. TOO MUCH WEIGHT COULD DAMAGE YOUR

CAMPER SHELL. KARGO MASTER MAKES NO REPRESENTATION

OR WARRANTY AS TO THE AMOUNT OF WEIGHT THAT CAN BE

CARRIED SAFELY BY OR WITHOUT DAMAGING YOUR SHELL. FOR

GUIDANCE, WE RECOMMEND THAT YOU CONSULT THE CAMPER

SHELL MANUFACTURER.

1111

NOTE:

Shaded numbers ( ) in this view

correspond to instruction steps in this

assembly package.

DRILLING HOLES IN THE CAMPER SHELL ROOF MAY VOID THE

WARRANTY. WE RECOMMEND THAT YOU HAVE AN AUTHORIZED

CAMPER SHELL DEALER DRILL AND MOUNT THE RACK FOOT

PLATES.

SECURE ALL CARGO PROPERLY FOR SAFE TRANSPORTATION.

2012 KargoMaster-TMCS-3:1

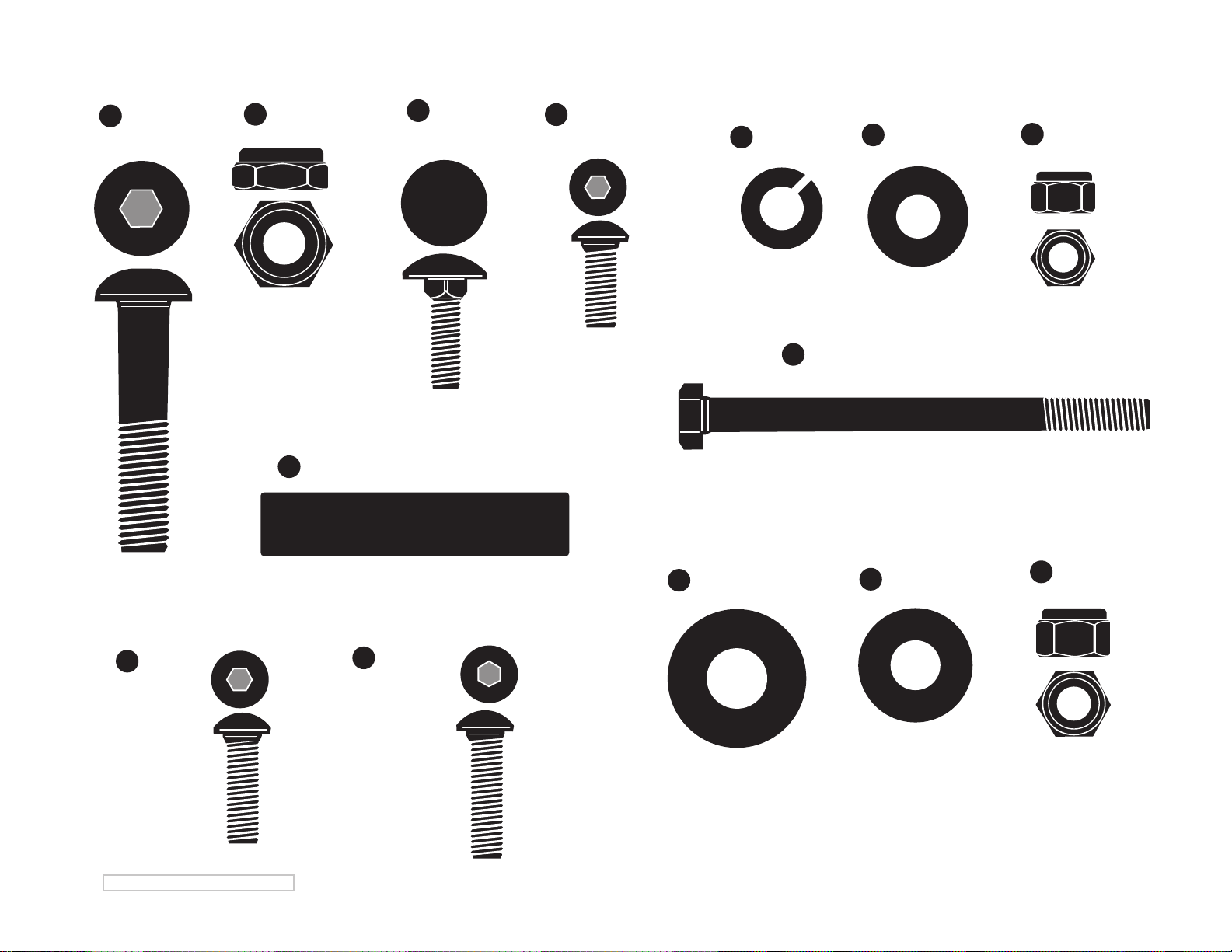

A

(4 ea.)

1/2" x 2 1/4"

Button Head Bolt

B

(4 ea.)

1/2" Nyloc Jam Nut

(4 ea.) Mounting Bracket Spacers

N

(16 ea.)

E

5/16" x 1"

Carriage Bolt

(8 ea.)

G

5/16" x 3/4"

Button Head Bolt

H

(8 ea.)

5/16" Lock Washer

(4 ea.)

K

3/8" x 4"

Hex Bolt

80070 Bolt Kit

I

(32 ea.)

5/16" Flat Washer

J

(24 ea.)

5/16" Lock Nut

(4 ea.)

D

M8 x 32

©2012 KARGO MASTER_TMCS 3:1

(8 ea.)

S

5/16" x 1 1/4"

Button Head Bolt

P

(4 ea.)

1/2" SAE Flat Washer

L

(8 ea.)

3/8" SAE Flat Washer

M

(4 ea.)

3/8" Lock Nut

TMCS_3:1

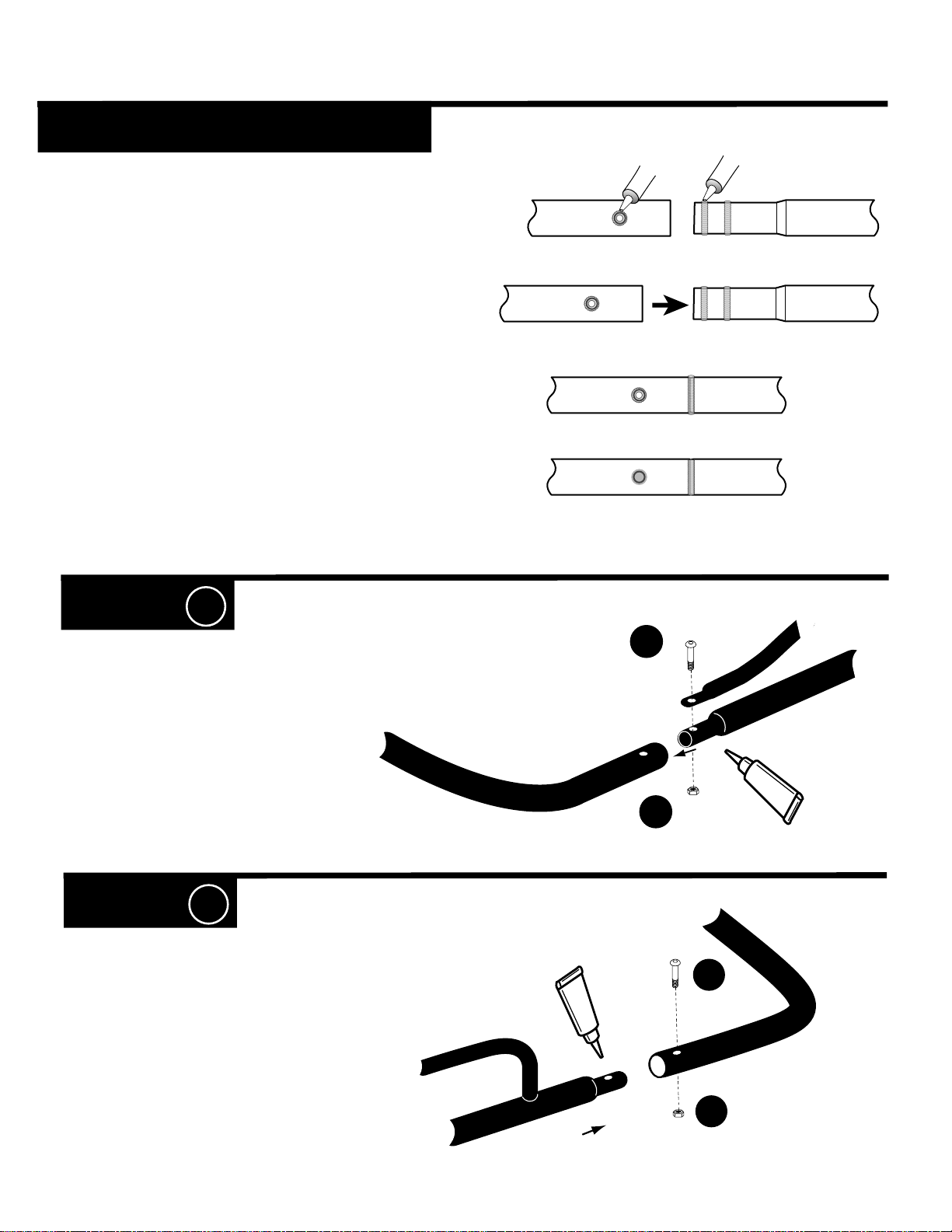

GOOP APPLICATION

Apply a healthy air tight bead of goop

around every swaged joint as shown, to

prevent moisture from leaking into and out

of the joint. If this is not done properly, the

inside surface of the tubes can rust and

rusty water can leak out. Maintain this

joint seal throughout the life of your rack.

Swaged joint & holes

GOOP

Smooth goop at swaged joint & holes

GOOP

STEP 1

#1 = Cover entire swedge joints with

goop and slide FRONT U- BAR onto side

rails and bolt together with bolts

jam nut

B.

A, and

STEP 2

#1 = Cover entire swedge joints with

goop and slide REAR U- BAR onto side

rails and bolt together with bolts

jam nut

B.

A, and

A

G

O

O

P

B

G

O

O

P

A

B

Loading...

Loading...