Kalmar TL2 Maintenance Manual

Terminal Tractor

Kalmar TL2

2018

All variants

Maintenance Manual

Original Instructions

A Foreword

B Safety

C Preventive maintenance

0 Complete machine

1 Engine

2 Transmission

Maintenance

manual

3 Driveline/axle

4 Brakes

5 Steering

6 Suspension

7 Load handling

8 Control system

9 Frame, body, cab and accessories

10 Common hydraulics

11 Common electrics

12 Common pneumatics

D Error codes

E Schematics

F Technical data

G Appendixes

1

Table of content

A Foreword 3

Feedback 3

Maintenance manual 4

Reading this manual 7

TL2 Maintenance Manual

591 003 Default

2

TL2 Maintenance Manual

591 003 Default

A Foreword – Feedback 3

A Foreword

Feedback

Form for giving feedback

It is the goal of Cargotec Oy, to provide everyone working with the

maintenance of Kalmar machines with access to the correct infor‐

mation for performing the work safely and efficiently.

Your feedback is important for us to be able to improve the informa‐

tion.

Copy this form, write down your views, and send the form to us.

Thank you for your participation!

To: Cargotec Finland Oy

After sales, technical support / Terminal tractors

P.O. Box 387

FI-33101 Tampere

FINLAND

From: Company / sender: ..............................................................................................................................

Telephone: ..........................................................................................................................................

E-mail: .................................................................................................................................................

Date: .................................... - .................. - ..................

Manual

information

Suggestions,

comments,

remarks, etc.

Name / publication number: ................................................................................................................

Section / page number: ......................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

TL2 Maintenance Manual

591 003 Default

4 A Foreword – Maintenance manual

Maintenance manual

General

The maintenance manual introduces the machine's maintenance

programme and items to the service personnel.

The manual provides instructions for the service personnel concern‐

ing safe working methods when servicing and adjusting the machine

according to the maintenance programme.

Support from our professional maintenance organisation and follow‐

ing the maintenance instructions described in the manuals are a

prerequisite for safe, reliable, and efficient operation of the machine

throughout its lifecycle.

Contact your superior if some parts of this manual lead to questions

or some important information of maintenance seems to be missing.

Contents

This maintenance manual contains the following information:

A Foreword General information about the purpose and contents of this maintenance

manual, instructions for reading the manual, and a form for giving feedback

B Safety Information regarding safety

C Preventive maintenance Information about preventive maintenance

Maintenance programme

0 Location of faults The adjacent sections include a description of the machine structure and

functions and some general instructions for locating the faults. All subjects in

1 Engine

2 Transmission

3 Driveline/Axle

4 Brakes

5 Steering

6 Suspension and wheels

7 Load handling

8 Control system

9 Frame, body, cab and accessories

the sections are listed in the following order:

the instructions for the service measures defined in the maintenance

1.

programme

ffunction-specific troubleshooting instructions

2.

technical information concerning maintenance work

3.

In addition to the general description of the machine operation, the manual

contains a detailed description of the operation of the maintenance item.

The sections describe the components related to the function in question. For

this reason, the most common components are mentioned in several

sections, but they are usually described in connection with the first function to

which the component is related.

If the function uses a component that has been described above, the

component is presented with a description relevant to the new function only.

10 Common hydraulics

11 Common electrics

12 Common pneumatics

TL2 Maintenance Manual

591 003 Default

D Error codes Error codes and instructions for reading the data

E Diagrams Electric, hydraulic, and pneumatic diagrams

F Specifications Technical specifications, conversion tables and unit conversion factors

G Terminology and index General terms and abbreviations, their explanations, and an index of

A Foreword – Maintenance manual 5

headings

Division into function groups

The above division of the maintenance manual into function groups

is the same for all machines manufactured by Cargotec Oy. The

groups are indicated by numbers with two digits (for example, 4.3

Power-assisted brake system). Machine specific adaptations of the

function groups are indicated by a third or fourth digit (for example,

4.3.9 Wheel brake or 4.3.9.1 Disc brake).

Certain headings (function groups) are omitted in the documentation

for certain machines if the machine lacks that particular function.

This means that there may be gaps in the function group number‐

ing, for example, 2.7 Cooling system may be included for certain

machines, but may be missing for other machines.

References between different manuals are used since the different

manual types have different purposes and thus different information

content.

References between sections within this maintenance manual are

indicated with the section and chapter number, for example, "See

section 4,

the same section is indicated by the page number, for example,

"

See Description of the fuel sensor on page 24

Brakes

, chapter 4.3.9.,

Wheel brake

". A reference within

".

Conditions

The maintenance instructions described in this manual are based

on the use of generally available standard tools. All lifting devices

required in the maintenance work, for example, slings, straps, and

ratchet blocks, must meet the national standards and regulations for

lifting devices.

Cargotec Oy, will not accept any responsibility for modifications per‐

formed without permission from the manufacturer, or if lifting devi‐

ces, tools, or work methods other than those described in this man‐

ual are used.

Storage

Keep this manual in good condition, and store it in a place where it

is always available to the service personnel.

About the machine

The information in this manual corresponds to the design and

appearance of the machine at the time of delivery. Information in the

manuals of the same machine type can differ from each other

depending on the machine that the customer has ordered.

TL2 Maintenance Manual

591 003 Default

6 A Foreword – Maintenance manual

All information and data in this manual are valid at the time of publi‐

cation.

Copyright

This document may not be copied, presented, or delivered to a third

party without our explicit permission, or used for purposes other

than those allowed by us.

We reserve the right to alter the adjustment values, equipment, and

service and repair instructions for the machine without prior notice.

Cargotec Oy

TL2 Maintenance Manual

591 003 Default

A Foreword – Reading this manual 7

Reading this manual

Information on possible safety hazards

This manual includes three types of warnings containing instructions

on how to avoid situations that may compromise safety.

DANGER

Warns about a situation that involves an immediate risk of personal

injury or death unless the safety instructions provided are observed.

WARNING

Warns about a situation that may cause personal injury, death,

and/or substantial damage to the machine or other property unless

the safety instructions provided are observed.

Fig. : This symbol indicates an accessory or optional

equipment.

CAUTION

Warns of a situation that may cause moderate personal injury

and/or damage to the product or other property unless the safety

instructions provided are observed.

Important information

The word NOTE is used to emphasise issues concerning safety or

the maintenance instructions to which special attention must be paid

while working on the machine.

An example of how the word NOTE appears is presented below.

NOTE

Calls the reader's attention to an instruction that, for example, empha‐

sises operational safety.

Optional equipment

The machine can be equipped with various accessories or optional

equipment. The equipment is marked with the symbol seen on the

left. The symbol is always accompanied with text representing and/

or describing the equipment.

The NOTE symbol is clearly distinguished from the text, and it is

placed next to the text and picture representing the equipment.

TL2 Maintenance Manual

591 003 Default

8

A Foreword – Reading this manual

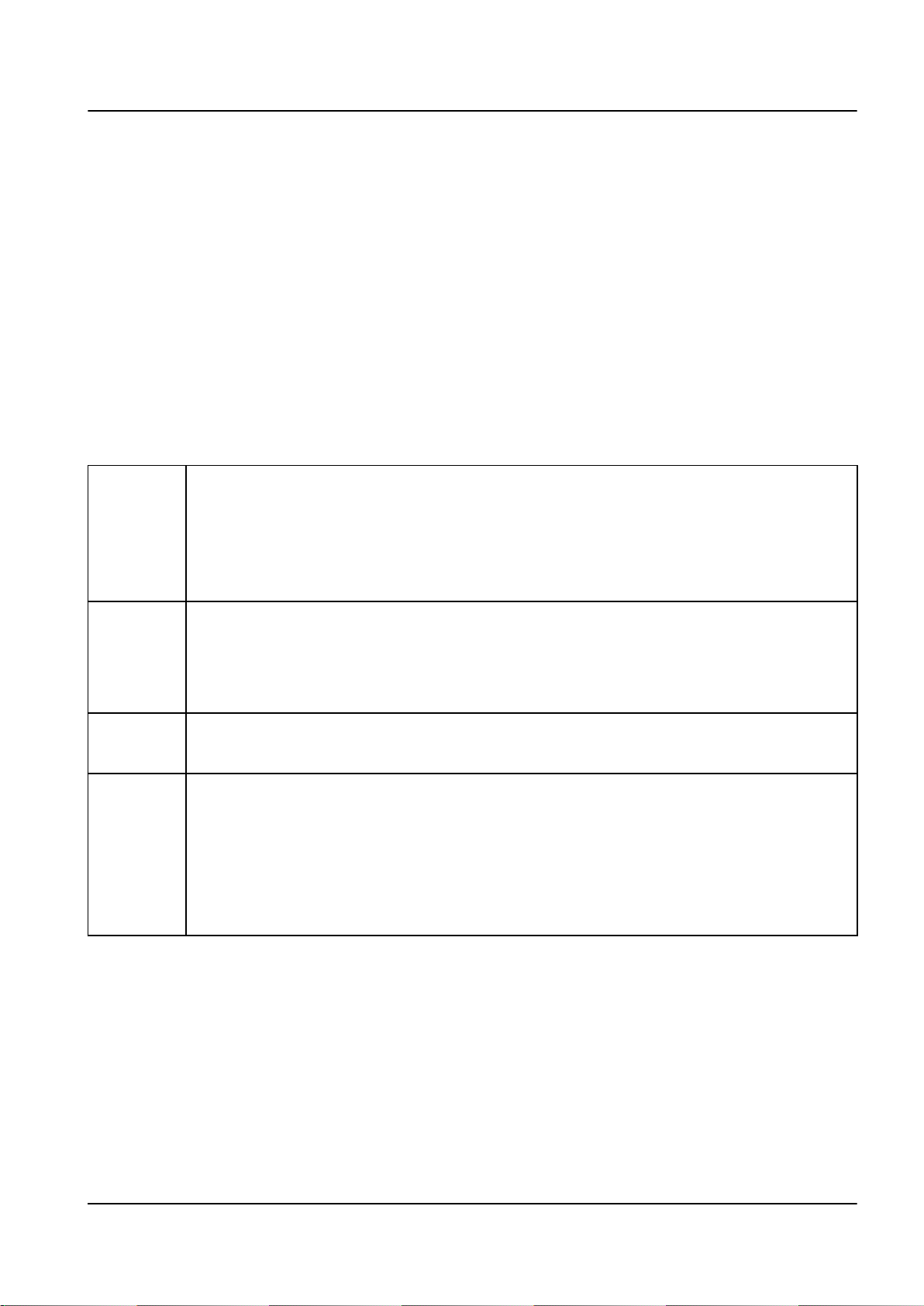

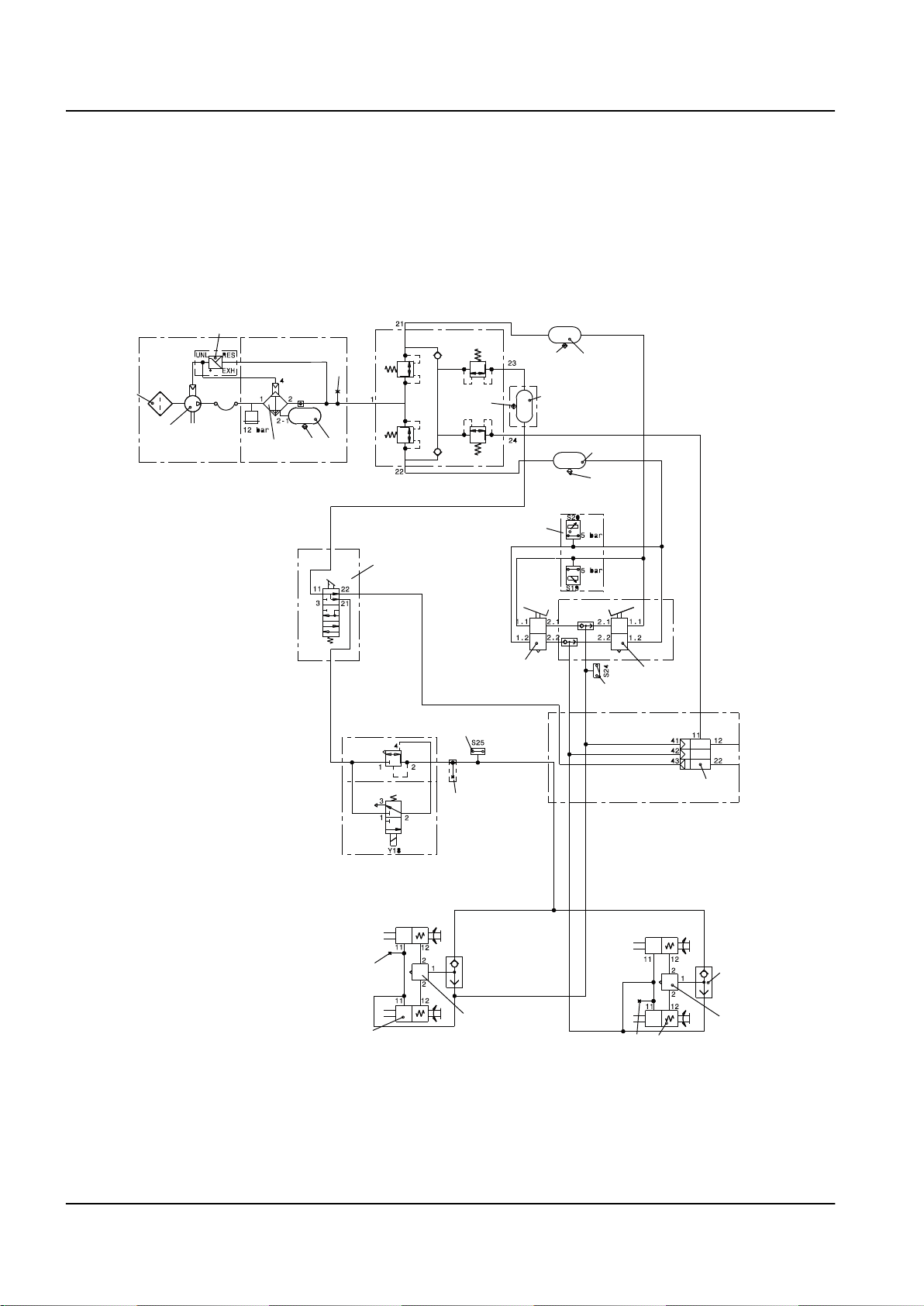

Function descriptions

The function descriptions are presented as circuit diagrams and

equipment position drawings that describe the function and the

associated components.

The function descriptions describe the function in a logical order.

The circuit diagrams use symbols to depict components such as

pumps, filters, valves, and sensors.

An example of a circuit diagram is provided on the following page.

3

6

1

8

7

9

7

69

2

3.1

7

9

4

7

10B

68

7

11

11B

12

14

60

64B

65

59

19

16

18

Circuit diagram component list

1. Terminal tractor air filter

2. Pneumatic air compressor

3. Pressure regulator

TL2 Maintenance Manual

591 003 Default

19

17

15

16

A Foreword – Reading this manual 9

3.1 Air drier

4. Air drier water separator container (6 litres)

6. Charging valve that fills the pneumatic system with compressed

air if the engine is not working or the compressor cannot be used

7. Drain valve

8. Four-circuit protection valve

9. Air tanks (2 x 30 litres)

10B. Pressure switch and measurement sensor

The measurement sensor is available as an option.

11. Front pedal valve

11B. The rear pedal valve and shuttle valve in tractors equipped

with a revolving seat

12. Brake light switch

14. Parking brake indicator light switch

15. Shuttle valve

16. Brake pressure quick release valve

17. Rear axle brakes and parking brake spring chamber

18. Front axle brakes

The parking brake spring chamber is an option.

19. Pressure measurement fitting

59. Parking brake solenoid valve

60. Parking brake relay valve

64B. Trailer brake control valve for the EC-compliant brake system

65. Parking brake release

68. Parking brake valve for the EC-compliant brake system

69. Air tank (30 litres) for the EC-compliant brake system

TL2 Maintenance Manual

591 003 Default

10 A Foreword – Reading this manual

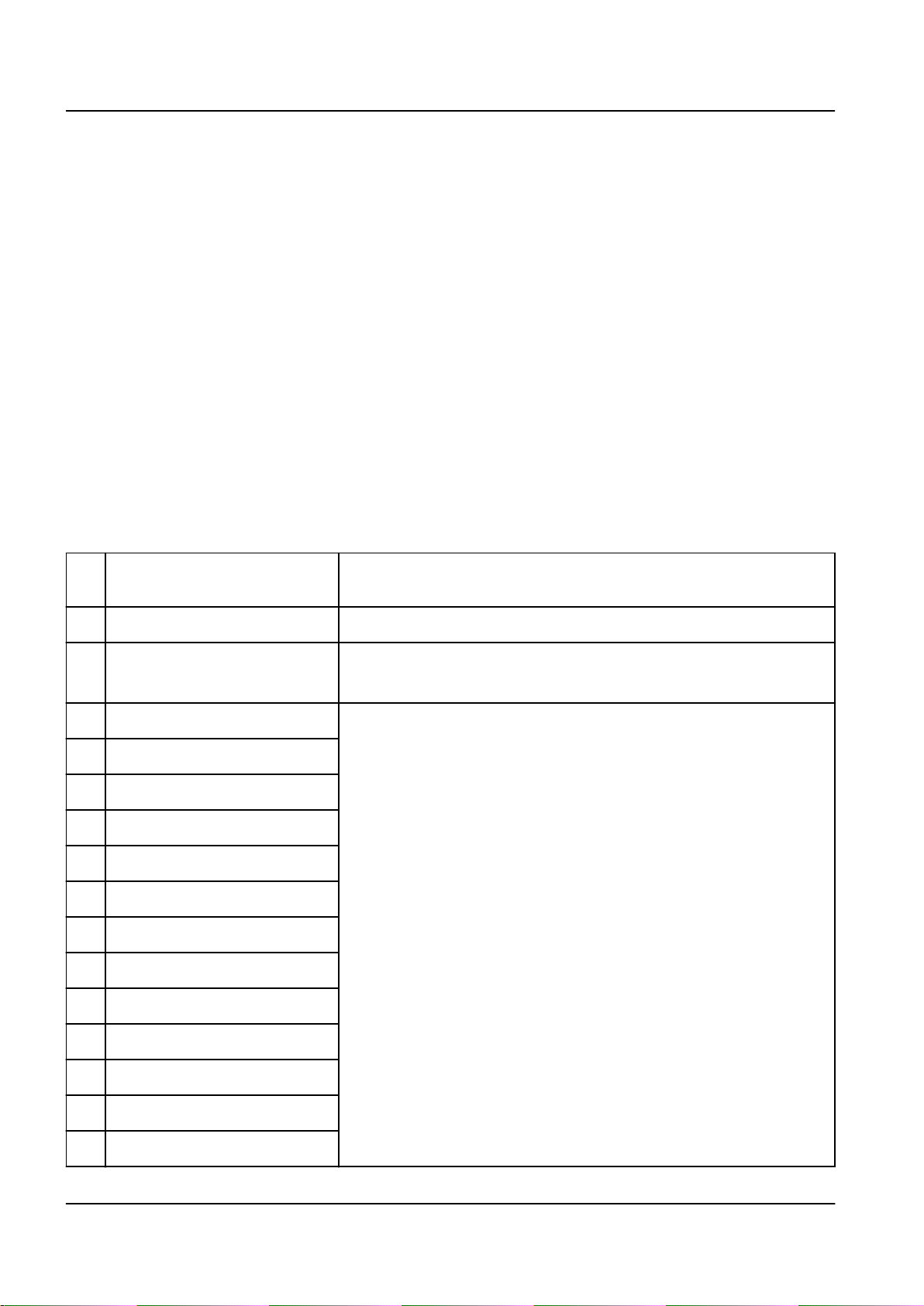

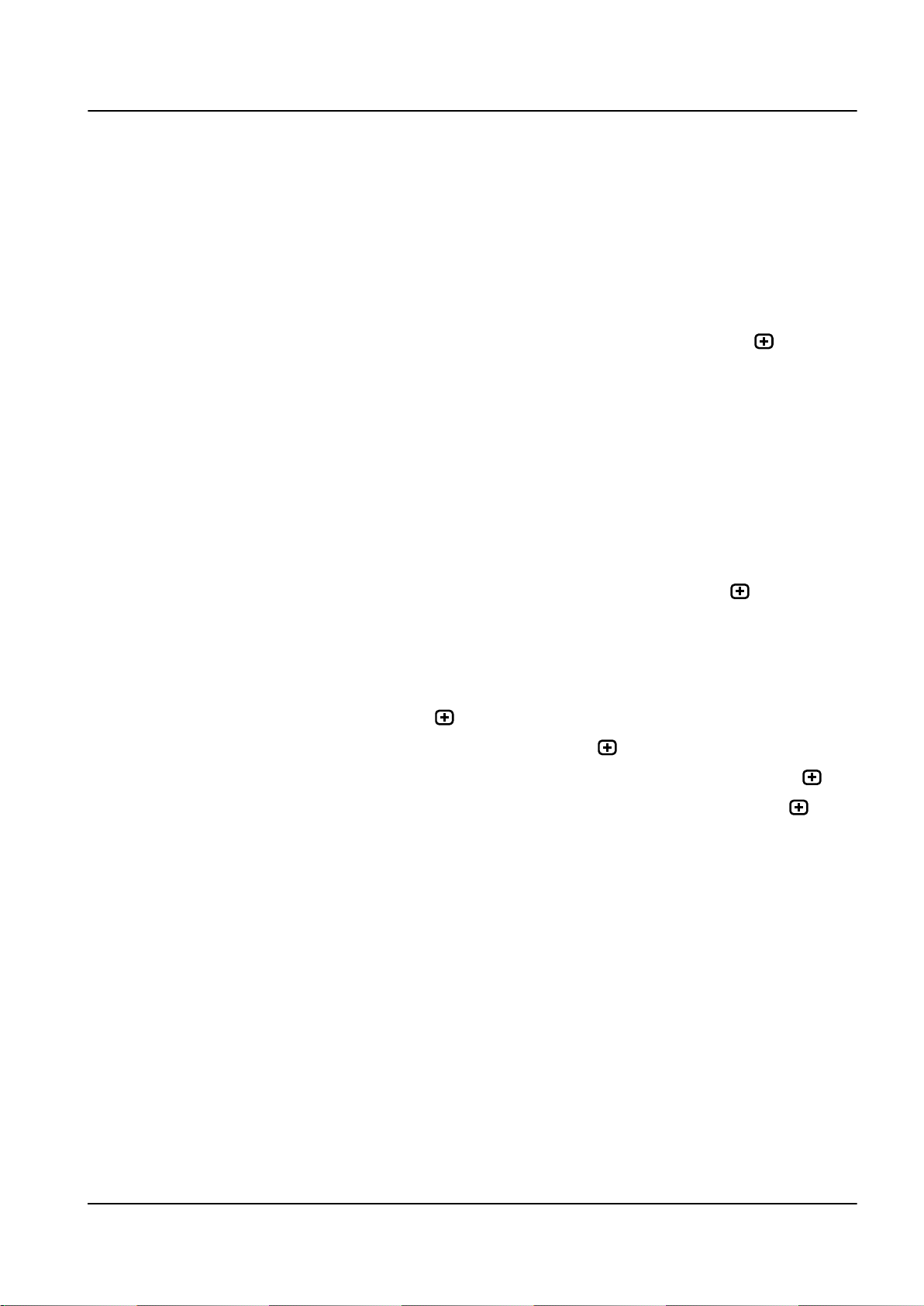

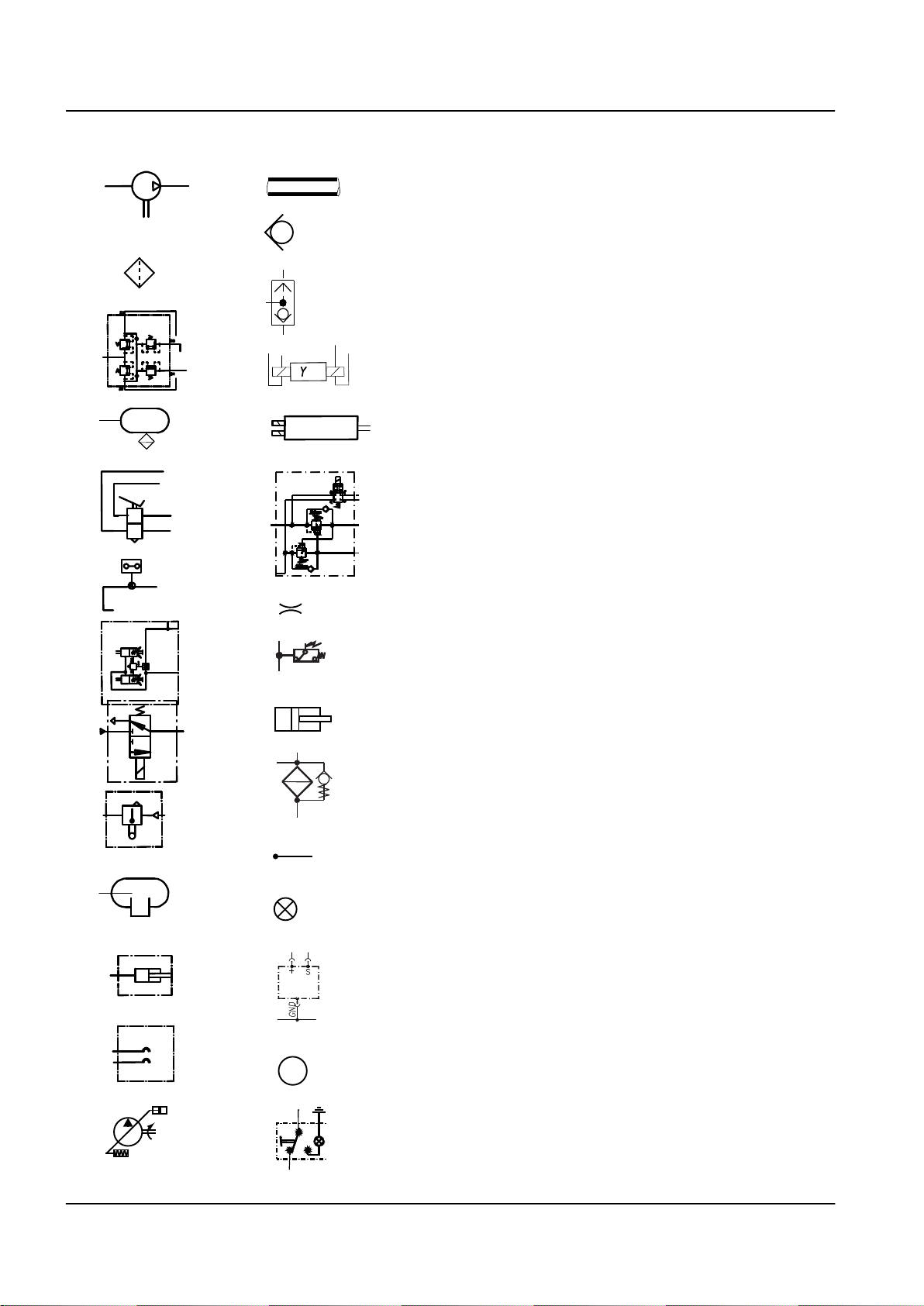

Explanation of the function description symbols

1

14

The following symbols are used in function descriptions. The sym‐

bols are based on standard symbols used in the electric and

hydraulic diagrams.

15

Pneumatic air compressor

2

16

3

a

17

4

5

18

19

b

A

B

6

20

7

21

22

8

23

1.

Air filter

2.

Four-circuit protection valve in the pneumatic system

3.

Air tank

4.

Brake pedal valve in the pneumatic system

5.

Pressure switch in the pneumatic system

6.

Service brake and parking brake chamber in the pneumatic

7.

system

Solenoid valve in the pneumatic system

8.

Level valve in the pneumatic system

9.

Air spring in the pneumatic system

10.

Cylinder in the pneumatic system

11.

Palm type couplings in the pneumatic system

12.

Variable-displacement pump in the hydraulic system

13.

Pressure/return line in the hydraulic system

14.

Throttle valve in the hydraulic system

15.

Pressure-controlled shuttle valve in the hydraulic system

16.

Electrically controlled solenoid valve in the hydraulic system

17.

Electrically controlled directional valve in the hydraulic system

18.

Load control valve in the hydraulic system

19.

Throttle valve in the hydraulic system

20.

Pressure switch in the hydraulic system

21.

Cylinder in the hydraulic system

22.

Return filter in the hydraulic system

23.

Cable in the electric system

24.

Indicator light in the electric system

25.

Level sensor in the electric system

26.

Electric motor

27.

Control switch in the electric system

28.

9

10

11

13

12

24

25

26

27

28

M

TL2 Maintenance Manual

591 003 Default

A Foreword – Reading this manual 11

Manual package

The following manuals are included in the machine delivery as

ordered:

Operator's manual

•

Maintenance manual

•

Spare parts catalogue

•

Each manual can be ordered separately, in case extra copies of

instruction manuals or spare parts catalogue for the machine are

needed later.

Ordering the manuals

The manuals can be ordered from the manufacturer's spare parts

department.

Refer to the serial number of the machine when placing the order.

TL2 Maintenance Manual

591 003 Default

12 A Foreword – Reading this manual

TL2 Maintenance Manual

591 003 Default

1

Table of content

B Safety 3

General safety instructions 3

Safety instructions 4

TL2 Maintenance Manual

591 003 Default

2

TL2 Maintenance Manual

591 003 Default

B Safety – General safety instructions 3

B Safety

General safety instructions

General

Everyone performing maintenance and adjustment procedures on

the machine must follow the safety instructions included in this man‐

ual.

Maintenance must be carried out only by professional and trained

personnel.

Training on maintenance and occupational safety issues can be

ordered from our service centre if necessary.

Remember:

Follow the safety instructions included in this manual.

•

Obtain the training required by the job and, if necessary, ask

•

your work instructor for guidance on the issues regarding

safety at work.

Follow local laws, safety instructions, and regulations.

•

Do the job with equipment and tools that you have been trained

•

to use safely and properly.

Always stop the engine before commencing maintenance or

•

adjustments.

Do not smoke or use an open flame when refueling or servicing

•

the fuel system.

Avoid skin contact with oils and lubricants. Use protective

•

gloves when handling oils and greases during maintenance.

When working, use suitable protective clothing, which does not

•

easily get caught in the machine components and which pro‐

vides good protection against oil and liquid splashes during

maintenance.

Work carefully but efficiently, and do not take any risks.

•

In this publication, Cargotec Oy has documented and warned about

situations and risks that may occur in connection with operation as

well as service and repairs of the machine under normal conditions.

Therefore, it is very important that all persons working with the

machine acquaint themselves with and act according to the informa‐

tion in the maintenance manual and the operator's manual.

TL2 Maintenance Manual

591 003 Default

4

B Safety – Safety instructions

Safety instructions

General

Read the safety instructions before starting servicing or other work

on the machine, and follow them strictly to keep operational safety

at the intended level.

Service position

The machine's service position is used during service, maintenance,

and other procedures during which the machine must be stationary.

Service position:

The machine is parked with the parking brake engaged.

•

The lifting frame is lowered to the ground level.

•

The engine is switched off.

•

The main power is not switched on.

•

Depressurizing the brake system

Place the machine in service position.

1.

Depressurize the brake system

2.

Switch the parking brake on and off several times with the

parking brake switch. The system has been depressurized

when the brake quick release valve does not emit any sound of

air flow anymore.

Depressurizing the hydraulic system

Place the machine into service position.

1.

Note the following when opening the pipe and hose connec‐

2.

tions:

If any pipe or hose connections of the hydraulic system are

opened during service, first ensure that opening them does not

cause any personal injuries or material damage resulting from

lowering of the load or a machine component.

DANGER

Working under the cab without the mechanical safety stop that pre‐

vents the cab from lowering is strictly prohibited!

Clothing

Wear appropriate work clothing. Remove any loosely hanging cloth‐

ing, for example a tie or a scarf. Do not wear clothes with wide

sleeves, wide trouser legs, and so on.

Remove jewellery as it may get caught in moving parts.

TL2 Maintenance Manual

591 003 Default

B Safety – Safety instructions 5

Long hair must be tied up securely, otherwise it may easily get

caught in moving parts. Be careful when welding or flame cutting

since hair catches fire easily.

Several mechanics working with the machine

WARNING

Be especially careful if several mechanics work with the machine at

the same time. Communicate so that everyone knows where the

others are and what they are doing.

Risks

Working with the wheels or axle suspension, attachments, and so

on, can cause the components on the other side to move and cause

damage or injury.

Movements controlled by the driver, such as lowering the lifting

frame during maintenance, can cause severe personal injuries.

Precautions

If the cab is tilted to service position, make sure that the

•

mechanical support that prevents the lifting frame from lower‐

ing is in place.

make sure that the lifting frame of the machine is fully lowered

•

or that it is mechanically supported in its elevated position.

Set the main switch to vertical position and remove the key

•

from the ignition key lock.

Be aware of all risks if several persons are involved in the

•

machine maintenance simultaneously.

Make your co-workers aware of which maintenance item you

•

are working with.

Working under the cab and machine

Working under the cab

Working under the cab without the mechanical safety stop that pre‐

vents the cab from lowering is strictly prohibited!

Working under the chassis

The machine may not be lifted by the components of the axle sus‐

pension system or steering system. Always support the machine

below the frame or axles.

Risks

Mechanical or hydraulic tools or lifting devices can tip over or lower

accidentally due to a fault or incorrect use.

Precautions

Use axle stands and supports that are positioned firmly.

Use only type approved and inspected lifting tools.

TL2 Maintenance Manual

591 003 Default

6

B Safety – Safety instructions

Lifting heavy components

WARNING

Careless handling of heavy components can lead to serious per‐

sonal injury and material damage.

Use only type approved lifting tools or other devices to move heavy

components. Make sure that the device is stable and intact.

Risks

Unsuitable lift slings, straps, and so on, may break or slip.

The centre of gravity (balance point) of the component can change

during the course of the work, and the component may then make

unexpected movements which can cause severe personal injuries

and material damage.

A component lifted with lifting equipment can start to turn if the com‐

ponent balance is upset.

A component lifted using an overhead crane may start to swing

back and forth, which can cause a risk of injury.

Precautions

Lift using a lifting device.

Use lifting tools or equipment, especially when such equipment

•

is available for specific work operations.

If lifting must be performed without a lifting device:

Keep the object near to your body when lifting.

•

Keep your back straight. Raise and lower with your legs and

•

arms, do not bend your back. Do not rotate your body while lift‐

ing. Ask for assistance in advance.

Wear gloves. Gloves provide good protection against minor

•

crushing injuries and cuts to fingers.

Always wear protective shoes.

•

Vibration

In case of long-term use of vibrating tools, for example, screwdrivers

or grinders, injuries may be sustained as vibrations are transmitted

from tools to hands. This happens especially when the fingers are

cold.

Precautions

Use heavy gloves to protect against cold and vibrations.

•

Do not continuously perform tasks that cause vibration to give

•

your body time to rest.

Change your working position and grip while working so that

•

your body is not stressed in only one position by the vibrations.

Noise

Noise louder than 85 dB (A) that lasts longer than 8 hours is consid‐

ered harmful to hearing. Tones at high frequencies are more dam‐

TL2 Maintenance Manual

591 003 Default

B Safety – Safety instructions 7

aging than low tones at the same sound level. Impact noise can

also be hazardous, for example, hammer blows.

Risks

Damage to hearing can occur at noise levels higher than the limits.

In severe cases, the damage to hearing can become permanent.

Precautions

Use hearing protection. Make sure that it has been tested and

•

that it protects against the corresponding noise level.

Solvents

Fluids that dissolve grease, paint, lacquer, wax, oil, adhesive, rub‐

ber, and so on, are called organic solvents.

Such liquids include white (petroleum) spirits, petrol, alcohols, die‐

sel, xylene, trichloroethylene, and toluene.

Many solvents are flammable and constitute a fire hazard.

Risks

Products that contain solvents produce fumes that can cause dizzi‐

ness, headaches, and nausea. They may also irritate mucous mem‐

branes in the throat and the respiratory tract.

If solvents come in direct contact with the skin, this may cause dry‐

ing and cracking. The risk of skin allergies increases. Solvents may

also cause injury if they penetrate through the skin and are absor‐

bed by the blood.

If the body is continuously exposed to solvents, the nervous system

may be damaged. Symptoms include sleep disorders, depression,

nervousness, memory disorder, or general tiredness and fatigue.

Continuous inhalation of petrol and diesel fumes is suspected to

cause cancer.

Precautions

Avoid inhaling solvent fumes and make sure the ventilation is

•

adequate. If necessary, wear a fresh-air mask or respiratory

device with a suitable filter for toxic gases.

Never leave a solvent container open; seal the lid carefully.

•

Use solvents with a low content of aromatic substances. This

•

reduces the risk of injuries.

Avoid skin contact.

•

Use protective gloves.

•

Make sure that work clothes are solvent-resistant.

•

Fire and explosion risks

Examples of explosive substances are oils, petrol, diesel fuel,

organic solvents (such as lacquer, plastic, and cleaning agents),

rust proofing agents, welding gas, gas for heating (acetylene), and

high concentrations of dust particles from combustible materials.

Machine and vehicle tyres are highly flammable and cause fires that

spread explosively.

Risks

Examples of the causes of ignition include welding, cutting, smok‐

ing, sparks produced by grinding, and flammable materials coming

into contact with hot machine parts.

TL2 Maintenance Manual

591 003 Default

8

B Safety – Safety instructions

Petrol fumes, for example, are heavier than air and can thus run

down a sloping grade or down into a grease pit where, for example,

welding flames can cause an explosion. Evaporated petrol has a

very powerful explosive force.

Special cases

Diesel fuel with added petrol has a reduced flash point. There is an

explosion risk even at room temperature. The explosion risk due to

warmed diesel fuel is greater than for petrol.

When changing oil in the engine, hydraulic system, and transmis‐

sion, keep in mind that the oil can be hot and may cause burn inju‐

ries.

Welding on or near the machine constitutes a fire hazard: if diesel or

other oils have leaked out and have been absorbed by rags,

absorbing agent, paper, or other porous material, welding sparks

can cause ignition and an explosive spread of fire.

When charging the battery, the battery electrolyte emits oxygen and

hydrogen gas. This mixture is highly explosive. The risk of explosion

is especially high when a booster battery or a rapid charge unit is

used, as these increase the risk of sparks.

Today's machines contain a lot of electronic equipment. The control

units must be disconnected and the main switch must be off when

welding. Otherwise, strong welding currents can shortcircuit the

electronics, destroy expensive equipment, and cause an explosion

or fire.

Never weld painted surfaces. Remove the paint at least 200 mm

around the welding or cutting point. Use gloves, respiratory protec‐

tion, and protective safety glasses when sand blasting and welding

the damaged item. Also, welding work must never take place near

plastic or rubber materials without first protecting them from the

heat. Paints, plastics, and rubber generate various substances that

may be hazardous to health when heated. Be careful with machines

that have been exposed to intense heat or fire.

Precautions

Store explosive substances in approved and sealed containers.

•

Make sure that there are no ignition sources near flammable or

•

explosive substances.

Make sure that ventilation is adequate or there is an air extrac‐

•

tion unit when handling flammable substances.

Fluid or gas under pressure

Pressure lines can be damaged during work, and fluid or gas can

stream out.

There may be high pressure in a line even if the pump has stopped.

Open the pipe or hose connection of the damaged pressure line

carefully, as liquid or gas under high pressure can flow from the

connection.

Risks

There are injury risks in connection with work on:

TL2 Maintenance Manual

591 003 Default

B Safety – Safety instructions 9

hydraulic and brake systems

•

fuel system

•

tyre repairs

•

air conditioning system

•

Precautions

Use safety glasses and protective gloves.

•

Never work on a pressurized system.

•

Never adjust a pressure relief valve to a higher pressure than

•

recommended by the manufacturer.

Replace the damaged hydraulic or pneumatic hose before con‐

•

tinuing to work with the machine. Check the hose connections

thoroughly.

Use fluid when checking for leaks.

•

Never blow clothes clean with compressed air.

•

Discarded accumulators must first be punctured before they

•

are deposited as waste to avoid risk of explosion. Drill a hole of

about 3 mm diameter carefully in the accumulator after

depressurizing.

Never use your bare hands to detect a leak. A fine high-pres‐

•

sure stream from a hydraulic hose can easily penetrate the

skin and cause very severe injuries.

Coolant

The coolant in the machine's cooling system consists of water, anticorrosion compound, and (when needed) antifreeze fluid, for exam‐

ple, ethylene glycol.

Coolant must not be drained into the sewer system or directly onto

the ground.

Risks

The cooling system is pressurized when the engine is warm. Hot

coolant can jet out and cause scalding when the expansion tank cap

is opened or if there is a leak in the system.

Inhaling ethylene glycol and anti-corrosion compound is dangerous

and hazardous to health.

Precautions

Use protective gloves and safety glasses if there is a risk of

•

splashing or spraying.

Open the expansion tank cap carefully so that the pressure is

•

released from the cooling system. Hot steam and coolant may

stream out.

Avoid working with the cooling system when the coolant is hot.

•

Refrigerant

Refrigerant is used in the machine's air conditioning system.

Risks

The air conditioning system operates with refrigerant at high pres‐

sure. Escaping refrigerant can cause freeze burns.

Heated refrigerant, for example during the repair of leaks in the air

conditioning system, produces gases that are very toxic if inhaled.

TL2 Maintenance Manual

591 003 Default

10 B Safety – Safety instructions

Precautions

The air conditioning system must be serviced only by author‐

•

ized and trained personnel. Follow the national legislation and

local regulations.

Use protective gloves and safety glasses if there is a risk of

•

leaks.

Before servicing, make sure that there are no heat-producing

•

sources or objects, for example a cigarette glow or a welding

flame, close to the maintenance item.

Air pollution

Air pollution is the impurities in the air that are regarded as hazard‐

ous to health.

The following air pollution hazardous to health is especially promi‐

nent in workshops:

Carbon monoxide (fumes):present in exhaust fumes, odourless

•

and therefore especially dangerous

Nitrogen oxides (nitrous gases):present in exhaust fumes

•

Welding smoke:especially hazardous to health when welding

•

on oily surfaces, galvanized, or lacquered materials

Oil mist:for example, when applying an anti-corrosion agent

•

Grinding dust and gases:generated when grinding and heating

•

plastics, lacquer, anti-corrosion agents, lubricants, paint, and

so on

Isocyanates:present in certain paints, fillers, adhesives, and

•

foam plastics

Risks

Sulphuric acid mist is corrosive and it injures the respiratory tract.

Sulphuric acid is generated when heating certain plastics and

paints.

Isocyanates can be released in the form of steam or dust when cut‐

ting, grinding, or welding the materials. Isocyanates may also be

present in aerosols. They can irritate mucous membranes, produc‐

ing symptoms similar to asthma and impairing lung function. Even

brief exposure to high concentrations can cause problems of persis‐

tent high sensitivity.

Precautions

Make sure adequate ventilation during welding, charging a bat‐

•

tery, and other work where hazardous gases are generated.

Use suitable gloves and respiratory protection when there is a

•

risk of oil mist. Make sure that the protective equipment is oilresistant.

Apply oil-resistant protective lotion on unprotected skin.

•

Ensure that an eye-wash station is in the immediate vicinity

•

when working with corrosive substances.

Avoid unnecessary operation of the engine inside the work‐

•

shop. If the engine must be operated in enclosed spaces, use

an exhaust gas extractor to lead the exhaust gas out. Connect

the exhaust gas extractor hose to the exhaust pipe to prevent

the exhaust gases from flowing to the workshop.

TL2 Maintenance Manual

591 003 Default

B Safety – Safety instructions 11

Tensioned springs

Examples of tensioned springs:

suspension elements in air suspension

•

return springs in the parking brake chamber

•

lock rings

•

gas springs

•

Risks

If a tensioned spring is released, it is shot out of its place by the

spring force and can also take adjoining parts with it.

Small springs can cause eye injuries.

Parking brake springs are tensioned with high force and can cause

very severe injuries if they are accidentally released in an uncontrol‐

led manner.

Gas springs are tensioned with high force and can cause very

severe injuries if they are accidentally released in an uncontrolled

manner.

Precautions

Use safety glasses.

•

Lock rings should be of a suitable type and in good condition.

•

Follow the instructions in this and other manuals when per‐

•

forming maintenance.

Always use the recommended tools.

•

Rotating components and tools

Examples of rotating components and tools:

cooling fans

•

drive belts

•

drive shafts

•

drills

•

grinders

•

Risks

Rotating components, for example, fans or shafts, can cause severe

injuries if touched.

Drills, grinders, and other machines with rotating parts can cause

severe injuries if clothes or hair get caught and are wound up in the

machine.

Precautions

See

•

Clothing on page 5

TL2 Maintenance Manual

591 003 Default

12 B Safety – Safety instructions

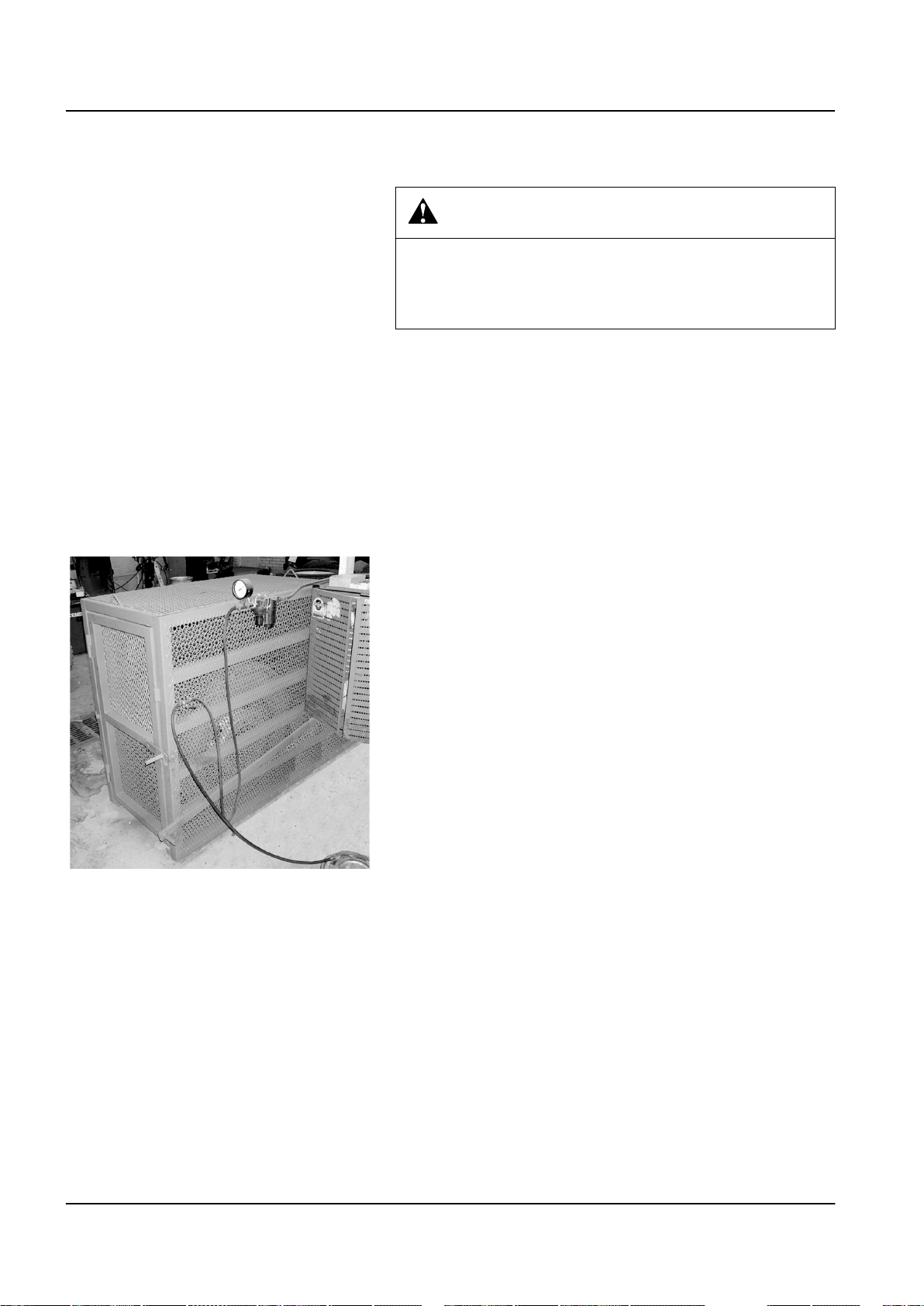

Tyres

DANGER

Tyres should be regarded as pressurized containers. They consti‐

tute a risk of injury if handled incorrectly.

Never repair damaged tyres, rims, or rim lock rings. Tyre repairs

should only be performed by authorized service personnel.

Risks

Dismantling wheels: tyres, rims, or lock rings can be thrown.

Tyre pressures: tyres, rims, or lock rings can be thrown.

Precautions

Deflate the tyre before starting to work with the wheel.

•

Check that tyres, rims, and lock rings are intact. Never repair

•

damaged tyres, rims, or lock rings.

Use a protective screen, hearing protection and safety glasses.

•

Fig. : Protective screen

TL2 Maintenance Manual

591 003 Default

1

Table of content

C Preventive maintenance 3

For the service personnel 3

Maintenance programme 5

Initial maintenance 5

Scheduled maintenance 6

TL2 Maintenance Manual

591 003 Default

2

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...