Kalmar DRF450-65A5X Workshop Manual

Reachstackers 40-45 tonnes

Publ. no VDRF03.02GB

Workshop Manual in original

WORKSHOP MANUAL

DRF 400-450

Workshop

manual

AForeword

BSafety

CPreventive maintenance

0 Complete machine

1 Engine

2 Transmission

3 Driveline/axle

4 Brakes

5 Steering

6 Suspension

7 Load handling

8 Control system

9 Frame, body, cab and accessories

10Common hydraulics

11Common electrics

12Common pneumatics

D Error codes

E Schematics

F Technical data

G Terminologi och Index

A Foreword |

1 |

|

|

Table of Contents A Foreword |

|

Foreword......................................................................................................... |

3 |

About the Workshop Manual ...................................................................... |

3 |

General ............................................................................................................. |

3 |

Conditions ......................................................................................................... |

3 |

Storage .............................................................................................................. |

3 |

About the machine version ................................................................................ |

3 |

Copyright ........................................................................................................... |

3 |

Reading instructions ................................................................................... |

4 |

Warning information .......................................................................................... |

4 |

Important information ........................................................................................ |

4 |

Read the Operator’s Manual ............................................................................. |

4 |

Read the Maintenance Manual ......................................................................... |

4 |

Workshop manual contents ............................................................................... |

5 |

Function group structure ................................................................................... |

6 |

References between different information types ............................................... |

7 |

Product alternatives and optional equipment .................................................... |

8 |

Machine card ..................................................................................................... |

8 |

Function descriptions ........................................................................................ |

9 |

About the documentation ......................................................................... |

12 |

Documentation sections .................................................................................. |

12 |

Ordering of documentation .............................................................................. |

12 |

Feedback .................................................................................................. |

13 |

Form for copying ............................................................................................. |

13 |

Workshop manual DRF 400-450 |

VDRF03.02GB |

2 |

A Foreword |

|

|

VDRF03.02GB |

Workshop manual DRF 400-450 |

A Foreword – Foreword |

3 |

|

|

Foreword

About the Workshop Manual

General

Thank you for choosing Cargotec as your machine supplier. We hope that we will meet your expectations.

Conditions

The instructions are based on the use of generally available standard tools. All lifting devices, such as slings, straps and ratchet blocks, must meet governing national standards and regulations for lifting devices.

Cargotec will not accept any responsibility for modifications performed without permission from Cargotec, or in the event of the use of lifting devices, tools or work methods other than those described in this manual.

Storage

NOTE

The workshop manual should be accessible to service personnel.

About the machine version

The information in this publication corresponds to the machine’s design and appearance at the time of delivery from Cargotec. Due to customisations, there may be variations and/or deviations.

Cargotec reserves the right to modify specifications and equipment without prior notice. All information and data in this manual are valid at the time of publication.

D A N G E R

External equipment must only be used if it is approved by Cargotec.

Danger to life and property!

Only use equipment approved by Cargotec.

Copyright

Cargotec Sweden AB

Duplication of the content in this manual, in whole or in part, is strictly prohibited without written permission from Cargotec Sweden AB.

Duplication by any means such as copying, printing, etc., is prohibited.

Workshop manual DRF 400-450 |

VDRF03.02GB |

4 |

A Foreword – Reading instructions |

|

|

Reading instructions

Warning information

Warnings inform on potential dangers which can, if the warnings are not heeded, result in personal injury or product damage.

D A N G E R

Situation that may result in serious personal injury, possible death, if the instruction is not followed.

W A R N I N G

Situation that may result in serious personal injury if the instruction is not followed.

C A U T I O N

Situation that may result in damage to the product if the instruction is not followed.

Important information

Important information marked with NOTE facilitates the work process, operation/handling or increases understanding of the information.

NOTE

Information that is important without being safety related.

Read the Operator’s Manual

The symbol to the left is used in certain cases on the machine and refers to important information in the operator’s manual.

<![if ! IE]><![endif]>000262

Read the Operator’s Manual

<![endif]>001128

Read the Maintenance Manual

Read the Maintenance Manual

The symbol to the left is sometimes found on the machine. It refers to important information in the Maintenance Manual.

VDRF03.02GB |

Workshop manual DRF 400-450 |

A Foreword – Reading instructions |

5 |

|

|

|

|

Workshop manual contents |

|

|

|

The Workshop Manual contains information to facilitate maintenance |

|

|

|

(part replacement) and is a supplement to the Maintenance Manual. |

|

|

|

Accompanying the Workshop Manual is supplier documentation for |

|

|

|

engine, transmission and drive axle. If possible, the Workshop Manual |

|

|

|

provides reference to supplier documentation instead of printing the |

|

|

|

same information twice. Methods for preventive maintenance and cer- |

|

|

|

tain checks are found in the Maintenance Manual, no references are |

|

|

|

given. Use the function groups to locate the information in the Mainte- |

|

|

|

nance Manual. |

|

|

|

The workshop manual is divided into the following sections. |

|

|

|

|

|

A |

Foreword |

General information about the workshop manual's purpose, contents and reading |

|

|

|

instructions as well as survey for feedback of views and any inaccuracies. |

|

|

|

|

|

B |

Safety |

Keep in mind for your safety. |

|

|

|

|

|

C |

Preventive maintenance |

Reference to maintenance manual: Preventive maintenance. |

|

|

|

|

|

0 |

Complete machine |

|

|

|

|

|

|

1 |

Engine |

|

|

|

|

|

|

2 |

Transmission |

|

|

|

|

|

|

3 |

Driveline/axle |

Technical description, comprehensive function descriptions and a description of the |

|

|

|

||

4 |

Brakes |

||

function of components included in the machine, divided into function groups. |

|||

|

|

The components used for each function are described under each subfunction. |

|

5 |

Steering |

||

|

|

Consequently, common components are described in several places, but in general |

|

6 |

Suspension |

||

under the first function to use the component. |

|||

|

|

||

7 |

Load handling |

Together with the general description is a detailed description of what is unique |

|

|

|

about the specific subfunction. The next subfunction to use the same component |

|

8 |

Control system |

||

only has a description what is unique for the new function. |

|||

|

|

||

9 |

Frame, body, cab and |

||

Work instructions for corrective maintenance (replacement of components). |

|||

|

accessories |

||

|

|

||

|

|

|

|

10 |

Common hydraulics |

|

|

|

|

|

|

11 |

Common electrics |

|

|

|

|

|

|

12 |

Common pneumatics |

|

|

|

|

|

|

D |

Error codes |

Error code information and instructions for reading error code information. |

|

|

|

|

|

E |

Schematics |

Wiring diagrams, hydraulic diagrams and list of electrical components. |

|

|

|

|

|

F |

Technical data |

Technical data, conversion tables, information for conversion of units. |

|

|

|

|

|

G |

Terminology and index |

General terminology and abbreviations, explanation of terms and abbreviations that |

|

|

|

can appear in the sections, index for headings in the manual. |

|

|

|

|

Workshop manual DRF 400-450 |

VDRF03.02GB |

6 |

A Foreword – Reading instructions |

|

|

Function group structure

The information in the manual is divided into a structure of functions at different levels based on machine structure and usage. The categories are known as function groups.

The highest level (called main group) indicates area, such as group 7 Load handling. The second level (called two-position) indicates function, such as 7.2 Lifting/lowering. The third and fourth levels are used to break down functions into smaller parts (components).

The main group and two-position group level structure for the function groups is used for all Cargotec machines, e.g. 4.3 Power-assisted brake system. Machine-specific function group adaptations are done at the third and fourth group level, e.g. 4.3.9 Wheel brake and 4.3.9.1 Disc assembly. Function groups (headings) are only included in the documentation of a machine if the machine has that function or component. Thus, there may be gaps in function group numbering, e.g. the three-position heading level 4.8.7 Oil cooler is included for some machines but not for others.

The function groups are intended as a search term to be able to find various types of information between different sections and manuals. The information of a function group is divided into smaller segments based on type of content, such as description or replacement.

The Maintenance Manual and Workshop Manual contain different information. The Maintenance Manual only contains information required for preventive maintenance and minor troubleshooting. The Workshop Manual contains more in-depth information and repair instructions.

References between sections in the same manual are indicated using section and group number, e.g., "see section 4 Brakes , group 4.3.9 Wheel brake ". Reference within a section are indicated with page number, e.g., "see Sensor fuel level, description page 24 ".

There are no references between the Maintenance Manual and Workshop Manual. If more information on a function group is required, search under the same function group in the other manual. For more in-depth information on where different types of information are located and what references are made, see References between different information types page 7.

VDRF03.02GB |

Workshop manual DRF 400-450 |

A Foreword – Reading instructions |

7 |

|

|

References between different information types

The maintenance manual and workshop manual are mainly divided into function groups, see Workshop manual contents page 5. Certain parts are broken out as separate parts to increase usability, e.g., "Technical data".

The basic rule of searching for information is to use function groups to find different types of information regarding the function or component in question. As a complement to this, there are references according to the below.

Function descriptions

(Technical description)

Hydraulic diagrams

(Section E)

Component descriptions |

|

Error codes |

(Technical description, usually in Workshop manual) |

|

(Section D) |

|

|

|

Diagnostics |

|

Wiring diagrams |

(Technical description, group 8.4) |

|

(Section E) |

|

|

|

|

• From Function description to Component description, to enable |

|

|

fast finding of more information about the different components |

|

|

that create a function. |

|

|

• From Function description to Hydraulic diagram, to enable fast |

|

|

finding of the right hydraulic diagram for the function in question. |

|

|

• From Component description or Function description to Diagnos- |

|

|

tics, to enable fast finding of the right diagnostic menu that can be |

|

|

used to check the component (only applies to electrical |

|

|

components). |

|

|

• From Diagnostics to Wiring diagrams. to enable fast finding of the |

|

|

right circuit diagram for further troubleshooting. |

|

|

• From Diagnostics to Component description or Function descrip- |

|

|

tion. To enable fast finding of more information about the compo- |

|

|

nent's appearance and position when troubleshooting. |

|

|

• From Error codes to Diagnostics, to enable fast finding of the right |

|

|

diagnostic menu to troubleshoot component or function in |

|

|

question. |

|

|

• From Error codes to Function description or Component descrip- |

|

|

tion, to enable fast finding of more information about components |

|

|

or function. |

|

Workshop manual DRF 400-450 |

VDRF03.02GB |

8 |

A Foreword – Reading instructions |

|

|

Product alternatives and optional equipment

<![endif]>000264

Symbol for optional equipment

The information in the manual is divided into modules. If a product alternative or optional equipment is fitted, handling may differ from that indicated in the modules depending on what is being described. See below.

Special equipment is not described in the manual. If uncertain as to what equipment is fitted to the machine, use the machine card to determine which information is relevant. See Machine card page 8.

Product alternative

Product alternative describes options that are fitted instead of a specific piece of standard equipment (e.g. engine alternative).

Equivalent information for different product alternatives are described consecutively in separate segments within the same function group. To indicate that there are different alternatives, "Product alternative" is added to the heading together with a simple description of the alternative, e.g. "(Product alternative Climate control system ECC)". In addition, the alternative that is an option is marked with the symbol for optional equipment.

Optional equipment

Optional equipment refers to options that can be added to standard equipment for more or improved functions.

Information on auxiliary equipment is described in separate segments together with the standard equipment. The optional equipment description covers how the equipment affects standard function and what components are added.

Machine card

NOTE

If the machine has been modified after delivery, information on the machine card may be incomplete or incorrect.

The machine card indicates of which drawings the machine consists, in many cases these can be associated options and product alternatives. For more information about handling of product alternatives and optional equipment, see Product alternatives and optional equipment page 8. The machine card is delivered with the parts catalogue.

The machine card is divided into the same function groups as the spare parts catalogue, maintenance manual and workshop manual. For reasons of practicality, the machine card only uses the first and second level of the function group register. The function groups are written in groups of four characters, e.g. group 0107 refers to group 1.7 Cooling system in the manual.

For more information on how the machine card is used to order spare parts, see the foreword of the spare parts catalogue.

If the information on the card machine does not help, contact

Cargotec.

VDRF03.02GB |

Workshop manual DRF 400-450 |

A Foreword – Reading instructions |

9 |

|

|

NOTE

All documents that accompany the machine are non-registered documents. No notification is made regarding changes.

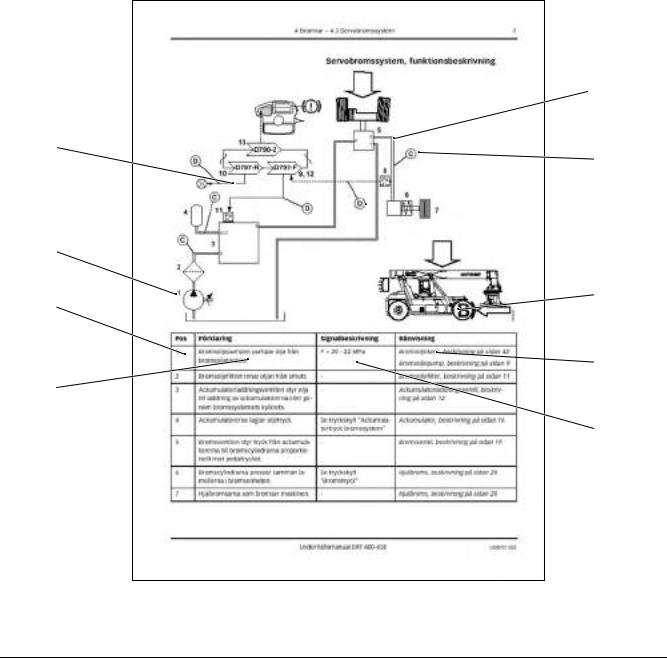

Function descriptions

Function descriptions are schematic overviews that describe how a function works as well as which components and signals work together.

Function descriptions describe the function in a logical flow from input signal to desired output signal. Most functions require that preset conditions are fulfilled for the function to be activated. In these cases, the conditions are listed above the illustration.

Function descriptions use symbols to illustrate components such as valves, sensors, etc.

1

10

2

3

3

9

4

8

5

5

7

6

<![if ! IE]><![endif]>000520

Workshop manual DRF 400-450 |

VDRF03.02GB |

10 |

A Foreword – Reading instructions |

|

|

Example of function description

1.Hydraulic force (solid double line)

2.Flag pressure check connection (Check point), indicates that there is pressure check connection for checking pressure signal

3.Flag diagnostic test, indicates that the signal can be checked with diagnostic test, see section 8 Control system, group 8.4 Diagnostics

4.Illustration of function, (apply brake)

5.Reference to description of component

6.Signal description, reference value for signal out from component

7.Description of component's function

8.Position number, reference to position in illustration

9.Position number in illustration, reference to row in table

10.Electric power (solid single line)

VDRF03.02GB |

Workshop manual DRF 400-450 |

1

3

5

7

9

11

13

15

17

19 ˚C

21 ˚C

23 Pa

25

26

28

A Foreword – Reading instructions |

11 |

2

4

6

8 M

10

12

D790-1

14

D797-F

16

18

20 ˚C

22 |

Pa |

24

27 |

|

29 |

<![if ! IE]> <![endif]>000523 |

|

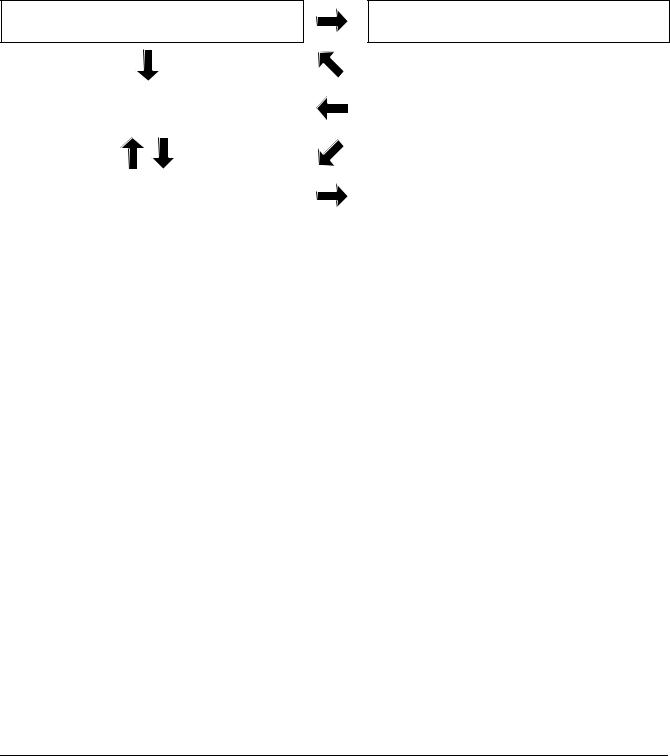

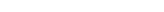

Symbol explanation function descriptions

The following symbols are used in function descriptions, the symbols are based on standard symbols used in wiring and hydraulic diagrams.

1.Electric control signal

2.Electric force

3.Hydraulic control signal

4.Hydraulic force

5.Hydraulic motor

6.Hydraulic oil pump with variable displacement

7.Hydraulic oil pump with fixed displacement

8.Electric motor

9.Accumulator

10.Disc brake

11.Filter

12.Radiator

13.Bulb

14.Control system, two control units with CAN-bus

15.Restriction

16.Adjustable restriction

17.Inductive position sensor

18.Electrically controlled servo valve

19.Thermal bypass valve

20.Temperature-controlled switch

21.Temperature sensor

22.Pressure sensor

23.Pressure-controlled switch

24.Hydraulic cylinder

25.Double-acting hydraulic cylinder

26.Spring brake cylinder

27.Valve block

28.Shuttle valve

29.Non-return valve

Workshop manual DRF 400-450 |

VDRF03.02GB |

12 |

A Foreword – About the documentation |

|

|

About the documentation

Documentation sections

The documentation to the machine comprises the following sections:

Operator’s manual

The operator’s manual is supplied with the machine in the cab.

Documentation kit

Maintenance manual and spare parts catalogue with machine card are supplied with the machine as a separate documentation kit.

Supplementary documentation

Supplementary documentation can be ordered for the machine.

•Workshop manual.

•Supplier documentation for engine, transmission and drive axle.

Ordering of documentation

Documentation is ordered from your Cargotec dealer.

Always specify the publication number when ordering.

See the machine card for publication number.

VDRF03.02GB |

Workshop manual DRF 400-450 |

A Foreword – Feedback |

13 |

|

|

Feedback

Form for copying

Cargotec’s ambition is that you who work with maintenance of a Kalmar machine shall have access to correct information.

Your feedback is important to be able to improve the information.

Copy this form, write down your views and send it to us. Thank you for your participation!

To: |

Cargotec Sweden AB |

|

|

|

|

Technical Documentation |

|

|

|

|

Torggatan 3 |

|

|

|

|

SE-340 10 Lidhult |

|

|

|

|

SWEDEN |

|

|

|

|

Fax: +46 372 263 93 |

|

|

|

|

|

|

|

|

From: |

|

|

|

|

|

Company / Sender: .......................................................................................................................................... |

|

|

|

|

Telephone: |

|

|

|

|

.......................................................................................................................................................... |

|||

|

E-mail: |

|

|

|

|

................................................................................................................................................................. |

|||

|

Date: .................................... |

- .................. |

- .................. |

|

|

|

|

|

|

Manual |

|

|

|

|

information |

Name / Publication number: |

|

|

|

|

|

|

||

|

Section / page number: ...................................................................................................................................... |

|

|

|

|

|

|

|

|

Sugges- |

|

|

|

|

tions, |

........................................................................................................................................................................... |

|||

views, |

||||

|

|

|

||

remarks, |

|

|

|

|

etc. |

........................................................................................................................................................................... |

|||

|

........................................................................................................................................................................... |

|||

|

........................................................................................................................................................................... |

|||

|

........................................................................................................................................................................... |

|||

|

........................................................................................................................................................................... |

|||

|

|

|

|

|

Workshop manual DRF 400-450 |

VDRF03.02GB |

14 |

A Foreword – Feedback |

|

|

VDRF03.02GB |

Workshop manual DRF 400-450 |

B Safety |

1 |

|

|

Table of Contents B Safety |

|

Safety .............................................................................................................. |

3 |

General safety information ......................................................................... |

3 |

Safety concerns everyone! ................................................................................ |

3 |

A near accident is a warning! ............................................................................ |

3 |

Safety instructions ...................................................................................... |

4 |

General ............................................................................................................. |

4 |

Service position ................................................................................................. |

4 |

Hydraulic and brake systems, depressurising ................................................... |

5 |

Oils .................................................................................................................... |

6 |

Fuel system ....................................................................................................... |

7 |

Clothing, etc. ..................................................................................................... 8 |

|

Several mechanics on the same machine ......................................................... |

9 |

Working under machine .................................................................................... |

9 |

Lifting heavy components ............................................................................... |

10 |

Vibrations ........................................................................................................ |

10 |

Noise ............................................................................................................... |

11 |

Solvents .......................................................................................................... |

11 |

Fire and explosion risks ................................................................................... |

12 |

Fluid or gas under pressure ............................................................................ |

13 |

Coolant ............................................................................................................ |

14 |

Refrigerant ...................................................................................................... |

14 |

Air pollution ..................................................................................................... |

15 |

Tensioned springs ........................................................................................... |

16 |

Electric motors ................................................................................................. |

16 |

Rotating components and tools ....................................................................... |

17 |

Tyres and rims ................................................................................................. |

18 |

Lifting equipment ............................................................................................. |

18 |

Spare parts ...................................................................................................... |

19 |

Non-ionised radiation ...................................................................................... |

20 |

Environment ............................................................................................. |

21 |

General ........................................................................................................... |

21 |

Workshop manual DRF 400-450 |

VDRF03.02GB |

2 |

B Safety |

|

|

VDRF03.02GB |

Workshop manual DRF 400-450 |

B Safety – Safety |

3 |

|

|

Safety

General safety information

Safety concerns everyone!

The safety information concerns everyone who works with the machine! Persons who do not follow the safety instructions given in this manual must make absolutely sure that the work is performed without risks of personal injury and without risk of damage to machine or machine property!

Remember to:

•follow the instructions in this manual

•be trained for the work in question

•follow local laws, safety rules and regulations

•use the correct equipment and tools for the job

•wear the correct clothes

•use common sense and work carefully. Do not take any risks!

Cargotec has in this publication documented and warned for situations and risks that may occur in connection with using as well as service or repairs of the machine during normal circumstances.

That is why it is important that all who work with the machine, or repair or service the machine, read and follow the information in the Workshop Manual and Operator’s Manual.

A near accident is a warning!

A near-accident is an unexpected event where neither persons, machine or property are injured or damaged. However, a near-accident indicates that there is an injury risk and actions must be taken to avoid the risk of injuries.

Workshop manual DRF 400-450 |

VDRF03.02GB |

4 |

B Safety – Safety instructions |

|

|

Safety instructions

General

Read, consider and follow the safety instructions below before starting to work in the machine:

•Service position page 4

•Hydraulic and brake systems, depressurising page 5

•Oils page 6

•Fuel system page 7

•Clothing, etc. page 8

•Several mechanics on the same machine page 9

•Working under machine page 9

•Lifting heavy components page 10

•Vibrations page 10

•Noise page 11

•Solvents page 11

•Fire and explosion risks page 12

•Fluid or gas under pressure page 13

•Coolant page 14

•Refrigerant page 14

•Air pollution page 15

•Tensioned springs page 16

•Electric motors page 16

•Rotating components and tools page 17

•Tyres and rims page 18

•Lifting equipment page 18

•Spare parts page 19

•Non-ionised radiation page 20

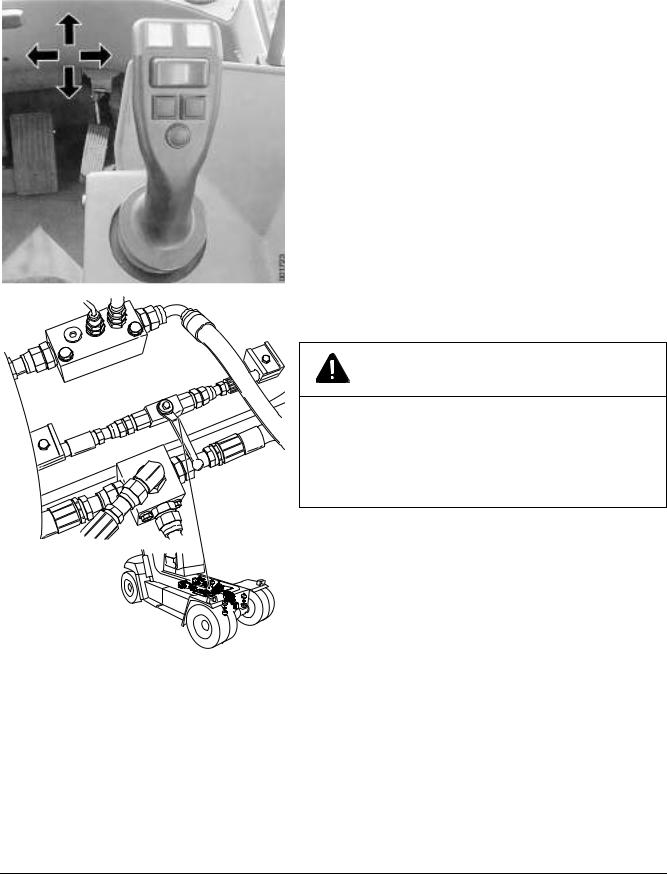

Service position

General

Service position is used for service, maintenance and other situations when the machine needs to be secured.

Service position means:

•Machine parked, that is, parking brake applied.

•Boom fully retracted and lowered to horizontal position.

• Engine off.

•Main electric power off (with battery disconnector).

|

<![if ! IE]> <![endif]>003603 |

Machine with a fully retracted and lowered boom |

|

VDRF03.02GB |

Workshop manual DRF 400-450 |

B Safety – Safety instructions |

5 |

|

|

Hydraulic and brake systems, depressurising

1Machine in service position.

2Depressurise the hydraulic system.

Turn the start key to position I and activate extension out, a strong hissing sound is heard if there is pressure in the hydraulic system. Activate lift, extension and side shift several times.

3Turn the start key to position 0 and turn off the main electric power.

4 Depressurise the attachment.

Open the relief valve for top lift.

C A U T I O N

Hydraulic oil may be directed the wrong way.

Risk of damage to the fine filter for hydraulic oil.

Check that the relief valve top lift is closed before the engine is started after the completion of work.

<![if ! IE]><![endif]>002269

The illustration above shows closed valve.

Workshop manual DRF 400-450 |

VDRF03.02GB |

6 |

B Safety – Safety instructions |

|

|

5Depressurise the brake system by opening the drain valve on the accumulator charging valve.

NOTE

Keep the drain valve open as long as work is in progress.

NOTE

After work is finished, close drain valve and tighten the lock ring.

Oils

The following safety instructions shall be followed for work when handling oils.

W A R N I N G

Warm and pressurised oil.

Always depressurise hydraulic and brake systems completely before starting to work in the systems. Hydraulic and brake systems are pressurised and the oil may cause personal injuries.

Avoid skin contact with the oil, use protective gloves. Warm oil can cause burn injuries, rashes and irritation! The oil may also be corrosive to mucous membranes in, e.g., the eyes, skin and throat.

I M P OR TA N T

Always clean the area around components and connections before they are loosened. Dirt in oil systems causes increased wear, resulting in subsequent material damages.

Always take action to avoid spills. In places where drain containers cannot be used, use a pump or hose for safe handling.

Always check that plugs seal tight before collection containers are moved.

Handle all oil as environmentally hazardous waste. Oils freely released cause damage to the environment and may also cause fires. Waste oils/fluids shall always be handled by an authorised company.

VDRF03.02GB |

Workshop manual DRF 400-450 |

B Safety – Safety instructions |

7 |

|

|

Fuel system

The following safety instructions shall be followed for work when handling fuel.

D A N G E R

Pay attention to the risk of fire when working on the fuel system.

Work on the fuel system shall be avoided when the engine is warm since fuel can spill on hot surfaces and may ignite.

Ensure that naked flames, sparks or glowing objects have been removed before work begins on or near the fuel system.

Do not smoke in the vicinity of the machine when working on the fuel system.

W A R N I N G

Use protective gloves and protective goggles. If a component is to be disconnected, hold a rag over the connection as protection and to collect fuel. The engine’s fuel system operates at very high pressure. The pressure is so high that the jet can injure the skin, resulting in severe injuries. Risk of personal injuries.

Avoid skin contact with fuel, use protective gloves. Fuel is corrosive to mucous membranes in, e.g., eyes, skin and throat.

C A U T I O N

Always clean the area around components and connections before they are loosened. Dirt in the fuel may cause malfunctions and engine stop in undesirable situations as well as increase wear, resulting in subsequent material damages.

Workshop manual DRF 400-450 |

VDRF03.02GB |

8 |

B Safety – Safety instructions |

|

|

I M P OR TA N T

Always take action to avoid spills. In places where drain containers cannot be used, use a pump or hose for safe handling.

Always check that plugs and connections seal tight before moving collection containers.

Handle the fuel as environmentally hazardous waste. Fuel freely released causes damage to the environment and may also cause fires. Fuel shall always be handled by an authorised company.

Clothing, etc.

Clothes should be in good condition. Remove loosely hanging clothing (tie, scarf, etc.). Do not wear clothes with wide sleeves, wide trouser legs, etc.

Remove jewellery as it may conduct electricity and get caught in moving parts.

Long hair should be adequately gathered since it can easily get caught in moving parts. Be careful when working with welding or an open flame since hair easily catches on fire.

VDRF03.02GB |

Workshop manual DRF 400-450 |

B Safety – Safety instructions |

9 |

|

|

Several mechanics on the same machine

W A R N I N G

A |

<![endif]>001977

Locks on lift mast for securing the liftable cab in the raised position.

If several mechanics are working on the same vehicle, take extra care so that unintentional movements do not injury another person. Communicate so that everyone knows where all are and what they are doing.

Risks

Work with wheels or axle suspension, mountings, etc. may result in components on the other side moving and causing damage/injury.

Movements performed from the operator’s station, e.g., movement of lifting equipment, may cause severe personal injuries.

Safety precautions

•Make sure that the machine's lifting equipment is completely lowered or secured in another way.

•Move battery disconnector to position zero, remove the key.

•Be aware of the risks when several persons work around the vehicle.

•Make your co-workers aware of what you’re working with.

•Do not work with drive wheels on the machine's both sides at the same time.

Working under machine

Working under cab

On machines with liftable cab, the cab must be secured in the raised position with the locks designed for this purpose.

Working under the frame

A raised vehicle may not, for any reason, be supported or lifted in parts that belong to the wheel suspension or steering. Always support under the frame or wheel axle.

Risks

Mechanical or hydraulic tools and lifting devices can fall over or accidentally be lowered due to malfunctions or incorrect use.

Safety precautions

Use axle stands and supports that stand securely.

Lifting tools should be inspected and type approved for use.

Workshop manual DRF 400-450 |

VDRF03.02GB |

10 |

B Safety – Safety instructions |

|

|

Lifting heavy components

W A R N I N G

Careless handling of heavy components can lead to serious personal injury and material damage.

Use type approved lifting tools or other devices to move heavy components. Make sure that the device is stable and intact.

Risks

Unsuitable lift slings, straps, etc. may break or slip.

The centre of gravity (balance point) of the component can change during the course of the work, and the component may then make unexpected movements which may cause severe personal injuries and material damage.

A component lifted with lifting equipment can start to turn if the equilibrium is upset.

A component lifted using an overhead crane may start to swing back and forth, which can cause severe crushing injuries or material damage.

Safety precautions

Lifting with lifting device. Use lifting tools or other tools, especially when there are such adapted for certain work. See workshop manual for methods.

If lifting must be performed without lifting device:

•Lift near the body.

•Keep your back vertical. Raise and lower with legs and arms, do not bend your back. Do not rotate your body while lifting. Ask for assistance in advance.

•Wear gloves. They're good protection against minor crushing injuries and cuts to fingers.

•Always use protective shoes.

Vibrations

In case of long-term use of vibrating tools, for example, impact nut runners or grinders, injuries may be sustained as vibrations can be transmitted from tools to hands. Especially when fingers are cold.

Safety precautions

Use heavy gloves to protect against cold and somewhat against vibrations.

Switch between work duties to give the body time to rest.

Vary work position and grip so that the body is not stressed in only one position by the vibrations.

VDRF03.02GB |

Workshop manual DRF 400-450 |

B Safety – Safety instructions |

11 |

|

|

Noise

Noise louder than 85 dB (A) that lasts for longer than 8 hours is considered harmful to hearing. (Limit values may vary between different countries.) High tones (high frequencies) are more damaging than low tones at the same sound level. Impact noise can also be hazardous, e.g. hammer blows.

Risks

At noise levels higher than the limits hearing damage can occur. In more severe cases, hearing damage can become permanent.

Safety precautions

Use hearing protection. Make sure that it is tested and protects against the noise level in question.

Limit noise with noise-absorbing dividers, for example, noise-absorb- ing materials in roof and on walls.

Solvents

Fluids that (as opposed to water) dissolve grease, paint, lacquer, wax, oil, adhesive, rubber, etc. are called organic solvents. Examples: White (petroleum) spirits, gasoline, thinner, alcohols, diesel, xylene, trichloroethylene, toluene. Many solvents are flammable and constitute a fire hazard.

Risks

Products containing solvents produce vapours that can cause dizziness, headaches and nausea. They may also irritate mucous membranes in the throat and respiratory tracts.

If the solvent ends up directly on the skin it may dry out and crack. Risk of skin allergies increases. Solvents may also cause injury if they penetrate through the skin and are absorbed by the blood.

If the body is continuously exposed to solvents, the nervous system may be damaged. Symptoms include sleep disorders, depressions, nervousness, poor memory or general tiredness and fatigue. Continuous inhalation of gasoline and diesel fumes is suspected to cause cancer.

Safety precautions

Avoid inhaling solvent fumes by providing good ventilation, or wearing a fresh-air mask or respiratory device with a suitable filter for the toxic gases.

Never leave a solvent container without tight-sealing lid.

Use solvents with a low content of aromatic substances. It reduces the risk of injury.

Avoid skin contact.

Use protective gloves.

Make sure that work clothes are solvent-resistant.

Workshop manual DRF 400-450 |

VDRF03.02GB |

12 |

B Safety – Safety instructions |

|

|

Fire and explosion risks

Examples of flammable and explosive substances are oils, gasoline, diesel fuel oil, organic solvents (lacquer, plastics, cleaning agents), rustproofing agents, welding gas, gas for heating (acetylene), high concentration of dust particles consisting of combustible materials. Rubber tyres are flammable and cause explosive fires.

Risks

Examples of cause of ignition is welding, cutting, smoking, sparks when working with grinders, contact between hot machine parts and flammable materials, heat development in rag drenched with oil or paint (linseed oil) and oxygen. Oxygen cylinders, lines and valves shall be kept free from oil and grease.

Fumes from, e.g., gasoline are heavier than air and may "run" down into a sloping plane, or down in a grease pit, where welding flames, grinding sparks or cigarette embers may cause an explosion. Evaporated gasoline explodes very forcefully.

Special cases

Diesel fuel oil with added gasoline has a lower ignition point. Risk of explosion already at room temperature. The explosion risk for warmed diesel fuel oil is higher than for gasoline.

When changing oil in the engine, hydraulic system and transmission, keep in mind that the oil may be hot and can cause burn injuries.

Welding on or near machine. If diesel and or other oils have leaked out and been absorbed by rags, absorbent agents, paper or other porous material, hot welding sparks can cause ignition and explosive fires.

When a battery is charged, the battery fluid is divided into oxygen and hydrogen gas. This mixture is very explosive. The risk of explosion is especially high when using a booster battery or quick-charger, as this increases the risk of sparks.

Today’s machines contain a lot of electronic equipment. When welding, the control units must be disconnected and the electric power must be turned off with the battery disconnector. Powerful welding currents may otherwise short-circuit the electronics, destroy expensive equipment or cause an explosion or fire.

Never weld on painted surfaces (remove paint, by blasting at least 10 cm around the welding or cutting point). Use gloves, breathing protection and protective glasses. Also, welding work may not be done near plastic or rubber materials without first protecting them from the heat. Paints, plastics, and rubber develop a number of substances that may be hazardous to health when heated. Be careful with machines that have been exposed to intense heat or fire.

VDRF03.02GB |

Workshop manual DRF 400-450 |

Loading...

Loading...