Kalmar DCG90, DCG180 Service Manual

Kalmar DCG90-180

Lift trucks 9 – 18 tonnes

Technical information, Stage IIIB/Tier 4i

Designed to deliver greater total lifetime savings

The DCG90-180 is a range of new Kalmar

trucks with a lifting capacity of 9 – 18

tonnes. The new DCG90-180 is the result

of our customer-focused product development activities as well as our deep

commitment to improving the performance of lift trucks. In fact, DCG90-180

capitalizes on insights we have gained

from the more than 10.000 worldwide

Introducing Kalmar DCG90-180

The new Kalmar DCG90-180 is designed,

built and delivered to oer greater

total lifetime savings. This new range of

Kalmar trucks oer these savings by improving the performance of your truckand-driver teams. Below is a summary

of how the Kalmar DCG90-180 benefits

your business.

Model designation

DCG160-12

Diesel engine

Counterbalance truck

Generation

Lifting capacity, in decitonnes

Load centre, in decimetres

users of Kalmar trucks with this lifting

capacity.

Give your savings a lift

The following pages provide you more

details about the Kalmar DCG90-180.

Contact your local Cargotec representative for a closer look and a test drive.

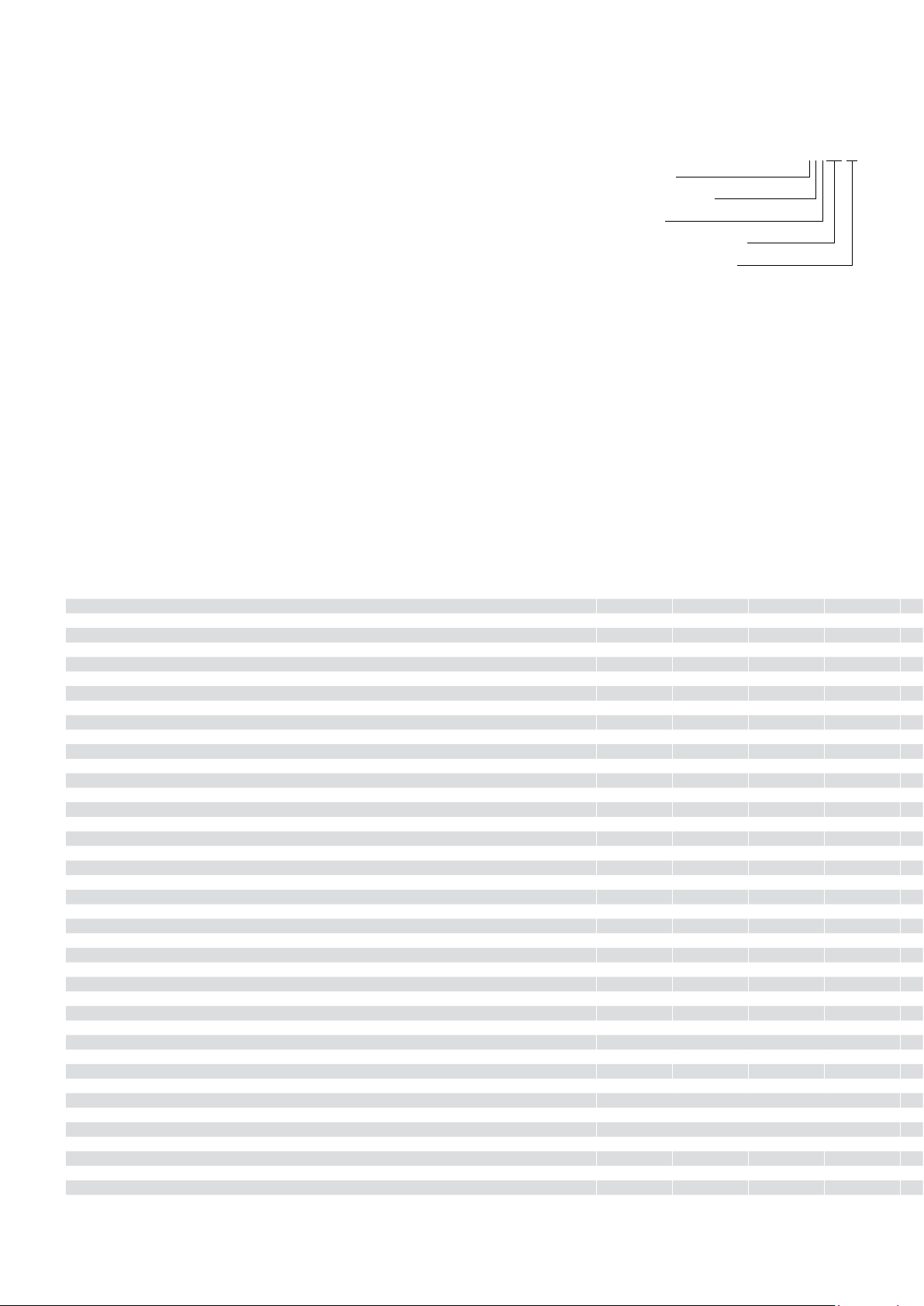

Dimensions

Lifting capacity Rated (kg)

Load centre (mm)

Truck Truck length (mm)

Truck width (mm)

Height, basic machine, EGO cabin (mm)

Height, basic machine, EGO cabin, OHG (mm)

Seat height, EGO cabin (mm)

Distance between centre of front axle – front face of fork arm (mm)

Wheelbase (mm)

Track (c-c), front – rear (mm)

Turning radius, outer – inner (mm)

Ground clearance, min. (mm)

Height when tilting cab, max. EGO cabin, OHG (mm)

Width when tilting cab, max. EGO cabin, OHG (mm)

Min. ailse width for 90° stacking with forks (mm)

Standard duplex mast Lifting height (mm)

Mast height, min. (mm)

Mast height, max (mm)

Mast tilting, forward – backward (°)

Ground clearance, min. (mm)

Forks Width (mm)

Thickness (mm)

Length of fork arm (mm)

Width across fork arms, max. – min. (mm)

Sideshift ± at width across fork arms (mm)

Weight Service weight (kg)

Axle load front, unloaded (kg)

Axle load front, at rated load (kg)

Axle load back, unloaded (kg)

Axle load back, at rated load (kg)

Wheels / tyres Type, front – rear Pneumatic – Pneumatic

Dimensions, front – rear / ply (inch)

Number of wheels, front – rear (*driven)

Pressure (Mpa)

Steering system Type – manoeuvring Hydraulic servo – Steering wheel

Service brake system Type – affected wheels Oil cooled disc brakes (Wet disc brakes) – drive wheels Oil cooled disc brakes (Wet disc brakes) – drive wheels

Parking brake system Type – affected wheels Dry, spring activated disc brake – drive wheels Dry, spring activated disc brake – drive wheels

Hydraulic pressure Max. (Mpa)

Hydraulic fluid volume (l)

Fuel volume (l)

AdBlue volume* (l)

*Only Volvo TAD761VE

L4 600 600 600 600 600 600 1200 1200 12000 600 900 1200 600 1220 1220

L 4470 4720 4725 4725 4985 5055 5065 5315 5325 5305 5315 5575 5065 5595 5845

B 2480 2480 2480 2480 2480 2540 2540 2540 2540 2540 2540 2540 2540 2540 2540

H6 2895 2895 2895 2920 2920 2920 2920 2920 2920 2920 2920 2920 2920 2920 2920

H6 2895 2895 2895 2895 2895 2895 2895 2895 2895 2895 2895 2895 2895 2895 2895

H8 1770 1770 1770 1790 1770 1770 1770 1770 1770 1770 1770 1770 1770 1770 1770

L2 895 895 900 900 910 980 990 – 1000 980 990 1000 990 1265 1265

L3 2800 3000 3000 3000 3250 3250 3250 3500 3500 3500 3500 3750 3250 3250 3500

S 1840 – 1960 1840 – 1960 1840 – 1960 1840 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 1855 – 1960 2210 – 1960

R1 – R2 3950 – 75 4180 – 75 4180 – 75 4180 – 75 4360 – 125 4360 – 125 4360 – 125 4785 – 420 4785 – 420 4785 – 420 4785 – 420 5175 – 600 4570 – 270 4360 – 125 4785 – 420

T1 3370 3370 3370 3395 3395 3395 3395 3395 3395 3395 3395 3395 3395 3395 3395

T2 3350 3350 3350 3380 3380 3380 3380 3380 3380 3380 3380 3380 3380 3380 3380

A1 6240 6470 6475 6475 6665 6735 7945 8370 8380 7160 8160 8770 6745 8900/13800 9200/13900

H4 5000 5000 5000 5000 5000 5000 5000 5000 5000 5000 5000 5000 5000 7000 10000

H3 4015 4015 4015 4035 4035 4195 4195 4195 4195 4195 4195 4195 4195 5195 7075

H5 6515 6515 6515 6535 6535 6695 6695 6695 6695 6695 6695 6695 6695 8695 12075

α - β

b 200 200 200 200 200 200 220 220 250 200 220 250 220 6064 6064

a 65 65 70 70 80 80 90 90 100 80 90 100 90 2120 2120

l 1200 1200 1200 1200 1200 1200 2400 2400 2400 1200 1800 2400 1200 – –

V 2330 – 570 2330 – 570 2330 – 570 2330 – 570 2330 – 570 2360 – 600 2360 – 640 2360 – 640 2360 – 700 2360 – 600 2360 – 640 2360 – 700 2360 – 640 – –

V1 – V 440 – 1450 440 – 1450 440 – 1450 440 – 1450 440 – 1450 440 – 1480 430 – 1500 430 – 1500 430 – 1530 440 –1480 430 – 1500 415 – 1530 430 – 1500 140 140

DCG90-6 DCG100-6 DCG120-6 DCG127-6

9000 10000 12000 12700 14000 15000 10000 12000 15000 16000 16000 16000 18000 7000 7000

330 330 330 330 350 350 350 350 350 350 350 350 350 350 350

5 – 10 5 – 10 5 – 10 5 – 10

250 250 250 250 250 250 250 250 250 250 250 250 250 250 250

15200 15600 16200 16700 16900 19800 18600 19700 22300 19200 21200 22400 21600 22900 23900

7800 8100 8300 8300 8400 10300 10000 10100 10200 10200 10200 10500 10300 14700 15600

21700 23100 26500 27350 28900 32650 26700 29600 34600 34800 34800 35800 37100 27100 27600

7400 7500 7900 8400 8500 9500 8600 9600 12000 11000 11000 11900 11300 8200 8300

2500 2500 1900 2050 2000 2150 1900 2100 2600 2400 2400 2600 2500 2800 3300

11,00×20/16PR 11,00×20/16PR 11,00×20/16PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR 12,00×20/20PR HD 12,00×20/20PR 12,00×20/20PR

4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2 4* – 2

0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 1,0 1,0 1,0 0,9 0,9

16,0 17,0 17,5 18,0 19,0 16,5 12,5 15,0 17,0 17,0 17,5 18,0 19,0 19,5 20,0

215 220 220 220 220 220 220 220 220 220 220 220 220 220 220

152 170 170 170 170 170 170 170 170 170 170 170 170 170 170

15 15 15 15 15 15 15 15 15 15 15 15 15 15 15

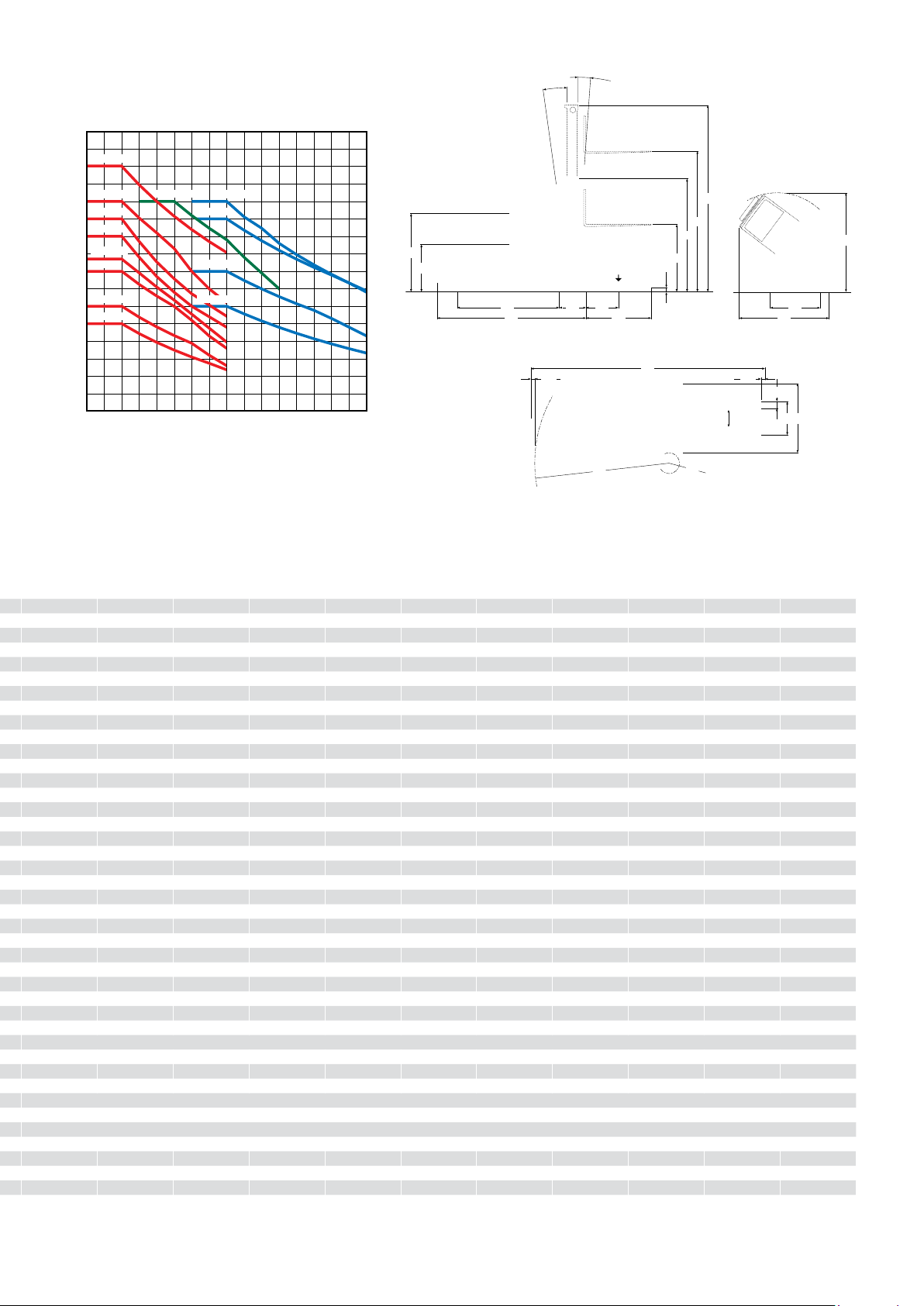

2

20

18

DCG180- 6

α

β

DCG160- 6

16

DCG150- 6

DCG140- 6

14

DCG127-6

DCG120-6

12

DCG100 -6

10

DCG90 -6

8

6

Liftin g capaci ty, in tonnes

4

Load cen tre, mm

DCG90 -6 to DCG180 -6 models:

Full lifti ng capaci ty up to 50 00 mm lif t height w ith duplex /duplex

freelif t/tr iplex mast s and integrated sideshif t/for k positioning carri age.

DCG160-9 DCG160-12

DCG150-12

DCG120-12

DCG100 -12

600 90 0 1200 1400 1600 1800 20 00

H5

H4

H3

H6

H8

L3

L

100

L2 L4

L1

R1

H2

a

S

T2

A1

R2

100

b

V1 V B

T1

5 – 10 5 – 10 5 – 10 5 – 10 5 – 10 5 – 10 5 – 10 5 – 10 5 – 10 3 – 5 3 – 5

Pneumatic – Pneumatic

Hydraulic servo – Steering wheel

3

New EGO cabin:

our most productive driving environment. Ever.

Improving a driver’s working environment – the cabin – stimulates productivity, eciency and safety. That’s why the new

DCG90-180 incorporates our most productive driving environment: the new EGO cabin. It’s loaded with outstanding ergonomics and smart features that help drivers optimally perform their work. As important, the truck has new electric and

hydraulic systems as well as modern lifting equipment to help

drivers boost productivity and operational savings.

EGO cabin enables driver productivity

The new EGO cabin is a spacious workplace. Its curved glass

window gives the operator excellent side-to-side and overhead visibility. Below is a closer look at some of the interior of

DCG90-180.

Ergonomic steering wheel

It’s adjustable and can also be

tilted to the side. This decreases

stress on the operator during

driving and reversing.

Climate package

Complete and flexible climate

control system that matches

the high demands of the climate

tested EGO cabin. Large air

intakes. Easy filter replacement

in the front. Complete driving

comfort from well-dimensioned

and -designed components.

Comfort pedals

A new flexible and safe pedal

system with an adjustable pedal

angle. Improves ergonomics and

minimizes strain on the driver’s

foot. A floor-based solution gives

a hanging pedal feel.

Work console

Easy to set, adjust, use and understand. All necessary controls,

switches, levers and indicators

easily accessible for effective

operations. Clear and well-placed

panels and steering wheel controls for data display.

Windshield wipers

Provides over 90% coverage of

the curved front window. Roof

wipers are also integrated. It all

means superior visibility and

safety.

Operating console

The complete unit for operators

who use the mini-wheel or steering lever. Integrated gear knobs.

Fully adjustable and individually

tested for optimal ergonomics.

The ergonomic steering wheel is

folded forward without limiting

vision.

Ergonomic multi-seat

Rotatable and fully integrated.

Built for maximum sitting posture, comfort and ergonomics

during long shifts and demanding operations.

Optimized visibility

Completely new open design.

Designed with smart profiles and

curved front and rear windows.

An optimized view at all angles,

with an exceptionally good view

diagonally forwards and backwards. Strong outdoors feeling.

4

Loading...

Loading...