OPERATOR’S MANUAL

Warning

Battery posts, terminals and related

accessories contain lead and lead

compounds, chemicals known to the

State of California to cause cancer

and reproductive ha rm. W a sh hands

after handlin g.

Proposition 65, a Califo rnia law, requires warnings

on products which expose individuals in California

to chemicals listed under that law, including

certain chemicals in diesel engine exhaust.

California

Proposition 65 Warning

Diesel engine exhaust and some of

its constituents are known to the

State of California to cause cancer,

birth defects, an d other reproductive

harm.

KALMAR

OPERATOR’S MANUAL

NOTICE

The information in this manual was current at the time of publication. Contents of this manual are

subject to change at the publisher’s discretion.

DO NOT REMOVE THIS MANUAL FROM THE VEHICLE. STUDY THIS MANUAL. READ AND COMPLY

WITH ALL WARNINGS IN T HIS MANUAL. IF THE VEHICL E IS SOLD, GIVE THIS MANUAL TO THE NEW

OWNER.

Kalmar Solutions, LLC

415 East Dundee Street

Ottawa, Kansas USA

(785) 242-2200

Fax (785) 242-6177

Notes

Notes

Table of Contents

Table of Contents

Foreword ...................................................................................................................................................... ...... ..... 1

From Kalmar to the Owner ................................................................................................................ ....... ...... ..... 1

About the Operator’s Manual ..................................... ....... ...... ...... ....... ...... ....... ...... ....................................... ..... 1

1 Introduction ................................................................................................................................... ...... ....... ...... ..... 2

1.2 Safety Summary ....................................................................................................................................... ..... 2

CAUTIONS and WARNINGS .......................................................................................................................... 2

NOTICES ............................... ....................................................................... .................................................. 2

1.5 Vehicle Towing ......................................................................................................................................... ..... 2

Towing Vehicle with Front Wheels Suspended ............................................................................................... 3

Towing Vehicle with Rear Wheels Suspended .......................................................................................... ..... 3

1.6 Vehicle Modifications .......................................................................................................................... ...... ..... 4

1.7 Safety Checks and Precautions .................................................................................................................... 4

Inspection ........................ ............. ............. ............. ............. ............. ............. ............. ............. ...... ....... ...... ..... 4

Axle — Front ............................................................................................................................................... 5

Axle — Rear ............................................................................................................................. ....... ........... 5

Brake System ........................................................................................................................... ....... ...... ..... 5

Cab ........................................................................... ....................................................................... ...... ..... 6

Seat Belt System ........................................................................................................................................ 6

Electrical ............................................................ ....................................................................... ....... ...... ..... 7

Exhaust System .................................................................................................................. ...... ....... ........... 8

Frame .......................................................................................................................... ...... . ...... ....... ...... ..... 8

Fuel System ................................................................................................................................................ 8

Propeller Shaft ................................................................................................................................ . ...... ..... 8

Steering ...................................................................................................................................................... 8

Suspension ................. .................................................... ............................................... ............................. 9

Transmission .............................................................................................................................................. 9

Wheels/Tires ............... .................... ................... ................... .................... ................... ............. ....... ...... ..... 9

1.8 Additional Manuals and Safety Informati on ................. ...... ...... ....... ...... ....... ...... ....... ...... ....... ...................... 11

1.9 Service Assistance ...................................................................................................................................... 12

3 Description and Operation .................................................................................................................................. 13

3.1 Cab/Deck .................................................................................................................................................... 13

Vehicle Entry and Exit ................................................................................................................................... 13

3.1.3 Cab Tilting ............................................................................................................................................ 14

To Tilt Cab ................................................................................................................................................ 15

To Lower Cab ........................................................................................................................................... 16

3.1.4 Seating ................................................................................................................................................. 17

Suspension-Type Seats ........................................................................................................................... 17

Seat Adjustment ....................................................................................................................................... 17

3.1.5 Instrument Panel Gauges, Controls and Indicators ............................................................................. 18

Instrument Panel Overview ...................................................................................................................... 18

3.1.6 Electrical Equipment ............................................................................................................................ 26

Accessory Connections ............................................................................................................................ 26

Relays/Breakers/Fuses ............................................................................................................................ 26

3.1.9 Occupant Restraint System ................................................................................................................. 29

Seat Belt Operation .................................................................................................................................. 29

3.2 Chassis ....................................................................................................................................................... 29

3.2.2 Powertrain ............................................................................................................................................ 29

Engine ...................................................................................................................................................... 29

Transmission ............................................................................................................................................ 32

Axles ........................... .................................................... .......................................................................... 32

3.2.4 Air System and Brakes ...................................................................................................

Air Pressure Indicators ...................................................................................................................... 34

Low

Service Brakes ........................ ....... ............................................. ...... ....... ...... ....... ...... ............................. 35

ABS .......................................................................................................................................................... 36

Traction Control ........................................................................................................................................ 36

Parking Brake ........................................................................................................................................... 37

Parking Brake and Trailer Air Supply Controls ......................................................................................... 37

Parking the Vehicle ................................................................................................................................... 37

..................... 33

i

Table of Con t ents

Manually Releasing Tractor Spring Brakes (Caging) ............................................................................... 38

Trailer Brakes ........................................................................................................................................... 39

Trailer Air Lines ........................................................................................................................................ 39

3.2.5 Hydraulic System ................................................................................................................................. 40

Hydraulic Fifth Wheel Lifting System ........................................................................................................ 40

Hydraulic Boom Operation ....................................................................................................................... 40

Fifth Wheel Unlatch Control Valve ............................................................................................................ 40

Basic Trailer Spotting Steps ..................................................................................................................... 41

3.2.7 Exhaust System — DOT/EPA-Approved Engines ............................................................................... 43

Diesel Particulate Filter (DPF) Regeneration ........................................................................................... 43

Exhaust-Related Engine Indicato r Lam ps ......................................... ....... ...... ....... ...... ....... ...... ................ 45

6 Scheduled Maintenance ..................................................................................................................................... 47

General Maintenance Program ......................................................................................................................... 47

6.1 Checklists .................................................................................................................................................... 48

Chassis Lubrication Diagram ................................................................................................................................. 48

Boom and Fifth Wheel Lubrication Diagram ................................................................................................. 49

Lubrication and Fluids ................................................................................................................................... 52

Automatic Transmission Fluid .................................................................................................................. 53

Axle Differential Lubricant ......................................................................................................................... 53

Coolant/Anti-Freeze ........... ................... .................... ................... ................... .......................................... 53

Fuel ............................. ............. ............. ............. ............. ............. ............. ............. ................................... 54

Engine Oil ................................................................................................................................................. 55

Diesel Exhaust Fluid (DEF) ...................................................................................................................... 55

Hydraulic System Fluid ............................................................................................................................. 56

Multi-Purpose Grease ............................................................................................................................... 56

Filters ............................................................................................................................................................ 56

Preventative Maintenance Guidelines .......................................................................................................... 57

Cab Interior ............................................................................................................................................... 57

Check HVAC System ............................................................................................................................... 58

Seat Belt System ...................................................................................................................................... 59

Cab Down — Exterior ............................................................................................................................... 60

Cab Up ..................................................................................................................................................... 61

Under Vehicle ........................................................................................................................................... 63

Chassis .............................. ............................................. ............................................ .............................. 64

Lubrication ................................................................................................................................................ 65

Test Drive ................................................................................................................................................. 66

7 Environment ....................................................................................................................................................... 67

General ............................................................................................................................................................. 67

Environmental Policy ......................................................................................................................................... 67

Environmental Awareness ................................................................................................................................. 68

Environmental Problems ................................................................................................................................... 68

Laws and Regulations ....................................................................................................................................... 68

Use of Materials and Energy ................... ...... ....... ...... ............................................. ....... ...... ... .......................... 69

Effects of Exhaust Gases .................................................................................................................................. 69

Recycling ....................... ................... .................... ................... ................... ....................................................... 70

Complete Overhaul or Disposal ........................................................................................................................ 70

Problem Waste .................................................................................................................................................. 71

Oils and Fluids .................................................................................................................................................. 71

Air Conditioning ................................................................................................................................................. 71

Occupational Health and Safety ........................................................................................................................ 72

Working In an Environment That is Hazardous To the Health .....................................................................

ember ........................................................................................................................................................ 72

Rem

Standards .......................................................................................................................................................... 73

Vibration Affecting the Hands ................................................................................................................... 73

Vibration Affecting the Whole Body .......................................................................................................... 73

Noise Levels ............................................................................................................................................. 73

CE Marking ..................................................................... ....... ...... ...... ....... ...... .......................................... 73

Exhaust Gas Emissions ............................................................................................................................ 73

...... 72

ii

Foreword

NOTICE

NOTICE

Foreword

Foreword

From Kalmar to the Owner

The manufacturer of these trucks cannot create a single

manual that would cover every option available.

We have tried to cover all the information that would be

included in a normally configured truck.

For information on some major components, you will need to

refer to the component manufacturer’s literature.

About the Operator’s Manual

The intent of this Operator’s Manual is to provide basic

information on the safe operation of the Kalmar tractor.

The Introduction section contains important informa tion

regarding the use of safety messages as indicated by the

signal words “Danger,” “Warning,” “Caution” or “Notice” that

are found throughout this manual. This section also contains

important safety and service support information.

The Description and Operation section provides infor mati on

about the features of the tractor and basic operating

information for the tractor itself.

The Scheduled Maintenance section covers basic opera t or

maintenance and lubrication information.

Remember that the safe operation of the Kalmar tractor

depends entirely on the operator. The operator of this vehicle

must be properly trained and fully knowledgeable BEFORE

attempting to operate it. Read this manual carefully and pay

close attention to all warnings, cautions and notices. Keep this

manual in the vehicle and make sure it goes to the new owner

if the truck is sold.

Because of the many variations and options associated with

Kalmar tractors, some optional equipment on your vehicle

may not be covered in this manual. If there are any questions

regarding the specific options or variations not covered in this

manual, contact your nearest Kalmar dealer for assistance.

The Kalmar tractor may also be referred to throughout this

manual as “vehicle” or “the vehicle”. Throughout this manual

reference is made to “Operator”. In the context of this

manual, the “Operator” refers to the actual driver of the

vehicle.

1

1 Introduction

NOTICE

NOTICE

1 Introduction

1 Introduction

1.2 Safety Summary

CAUTIONS and WARNINGS

Throughout this manual you will find Warnings and Cautions.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in injury.

NOTICES

Throughout this manual you will see Notices. Notices will be

used to show special procedures or point out important facts.

Notices will also designate important information regarding

this manual and its use.

1.5 Veh ic l e Tow in g

Towing a vehicle requires special equipment and training.

Kalmar Solutions, LLC, recommends that a professional towing

service be used whe n t owin g a d isa bl ed Kalm ar tra cto r.

The best way to tow a Kalmar tractor is with the rear wheels

lifted off the road. This prevents any possible damage to the

transmission and drivetrain. Towing the vehicle with the rear

wheels lifted avoids having to disconnect the driveline or axle

shafts. Also, towing with the rear wheels lifted does not require

the spring brakes to be caged unless there are spring brakes

on the front wheels.

2

If it is impossible to tow the vehicle with the rear wheels lifted,

be sure to follow the steps listed below, “Towing Vehicle with

Front Wheels Suspended”.

Some vehicles are equipped with “Off Highway” tires. Tire

damage may occur if towed on the road.

1 Introduction

Towing Vehicle with Front

Wheels Suspended

It is not recommended to tow a vehicle with the front wheels

lifted and the rear drive wheels on the road. This practice may

result in serious vehicle damage. Pay close attention to the

following rules to prevent vehicle damage if you must tow your

Kalmar tractor with the rear wheels on the road.

Always obey the following when towing a Kalmar tractor

with the front wheels lifted and the rear wheels on the

road. Failure to do so could result in death or serious

injury.

1. Always use a rigid towing bar or properly restrain the

towed vehicle. Using a chain or cable to tow the

vehicle is not recommended.

2. Always disconnect the driveline to the rear drive

axle(s), or remove all axle shafts from all rear drive

axles.

3. Always cage the spring brakes on all rear drive wheels.

[See page 38, Manually Releasing Tractor Spring

Brakes (Caging).] A loss of air pressure could occur

while towing the vehicle. This would apply the spring/

parking brakes and lock the rear wheels on the towed

vehicle.

When manually releasing the spring brakes, make sure

that the vehicle wheels are properly blocked. If the wheels

are not blocked, the vehicle could move suddenly when

the spring brakes are released and cause death or severe

injury.

If the disabled vehicle is connected to a tow vehicle before

the spring brakes are released, make sure that the tow

vehicle’s parking brakes are applied and its wheels are

blocked to prevent movement. Failure to do so could

result in death or serious injury.

Towing Vehicle with Rear

Wheels Suspended

The recommended way to tow a disabled vehicle is with the

rear wheels lifted off the ground. The steering axle must be

locked in the straight-ahead position. If there are spring brakes

on the front axle, the springs must be caged. [See page 38,

Manually Releasing Tractor Spring Brakes (Caging).]

3

1 Introduction

1.6 Vehicle Modifications

Do not make modifications to your Kalmar tractor without

written approval from Kalmar Solutions, LLC. Your vehicle has

been designed and manufactured with safety and reliability in

mind. Any modifications by the operator or owner could

decrease the safety and reliability of your vehicle. Any

unauthorized vehicle modifications may also void the Kalmar

Solutions, LLC Limited Warranty. Do not risk personal safety or

vehicle reliability by making unauthorized modifications to your

Kalmar tractor. Contact Kalmar Solutions, LLC concerning any

proposed modifications to this vehicle.

1.7 Safety Checks and

Precautions

All spotting applications are demanding on the vehicle.

Maintenance is critical for the continued SAFE performance of

your tractor. Before operating your Kalmar tractor, it is

essential that the vehicle is in proper and safe working

condition.

The following section is intended to provide a basic knowledge

of important safety check procedures. These checks must be

performed regularly to ensure safe vehicle operation. The

frequency of these checks depends on the application of the

vehicle.

In general, the best time to make the following safety checks

would be during normal maintenance and during daily PreOperation Safety Inspections.

All operators should comp let e a Kalmar Daily Inspection

before climbing into the driver’s seat. This “Walk Around” is a

good way to prevent potential problems. A sample daily

inspection form is provided on page 10 of this section. Use this

as a guide to come up with an appropriate checklist for your

individual vehicle.

When performing inspections, always park the tractor on a

level surface, apply the parking brakes and chock the wheels.

Inspection

4

If the vehicle is used in a severe application, such as a rail

yard operation or in 24-hour operations, a more frequent

schedule should be followed. Failure to maintain the

vehicle on an appropriate schedule can lead to

component damage or injury.

1 Introduction

During each scheduled maintenance interval or at least once a

month, a qualified mechanic should inspect all of the following

areas.

Axle — Front

Maintaining correct front axle alignment is critical and should

be performed by a qualified mechanic.

Check to ensure that the axle mounting bolts are securely

tightened. Regularly check the front axle for damage, binding

or worn parts, and adequate lubrication. Pay special attention

to the axle stops and rubber snubbers. Do not operate the

vehicle without the proper axle stops in place.

Axle — Rear

Check to ensure that the axle mounting bolts are securely

tightened. Regularly check the rear axle for damage and oil

leaks. Unusual noises and signs of extreme heat may indicate

axle damage.

Brake System

Do not operate the vehicle until the brake system has

been thoroughly inspected. Failure to conduct a complete

Kalmar Daily Inspection prior to operation could lead to

serious injury or death.

Check the following:

1. Check brake controls for proper operation. Make sure the

foot-operated treadle in the cab is operating smoothly and

is not damaged.

2. Visually inspect the brake drums, brake chambers, and

slack adjusters. Check for loose, missing or broken

components. Check brake chambers and slack adjusters

for cracks and other signs of severe wear.

3. Listen for air leaks in the cab and underneath the chassis.

Check air pressure regularly using the dash-mounted

gauge. Be alert for any sudden drops in pressure while

operating the vehicle and after the engine is shut off. A

minimum air pressure of 70 P.S.I. (4.83 bar) is required to

operate this vehicle.

4. Visually check hoses and pneumatic lines for damage and

chafing.

5. Check the operation of both the service and parking brake

systems. Be alert for any reduction in braking performance

or unusual noises while braking.

5

1 Introduction

Cab

Defroster — Operate the defroster to make sure sufficient air

is being directed against the windshield. Make sure the blower

is operating before the weather requires the defroster.

Door Latches — Check for positive closing, latching and

locking.

Walkways/Steps — Check to ensure that all factory-installed

walkways, platforms and steps are installed onto the vehicle

securely and are not damaged or loose. Make sure that all

walkways, platforms and steps are free of dirt, debris, ice, mud

and any other potentially hazardous obstructions.

Handholds/Grab Handles — Check to ensure all handholds

are installed and are not loose or damaged.

Glass — Check for cracked, broken, scratched or dirty glass.

Cleaning Instructions for Optional Plastic Glazing — Wa sh

windows with a clean sponge or soft cloth using lukewarm

water and mild detergent or window cleaner. Rinse with clean

water. Do not use abrasive or highly alkaline cleaners. Never

scrape with squeegees, razor blades or other sharp

instruments. Remove ice and frost with the cab heater/

defroster or by applying heat.

Mirrors — Check to be certain all mirrors are installed and that

they are clean, undamaged and properly adjusted.

Seat Belt System

Always check the seat belt system for wear and proper

operation. All components must be in good condition and

ready to function correctly when necessary. Failure to

check the seat belt system could lead to serious injury or

death.

Inspect the seat belt system every 20,000 miles (32,187 km) or

more often if exposed to severe environmental conditions or

vocation. Check the following:

1. Inspect belt on entire system for cuts, fraying, extreme or

unusual wear. Most common areas of belt wear include the

buckle/latch area, the shoulder loop area and any place

where the bel t mak es contact with vehicle or seat. Replace

the entire belt system if necessary.

2. Inspect buckle for proper operation by inserting latch and

listening for an audible click. Verify the buckle is not

damaged, cracked or broken. Replace the entire belt

system.

6

3. Inspect buckle cable (optional component) black coating

on buckle cable must not be damaged. Internal cable wires

must not be exposed, frayed or broken. Replace the entire

system.

1 Introduction

4. Inspect latch for proper operation by inserting into buckle.

Latch must insert smoothly and you must hear an audible

click. Verify proper latching by tugging on belt. Latch must

not be worn, deformed or corroded. Replace the entire belt

system.

5. Inspect shoulder loop web guide (optional component)

Seat belt must move freely through shoulder loop.

Shoulder loop must also pivot freely and be free of

obstructions. If necessary, adjust shoulder loop hardware

and/or remove obstruction.

6. Inspect seat belt height adjuster (optional component)

for damage. Mover adjuster up and down. It must move

freely and lock at the di ff erent heig ht pos ition s. Replace the

entire belt system if necessary.

7. Inspect retractor operation. When pulled and released

slowly, seat belt must spool out and retract without locking.

Replace the entire belt system if necessary.

8. Inspect mounting hardware on both sides of seat.

Hardware should be tight. Hardware must not be missing,

rusted, corroded or damaged. If necessary, replace

defective or missing hardware with authorized parts and/or

tighten hardware.

9. Inspect tethers for cuts, fraying, extreme or unusual wear.

Tethers must also be inspected for proper attachment and/

or adjustment. If necessary, replace defective tethers.

Tighten and/or properly adjust tethers according to the

Seat Adjustment section on page 17.

®

10.Inspect Komfort Latch

and ability to clamp on web. Replace the entire system if

necessary.

Cleaning of Seat Belt Fabric — Sponge the seat belt clean

with mild soap and water. DO NOT use bleach, dye or

household detergents.

(optional component) for function

Electrical

Horn — Operate the steering wheel-mounted horn to check

operation. (Check optional air horns if equipped.)

Instruments — Check operation of all instruments and

gauges.

Lights — Check to make sure all lights (interior, exterior,

headlights, etc.) function properly. Make sure the gauge and

dash backlighting is working prop er ly.

Wiring — Check to ensure all wiring is properly secured and

protected. Replace worn, cracked or chafed wires and looms.

Make sure factory wiring has not been compromised by

improper splicing o r modifi ca tions.

7

1 Introduction

Exhaust System

Maintain the exhaust system (mufflers, pipes, stacks, joints)

integrity to ensure no exhaust fumes can enter the cab. Look

for loose, damaged or missing exhaust components. Be alert

to any exhaust fumes or unusual odors in the cab.

Frame

Check for cracks and signs of damage. Pay close attention to

highly stressed areas of the frame such as the boom piv ot

area. Contact your dealer for instructions on frame repair. Do

not weld on frame rails unless directed to do so by your Kalmar

dealer or by the factory.

Fuel System

The throttle should operate smoothly and with minimal effort.

Always replace damaged throttle components with factory

replacement parts.

Check the fuel system for leaks and hose chafing. Repair any

problems before operating the vehicle.

Check the DEF system for leaks and hose chafing. Repair any

problems before operating the vehicle.

Propeller Shaft

Check the universal joints for wear. If propeller shaft vibrations

occur, stop the vehicle immediately to prevent serious damage

to the vehicle drivetrain.

Steering

Be alert to any change or feel in steering while driving the

vehicle. This change or feel may include a change in steering

effort, unusual sounds when turning, or excessive wheel play

or pulling to either side.

If a problem is suspected or felt, check steering components

for loose, damaged or worn parts. All steering components

such as the tie rod and drag link must be tight.

Check the power steering system for leaks and hose chafing.

Repair any problems before operating the vehicle. Regularly

inspect all steering linkages.

8

Do not operate the vehicle with broken, damaged, worn or

non-OEM steering system components. If the Kalmar

Daily Inspection reveals any of these issues, have the

vehicle repaired immediately by a qualified technician.

Failure to do so could result in serious injury or death.

1 Introduction

NOTICE

Suspension

Check the condition of the front and optional rear (if

installed) suspension components such as mounting

brackets and bushings. Check for worn and damaged

parts. Failure to do so could result in injury.

Check and maintain the specified torque on all mounting bolts

and nuts. Check the springs and replace broken or distorted

springs.

Transmission

Follow the transmission manufacturer’s guidelines for proper

maintenance.

Wheels/Tires

Check the condition and maintain the specified torque on all

wheel mounting nuts. Replace missing or broken studs and

nuts. Check tire inflation and wear. Do not operate this vehicle

with badly worn or damaged tires. Do not operate this vehicle

with damaged wheels.

Because of the many options available on Kalmar tractors, it

is critical that the owner be aware of all options that may

affect the safe operation of the vehicle and take appropriate

measures to maintain his/her specific vehicle. Always contact

your Kalmar dealer if any questions arise regarding safe

operation of this vehicle.

9

1 Introduction

Kalmar Daily Inspection Form

(Walk Around Inspection)

_____ Check tires and wheels for damage and proper inflation.

_____ Check cab hold down latch (air suspension unit) for proper latching.

_____ Check all fluid levels: engine oil, hydraulic and coolant.

_____ Drain any moisture from air tanks.

_____ Check cab doors and latches for proper operation.

_____ Ensure that all steps, walkways and handholds are installed and in good working order.

_____ Start engine and check transmission fluid level with parking brake applied and transmission shift selector

in “neutral”.

_____ Check windshield wiper for proper operation.

_____ Check steering system for any binding. Make sure steering effort is smooth and light.

______ Check accelerator for proper operation. The accelerator should operate smoothly.

_____ Check all rear view mirrors; adjust and clean if needed.

_____ Check cab and frame for any structural damage or cracks.

_____ Inspect trailer electrical cable and trailer air lines for damage. Make sure both air lines are installed.

_____ Clean all windows if needed.

_____ Check transmission shift lever for proper operation.

_____ Check boom control lever for proper operation.

_____ Check all lights for proper operation: headlights, turn signals, brake lights, hazard lights and marker lights.

_____ Check horn(s) for proper operation.

_____ Check and fill fuel tank.

_____ Drain fuel water separator.

_____ Check and fill DEF tank.

10

1 Introduction

1.8 Additional Manuals and

Safety Information

Kalmar Solutions, LLC offers an Operator Orientation Video

DVD. This video covers important information that all Kalmar

operators must know. The video should be used in conjunction

with this manual to instruct the operator on the proper

operation of the Kalmar tractor. Shipped with every tractor, this

video is also available through your Kalmar dealer or directly

from Kalmar Solutions, LLC.

Figure 1

Operator Orientation Video

11

1 Introduction

1.9 Service Assistance

Kalmar Solutions, LLC has an established dealer network

throughout the world. Whenever assistance is needed, contact

your local dealer first. For contact information, visit our website

at Kalmarind.com or contact Kalmar sales.

When parts or service are required, always have the serial

number of the vehicle ready before contacting your Kalmar

dealer. The serial number is located on an ID plate inside of

the cab.

Kalmar is proud to have been the leader in the Port and

Terminal Tractor Industry for over 50 years. We strive to serve

our customers in every way possible. Thank you for buying our

Kalmar tractor. We know it will serve you well for many years.

If, for any reason, you are not able to obtain assistance from

any Kalmar dealer, feel free to contact Kalmar Solutions, LLC

directly.

For assistance call:

Kalmar Solutions, LLC

Service Department

USA +1 (785) 242-2200

Europe +358 (0) 20 777 5000

12

3 Description and Operation

3 Description and Operation

3 Description and

Operation

The following section on Description and Operation should

be read carefully. It covers important information that every

operator must know before operating any Kalmar tractor.

This manual is intended to cover the standard Kalmar tractor

and some of the most common options. Not all of the

customer-ordered optional equipment or systems are covered

in this manual. If the operation of any component or system on

your vehicle is not covered in this manual, call your Kalmar

dealer for assistance.

All individuals who operate this vehicle must have

sufficient training to operate this type of vehicle and

should have a valid commercial driver’s license. This

manual is not intended to be a training guide for yard

tractor operation. It is the operator's responsibility to

obtain sufficient training in order to operate this vehicle

safely. DO NOT ATTEMPT TO OPERATE THIS VEHICLE

WITHOUT ADEQUATE TRAINING. OPERATING THIS

VEHICLE WITHOUT ADEQUATE TRAINING COULD

RESULT IN SERIOUS INJURY OR DEATH.

3.1 Cab/Deck

Vehicle Entry and Exit

The Kalmar tractor is designed for easy entry and exit. The

walkways, steps and handholds are designed with operator

safety in mind. As with any vehicle of this type, care must be

taken when climbing in or out of your Kalmar tractor.

Remember, be careful!

Always exercise caution when entering or exiting the

vehicle. To avoid serious injury or death, read the

following instructions and warnings before entering and

exiting the vehicle.

1. Entry and exit should be made slowly and carefully.

2. A three-point stance should be used. Three out of the

four extremities (hands and feet) should be in contact

with the vehicle at all times.

3. Face inward toward steps when entering and exiting.

4. Keep steps, walkways and handholds in good condition.

5. Keep steps, handholds, walkways and shoes free of

grease, mud, dirt, fuel, ice and snow.

6. Use extra care during bad weather, especially when

steps and handholds may be icy or wet.

13

3 Description and Operation

Do not remove or modify factory-installed walkways,

steps or handholds. Do not operate your v ehicle unless all

of the factory-installed steps, walkways and handholds

are installed and in good working condition. If the

walkways, steps or handholds have been modified or

removed, or are not in good working order, anyone

attempting to enter or exit the vehicle could be injured or

killed.

3.1.3 Cab Tilting

The tractor comes equipped with an electrically operated cab

tilt system as standard equipment. Under power assist, the cab

can be tilted to 45 degrees. At 45 degrees, the safety prop is

automatically engaged.

The cab can be tilted MANUALLY to 90 degrees if needed.

This requires that the tilt cylinder be disconnected, and that a

suitable hoist be used to tilt the cab all the way to the 90degree position.

All tractors come standard with a cab air suspension. These

units are designed to work with the power cab tilt, and unlatch

automatically.

The electric cab tilt is designed to tilt the cab to 45 degrees at

which point the cab safety prop is automatically engaged. The

tilt system is not designed to provide a safety prop at any point

other than 45 degrees. Figure 3 shows proper engagement

of the cab safety prop.

Never work under the cab unless the safety prop is

properly engaged. The cab could fall and cause serious

injury or death. (See Figure 3 and Figure 4.)

Only tilt the cab far enough past the 45-degree point to

engage the safety bar. Attempting to fully extend the

cylinder past 45 degrees can cause pump and motor

damage. Check the cab tilt cylinder and bracket mounting

bolt for proper torque and wear! Failure to check and

operate the cab tilt system correctly can result in injury.

14

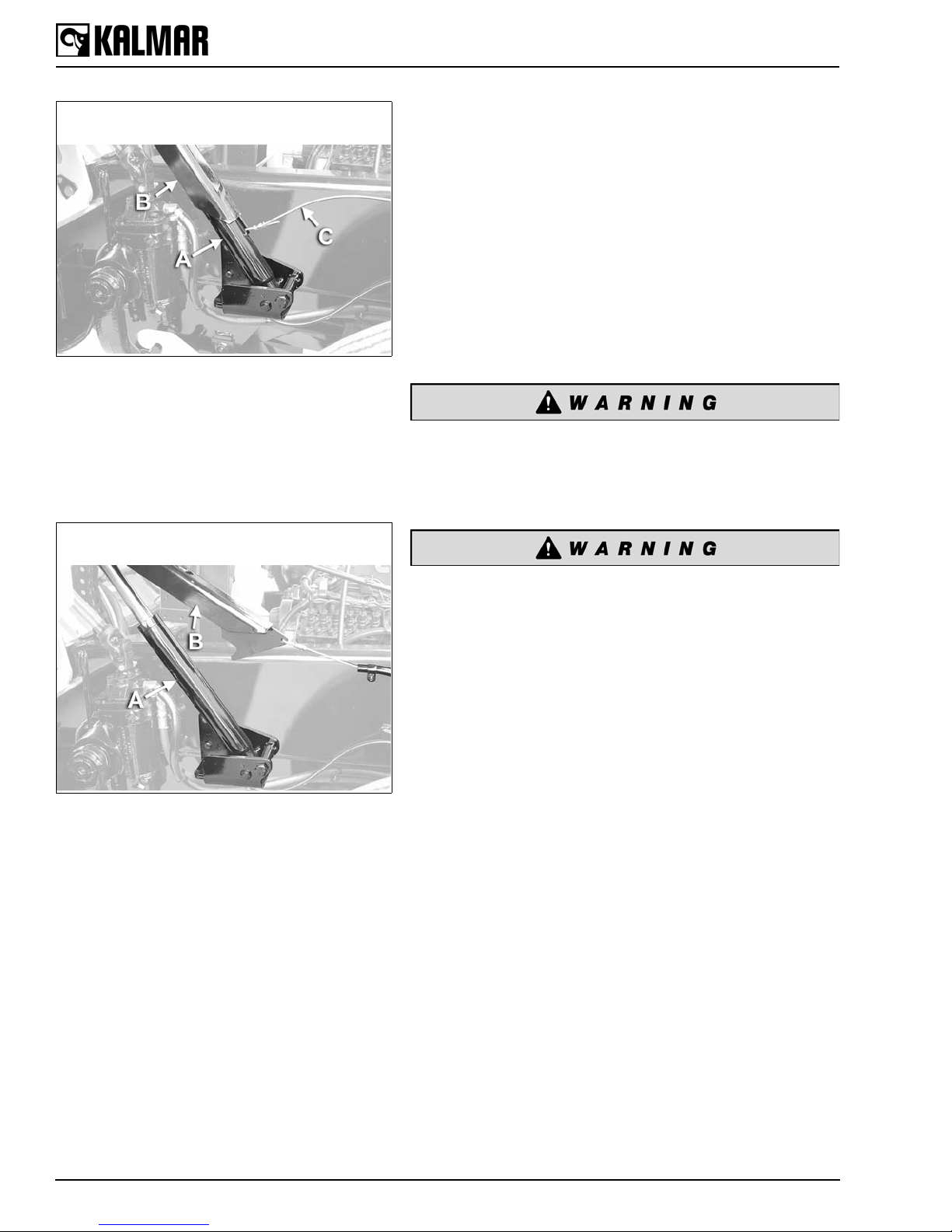

3 Description and Operation

A

B

Figure 2

A — Cab Tilt Control Switch

B — Safety Prop Release Cable

To Tilt Cab

In most cases, the cab tilt control switch is located on the lefthand frame rail (Figure 2). The safety prop release cable is

located on the left-hand rail, within reach of the tilt switch.

Ensure that no part of the body is under the cab while

tilting. Stand clear of the rear of the cab and ensure that

the cab does not strike you when it is being raised. Failure

to do so can lead to serious injury or death.

Ensure that the safety prop is properly engaged before

working under the cab. The safety prop must be able to

move freely to engage automatically. Always check the

safety prop before working under the cab and make sure

to properly maintain this important safety system. Failure

to do so can result in serious injury or death.

1. Locate the cab tilt control switch and safety prop release

cable.

2. Pull the safety prop release cable and hold the cable to the

rear.

3. While holding the cable to the rear, move the tilt control

switch to the UP position.

4. After the cab has traveled about 15 inches (381 mm),

release the safety prop cable and continue tilting the cab.

5. As the cab approaches the 45-degree position, watch for

the safety prop to drop over the tilt cylinder on the driver’s

side of the frame. (Figure 3 and Figure 4) STOP!

6. After the safety prop has dropped over the cylinder, move

the tilt control switch to the DOWN position (Figure 2) and

lower the cab slightly until the safety prop rests fully on the

top of the tilt cylinder (Figure 3).

7. Make sure that the safety prop is resting properly on top of

the tilt cylinder. Pull on the safety prop release cable and

ensure that the safety prop is secure. It should not move

with the weight of the cab on the prop.

15

3 Description and Operation

CAB SAFETY PROP IS ENGAGED

CORRECTLY

Figure 3

A — Tilt Cylinder

B — Safety Prop

C — Safety Prop Release Cable

The Safety Prop (B) is resting flush against the

Tilt Cylinder (A). The Safety Prop is properly

engaged.

CAB SAFETY PROP IS NOT ENGAGED

CORRECTLY

To Lower Cab

1. Move the cab tilt switch to the UP position and raise the

cab slightly until the safety prop is free from the top of the

tilt cylinder.

2. Pull the safety prop release cable to the rear and hold in

the rearward position.

3. Move the tilt switch to the DOWN position with the safety

prop disengaged and allow the cab to lower onto the rear

cab latch.

4. Hold the cab tilt switch in the DOWN position for 5 seconds

after the cab has come to rest on the lower latch units to

ensure that the mechanical cab latches are fully engaged.

Ensure that the cab latch is fully engaged after lowering

the cab. If the cab latch is not properly locked down, the

cab could tilt while the vehicle is in motion, resulting in

serious injury or death.

Figure 4

Safety Prop (B) is NOT resting flush against Tilt

Cylinder (A). The Safety Prop is NOT properly

engaged.

If a cab latch fails or the tilt system malfunctions, the

safety prop is designed to act as a secondary hold down.

Ensure that the release cable is operating freely and that

the safety prop rests against the tilt cylinder when the cab

is in the lowered and latched position. Failure to do so can

result in serious injury or death.

16

3 Description and Operation

3.1.4 Seating

Suspension-Type Seats

All Kalmar tractors have an air suspension-type seat as

standard equipment.

Due to the vertical travel of suspension seats, the

operator must ensure that there is adequate head

clearance when the seat is at the top of its upward travel.

Failure to do so can result in serious injury or death.

Seat Adjustment

Refer to the seat manufacturer’s information packet provided

with the vehicle or to the decal located on the seat base. Your

local Kalmar dealer can assist with any questions.

Adjust the seat to the comfortable position for the operator to

have full control of all cab controls and displays. This position

is obtained by changing the air pressure in the suspension,

which changes the height. The fore and aft position is obtained

by moving the seat cushion back on its slides. Once this

position is achieved, tighten the seat belt tether securely on

both sides. The tether will restrain the seat from raising above

this position. Now, the seat air suspension may be adjusted to

the operator’s desired firmness.

Do not adjust the driver’s seat unless the vehicle is

parked. The seat could move suddenly and unexpectedly,

resulting in loss of control of the vehicle, serious injury or

death.

The Kalmar tractor is designed and equipped to carry only

the driver (unless built with a trainer seat). Never allow

anyone to ride anywhere inside or outside of the cab.

Carrying a passenger is extremely dangerous and can

result in serious injury or death. NEVER CARRY

PASSENGERS WITH YOUR KALMAR TRACTOR.

17

3 Description and Operation

4

1 2 3

5 67 9 10

11

12

8

22

25

27

13

14

14

21 29

23

24

28

26

18

17

16

15

20

19

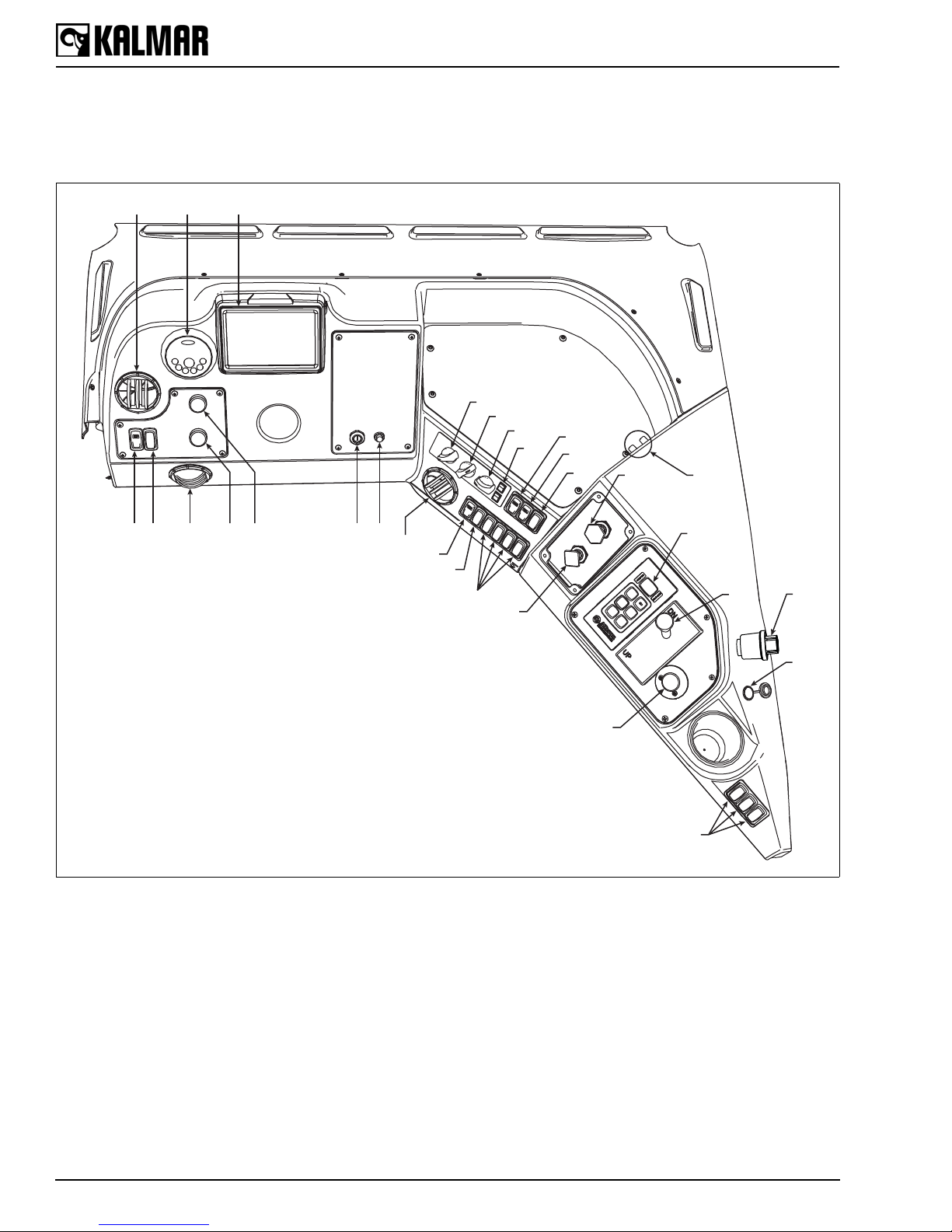

3.1.5 Instrument Panel Gauges, Controls and Indicators

Instrument Panel Overview

Figure 5

18

3 Description and Operation

S=Standard A=Assigned options

U=Unassigned options

POS Name

1 Air Diffuser S S

2 Radio A A

3 Main Gauge Panel S S

4 Headlight Switch S S

5 Dimmer Switch S A

6 Air Diffuser S S

7 Rear Wiper Switch A A

8 Front Wiper Switch S S

9 Ignition Switch S S

10 Push Button Start A A

11 Air Diffuser S S

12 Dome Light S S

13 Air Horn A A

14 Option Switches U U

15 Heater Control S S

16 Heater Control S S

17 Heater Control S S

18 Heater Control S S

19 Front Floodlight S S

20 Rear Floodlight S S

21 Trailer Air Supply S S

22 Parking Brake Control S S

23 Transmission Shifter S S

24 5th Wheel Control S S

25 5th Wheel Latch Control S S

26 Power Outlet A A

27 Option Switches U U

28 Air Restriction Indicator A A

29 Power Studs A A

Standard DOT/EPA

Tractor

Off-Highway Tractor

19

Figure 6

152 64 73

1 2 3

65 4

Left Dash Panel

3 Description and Operation

Left Dash Panel

1. Headlight Switch

Controls headlights and running lights on the tractor and

trailer. This switch also activates the interior dash and

gauge lights when either the headlights or the running lights

are on.

2. Dimmer Switch (optional)

Controls light level of dash panel controls.

3. Front Wiper Switch

Operates the front windshield wiper. Turning the control

clockwise increases the speed of the wiper. Turning the

control counterclockwise completely parks the wiper.

4. Rear Wiper Switch (optional)

Operates the rear windshield wiper. Turning the control

clockwise increases the speed of the wiper. Turning the

control counterclockwise completely parks the wiper.

5. Radio (optional)

Refer to the manufacturer's owner manual for features and

operating information.

6. Ignition Switch

Standard switch used to start the tractor. Refer to page 25

for more information.

7. Push Button Starter

Optional method to start the tractor. Refer to page 26 for

more information.

Main Gauge Panel

1. DEF Gauge

Indicates the level of diesel exhaust fluid in the tank in 1/4

increments. DOT/EPA Tractors Only.

Volt Meter

Indicates the status of the charging system in volts. If the

engine is running, the gauge indicates the alternator output

voltage. If the engine is not running, the voltmeter indicates

the output voltage of the battery. Off-Highway Tractors

Only.

2. Speedometer

Indicates vehicle speed in M.P.H. or K.P.H. This gauge may

also come with an odometer feature built in.

3. Fuel Gauge

Indicates the level of fuel in the fuel tank in 1/4 increments.

Figure 7

Main Gauge Panel

20

4. Rear Brake Air Pressure Gauge

Indicates air pressure in the rear air system in P.S.I.

5. Odometer and Hour Meter

Indicates vehicle distance traveled in miles and total hours

of operation.

6. Front Brake Air Pressure Gauge

Indicates air pressure in the front air system in P.S.I.

3 Description and Operation

LEFT CENTER RIGHT

ATC

ABS

ABS

1 2 3

456

Figure 8

Indicator Lights on the Main Gauge Panel

Tell Tale Indicator Lights

The indicator lights are located along the top of the main

gauge panel (Figure 8). The standard indicators are listed

below:

Left Side Indicator Lights

Figure 9

Left Side Indicator Lights

1. Left Turn Signal

Indicates left-hand turn signal is on when flashing.

2. Charger

Indicates the charging system is not functioning properly

and the battery power is low.

3. Water-in-fuel

Indicates water has been detected in the fuel system and

should be corrected.

4. ATC

Indicates the automatic traction control is operating.

5. Trailer ABS

Indicates the trailer anti-lock braking system is operating.

6. Tractor ABS

Indicates the tractor anti-lock braking system is operating.

21

7 8 9

CHECK

ENGINE

11 12 13

Figure 10

Center In dicator Lights

BRAKE

AIR

STOP

ENGINE

10

CHECK

TRANS

14

3 Description and Operation

Center Indicator Lights

7. Low DEF Level

Indicates the diesel exhaust fluid level is low and should be

filled. DOT/EPA Tractors Only.

Lamp function indicates the following status:

Low: First warning to the driver that the reducing agent is low.

The DEF lamp light will be solid.

Warning: Intermediate warning to the driver that a derate will

be activated if the reducing agent is not refilled. The DEF lamp

will start to flash.

Low Level Inducement: Second warning to the d river that th e

reducing agent is low and inducement derate will be activated

at this level. The DEF lamp will flash and the amber warning

lamp will be solid.

Severe Inducement: Once the DEF tank is empty and a key

cycle has occurred or after an extended idle operation, the

vehicle will be restricted to 5 M.P.H. and R.P.M. limit. The DEF

lamp will flash and the red lamp is solid.

8. High Beam

Indicates the high-beam lamps have been activated.

9. Brake Air

Alerts the driver that the brake system air pressure is

70 P.S.I. (4.83 bar) or lower.

10.Low Fuel

Indicates the fuel tank has 1/8 tank or less of fuel

remaining.

11. Malfunction Indicator Lamp (MIL)

Indicates the engine is malfunctioning and should be

checked. DOT/EPA Tractors Only.

12.Check Engine

Alerts the driver that the engine has an issue that requires

immediate attention. Shut the tractor down immediately

and have it serviced.

13.Stop Engine

Indicates a serious condition has occurred. Shut down the

tractor immediately and have it serviced.

14.Check Transmission

Alerts the driver to check the transmission/transmission

fluid level.

22

3 Description and Operation

1 2 3

8

9 10

657104

15 16 17

Right Side Indicator Lights

15.Wait to Start

Indicates the engine temperature is too cool to start the

engine immediately. Wait until the engine has been

properly heated before starting the engine.

WAIT TO

START

18 19 20

Figure 11

Right Indicator Lights

SERVICE

16.Seat Belt

Indicates the seat belt should be fastened.

17.Right Turn Signal

Indicates right-hand turn signal is on when flashing.

18.High Exhaust System Temperat ure

Indicates that high exhaust temperatures exist. Shut down

the engine and allow the exhaust system to cool before

restarting the engine. Refer to the Exhaust System section

for more information. DOT/EP A Tractors Only.

19.DPF (Diesel Particulate Filter) Regen Needed

Indicates the diesel particulate filter requires regeneration

within the next 2-6 hours of operation. Refer to the Exhaust

System section for more information. DOT/EPA Tractors

Only.

20.Service

Indicates the tractor requires immediate service.

Center Dash Panel

1. Fan Speed Control

Adjusts the fan speed. Rotate the dial clockwise to increase

the speed. Full counter-clockwise is the OFF position.

2. Mode Selector

Directs air flow to passenger compartment vents or to the

windshield for defrosting.

Figure 12

Center Dash Panel

3. Temperature Control

Controls the temperature of the air flowing into the cab. The

dial can be rotated between COLD (full counter-clockwise)

and HOT (full clockwise) to obtain the desired amount of

heat or cold air.

4. Air Recirculation Switch

Re-circulates air in the passenger compartment.

5. Air Conditioner Switch (Optional)

Activates the air conditioning compressor when the

optional air conditioning is installed.

6. Front Floodlights

Activates the floodlights at the front of the vehicle.

7. Rear Floodlight

Activates the floodlight at the rear of the vehicle.

8. Dome Light

Activates the interior light in the cab.

9. Air Horn

Activates the air horn.

10.Optional Switches

23

Figure 13

8

1 3 4 9

5

7

6

2

Right Dash Panel

3 Description and Operation

Right Dash Panel

1. Trailer Air Supply

Activates the trailer air supply. (See page 37, Parking

Brake and Trailer Air Supply Controls.)

2. Parking Brake Control

Operates the parking brakes on the vehicle and trailer.

(See page 37, Parking Brake.)

3. Transmission Shift Selector

Selects the operating range of the transmission. (See page

32, Transmission.)

4. Boom Control Lever

Operates the hydraulic boom and fifth wheel. (See page

40, Hydraulic Boom Operation.)

5. Fifth Wheel Unlatch Control

Engages the fifth wheel jaw locking mechanism. (See page

40, Fifth Wheel Unlatch Control Valve.)

6. Power Outlet

Cigar lighter port provides 12-volts of power.

7. Optional Switches

Figure 14

A — High Beam Switch

B — Turn Signal Lever

C — Emergency Flasher Switch

8. Power Studs

Provides positive and negativ e co nnecti on poi nts for CB

radio or other devices.

9. Air Restriction Indicator

Monitors resistance of airflow through the air cleaner

system. If a significant restriction arises, the indicator

button will pop up, indicating it is time to change the air

filter. Push the button back down to reset the indicator.

Turn Signal, High Beam and Emergency Flasher

Control

The column-mounted control on the Kalmar tractor has three

functions. It is located on the left-hand side of the steering

column (Figure 14).

1. Moving the lever (Figure 14, B) forward activates the right

turn signal. Moving the lever to the rear activates the left

turn signal. The turn signal is not self canceling and must

be returned to the center (OFF) position manually after it is

engaged. The green arrows on the dash panel light up and

flash when the switch is activated.

2. The button on the end of the lever operates the high beam

lights (Figure 14, A). The headlights must be on for the

switch to work. When the high beam headlights are on, the

high beam indicator on the dash will light up.

3. The pull out switch under the lever activates the emergency

flashers (Figure 14, C). Pulling out on the switch turns the

flashers on. To turn the flashers off, move the turn signal

lever forward or backward.

24

3 Description and Operation

NOTICE

Driver Controlled Differential Lock

(Optional on drive axles)

Drive axles may be equipped with a driver controlled

differential lock. This is a servo-controlled, air-actuated traction

device that can be manually controlled inside the cab by the

operator. By actuating a dash-mounted control, the operator

can lock or unlock the differential.

The differential must not be engaged when traveling at

higher speeds or down steep grades with limited traction.

앫 When the differential is fully locked, the vehicle will

have reduced steering capability. Do not use the

differential when driving at higher speeds or loss of

vehicle control, serious injury or death can result.

앫 The differential must not be engaged when traveling

down steep grades when traction is limited. This can

result in loss of vehicle control, damage to

components, serious injury or death. Refer to the axle

manufacturer for the correct operational and

maintenance procedures.

Figure 15

Driver Controlled Differential Lock

Ignition Switches

The standard ignition switch on the Kalmar tractor is a key

type, similar to the kind found on automobiles. Push button

and other types of ignition switches are installed as optional

equipment.

Key-Type Ignition

There are three positions: OFF, ACCESSORY and

RUN/START. The full left (counterclockwise) position is the

OFF position. The second position to the right (clockwise) is

the ACCESSORY position. The third position to the right

(clockwise) is the RUN/STAR T position.

The RUN/START position is used to engage the starter motor.

Moving the switch to the full right position engages the starter

and upon release of the key, the switch automatically stays in

the RUN position.

The ACCESSORY position activates the tractor’s electrical

accessory circuit.

The OFF position cuts all power to the electrical system and

shuts down the engine.

The OFF position on the standard three-position key-type

switch is designed to function as the engine stop. There is no

other engine stop device other than the ignition switch on the

standard Kalmar tractor.

25

3 Description and Operation

NOTICE

Push Button Starter

Push button starters are optional on Kalmar tractors. There are

two basic types of toggle ignition switches: three position and

two position.

The three-position type functions like the standard key type

with OFF, ACCESSORY and RUN positions. The button

engages the starter when the switch is in the RUN position

only .

The two-position switch has only the OFF and RUN positions.

It has no provision for the ACCESSORY position. The button

engages the starter in the RUN position only.

If the engine does not start within 30 seconds, release the

starter switch and wait 3 minutes to allow the starter

motor to cool. If after three repeated attempts the engine

still fails to start, stop and determine the cause. The

starter motor may be damaged by repeat ed attempts to

start the engine.

Some vehicles may be equipped with optional shut down

systems or optional starter switches. Contact your Kalmar

dealer if you have any questions regarding the operation of

any optional starter switches or shut down systems.

For starting the vehicle, refer to page 30, Starting the Engine.

3.1.6 Electrical Equipment

Accessory Connections

The wiring harness in the Kalmar tractor is designed to support

many vehicle options. These options may or may not already

be on your vehicle. If any electrical equipment is installed on

the vehicle after it leaves the factory, contact your Kalmar

dealer first. Your dealer can provide you with information on

proper electrical modifications and installations. Generally,

there will be an accessory location on the harness where you

will need it. Do not risk damaging your vehicle or voiding the

warranty by making improper and poor electrical modifications.

Contact your Kalmar dealer first.

Relays/Breakers/Fuses

26

The Kalmar tractor is equipped with two power boards. One

power board is located in the cab under the center panel of the

dash. The second power board is located in the chassis over

the transmission on the left side. See following figures for fuse,

breaker and relay locations.

3 Description and Operation

Figure 16

Cab Power Board

27

3 Description and Operation

Figure 17

Chassis Power Board

28

3 Description and Operation

NOTICE

3.1.9 Occupant Restraint

System

THE KALMAR TRACT OR IS E QU IPP ED WI TH S EAT BELTS.

THEY SHOULD BE USED WHENEVER THE VEHI CLE IS IN

OPERATION.

Seat Belt Operation

Always use seat belts whenever the vehicle is in

operation. In the event of a sudden stop or accident,

unbelted riders can be thrown about the cab or into the

windshield, resulting in serious injury or death.

The seat belt system used on Kalmar tractors is a lap-type

restraint with an automatic retractor.

Before fastening the seat belt, be sure to adjust the seat to a

comfortable driving position. T o fasten the belt, pull the belt low

across the hips and insert the tongue into the buckle.

T o release the seat belt, press the button on the buckle and the

belt will retract automatically.

3.2 Chassis

3.2.2 Powertrain

Engine

Kalmar tractors come equipped with a variety of engines.

Kalmar provides the manufacturer’s Engine Operation Manual

with each vehicle.

It is the operator’s responsibility to read the Engine

Operation Manual and follow all instructions provided by

the engine manufacturer. Failure to do so can result in

injury.

Engine performance is very important to the efficient operation

of the Kalmar tractor. Failure to properly maintain and operate

any engine can lead to very costly repairs and extensive down

time. KNOW YOUR ENGINE AND MAINTAIN IT!

This manual only contains basic information on engine

operation that applies specifically to the Kalmar tractor, or is

applicable to all diesel engines. For additional information,

contact the individual component manufacturer directly or via

the internet to obtain manuals.

29

3 Description and Operation

NOTICE

If you did not receive an Engine Operation Manual,

contact your Kalmar dealer.

Failure to read and follow the engine manufacturer’s

instructions regarding engine operation may lead to

severe engine damage. Read the Engine Oper atio n

Manual before operating this vehicle.

Starting the Engine

Never attempt to start the vehicle from any position other

than the driver’s seat. Attempting to start the vehicle while

standing, out side of the cab, or in the engine compartme nt

may cause the vehicle to move uncontrolled and cause

serious injury or death.

Always set the parking brake and place the shifter in

neutral before attempting to start the engine. Failure to do

so may cause the vehicle to move suddenly and

unexpectedly when the starter is engaged. Serious injury

or death can result.

All Kalmar tractors are designed to start in NEUTRAL

ONLY. If the vehicle you are operating starts while it is in

gear, DO NOT OPERA TE THE VEHICLE. Shut the vehicle

down and have the neutral lock-out system repaired

before operating the vehicle.

The following is provided as gener al gui deline information.

Always follow all instructions provided in the manufacturer’s

Engine Operation Manual. Different makes and models of

engines have different operating characteristics and

requirements. There are some important guidelines to follow

when starting any Kalmar equipped with a diesel engine.

These are listed below.

To start a vehicle equipped with the standard electrical starting

system, follow these steps:

30

Starting Procedure

All Kalmar tractors are designed to start in NEUTRAL ONLY.

The starter should not operate if the vehicle is in any other

gear.

1. Set the parking brake.

3 Description and Operation

NOTICE

NOTICE

NOTICE

2. Place the transmission control in NEUTRAL.

3. Apply the service brakes using the foot-operated treadle

valve and hold the brakes in this position.

4. Turn the ignition switch to the OFF position (if your vehicle

is not equipped with an ignition-operated engine shut

down, then use the engine shut down button or control to

stop the engine).

5. Wait for the “Wait to Start” light on the dash to go out if the

vehicle is equipped with one.

6. Turn the key to the START position. When the engine

starts, release the key and allow the switch to remain in the

RUN position.

If the engine does not start within 30 seconds, release the

starter switch and wait 3 minutes to allow the starter motor to

cool. If after three repeated attempts, the engine still fails to

start, stop and determine the cause. The starter motor may

be damaged by repeated attempts to start the engine.

Engine Shut Down

Diesel engines generate large amounts of heat. Internal

engine parts on any diesel engine need to cool down before

the engine is shut off. The operator should allow the engine to

idle for at least 3 minutes prior to shutting the engine down.

This cool down period allows the coolant to dissipate internal

engine heat. Shutting a hot engine down without a cool down

period may cause an immediate and excessive increase in

engine temperature. This could severely damage internal

engine components.

Always refer to the Engine Operation Manual for complete

information on engine shut down procedures.

Shut Down Procedure

1. Place the transmission in NEUTRAL.

2. Set the parking brake.

3. Allow the engine to idle at low idle for at least 3 minutes.

4. Turn the ignition switch to the OFF position (if your vehicle

is not equipped with an ignition-operated engine shut

down, then use the engine shut down button or control to

stop the engine).

5. Make sure all electrical accessories and lights are off and

the vehicle is in NEUTRAL.

Failure to follow the engine manufacturer’s guidelines

regarding engine shut down procedures may cause severe

engine damage.

31

3 Description and Operation

Engine Oil

Always refer to the Engine Operation Manual for complete

information on engine oil requirements. Service intervals, oil

types and refill quantities are all covered in the Engine

Operation Manual. READ IT!

Transmission

Standard tractors are equipped with an Allison Automatic

Transmission. This heavy-duty transmission is designed for

stop-and-go operation. An Allison Transmission Operator’s

Manual is provided with every Kalmar tractor. This manual

provides important information on operation of the

transmission.

The following information can be found in your Allison

Operator’s Manual:

1. Gear selection

2. Shifting the transmission

3. Driving tips

4. Care and maintenance

5. Check oil level with shift er

6. Check/clear fault codes

7. Prognostics

The operator of this vehicle must read and follow the

instructions in the Allison Operator’s Manual. Failure to

do so may lead to serious vehicle damage or personal

injury.

The forward t o reverse shif ts of the tran smissi on are co ntrol led

by the ECM.

Parking with an Automatic Transmission

The Allison transmission does not have a PARK position like

an automobile transmission. For information on how to

properly park your Kalmar tractor, see the following sections in

this manual:

32

Page 37, Parking the Vehicle

Page 37, Parking Brake

Axles

Kalmar tractors may be ordered with a variety of axle

configurations, makes and models. It is important to refer to

the axle manufacturer’s information for your specific axle. You

can obtain axle operation and maintenance information from

3 Description and Operation

NOTICE

your local Kalmar dealer. The following is general axle

information and may not apply to your particular axle.

This manual does not contain complete operational

information on any axle. The operator must obtain and refer

to the axle manufacturer’s information on operation, service

and maintenance.

Axle Operating Temperature

Normally, axle operating temperatures will not exceed more

than 100°F (37°C) above ambient temperature. Operating

temperatures above 230°F (110°C) significantly increase the

rate of lubricant oxidation and shorten the effective life of the

lubricant. This makes more frequent changes necessary.

Rear Axles with Locking Differentials

Kalmar tractors may be equipped with a variety of special axle

and differential combinations. Because of the affect of special

differentials on vehicle operation, it is important to understand

how your particular differential operates. Locking or limited slip

differentials are not standard on Kalmar tractors. If you do not

know if your vehicle is equipped with a special axle and

differential, contact your Kalmar dealer.

“No Spin” Positive Locking Differential

Kalmar tractors may be equipped with an optional “No Spin”

differential. This locking differential has very special operating

characteristics. IT IS VERY IMPORTANT FOR THE

OPERATOR OF A VEHICLE EQUIPPED WITH THIS

FEATURE TO OBTAIN AND FOLLOW ALL OF THE

OPERATION AND MAINTENANCE INFORMATION

PROVIDED BY THE DIFFERENTIAL MANUFACTURER.

Contact your Kalmar dealer for assistance on operating and

maintaining this differential.

3.2.4 Air System and Brakes

Brakes must be kept in proper working condition.

Operating a vehicle with poorly maintained brakes or worn

out brakes can cause a loss of vehicle control. This may

lead to serious injury or death. Never operate the vehicle

unless the brakes are working properly.

Do not allow moisture to collect in the air tanks. The air

tanks must be drained daily. Failure to drain the air tanks

can damage the air brake system and lead to injury.

33

Figure 18

B A

A — Accelerator Pedal

B — Brake Treadle/Pedal

3 Description and Operation

Kalmar tractors come equipped with a pneumatic (air) brake

system. This system has two basic parts: the service brakes

and the spring parking brakes.

The service brakes are the part of the system that the driver

uses when he operates the foot-operated treadle valve (or foot

pedal) in the cab (Figure 18).

The service brakes are the primary brakes used by the

operator. The service brakes require air to operate. If there is