Page 1

Page 2

1

KALMAR

OPERATOR’S MANUAL

Section Title Page Prefix

OWNER INFORMATION..................................................4

OPERATION....................................................................12

MAINTENANCE..............................................................40

NOTE

The information in this manual was current at the time of publication. Contents of

this manual are subject to change at publishers discretion.

DO NOT REMOVE THIS MANUAL FROM THE VEHICLE. STUDY THIS MANUAL. READ

AND COMPLY WITH ALL WARNINGS IN THIS MANUAL. IF THE VEHICLE IS SOLD,

GIVE THIS MANUAL TO THE NEW OWNER.

Kalmar Industries Corp.

415 East Dundee Street

Ottawa, Kansas USA

(785) 242-2200

Fax (785) 242-6177

Page 3

2

FROM KALMAR

TO THE OWNER:

The manufacturer of these trucks cannot create a single

manual that would cover every option available.

We have tried to cover all the information that would be

included in a normally configured truck.

For information on some major components you will need

to refer to the manufacturer’s literature.

Page 4

3

CONTENTS

Section “A”

INTRODUCTION ...............................................................................................4

CAUTIONS AND WARNINGS ............................................................................4

NOTES ................................................................................................................4

SERVICE ASSISTANCE .........................................................................................4

VEHICLE MODIFICATIONS ................................................................................5

SAFETY CHECKS AND PRECAUTIONS ...............................................................5

Axle - Front ...................................................................................................6

Axle -Rear ....................................................................................................6

Brake System .........................................................................................6

Cab ........................................................................................................6

Electrical ................................................................................................7

Exhaust System ......................................................................................7

Frame .....................................................................................................7

Fuel System ............................................................................................7

Propeller Shaft ..........................................................................................7

Steering ..................................................................................................7

Suspension .............................................................................................7

Transmission ...........................................................................................8

Wheels ...................................................................................................8

ADDITIONAL MANUALS AND SAFETY INFORMATION ....................................8

SAMPLE PRE-OPERATION SAFETY CHECKLIST ..................................................9

VEHICLE WARRANTY .......................................................................................10

Owner Information

Page 5

4

CAUTIONS &

WARNINGS

Throughout this manual you will find

Warnings and Cautions:

DANGER - Warning will

indicate a potentially

hazardous situation that

could lead to serious injury

of death.

WARNING - Failure of the

operator of this vehicle to

read and be aware of all the

warnings published in this

manual may lead to serious injury

or death. READ THIS MANUAL!

CAUTION - Cautions will

indicate procedures or

situations that could result

in vehicle and/or property

damage.

NOTES

NOTE — Throughout this manual you will see

notes. Notes will be used to show special

procedures or point out important facts. Notes

will also designate important information

regarding this manual and its use.

SERVICE

ASSISTANCE

Kalmar Industries Corp. has an established

dealer network throughout the country.

Whenever assistance is needed contact

local dealer first. For the number of your

nearest dealer visit our web site at www.

kalmarind-northamerica.com or contact

Kalmar sales.

INTRODUCTION

The intention of this section is to provide

basic information on the safe operation of

the Kalmar tractor.

The first section, “To The Operator”, con-

tains important information on the use of

Warnings, Cautions, and Notes that are

found throughout this manual. This section also contains important safety and

service support information.

The second section, “Operation”, covers

basic safety and operating information on

the tractor itself.

The third section, “Maintenance”, covers

basic operator maintenance and lubrication information.

Remember that the safe operation of the

Kalmar tractor depends entirely on the

operator. The operator of this vehicle must

be properly trained and fully knowledgeable BEFORE attempting to operate it.

Read this manual carefully and pay close

attention to all warnings, cautions and

notes. Keep this manual in the vehicle

and make sure it goes to the new owner

if the truck is sold.

NOTE — Because of the many variations and

options associated with the Kalmar tractors,

some optional equipment on your vehicle may

not be covered in this manual. If there are any

questions regarding the specific options or

variations not covered in this manual, contact

your nearest Kalmar dealer for assistance.

NOTE — The Kalmar tractor may also be

referred to throughout this manual as “vehicle”

“the vehicle”. Throughout this manual

reference is made to “Operator”. In the context

of this manual the “Operator” refers to the

actual driver of the vehicle.

Owner Information

Page 6

5

Owner Information

SAFETY-CHECKS

AND

PRECAUTIONS

All spotting applications are demanding

on the vehicle. Maintenance is critical for

the continued SAFE performance of your

tractor. Before operating your Kalmar it is

extremely important that the vehicle is in

proper and safe working condition.

The following section is intended to

provide a basic knowledge of important

safety check procedures and what to look

for. These checks must be performed regularly to ensure safe vehicle operation. The

frequency of these checks depends on the

application of the vehicle.

In general, the best time to make the following safety checks would be during

normal maintenance and during daily

Pre-Operation Safety Inspections.

Kalmar Industries Corp. highly recommends that all operators complete a

Pre-Operation Safety Inspection before

climbing into the drivers seat. This “WalkAround” is a good way to prevent potential problems. A sample “Pre-Operation

Safety Checklist is provided on page A-6

of this section. Use this as a guide to come

up with an appropriate checklist for your

individual vehicle.

During each scheduled maintenance

interval or at least once a month, a qualified mechanic should inspect all of the

following areas:

NOTE - If the vehicle is used in a severe

application, such as a rail yard operation or in

24 hour operations, a more frequent schedule

may be required.

When parts or service are required always

have the serial number of the vehicle

ready before contacting your Kalmar

dealer. The serial number is located on

an ID plate inside of the cab.

Kalmar is proud to have been the leader in

the Port and Terminal Tractor Industry for

over 40 years. We strive to serve our customers in every way possible. Thank you

for buying our Kalmar tractor. We know it

will serve you well for many years.

If, for any reason, you are not able to

obtain assistance from any Kalmar dealer,

feel free to contact Kalmar Industries Corp.

directly.

For Assistance Call:

Kalmar Industries Corp.

Service Department

785-242-2200

VEHICLE

MODIFICATIONS

Do not make modifications to your tractor without written approval from Kalmar

Industries Corp.. Your vehicle has been

designed and manufactured with safety

and reliability in mind. Any modifications

by the operator or owner could decrease

the safety and reliability of your vehicle.

Any unauthorized vehicle modifications

may also void the Kalmar Industries Corp.

Limited Warranty. Do not risk personal

safety or vehicle reliability by making unauthorized modifications to your Kalmar

tractor. Contact Kalmar concerning any

proposed modifications to this vehicle.

SAFETY-CHEC

KS AND

Page 7

6

Owner Information

AXLE-FRONT

Maintaining correct front axle alignment

is critical and should be performed by a

qualified mechanic.

Check to ensure that the axle mounting

bolts are securely tightened. Regularly

check the front axle for damage, binding

or worn parts, and adequate lubrication.

Pay special attention to the axle stops

and rubber snubbers. Do not operate the

vehicle without the proper axle stops in

place.

AXLE - REAR

Check to ensure that the axle mounting

bolts are securely tightened. Regularly

check the rear axle for damage and oil

leaks. Unusual noises and signs of extreme

heat may indicate axle damage.

BRAKE SYSTEM

Check the following:

1. Check brake controls for proper operation. Make sure the foot operated treadle

in the cab is operating smoothly and is

not damaged.

2. Visually inspect the brake drums, brake

chambers, and slack adjusters. Check for

loose, missing or broken components.

Check brake chambers and slack adjusters

for cracks and other signs of sever wear.

3. Listen for air leaks in the cab and underneath the chassis. Check air pressure

regularly using the dash mounted gauge.

Be alert for any sudden drops in pressure

while operating the vehicle and after the

engine is shut off. A minimum air pressure

of 70 PSI is required to operate

this vehicle.

4. Visually check hoses and pneumatic

lines for damage and chaffing.

5. Check the operation of both the service

and parking brake systems. Be alert for

any reduction in braking performance or

unusual noises while braking.

CAB

Defroster - Operate the defroster to make

sure sufficient air is being directed against

the windshield. Make sure the blower is

operating before the weather requires the

defroster.

Door Latches - Check for positive closing,

latching and locking.

Walkways/Side Step - Check to ensure

that all factory installed walkways, platforms and steps are installed on vehicle

securely and are not damaged or loose.

Handholds/Grab Handles - Check to ensure all handholds are installed and are

not loose or damaged.

Glass - Check for cracked, broken,

scratched or dirty glass.

Cleaning instructions for optional plastic glazing - Wash window with a clean

sponge or soft cloth using lukewarm water

and mild detergent or window cleaner.

Rinse with clean water. Do not use

abrasive highly alkaline cleaners. Never

scrape with squeegees, razor blades, or

other sharp instruments. Remove ice and

frost with the cab heater/defroster or by

applying heat.

Mirrors - Check to be certain all mirrors

are installed and that they are clean, un-

Page 8

7

Owner Information

Seat Belts - Check entire seat belt system

for wear and proper operation. Make sure

anchor mountings are tight.

ELECTRICAL

Horn - Operate steering wheel mounted

horn to check operation. (Check optional

air horns if equipped)

Instruments - Check operation of all instruments and gauges.

Lights - Check to make sure all lights

(interior, exterior, headlights, etc.) function properly. Make sure gauge and dash

backlighting is working properly.

Wiring - Check to ensure all wiring is

properly secured and protected. Replace

worn, cracked or chaffed wires and looms.

Make sure factory wiring has not been

compromised by improper splicing or

modifications.

FRAME

Check for cracks and signs of damage. Pay

close attention to highly stressed areas of

the frame such as the boom pivot area.

Contact your dealer for instructions on

frame repair. Do not weld on frame rails

unless directed to do so by your Kalmar

dealer or by the factory.

FUEL SYSTEM

Frequently check throttle linkage for signs

of binding and wear. Throttle should

operate smooth and with minimal effort.

Always replace damaged throttle components with factory replacement parts.

PROPELLER SHAFT

Check universal joints for wear. If propeller shaft vibrations occur, stop the vehicle

immediately to prevent serious damage to

the vehicle drivetrain.

STEERING

Be alert to any change or feel in steering

while driving the vehicle. This change or

feel may include a change in steering effort, unusual sounds when turning, excessive wheel play or pulling to either side.

If a problem is suspected or felt, check

steering components for loose, damaged

or worn parts. All steering components

such as the tie rod and drag link must

be tight.

Check power steering system for leaks and

hose chaffing. Repair any problems before

operating the vehicle. Regularly inspect all

steering linkages.

WARNING - If any of the

above are evident have the

vehicle repaired by a quali-

fied steering technician. Do

not operate this vehicle with broken, damaged, worn, or non OEM

steering system components.

SUSPENSION

Check condition of front and optional rear

(if installed) suspension components such

as mounting brackets and bushings. Check

for worn and damaged parts.

Check and maintain the specified torque

Page 9

8

Owner Information

on all mounting bolts and nuts. Check

springs and replace broken or distorted

springs.

TRANSMISSION

Follow transmission manufacturer’s guidelines for proper maintenance.

WHEELS

Check condition and maintain specified

torque on all wheel mounting nuts. Replace missing or broken studs and nuts.

Check tire inflation and wear. Do not

operate this vehicle with badly worn or

damaged tires.

NOTE - Because of the many options available

on Kalmar tractors, it is critical that the owner

be aware of all options that may affect the safe

operation of the vehicle and take appropriate

measures to maintain his/her specific vehicle.

Always contact your Kalmar dealer if any

questions arise regarding safe operation of this

vehicle.

ADDITIONAL

MANUALS

AND SAFETY

INFORMATION

“OTTO Shows and Tells” booklet

Do not forget to read your safety booklet

that is provided with your Kalmar tractor.

This little manual is filled with important

operating tips. “OTTO” makes important procedures easy to remember with

pictures and simple explanations. If you

did not receive your “OTTO Shows and

Tells” booklet, contact your dealer for a

copy or contact Kalmar Industries Corp.

directly.

Operator Orientation Video

Kalmar Industries Corp. offers an Operator

Orientation Video CD. This video covers

important information that all Kalmar

operators must know. The video should be

used in conjunction with the “Otto Shows

and Tells” booklet and this manual to

instruct the operator on the proper operation of the Kalmar tractor. Shipped with

every truck, this video is also available

through your Kalmar dealer or directly

from Kalmar Industries Corp..

Page 10

9

SAMPLE PRE-OPERATION CHECKLIST

(Walk Around Inspection)

________ Check tires for damage and proper inflation

________ Check cab hold down latch (air suspension unit) for proper latching

________ Check all fluid levels: engine oil, hydraulic, and coolant

________ Drain any moisture from air tanks

________ Check cab doors and latches for proper operation

________ Ensure that all steps, walkways and handholds are installed and in good

working order

________ Start engine and check transmission fluid level with parking brake

applied and transmission shift selector in “neutral”

________ Check windshield wiper for proper operation

________ Check steering system for any binding. Make sure steering effort is

smooth and light

________ Check accelerator for proper operation. Should operate smoothly and

without any binding.

________ Check all rear view mirrors, adjust and clean if needed

________ Check cab and frame for any structural damage or cracks

________ Inspect trailer electrical cable and trailer air lines for damage. Make sure

both air lines are installed

________ Clean all windows if needed

________ Check transmission shift lever for any binding

________ Check boom control lever for proper operation

________ Check all lights for proper operation: headlights, turn signals, brake

lights, hazard lights, and marker lights

________ Check horn(s) for proper operation

________ Check and fill fuel tank

Page 11

10

Kalmar Terminal Tractor

North American Warranty Policy

KALMAR INDUSTRIES CORP (hereafter KALMAR) warrants to the original

owner that each new KALMAR Terminal Tractor will be free from defects in

material or workmanship under normal use and service for a period not to

exceed Three Hundred Sixty Five (365) days or Three Thousand (3,000) hours,

whichever occurs first, from commencement of service. The first 182 days or

1,500 hours both labor and parts will be warranted. The remaining 183 days

or 1,500 hours parts only will be warranted.

In addition, KALMAR warrants, to the original owner and in only the original

approved application, that each new KALMAR Terminal Tractor mainframe

will be free from defects in material or workmanship for a period of seven (7)

years. This extended frame warranty applies if, and only if: a) the tractor is

being used by the original owner; b) the failure cannot be attributed to lack

of routine maintenance; c) the tractor has not been involved in an accident;

d) the tractor is being used in the original KALMAR Terminal Tractor approved

application; e) the tractor has not been used in an application where the requirements of which are greater than the specification published at the time

of manufacture; f) the tractor frame has not been modified by welding on,

cutting into or drilling into the original structure.

The repair or replacement of defective parts or workmanship under the terms

of this warranty will be made by KALMAR or KALMAR Terminal Tractor

authorized Parts and Service Dealer, without charge for parts or labor, if

the defect occurs within the first 182 days of service and if the prepaid

returned parts are judged by KALMAR to be faulty or defective. If the defect occurs between 183 and 365 days of service KALMAR or KALMAR

Terminal Tractor authorized Parts and Service Dealer will repair or replace

parts only and will not reimburse for any labor charges. KALMAR will

not honor invoices for parts purchased from outside sources, unless written authorization is first given by the KALMAR Terminal Tractor Service

Department. Further, KALMAR will not honor invoices for labor charges,

unless the rate per hour charged and the number of hours involved are first

authorized by KALMAR.

THE OBLIGATION OF KALMAR UNDER THIS WARRANTY IS LIMITED

SOLELY AND EXCLUSIVELY TO REPAIRING OR REPLACING, AS KALMAR

MAY ELECT, ANY PART OR PARTS WHICH ARE RETURNED TO US, TRANSPORTATION PREPAID, AND WHICH, UPON EXAMINATION, ARE DETERMINED BY KALMAR OR THE SUPPLIER TO BE DEFECTIVE IN MATERIAL

AND/OR WORKMANSHIP. IN NO EVENT, SHALL KALMAR BE LIABLE FOR

ANY SPECIAL OR CONSEQUENTIAL DAMAGES.

Page 12

11

Excluded from this warranty are engines, Transmissions, Tires and batteries or

ant other components which have warranties covered by their manufactures.

The provisions of this warranty do not apply to the prime product or any component part thereof, which has been subject to misuse, or damaged through

negligence or accident, or has been repaired or altered by anyone other than

KALMAR or KALMAR Terminal Tractor authorized Parts and Service dealer.

Further excluded, are such parts as filters, belts, brake linings, lights, breakers,

and lubricants which are part of normal maintenance service replacements. The

KALMAR warranty does not cover towing charges or rental replacements.

A Warranty Registration form is mailed for every tractor. It is the obligation of

the purchaser to complete and sign the Warranty Registration form and return

it to KALMAR Terminal Tractor within 30 days after receipt of the tractor.

THIS WARRANTY IS A LIMITED WARRANTY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, OF ANY KIND OR

NATURE WHATSOEVER.

KALMAR reserves the right, at any time, to make changes in the design, material, and/or specification of this product, or accessories thereof, without thereby

becoming liable to make similar changes in such equipment or accessories

previously manufactured.

KALMAR INDUSTRIES CORP.

415 East Dundee Street

Ottawa, Kansas 66067 USA

785 242 2200

Page 13

12

CONTENTS

Section “B”

INTRODUCTION ...............................................................................................14

VEHICLE ENTRY AND EXIT ................................................................................14

OCCUPANT RESTRAINT SYSTEM ....................................................................14

Seat Belt Operation ..............................................................................15

Suspension Type Seats ...........................................................................15

Seat Adjustment .................................................................................... 15

INSTRUMENT PANELS AND CONTROLS ........................................................16

Control and Display Location ...............................................................17

Control and Display Description ..........................................................18

STARTING THE VEHICLE ...............................................................................22

Ignition Switches ................................................................................22

Key Type Ignition ................................................................. .. 22

Push Button Starter ...............................................................22

PARKING THE VEHICLE ................................................................................ 23

AIR BRAKE SYSTEM ............................................................................... 23

Low Air Pressure Indicators .......................................................... .......24

Service Brakes ....................................................................................... 24

ABS .....................................................................................................25

Traction Control ..................................................................................26

PARKING BRAKE ............................................................................................26

Parking Brake and Trailer Air Supply Controls .....................................26

MANUALLY RELEASING TRACTOR SPRING BRAKES (CAGING) ..................... 26

TRAILER BRAKES .............................................................................................28

Trailer Air Lines ....................................................................................28

Operation

Page 14

13

ENGINE .........................................................................................................28

Starting the Engine ................................................................................29

Starting Procedure ......................................................... .. 29

Engine Shut Down ..............................................................................30

Shut Down Procedure .........................................................30

Engine Oil ............................................................................30

TRANSMISSION ...........................................................................................30

Parking with an Automatic Transmission .............................................31

HYDRAULIC FIFTH WHEEL LIFTING SYSTEM ..............................................31

Hydraulic Boom Operation ...............................................................31

Fifth Wheel Unlatch Control Valve .....................................................32

BASIC TRAILER SPOTTING STEPS ................................................................32

TOWING THE VEHICLE ...................................................................................34

Towing vehicle with front wheels suspended .....................................34

Towing vehicle with rear wheels suspended .......................................35

AXLES .............................................................................................................35

Axle operating temperature .................................................................35

Rear axles with locking or limited slip differentials ............................35

CAB TILTING AND LOWERING .....................................................................36

To tilt cab ............................................................................................ 36

To lower cab ........................................................................................37

ELECTRICAL ...................................................................................................38

Accessory connections ........................................................................38

Breakers, Relays and Fuses .................................................................. 38

Operation

Page 15

14

VEHICLE ENTRY

AND EXIT

The Kalmar tractor is designed for easy

entry and exit. The walkways, steps, and

handholds are designed with operator

safety in mind. As with any vehicle of this

type, care must be taken when climbing in

or out of your Kalmar tractor. Remember,

be careful!

WARNING - Never remove

factory installed walkways,

steps or handholds. Do

not operate your Kalmarunless all of the factory installed

steps, walkways and handholds

are installed and in good working

condition.

WARNING - Failure to

exercise caution when

entering and exiting this

vehicle can result in

personal injury.

1. Entry and exit should be made

slowly and carefully

2. A three-point stance should be

used. Three out of the four extremities (hands and feet) should be

in contact with the vehicle at all

times.

3. Face inward toward steps when

entering and exiting.

4. Keep steps, walkways and handholds in good condition.

5. Keep steps, handholds, walkways and shoes free of grease,

mud, dirt, fuel, ice and snow.

6. Use extra care during bad

weather, especially when steps and

handholds may be icy or wet.

INTRODUCTION

The following section on OPERATION

should be read carefully. It covers important information that every operator

must know before operating any Kalmar

tractor.

This manual is intended to cover the standard Kalmar tractor and some of the most

common options. Not all of the customer

ordered optional equipment or systems

are covered in this manual. If the operation of any component or system on your

vehicle is not covered in this manual, call

your Kalmar dealer for assistance.

CAUTION - Kalmar Industries Corp. highly recom-

mends that all individuals

that operate this vehicle have a

valid drivers license and have sufficient training to operate this type of

vehicle. Although most Kalmar tractors are not sold as highway legal

vehicles, this does not mean they

are intended to be operated by

untrained personnel. This manual is

not intended to be a training guide

for Yard Tractor operators. It is the

operator’s responsibility to obtain

sufficient training in order to operate this vehicle safely. DO NOT ATTEMPT TO OPERATE THIS VEHICLE

WITHOUT ADEQUATE TRAINING.

Operation

Page 16

15

OCCUPANT

RESTRAINT SYSTEM

THE KALMAR TRACTOR IS EQUIPPED

WITH SEAT BELTS. THEY SHOULD BE

USED WHENEVER THE VEHICLE IS IN

OPERATION.

SEAT BELT OPERATION

The seat belt system used on Kalmar

tractors is a lap type restraint with an

automatic retractor.

Before fastening the seat belt, be sure to

adjust the seat to a comfortable driving

position. To fasten the belt, pull the belt

low across the hips and insert the tongue

into the buckle.

To release the seat belt, press the button

on the buckle and the belt will retract

automatically.

SUSPENSION TYPE SEATS

All Kalmar tractors have a suspension type

seats as standard equipment.

WARNING—Due to the

vertical travel of suspension

seats, the operator must in-

sure that there is adequate

head clearance when the seat is at

the top of its upward travel.

Operation

SEAT ADJUSTMENT

Refer to seat manufacturer’s information

packet provided with the vehicle or to

the decal located on the seat base. Your

local Kalmar dealer can assist with any

questions.

Adjust the seat to the comfortable position

for the operator to have full control of all

cab controls and displays. This position is

obtained by changing the air pressure in

the suspension, which changes the height.

The fore and aft position is obtained by

moving the seat cushion and back on its

slides. Once this position is achieved,

tighten the seat belt tether securely on

both sides. The tether will restrain the seat

from raising above this position. Now,

the seat air suspension may be adjusted

to operator’s desired firmness.

WARNING - Do not adjust

drivers seat unless vehicle

is parked. The seat could

move suddenly and unexpectedly and cause loss of control

of the vehicle.

WARNING - The Kalmar tractor is designed

and equipped to carry

only the driver (unless built with a 2 man cab).

Never allow anyone to ride

anywhere inside or outside of

the cab. Carrying a passenger

is extremely dangerous and

can result in serious injury or

death. NEVER CARRY PASSENGERS WITH YOUR KALMAR.

Page 17

16

Operation

Page 18

17

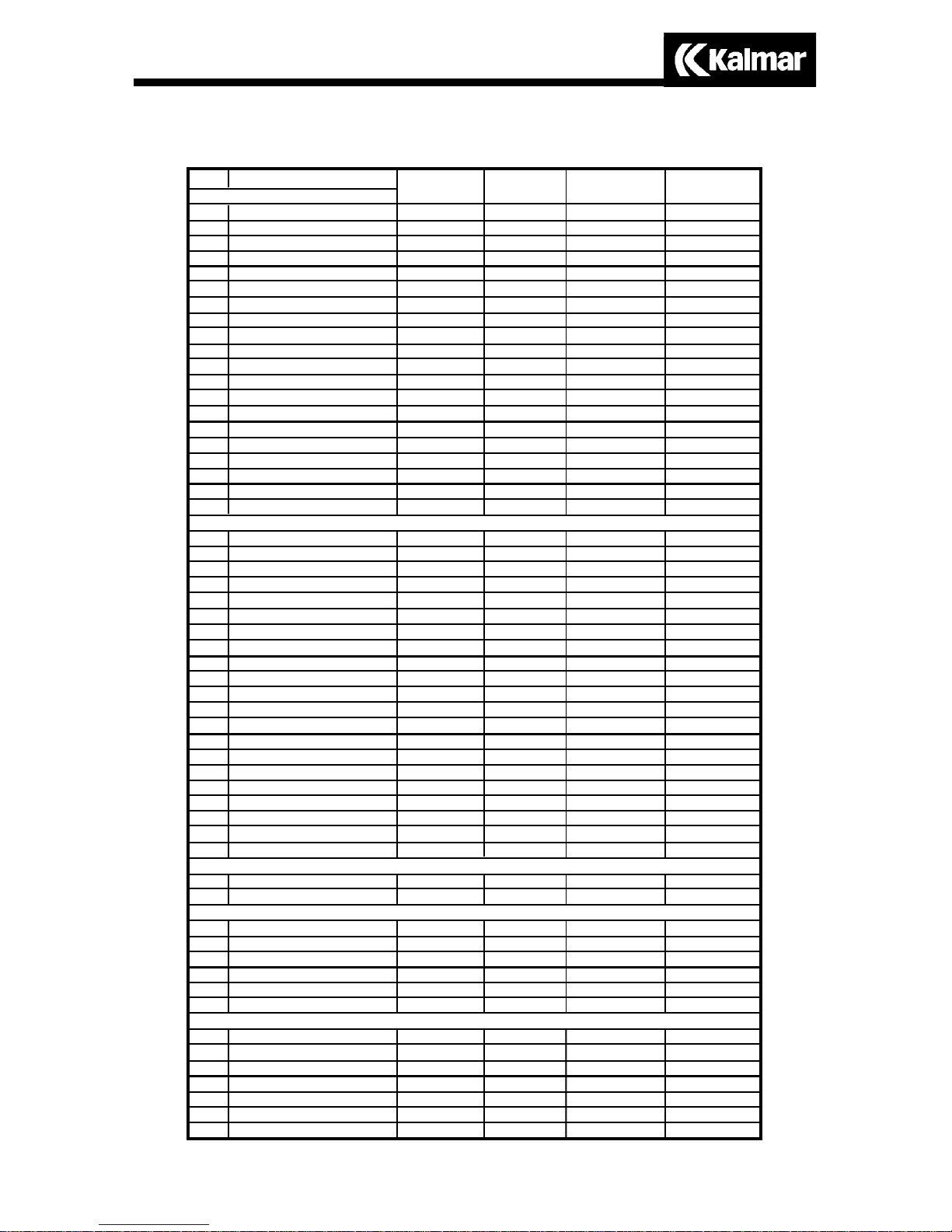

POS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42-52

53

54

55

56

57

58

59

60

61

62

63

65

66

NAME

WATER TEMP GAUGE

TACHOMETER

OIL PRESSURE GAUGE

SPEEDOMETER

FUEL GAUGE

AIR DIFFUSER

HEADLIGHT SWITCH

PANEL LTS DIMMER

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

INDICATOR LIGHT

STOP ENGINE IND LIGHT

INDICATOR LIGHT

LH TURN SIGNAL IND LT

VOLT METER

HOUR METER

A/C SWITCH

WASHER SWITCH

BEACON LT SWITCH

OPTIONAL SWITCH

FLOOD LIGHT SWITCH

ETHER START

IGNITION SWITCH

PUSH BUTTON START

HEATER CONTROLS

HEATER CONTROLS

HEATER CONTROLS

HI BEAM INDICATOR LT

RH TURN SIGNAL IND LT

INDICATOR LIGHT

HEATER FAN CONTROL

INDICATOR LIGHT

TRANS TEMP IND LIGHT

BRAKE AIR INDICATOR LT

WIPER SWITCH

GAUGE

STANDARD AIR GAUGE

2nd AIR GAUGE

TRACTOR PARK CONTROL

GAUGE

TRAILER PARK CONTROL

GAUGE

SHIFTER CONTROL

5th WHEEL CONTROL

5th WHEEL LATCH

DOLLY MASTER

LOAD GAUGE

INTER AXLE DIFF LOCK

DIFFERENTIAL LOCK

STD

OFF HWY

s

a

s

a

s

s

s

a

n

u

n

u

n

u

n

u

n

s

n

s

s

s

a

a

a

u

s

a

s

a

s

s

s

s

s

u

s

u

s

s

s

u

s

a

s

u

s

u

a

s

s

a

a

a

a

CUMMINGS

ISB/ISC

s

a

s

s

s

s

s

s

u

s

u

s

u

s

u

s

u

s

u

s

s

s

a

a

a

u

s

a

s

a

s

s

s

s

s

u

s

u

s

s

s

u

s

a

s

u

s

u

a

s

s

a

a

a

a

CATERPILLAR

3126

s

a

s

s

s

s

s

s

u

u

u

s

u

s

u

s

u

s

u

s

s

s

a

a

a

u

s

a

s

a

s

s

s

s

s

u

s

u

s

s

s

u

s

a

s

u

s

u

a

s

s

a

a

a

a

DETROIT

DIESEL S40 E

s

a

s

s

s

s

s

s

u

u

u

s

u

u

u

s

u

s

u

s

s

s

a

a

a

u

s

a

s

a

s

s

s

s

s

u

s

u

s

s

s

u

s

a

s

u

s

u

a

s

s

a

a

a

a

s=standard a=assigned options

u=unassigned options n=not available

Operation

Page 19

18

Ignition Switch ..........................17

Indicator Light Strip...................20

Optional Gauges.......................17

Optional Controls.....................17

Optional Switches.....................17

Parking Brake Control................21

Speedometer (optional).............20

Tachometer (optional)................20

Trailer Air Supply Control..........21

Transmission Shift Selector........21

Warning Light...........................20

Turn Signal Control...................21

Voltmeter..................................19

Windshield Wiper Control.........17

Windshield Washer...................17

Air-conditioner Switch ..............20

Air Pressure Gauge...................21

Beacon Switch (optional)..........17

Boom Control Lever..................21

Coolant Temperature Gauge......19

Engine Oil Pressure Gauge.......19

Emergency 4 Way Flasher.........21

Fan Control (heater/air-conditioner) 20

Fifth Wheel Unlatch Control.....21

Floodlight Switch......................20

Fuel Gauge...............................19

Headlight Control Switch..........19

Heater Controls........................20

High Beam Indicator.................20

High Beam Switch....................21

Hour Meter...............................19

CONTROL AND DISPLAY DESCRIPTION

Transmission Temp.

Operation

Page 20

19

PANELS 1 and 2

1. Dash Panel Light Dimmer

2. Headlight/Running Light Control

This switch controls headlights and running lights on the tractor and trailer. This

switch also activates the interior dash and

gauge lights when either the headlights or

the running lights are on. The switch has

three positions.

3. Fuel Gauge

Indicates the level of fuel in the fuel tank

in 1/4 increments.

4. Engine Oil Pressure Gauge

Indicates the engine oil pressure in P.S.I.

5. Coolant Temperature Gauge

Indicates the temperature of the engine

coolant in degrees Fahrenheit.

6. Voltmeter (Ammeter Optional)

Indicates the status of the charging system

in volts. If the engine is running the gauge

indicates the alternator output voltage. If

the engine is not running the voltmeter indicates the output voltage of the battery.

7. Hour Meter

Indicates engine operating hours.

Operation

Page 21

20

8. Heater Control

This lever controls the heater temperature.

The full down position shuts off the heater.

The lever can be adjusted to provide the

desired amount of heat by moving it up

from the OFF position.

9. Fan Speed ON/OFF Switch

The switch has four positions. Full counterclockwise is the OFF position.

10. Windshield Wiper Control

This control operates the windshield

wiper. Turning the control clockwise increases the speed of the wiper. Turning

the control counterclockwise completely

will park the wiper.

11. Floodlight Control

Activates a normally rear facing flood

light. The switch is two position, up (ON)

and down (OFF).

12. Air-conditioner Switch (Optional)

This switch activates the air-conditioning

compressor when the optional air-conditioning is installed.

13. Tachometer (Optional)

Indicates engine R.P.M.

14. Speedometer (Optional)

Indicates vehicle speed in M.P.H. or K.P.H.

This gauge may also come with an odometer feature built in.

15. Heater/Air-Conditioner Duct

Directional and closeable duct for the

heater and air-conditioner.

Indicator Light Strip

The indicator lights are located along the

top of dash panels 1 and 2. These panels

contain the 5 STANDARD indicators and

any optional indicators. The 5 standard

indicators are listed below:

1. Left Turn Signal Indicator

(green arrow) Indicates left hand turn

signal is on when flashing.

2. Right Turn Signal Indicator

(green arrow) Indicates right hand turn

signal is on when flashing.

3. High Beam Indicator

(blue light symbol) Indicates high beams

are on when illuminated.

4. High Transmission Temperature

(trans temp) Indicates transmission fluid

temperature is above 300° F. when

illuminated.

5. Low Air Pressure

(brake air) Indicates system air pressure is

below 70 P.S.I. when illuminated.

Operation

Page 22

21

1. Standard Air Gauge

Indicates air pressure in the air system

in P.S.I.

2. 2nd Air Gauge

Indicates air pressure in the air system

in P.S.I.

3. Transmission Shift Selector

This control selects the operating range

of the transmission. (See page 30, Transmission)

4. Boom Control Lever

This control operates the hydraulic boom

and fifth wheel. (See page 31, Hydraulic

Boom Operation)

5. Fifth Wheel Unlatch Control

This control engages the fifth wheel jaw

locking mechanism. (See page 32, Fifth

Wheel Unlatch Control)

6. Parking Brake Control

This control operates the parking brakes

on the vehicle and trailer. (See page 26,

Parking Brakes)

7. Trailer Air Supply

This control activates the trailer air supply.

(See page 26, Parking Brake and Trailer

Air Supply)

Figure 1

A High Beam Switch

B Turn Signal Lever

C Emergency Flasher Switch

The column mounted control on the

Kalmar tractor has three functions. It is

located on the left hand side of the steering column (Fig. 1).

1. Moving the lever (Fig. 1, B)

forward activates the right turn signal.

Moving the lever to the rear activates the

left turn signal. The turn signal is not self

canceling and must be returned to the

center (off) position manually after it is

engaged. The green arrows on the dash

panel light up and flash when the switch

is activated.

2. The button on the end of the lever

operates the high beam lights (Fig. 1, A).

The headlights must be on for the switch

to work. When the high beam headlights

are on, the high beam indicator on the

dash will light up.

3. The pull out switch under the

lever activates the emergency flashers

(Fig. 1, C). Pulling out on the switch

turns the flashers on. To turn the flashers

off, move the turn signal lever forward or

backwards.

PANELS 4 and 5

TURN SIGNAL, HIGH BEAM AND

EMERGENCY FLASHER CONTROL

Operation

Page 23

22

KEY TYPE IGNITION

There are three positions; OFF, ACCESSORY and RUN/START. The full left

(counterclockwise) position is the OFF

position. The second position to the right

(clockwise) is the ACCESSORY position.

The third position to the right (clockwise)

is the RUN/START position.

The RUN/START position is used to engage the starter motor. Moving the switch

to the full right position engages the starter

and upon release of the key, the switch

automatically stays in the RUN position.

The ACCESSORY position activates the

tractor’s electrical accessory circuit.

The OFF position cuts all power to the

electrical system and shuts down the

engine.

NOTE - The Off position on the standard three

position key type switch is designed to function

as the engine stop. There is no other engine

stop device other than the ignition switch on

the standard Kalmar tractor.

PUSH BUTTON STARTER

Push button starters are optional on Kalmar tractors. There are two basic types of

toggle ignition switches, three position

and two position.

The three position type functions like the

standard key type with OFF, ACCESSORY

and RUN positions. The button engages

the starter when the switch is in the RUN

position only.

The two position switch has only the OFF

and RUN positions. It has no provision for

and ACCESSORY position. The button engages the starter in the RUN position only.

DRIVER CONTROLLED

DIFFERENTIAL LOCK

(Optional on drive axles)

Drive axles may be equipped with a driver

controlled differential lock. This is an air

actuated traction device that can be

manually controlled inside the cab by the

operator. By actuating a dash mounted

control, the operator can lock or unlock

the differential.

NOTE: When this differential is fully locked the

vehicle will have reduced steering capability.

The driver must limit the use of the differential

to slow speeds. Also, the differential must

not be engaged when traveling down steep

grades when traction is limited. Refer to axle

manufacturer for operational & maintenance

procedures.

STARTING THE

VEHICLE

(See page 29, Starting The Engine)

IGNITION SWITCHES

The standard ignition switch on the

Kalmar tractor is a key type, similar to the

kind found on automobiles. Push button

and other types of ignition switches are

installed as optional equipment.

Operation

Page 24

23

ing it in gear. Always place the

transmission shifter selector in the

“Neutral” position.

3. Never park a tractor trailer combination unless the trailer parking

brakes are operational and applied.

NOTE - If the vehicle is parked in gear, the

vehicle will not start.

AIR BRAKE SYSTEM

DANGER - Brakes must

be kept in proper working condition. Operating a

vehicle with poorly maintained, brakes or worn out brakes

can cause a loss of vehicle control.

This may lead to serious injury or

death. Never operate the vehicle

unless the brakes are working

properly.

CAUTION - Do not allow

moisture to collect in the

air tanks. The air tanks must

be drained daily. Failure to

drain the air tanks can damage the

air brake system.

Kalmar tractors come equipped with

pneumatic (air) brake systems. This system

has two basic parts, the service brakes,

and the spring parking brakes.

The service brakes are the part of the system that the driver uses when he operates

the foot operated treadle valve (or foot

pedal) in the cab (Fig.1 page 24).

CAUTION - If the engine

does not start within 30

seconds, release the starter

switch and wait 3 minutes to allow

the starter motor to cool. If after 3

repeated attempts, the engine still

fails to start, stop and determine

the cause. The starter motor may be

damaged by repeated attempts to

start the engine.

NOTE - Some vehicles may be equipped with

optional shut down systems or optional starter

switches. Contact your Kalmar dealer if you

have any questions regarding the operation

of any optional starter switches or shut down

systems.

PARKING THE

VEHICLE

(See page 30, Transmission)

(See page 26, Parking Brake)

Standard Kalmar tractors are equipped

with an Allison automatic transmission

and spring operated parking brakes. Allison transmissions are unlike an automobile transmission in one important regard.

They do not have a park position.

When parking your Kalmar tractor there

are some important rules that must be

followed.

DANGER - Failure to

observe the following rules

when parking the vehicle

may result in serious injury

or death.

1. Always apply the parking brake.

2. Never park the vehicle by leav-

Operation

Page 25

24

air pressure in the system. The warning

buzzer will shut off after air pressure has

reached 70 P.S.I.. (See page 21)

If the warning light and buzzer do not shut

off at least 5 minutes after start-up, shut

the engine down and determine why the

air system is not charging.

If the Low Air indicator light or buzzer

indicates a loss of air pressure while

driving, the vehicle should be stopped

immediately. The vehicle should not be

operated until the air system is repaired

and functioning properly.

Danger - Do not operate

the vehicle if the air brake

system is not working

properly.

SERVICE BRAKES

The Service Brake system is controlled by

a foot operated treadle valve (foot pedal)

in the cab. This is the left hand pedal, located to the right of the steering column

(Fig. 1, page 24). The amount of foot

pedal pressure determines the amount of

air pressure delivered to the brakes. The

more pressure on the treadle valve (pedal),

the more braking force applied. The service brakes should be applied in smooth

constant applications. They should not be

pumped or fanned while slowing or stopping the vehicle. Even in an emergency

stop situation, the service brakes should

not be rapidly “pumped”.

NOTE - Air brakes do not respond like the

brakes in a car, and pumping them in an

emergency stop is not advised. Rapidly

“pumping” the brakes is more likely to use up

all of the air in the system and cause the spring

brakes to apply and lock the rear wheels. This

will cause an out of control skid.

Figure 1

A Accelerator Pedal

B Brake Treadle/Pedal

The service brakes are the primary brakes

used by the operator. The service brakes

require air to operate. If there is insufficient air in the system, the service brakes

will not operate.

The spring brakes are used for parking

the vehicle. They are also called the

parking brakes because the parking brake

control applies the spring brakes. The

spring brakes use the mechanical force

of a spring to operate. They do not need

air to operate, but they do need air to be

released. If there is a loss of pressure in

the system, these brakes will automatically

apply. This is why the spring brakes are

sometimes called “emergency” brakes.

Remember, if there is no air in the system

the spring (parking) brakes will not fully

release.

LOW AIR PRESSURE INDICATORS

When air pressure in the brake system is

below 70 P.S.I., the warning buzzer will

sound and the LOW AIR warning indicator on the dash panel will light up. The

air pressure gauges should indicate low

Operation

B

A

Page 26

25

braking ability of the tractor trailer

combination and creates a serious

hazard. This increases the possibility of an accident and could result

in serious injury or death.

WARNING - Never operate the vehicle when

system air pressure is

below 70 P.S.I. There may

not be enough air in the system to

stop or slow the vehicle. Have the

brake system checked by a certified air brake mechanic if there is

any doubt about the brake system

performance.

A.B.S.

Some trucks may be equipped with the

Antilock Braking System (A.B.S.). The

A.B.S. system is designed to prevent wheel

lock up during hard braking.

Trucks equipped with A.B.S. have an indicator light located in dash panel number

one. The indicator light will warn the

operator if there is a potential problem in

the system.

Trucks should not be operated if the indicator light is on. Contact your nearest

Kalmar dealer for qualified service on the

A.B.S. system.

Trucks built with A.B.S. after March of

2002 will have the capability to check

the trailer for a properly operating system.

After connecting a trailer to the truck, the

system will run a diagnostics check. If a

problem is detected with the trailer side of

the A.B.S. system, a trailer warning indicator light on the dash will illuminate.

While the engine is running, the air

compressor replenishes the brake system

air supply. This air supply provides the

pressure necessary to operate the service

brakes.

The service brakes require at least 70

P.S.I. to operate effectively. If the system

is not up to at least 70 P.S.I., there may

not be enough air in the system to stop

the vehicle. Several hard brake applications can quickly deplete the pressure in

the air system and could possibly cause

the pressure to drop below 43 P.S.I.. If this

happens the spring brakes will apply automatically, possibly causing the operator

to loose control of the vehicle.

The service brake system is integrated

with the parking brake system. Should the

service brake system fail because of a lack

of air pressure (below 43 P.S.I.), the spring

brakes will automatically be applied for

emergency braking.

WARNING - Rapid successive brake application

and release, sometimes

referred to as “fanning” or

“pumping” the brakes, should be

avoided. This is an inefficient way

to slow or stop a vehicle with air

brakes and may use up all of the

air in the system before the vehicle

is stopped or slowed completely.

This could result in serious injury or

death.

WARNING - Always

connect both trailer air

lines when towing a trailer.

Failure to connect both the trailer

service (BLUE), and the trailer supply (RED) air lines greatly reduces

Operation

Page 27

26

Trouble-shooting or clearing fault codes

is performed at the EC module mounted

in the left front wheel well.

TRACTION CONTROL

Automatic traction control (A.T.C.) is

available as an option on trucks equipped

with the Antilock Braking System. When

activated, the A.T.C. active/warning lamp

will be on and the system will limit wheel

spin during hard acceleration. The system

is activated by turning on the A.T.C. enable/disable switch located on the dash.

During activation, the warning lamp will

blink to advise the driver that drive-wheel

spin is occurring.

A.T.C. can be disabled while the vehicle is

stationary or in motion. However, A.T.C.

will not re-enable until the vehicle comes

to a complete stop, even with the switch

turned to the enable position.

Danger - Never operate

the vehicle if the truck

or trailer A.B.S. warning

(indicator) lights remain

illuminated.

PARKING BRAKE

Otttawa tractors are equipped with spring

brakes of parking. The parking system is

operated manually by a cab mounted

parking brake control valve (Fig 1) (Also

see page 21, Items 6 and 7)

The purpose of the parking (spring) brakes

are to hold the vehicle while in the parked

position.

(RED)

(YELLOW)

WARNING-Never apply

the parking brake during

normal driving. Doing this

will lock the rear wheels,

possibly causing an uncontrolled

stop.

PARKING BRAKE AND TRAILER

AIR SUPPLY CONTROLS

NOTE - Air pressure in the system must be at

least 70 P.S.I. before the Parking Brake Control

or the Trailer Air Supply Control can be pushed

in (releasing the spring brakes).

NOTE - If the tractor air system is completely

discharged, the Trailer Parking Brake Controls

will be applied. The trailer parking brake

should not be released until the tractor brakes

are rolling.

Figure 1

Parking Brake and Trailer

Air Supply Controls

MANUALLY

RELEASING

TRACTOR SPRING

BRAKES (CAGING)

When air pressure in the system drops below approximately 43 P.S.I., the spring

Operation

Page 28

27

1. Shut the engine off and remove the

key.

2. BLOCK ALL wheels front and rear to

prevent the vehicle from rolling forward

and backwards.

3. Determine whether the chamber has an

internal (FIGURE 1) or external (FIGURE

2) caging tool. Proceed to step 4 with

an externally mounted tool. Step 8 for

internal types.

4. Remove the access plug from the brake

canister.

5. Insert the caging tool into the access

hole, “T” end first.

Figure 2

6. Turn the caging tool 1/4 turn to engage

with the slot on the pressure plate.

7. Try to pull the caging tool out, it should

not pull out. If it does repeat steps 5 and 6.

8. Thread the nut and washer down onto

the threaded end of the caging tool all the

way to the canister.

9. Tighten the nut until the threaded portion of the release tool is out. It should

extend approximately 3” out of the nut.

3.00 inches - Type 2430 and 3030 Chambers

4.00 inches - Type 3036 and 3636 Chambers

parking brakes will apply automatically. To

release the spring brakes, the air pressure

must be returned to 70 P.S.I.. If the system

cannot be recharged and the vehicle must

be moved, the spring parking brakes can

be released manually (caged).

To release the spring brakes, the actual

spring in the brake canisters must be mechanically compressed. A release stud, or

spring caging tool, must be used to manually compress the brake chamber.

DANGER - Never manually

release (cage) the spring

breaks before the wheels

are properly blocked. If the

wheels are not properly blocked

before releasing the spring brakes,

the vehicle may move unexpectedly. This could result in serious

injury or death.

Figure 1

The following steps can be used to release the standard brake chambers used

on most Kalmar tractors. If your vehicle

is equipped with other optional brake

chambers, refer to that manufacturer’s

operation or service manual.

Operation

Page 29

28

CAUTION - Never use an

impact wrench to tighten

the nut onto the release

bolt. Never exceed the

above lengths and never exceed 50

lbs-ft. of torque on the release nut

or the chamber may be damaged.

TRAILER BRAKES

Kalmar tractors are designed to use the

trailer’s brakes when towing trailers. All

Kalmar tractors are equipped with a trailer

Supply air line and a trailer Service air

line. The service line is BLUE. The supply

line is RED.

When the vehicle is towing a trailer and

the service and supply line are connected

to the trailer, the trailer brakes become

part of the tractor’s brake system. The

tractor service brakes control the trailer

service brakes. The tractor parking brake

control operates the tractor and trailer

spring brakes. This is why it is critical that

the operator always connect both air lines

to the trailer.

TRAILER AIR LINES

The service air line (blue hose) operates

the trailer service brakes. The supply air

line (red hose) only supplies air to the

trailer spring brakes to release them. If

only the supply air line is attached to the

trailer, the trailer service brakes will not

operate. The tractor service brakes will be

doing all the braking for the combination

and braking distances will be dramatically increased. Without the trailer service

brakes working, jack-knifing and loss of

vehicle control is much more likely during

heavy braking.

WARNING - Always

connect both trailer air

lines when towing a trailer.

Failure to connect both

the trailer service (BLUE), and the

trailer supply (RED) air lines greatly

reduces braking ability of the tractor trailer combination and creates

a serious hazard. This increases the

possibility of an accident and could

result in serious injury of death.

ENGINE

Kalmar tractors come equipped with a

variety of engines. Kalmar provides the

engine manufacturer’s operation manual

with each vehicle. It is the operators responsibility to read the engine operation

manual and follow all instructions provided by the engine manufacturer.

Engine performance is very important

to the efficient operation of the Kalmar

tractor. Failure to properly maintain and

operate any engine can lead to very

costly repairs and extensive down

time. KNOW YOUR ENGINE AND

MAINTAIN IT!

NOTE - This manual only contains basic

information on engine operation that apply

specifically to the Kalmar tractor, or is

applicable to all diesel engines.

If you did not receive an engine operation

manual, contact your Kalmar dealer.

CAUTION - Failure to read

and follow engine manufacturer’s instructions regarding

engine operation may lead

to severe engine damage. Read the

Engine Operation Manual before

operating this vehicle.

Operation

Page 30

29

To start a vehicle equipped with the

standard electrical starting system, follow

these steps:

STARTING PROCEDURE

NOTE - All Kalmar tractors are designed to

start in NEUTRAL ONLY. The starter should not

operate if the vehicle is in any other gear.

1. Set the parking brake.

2. Place the transmission control in NEUTRAL.

3. Apply the service brakes using the floor

mounted treadle valve and hold the brakes

in the position.

4. Insert the ignition key into the switch

and rotate the key clockwise to the RUN

position.

5. Wait for the “Wait to Start” light on the

dash to go out if the vehicle is equipped

with one.

6. Turn the key to the start position. When

engine starts, release the key and allow the

switch to remain in the Run position.

CAUTION - If the engine

does not start within 30

seconds, release the starter

switch and wait 3 minutes

to allow the starter motor to cool.

If after 3 repeated attempts, the

engine still fails to start, stop and

determine the cause. The starter

motor may be damaged by repeated attempts to start the engine.

STARTING THE ENGINE

(See page 22, Starting the Vehicle)

WARNING - Always set

parking brake and place

shifter in neutral before

attempting to start engine. Failure to do so may cause

the vehicle to move suddenly and

unexpectedly when the starter is

engaged.

WARNING - All Kalmar

tractors are designed to

start in NEUTRAL ONLY. If

the vehicle you are operating starts while it is in gear, DO

NOT OPERATE THE VEHICLE. Shut

the vehicle down and have the neutral lock-out switch repaired before

operating the vehicle.

DANGER - Never attempt

to start the vehicle from

any position other than the

driver’s seat. Attempting

to start the vehicle while standing, outside of the cab, or in the

engine compartment may cause the

vehicle to move uncontrolled and

cause serious injury or death.

The following is provided as general

guideline information. Always follow

all instructions provided in the engine

manufacturer’s operation manual. Different makes and models of engines have

different operating characteristics and

requirements. There are some important

guidelines to follow when starting any

Kalmarequipped with a diesel engine.

These are listed below.

Operation

Page 31

30

ENGINE OIL

Always refer to the engine operation manual for complete information on engine oil

requirements. Service intervals, oil types

and refill quantities are all covered in the

engine operation manual. READ IT!

TRANSMISSION

Standard tractors are equipped with an

Allison Automatic Transmission, RDS series. These heavy duty transmissions are

designed for stop and go operation. An

Allison Transmission operator’s manual is

provided with every Kalmar. This manual

provides important information on operation of the RDS series transmissions.

The following information can be found

in your Allison Operator’s Manual:

1. Gear Selection

2. Shifting the Transmission

3. Driving Tips

4. Care and Maintenance

5. Check oil level w/shifter

6. Check/clear fault codes

WARNING - The operator

of this vehicle must read

and follow the instructions

in the Allison Operator’s

Manual. Failure to do so may lead

to serious vehicle damage and

personal injury.

The forward to reverse shifts of the transmission are controlled by the “ECM”.

ENGINE SHUT DOWN

Diesel engines generate large amounts of

heat. Internal engine parts on any diesel

engine need to cool down before the engine is shut off. The operator should allow

the engine to idle for at least 3 minutes

prior to shutting the engine down. This

cool down period allows the coolant to

dissipate internal engine heat. Shutting a

hot engine down without a cool down period may cause an immediate and excessive increase in engine temperature. This

could severely damage internal engine

components.

NOTE - Always refer to the engine operation

manual for complete information on engine

shut down procedures.

SHUT DOWN PROCEDURE

1. Place transmission in neutral.

2. Set parking brake.

3. Allow engine to idle at low idle for at

least 3 minutes.

4. Turn ignition switch to OFF position (if

your vehicle is not equipped with an ignition operated engine shut down then use

the engine shut down button or control

to stop engine).

5. Make sure all electrical accessories

and lights are off and the vehicle is in

neutral.

CAUTION - Failure to follow engine manufacturers

guidelines regarding engine

shut down procedures may cause

severe engine damage.

Operation

Page 32

31

is located on the console to the right of the

seat and next to the shift lever (Page 21).

Figure 1

A - Fifth Wheel Plate

B - Boom

DANGER - Never raise or

lower the boom while the

tractor and trailer combina-

tion are moving. Raising the

boom while the tractor and trailer

are moving creates a “roll over”

hazard and may cause the vehicle

to roll over. Possibly resulting in

injury of death. DO NOT OPERATE THE BOOM CONTROL LEVER

WHILE THE VEHICLE IS MOVING A

TRAILER.

To Raise Fifth Wheel: To raise the boom

the engine must be running. Pushing the

lever to the “UP” position, indicated on

the boom operating lever, raises the fifth

wheel. To increase the rate of travel of the

boom, the engine may be idled higher

while the vehicle is in NEUTRAL ONLY.

To Lower Fifth Wheel: To lower the boom,

the engine must be running, the transmission in NEUTRAL. Pulling the boom control lever to the “DOWN” position,

PARKING WITH AN

AUTOMATIC TRANSMISSION

The Allison RDS series transmissions do

not have a “PARK” position like an automobile transmission. For information on

how to properly park your Kalmar, see the

following sections in this manual:

Page 23, Parking the Vehicle

Pages 26 thru 28, Parking Brake

HYDRAULIC FIFTH

WHEEL LIFTING

SYSTEM

The standard fifth wheel lifting system on

Kalmar tractors is hydraulically operated.

A P.T.O. and hydraulic pump mounted

on the transmission provide the hydraulic power to operate the Hydraulic Fifth

Wheel Lifting System. The Fifth Wheel

is mounted to a hydraulically operated

“Boom” (fig. 1). This “Boom” assembly

is attached to the frame at a pivot behind

the cab. The system operates like a large

hydraulic floor jack.

The following are general operating instructions and may not apply to you particular vehicle. If there are any questions

regarding the operation of your vehicle or

a particular option, contact your Kalmar

dealer.

HYDRAULIC BOOM OPERATION

The hydraulically operated boom is controlled by a lever inside the cab. The lever

Operation

Page 33

32

marked on the boom operating lever, lowers the boom and fifth wheel. To increase

the rate of travel of the boom, the engine

may be idled higher while the vehicle is in

NEUTRAL ONLY. Standard configuration

of the boom allows both power up and

down capability.

FIFTH WHEEL UNLATCH

CONTROL VALVE

The Kalmar tractor comes standard with

an air operated fifth wheel unlatch cylinder. The cylinder is operated by a “push

type” valve located on the right hand console behind the shifter (Page 21). Pressing

the fifth wheel unlatch valve opens the

king pin jaws in the fifth wheel. After the

jaws are opened, they remain open until

the fifth wheel is connected to a trailer

kingpin.

NOTE - When pulling out from under a trailer,

the control must be depressed and held until

the fifth wheel is clear of the trailer king pin.

BASIC TRAILER

SPOTTING STEPS

NOTE - The following information is for

reference only. Kalmar Industries Corp. highly

recommends using the following information

to create procedures that match your particular

application and vehicle. It is the operator’s

responsibility to ensure that proper trailer

moving procedures are used for a particular

situation and vehicle application.

1. Maintain optimum tractor air pressure

(120 PSI). The fifth wheel should be in

the FULL DOWN position. Be absolutely

positive that the fifth wheel jaws are in

the UNLATCH position by depressing the

unlatch control valve located to the right

of the shifter. (See page 21).

2. Line the tractor up to the front of the

trailer by centering the fifth wheel to the

center line of the trailer. Make sure that

the tail of the fifth wheel is BELOW the

trailer skid ramp.

3. Back the tractor UNDER the trailer until

the ENTIRE fifth wheel DISAPPEARS UNDER the front edge of the trailer floor/skid

plate.

4. With your foot firmly on the brake

treadle and the tractor shift lever in

NEUTRAL, move the boom control lever

to the UP position and raise the trailer

until the trailer support is JUST OFF THE

GROUND. DO NOT raise the trailer any

more than a few inches to provide clearance between the trailer landing gear and

the ground at this step.

5. After you have obtained adequate

ground clearance at the trailer landing

gear, place the shift selector in REVERSE,

release your foot from the brake treadle

and back FIRMLY into the kingpin jaws

until you feel full engagement. REMEMBER, the latching jaws in the fifth wheel

MUST BE FULLY IN THE UNLATCH

POSITION BEFORE attempting kingpin

engagement.

6. Place the transmission shift lever into

a forward drive gear and give a “TUG” at

the kingpin to ensure positive lock of the

jaws around the kingpin. BE PREPARED to

stop if the fifth wheel jaws have not fully

latched to avoid pulling out from under

the trailer and dropping it.

7. Place the shift lever in the NEUTRAL

position and raise the boom using the

boom control lever. Raise the fifth wheel

to the necessary height to maintain ground

clearance while towing the trailer to the

new location. Be aware of potential overhead damage to a trailer if it is

Operation

Page 34

33

raised too high.

8. Once proper trailer height is reached,

apply the tractor parking brake. Now

hook BOTH the trailer emergency and

service airlines to the trailer (blue & red

airlines) and plug in the trailer electrical

cable.

9. With the brake treadle FULLY applied,

push in BOTH the parking brake control

(yellow) and the trailer air supply (red),

this will charge the trailer air supply and

release the trailer spring/parking brakes.

10. After the tractor air system is fully

charged, move the transmission shift lever

to the proper gear and release pressure on

the foot operated brake treadle and allow

the vehicle to roll a VERY SHORT distance

and then depress the brake treadle again

to stop the vehicle. This procedure will

insure that the service brakes on the trailer

are working properly. NOW, and ONLY

NOW, are you ready to move (“SPOT”)

the trailer.

11. Once the trailer is relocated and

the vehicle combination is completely

stopped, place the shift lever in NEUTRAL

and pull out on the trailer air supply

control (red). This will apply the trailer

parking brakes only. The parking brake

control (yellow) should remain “in”, with

the tractor parking brake released.

12. Using the boom control lever, lower

the trailer until the trailer supports are

resting completely on the ground.

13. Disconnect and STORE the air lines

and electrical cable.

14. DEPRESS and HOLD the fifth wheel

unlatch control valve as you slowly pull

away from the trailer. Once the fifth wheel

is completely clear of the kingpin, release

the fifth wheel unlatch control and go the

next trailer.

WARNING - When the tractor is operated on public

streets or highways, the

5th wheel manual secondary lock MUST be engaged.

The secondary lock is engaged by

removing the hairpin clip on the

lock handle allowing the lock to

pivot behind the locking yoke. The

fifth wheel MUST be in the DOWN

position to operate the vehicle on

public streets or highways.

WARNING - Never raise

or lower the boom while

the vehicle has a trailer at-

tached and is in motion.

WARNING - DO NOT

EXCEED 15 MPH WHEN

TOWING TRAILERS. Op-

erating at speeds in excess

of 15 MPH may lead to loss of

vehicle control. NEVER take turns

at excessive speeds, this may cause

the vehicle and trailer to roll over.

The majority of roll over accidents

are caused by excessive cornering speed. ALWAYS SLOW WHEN

CORNERING. Roll over accidents

may lead to serious injury or death.

WARNING - Never tow

trailers without BOTH the

service and emergency brake

lines connected to the trailer.

Never tow trailers without functioning

service and emergency brake systems.

Operating the vehicle while towing

trailers without functioning trailer brake

systems may lead to loss of control of

the vehicle, serious injury or death.

Operation

Page 35

34

TOWING VEHICLE WITH FRONT

WHEELS SUSPENDED

It is not recommended to tow a vehicle

with the front wheels lifted and the rear

drive wheels on the road. This practice

may result in serious vehicle damage.

Pay close attention to the following rules

to prevent vehicle damage if you must

tow your Kalmar with the rear wheels on

the road.

WARNING - Always obey

the following when towing

a Kalmar tractor with the

front wheels lifted and the

rear wheels on the road.

1. Always use a rigid towing bar or

properly restrain the towed vehicle.

Using a chain or cable to tow the

vehicle is not recommended.

2. Always disconnect the drive line

to the rear drive axle(s), or remove

all axle shafts from all rear drive

axles.

3. Always cage the spring brakes on

all rear drive wheels. (See page

B-14, Manually Releasing Spring

Brakes) A loss of air pressure could

occur while towing the vehicle. This

would apply the spring/parking

brakes and lock the rear wheels on

the towed vehicle.

WARNING - When manually releasing spring brakes,

make sure that the vehicle

wheels are properly blocked.

If the wheels are not blocked, the

vehicle could move suddenly when

the spring brakes are released and

cause sever injury.

WARNING - Never tow a

trailer above the minimum

height required to clear

the landing gear from the

ground. Lifting the fifth wheel and

trailer too high drastically raises the

center of gravity of the trailer and

increases the chance of a roll over.

TOWING THE

VEHICLE

Towing a vehicle requires special equipment and training. Kalmar Industries Corp.

recommends that a professional towing

service be used when towing a disabled