Page 1

00

General

Technical

Handbook

ContChamp

DRD

S

This Handbook deals with the design

and maintenance of Kalmar machines,

type DRD-S for the handling of containers.

In addition, it gives details of troubleshooting and the most common

corrective maintenance.

10

20

30

40

50

Chassis and cab

Electrical system

Engine

Transmission,

drive axle, brakes

Operation and other matters that are

primarily of interest to the operator are

included it the Instruction Manual.

Kalmar Industries AB

This handbook applies to

machines from and including

machine number T34107.0784 as

well as T34107.0621 and

T34107.0769, see next page.

We reserve the right to modify

our design and material specifications without prior notice.

Publ. Nr 920 937 9407 04-10

AdEra Dokument AB, Växjö 2004

60

70

80

90

Steering axle

Hydraulic system

Boom and attachment

Periodic supervision

Page 2

This Handbook applies to machines from and including machine number

T34107.0784 as well as T34107.0621 and T34107.0769

These machines are of a new design that entails the f ollowing dif ferences from ol der machines. The changes do not apply to machines with combi-attachments or top-lift with pileslope.

1. The electrical system is equipped with a separat e KDU for the top-lift, comp onent number 791. The KDU

communicates with ECU 2 via a CAN bus.

2. The main valve of the top-lift is fed by a variable hydraulic pump.

The main valve is common for all of the top-lift’s functions.

3. The length adjustment of the top-lift is manoeu vred by means of a hydraulic motor and chain.

4. The top-lift rotation brake is manoeuvred completely hydraulically.

Page 3

ContChamp DRD-S

Technical Handbook

9407

Contents

04-10

S.Grupp 00

1

Contents

Group 00

Safety regulations...................................... .... ........................... 2

General...................................................................................... 6

Design – Overview .............................................................. 6

Component units ........................................... ... ... ............... 7

Supplementary books ......................................................... 9

Replacement system – Spare parts ................................... 9

Tools .............................. .......................... ......................... .. 9

Tightening torques.............................................................. 10

System of units ................................................................. 12

Page 4

ContChamp DRD-S

Technical Handbook

Safety regulations

9407

04-10

S.Grupp 00

2

It is important that you read the instruction

manual.

Incorrect handling can lead to personal injury or damage to products and/or property . Therefore , read the instruction book very carefully before ope rating the truck.

The instruction manual contains important information

about your Kalmar truck, about the operation of the

truck, about safety during oper ation and about the

truck's daily maintenance. In addition, you will find useful information that will make operations easier for y ou

in your daily work.

The instruction manual must always be kept in the machine. If the manual should be lost, a replacement m ust

be immediately obtained. Never use a machine with a

missing instruction manual.

Ask your foreman/group leader if there is anything in

the manual that you do not understand or if you f eel that

information is missing in any area.

The symbol is used on our products in certain

cases and then refers to important information contained in the instruction manual. Make sure that warn ing and information symbols are always clearly visible

and legible. Replace symbols tha t have been d amaged

or painted over.

In this instruction manual war n in gs ar e inserted that

apply to your own safety. Warnings point out the risk of

accident that can cause personal injury.

WARNING!

Warns of the risk of seriou s personal injury, possible death and/or serious dama ge to product or

property if the regulations are not followed.

For technical warnings, that point out the risk of break

down, the word IMPORTANT is used:

Safety regulations aimed at reducing the

risk of personal injury and damage to

loads or other property.

Intended of use

z The truck may only be used for the purpose for

which it was intended, namely, to lift and transport

goods, the weight of which doe s not exceed the

maximum permitted load capacity of the truck.

z The truck may not, without specific permission

from Kalmar, be mod ified or re-built so that its function or performance is altered.

z The truck may not be driven on public highways if

it has not been adapted to comply with national

road safety regulations.

Operator requirements

z The truck may only be driven by operators who

have been specially trained and who have the

company's authority to do so.

z Laws and other regulations relati ng to driving li-

cence, operator ID, log book, etc., must be followed at all times.

z The operator must be aw are of and f oll ow all local

safety regulations.

z It is always the responsibility of the operator to en-

sure that the truck has appro v ed fire e xt inguishing

equipment in accordance with currently applicab le

regulations.

Operation of the truck is prohibited:

z If any of the fitted safety equipment, such as rear

view mirrors, headlights, reversing alarm (optional), does not function correctly.

z If there is a fault with the brakes, steering or lift

equipment.

z If it has been repaired, modified or adjusted with-

out the approval of the work supervisor.

z If the truck is fitted with tyres not appro ved by

Kalmar.

IMPORTANT!

Is used to draw attention to such occurrences

that can cause damage to the product or

property.

For information that facilitates the working process or

handling, N.B. is used:

N.B. Draws attention to useful information tha t

helps the working process.

Emergency exit

If the doors should not o pen in an emergency, open the

rear window for emergency exit.

A rear window that can be opened is standard on machines with hydraulically moveable cab. Optional on

other machines.

Continued on next page

KL749

Page 5

ContChamp DRD-S

Technical Handbook

Safety regulations

9407

04-10

S.Grupp 00

3

Continued from previous page

Operating regulations

z Before starting, make sure that the cab is locked

in the rear-most position by me ans of the latches,

one on each side. The latches must be secured

with spring pins. (Applies to manually moveable

cabs).

z Before starting, always check to ensure that no-

body is in the way of the truck or its equipment.

z The operator must alw ays f ace the direction of op -

eration and take particular care in areas wher e

persons or other vehicles are likely to appear in

the vicinity . If visibility is limited by the load, the operator should operate the truck in reverse.

z It is prohibited to walk or stand underneath raised

forks or other equipment, whether the y are loaded

or not.

z It is prohibited to transport passengers on the

truck outside the cab or on the load. Passengers

may be transported inside the cab only on condition that it is equipped with a fixed passenger

seat.

z It is prohibited to lift people if the truck is not

equipped with an approved lift cage.

z It is prohibited to exceed the load capacity of the

truck. See capacity plate and loading diagram.

z It is prohibited to transport loads in the raised po-

sition as this entails a risk of the truck tipping. All

transportation shall take place with the load in the

transport position.

z The operator must adapt the speed of the truck to

the character of the load, conditions of visibility,

the character of the roadway/surface, etc.

z The operator shall avoid powerful acceleration

and braking when turning. In addition, the operator shall always moderate the speed of the truck

when turning so as to avoid the risk of lateral skidding or tipping.

z The operator shall take pa rticular care when oper-

ating in the vicinity of electrical power lines, viaducts, quay-sides, ramps, gates/doors etc.

z Safety belts must always be worn, if fitted. In the

event of the truck tipping, always remain in the cab

and grip the steering wheel securely. Never try to

jump out of the cab.

z The parking brake can also be used as an EMER-

GENCY BRAKE. However, having been used f or

emergency braking, the brake linings must be

checked and repl aced if necessary. If the parking

brake has been mechanically released, it must

always be rese t in order for the truck to regain the

parking brake function.

Interrupted operation, parking

z Always check that the gear lever is in the neutral

position before turning the ignition k ey to restart or

to reset an emergency stop.

z Never leave the operator's cab without applying

the parking brake (ON position).

z Always remov e the ignition key if the truck is to be

left unattended.

Other important points to remember

z The truck's hydraulic system includes high pres-

sure hydraulic accumulators . Always be extremely

careful when working with the hydraulic system

and avoid being unnecessarily close to the hydraulic equipment, lines and hoses. Before working on the hydraulic system, t he accumulators

must be emptied into the tank, with the help o f the

special accumulator evacuation valve.

z Handle batteries and junction boxes with great

care. The batteries must alwa ys be protected over

the poles and connections.

z Always rectify any damage or wear and tear that

can risk personal safety or that can af fect the functions of the truck or its service life.

z Avoid touching oils and greases. Avoid inhaling

exhaust and oil fumes.

z Always use step s and handrails when en tering or

leaving the machine - Never jump!

T o avoid t he risk of slipping, tread only on anti-slip

surfaces. If the anti-slip protection has become

worn, loose or in any way less effective, it should

be replaced.

z Welding painted steel produces poisonous gas-

ses. Paint should therefore be stripped before

welding, good ventilation ensured and/or face

mask with filter used.

z Mobile phones used in the cab must alw a ys ha v e

fixed connections to the machine’s elec trical system, with a fixed antenna outside the machine,

mounted in accordance with the manufacturer’s

instructions. This will avoid interference with the

machine’s important electronic functions.

Operating with attachments

z The operator must always take the effect of the

wind into account when handling containers.

Avoid lifting with a wind strength in excess of 12

m/s (27 mph/40 feet per second).

z Always drive carefully so as to avoid attachments

colliding with pillars, cables, etc.

z Carefully study the "Lift methods" section of the

instruction manual.

z The tensile strength of the top pane can be seri-

ously weakened by exposure to elements that

contain: Aromatic hy droca rbo n, ketone, esters or

chlorinated hydrocarbon.

Regularly check the surface condition of the top

pane and clean only with screen wash or other

mild cleaning fluid. After cleaning, rinse tho roughly with warm water. It is prohibited to modify or in

any other way make altera tions to the top pane.

Immediately replace damaged top panes t hat

show signs of cracking or scratching.

CE marking

All trucks and equipment (though not thoses fitted on

the truck or intended as spare parts) supplied from Kalmar are CE marked, which indicates that th ey co mply

with the requirements of the EU Machine Saf ety Directive. In addition, each truck has a so called, “EU Declaration of Conformity” which is the legal pr oof that the

truck complies with the “health and safety” requirements laid down in the Machine Safety Directive, the

EMC directive (electro-magnetic compatibility) and the

LVD directive (electrical equipment).

Vibration standard

The truck complies with and is below the limits for vibration standard EN 13059.

Page 6

ContChamp DRD-S

Technical Handbook

Safety regulations

Safety regulations

9407

04-10

S.Grupp 00

4

z Only authorized and qualified personnel may

work with the safety system. (ECS-system)

z If the overload safety system override functio n

has been used, there is a risk of forw ard tipping.

The truck should be operated with e xtreme car e

to prevent accidents.

z Great care must be exercised at all times when

driving the machine. Always re member the great

height and width of the machine so that collision

with beams, cables etc. is avoided

z It is prohibited to start lifting a container if the

warning light TWIST -LOCK UNLOCKED (red) is

lit or if any of the warning lights TWIST-LOCK

LOCKED (green) or ALIGNMENT (orange) are

extinguished. N.B. the ALIGNMENT warning

light goes out once the lift has begun.

z If the safety system warning lamps are not func-

tioning, the system must be immediately repaired. To use a truck with faulty w arning lamps

is a great safety risk.

z Do not drive the truck with load raised high

above the gr ound, since the truck ma y ov erturn.

The transport of heavy loads must be carried out

with the load as close to the truck as possible,

i.e. with the boom retracted and lowered as far

as possible without obstructing vision, see picture below.

z Never run hands or fingers along any tu bes,

pipes or hoses whilst investigating for possible

leaks as some of these lines (diesel fuel, hydraulic, steering, etc.) operate at extremely high

pressures and even the most minute of leaks

can cause oil or fluid to penetrate the skin.

z Under no circumstances may compressed air be

used to remove a hydraulic piston from its cylinder.

z Always attend to damage and w ear that ma y be

of significance to the perf ormance and useful life

of the truck or to the safety of the personnel.

z Follow the safety rules whenever carrying out

service work on the air conditioner. The refrigerant is injurious to the skin and eyes. Only authorized service personnel may repair the system.

z The truck’s h ydraulic syst em includes high pres-

sure hydraulic accumulators. Bef ore working on

the hydraulic system, the accumulators must be

emptied into the tank, with the help of the special

accumulator evacuation valve. Also valve B for

emergency pressure to servo system must be

opened.

z Never carry out any service work on the boom or

attachment when the engine is running.

Transport position

KL591

KL1103

A. Quick evacuation valve, accumulators

B. Valve for emergency pressure to servo system

Page 7

ContChamp DRD-S

Technical Handbook

Safety regulations

Safety instructions for working with tyres

9407

04-10

S.Grupp 00

5

z Tyre changing can be dangerous and should only be

carried out by specially trained

personnel using proper tools and procedures. Failure to comply with these procedures may result in

faulty positioning of the tyre and/or rim and cause the

assembly to burst with explosive force sufficient to

cause physical injury or death. Never fit or use damaged tyres or rims.

z Ne v er attempt to weld on an inflated tyr e/rim assem-

bly.

z Never let anyone assemble or disassemble tyres

without proper training.

z Never run the truck on one tyre of a dual assembly.

The load capacity of a single tyre is then dangerously exceeded and oper ation in this manner may damage the rim.

z Deflation and dismantling

– Always block the tyre and wheel on the opposite

side of the vehicle bef ore yo u place the jac k in position. Always crib up the blocks to prevent the

jack from slipping.

– Always check the tyre/rim assembly for proper

component seating prior to removal from the

truck.

– Always deflate the t yre by removing the v alve core

prior to removing the complete assembly from the

truck or dismantling any of th e component. Before

loosening mounting bolts, run a wire through the

valve stem to en sure that it is not blocked. Ice or

dirt can prevent all the air from escaping. Deflate

and remove valve cores from both tyres of a dua l

assembly.

– Never position body in front of the rim during de-

flation.

– Always follow assembly and dismantling proce-

dures outlined in the manufacturer’s instruction

manual, or other reconized indu stry instruction

manuals. Use proper rubber lubricant.

– Never use a steel hammer to assembling or dis-

mantling rim components – use a lead, brass or

plastic type mallets. The correct tools are available through rim/wheel distributors.

– remove bead seat band slowly to prevent acci-

dents. support the band with your thigh and ro ll it

slowly to the ground in order to protect back and

toes.

– Disassembly tools apply pressure to rim flanges

to unseat tyre beads. Keep your fingers clear.

Slant disassembly tool about 10 degrees to keep

it firmly in place. Always stand to one side when

applying hydraulic pressure. Should the tool slip

off, it may cause fatal injury.

z Rim inspection

– Check rim components periodically for fatigue

cracks. Replace all cracked, badly worn, damaged and sev erely rusted components.

– Always select the correct tyre size and construc-

tion matching the manuf actur er’s rim or wheel rating and size.

– Do not use over-size tyres, too large for the rims,

e.g. 14.5 inch tyres with 14 inch rims or 16.5 inch

tyres with 16 inch rims.

– Never use damaged, worn or corroded rims/

wheels or fitting hardware. Always verify that the

rim is in a serviceable conditioning.

– Always clean and repaint lightly rusted rims.

– Never use a rim/wheel component that ca n not be

identified. Check rim parts against multi-

piece rim/wheel matching charts.

z Assembly and inflation

– It is important that the inflation equipment is

equipped with a water separator to remove mois-

ture from the air line in order to pr ev ent co rrosion.

Check the separator periodically to ensure that it

is working properly.

– Make sure that the lockring is in its right position.

– Never mi x different manuf acturer’ s parts since this

is potentially dangerous. Always check manufac-

turer for approval.

– Never seat rings with hammering while the tyre is

inflated. Do not hammer on an inflated or partially

inflated tyre/rim assembly.

– Always double check to ensure that the rim as-

semblies have been correctly assembled and that

securing studs and nuts are tightened to the cor-

rect torque setting.

– Never inflate tyres before all side and lockrings

are in place. Check components for proper as-

sembly after pumping to appro xim ately 5 psi (=34

kPa, =0.34 bar)

– When adding air to a tyre on an industrial truck,

use a clip-on chuck and stay out of the dange r ar-

ea. If the tyres has been run flat then the rim must

be dismantled and all parts inspected f or damage .

– Under-inflated tyres have a serious effect on the

stability of the truck and reduces the safe load

handling capacity. Always maintain tyres at the

correct inflation pressures. Check inflation pres-

sure daily. Do not over-inflate.

– Inspect tyres regulary – every day if possible.

Look for and remove brok en gla ss, torn pieces of

tread, embedded metal chips etc. Inspect f or une-

ven or rapid tread wear, usually caused by me-

chanical irregularities, such as brakes out of

adjustment or excessive toe-in and toe-out. If dis-

covered, correc t the irregularity immediately.

z When installing and tight ening trail wheel bolts, ob-

serve the following:

– Ensure that trail wheel or hub mounting surfaces

and trail wheel fastener mounting surfaces are

clean and free from paint and grease.

– Tighten bolts to specified torque settings . use

staggered sequence; i.e. top bolt , bott om bolt e tc.

Page 8

ContChamp DRD-S

Technical Handbook

General

9407

04-10

S.Grupp 00

6

Design – Overview

Kalmar DRD420–450 model S diesel trucks are of sturdy design

for particularly heavy duty handling of 20-40' loaded con tainers.

They are built around a chassis which has high strength and torsional stiffness and an extremely low centre of gravity.

The operator’ s cab is prov ided with vibr ation isolat ion and so und

insulation and offers excellent all-round visibility.

There are many adjustments that can be made to the operator's

driving position. The position of the seat, back support and firmness of the driving seat can be adjusted in a number of ways.

The trucks are equipped with a sliding cab . This puts the opera tor

in an exceptional position to superwise th e top lift attachment and

offers excellent accessibility to the transmission and hydraulic

pumps. The engine is easily accessib le through a remo vab le running board.

To special order, the trucks are equipped with hydraulically powered sliding cab.

DRD420-60S5

KL586C

DRD420-65S5 with 20-40’ adjustable top lift

Page 9

ContChamp DRD-S

Technical Handbook

General

9407

04-10

S.Grupp 00

7

The Volvo six-cylinder turbocharged engine, combined with a

four-speed gearbox with torque converter, prov ides smooth

power whenever needed.

The drive axle with hub reduction, oil-cooled h y draulic br ak e system and pendulum-mounted steered axle with double-acting

steering cylinder satisfy very strict demands on strength and mobility when travelling on irregular surfaces.

The hydraulic system is reliable and has high performance.

Component units

z Sound-insulated operator’ s cab with excellent all-round visibil-

ity. The non-slip, substantial steps provide convenient access

to the cab. As an optional extra, a hydraulically movable cab

is available.

z ECS-system which controls the electric servo circuits and also

overload protection system. (With elect ronic balance, module

60 or 52, the loading conditions are indicated on a displa y on

the ECS-terminal in the operator’s cab.)

z Engine - Volvo TWD1031VE/TWD1231VE six-cylinder, four-

stroke, turbocharged di esel engine with direct injection and

thermostatically controlled water cooling.

The engine is equipped with:

– Injection pump with centrifugal gov ernor that compensates

for load variations.

– Smoke limiter f or reduced free acceleration and full load

smoke.

–Alternator.

z Gearbox with torque converter

– Constant-mesh gearbox changes b y means of hydraulically

activated clutches which are electrically operated.

– Torque converter, which is a hydraulic coupling that ampli-

fies the output torque on an increase in load. Torque conversion takes place smoothly and steplessly throughout th e

engine speed range.

– Oil cooler connected to the engine cooling system for cool-

ing the oil in the gearbox and torque converter.

– Oil pump which supplies oil under pressure to the gearbo x

and torque converter.

– Full-flow oil filter for effective cleaning of the gearbox oil.

z Drive axle with two-stage reduction - in the diffe rential and the

hub reductions.

– Hydraulic, oil cooled disk brak es – wet disk brak es – for the

foot brake.

– Disc type parking brake applied by sturdy springs and re-

leased by hydraulic oil pressure.

Page 10

ContChamp DRD-S

Technical Handbook

General

z Hydraulic system, that occurs in two versions:

9407

04-10

S.Grupp 00

8

1. With common tank for all hydraulic and brake circuits.

– a double variab le hydr aulic pump , feeds L ift 1, Extension 1,

hydraulic servo, steering system

– a double variab le hydr aulic pump , feeds L ift 2, Extension 2,

attachment functions

– a fixed, wing type pum p f or the feeding of the brake system

– hydraulic fluid cooler for the brake system cooling circuit

2. With a separate tank f or th e working hydraulics and a separ ate tank for the brake circuit.

– a double variab le hydr aulic pump , feeds L ift 1, Extension 1,

hydraulic servo, steering system

– a double variab le hydr aulic pump , feeds L ift 2, Extension 2,

attachment functions

– a fixed, wing type pum p f or the feeding of the brake system

– a hydraulic fluid cooler for the brake system cooling circuit

– a fixed, wing type pump for the circulation of the main tank’ s

hydraulic fluid through a hydraulic fluid cooler

– hydraulic fluid cooler for the main tank

z Main valves for controlling the main hydraulics . The valves are

controlled by an electro-hydraulic servo system from the cab.

An electro-hydraulic servo system is available as an option.

z High pressure filters for effe ctive cleaning of the h ydraulic fluid

before it is returned to the tank.

z Priority valve giving priority to the steering system when re-

quired.

z Steering valve (Orbitrol) - flow-control valve which supplies h y-

draulic fluid to the steering cylinder.

z A hydraulic oil cooler with electrically powered fan

z Steered axle with pendulum mounting and double-acting

steering cylinder.

z Lift cylinders equipped with blocking valves, which eliminate

any undesirable sinking of the load. A regeneration system

gives high lifting speed at no load conditions.

z Boom of a slender, high -tensile ste el construction. Th e boom

is pivot-mounted and comprises a fixed and a telescope section manoeuvred by means of a double-acting extension cylinder. The extension system is equipped with regeneration

system for quick boom-out speed at no-load conditions.

z Top-lift attachment, adjustable for handling 20 and 40 foot

containers.

Page 11

ContChamp DRD-S

Technical Handbook

General

9407

04-10

S.Grupp 00

9

Supplementary books

In addition to the Instruction Manual and the Technical Handbook, the following books are delivered with every truck.

Spare parts catalogue

Instruction Manual for Volvo Industrial engines

Replacement system - Spare parts

Kalmar operates a system of replacement parts, repair kits and

gasket sets covering most of the vital components of the truck.

For the contents of these kits, see the Spare parts catalogue.

Tools

Kalmar offers a wide range of tools for truck maintenance work.

For further information, please contact Kalmar's service depart-

ment.

Page 12

ContChamp DRD-S

Technical Handbook

General

9407

04-10

S.Grupp 00

10

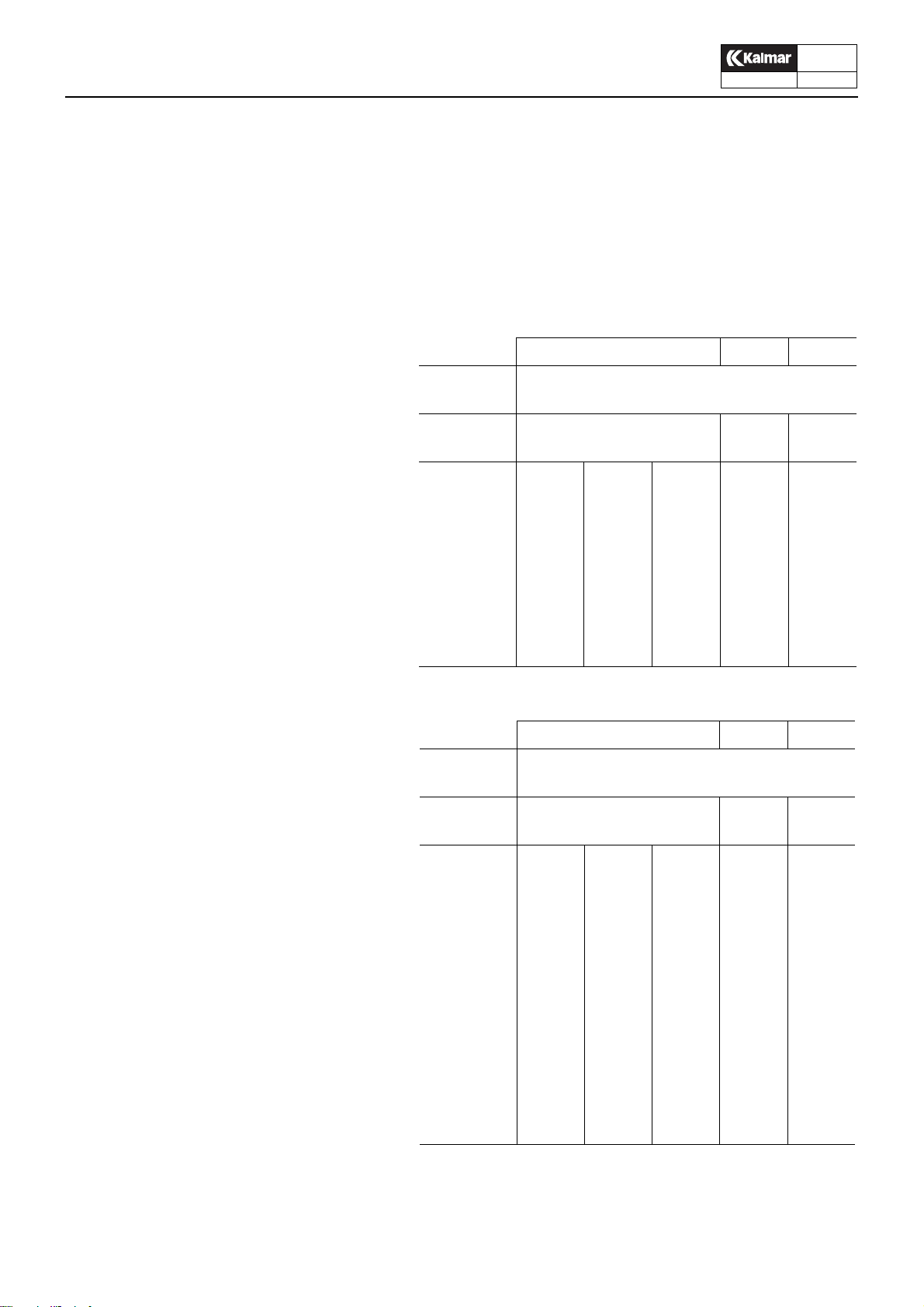

Tightening torques

(According to Kalmar K Standards 20060.0001)

The tightening torques are applicab le to steel bolts and n uts tight-

ened with a torque wrench under the following conditions:

Surface treatment

Condition Lubriation

Bolt Nut

1 untreated untreated oiled

bright galvanised

2

3 hot-dip galvanised bright galvanised dry or oiled

The values specified in Table 1 are applicable to nut-and-bolt

joints, but can also be used f or bolts fitted into tapped holes . However , in the latter case, the preloading f orce will be somewhat lower, depending on its depth of engagement.

When tightening by machine, the torque specified in Table 1

should be reduced by approx. 5%, due to the increased scatter

and to prevent the bolt from being tightened beyond its yield

point.

Quality 8,8 10,9 12,9

Thread

M fin

M8×1

M10×1,25

M12×1,25

M16×1,5

M18×1,5

bright galvanised

bright galvanised

Tightening torque, Nm

12311

27

54

96

230

330

24

48

85

205

294

untreated

bright galvanised

bright galvanised

Condition

30

61

108

260

373

135

323

466

dry or oiled

39

76

46

91

162

388

559

M20×1,5

M24×2

M30×2

M36×3

460

786

2660

1560

409

700

1388

2367

520

888

1763

3005

647

1100

2200

3730

777

1330

2640

4480

Page 13

ContChamp DRD-S

Technical Handbook

General

To reduce the risk of settlement of the material and the

associated reduction in the preloading f orce if the hardness of t he

surface supporting the bolt head or nut is lower than 200 HB, a

washer should be fitted under the bolt head and nut. This is not

applicable if flanged bolts or flanged nuts are used.

When tightening is carried out, the specified torque shou ld be applied without pause, to ensure that the torque wrench will not be

tripped by the static friction before the joint has been tightened to

the specified torque.

Quality 8,8 10,9 12,9

Tightening torque, Nm

Condition

Thread

M

12311

9407

04-10

S.Grupp 00

11

4

5

6

8

10

12

16

20

24

30

Quality 8,8 10,9 12,9

Thread

UNC

1/4

5/16

3/8

7/16

1/2

3,2

6,4

11

26

52

91

220

430

750

1480

12311

12,5

25

44

70

107

2,9

5,7

9,8

24

47

81

198

386

668

1317

Tightening torque, Nm

11,1

22,3

39

62

95

3,6

7,2

12,5

30

59

103

250

49

848

1672

Condition

14,1

28,3

50

79

121

4,6

9,1

16

38

74

128

313

620

1050

2080

17,6

35

62

100

151

5,5

11

19

45

89

154

375

732

1270

2500

20

42

73

118

178

9/16

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

153

210

370

594

889

1260

1760

2320

3060

136

187

390

528

791

1120

1565

2065

2720

173

237

418

671

1005

1424

1990

2620

3455

216

298

524

839

1260

1780

2490

3280

4320

255

353

619

990

1480

2100

2940

3870

5100

Page 14

ContChamp DRD-S

Technical Handbook

General

Quality 8,8 10,9 12,9

Tightening torque, Nm

Condition

Thread

UNF

12311

9407

04-10

S.Grupp 00

12

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

13

26

47

75

114

164

227

396

629

937

1350

1860

2500

3260

11

23

42

66

101

145

202

352

560

834

1200

1655

2225

2900

14

29

53

85

128

185

256

447

710

1058

1525

2100

2825

3680

19

37

67

107

162

231

321

559

889

1320

1900

2630

3530

4610

System of units

The SI system of units is employed in this handbook:

The conversion factors are as follows:

Pressure

megapascal bar Kilogram-force per

square centimetre,

kpf/cm²

Atmosphere, at

Pound-force

per square

inch,

psi

22

44

79

126

191

273

379

661

1050

1560

2250

3110

4170

5450

1

0,1

0,098

Torque

Newtonmeter

Nm

1

9,81

Power

Kilowatt

kW

1

0,735

10

1

0,98

10,2

1,02

1

Kilogram force-metre

kgf m

0,102

1

Horsepower (metric)hpHorsepower

1,36

1

145

14.5

14.2

Pound-force foot

lbf ft

0.74

7.23

hp

1.34

0.986

Page 15

ContChamp DRD-S

Technical Handbook

9407

Contents

04-10

S.Grupp 10

1

Group 10

Chassis and cab

Specification .............................................................................. 2

Chassis...................................................................................... 3

Description ........................................................................... 3

Chassis............................................................................ 3

Support jacks................................................................... 3

Operator’s cab................................................................. 4

Steering column .............................................................. 9

Hydraulics control unit................................................... 10

Service ............................................................................... 11

Changing the fresh air filter ........................................... 11

Check and lubrication of brake pedal............................ 11

Windscreen wipers........................................................ 12

Air conditioning unit ................................................................. 13

Description ......................................................................... 13

Service ............................................................................... 16

Checking the air conditioning unit ................................. 16

Page 16

ContChamp DRD-S

Technical Handbook

Specifications

Air conditioner

z Cab unit

Circulated air flow 500-600 m

Electric power consumption approx. 350 W

z Compressor

Max. speed 4000 r/min

Refrigerant R134a *)

Electric power consumption approx. 50 W

Oil capacity Zexel PAG SP-20 1.5 dl

z Condenser

Electric power consumption 250 W

z Cooling effect 6-8,5 kW

z Heating effect approx. 11 kW

*) Refrigerant R12 is no longer in production due to legislation

3

/h

9407

04-10

S.Grupp 10

2

Page 17

ContChamp DRD-S

Technical Handbook

Chassis

Description

9407

04-10

S.Grupp 10

3

Chassis

The chassis consists of:

z A unit construction frame built up around t wo box- sections for

best possible strength.

z Mountings for the drive axle, steered axle, telescope-boom,

lifting cylinders and transmission.

z The necessary counterweights to provide a very low centre of

gravity. Moreover , the ste ered axle is designed to serve as an

additional counterweight.

The hydraulic oil tank and t he fuel tank are produced as separat e

units and are bolted to the side of the chassis. The tanks have a

low profile, which contributes to the good visibility.

Support jacks

Certain machines are equipped with support jacks to increase

the capacity in the third container row, see group 20.

KL1436

Page 18

ContChamp DRD-S

Technical Handbook

Operator’s cab

Description

9407

04-10

S.Grupp 10

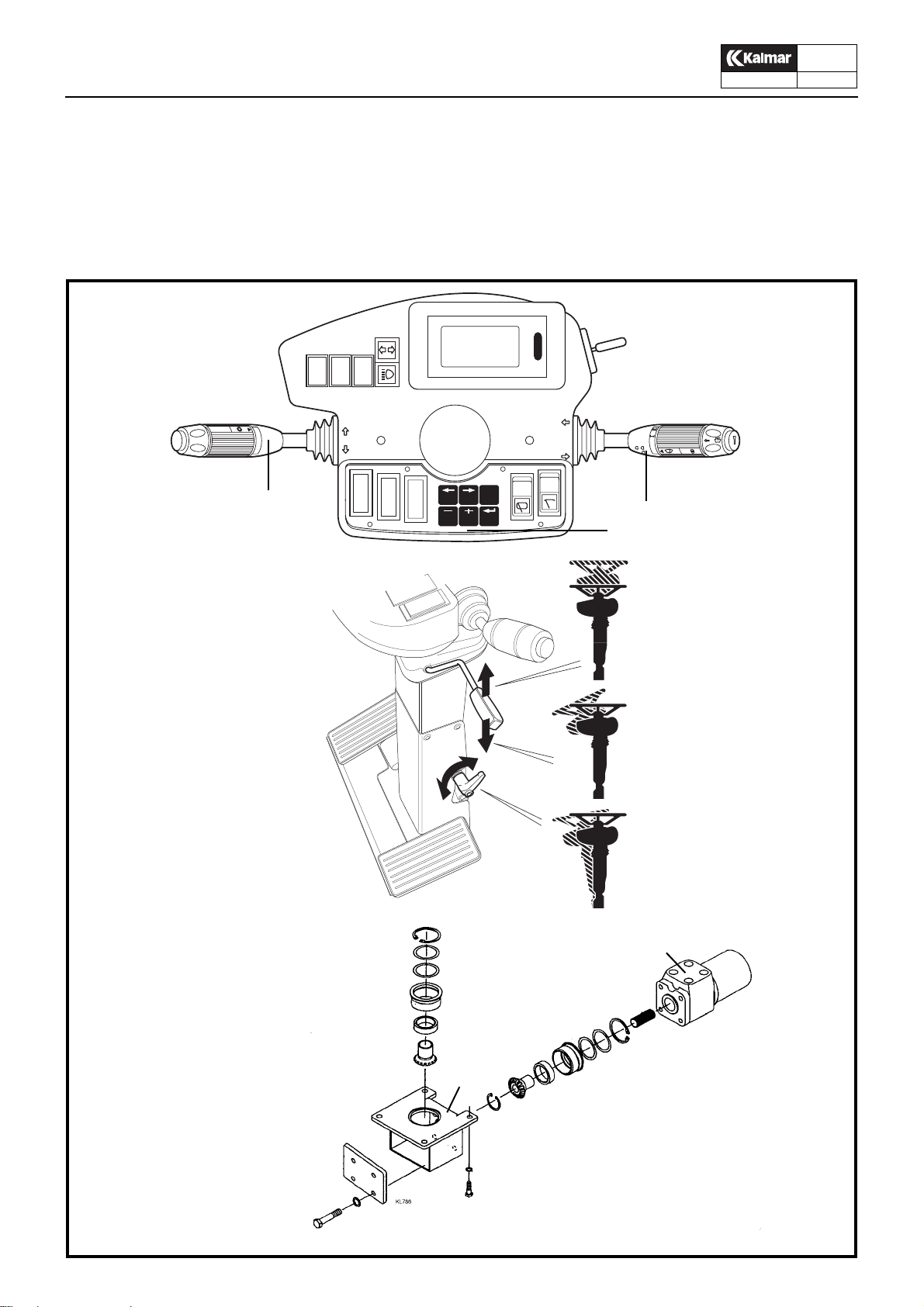

Operator’s cab

The operator’ s cab is a separ ate structure and rests on the chassis on rubber dampers. The operator’s seat, steering wheel and

hydraulic control le vers can be adjusted for best possible operator

comfort. Effective insulation minimises the vibrations and sound

level in the cab.

The standard heating system consists of a fan and heater for

heating the air in the cab by recirculation. Fresh air is drawn in

through a ventilation air filter. Full air conditioning, with cooling,

heating and dehumidification, is available to special order.

4

1

4

2

3

1. Steering column with control levers and switches, ECS-terminal

2. Heating system

3. Air filter

4. Electrical central unit

Page 19

ContChamp DRD-S

Technical Handbook

31 4 5 2 6

Operator’s cab

Description

9407

04-10

S.Grupp 10

5

1

23

4

F

N

R

R

45

3

L

0

789 10111213

1. Gear selector

FORWARD/NEUTRAL/REVERSE 1/2/3/4

2. Lever DIRECTION INDICATORS/HORN

FRONT WINDSCREEN WASHER/

FRONT WIPERS/MAIN BEAM

3. Instrument panel

4. Steering wheel panel

5. Starting switch

KL1406

6. Control lever and control panel for hydraulic functions

7. Electrical central unit with fuses and relays

8. Brake pedals, normal driving brake

9. Release clutch

10.Accelerator pedal

11.Steering wheel adjustment

12.Servo circuit breaker

13.Parking brake

Page 20

ContChamp DRD-S

Technical Handbook

Operator’s cab

Description

9407

04-10

S.Grupp 10

6

66

21

24

25

26

27

28

22

29

1

23

4

30

31

54

23

33

32

55 56 60 59

F

N

R

34

KL581

39

38

37

36

35

40 41 42 43 44 45 52 53

46

47 48 49 50 51

R

1

2

3

4

5

KL580

KL582

L

0

57 58 64 61 62 63

21. Pressure gauge, gearbox oil pressure

22. Fuel gauge

23. Temperature gauge, engine coolant temperature

24. Switch, working lights

25. Switch, working lights

26. Switch, working lights

27. Switch, flashing beacon

28. Switch, hazard warning lights

29. Switch, driving lights

30. Spare

31. Spare

32. Spare

33. Spare

34. Switch, compressor air conditioning

1)

35. Control, recirculation/fresh air

36. Control, defrost/cab

37. Switch, fan

38. Control, heat

39. Control, cold

KL675

1)

40. Spare

41. Spare

42. Warning lamp, battery charging

43. Warning lamp, low engine oil pressure

44. Warning lamp, low gearbox oil pressure

45. Warning lamp, low brake pressure

(accumulator pressure)

46. Warning lamp, low engine coolant level

47. Indicating lamp, preheating

48. Warning lamp, high engine coolant temperature

49. Warning lamp, high gearbox oil temperature

50. Spare

51. Warning lamp, parking brake ON

52. Spare

53. Spare

54. Spare (Green lamp TWIST-LOCKS LOCKED)

55. Spare (Orange lamp ALIGNMENT)

56. Spare (Red lamp TWIST-LOCKS UNLOCKED)

57. Spare (LOCK/UNLOCK TWIST-LOCKS)

58. Spare (LENGTH ADJUSTMENT 20-40')

59. Indicating lamp, headlights

60. Indicating lamp, direction indicators

61. ECS terminal

62. Switch, windscreen wiper, rear

63. Switch, windscreen wiper, roof

64. Spare

65. Fuses

66. Hour meter

1)

Optional

65

Page 21

ContChamp DRD-S

Technical Handbook

Operator’s cab

Description

9407

04-10

S.Grupp 10

7

1

2a

3

4

2b

56

7

8

9

10

Joy-stick functions

1)

1. Tilt

2. a. Locking of til t

b. Locking of levelling

3. Rotation

4. Side shift

5. Vertical lift

6. Boom OUT/IN

7. Levelling

8. Length adjustment 20'–40'

9. Unlocking of twist-locks

10.LIFT/LOWER

1)

Optional

1)

1)

1)

1)

Switch functions

13. Rotation limiting

15. AUT = Automatic locking of

twist-locks. The parking brake must

be OFF

MAN = Manual locking of

twist-locks (spring-back)

Unlocking off twist-locks,

see Joy-stick function 9 above

17. Stop at 30' and 35'

18. Cab movemen t ho rizontal/vertical

19. Support jacks DOWN/UP 1)

20a. Red lamp, the support jacks have

left the upper position

20b. Green lamp, support jacks down

1)

Optional

1)

1)

1)

1)

Button 17 for the connection and disconnection of

the 30' and 35' stops

The position gives crawling speed the whole time during extension and retraction. In order to by-pass the 30' stop press

and thereafter . The next stop will be 35'.

It is practical to connect in once the 30' position has been

passed.

N.B. When operating a machine

which is equipped with hydraulically moveable cab, the doors should

be closed or the ca b in it s rea r posi tion otherwise all functions will be

broken.

Page 22

ContChamp DRD-S

Technical Handbook

Operator’s cab

Description

9407

04-10

S.Grupp 10

8

Lamp panel on the boom

Container handling

A. Twist-locks locked, green

B. Alignment, orange

C. Twist-locks unlocked, red

Lit lamps at container lift:

A+B

Go out after lift: B

A

C

KL20

B

WARNING!

Overriding of the safety

system is at one's own risk

and involves a risk of forward tipping.

Engagement and

disengagement

of servo circuits

Override

(Only in emergency situations)

1. Lower

2. Container coupling

KL 1407

Page 23

ContChamp DRD-S

Technical Handbook

Operator’s cab

Description

9407

04-10

S.Grupp 10

Steering column

Surrounding the steering column are multi-function levers for

gear changing, indicators, windshie ld wipers , et c., as w ell as the

instrument panel with the ECS terminal. At the very foot of the

steering column is the steering valve (Orbitrol), activated by the

steering wheel via an angled gear. The steering column is

equipped with an adjustment knob for the alteration of steering

wheel height and rake.

.

9

1

23

4

1

F

N

R

R

1

2

3

4

5

L

0

2

3

KL580A

4

1. Gear lever

2. Multi-function lever

3. ECS terminal

4. Steering wheel adjustment

knob

5. Angled gear

6. Orbitrol steering valve

KL588

6

5

Column steering

Page 24

ContChamp DRD-S

Technical Handbook

KL 1407

Operator’s cab

Description

9407

04-10

S.Grupp 10

Hydraulics control unit

Control lever and switches used to manoeuvre the hydraulics

system are located on an adjustable console with comfortable

working position

The control lever is a jo ystick that is electroh ydr aulically connected to the main valves.

10

1

1. Control lever

2. Connection and disconnection of servo circuits

3. Control switches for attachment

4. Switch for overriding of safety system (for

use in emergency situations only). Affects

both overload protection and container connection.

23

4

WARNING!

Overriding of the safety sy stem is carried out at y our own

risk as such overriding i nvolves a ri sk of f or war d tippin g.

Page 25

ContChamp DRD-S

Technical Handbook

Operator’s cab

Service

04-10

S.Grupp 10

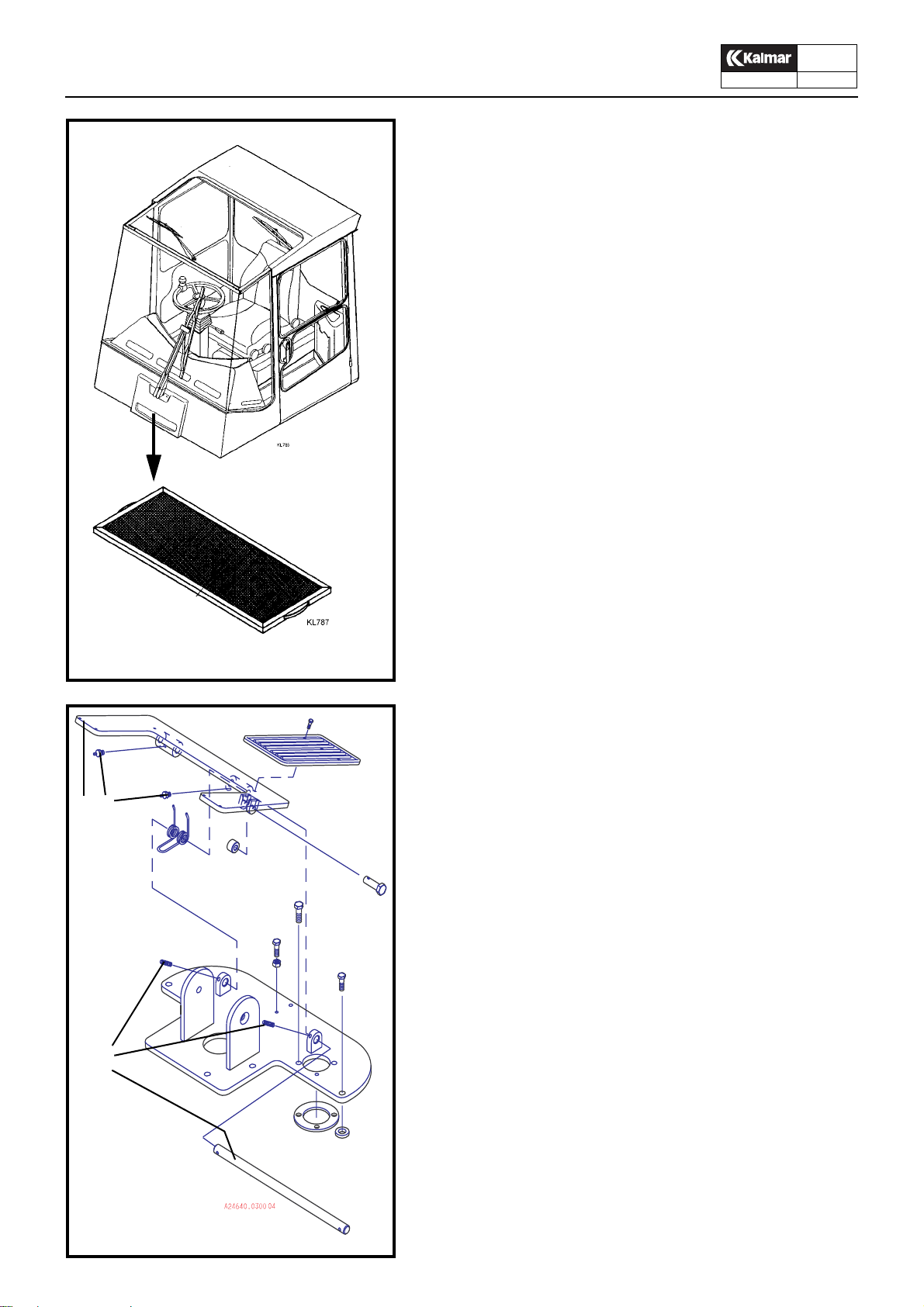

Changing the fresh air filter

(every 200 hours or when needed)

1. Remove the filter casing retaining bolts and remove the filter

element.

2. Wash the filter insert with water and detergent or by using a

high pressure washer. Replace the insert if necessary.

3. Reinstall the filter insert.

9407

11

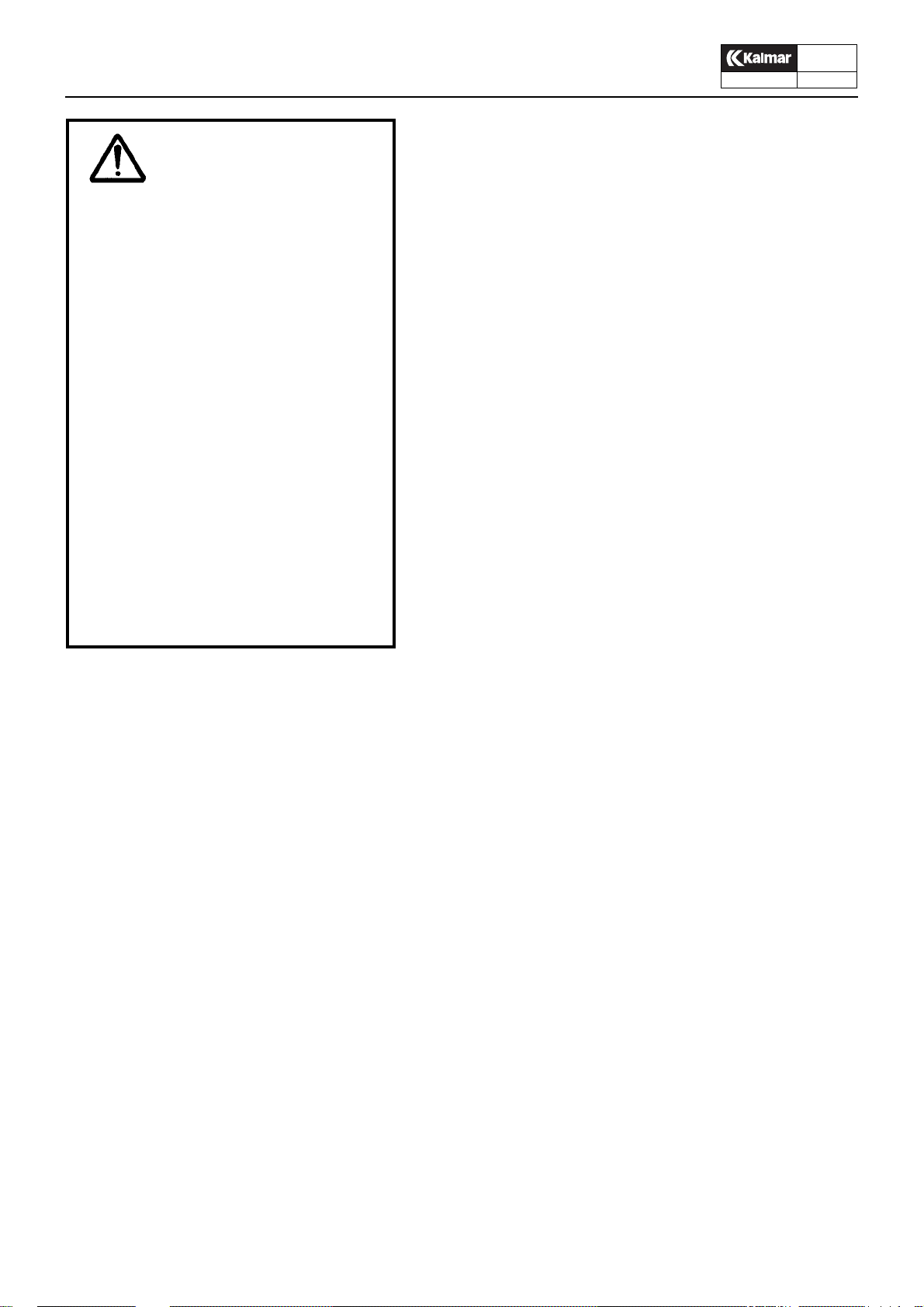

Check and lubrication of brake pedal

(Every 1000:e hours)

1. Check and tighten the loc king screws 3, so that the br ake ped-

2

1

3

4

al is securely fitted in the console.

2. Lubricate the brake pedal shaft through the nipples 2.

1. Brake pedal

2. Lubricating nipple

3. Locking screw

4. Shaft

Page 26

ContChamp DRD-S

Technical Handbook

Operator’s cab

Service

9407

04-10

S.Grupp 10

12

Windscreen wipers

The wiper arms are fixed to the wiper motor shafts via conical

splines. The shafts are manufactured of hardened steel and the

wiper arm mounting of soft, pressed metal. When fit ting, the nu ts

must be tightened so hard that the splines are pressed well into

the mounting and function as a carrier.

Removal

1. Remove the wiper arms by loosening the nuts and thereafter

tapping and carefully rocking the arms to and fro.

Fitting

1. Check to ensure that the splines on the motor shaft are free

from the softer material from the wiper arm mounting.

1

If this is not the case, clean the splines so that they can

pressed fully into the wiper arm mounting.

2. Fit the wiper arms onto the motor shafts and tighten the nuts

to a torque of 16-20 Nm.

Hold the wiper arm to take up the torque pressure so that it is

not transferred to the motor, which could result in damage

.

IMPORTANT!

2

3

The nuts must be tightened sufficiently hard, otherwise

the shafts may start to slip in side the wiper arm mounti ng,

resulting in damage.

1. Wiper arm fitting

2. Securing nut, wiper arm

3. Grooved cone on motor shaft

4. Wiper motor

4

Page 27

ContChamp DRD-S

Technical Handbook

1

Air conditioning unit

Description

Air conditioning unit

The air conditioning unit consists of the parts shown in the illustration and its function is to maintain the climate in the operator’s

cab as comfortable as possible. The air conditioning unit:

z heats the air when it is cold

z dehumidifies the air when it is humid

z removes impurities from the air

z cools the air when it is warm

The equipment is controlled by switches and controls on the instrument panel.

5

6

4

9407

04-10

S.Grupp 10

13

1.Heating control

2.Heat exchanger

3.Vapourizer

4.Expansion v alve

5.To condenser

6.To compressor

7.Heating valve

8.From engine

9.To engine

10.Fan

11.Fan

12.Fan control

13.Fresh air filter

14.Air disperser

15.Control defrost/cab

16.Defroster outle t

3

8

9

7

2

15 16

12

14

10

11

13

The heating and ventilating system

Page 28

ContChamp DRD-S

Technical Handbook

Air conditioning unit

Description

9407

04-10

S.Grupp 10

14

F

2

4

D

C

E

E

3

7

A

B

6

1. Liquid receiver/filter dryer

2. Evaporator

3. Fan

4. Expansion valve

6. Condenser

7. Compressor

1

G

A High-pressure gas

B High-pressure liquid

C Low-pressure liquid

D Low-pressure gas

E Warm air in cab

F Cooled air to the cab

G Outside air for removing heat

Page 29

ContChamp DRD-S

Technical Handbook

Air conditioning unit

Description

Compressor

The air conditioning system is driven by the compressor. This

performs as a pump, drawing cold, low-pressure gas from the

evaporator, compressing it and thereby raising its temperature,

and discharging it at high pressure to the condenser.

The compressor is driven by V-belts directly from the diesel engine. Switching between operation and idling is controlled by an

electro-magnetic clutch which, in turn, is controlled by a thermostat whose sensor is located between the fins of the evaporator

coil. The thermostat switches off the compressor at low temperatures, to prevent icing of the evaporator.

Condenser

The function of the condenser is to convert the hot high-pressure

gas from the compressor into liquid form. The tubes and fins of

the condenser coil absorb heat, which is then remov ed b y the air

delivered by the fan.

The temperature of the refrigerant in the condenser varies from

about +50°C to +70°C. The pressure varies between 12 and 20

bar, depending on the ambient temperature and the flow of air

through the condenser. When the refrigerant is condensed into

liquid form, it is transferred under pressure to the liquid receiver/

filter dryer.

9407

04-10

S.Grupp 10

15

Liquid receiver with filter-dryer

The function of the liquid receiv er with integrated filter dryer is to

collect the liquid coolant, bind the moisture, and to filter and remove impurities. The receiver, which is located in the condenser

housing, also serves as the expansion v essel in t he refrigeration

circuit.

After flowing through the dryer in the bottom of the liquid receiver ,

the refrigerant flows through a riser tube. A sight glass enables

the operator to check that the liquid flows without the presence

of any bubbles, and that the system is filled with a sufficient

amount of refrigerant.

Expansion valve

The expansion valve throttles the flow and passes an optimised

quantity of refrigerant that the evaporator is capable of ev aporating.

The expansion v alve is also the part of the circuit which separ ates

the high- pressure side from the low-pressure side. The refrigerant flows to the e xpansion valve under hig h pressure and lea v es

it under low pressure.

The amount of refrigerant which passes the evaporator varies,

depending on the thermal load. The valve operates from ’fully

open’ to ’fully closed’ and in-between se arches f or a point to g ive

optimum evaporation.

Evaporator

The heat necessary for evaporating the refrigerant is extracted

from the cab air which is circulat ed b y a fan through the evaporator coil. The cab air is thus cooled, and is distributed and returned

to the cab.

In the ev aporator , the refrigerant re verts to the gaseous state an d

returns to the compressor suction, thereby completing the cycle.

Page 30

ContChamp DRD-S

Technical Handbook

WARNING!

z If the refrigerant hose should fail or if

other refrigerant leakage should occur ,

switch off the air conditioner immediately.

z Refrigerant is injurious to the skin and

eyes.

z Never release refrigerant in an en-

closed space. If released into a service

pit, for instance, the gas ma y cause asphyxia.

z It is forbidden by law to discharge re-

frigerants into the airintentionally.

z Never carry out welding on a charged

refrigeration system or in its vicinity.

z Only authorised service mechanics are

allowed to drain off and fill refrigerant in

the air conditioning system.

Only the prescribed refrigerant may be

used when refilling.

Air conditioning unit

Service

The liquid refrigerant should be completely evaporated before it

is allowed to flow from the ev aporator. The refrigerant is still cold

even when it has completely evapora ted. The cold v ap our which

flows through what remains of the e vaporator contin ues to absorb

heat, and then becomes overheated. This means that the

temperature of the refrigerant has risen to abo ve th e point where

it evaporates without changing the pressure.

In an evaporator which operates at a suction pressure of 2 bar,

the liquid refrigerant will have a temperature of –1.1°C . When the

refrigerant is subsequently e vaporated through heat absorption

in the evaporator, the temperature of the gas will rise at the evaporator outlet to +1.6°C. This represents a difference of 2.7°C between the evaporation temper ature and the temperature at the

outlet. This is called overheating.

All expansion valv es should be adjusted at the plant in such a wa y

that maximum evaporation with overheating is performed in the

air conditioning system.

Checking the air conditioning unit

If the unit is in continuous operation, this chec k should be carried

out every week from early spring to late autumn and during extended periods of high humidity during the winter.

9407

04-10

S.Grupp 10

16

If the unit is used very little during cold and dry winter periods, th e

compressor should be run for a f e w min utes every week, to lubricate the rubber hoses, couplings, seals and shaft seal.

1. Start the engine and start the air conditioner.

At an outdoor temperature belo w 0°C, the system cannot start

since the low-pressure relay breaks contact.

2. After 10 minutes of operation, check that no bubb les are

visible in the sight glass of the filter-dryer. (Bubbles should

occur only when the compressor is started and stopped.)

If there are any air bubbles, subsequent filling should be performed by an authorised service mechanic.

3. Check that the condenser is not clogged. If necessary, clean

the condenser fins and the fans with compressed air.

4. Change the fresh air filter as necessary.

5. Check the V-belt tension and the compressor mounting.

6. Check that the magnetic coupling engages and disengages

satisfactorily.

7. Check that the condensate drain from the cooling element is

not clogged. Check for leakage.

Page 31

ContChamp DRD-S

Technical Handbook

IN CAB UNIT CONDENSER UNIT

Air conditioning unit

Service

9407

04-10

S.Grupp 10

17

RD 1,5

A

1

GL 1,5

L

SV 1,5

M

H

RD 1,5

C

4

4

RR

BR 1,5

M

2

3

GL 1,5

VT 1,5

RD 1,5

30

85

8

87

86

BR 1,5

M

M

BR 1,5

7

HIGH

LOW

10

1.Fan switch

2.Cooler on/off

3.Anti-freeze thermostat

4.Resistor

5.Fan motor

6.Indicator lamp – cold (in push button)

7.High-/low-pressure monitor

8.Relay

9.Condenser fan

10.Compressor

Page 32

Tom sida

Empty page

Leere Seite

Face vide

Page 33

ContChamp DRD-S

Technical Handbook

Group 20

Electrical system

Contents

9407

04-10

S.Grupp 20

1

Specifications..............................................................2

Electrical system.........................................................3

Description...............................................................3

Checking the electrolyte level of the batter ies .... 5

Fuses..................................................................5

Relays.................................................................6

Bulbs...................................................................7

Starting from another battery..............................8

Air operated operator’s seat................................8

ECS-system

Overview..................................................................9

Terminal ................................................................ 10

Menu structure..................................................10

Operating menues ........................ ....................11

Error messages.................................................15

Service menues ...................... ... .......................20

ECU-processor unit................................................22

Transmission data kit....... .................................23

Engine data kit ........................... .......................23

ECU 1

Functions................................................................24

Circuit board...........................................................26

01 Automatic gear changing .............................27

04 Lever steering ..............................................28

07 Monitoring ....................................................31

ECU 2

Functions................................................................33

Circuit board...........................................................34

Installation, boom.................. .... ... ..........................35

Electric servo..........................................................36

Control lever......................................................37

Pressure sensors right and left lift cylinders ..... 41

Lift - regeneration - lower.................................. 42

Boom extension - regeneration.........................45

Rotation.............................................................49

Twist-locks........................................................51

Side-shift...........................................................53

Length adjustment 20-40’ .................................54

Module 50 Mechanical Overload Protection..........56

Module 51 Vertical lift for Module 50...................... 59

Module 52 Vertical lift + Balance for Module 50.....60

Module 57 Hydraulic Balance ................................ 61

Module 59 Limitation Height/

LC-distance for Module 50/60................................62

Module 60 Electronic Overload Protection.............63

ECU 3

Functions............................................................... 66

Circuit board .......................................................... 67

Module 54 Tilt........................................................ 68

Module 56 Cab movement..................................... 69

Module 61 Support jacks ....................................... 71

Diagrams

Gearchanging systems......................... ... .............. 73

Components, A38630.0100 and A38630.0200......77

ECS overview.................................... ... ... .... ... ....... 78

Electrical diagram explanations............................. 79

Cable markings...................................................... 80

Component list

Electrical diagrams ECS top lift – page

A24925.2000 - 1, 2, 3 A24925.2200 - 1

A24927.2000 - 1, 2 A24927.2200 - 1, 2

A24929.2000 - 1, 2

Electrical diagram, truck body....................A08334.1200

Electrical diagram, inner, standard............A08333.1000

El-servo, singel ECU (S)............................A38630.0100

El-servo, double ECU (S) .......................... A38630.0200

Diagram attachment, 4 pages..............A38414.0100,1-4

Feed ........... ........................ A38414.0100, 1/4

Indication............................ A38414.0100, 2/4

Servo.................................. A38414.0100, 3/4

Working lights..................... A38414.0100, 4/4

Cable to twist-locks.............................. ... ... A38636.0100

Cable feed KDU 791..................................A38415.0100

Page 34

ContChamp DRD-S

Technical Handbook

Specifications

Alternator rating 1920 W

Starting battery voltage 24 V (2 x 12 V)

capacity 140 Ah

earthing negative

9407

04-10

S.Grupp 20

2

Page 35

ContChamp DRD-S

Technical Handbook

IMPORTANT!

Always open the main switch whenever work is to be carried out on the

electrical system, if the truck is to

remain idle for some time and whenever welding work is to be carried out

on the truck.

5

4

Electrical system

Description

The system voltage is 24V and the supply is taken from two 12V

batteries connected in series and charged by an alternator

across electronic rectifying and voltage stabilisation circuits.

.

The negative and positive poles are both connected across a

main switch. The negativ e po le is then connected to the chassis.

Warning lamps and instruments are clearly arranged on the in-

strument panel. The central electrical unit with fuses and relays

is located on the lower section of the cab’s rear wall.

3

9407

04-10

S.Grupp 20

3

2

1

1. Main switch

2. 24 V battery

3. Running lights

4. Rear lights

5. Rotating warning light

Page 36

ContChamp DRD-S

Technical Handbook

Electrical system

Description

9407

04-10

S.Grupp 20

4

34

2

5

6

78

9

1

10

11

12

1. Sensor, outgoing revs (ECS or reversing block)

2. Sensor, gearbox oil temperature, warning lamp and meter

3. Sensor, gearbox oil pressure, warning lamp and meter

4. Main fuses 2 X 50A

5. Relay preheater

6. Sensor, engine oil pressure, warning lamp

7. Sensor, engine oil pressure, meter

8. Sensor, coolant temperature, warning lamp

9. Sensor, coolant temperature, meter

10.Starter motor

11.Sensor, coolant level

12.Alternator

13.Solenoid valve, stop engine

14.Throttle lever, injection pump

15.Sol enoid valve for gear changing

13

14 15

Engine electrics

Page 37

ContChamp DRD-S

Technical Handbook

Electrical system

Description

9407

04-10

S.Grupp 20

5

N.B.

The starting batteries accompanying

the truck are of the maintenan ce-free

type, which implies that it should not

be necessary to top-up with electrolyte during the life of the batteries.

However, the level of the electrolyte

should preferably be c hecked once or

twice a year. Fill as required by adding de-ionized water.

S1-6 7-12 13-18 19-24 25-30 31-36

KL1749

WARNING!

Never use fuses of a higher amperage

than stated on the lid decal. Risk of

damage or fire.

WARNING!

It is prohibited to connect extra

consumers to any fuse.

B

Checking the electrolyte level of the batteries

The batteries are fitted behind a cov er on the left-hand side of the

truck. The electrolyte level should be about 10 mm above the

cells. Top up with de-ionized water as necessary.

Relay box in cab – fuses

Fuse Rating

No. Circuit protected A

S1 Wiper motor front, direction indicators,

seat buzzer, parking brake sensor............................... 10

S2 Ignition key, preheater, starter motor,

air conditioner, cab lighting ......................................... 15

S3 Container attachment, safety interlock........................ 15

S4 Electric gear-changing ............................................... 5

S5 Warning lamps, instrument illumination, relay,

coolant level .................................................................. 5

S6 Brake lights, reversing lights, reversing alarm ............ 15

S7 Fan (Option: Air condit ioning)

S8 Spare (Option:Container lights)

S9 Working lights (15 A for 4 lamps)

Hazard beacon ........................................................... 10

S10 Working lights, standard (15 A for 4 lamps) ............... 10

S11 Horn, screenwash motor, wiper rear and roof,

wiper front, intermittent relay....................................... 10

S12 Driving lights (main fuse), rear lights

(main fuse), position lights 15

S13 Main beam, right-hand .................................................. 5

S14 Main beam, left-hand..................................................... 5

S15 Dipped beam, right-hand............................................... 5

S16 Dipped beam, left-hand................................................. 5

S17 Rear light, left-hand....................................................... 5

S18 Rear light, right-hand..................................................... 5

S19 ECU1

S20 ECU2........................................................................... 10

S21 Voltage converter .......................................................... 5

S22-S24 Extra........................................................................... –

S25-S30 Extra........................................................................... –

S31 Illumination entry steps, engine compartment

S32 Compressor, air operated chair

S33 electrically operated parking brake............................. 5

S34 Oil cooler, hydraulic oil

S36 Central lubrication

S36 Water separator1) ...................................................... –

1

)Optional equipment

1

)........................................................................ 10

1)

....................................... ............ –

1

).................................. 25

1

)............................... 15

1

)

1)

1)

.............................. –

1)

............................................ –

........ –

A

D

KL593A

Miscellaneous fuses

A Main switch

B Main fuse, boom (1x25 A)

D Main fuse for truck electrical system

Fitted on the engine, 2x50 A

Page 38

ContChamp DRD-S

Technical Handbook

Electrical system

Description

Relays

305 Reversing light

314 Parking brake, disengagement

315 High power (Starting switch)

316 Wiper motor, front

320 Electric stop (ECS 07)

322 Coolant level (ECS 07)

323 Pulse relay, direction indicators

328 Gear shift (ECS 01)

330 Starting block

331 Propulsion forward

332 Propulsion reverse

334 Clutch release (ECS 01)

367 Lever steering (ECS 04)

322-1 Coolant level

322-2 Coolant level (ECS 07)

399 Spare

Miscellaneous

321-1 Intermittent relay wiper front

321-2 Intermittent relay wiper rear

960 Reversing interlock (excluded at ECS 01)

1

) Optional equipment

1

)

1

)

1

)

1

)

1

)

1

)

1

)

9407

04-10

S.Grupp 20

6

KL 1541

Page 39

ContChamp DRD-S

Technical Handbook

Electrical system

Description

9407

04-10

S.Grupp 20

7

KL 1542

Bulbs

Rating

Description Watts Base

Instruments 3 BA7s

Indicating lamps 1,2 W2x4,6d

Cab lighting 10 S8,5

Rear lights, red 5 BA15s

Brake lights 21 BA15s

Direction indicators 21 BA15s

Position lights 5 SV8,5

Driving lights (full/dipped beam) 75/70 P43t-38

Reversing lights, white 70 PK22s

Working lights 70 PK22s

Hazard beacon 70 PK22s

Page 40

ContChamp DRD-S

Technical Handbook

Electrical system

Description

Starting from another battery

Make sure the auxiliary batteries are connected in series, so

that 24 V will be supplied.

N.B. Do not disconnect the truck-battery cables

9407

04-10

S.Grupp 20

8

WARNING!

Batteries emit oxyhydrogen which is

an explosive gas. A spark, for

example from incorrectly connected

starting cables, could cause a battery

to explode and result in serious injury

and damage.

Connect the jumper cables in the following order:

1. Red cable (+) to auxiliary battery

2. Red cable (+) to truck battery

3. Black cable (–) to auxiliary battery

4. Black cable (–) to a location some distance away from

the truck battery, such as the negative cable connection on

the chassis.

Start the engine

Do not disturb the jumper cables while starting, as sparks

may otherwise be caused. Do not lean over either battery.

Disconnect the jumper cables in exactly the reverse order.

1

1. Motor and compressor

Installed in a box on the right hand

side of the machine or beneath the

cab

2. Pressure monitor

3. Fuse 3, 56.3

1

2

Air operated operator’s seat

Page 41

ContChamp DRD-S

Technical Handbook

ECS

Overview

9407

04-10

S.Grupp 20

9

Kalmar’s ECS - Electronic Control System - is a modular control

and monitoring system to ensure optimum operational security

and total economy . It is possible to combine the system’ s diff erent

modules in a number of different ways.

All vital points of the trucks different systems are connected to

one or several central computer units, ECUs. A terminal display

in the operator’s cab shows current values and generates an

alarm if the values exceed the programmed tolerances.

DRD Container machines are equipped with ECS as standard.

Depending on how respective machines are equipped, one, two

or three ECU central units ma y be fitted.

ECU 1 is used for different additional modules, such as 01 Au -

tomatic Gear Changing, 04 Lever Steering, 06 Mini-steering, 07

Monitoring. See separate descriptions in respective sections.

ECU 2 is obligatory and is used to control the El-Servo cir-

cuits. See the El-Servo section. ECU 2 also functions as

overload protection and for the regeneration system.

ECU 3 is used for machines with modules according to the

table below.

ECU 3

DRD400-60S5

2

1

KL621b-c

1)

ECU 1

01 Automatic

Gear Changing

04 Lever Steering

06 Mini-steering

07 Monitoring

1)

Optional equipment

1)

ECU 2 ECU 3

El-Servo

1)

50 Mechanical over-

1)

1)

load protection

Regeneration

51 Vertical lift

52 Balance + vertical

1)

lift

53 Locking tilt

57 Hydraulic

balance

58 Container

counter

59 Limitation Height/

LC-distance

70 PC/Printer

60 Electronic over-

load protection

Regeneration

V ertical lift

53 Locking tilt

58 Container

counter

59 Limitation Height/

LC-distance

70 PC/Printer

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

Bottom lift

1)

54 Tilt

55 Pile slope

61 Support jacks

The ECS:

– monitors the engine and gearbox to ensure reasonable

operating conditions

– monitors the components in the system, e.g., sensors, to

ensure their correct function

– provides torque controlled automatic gear ch anging

– interrupts hydraulic functions when ove rload of the steer-

ing axle occurs

– controls the regeneration func tion for boom e xtension and

lift cylinders

– controls vertical lift, balance, pile slope etc.

If a fault occurs:

– a red warning lamp blinks on the terminal

– an error message appears on the terminal display

– The ECS limits the functions of the truck in different ways

depending on the seriousness of the fault. Certain func-

tions are monitored on two le v e ls, whe re le vel 2 limits the

functions of the truck. See the error messages on the ter-

minal display on the following pages.

1)

1)

Page 42

ContChamp DRD-S

Technical Handbook

1

23

4

F

N

R

1

3

2

4

5

1

2

4

5

ECS

Terminal

9407

04-10

S.Grupp 20

10

Terminal functions

78

KL580B

R

R

3

1. Arr ow left is used to sc ro ll betwee n th e different menus.

2. Arrow right is used to scroll between the different menus.

3. R is used to reset the display after an error message. All errors, with the ex ception of certain lev el 2 errors ca n be reset

by pressing this button. The red warning lamp is then extinguished. The lamp begins to b link again af te r 3-1 0 m inutes,

depending on the fault, if it has not been rectified.

4. - is used to decrease a value.

5. + is used to increase a value.

L

6. ENTER is used to access the service menus and to save

0

new values when setting up and calibrating the system.

Access to the service menus also requires the use of spe cial

codes, that are separately obtainable from Kalmar.

7. A red warning light blinks in the event of an error and is extinguished when reset by pressing button 3.

8. The terminal displa y has 4 lines with space for 20 chara cters

on each line. Graphical presentation of operating menus and

error messages.

Menu structure

There are three types of menu:

1. Operating menus

6

The operating menus are accessible to the operator. The

menus that can be selected depend on how the truck is

equipped and are determined in SETUP. All operating me nus are part of a connected loop. Use arrow RIGHT/LEFT to

move around the loop. The loop also contains:

1.a Overload indicator

Depends on the selected overload protection, module 50/

60.

2. Error messages

Displayed automatically and have priority over other menus.

3. Serv ice menus

The operating menu loop always contains the KALMAR INDUSTRIES SERVICE main menu.The service sub-menus

under this main menu require access to codes that can be

found on a special list from Kalmar. If ENTER is pressed by

mistake in the service menu and the ENTER CODE menu is

displayed, return to the operating menu b y pressing ENTER.

For further information, refer to the respective headings.

KL1409

1.

1a.

1a.

1.

2.

1.

1.

1.

Enter

1.

3.

Page 43

ContChamp DRD-S

Technical Handbook

01 Automatic gear changing

07 Monitoring

50 Mechanical overload protection system

60 Electronic overload protection system

50

ECS

Terminal

9407

04-10

S.Grupp 20

11

Operating menus

The menus that are displayed on the terminal depend on the

modules with which the truck’s ECS is equipped. The overview

below shows the possible combinations. Use either arrow

RIGHT/LEFT to switch between m enus . All operating men us are

in a connected loop.

Access to the sub-menus under the service menu requires an access code. If ENTER CODE is displayed by mistak e, return to the