Page 1

Technical Information

9-18 tonnes forklift trucks

Kalmar DCE90-180, diesel

Page 2

A truck

offering many

possibilities

The Kalmar 9 -18 tonne series is an entirely

new range of medium-size trucks.

Our highly praised medium range of trucks

has now been further developed and

improved. It has also beneted from many

entirely new solutions.

The aim of our development work has been

the creation of a unique driving experience,

visibility and handling which, together with

high quality, long life and ease of service,

provide the conditions for efcient working

and excellent overall economy.

Powerful and hard-wearing power

trains with new improved gearboxes

or electronically controlled gear units,

perfectly matched with optional,

environmentally friendly engines; wellbalanced bodies for optimum dynamic

stability and visibility; the number of

options providing an unbelievable driving

experience, safety and efciency. Design

and technical solutions result in increased

lifetime and longer service intervals;

simplied service and daily inspection, and

in addition to all this, a wide selection of

high-quality driving environments.

DCE 90- 6

Spirit D elta

L3= 2750mm

DCE 100-6, DCE 120- 6

Spirit D elta

L3= 3000 mm

DCE 140- 6, DCE 100-12, DCE 180-6

Spirit D elta

L3= 3250mm

DCE 90- 6

FlexCab

L3= 2750mm

DCE 100-6, DCE 120- 6

FlexCab

L3= 3000 mm

DCE 140- 6, DCE 100-12, DCE 180-6

FlexCab

L3= 3250mm

Welcome to the Kalmar 9 -18 tonne range.

Model designation

Diesel engine

Counterbalance truck

Generation

Lifting capacity, in decitonnes

Load centre, in decimetres

2

DCE160-12

DCE 120-12, DCE 150 -12, DCE 160-6

Spirit D elta

L3= 3500mm

DCE 160-12

Spirit D elta

L3= 3750mm

DCE 120-12, DCE 150 -12, DCE 160-6

FlexCab

L3= 3500mm

DCE 160-12

FlexCab

L3= 3750mm

Page 3

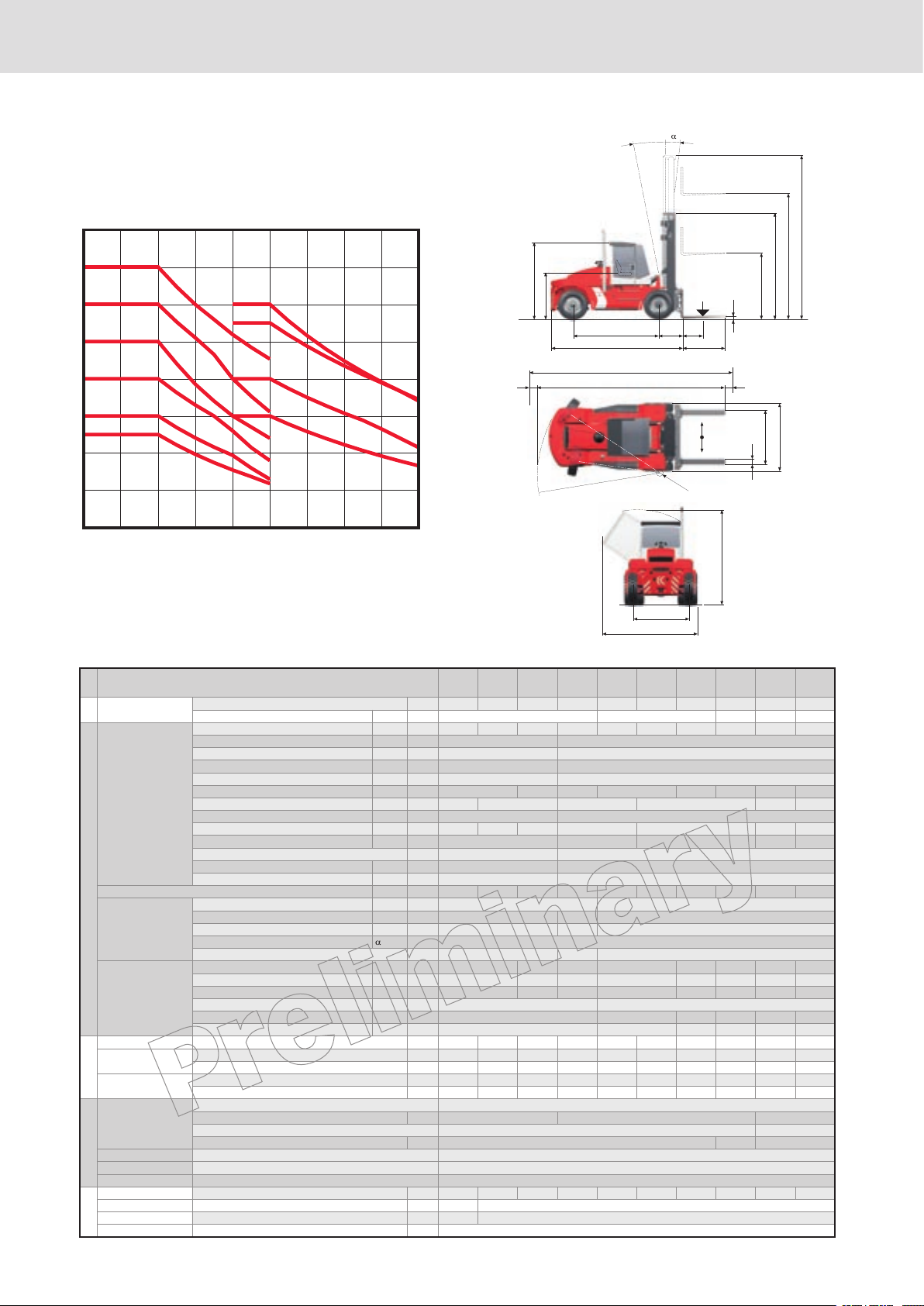

L

L3 L2 L4

I

H6

H8

H2

H3

H4

H5

a

ß

S

T2

T1

A1

100

100

V1

VbB

R2

R1

200012001000600

10

8

6

4

12

14

16

18

20

DCE90-6

DCE100-6

DCE120-6

DCE140-6

DCE160-6

DCE180-6

DCE100-12

DCE120-12

DCE150-12

DCE160-12

Load diagram

Lifting capacity, in tonnes

Load centre, mm

Dimensions

DCE

DCE

DCE

DCE

DCE

DCE

DCE

DCE

DCE

90-6

100- 6

120-6

140-6

100-12

120-12

150-12

160-6

Lift ca pacity Rated kg 9000 10000 12000 14000 10000 12000 15000 16000 16000 18000

Liftin g

Truck Truck leng th without forks L mm 4470 4720 4725 4985 5 065 5315 5 375 5305 55 75 5115

Min, aisle w idth for 90 ° stacking w ith forks A1 mm 6240 6470 6475 6665 7945 8370 8380 7160 8770 6745

Dimensi ons

Standard duplex

mast

Forks Width b mm 200 200 200 220 250 200 250 220

Servi ce weight kg 1480 0 14800 15600 16100 18900 19700 21400 19200 2240 0 21100

Axle load front Unloaded kg 7300 73 00 7900 770 0 10300 10100 940 0 10000 10500 9800

Weight

Axle load back Unloa ded kg 7500 7500 7700 8 400 8600 96 00 1200 0 9200 11900 11300

Wheels /tyres Typ e, front-rea r Pneumat ic

Steerin g system Type - manoeuvr ing Hydraul ic servo - Steering wheel

Servi ce brake system Type - affe cted whee ls Oil cooled disc brakes ( Wet disc brakes - drive wheels)

Wheels, brakes, ste ering

Parking b rake system Type - affecte d wheels Dry, spring activated disc brake - dr ive wheels

Hydraul ic pressur e Max. MPa 16,0 17,5 17,5 18,5 19,5 15,0 16,5 17,5 17,5 19,0

Hydraul ic uid volume

Fuel volum e l 140 200

Misc.

Starting battery Voltage - c apacity V-Ah 2x12 - 140

Load Cen tre L4 mm 600 1200 600 1200 600

Truck width B mm 2480 2540

Height, basic machine, Spirit Delta H6 mm 2895 2920

Height, basic machine, FlexCab H6 mm 2990 3020

Seat heig ht H8 mm 1770 1790

Distance between centre of front axle - front face of fork arm

Wheelb ase L3 mm 2750 3000 3250 3500 3750 3250

Track (c-c ) front - rear S mm 1840 - 1960 1855 - 1960

Turning radius, outer R1 mm 3950 4180 4181 43 60 4785 5175 4360

Turning radius, inner R 2 mm 75 125 420 600 125

Ground cl earance, min mm 33 0 350

Max heig ht when tilting cab T1 mm 3370 (3450 ) 3395 (3475)

Max widt h when tilting cab T2 mm 3350 ( 3440) 3380 (3470)

Liftin g height H4 mm 5000 5000

Mast height, min. H3 mm 4015 4035 4195

Mast height, max. H5 mm 6515 6535 6695

Mast tilting, for wards - back wards -ß ° 5 - 10

Ground cl earance, min . mm 25 0 250 250

Thickness a mm 65 70 80 90 100 80 100 90

Lenght of fork arm l mm 1200 1200 1200 2400 2400 1200 2400 120 0

Width across fork ar ms, max. V mm 2330 2360

Width across fork ar ms, min V mm 570 640 700 600 70 0 640

Sideshi ft ± at width across fork a rms V1 - V mm 440 - 1450 430 - 1500

At rated load kg 21200 2230 0 25900 28200 27000 29600 33800 33200 35800 3660 0

At rated load kg 2600 2500 1700 190 0 1900 2100 2600 200 0 2600 2500

Dimensi ons, front-r ear inch 11,00x20/16PR 12,00x 20/20P R 12,00x20/20PR HD

Number of wheels, fro nt-rear (*dri ven) 4* - 2

Pressure MPa 0,9 1,0 1,0

L2 mm 895 900 910 9 90 1000 980 1000 990

415 - 1450 440 - 1480 415 - 1530 430 - 1500

l 205 225

160-12

DCE

180-6

3

Page 4

Choose your own driving environment

Spirit Delta

The scientic work that has featured

throughout the development process has

made the Spirit Delta the best designed

driving environment available in the industry.

Priority has been given to ergonomics for

the driver. After a demanding shift in a

Spirit Delta, the driver should be alert and

attentive, resulting in improved working

safety.

The overall design and all the adjustment

options mean that the Spirit Delta will

benet every driver. Instruments and control

layout allow the driver to see at a glance and

have control over all the machine’s various

functions, while at the same time allowing

the driver to work in an efcient and relaxed

way. Visibility has been optimised and has

further beneted from the truck’s new soft

design lines. Comfort with regard to noise

level, climate, lighting and accessibility is at

the highest level possible.

The driver of the Spirit Delta can have

Kalmar’s range of intelligent efciency and

safety options in one place.

FlexCab

FlexCab is a robust alternative for those

operations that do not require the total

concept represented by Spirit Delta.

At the same time FlexCab provides good

ergonomics, good visibility and also

practical exibility. FlexCab can be quickly

and simply converted from a complete

cabin to an open safety cage with or

without windows, side panels and heating

system, depending on climate.

The robust body has been designed to

provide optimal visibility. This is especially

noticeable at the corner posts and roof

rails, which have the smallest cross-section

possible for the benet of the driver. The

elds of vision are substantial and the

distance between the driver’s seat and the

roof has been generously increased.

Efcient operation is ensured by control

and instrument layout and the degree of

comfort of the driver’s seat.

Kalmar’s electronic system gives the truck intelligence

Kalmar’s electronic system is a fast,

intelligent and stable auxiliary electronic

system that makes the truck driver-friendly,

effective, safe and economical.

Kalmar’s electronic system has been

thoroughly upgraded using CANbus

technology and new software to deliver

high speeds and a high level of exibility

and operational safety.

4

We have also produced for the Kalmar 9

- 18 tonne range a new, very simple and

non-language-specic interface for the

information on the steering wheel display.

Information is provided in three areas diagnostics, operation and alarms.

There are plenty of options available, from

ergonomic functions such as lever and

mini steering wheel control, to functions

for reduced fuel consumption (Optirev) or

increased lifting speed (Optispeed).

Page 5

A complete program of lifting equipment

Choosing lifting equipment always involves

a combination of different requirements

- lift height, clearance, free lift, vehicle

exibility, as well as in-built functions in the

vehicle.

Whatever the requirements, Kalmar has the

combination that allows efcient operation

and optimum visibility conditions.

The mast frame on the new Kalmar 9 - 18

series has been further improved, primarily

in terms of the driver’s visibility. Thin frame

and cross bars have been combined with

well-placed hoses and hoist chains that are

“invisible” during normal operation. The

xing points for the tilt cylinders have also

been strengthened to meet the ever-greater

We are now able to offer a very interesting

number of new options that make operation

both more efcient and safer - Optispeed

(increased lifting speed), lift height pre-set

(going directly to the right height), vertical

hold (always vertical) and chain-slack

elimination.

demands for heavier and more robust

operations.

Masts Carriages

Mast

Mast height Fre e lift Mas t height Free lift

Lift

H3 min. H5 max. H2 H3 min. H5 max. H2

height

3000 3015 4515 - 3195 4695 3250 3140 4765 - 3320 4945 3500 3265 5015 - 34 45 5195 3750 339 0 5265 - 3570 5445 4000 3515 5515 - 3695 5695 4250 364 0 5765 - 382 0 5945 4500 3765 6015 - 3945 6195 4750 3890 6265 - 4070 64 45 5000 4015 6515 - 4195 6695 5250 4140 6765 - 4320 6945 5500 4265 7015 - 44 45 7195 5750 439 0 7265 - 4570 7445 6000 4515 7515 - 4695 7695 -

Duplex st andard, cl ear view

6250 4640 7765 - 482 0 7945 6500 4765 8015 - 4945 8195 6750 4890 8265 - 5070 8445 7000 5015 8515 - 5195 8695 3000 3015 4515 1500 3195 4 695 1500

3250 3140 4765 1625 3320 4945 1625

3500 3265 5015 1750 3445 5195 1750

3750 339 0 5265 1875 3570 5445 1875

4000 3515 5515 200 0 3695 5695 200 0

4250 364 0 5765 2125 3820 5945 2125

4500 3765 6015 2250 3945 6195 2250

4750 3890 6265 2375 4070 6445 2375

5000 4015 6515 250 0 4195 6695 2500

5250 4140 6765 2625 4 320 6945 2625

5500 4265 7015 2750 4445 7195 2750

5750 439 0 7265 2875 4570 7445 2875

6000 4515 7515 3000 4695 7695 30 00

Duplex full free lift, clear view

6250 4640 7765 3125 4820 7945 3125

6500 4765 8015 3250 4945 8195 3250

6750 4890 8265 3375 5070 8445 3375

7000 5015 8515 350 0 5195 8695 3500

4500 2 950 5950 150 0 3130 6190 150 0

4750 303 3 6200 1583 3213 6440 1583

5000 3117 6450 1667 3297 6690 1667

5250 320 0 6700 1750 3380 6940 1750

5500 3283 6950 1833 3463 7190 1833

5750 33 67 7200 1917 35 47 7440 1917

6000 3 350 7450 20 00 3630 7690 20 00

6250 353 3 7700 208 3 3713 7940 2083

6500 3617 7950 2167 3797 8190 2167

6750 3700 8200 2250 3880 8440 2250

Triplex full fr ee lift, cle ar view

7000 3783 8450 23 33 3963 8690 2333

+25 mm on H3 and H 5 on the DCE140

90-140 120 -180

Fixed for m anually

moveable forks

Duplex standard, clear view

Fork pos itioning

and side shift

Forks

Duplex full free lif t, clear view

Standard forks for manual

adjustment

Centre levelling

Sideshift

Fork sha ft system with

separate carriers for each fork

Triplex full free li ft, clear view

Roller ttings for

hydraulic adjustment

Hydraulic levelling

5

Page 6

The most interesting

power trains on the market

We have tted the Kalmar 9 - 18 range with

the very best power trains. Engine, gearbox,

drive shaft and wet disc brakes - everything

has been built and combined into a unit with

the highest performance and durability

possible. Together with the excellent

dynamic stability of the new series, this

provides a driving experience and level

of control throughout the work cycle that

cannot be compared with anything that has

gone before.

Low emission engines - a requirement

We can offer seven different power trains

based on Volvo and Cummins engines. Both

engines provide high torque even at low

revolutions.

The engines fall well within the latest

emission requirements and they also

conform to the new noise power standards

(previously noise pressure).

Level 2 engines require more powerful

cooling than before and so the trucks come

tted with an efcient and easy-to-service

split cooling system - for air and fuel and

coolant to the engine and gearbox.

The air lter is a two-stage Donaldson

with a pre-cleaner in stage one and a ner

cellulose lter for the smallest particles in

stage two. This can also be replaced by a

metallic or dust particle lter as an option.

The lter has a high cleaning capacity and is

easy to replace.

Unique transmission

gives an unbelievable experience

We are able to offer ve types of gearboxes.

First there is the Dana 20000, an improved

version of the Clark 20000 with hydraulic

modulation for 3 +3 gears. Automatic gear

changing is also available as an option using

Kalmar’s electronic system.

The Dana 28000 and 32000 are two tried and

tested high-performance gearboxes.

The others, the Dana 13000 and 17000,

which were developed in collaboration with

Kalmar, are two entirely new gearboxes with

integrated electronic control, monitoring

and intelligence. The gearboxes have built-in

6

reversing lock and modulation, providing safe

and smooth gear changing. In addition we

also optimise slipping electronically before

delivery to provide the best gear-changing

characteristics depending on power train,

wheel dimension and drive shaft.

There are three optional grades of

“intelligence” to choose from: innitely

variable automatic gear-changing,

Optidrive (for precision driving with entirely

independent working hydraulics) and

electronic inching with controlled slipping.

Page 7

Power trains

Volvo TAD620VE ( 85kW) + Dan a FT2000 0 Perfo rmance

Engine Manu facturer - type designation Volvo - TAD620V E

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 85/116 - 2300

Peak torque ISO 3046 - a t revs Nm- rpm 477 - 1650

Number of cylinder s - displacement cm³ 6 - 5702

Gearbox Manufacturer - t ype desig nation Dana - FT20 000

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Fuel consumption, no rmal driving l /h 6-8

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

(Turbo-Interco oler)

Powersh ift

tial and hu b reductio n

Volvo TAD620VE (145k W) + Dana FT28000 Perfo rmance

Engine Manu facturer - type designation Volvo - TAD620V E

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 145/197 - 230 0

Peak torque ISO 3046 - a t revs Nm- rpm 700 - 1500

Number of cylinder s - displacement cm³ 6 - 5702

Gearbox Manufacturer - t ype desig nation Dana - FT32000

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Volvo TAD720VE (174kW) + Dana FT32000 Perfo rmance

Engine Manu facturer - type designation Volvo - TAD720VE

Gearbox Manufacturer - t ype desig nation Dana - FT32000

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Fuel consumption, no rmal driving l /h 8-11

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 174/237 - 230 0

Peak torque ISO 3046 - a t revs Nm- rpm 86 4 - 1400

Number of cylinder s - displacement cm³ 6 - 7145

Fuel consumption, no rmal driving l /h 8-11

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

(Turbo-Interco oler)

Powersh ift

tial and hu b reductio n

(Turbo-Interco oler)

Powersh ift

tial and hu b reductio n

Volvo TAD620VE (145k W) + Dana TE13000 Perfor mance

Engine Manu facturer - type designation Volvo - TAD620V E

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 145/197 - 230 0

Peak torque ISO 3046 - a t revs Nm- rpm 700 - 1500

Number of cylinder s - displacement cm³ 6 - 5702

Gearbox Manufacturer - t ype desig nation Dana - TE13000

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Volvo TAD720VE (174kW) + Dana TE17000 Perfor mance

Engine Manu facturer - type designation Volvo - TAD720VE

Gearbox Manufacturer - t ype desig nation Dana - TE1700 0

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Fuel consumption, no rmal driving l /h 8-11

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 174/237 - 230 0

Peak torque ISO 3046 - a t revs Nm- rpm 86 4 - 1400

Number of cylinder s - displacement cm³ 6 - 7145

Fuel consumption, no rmal driving l /h 8-11

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

(Turbo-Interco oler)

Powersh ift

tial and hu b reductio n

(Turbo-Interco oler)

Powersh ift

tial and hu b reductio n

Cummins 6B 5,9e (138kW) + Dana FT 28000 Perfo rmance

Engine Manu facturer - type designation Cummins 6 B5,9e

Gearbox Manufacturer - t ype desig nation Dana - FT32000

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 138/188 - 220 0

Peak torque ISO 3046 - a t revs Nm- rpm 780 - 1400

Number of cylinder s - displacement cm³ 6 - 590 0

Fuel consumption, no rmal driving l /h 8-11

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

Powersh ift

tial and hu b reductio n

Cummins 6B 5,9e (138kW) + Dana TE1300 0 Perfor mance

Engine Manu facturer - type designation Cummins 6 B5,9e

Gearbox Manufacturer - t ype desig nation Dana - TE13000

Drive train

Alternator Type - p ower W AC - 1540

Driving axle Type Kessler D 81 - Differen -

Fuel - typ e of engine Diesel 4-stroke

Rating IS O 3046 - at revs kW/hp -rpm 138/188 - 220 0

Peak torque ISO 3046 - a t revs Nm- rpm 780 - 1400

Number of cylinder s - displacement cm³ 6 - 590 0

Fuel consumption, no rmal driving l /h 8-11

Clutch, t ype Torque conve rter

Gearbox , type Hydro-dynamic

Number s of gears, fo rward - reve rse 3 - 3

Powersh ift

tial and hu b reductio n

7

Page 8

Performance

Volvo TAD620VE ( 85kW) + Dan a FT2000 0 DCE90-6 DCE100-6 DCE120-6 DCE140-6 DCE100-12

Liftin g speed U nloaded m/s 0,40 0,4 0 0,35 0,35 0, 35

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0,40

Travelling sp eed, f/r Unload ed km/ h 30 30 3 0 30 30

Gradeability Max unloaded % 58 58 54 49 40

Performance

Drawbar pull Max kN 76 76 76 73 73

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

Volvo TAD620VE (145k W) + Dana FT28000 DCE90-6 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160-6 DCE160-12 DCE180-6

Liftin g speed Unloade d m/s 0,50 0,50 0,40 0,40 0,50 0,40 0, 40 0,40 0,40 0,40

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40 0,40

Travelling sp eed, f/r Unload ed km/ h 30 30 3 0 30 30 30 30 30 30 30

Gradeability Max unloaded % 103 103 92 81 63 59 53 62 50 54

Performance

Drawbar pull Max kN 107 107 107 103 103 103 103 103 103 103

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

At rated load m/s 0,35 0,35 0,30 0,30 0,30

At rated load m/s 0,40 0,40 0,40 0,40 0,40

At rated load km/h 28 28 28 28 28

at rated load % 32 32 27 23 24

At 2 km/h unlo aded % 41 41 38 35 29

at rated load % 23 22 19 17 18

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 8 5 85 85

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78

LwA (outside) dB (A) 109 109 109 109 109

At rated load m/s 0,45 0,45 0,35 0,35 0, 45 0,35 0,35 0,35 0, 35 0,35

At rated load m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40

At rated load km/h 30 30 30 30 30 30 30 30 30 30

at rated load % 4 8 46 40 34 36 32 28 29 26 25

At 2 km/h unlo aded % 65 65 60 55 44 42 38 43 36 39

at rated load % 35 33 29 25 27 24 20 21 19 19

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 8 5 85 85 85 85 85 85 73

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78 78 78 78 78 78

LwA (outside) dB(A) 109 109 109 109 109 109 109 109 109 109

Volvo TAD720VE (174kW) + Dana FT32000 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160-6 DCE160-12 DCE180-6

Liftin g speed U nloaded m/s 0,50 0,40 0,40 0,50 0,40 0, 40 0,40 0,40 0,40

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0, 40 0,40 0,40 0,40 0, 40

Travelling sp eed, f/r Unload ed km/ h 30 30 30 30 30 30 30 30 30

Gradeability Max unloaded % >120 >120 >120 100 92 79 97 74 81

Performance

Drawbar pull Max kN 141 141 135 135 135 135 135 135 135

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

Cummins 6B 5,9e (138kW) + Dana TF28 000 DCE90-6 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160-6 DCE160-12 DCE180-6

Liftin g speed U nloaded m/s 0,50 0,50 0,40 0,40 0,50 0,40 0,40 0,40 0, 40 0,40

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40 0,40

Travelling sp eed, f/r Unload ed km/ h 30 30 3 0 30 30 30 30 30 30 30

Gradeability Max unloaded % 111 111 96 84 65 61 54 63 51 55

Performance

Drawbar pull Max kN 111 111 109 105 105 105 105 105 105 105

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

At rated load m/s 0,4 5 0,35 0,35 0, 45 0,35 0,35 0,35 0,35 0,35

At rated load m/s 0,4 0 0,40 0,40 0, 40 0,40 0,40 0,40 0, 40 0,40

At rated load km/h 30 30 30 30 30 30 30 30 30

at rated load % 67 57 48 51 45 38 40 36 35

At 2 km/h unlo aded % 106 95 83 64 60 54 62 50 55

at rated load % 47 41 35 37 33 28 29 26 26

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 85 85 85 85 85 85 85

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78 78 78 78 78

LwA (outside) dB (A) 110 110 110 110 110 110 110 110 110

At rated load m/s 0,45 0,45 0,35 0,35 0, 45 0,35 0,35 0,35 0, 35 0,35

At rated load m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40

At rated load km/h 30 30 30 30 30 30 30 30 30 30

at rated load % 51 48 41 35 37 33 28 29 26 26

At 2 km/h unlo aded % 69 69 62 56 4 5 43 39 44 37 40

at rated load % 3 6 35 30 26 27 24 21 22 20 19

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 8 5 85 85 85 85 85 85 85

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78 78 78 78 78 78

LwA (outside) dB (A) 109 109 109 109 109 109 109 109 109 109

8

Page 9

Combint aion Table DCE90-6 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160-6 DCE160-12 DCE180-6

Volvo TAD 620 VE, 8 5 kW Dana FT20000 x x x x x

Volvo TAD 620 VE, 145 k W Dana H R28000 x x x x x x x x x x

Volvo TAD 620 VE, 145 k W Dana T E13000 x x x x x x x x x x

Volvo TAD 720 VE, 174 kW Dana H R32000 x x x x x x x x x

Volvo TAD 720 VE, 174 kW Dana T E17000 x x x x x x x x x

Cummins 6B 5,9e 138 kW Dana HR 28000 x x x x x x x x x x

Cummins 6B 5,9e 138 kW Dana TE1300 0 x x x x x x x x x x

Drive train

Drive ax le with oil co oled brakes x x x x x x x x x x

Pneumat ic rubber t yres 11,00 x 20 x x x

Automat ic gear change*

Automat ic gear change (Dana TE13000/17000) x x x x x x x x x x

Electronic inching (Dana T E13000/1700 0) x x x x x x x x x x

Option s

Optidrive (Dana TE13000 /17000) x x x x x x x x x x

* Only in com bintaion wit h Spirit Delta ca b and Kalmar ele ctronic

Volvo TAD620VE (145k W) + Dana TE13000 DCE90-6 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160-6 DCE160-12 DCE180-6

Liftin g speed U nloaded m/s 0,50 0,50 0,40 0,40 0,50 0,40 0,40 0,40 0, 40 0,40

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40 0,40

Travelling sp eed, f/r Unload ed km/ h 30 30 3 0 30 30 30 30 30 30 30

Gradeability Max unloaded % 103 103 92 81 63 59 53 62 50 54

Performance

Drawbar pull Max kN 107 107 107 103 103 103 103 103 103 103

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

12,00 x 20 x x x x x x

12,00 x 20 HD x

(Dana F T2000 0, HR28000/320 00)

At rated load m/s 0,45 0,45 0,35 0,35 0, 45 0,35 0,35 0,35 0, 35 0,35

At rated load m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40

At rated load km/h 30 30 30 30 30 30 30 30 30 30

at rated load % 4 8 46 40 34 36 32 28 29 26 25

At 2 km/h unlo aded % 65 65 60 55 44 42 38 43 36 39

at rated load % 35 33 29 25 27 24 20 21 19 19

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 8 5 85 85 85 85 85 85 85

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78 78 78 78 78 78

LwA (outside) dB (A) 109 109 109 109 109 109 109 109 109 109

x x x x x

Volvo TAD720VE (174kW) + Dana TE17000 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160-6 DCE160-12 DCE180-6

Liftin g speed U nloaded m/s 0,50 0,40 0,40 0,50 0,40 0, 40 0,40 0,40 0,40

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0, 40 0,40 0,40 0,40 0, 40

Travelling sp eed, f/r Unload ed km/ h 30 30 30 30 30 30 30 30 30

Gradeability Max unloaded % >120 >120 >120 100 92 79 97 74 81

Performance

Drawbar pull Max kN 141 141 135 135 135 135 135 135 135

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

Cummins 6B 5,9e (138kW) + Dana TE1300 0 DCE90-6 DCE100-6 DCE120-6 DCE140-6 DCE100-12 DCE120-12 DCE150-12 DCE160- 6 DCE160-12 DCE180-6

Liftin g speed U nloaded m/s 0,50 0,50 0,40 0,40 0,50 0,40 0,40 0,40 0, 40 0,40

Lowering speed Unloaded m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40 0,40

Travelling sp eed, f/r Unload ed km/ h 30 30 3 0 30 30 30 30 30 30 30

Gradeability Max unloaded % 111 111 96 84 65 61 54 63 51 55

Performance

Drawbar pull Max kN 111 111 105 105 105 105 105 105 105 105

Noise lev el accordin g

to EN12053

Noise

Noise lev el accordin g

to 2000/14/EC

At rated load m/s 0,3 5 0,35 0,35 0, 35 0,35 0,35 0,35 0,35 0,35

At rated load m/s 0,4 0 0,40 0,40 0, 40 0,40 0,40 0,40 0, 40 0,40

At rated load km/h 30 30 30 30 30 30 30 30 30

at rated load % 67 57 48 51 45 38 40 36 35

At 2 km/h unlo aded % 106 95 85 64 60 54 62 50 55

at rated load % 47 41 35 37 33 28 29 26 26

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 85 85 85 85 85 85 85

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78 78 78 78 78

LwA (outside) dB (A) 110 110 110 110 110 110 110 110 110

At rated load m/s 0,45 0,45 0,35 0,35 0, 45 0,35 0,35 0,35 0, 35 0,35

At rated load m/s 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0,40 0, 40 0,40

At rated load km/h 30 30 30 30 30 30 30 30 30 30

at rated load % 51 48 41 35 37 33 28 29 26 26

At 2 km/h unlo aded % 69 69 62 56 4 5 43 39 44 37 40

at rated load % 3 6 35 30 26 27 24 21 22 20 19

LpAZ ( inside) Sp irit Delta dB(A) 73 73 73 73 73 73 73 73 73 73

LpAZ ( inside) OHG dB(A) 85 85 8 5 85 85 85 85 85 85 85

LpAZ ( inside) OHG FlexCab dB (A) 78 78 78 78 78 78 78 78 78 78

LwA (outside) dB (A) 109 109 109 109 109 109 109 109 109 109

9

Page 10

M

I

L

J

Ö

M

Ä

R

K

T

3

4

1

2

9

3

A quality machine for optimum overall economy

Reducing operating costs

The Kalmar 9 -18 range consists of a series

of models that have been designed in every

respect to provide long life with minimum

downtime. This has been achieved by

using technical solutions and components,

but not subjecting the truck to “in-built”

stresses that result in unnecessary wear

and higher costs. In this case we have

made a lot of improvements to something

that was already good.

Optimised chassis modules, xings,

frames, dynamic stability, electronically

controlled power trains, wet disc brakes,

more reliable and more efcient hydraulic

systems, smart options such as variable

piston pumps or Optirev, and not least, an

unbelievable driving experience. It is the

entire package that determines the quality.

Daily inspection

Daily inspections must be simple and

easy to carry out. All check points for

daily inspection are directly accessible at

working height under the engine cover on

the side of the truck. It can all be done in

just a few minutes.

Safety

All Kalmar trucks are CE-marked and

designed according to the following

standards:

• Machine directive 98/37/EG

• EMC directive 89/336

• Sound emission directive 2000/14/EC

Greater service intervals

Service intervals for the Kalmar 9 - 18 range

have been extended. Regular services

are needed only after 500 hours’ driving.

A simple calculation shows that a longer

service interval alone reduces a truck’s

operating costs by as much as 15% - and

then there is the service downtime.

www.kalmarind.com

Fast service and maintenance

The new Kalmar 9 - 18 range has been

designed to provide the best possible

accessibility. Tilting the cabin and opening

the engine cover exposes the entire power

train with easy accessibility to all vital

components and ser vice points.

Optirev - lower noise level, reduced fuel

consumption and lower emissions

The system, which is patented, reduces

the noise and keeps fuel consumption to

a minimum during lifting sequences in the

operating cycle by optimising the engine

revolutions compared to the weight of

the load, deection of the mast and the

machine speed at the time. The intelligent

and microprocessor-controlled Optirev

system is variable and installed in parallel

with the standard hydraulic system.

921524-0701/ 02-07 Råd & Re sultat Kommu niktion AB

We reser ve the right t o change the design and te chnical dat a without prior notice.

A Partek Company

Kalmar Industries AB SE-341 81 Ljungby, Sweden, tel. +46 372 26 0 00, fax +46 372 263 90. Kalmar Industries Sverige Torggatan 3 SE-340 10 Lidhult ,

tel. + 46 372 260 10, fax + 46 372 659 77. Kalmar Industries Oy AB p.o box 387 FI -33101 Tampere, tel. +358 3 265 81111, fax +358 3 265 8201.

Kalmar Pacic Limited Rm 1501-04, prosperity centre, 77-81 Container port road, Kwai chung, n.t. Hongkong, tel. +852 2944 8383, fax + 852 2944 9966.

Kalmar Industri es USA Inc. 415 East Dundee street, Ott awa, Kansas 66067, tel. +1 785 242 2200, fa x +1 785 242 6117

Loading...

Loading...