Page 1

GB

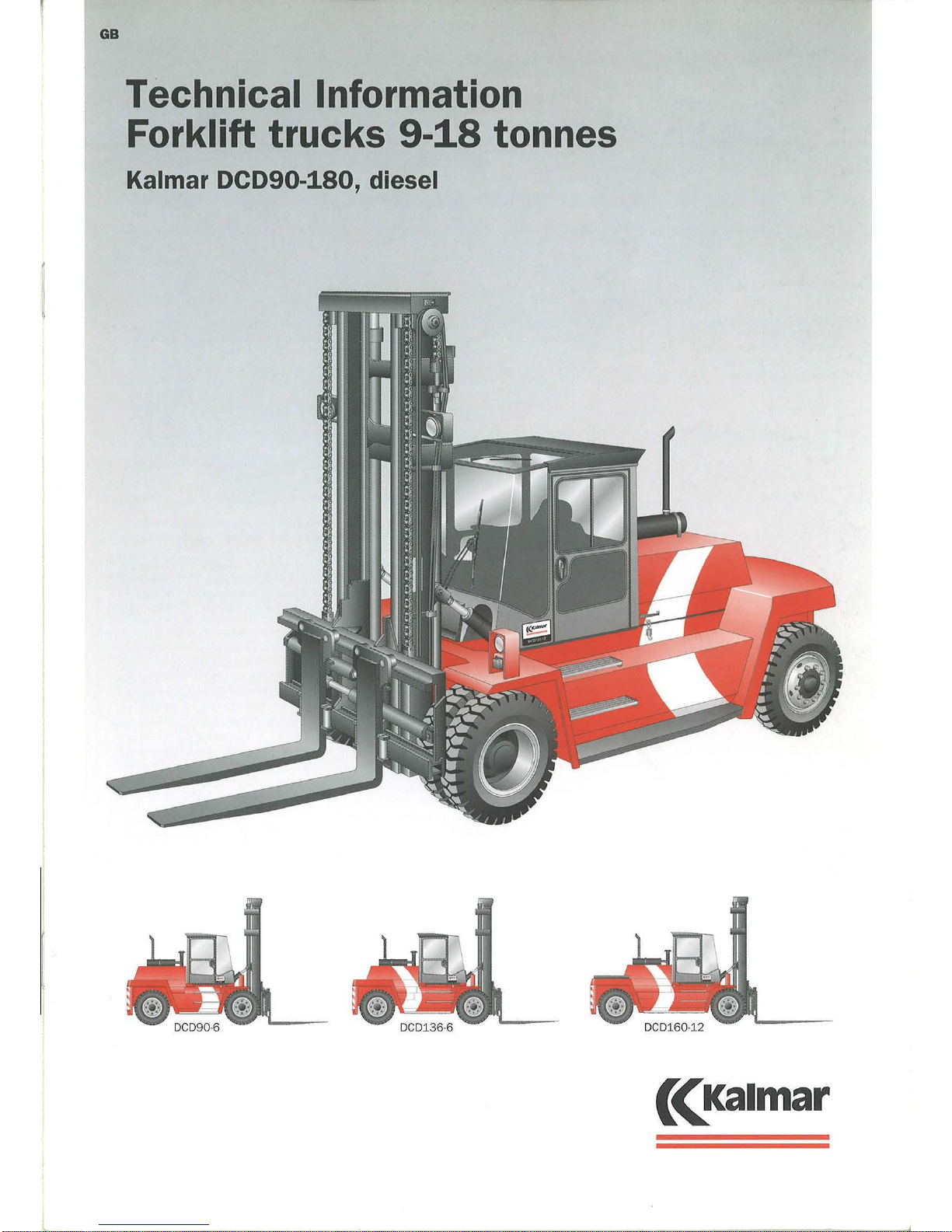

Technical Information

Forklift

trucks

9-18 tonnes

Kalmar DCD90-180, diesel

Page 2

l

Ka

lmar Industries

DCD90·180

The DCD90-180 with a lift

cap

acity

of

9-

18 tonnes

is the n

ew

generation

of

fo

rklift trucks in the medium segment

of

Kalmar's c

ompr

ehen sive range

of

4-

90 ton trucks - a well prov

en

range

of

tru

cks incorporating the latest design

so

lutions for o

ptimum productivity and

overa

ll

eco

nom

y.

A compr

ehe nsi

ve

range of o p tional

e

quipm

en t

pac

kages facilitat

es adaptation to sp ecial h andling environments

and

different typ es

of

goods.

Ty

pe designation:

DCD100·

12

Co

unter_-b

alan

ce

tru

ck

Dk

sel engine

::"_J

I T

Generation

---

- -

Lift

capacity, dec

itonnes

Load ce

ntr

e, decimetre

Opera

tor

Environment

The S

pir

it Delta cab is

of a co

mple

tely

n

ew

and mod e

rn des

ign that p rovid

es

th

e operator

with

an efficie

nt and

safe

place of wo rk.

Th

e design

of

the cab is

th

e result

of a co

mpr

eh ensi

ve

analysis

of

ope

rators ' working condition s

providing o

ptimum

visibility w it h large

glass areas and n o forward

corner p osts

to inhibit

th

e field of vision . The ins

tru

-

ment panel is gently ro

und

ed and ergo-

nomically designed

with

an

uninhibited clear

vi

ew

of a

ll

essential

informati

on. Access

to

the cab is

comfortable a

nd

secure thanks to the

thr

ee

ste p s

up

to th

e c

ab

and many well

located ha

nd

rails.

All cabs in th e seri

es can be tilted, for

op

timum

service

access. Noi

se

and

vibration levels are extr

emely l

ow

thank

s to the insulated mounting to the

ch assis. The tilting cylinders

ope

rate

against the

cab

whi

ch is isolated by

m

ea

ns

of

r ubb

er

elements.

The

ope

rator 's seat, steerin

g whe el and

hy

dr

aulic contr

ols are a

ll

individually

adjustable for

op

timum working

pos

ition. Two easily operated , ergonomically p osition ed multi-function l

eve

rs

are provid

ed for gear chang in

g,

wind-

scree

n wipers, washers a

nd horn

.

An

extremely

powe

rful h

eating/ve

ntila-

tio n unit e ns

ur

es a comfort

abl e cab

te

mp

erature. An easily replaced fre

sh

a

ir

filter cleans the incomin

g a

ir.

2

Technical Information DCD90-

180

Th

e unit sli

des

out to give easy access

for

se

rvice.

As

standard, t he e quipment

includ

es

a p

owe

rful

3-spee

d fan for

coo

lin

g, heat

ing, defrosting and recir-

culation.

O

pti

onal Extra

s:

• Extr

a h igh

cab

, +200

mm

• Elevated cab, + 300

mm

• Overhea

d g uard

• Roof mounted grid p rotection

• Co

mpl

ete

climate co

ntr

ol system

• Partially /fully rotatable

oper

ator se

at

Ins

trumenta

tion

Th

e instrument panel has logically

grou

pe

d units , a

ll

w ithin easy r each.

Sta

nd

ard ins

trument

ation includes

wa

rnin

g lamps for batte ry chargin

g,

l

ow

engine lubrication o

il

pressm e,

l

ow brake pressure, high

coo

lant

te m

pe

rature, high gearb

ox

oil tempera-

tur

e a

nd

applied parking brake.

In

add i-

tion, gauges display valu

es for engine

coolant

temperature, fu el quantity a

nd

op erating time .

Truc ks fitted w ith

ECS

mo nitorin

g are

not normally e

quipp

ed with wa

rnin

g

la

mp

s o r gauges. Th

ese functions are

handled by the

ECS

w hic h has a single

war

ning la

mp and

full text display

sh

ow

ing c urren t valu

es and

any faults

that

occ

ur.

Chassis

Th e chassis is built

of

fully welded ste

el

p ro

fil

es which g ives a rigid con

struc-

tion w

ith extr

emely strong mounting

po

int

s for the drive axle a

nd

lift equip-

ment.

S

tr

ess concentr ations have been elimi-

Jut

ed for o

ptimum

te nsile stren gth.

Th e chassis is flexible and is used

fo

r a

numb

er

of

differe nt drive line comb

ina-

tion s. The sp ace at the re

ar

of the

c

ha

ssis is used for count

er-weights, the

numb

er

of

w hich are adapted

to th

e

m

ac

hine in question.

Th e chassis

ha

s an

ext

rem e ly l

ow

profil

e for good visibilit

y.

Th e tanks are

separate

ly con

str

ucted and bolted to

th

e chassis in a position that al

so

co

ntribu

tes to good visibilit

y.

Page 3

Technical Information DCD90-180

Electrical System

The elect

rical system is logically struc-

tured, easily serviced a

nd

comp

letely

coordi

nat

ed

wit

h the

other

trucks

in

the

Kalmar range.

The

system

is

suppli

ed

by

two

12V batteries

connected

in

ser

ies c harged by

an alt

er-

nator,

with related electronics for recti-

ficati

on

and

current

stab

ilization.

The

system

provides

high

power

levels

even

at

low

engin e revs. Th e electrical

fuses, relays and

connectors

are

l

ocated

in

an

easily accessible

position

withi

n a

centra

l electrical unit inside

the

cab,

behind

the

operator

's seat.

KL898

Central electrica l unit

ECS (Optional)

· Electronic Control

System

Trucks can

be

equ

ipp

ed with

ECS,

a

sta

te

of

the

art

system for

optimum

operational security

and

overa

ll

eco

nomy.

The

systems consists

of

a

numb

er

of

modules that

can

be

combined

in different ways,

depending

on

the

nature

of

the

operations. For

examp

le,

the

foll

owing

function s are

ava

il

able:

• Automatic

gear

changing

(Load sensing system)

• Lever

steering

• Mini-steering

• Monitoring

• Electr

o-servo

See also

separate informati

on

about

the

Kalmar

ECS

System.

Engine

As

standard,

the

DCD90-180

truck

is

equipped

with

Volvo 's TD640VE diesel

engine and as

option

the

DCD90-136

with

the

Perkins 1006-60T1,

both

turbo-charged straig

ht

six diesel

engines

adapted

to

the

specialized

working requirements

of

a forkl ift

truck

, w i

th

high

power

and

torque

level

s,

even

at l

ow

engine

speeds. The

eng

ine has l

ow

exhaust

emission l

eve

ls

and

comp

lies

wit

h today's stringent

legal

enviro

nment

al

demands

(EU,

CARB,

EPA).

All engines

are characterized by l

ow

fuel consumpti

on

and l

ow

noise and

vibration levels.

Alternative engines:

• Perkins l 006-60T2

•

Volvo TD730VE

• Volvo TWD731VE

• Scania DI9

• C

ummins 6BTA

5.9-C200

See

Alternative drive lin

es

table

Transmission

Al

l trucks in

the

series

are

equipped

wit

h Clark's well

proven

hydro-

dynamic transmission systems

(3+3)

,

with integrated gea

rb

ox

and

torque

converter

, for

smooth, quick

acce

lera-

tion w

ith

a minimum

of

"clutch-slip".

A

number

of

different transmissi

ons

systems are ava ilable,

depending

on

the

sel

ected

engine

(see separate combin

a-

tion

table). Constant

mesh

gears and

gear

cha

nging by hydraulically

applied

clutches

(Powers

hift) are, h

owever

,

common

to all gearboxes.

Gear ch anging is el

ectrically achieved

via sol

enoid

valves,

with

three

reverse

and

three

forward gears,

controll

ed

by

means

of

an

easily

ope

rated multi-func-

tion lever.

Drive

axle

The

Kessler

D81

drive axle is

of

an

extreme

ly robust design to

be

able to

cope with

tough working environ-

ments

such

as

in

the

paper

and

pulp

industries, saw mills,

steel wo

rks,

ports

and terminals.

The

axle has reduction in

two

stages -

diff

ere

ntial and

hub

reduction -which

ensures

a minimum

of

strain

on

the

transmission system.

The

drive axle is

fitted w

ith

hydraulic braking system

(see

Servi

ce

Brake System).

Parking Brake System

The

parking brake system consists

of

a

dry

disc

brake

on

the

in-going shaft

of

the

drive axle. The disc brake

is

applied

by

means

of

a powerful spring in

the

parking

brake

cylind

er

and

is released

by

means

of

hydraulic

pressure

from

the

parking brake valve

in

the

cab.

Kalmar Industries

Volvo

TD640VE (6-cyl with turbo)

Service Brake System

The

service brake system

is

of

the

Wet

Disc Brake type, a system w

ith oil

-

coo

led discs

that

are alternate

ly

fixed

to

and rotating

with

the

hub.

When

the

brakes

are

app

li.ed,

the

discs are

pressed

together

by

hydraulic

pressure

from

the

brake pedal,

which provides

extremely effective braking.

The

system is v

irtually maintenance

free

and

can

cope

wit

h heavy l

oads

over

an

extended

period

of

time,

with

no fade

and

w i

thout

the

need

for

brake

adjust-

ments. The

heat

generated

durin

g

braking is dissipated via a

coo

ling

circ

uit

in w hi

ch

th e

truck

's total

volume

of

hydraulic fluid

comes

int

o

play. A

spec

ial filter

protects

the

braking system from any impmities.

Hub reduction

Kessler drive

axle

3

Page 4

Kalmar Industries

Load

diagramme

19

18

17

16

15

14

13

12

11

10

oco~aJ!BJ

1\.

ocoi6o.~(BJ

~

DC

D

160-9(B)

DCD

160-12 (B)

1\

r'\

f'

DCD

-

~

150-12

(B)

I

"\

"\

'

~

I'

~~

~

~

(A)

"'

~

~

~

~

~

1\.

~

'

"'~

DCD ......

~

"""

~

DCD120·6

(A)

1\.

120-12 (B)

~

"

'

"'

~

~

~

~

!oo..

DC D

~O().~

(A)

'

~

~

DCD100-L

(Al

['..

~

r

.......::

"'

<ll

9

c

c

B

8

z:.

'

(3

(I)

7

a.

(I)

0

o

co19().6

~

~

~

~

I'

~

.....

!'-

I"-

"

~

I'.

"""'

R

""'~

r-....

i'.

~

~~

.....

r--....

r--.

-

~

W)

c

6

;£?

::;

5

KL1073

600

900

1.200

1500 1800

2000

Load Centre, mm

A.

Perkins engine

B. Vol

vo

engine

1.

DCD

90·6

to DCD180·6 model

s:

Full lifting capacity

up

to

5000

mm

lift heig

ht wit

h Duplex/Duplex free-

lift

/T

riplex masts and integrated sidesh

ift/fork

positioning carriage.

4

Technical Information DCD90-

180

1 Model

Lifting capacity, deciton - Load centre distance, declmetre

A=

Perkins engine B = Volvo engine

2 Lifting capacity Rated

kg

!l

At max lifting height kg

..

...,

3 Lifting speed Unloaded

m

/s

'M

"'

At rated load

m/s

i2

4 Loweri

ng

speed

Un

loaded

m

/S

:J

At rated load

mjs

5 Driving speed forward/

Unloaded

km/ h

reverse

At rated load

km/h

.,

IJ

6 Gradient capability

Max, unloaded

%

c

..

Max

at

rated load %

E

.g

At 2

km/h

, unloaded

%

"

At 2

km/h,

at rated load %

D.

7 Draw bar pull

Max

kN

8 Stability

ISO

1.074/

10525

Yes/No

9 Service weight

kg

l:

10 Axle load front

Unloaded

kg

'M

At rated load

kg

-.;

~

1.1

Ax

le load back

Unloaded

kg

At rated load

kg

12

Engine

A.

Perkins B.

Volvo

Manufacturer- type designation

Fuel

· type

of

engine

Rating

ISO

3046 -at

revs [kW/ hp · rprr

Peak torque

I

SO

3046

·at

revs

Nm-rpm

e

.,

No of cylinders -

dis

placement cm

3

t>

,.,

Fuel consumption, normal operation

1/h

13

Alternator

Type- power

"'

w

.,

14

Starting battery Voltage -capacity

V-Ah

>

5

15

Gearbox

C.

Clark

20000

D. Clark

28000

Manufacturer · type

des

ignation

Clutc

h, type

Gearbox, type

No.

of

gears forward - reverse

16

Drive axle

Type

17

Wheels/ tyres

Type

front

and

rear

vi

Dimensions, front and rear/

Ply

inches,

.,

'!lO

numbe

D·e

No.

of

wheels, front - rear (* dnven)

_.,

Inflation pr

ess

ure

~$

MPa

::"'

18

Steering system

Ty

pe - maneuvering

.::

~

19

Service brake syst

em

Type

-affected wheels

20

Parking brake system

Type

-affected wheels

21

Hydraulic pressure Max MPa

0

22

Noise level DIN

45635

·36

Equivalent n

oise

level in cab (Lm) dB(A)

"'

~

23

Fuel volume L

24 Hydraulic

fluid volume L

25

Minimum

ais

le width for

90°

stacking with forks A1

mm

26

Tru

ck Truck length without for

ks

L

mm

Truck

width

B

mm

Height, basic machine

H6

mm

Seat height

H8

mm

Di

stance between centre of front L2

mm

axle - front face

of

fork

arm

Wheelbase L3

mm

Load centre L4

mm

Track

(c-c) front - rear

s

mm

Turning radius, outer

R1

mm

"'

Turning radius, inn

er

R2

mm

c

0

Ground clearance, min

·;;;

mm

c

Max height when tilting cab T1

.,

mm

E

Max width,

tilted

cab

T2

Ci

mm

27

Standard duplex

mast

Lifting height H4

mm

Mast

height, min.

H3

mm

Mas

t height. max.

H5

mm

Mast tilting, forwar

ds

-backwards

n·P

.

Grou

nd clearance, min mm

28

Forks

Width b

mm

Thickness

a

mm

Length

of

fork arms

I

mm

Width across fork arms, max v

mm

Width across fork arms, min

v

mm

Sideshift ±

at

width acr

oss

fork

arm

V1-V mm

This table relat

es

to trucks fitted with standard equipment,

for opti

onal equipment,

see separate tables.

1

l More powerful engines are available, up

to

167 kW/

230

hp

2

> Stronger gearboxes are available , Clark

32000

(3+3)

3

l

Semi-solid tyr

es

are available for all models (Super-Elastic)

We

reserve the right to alter design and material specifications, without pri

or noti

ce

Page 5

Page 6

L

Kalmar Industries

Steering System

The steering system is compl

etely

hydraulic

and

is

ted

from hydraulic

pump

1 (see the hydraulic system

diagram), via a priority valve.

Wh

en the

st

ee

ring

whee

l is

turned, th

e steering

v

al

ve transmits a load signal to the

priority val

ve

which

ensures

that

the

steering system always has sufficient

hydraulic

pr

essure.

Th

e steering axle

is

an

extremely

robust construction with double-action

cylinder.

Th

e pendulum suspension

of

the axle

over powerful,

spherical rubber

bear

-

ings has a lo

ng

operative lif

espan

and

pro

vides good shock-absorption .

The

minimal

numb

er of parts e nsures

oper

-

ational reliability, a minimum

of service

point

s and easy ma

int

enance. The

st

ee

ring

geometry

allows large

whe

el

displa

cement

and

thereb

y,

a tig

ht

tmning

circle.

Hydraulic System

Th

e hydraulic system includ

es the

following sub-systems:

• Working hydrauli

cs

• Service bral{e system

with braking

circuit and cooling circuit

• Parking brake sys

tem

• Hydraulic servo (standard)

• Steerin

g system

In standard form,

the

hydraulic system

is built a

round

two

gear

wheel

type

pump

s -

one

double and

one

single.

The pumps

are driven from the outlet

of

the torque

converter.

The flow

from

the pumps

is

feel

to a valve block

with

a

large

number

of

in-built f unctions (see

diagram). The valve block enabl

es

easy

installation

with

a minimum

number

of

hydraulic lin

es/hoses.

The

oute

r section

of the double

pump

feeds

the

lift

and

tilt functions, whil

st

the

inner

section

feeds

other

working

hydraulic function

s.

With fu

ll

exten-

sion

of the lift function, both

sec

tions

of

the

double

pump

operate

to provide

maximum

lift capa

city.

The

separate single

pump fee

ds

the

hydraulic accumulator,

which

in

turn

,

suppli

es the brake

and

servo systems.

As

a safety measure,

the

accumu

lator

ensures suffici

ent

brake pressure

to

be

able to

br

ake several times, should the

engine temporarily stop.

Th

e excess

flow

from

the

pump

s is l

ed

to the brake cooling circuit to dissipate

the he

at

generated during braking,

befo

re

being re

turned

to

the

hydraulic

tank.

Optional extras:

• Load sensing variable

pump

s

• Electro-servo controls

• Piston

type

accumul

ator

• Additional hydraulic functions

• Hydraulic joystick

6

Technical Information DCD90-180

Double-action

cylinde

r

Spherical

rubber bea ring

Steering

axle

1. Hydraulic

pu

mp, working

hyd

raulics,

steering system

2.

Hydraulic pump,

lift/t

ilt

3. Hydraulic pump, accumula tor charging

4. H1gh

pressure filter

5. High pressure filter

6. Main valve wi

th

double val

ve

block

a.

Accumulator

charge

valve

With fully charged accumulator feed to

brake

cooling circuit or return to tank

b.

Feed,

servo system

c.

Priority valve, steering syst

em

d.

Feed,

steering system

e.

Main pressure limitation val

ve

f. Contr

ol

valve,

LEVELLING

g .. Contr

ol

valve,

FORK

POSITIONING

h Contr

ol

valve,

SIDE-SHIFT

j.

Control valve,

TILT

k. Contr

ol

valve,

Ll

FT

m. Main pressure limitation valve

KL695

Hydra

ulic system

fo

r tru

ck

with Vol

vo

engine

7. Steering system

8.

Cooling circ

uit for servi

ce

brake system

9. Brake circuit, service brake system

10

.

Pa

rking brake system

11

. Accumulator

12.

Servo

assisted control levers

13.

Hyd

raulic tank

14.

Breather filter, hydraulic tank

Trucks

with

Perkins engines

are

equipped

with a simpl

er

hydr

aulic

system

with only

one

double

pump.

One

section

of the

pump

feeds

the

working hydrauli

cs

whilst

the

other

sect

ion fee

ds

the

steer

ing system a

nd

charges

the

accumulator.

The

main

va

lve is fitted

with

a valve block,

input

section and main pressure limitation

va

lve.

--

Page 7

Technical Information DCD90-

180

Lift

Mas

ts

All masts, b

ot

h d u p l

ex and tri

p lex, are

constructed

on

th e "free visibility p rin-

ciple"

and

can

be supplied with

the

area

steered

free-Lift

system whic

h, in

term

s of fun

ctio

n, is extr

eme

ly reliable

a

nd

secure.

The

rob

ust mast profil

es

are

of

high

tensil

e steel, di men sio ned fo r minimal

ob

struction

of

th e fie

ld

of

visio n a

nd

long servi

ce

life. Th e lift cylinde rs

are

pos

itio n

ed

in the "

dea

d " angl

es

of th e

mas

t.

All mast wh

ee

ls are harde ne d a

nd

fitted with high q uality bearings.

As

standard, trucks are fitte d w ith the

dup l

ex free

visibility mast.

Optional extras:

• Dupl

ex

free visib

ili

ty m

ast

w it h

free-lift

• Trip l

ex free

visibili

ty

mast wi

th

free-lift

Duplex free

visibility mast

Dupl

ex

free

visibility

mast

with

free·

lift

Triplex free

visibi li

ty

mast

wi

th

free·

lift

90·136,

two free·

lift

cylinders

(150-180,

one

ce

ntr

al free-l

ift

cylinder)

Fork Carriages

A nu mb e r

of

different models

of

fork

carr

iages are available, a

ll

of

them

wit

h

excellent th

roug

h-vision. T h e stan dard

mode

l has ma nu ally

moveab

le forks.

Howev

er,

the

majority

of

trucks are

suppli

ed

with hydraulic side-shift a nd

fork

posi

tioning.

Option al extras:

• For k

pos

itionin

g/s

ide-shift

• Fo rk

pos

itionin

g/side-shift w i

th

levelling

• Fork

pos

itio nin

g/s

ide-shift w ith

ce

nt re levelling

• Side-s hi ft ca

rri

age

•

Fork shaft system

• Ad di tional types

of

clamp

attachments

• Coil rams fo r

steel han

dling

Side-

shift

carriage

F

orks

Th e forks

are

one-pi

ece

for

ged

in

hig h

tens

ile stee

l.

Th e standard fitti ng is

over

hooks o n the fork carriage , w hil st

hydraulically co

ntroll

ed forks are fitt ed

ove

r rollers

runnin

g on bearings - fo

ur

up

per roll

ers a

nd

two lower suppo

rt

fo r

each fo

rk.

For

ease

of

changing bet

ween fo

rks and

other attachments, a fork sh aft system

is available , w h

ere

the forks

are

mounte

d on a separate fo rk ho lder.

1.

Standard forks

for

manual

manoeuvring

2. Forks with

roller

fittings for hydraulic

manoeuvring

3.

Fo

rk shaft system

with separate

ho

lder

for each fork

4.

Forks with

hydraulic levelling

3

Kalmar Industries

Lift

Uft

Lift mast

Free

· Lift mast

Free-

mast

heigl'lt

heig

ht

lift

height

lift

Min Max

Min

Max

H4

1)

H3

1)

H5

H2

H3 H5

H2

mm

mm

mm mm

mm

mm mm

90

·6-

136

-6

100-1 2-

180

-6

Dupl

ex

3000 3000

4500

-

3185 4685

-

fr

ee

3250

3125 4750

-

3310

4935

-

vis

i-

bility

3500 3250 5000

-

3435

5185

-

3750 3375 5250

-

3560 5435 -

4000 3500 5500

-

3685 5685

-

4250 3625 5750 - 3810

5935 -

4500 3750

6000

-

3935 6185 -

4750 3875

6250

-

4060

6435

-

5000

4000

6500

-

4185 6685 -

5250 4125 6750

-

4310 6935 -

5500 4250 7000 - 4435 7185

-

5750 4375 7250 - 4560 7435

-

6000

4500 7500

-

4685 7685

-

6250

4625 7750

-

4810

7935

-

6500

4750

8000

-

4935

8185

-

6750 4875 8250 - 5060

8435

-

7000 5000 8500 - 5185

8685

-

Duplex

3000

3000 4500 1500 3175 4675 1500

fr

ee

3250 3125

4750

1625 3300

4925

1625

vi

si-

bility,

3500 3250 5000 1750 3425 5175 1750

fr

ee-

3750 3375 5250 1875 3550 5425 1875

lift

4000 3500 5500 2000 3675 5675 2000

4250 3625 5750 2125 3800 5925 2125

4500 3750

6000

2250 3925 6175 2250

4750

3875 6250 2375

4060

6425 2375

5000 4000 6500 2500 4175 6675 2500

5250 4125 6750 2625 4300 6925 2625

5500 4250 7000 2750 4425 7175 2750

5750 4375

7250

2875 4550

7425 2875

6000

4500 7500

3000

4675 7675

3000

6250 4625 7750 3125 4800 7925 3125

6500 4750

8000

3250 4925

8175

3250

6750 4875

8250

3375 5050

8425

3375

7000 5000

8500

3500 5175 8675 3500

Triplex, 4500 2940 5940 1500 3120

6180

1500

free

4750

3025

6190

1580

3205

6435

1580

vis~

bility

,

5000

3110 6440 1665 3285

6685

1665

fr

ee-

5250 3195 6690 1750

3370

6930

1750

lift

55

00

3280 6940 1830 3450 7180 1830

5750 3360 7190 1915 3535 7435 1915

6000 3445 7440 2000 3615 7685 2000

6250 3530 7690 2080

3700 7940

2080

6500

3615

7940

21

65

3780

8180

2165

6750 3700

8190 2250

3865

8435

2250

7000 3780 8440 2340 3945

8685

2340

1)

These figures are based on the 1

20·6

and

va~

wi

th

tyre dimen sions. H3 and H5 alter

-

1 mm for

90-100

·6

+20

mm for 1

36-6

:!"

Ia

~

I

~):1,

2

........

~

f

•

~

..

~

.......

·t:

~

,

~

4

l i

~

~

l

""'

~

......

~

7

Page 8

Kalmar Industries

Service Access

Ro

utin

e daily service

checks

cont

ribu

te

to

a safer

work

place and reduce the

risk

of break

-downs.

Daily servi

ce che

cks are

made

easier

thanks to well

thought out and

grouped servi

ce

points. The

ope

rator

can r

eac

h a

ll

servi

ce

points without

having to climb

up onto the

truck

.

The

cab can

be

tilted

by

means

of

a

hydrauUc cylind

er

ope

rated

by

a

manual

pump. When

the

cab has been

tilted, the

gearbox, hydraulic

pumps

,

hyclrauUc fluid fil ter, parking brake,

main

va

lves, control valves, etc., are

readily accessible for servi

ce

.

The

eng

ine ho

od

is divided into

thr

ee

sect

ions - a fixed middle

section

that

bears

the silencer

and

hinged out

er

sect

ions to

each si

de.

1.

Indicator for air filter

2. Gearbox

oil, dip-stick and filler cap

3. Engine

oil, dip-stick and filler cap

4.

Coolant

5. Screen wash liquid

6.

Fuel,

filler cap

7. Main switch,

electrical system

8. Batteries 2x12 V -

140

Ah

Truck with overhead guard.

I

CRTRRCOM

INV

z:,~EENG

E

3M3~"EG

7 Tel. +32 {0)3 541

77

22

••

• Fax +32 (0)3

541

28 23

2030 ANTWERP

EN-

3 E-mail info@catracom.

be

BELGI

UM

www.catracom.com

Technical Informati

on

DCD90-

180

Standard equipment

The

standard

spec

ifi

cati

on

of

our

trucks includes

imp

ortant

and

vital

co

mponents that

con

tribute

to

the

effi-

cien cy and safety

of

the

truck.

• Robu

st

truck

chassis 9-18 ton

• Spir

it

Delta operator environ

ment

w ith l

ow

noise level

•

Til

table

cab

insulated again

st

vibration

• P

owe

rful

ven

tilation

unit

wit

h effi-

cient

filt

er

• Roof

window

of lexa

n

• Sliding w

ind

ow

on

the

left hand side

•

Wash/wipers

, front, r

ear

and

roof

• Lockable

cab

doors

· •

Wiele

bottom

access

step and

two

extra

steps

on

both

sid

es

Adjustable,

shock

absorbing, e rgo-

nomic

operator

seat w ith safety b elt

• Three-way adjustable

stee

ring console

• Two-way adjustable hydraulic lever

conso

le

•

Ann support

on right

hand

side

• Environme

nt

friendly powerful engines

• Fully dim

ensioned

radi

ator for

engine

and

oil

cooler

for gearbox

• Powerful gearboxes

with

powershift

• Drive axle with o

il

coo

led

eli

se brakes

• Free visibility lift equipm

ent

• Steering axle

with

double-action cyl-

ind

er

• Hydraulic system with finger tip control

• Simple, reliab

le electrical system

• Co

mpr

ehe nsive and logically

gro

up

ed instrumentation

• Accelerator, brake

pedal

and

forward-

reverse selector

• Lig

htin

g:

Working ligh ts, indicators,

brake, reversing and

pos

itional lights

• Large servi

ce hatc

hes and tiltable cab

for daily i

nspections

• Towing p in (manual)

•

Comp

lete

documentation

Alternative drive lines

e = Standard 0 = Optional

En

gine *Turbo **Turbo, intercooler

Volvo

TD640VE*

129

kW/690

Nm

Perkins 1006-60T1 •

85

kW I 465

Nm

Volvo TD730VE*

15

0 kW/800

Nm

Volvo

TW0731VE

**

1

67

kW/893

Nm

Perkins 1006·60T2*

114

kW/620

Nm

Scan

ia

019

**

1

67 kW/930

Nm

Cummins

6BTA5.9-C200

**

162 kW/814

Nm

Gearbox wi

th

powershift,

3+3

gears

Cl

ark

13.

7HR

28000

(Volvo

TD640VE, TD730VE,

Perk

ins 1006·60T2, Cummins

6BTA)

Cl

ark

1207

FT

20302

(Perkins 1

006

·60T1)

Cl

ark

13.

7HR

32000

(Vo

lvo TD640VE,

TD730VE.

Volvo

TWD731VE,

Scania

01

9, Cummins

6BTA)

Drive axle wi

th

Wet

Disc Brakes

Pn

eumatic tyres

10.00x20"/16

PR

11.00x20"/16

PR

12

.00x20' '/20PR

Optional: Semi

-so

lid tyres (Super-Elastic)

Safety

A

ll Kalm

ar

trucks are CE-marke

cl

and

are con

structed to

and

comp

ly w

ith

the

followin

g norms:

•

EN1551

•

ASME

B56.1

(USA,

trucks

up

to

13.6

tonnes)

• EN12895 (EMC

test

, Europe)

Optional equipment

A

wide

range

of

optional eq

uipm

ent

and packages are available for

our

trucks, to satisfy furt

her

spec

ializa

tion

and provide added efficiency

• Alternative

engines

and

gearboxes

• Load sen sing hydraulic syst

em

• Exterior and interior

cab equi

pment,

such

as air

cond

itioning,

etc

.

• Lighting, mirrors

and

protective

grid

• Different types

of

lift equipm

ent,

at-

tachments

, ex

hau

st contr

ols, air

fil-

ters, etc.

•

ECS

wit

h different types

of

module

• Catalytic

converte

r and particle filter

Summary

Ka

lmar's

medium

trucks

are

of a we

ll

proven

design, ma

nuf

actured in large

volumes for demanding en

vironm

ents

su

ch

as:

• Timber,

paper

and

pulp

indu

stries

• Steel

wor

ks and foundries

•

Concrete

industry

• Ports

and

terminals

•

Other

heavy industri

es

A well

planned

and

protected

operator

envi1'onment mak es Kalmar's trucks

efficie

nt

and comf

ortable

wor

king

implements.

R

ea

dily

acce

ssible set·vi

ce

points for

ease

of

maintenance.

•

•

• • • • •

• • • •

0 0 0 0 0

0 0 0 0 0 0 0 0 0

0

0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0

0

0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0

• •

•

•

•

• •

• •

• •

0 0 0 0 0

0 0 0 0 0 0 0 0 0 0

0

•

•

• • • • • • • • •

• •

•

• • • • • •

•

•

0 0 0 0 0 0 0 0 0 0 0

. almar Industries Sverige AB

E-341

81

Ljungby, Sweden

Kalmar Industries

Oy

Ab

P.O. Box

387

Kalmar Industries USA Inc •

415

East Dundee Street

Ottawa,

Kan

sas

66067, USA

Tel.

+1

785

242

2200

31.

+46

372

260

00

ax +46

372

263

90

FIN-331 01 Tampere, Finland

Tel.

+358 3 265

8111

Fax

+358 3 265

8201

Fax

+1

785

242

6117

A Partek Company

Loading...

Loading...