Page 1

00

General

Technical

Handbook

DCD90-180

DCD70-32E3 - 70-40E5

This Handbook deals with the design

and maintenance of Kalmar forklift

trucks, type DCD.

10

20

30

40

Chassis and cab

Electrical system

Engine

Transmission,

drive axle, brakes

In addition, it gives details of

troubleshooting and the most common

corrective maintenance.

Operation and other matters that are

primarily of interest to the operator are

included in the Instruction Manual.

Kalmar Industries AB

We reserve the right to modify

our design and material specifications without prior notice.

50

60

70

80

Steered axle

Hydraulic system

Lifting mast and

fork carriage

Publ. No. 920 937 – 9350 02-08

AdEra Dokument AB, Växjö 2002

90

Periodic supervision

Page 2

Page 3

DCD90-180

Technical Handbook

9350

00-11

Contents

P.Group 00

1

Group 00

Contents

Safety regulations ..................................................................... 2

General ..................................................................................... 5

Applications ......................................................................... 5

Design ................................................................................. 6

Component units ................................................................. 6

Main components ................................................................ 8

Supplementary books .......................................................... 9

Replacement system – Spare parts .................................... 9

Tools .................................................................................... 9

Tightening torques ............................................................. 10

System of units .................................................................. 12

Page 4

DCD90-180

Technical Handbook

Safety regulations

It is important that you read the instruction manual

Incorrect handling can lead to personal injury or damage to products and/or property. Therefore, read the instruction book very

carefully before operating the truck. The instruction manual contains important information about your Kalmar truck, about the

operation of the truck, about safety during operation and about

the truck’s daily maintenance. In addition, you will find useful information that will make operations easier for you in your daily

work.

Ask your foreman/group leader if there is anything in the manual

that you do not understand or if you feel that information is missing in any area.

The symbol is used on our products in certain cases and

then refers to important information contained in the instruction

manual. Make sure that warning and information symbols are always clearly visible and legible. Replace symbols that have been

damaged or painted over.

9350

00-11

P.Group 00

2

Safety regulations

In this handbook warnings are inserted that apply to your own

safety. Warnings point out the risk of accident that can cause personal injury.

WARNING!

Warns of the risk of serious personal injury, possible

death and/or serious damage to product or property if the

regulations are not followed.

For technical warnings, that point out the risk of break down, the

word IMPORTANT is used:

IMPORTANT!

Is used to draw attention to such occurrences that can

cause damage to the product or property.

For information that facilitates the working process or handling,

N.B. is used:

N.B. Draws attention to useful information that helps the

working process.

Page 5

DCD90-180

Technical Handbook

Safety regulations

Safety regulations aimed at reducing the risk of personal

injury and damage to loads or other property.

9350

00-11

P.Group 00

3

Intended of use

z The truck may only be used for the purpose for

which it was intended, namely, to lift and transport

goods, the weight of which does not exceed the

maximum permitted load capacity of the truck.

z The truck may not, without specific permission

from Kalmar, be modified or re-built so that its

function or performance is altered.

z The truck may not be driven on public highways if

it has not been adapted to comply with national

road safety regulations.

Operator requirements

z The truck may only be driven by operators who

have been specially trained and who have the

company’s authority to do so.

z Laws and other regulations relating to driving li-

cence, operator ID, log book, etc., must be followed at all times.

z The operator must be aware of and follow all local

safety regulations.

Operation of the truck is prohibited:

z If any of the fitted safety equipment, such as rear

view mirrors, headlights, reversing alarm (optional) does not function correctly.

z If there is a fault with the brakes, steering or lift

equipment.

z If the truck is fitted with tyres not approved by

Kalmar.

Operating regulations

z Before starting, always check to ensure that no-

body is in the way of the truck or its equipment.

z Make sure that nobody walks or stands under-

neath raised forks or other equipment, whether

they are loaded or not.

z The operator must always face the direction of op-

eration and take particular care in areas where

persons or other vehicles are likely to appear in

the vicinity. If visibility is limited by the load, the operator should operate the truck in reverse.

z It is prohibited to transport passengers on the

truck outside the cab or on the load. Passengers

may be transported inside the cab only on condition that it is equipped with a fixed passenger

seat.

z It is prohibited to lift people if the truck is not

equipped with an approved lift cage.

z It is prohibited to exceed the load capacity of the

truck. See capacity plate and loading diagram.

z It is prohibited to transport loads in the raised po-

sition as this entails a risk of the truck tipping. All

transportation shall take place with the load in the

lowered position and with the mast tilted backwards to the maximum.

z The operator must adapt the speed of the truck to

the character of the load, conditions of visibility,

the character of the roadway/surface, etc.

z The operator shall avoid powerful acceleration

and braking when turning. In addition, the operator shall always moderate the speed of the truck

when turning so as to avoid the risk of lateral skidding or tipping.

z The operator shall take particular care when oper-

ating in the vicinity of electrical power lines, viaducts, quay-sides, ramps, gates/doors etc.

z Safety belts must always be worn, if fitted. In the

event of the truck tipping, always remain in the

cab and grip the steering wheel securely. Never

try to jump out of the cab.

z The parking brake can also be used as an EMER-

GENCY BRAKE. However, having been used for

emergency braking, the brake linings must be inspected and replaced if needed. If the parking

brake has been mechanically released, it must

always be reset in order for the truck to regain

the parking brake function.

Interrupted operation, parking

z Always check that the gear lever is in the neutral

position before turning the ignition key to restart or

to reset an emergency stop.

z Never leave the operator’s cab without applying

the parking brake (ON position).

z Always remove the ignition key if the truck is to be

left unattended.

Other important points to remember

z The truck’s hydraulic system includes high pres-

sure hydraulic accumulators. Always be extremely careful when working with the hydraulic system

and avoid being unnecessarily close to the hydraulic equipment, lines and hoses. Before working on the hydraulic system, the accumulators

must be emptied into the tank, with the help of the

special accumulator evacuation valve.

z Handle batteries and junction boxes with great

care. The batteries must always be protected over

the poles and connections.

z Always rectify any damage or wear and tear that

can risk personal safety or that can affect the

functions of the truck or its service life.

z Trucks with tippable cabs: The cab must always

be tipped over the point of balance. If there is insufficient lateral space the cab must always be secured against accidental lowering with a brace or

similar.

z Avoid touching oils and greases. Avoid inhaling

exhaust and oil fumes.

z Welding painted steel produces poisonous gas-

ses. Paint should therefore be stripped before

welding, good ventilation ensured and/or face

mask with filter used.

Operating with attachments

zThe operator must always take the effect of the wind

into account when handling containers. Avoid lifting

with a wind strength in excess of 12 m/s (27 mph/40

feet per second).

zAlways drive carefully so as to avoid attachments

colliding with pillars, cables, etc.

zCarefully study the "Lift methods" section of the

instruction manual.

Page 6

DCD90-180

Technical Handbook

Safety regulations

Safety instructions for working with tyres

9350

00-11

P.Group 00

4

z Tyre changing can be dangerous and should only

be carried out by specially trained personnel using

proper tools and procedures.

Failure to comply with these procedures may result in faulty positioning of the tyre and/or rim and

cause the assembly to burst with explosive force

sufficient to cause physical injury or death. Never

fit or use damaged tyres or rims.

z Never attempt to weld on an inflated tyre/rim

assembly.

z Never let anyone assemble or disassemble tyres

without proper training.

z Never run the truck on one tyre of a dual assembly.

The load capacuty of a single tyre is then dangerous-ly exceeded and operation in this manner may

damage the rim.

z Deflation and dismantling

– Always block the tyre and wheel on the opposite

side of the vehicle before you place the jack in

position. Always crib up the blocks to prevent

the jack from slipping.

– Always check the tyre/rim assembly for proper

component seating prior to removal from the

truck.

– Always deflate the tyre by removing the valve

core prior to removing the complete assembly

from the truck or dismantling any of the component. Before loosening mounting bolts, run a

wire through the valve stem to ensure that it is

not blocked. Ice or dirt can prevent all the air

from escaping. Deflate and remove valve cores

from both tyres of a dual assembly.

– Never position body in front of the rim during de-

flation.

– Always follow assembly and dismantling proce-

dures outlined in the manufacturer’s instruction

manual, or other reconized industry instruction

manuals. Use proper rubber lubricant.

– Never use a steel hammer to assembling or dis-

mantling rim components – use a lead, brass or

plastic type mallets. The correct tools are available through rim/wheel distributors.

– remove bead seat band slowly to prevent acci-

dents. support the band with your thigh and roll

it slowly to the ground in order to protect back

and toes.

– Disassembly tools apply pressure to rim flanges

to unseat tyre beads. Keep your fingers clear.

Slant disassembly tool about 10 degrees to

keep it firmly in place. Always stand to one side

when applyin g hydraulic pressure. Should the

tool slip off, it may cause fatal injury .

z Rim inspection

– Check rim components periodically for fatigue

cracks. Replace all cracked, badly worn,

damaged and severely rusted components.

– Always select the correct tyre size and construc-

tion matching the manufacturer’s rim or wheel

rating and size.

– Do not use over-size tyres, too large for the

rims, e.g. 14.5 inch tyres with 14 inch rims or

16.5 inch tyres with 16 inch rims.

– Never use damaged, worn or corroded rims/

wheels or fitting hardware. Always verify that the

rim is in a serviceable conditioning.

– Always clean and repaint lightly rusted rims.

– Never use a rim/wheel component that can not

be identified. Check rim parts against multipiece rim/wheel matching charts.

z Assembly and inflation

– It is important that the inflation equipment is

equipped with a water separator to remove

moist-ure from the air line in order to prevent coorosion. Check the separator periodically to ensure that it is working properly.

– Make sure that the lockring is in its right posi-

tion.

– Never mix different manufacurer’s parts since

this is potentially dangerous. Always check

manufacturer for approval.

– Never seat rings with hammering while the tyre

is inflated. Do not hammer on an inflated or partially inflated tyre/rim assembly.

– Always double check to ensure that the rim as-

semblies have been correctly assembled and

that securing studs and nuts are tightened to the

correct torque setting.

– Never inflate tyres before all side and lockrings

are in place. Check components for proper

assembly after pumping to approximately 5 psi

(=34 kPa, =0.34 bar)

– When adding air to a tyre on an industrial truck,

use a clip-on chuck and stay out of the danger

area. If the tyres has been run flat then the rim

must be dismantled and all parts inspected for

damage.

– Under-inflated tyres have a serious effect on the

stability of the truck and reduces the safe load

handling capacity. Always maintain tyres at the

correct inflation pressures. Check inflation

pressure daily. Do not over-inflate.

– Inspect tyres regulary – every day if possible.

Look for and remove broken glass, torn pieces

of tread, embedded metal chips etc. Inspect for

uneven or rapid tread wear, usually caused by

mechanical irregularities, such as brakes out of

adjustment or excessive toe-in and toe-out. If

discovered, correct the irregularity immediately.

z When installing and tightening trail wheel bolts, ob-

serve the following:

– Ensure that trail wheel or hub mounting surfac-

es and trail wheel fastener mounting surfaces

are clean and free from paint and grease.

– Tighten bolts to specified torque settings. use

staggered sequence; i.e. top bolt, bottom bolt

etc.

Page 7

DCD90-180

Technical Handbook

General

9350

00-11

P.Group 00

5

Applications

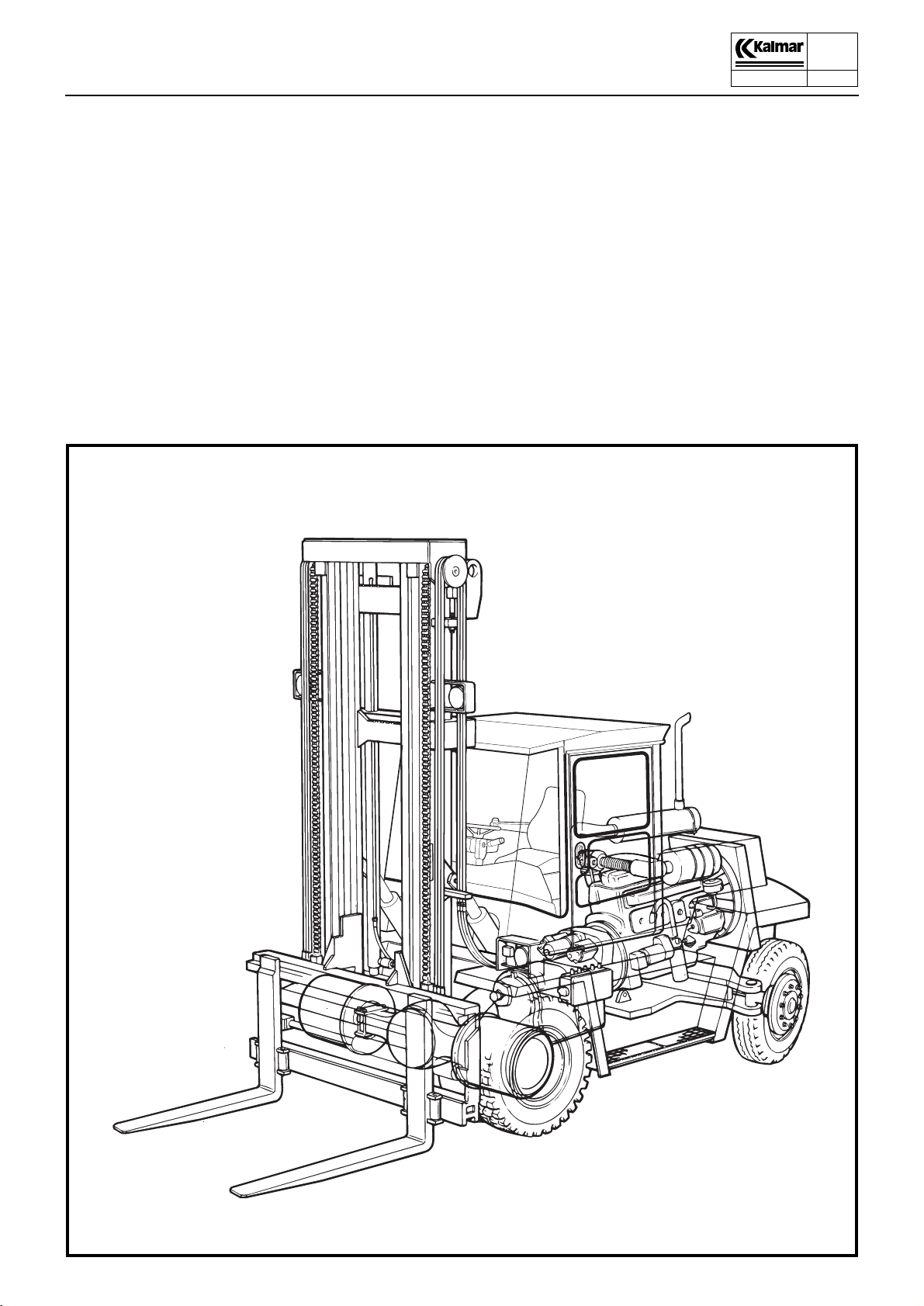

The Kalmar DCD90-180 range of trucks is based on an entirely

new approach to the design and production of medium-heavy,

diesel-powered forklift trucks. The trucks are durable and safe

and their accessibility for service and maintenance is unexcelled.

Due the their versatility, the trucks can be used in a number of applications, such as:

z Steelworks and heavy engineering industry, where the

trucks handle individual tasks in the handling of mediumheavy goods.

z The forest industry for handling logs by means of a log grap-

ple attachment, sorting of logs at sawmills and handling of

sawn timber in units loads.

z Ports and container terminals for handling medium-heavy

goods and handling empty containers.

z Factories producing houses – lifting of house sections.

KL734

DCD90-180

Page 8

DCD90-180

Technical Handbook

General

9350

00-11

P.Group 00

6

Design – general survey

Kalmar DCD90-180 diesel trucks are of sturdy design for heavy

duty. They are built around a chassis which has high strength and

torsional stiffness and an extremely low centre of gravity.

The operator’s cab is provided with vibration isolation and sound

insulation and offers excellent all-round visibility.

The operator is provided with many facilities for adjusting his

seating attitude. The seat, backrest and springing of the operator’s seat can be adjusted in a wide variety of ways.

The cab is tiltable and offers excellent accessibility to the transmission and pumps. The engine is easily accessible through a

casing, divided in two halves.

The Volvo or Perkins six-cylinder turbocharged engine TD640VE

or TD730VE/TWD731VE, combined with a three-speed gearbox

with torque converter, provides smooth power whenever needed.

The drive axle with hub reductions, the oil-cooled hydraulic brake

system and the pendulum-mounted steered axle with double-acting steering cylinder satisfy very strict demands on strength and

mobility when travelling on irregular surfaces.

The hydraulic system is reliable and has high performance

charged by two or three hydraulic pumps.

For further details, see group 70.

Component units

z Sound-insulated and safety-tested operator’s cab with ex-

cellent all-round visibility. The non-slip, substantial steps provide convenient access to the cab. All models in the series

can be equipped with a rotatable operator’s seat.

z Clearly arranged instrument panel.

z Engine – Volvo TD640VE or TD730VE/TWD731VE six-cyl-

inder, four-stroke, turbocharged diesel engine with direct injection and thermostatically controlled water cooling.

The engine is equipped with:

– Injection pump with centrifugal governor that compensate

for load variations.

– Alternator.

– For alternatives, see separate table.

Page 9

DCD90-180

Technical Handbook

General

z Gearbox with torque converter

9350

00-11

P.Group 00

7

– Constant-mesh gearbox in which hydraulically actuated

clutches for the different gears. The clutches are electrically operated.

– Torque converter, which is a hydraulic coupling that ampli-

fies the output torque on an increase in load. Torque conversion takes place smoothly and steplessly throughout

the engine speed range.

– Oil cooler connected to the engine cooling system for

cooling the oil in the gearbox and torque converter.

– Oil pump which supplies oil under pressure to the gearbox

and torque converter.

– Full-flow oil filter for effective cleaning of the gearbox oil.

z Drive axle with two-stage reduction - in the differential and

the hub reductions.

– Oil cooled hydraulic brakes for the foot brake, e.g. Wet

disc brakes.

– Disc type parking brake applied by a sturdy spring and

released by hydraulic oil pressure.

z Hydraulic system with

– Gear type hydraulic pumps connected to take-offs on the

torque converter. One pump for working hydraulics and

one for steering and accumulator charging, which in turn

serves the brake circuits.

– Main valve for controlling the main hydraulics. The valve

is controlled hydraulically from the cab. An electro-hydraulic servo system is available as an option.

– A high pressure filter after each pump for effective clean-

ing of the hydraulic fluid before it is fed to the system.

– Steering valve (Orbitrol) - flow-control valve which sup-

plies hydraulic fluid to the steering cylinder.

z Steered axle with pendulum mounting and double-acting

steering cylinder.

z Sturdy clear-vision mast. Of duplex or triplex design, with or

without free lift.

– Outer mast with hydraulically controlled 5° forward and

10° backward tilting.

– Tilting cylinders with back-pressure valves to prevent the

load from tilting the mast forward.

– Inner mast with support rollers that carry the forces on the

mast. Yoke with guide rollers for the hydraulic hoses and

guide sprockets for the lifting chains.

– Lifting cylinders - two cylinders mounted on the outer

mast.

z Fork carriage designed for optimum visibility and equipped

hydraulic with fork positioning and sideshifting (optional).

Page 10

DCD90-180

Technical Handbook

General

9350

00-11

P.Group 00

8

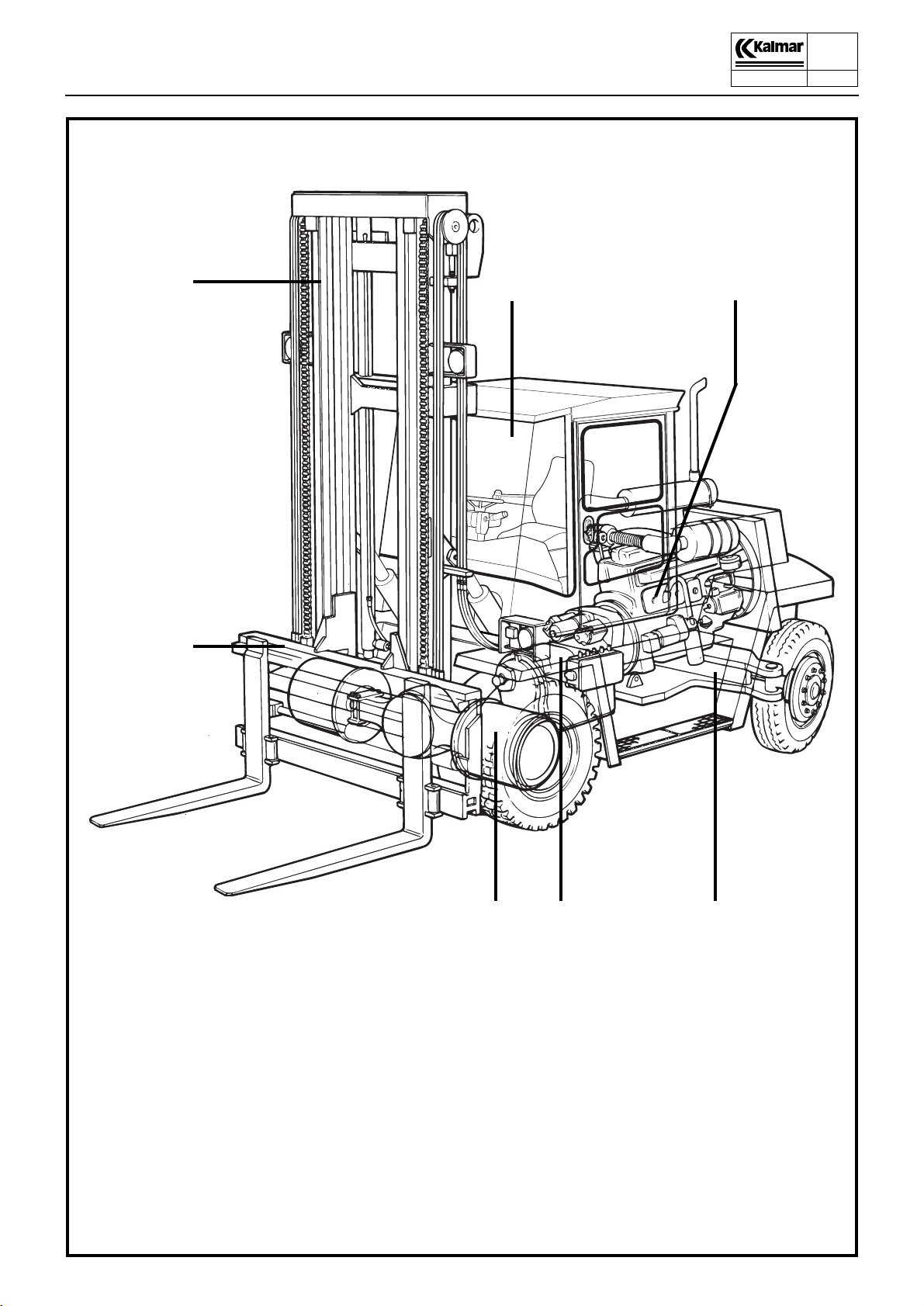

1

23

7

KL734

1. Free -visibility mast, with two lifting cylinders

2. Operator’s cab, rubber suspended cab

3. Engine, six-cylinder diesel engine with

turbo-compressor

4. Steering axle, with pendulum suspension and

double acting steering cylinder

65 4

5. Gearbox, combined with torque converter

6. Drive axle, with hub gearing and oil-cooled

hydraulic brake

7. Fork carriage, hydraulically controlled fork

positioning and sideshift

Main component units

Page 11

DCD90-180

Technical Handbook

General

9350

00-11

P.Group 00

9

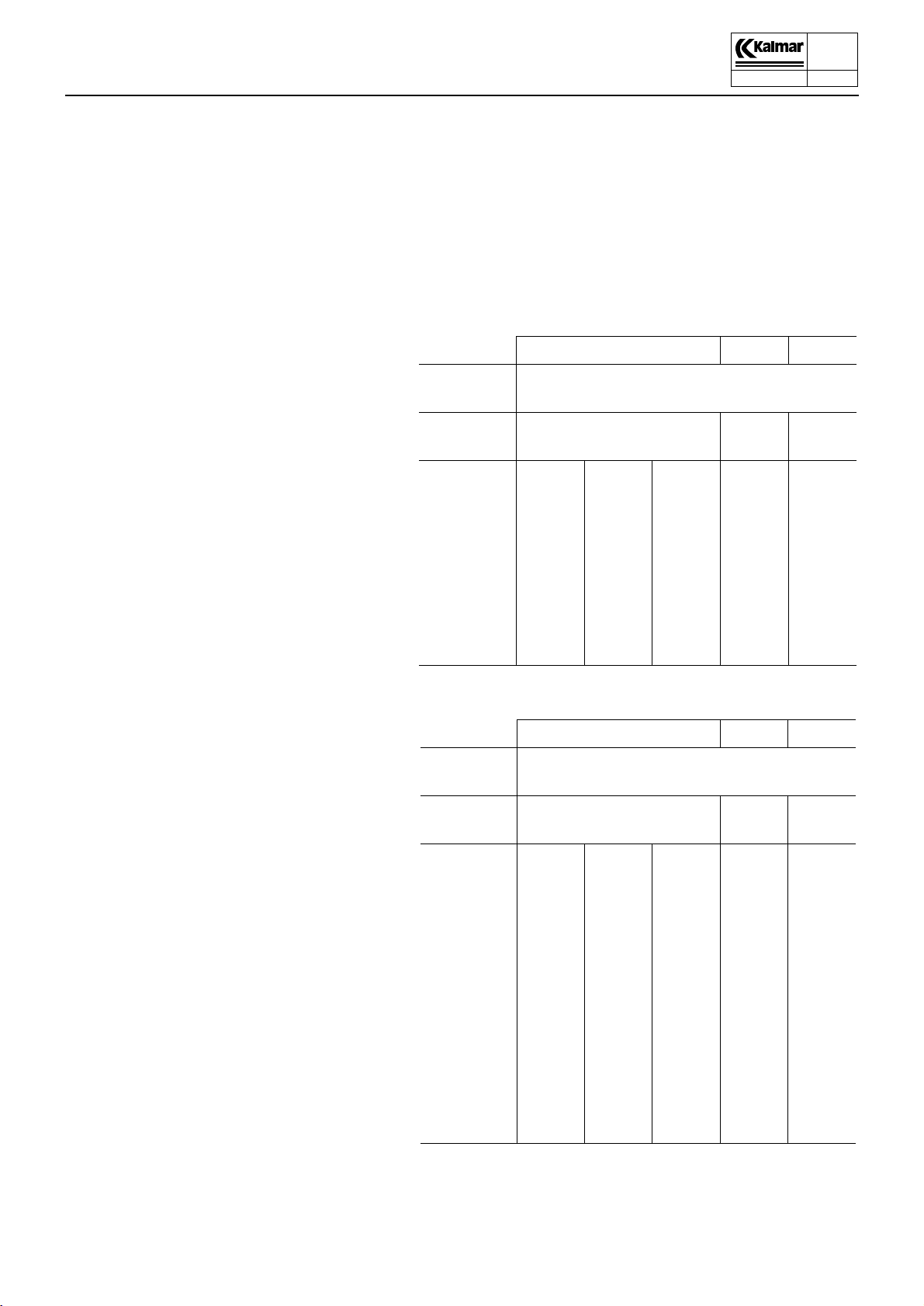

Main components

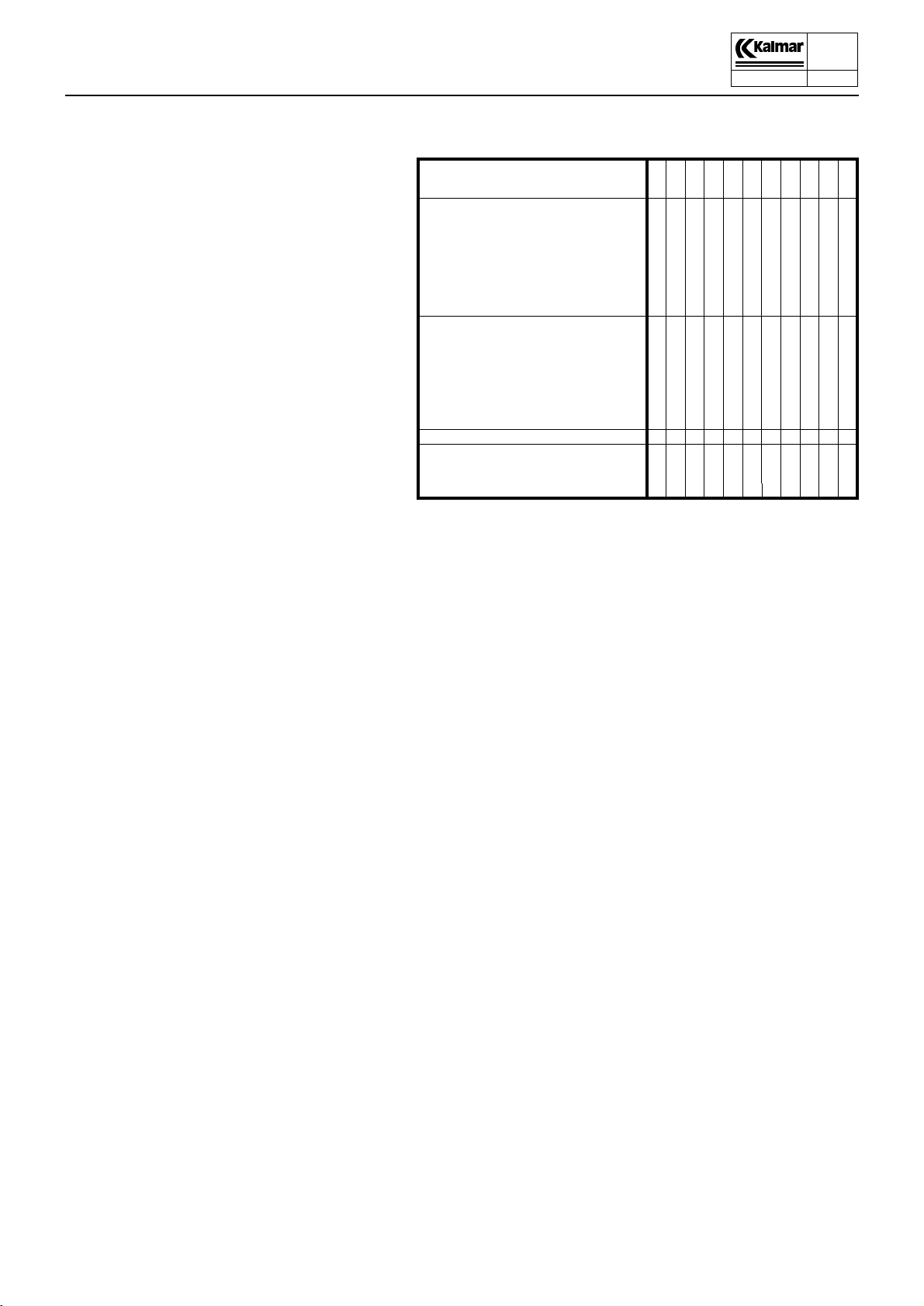

Alternative drive lines

● = Standard ❍ = Optional

Engine *Turbo **Turbo, intercooler

Volvo TD640VE* 129 kW/690 Nm ●●●●●●●●●●●

Perkins 1006-60T1* 85 kW/465 Nm ❍❍❍❍❍

Volvo TD730VE* 150 kW/800 Nm ❍❍❍❍❍❍❍❍❍❍

Volvo TWD731VE** 167 kW/893 Nm ❍❍❍❍❍❍❍❍❍❍

Perkins 1006-60T2* 114 kW/620 Nm ❍❍❍❍❍❍❍❍❍❍❍

Scania DI9** 167 kW/930 Nm ❍ ❍❍❍❍❍❍❍

Cummins 6BTA5.9-C200** 162 kW/814 Nm ❍❍❍❍❍❍❍❍❍❍❍

Gearbox with powershift, 3+3 gears

Clark 13.7HR 28000

(Volvo TD640VE, TD730VE,

Perkins 1006-60T2, Cummins 6BTA)

Clark 1207 FT 20302

(Perkins 1006-60T1)

Clark 13.7HR 32000

(Volvo TD640VE, TD730VE, Volvo TWD731VE,

Scania DI9, Cummins 6BTA)

Drive axle with Wet Disc Brakes ●●●●●●●●●●●

Pneumatic tyres 10.00x20ÆÆ/16PR

Optional: Semi-solid tyres (Super-Elastic) ❍❍❍❍❍❍❍❍❍❍❍

11.00x20ÆÆ/16PR

12.00x20ÆÆ/20PR

90-6

100-6

100-12

120-6

136-6

120-12

150-12

160-6

160-9

160-12

●●●●●●●●●●●

❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍

●●

●●●●●●●●●

180-6

Supplementary books

In addition to the Instruction Manual and the Technical Handbook, the following books are delivered with every truck.

Spare parts catalogue

Instruction Manual for Volvo Industrial engines

Workshop Manual for Industrial engines

Workshop Manual for the Perkins engine

Replacement system - Spare parts

Kalmar operates a system of replacement parts, repair kits and

gasket sets covering most of the vital components of the truck.

For the contents of these kits, see the Spare parts catalogue.

Tools

Kalmar offers a wide range of tools for truck maintenance work.

For further information, please contact Kalmar’s service depart-

ment.

Page 12

DCD90-180

Technical Handbook

General

9350

00-11

P.Group 00

10

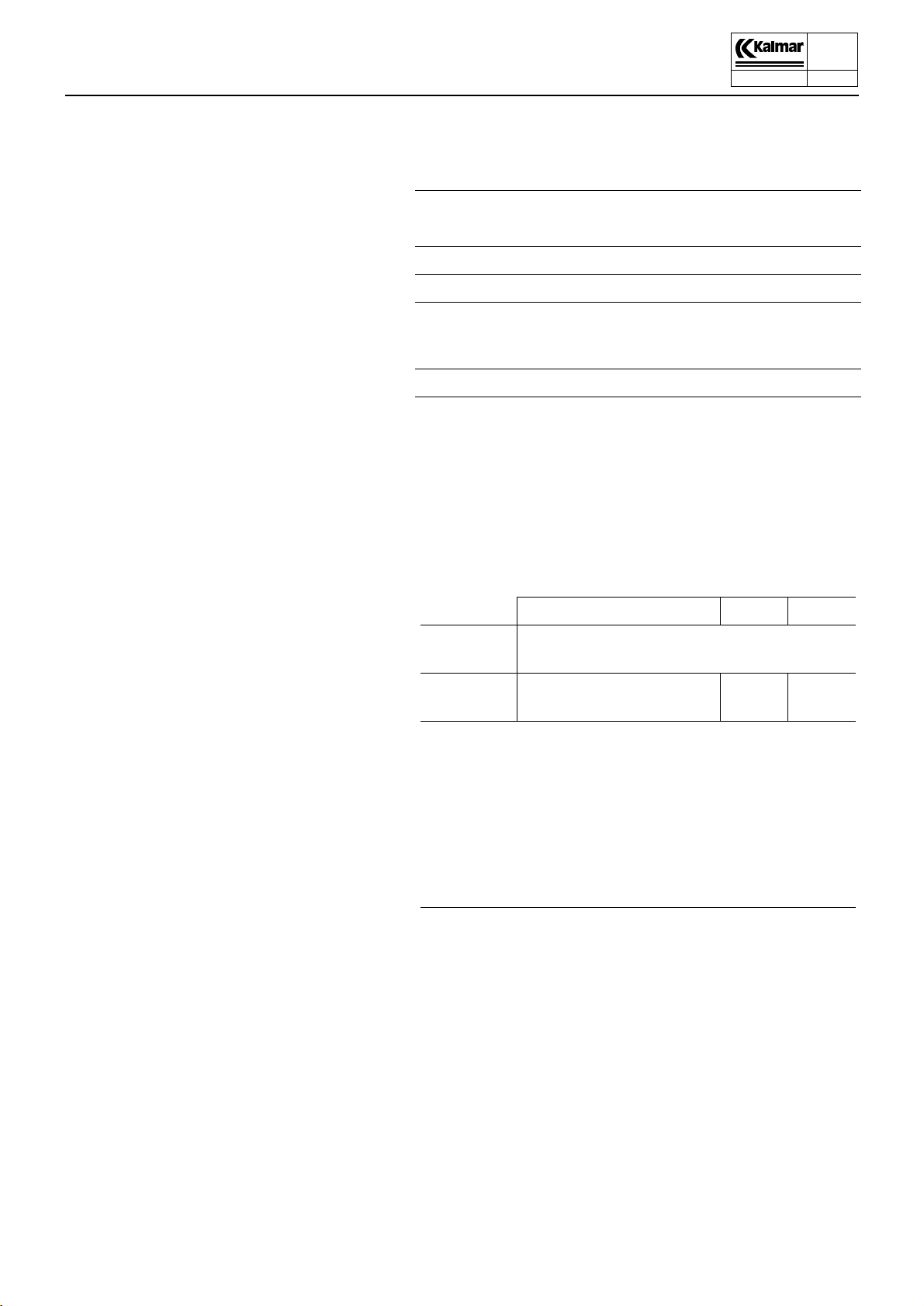

Tightening torques

The tightening torques are applicable to steel bolts and nuts tightened with a torque wrench under the following conditions:

Surface treatment

Condition Lubriation

Bolt Nut

1 untreated untreated oiled

bright galvanised

2

3 hot-dip galvanised bright galvanised dry or oiled

The values specified in Table 1 are applicable to nut-and-bolt

joints, but can also be used for bolts fitted into tapped holes. However, in the latter case, the preloading force will be somewhat

lower, depending on its depth of engagement.

When tightening by machine, the torque specified in Table 1

should be reduced by approx. 5%, due to the increased scatter

and to prevent the bolt from being tightened beyond its yield

point.

Quality 8,8 10,9 12,9

Thread

M fin

M8×1

M10×1,25

M12×1,25

M16×1,5

M18×1,5

bright galvanised

bright galvanised

Tightening torque, Nm

12311

27

54

96

230

330

24

48

85

205

294

untreated

bright galvanised

bright galvanised

Condition

30

61

108

260

373

135

323

466

dry or oiled

39

76

46

91

162

388

559

M20×1,5

M24×2

M30×2

M36×3

460

786

2660

1560

409

700

1388

2367

520

888

1763

3005

647

1100

2200

3730

777

1330

2640

4480

Page 13

DCD90-180

Technical Handbook

General

To reduce the risk of settlement of the material and the

associated reduction in the preloading force if the hardness of the

surface supporting the bolt head or nut is lower than 200 HB, a

washer should be fitted under the bolt head and nut. This is not

applicable if flanged bolts or flanged nuts are used.

When tightening is carried out, the specified torque should be applied without pause, to ensure that the torque wrench will not be

tripped by the static friction before the joint has been tightened to

the specified torque.

Quality 8,8 10,9 12,9

Tightening torque, Nm

Condition

Thread

M

12311

9350

00-11

P.Group 00

11

4

5

6

8

10

12

16

20

24

30

Quality 8,8 10,9 12,9

Thread

UNC

1/4

5/16

3/8

7/16

1/2

3,2

6,4

11

26

52

91

220

430

750

1480

12311

12,5

25

44

70

107

2,9

5,7

9,8

24

47

81

198

386

668

1317

Tightening torque, Nm

11,1

22,3

39

62

95

3,6

7,2

12,5

30

59

103

250

49

848

1672

Condition

14,1

28,3

50

79

121

4,6

9,1

16

38

74

128

313

620

1050

2080

17,6

35

62

100

151

5,5

11

19

45

89

154

375

732

1270

2500

20

42

73

118

178

9/16

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

153

210

370

594

889

1260

1760

2320

3060

136

187

390

528

791

1120

1565

2065

2720

173

237

418

671

1005

1424

1990

2620

3455

216

298

524

839

1260

1780

2490

3280

4320

255

353

619

990

1480

2100

2940

3870

5100

Page 14

DCD90-180

Technical Handbook

General

Quality 8,8 10,9 12,9

Tightening torque, Nm

Condition

Thread

UNF

12311

9350

00-11

P.Group 00

12

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

13

26

47

75

114

164

227

396

629

937

1350

1860

2500

3260

11

23

42

66

101

145

202

352

560

834

1200

1655

2225

2900

14

29

53

85

128

185

256

447

710

1058

1525

2100

2825

3680

19

37

67

107

162

231

321

559

889

1320

1900

2630

3530

4610

System of units

The SI system of units is employed in this handbook:

The conversion factors are as follows:

Pressure

megapascal bar Kilogram-force per

square centimetre,

kpf/cm²

Atmosphere, at

Pound-force

per square

inch,

psi

22

44

79

126

191

273

379

661

1050

1560

2250

3110

4170

5450

1

0,1

0,098

Torque

Newtonmeter

Nm

1

9,81

Power

Kilowatt

kW

1

0,735

10

1

0,98

10,2

1,02

1

Kilogram force-metre

kgf m

0,102

1

Horsepower (metric)hpHorsepower

1,36

1

145

14.5

14.2

Pound-force foot

lbf ft

0.74

7.23

hp

1.34

0.986

Page 15

DCD90-180

Technical Handbook

9350

00-11

Contents

P.Group 10

1

Group 10

Chassis and cab

Specifications ........................................................................... 2

Chassis...................................................................................... 3

Description ........................................................................... 3

Operator’s cab ........................................................................... 4

Description ........................................................................... 4

Steering column .............................................................. 7

Pump and cylinder for cab tilting ..................................... 8

Accelerator pedal with change-over switches for

forward and reverse ........................................................ 9

Gear selector type RMH ................................................ 10

Hydraulic weight indicator ............................................. 11

Service ............................................................................... 12

Changing the fresh air filter ........................................... 12

Check and lubrication of brake pedal ............................ 12

Windscreen wipers ........................................................ 13

Air conditioning unit ................................................................. 14

Description ......................................................................... 14

Service ............................................................................... 17

Checking the air conditioning unit ................................. 17

Page 16

DCD90-180

Technical Handbook

Specifications

Air conditioner

z Cab unit

Circulated air flow 500-600 m

Electric power consumption approx 350 W

z Compressor

Max. speed 4000 r/min

Refrigerant R134a *)

Electric power consumption approx 50 W

Oil capacity Zexel PAG SP-20 1.5 dl

z Condenser

Electric power consumption 250 W

z Cooling effect 6-8,5 kW

z Heating effect approx 11 kW

*) Refrigerant R12 is no longer in production due to legislation

3

/h

9350

00-11

P.Group 10

2

Page 17

DCD90-180

Technical Handbook

1

Chassis

Description

9350

00-11

P.Group 10

3

Chassis

The chassis consists of:

z A unit construction frame built up around two beams with a

minimum of welds for best possible strength.

z Mountings for the drive axle, steered axle, mast, lifting cylin-

ders and transmission.

z The necessary counterweights to provide a very low centre

of gravity. Moreover, the steered axle is designed to serve as

an additional counterweight.

z The hydraulic oil tank and the fuel tank are produced as sep-

arate units and are bolted to the side of the chassis. The

tanks have a low profile, which contributes to the good visibility.

1. Hydraulic tank

2. Counterweights

3. Service hatch for the battery

4. Fuel tank

2

3

4

Chassis 90-180

Page 18

DCD90-180

Technical Handbook

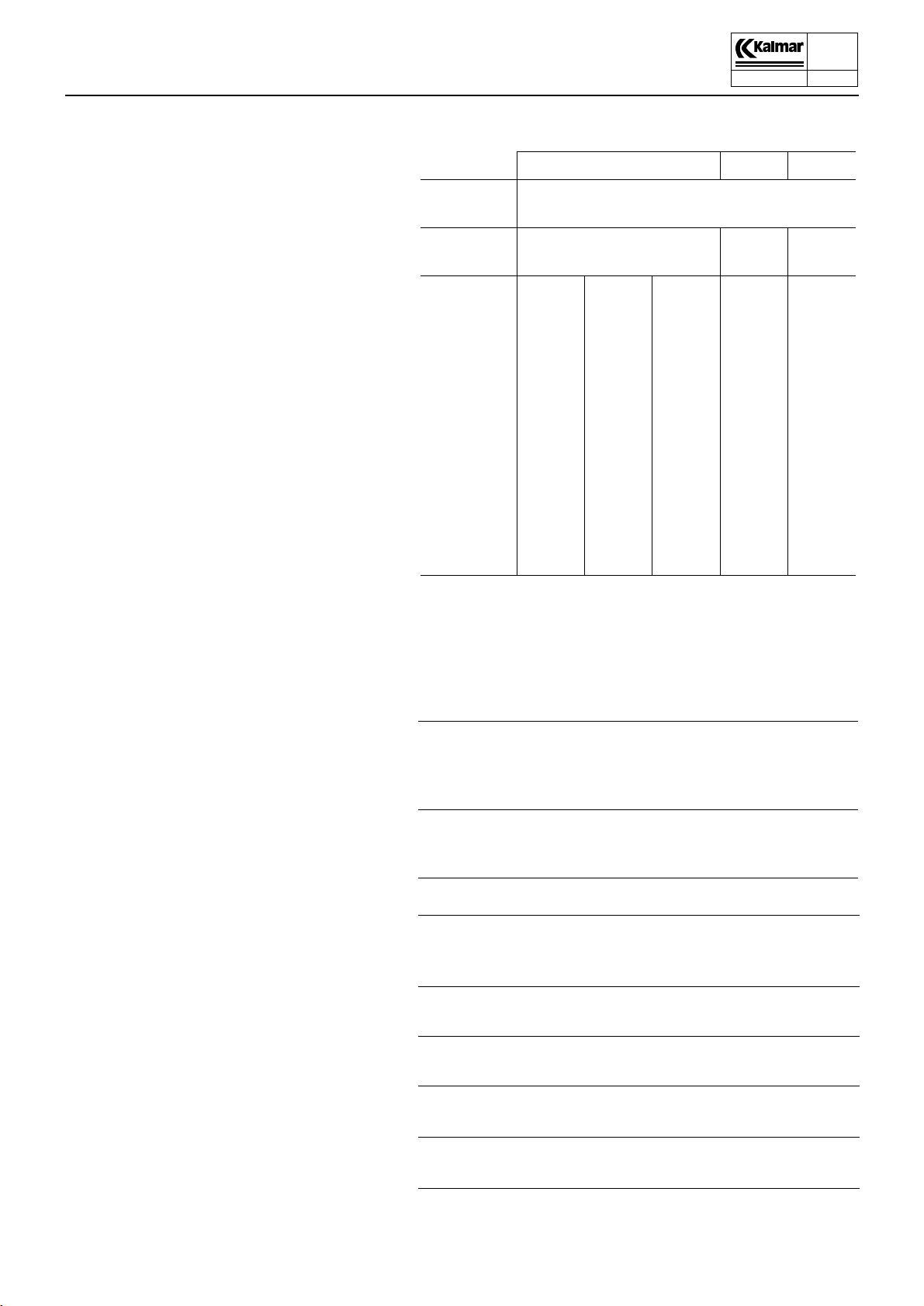

Operator’s cab

Description

Operator’s cab

The operator’s cab is a separate structure and rests on the chassis on rubber dampers. The operator’s seat, steering wheel and

hydraulic control levers can be adjusted for best possible operator comfort. Effective insulation minimises the vibrations and

sound level in the cab.

The standard heating system consists of a fan and heater for

heating the air in the cab by recirculation. Fresh air is drawn in

through a ventilation air filter. Full air conditioning, with cooling,

heating and dehumidification, is available to special order.

9350

00-11

P.Group 10

4

1

2

3

1. Steering column with instrument panel and switches, ECS-terminal (option)

2. Air filter

3. Heating system

4. Electrical central unit

4

Page 19

DCD90-180

Technical Handbook

31 4 5 2 6

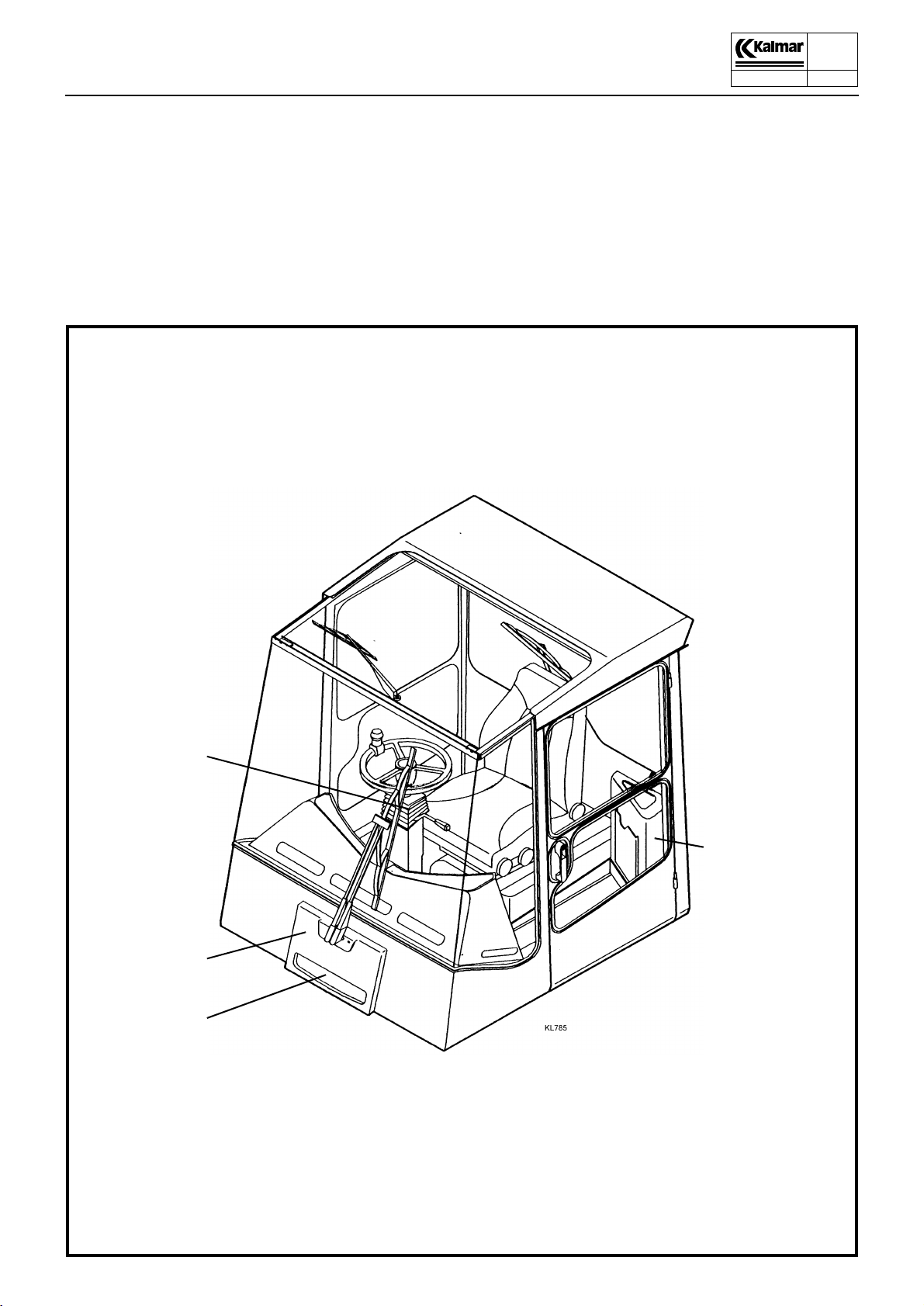

Operator’s cab

Description

9350

00-11

P.Group 10

5

KL735

1

23

4

F

N

R

R

145

23

L

0

a

bc

d

7

KL743

1. Gear selector

FORWARD/NEUTRAL/REVERSE 1/2/3

2. Lever DIRECTION INDICATORS/HORN

FRONT WINDSCREEN WASHER/

FRONT WIPERS/MAIN BEAM

3. Instrument panel

4. Steering wheel panel

5. Starting switch

6. Control lever, hydraulic functions

a. Lift, b. Tilt, c. Sideshift, d. Fork positioning

8 9 10 11 12 13 14

7. Electrical central unit with fuses and relays

8. Brake pedals, normal driving brake

9. Release clutch

10. Accelerator pedal

11. Steering wheel adjustment

12. Stop control

13. Parking brake

14. Operator’s seat

Page 20

DCD90-180

Technical Handbook

Operator’s cab

Description

9350

00-11

P.Group 10

6

66

21

24

25

26

27

28

22

29

1

23

4

30

23

32

31

54

55 56 60 59

F

N

R

33

34

KL581

39

38

37

36

35

40 41 42 43 44 45 52 53

46

47 48 49 50 51

R

1

2

3

4

5

KL580

KL582

L

0

57 58 64 61 62 63

21. Pressure gauge, gearbox oil pressure

22. Fuel gauge

23. Temperature gauge, engine coolant temperature

24. Switch, working lights

25. Switch, working lights

26. Switch, working lights

27. Switch, flashing beacon

28. Switch, hazard warning lights

29. Switch, driving lights

30. Spare

31. Spare

32. Spare

33. Spare

34. Switch, compressor air conditionin

1)

g

35. Control, recirculation/fresh air

36. Control, defrost/cab

37. Switch, fan

38. Control, heat

39. Control, cold

KL675

1)

40. Spare

41. Spare

42. Warning lamp, battery charging

43. Warning lamp, low engine oil pressure

44. Warning lamp, low gearbox oil pressure

45. Warning lamp, low brake pressure

(accumulator pressure)

46. Warning lamp, low engine coolant level

47. Indicating lamp, preheating

48. Warning lamp, high engine coolant temperature

49. Warning lamp, high gearbox oil temperature

50. Spare

51. Warning lamp, parking brake ON

52. Spare

53. Spare

54. Spare (Green lamp TWIST-LOCKS LOCKED)

55. Spare (Orange lamp ALIGNMENT)

56. Spare (Red lamp TWIST-LOCKS UNLOCKED)

57. Spare (LOCK/UNLOCK TWIST-LOCKS)

58. Spare (LENGT ADJUSTMENT 20-40’)

1)

1)

1)

59. Indicating lamp, headlights

60. Indicating lamp, direction indicators

61. ECS terminal

1)

62. Switch, windscreen wiper, rear

63. Switch, windscreen wiper, roof

64. Spare

65. Fuses

66. Hour meter

1)

Optional

1)

1)

Page 21

DCD90-180

Technical Handbook

Operator’s cab

Description

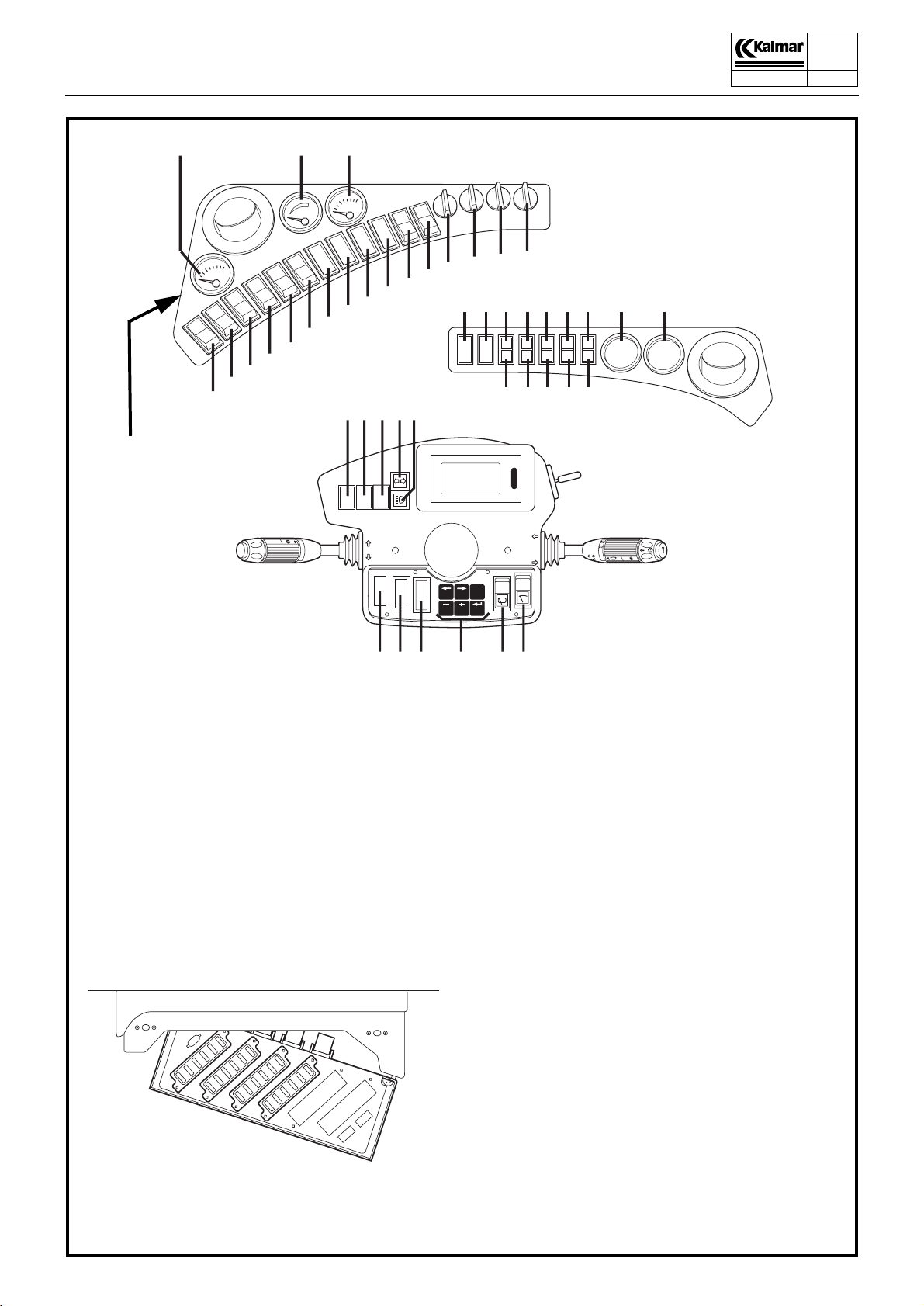

Steering column

Surrounding the steering column are multi-function levers for

gear changing, indicators, windshield wipers, etc., as well as the

instrument panel with the ECS terminal. At the very foot of the

steering column is the steering valve (Orbitrol), activated by the

steering wheel via an angled gear. The steering column is

equipped with an adjustment handles for the alteration of steering

wheel height and rake.

9350

00-11

P.Group 10

7

1

23

4

1

F

N

R

R

1

2

3

4

5

L

0

2

3

KL580A

4

1. Gear lever

2. Multi-function lever

3. ECS terminal

4. Steering wheel adjustment

handles

5. Angled gear

6. Orbitrol steering valve

KL588

6

5

Steering column

Page 22

DCD90-180

Technical Handbook

Operator’s cab

Description

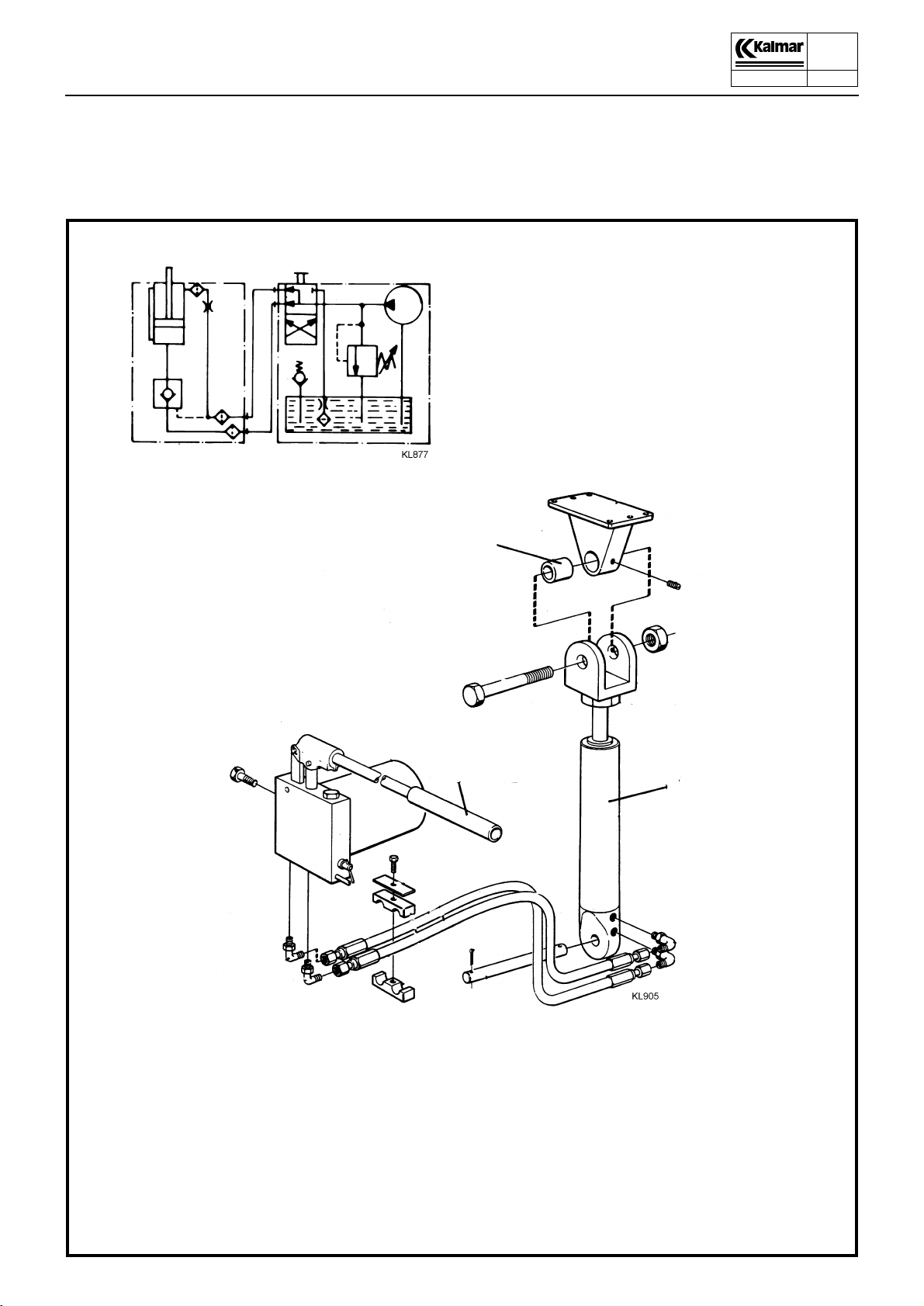

Pump and cylinder for cab tilting

A hydraulic cylinder is provided for tilting the cab. The hydraulic

fluid pressure for this purpose is generated by a manually operated pump. The pump is fitted with a reversing valve for upward or

downward tilting.

9350

00-11

P.Group 10

8

1

2

3

2

4

1. Cab tilting cylinder

2. Manual pump

3. Vibration damper

4. Cab tilting cylinder

Pump and cylinder for cab tilting

Page 23

DCD90-180

Technical Handbook

Operator’s cab

Description

9350

00-11

P.Group 10

9

3

1

1. Push-button, reverse gear

2. Push-button, forward gear

3. Microswitch

4. Engagemant and disenagagement of the

foot operated gear changing system

4

2

Accelerator pedal with change-over switches for forward and reverse

Page 24

DCD90-180

Technical Handbook

Operator’s cab

Description

9350

00-11

P.Group 10

10

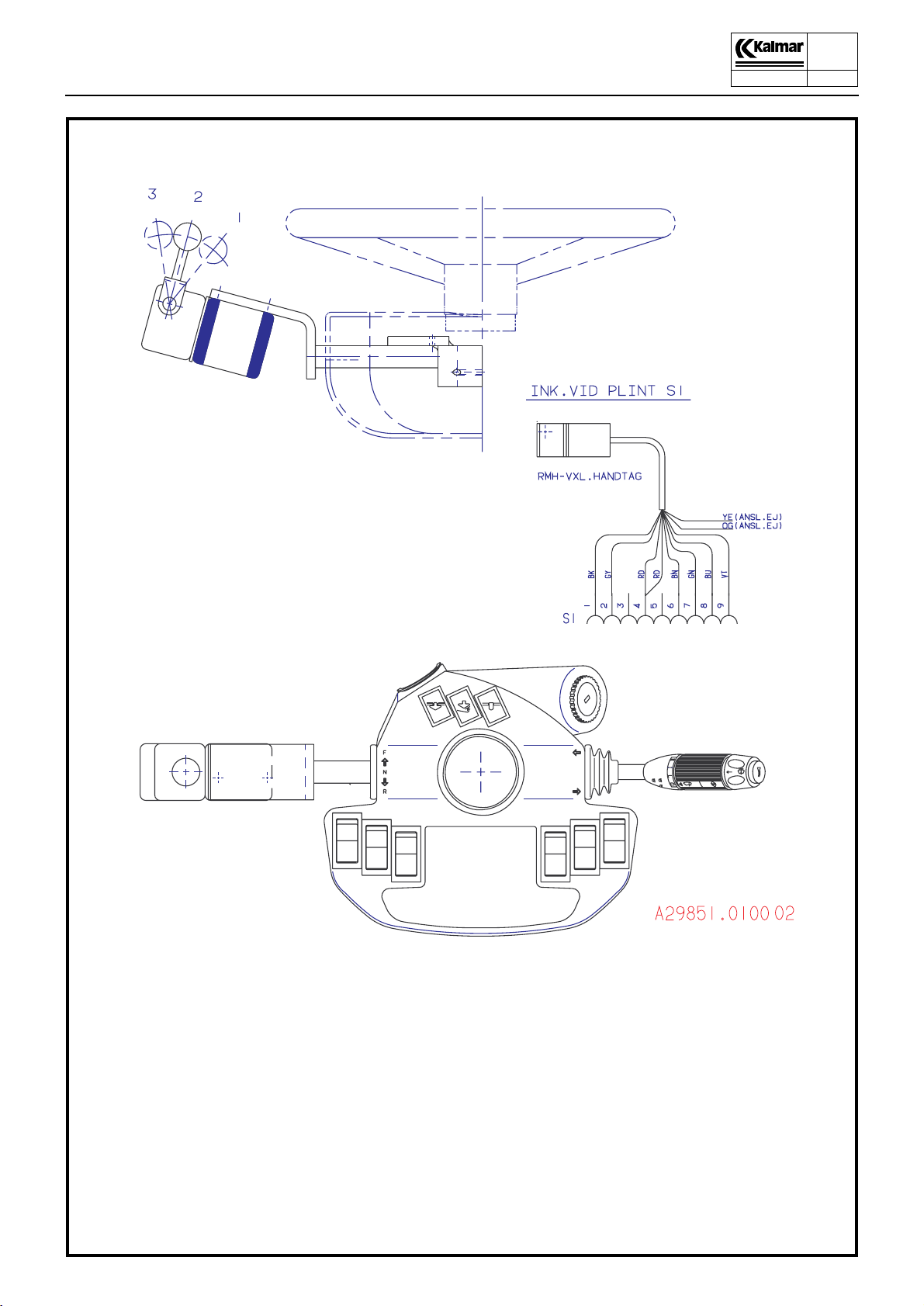

Gear selector type RMH

Page 25

DCD90-180

Technical Handbook

Operator’s cab

Description

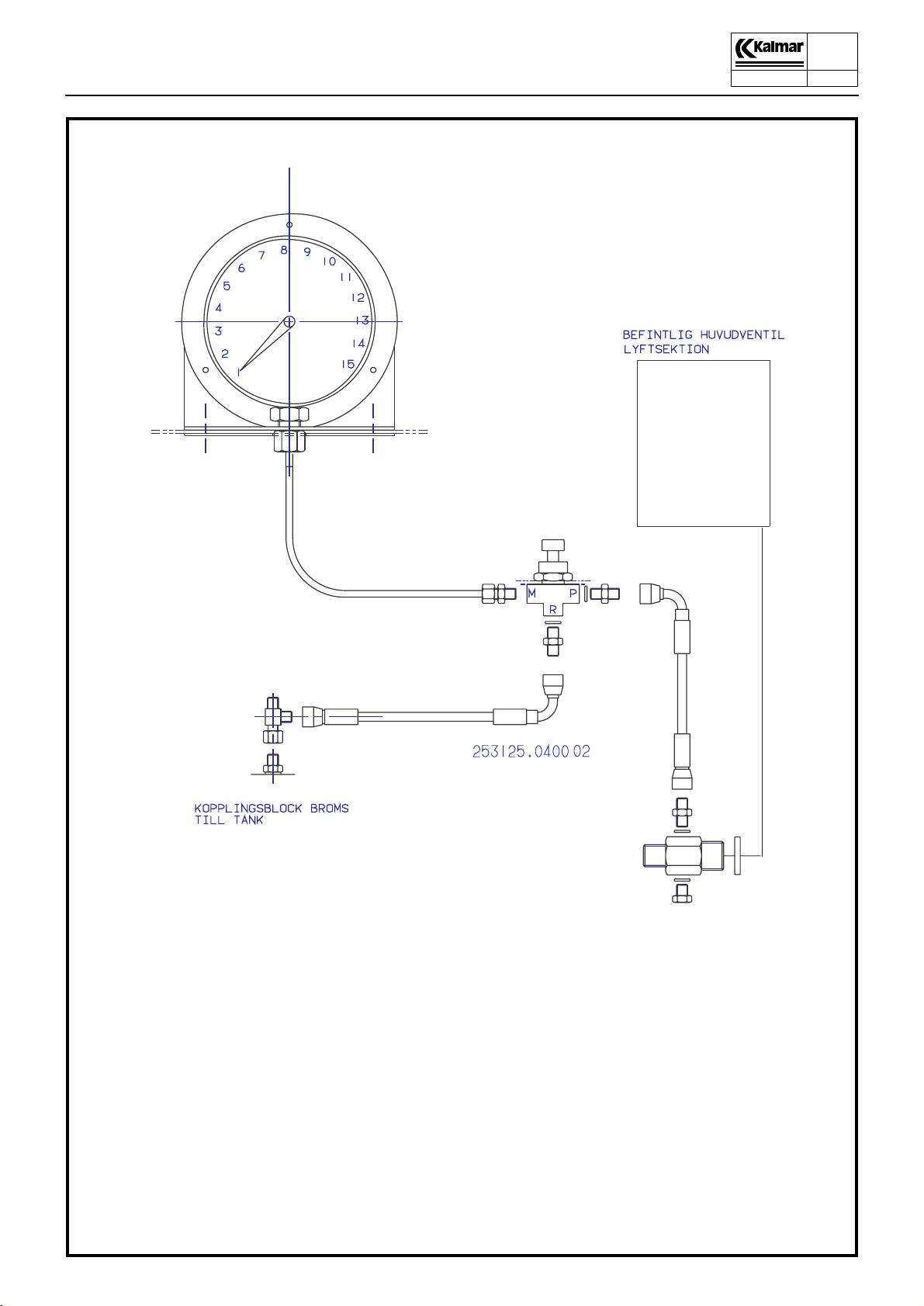

1

9350

00-11

P.Group 10

11

4

3

2

1. Indicator scale in the cab

2. Tank connection to the brake valve connecting block

3. Foot switch for weighing

4. Connection to the main valve LIFT section

Hydraulic weight indicator

Page 26

DCD90-180

Technical Handbook

Operator’s cab

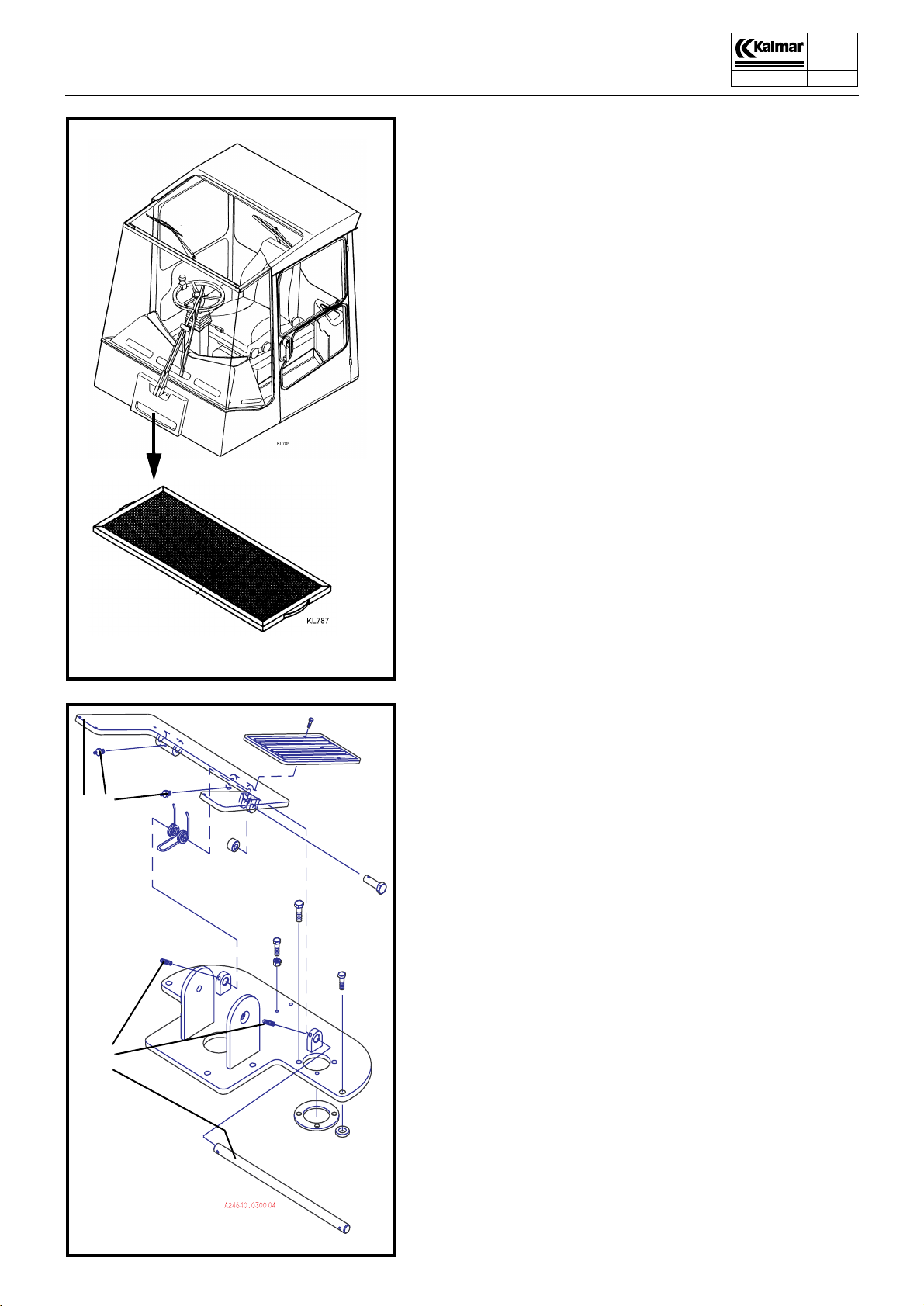

Service

Changing the fresh air filter

(every 200 hours or when needed)

1. Remove the filter casing retaining bolts and remove the filter

element.

2. Wash the filter insert with water and detergent or by using a

high pressure washer. Replace the insert if necessary.

3. Reinstall the filter insert.

9350

00-11

P.Group 10

12

2

1

3

4

1. Brake pedal

2. Lubricating nipple

3. Locking screw

4. Shaft

Check and lubrication of brake pedal

(every 1000 hours)

1. Check and tighten the locking screws 3, so that the brake

pedal is securely fitted in the console.

2. Lubricate the brake pedal shaft through the nipples 2.

Page 27

DCD90-180

Technical Handbook

Operator’s cab

Service

9350

00-11

P.Group 10

13

Windscreen wipers

The wiper arms are fixed to the wiper motor shafts via conical

splines. The shafts are manufactured of hardened steel and the

wiper arm mounting of soft, pressed metal. When fitting, the nuts

must be tightened so hard that the splines are pressed well into

the mounting and function as a carrier.

Removal

1. Remove the wiper arms by loosening the nuts and thereafter

tapping and carefully rocking the arms to and fro.

Fitting

1. Check to ensure that the splines on the motor shaft are free

from the softer material from the wiper arm mounting.

1

If this is not the case, clean the splines so that they can

pressed fully into the wiper arm mounting.

2. Fit the wiper arms onto the motor shafts and tighten the nuts

to a torque of 16-20 Nm.

Hold the wiper arm to take up the torque pressure so that it

is not transferred to the motor, which could result in damage

.

IMPORTANT!

2

3

The nuts must be tightened sufficiently hard, otherwise

the shafts may start to slip inside the wiper arm mounting,

resulting in damage.

1. Wiper arm fitting

2. Securing nut, wiper arm

3. Grooved cone on motor shaft

4. Wiper motor

4

Page 28

DCD90-180

Technical Handbook

1

Air conditioning unit

Description

Air conditioning unit

The air conditioning unit consists of the parts shown in the illustration and its function is to maintain the climate in the ope-rator’s cab as comfortable as possible. The air conditioning unit:

z heats the air when it is cold

z dehumidifies the air when it is humid

z removes impurities from the air

z cools the air when it is warm

The equipment is steered by switches and controls on the instrument panel.

5

6

4

9350

00-11

P.Group 10

14

1. Heating control

2. Heat exchanger

3. Vapourizer

4. Expansion valve

5. To condenser

6. To compressor

7. Heating valve

8. From engine

9. To engine

10. Fan

11. Fan

12. Fan control

13. Fresh air filter

14. Air disperser

15. Control defrost/cab

16. Defroster outlet

3

8

9

7

2

15 16

12

14

10

11

13

The heating and ventilating system

Page 29

DCD90-180

Technical Handbook

Air conditioning unit

Description

9350

00-11

P.Group 10

15

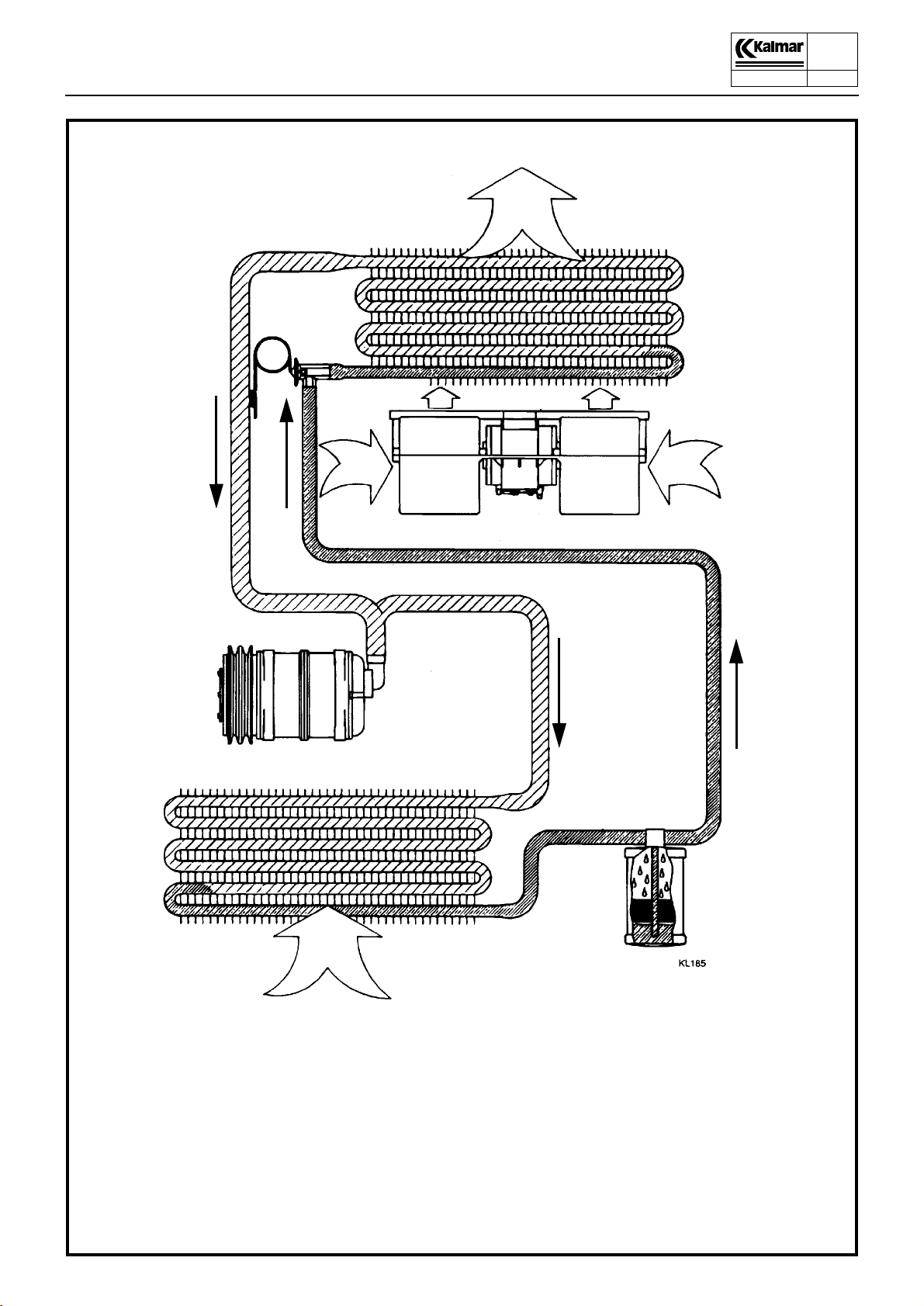

F

2

4

D

C

E

E

3

7

A

B

6

1. Liquid receiver/filter dryer

2. Evaporator

3. Fan

4. Expansion valve

6. Condenser

7. Compressor

1

G

A High-pressure gas

B High-pressure liquid

C Low-pressure liquid

D Low-pressure gas

E Warm air in cab

F Cooled air to the cab

G Outside air for removing heat

Page 30

DCD90-180

Technical Handbook

Air conditioning unit

Description

Compressor

The air conditioning system is driven by the compressor. This

performs as a pump, drawing cold, low-pressure gas from the

evaporator, compressing it and thereby raising its temperature,

and discharging it at high pressure to the condenser.

The compressor is driven by V-belts directly from the diesel engine. Switching between operation and idling is controlled by an

electro-magnetic clutch which, in turn, is controlled by a thermostat whose sensor is located between the fins of the evaporator

coil. The thermostat switches off the compressor at low temperatures, to prevent icing of the evaporator.

Condenser

The function of the condenser is to convert the hot high-pressure

gas from the compressor into liquid form. The tubes and fins of

the condenser coil absorb heat, which is then removed by the air

delivered by the fan.

The temperature of the refrigerant in the condenser varies from

about +50°C to +70°C. The pressure varies between 12 and 20

bar, depending on the ambient temperature and the flow of air

through the condenser. When the refrigerant is condensed into

liquid form, it is transferred under pressure to the liquid receiver/

filter dryer.

9350

00-11

P.Group 10

16

Liquid receiver with filter-dryer

The function of the liquid receiver with integrated filter dryer is to

collect the liquid coolant, bind the moisture, and to filter and remove impurities. The receiver, which is located in the condenser

housing, also serves as the expansion vessel in the refrigeration

circuit.

After flowing through the dryer in the bottom of the liquid receiver,

the refrigerant flows through a riser tube. A sight glass enables

the operator to check that the liquid flows without the presence of

any bubbles, and that the system is filled with a sufficient amount

of refrigerant.

Expansion valve

The expansion valve throttles the flow and passes an optimised

quantity of refrigerant that the evaporator is capable of evaporating.

The expansion valve is also the part of the circuit which separates

the high- pressure side from the low-pressure side. The refrigerant flows to the expansion valve under high pressure and leaves

it under low pressure.

The amount of refrigerant which passes the evaporator varies,

depending on the thermal load. The valve operates from ’fully

open’ to ’fully closed’ and in-between searches for a point to give

optimum evaporation.

Evaporator

The heat necessary for evaporating the refrigerant is extracted

from the cab air which is circulated by a fan through the evaporator coil. The cab air is thus cooled, and is distributed and returned

to the cab.

In the evaporator, the refrigerant reverts to the gaseous state and

returns to the compressor suction, thereby completing the cycle.

Page 31

DCD90-180

Technical Handbook

WARNING!

z If the refrigerant hose should fail or if

other refrigerant leakage should occur, switch off the air conditioner immediately.

z Refrigerant is injurious to the skin and

eyes.

z Never release refrigerant in an en-

closed space. If released into a service pit, for instance, the gas may

cause asphyxia.

z It is forbidden by law to discharge re-

frigerants into the air intentionally.

z Never carry out welding on a charged

refrigeration system or in its vicinity.

z Only authorised service mechanics

are allowed to drain off and fill refrigerant in the air conditioning system.

Only the prescribed refrigerant may be

used when refilling.

Air conditioning unit

Service

The liquid refrigerant should be completely evaporated before it

is allowed to flow from the evaporator. The refrigerant is still cold

even when it has completely evaporated. The cold vapour which

flows through what remains of the evaporator continues to

absorb heat, and then becomes overheated. This means that the

temperature of the refrigerant has risen to above the point where

it evaporates without changing the pressure.

In an evaporator which operates at a suction pressure of 2 bar,

the liquid refrigerant will have a temperature of –1.1°C. When the

refrigerant is subsequently evaporated through heat absorption

in the evaporator, the temperature of the gas will rise at the evaporator outlet to +1.6°C. This represents a difference of 2.7°C between the evaporation temperature and the temperature at the

outlet. This is called overheating.

All expansion valves should be adjusted at the plant in such a

way that maximum evaporation with overheating is performed in

the air conditioning system.

Checking the air conditioning unit

If the unit is in continuous operation, this check should be carried

out every week from early spring to late autumn and during extended periods of high humidity during the winter.

If the unit is used very little during cold and dry winter periods, the

compressor should be run for a few minutes every week, to lubricate the rubber hoses, couplings, seals and shaft seal.

9350

00-11

P.Group 10

17

1. Start the engine and start the air conditioner.

At an outdoor temperature below 0°C, the system cannot

start since the low-pressure relay breaks contact.

2. After 10 minutes of operation, check that no bubbles are

visible in the sight glass of the filter-dryer. (Bubbles should

occur only when the compressor is started and stopped.)

If there are any air bubbles, subsequent filling should be performed by an authorised service mechanic.

3. Check that the condenser is not clogged. If necessary, clean

the condenser fins with compressed air.

4. Change the fresh air filter as necessary.

5. Check the V-belt tension and the compressor mounting.

6. Check that the magnetic coupling engages and disengages

satisfactorily.

7. Check that the condensate drain from the cooling element is

not clogged. Check for leakage.

Page 32

DCD90-180

Technical Handbook

IN CAB CLIMATE UNIT CONDENSER UNIT

Air conditioning unit

Service

9350

00-11

P.Group 10

18

A

RD 1,5

1

2

3

GL 1,5

L

SV 1,5

M

H

RD 1,5

C

4

R

4

R

GL 1,5

M

5

BR 1,5

RD 1,5

8

30

85

87

86

BR 1,5

M

9

M

6

BR 1,5

VT 1,5

7

HIGH

LOW

10

1. Fan switch

2. Cooler on/off

3. Anti-freeze thermostat

4. Resistor

5. Fan motor

6. Indicator lamp – cold (in push button)

7. High-/low-pressure monitor

8. Relay

9. Condenser fan

10. Compressor

Circuit diagram in cab climate unit/condenser unit

Page 33

DCD90-180

Technical Handbook

9350

00-11

Contents

P.Group 20

1

Group 20

Electrical system

Specifications .............................................................................2

Electrical system ........................................................................3

Description ............................................................................3

Service ..................................................................................6

Checking the electrolyte level of the batteries..................6

Fuses ...............................................................................6

Bulbs ................................................................................6

Relays ..............................................................................7

Starting from another battery ...........................................7

Cable markings ................................................................8

Diagrams

Gear changing systems.........................................................9

Clark 18000/20000, fixed operator’s seat .....................10

Clark 18000/20000, rotatable operator’s seat ...............12

Clark 28000/32000, fixed operator’s seat .....................14

Clark 28000/32000, rotatable operator’s seat ...............16

Engine shut down at low/high coolant temperature

Engine with stop solenoid ..............................................18

Engine with fuel shut off valve........................................19

Engine shut down, connected to the operator’s seat

Electrically controlled extra hydraulic function.....................21

Safety interlock system .......................................................22

Component list DCD90-450

Wiring diagram, truck body ............................... A08334.1000

Wiring diagram, inner, standard ........................ A08333.1000

Wiring diagram, inner, rotatable operator’s seat

..................................................................... A08333.1100

Safety interlock system, empty container attachment, Volvo

..................................................................... A28047.0600

Safety interlock system, empty container attachment, Perkins

.................................................................. A28047.0700

Page 34

DCD90-180

Technical Handbook

Specifications

Alternator rating Perkins: 1260 W

Volvo: 1540 W

Starting battery, voltage 2 x 12 V

capacity 140 Ah

earthing negative

9350

00-11

P.Group 20

2

Page 35

DCD90-180

Technical Handbook

IMPORTANT!

Always open the main switch whenever work is to be carried out on the

electrical system, if the truck is to

remain idle for some time and whenever welding work is to be carried out

on the truck.

Electrical system

Description

The system voltage is 24V and the supply is taken from two 12V

batteries connected in series and charged by an alternator

across electronic rectifying and voltage stabilisation circuits. .

The positive pole is connected across a main switch. The negative pole is then connected to the chassis.

Warning lamps and instruments are clearly arranged on the instrument panel. The central electrical unit with fuses and relays

is located on the lower section of the cab’s rear wall.

9350

00-11

P.Group 20

3

1. Main switch

2. Battery

1

2

Page 36

DCD90-180

Technical Handbook

Electrical system

Description

9350

00-11

P.Group 20

4

1. Transmitter, warning lamp low oil pressure and gearbox oil pressure instrument

2. Transmitter, warning lamp low oil temperatur and gearbox oil temperatur instrument

3. Fuse

4. Relay preheater element

5. Transmitter, coolant temp instrument

6. Transmitter, high coolant temp instrument

7. Transmitter, engine oil pressure instrument

8. Transmitter, low engine oil pressure warning lamp

9. Starter motor

10. Transmitter, low coolant level warning lamp

11. Engine wiring

Electrical components, Volvo engine

Page 37

DCD90-180

Technical Handbook

12 34 5 67

Electrical system

Description

9350

00-11

P.Group 20

5

11

98

10

1. Sensor, coolant temperature

2. Sensor, engine temperature (cold start)

3. Stop solenoid valve

4. Solenoid valve, disconnection cold start

5. Resistor for stop solenoid valve

6. Resistor for pre-heating glowplug

7. Main fuse electrical system 2 x 50 A

8. Sensor, warning lamp low gearbox oil pressure

9. Glowplug, inlet air pre-heating

10. Sensor, instrument gearbox oil temperature

11. Sensor, warning lamp low engine oil pressure

Electrical components , Perkins engine

Page 38

DCD90-180

Technical Handbook

N.B.

The starting batteries accompanying

the truck are of the maintenance-free

type, which implies that it should not

be necessary to top-up with electrolyte during the life of the batteries.

However, the level of the electrolyte

should preferably be checked once or

twice a year. Fill as required by adding

de-ionized water.

S1-6 7-12 13-18 19-24

Electrical system

Service

Electrical system

The electrical system operates at 24 V. The source of power supply are two 12 V batteries which are charged by an alternator. The

negative pole is connected to the chassis.

The positive pole is connected to a main switch A.

IMPORTANT!

When working with the electrical system, when carrying

out welding on the truck or at long time parking, always

isolate the batteries.

A Main switch

Checking the electrolyte level of the batteries

The batteries are fitted behind a cover on the left-hand side of the

truck. The electrolyte level should be about 10 mm above the

cells. Top up with de-ionized water as necessary.

Relay box in cab – fuses

Fuse Rating

No. Circuit protected A

S1 Wiper motor front, direction indicators,

seat buzzer, parking brake sensor ........................... 10

S2 Ignition key, pre-heater, starter motor,

cab lighting (Air conditioner 25 A

S3 Container attachment, safety interlock ..................... 15

S4 Electric gear-changing ............................................ 5

S5 Warning lamps, instrument illumination, relay,

coolant level .............................................................. 5

S6 Brake lights, reversing lights, reversing alarm ......... 15

S7 Fan (Air conditioner

1)

) .............................................. 25

S8 Spare (Working lights, container

S9 Working lights (15 A for 4 lamps

Hazard beacon ........................................................ 10

S10 Working lights, standard (15 A for 4 lamps) ............ 10

S11 Horn, screenwash motor, wiper rear and roof,

wiper front, intermittent relay .................................... 10

S12 Driving lights (main fuse), rear lights

(main fuse), position lights ...................................... 15

S13 Main beam, right-hand (Main beam, front 10A

S14 Main beam, left-hand (Main beam, rear 10A

S15 Dipped beam, right-hand (Dipped beam, front

S16 Dipped beam, left-hand (Dipped beam, rear

S17 Rear light, left-hand (Rear light, front

S18 Rear light, right-hand (Rear light, rear

S19 ECU 1

S20 ECU 4

1)

................................................................... 10

1)

................................................................... 10

S21 Voltage converter 24/12 ............................................. 5

S22-24 Spare........................................................................... -

1)

Optional equipment

2)

Rotatable operator’s seat

Bulbs

1)

).......................... 15

1)

) ......................... 15

1)

)

2)

2)

2)

) .................... 5

2)

) ................... 5

9350

00-11

P.Group 20

6

2)

) ...... 5

) ......... 5

2)

) ...... 5

) ......... 5

Rating

Description Watts...................................... Base

B

Instruments 3 ............................................. BA7s

Indicating lamps 1,2 .................................... W2x4,6d

Cab lighting 10............................................ S8,5

Rear lights, red 5 ........................................... BA15s

Brake lights 21 ......................................... BA15s

Direction indicators 21 ......................................... BA15s

Position lights 5 ............................................SV8,5

Driving lights 75/70 .................................. P43t-38

(full/dipped beam)

Reversing lights, white 70......................................... PK22s

Working lights 70 ......................................... PK22s

Hazard beacon 70 ......................................... PK22s

Page 39

DCD90-180

Technical Handbook

Electrical system

Service

Relays

9350

00-11

P.Group 20

7

305 Reversing light

313-1 Brake light (rear-front)

313-3 Direction indicators (right-left)

313-4 Direction indicators (left-right)

313-5 Rear light (rear-front)

313-6 Dipped beam (front-rear)

313-7 Reversing light (rear-front)

313-8 Main beam (front-rear)

313-9 Shifting (rear-front)

313-10 Shifting (front-rear)

2)

2)

2)

2)

2)

2)

2)

2)

2)

314 Parking brake, disengagement

315 High power (Starting switch)

316 Wiper motor, front

320 Electric stop (ECS 07)

322-1 Coolant level

322-2 Coolant level (ECS 07)

323 Pulse relay, direction indicators

328 Lever steering (ECS 04)

1)

1)

1)

330 Starting block

331 Propulsion forward

332 Propulsion reverse

334 Release clutch at automatic gearbox (ECS 01)

368 Low brake pressure (ECS 07)

1)

399 Spare

Miscellaneous

321-1 Intermittent relay wiper front

321-2 Intermittent relay wiper rear

960 Reversing block

1)

Optional equipment

2)

Rotatable operator’s seat

1)

1)

A

WARNING!

Batteries emit oxyhydrogen which

is an explosive gas. A spark, for

example from incorrectly connected

starting cables, could cause a battery

to explode and result in serious injury

and damage.

Main fuse

for electrical system

Fitted on the engine

2 x 50 A

Starting from another battery

z Make sure the auxiliary batteries are connected in series, so

that 24 V will be supplied.

Note: Do not disconnect the truck-battery cables

z Connect the jumper cables in the following order:

1. Red cable (+) to auxiliary battery

2. Red cable (+) to truck battery

3. Black cable (–) to auxiliary battery

4. Black cable (–) to a location some distance away from

the truck battery, such as the negative cable connection on

the chassis.

z Start the engine

Do not disturb the jumper cables while starting, as sparks

may otherwise be caused. Do not lean over either battery.

z Disconnect the jumper cables in exactly the reverse order.

Page 40

DCD90-180

Technical Handbook

Electrical system

Service

Cable markings

All cables are marked with a number for identifying the terminal

points as follows:

9350

00-11

P.Group 20

8

P = Pressure

T = Temperature

η = Coolant level

o = Fuel level

V = ON/OFF

G = Variable sensor

Cable Destination

103A

271

(26.1)

Goes from Runs to

terminal component

block 27 657

Terminal 1

in block 27

If there is a dot in the destination number it describes a terminal

block.

If the cable has a jumper, e.g. a common cable for supplying several functions, a capital letter is added to the cable number.

Cable Destination

Goes from Runs to

terminal terminal

block 10 block 26

Terminal 3

in block 10

(657)

Terminal 1 in block 26

Connected to

supply the next function

Jumper

Page 41

DCD90-180

Technical Handbook

Diagrams

Gear changing systems

Manual electrical gear-changing system

The manual electric gear-changing system is electro-hydraulic

and controls the transmission by means of solenoid valves. Oil

under pressure is supplied to the solenoid valves from the oil

pump built into the transmission.

An inductive sensor senses the speed of the propeller shaft and

applies a signal to a speed monitor which prevent gear-changing

at speeds above 3 km/h.

See the circuit diagrams on the following pages.

9350

00-11

P.Group 20

9

Page 42

DCD90-180

Technical Handbook

Diagrams

Gear changing systems

Manual electric gear-changing system

Clark 18000/20000 Fixed operator’s seat

A09509.0400

This diagram can also be found integrated in the general electric

diagrams DCD90-450 in this Handbook.

A. Gearbox control valve

B. Employed gear

C. Avtivated solenoids

D. To seat buzzer switch

F. To starter motor (50)

G. From start switch

H. From alternator (D+)

J. To parking brake warning lamp

3. Gear selector

5. Speed sensor on gearbox output shaft (output speed)

6. Valve cover with solenoid valves

7. Electrical central unit

8. Switch at parking brake – ON when brake is released

9. Switch at inching – OFF when inching

10. Relays

3. Wiper motor

4. Starting interlock

5. Stop

6. –

7. Reversing lights

8. Inching

9. Reverse gear

10. Forward gear

11. Reversing interlock

9350

00-11

P.Group 20

10

Cable colours

Svart = Black

Grå =Grey

Röd=Red

Blå =Blue

Gul = Yellow

Grön= Green

Brun = Brown

Vit = White

Rosa = Pink

Page 43

DCD90-180

Technical Handbook

D

9

8

10

Diagrams

Gear changing systems

9350

00-11

P.Group 20

11

J

G

H

F

11

7

5

6

3

C

A

B

Clark 18000/20000

Manual electric gear-changing system

Fixed operator’s seat

Page 44

DCD90-180

Technical Handbook

Diagrams

Gear changing systems

Manual electrical gear-changing system

Clark 18000/20000 Rotatable operator’s seat

A09510.0400

This diagram can also be found integrated in the general electric

diagrams DCD90-450 in this Handbook.

A. Gearbox control valve

B. Employed gear

C. Avtivated solenoids

D. To seat buzzer switch

F. To starter motor (50)

G. From start switch

H. From alternator (D+)

J. To parking brake warning lamp

3. Gear selector

5. Speed sensor on gearbox output shaft (output speed)

6. Valve cover with solenoid valves

7. Electrical central unit

8. Switch at parking brake – ON when brake is released

9. Switch at inching – OFF when inching

10. Relays

3. Wiper motor

4. Starting interlock

5. Stop

6. –

7. Reversing lights

8. Inching

9. Reverse gear

10. Forward gear

11. Reversing interlock

12. PCB 2 – rotatable opertor’s seat

9350

00-11

P.Group 20

12

Cable colours

Svart = Black

Grå =Grey

Röd=Red

Blå =Blue

Gul = Yellow

Grön= Green

Brun = Brown

Vit = White

Rosa = Pink

Page 45

DCD90-180

Technical Handbook

10

Diagrams

Gear changing systems

9350

00-11

P.Group 20

13

12

10

D

9

8

GHJ

F

11

7

5

6

3

C

B

A

Clark 18000/20000

Manual electric gear-changing system

Rotatable operator’s seat

Page 46

DCD90-180

Technical Handbook

Diagrams

Gear changing systems

Manual electrical gear-changing system

Clark 28000/32000 Fixed operator’s seat

A06526.0200

This diagram can also be found integrated in the general electric

diagrams DCD90-450 in this Handbook.

A. Gearbox control valve

B. Employed gear

C. Avtivated solenoids

D. To seat buzzer switch

F. To starter motor (50)

G. From start switch

H. From alternator (D+)

J. To parking brake warning lamp

3. Gear selector

5. Speed sensor on gearbox output shaft

6. Valve cover with solenoid valves

7. Electrial central unit

8. Switch at parking brake – ON when brake is released

9. Switch at inching – OFF when inching

10. Relays

3. Wiper motor

4. Starting interlock

5. Stop

6. –

7. Reversing lights

8. Inching

9. Reverse gear

10. Forward gear

11. Reversing interlock

9350

00-11

P.Group 20

14

Cable colours

Svart = Black

Grå =Grey

Röd=Red

Blå =Blue

Gul = Yellow

Grön= Green

Brun = Brown

Vit = White

Rosa = Pink

Page 47

DCD90-180

Technical Handbook

D

9

8

10

Diagrams

Gear changing systems

9350

00-11

P.Group 20

15

J

G

F

H

K

11

7

5

6

C

3

A

B

Clark 28000/32000

Manual electric gear-changing system

Fixed operator’s seat

Page 48

DCD90-180

Technical Handbook

Diagrams

Gear changing systems

Manual electrical gear-changing system

Clark 28000/32000 Rotatable operator’s seat

A06526.0100

This diagram can also be found integrated in the general electric

diagrams DCD90-450 in this Handbook.

A. Gearbox control valve

B. Employed gear

C. Avtivated solenoids

D. To seat buzzer switch

F. To starter motor (50)

G. From start switch

H. From alternator (D+)

J. To parking brake warning lamp

3. Gear selector

5. Speed sensor on gearbox output shaft (output speed)

6. Valve cover with solenoid valves

7. Electrical central unit

8. Switch at parking brake – ON when brake is released

9. Switch at inching – OFF when inching

10. Relays

3. Wiper motor

4. Starting interlock

5. Stop

6. –

7. Reversing lights

8. Inching

9. Reverse gear

10. Forward gear

11. Reversing interlock

12. PCB 2 – rotatable opertor’s seat

9350

00-11

P.Group 20

16

Cable colours

Svart = Black

Grå =Grey

Röd=Red

Blå =Blue

Gul = Yellow

Grön=Green

Brun = Brown

Vit = White

Rosa = Pink

Page 49

DCD90-180

Technical Handbook

D

9

12

10

10

Diagrams

Gear changing systems

9350

00-11

P.Group 20

17

H

J

F

G

K

8

11

7

5

13

C

3

A

B

6

Clark 28000/32000

Manual electric gear-changing system

Rotatable operator’s seatl

Page 50

DCD90-180

Technical Handbook

Diagrams

Engine stop high/low temp

9350

00-11

P.Group 20

18

Engine stop at high/low coolant temperature

Engine with stop solenoid

Page 51

DCD90-180

Technical Handbook

Diagrams

Engine stop high/low temp

9350

00-11

P.Group 20

19

Engine stop at high/low coolant temperature

Engine with fuel shut off valve

Page 52

DCD90-180

Technical Handbook

Diagrams

Automatic engine stop, operator’s seat

9350

00-11

P.Group 20

20

ter the operator has left the cabin. After 5 min the eng-

The engine is automatically shut down a certain time af-

ine rpm is reduced to idle speed.

340. Time relay, after set time restart is permitted

Engine stop, operator’s seat

Page 53

DCD90-180

Technical Handbook

Diagrams

El-operated extra hydraulic function

9350

00-11

P.Group 20

21

1. Control section in the main valve, extra function

199. Push-button for extra function in the 4th or 5th control

lever

Electrically operated extra hydraulic function

1

Page 54

DCD90-180

Technical Handbook

WARNING!

The truck must not be operated with

by-passed safety interlock system!

Diagrams

Safety interlock system

Safety interlock for container handling

The safety interlock comprises three solenoid valves which are

activated by switches or sensors on the container attachment.

The valves interrupt the servo supply from control levers to main

valve in two cases:

1. Interrupt LIFT if not every twist-locks is either open or locked.

This prevents lifting of a container if accidentally only one

side of the container has been properly locked with the twistlocks.

2. Interrupt locking of the twist-locks if the attachment is not fully aligned onto the container, i.e. all corners are not close up

to the container.

In case of emergency, the safety interlock system is possible to

by-pass with a key operated switch.

N.B. The operator is responsible for by-passing with the key.

When the key is turned to ON-position, the safety interlock

system is out of function!

9350

00-11

P.Group 20

22

Page 55

DCD90-180

Technical Handbook

Diagrams

Safety interlock system

Safety interlock system

Volvo engine: A28047.0600

Perkins engine: A28047.0700

1. Switch, twist-locks

2. Switch, length adjustment 20–40’

3. Indicating lamp TWIST-LOCKS LOCKED

4. Indicating lamp ALIGNMENT

5. Indicating lamp TWIST-LOCKS OPEN

6. Terminal in chassis

7. Terminal in fork carriage

8. Sockets in the electrical central unit

9. Key operated by-pass switch

10. Solenoid valves, cut off servo pressure for twist-locks if there

is no alignment signal

11. Solenoid valve cuts off servo pressure for lift if twist-locks are

neither unlocked nor locked

12. Attachment electrical system

13. Sensor TWIST-LOCKS LOCKED

14. Sensor TWIST-LOCKS OPEN

15. Sensor ALIGNMENT

16. Indicating lamp, lights up when the system is by-passed with

key switch 9

9350

00-11

P.Group 20

23

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

DCD90-180

Technical Handbook

Contents

Group 30

Volvo TD640VE

Specifications............................................................. 3

Engine TD640VE ....................................................... 4

Description............................................................ 4

Volvo TD730VE/TWD731VE

Specifications............................................................. 7

Engine TD730VE/TWD731VE ................................... 8

Description............................................................ 8

Overview.......................................................... 8

Cooling system .............................................. 10

Fuel system ................................................... 12

Lubrication system......................................... 15

Combusting air system .................................. 17

Service................................................................ 19

Coolant quality............................................... 19

Lubrication oil quality ..................................... 19

Draining the water from the fuel tank............. 19

Inspection of air cleaner and changing

the filter element ............................................ 19

Changing the oil and oil filter ........................ 20

Checking V-belt tension................................. 20

Checking and adjusting the valve clearances21

Changing the fuel filters................................. 21

Preventive maintenance on turbo-charger .... 22

9350

02-08

P.Group 30

Perkins 1006-60T

Specifications ............................................................. 40

Engine Perkins 1006-60T ........................................... 41

Description ............................................................ 41

General ............................................................ 41

Cooling system................................................. 42

Fuel system...................................................... 43

Service .................................................................. 44

Coolant quality ................................................. 44

Lubrication oil quality........................................ 44

Draining the water from the fuel tank ............... 44

Inspection of air cleaner and changing

the filter element............................................... 44

Changing the oil and oil filter ........................... 45

Checking V-belt tension ................................... 46

Checking and adjusting the valve clearances.. 46

Changing the fuel filters ................................... 47

Preventive maintenance on turbo-charger ....... 48

Cummins 6BTA5.9