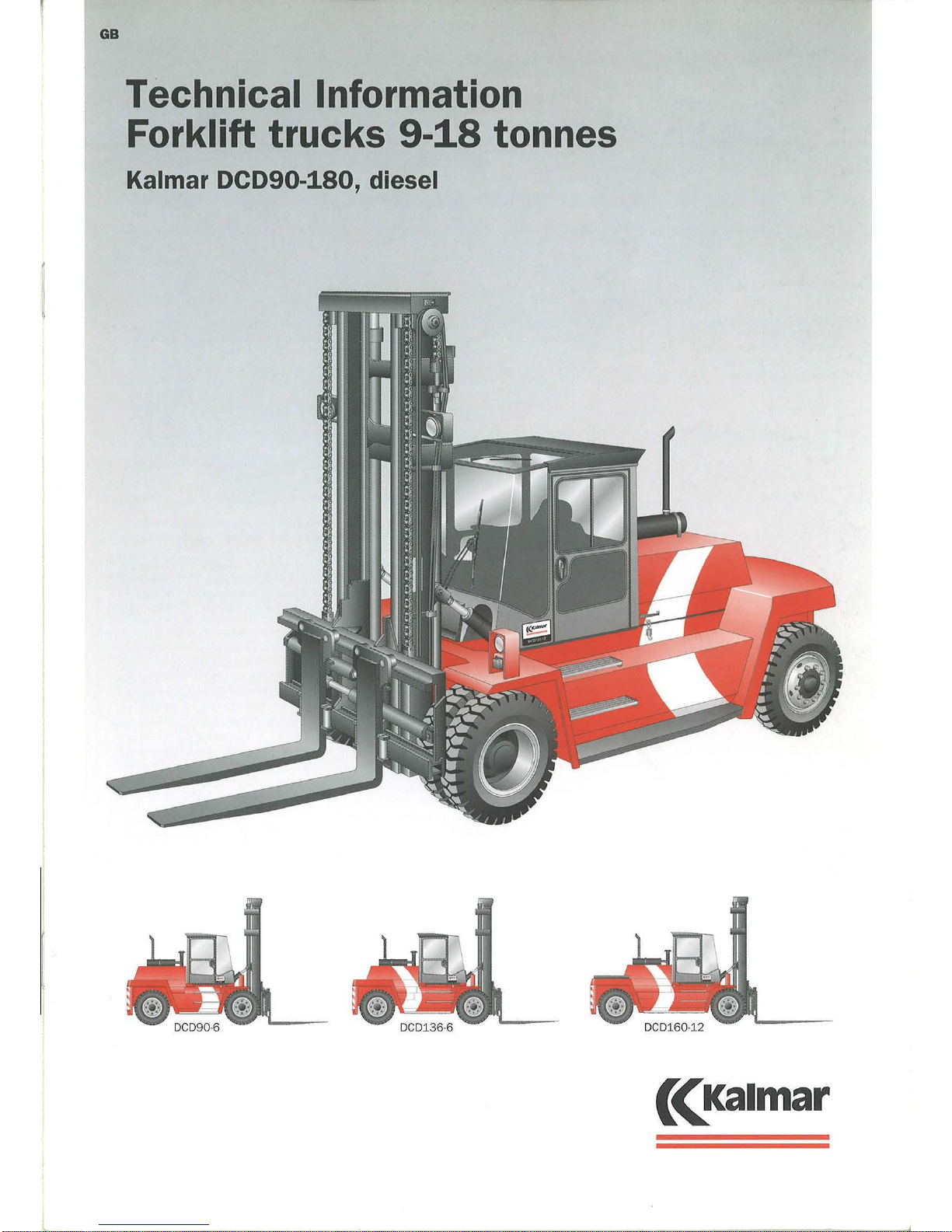

Kalmar DCD90-180, DCD90-6, DCD136-6, DCD160-12 Technical Information

GB

Technical Information

Forklift

trucks

9-18 tonnes

Kalmar DCD90-180, diesel

l

Ka

lmar Industries

DCD90·180

The DCD90-180 with a lift

cap

acity

of

9-

18 tonnes

is the n

ew

generation

of

fo

rklift trucks in the medium segment

of

Kalmar's c

ompr

ehen sive range

of

4-

90 ton trucks - a well prov

en

range

of

tru

cks incorporating the latest design

so

lutions for o

ptimum productivity and

overa

ll

eco

nom

y.

A compr

ehe nsi

ve

range of o p tional

e

quipm

en t

pac

kages facilitat

es adaptation to sp ecial h andling environments

and

different typ es

of

goods.

Ty

pe designation:

DCD100·

12

Co

unter_-b

alan

ce

tru

ck

Dk

sel engine

::"_J

I T

Generation

---

- -

Lift

capacity, dec

itonnes

Load ce

ntr

e, decimetre

Opera

tor

Environment

The S

pir

it Delta cab is

of a co

mple

tely

n

ew

and mod e

rn des

ign that p rovid

es

th

e operator

with

an efficie

nt and

safe

place of wo rk.

Th

e design

of

the cab is

th

e result

of a co

mpr

eh ensi

ve

analysis

of

ope

rators ' working condition s

providing o

ptimum

visibility w it h large

glass areas and n o forward

corner p osts

to inhibit

th

e field of vision . The ins

tru

-

ment panel is gently ro

und

ed and ergo-

nomically designed

with

an

uninhibited clear

vi

ew

of a

ll

essential

informati

on. Access

to

the cab is

comfortable a

nd

secure thanks to the

thr

ee

ste p s

up

to th

e c

ab

and many well

located ha

nd

rails.

All cabs in th e seri

es can be tilted, for

op

timum

service

access. Noi

se

and

vibration levels are extr

emely l

ow

thank

s to the insulated mounting to the

ch assis. The tilting cylinders

ope

rate

against the

cab

whi

ch is isolated by

m

ea

ns

of

r ubb

er

elements.

The

ope

rator 's seat, steerin

g whe el and

hy

dr

aulic contr

ols are a

ll

individually

adjustable for

op

timum working

pos

ition. Two easily operated , ergonomically p osition ed multi-function l

eve

rs

are provid

ed for gear chang in

g,

wind-

scree

n wipers, washers a

nd horn

.

An

extremely

powe

rful h

eating/ve

ntila-

tio n unit e ns

ur

es a comfort

abl e cab

te

mp

erature. An easily replaced fre

sh

a

ir

filter cleans the incomin

g a

ir.

2

Technical Information DCD90-

180

Th

e unit sli

des

out to give easy access

for

se

rvice.

As

standard, t he e quipment

includ

es

a p

owe

rful

3-spee

d fan for

coo

lin

g, heat

ing, defrosting and recir-

culation.

O

pti

onal Extra

s:

• Extr

a h igh

cab

, +200

mm

• Elevated cab, + 300

mm

• Overhea

d g uard

• Roof mounted grid p rotection

• Co

mpl

ete

climate co

ntr

ol system

• Partially /fully rotatable

oper

ator se

at

Ins

trumenta

tion

Th

e instrument panel has logically

grou

pe

d units , a

ll

w ithin easy r each.

Sta

nd

ard ins

trument

ation includes

wa

rnin

g lamps for batte ry chargin

g,

l

ow

engine lubrication o

il

pressm e,

l

ow brake pressure, high

coo

lant

te m

pe

rature, high gearb

ox

oil tempera-

tur

e a

nd

applied parking brake.

In

add i-

tion, gauges display valu

es for engine

coolant

temperature, fu el quantity a

nd

op erating time .

Truc ks fitted w ith

ECS

mo nitorin

g are

not normally e

quipp

ed with wa

rnin

g

la

mp

s o r gauges. Th

ese functions are

handled by the

ECS

w hic h has a single

war

ning la

mp and

full text display

sh

ow

ing c urren t valu

es and

any faults

that

occ

ur.

Chassis

Th e chassis is built

of

fully welded ste

el

p ro

fil

es which g ives a rigid con

struc-

tion w

ith extr

emely strong mounting

po

int

s for the drive axle a

nd

lift equip-

ment.

S

tr

ess concentr ations have been elimi-

Jut

ed for o

ptimum

te nsile stren gth.

Th e chassis is flexible and is used

fo

r a

numb

er

of

differe nt drive line comb

ina-

tion s. The sp ace at the re

ar

of the

c

ha

ssis is used for count

er-weights, the

numb

er

of

w hich are adapted

to th

e

m

ac

hine in question.

Th e chassis

ha

s an

ext

rem e ly l

ow

profil

e for good visibilit

y.

Th e tanks are

separate

ly con

str

ucted and bolted to

th

e chassis in a position that al

so

co

ntribu

tes to good visibilit

y.

Technical Information DCD90-180

Electrical System

The elect

rical system is logically struc-

tured, easily serviced a

nd

comp

letely

coordi

nat

ed

wit

h the

other

trucks

in

the

Kalmar range.

The

system

is

suppli

ed

by

two

12V batteries

connected

in

ser

ies c harged by

an alt

er-

nator,

with related electronics for recti-

ficati

on

and

current

stab

ilization.

The

system

provides

high

power

levels

even

at

low

engin e revs. Th e electrical

fuses, relays and

connectors

are

l

ocated

in

an

easily accessible

position

withi

n a

centra

l electrical unit inside

the

cab,

behind

the

operator

's seat.

KL898

Central electrica l unit

ECS (Optional)

· Electronic Control

System

Trucks can

be

equ

ipp

ed with

ECS,

a

sta

te

of

the

art

system for

optimum

operational security

and

overa

ll

eco

nomy.

The

systems consists

of

a

numb

er

of

modules that

can

be

combined

in different ways,

depending

on

the

nature

of

the

operations. For

examp

le,

the

foll

owing

function s are

ava

il

able:

• Automatic

gear

changing

(Load sensing system)

• Lever

steering

• Mini-steering

• Monitoring

• Electr

o-servo

See also

separate informati

on

about

the

Kalmar

ECS

System.

Engine

As

standard,

the

DCD90-180

truck

is

equipped

with

Volvo 's TD640VE diesel

engine and as

option

the

DCD90-136

with

the

Perkins 1006-60T1,

both

turbo-charged straig

ht

six diesel

engines

adapted

to

the

specialized

working requirements

of

a forkl ift

truck

, w i

th

high

power

and

torque

level

s,

even

at l

ow

engine

speeds. The

eng

ine has l

ow

exhaust

emission l

eve

ls

and

comp

lies

wit

h today's stringent

legal

enviro

nment

al

demands

(EU,

CARB,

EPA).

All engines

are characterized by l

ow

fuel consumpti

on

and l

ow

noise and

vibration levels.

Alternative engines:

• Perkins l 006-60T2

•

Volvo TD730VE

• Volvo TWD731VE

• Scania DI9

• C

ummins 6BTA

5.9-C200

See

Alternative drive lin

es

table

Transmission

Al

l trucks in

the

series

are

equipped

wit

h Clark's well

proven

hydro-

dynamic transmission systems

(3+3)

,

with integrated gea

rb

ox

and

torque

converter

, for

smooth, quick

acce

lera-

tion w

ith

a minimum

of

"clutch-slip".

A

number

of

different transmissi

ons

systems are ava ilable,

depending

on

the

sel

ected

engine

(see separate combin

a-

tion

table). Constant

mesh

gears and

gear

cha

nging by hydraulically

applied

clutches

(Powers

hift) are, h

owever

,

common

to all gearboxes.

Gear ch anging is el

ectrically achieved

via sol

enoid

valves,

with

three

reverse

and

three

forward gears,

controll

ed

by

means

of

an

easily

ope

rated multi-func-

tion lever.

Drive

axle

The

Kessler

D81

drive axle is

of

an

extreme

ly robust design to

be

able to

cope with

tough working environ-

ments

such

as

in

the

paper

and

pulp

industries, saw mills,

steel wo

rks,

ports

and terminals.

The

axle has reduction in

two

stages -

diff

ere

ntial and

hub

reduction -which

ensures

a minimum

of

strain

on

the

transmission system.

The

drive axle is

fitted w

ith

hydraulic braking system

(see

Servi

ce

Brake System).

Parking Brake System

The

parking brake system consists

of

a

dry

disc

brake

on

the

in-going shaft

of

the

drive axle. The disc brake

is

applied

by

means

of

a powerful spring in

the

parking

brake

cylind

er

and

is released

by

means

of

hydraulic

pressure

from

the

parking brake valve

in

the

cab.

Kalmar Industries

Volvo

TD640VE (6-cyl with turbo)

Service Brake System

The

service brake system

is

of

the

Wet

Disc Brake type, a system w

ith oil

-

coo

led discs

that

are alternate

ly

fixed

to

and rotating

with

the

hub.

When

the

brakes

are

app

li.ed,

the

discs are

pressed

together

by

hydraulic

pressure

from

the

brake pedal,

which provides

extremely effective braking.

The

system is v

irtually maintenance

free

and

can

cope

wit

h heavy l

oads

over

an

extended

period

of

time,

with

no fade

and

w i

thout

the

need

for

brake

adjust-

ments. The

heat

generated

durin

g

braking is dissipated via a

coo

ling

circ

uit

in w hi

ch

th e

truck

's total

volume

of

hydraulic fluid

comes

int

o

play. A

spec

ial filter

protects

the

braking system from any impmities.

Hub reduction

Kessler drive

axle

3

Loading...

Loading...