Juki DLN-415 Instruction Manual

BE4150S0B0B

MODEL

DLN-415

HIGH

SPEED, SINGLE NEEDLE,

LOCKSTITCH

NEEDLE

FEED

INDUSTRIAL

SEWING

MACHINE

Instruction

Book

OLN'A1S

CiiE=>

TOKYO

JOKI

INDUSTRIAL

C0..1TD

DLN-415

SPECIFICATIONS

Sewing

speed Upto 5,000 s.p.m.

(DLN-415L

3,000 s.p.m.)

Stitch length

04mm

{5/32")

(DLN415L

0~6mm

(15/64"))

Stitch adjuster Dial system

Reverse sewing Lever system

Needles DBx

1(16

x 231)

#11,

#14,

#16,

#18

(DLN

415L

DB x 1

#22)

Lubricating oil New Defrix Oil No. 1

DLN-415

CONTENTS

Page

Installing

the

oil

reservoir

2

Motor

pulley

and

the

belt

2

Cautions

on

operating

the

machine

3

Lubrication

3

1.

Adjusting

the

oil

supply

to

the

face

part

4

2.

The

oil adjusting pin 4

3.

Adjusting

the

oil

supply

to

the

hook

components

4

Threading

the

machine

5

Preparation

of

the

bobbin

thread

6

1. Inserting &

removing

the

bobbin

case

6

2.

Winding

the

bobbin

thread

6

3.

How

to

insert

the

bobbin

6

The

thread

tension

7

Adjusting

the

needle

thread

tension

7

Thread

take-up

spring

7

Adjusting

the

bobbin

thread

.tension

7

Presser

foot

and

feed

dog

8

Adjusting

the

pressure

of

the

presser

foot

8

The

presser

foot

hand

lifter

8

Height

of

the

feed

dog

.'. ; 8

The

stitch

length

•.

9

Adjusting

the

stitch

length

9

Reverse

sewing

9

Pushing

pressure

of

the

feed

lever

9

Inserting

the

needle

10

Installing

and

removing

the

sewing

hook

10

Relation

between

the

hook

and

the

needle

11

Adjusting

the

height

of

the

presser

bar

12

Adjusting

the

amount

of

the

thread

take-up

12

DLN-415-L

INSTRUCTION

BOOK

13

(Note) Due

to

improvements

on

the

machine,

some

parts of

the

operational

procedures

of

this

INSTRUCTION

BOOK

might

be

changed

without

notice.

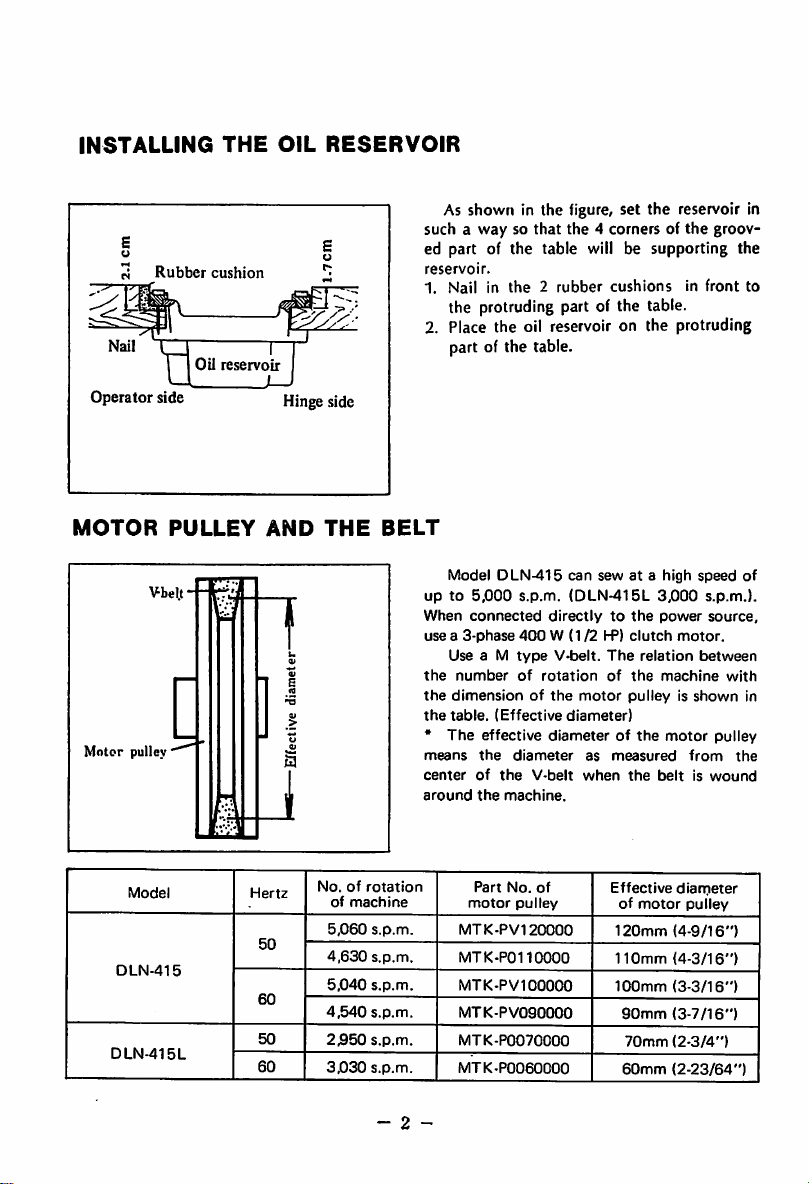

INSTALLING

THE

OIL

RESERVOIR

Rubber

cushion

I 1

Oil

reservoir

1_

Operator

side

Hinge side

As shown in the figure, set the reservoir in

such a way so that the 4 corners of

the

groov

ed part of the table will be supporting the

reservoir.

1. Nail in

the

2

rubber

cushions

in

front

to

the protruding part of the table.

2. Place the oil reservoir on the protruding

part of the table.

MOTOR

PULLEY

AND

THE

BELT

Motor

pullev

Model

DLN-415

can

sew

at

a

high

speed

of

up

to

5,000

s.p.m.

(DLN-415L

3,000

s.p.m.).

When

connected

directly

to

the

power

source,

use

a

3-phase

400

W (1

/2

HP)

clutch

motor.

Use a M

type

V-belt.

The

relation

between

the

number

of

rotation

of

the

machine

with

the

dimension

of

the

motor

pulley

is

shown

in

the

table.

(Effective

diameter)

•

The

effective

diameter

of

the

motor

pulley

mrans

the

diameter

as

measured

from

the

center

of

the

V-belt

when

the

belt

is

wound

around

the

machine.

Model

Hertz

No.

of

rotation

of

machine

Part

No.

of

motor

pulley

Effective

dian^ieter

of

motor

pulley

DLN-415

50

5,060

s.p.m.

MTK-PV120000

120mm

(4-9/16")

4,630

s.p.m.

MTK-P0110000

110mm

(4-3/16")

60

5,040

s.p.m.

MTK-PV100000

100mm

(3-3/16")

4,540

s.p.m.

MTK-PV090000

90mm

(3-7/16")

DLN-415L

50

2,950

s.p.m.

MTK-P0070000

70mm

(2-3/4")

60

3,030

s.p.m.

MTK-P0060000

60mm

(2-23/64")

- 2 -

CAUTIONS

ON

OPERATING

THE

MACHINE

® Do not run the

machine,

under any

circumstances,

before the oil

reservoir

is

filled

up

with

fresh

oil.

® Always rotate the machine toward the operator. Do not run the machine in the re

verse

direction.

® This machine can run with a speed of up to 5,000 s.p.m. but for the first month drop

the speed to

about

4,500 s.p.m. (DLN-415L 2,500 s.p.m.)

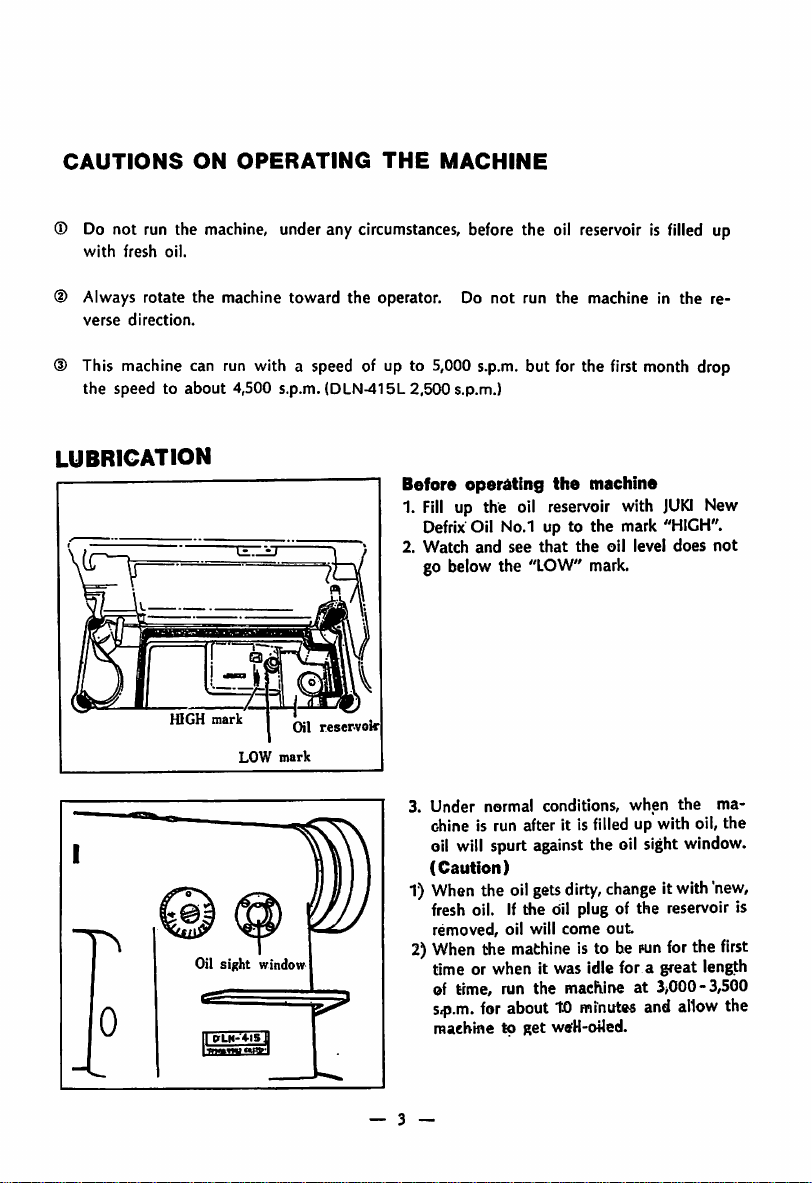

LUBRICATION

Before

operating

the

machine

1.

Fill

up the oil reservoir with

JUKI

New

Defrix

Oil No.1 up to the mark

"HIGH".

2.

Watch

and

see

that

the

oil level

does

not

go below the

"LOW"

mark.

HIGH

mark

Oil

reservoir

LOW

mark

Oil sight window

0

OLM-4-15]

3.

Under

normal

conditions,

when

the

ma

chine is run after it Is filled up with oil, the

oil

will

spurt

against

the oil sight

window.

(Caution)

1) When the oilgets

dirty,

change

itwith

"new,

fresh oil. Ifthe oil plug of the reservoir is

removed,

oil will

come

out

2)

When

the

machine

isto be

pun

for

the

first

time or when it was idle for a great length

of time, run the

macFiirie

at

3>000-3,500

S4).m.

for

abouttO

minutes

and

allow

the

machine to get wtfH-oUed.

— 3 —

Loading...

Loading...