Page 1

Operation and Safety Manual

TOUCAN 800

TOUCAN 870

English - Operation and Safety Manual - Original Instructions

31210031

January 01, 2010

Page 2

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

Other Publications Available:

Service and Maintenance Manual French ........................................... MA0306

Service and Maintenance Manual English .......................................... MA0318

Illustrated Parts Manual Toucan 800..................................................31210056

Illustrated Parts Manual Toucan 870..................................................31210058

Hydraulic schematic Toucan 800.......................................................... FL0147

Hydraulic schematic Toucan 870.......................................................... FL0146

Electrical schematic .............................................................................. ELE240

31210031 – JLG Lift – a

Page 4

FOREWORD

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL

DECAL WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

DECAL WILL HAVE AN ORANGE BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES.

INDICATES PROCEDURES ESSENTIAL FOR SAFE OPERATION.

THIS DECAL WILL HAVE A YELLOW BACKGROUND.

RESULT IN SERIOUS INJURY OR DEATH. THIS

RESULT IN SERIOUS INJURY OR DEATH. THIS

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS, CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED JLG REPRESENTATIVE FOR INFORMATION REGARDING

SAFETY-RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED

FOR THIS PRODUCT.

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO

THE OWNER OF RECORDS OF THIS MACHINE. CONTACT JLG

INDUSTRIES, INC. TO ENSURE THAT THE CURRENT OWNER

RECORDS ARE UPDATED AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN

AN ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO

PERSONAL PROPERTY OR THE JLG PRODUCT.

For:

• Accident Reporting

• Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Safety

CONTACT:

• Standards and Regulations Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding Product Modifications

In USA: Outside USA:

JLG Industries, Inc.

Product Safety & Reliability Department,

13224 Fountain Head Plaza

Hagerstown, MD

USA 21742

Toll Free :+1 (877) 554-7233

Tel. : +1 (240) 420-2661

Fax : +1 (301) 745-3713

Email : ProductSafety@JLG.com

JLG Industries,

Wright Business Centre,

1 Lonmay Road

Queenslie

Glasgow,

Scotland G33 4EL

Tel : +44(0)141 781 6700

Fax : +44(0)141 773 1907

Email : ProductSafety@JLG.com

IMPORTANT

IMPORTANT

or Your Local JLG Office

(see adresses on manual rear cover)

b – JLG Lift – 31210031

Page 5

REVISION LOG

Original Issue - September 14, 2007

Revision - January 01, 2010

FOREWORD

31210031 – JLG Lift – c

Page 6

FOREWORD

d – JLG Lift – 31210031

Page 7

TABLE OF CONTENTS

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 PRE-OPERATION. . . . . . . . . . . . . . . . . . . . . 1-1

Operator Training and Knowledge. . . . . 1-1

Workplace Inspection. . . . . . . . . . . . . . . 1-1

Machine Inspection . . . . . . . . . . . . . . . . 1-1

1.3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Trip and Fall Hazards . . . . . . . . . . . . . . . 1-2

Electrocution Hazards . . . . . . . . . . . . . . 1-2

Tipping Hazards . . . . . . . . . . . . . . . . . . . 1-3

Crushing and Collision Hazards . . . . . . 1-3

1.4 TOWING, LIFTING, AND HAULING . . . . . . . 1-4

1.5 ADDITIONAL HAZARDS / SAFETY . . . . . . . 1-4

SECTION - 2 - USER RESPONSIBILITIES, MACHINE

PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . 2-1

Training Supervision. . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND MAINTE-

NANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 PRE-START INSPECTION . . . . . . . . . . . . . . 2-3

2.3.1 Walk-Around Inspection. . . . . . . . . . . . . . . . 2-5

2.3.2 Function Check . . . . . . . . . . . . . . . . . . . . . . 2-6

Control Stations . . . . . . . . . . . . . . . . . . . 2-6

Tilt Sensor Check . . . . . . . . . . . . . . . . . . 2-6

Overload Sensor Check (Toucan 800 & Toucan

800 DI) 2-7

Slack / Broken Chain Sensors Check . . 2-8

Gate sensors check (Toucan 800 DI only) 2-8

SECTION - 3 - MACHINE CONTROLS AND INDICATORS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 CONTROLS AND INDICATORS. . . . . . . . . . 3-2

Ground Control Station . . . . . . . . . . . . . 3-3

Manual Lowering Controls . . . . . . . . . . . 3-5

Platform Control Station . . . . . . . . . . . . . 3-6

Platform Control Indicator Panel. . . . . . . 3-7

SECTION - 4 - MACHINE OPERATION

4.1 EMERGENCY CONTROL OPERATION . . . . 4-1

Platform/Off/Ground Selector Switch. . . 4-1

Emergency Stop Switch. . . . . . . . . . . . . 4-1

4.2 PLATFORM CONTROLS . . . . . . . . . . . . . . . 4-1

Drive Speed Selector Switch . . . . . . . . . 4-1

Traveling (Driving) . . . . . . . . . . . . . . . . . 4-1

Raising And Lowering The Mast . . . . . . 4-3

Raising And Lowering The Jib . . . . . . . . 4-4

Slewing The Turntable . . . . . . . . . . . . . . 4-4

Work Platform Functions Combination . 4-4

4.3 MANUAL LOWERING CONTROLS . . . . . . . 4-4

4.4 ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Motion Alarm . . . . . . . . . . . . . . . . . . . . . 4-4

Tilt Light And Alarm . . . . . . . . . . . . . . . . 4-4

Overload Light And Alarm (Toucan 800 only)4-4

Slack Chain Light And Alarm . . . . . . . . 4-4

Soft Touch System Light and Alarm (Option)4-5

4.5 SHUT DOWN AND PARK . . . . . . . . . . . . . . 4-5

4.6 CHARGERS . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ZIVAN BC1 High Frequency Electronic Charger4-6

EMB-MP HAWKER Charger (40 or 70 A) 4-7

4.7 EMERGENCY TOWING. . . . . . . . . . . . . . . . 4-8

4.8 LIFTING AND TIE DOWN . . . . . . . . . . . . . . 4-8

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.9 LOADING AND UNLOADING . . . . . . . . . . . 4-9

Using a fork lift truck . . . . . . . . . . . . . . . . 4-9

Using a winch for loading . . . . . . . . . . . . 4-9

SECTION - 5 - DECALS

SECTION - 6 - EMERGENCY PROCEDURES

6.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 INCIDENT NOTIFICATION . . . . . . . . . . . . . 6-1

6.3 EMERGENCY OPERATION. . . . . . . . . . . . . 6-1

Operator Unable to Control Machine . . . 6-1

Platform or Mast Caught Overhead. . . . . 6-1

6.4 EMERGENCY LOWERING . . . . . . . . . . . . . 6-1

6.5 EMERGENCY TOWING PROCEDURES . . . 6-1

SECTION - 7 - INSPECTION AND REPAIR LOG

SECTION - 8 - GENERAL SPECIFICATIONS & OPERATOR

MAINTENANCE

8.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 OPERATING SPECIFICATIONS . . . . . . . . . 8-2

Fluid Capacities . . . . . . . . . . . . . . . . . . . . 8-3

Hydraulic Power Unit . . . . . . . . . . . . . . . . 8-3

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.3 OPERATOR MAINTENANCE. . . . . . . . . . . . 8-5

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Hydraulic filters . . . . . . . . . . . . . . . . . . . . 8-8

Turntable Lubrication. . . . . . . . . . . . . . . . 8-9

Lifting chains lubrication . . . . . . . . . . . . . 8-9

Mast Section Lubrication . . . . . . . . . . . . . 8-9

Wheel Bearing & Steering Knuckle Lubrication8-9

Hydraulic Oil Reservoir . . . . . . . . . . . . . 8-10

Steering hydraulic unit reservoir . . . . . . 8-11

Tires And Wheels. . . . . . . . . . . . . . . . . . 8-11

Verification Of The Overload Detection Setting

(Toucan 800 only) . . . . . . . . . . . . . . . . . 8-12

Verification Of The Tilt Alarm Setting. . . 8-12

31210031 – JLG Lift – 1

Page 8

TABLE OF CONTENTS

2 – JLG Lift – 31210031

Page 9

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for

proper and safe machine operation and maintenance.

For proper machine use, it is mandatory that a daily

routine is established based on the content of this

manual. A maintenance program, using the

information provided in this manual and the Service

and Maintenance Manual, must also be established by

a qualified person and followed to ensure the machine

is safe to operate.

If there are any questions with regard to safety,

training, inspection, maintenance, application, and

operation, please contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED

IN THIS MANUAL COULD RESULT IN MACHINE DAMAGE,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

1.2 PRE-OPERATION

Operator Training and Knowledge

• Read and understand this manual before operating

the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all

hazards in the work area prior to machine operation.

• Do not operate or raise the platform while on trucks,

trailers, railway cars, floating vessels, scaffolds or

other equipment unless approved in writing by JLG.

• Do not operate the machine in hazardous

environments unless approved for that purpose by

JLG.

• Be sure that the ground conditions are able to

support the maximum load of the machine.

• This machine can be operated in temperatures of

o

C to 40oC. Consult JLG for operation outside

-20

this range.

• This machine must be used in a sufficient ambient

light.

Machine Inspection

• Before machine operation, perform inspections and

functional checks. Refer to Section 2 of this manual

for detailed instructions.

• Do not operate this machine until it has been

serviced and maintained according to requirements

specified in the Service and Maintenance Manual.

• Be sure the footswitch and all other safety devices

are operating properly. Modification of these

devices is a safety violation.

• Do not operate this machine until complete training

is performed by authorized persons.

• Only authorized and qualified personnel can

operate the machine.

• Read, understand, and obey all DANGERS,

WARNINGS, CAUTIONS, and operating instructions

on the machine and in this manual.

• Use the machine in a manner which is within the

scope of its intended application set by JLG.

• All operating personnel must be familiar with the

emergency controls and emergency operation of

the machine as specified in this manual.

• Read, understand, and obey all applicable

employer, local, and governmental regulations as

they pertain to operation of the machine.

MODIFICATION OR ALTERATION OF AN AERIAL WORK

PLATFORM SHALL BE MADE ONLY WITH WRITTEN PERMISSION

FROM THE MANUFACTURER

• Do not operate any machine on which safety or

instruction placards or decals are missing or

illegible.

• Avoid any buildup of debris on the platform floor.

Keep mud, oil, grease, and other slippery

substances from footwear and platform floor.

• Do not clean electrical components with a high

pressure cleaner.

1.3 OPERATION

General

• Do not use the machine for any purpose other than

positioning personnel, their tools, and equipment.

• Never operate a machine that is not working

properly. If a malfunction occurs, shut down the

machine.

• Never slam a control switch or lever through neutral

to an opposite direction. Always return switch to

31210031 – JLG Lift – 1-1

Page 10

SECTION 1 - SAFETY PRECAUTIONS

neutral and stop before moving the switch to the

next function. Operate controls with slow and even

pressure.

• Park the machine in stowed position when not in

service.

• Do not allow personnel to tamper with or operate

the machine from the ground with personnel in the

platform, except in an emergency.

• Do not carry materials directly on platform railing

unless approved by JLG.

• When two persons are in the platform, the operator

shall be responsible for all machine operations.

• Always ensure that power tools are properly stowed

and never left hanging by their cord from the

platform work area.

• Supplies or tools which extend outside the platform

are prohibited unless approved by JLG.

• When driving, always position extending structure

over rear axle in line with the direction of travel.

Remember, if extending structure is over the front

axle, steer and drive functions will be reversed.

• Do not assist a stuck or disabled machine by

pushing, pulling, or by using extending structure

functions. Only pull the unit from the towing points

on the chassis.

• Do not place extending structure or platform against

any structure to steady the platform or to support

the structure.

• Stow extending structure and shut off all power

before leaving machine.

• Keep both feet firmly positioned on the platform

floor at all times. Never use ladders, boxes, steps,

planks, or similar items on platform to provide

additional reach.

• Always enter or leave the platform using the access

gate.

• Use extreme caution when entering or leaving

platform. Be sure that the mast assembly is fully

lowered. Face the machine, maintain “three point

contact” with the machine, using two hands and one

foot or two feet and one hand during entry and exit.

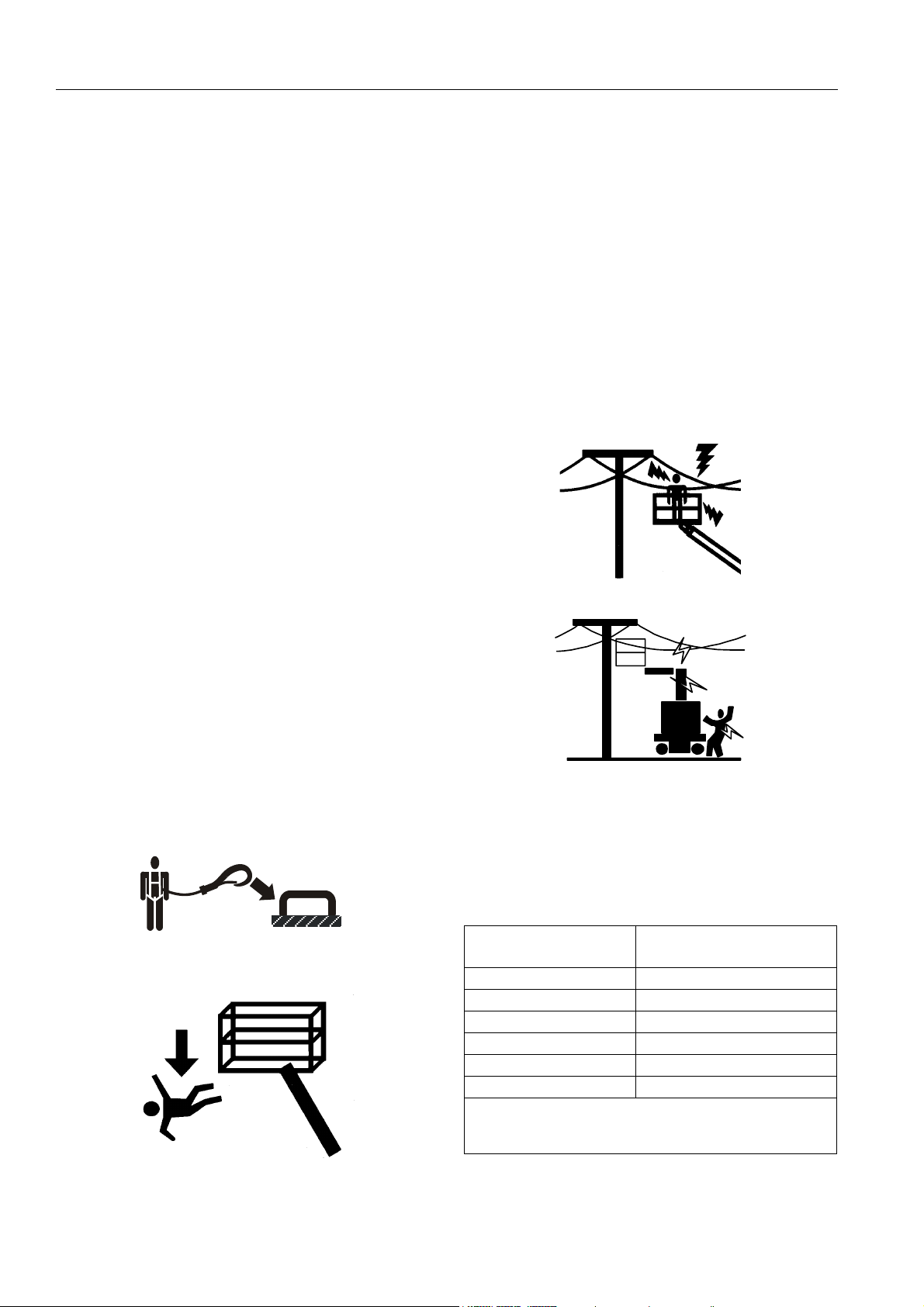

Electrocution Hazards

• This machine is not insulated and does not provide

protection from contact or proximity to electrical

current.

Trip and Fall Hazards

JLG recommends that occupants of the platform wear

a full body harness with a lanyard attached to an

authorized lanyard anchorage point. For further

information regarding fall protection requirements on

JLG products, contact JLG Industries, Inc.

• Before operating the machine, make sure all gates

are closed and fastened in their proper position.

• Maintain distance from electrical lines, apparatus, or

any energized (exposed or insulated) parts

according to the Minimum Approach Distance

(MAD) as shown in Table 1-1.

• Allow for machine movement and electrical line

swaying.

Table 1-1. Minimum Approach Distances (M.A.D.)

Voltage Range

(Phase to Phase)

0 to 50 kV 3

Over 50 kV to 200 kV 5

Over 200 kV to 350 kV 6

Over 350 kV to 500 kV 8

Over 500 kV to 750 kV 11

Over 750 kV to 1000 kV 14

NOTE: This requirement shall apply except where

employer, local or governmental regulations

are more stringent.

MINIMUM APPROACH DISTANCE

in Meters

1-2 – JLG Lift – 31210031

Page 11

DO NOT MANOEUVER MACHINE OR PERSONNEL INSIDE

PROHIBITED ZONE (MAD). ASSUME ALL ELECTRICAL PARTS

AND WIRING ARE ENERGIZED UNLESS KNOWN OTHERWISE.

Maintain a clearance of at least 3 m between any part

of the machine and its occupants, their tools and their

equipment from any electrical line or apparatus

carrying up to 50 000 volts. A 0,3 m additional

clearance is required for every additional 30 000 volts

or less.

The minimum approach distance may be reduced if

insulating barriers are installed to prevent contact and

the barriers are rated for the voltage of the line being

guarded. These barriers shall not be part of (or

attached to) the machine. The minimum approach

distance shall be reduced to a distance within the

designed working dimensions or the insulating barrier.

This determination shall be made by a qualified person

in accordance with employer, local or governmental

requirements for work practices near energized

equipment.

SECTION 1 - SAFETY PRECAUTIONS

• Keep the chassis of the machine at least 0,6 m from

holes, bumps, drop-offs, obstructions, debris,

concealed holes, and other potential hazards on the

floor/surface.

• Do not push or pull any object with the extending

structure.

• Never attempt to use the machine as a crane. Do

not tie-off machine to any adjacent structure.

• Do not operate the machine when wind conditions

exceed the rating specified on the manufacturer’s

nameplate.

• Do not increase the surface area of the platform or

the load. Increase of the area exposed to the wind

will decrease stability.

• Do not increase the platform size with unauthorized

deck extensions or attachments.

• If extending structure assembly or platform is in a

position that one or more wheels are off the ground,

all persons must be removed before attempting to

stabilize the machine. Use appropriate equipment to

stabilize machine and remove personnel.

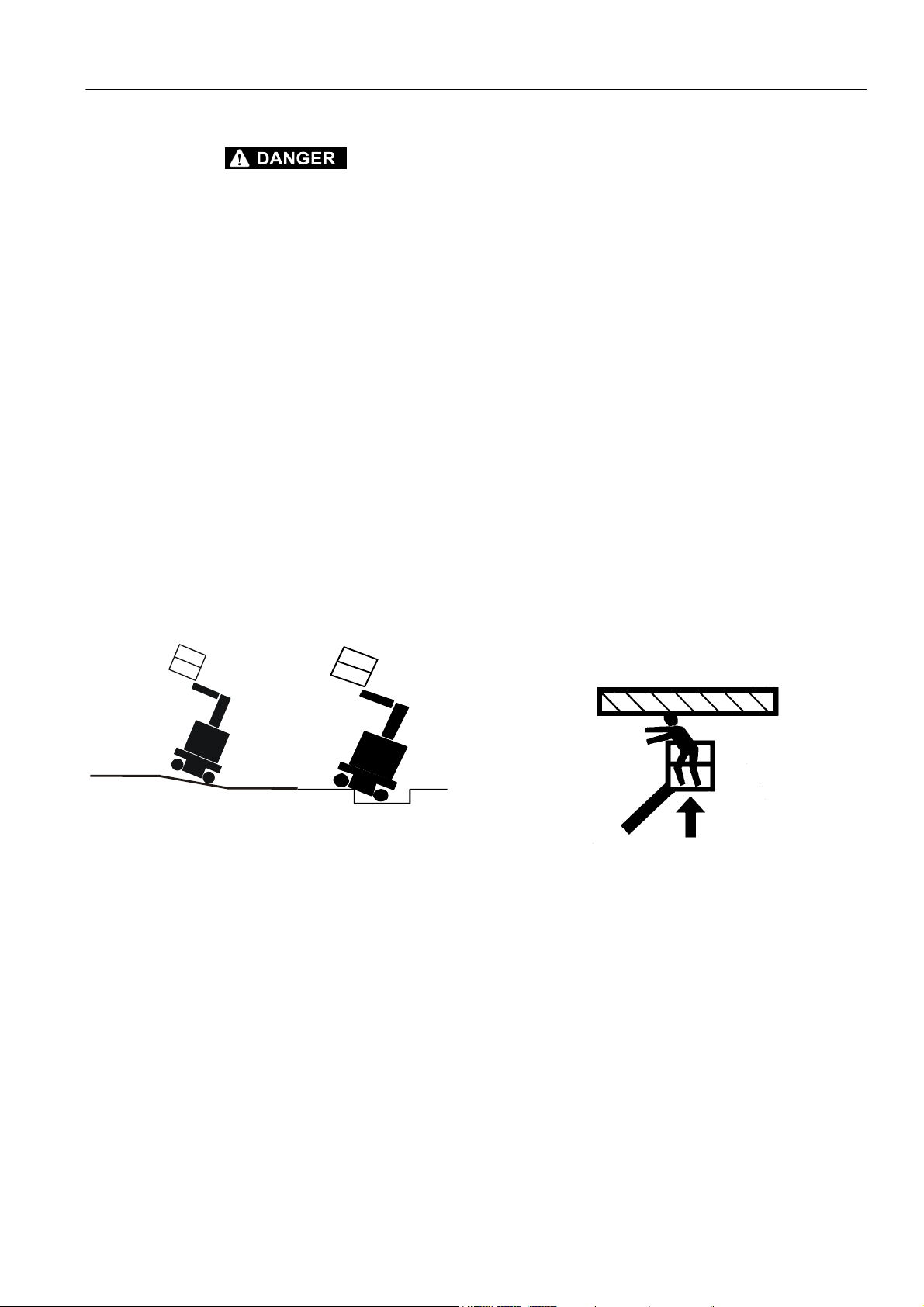

Tipping Hazards

• The user should be familiar with the surface before

driving. Do not exceed the allowable sideslope and

grade while driving.

• Never exceed the maximum platform capacity.

Distribute loads evenly on platform floor.

• Before driving on floors, bridges, trucks, and other

surfaces, check allowable capacity of the surfaces.

Check the ramp or slope for good adhesion of the

wheels. Ensure that the driving surfaces are free of

moisture, ice, grease or from any other substance

that could affect wheel adhesion.

• Do not elevate platform or drive with platform

elevated while on a sloping, uneven, or soft surface.

• Do not raise the platform or drive from an elevated

position unless the machine is on firm, level

surfaces and evenly supported.

• When travelling on slopes (Refer to section 8), the

platform MUST be fully lowered, the machine MUST

travel in second gear. It is recommended to drive up

the slope in FORWARD gear and to REVERSE down

the slope as the machine will perform better.

Crushing and Collision Hazards

• Approved head gear must be worn by all operating

and ground personnel.

• Check work area for clearances overhead, on sides,

and bottom of platform when lifting, slewing or

lowering platform, and driving.

• During operation, keep all body parts inside

platform railing.

• Always post a lookout when driving in areas where

vision is obstructed.

• Keep non-operating personnel at least 1,8 m away

from machine during all driving and slewing

operations.

• Limit travel speed according to conditions of ground

surface, congestion, visibility, slope, location of

personnel, and other factors which may cause

collision or injury to personnel.

• Be aware of stopping distances in all drive speeds.

When driving in high speed, slow down the machine

using the controller before stopping.

• Do not use high speed drive in restricted or close

quarters or when driving in reverse.

31210031 – JLG Lift – 1-3

Page 12

SECTION 1 - SAFETY PRECAUTIONS

• Exercise extreme caution at all times to prevent

obstacles from striking or interfering with operating

controls and persons in the platform.

• Be sure that operators of other overhead and floor

level machines are aware of the aerial work

platform’s presence. Disconnect power to overhead

cranes.

• Warn personnel not to work, stand, or walk under a

raised extending structure or platform. Position

barricades on floor if necessary.

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing,

lifting, or hauling.

• This machine should not be towed, except in the

event of emergency, malfunction, power failure, or

loading/unloading. Refer to the Emergency

Procedures section of this manual for emergency

towing procedures.

• Ensure extending structure is in the stowed position

prior to towing, lifting or hauling. The platform must

be completely empty of tools.

• When lifting machine, lift only at designated areas of

the machine. Lift the unit with equipment of

adequate capacity.

• Refer to the Machine Operation section of this

manual for lifting information.

1.5 ADDITIONAL HAZARDS / SAFETY

• Do not use machine as a ground for welding.

• When performing welding or metal cutting

operations, precautions must be taken to protect the

chassis from direct exposure to weld and metal

cutting spatter.

• Battery fluid is highly corrosive. Avoid contact with

skin and clothing at all times.

• Charge batteries only in a well ventilated area.

1-4 – JLG Lift – 31210031

Page 13

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it

is necessary that it be operated and maintained only

by trained personnel.

Persons under the influence of drugs or alcohol or who

are subject to seizures, dizziness or loss of physical

control must not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform

and at the ground, emergency controls and safety

systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government

regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of

the machine to recognize a malfunction or

potential malfunction.

6. The safest means to operate the machine where

overhead obstructions, other moving equipment,

and obstacles, depressions, holes, drop-offs.

2.2 PREPARATION, INSPECTION, AND

MAINTENANCE

The following table covers the periodic machine

inspections and maintenance required by JLG

Industries, Inc. Consult local regulations for further

requirements for aerial work platforms. The frequency

of inspections and maintenance must be increased as

necessary when the machine is used in a harsh or

hostile environment, if the machine is used with

increased frequency, or if the machine is used in a

severe manner.

7. Means to avoid the hazards of unprotected

electrical conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a

qualified person in an open area free of obstructions

until the trainee has developed the ability to safely

control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the

responsibility and authority to shut down the machine

in case of a malfunction or other unsafe condition of

either the machine or the job site.

31210031 – JLG Lift – 2-1

Page 14

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

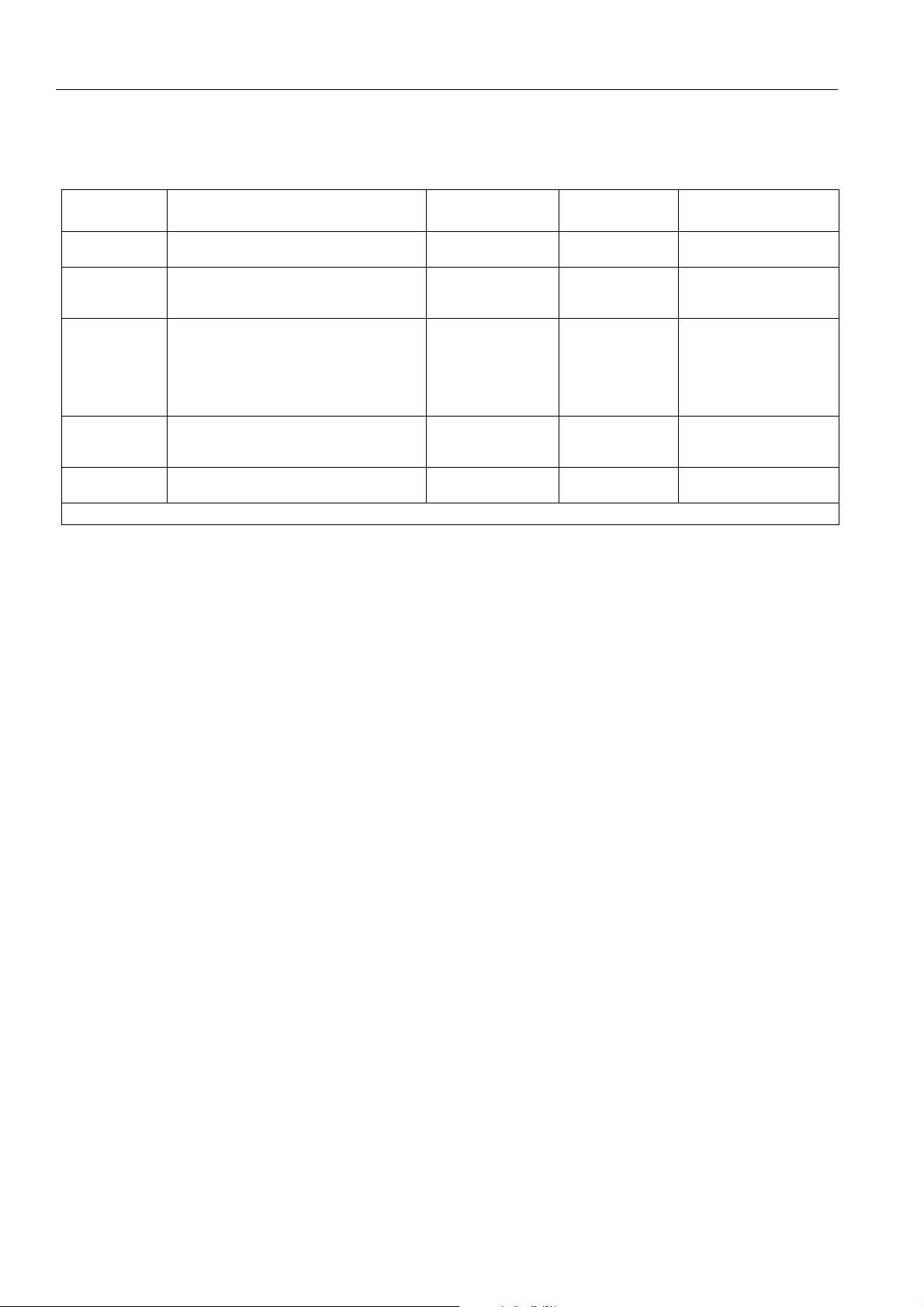

Table 2-1.Inspection and Maintenance Table

Type Frequency

Pre-Start Inspection

Pre-Delivery

Inspection (See

Note)

Frequent

Inspection

(See Note)

Annual Machine

Inspection

(See Note)

Preventative

Maintenance

Before using each day; or

whenever there’s an Operator change.

Before each sale, lease, or rental delivery. O w n er, D e a le r, or

In service for 3 months or 150 hours, whichever comes first; or

Out of service for a period of more than 3

months; or

Purchased used.

Annually, no later than 13 months from the

date of prior inspection.

At intervals as specified in the Service and

Maintenance Manual.

Primary

Responsibility

User or Operator User or Operator Operator and Safety Man-

User

Owner, Dealer, or

User

Owner, Dealer, or

User

Owner, Dealer, or

User

Service

Qualification

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Qualified JLG

Mechanic

Reference

ual

Service and Maintenance

Manual and applicable

JLG inspection form

Service and Maintenance

Manual and applicable

JLG inspection form

Service and Maintenance

Manual and applicable

JLG inspection form

Service and Maintenance

Manual

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

2-2 – JLG Lift – 31210031

Page 15

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.3 PRE-START INSPECTION

The Pre-Start Inspection should include each of the

following:

1. Cleanliness – Check all surfaces for leakage (oil

or battery fluid) or foreign objects. Report any

leakage to the proper maintenance personnel.

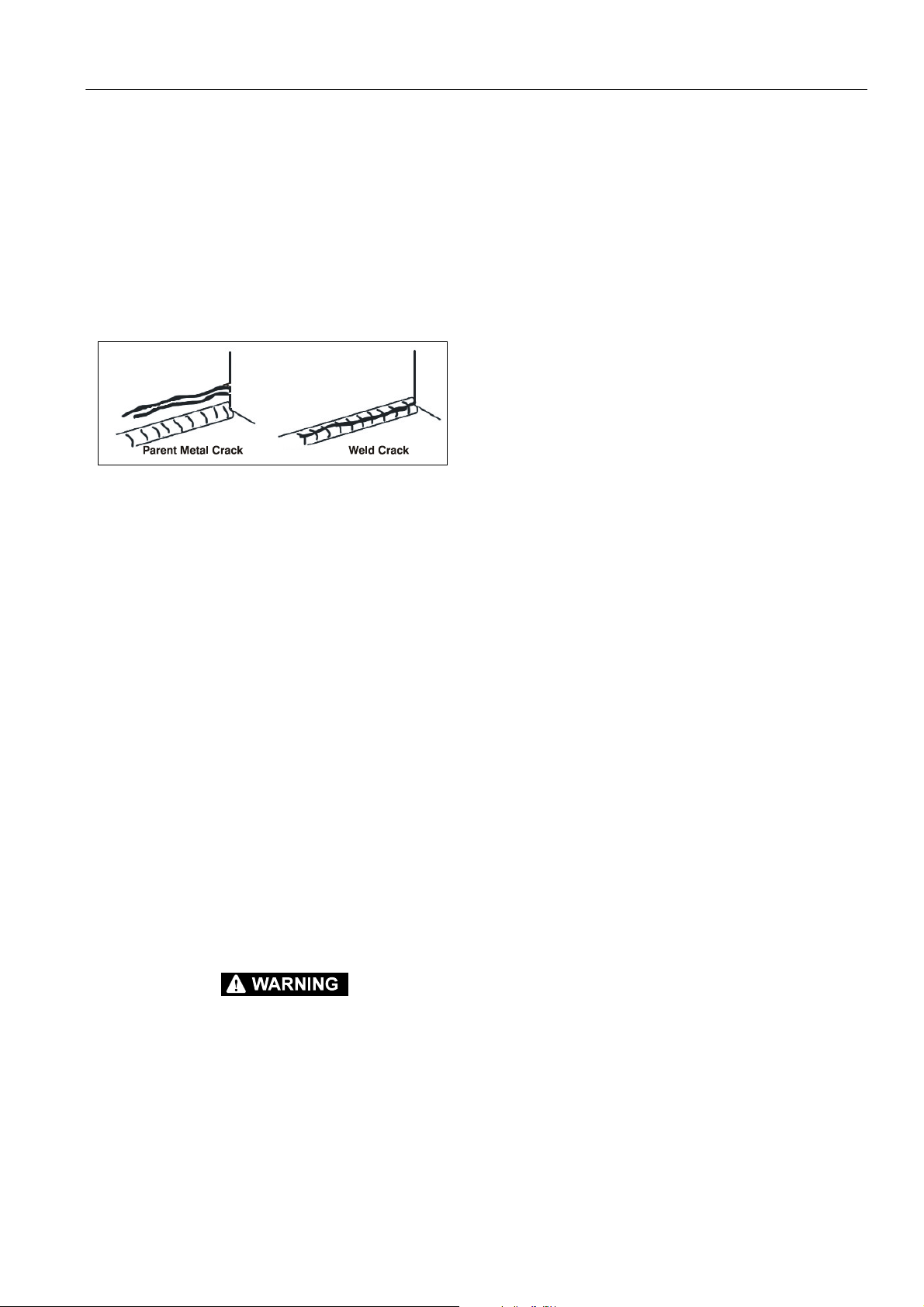

2. Structure – Inspect the machine structure for

dents, damage, weld or parent metal cracks or

other discrepancies.

3. Decals and Placards – Check all for cleanliness

and legibility. Make sure none of the decals and

placards are missing. Make sure all illegible

decals and placards are cleaned or replaced.

4. Operation and Safety Manuals – Make sure a

copy of the Operator and Safety Manual, AEM

Safety Manual (ANSI markets only), and ANSI

Manual of Responsibilities (ANSI markets only) is

enclosed in the weather resistant storage

container.

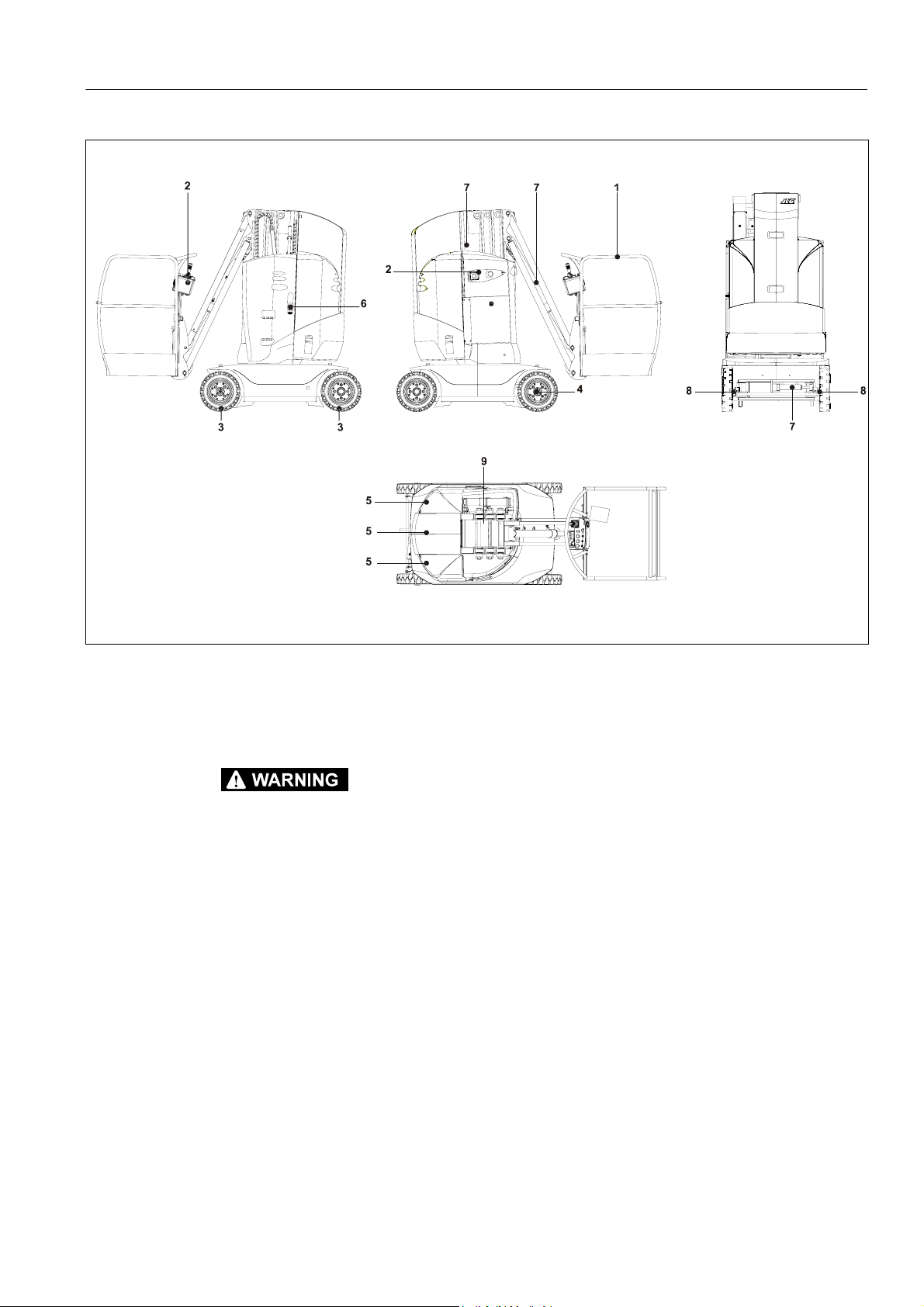

5. “Walk-Around” Inspection – Refer to Figure 2-1.

6. Battery – Charge as required.

7. Hydraulic Oil – Check the hydraulic oil level.

Ensure hydraulic oil is added as required.

8. Accessories/Attachments - Reference the

Operator and Safety Manual of each attachment or

accessory installed upon the machine for specific

inspection, operation, and maintenance

instructions.

9. Function Check – Once the “Walk-Around”

Inspection is complete, perform a function check

(section 2.3.2) of all systems in an area free of

overhead and ground level obstructions. Refer to

Section 4 for more specific operating instructions.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF

THE MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE

PROPER MAINTENANCE PERSONNEL. DO NOT OPERATE THE

MACHINE UNTIL IT IS DECLARED SAFE FOR OPERATION.

31210031 – JLG Lift – 2-3

Page 16

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

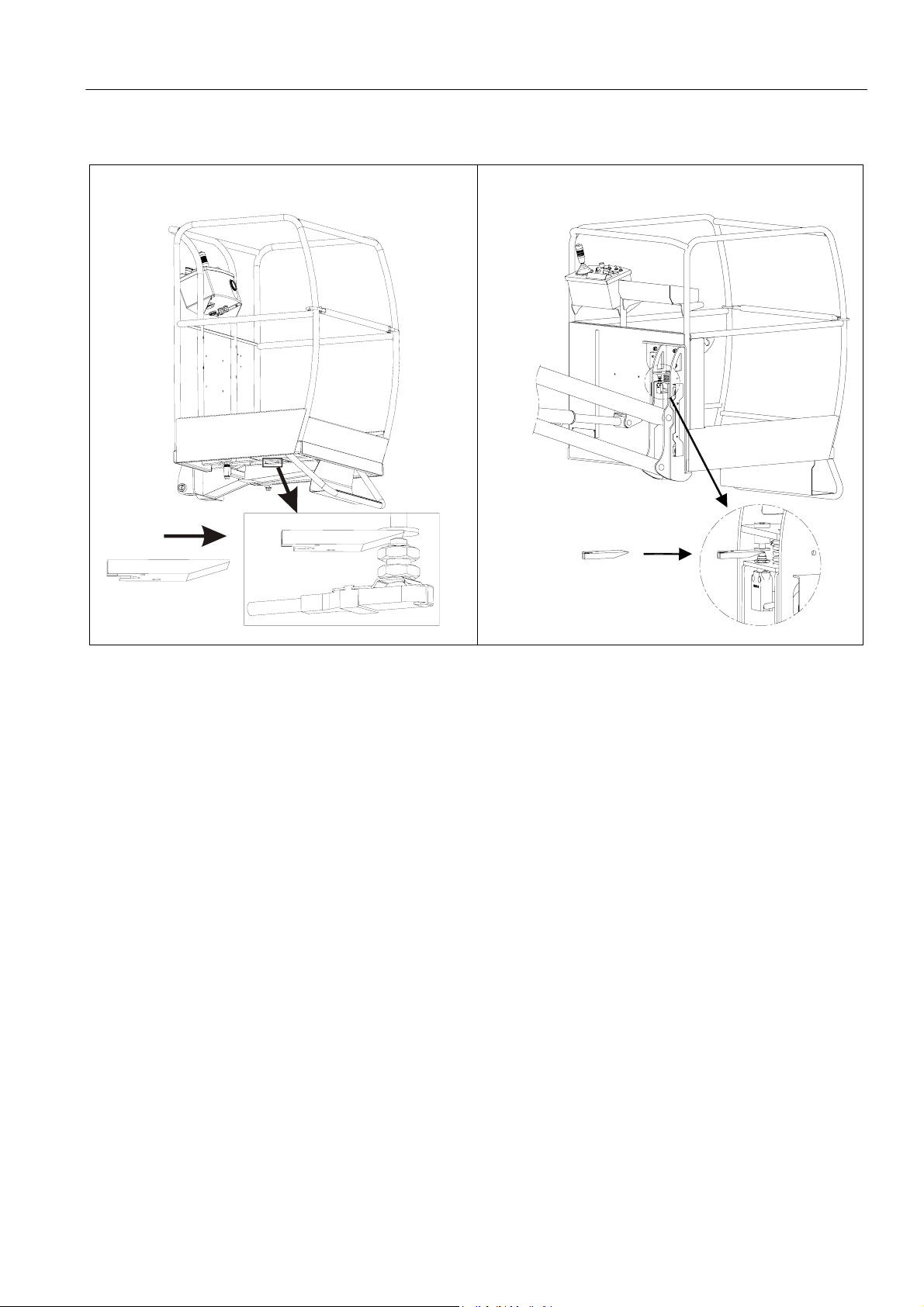

Toucan 800

Toucan 800 DI

2-4 – JLG Lift – 31210031

Page 17

Toucan 870

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Figure 2-1. Daily Walk-Around Inspection

2.3.1 Walk-Around Inspection

Begin the "Walk-Around Inspection" at Item 1, as noted

on the diagram. Continue checking each item in

sequence for the conditions listed in the following

checklist.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS

OFF.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE

BEEN CORRECTED.

INSPECTION NOTE: On all components, make sure

there are no loose or missing parts, that they are

securely fastened, and no visible damage, leaks or

excessive wear exists in addition to any other criteria

mentioned.

1. Platform Guardrails and Gate - Footswitch works

properly, not modified, disabled or blocked. The

gate opens and closes properly.

2. Platform & Ground Control Consoles - Switches

and levers return to neutral, decals/placards

secure and legible, control markings legible.

6. Hand Pump - See Inspection Note.

7. All Hydraulic Cylinders - No visible damage;

pivot pins and hydraulic hoses undamaged, not

leaking.

8. Steering Spindles - See Inspection Note.

9. Lifting Chains, Chain Yo k e s an d C l evi s Pins -

Must be installed and in good condition. Chains

must be correctly tensioned and lubricated.

3. Wheel/Tire Assemblies - Properly secured, no

missing lug nuts.

4. Drive Motor, Brake - No evidence of leakage.

5. Hood Assemblies - See Inspection Note.

31210031 – JLG Lift – 2-5

Page 18

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.3.2 Function Check

Refer to section 3 & 4 for description and operation of

machine functions.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE

BEEN CORRECTED.

Perform the Function Check as follows:

Control Stations

1. From the Ground Control Console :

• Operate all functions;

• Ensure that all machine functions are disabled

when the Emergency Stop Button is pushed in;

• Position the selector switch to Platform Control

Console ; try to use the Ground Control Cons

- No movement shall occur.

2. From the Platform Control Console :

• Ensure that the platform control console is firmly

secured;

• Ensure proper operation of horn;

• Ensure proper operation of all functions;

• Ensure that all machine functions are disabled

when the Emergency Stop Button is pushed in;

• Ensure that no functions can be operated unless

the footswitch is depressed;

• Activate simultaneously a drive movement and

superstructure movement. No movement shall

occur.

• Drive the machine on a grade, not to exceed the

rated gradeability and stop to ensure the brakes

hold.

ole :

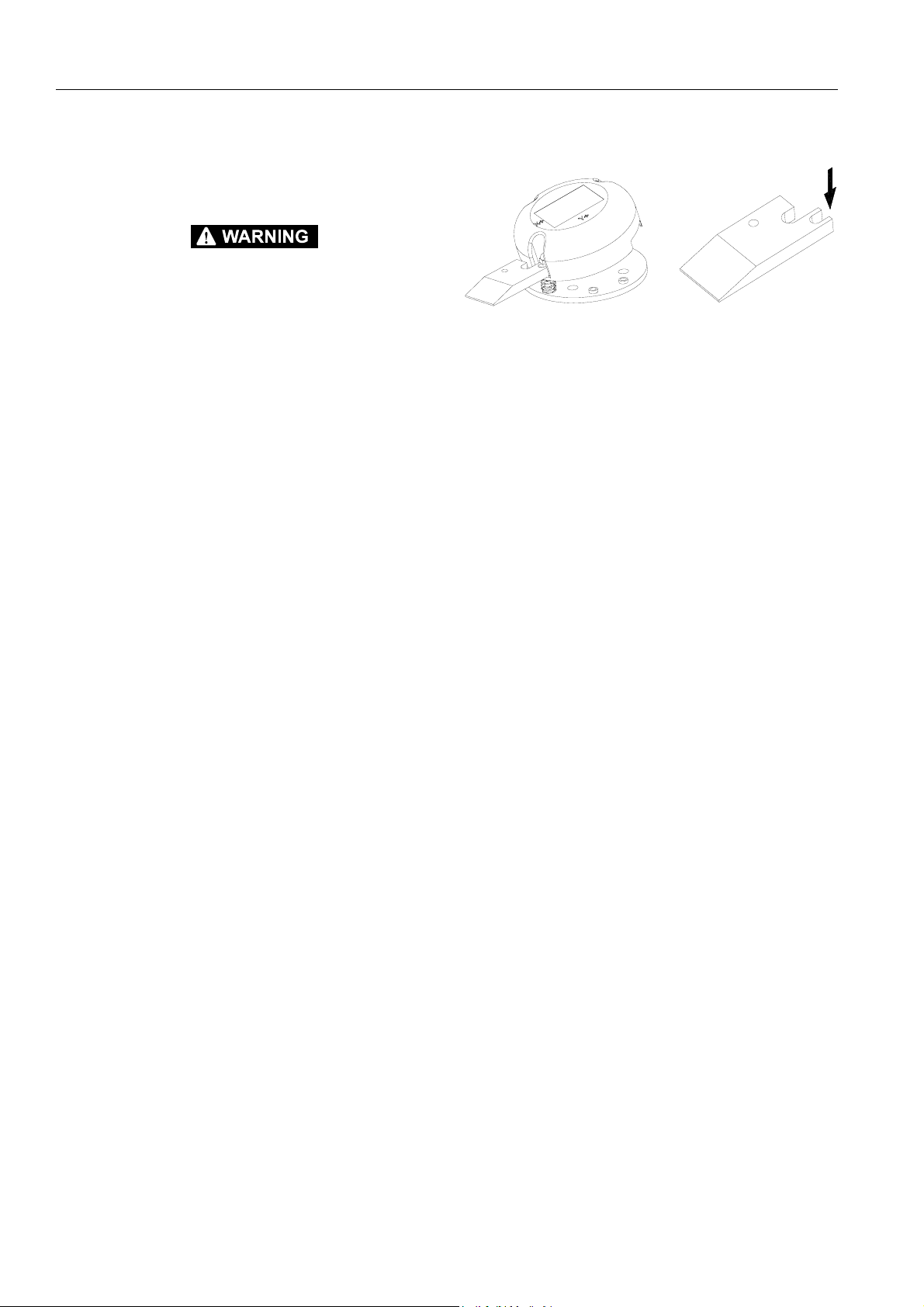

Tilt Sensor Check

Check the tilt sensor, located on the left side (Toucan

800), on the right side (Toucan 870) of the chassis, to

ensure proper operation. Wedge a block (P/N :

ST2741, located in the manual storage container) as

illustrated above to activate the tilt sensor and keep it

tilted. Raise the mast by approximately 1m.

The system is functioning properly if :

1. From the Platform Control Console :

• An acoustic alarm sounds.

• The red tilt indicator lights up on the Platform

Control Panel.

• The drive function is disabled.

• The jib raising function is performed at reduced

speed.

• The mast raising function is performed at

reduced speed.

• The slewing movements are performed at

reduced speed.

• All other functions are working normally.

• Prohibited movements are indicated by the

orange light indicator on the platform control

panel.

2. From the Ground Control Console :

• An acoustic alarm sounds.

2-6 – JLG Lift – 31210031

Page 19

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Overload Sensor Check (Toucan 800 & Toucan 800 DI)

Machine manufactured before 2010

Machine manufactured after 2010

Check the overload sensor, located on the platform

support, to ensure proper operation. Wedge a block (P/N :

ST2741) as illustrated above to activate the overload

sensor and keep it activated. The system is functioning

properly if :

1. From the Platform Control Console :

• An acoustic alarm sounds.

• The overload red light indicator flashes on the

platform control panel.

• Each attempt to perform a movement actuates

the orange light indicator on the platform control

panel.

• Every function is disabled from the upper control

panel.

2. From the Ground Control Console :

• An acoustic alarm sounds.

• The overload red indicators on the platform

control panel and on the ground control console

flash.

• Every function is disabled from the ground

control console.

31210031 – JLG Lift – 2-7

Page 20

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Slack / Broken Chain Sensors Check

Gate sensors check (Toucan 800 DI only)

Check the slack/broken chain sensors to ensure proper

operation :

2 sensors.

Location : one at the top of mast 1 and one at the bottom of

mast 4.

NOTE: The mast 1 is attached to the turntable and mast 4

Wedge a block (P/N : ST2741) as illustrated above to

activate the slack chain sensor and keep it activated.

The system is functioning properly if :

supports the jib.

1. From the Platform Control Console :

• An acoustic alarm sounds.

• The red slack chain indicator lights up on the

Platform Control Panel.

• The jib and mast lowering functions are

disabled.

• The slewing movements are disabled.

• The driving function is disabled.

• Prohibited movements are indicated by the

orange light indicator on the platform control

panel.

• All other functions work normally.

2. From the Ground Control Console :

• An acoustic alarm sounds.

Check the gate sensors to ensure proper operation :

2 sensors.

Location : under gate articulation axis.

Open the right gate. The system is functioning properly if :

1. From the Platform Control Console :

• The orange light indicator is continuously lit.

• Every function is disabled from the upper control

console.

2. From the Ground Control Console :

• Every function is disabled from the ground control console.

3. Repeat steps 1 to 2 for each slack chain sensor.

2-8 – JLG Lift – 31210031

Page 21

Toucan 800 - Toucan 800 DI

SECTION 3 - MACHINE CONTROLS AND INDICATORS

SECTION 3. MACHINE CONTROLS AND INDICATORS

Toucan 870

1. Driving wheels

2. Steering wheels

3. Counter weight

4. Jib

5 . G r o un d co n tr o l st a ti o n

6. Charger

7. Telescopic mast

8 . H a n d p u mp

9 . P l a tf o rm

10. Platform control station

11. Manual storage container

12. Battery cover

13. Manual lowering controls

14. Chassis cover

15. Circuit-breaker (Toucan 800 : ¼ turn - Toucan 870 : Push/Pull)

Figure 3-1. Basic Nomenclature

31210031 – JLG Lift – 3-1

Page 22

SECTION 3 - MACHINE CONTROLS AND INDICATORS

3.1 GENERAL

This section provides the necessary information

needed to understand control functions.

NOTICE

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE

APPLICATION AND OPERATION. THE USER AND OPERATOR ARE

RESPONSIBLE FOR CONFORMING WITH GOOD SAFETY

PRACTICES.

3.2 CONTROLS AND INDICATORS

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY

CONTROL LEVERS OR TOGGLE SWITCHES CONTROLLING

PLATFORM MOVEMENT DO NOT RETURN TO THE OFF POSITION

WHEN RELEASED.

Ground Control Station

NOTICE

DO NOT OPERATE FROM GROUND CONTROL STATION WITH

PERSONNEL IN THE PLATFORM EXCEPT IN AN EMERGENCY.

NOTICE

WHEN THE MACHINE IS SHUT DOWN FOR OVERNIGHT PARKING

OR BATTERY CHARGING, THE PLATFORM/OFF/GROUND

SELECTOR AND THE EMERGENCY STOP SWITCHES MUST BE

POSITIONED TO OFF TO PREVENT DRAINING THE BATTERIES.

3-2 – JLG Lift – 31210031

Page 23

Toucan 800

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1. Platform /Off/Ground Selector Switch

2 . E m e rg e nc y St o p Sw i tc h

3. Function Enable Switch

4. Jib Up / Down Switch

5 . M as t Up / D o wn Sw i tc h

6. Turntable Slewing Switch

7. Charger Indicator

8. Circuit Breaker

9. Overload Indicator

10. Battery Filling Pump Switch

11. Main Circuit Breaker

Toucan 870

1. Platform /Off/Ground Selector Switch

2 . E m e rg e nc y St o p Sw i tc h

3. Function Enable Switch

4. Jib Up / Down Switch

5 . M as t Up / D o wn Sw i tc h

6. Turntable Slewing Switch

7. Charger Indicator (if fitted)

8. Circuit Breaker

10. Battery Filling Pump Switch

11. Main Circuit Breaker

Figure 3-2. Ground Control Stations

31210031 – JLG Lift – 3-3

Page 24

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1. Platform / Off / Ground Selector Switch

Movement Control from the Platform Controls

Control Circuit Off Position

Movement Control From The Ground Controls

2. Emergency Stop Switch.

Depress the switch to stop all functions. The

switch must be turned clockwise to restore the

machine’s function.

3. Function Enable Switch.

Must be pushed and held to operate any function.

4. Jib Up / Down Switch.

Move the switch UP to RAISE the jib. Move the

switch DOWN to LOWER the jib.

5. Mast Up / Down Switch.

Move the switch UP to RAISE the mast. Move the

switch DOWN to LOWER the mast.

6. Turntable Slewing Switch.

Move the switch to the RIGHT to slew the turntable

to the RIGHT or to the LEFT to slew the turntable

to the LEFT.

7. Charger Indicator

(Depending on equipment, see § 4-6)

8. Circuit Breaker.

Protection of the control circuit.

9. Overload Indicator

Flashing red light indicator.

10. Battery Filling Pump Switch.

Depress the push button to activate the battery

filling pump.

(See Maintenance section for further instructions).

11. Main Circuit Breaker

T800

(horizontal lever) to insulate the battery "+".

Position the circuit-breaker to its "I" position (vertical

lever) to restore battery supply.

T870

battery.

Pull the circuit breaker knob to restore the battery

supply.

: Position the circuit-breaker to its "O" position

: Push the circuit breaker knob to insulate the

3-4 – JLG Lift – 31210031

Page 25

Manual Lowering Controls

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Toucan 800

Toucan 870

1. Jib Raising / Lowering Control Valve

2. Mast Raising / Lowering Control Valve

3. Slewing Control Valve

4 . P u mp H a nd l e

5 . H a n d P u mp

Figure 3-3. Manual Lowering Controls

Electro-Hydraulic Control Valve With Manual Control Push Buttons

1. Jib Raising / Lowering Control Valve :

Depress and keep depressed the top push button

while activating the hand pump to lower the jib.

Depress and keep depressed the bottom push

button while activating the hand pump to raise the

jib.

2. Mast Raising / Lowering Control valve :

Depress and keep depressed the top push button

while activating the hand pump to lower the mast.

Depress and keep depressed the bottom push

button while activating the hand pump to raise the

mast.

3. Slewing Control Valve :

Depress and keep depressed the top push button

while activating the hand pump to slew the

turntable to the right. Depress and keep

depressed the bottom push button while

activating the hand pump to slew the turntable to

the left.

4. Pump Handle :

Insert the pump handle in the hand pump to

activate a movement.

5. Hand Pump :

Operate the hand pump while activating the

desired movement.

31210031 – JLG Lift – 3-5

Page 26

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Platform Control Station

Figure 3-4. Platform Control Console

1. Emergency Stop Switch

2. Footswitch

3 . J ib Fu n ct i on Co n tr ol S wi t ch

4. Mast Function Control Switch

5. Turntable Slewing Control Switch

6 . F un ct i on S pe ed C on tr o l

7. Battery Discharge Indicator

8. Auxiliary Power Button

9. Drive Control Joystick

10. Drive Speed Selector Switch

11. Horn

12. Steering Control

(See Figure 3-5., Platform Control Indicator Panel)

1. Emergency Stop Switch

Depress the switch to stop all the functions of the

machine. The switch must be turned clockwise to

restore the machine’s functions.

2. Footswitch

Must be depressed before any movement is

controlled. The controls are enabled for a period

of 5 seconds. If no function is operated within this

period, the footswitch must be recycled.

3. Jib Function Control Switch

Pull the switch to raise the jib.

Push the switch to lower the jib.

4. Mast Function Control Switch

Pull the switch to raise the mast.

Push the switch to lower the mast.

5. Turntable Slewing Control Switch

Toggle the switch to the right to slew the turntable

to the right.

Toggle the switch to the left to slew the turntable

to the left.

6. Function Speed Control

When the knob is turned counter-clockwise to the

left (

movement) are performed at low speed. Turn the

knob clockwise to the right (

speed of the movements.

7. Battery Discharge Indicator

As the battery discharges, the bar lit in (1) moves

from the right to the left (5 green bars followed by

3 orange bars).

At this point, the LED flashes indicating "energy

reserve" (70% discharged).

The 2 red LEDs most to the left flash indicating

"empty" (80% discharged). At this point, power is

cut-off. The battery must be recharged.

1 - Discharge Indicator

2 - Hourmeter

), the movements (except the drive

)to increase the

3-6 – JLG Lift – 31210031

Page 27

SECTION 3 - MACHINE CONTROLS AND INDICATORS

8. Auxiliary Power Button

Once the electrical power is cut due to excessive

battery discharge (80%), the Auxiliary Power

Button can be pressed to use the remaining

battery charge to travel to the charging station.

NOTE: The button must be actuated and held BEFORE the

controls are enabled and the desired movement is

controlled. An intermittent acoustic signal is

actuated when the button is actuated.

IMPORTANT

A TOTAL DISCHARGE WILL RESULT IN IRREVERSIBLE DAMAGE

TO THE BATTERY.

9. Drive Control Joystick

Move the controller forward to drive forward.

Move the controller backward to reverse.

10. Drive Speed Selector Switch

1st gear or slow speed

2nd gear or climbing speed (max. 20%)

3rd gear or high speed

11. Horn

Sounds when the button is depressed.

12. Steering control

Push the right side of the thumb switch to steer the

wheels to the right. Push the left side of the thumb

switch to steer the wheels to the left.

Platform Control Indicator Panel.

Figure 3-5. Platform Control Indicator Panel

1. Tilt Indicator Light and Alarm

2. Slack Chain Indicator Light and Alarm

3. Overload Indicator Light and Alarm

4. Unauthorized Movement Indicator

5. Power Enable Indicator

1. Tilt Indicator Light and Alarm.

Excessive tilt. Red light and audible alarm

indicates the rated slope has been exceeded.

2. Slack Chain Indicator Light and Alarm.

Slack lifting chain. Red light and audible alarm

indicates slack chain condition has been detected.

3. Overload Indicator Light And Alarm

Flashing red light and audible alarm indicates the

platform has been overloaded (Toucan 800 only).

4. Unauthorized Movement Indicator.

Orange light which indicates the machine is in a

configuration where the activation of movement is

not permitted.

5. Power Enable Indicator.

Green light indicates that the controls are ready.

31210031 – JLG Lift – 3-7

Page 28

SECTION 3 - MACHINE CONTROLS AND INDICATORS

3-8 – JLG Lift – 31210031

Page 29

SECTION 4 - MACHINE OPERATION

SECTION 4. MACHINE OPERATION

NOTE: A delay-timer, integrated to the electrical system,

disconnects the control boxes approximately 4

hours after the last operation of the machine. This

system preserves the battery should the operator

forget to disconnect the machine. After cut out, the

emergency stop switch on the ground control

console must be depressed then turned clockwise

to restore the functions of the machine.

• To energize the machine :

Toucan 800 : turn the circuit-breaker handle to "I"

position.

Toucan 870 : pull the knob of the circuit-breaker

to "I" position.

4.2 PLATFORM CONTROLS

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY

CONTROL LEVERS OR SWITCHES CONTROLLING THE PLAT

FORM MOVEMENT DOES NOT RETURN TO THE OFF OR NEUTRAL POSITION WHEN RELEASED.

IF THE PLATFORM DOES NOT STOP WHEN CONTROL LEVER OR

THE ENABLE SWITCH/TRIGGER IS RELEASED, USE THE EMER

GENCY STOP SWITCH TO STOP THE MACHINE.

Drive Speed Selector Switch

The DRIVE SPEED selector switch can be positioned

either to 3rd gear ( ), 2nd gear ( ) or 1st ( )

position and that speed will be obtained. When the

mast is raised (and/or the jib is raised for Toucan 800

manufactured before 2010), the high speed drive

(TORQUE or HIGH position) is cutout and only the low

drive speed is attainable.

Trav eli ng ( Dri v ing )

See Figure 4-1., Grade and Side Slope

NOTE: Refer to the General Specifications (Section 8) for

Gradeability and Side slope ratings.

All ratings for Gradeability and Side slope are based

upon the machine in transport mode with the mast

and jib being in the stowed position, fully lowered,

and retracted.

-

-

4.1 EMERGENCY CONTROL OPERATION

The machine has a Ground Control Station which will

override the Platform Control Station. Ground Controls

operate Lift and Slew, and are to be used in an

emergency to lower the platform to the ground should

the operator in the platform be unable to do so.

Platform/Off/Ground Selector Switch

With the switch in the ground position, power is

supplied to the Ground Control Station. When the

switch is in the platform position, power is supplied to

the Platform Control Station.

Operate the ground controls as follow :

1. Position PLATFORM/OFF/GROUND CONTROLS

selector switch to GROUND CONTROLS (

2. Push and hold the Function Enable Switch.

3. Activate slewing, mast or jib function switch.

Emergency Stop Switch

This switch, when in the on (out) position, provides

electrical power to the ground controls or platform

controls, as applicable. In addition, the switch can be

used to turn off power (push the switch IN) to the

function controls in the event of an emergency.

rd

NOTE: When the platform is driven in 3

steeper than 5%, the machine switches automati-

cally to 2

when the platform is driven on a slope below 5%.

Either of the following actions must be done :

- release and activate the enable control again.

- return the joystick to neutral and control the movement again.

- position the drive speed selector to 2nd gear

( ) and return it to 3

DO NOT DRIVE WITH MAST OUT OF TRANSPORT MODE EXCEPT

ON A SMOOTH, FIRM AND LEVEL SURFACE.

).

TO AVOID LOSS OF TRAVEL CONTROL OR “TIP OVER”, DO NOT

DRIVE MACHINE ON GRADES EXCEEDING THOSE SPECIFIED IN

SECTION 8.2 OF THIS MANUAL.

USE EXTREME CAUTION WHEN DRIVING IN REVERSE AND AT

ALL TIMES WHEN THE PLATFORM IS ELEVATED.

BEFORE DRIVING, LOCATE THE BLACK/WHITE ORIENTATION

ARROWS ON BOTH THE CHASSIS AND THE PLATFORM

nd

gear. The 3rd gear will be restored only

rd

gear ( ).

gear on a slope

31210031 – JLG Lift – 4-1

Page 30

SECTION 4 - MACHINE OPERATION

CONTROLS. MOVE THE DRIVE CONTROLS IN A DIRECTION

MATCHING THE DIRECTIONAL ARROWS.

With the machine in transport mode, traveling is limited

by two factors, gradeability and side slope.

Gradeability is the percent of grade of the incline the

machine can climb. Sideslope, is the angle of the slope

the machine can be driven across. Reference section 8

for gradeability and side slope ratings.

When the mast (or the jib for Toucan 800

manufactured before 2010) is extended, the machine

must not be operated on grades or side slopes that are

greater than that specified in Section 8. The tilt alarm

will sound and tilt indicator will light to alert the

operator when the machine has exceeded the rated

slope. The drive movements are cut and the slewing,

jib and mast raising movements switch automatically

to slow speed.

4-2 – JLG Lift – 31210031

Page 31

Figure 4-1. Grade and Side Slope

SECTION 4 - MACHINE OPERATION

Forward

1. Position the DRIVE SPEED selector to 1st gear

), 2nd gear ( ) or 3rd gear ( ).

(

2. Match the black and white direction arrows on

both platform control panel and chassis to

determine the direction the machine will travel.

3. Depress footswitch.

4. Push the controller forward within 5 seconds after

the footswitch has been depressed.

Stopping

Stopping is accomplished by slowly returning the

DRIVE controller to the neutral position. The brakes will

apply automatically.

Reverse

Traveling in reverse is accomplished the same way as

traveling forward except for pulling the DRIVE

controller toward the operator to reverse (REV).

Steering

Steering is accomplished by pressing the left side of

the THUMB switch (on top of the controller) to steer to

the left or the right side of the THUMB switch (on top

on the controller) to steer to the right.

TO AVOID TIP OVER, LOWER PLATFORM TO GROUND LEVEL.

THEN DRIVE MACHINE TO A LEVEL SURFACE BEFORE RAISING

MAST.

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY

CONTROL LEVER OR TOGGLE SWITCH CONTROLLING

PLATFORM MOVEMENT DOES NOT RETURN TO THE ’OFF’ OR

NEUTRAL POSITION WHEN RELEASED.

IF THE PLATFORM DOES NOT STOP WHEN A CONTROL SWITCH

OR LEVER IS RELEASED, REMOVE FOOT FROM FOOTSWITCH

OR USE EMERGENCY STOP SWITCH TO STOP THE MACHINE.

Raising And Lowering The Mast

Raising the mast :

1. Depress footswitch.

2. Pull the mast function control switch toward the

operator to raise the mast within 5 seconds after

the footswitch has been depressed.

3. Adjust the speed movement using the function

speed control.

Lowering the mast :

1. Depress footswitch.

2. Push the mast function control switch away from

the operator to lower the mast within 5 seconds

after the footswitch has been depressed.

3. Adjust the speed movement using the function

speed control.

31210031 – JLG Lift – 4-3

Page 32

SECTION 4 - MACHINE OPERATION

Raising And Lowering The Jib

Raising the jib :

1. Depress footswitch.

2. Pull the jib function control switch toward the

operator to raise the jib within 5 seconds after the

footswitch has been depressed.

3. Adjust the speed movement using the function

speed control.

Lowering the jib :

1. Depress footswitch.

2. Push the jib function control switch away from the

operator to lower the jib within 5 seconds after the

footswitch has been depressed.

3. Adjust the speed movement using the function

speed control.

Slewing The Turntable

To s l e w :

1. Depress footswitch.

2. Move the turntable slewing control switch to the

right to slew the turntable to the right. Move the

turntable slewing control switch to the left to slew

the turntable to the left. The switch has to be

operated within 5 seconds after the footswitch has

been depressed.

3. Adjust the speed movement using the function

speed control.

4.4 ALARMS

Horn

Horn is activated when the corresponding push button

located on the Platform Control Console is depressed.

Motion Alarm

The machine is fitted with 2 lights (beacons) that come

on as soon as a function is controlled from the platform

control panel or from the ground control panel.

Tilt Light And Alarm

The alarm is triggered by a tilt sensor located on the

right hand side (Toucan 870), left hand side (Toucan

800) of the chassis under the chassis cover. This alarm

is active once the mast (and/or the jib for Toucan 800

manufactured before 2010), has left its lowered

position. It consists of a light on the platform control

panel and an alarm. The alarm and light indicate that

the work platform is at its maximum out of level limit

(refer Table 8.1) and is nearing an unstable position.

Drive function is disabled and the jib, mast and

turntable slewing movements are operable at a

reduced speed.

When the tilt light or alarm is activated, it is

recommended to place the machine in the following

configuration :

1. Mast lowered.

2. Jib in line with the chassis length.

3. Jib lowered.

The tilt alarm and light are also operational from the

ground control panel.

Work Platform Functions Combination

A drive movement cannot be combined with a structure

movement.

If a mast or jib raising movement is activated with a

slewing movement, only one function will work and only at

low speed (lower than normal slewing speed) will be

attainable.

4.3 MANUAL LOWERING CONTROLS

The manual lowering controls should be used in

emergency situations or mechanical breakdown. The

manual lowering controls provide an auxiliary means of

lowering and raising the platform and slewing the

turntable in the event of primary power loss.

DO NOT RAISE MAST OR OPERATE JIB WITH MAST RAISED

WHEN MACHINE IS OUT OF LEVEL.

Overload Light And Alarm (Toucan 800

only)

A sensor located on the platform support is actuated

when the maximum rated load is exceeded. In case of

overload, all functions are disabled, the red indicator

on the platform control panel and on the emergency

control panel flash and an acoustic alarm is triggered.

The work platform must be unloaded until the flashing

light and acoustic alarm stop.

Slack Chain Light And Alarm

The slack chain detection system prevents movements

if the platform or the jib come to rest on an obstacle

while lowering the mast or jib.

When a slack chain is detected, the sensor actuates an

acoustic alarm and a red light is lit on the platform

control panel. All functions of the machine, except the

mast and jib raising movements, are disabled.

Procedure to follow in case this feature is activated :

4-4 – JLG Lift – 31210031

Page 33

SECTION 4 - MACHINE OPERATION

1. Raise the mast or the jib (generally the reverse

movements to the one that caused the alarm to

sound).

2. Identify the cause.

3. Perform the movement which will clear the

machine and prevent contact with the obstacle.

If the examination of the surroundings does not reveal

any possible obstacle, the alarm may have been

triggered by the telescopic mast jamming which could

be due to :

• A foreign body entering the guiding system.

• A lack of lubrication.

• Incorrect operation.

NOTE: The slack chain and light alarms are also

operational from the ground control station.

IF THE SLACK CHAIN ALARM HAS BEEN TRIGGERED BY MAST

JAMMING, DISCONTINUE OPERATION IMMEDIATELY. DO NOT

USE THE MANUAL LOWERING CONTROLS. PLATFORM

OCCUPANTS MUST BE RESCUED AND THE MACHINE SERVICED

BY A QUALIFIED TECHNICIAN.

4.5 SHUT DOWN AND PARK

To shut down and park the machine, the procedures

are as follow :

1. Drive machine to a reasonably well protected

area.

2. Ensure mast is lowered and jib stowed.

3. Push in the Emergency Stop at Platform Control

Station.

4. Push in the Emergency Stop at Ground Control

Station. Position Platform/Off/Ground select

switch to center OFF.

5. Toucan 800 : Position the circuit-breaker to its "O"

position.

Toucan 870 : Depress the circuit breaker push

button.

6. If necessary, cover Platform Controls to protect

instruction placards, warning decals and

operating controls from hostile environment.

7. Charge the batteries if the LEDs on the discharge

indicator are orange or red.

Soft Touch System Light and Alarm (Option)

The soft touch system detects contacts with outside

obstacles under the platform.

When this system is actuated, all the movements of the

platform are disabled, an acoustic alarm sounds and

the movement cut off indicator (orange) lights up on

the platform control panel.

Procedure to follow in case this feature is actuated :

1. Return all controls to neutral.

2. Locate the part of the platform contacting or

interfering with the outside obstacle.

3. Determine the appropriate clearance movement

(generally the opposite movement to the one that

caused the contact).

4. Actuate and keep actuated the auxiliary power

button (

required to clear the obstacle.

This feature is operational only when the platform is

controlled from the platform control panel.

) BEFORE operating the functions

31210031 – JLG Lift – 4-5

Page 34

SECTION 4 - MACHINE OPERATION

4.6 CHARGERS

The work platform on-board electronic charger is

designed to automatically charge 24 V DC lead-acid

rechargeable batteries.

Several types of chargers can be fitted on the machine

depending on the capacity of the battery.

The covers of the machine must be open during

battery charge.

LEAD-ACID BATTERIES MAY EMIT HIGHLY EXPLOSIVE GASES.

THE EMISSION IS GREATLY INCREASED DURING CHARGING.

NEVER INTRODUCE FLAMES, SPARKS OR OTHER SOURCES OF

IGNITION TO BATTERY AREA. FAILURE TO COMPLY WITH THIS

WARNING COULD RESULT IN DEATH OR INJURY TO

PERSONNEL. ALWAYS CHARGE BATTERIES IN A WELLVENTILATED AREA.

DO NOT DISCONNECT BATTERY PLUG WHEN THE CHARGER IS

ON. THE RESULTING ARCING COULD CAUSE BATTERY TO

EXPLODE AND BURNS TO THE OPERATOR.

NOTE: It is not necessary to charge the battery if the

electrolyte specific gravity has not dropped under

1.240 kg/l. Regular charge of a battery when its

specific gravity is higher then 1.240 kg/l can greatly

reduce the battery life.

NOTE: The charger has an interlock feature which causes

the work platform power circuit to open anytime the

charger is plugged into a live AC outlet.

NOTE: If power supply is stopped during the charge cycle,

the charger switches to a waiting mode and restarts

automatically as soon as the power returns.

Supply Voltage :

Always ensure the voltage selected corresponds to the

network voltage and the socket protection is sufficient

to support the charger power.

Incorrect setting of the charger voltage may result in

malfunction or breakdown.

The chargers are factory preset based upon the plug

type fitted.

ZIVAN BC1 High Frequency Electronic Charger

Charging the battery :

- Plug the charger into the mains (single phase 2 poles

+ ground).

- The charger starts automatically.

Remote charge-phase indicator on emergency control

unit :

Red LED :

The charger is in the charge initial phase (phase 1).

Flashing Red LED :

At the end of this phase, the battery is 80% charged

(phase 2).

Red and Green fixed LED :

Battery between 80 and 100% charged.

Green LED :

Battery charge complete, the charging process stops.

Alarms :

A flashing LED and an intermittent acoustic alarm indicate a faulty situation. When the alarm is on, the

charger does no longer deliver any current.

Troubleshooting :

TYPE OF ALARM DESCRIPTION (Action)

Temporisation

Battery current

Battery voltage

The charging phase 1 is lasting longer than the

maximum authorised (check the capacity of the

battery. Contact JLG Product Support).

Loss of control of the output current (fault on

control logic : Contact JLG Product Support).

Loss of control on output voltage (fault on control

logic : Contact JLG Product Support).

Thermal safety

Overheating of semi-conductors (check for proper

operation of the fan).

4-6 – JLG Lift – 31210031

Page 35

SECTION 4 - MACHINE OPERATION

EMB-MP HAWKER Charger (40 or 70 A)

a. Charge indicator (green)

b. Final charge indicator (yellow)

c. Battery indicator charge completed (green)

d. Fault indicator (red)

e. Circuit breaker

Charging the battery :

- Plug the charger into the mains (single phase 2 poles +

ground).

- Once the charger is connected, all the leds begin to flash

for a short period of time, indicating the charger is completing a self-test.

- The leds (c) and (d) will then flash for a short period of

time, indicating the charger is in "automatic starting"

mode.

- The charging phase starts, the green led (a) flashes

slowly (Frequency = 1 second) during the duration of

the charge.

- Once the final charging phase has been reached

(approximately 80%), led (a) still flashes and led (b)

lights up fixed.

- At the end of the charging process, both leds (a) and (c)

are on fixed.

Equalization charge :

- When the charger is doing an equalization charge :

• both leds (a) and (c) flash slowly.

• Led (b) is lit fixed.

Fault indicator :

- Should the transformer overheat, the red led (d) flashes

quickly (Frequency = 0,2 second).

- If the battery does not reach 2.4 V/cell after a 10 hour

charge, the charging process stops and the red led (d)

lights up.

It is advisable to have either the charger or the battery

checked by a technician.

Leds signal :

OFF = the led is off

ON = the led is lit fixed

BL = the led flashes (T=1 second)

BV = the led flashes quickly (T = 0.2 second)

* = the led can be on or off, depending on the state of

charge of the battery and on the charger’s operation at that moment.

31210031 – JLG Lift – 4-7

Page 36

SECTION 4 - MACHINE OPERATION

4.7 EMERGENCY TOWING

Towing is discouraged and must only be performed as

a last option.

IMPORTANT

VERIFY THE CAPACITY OF THE EQUIPMENT USED TO TOW THE

MACHINE.

ENSURE THE MACHINE IS ON LEVEL GROUND BEFORE

RELEASING THE BRAKES.

THE MACHINE MUST ALWAYS BE IN STOWED POSITION DURING

TOWING PROCEDURE.

NO PERSONNEL IS ALLOWED ON THE PLATFORM DURING

TOWING PROCEDURE.

To tow, release the brakes and the wheel motors as follow:

1. Fully lower the platform.

2. Remove the pump handle from its support.

3. Before releasing the valve, wait 30 seconds after

the end of a drive movement.

4. Pull the lever of the brake release valve (located at

the rear side of the chassis) to "BRAKE

UNLOCKED" position (

5. Insert the handle in the hand pump.

).

4.8 LIFTING AND TIE DOWN

IMPORTANT

WHEN TRANSPORTING THE MACHINE, THE MACHINE MUST BE

STOWED.

Lifting

1. The weight of the machine is stamped on the

serial number plate (See § 8.2). If the plate is

missing or illegible, call JLG Industries or weigh

the individual unit to find out the Gross Vehicle

Weight.

2. Place the machine in the stowed position.

3. Remove all loose items from the machine.

4. Attach lifting device and equipment only to the

designated lifting points. (See below).

To uc an 80 0

6. Activate the hand pump until the movement gets

harder.

7. Use a winch to tow the machine (if a winch is not

available, use another low speed towing device).

THERE IS ONE TIE DOWN/EMERGENCY TOW LUG INSTALLED

ON EACH END OF THE CHASSIS OF THE WORK PLATFORM.

8. At the end of the procedure, return the release

valve to NORMAL USE ( ). The machine and

the brakes are operational.

MACHINE HAS NO TOWING BRAKES. TOWING VEHICLE MUST

BE ABLE TO CONTROL MACHINE AT ALL TIMES, ON-HIGHWAY

TOWING NOT PERMITTED, FAILURE TO FOLLOW INSTRUCTIONS

COULD CAUSE SERIOUS INJURY OR DEATH. MAXIMUM TOWING

GRADE 20%.

BEFORE TOWING, THE BRAKES AND THE WHEEL MOTORS

MUST BE RELEASED. TOWING IS LIMITED TO EXTREMELY

SHORT DISTANCES AT A MAXIMUM SPEED OF 1 KM/H. SEVERE

DAMAGE TO THE DRIVE SYSTEM MAY RESULT IF TOWING IS

OTHERWISE ACCOMPLISHED.

Toucan 870

USE BOTH RINGS TO LIFT THE MACHINE.

5. Properly adjust the rigging to prevent damage to

the machine.

4-8 – JLG Lift – 31210031

Page 37

SECTION 4 - MACHINE OPERATION

Tie Down

1. Place the machine in the stowed position.

2. Remove all loose items from the machine.

3. Chock wheels in both directions.

4. Secure the chassis using straps or chains of

adequate strength and attached to the designated

tie down points.

Toucan 800

4.9 LOADING AND UNLOADING

Using a fork lift truck

Toucan 800

Toucan 870

Toucan 870

Figure 4-2. Position of the forks

VERIFY THE CAPACITY OF THE FORKLIFT TRUCK AND OF ITS

EQUIPMENT. FORK LIFT ONLY AT THE DESIGNATED POINTS. ANY

OTHER POSITION OF THE FORKS WILL CAUSE THE MACHINE TO

TIP OVER. NOBODY MUST BE ON THE PLATFORM OF THE

MACHINE DURING LOADING AND UNLOADING OPERATIONS.

THE WORK PLATFORM MUST BE KEPT AS NEAR TO THE

GROUND AS POSSIBLE DURING FORK LIFT OPERATION.

Using a winch for loading

If the work platform cannot be loaded safely using the

work platform controls, use a winch (release brakes

prior to the operation).

CHECK THE CAPACITY OF THE EQUIPMENT USED. PLACE THE

MACHINE IN TOWING MODE (SEE § 4.7) FOR THE LOADING AND

UNLOADING PROCEDURES. NOBODY MUST BE IN THE

PLATFORM DURING THIS OPERATION.

31210031 – JLG Lift – 4-9

Page 38

SECTION 4 - MACHINE OPERATION

4-10 – JLG Lift – 31210031

Page 39

Tou ca n 8 00

SECTION 5 - DECALS

SECTION 5. DECALS

Instructions AU1743

Loads AU1095

31210031 – JLG Lift – 5-1

Page 40

SECTION 5 - DECALS

5-2 – JLG Lift – 31210031

Page 41

Toucan 800 DI

SECTION 5 - DECALS

Instructions AU1743

Loads AU1755

Load Transfer AU1387

31210031 – JLG Lift – 5-3

Page 42

SECTION 5 - DECALS

5-4 – JLG Lift – 31210031

Page 43

Toucan 870

SECTION 5 - DECALS

Standard Platform

Instructions AU1757

Loads AU1756

Large Platform

Instructions AU1757

Loads AU1758

31210031 – JLG Lift – 5-5

Page 44

SECTION 5 - DECALS

5-6 – JLG Lift – 31210031

Page 45

SECTION 6 - EMERGENCY PROCEDURES

SECTION 6. EMERGENCY PROCEDURES

6.1 GENERAL

This section explains the steps to be taken in case of

an emergency situation while operating.

6.2 INCIDENT NOTIFICATION

JLG Industries, Inc. must be notified immediately of

any incident involving a JLG product. Even if no injury

or property damage is evident, the factory should be

contacted by telephone and provided with all

necessary details.

In USA : 877-JLG-SAFE (Toll free)

Outside USA: +44 (0) 141 781 6700

E-mail:ProductSafety@JLG.com

Failure to notify the manufacturer of an incident

involving a JLG Industries product within 48 hours of

such an occurrence may void any warranty

consideration on that particular machine.

IMPORTANT

FOLLOWING ANY ACCIDENT, THOROUGHLY INSPECT THE

MACHINE AND TEST ALL FUNCTIONS FIRST FROM THE GROUND

CONTROLS, THEN FROM THE PLATFORM CONTROLS. DO NOT

LIFT ABOVE 3 M UNTIL YOU ARE SURE THAT ALL DAMAGE HAS

BEEN REPAIRED, IF REQUIRED, AND THAT ALL CONTROLS ARE

OPERATING CORRECTLY.

6.4 EMERGENCY LOWERING

If primary power is lost, the platform may be lowered

manually. Reference section 3 for Manual Lowering

Control procedures.

6.5 EMERGENCY TOWING PROCEDURES

Towing this machine is discouraged. However,

provisions for towing the machine in emergency

situations have been incorporated. For specific

procedures, refer to Section 4.

6.3 EMERGENCY OPERATION

Operator Unable to Control Machine

IF THE PLATFORM OPERATOR IS PINNED, TRAPPED

OR UNABLE TO OPERATE OR CONTROL MACHINE:

1. Other personnel should operate the machine from

ground controls only as required.

2. Other qualified personnel on the platform may use

the platform controls. DO NOT CONTINUE

OPERATION IF CONTROLS DO NOT FUNCTION

PROPERLY.

3. Appropriate equipment can be used to remove

platform occupants and stabilize motion of the

machine.

Platform or Mast Caught Overhead

If the platform or mast becomes jammed or snagged in

overhead structures or equipment, rescue platform

occupants prior to freeing the machine.

31210031 – JLG Lift – 6-1

Page 46

SECTION 7 - INSPECTION AND REPAIR LOG

SECTION 7. INSPECTION AND REPAIR LOG

Type of machine :_______________________________________ Machine Serial Number :__________________________________

Table 7-1. Inspection and Repair Log

Date Comments

Name :______________________________________

Signature :____________________________________

31210031 – JLG Lift – 7-1

Page 47

SECTION 8 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

SECTION 8. GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

8.1 INTRODUCTION

This section of the manual provides additional

necessary information to the operator for proper

operation and maintenance of this machine.

The maintenance portion of this section is intended as

information to assist the machine operator to perform

daily maintenance tasks only, and does not replace the

more thorough Preventive Maintenance and Inspection

Schedule included in the Service and Maintenance

Manual.

Other Publications Available :

Service and Maintenance Manual French........ MA0306

Service and Maintenance Manual English ....... MA0318

Illustrated Parts Manual Toucan 800 ..............31210056

Illustrated Parts Manual Toucan 870 ..............31210058

Hydraulic schematic Toucan 800 .......................FL0147

Hydraulic schematic Toucan 870 .......................FL0146

Electrical schematic........................................... ELE240

31210031 – JLG Lift – 8-1

Page 48

SECTION 8 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

8.2 OPERATING SPECIFICATIONS

Table 8-1. Operating Specifications And Dimensions

TOUCAN 800 A TOUCAN 800 A TOUCAN 800 DI TOUCAN 870 TOUCAN 870

Platform Size 700 x 900 1010 x 900 1300 x 900 700 x 900 1010 x 900

220 kg

Maximum Work Load 200 kg (2 persons + 40 kg material)

Slewing 360° non-continuous 180°

Max. Platform Height 6.10 m 6.72 m

Horizontal Reach

( fr o m ce n te r li n e of m ac h in e )

( fr o m re a r w h ee l e dg e )

( fr o m s i de w he e l e d ge )

Up and Over Clearance 5.35 m 5.42 m

Max. Hydraulic System Pressure 23 MPa

Maximum Operating Wind Speed 45 km/h (12.5 m/s) 0 km /h 45 km/h (12.5 m/s)

Maximum Horizontal Manual Force 400 N

Electrical System Voltage 24V

Gross Machine Weight

Gross Machine Weight

Overall Length before 2010 1.90 m 2.20 m 2.50 m 2.67 m 2.99 m

Overall Length since 2010 1.94 m 2.25 m 2.53 m 2.67 m 2.99 m

Overall Height 1.99 m

Overall Width 0.99 m

Maximum Wheel Load 1400 kg 1500 kg 1950 kg

Maximum Travel Grade (Gradeability)

With mast in stowed position and jib below horizontal

Maximum Travel Grade (Side slope)

With mast in stowed position and jib below horizontal

Tilt Sensor Setting 2°

Tu rn in g R ad iu s

Inside :

Outside :

Vibration levels

Acoustic pressure

(Platform Empty) before 2010 1950 kg 2000 kg 2980 kg

(Platform Empty) since 2010 2100 kg 2200 kg 2980 kg

1.89 m

1.10 m

1.40 m

The weighed root mean square acceleration value to which the arms are subjected (control levers)

is inferior to 2,5m/s/s.

The weighed root mean square acceleration value to which the feet are subjected (platform floor)

is inferior to 0,5m/s/s/.

The equivalent continuous ’A’ weighed sound pressure level at the work station is <to 70 dB(A).

The measure has been taken by placing the sonometer at 1,60 m above the platform floor.

2.19 m

1.40 m

1.70 m

20% (11°) 15% (8.5°)

2.40 m

1.60 m

1.90 m

1.05 m

2.40 m

(2 persons + 60 kg

material)

2.64 m

1.84 m

2.15 m

5°

200 kg

(2 persons + 40 kg

material)

2.96 m

2.15 m

2.46 m

8-2 – JLG Lift – 31210031

Page 49

SECTION 8 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

Fluid Capacities

Table 8-2. Capacities

Main Hydraulic Tank 19 l

Hydraulic Power Unit

Table 8-3. Hydraulic Power Unit Specifications

Maximum 24 MPa

Powe r 4.8 k W

Vol tage 24 V DC

Flow Rate 9.1 l/mn

Displacement 3.5 cm³/t

Powe r 0.8 k W

Vol tage 24 V DC

Main

Power

Unit

Steering

Unit

Motor

Pump

Maximum 12 MPa

Motor

Pump Displacement 0.5 cm³/t

Batteries

Table 8-4. Battery Specifications

Voltage 24 Volt

Amp Hour Rating

Life Cycle Rating 1200 Cycles

Toucan 800 240 Ah (5h rate)

Toucan 870 620 Ah (5h rate)

31210031 – JLG Lift – 8-3

Page 50

SECTION 8 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

To uc a n 8 00

To uc a n 8 70

Figure 8-1. Operator Maintenance & Lubrication Diagram

1 - B a t te r ie s

2- Hydraulic Filters

3- Turntable Lubrication

4- Lifting Chains Lubrication

5 - M a s t S e ct i on L u br i ca t io n

6 - W h ee l B ea r in g & S t eering Knuckles Lubrication

7- Hydraulic Oil Reser voir

8- Steering Hydraulic Unit Reservoir

9- Tires & Wheels

10- Verification of the Overload Detection Setting (if fitted)

11- Verification of the Tilt Alarm Setting

8-4 – JLG Lift – 31210031

Page 51

SECTION 8 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

8.3 OPERATOR MAINTENANCE

1. Batteries