Page 1

Operation & Safety, Service &

Maintenance & Illustrated Parts

Manual Supplement

JLG

LOAD

SENSING

SYSTEM

Vertical Lift Products

P/N

3124289

July 29, 2013

Page 2

Page 3

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

INTRODUCTION

GENERAL

This section contains the general safety precautions

which must be observed during maintenance of the aerial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themselves or others, or

damage to the equipment. A maintenance program must

be followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLATION.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the manual.

These precautions are, for the most part, those that apply

when servicing hydraulic and larger machine component

parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never attempt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANCE,

SAFETY IN THIS AREA IS THE RESPONSIBILITY OF THE OWNER/

OPERATOR.

MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL

INJURY OR DEATH AND IS A SAFETY VIOLATION.

• REMOVE ALL RINGS, WATCHES AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICE MANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• NEVER WORK UNDER AN ELEVATED PLATFORM

UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED

FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems

operate at extremely high, potentially dangerous pressures. Every effort should be made to relieve any system

pressure prior to disconnecting or removing any portion of

the system.

3124289 – JLG Lift – A

Page 4

INTRODUCTION

July 1, 2003 - Original issue of Manual

March 1, 2004 - Revised

May 17, 2005 - Revised

July 15, 2006 - Revised

March 31, 2011 - Revised

March 1, 2012 - Revised

August 11, 2012 - Revised

January 23, 2013 - Revised

July 29, 2013 - Revised

REVISION LOG

B – JLG Lift – 3124289

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION - INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

HYDRAULIC SYSTEM SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

EFFECTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

SECTION 1 - OPERATION

1.1 INTRODUCTION & OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Overload Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overload Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

2.1 LOAD SENSING SYSTEM (LSS) DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Manually Propelled Vertical Lift - Overload Detection (Manually Propelled Lifts). . . . . . . . . . 2-1

Drivable Vertical Lift - Overload Detection (Drivable Vertical Lifts) . . . . . . . . . . . . . . . . . . . . .2-1

2.2 LSS - SETUP AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Procedure Overview (All Vertical Lifts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Adjustment Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

LSS Operation Function Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3 COMPONENT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

LSS Panel Component Installation - (Manually Propelled Lifts Only). . . . . . . . . . . . . . . . . . .2-5

LSS Indicators (Drivable Vertical Lifts Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

LSS Platform Mount Attach Arms to Mast Header Installation (All Lifts). . . . . . . . . . . . . . . . . 2-6

LSS Limit Switch Installation (All Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

LSS Platform Mount, Coil Spring to Mast Crossmember Installation (All Lifts) . . . . . . . . . . . 2-6

2.4 LSS TIMING MODULE - (MANUALLY PROPELLED LIFTS ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.5 GROUND CONTROL MODULE (DRIVABLE VERTICAL LIFTS ONLY) . . . . . . . . . . . . . . . . . . . . . . 2-8

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.6 PLATFORM CONTROL CONSOLE (DRIVABLE VERTICAL LIFTS ONLY) . . . . . . . . . . . . . . . . . . .2-8

2.7 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

SECTION 3 - ILLUSTRATED PARTS

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3124289 – JLG Lift – i

Page 6

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. L.S.S. Indicator Panel Location - (Manually Propelled Vertical Lifts) . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2. Load Sensing System - Indicators (Drivable Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2-1. Load Sensing System - Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-2. Load Sensing System - Indicators (Drivable Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-3. Platform Console LED Indicators (Drivable Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4. LSS Component Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-5. LSS Wiring Diagram - (For Manually Propelled Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-6. LSS Wiring Diagram - (For Drivable Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

3-1. Platform Support & Load Sensing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

2-1 Test Weight Requirement Per Machine Model. (Percent of Maximum Platform Capacity) . . . . . .2-3

2-2 LSS Timing Module (J1 - Black Connector) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-3 Ground Control Module Programming - Drivable Lifts ONLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-4 Troubleshooting - Machine Indicates (Possible False) Platform Overload Condition -

(Manually Propelled Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-5 Troubleshooting - Machine Indicates (Possible False) Platform Overload Condition -

(Drivable Vertical Lifts). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

ii – JLG Lift – 3124289

Page 7

SECTION 1. OPERATION

–+

NOTE: This manual is intended as a supplement to the indi-

vidual machine’s Operators and Safety Manual, Service and Maintenance Manual and Illustrated Parts

Manual.

1.1 INTRODUCTION & OPERATION

NOTE: It is the responsibility of the owner/user/operator/les-

sor/lessee to read & understand this manual and the

machine Operators & Safety Manual and to prevent

overloading the platform. Do not operate a machine

with a disconnected or inoperative Load Sensing

System.

The JLG Load Sensing System (LSS) for Vertical Mast

Products is designed to detect when actual platform load

exceeds the machine’s Maximum Rated Load Capacity.

Overload Indication

When the Maximum Rated Load Capacity is exceeded the

following will occur:

SECTION 1 - OPERATION

NOTE: There is a three (3) second delay between detection

and overload indication.

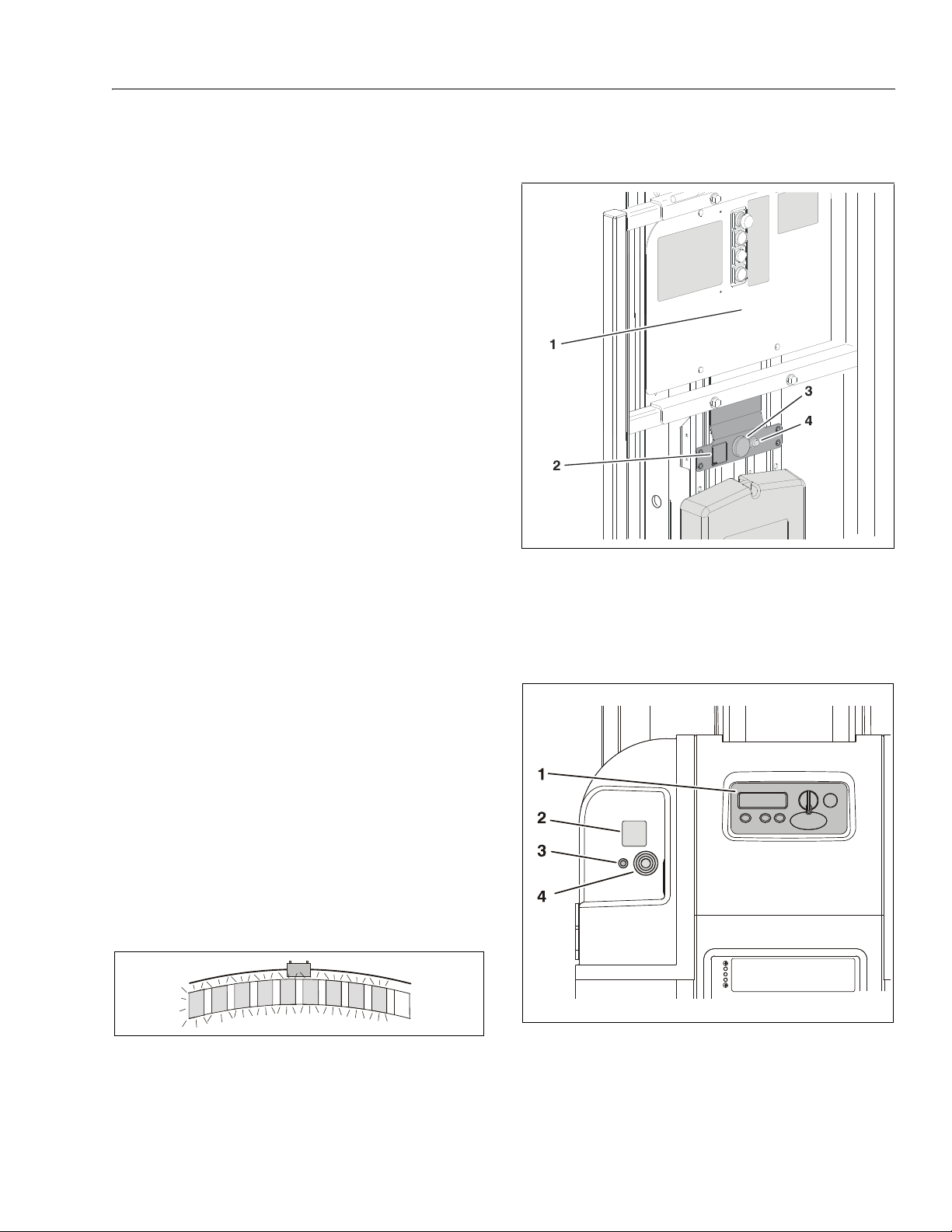

MANUALLY PROPELLED LIFTS (See Figure 1-1.)

1. The LSS Warning Alarm and Lamp will activate 1

second ON, and 2 seconds OFF.

2. The platform lift up/down function will be disabled to

prevent movement of the overloaded platform.

DRIVABLE LIFTS (See Figure 1-2.)

1. The LSS Warning Alarm and Lamp will activate 5

seconds ON, and 2 seconds OFF. Also a 9 LED

code will flash on the platform control console (see

below), and the Ground Control Module LCD screen

will indicate a platform overload condition.

2. The platform lift up/down and driving functions will

be disabled to prevent movement of the overloaded

platform.

NOTE: Ground control functions may be disabled depen-

dent on Ground Control Module programming.

Figure 1-1. L.S.S. Indicator Panel Location -

(Manually Propelled Vertical Lifts)

1. Platform Control Panel 3. LSS Warning Alarm

2. L.S.S. Indicator Panel 4. LSS Warning Lamp

Platform Console LED Indicators

(Drivable Vertical Lifts)

1. The platform console LED bar will flash 9 (Nine) LEDs

to indicate a Platform Overload condition.

3124289 – JLG Lift – 1-1

Figure 1-2. Load Sensing System - Indicators

(Drivable Vertical Lifts)

1. Ground Control Module 3. LSS Warning Lamp

2. LSS Warning Decal 4. LSS Warning Alarm

Page 8

SECTION 1 - OPERATION

Overload Recovery

Further movement of the platform is permitted by removing excess platform load until the LSS resets. This may

require removing load until a load less than rated capacity

is achieved.

NOTE: There is a 5 second delay between overload reset

and machine function activation.

THE LOAD SENSING SYSTEM WILL REQUIRE ADJUSTMENT

WHEN ONE OR MORE OF THE FOLLOWING CONDITIONS

OCCUR:

• Load Sensing System initial installation

• LSS component is disassembled or replaced

THE LOAD SENSING SYSTEM REQUIRES PERIODIC FUNCTION

VERIFICATION NOT TO EXCEED 6 MONTHS FROM PREVIOUS

VERIFICATION.

1-2 – JLG Lift – 3124289

Page 9

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

32491011781

6

5

SECTION 2. SERVICE PROCEDURES - LOAD SENSING SYSTEM

2.1 LOAD SENSING SYSTEM (LSS) DESCRIPTION

The LSS system for Vertical Mast model machines consists of a floating platform mount weldment (rails)

attached to the sides of the mast header section, transferring the platform load to a load bearing crossmember. The

platform mount load bearing crossmember is supported

by coil springs mounted between the platform crossmember and a crossmember attached to the mast header section. Also attached to the platform mount weldment (rails)

is an adjustable actuator. The actuator, when adjusted

properly, trips the LSS limit switch mounted on the mast

crossmember when the platform is overloaded.

While the mechanical portion of the LSS system operates

the same for both the manually propelled and drivable

vertical lifts, the limit switch circuit (electrical) is monitored

differently as described following.

Manually Propelled Vertical Lift - Overload Detection

(See Figure 2-1.)

The limit switch circuit on the manually propelled lifts is

monitored by an LSS Timing Module which disables the

platform lift up/lift down function, sounds an audible warning alarm and activates a flashing warning lamp when a

platform overload condition is detected. The LSS Timing

Module is mounted behind the LSS Indicator Panel

located behind the platform railing.

Drivable Vertical Lift - Overload Detection

(See Figure 2-1., Figure 2-2. and Figure 2-3.)

The limit switch circuit on the drivable lift is monitored by

the Ground Control Module (GCM) which controls all

machine functions and is mounted inside the machine’s

rear covers. Like the LSS Timing Module on the manually

propelled lifts, on overload detection the GCM on the drivable lift disables the platform lift up/lift down function, in

addition the drive function is also disabled. Indicators of

an overload condition are; an audible warning alarm;

flashing warning lamp; 9 LEDs flash on the platform control console and GCM LCD screen will flash "Platform

Overload". On the drivable lift, the audible warning alarm

and flashing warning lamp are located on the machine’s

left rear cover. (See Figure 2-2.)

On initial LSS installation or GCM replacement, the GCM

must be programmed to detect the LSS system in order to

function properly. See Section 2.5, "Ground Control Module" in this manual for instructions on GCM - LSS detection programming.

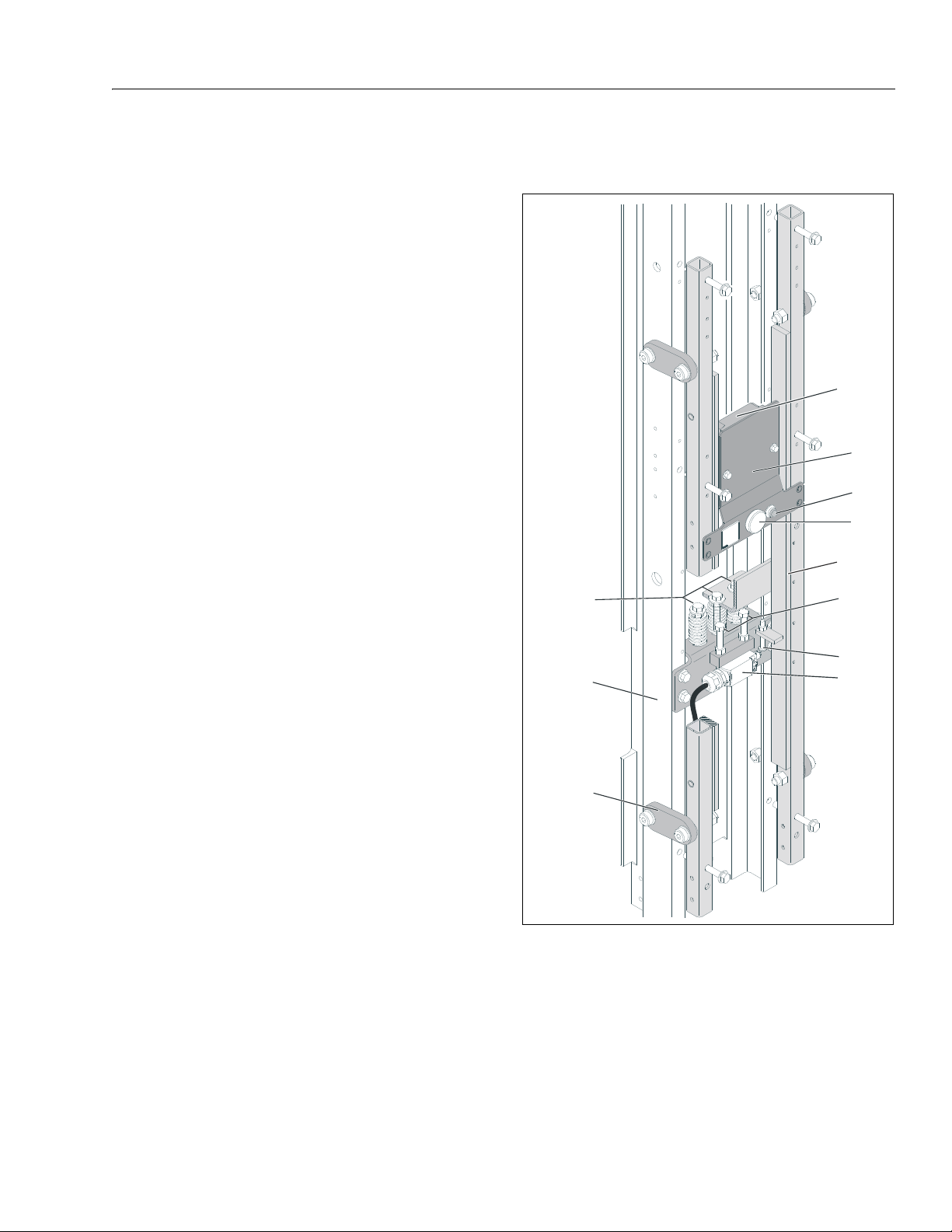

Figure 2-1. Load Sensing System - Components.

1. LSS Timing Module (a) 7. Crossmember Stops

2. LSS Indicator Panel (a) 8. LSS Overload Actuator

3. LSS Warning Lamp (b) 9. LSS Limit Switch

4. LSS Warning Alarm (b) 10. Mast Header

5. Platform Mount (c) 11. LSS Arm Linkage

6. Coil Spring Assemblies

Note: (a) Manually propelled lifts only.

(b) Relocated on drivable lifts (See Figure 2-2.)

(c) Shown cut-away for illustrative purposes only.

3124289 – JLG Lift – 2-1

Page 10

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

–+

Figure 2-2. Load Sensing System - Indicators

(Drivable Vertical Lifts)

1. Ground Control Module 3. LSS Warning Lamp

2. LSS Warning Decal 4. LSS Warning Alarm

2.2 LSS - SETUP AND ADJUSTMENT

Procedure Overview (All Vertical Lifts)

The mechanical portion of the LSS system requires three

(3) adjustments to operate properly.

• Platform Crossmember/Coil Spring Pre-load Height

Adjustment; sets the coil spring pre-load between the

platform and mast crossmember with no load in the

platform.

• Mast Header Crossmember Positive Stop Adjust-

ment; sets the maximum amount of downward travel of

the platform, if the platform is overloaded.

• LSS Overload Actuator Adjustment; sets the actuator

to trip the LSS limit switch, signaling an overload situation, when the platform is overloaded. There is a three

(3) second delay between switch opening and warning

activation.

THESE SETUP PROCEDURES WILL REQUIRE ACCURATELY

MEASURED WEIGHT UP TO AND OF A PERCENTAGE OVER THE

PLATFORM’S MAXIMUM CAPACITY. SEE TABLE 2-1 IN THE FOLLOWING SUB-SECTION.

Figure 2-3. Platform Console LED Indicators

(Drivable Vertical Lifts)

1. The platform console LED bar will flash 9 (Nine) LEDs

to indicate a Platform Overload condition.

Figure 2-4. LSS Component Adjustments

1. Coil Spring Pre-Load Height Adjustment

2. Crossmember Positive Stop Adjustment

3. Overload Actuator Adjustment

Notes: Shown with manual storage box removed and

with little or no load in the platform.

2-2 – JLG Lift – 3124289

Page 11

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

Adjustment Preparation

Before performing the LSS adjustments:

• Move machine to a smooth, firm, level surface.

• Remove the platform manual storage box from main

mast header. The storage box fasteners are located

inside the manual storage box.

• Have applicable test weight to maximum platform

weight capacity, plus percentage of overload amount

available with equipment capable of hoisting the weight

into the platform.

• Set-up machine for normal operation.

Table 2-1. Test Weight Requirement Per Machine Model.

(Percent of Maximum Platform Capacity)

OVERLOAD

MODEL

ADJUSTMENT

TEST WEIGHT

All Vertical Lifts 110% 120%

Example:

110% Overload Test Weight = Max. Platform Capacity + 10%

120% Positive Stop Test Weight = Max. Platform Capacity + 20%

Capacity 110% 120%

300 lb.

(136kg)

350 lb.

(159kg)

500 lb.

(227kg)

330 lb.

(150kg)

385 lb.

(175kg)

550 lb.

(250kg)

WHEN PERFORMING THE FOLLOWING ADJUSTMENTS - DO NOT

ADD TO THE WEIGHT IN THE PLATFORM BY ALLOWING ANY

PART OF YOUR BODY TO REST ON THE PLATFORM.

POSITIVE STOP

TEST WEIGHT

360 lb.

(163kg)

420 lb.

(191kg)

600 lb.

(272kg)

Adjustment Procedures

Coil Spring Pre-Load Adjustment Procedure

(As viewed from rear with mast hidden)

1. Perform the spring pre-load adjustment with NO

LOAD IN THE PLATFORM.

2. Adjust the coil spring height (item 1) between the

mast crossmember (item 2) and the platform crossmember (item 3) to two (2) inches (51mm) by loosening or tightening the locknut on the bottom of the

center bolt (item 4) (see note below).

3. Adjust outside spring bolts (items 5) until the locknuts

on the bottom of the bolts are flush with the end of

each bolt. The outside bolts will be loose.

NOTE: Machines with capacities up to 300 lb. (136kg)

only require two coils springs installed on the

outside bolt positions. Machines with capacities

over 300 lb. (136kg) require coil springs installed

in all three bolt positions.

3124289 – JLG Lift – 2-3

Page 12

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

WHEN PERFORMING THE FOLLOWING ADJUSTMENTS - DO NOT

ADD TO THE WEIGHT IN THE PLATFORM BY ALLOWING ANY

PART OF YOUR BODY TO REST ON THE PLATFORM.

Limit Switch Overload Actuator Adjustment

1. Perform the limit switch overload actuator adjustment

with 110% OF MAXIMUM CAPACITY load in the platform.

2. Setup and power machine on.

Crossmember Positive Stop Adjustment

1. Perform the crossmember positive stop adjustment

with 120% OF MAXIMUM CAPACITY load in the platform.

2. Adjust the height between the top of the positive stop

bolts (item 3) and the platform crossmember (item 1)

to 1/16 - 1/8 inch (2 to 3mm) (item 2) by loosening

the nuts (item 4) at the bottom of the bolts (item 1).

Adjust both stop bolts until the proper height is

achieved.

3. Tighten both nuts (item 4) when proper adjustment is

achieved.

3. With weight in platform, loosen the actuator lock nut

(item 1) and turn the actuator (item 2) and align with

the end of plunger on the switch (item 3).

4. Remove the limit switch cover (item 4) and use a volt/

ohm meter to watch for switch open circuit. Adjust the

actuator down until the switch contact opens. (See

Notes (a) and (b).

5. Once circuit is open, re-tighten the actuator lock nut

and replace the cover on the limit switch when complete.

NOTE: (a) There is a three (3) second delay pro-

grammed into the LSS Timing Module (Manually

Propelled Lifts) and Ground Control Module

(Driveable Vertical Lifts) between switch opening

and module activation of the LSS warning indicators.

NOTE: (b) There is a 5 second RESET delay once the

limit switch circuit is closed and before the module resumes normal machine operation.

LSS Operation Function Check

After performing the adjustments outlined previously

check the following:

• Machine operates properly when loaded to 100% rated

platform capacity.

• Machine cuts out applicable functions and indicates an

overload condition when loaded to 110% rated platform

capacity.

2-4 – JLG Lift – 3124289

Page 13

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

1

2

3

2.3 COMPONENT REMOVAL

General

Before disconnecting any electrical component always

turn off the machine power supply.

Refer to wiring schematic in the Troubleshooting section

for wiring connection information.

Platform removal will depend on machine model, consult

the machine’s Service/Maintenance Manual.

LSS Panel Component Installation - (Manually Propelled Lifts Only)

LSS Panel Installation

1. LSS Panel 3. Drop panel down and lift out

2. Panel Fasteners

Note: Wiring harness connectors to module, alarm and

lamp may need to be disconnected when removing

panel.

LSS Warning Alarm Installation

1. Alarm Body 2. Alarm Attach Nut

LSS Warning Lamp Installation

1. Lamp Attach Nut and Washer

2. Lamp Assembly

Note: Shown with alarm removed for illustrative purposes

only.

1. LSS Indicator Panel 3. LSS Timing Module

2. Module Fasteners

LSS Timing Module Installation

3124289 – JLG Lift – 2-5

Page 14

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

LSS Indicators (Drivable Vertical Lifts Only)

LSS Indicator Installation (Drivable Lifts Only)

1. Open/unbolt Left Rear Cover 3. LSS Warning Alarm

2. LSS Warning Lamp

LSS Platform Mount Attach Arms to Mast Header Installation (All Lifts)

LSS Limit Switch Installation (All Lifts)

LSS Limit Switch Installation

1. Switch Mounting Nut (a) 3. Switch Fasteners

2. Limit Switch

Note: (a) Located behind mast crossmember.

LSS Platform Mount, Coil Spring to Mast Crossmember Installation (All Lifts)

View From Rear Of Crossmembers

(View From Rear - Mast Header Hidden)

Platform Mount to Mast Header Attach Arm Installation

(Top Side Arm Shown - Installation Same Both Sides)

1. Shoulder Bolt (2.75 in.) 5. Bronze Washer (.125 in.)

2. Shoulder Bolt (1.5 in.) 6. Hex Nuts (a)

3. Bronze Washer

4. Attach Arm Assy. 8. Platform Mount Assy.

Note: (a) Apply Loctite #271 to threads on final assembly

and torque to 45 ft. lb. (61 N, m).

(.0625 in.) 7. Mast Header

1. Platform Mount Crossmember 4. Coil Springs (a)

2. Spring Preload Adjust Bolts 5. Lock Nuts

3. Flat Washers 6. Mast Header Crossmember

NOTE: (a) Machines with capacities up to 300 lb.

(136kg) only require two coils springs installed

on the outside bolt positions. Machines with

capacities over 300 lb. (136kg) require coil

springs installed in all three bolt positions.

2-6 – JLG Lift – 3124289

Page 15

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

12

3

4

Load Sensing System

Timing Module

P/N 1600357

S/N_________________________________

HW Rev.________ SW Rev.________

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

IGNITION

GROUND

Over loa d Limi t S wit ch i nput

Spare I nput 1

Spare I nput 2

Spare I nput 3

Over loa d Sta tus Ou tpu t

Visual Warning Output

Audible Warning Output

Spare Out put 3

Spare Out put 4

Spare Out put 5

+5 An alo g Re fer en ce

Spare Ana log 0

Analog Ground

+5 An alo g Re fer en ce

Spare Ana log 1

Analog Ground

Spare Ana log 2

Spare Ana log 3

CANBus CANH

CANBus CANL

Analyzer Pin #3

Analyzer Pin #2

PIN FUNCTION

PIN FUNCTION

J1 - BLACK J2 - GREY

1705760A

1

23

45

2.4 LSS TIMING MODULE (MANUALLY PROPELLED LIFTS ONLY)

The LSS Timing Module is fastened to the back of the LSS

Indicator Panel at the back of the platform on the mast

header. (See Section 2.3, Component Removal for instruc-

tions on removing the module).

LSS Module Location

1. Timing Module 3. J2 Grey Connector

2. J1 Black Connector 4. LSS Indicator Panel

LSS Timing Module Identification Decal

with Connector Pin Assignments

1. Module Serial Number

2. Hardware Revision Level

3. Software Revision Level

4. J1 Black - Pin Assignments (used)

5. J2 Grey - Pin Assignments (unused)

Table 2-2. LSS Timing Module

(J1 - Black Connector)

Pin Assignments

1. Timing Module 3. J2 Grey Connector (unused)

2. Identification Decal 4. J1 Black Connector (used)

LSS Timing Module

3124289 – JLG Lift – 2-7

Pin Signal Description

112V +Ignition

2Neg. (—)Ground

312V +Overload Limit Switch Input

4–Spare Input 1

5–Spare Input 2

6–Spare Input 3

712V +Overload Status Output

812V +Visual Warning Output

912V +Audible Warning Output

10 – Spare Input 4

11 – Spare Input 5

12 – Spare Input 6

Note: Also refer to wiring diagram Figure 2-5.

Page 16

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

00000.0

1

2

–+

2.5 GROUND CONTROL MODULE (DRIVABLE VERTICAL LIFTS ONLY)

The following instructions are supplemental to the DVL/

DVSP Operators and Service manuals and show additional features on the ground control module for machines

equipped with the Load Sensing System.

Programming

The Ground Control Module must be programmed to

detect the Load Sensing System before the LSS will function properly.

1. Enter the Service Programming Mode (Level 2 -

Password) at the Ground Control Module (Refer to

the machine’s Service Manual for instructions).

2. Enter the Program menu and scroll through the item

list to find and set the LSS programming item range

as shown following:

Table 2-3. Ground Control Module Programming -

Drivable Lifts ONLY.

PROGRAMMABLE

ITEM

Enable Detection of

LSS

FACTORY

PRESET

2 0 - Detection Disabled

SETTING RANGE

1 - Enabled - Warning Disables

Platform Functions Only

2 - Enabled - Warning Disables

Platform and Ground

C o nt r ol F un c ti o ns

2.6 PLATFORM CONTROL CONSOLE (DRIVABLE VERTICAL LIFTS ONLY)

Platform Console LED Indicators

1. The platform console LED bar will flash 9 (Nine) LEDs

to indicate a Platform Overload condition.

LCD Display

When an overload warning is detected the following alternating screens are displayed on the Ground Control Module LCD screen:

LCD Display Symbols

1. Drive and Lift Up/Down Functions - Disable Indicators

2. Description of Warning - Platform Overloaded

Note: When the Overload condition is indicated the LCD screen will

alternate between the text and symbol display modes.

2-8 – JLG Lift – 3124289

Page 17

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

2.7 TROUBLESHOOTING

The following tables are furnished to provide possible resolutions for common Load Sensing System difficulties.

The wiring connectors and pins referenced in these troubleshooting tables can be located on the electrical wiring

diagrams on the pages following these tables.

Table 2-4. Troubleshooting - Machine Indicates (Possible False) Platform Overload Condition -

(Manually Propelled Vertical Lifts)

Check For These Obvious Conditions First:

• Is the LSS platform mounting system secure and undamaged and all mounting arm joints working smoothly.

• Damaged or loose connectors or wires to LSS components.

STEP ACTION SPEC YES NO

1. Is platform load at or below the maximum rated platform capacity? See Capacity

Go to Step 2 Reduce Platform

Decal on Machine

2. Perform adjustment procedures (Section 2.2, LSS - Setup And

– Go to Step 3 Done

Adjustment). Reload platform to rated capacity, is system still indicating an overload condition?

3. Set up and power machine on. Check voltage at Timing Module - J1

connector - Pin 3. Is voltage up to spec?

4. Check continuity between Timing Module J1 - Pin 3 and Pin 22 on

12V Replace Timing

Module

Go to Step 5 Repair or Replace

the Limit Switch. Is there continuity?

5. At the Limit Switch check voltage on Pin 21. Is voltage up to spec? 12V Replace Limit

Switch

6. At the Limit Switch, check Pin 21 connector for loose or damaged

condition. Is connector loose or damaged?

Table 2-5. Troubleshooting - Machine Indicates (Possible False) Platform Overload Condition -

(Drivable Vertical Lifts)

Check For These Obvious Conditions First:

• Is the LSS platform mounting system secure and undamaged and all mounting arm joints working smoothly.

• Damaged or loose connectors or wires to LSS components.

– Repair or Replace

Connector

Load

Go to Step 4

Wiring

Go to Step 6

Replace Limit

Switch

STEP ACTION SPEC YES NO

1. Is platform load at or below the maximum rated platform capacity? See Capacity

Decal on Machine

Go to Step 2 Reduce Platform

Load

3124289 – JLG Lift – 2-9

Page 18

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

Table 2-5. Troubleshooting - Machine Indicates (Possible False) Platform Overload Condition -

(Drivable Vertical Lifts)

STEP ACTION SPEC YES NO

2. Perform adjustment procedures (Section 2.2, LSS - Setup And

Adjustment). Reload platform to rated capacity, is system still indicating an overload condition?

3. Check continuity between Ground Control Module - P2 connector Pins 4 and 13. Is there continuity?

4. Check continuity from Limit Switch Terminal 22 to the Ground Control Module - P2 Connector - Pin 4. Is there continuity?

5. Check continuity from Limit Switch Terminal 21 to the Ground Control Module - P2 connector - Pin 13. Is there continuity?

– Go to Step 3 Done

Replace Ground

G o t o St e p 4

Control Module

Go to Step 5 Repair or Replace

Wiring

Readjust or

Replace Limit

Repair or Replace

Wiring

Switch

2-10 – JLG Lift – 3124289

Page 19

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

Figure 2-5. LSS Wiring Diagram - (For Manually Propelled Vertical Lifts).

3124289 – JLG Lift – 2-11

Page 20

SECTION 2 - SERVICE PROCEDURES - LOAD SENSING SYSTEM

AUX #2

1

2

3

Figure 2-6. LSS Wiring Diagram - (For Drivable Vertical Lifts).

1. Wires from Platform Junction Box - Auxiliary Connector to LSS Limit Switch 3. LSS Warning Alarm

2. LSS Warning Lamp

2-12 – JLG Lift – 3124289

Page 21

SECTION 3. PARTS

TABLE OF CONTENTS

FIgure Description Page

3-1 LOAD SENSING INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3124289 – JLG Lift – 3-1

Page 22

31

41

41

4040272829

2

23

15

5

15

26

15

6

10

11

3

4

16

21

21

1A1A20

20

14

14

17

1

103

304

302

303

10915104

209

101

202

105

210

106

211

18

18

30115102

108

107

25

13

2222221919

8

8

131212

12

9

777

24

B

C

A

B

C

A

Figure 3-1. PLATFORM SUPPORT & LOAD SENSING INSTALLATION

3-2 – JLG Lift – 3124289

Page 23

.

FIGURE 3-1 PLATFORM SUPPORT & LOAD SENSING INSTALLATION

FIG & ITEM # PART NUMBER DESCRIPTION QTY. REV.

LOAD SENSING SYSTEM INSTALLATION (CE SPEC) Ref.

0273264 20AM/25AM Models Ref. C

0273265 30AM/36AM/41AM Models Ref. C

0273264 AMI Models Ref. C

0273266 DVL/DVSP/MVL/MSP Models with Bolt-on Platforms Ref. D

0273267 DVL/DVSP/MVL/MSP Models with Quick Change

Ref. D

Platforms

0273047 MP Models Ref. D

1 0273144 Arm Assembly 4

0440268 Bushing ( 2 Per Arm) 8

2 0273162 Load Sensor Controller Assembly (See Items 101-109)

1

(Note: Machine must be recalibrated when replaced)

Note: Used on all Machines except DVL/DVSP/MVL/MSP

Models.

3 0630570 Bolt, Special 1

4 Bolt 1/4-20NC x 2” Options: A/R

0641416 AM/AMI Models 4

Not Required DVL/DVSP/MVL/MSP Models with Bolt-on Platforms 0

0641416 DVL/DVSP/MVL/MSP Models with Quick Change Plat-

4

forms

Not Required MP Models 0

5 Bolt 1/4-20NC x 2 1/4” Options: A/R

0641418 AM/AMI Models 4

Not Required DVL/DVSP/MVL/MSP Models with Bolt-on Platforms 0

0641418 DVL/DVSP/MVL/MSP Models with Quick Change Plat-

4

forms

Not Required MP Models 0

6 0641620 Bolt 3/8”-16NC x 2 1/2” 2

7 0641628 Bolt 3/8”-16NC x 3 1/2” 3

8 0791610 Screw 3/8”-16NC x 1 1/4” 4

9 3300475 Nut 1

10 3311401 Nut 1/4”-20NC 1

11 3311601 Nut 3/8”-16NC 2

12 3311605 Locknut 3/8”-16NC 3

13 3311608 Nut, Flanged 3/8”-16NC 4

14 3311801 Nut 1/2”-13NC 8

15 3820032 Rivet 10

16 3900346 Bolt, Shoulder 3/8” x 3/4” 4

17 3900347 Bolt, Shoulder 3/8” x 2” 4

18 3911024 Screw #10-24NC x 1 1/2” 2

19 4160205 Spring Options: A/R

20AM/25AM Models 2

30AM/36AM/41AM Models 3

AMI Models 2

DVL/DVSP/MVL/MSP Models 3

MP Models 3

20 4740529 Thrustwasher, Bronze 8

21 4740530 Thrustwasher, Bronze 8

22 4751600 Flatwasher 3/8” Wide 6

3124289 – JLG Lift – 3-3

Page 24

FIGURE 3-1 PLATFORM SUPPORT & LOAD SENSING INSTALLATION

FIG & ITEM # PART NUMBER DESCRIPTION QTY. REV.

23 4846859 Load Sensor Weldment 1

24 4846877 Support, Spring & Switch 1

25 Load Sensing Harness Assembly Options: 1

4922923 AM/AMI/MP Models (See Items 301-304 for Breakdown)

4922924 DVL/DVSP/MVL/MSP Models (See Items 401-404 for

Breakdown)

26 4061060 Shield 2

27 0721006 Screw, Machine #10-24NC x 3/4” 1

28 3311001 Nut #10-24NC 1

29 4771000 Starwasher #10 2

30 0100019 Loctite #271 (Not Shown) A/R

31 3520072 Cap-Plug 2

32 to 39 Not Used

40 Bolt 3/8”-16NC x 3 1/4” Options: A/R

Not Required AM/AMI Models 0

0641626 DVL/DVSP/MVL/MSP Models with Bolt-on Platforms 6

Not Required DVL/DVSP/MVL/MSP Models with Quick Change Plat-

forms

0641626 MP Models 6

41 4711600 Flatwasher 3/8” Narrow (MP Models Only) 3

0

0273162 LOAD SENSOR CONTROLLER ASSEMBLY

Note: Used on all Machines except DVL/DVSP/MVL/MSP

Models.

101 0140011 Alarm, Warning 1

102 0791408 Screw 1/4”-20NC x 1” 2

103 1600357 Module, Control 1

104 1705756 Decal - Warning 1

105 2920026 Lamp, Indicator 1

106 2920029 Bulb, Light 1

107 3311408 Nut, Flanged 1/4”-20NC 2

108 3574518 Plate, Mounting 1

109 4460908 Connector, Female 12 Position 1

LOAD SENSING SYSTEM INSTALLATION (CE SPEC)

Note: Components Located on Hood.

0273266 DVL/DVSP/MVL/MSP Models with Bolt-on Platforms Ref. D

0273267 DVL/DVSP/MVL/MSP Models with Quick Change Plat-

forms

201 Not Used

202 0140011 Alarm, Warning 1

203 to 208 Not Used

209 1705756 Decal - Warning 1

210 2920026 Lamp, Indicator 1

211 2920029 Bulb, Light 1

Ref. B

Ref.

Ref. D

3-4 – JLG Lift – 3124289

Page 25

FIGURE 3-1 PLATFORM SUPPORT & LOAD SENSING INSTALLATION

FIG & ITEM # PART NUMBER DESCRIPTION QTY. REV.

4922923 LOAD SENSING HARNESS ASSEMBLY

(AM/AMI/MP MODELS)

301 4360546 Switch, Limit 1

302 4460320 Plug, Male - 2 Position 1

4460226 Socket, Female 2

4460424 Connector, Female - 2 Position 1

4460227 Pin, Male 2

303 4460909 Connector, Female - 12 Position 1

4460517 Socket, Female 8

4460466 Seal, Plug 6

4460915 Lock, Wedge 1

304 4461000 Connector, Strain Relief 1

Ref. C

4922924 LOAD SENSING HARNESS ASSEMBLIES

(DVL/DVSP/MVL/MSP MODELS) (NOT SHOWN)

401 Not Available Cable Assembly - Light/Alarm Harness (Plugs into Item 402)

(Purchase p/n 4922924)

4460424 Connector, Female - 2 Position 1

4460267 Pin, Male 2

402 Not Available Cable Assembly - Aux Output 1 to Light/Alarm Harness (Plugs

into Item 401) (Purchase p/n 4922924)

4460424 Connector, Female - 2 Position (To Aux Output 1) 1

4460226 Socket, Female 1

4460267 Pin, Male 1

4460320 Plug, Male - 2 Position (To Light/Alarm Harness) 1

4460226 Socket, Female 2

403 Not Available Cable Assembly - Tilt Plug to Platform Harness (Purchase p/n

4922924)

4460326 Plug, Male - 3 Position (To Tilt Plug) 1

4460226 Socket, Female 3

4460445 Connector, Female - 3 Position (To Platform Harness) 1

4460267 Pin, Male 3

404 Not Available Cable Assembly - Limit Switch Harness (Purchase p/n

4922924)

4460320 Plug, Male - 2 Position 1

4460226 Socket, Female 2

4360546 Switch, Limit 1

Ref. D

1

1

1

1

3124289 – JLG Lift – 3-5

Page 26

FIGURE 3-1 PLATFORM SUPPORT & LOAD SENSING INSTALLATION

FIG & ITEM # PART NUMBER DESCRIPTION QTY. REV.

3-6 – JLG Lift – 3124289

Page 27

Page 28

McConnellsburg PA. 17233-9533

3124289

JLG Worldwide Locations

Corporate Office

JLG Industries, Inc.

1 JLG Drive

USA

(717) 485-5161

(717) 485-6417

JLG Industries (Australia)

P.O. Box 5119

11 Bolwarra Road

Port Macquarie

N.S.W. 2444

Australia

+61 2 65 811111

+61 2 65 813058

JLG Deutschland GmbH

Max-Planck-Str. 21

D - 27721 Ritterhude - Ihlpohl

Germany

+49 (0)421 69 350 20

+49 (0)421 69 350 45

Plataformas Elevadoras

JLG Iberica, S.L.

Trapadella, 2

P.I. Castellbisbal Sur

08755 Castellbisbal, Barcelona

Spain

+34 93 772 4700

+34 93 771 1762

JLG Latino Americana Ltda.

Rua Eng. Carlos Stevenson,

80-Suite 71

13092-310 Campinas-SP

Brazil

+55 19 3295 0407

+55 19 3295 1025

JLG Equipment Services Ltd.

Rm 1107 Landmark North

39 Lung Sum Avenue

Sheung Shui N. T.

Hong Kong

(852) 2639 5783

(852) 2639 5797

JLG Sverige AB

Enkopingsvagen 150

Box 704

SE - 176 27 Jarfalla

Sweden

+46 (0)850 659 500

+46 (0)850 659 534

www.jlg.com

JLG Industries (UK) Ltd

Bentley House

Bentley Avenue

Middleton

Greater Manchester

M24 2GP - England

+44 (0)161 654 1000

+44 (0)161 654 1001

JLG Industries (Italia) s.r.l.

Via Po. 22

20010 Pregnana Milanese - MI

Italy

+39 029 359 5210

+39 029 359 5845

JLG France SAS

Z.I. de Baulieu

47400 Fauillet

France

+33 (0)5 53 88 31 70

+33 (0)5 53 88 31 79

Oshkosh-JLG Singapore

Technology Equipment Pte

Ltd

29 Tuas Ave 4,

Jurong Industrial Estate

Singapore, 639379

+65-6591 9030

+65-6591 9031

Loading...

Loading...