Page 1

ANSI / CSA

Operation, Safety, Service

and Maintenance Manual

Keep this manual with the machine at all times.

LiftPod Models

FS80 & FS60

1-877-254-3876 LIFTPOD by JLG

1-877-2-LIFTPOD www.liftpod.com

P/N - 1001070451

May 10, 2011

Page 2

This page intentionally left blank.

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. (JLG) reserves the right to make specification changes

without prior notification. Contact JLG for updated information.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com a

Page 4

FOREWORD

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL

WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

DECAL WILL HAVE AN ORANGE BACKGROUND.

1001070451 LIFTPOD by JLG 1-877-254-3876

b www.liftpod.com 1-877-2-LIFTPOD

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

RESULT IN SERIOUS INJURY OR DEATH. THIS

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE A

YELLOW BACKGROUND.

RESULT IN MINOR OR MODERATE INJURY. IT MAY

Page 5

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLE-

NOTICE

TINS. CONTACT JLG OR THE LOCAL AUTHORIZED JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY RELATED BULLETINS

WHICH MAY HAVE BEEN ISSUED FOR THIS PRODUCT.

JLG MUST BE NOTIFIED IMMEDIATELY IN ALL INSTANCES WHERE JLG

PRODUCTS HAVE BEEN INVOLVED IN AN ACCIDENT INVOLVING

BODILY INJURY OR DEATH OF PERSONNEL OR WHEN SUBSTANTIAL

DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG

PRODUCT.

For:

• Accident reporting

• Product safety publications

• Current owner updates

• Questions regarding

product safety

• Standards and regulations

compliance information

• Questions regarding special product applications

• Questions regarding product modifications

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13244 Fountainhead Plaza

Hagerstown, MD 21742

USA

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

Phone: 717-485-6591

E-mail: ProductSafety@JLG.com

or your local JLG office

(see addresses on manual’s rear cover)

FOREWORD

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com c

Page 6

FOREWORD

REVISION LOG

Original Issue of Manual . . . . . . . . . . . . . . . . . . . May 14, 2008

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . June 04, 2008

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . September 25, 2008

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . September 29, 2008

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . February 11, 2009

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . December 02, 2010

Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . May 10, 2011

1001070451 LIFTPOD by JLG 1-877-254-3876

d www.liftpod.com 1-877-2-LIFTPOD

Page 7

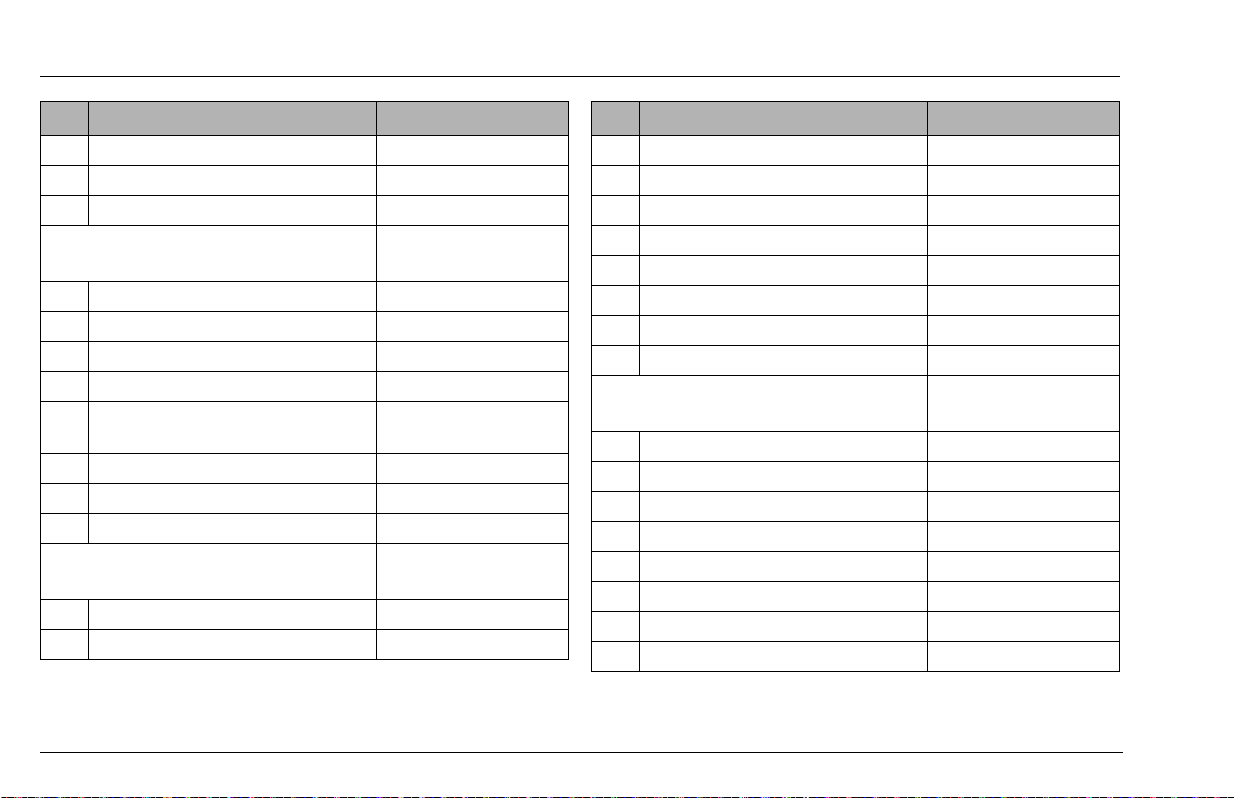

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operator Training and Knowledge . . . . . . . . . . . 1-2

Workplace Inspection . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Inspection. . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trip and Fall Hazard . . . . . . . . . . . . . . . . . . . . . . 1-4

Electrocution Hazard . . . . . . . . . . . . . . . . . . . . . 1-5

Tipping Hazards . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Crushing and Collision Hazards . . . . . . . . . . . . . 1-7

1.4 MOVING, LIFTING AND REPOSITIONING. . . . . . . 1-8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Additional Safety Information . . . . . . . . . . . . . . . 1-8

SECTION - 2 - PREPARATION AND INSPECTION

2.1 PERSONNEL TRAINING. . . . . . . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 DAILY WALK-AROUND INSPECTION . . . . . . . . . . 2-4

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com i

2.4 FUNCTION CHECK. . . . . . . . . . . . . . . . . . . . . . . . 2-10

SECTION - 3 - MACHINE OPERATION

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 MACHINE DESCRIPTION . . . . . . . . . . . . . . . . . . . . 3-1

3.3 MACHINE OPERATION. . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 POWERPACK (OPTIONAL EQUIPMENT). . . . . . . 3-11

3.5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Walk-Around Inspection Components . . . . . . . . 2-5

Tool Tray Pre-Start Inspection. . . . . . . . . . . . . . . 2-9

Function Check Items . . . . . . . . . . . . . . . . . . . . 2-10

Detailed Description . . . . . . . . . . . . . . . . . . . . . . 3-2

Platform Configuration. . . . . . . . . . . . . . . . . . . . . 3-3

Mast/Carriage Components . . . . . . . . . . . . . . . . 3-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Assembly of the Machine . . . . . . . . . . . . . . . . . . 3-5

Disassembly of the Machine . . . . . . . . . . . . . . . 3-10

Battery Charging Operation. . . . . . . . . . . . . . . . 3-11

Battery Charge Status Lights. . . . . . . . . . . . . . . 3-11

Charging the Batteries Using the Fast Charge

Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Fast Charge Indicator Light Guide . . . . . . . . . . 3-13

Power Supply Cord . . . . . . . . . . . . . . . . . . . . . . 3-13

Cordless Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Page 8

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

Powerpack Control Console (Optional

Equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Elevating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Descending . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Powerpack Emergency Stop/Shutdown Button 3-18

Unpowered Descent . . . . . . . . . . . . . . . . . . . . . 3-18

3.6 TRANSPORT AND MANEUVERING (MOVING) . . 3-19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Fully Assembled Maneuvering . . . . . . . . . . . . . 3-19

Disassembled Maneuvering . . . . . . . . . . . . . . . 3-21

Parking and Storage . . . . . . . . . . . . . . . . . . . . . 3-22

Vehicle Transport. . . . . . . . . . . . . . . . . . . . . . . . 3-22

SECTION - 4 - EMERGENCY PROCEDURES

4.1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . 4-1

Manual Descent Crank . . . . . . . . . . . . . . . . . . . . 4-1

Discharged Battery . . . . . . . . . . . . . . . . . . . . . . . 4-1

Operator Unable to Control Machine . . . . . . . . . 4-2

Platform Caught Overhead . . . . . . . . . . . . . . . . . 4-3

Rope Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . 4-5

SECTION - 5 - GENERAL SPECIFICATIONS

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 DECAL INSTALLATION. . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . 5-10

1001070451 LIFTPOD by JLG 1-877-254-3876

ii www.liftpod.com 1-877-2-LIFTPOD

SECTION - 6 - SERVICE AND MAINTENANCE

6.1 INTRODUCTION - MAINTENANCE SAFETY

6.2 MACHINE PREPARATION, INSPECTION AND

6.3 PREVENTIVE MAINTENANCE AND INSPECTION

6.4 SERVICING AND MAINTENANCE GUIDELINES . 6-8

Machine Specifications (assembled) . . . . . . . . . 5-10

Optional Powerpack Electrical Specifications . .5-11

Platform Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Interchangeable Modules. . . . . . . . . . . . . . . . . . 5-13

Machine Component Weights . . . . . . . . . . . . . . 5-14

Serial Number Locations . . . . . . . . . . . . . . . . . . 5-14

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . 6-2

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Preparation, Inspection, and Maintenance . . . . . 6-3

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . 6-3

Frequent and Pre-Delivery Inspection . . . . . . . . .6-3

Annual Machine Inspection . . . . . . . . . . . . . . . . . 6-3

5 Year Machine Inspection & Rope

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . 6-4

SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Page 9

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Safety and Workmanship . . . . . . . . . . . . . . . . . . 6-8

Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Component Disassembly and Reassembly . . . . 6-8

6.5 REPLACEMENT KITS OVERVIEW . . . . . . . . . . . . . 6-9

6.6 DECAL REPLACEMENT . . . . . . . . . . . . . . . . . . . . 6-12

6.7 MAST ROPE INSPECTION PROCEDURE . . . . . 6-13

1. Rope Wear . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

2. Rope Misaligned . . . . . . . . . . . . . . . . . . . . . . 6-13

3. Rope Loose . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

SECTION - 7 - TROUBLESHOOTING

7.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting Information . . . . . . . . . . . . . . . 7-1

SECTION - 8 - INSPECTION AND REPAIR LOG

8.1 INSPECTION AND REPAIR LOG TABLE . . . . . . . . 8-1

LIST OF FIGURES

1-1. Read your manual . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2-1. Daily Walk-Around Inspection (Sheet 1 of 2) . . . . . 2-5

2-2. Examples of cracks . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-3. Daily Walk-Around Inspection (Sheet 2 of 2) . . . . . 2-6

2-4. Examples of new, acceptable and unacceptable

ropes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com iii

2-5. Ropes retained in mast cap . . . . . . . . . . . . . . . . . . 2-7

2-6. Rope anchor points . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-7. Platform latch shown engaged . . . . . . . . . . . . . . . . 2-8

2-8. Location of manual descent crank . . . . . . . . . . . . . 2-8

2-9. Tool tray installation . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3-1. Main components . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2. Base frame component description - FS80 . . . . . . 3-2

3-3. Base frame component description - FS60 . . . . . . 3-3

3-4. Platform component description . . . . . . . . . . . . . . 3-3

3-5. Mast/carriage component description . . . . . . . . . . 3-4

3-6. Carriage/mast to base mounting . . . . . . . . . . . . . . 3-6

3-7. Castor lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-8. Detail view of level bubble . . . . . . . . . . . . . . . . . . . 3-6

3-9. Attaching the platform to the carriage . . . . . . . . . . 3-7

3-10. Platform attachment checks . . . . . . . . . . . . . . . . . . 3-7

3-11. Cordless drill installation . . . . . . . . . . . . . . . . . . . . . 3-8

3-12. Powerpack positioned and latched into place . . . . 3-9

3-13. Tool tray load restriction . . . . . . . . . . . . . . . . . . . . 3-10

3-14. Battery charging plug and tester . . . . . . . . . . . . . 3-11

3-15. Charge status lights . . . . . . . . . . . . . . . . . . . . . . . 3-11

3-16. Removing the battery from the powerpack . . . . . 3-12

3-17. Recharge dock operations and indicators . . . . . . 3-12

3-18. Typical cordless drill interface devices . . . . . . . . . 3-13

3-19. Powerpack control console . . . . . . . . . . . . . . . . . 3-14

Page 10

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

3-20. Cordless drill elevation . . . . . . . . . . . . . . . . . . . . . 3-15

3-21. Detail view of direction selector . . . . . . . . . . . . . . 3-16

3-22. Detail view of enable & speed triggers . . . . . . . . . 3-16

3-23. Emergency stop button operation . . . . . . . . . . . . 3-18

3-24. Activate the handle to extend the swivel castor . . 3-19

3-25. Maneuvering when tilted back . . . . . . . . . . . . . . . 3-20

3-26. Maneuvering FS60 through doorway . . . . . . . . . . 3-20

3-27. Mast/carriage handle . . . . . . . . . . . . . . . . . . . . . . 3-21

3-28. Moving base through a door . . . . . . . . . . . . . . . . 3-21

4-1. Manual descent crank operation from inside

platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-2. Manual descent crank operation from outside

platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3. Releasing the drive interlock using the lanyard . . . 4-3

5-1. Base Decal Installation - ANSI - FS80. . . . . . . . . . . 5-4

5-2. Base Decal Installation - ANSI - FS60. . . . . . . . . . . 5-5

5-3. Carriage/Mast Decal Installation - ANSI - FS80 . . . 5-6

5-4. Carriage/Mast Decal Installation - ANSI - FS60 . . . 5-7

5-5. Platform Decal Installation - ANSI . . . . . . . . . . . . . . 5-8

5-6. Powerpack Decal Installation - ANSI . . . . . . . . . . . 5-9

6-1. Replacement Kits . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-2. Replacement Kits for 30FS Base . . . . . . . . . . . . . 6-10

6-3. Drum view through inspection window . . . . . . . . 6-13

6-4. Rope alignment through carriage. . . . . . . . . . . . . 6-14

1001070451 LIFTPOD by JLG 1-877-254-3876

iv www.liftpod.com 1-877-2-LIFTPOD

6-5. Loose rope being re-tensioned . . . . . . . . . . . . . . .6-14

LIST OF TABLES

1-1 Minimum Approach Distances (M.A.D.) . . . . . . . . . 1-5

2-1 Inspection and Maintenance Table . . . . . . . . . . . . .2-3

5-1 Decal Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2 Machine Specifications (assembled) . . . . . . . . . . 5-10

5-3 Optional Powerpack Electrical Specifications. . . . 5-11

5-4 Platform Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

5-5 Interchangeable Modules . . . . . . . . . . . . . . . . . . . 5-13

5-6 Module Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5-7 Machine Component Weights . . . . . . . . . . . . . . . .5-14

6-1 Preventative Maintenance & Inspection Schedule .6-7

7-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

8-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . .8-2

Page 11

1.1 GENERAL

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

This section outlines the necessary precautions for proper and

safe machine usage and maintenance. For proper machine use, it

is mandatory that a daily routine is established based on the content of this manual. A maintenance program, using the information

provided in this manual must also be established by a qualified

person and must be followed to ensure that the machine is safe to

operate.

Before operation, the operator shall:

1. Read and understand the manufacturer’s (remanufacturer’s) operating instruction(s) and user’s safety rules

or have them explained.

2. Understand all labels, warnings and instructions displayed on the aerial platform or have them explained.

3. Ensure all occupants of the aerial platform wear appropriate personal protection equipment (PPE) for the conditions, including the environment in which the aerial

platform will be operated.

If there are any questions with regard to safety, training, inspection, maintenance, application, and operation, please contact JLG.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 1-1

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN THIS

MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Page 12

SECTION 1 - SAFETY PRECAUTIONS

1.2 PRE-OPERATION

Figure 1-1. Read your manual

Operator Training and Knowledge

• Do not operate this machine until complete training is performed by authorised persons.

• Only authorised and qualified personnel can operate the

machine.

• Read, understand, and obey all DANGERS, WARNINGS,

CAUTIONS, and operating instructions on the machine

and in this manual.

• Use the machine in a manner which is within the scope of

its intended application set by JLG.

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine

as specified in this manual.

• Read, understand, and obey all applicable employer,

local, and governmental regulations as they pertain to

operation of the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all hazards in the work area prior to machine operation.

• Do not operate or raise the platform while on trucks, trailers, railway cars, floating vessels, scaffolds or other equipment unless approved in writing by JLG.

• This machine can be operated in temperatures of 0°C to

40°C (32°F to 104°F). Consult JLG for operation outside

this range. Machine performance may vary from published specification in very hot or cold conditions.

Machine Inspection

• Before machine operation, perform inspections and functional checks. Refer to Section 2 of this manual for further

instructions.

• Do not operate this machine until it has been serviced and

maintained according to requirements specified in accordance with this manual.

1001070451 LIFTPOD by JLG 1-877-254-3876

1-2 www.liftpod.com 1-877-2-LIFTPOD

Page 13

SECTION 1 - SAFETY PRECAUTIONS

1.3 OPERATION

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM

SHALL BE MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE

MANUFACTURER.

• Do not operate any machine on which the safety or

instruction placards or decals are missing or illegible.

• Avoid any build up of debris on platform floor. Keep mud,

oil, grease, and other slippery substances from footwear

and platform floor.

General

• Do not use the machine for any purpose other than positioning personnel, their tools and equipment.

• Never operate a machine that is not working properly. If a

malfunction occurs, shut down the machine and contact

JLG.

• Never slam a control switch or lever through neutral to an

opposite direction. Always return switch to neutral and

stop before moving the switch to the next function. Operate controls with slow and even pressure.

• Do not allow personnel to tamper with, or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing unless

approved by JLG.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Fully lower platform and shut off all power before leaving

machine.

• No riders are permitted on the machine. Only the operator

is permitted in the machine during operation.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 1-3

Page 14

SECTION 1 - SAFETY PRECAUTIONS

• Do not allow ropes to contact surfaces with a temperature

higher than 60°C/140°F

• When performing welding, cutting or grinding operations,

avoid direct contact of heat, sparks and debris with the

ropes and carriage drive assembly.

• Charge batteries only in a well ventilated area.

This machine is a powered personnel lift equipped with a work

platform that travels up and down a mast. Vibrations emitted by

this machine is not hazardous to an operator in the work platform.

The equivalent continuous A-Weighted sound pressure level at the

work platform is less than 70dB(A).

Trip and Fall Hazard

• Do not enter or leave the platform while elevated.

MAX = 36 in (91.4cm)

• JLG recommends that the operator utilises a fall restraint

system in the platform with a maximum 36 inch (91.4cm)

lanyard attached to the authorised lanyard anchorage

point. For further information regarding fall protection

requirements on JLG products, contact JLG.

• Before operating the machine, make sure all railings and

gates are fastened in their proper position.

• Keep both feet firmly positioned on the platform floor at all

times. Never use ladders, boxes, steps, planks, or similar

items on platform to provide additional reach.

• Never use the mast assembly to enter or leave the platform.

1001070451 LIFTPOD by JLG 1-877-254-3876

1-4 www.liftpod.com 1-877-2-LIFTPOD

Page 15

SECTION 1 - SAFETY PRECAUTIONS

• Use extreme caution when entering or leaving the platform. Ensure that the mast assembly is fully lowered. Face

the machine when entering or leaving the platform.

• Always maintain "three point contact" with the machine,

using two hands and one foot or two feet and one hand at

all times during entry and exit.

Electrocution Hazard

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in

Table 1-1.

• Allow for machine movement and electrical line swaying.

Table 1-1. Minimum Approach Distances (M.A.D.)

VOLTAGE RANGE

(PHASE TO PHASE)

0-50KV 10 (3)

Over 50KV to 200KV 15 (5)

Over 200KV to 350KV 20 (6)

Over 350KV to 500KV 25 (8)

Over 500KV to 750KV 35 (11)

Over 750KV to 1000KV 45 (14)

NOTE: This requirement shall apply except where empl oyer, local, or gov-

ernmental regulations are more stringent.

• Maintain a clearance of at least 10 ft. (3m) between any

part of the machine and its occupants, their tools, and

their equipment from any electrical line or apparatus car-

MINIMUM SAFE APPROACH

DISTANCE - Feet (Meters)

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 1-5

Page 16

SECTION 1 - SAFETY PRECAUTIONS

rying up to 50,000 volts. One foot (0.3m) additional clearance is required for every additional 30,000 volts or less.

• The minimum safe approach distance may be reduced if

insulating barriers are installed to prevent contact, and if

the barriers are rated for the voltage of the line being

guarded. These barriers shall not be part of (or attached

to) the machine. The minimum safe approach distance

shall be reduced to a distance within the designed working dimensions of the insulating barrier. This determination shall be made by a qualified person in accordance

with employer, local, or governmental requirements for

work practices near energized equipment.

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED

ZONE (MAD). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE

ENERGIZED UNLESS KNOWN OTHERWISE.

Tipping Hazards

• Only elevate the platform on a firm and level surface.

• Check that the two wheels and the two adjustable feet are

in contact with the ground prior to using the machine.

Adjust the front feet to eliminate any base frame movement and check the bubble level indicates level prior to

use.

• Ensure castor wheels are locked (if equipped).

1001070451 LIFTPOD by JLG 1-877-254-3876

1-6 www.liftpod.com 1-877-2-LIFTPOD

Page 17

SECTION 1 - SAFETY PRECAUTIONS

• Do not perform work that will subject unit to a horizontal

force or create a swaying motion of the platform.

• Do not elevate in windy conditions. See Table 5-2 Machine

Specifications

• The user should be familiar with the operating surface.

• Do not elevate platform while on a slope, or on an uneven

or soft surface.

• Before using on floors, bridges, and other surfaces, check

allowable capacity of the surfaces.

• Never exceed the maximum platform capacity. Distribute

loads evenly on platform floor and tool tray.

• Keep the base of the machine a minimum of 0.6m (2 ft)

from holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards at the ground

level.

• Never attempt to use the machine as a crane. Do not tieoff machine to any adjacent structure.

• Do not increase the platform size with unauthorised extensions or attachments, increasing the area exposed to wind

will decrease stability.

• If mast assembly or platform is caught so that one or more

wheels are off the ground, the operator must be removed

before attempting to free the machine. Use cranes, forklift

trucks, or other appropriate equipment to stabilize

machine and remove personnel.

Crushing and Collision Hazards

• Appropriate personal protection equipment must be worn

by all operating and ground personnel.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 1-7

Page 18

SECTION 1 - SAFETY PRECAUTIONS

• Check work area clearances above, on sides, and bottom

of platform while moving, lifting or lowering platform.

• During operation keep all body parts inside platform railing.

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and persons in the platform.

• Ensure that operators of other overhead and floor level

machines are aware of the aerial work platform's presence. Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk under a raised

platform. Position barricades on floor as necessary.

1.4 MOVING, LIFTING AND REPOSITIONING

General

Never allow personnel in platform while moving, lifting or repositioning the machine.

This machine shall not be towed by a vehicle.

Ensure platform is fully retracted and completely empty of tools

prior to disassembly, lifting or hauling.

Remove powerpack and tool tray (if fitted) from platform when

transporting in a vehicle.

Refer to the Machine Operation section of this manual for lifting

information.

Additional Safety Information

• Do not use machine as ground for welding.

• Keep all naked flames and sharp edges away from ropes.

• Do not attempt to transport assembled machinery by forklift.

1001070451 LIFTPOD by JLG 1-877-254-3876

1-8 www.liftpod.com 1-877-2-LIFTPOD

Page 19

SECTION 2 - PREPARATION AND INSPECTION

SECTION 2. PREPARATION AND INSPECTION

2.1 Personnel Training

The aerial platform is a personnel handling device; so it is necessary that it be operated and maintained only by trained personnel.

The manual supplied with the machine is an important part of

operator training.

Persons under the influence of drugs or alcohol or who are subject

to seizures, dizziness or loss of physical control must not operate

this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and emergency controls.

2. Decals, instructions, and warnings on the machine.

3. Rules of the employer and government regulations.

4. Correct assembly of the machine.

5. Use of approved fall protection device.

6. Enough knowledge of the mechanical operation of the

machine to recognize a malfunction or potential malfunction.

7. The safest means to operate the machine where overhead obstructions, other moving equipment, and obstacles, depressions, holes, drop-offs are present.

8. Means to avoid the hazards of unprotected electrical conductors.

9. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified person

in an open area free of obstructions until the trainee has developed the ability to safely control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility

and authority to shut down the machine in case of a malfunction or

other unsafe condition of either the machine or the job site.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 2-1

Page 20

SECTION 2 - PREPARATION AND INSPECTION

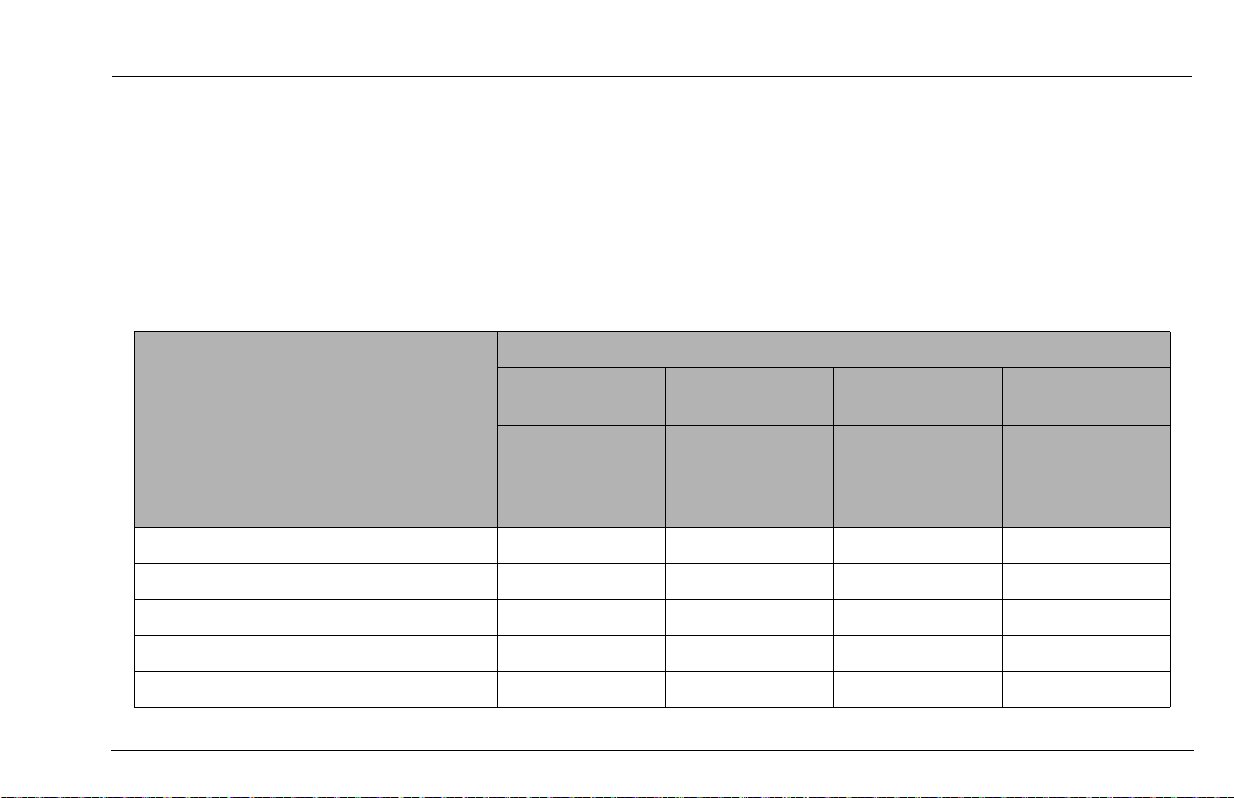

2.2 Preparation, Inspection, and Maintenance

The following table covers the periodic machine inspections and

maintenance recommended by JLG. Consult local regulations for

further requirements for aerial work platforms.

The frequency of inspections and maintenance must be increased

as necessary when the machine is used in a harsh or hostile environment, if the machine is used with increased frequency, or if the

machine is used in a severe manner.

1001070451 LIFTPOD by JLG 1-877-254-3876

2-2 www.liftpod.com 1-877-2-LIFTPOD

Page 21

SECTION 2 - PREPARATION AND INSPECTION

Table 2-1. Inspection and Maintenance Table

TYPE FREQUENCY

Pre-Star t

Inspection

Frequent

Inspection

Annual Machine

Inspection

5 Year

Replacement

NOTE: Use this manual to perform inspections.

NOTE: (*) A person who has acquired by training, qualifications, experience or a combination of these, the knowledge and skill enabling the person to

inspect and repair the machine to the level required by the complexity of the task.

Before star ting each day or at each workshift

change

In service for 3 months; out of ser vice for a

period of more than 3 months; or purchased

used.

Every 12 months Owner, Dealer or User Qualified Mechanic

W h e n r o p e i s w o r n o r n o m o r e t h a n 5 y e a r s f r o m

first use. Refer to Figure 2-4. for wear criteria.

PRIMARY

RESPONSIBILITY

Operator User or Operator Operation, Safety, Service &

Owner, Dealer or User Qualified Mechanic

Owner, Dealer or User Authorized JLG

SERVICE

QUALIFICATION

(*)

(*)

Service Centre

REFERENCE

Maintenance Manual

Operation, Safety, Service &

Maintenance Manual and

applicable JLG LiftPod

inspection form

Operation, Safety, Service &

Maintenance Manual and

applicable JLG LiftPod

inspection form

Factory Training

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 2-3

Page 22

SECTION 2 - PREPARATION AND INSPECTION

Pre-Start Inspection

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage, debris or

foreign objects.

2. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards are

missing. Make sure all illegible decals and placards are

cleaned or replaced. (Reference Section 5.2, Decal

Installation).

3. Operation, Safety Service & Maintenance Manual –

Make sure a copy of the Operation, Safety, Service &

Maintenance Manual and ANSI Manual of Responsibilities (U.S.A. only) is enclosed in the weather resistant

storage container.

4. Assembly – The machine must be fully assembled in

accordance with Section 3.3.

5. Walk-Around Inspection – Refer to Section 2.3.

6. Powerpack – Charge as required (Section 3.4).

7. Function Check – Once the Walk-Around Inspection is

complete, perform a function check of all systems in an

area free of overhead and ground level obstructions.

Refer to Section 2.4 for more specific instructions.

2.3 DAILY WALK-AROUND INSPECTION

Begin the Walk-Around Inspection at item one (1) as noted on the

diagram Figure 2-1. Continue around machine checking each item

in sequence for the conditions listed in the following check list.

TO AVOID POSSIBLE INJURY, BE SURE DIRECTION SELECTOR IS IN THE

“OFF” POSITION DURING WALK-AROUND INSPECTION.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN

CORRECTED.

NOTE: Do not overlook visual inspection of the base frame

underside. Check this area for objects, debris, corrosion

and cracks.

NOTE: The mast and carriage components should be clean and

free from oil, grease and dirt. Do not lubricate mast or carriage components, especially brake shoes.

1001070451 LIFTPOD by JLG 1-877-254-3876

2-4 www.liftpod.com 1-877-2-LIFTPOD

Page 23

SECTION 2 - PREPARATION AND INSPECTION

1

2

3

4

REAR

FRONT

(FS80 base shown)

Walk-Around Inspection Components

Figure 2-1. Daily Walk-Around Inspection

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 2-5

(Sheet 1 of 2)

NOTE: On all components, make sure there are no loose or miss-

ing parts, everything is securely fastened, no visible damage, or excessive wear exists in addition to any other

criteria mentioned.

1. Rear Wheels - Check for any debris stuck to or around wheels. Make sure bolts are fastened. Make sure castor locks operate properly (if equipped).

2. Base Frame - Check for cracks or corrosion, especially around the mast-stump base (see Figure 2-2.). Check level bubble is clean and secure.

3. Mast Assembly - No cracks or corrosion, especially

around base and flange; no excess wear, kinks, nicks or

damage; carriage running surfaces smooth and unobstructed; free of dust, oil & grease.

4. Carriage Frame - check for visible cracks; check rollers

for visible wear; check carriage frame welds for visible

cracks (see Figure 2-2.).

5. Gearbox - check for any oil leaks, especially around bottom shaft seal.

6. Swivel Castor Mechanism and Adjustable Feet Check for any debris stuck to or around wheels or

mechanism. Check adjustable feet for damage. Rubber

pads and tire must be in good order.

Page 24

SECTION 2 - PREPARATION AND INSPECTION

Parent Metal Crack

Weld Crack

5

7

9

10

8

FRONT

REAR

11

6

(FS80 base shown)

Figure 2-2. Examples of cracks

7. Rope Assembly - Check rope is not frayed or damaged

(Figure 2-4.). Ensure it is tensioned tightly and seated

properly around take-up drum (view via carriage inspection window - see Figure 6-3.). Ensure it is seated correctly over mast-cap (Figure 2-5.) and at anchor point at

back of mast (Figure 2-6.). Indications that rope needs

replacement include:

1. Frayed or fluffy rope (Figure 2-4.)

2. Braiding no longer visible

3. Sections of rope thinned down in diameter.

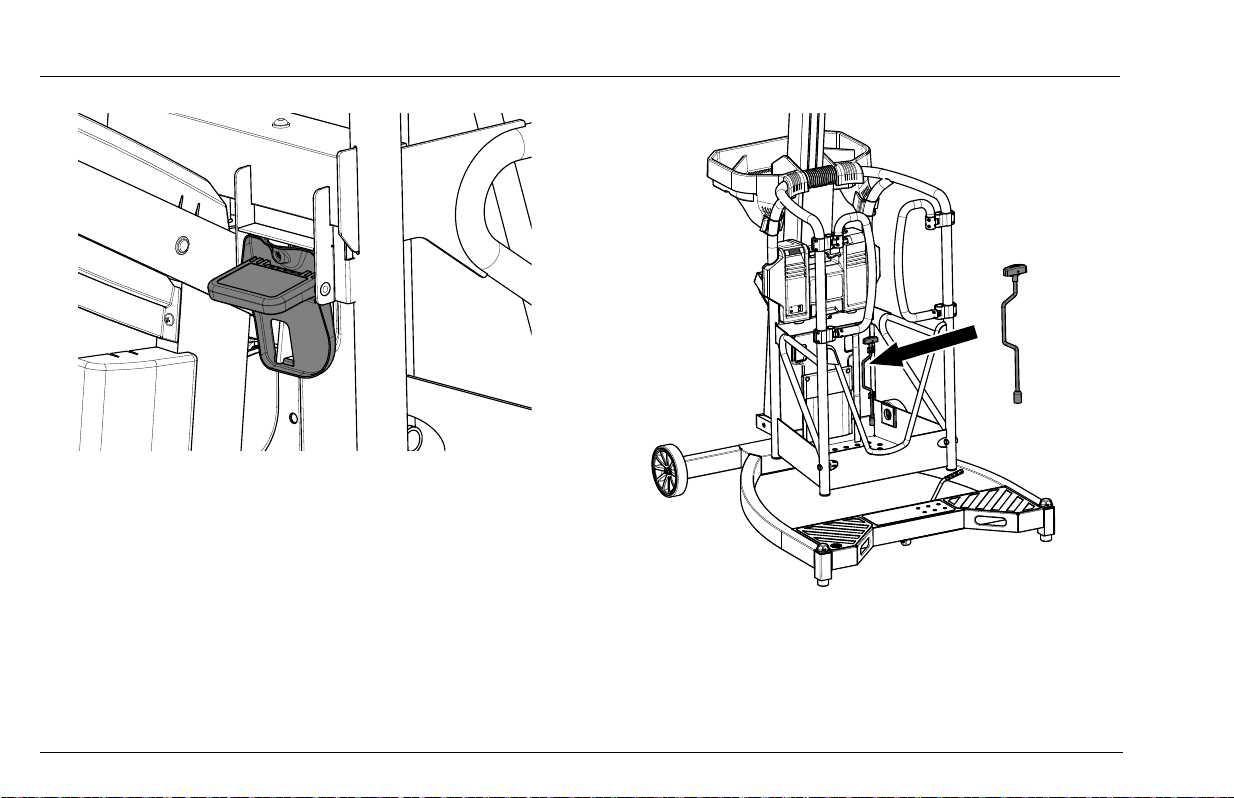

8. Manual Descent Crank - Ensure it is present and securely attached (Figure 2-8.).

9. Powerpack and Control Console (optional) - Ensure it

is properly mounted and secured. Button, triggers and

switches not obscured or damaged; decals secure and

1001070451 LIFTPOD by JLG 1-877-254-3876

2-6 www.liftpod.com 1-877-2-LIFTPOD

Figure 2-3. Daily Walk-Around Inspection

(Sheet 2 of 2)

Page 25

Check both ropes

are retained in

groove in cap

Mast

Mast Cap

Check that each termination is

engaged under its anchor point

by viewing through the cover.

The two upper rope tails

should be slack.

The lower rope loop should

be tight around anchor.

Top of

Mast

SECTION 2 - PREPARATION AND INSPECTION

legible; emergency stop switch reset for operation; control markings legible. Battery is installed and secure.

10. Platform Assembly and Gate - Check mounting pins are not loose; platform railing is undamaged; platform latch is engaged on carriage (Figure 2-7.); self-closing entry gates are in proper working order; no cracks or corrosion visible.

11. Tool Tray - See next page for Tool Tray Pre-Start Inspection Procedure.

Figure 2-4. Examples of new, acceptable and

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 2-7

unacceptable ropes

Figure 2-5. Ropes retained in mast cap

Figure 2-6. Rope anchor points

Page 26

SECTION 2 - PREPARATION AND INSPECTION

Figure 2-7. Platform latch shown engaged

Figure 2-8. Location of manual descent crank

1001070451 LIFTPOD by JLG 1-877-254-3876

2-8 www.liftpod.com 1-877-2-LIFTPOD

Page 27

Tool Tray Pre-Start Inspection

Prior to use of the tool tray, check the following:

• Tool tray is seated securely on the platform rail.

• No cracks or bends in tray.

• Both of the clips are securely attached to the platform rail

(Figure 2-9.).

• Capacity decal is in place and legible.

Maximum Load: The maximum permissible load on the tool tray

is 15kg (33 lb.) evenly distributed.

SECTION 2 - PREPARATION AND INSPECTION

Figure 2-9. Tool tray installation

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 2-9

Page 28

SECTION 2 - PREPARATION AND INSPECTION

2.4 FUNCTION CHECK

Once the Walk-Around inspection is complete, perform a function

check of all systems in an area free of overhead and ground level

obstructions.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF THE

MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE PROPER

MAINTENANCE PERSONNEL. DO NOT OPERATE THE MACHINE UNTIL IT

IS DEEMED SAFE FOR OPERATION.

Function Check Items

1. Base Brake - Step on base to ensure the swivel castor retracts properly.

2. Adjustable Feet - Check both rotate freely up and down; check that rubber pads are installed and not excessively worn.

3. Emergency Stop Button (optional powerpack) - ensure all machine functions are disabled when the emergency stop button is activated (pressed in) - then RESET the emergency stop button by twisting it in the direction indicated by the arrows.

TO AVOID COLLISION AND INJURY IF PLATFORM DOES NOT STOP

WHEN A CONTROL IS RELEASED, USE THE EMERGENCY STOP BUTTON

TO STOP THE MACHINE.

1001070451 LIFTPOD by JLG 1-877-254-3876

2-10 www.liftpod.com 1-877-2-LIFTPOD

Page 29

SECTION 3 - MACHINE OPERATION

1

2

3

6

5

7

4

SECTION 3. MACHINE OPERATION

3.1 GENERAL

NOTE: The manufacturer has no direct control over machine

application and operation. The user and operator are

responsible for conforming with good safety practices.

This section provides the necessary information needed to understand control function and operation.

3.2 MACHINE DESCRIPTION

The JLG LiftPod is a battery powered aerial work platform. The

platform is mounted to a mast and elevating carriage mechanism.

The personnel lift's intended purpose is to provide personnel

access to areas above level ground. The platform must only be

elevated on a firm, level, uniform surface.

The machine consists of seven parts:

1. Base Frame (FS80 base shown)

2. Carriage/Mast Assembly

3. Platform

4. Powerpack (optional)

5. Spare Battery (optional)

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-1

Figure 3-1. Main components

6. Charger (optional)

7. Tool Tray (optional)

Page 30

SECTION 3 - MACHINE OPERATION

Fixed Wheel

Adjustable Foot

Self Retracting Swivel Castor

Adjustable Foot

Fixed Wheel

Carriage Rests

Mast Stump

Level Bubble

Retracting Castor

Release Lever

FRONT

(travel stops)

Step Plate

The primary control console is located within the removable and

rechargeable powerpack.

The powerpack is attached to the machine within the platform.

With the installed powerpack, the operator can raise or lower the

platform through its controls.

The machine has a self retracting swivel castor mounted under the

front of the base which retracts out of ground contact when

loaded.

The base of the FS80 machine consists of two fixed wheels and

two adjustable feet, for leveling and stabilizing the base within 2

degrees of level from front and back only. Prior to operation the

adjustable feet are to be engaged to a point where the base is

level as seen on the level bubble (Figure 3-8.).

The base of the FS60 machine consists of two rotating castors

and two adjustable feet. Prior to operation the adjustable feet are

to be engaged to a point where the base is level as seen on the

bubble level. Also, the castor wheels must be locked prior to operation.

Detailed Description

Figure 3-2. Base frame component description - FS80

1001070451 LIFTPOD by JLG 1-877-254-3876

3-2 www.liftpod.com 1-877-2-LIFTPOD

Page 31

SECTION 3 - MACHINE OPERATION

Rotating castor

Adjustable Foot

Self Retracting Swivel Castor

Adjustable Foot

Carriage Rests

Mast Stump

Level Bubble

Retracting Castor

Release Lever

FRONT

(travel stops)

Step Plate

Rotating castor

Platform Swing Gates

Mounting Pin

Authorized Lanyard Anchorage Point

Platform Locator

Platform Latch

Mounting Pin

Powerpack Mounts

Powerpack Latch Mount

Manual Storage

Compartment (other side)

Platform Configuration

Figure 3-3. Base frame component description - FS60

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-3

Figure 3-4. Platform component description

Page 32

SECTION 3 - MACHINE OPERATION

Mast Cap

Carriage Frame

Gearbox

Carry Handle

Drum Inspection

Rope Anchor (at back)

Driveshaft

Lifting Ropes

Window

Platform Mounting

Pin Holes

Mast

(orange)

Lower Facing Shaft Stub

Mast/Carriage Components

Figure 3-5. Mast/carriage component description

3.3 MACHINE OPERATION

General

When the platform reaches the bottom of its travel, the rest position, the drive mechanism overrunning clutch creates a ratcheting,

or buzzing noise, indicating that the machine has reached the fully

lowered position.

The machine is fitted with an emergency brake which activates

when the tension in the lifting ropes goes below 40kg (88 lbs).

When the platform is lowered to the rest position, the emergency brake swings into position, stopping further rotation of

the rope drum and engaging a carriage lock-down latch onto

the mast.

IN THE EVENT THAT THE CARRIAGE LATCHES TO THE MAST WHEN

FULLY LOADED OR THE ROPE CONTINUES TO FEED OUT AFTER THE

PLATFORM HAS REACHED THE REST POSITION, THE MACHINE IS NOT

WORKING PROPERLY AND MUST NOT BE USED UNTIL IT IS INSPECTED

AND REPAIRED BY A QUALIFIED PERSON.

NOTE: Do not attempt to lift the mast off the base unless the car-

riage has been fully lowered.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-4 www.liftpod.com 1-877-2-LIFTPOD

Page 33

SECTION 3 - MACHINE OPERATION

Getting Started

The following control conditions must be met before the machine

can be operated from the platform controls:

• Batteries must contain enough voltage to operate. Low

battery warning on battery test panel indicates the need to

charge the batteries. Batteries should be charged for 24

hours prior to first use.

• Emergency stop switch on optional powerpack must be in

the RESET position (out).

• Both platform swing-in entry gates must be closed.

Assembly of the Machine

The JLG LiftPod is a user assembled machine. There are three

basic parts that need to be assembled for operation. These parts

are the Base Frame 1, Carriage/Mast Assembly 2, and the Platform 3. Optional parts include the Powerpack 4, and the Tool Tray

5 (Figure 3-1.).

DO NOT ATTEMPT TO ASSEMBLE OR USE A MAST ONTO A BASE FOR

WHICH IT IS NOT INTENDED. EACH MAST HAS A "V" SHAPED GROOVE

ALONG ITS LENGTH, WHICH WILL FIT WITHIN THE GROOVE ON A BASE

STUMP FOR WHICH IT IS INTENDED. ALWAYS CHECK THE MAST IS

FULLY INSERTED ONTO THE BASE STUMP PRIOR TO OPERATION.

1. Position the base frame on a firm, level, uniform, supporting surface.

2. Push down on the base frame’s step plate until the swivel castor retracts and the base sits on the adjustable feet (Figure 3-6.). The machine now rests on the two rear wheels, and the two adjustable feet at the front.

3. For the FS60 machine’s base (the 30FS base module), lock the castor wheels (Figure 3-7.).

CRUSH HAZARD - KEEP FEET CLEAR OF ADJUSTABLE FEET AND

UNDERNEATH BASE WHEN STEPPING ON BASE TO RETRACT CASTOR.

4. Turn the adjustable feet until the level bubble is centred (see Figure 3-8.)

DO NOT USE THE MACHINE IF THE BASE CAN NOT BE LEVELLED.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-5

Page 34

SECTION 3 - MACHINE OPERATION

PUSH DOWN

Adjustable Foot

Adjustable Foot

PUSH DOWN

Locking Tab

Level Bubble

Rotating Knob

adjusts foot height

Figure 3-6. Carriage/mast to base mounting

Figure 3-7. Castor lock

Figure 3-8. Detail view of level bubble

1001070451 LIFTPOD by JLG 1-877-254-3876

3-6 www.liftpod.com 1-877-2-LIFTPOD

Page 35

Fully Engaged

(C)

(B)

(A)

SECTION 3 - MACHINE OPERATION

5. Slide the carriage/mast assembly onto the mast stump.

Make sure it is properly aligned and fully engaged.

Never force it into position (see Figure 3-6.).

Figure 3-10. Platform attachment checks

•Ensure the platform locator (B) is properly

Figure 3-9. Attaching the platform to the carriage

6. Attach the platform to the carriage (see Figure 3-9.).

• Make sure the platform’s mounting pins are

aligned with the holes in the carriage (A), then

drop slowly down to seat properly.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-7

engaged in the bottom of the carriage frame.

• Make sure the platform latch (C) is fully

engaged. CHECK: Try to lift the platform out,

if it does not release, then the platform has

engaged properly.

Page 36

SECTION 3 - MACHINE OPERATION

Driveshaft

Drive Socket

Lanyard

Cordless Drill

(optional)

Manual Pouch

NOTE: When reversing the procedure to disassemble the

machine, pull the platform latch handle (C) to disengage

the platform from the carriage.

7. Fasten lanyard securely around the handle of the cordless drill. Attach the cordless drill to the top of the driveshaft, either using the supplied 7/16 (11mm) deep well

drive socket (located in manual pouch), or by tightening

the drill chuck directly to the hexagon on top of the

driveshaft (see Figure 3-11.).

CORDLESS DRILL LANYARD MUST BE INSTALLED BEFORE ELEVATING.

DO NOT DROP DRILL.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-8 www.liftpod.com 1-877-2-LIFTPOD

Figure 3-11. Cordless drill installation

Page 37

SECTION 3 - MACHINE OPERATION

8. Place the powerpack (optional equipment) against the

platform uprights, closest to the mast, and slide it down

until it clicks, indicating it is fully seated (see Figure 3-

12.).

Figure 3-12. Powerpack positioned and latched into

place

NOTE: When reversing the procedure to disassemble the

machine, pull the powerpack release latch (see Figure 3-

19.) while lifting to disengage the powerpack from the

platform.

9. Tool tray: (optional equipment) Place on top rail of platform, and fasten the two clips firmly around the rail (see Figure 2-9.).

THE WEIGHT OF OBJECTS CARRIED IN A PLATFORM ACCESSORY,

ALONG WITH PERSONNEL AND EQUIPMENT PLACED IN THE PLATFORM

MUST NOT EXCEED THE MAXIMUM RATED PLATFORM CAPACITY. SEE

TABLE 5-4.

DO NOT PLACE ITEMS IN THE TOOL TRAY IN THE INDICATED AREA

WHEN MAST IS BELOW THE TOOL TRAY’S TOP SURFACE (SEE FIGURE

3-13.).

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-9

Page 38

SECTION 3 - MACHINE OPERATION

NO-LOAD AREA

Figure 3-13. Tool tray load restriction

Disassembly of the Machine

Reverse the above steps to disassemble the machine.

DO NOT ATTEMPT TO LIFT THE MAST OFF THE BASE UNLESS THE CARRIAGE HAS BEEN FULLY LOWERED.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-10 www.liftpod.com 1-877-2-LIFTPOD

Page 39

3.4 Powerpack (Optional Equipment)

Charge Status Test Button

Charge Status Lights

3 green lights - Battery

is fully charged.

2 green lights - Battery

needs recharging/

replacing soon.

1 green light - Battery

needs recharging/

replacing as soon as

possible.

Battery Charging Operation

DO NOT SHORT CIRCUIT THE BATTERY. DO NOT OPEN THE BATTERY

PACK AS THERE IS A DANGER OF CAUSING A SHORT CIRCUIT.

PROTECT THE BATTERY AGAINST HEAT, INCLUDING AGAINST CONTINUOUS DIRECT SUN EXPOSURE OR OPEN FLAME.

SECTION 3 - MACHINE OPERATION

New batteries and batteries that have not been used for a long

period must be fully charged. They will not reach their full capacity

until fully charged and discharged through several cycles. Battery

performance will be limited at low temperatures. The battery can

be charged and discharged hundreds of times but will eventually

wear out and need to be replaced.

ing period after charging indicates that the battery must be

replaced.

A significantly reduced operat-

Figure 3-14. Battery charging plug and tester

Battery Charge Status Lights

The powerpack batteries indicates battery low voltage at three (3)

warning levels.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-11

Figure 3-15. Charge status lights

Page 40

SECTION 3 - MACHINE OPERATION

Pull and lift battery

release latch to

disengage battery

from powerpack

Fault Indicator (RED)

Charge Indicator (GREEN)

Battery

Battery Release

Recharging Dock

Charging the Batteries Using the Fast Charge Station

NOTE: USE ONLY THE SUPPLIED CHARGING STATION.

1. Remove battery from powerpack (Figure 3-16.).

2. Place battery into recharging dock.

Figure 3-17. Recharge dock operations and indicators

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, CAREFULLY FOLLOW THESE INSTRUCTIONS.

Figure 3-16. Removing the battery from the powerpack

3. Plug recharge dock into AC voltage wall outlet.

4. Once the green LED has stopped flashing, the power-

pack is fully charged.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-12 www.liftpod.com 1-877-2-LIFTPOD

If the shape of the plug does not fit the power outlet, use an

attachment plug adaptor of the proper configuration for the power

outlet.

Unless the battery is being charged, always remove the battery

from the fast charger.

Always charge the battery for 12hrs for first charge. Batteries will

take several full charge/discharge cycles before they reach their

peak performance.

Page 41

SECTION 3 - MACHINE OPERATION

7

3

2

8

5

6

1

4

Fast Charge Indicator Light Guide

SOLID GREEN: Insert battery or remove fully charged battery

FLASHING GREEN: Battery is charging.

SOLID RED: Charging is temporarily halted to allow battery to

cool down. Charging will continue automatically.

FLASHING RED: Please reinsert battery. If the red light continues

to flash, the battery or the charger may be faulty.

To troubleshoot whether the battery or the charger is at fault, insert

another battery. If this battery charges, the other battery is faulty

and must not be used. If the red light continues to flash, the

charger is faulty.

3.5 Operation

Cordless Drill

Power Supply Cord

Below is the specification of the power supply chord to be used

with the fast charger within the U.S.A.

Use UL listed detachable power supply cord - No. 18 AWG, two

conductors, VW-1, 221°F (105°C), 125V, Type:SPT-2, minimum 5 ft.

11 in. (1.8m), maximum 9 ft. 10 in. (3m) long. Provided with a

molded-on, polarized attachment plug with a 15A, 125V (NEMA 115P) configuration and a molded-on connector which mates with

the power inlet.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-13

Figure 3-18. Typical cordless drill interface devices

1. Drive Socket (optional)

2. Chuck

3. Torque Control (optional)

4. Power Trigger

5. Speed Controller (optional)

6. Drill/Hammer Function Selector (optional)

Page 42

SECTION 3 - MACHINE OPERATION

1

2

3

4

5

6

7

7. Direction Selector

8. Battery Pack

Please follow the manufacturer’s instructions on safe operation

and maintenance of the cordless drill.

JLG recommends a cordless drill of at least 18V capacity.

Ensure cordless drill’s optional "Hammer" setting is disabled and

cordless drill is in "Drill" mode on medium to high torque. Do not

set to maximum torque setting.

USE ONLY CORDLESS DRILLS. DISCONTINUE USE OF THE CORDLESS

DRILL IF A FAULT IS DETECTED. ENSURE CORDLESS DRILL IS IN

"DRILL" MODE ON MEDUIM TO HIGH TORQUE SETTING, BUT NOT MAXIMUM TORQUE SETTING TO AVOID INJURY.

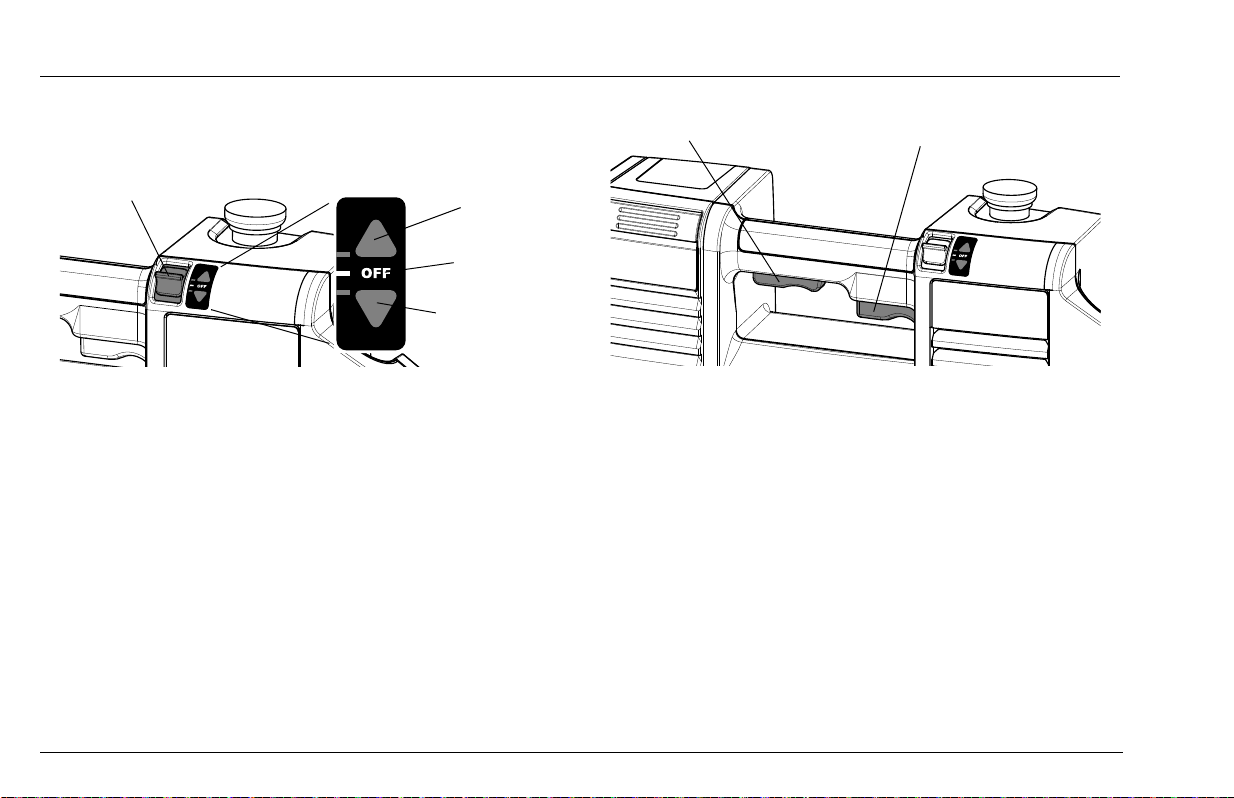

Powerpack Control Console (Optional Equipment)

Figure 3-19. Powerpack control console

1. Enable Trigger

2. Battery Release Latch

3. Battery Trickle Charge Plug

4. Emergency Stop Button

5. Direction Selector

6. Speed Trigger

7. Powerpack Release Latch

1001070451 LIFTPOD by JLG 1-877-254-3876

3-14 www.liftpod.com 1-877-2-LIFTPOD

Page 43

SECTION 3 - MACHINE OPERATION

NOTICE

NOTICE

The powerpack is splash resistant allowing a safe descent if it

starts to rain while the unit is elevated, but JLG does not recommend that the powerpack be used in rain or exposed to water.

Whenever the machine is not in use, set the direction selector to

the OFF position.

DISCONTINUE USE OF THE POWERPACK IF A FAULT IS DETECTED.

DO NOT PRESSURE-WASH THE POWERPACK.

MAKE SURE YOU CHECK THE REMAINING CHARGE INSIDE THE POWERPACK’S BATTERY BEFORE ELEVATING THE PLATFORM BY PRESSING

THE CHARGE INDICATOR TEST BUTTON. IF ONLY ONE LIGHT COMES

ON, REPLACE WITH FULLY CHARGED BATTERY.

IF THE POWERPACK DOES NOT ACTIVATE WITH A CHARGED BATTERY

INSTALLED, THE EMERGENCY BUTTON MAY NEED TO BE RESET

(TWIST IN DIRECTION OF ARROWS AND POP OUT).

Elevating

Make sure the pre-start inspection has been completed, the

machine is safe to use, and the base is level.

Move the cordless drill’s direction selector to the "screw-in" (clockwise) direction.

Hold the drill’s handle firmly, push it down to automatically disengage the driveshaft interlock, and squeeze the trigger to elevate.

Stop using the cordless drill if any part of it becomes excessively

hot. Wait until drill has cooled down and then continue operation.

Figure 3-20. Cordless drill elevation

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-15

Page 44

SECTION 3 - MACHINE OPERATION

Direction Selector

UP Position

DOWN Position

OFF Position

Enable Trigger

Speed Trigger

If using the optional powerpack instead of a cordless drill, move

the direction selector switch to the UP position (Figure 3-21.).

Figure 3-21. Detail view of direction selector

Hold the handle so the enable trigger is pressed and squeeze the

speed trigger. The function speed is proportional to how far the

speed trigger is pressed.

To stop, simply release the speed trigger. A slow release makes

the platform come to a smooth stop.

Most cordless drills and the motor in the powerpack are fitted with

thermal overload protection. In case of overheating, this cuts

power to the motor. The cutout automatically resets itself when the

motor has cooled down, allowing normal operation to resume.

Depending on ambient temperature this can take 5 to 30 minutes.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-16 www.liftpod.com 1-877-2-LIFTPOD

Figure 3-22. Detail view of enable & speed triggers

Engaging the triggers to run the cooling fan will decrease the thermal reset time.

The manual descent procedure (Section 4.1) can be used to lower

the platform if required.

• Do not attempt to elevate with no load in the platform.

• The platform has a total capacity of 150kg (330 lb.).

• The machine is not intended for use by children.

• Children must be supervised to ensure they do not use or

play with the machine.

Page 45

SECTION 3 - MACHINE OPERATION

•Only one person is allowed to be lifted by the platform.

Descending

CRUSHING HAZARD - BE AWARE OF DESCENDING PLATFORM WHEN

LOWERING THE PLATFORM. KEEP HANDS OR FEET OFF THE MAST

ASSEMBLY AND FROM BENEATH PLATFORM.

On the cordless drill, move the direction selector to the "unscrew"

(anti-clockwise) direction. Push the cordless drill down to disengage the driveshaft interlock and squeeze the trigger to descend.

If using the optional powerpack, move the direction selector to the

DOWN position. Hold the handle so the enable trigger is pressed

and squeeze the speed trigger.

To stop at anytime, simply release the speed trigger.

To exit the platform, ensure the platform is all the way down until it

touches-down on the base. This will engage the drive mecha-

nism’s overdrive ratchet, making a ratcheting sound. This means

the platform has reached its lowest position and the trigger should

be released.

NOTE: Before transporting, maneuvering or disassembling

machine, ensure the platform is all the way down. The

carriage lock is engaged automatically when the platform

is fully lowered and all load is removed.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-17

Page 46

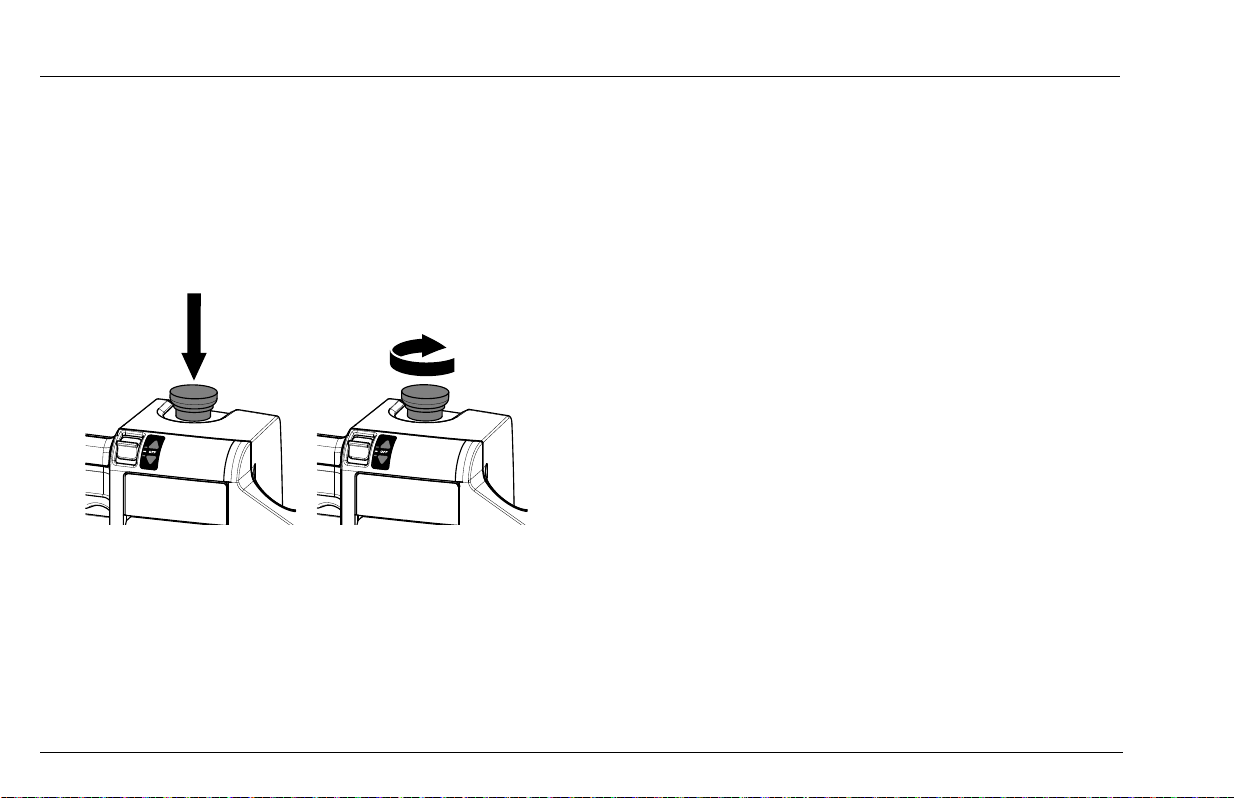

SECTION 3 - MACHINE OPERATION

Press down to activate

Rotate clockwise

Emergency Stop

to release/reset

Emergency Stop

Powerpack Emergency Stop/Shutdown Button

If the platform stops responding to operator input at any time while

the platform is moving, use the emergency stop button to cut the

power to the motor.

Figure 3-23. Emergency stop button operation

Unpowered Descent

The platform manual descent crank (Figure 2-8.) is provided to:

• Allow the platform operator to lower the platform in the

event that the cordless drill or powerpack batteries run out

of sufficient charge to lower the platform;

• Allow ground personnel to lower the platform in event that

the platform operator becomes incapacitated.

For emergency operation please see Section 4 - Emergency Procedures.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-18 www.liftpod.com 1-877-2-LIFTPOD

Page 47

SECTION 3 - MACHINE OPERATION

3.6 TRANSPORT AND MANEUVERING (MOVING)

General

The machine may be manually maneuvered or transported in a

vehicle disassembled.

DO NOT ATTEMPT TO TRANSPORT OR MOVE MACHINE UNLESS THE

CARRIAGE IS FULLY DOWN AND THE CARRIAGE TO MAST LOCK IS

ENGAGED. DO NOT MOVE MACHINE WITH PERSONNEL IN PLATFORM.

WHEN TRANSPORTING THE MACHINE, ENSURE THE ROPES ARE PROTECTED AND NOT DAMAGED.

The machine may be moved around a worksite using the following

methods:

• Fully assembled, pushed around the floor using the

wheels and castor;

• Fully assembled, tilted over.

• Disassembled, with each major component carried separately.

Fully Assembled Maneuvering

There are two ways to move the assembled machine:

PUSHED UPRIGHT

The machine can be pushed around using the built-in wheels and

castor. The floor is required to be smooth, level, clean and dry.

There can be no significant load on the machine while it is being

rolled around, or the swivel castor will retract automatically.

Figure 3-24. Activate the handle to extend the swivel

castor

Lift the handle to engage the swivel castor.

The machine is easily positioned as required.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-19

Page 48

SECTION 3 - MACHINE OPERATION

The swivel castor underneath the step plate toggles out of the way

when loaded, and the machine rests securely on the rear wheels

and two adjustable feet.

PUSHED TILTED OVER

The machine can be tilted over and maneuvered as shown in

Figure 3-25.

Figure 3-25. Maneuvering when tilted back

Figure 3-26. Maneuvering FS60 through doorway

NOTE: Ensure powerpack and tool tray are securely attached

and tool tray and platform are empty before moving.

FULLY ASSEMBLED THROUGH DOORWAY

The FS60 can be tilted back and pushed through a doorway as

shown in Figure 3-26.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-20 www.liftpod.com 1-877-2-LIFTPOD

Page 49

ONLY ATTEMPT TO TILT THE UNIT BACK, OR RETURN TILTED UNIT TO

THE UPRIGHT POSITION, ON A FLAT AND LEVEL SURFACE, CLEAR OF

ANY PERSONNEL. ENSURE A FIRM GRIP WITH TWO HANDS ON THE

MAST, AND ENSURE WEIGHT IS DISTRIBUTED TO AVOID THE USER OR

THE MACHINE BEING THROWN BY THE MOVING WEIGHT OF THE

MACHINE.

Disassembled Maneuvering

The machine is designed to be used and assembled by a single

operator. To improve portability, it is divided into a number of self

contained sub-assemblies (see Figure 3-1.).

TAKE PRECAUTIONS TO AVOID MANUAL HANDLING INJURIES. USE

PROPER LIFTING TECHNIQUES: BEND AT KNEES ONLY, NEVER TWIST

YOUR BACK WHEN HOLDING OR CARRYING A LOAD, AND/OR GET HELP.

ONLY CARRY ONE COMPONENT AT A TIME.

The mast/carriage assembly can be carried by the built-in handle

(see Figure 3-27.).

The base frame can be moved by the mast stump and the frame to

fit through doorways sideways (see Figure 3-28.).

SECTION 3 - MACHINE OPERATION

Figure 3-27. Mast/carriage handle

Figure 3-28. Moving base through a door

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 3-21

Page 50

SECTION 3 - MACHINE OPERATION

NOTICE

NOTICE

Parking and Storage

• Move machine to a dry, well-protected and well-ventilated

area out of direct sunlight.

• Ensure the platform is fully lowered. If installed, move the

powerpack’s direction control switch to the OFF position.

• If necessary, remove the cordless drill or optional powerpack from the platform to prevent unauthorized use.

• Ensure the swivel castor is retracted and the machine is

resting on the adjustable feet.

DO NOT STORE IN LOCATIONS WHERE THE MACHINE MAY ACCUMULATE ICE, GREASE OR AIRBOURNE DEBRIS.

Vehicle Transport

When transporting the machine by vehicle, it should be disassembled into its major components (see Figure 3-1.) and each component secured separately. Restrain each component of the machine

securely during transport. Ensure the swivel castor is retracted in

the base frame and the base frame is resting on the adjustable

feet.

USE OF EXCESSIVE FORCE WHEN SECURING MACHINE CAN CAUSE

DAMAGE TO THE MACHINE.

Secure machine to the transport vehicle with adequately rated

rope or straps. Do not overtension such devices and place a

buffer between the device and any part of the machine.

1001070451 LIFTPOD by JLG 1-877-254-3876

3-22 www.liftpod.com 1-877-2-LIFTPOD

Page 51

SECTION 4 - EMERGENCY PROCEDURES

NOTICE

SECTION 4. EMERGENCY PROCEDURES

4.1 GENERAL INFORMATION

This section explains the steps to be taken in case of an emergency situation during operation.

Manual Descent Crank

The platform manual descent crank is provided to:

• Allow the platform operator to lower the platform in the

event that the cordless drill or powerpack batteries run out

of sufficient charge to lower the platform;

• Allow ground personnel to lower the platform in the event

that the platform operator cannot lower the platform once

elevated.

THE CRANK IS DESIGNED FOR DESCENT IN CASE OF LOSS OF POWER

ONLY. IT MUST NOT BE USED TO ELEVATE THE PLATFORM OR FOR

GENERAL OPERATIONS.

IF THE BATTERIES ARE DISCHARGED WHILE THE UNIT IS ELEVATED,

DO NOT CLIMB OUT OF THE PLATFORM. USE THE MANUAL DESCENT

CRANK.

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 4-1

Discharged Battery

If the battery should run out of charge before the platform has fully

descended:

1. Remove the cordless drill and place it inside the platform. If the optional powerpack is installed, remove it

and place it sideways against the back panel in the platform (see Figure 4-1.).

2. Remove the manual descent crank from the mounting clips inside the platform.

3. Engage the hexagon at the top of the driveshaft with the socket end of the manual crank.

4. Push down on top of the handle to disengage the driveshaft lock and wind anti clockwise until the platform

comes to rest against the stops on the base.

Page 52

SECTION 4 - EMERGENCY PROCEDURES

Shaft Stub

Figure 4-1. Manual descent crank operation from

inside platform

Operator Unable to Control Machine

If the platform operator is pinned, trapped or unable to operate or

control the machine other personnel should operate the machine

from ground using the manual descent crank on the lower facing

shaft stub.

Figure 4-2. Manual descent crank operation from

outside platform

1001070451 LIFTPOD by JLG 1-877-254-3876

4-2 www.liftpod.com 1-877-2-LIFTPOD

Page 53

NOTICE

IF THE OPTIONAL POWERPACK IS NOT INSTALLED, USE THE LANYARD

IN THE PLATFORM TO SECURE THE DRIVESHAFT IN A DEPRESSED

(PUSHED-IN) POSITION, RELEASING THE DRIVE INTERLOCK. WHEN

USING THE LANYARD, THE MANUAL DESCENT CRANK SHOULD BE

USED TO LOWER THE PLATFORM AS SHOWN IN FIGURE 4-2.

DO NOT ACTIVATE THE POWERPACK WHILE THE MANUAL DESCENT

CRANK IS ATTACHED.

Platform Caught Overhead

If the platform becomes jammed or snagged in overhead structures or equipment, rescue the platform occupant prior to freeing

the machine.

Rescue equipment can be used to remove the platform occupant.

Cranes and forklifts can be used to stabilize motion of the

machine.

SECTION 4 - EMERGENCY PROCEDURES

Figure 4-3. Releasing the drive interlock using the

lanyard

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 4-3

Page 54

SECTION 4 - EMERGENCY PROCEDURES

Rope Failure

The carriage and platform are elevated by two ropes.

Single Rope Failure

If one of the ropes fails while the platform is elevated, the other

rope will allow safe descent.

Upon failure of one of the ropes, immediately lower the platform.

Inform other personnel that the machine is out of service. Disassemble and clearly label the machine as being out of service. Contact your nearest Authorized JLG Service Center to arrange rope

replacement.

DO NOT ELEVATE PLATFORM WHEN IT IS ONLY SUPPORTED BY A SINGLE ROPE.

ROPE REPLACEMENT SHALL ONLY BE CARRIED OUT BY AN AUTHORIZED JLG SERVICE CENTER.

Double Rope Failure

If both ropes fail while the platform is elevated, the emergency

brake will activate automatically, locking the carriage to the mast.

In this condition the manual descent crank cannot be used to

lower the platform.

Operator elevated in Platform - Platform will not lower

If the operator cannot lower the platform to the support surface

call for help. The operator should then be safely removed from the

platform using suitable equipment.

DO NOT CLIMB OUT OF THE PLATFORM WHILE ELEVATED. THIS MAY

AFFECT THE MACHINE'S BALANCE, CAUSING IT TO TIP OVER. ONLY

EXIT THE PLATFORM VIA THE PLATFORM GATES. DO NOT ATTEMPT TO

CLIMB DOWN MAST.

1001070451 LIFTPOD by JLG 1-877-254-3876

4-4 www.liftpod.com 1-877-2-LIFTPOD

Page 55

4.2 INCIDENT NOTIFICATION

NOTICE

JLG Industries, Inc. must be notified immediately of any incident

involving a JLG product. Even if no injury or property damage is

evident, the factory should be contacted by telephone and provided with all necessary details.

Product Safety and Reliability Department

JLG Industries, Inc.

13244 Fountainhead Plaza

Hagerstown, MD 21742

USA

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

Phone: 717-485-6591

E-mail: ProductSafety@JLG.com

Failure to notify the manufacturer of an incident involving a JLG

Liftpod product within 48 hours of such an occurrence may void

any warranty consideration on that particular machine.

FOLLOWING ANY ACCIDENT, THOROUGHLY INSPECT THE MACHINE

AND TEST ALL FUNCTIONS. DO NOT ELEVATE PLATFORM UNTIL YOU

ARE SURE THAT ALL DAMAGE HAS BEEN REPAIRED IF REQUIRED, AND

THAT ALL CONTROLS ARE OPERATING CORRECTLY.

SECTION 4 - EMERGENCY PROCEDURES

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 4-5

Page 56

SECTION 4 - EMERGENCY PROCEDURES

This page intentionally left blank.

1001070451 LIFTPOD by JLG 1-877-254-3876

4-6 www.liftpod.com 1-877-2-LIFTPOD

Page 57

SECTION 5 - GENERAL SPECIFICATIONS

SECTION 5. GENERAL SPECIFICATIONS

5.1 Introduction

This section of the manual provides operating specifications and

information necessary for proper maintenance of this machine.

5.2 Decal Installation

No. ANSI JLG Part Number

Replacement Decal Kit,

BASE, ANSI-FS80

A1 Cr ushing Hazard-ANSI 100 107 0306

A2 Bubble Level-ANSI 100 107 0413

A3 Base Cr ush Hazard-ANSI 100 107 0438

A4 Step Plate Decal 100 107 0280

A5 General Brand 100 107 0281

A6 Max Wheel Load-ANSI 100 107 0310

A7 Contact Branding Base 100 107 0449

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 5-1

100 107 1564

No. ANSI JLG Part Number

Replacement Decal Kit,

30FS BASE, ANSI

B1 Cr ushing Hazard-ANSI 100 107 0306

B2 Bubble Level-ANSI 100 107 0413

B3 30FS Base Cr ush Hazard-ANSI 100 107 1389

B4 30FS Step Plate Decal 100 107 1387

B5 General Brand 100 107 0281

B6 30FS Max Wheel Load-ANSI 100 107 1390

B7 Contact Branding Base 100 107 0449

Replacement Decal Kit,

MAST/CARRIAGE, ANSI-FS80

C1 Patent 100 107 0307

C2 Manual Descent-ANSI 100 107 0309

C3 Manufacturer Nameplate-ANSI-FS80 100 107 0442

C4 Mast Cap Warning-ANSI 100 107 0432

Sharp Object & Mast Disassembly

C5

Combo-ANSI

100 107 1392

100 107 1253

100 107 0433

Page 58

SECTION 5 - GENERAL SPECIFICATIONS

No. ANSI JLG Part Number

C6 Cowling Side Brand 100 107 0410

C7 General Brand 100 107 0281

C8 FS80 M ast Branding 100 107 0414

Replacement Decal Kit,

MAST/CARRIAGE, ANSI-FS60

D1 Patent 100 107 0307

D2 Manual De scent-ANSI 100 107 0309

D3 Manufacturer Nameplate-ANSI-FS60 100 107 0497

D4 Mast Cap Warning-ANSI 100 107 0432

Sharp Object & Mast Disassembly

D5

Combo-ANSI

D6 Cowling Side Brand 100 107 0410

D7 General Brand 100 107 0281

D8 FS60 Ma st Branding 100 107 0444

Replacement Decal Kit,

PLATFORM, ANSI

E1 Capacity-ANSI 100 107 0441

E2 Electrocution-ANSI 100 107 0303

100 107 1385

100 107 0433

100 107 1356

No. ANSI JLG Part Number

E3 Platform Warning Chevrons 100 107 0409

E4 Platform Latch Release 100 107 0429

E5 Drill Instructions 100 107 0445

E6 Summary-ANSI 100 107 0302

E7 Lanyard Location-Length-ANSI 100 107 0411

E8 FS Quickstart Guide 100 107 0415

E9 Manual 100 107 0451

E10. Contact Branding Platform 100 107 0448

Replacement Decal Kit,

POWERPACK, ANSI

F1 Powerpack Socket Warning 100 107 0400

F2 E-Stop 100 107 0401

F3 Powerpack Drive Directions 100 107 0403

F4 Powerpack Battery Test 100 107 0404

F5 Powerpack Front Main Housing 100 107 0405

F6 Powerpack Instructions 100 107 0406

F7 Battery Charger Front 100 107 0407

F8 Battery Latch Instructions 100 107 0416

100 107 1602

1001070451 LIFTPOD by JLG 1-877-254-3876

5-2 www.liftpod.com 1-877-2-LIFTPOD

Page 59

No. ANSI JLG Part Number

F9 Battery Warning 100 107 0440

F10 Fast Charger Back 100 107 0443

F11 Battery Charger Branding 100 107 0408

F12 General Brand 100 107 0281

Replacement Decal Kit,

ACCESSORY TRAY, ANSI

G1 Tool Tray-ANSI 100 107 0425

Table 5-1. Decal Descriptions.

100 107 1358

SECTION 5 - GENERAL SPECIFICATIONS

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 5-3

Page 60

SECTION 5 - GENERAL SPECIFICATIONS

A1.

A1.

A6.

A6.

A2.

A3.

A5.

A4.

FS80 Base Module Serial Number

A7.

A7.

1001070451 LIFTPOD by JLG 1-877-254-3876

Figure 5-1. Base Decal Installation - ANSI - FS80

5-4 www.liftpod.com 1-877-2-LIFTPOD

Page 61

B1.

B1.

B6.

B6.

B2.

B3.

B5.

B4.

B7.

B7.

30FS Base Module Serial Number

SECTION 5 - GENERAL SPECIFICATIONS

Figure 5-2. Base Decal Installation - ANSI - FS60

1-877-254-3876 LIFTPOD by JLG 1001070451

1-877-2-LIFTPOD www.liftpod.com 5-5

Page 62

SECTION 5 - GENERAL SPECIFICATIONS

C1.

C3.

C2.

C8.

C5.

C6.

C7.

C7.

FS80 Mast/Carriage Serial Number

C8.

C4.