Janome MB-4 with RCS Instruction Manual

Instruction Book

MB-4

IMPORTANT SAFETY INSTRUCTIONS

The machine is not intended for use by children or mentally infirm persons without proper supervision.

This machine is designed and manufactured for household use.

When using an electrical appliance, basic safety precautions should always be followed, including the followings: Read all instructions before using this machine.

DANGER To reduce the risk of electric shock:

1.The machine should never be left unattended when plugged in. Always unplug this machine from the electric outlet immediately after using and before cleaning.

WARNING To reduce the risk of burns, fire, electric shock, or injury to persons:

1.Do not allow the machine to be used as a toy. Close attention is necessary when this machine is used by or children.

2.Use this machine only for its intended use as described in this instruction book.

3.Never operate this machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water.

Return this machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4.Never operate this machine with any air openings blocked. Keep ventilation openings of this machine free from accumulation of lint, dust and loose cloth.

5.Never drop or insert any object into any opening.

6.Do not use outdoors.

7.Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8.Connect this machine to a properly grounded outlet only. See Grounding Instructions.

9.To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

10.Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

11.Keep fingers away from all moving parts. Special care is required around the machine needle.

12.Do not use bent needles.

13.Do not hold the embroidery hoop while stitching. It may deflect the needle causing it to break.

14.Switch the machine off (“o”) when making any adjustment in the needle area, such as threading the needle with your hand, changing the needle, inserting the bobbin, and the like.

15.Always unplug this machine from the electrical outlet when making any adjustments mentioned in this instruction book.

SAVE THESE INSTRUCTIONS

The design and specifications are subject to change without a prior notice.

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation relating to electrical/electronic products. If in doubt please contact your retailer

for guidance. (European Union only)

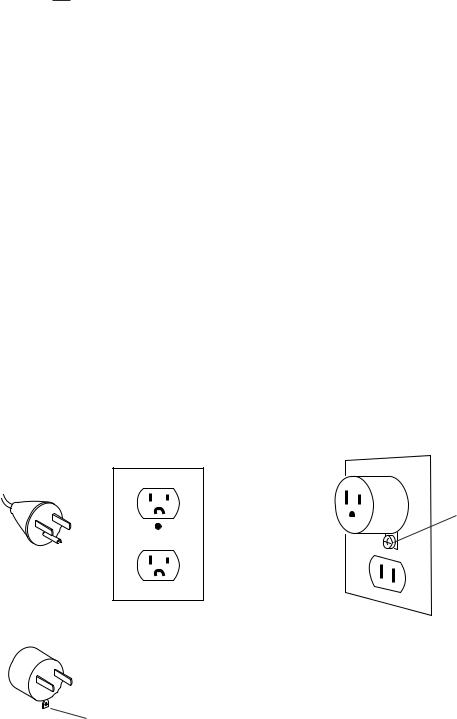

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

This product is equipped with a cord having an equipment grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER Improper connection of the equipment-grounding conductor can result in a risk of

electric shock.

1.The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor.

2.If repair or replacement of the cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

3.Check with a qualified electrician or serviceman if the grounding instructions are not completely understood, or if in doubt as to whether the product is properly grounded.

Do not modify the plug provided with the product if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

4.This product is for use on a nominal 120 V circuit, and has a grounding plug that looks like the plug illustrated in Fig. A. A temporary adaptor, which looks like the adaptor illustrated in Fig. C, may be used to connect this plug to a 2-pole receptacle as shown in Fig B. If a properly grounded outlet is not available, the temporary

adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. The green colored rigid ear, lug, and the like, extending from the adaptor must be connected to a permanent

ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be held in place by the metal screw.

Fig.C

Fig.B

Fig. A

Metal screw

Fig.C

grounding means

TABLE OF CONTENTS

SECTION 1. SETTING UP THE MACHINE |

|

Installing the Machine ............................................... |

2 |

Adjusting the feet ................................................. |

3 |

Removing the Head Stoppers ................................... |

3 |

Names of Parts ......................................................... |

5 |

Sub control panel ................................................. |

6 |

RCS unit (optional item) ....................................... |

6 |

Standard accessories .......................................... |

7 |

Assembling the Spool Stand ..................................... |

9 |

Setting the Thread Cones or Spools of Thread ....... |

10 |

Setting the spool cone ....................................... |

10 |

Setting the spool of thread ................................. |

10 |

Installing the Hoop Supporter................................... |

11 |

Installing the RCS unit (optional item) ..................... |

12 |

Connecting the Power Supply ................................. |

13 |

Direct PC-Link ......................................................... |

14 |

Bobbin Threads ....................................................... |

15 |

Stabilizers................................................................ |

15 |

Winding the Bobbin ................................................. |

16 |

Removing the bobbin case ................................ |

17 |

Removing the bobbin ......................................... |

17 |

Inserting the bobbin case ................................... |

18 |

Threading the Needle.............................................. |

19 |

Threading the needle with the needle threader ..... |

21 |

Setting the Fabric in the Embroidery Hoop ............. |

22 |

Setting the Embroidery Hoop .................................. |

23 |

Adjusting the Hoop Supporter for Optional Hoops .. |

23 |

SECTION 2. BASIC OPERATION |

|

Basic Operation with the Sub Control Panel ........... |

24 |

Machine operating buttons ................................. |

24 |

LCD screen ........................................................ |

25 |

Machine Settings..................................................... |

26 |

Starting Embroidery ................................................ |

27 |

Removing the Hoop ................................................ |

29 |

Adjusting the Thread Tension .................................. |

30 |

Adjusting the bobbin thread tension ................... |

30 |

Replacing the Needle .............................................. |

31 |

Basic Operation of the Optional RCS Unit .............. |

32 |

Machine operating buttons ................................. |

32 |

Function keys ..................................................... |

33 |

On-screen Help Movie ............................................ |

34 |

Disconnecting the RCS Unit.................................... |

35 |

SECTION 3. ADVANCED OPERATION WITH THE |

|

OPTIONAL RCS UNIT |

|

Selecting the Embroidery Patterns.......................... |

36 |

Selecting the built-in designs ............................. |

37 |

Manual color assignment ................................... |

39 |

Monogramming ....................................................... |

40 |

Function keys ..................................................... |

41 |

Entering the characters ...................................... |

42 |

Saving the monogram ........................................ |

42 |

Correcting the text .............................................. |

43 |

Placement of monogramming ............................ |

44 |

Multi-color monogramming ................................ |

45 |

Editing ..................................................................... |

46 |

Editing Functions..................................................... |

47 |

Selecting the hoop ............................................. |

47 |

Moving the pattern ............................................. |

47 |

Resizing the pattern ........................................... |

47 |

Rotating the pattern ........................................... |

48 |

Deleting the pattern ............................................ |

48 |

Saving the file .................................................... |

48 |

Duplicating the pattern ....................................... |

49 |

Flipping the pattern ............................................ |

49 |

Monogramming in an arc ................................... |

50 |

Customizing the color setting ............................. |

51 |

Combining the Patterns and Lettering..................... |

52 |

Starting to Embroider .............................................. |

55 |

Customizing the Settings |

|

with the Sub Control Panel...................................... |

57 |

Buzzer sound control ......................................... |

57 |

Eco mode setting ............................................... |

57 |

Machine ID number ............................................ |

57 |

Formatting the memory ...................................... |

58 |

Resetting all to defaults ...................................... |

58 |

Maximum sewing speed .................................... |

58 |

Thread selection ................................................ |

58 |

Reminder message ON/OFF ............................. |

59 |

Ignoring short stitches ........................................ |

59 |

Setting the trim tail length .................................. |

59 |

Setting the thread detector sensitivity ................ |

59 |

Jump thread trimming ON/OFF .......................... |

60 |

Jump thread trimming threshold ........................ |

60 |

Customizing the Settings |

|

with the Optional RCS Unit ..................................... |

61 |

Language selection ................................................. |

69 |

File Management .................................................... |

70 |

Saving the pattern as a file ................................ |

70 |

Creating a new file ............................................. |

71 |

Opening a file ..................................................... |

72 |

Deleting the folder .............................................. |

73 |

Deleting the file .................................................. |

73 |

SECTION 4. OPTIONAL ITEMS |

|

PC Design Cards .................................................... |

74 |

USB Memory ........................................................... |

75 |

CD-ROM Drive ........................................................ |

76 |

SECTION 5. CARE AND MAINTENANCE |

|

Cleaning the Hook................................................... |

77 |

Cleaning the Auto Thread Cutter Mechanism ......... |

78 |

Oiling ....................................................................... |

79 |

Error Messages ....................................................... |

80 |

Troubleshooting ...................................................... |

81 |

1

q

SECTION 1. SETTING UP THE MACHINE

Installing the Machine

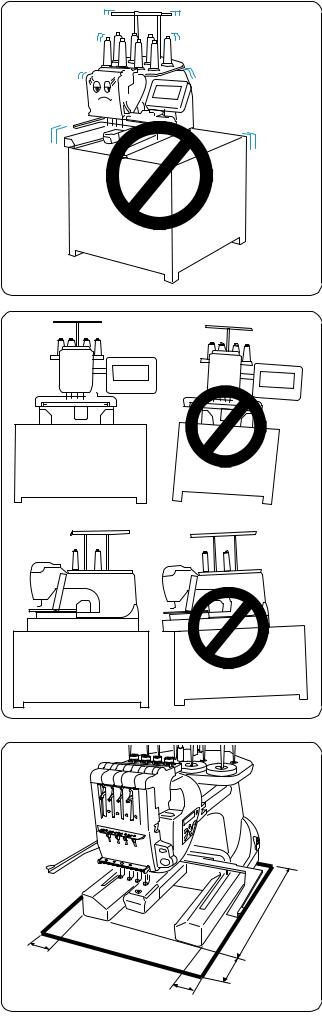

Place the machine on a flat and stable surface such as a sturdy table that could withstand the machine’s weight and vibration.

Place the machine on the flat and level surface.

Make sure that all the feet firmly contact the surface.

Provide a sufficient space around the machine to allow the hoop to move freely.

q 8.5 cm (3–3/8”) w 20 cm (7–7/8”) e 30 cm (11–7/8”)

e

w

q

2

|

|

Adjusting the feet |

|

|

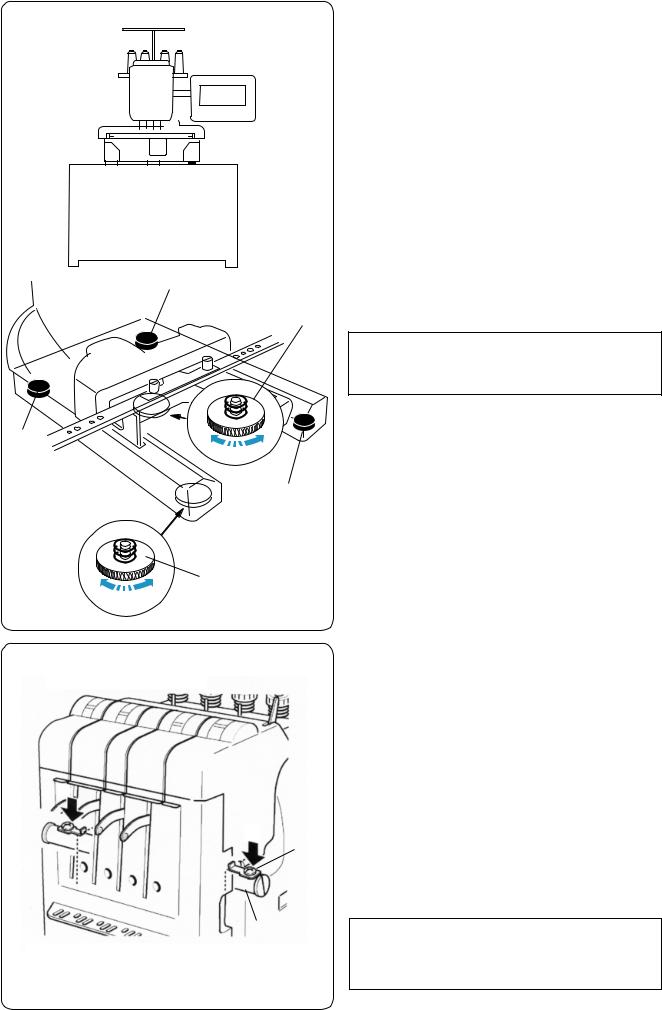

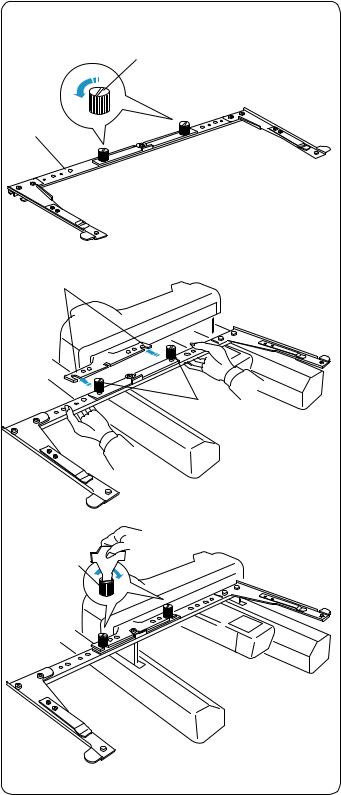

Turn the adjusting screw counterclockwise (in the |

|

|

direction of A) as much as possible, before placing |

|

|

the machine on a surface. |

|

|

q Adjusting screw |

|

|

Place the machine on a flat and level surface. |

|

|

Turn the adjustable foot so the four feet firmly |

|

|

contact the surface. |

|

|

w Adjustable foot |

|

|

e Foot |

|

e |

Turn the adjusting screw clockwise (in the direction B) |

|

|

until it contacts the surface. |

|

|

q |

|

|

NOTE: |

|

|

Make sure that the machine sits on the surface |

|

|

without shaking. |

e |

B |

A |

|

|

e |

w

Removing the Head Stoppers

To prevent the machine from a damage during transportation, the machine is delivered with the head stoppers installed on the guide bar to fix the needle bar head.

Make sure to remove the two head stoppers on both sides of the guide bar before operating the machine.

q Head stopper w Guide bar

q

When you repack the machine for transportation, attach the two head stopper against the metal frame with the screws to fix the needle bar head.

wNOTE:

Select the needle bar No. 3 in the Ready to Sew mode and turn the power off then attach the stoppers (refer to pages 26, 39) .

3

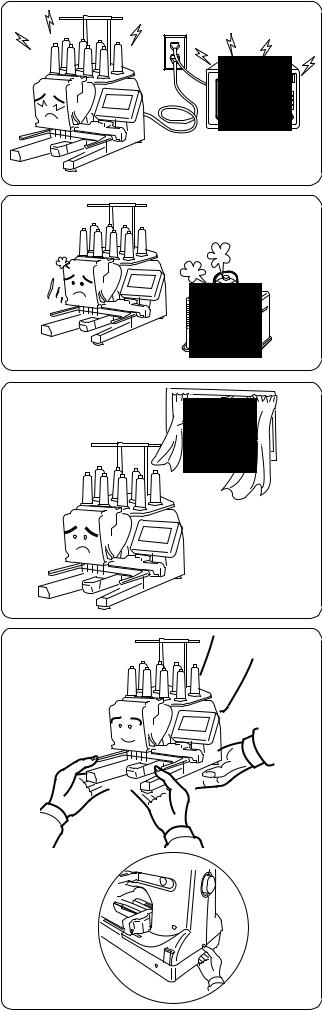

Do not use the machine near appliances that radiate electromagnetic noise such as a microwave oven, or do not plug in the machine to the same branch circuit where such appliances are connected.

Do not use or store the machine near a heat radiator or in a place with dust or high humidity.

Do not expose the machine to direct sunlight or open air.

When transporting the machine, be sure it is lifted by two persons.

Hold the machine by the two legs and the hand grip on the bottom of the backside of the machine.

Remove the hoop supporter when transporting the machine to avoid damage by hitting the supporter.

4

q

!1

w

e |

!2 |

|

!0

r

t

o

y

i

u

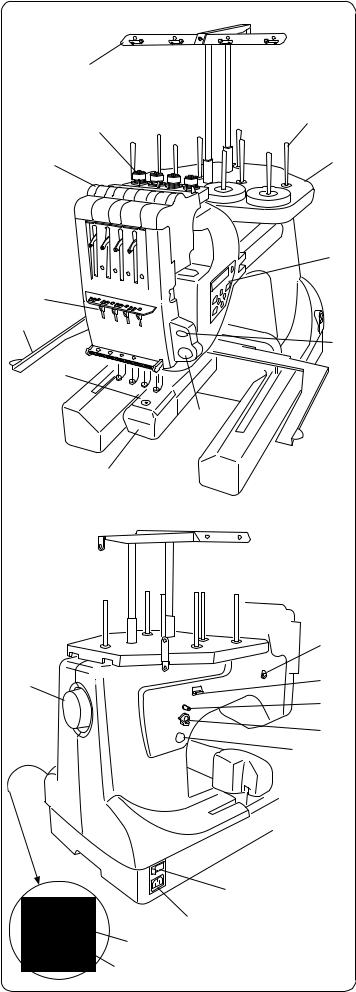

Names of Parts

q Thread guide bar w Pre-tension control e Tension control

r Check spring t Hoop supporter y Needle plate u Hook cover

i Start/Stop button

o Auto thread cutter button !0Sub control panel

!1Spool pins !2Spool stand

|

!9 |

@2 |

!8 |

|

|

|

!7 |

|

!6 |

|

!5 |

!4

!3

@0

@1

!3Machine socket !4Power switch

!5Bobbin winder button !6Bobbin winder stopper !7Bobbin winder spindle !8Bobbin thread cutter

!9Bobbin winder thread guide @0RCS connector socket

@1USB port @2Handwheel

5

y |

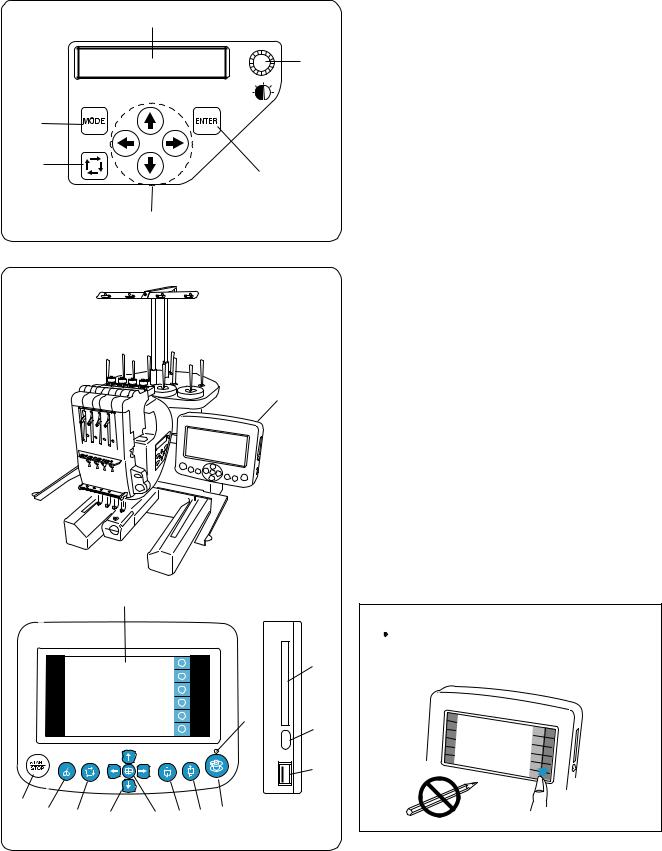

Sub control panel |

|

|

t |

q Mode button |

w Trace button |

|

|

e Arrow button |

|

r Enter buttons |

q |

t LCD brightness adjusting dial |

|

y LCD display |

w

r

e

RCS unit (optional item)

q RCS unit

w Start/Stop button

e Auto thread cutter button r Trace button

q

t Jog buttons

y Carriage return button u Stitch back button

i Stitch forward button o Bobbin winder button !0Bobbin winder indicator !1Card slot

!2Card ejector button !3USB port

!4LCD touch panel

!4

|

!1 |

!0 |

!2 |

|

|

|

!3 |

w e r t y u i o

CAUTION:

CAUTION:

Do not press the LCD touch panel with hard or sharp pointed objects like pencils, screwdrivers or the like.

6

q |

w |

e |

r |

t |

y |

u |

|

i |

|

o |

!0 |

!1 |

!2 |

|

!3 |

!4

!5

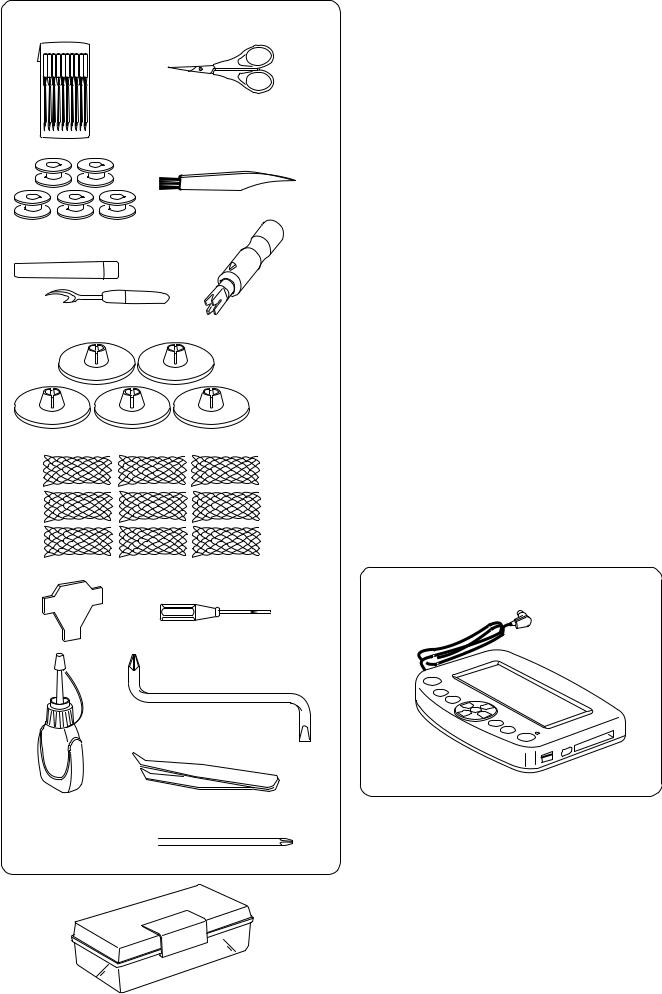

Standard Accessories

q Needle (DB x K5Q1-NY) w Scissors

e Bobbins r Lint brush

t Seam ripper

y Handy needle threader u Spool caps

i Spool net o Screwdriver

!0Screwdriver (small) !1Oiler

!2Offset screwdriver !3Tweezers

!4Screwdriver (large) !5Accessory box

Optional RCS unit

7

q

e

t

u

i

o

!2

!5

w

r

y

!0 !1

!3

!4

!6

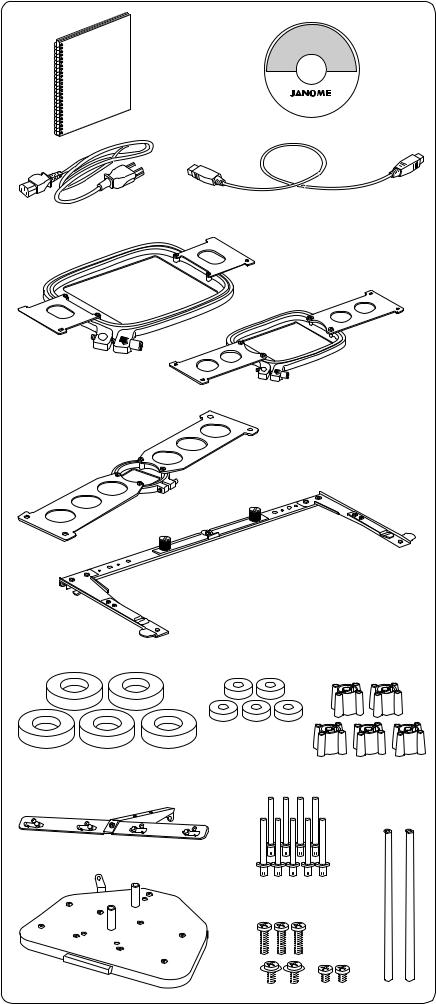

Standard Accessories q Instruction book

w Instructional movie CD-ROM e Power supply cable

r USB cable

t Hoop M1 (MB Hoop 240 X 200) y Hoop M2 (MB Hoop 126 X 110) u Hoop M3 (MB Hoop 50 X 50) i Hoop supporter

o Felt ring (large) !0Felt ring (small) !1Spool rest

!2Thread guide bar !3Spool pin

!4Thred guide pole !5Spool stand

!6Setscrew

8

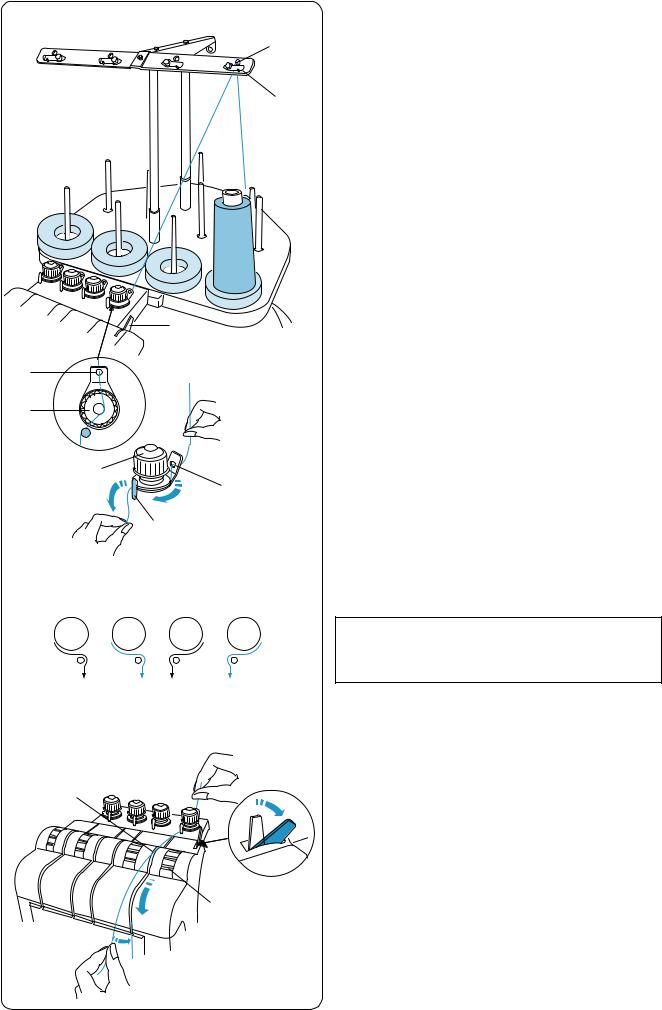

|

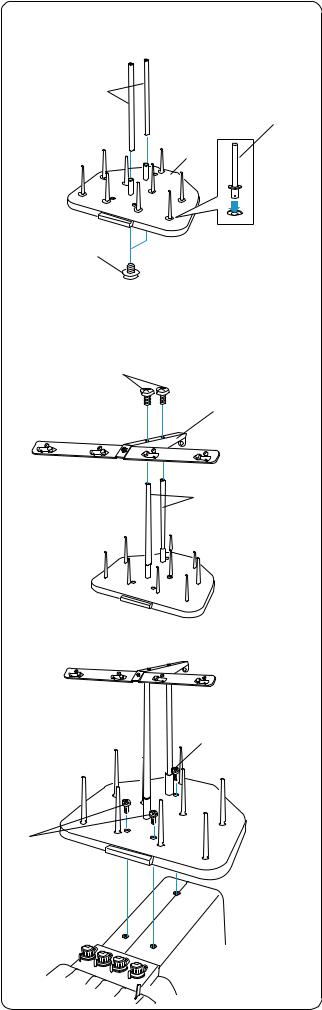

Assembling the Spool Stand |

z |

z Insert the thread guide poles into the sleeve of the |

|

spool stand. Secure the poles with setscrews (A) |

|

from the bottom. |

q |

Insert the spool pins into the spool stand. |

rq Thread guide poles w Setscrews (A)

e |

e Spool stand |

|

r Spool pin |

w

xy

t

xAttach the thread guide bar to the thread guide poles with the setscrews (B).

t Thread guide bar y Setscrews (B)

q

c

u

cAttach the assembled spool stand to the machine with the 3 setscrews (C).

u Setscrews (C)

u

9

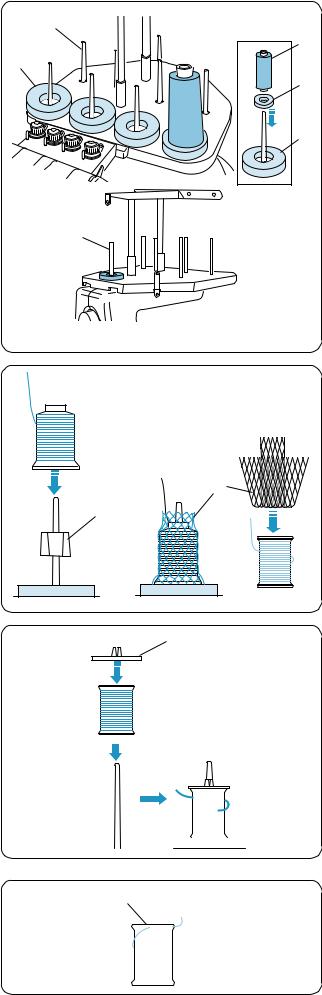

Setting the Thread Cones or Spools of Thread

q |

|

Use the 4 spool pins in the front row for sewing, and |

|

r |

|

|

second row spool pins are for the standby spools. |

|

w |

|

|

|

Use the rear most spool pin for bobbin winding. |

|

|

e |

|

|

|

|

|

|

Felt rings of two sizes are provided to accommodate |

|

w |

various types of spools of thread and thread cones. |

|

Use the large felt rings for large thread cones. For small |

|

|

|

|

|

|

thread cones or spools of thread, insert the small felt |

|

|

rings into the large rings. |

|

|

q Spool pin |

t |

|

w Felt ring (large) |

|

|

e Felt ring (small) |

|

|

r Small spool of thread |

|

|

t Spool pin for bobbin winding |

|

Setting the thread cone |

|

Attach the spool rests on the spool pins. |

|

Place the thread cones on the spool pins. |

|

Cover the thread cone with the spool net if the thread is |

u |

shaky or kinky when sewing. |

If the net is too long for a spool, fold the net and place it |

|

y |

on the spool. |

|

y Spool rest |

|

u Spool net |

i

Setting the spool of thread

Place the spool of thread on the spool pin, with the thread coming out from the left backside.

Attach the spool cap and firmly press it against the spool. i Spool cap

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

|

|

|

|

|

|

|

NOTE: |

|||

|

|

|

|

|

|

|

|

|

|

|

|

To prevent the thread from unraveling, leave the net on |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the thread cone or hook the thread end into the notch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of the spool when it is not in use. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o Notch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10

|

|

Installing the Hoop Supporter |

z |

w |

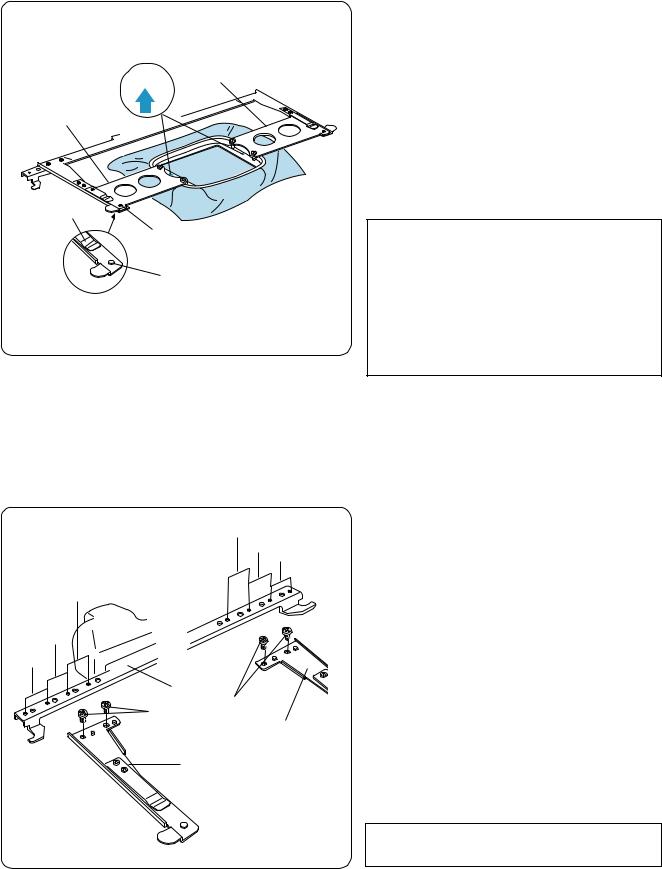

z Loosen the two thumbscrews on the hoop |

|

supporter. |

|

|

|

|

|

|

q Hoop supporter |

|

|

w Thumbscrew |

q

xe

|

x Turn the power switch on to move the carriage to |

|

the center. |

|

Hold the hoop supporter with both hands and |

|

place it under the carriage plate by |

|

inserting the necks of both thumbscrews into the |

w |

slots in the carriage plate. |

|

e Slot in the carriage plate |

c |

c Tighten the thumbscrews with the screwdriver to |

w |

secure the hoop supporter.

11

z x

r

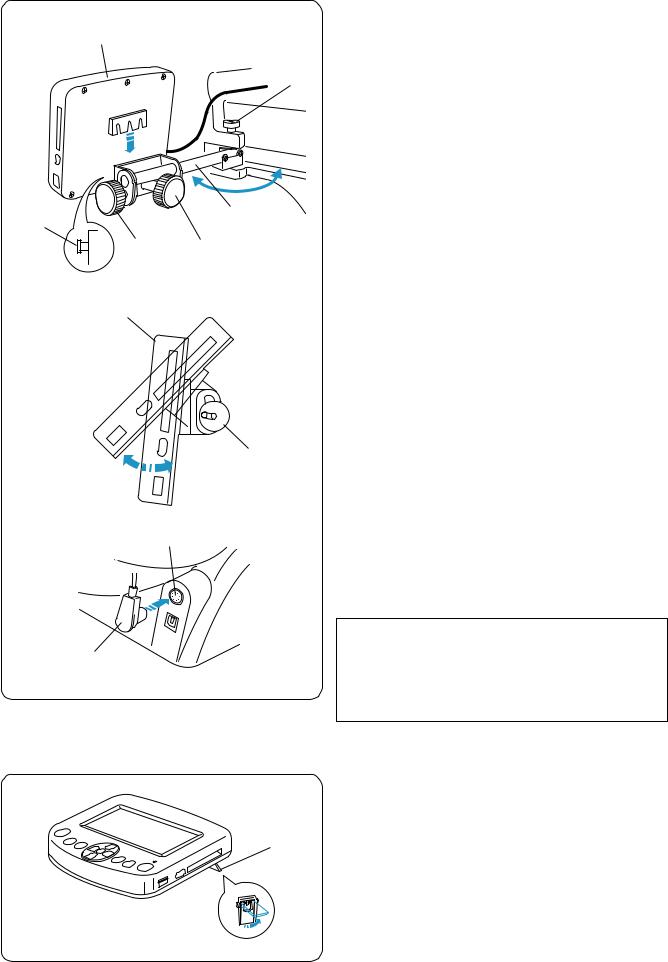

Installing the RCS Unit (optional item)

z Loosen the thumbscrew and open the mounting arm. q Thumbscrew

w Mounting arm

q

x Loosen the screw knob A and set the RCS unit on

|

|

|

the mounting arm by hooking the RCS unit on the |

|

|

|

pins. |

|

|

|

Tighten the screw knob A to secure the RCS unit. |

|

|

|

Adjust the angle of the mounting arm as desired and |

|

|

w |

tighten the thumbscrew. |

t |

|

e Screw knob A |

|

|

|

||

y |

e |

|

r RCS unit |

|

|

|

t Pin |

c |

|

|

c Loosen the screw knob B on the end of the mounting |

r |

|

|

arm and tilt the RCS unit to adjust the angle of the |

|

|

|

|

|

|

|

LCD screen for easier viewing. |

|

|

|

Tighten the screw knob B to secure the RCS unit. |

|

|

|

y Screw knob B |

|

y |

v |

v Insert the connector into the connector socket on |

i |

the back of the machine. |

|

Fold the cable and put it under the spool stand. |

|

u Connector |

|

i Connector socket |

|

NOTE: |

u |

You can connect the RCS unit when the machine is |

|

turned on. However do not connect the RCS unit while |

|

the machine is running or the LCD screen of the sub |

|

control panel is displaying a message. |

If you are using the RCS unit on the tabletop, simply insert the connector into the connector socket on the back of the machine.

q

Extend the two legs on the backside of the RCS unit so that it rests on an angle for easier viewing.

q Leg

12

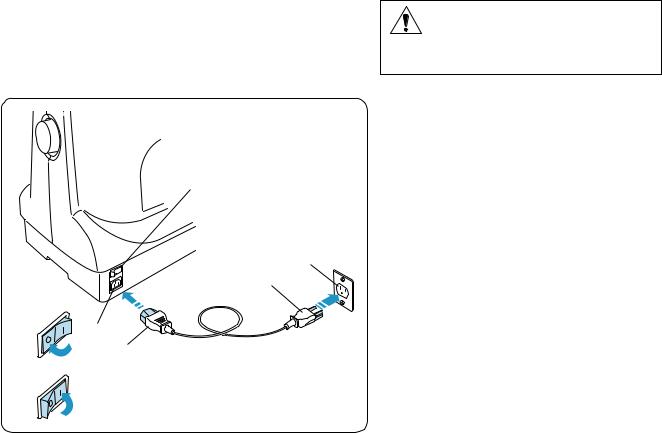

Connecting the Power Supply

|

|

|

CAUTION: |

|

|

|

Turn the power switch off before connecting |

|

|

|

the machine to the power supply. |

|

|

|

z Turn the power switch off. |

|

|

|

q Power switch |

|

|

q |

x Insert the machine plug into the machine |

|

|

socket. |

|

|

|

|

|

|

|

|

w Machine plug |

|

|

|

e Machine socket |

|

|

t |

c Insert the power supply plug into the |

|

|

r |

|

|

x |

properly grounded outlet. |

|

|

|

||

|

|

c |

r Power supply plug |

z |

e |

t Wall outlet (grounded) |

|

|

w |

|

|

|

|

|

v Turn the power switch on. |

v

Grounding Instructions:

This machine is equipped with a grounding cable and plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded. If a properly grounded outlet is not available, contact a qualified electrician to install the properly grounded outlet.

Refer to page II for more instructions.

13

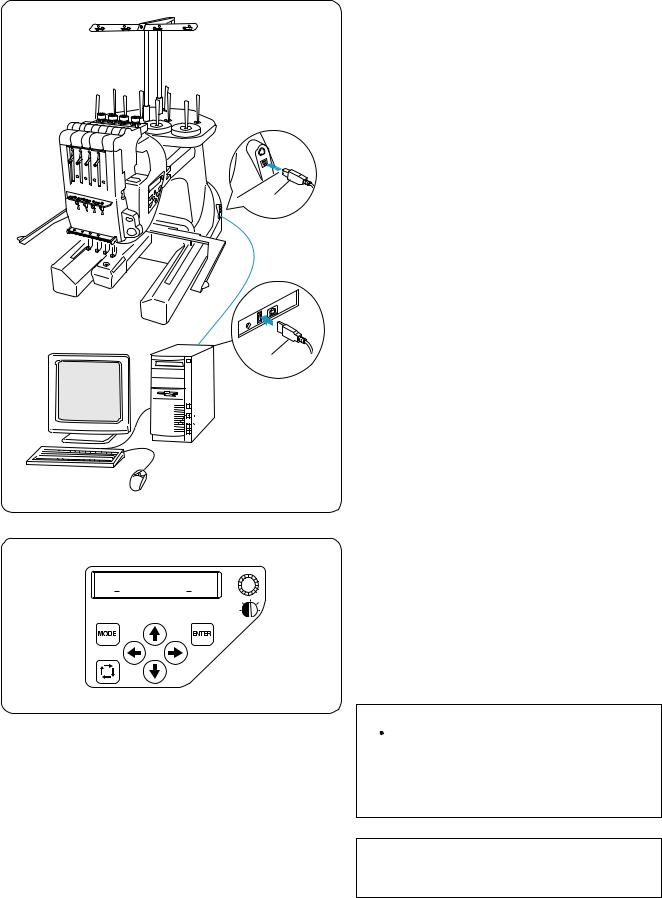

Direct PC-Link

The MB-4 can be connected to the PC with the USB cable included as standard accessory.

You need Digitizer MB for multi-needle software (optional item) to operate the machine via direct PC-link.

Connecting the Machine and PC

Start up the MB-4 and PC, and insert the type A

wUSB connector in to the PC.

Insert the type B USB connector into the USB port on the machine.

q Type A USB connector w Type B USB connector

q

PC

PC M

M

Transfer the embroidery pattern data files between the machine and PC by using optional Digitizer MB for multi-needle.

After the data transfer is finished, the LCD screen will show the Ready to Sew mode display or return to the previous screen, depending on the setting you have made on Digitizer MB for multi-needle.

CAUTION:

CAUTION:

Do not turn the power switch off or disconnect the USB cable while the data transfer is in progress. Otherwise the data will be lost or the memory will be damaged.

NOTE:

Refer to instruction book of optional Digitizer MB for multi-needle for further details.

14

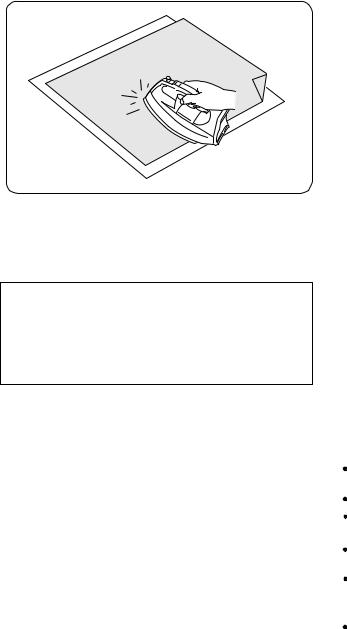

Adhesive (Iron-on) Stabilizer

Place the Wrong side of fabric and the glossy side of the stabilizer together. Fold up a corner of the stabilizer and fuse it with an iron.

NOTES:

Fold up a corner of the stabilizer, to make it easier to peel off the excess stabilizer after

Fold up a corner of the stabilizer, to make it easier to peel off the excess stabilizer after

stitching.

stitching.

Ironing temperatures vary depending on kind of adhesive type stabilizer.

Bobbin Threads

Cotton or spun rayon threads sizes 80 to 120 (74 to 100 dtex/2) are recommended for bobbin thread.

Do not use poor quality prewound bobbins.

Needles

Use the DB x K5Q1-NY, size 11 needles (Janome part number 770811000).

Stabilizers

To obtain the best quality embroidery, it is important to use stabilizers.

Types of stabilizer

Tear-away stabilizer:

Use tear-away stabilizers for stable woven fabrics.

Iron-on stabilizer:

Fuse it to the wrong side of the fabrics with an iron.

Cut-away stabilizer:

Use cutaway stabilizers for knits and all kinds of unstable fabrics.

Water soluble stabilizer:

Use this stabilizer for cutwork or lace embroidery, and also for the right side of looped fabrics such as towelling to avoid loops coming through the embroidery.

Sticky stabilizer:

This stabilizer is a sticky paper used for securing a small fabric or work that cannot be secured in the hoop.

It is also used for velvet and other napped fabric that would be permanently marked by the hoop.

Usage:

The stabilizer should be attached to the wrong side of fabric.

More than one layer may be required.

Felt or stable fabrics do not need to be stabilized and you may embroider directly on them.

For firm fabrics, you may place a thin paper under the fabric.

The non-adhesive type should be used when embroidering fabric, which cannot be ironed or for sections, which are difficult to iron.

Cut the stabilizer larger than the embroidery hoop and set it on the hoop so that the entire piece is fastened within the hoop to prevent looseness of the fabric.

15

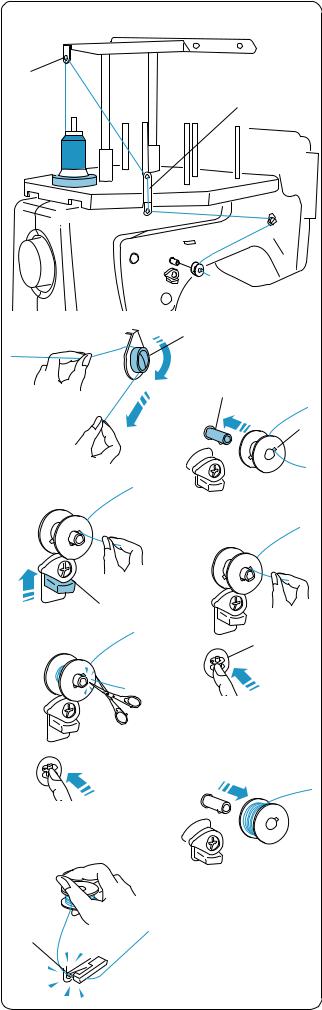

z x |

|

Winding the Bobbin |

|

|

|

|

|

z Place the thread cone (spool of thread) on the rear |

q |

|

most spool pin. |

|

w |

Pass the thread through the thread guide A. |

|

q Thread guide A |

|

|

|

x Pass the thread through the upper hole and lower hole in the thread guide B.

w Thread guide B

c |

e |

|

|

|

|

c Draw the thread to the front. |

|

|

|

|

|

|

|

|

Hold the thread with both hands and pass the |

|

t |

|

thread firmly around and under the tension disk. |

|

|

e Tension disk |

|

|

|

|

|

|

v |

r |

v Pass the thread through the hole in the bobbin |

|

|

|

|

|

|

|

from the inside. |

|

|

|

Put the bobbin on the bobbin winder spindle. |

|

|

|

r Hole in the bobbin |

|

|

|

t Bobbin winder spindle |

b |

|

|

b Push the bobbin winder stopper up against the |

|

|

|

|

|

n |

|

bobbin. |

|

|

y Bobbin winder stopper |

|

|

|

|

n Press the bobbin winding button while holding the |

|

y |

|

thread end. |

|

u |

|

u Bobbin winder button |

m |

|

|

m Press the bobbin winder button to stop the |

|

|

|

|

|

|

|

machine when the bobbin has wound a few layers. |

|

|

|

Cut the thread close to the bobbin and press the |

|

|

|

bobbin winder button again. |

,

, When the bobbin is fully wound, the machine will stop automatically.

Remove the bobbin from the bobbin winder

spindle.

.

. Cut the thread with the bobbin thread cutter. i Bobbin thread cutter

i

16

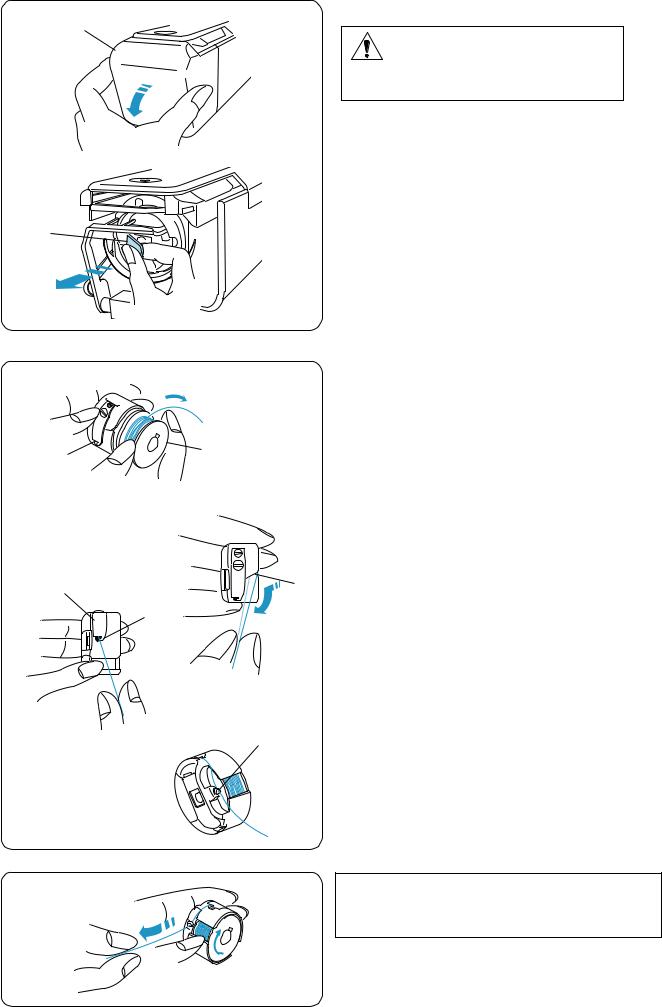

|

Removing the bobbin case |

|

q |

z |

CAUTION: |

|

|

|

Turn the power switch off before removing the |

|

bobbin case. |

|

z Open the hook cover toward you. |

|

q Hook cover |

x |

x Hold and open the latch of the bobbin case. |

Take the bobbin case out from the machine. |

|

w |

w Latch |

|

Inserting the bobbin

z

w |

q |

|

x

zInsert the bobbin into the bobbin case leaving a 2” (5 cm) thread tail as illustrated.

q Bobbin

w Bobbin case

xDraw the thread to slip it into the slit of the bobbin case.

e Slit

|

r |

|

e |

c |

t |

|

c Pull the thread to slide it under the tension blade |

|

|

||

|

|

|

until the thread comes out from the opening. |

|

|

|

r Tension blade |

|

|

|

t Opening |

|

v |

y |

v Pass the thread through the pigtail by spiralling the |

|

|

|

thread around the pigtail. |

|

|

|

y Pigtail |

NOTE:

The bobbin should turn clockwise when the thread is pulled.

17

e

q

w

w

Inserting the bobbin case

Hold the bobbin case with the latch and insert the bobbin case into the hook, aligning the rib with the notch. Push the bobbin case as far as it will go and release the latch.

q Latch

w Rib e Notch

r

Close the hook cover. r Hook cover

18

|

|

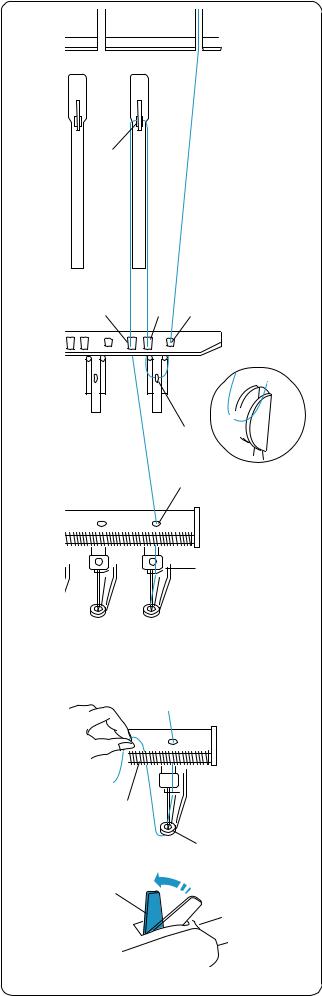

Threading the Needle |

|

q |

The threading path of all needles is similar. Review |

|

the threading procedure of the first needle when |

|

|

|

|

|

|

threading other needles. |

|

w |

Threading needle No.1 |

z |

|

|

|

z Place a thread cone on the front right spool pin. |

|

|

|

|

|

|

Draw the thread up and pass it through the right |

|

|

hole in the thread guide bar from behind. |

|

|

Slip the thread under the tension leaf. |

|

|

q Hole in the thread guide bar |

|

|

w Tension leaf |

u |

|

x |

x Draw the thread to the right pre-tension control. |

|

|

e |

Pass the thread through the guide hole from |

|

behind. |

r |

While holding the thread with both hands, slip the |

|

thread under the tension disk of the pre-tension |

|

control. |

r |

Hook the thread aroung the guide pin from right to |

e |

left. |

t |

Make sure to insert the thread under the tension |

disk by tugging the thread. |

e Guide hole

r Pre-tension control t Guide pin

c v

i

NOTE:

Refer to the illustration for the thread path of each pre-tension.

cPush back the tension release lever so the tension disk of the tension control will open.

y Tension release lever u Tension control

v Hold the thread with both hands and pull it down

yalong the right channel.

i Channel

u

19

,

b n m

.

⁄0

⁄1

⁄22

⁄3

⁄4

r

te q

w

y

u

o

i

!0

bDraw the thread down and pass it through the right hole in the guide plate.

q Right hole in the guide plate

nPass the thread through the eye of the right check spring.

w Eye of the check spring

mPull the thread up and pass it through the second hole from the right.

e Second hole from the right

,Continue to pull the thread up to the right take-up lever. Pass the thread through the eye of the takeup lever.

r Take-up lever

.Draw the thread down and pass it through the third hole from the right in the guide plate.

t Third hole from the right

⁄0Continue to draw the thread down to the lower guide plate and pass the thread through the right hole.

y Right hole in the lower guide plate

⁄1Hold the thread with both hand and slip the thread behind in the right needle bar thread guide.

u Needle bar thread guide

⁄2Thread the needle with the handy needle threader (refer to the next page).

⁄3Pass the thread through the hole in the presser foot.

Draw the thread up and pinch the thread tail with the holder spring.

i Hole in the presser foot o Holder spring

⁄4Pull up the tension release lever to close the tension disks.

!0Tension release lever

20

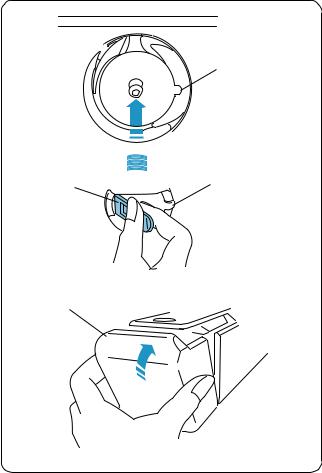

|

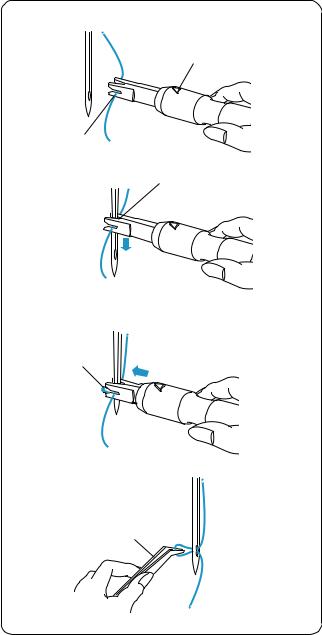

|

Threading the needle with the needle threader |

z |

|

z Hold the needle threader with a triangle mark facing |

|

q |

up. Insert the thread into the Y-notch of the threader |

|

|

from the right. |

|

|

q Triangle mark |

|

|

w Y-notch |

|

w |

|

x |

e |

x Slide the threader down along the needle while |

|

||

|

|

|

|

|

pushing it gently until the threader pin goes into |

|

|

the needle eye. |

|

|

Place the V-notch over the needle just above the |

|

|

needle eye. |

|

|

e V-notch |

c |

|

c Push the threader until the threader pin comes out |

|

r |

through the needle eye with a loop of thread. |

|

r Threader pin |

|

|

|

v |

v Remove the threader from the needle slowly, |

|

|

|

leaving the thread loop behind the needle eye. |

t |

Using the tweezers, pull the loop of the thread out |

|

to the back. |

|

t Tweezers |

21

|

|

|

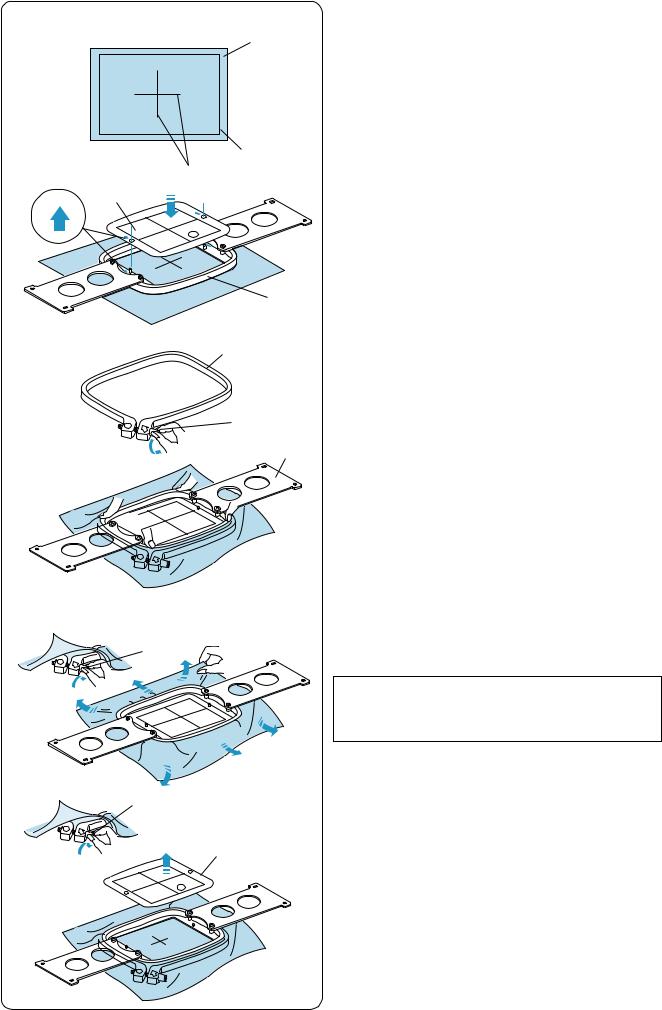

Setting the Fabric in the Embroidery Hoop |

z |

q |

|

z Attach stabilizer to the wrong side of the fabric. |

|

Mark the centerlines for pattern placement on the |

||

|

|

|

|

|

|

|

right side of the fabric. |

|

|

|

q Fabric |

|

|

|

w Centerlines |

|

|

|

e Stabilizer |

|

e |

|

|

x |

w |

|

x Place the inner hoop with the template on the |

|

|

||

t |

|

|

|

y |

|

|

fabric. Make sure that the arrow marks on the |

|

|

|

hoop and template are facing away from you. |

|

|

|

Align the centerlines on the fabric and |

|

|

|

template. |

|

|

r |

r Inner hoop |

|

|

t Template |

|

|

|

|

|

|

|

|

y Arrow mark |

|

u |

|

|

c |

|

|

c Loosen the hoop tightening screw on the outer |

|

|

|

hoop. |

|

i |

|

u Outer hoop |

|

|

i Hoop tightening screw |

|

|

|

|

|

|

|

o |

|

v |

|

|

v Hold the inner hoop and fabric together and push |

|

|

|

them into the outer hoop. Make sure to keep the |

|

|

|

centerlines aligned. |

|

|

|

Do not push the setting plates, push the 4 corners |

|

|

|

of the inner hoop |

|

|

|

o Setting plate |

b |

|

|

b Tighten the hoop tightening screw slightly. Pull the |

i |

|

|

edge of the fabric to stretch it drum-tight. |

|

|

|

NOTE: |

|

|

|

Make sure the bottom of the inner hoop is level with |

|

|

|

the outer hoop. |

n |

i |

n Tighten the hoop tightening screw securely. |

|

||

|

|

t |

m |

|

m Remove the template. |

22

tq

q

w

e

r

C

B A

C

B

A

r

q q

e

w

Setting the Embroidery Hoop

Hold the setting plate with both hands and insert them under the holder clips.

Slide the hoop on the hoop supporter until the holes catch the positioning pins on the hoop supporter.

q Setting plate w Holder clip

e Hole in the setting plate r Positioning pin

NOTES:

Do not set the hoop front-side back or upside down. The arrow mark on the inner hoop should face away from you.

t Arrow mark

Be careful not to pinch the fabric edge under the hoop supporter.

Adjusting the Hoop Supporter for Optional Hoops

The hoop supporter provides 2 alternate positions to adapt optional hoops available on the market, such as Tajima’s hoop.

Remove setscrews on both left and right hoop supporter arms and remove them.

q Setscrew

Attach both hoop supporter arms to the hoop supporter bar in the position B or C depending on the hoop you wish to use.

Secure the supporter arms with the setscrews. w Left hoop supporter arm

e Right hoop supporter arm r Hoop supporter bar

NOTE:

Position A is for the standard hoops.

23

|

|

SECTION 2. BASIC OPERATION |

||

|

|

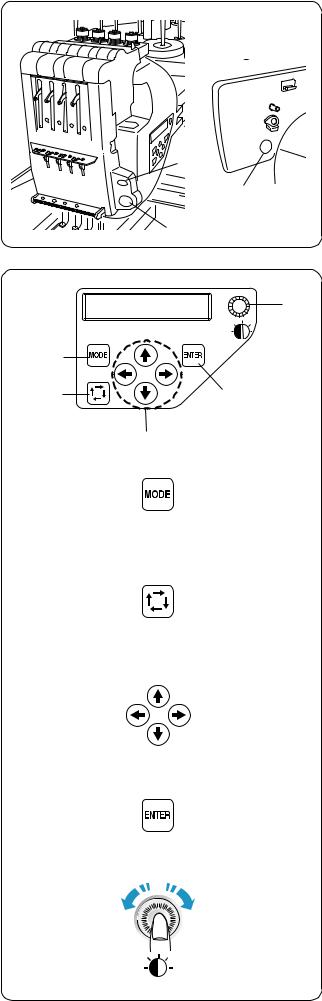

Basic Operation with the Sub Control Panel |

||

|

|

Machine operating buttons |

||

|

|

q Start/Stop button |

||

|

|

Press this button to start or stop the machine. |

||

|

|

The button glows red when the machine is stitching, |

||

|

|

and green, when the machine has stopped. |

||

|

w |

w Auto thread cutter button |

||

|

|

|||

|

e |

Press this button to trim the threads. |

||

|

q |

e Bobbin winding button |

||

|

Press this button to wind the bobbin. |

|||

|

|

|||

|

|

Use the sub control panel to operate the machine |

||

|

|

without the RCS unit. |

||

|

|

t |

|

|

|

|

Function buttons |

||

q |

|

q MODE button |

||

|

Press this button to select one of the following |

|||

|

|

|||

w |

r |

modes. |

|

|

1. |

Ready to Sew |

|||

|

||||

|

|

2. |

Stitch count setting |

|

|

e |

3. |

Color section setting |

|

|

|

4. |

Needle bar number setting |

|

|

|

5. |

Pattern selection |

|

|

q |

6. |

My setting |

|

w |

w Trace button |

|

Press this button to trace the outline of the |

|

embroidery pattern without stitching. |

e |

e Arrow buttons |

|

|

|

These buttons can be used as Jog buttons in the |

|

Ready to Sew mode. |

|

In other modes, these button are used for selecting |

|

the items. |

r |

r ENTER button |

|

Press this button to confirm your selection or register |

|

the settings. |

t |

t LCD brightness adjusting dial |

|

Turn this dial with your fingertip to adjust the |

|

brightness of the LCD screen. |

24

Loading...

Loading...