TECHNICAL BULLETIN

Poor Hot Start – Tank Pressure

Control Valve – Check Operation

MODEL XJS Range 1995-96 MY

VIN 194775 - 226645

Remove and destroy Bulletin 17-8, dated 5/96.

Replace with this Bulletin.

Revisions are marked with a bar and in

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

When investigating a customer complaint of poor “hot start” on 1995-96 MY XJS

Range vehicles within the above VIN range, verify that the fuel tank pressure

control valve (Rochester valve) is operating properly.

ACTION:ACTION:

ACTION:

ACTION:ACTION:

After verifying a customer complaint of poor “hot start” (extended cranking) on

1995-96 MY XJS Range vehicles within the above VIN range, check the fuel tank

pressure control valve as follows:

1. Raise vehicle on hoist.

2. Remove the left front wheel.

3. Remove the liner from the wheel well.

DATE 5/96

bold textbold text

bold text.

bold textbold text

17-8

Amended

1/97

4. Disconnect the vacuum hose from the control valve.

5. Connect a vacuum tester to the pressure control valve fitting.

6. Apply a vacuum of

be held

7. Disconnect the vacuum tester from the control valve.

8. If the valve held vacuum, reconnect the vacuum hose and lower the vehicle.

9. If the valve is faulty, cut the retaining strap from the fuel tank vent hose.

Remove the retaining clip and disconnect the vent hose of fuel tank from the

valve.

10. Loosen the retaining clip and disconnect the hose of the carbon canister from

the valve.

11. Remove the defective valve.

12. Check a new valve by applying a vacuum of

as in step 4.

13. Install the new valve after checking.

14. Reconnect the hose of the carbon canister to the valve.

15. Reconnect the vent hose of the fuel tank to the valve. Install a new tie strap.

for 2-3 seconds for 2-3 seconds

for 2-3 seconds, the valve is faulty.

for 2-3 seconds for 2-3 seconds

2.94-14.7 in. Hg. (0.1-0.5 bar)2.94-14.7 in. Hg. (0.1-0.5 bar)

2.94-14.7 in. Hg. (0.1-0.5 bar). If this vacuum cannot

2.94-14.7 in. Hg. (0.1-0.5 bar)2.94-14.7 in. Hg. (0.1-0.5 bar)

2.94-14.7 in. Hg. (0.1-0.5 bar)2.94-14.7 in. Hg. (0.1-0.5 bar)

2.94-14.7 in. Hg. (0.1-0.5 bar)

2.94-14.7 in. Hg. (0.1-0.5 bar)2.94-14.7 in. Hg. (0.1-0.5 bar)

Bulletin Number 17-8 Date of issue 1/97 Page 1 of 2

16. Reconnect the vacuum hose.

17. Reinstall the wheel well fender liner.

18. Reinstall the left front wheel and lower the vehicle.

PP

ARAR

TS INFORMATS INFORMA

P

AR

TS INFORMA

PP

ARAR

TS INFORMATS INFORMA

TION:TION:

TION:

TION:TION:

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Fuel tank pressure control valve CBC 7714 1

Tie strap ADU 9028 1

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

FF

AA

ULUL

F

A

UL

FF

AA

ULUL

CODECODE

CODE

CODECODE

BK BB HM 17.15.48 Remove & install fuel tank 0.55 hrs.

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TT

T

TT

TION:TION:

TION:

TION:TION:

R.O.R.O.

R.O.

R.O.R.O.

NUMBERNUMBER

NUMBER

NUMBERNUMBER

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

pressure control valve

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

QTYQTY

QTY

QTYQTY

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

ANCEANCE

W

ANCE

WW

ANCEANCE

Page 2 of 2 Date of issue 1/97 Bulletin Number 17-8

TECHNICAL BULLETIN

AIR Pump Clutch –

Intermittent Operation –

17-9

Amended

Service Action S458

MODEL 1993-94 MY 4.0L Sedan & XJS DATE 5/97

Remove and destroy Bulletin 17-9, dated 5/97.

Replace with this Bulletin.

Revisions are marked with a bar and in

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

Some 1993-94 MY Sedan (4.0L) Range and XJS (4.0L) Range vehicles may

experience intermittent operation of the AIR pump. The operation of the AIR pump

clutch is controlled by a relay located in the engine compartment. The contacts of

this relay may become contaminated by the entry of water or cleaning solutions

containing silicones.

Jaguar Cars will contact all customers with 1993-94 MY Jaguar vehicles within the

above VIN ranges to advise them to make dealer service appointments to verify

proper operation of the relay.

bold textbold text

bold text.

bold textbold text

8/97

AA

CTION:CTION:

A

CTION:

AA

CTION:CTION:

The 1993-94 MY Sedan (4.0L) Range and XJS (4.0L) Range vehicles must be

checked as described below.

For vehicles registered in states

AIR pump clutch as described below.

For vehicles serviced and/or registered

relay with a sealed unit and verify the operation of the AIR pump clutch as

described on the following page.

VEHICLES REGISTERED AND SERVICED OUTSIDE CALIFORNIA

1. Open hood and observe the AIR pump clutch while an assistant starts the

engine. The clutch should engage as cranking begins.

On a hot engine, the clutch should disengage after a few seconds.

On a cold engine, more time will elapse until the clutch disengages at a

coolant temperature of 34°C (95°F). Do not wait until the clutch disengages.

2. If proper operation is observed, no further action is required. Stop the engine

and close the hood.

3. If the AIR pump clutch does not engage, follow normal diagnostic procedures

(refer to AJ6 4.0L Engine Management System/OBD I Diagnostic Guide) and

repair. Submit a claim under normal warranty procedures.

other than Californiaother than California

other than California, verify the operation of the

other than Californiaother than California

in Californiain California

in California, replace the AIR pump clutch

in Californiain California

If diagnosis shows that the AIR pump relay

green mounting base on XJS)green mounting base on XJS)

green mounting base on XJS) is defective, install a sealed relay part no. LHF

green mounting base on XJS)green mounting base on XJS)

Bulletin Number 17-9 Amended 8/97 Date of issue 5/97 Page 1 of 5

(red mounting base on S(red mounting base on S

(red mounting base on S

(red mounting base on S(red mounting base on S

edan;edan;

edan;

edan;edan;

6703AA under the terms of this service action.

VEHICLES SERVICED OR REGISTERED IN CALIFORNIA

1. Open hood and replace the AIR pump relay

green mounting base on XJSgreen mounting base on XJS

green mounting base on XJS) with a sealed relay part no. LHF 6703AA.

green mounting base on XJSgreen mounting base on XJS

(red mounting base on S(red mounting base on S

(red mounting base on S

(red mounting base on S(red mounting base on S

edan;edan;

edan;

edan;edan;

2. Observe the AIR pump clutch while an assistant starts the engine. The clutch

should engage as cranking begins.

On a hot engine, the clutch should disengage after a few seconds.

On a cold engine, more time will elapse until the clutch disengages at a

coolant temperature of 34°C (95°F). Do not wait until the clutch disengages.

2. If proper operation is observed, no further action is required. Stop the engine

and close the hood.

3. If the AIR pump clutch does not engage, follow normal diagnostic procedures

(refer to AJ6 4.0L Engine Management System/OBD I Diagnostic Guide) and

repair. Submit a claim under normal warranty procedures.

LL

OCAOCA

TION OF SEDTION OF SED

L

OCA

TION OF SED

LL

OCAOCA

TION OF SEDTION OF SED

FRONFRON

FRON

FRONFRON

AN (4.0L) RANGE AN (4.0L) RANGE

AN (4.0L) RANGE

AN (4.0L) RANGE AN (4.0L) RANGE

T OF T OF

VEHICLEVEHICLE

T OF

VEHICLE

T OF T OF

VEHICLEVEHICLE

11

993 MY993 MY

1

993 MY

11

993 MY993 MY

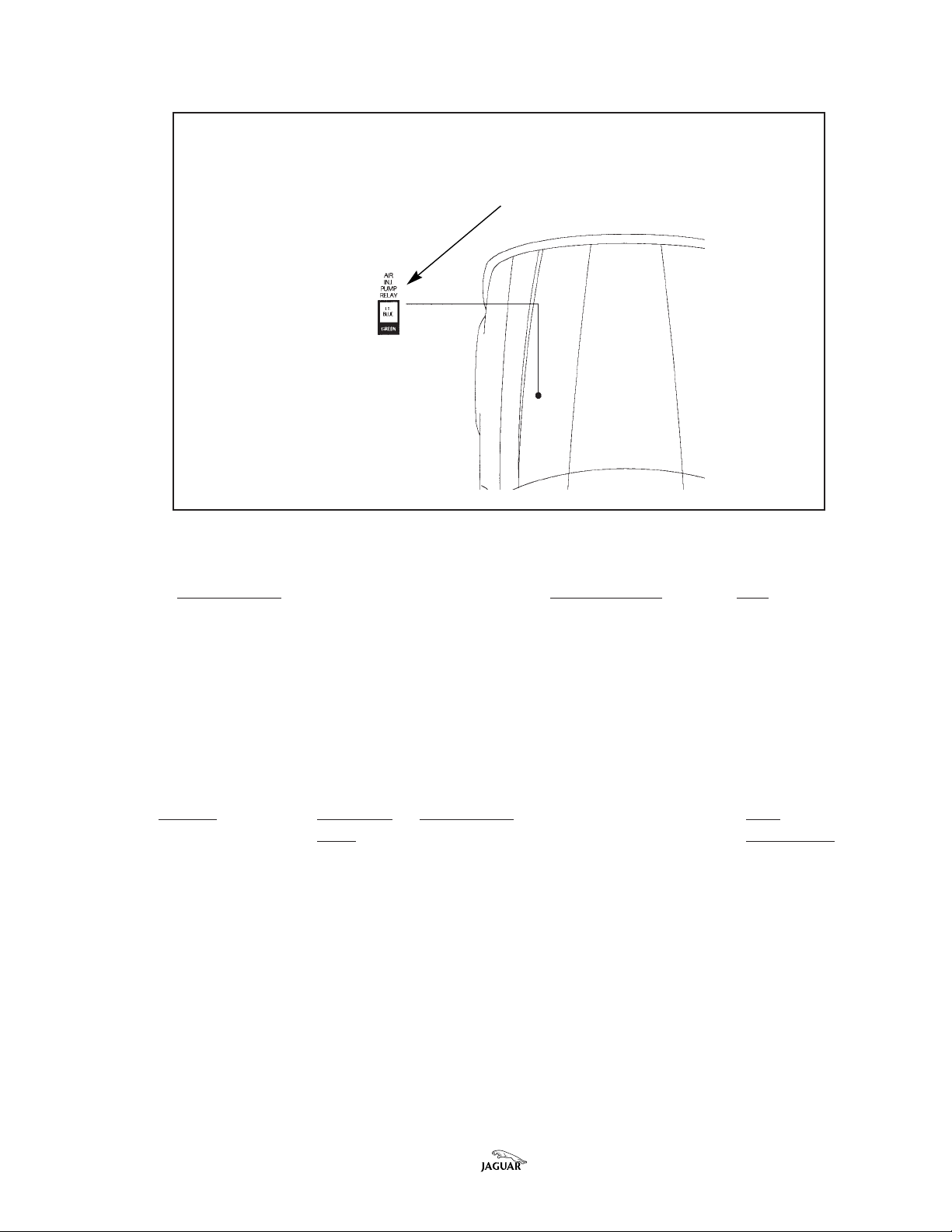

AIR PUMP RELAAIR PUMP RELA

AIR PUMP RELA

AIR PUMP RELAAIR PUMP RELA

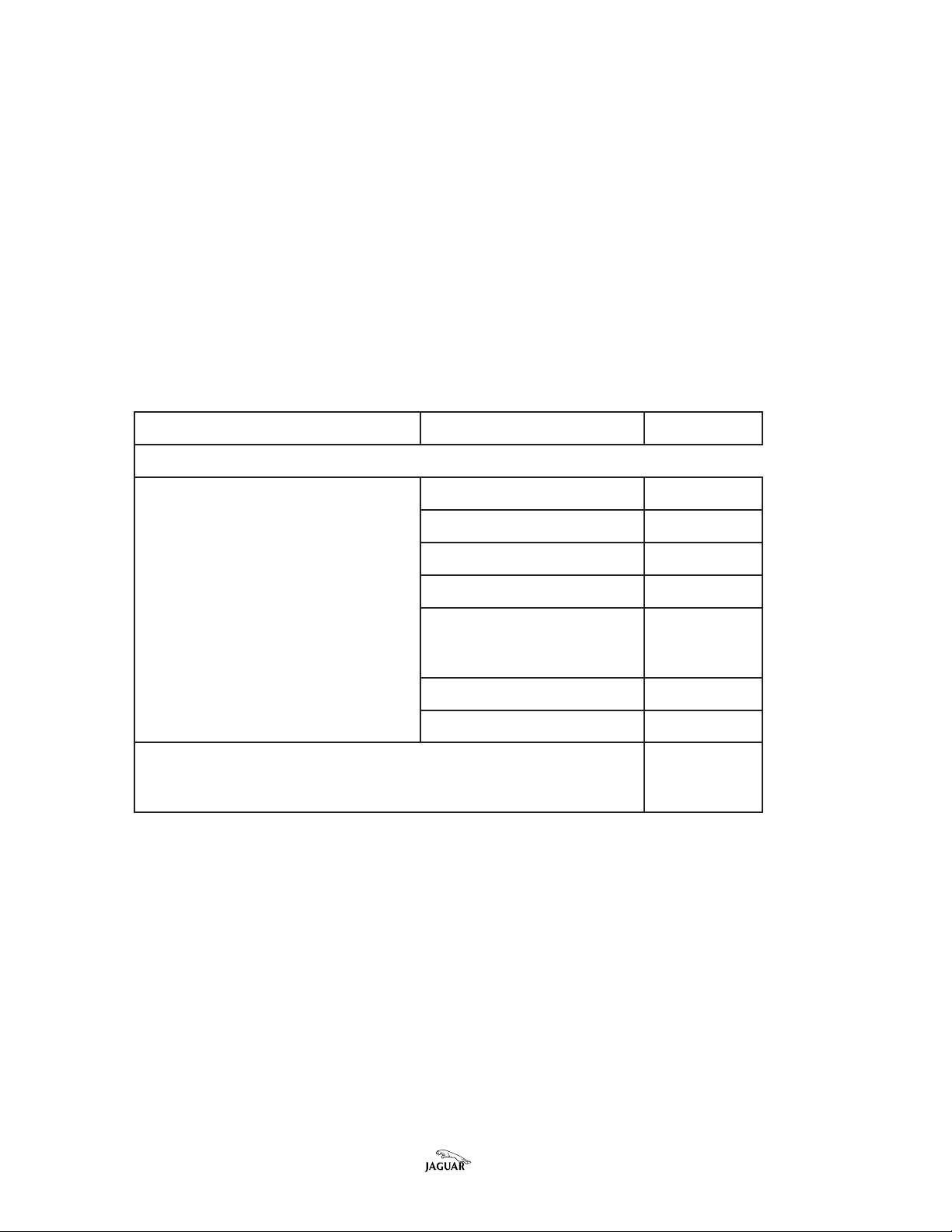

ILLUSTRA TION 1

YY

Y

YY

FRONFRON

FRON

FRONFRON

T OF T OF

T OF

T OF T OF

VEHICLEVEHICLE

VEHICLE

VEHICLEVEHICLE

11

1

11

994 MY994 MY

994 MY

994 MY994 MY

Page 2 of 5 Date of issue 5/97 Bulletin Number 17-9 Amended 8/97

LL

OCAOCA

TION OF XJS (4.0L) RANGE TION OF XJS (4.0L) RANGE

L

OCA

TION OF XJS (4.0L) RANGE

LL

OCAOCA

TION OF XJS (4.0L) RANGE TION OF XJS (4.0L) RANGE

AIR PUMP RELAAIR PUMP RELA

AIR PUMP RELA

AIR PUMP RELAAIR PUMP RELA

YY

Y

YY

AIR PUMP RELAAIR PUMP RELA

AIR PUMP RELA

AIR PUMP RELAAIR PUMP RELA

YY

Y

YY

FRONFRON

T OF T OF

T OF

T OF T OF

VEHICLEVEHICLE

VEHICLE

VEHICLEVEHICLE

FRON

FRONFRON

ILLUSTRA TION 2

PP

ARAR

TS INFORMATS INFORMA

P

AR

TS INFORMA

PP

ARAR

TS INFORMATS INFORMA

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

TION:TION:

TION:

TION:TION:

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

Sealed relay LHF 6703AA 1

QTYQTY

QTY

QTYQTY

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TION:TION:

TION:

TION:TION:

Service Action S458

VEHICLEVEHICLE

VEHICLE

VEHICLEVEHICLE

CALIFORNIACALIFORNIA

CALIFORNIA

CALIFORNIACALIFORNIA

4.0L 1 993-94 MY ST Replace AIR pump relay 0.10 hrs.

Sedan -without drive-in/out time

MODEL CODE (performed with another repair)

4064, 4082

4.0L 1993-94 MY

XJS MODEL CODE

2000, 2030, 3000,

3030, 4234, 4235

Bulletin Number 17-9 Amended 8/97 Date of issue 5/97 Page 3 of 5

SUMMARSUMMAR

SUMMAR

SUMMARSUMMAR

CODECODE

CODE

CODECODE

YY

DESCRIPTIONDESCRIPTION

Y

DESCRIPTION

YY

DESCRIPTIONDESCRIPTION

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

ANCEANCE

W

ANCE

WW

ANCEANCE

VEHICLEVEHICLE

VEHICLE

VEHICLEVEHICLE

SUMMARSUMMAR

SUMMAR

SUMMARSUMMAR

CODECODE

CODE

CODECODE

YY

DESCRIPTIONDESCRIPTION

Y

DESCRIPTION

YY

DESCRIPTIONDESCRIPTION

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

W

WW

ANCEANCE

ANCE

ANCEANCE

4.0L 1 993-94 MY SU Replace AIR pump relay 0.25 hrs.

Sedan -with drive-in/out time

MODEL CODE

4064, 4082

4.0L 1993-94 MY

XJS MODEL CODE

2000, 2030, 3000,

3030, 4234, 4235

EXC. CALIFORNIAEXC. CALIFORNIA

EXC. CALIFORNIA

EXC. CALIFORNIAEXC. CALIFORNIA

4.0L 1993-94 MY SW Check operation of AIR pump relay 0.10 hrs.

Sedan no fault found

MODEL CODE -without drive-in/out time

4064, 4082 (performed with another repair)

4.0L 1993-94 MY

XJS MODEL CODE

2000, 2030, 3000,

3030, 4234, 4235

4.0L 1993-94 MY SX Check operation of AIR pump relay 0.25 hrs.

Sedan no fault found

MODEL CODE -with drive-in/out time

4064, 4082

4.0L 1993-94 MY

XJS MODEL CODE

2000, 2030, 3000,

3030, 4234, 4235

4.0L 1993-94 MY SY Check operation of AIR pump relay 0.20 hrs.

Sedan fault determined, replace relay

MODEL CODE -without drive-in/out time

4064, 4082 (performed with another repair)

4.0L 1993-94 MY

XJS MODEL CODE

2000, 2030, 3000,

3030, 4234, 4235

Page 4 of 5 Date of issue 5/97 Bulletin Number 17-9 Amended 8/97

VEHICLEVEHICLE

VEHICLE

VEHICLEVEHICLE

4.0L 1993-94 MY SZ Check operation of AIR pump relay 0.35 hrs.

Sedan fault determined, replace relay

MODEL CODE -with drive-in/out time

4064, 4082

4.0L 1993-94 MY

XJS MODEL CODE

2000, 2030, 3000,

3030, 4234, 4235

NONO

TE:TE:

NO

TE: California dealerships must claim either summary code

NONO

TE:TE:

SUMMARSUMMAR

SUMMAR

SUMMARSUMMAR

CODECODE

CODE

CODECODE

YY

DESCRIPTIONDESCRIPTION

Y

DESCRIPTION

YY

DESCRIPTIONDESCRIPTION

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

ANCEANCE

W

ANCE

WW

ANCEANCE

‘ST’ or ‘SU’ regardless of vehicle’s state of registration. NonCalifornia dealerships must claim either summary code ‘ST’ or

‘SU’ on vehicles registered in the state of California.

CLAIM SUBMISSION PROCEDURE:

Warranty summary codes have been assigned to this service action in order to

simplify claim submission. The dealership will be reimbursed the parts and labor

time allowance as indicated.

DCS DEALERS

Submit claims using the appropriate summary code for the vehicle model and

work performed. Follow standard campaign submission procedures.

NON-DCS DEALERS

Submit claims on the Recall Campaign Summary form W-25. Enter the appropriate summary code for the vehicle model and work performed in the Repair Code

column. Do not use the W-1 warranty claim form.

Bulletin Number 17-9 Amended 8/97 Date of issue 5/97 Page 5 of 5

TECHNICAL BULLETIN

Insufficent AIR Flow – AIR Pump

(AIRP) – Diagnosis

MODEL

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

A revised AIR pump which is more heat resistant is now available.

The pump can be identified by a Julian date code of 002/*/96 or later. (The * in

the date code indicates the shift during which the pump was assembled which is

not relevant to the design of the pump.)

This technical bulletin provides a diagnostic procedure to aid diagnosis when DTC

P0411 has been flagged. Replacing the ECM will not solve the complaint of

flagging DTC P0411.

AA

CTION:CTION:

A

CTION:

AA

CTION:CTION:

In case of a customer complaint on a XJS (4.0L) Range vehicle, within the above

VIN range, of MIL illumination, with DTC P0411 flagged, follow the diagnostic

flowcha rt located on the last page of this bulletin. The following text provides

additional information.

The statements in boxes correspond to boxes in the flow chart.

Perform diagnosis with the engine at normal operating temperature to ensure that

the HO2S feedback is operating.

1995-96 MY XJS (4.0L) Range

VIN 194775-199152

DATE 8/97

17-10

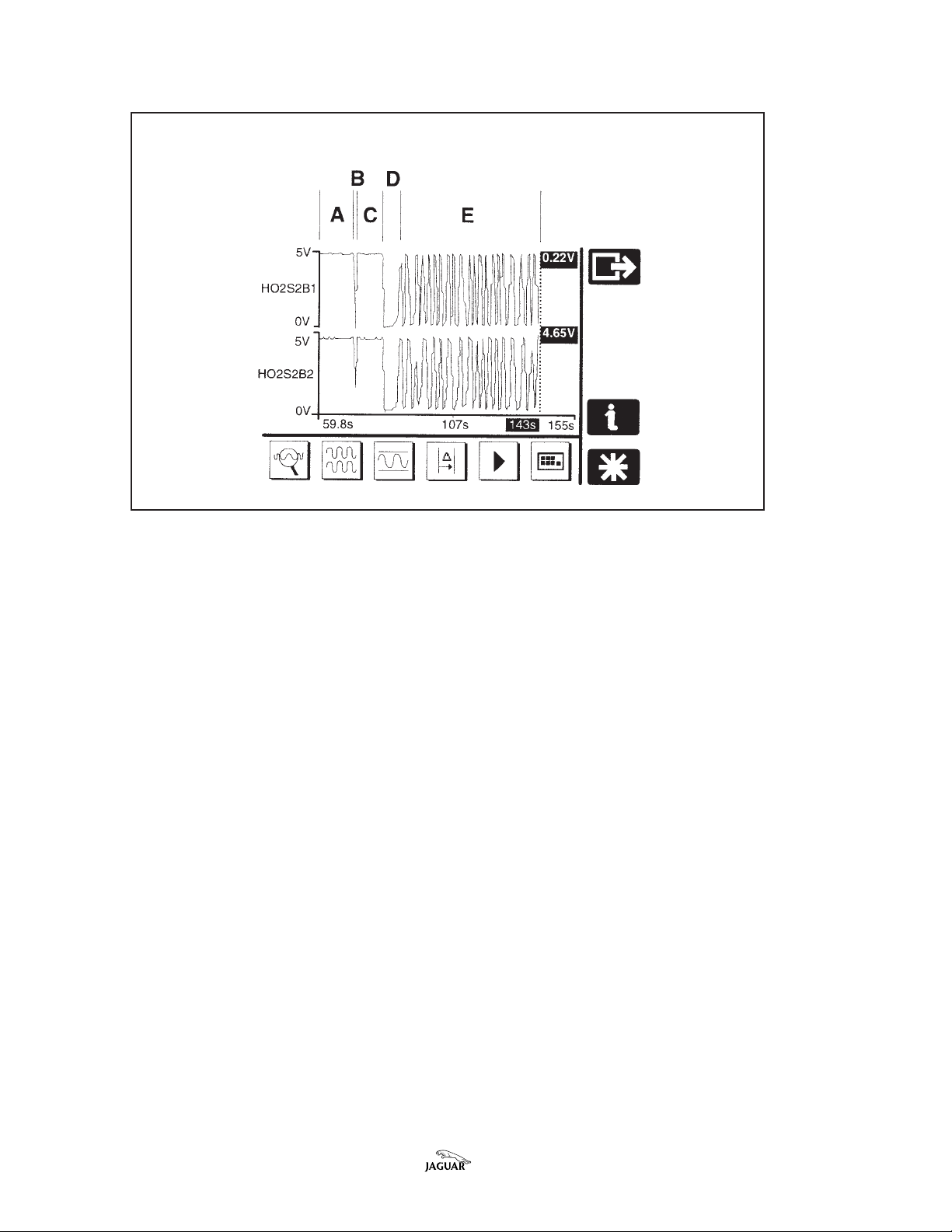

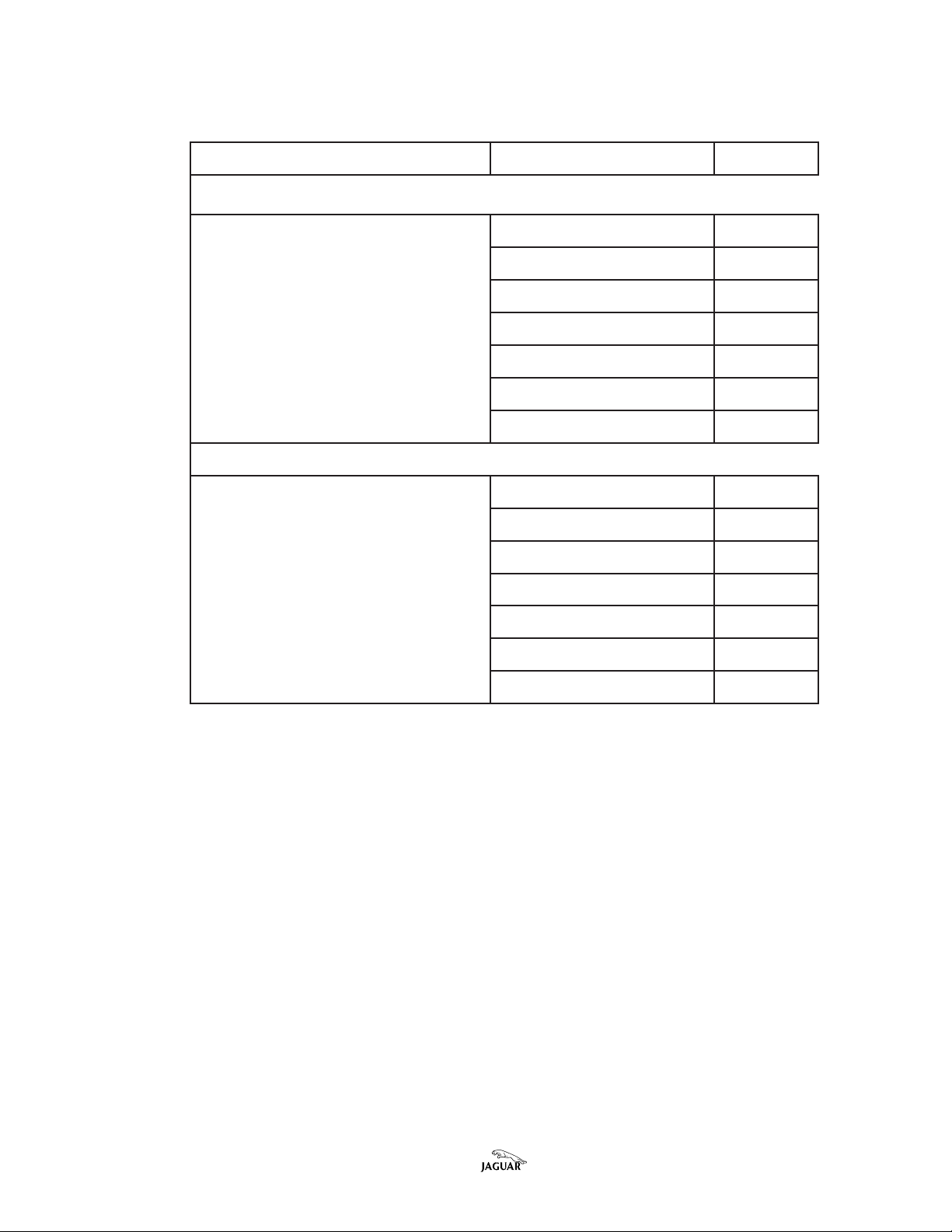

Does AIR pump operate?

The pump can be heard running and a light vibration can be felt.

The AIR pump operates for a short period of time following every engine start. It

typically operates for approximately 10-20 seconds at normal operating

temperatures, then switches off for approximately 5-10 seconds, and then restarts

to allow the system diagnostic check to occur. This check also takes approximately

5-10 seconds. See Illustration 1, sample of PDU trace. This complete cycle takes

place each time the engine is started.

cc

harhar

t.t.

c

har

t.

cc

harhar

t.t.

Bulletin Number 17-10 Date of issue 8/97 Page 1 of 5

This is the re-test referThis is the re-test refer

This is the re-test refer

This is the re-test referThis is the re-test refer

red to in the flowred to in the flow

red to in the flow

red to in the flowred to in the flow

PDU PDU

PDU

PDU PDU

TRATRA

TRA

TRATRA

CE SHOCE SHO

CE SHO

CE SHOCE SHO

WING CORRECT WING CORRECT

WING CORRECT

WING CORRECT WING CORRECT

AIR PUMP OPERAAIR PUMP OPERA

AIR PUMP OPERA

AIR PUMP OPERAAIR PUMP OPERA

ILLUSTRA TION 1

TIONTION

TION

TIONTION

JSI-3154

Zone ‘A’ shows the initial operation of the air pump (air flow causes lean reading).

Zone ‘B’ shows the pump switched off, prior to the diagnostic test (stopping air

flow causes rich reading).

Zone ‘C’ shows the pump operating during the diagnostic test cycle.

Zone ‘D’ shows the pump switched off when the test is complete.

Zone ‘E’ shows the lambda voltage switching under normal lambda operation.

Page 2 of 5 Date of issue 8/97 Bulletin Number 17-10

PDU PDU

TRATRA

PDU

PDU PDU

TRA

TRATRA

CE SHOCE SHO

CE SHO

CE SHOCE SHO

WING INADEQWING INADEQ

WING INADEQ

WING INADEQWING INADEQ

UAUA

TE TE

AIR FLAIR FL

UA

TE

UAUA

TE TE

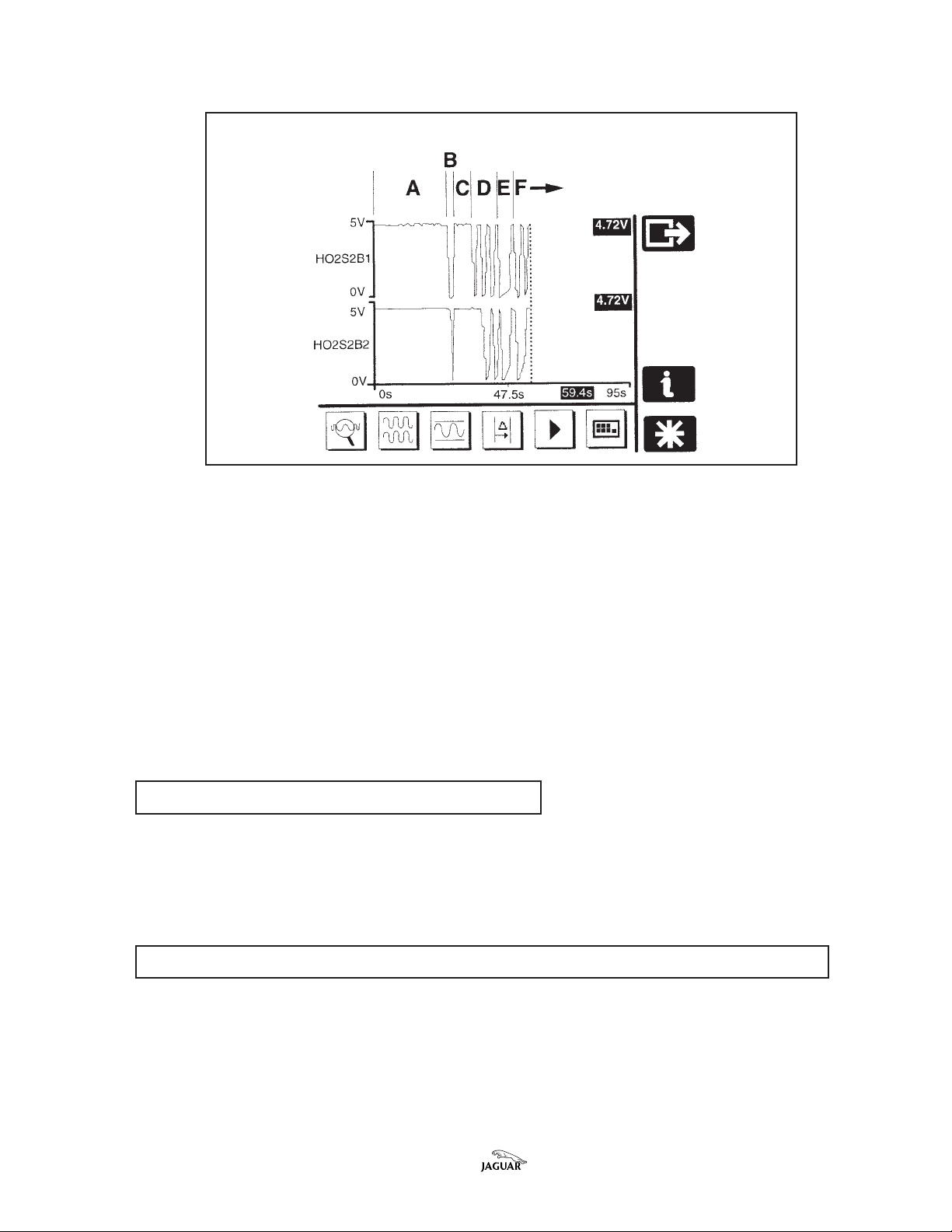

ILLUSTRA TION 2

AIR FL

AIR FLAIR FL

OO

O

OO

WW

W

WW

JSI-3155

Illustration 2 shows a PDU trace where there is inadequate air flow from the air

pump.

Zone ‘A’ shows the initial operation of the air pump (air flow causes lean reading).

Zone ‘B’ shows the pump switched off, prior to the diagnostic test (stopping air

flow causes rich reading).

Zone ‘C’ shows the pump operating during the diagnostic test cycle.

Zone ‘D’ shows the lambda voltage switching to normal feedback, as there is

insufficient air flow to sustain the voltage at 5v.

Zone ‘E’ shows the air pump switched off at the end of the diagnostic cycle.

Zone ‘F’ shows the lambda voltage switching under normal lambda operation.

Check outlet port of pump for strong air flow

The air flow from the air pump should be strong enough to almost prevent the

palm of the hand from staying pressed against the outlet port of the pump. In

situations where DTC P0411 is flagged, the air flow from the pump outlet will be

very weak.

Check ports of pump for signs of overheating or excessive build-up of carbon.

This check should be performed when the voltage trace is correct, in case of

intermittent operation of the pump. Look for excessive buildup of carbon on the

outlet port, and check if the foam filter in the inlet port has melted or is out of

position. In such cases, replace the outlet check valve also.

Bulletin Number 17-10 Date of issue 8/97 Page 3 of 5

Follow electrical diagrams in XJS Electrical Guide

If the AIR pump does not operate as described on page 1, refer to Fig. 25 of the

XJS Range 1995/6 Electrical Guide.

Is “bleed nipple” hose fitted?

On vehicles from VIN 194775 - 199153, check that the hose between the air pump

and check valve is the type incorporating an anti-vacuum bleed nipple, as

introduced in production from VIN 199154 (refer to Technical Bulletin 18-47

Amended 4/95.) If not, install the appropriate later-design hose.

PP

ARAR

TS INFORMATS INFORMA

P

AR

TS INFORMA

PP

ARAR

TS INFORMATS INFORMA

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Air Injection Pump LHE 1545A C 1

Check V alve EBC 1 1499 1

Hose, pump to check valve, Normally aspirated NBC 4798AA 1

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

FF

AA

ULUL

F

A

UL

FF

AA

ULUL

CODECODE

CODE

CODECODE

BG BB ** 17.25.07 Air pump - renew 0.60 hours

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TT

T

TT

TION:TION:

TION:

TION:TION:

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

TION:TION:

TION:

TION:TION:

R.OR.O

..

R.O

.

R.OR.O

..

NUMBERNUMBER

NUMBER

NUMBERNUMBER

17.25.21 Check valve - renew 0.20 hours

86.99.01 Read and clear DTCs. 0.50 hours

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

(including diagnostic time)

Fill out Form S93.

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

W

WW

ANCEANCE

ANCE

ANCEANCE

QTYQTY

QTY

QTYQTY

Page 4 of 5 Date of issue 8/97 Bulletin Number 17-10

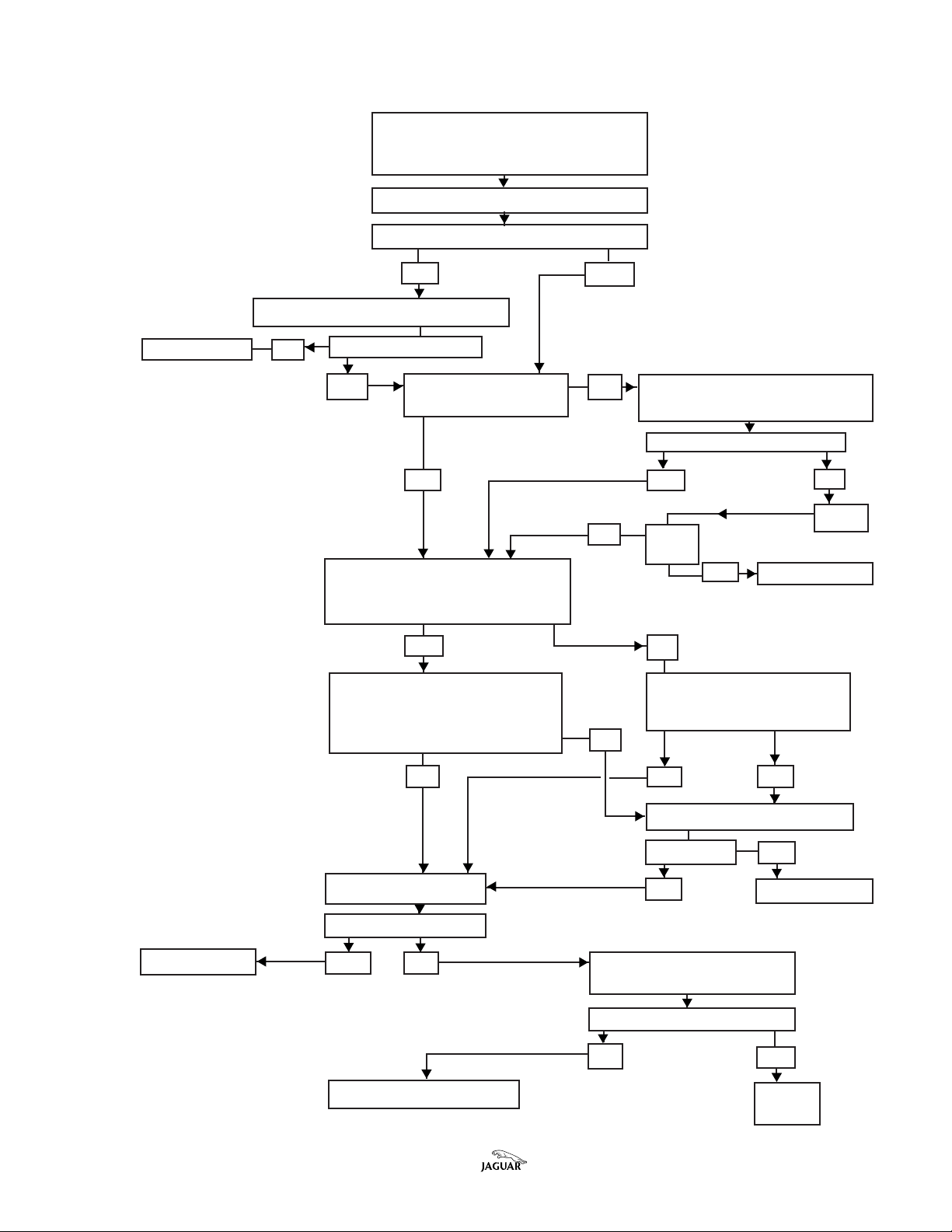

DIADIA

GNOSGNOS

DIA

GNOS

DIADIA

GNOSGNOS

With the engine at normal operating

temperature, connect the PDU and

read DTC P0411. Fill out form S93.

Is ‘bleed nipple’ hose installed?

NO YES

Install ‘bleed nipple’ hose. Retest

Return vehicle NO Defect still present?

YES Does AIR pump NO Refer to electrical diagrams in

operate? XJS Electrical Guide

YES YES NO

In PDU Datalogger, run engine YES Return vehicle

while monitoring HO2S voltage.

Is voltage trace correct?

TIC FLTIC FL

OO

TIC FL

TIC FLTIC FL

Clear DTC.

WCHARWCHAR

O

WCHAR

OO

WCHARWCHAR

TT

T

TT

NO Retest

OK?

Circuit OK?

Repair

YES NO

Check ports of pump for signs Check outlet port of pump

of overheating or excessive for strong air flow.

buildup of carbon. Strong air flow?

Pump OK? NO

YES YES NO

Replace pump

Retest OK? YES

Replace c heck valve NO Return vehicle

Retest OK?

Return vehicle YES NO Check pipe for blockage.

Clear/replace as necessary .

Retest, OK?

NO YES

Contact Technical Hotline Return

vehicle

Bulletin Number 17-10 Date of issue 8/97 Page 5 of 5

TECHNICAL BULLETIN

Throttle Difficult to Open on Cold Engine

– Normally Aspirated Engines –

Modify Crankcase Breather System

MODEL 1995-96 MY XJS

VIN 194775-226643

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

On some 4.0L XJS vehicles, owners may experience slight difficulty in opening

the throttle from the closed position after the vehicle has been sitting for some

time. Under certain circumstances, oil mist from the crankcase may collect and

harden on the throttle body and plate when the engine is cold, where it may cause

this condition.

AA

CTION:CTION:

A

CTION:

AA

CTION:CTION:

Perform the following modification to include an oil separator in the crankcase

ventilation system, along with cleaning operations on the throttle body unit,

when there is a history of customer complaint of the condition described above.

DATE 12/98

17-11

onlyonly

only

onlyonly

MODIFICATION PROCEDURE

1. Open the hood and install fender covers.

2. Disconnect the multiple connectors from the intake air temperature sensor

(IATS) and from the mass air flow sensor (MAFS).

3. Disconnect the convoluted hose from the throttle body.

4. Remove the nut that secures the rubber mounting bobbin to the induction

elbow; release the air cleaner to MAFS retaining clips and remove the MAFS/

induction elbow assembly to provide further access.

5. Unscrew by ONE turn the throttle stop adjustment screw, so that no air gap

exists on either side of the throttle plate. It will be necessary to shorten a

standard hexagon wrench (Allen wrench) for access to this screw.

6. Hold the throttle closed and remove the screws that retain the throttle plate to

the shaft.

7. Note the direction of assembly to assist during reassembly and then remove

the throttle plate after opening the throttle shaft.

Note: Note:

Note: During the above operation, ensure that the shaft is not

Note: Note:

pulled out of the potentiometer. If this occurs, removal of the

potentiometer will be required to permit reassembly.

8. Gently return the shaft to the ‘closed’ position.

9. Use a suitable solvent and shop towel to carefully remove all residual

Bulletin Number 17-11 Date of issue 12/98 Page 1 of 5

contaminants from the throttle plate and throttle body air passage. Use care

not to allow excess solvent to run down the throttle shaft or enter the intake

manifold. Use a mirror to assist in checking that all deposits have been

removed. Dry off any residual solvent/deposits.

10. Using care not to disengage the throttle shaft from the potentiometer below,

and noting the correct orientation, reinstall the throttle plate in the shaft.

Apply thread locking compound to the threads of the securing screws and

start, but do not fully tighten, the two securing screws.

11. Check with a mirror that the throttle plate is centered with the throttle fully

closed, as the retaining screws are tightened enough to grip the plate. Open

the throttle against spring pressure, then allow it to snap closed - this will help

center the throttle plate on the shaft and to the venturi. Repeat if necessary,

then fully tighten the throttle plate retaining screws.

Caution:Caution:

Caution: No specific torque setting is available for the throttle

Caution:Caution:

plate screws. Tighten them appropriately for brass screws of this

size.

12. Check that the locking patch of the throttle stop screw is still effective.

Sufficient drag must remain to ensure that any setting will not be disturbed by

vibration, otherwise apply fresh locking compound. Adjust the screw to open

the throttle plate until a narrow 0.002 inch feeler blade can fit between the

throttle plate and the venturi.

13. Remove the screws that retain the fuel rail cover and remove the cover.

14. Loosen the clamps and remove the breather hose from the engine.

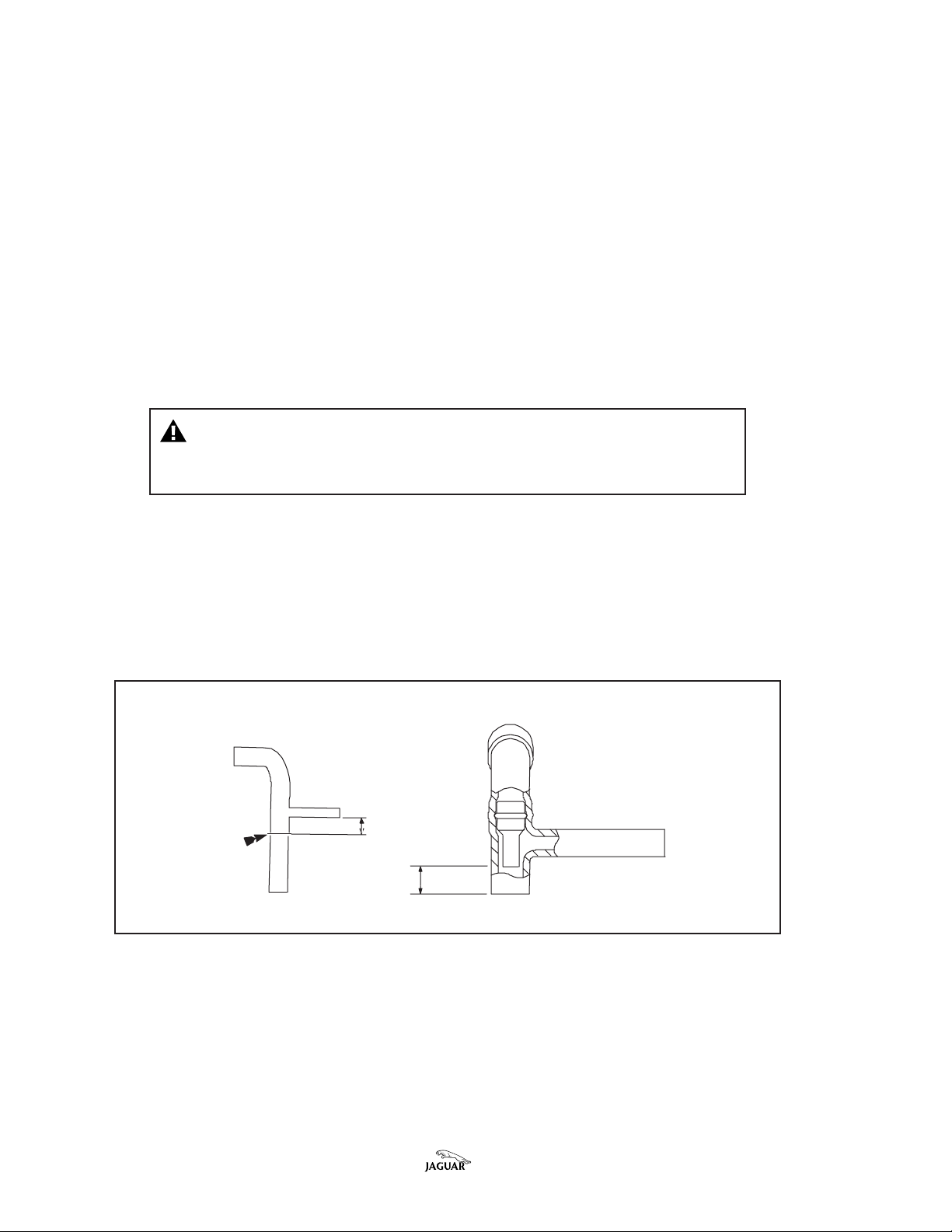

MODIFYING EXISMODIFYING EXIS

MODIFYING EXIS

MODIFYING EXISMODIFYING EXIS

CUT HERECUT HERE

CUT HERE

CUT HERECUT HERE

DETDET

AIL FOR CUTTINGAIL FOR CUTTING

DET

AIL FOR CUTTING

DETDET

AIL FOR CUTTINGAIL FOR CUTTING

EXISEXIS

TING BREATING BREA

EXIS

TING BREA

EXISEXIS

TING BREATING BREA

TING BREATING BREA

TING BREA

TING BREATING BREA

11

6 MM (5/8 INCH)6 MM (5/8 INCH)

1

6 MM (5/8 INCH)

11

6 MM (5/8 INCH)6 MM (5/8 INCH)

THER HOSETHER HOSE

THER HOSE

THER HOSETHER HOSE

THER HOSETHER HOSE

THER HOSE

THER HOSETHER HOSE

22 MM (7/8 INCH)22 MM (7/8 INCH)

A

22 MM (7/8 INCH)

22 MM (7/8 INCH)22 MM (7/8 INCH)

B

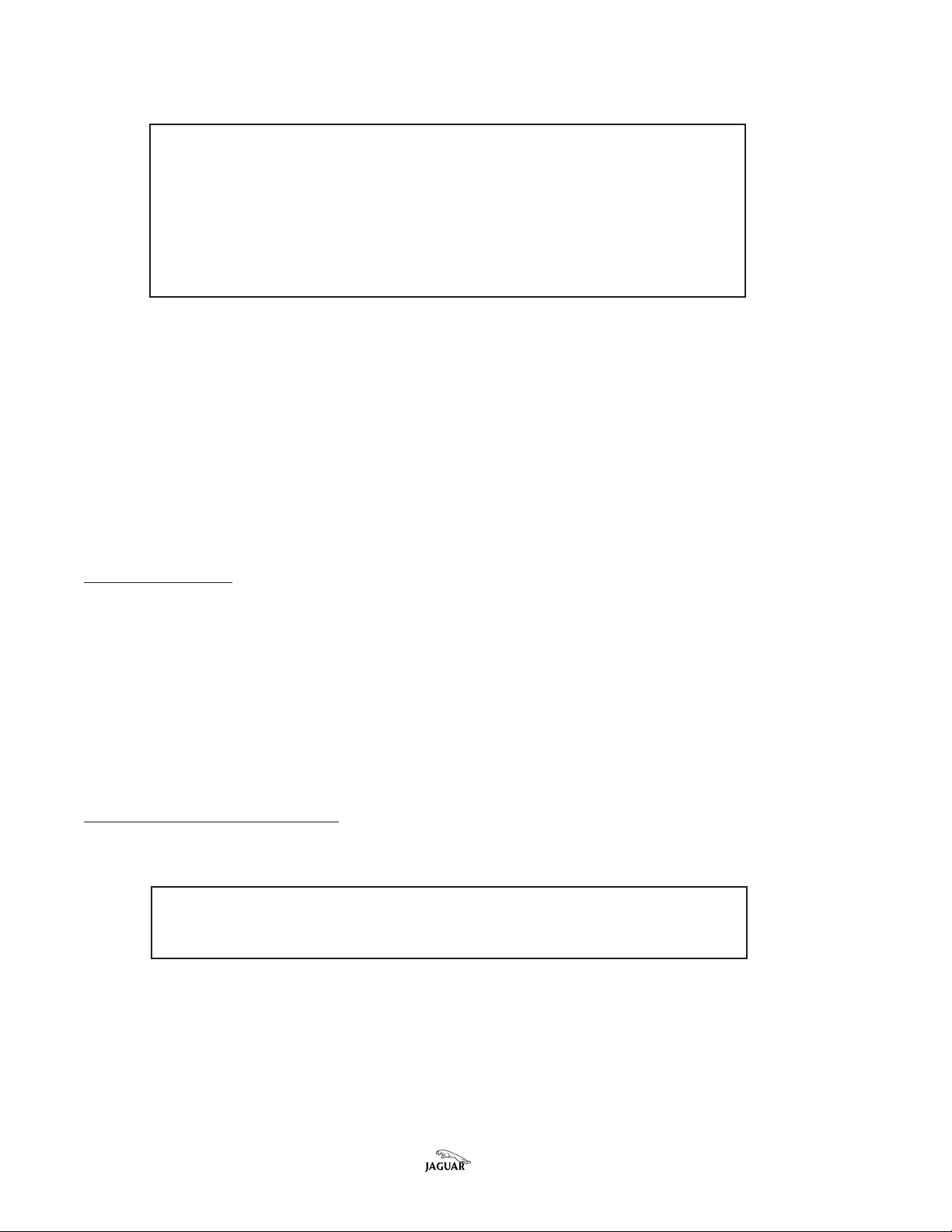

ILLUSTRATION 1

LOCALOCA

TION FOR RESTION FOR RES

LOCA

TION FOR RES

LOCALOCA

TION FOR RESTION FOR RES

TRICTERTRICTER

TRICTER

TRICTERTRICTER

JSI.3438

15. Cut the existing breather hose as shown in Illustration 1. Make sure that a

clean cut is made, maintaining the 22 mm (7/8 inch) dimension consistently.

16. Insert the larger diameter of a restricter (Part No. NNB 3956AA ) into the cut

upper end of the hose. Push the restricter fully into the hose, until the lower

end is 16 mm (5/8 inch) from the cut end, as in Illustration 1.

Page 2 of 5 Date of issue 12/98 Bulletin Number 17-11

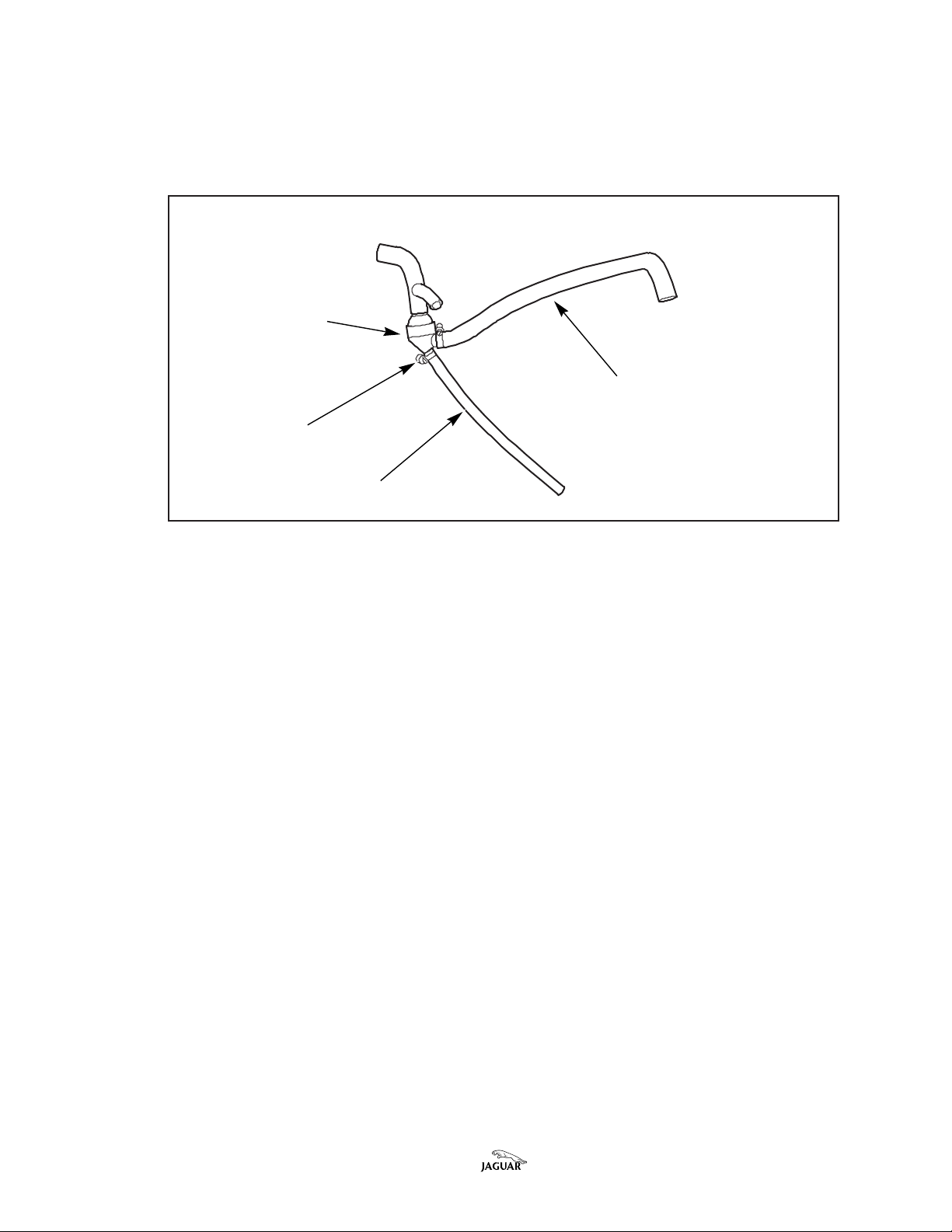

17. Install a worm drive hose clamp (Part No. JHC 200401) and connect the upper

portion of the breather hose to the top stub of the oil separator (Part No. NNB

2102AA), as in Illustration 2.

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

VV

V

VV

Y OF HOSES Y OF HOSES

Y OF HOSES

Y OF HOSES Y OF HOSES

APOR SEPAPOR SEP

APOR SEP

APOR SEPAPOR SEP

HOSE CLAMPHOSE CLAMP

HOSE CLAMP

HOSE CLAMPHOSE CLAMP

ARAARA

ARA

ARAARA

TT

O OIL SEPO OIL SEP

T

O OIL SEP

TT

O OIL SEPO OIL SEP

TT

OROR

T

OR

TT

OROR

DRAIN HOSEDRAIN HOSE

DRAIN HOSE

DRAIN HOSEDRAIN HOSE

ARAARA

TT

OROR

ARA

T

OR

ARAARA

TT

OROR

ILLUSTRATION 2

EXISEXIS

TING HOSETING HOSE

EXIS

TING HOSE

EXISEXIS

TING HOSETING HOSE

JSI.3432

18. Installing a worm drive hose clamp (JHC 200401) to the lower portion of the

existing breather tube, connect it to the side stub of the oil separator, and with

a hose clamp (JHC 200101) install the drain hose (NNB 5961AA) to the lower

stub of the oil separator, as in Illustration 2.

It is imporIt is impor

It is impor

It is imporIt is impor

‘‘

engineengine

‘

engine

‘‘

engineengine

tant that the worm housing of the hose clamp is installed facing thetant that the worm housing of the hose clamp is installed facing the

tant that the worm housing of the hose clamp is installed facing the

tant that the worm housing of the hose clamp is installed facing thetant that the worm housing of the hose clamp is installed facing the

’ side of the hose and oil separator’ side of the hose and oil separator

’ side of the hose and oil separator

’ side of the hose and oil separator’ side of the hose and oil separator

..

.

..

19. Tighten the hose clamps with the hoses positioned as in Illustration 2.

20. Remove the dipstick from the dipstick tube. Wipe it clean and place it aside in

a clean location until reinstalled later.

21. Remove the retaining screw at the support bracket and remove the existing

dip stick tube from the engine. Remove the existing ‘P’ clip for reuse before

discarding the existing dip stick tube.

22. Ensure that the rubber sealing tube for the dip stick tube remains on the

engine.

23. Transfer the ‘P’ clip to the replacement dip stick tube (NNB 3908AA), install the

dip stick tube on the engine (ensuring that it is fully seated). Reinstall the

retaining screw on the tube and bracket.

Bulletin Number 17-11 Date of issue 12/98 Page 3 of 5

FEEDING BREAFEEDING BREA

FEEDING BREA

FEEDING BREAFEEDING BREA

THER THER

TUBE UNDER FUEL RAILTUBE UNDER FUEL RAIL

THER

TUBE UNDER FUEL RAIL

THER THER

TUBE UNDER FUEL RAILTUBE UNDER FUEL RAIL

JSI.3433

BREABREA

BREA

BREABREA

THER HOSETHER HOSE

THER HOSE

THER HOSETHER HOSE

ILLUSTRATION 3

24. As shown in Illustration 3, route the end of the longer breather hose (attached

to the side stub of the new oil separator) under the fuel rail. When part-way

under the fuel rail, route the thinner drain tube (attached to the bottom stub of

the oil separator) between the runners of the intake manifold so that it can

eventually be connected to the new dip stick tube.

HOSE INSHOSE INS

HOSE INS

HOSE INSHOSE INS

TT

ALLED ALLED

T

ALLED

TT

ALLED ALLED

BREABREA

BREA

BREABREA

WITH WITH

VV

WITH

V

WITH WITH

VV

THER HOSETHER HOSE

THER HOSE

THER HOSETHER HOSE

APOR SEPAPOR SEP

APOR SEP

APOR SEPAPOR SEP

ARAARA

ARA

ARAARA

TT

T

TT

OROR

OR

OROR

JSI.3431

VV

APOR SEPAPOR SEP

V

APOR SEP

VV

APOR SEPAPOR SEP

ARAARA

ARA

ARAARA

TT

OROR

T

OR

TT

OROR

ILLUSTRATION 4

25. Continue to align the breather hose assembly until the upper breather hose

can be reconnected to the stub pipe on the camshaft cover and the original

hose clamp tightened, as in Illustration 4.

26. Install the drain hose on the side connection on the replacement dip stick

tube, installing a worm drive hose clamp (JHC 200101) over the hose, and

tightening the clamp once the hose is fully connected and free of any kinks.

27. Check that the dip stick is clean and reinstall it.

28. Reinstall the MAFS/induction elbow assembly and reconnect the multiplugs.

29. Connect the lower end of the breather hose to the stub on the induction elbow

and tighten the hose clamp.

Page 4 of 5 Date of issue 12/98 Bulletin Number 17-11

30. Reconnect the side hose above the oil separator to its original stub pipe and

tighten the hose clamp.

31. At the PDU base station, load JTP 626/4. Select Diagnostics, Vehicle Setup,

then select Engine Setup. Connect the PDU to the vehicle. Under Engine

Setup, select Throttle Position Sensor Adaption Test. Answer YES to the

question, “Has a new throttle position sensor been fitted?” After the test

passes, the idle speed will be correct.

32. Remove the fender covers and close the hood.

PP

ARAR

TS INFORMATS INFORMA

P

AR

TS INFORMA

PP

ARAR

TS INFORMATS INFORMA

TION:TION:

TION:

TION:TION:

The following should be ordered from Jaguar Parts Operations:

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Breather Kit JLM 20709 1

Screw, throttle plate retaining JLM 20936 *

* only needed if lost or damaged

CONTENTS LIST - BREATHER KIT JLM 20709 (For Information Only)

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Breather-Oil Separator NNB 2102AA 1

Restricter - Part Load Breather NNB 3956AA 1

Tube - Dipstick NNB 3908AA 1

Hose - Oil Drain NNB 5961AA 1

Clamp, Hose, Worm Drive JHC 200101 2

Clamp, Hose, Worm Drive JHC 200401 2

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

FF

AA

ULUL

F

A

UL

FF

AA

ULUL

CODECODE

CODE

CODECODE

CD KF 69 17.91.33 Engine Breather System 0.85 hrs.

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TT

T

TT

TION:TION:

TION:

TION:TION:

R.OR.O

..

R.O

.

R.OR.O

..

NUMBERNUMBER

NUMBER

NUMBERNUMBER

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Modification (includes throttle position

adaption test)

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

PP

ARAR

T NOT NO

P

AR

T NO

PP

ARAR

T NOT NO

QTYQTY

QTY

QTYQTY

..

.

..

QTYQTY

QTY

QTYQTY

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

ANCEANCE

W

ANCE

WW

ANCEANCE

Bulletin Number 17-11 Date of issue 12/98 Page 5 of 5

TECHNICAL BULLETIN

Recall T493 - 1995 MY/Recall

R493 - 1996 MY

– AJ16 EGR System –

Replace PROMs and EGR Valve

MODEL 1995-96 MY XJS 4.0L

VIN 194775-226645

Remove and destroy Bulletin 17-12, amended 11/01.

Replace with this Bulletin.

This Recall supersedes Service Action S483.

Note:Note:

Note: In January 2002 Jaguar advised you that the above recall

Note:Note:

action required on 1995 MY vehicles was temporarily suspended

due to unforeseen problems with one of the components

associated with this recall. Jaguar had requested that dealers

cease conducting further actions on 1995 MY vehicles until the

problem with the affected component had been resolved.

JJ

aguar is now pleased to inform you that the issue with theaguar is now pleased to inform you that the issue with the

J

aguar is now pleased to inform you that the issue with the

JJ

aguar is now pleased to inform you that the issue with theaguar is now pleased to inform you that the issue with the

PROMs has been resolved, and that JPROMs has been resolved, and that J

PROMs has been resolved, and that J

PROMs has been resolved, and that JPROMs has been resolved, and that J

contacting ownercontacting owner

contacting owner

contacting ownercontacting owner

have the repair performed.have the repair performed.

have the repair performed.

have the repair performed.have the repair performed.

s requesting that they contact their dealer tos requesting that they contact their dealer to

s requesting that they contact their dealer to

s requesting that they contact their dealer tos requesting that they contact their dealer to

aguar once agaguar once ag

aguar once ag

aguar once agaguar once ag

DATE 11/01

ain will beain will be

ain will be

ain will beain will be

17-12

Amended

08/02

This version of the recall bulletin has a revised part number for

the 1995 MY vehicle. Additional Warranty Information has been

added for those 1995 MY vehicles previously re-worked under

this Recall Action. Please destroy all previous versions of Recall

Action Bulletin R493 and replace it with this version.

Please note that the Recall number for 1995 MY vehicles is now

T493, R493 will continue to be used for 1996 MY vehicles.

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

Since the introduction of the AJ16 engine Jaguar has seen a high rate of

replacement of EGR valves following illumination of the malfunction indicator

lamp (MIL). This is understood to be a result of accumulated contamination within

the EGR valve that can produce possible drivability issues such as rough idle,

hesitation, and difficult starting.

Following consultation with the US En vironmental Protection Agency (EPA) Jaguar

has decided to recall all vehicles equipped with this engine and carry out a

number of modifications including the introduction of a cleaning cycle to the EGR

valve. The following actions apply to all vehicles within the above VIN ranges.

• Replace PROMs within Engine Control Module (ECM). J aguar Cars has

upgraded the PROMs within the ECM to provide a cleaning cycle of the EGR

system.

Bulletin Number 17-12 Amended 08/02 Date of issue 11/0 1 Page 1 of 16

• Replace EGR valve and gasket, to ensure that it is free from contamination.

• Replace throttle return spring. Some vehicles may experience customer

complaints of high idle speeds.

Jaguar Cars is writing to all owners of the above vehicles (in timed mailings) to

advise them to take their vehicles into their local dealer to have the above

modifications made.

This recall will supersede Service Action S483, S675, and S676, no further claims

for these Service Actions will be accepted.

AA

CTION:CTION:

A

CTION:

AA

CTION:CTION:

Refer to the following charts to determine the appropriate course of action.

RAEYLEDOMRAEYLEDOM

RAEYLEDOMRAEYLEDOMTNENOPMOCTNENOPMOC

RAEYLEDOM

demrofrepylsuoiverpllaceR-YM59

evlaVRGEX

TNENOPMOCTNENOPMOCSJXSJX

TNENOPMOC

teksaGevlaVRGEX

deriuqeRsAtloBevlaVRGEX

SJXSJX

SJX

rehtruFoN

tnemecalpeRgnirpSelttorhT

tnemecalpeRMORPEX

demrofrepylsuoiverpllaceR-YM69

noitcA

deriuqeR

rehtruFoN

noitcA

deriuqeR

Page 2 of 16 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

llaceR-YM59tonton

tontondemrofrepylsuoiverp

ton

RAEYLEDOMRAEYLEDOM

RAEYLEDOMRAEYLEDOMTNENOPMOCTNENOPMOC

RAEYLEDOM

TNENOPMOCTNENOPMOCSJXSJX

TNENOPMOC

evlaVRGEX

teksaGevlaVRGEX

SJXSJX

SJX

llaceR-YM69tonton

tontondemrofrepylsuoiverp

ton

tloBevlaVRGEderiuqeRsAderiuqeRsA

tnemecalpeRMORPEX

evlaVRGEX

teksaGevlaVRGEX

tloBevlaVRGEderiuqeRsAderiuqeRsA

tnemecalpeRMORPEX

deriuqeRsAderiuqeRsAX

deriuqeRsA

tnemecalpeRgnirpSelttorhTX

deriuqeRsAderiuqeRsAX

deriuqeRsA

tnemecalpeRgnirpSelttorhTX

Bulletin Number 17-12 Amended 08/02 Date of issue 11/0 1 Page 3 of 16

Note:Note:

Note: In the case of customer brings to the dealer a vehicle that

Note:Note:

exhibits a drivability concern that the recall action does not

eradicate, normal diagnostic procedures can be followed as

necessary to determine the root cause. The completion of any

subsequent repairs are subject to normal New Car Warranty or

Select Edition Warranty, or customer pay authorization as

appropriate.

Remove the ECM from the vehicle by the following procedure.

1. Connect the WDS to the vehicle’s data link connector.

2. Record any diagnostic trouble codes stored in the ECM, then clear them from

the system.

3. Turn the ignition switch to ‘off’, wait 20 seconds before continuing with this

procedure.

4. Note customer settings such as radio stations.

5. Open the luggage compartment, remove the cover from the battery and

disconnect the battery ground cable.

REMOVING ECM

1. Open the right hand door and remove the carpet from the foot well.

2. Remove the ECM cover insulation pad.

3. Remove the securing nuts and remove the cover from the ECM.

4. Remove the ECM from its mounting, disconnect both harness connectors and

remove the ECM from the vehicle.

5. Mark the VIN on the side of the ECM to prevent confusion when more than

one ECM is being modified.

ISSUE 1 - REPLACING PROM

1. Check that the ‘anti-back out’ plate on the face of each harness connector is

still in place after disconnecting the connector.

Note: Note:

Note: In the event of the anti-back out plate becoming loose or

Note: Note:

detached, secure it to the face of the connector, pressing it firmly

in place.

Page 4 of 16 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

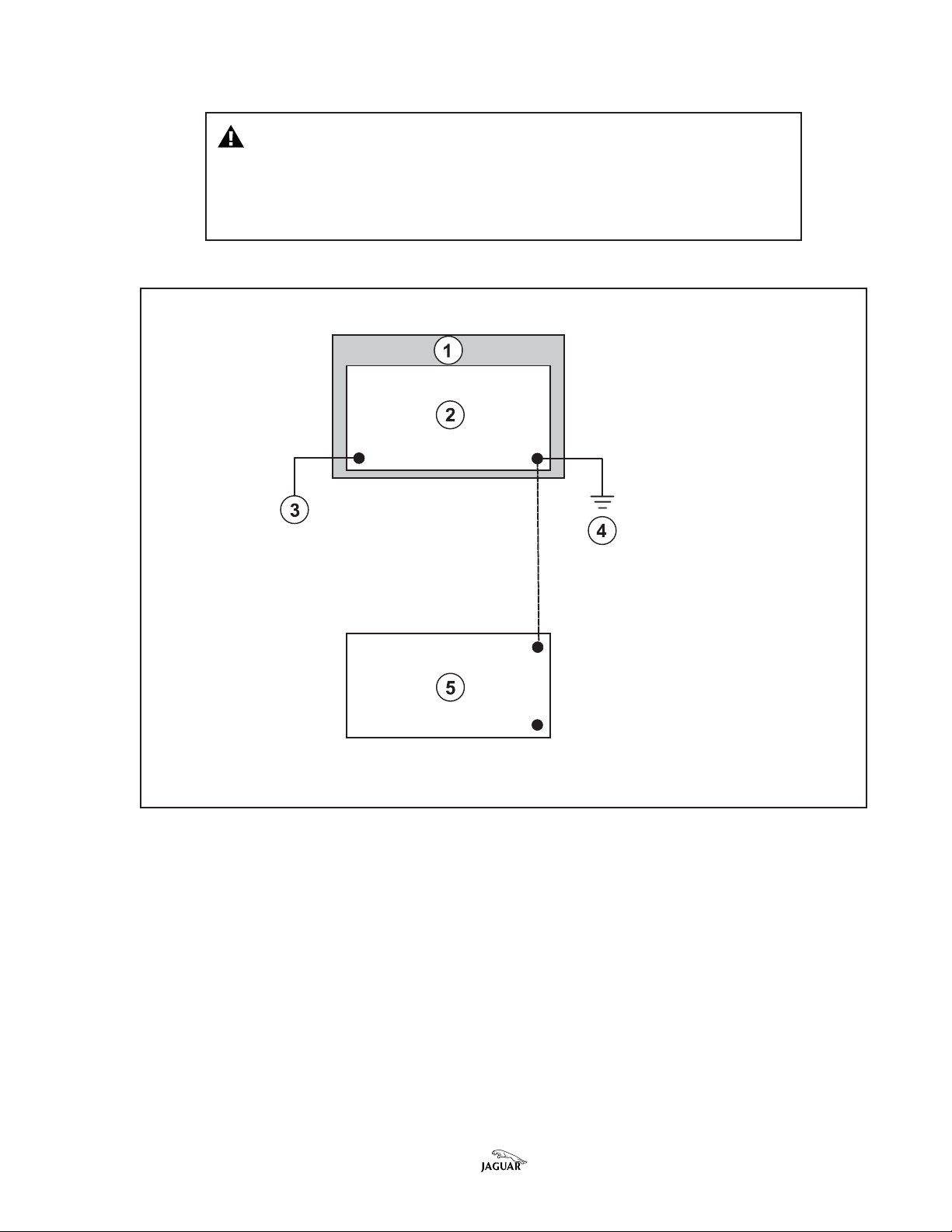

ANAN

AN

ANAN

Caution:Caution:

Caution: Perform the following operations at an antistatic

Caution:Caution:

workstation (previously supplied) while wearing a grounding

wrist-strap (Illustration 1). Additional work mats can be sourced

locally, such as Radio Shack cat. no. 910-3780.

TI-STI-S

TT

AA

TIC TIC

WW

ORKSORKS

TT

AA

TI-S

TI-STI-S

T

A

TIC

W

TIC TIC

ORKS

WW

ORKSORKS

TT

AA

T

TT

TIONTION

A

TION

AA

TIONTION

1 – WORK BENCH

2 – WORK MAT

3 – WRIST STRAP CONNECTION

4 – GROUND CONNECTION

5 – FOOT MAT

JSI 2663

ILLUSTRATION 1

2. Place the ECM on the anti-static work mat, with one flat face to the mat.

Looking towards the two connectors, the red connector should be to the

upper right, the blac k connector to the lower left.

3. Note the orientation of the top cover with its mounting lugs, relative to the

ECM casing. Mark both the cover and casing, using a felt-tip marker pen, to

assist when reassembling.

4. Remove the four retaining screws of the top ECM cover (i.e. the cover

adjacent to the red connector) using a Torx 20 anti-tamper type bit. Remove

the cover.

Bulletin Number 17-12 Amended 08/02 Date of issue 11/0 1 Page 5 of 16

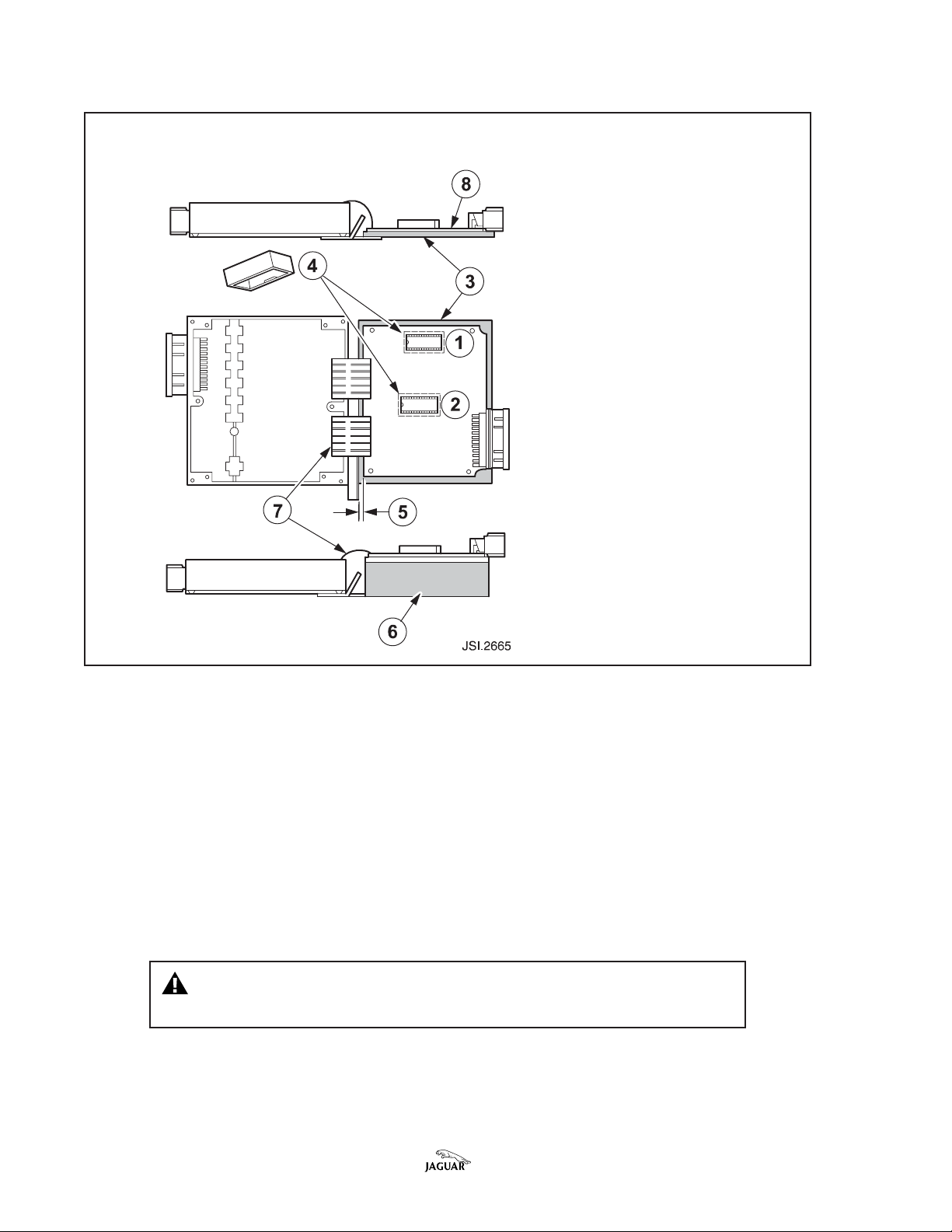

LL

OCAOCA

TION OF PROMS IN ECMTION OF PROMS IN ECM

L

OCA

TION OF PROMS IN ECM

LL

OCAOCA

TION OF PROMS IN ECMTION OF PROMS IN ECM

1 – 28 PIN PROM1 – 28 PIN PROM

1 – 28 PIN PROM

1 – 28 PIN PROM1 – 28 PIN PROM

2 – 32 PIN PROM2 – 32 PIN PROM

2 – 32 PIN PROM

2 – 32 PIN PROM2 – 32 PIN PROM

3 – ECM CO3 – ECM CO

3 – ECM CO

3 – ECM CO3 – ECM CO

4 – PROM CO4 – PROM CO

4 – PROM CO

4 – PROM CO4 – PROM CO

5 – CLEARANCE SP5 – CLEARANCE SP

5 – CLEARANCE SP

5 – CLEARANCE SP5 – CLEARANCE SP

6 – 6 –

WOOD SUPPORWOOD SUPPOR

6 –

WOOD SUPPOR

6 – 6 –

WOOD SUPPORWOOD SUPPOR

7 – RIBBON CABLES7 – RIBBON CABLES

7 – RIBBON CABLES

7 – RIBBON CABLES7 – RIBBON CABLES

8 - PRIN8 - PRIN

8 - PRIN

8 - PRIN8 - PRIN

VERVER

VER

VERVER

VERSVERS

VERS

VERSVERS

TED CIRCUIT BOTED CIRCUIT BO

TED CIRCUIT BO

TED CIRCUIT BOTED CIRCUIT BO

AA

CECE

A

CE

AA

CECE

TT

T

TT

ARDARD

ARD

ARDARD

ILLUSTRATION 2

5. Remove the seven retaining screws of the printed circuit board (8, Illustration

2). Fold the printed circuit board away from the body of the ECM unit and

support it on a block of wood (6, Illustration 2) so that no strain is placed on

the ribbon connectors (7, Illustration 2). Allow a clearance space (5,

Illustration 2) so that no damage can occur from contact with the mounting

brackets.

6. The modification kit contains two microc hips, one each of the 28-pin (1,

Illustration 2) and 32-pin (2, Illustration 2) design.

7. Remove the covers (4, Illustration 2) from the microchips on the printed circuit

board. Remove each cover by applying a side-to-side rocking action, gripping

the cover lightly with combination pliers midway along each long side.

Caution: Caution:

Caution: Do not touc h the printed circuit board with the

Caution: Caution:

pliers, or mark the surface of the printed circuit board.

Page 6 of 16 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

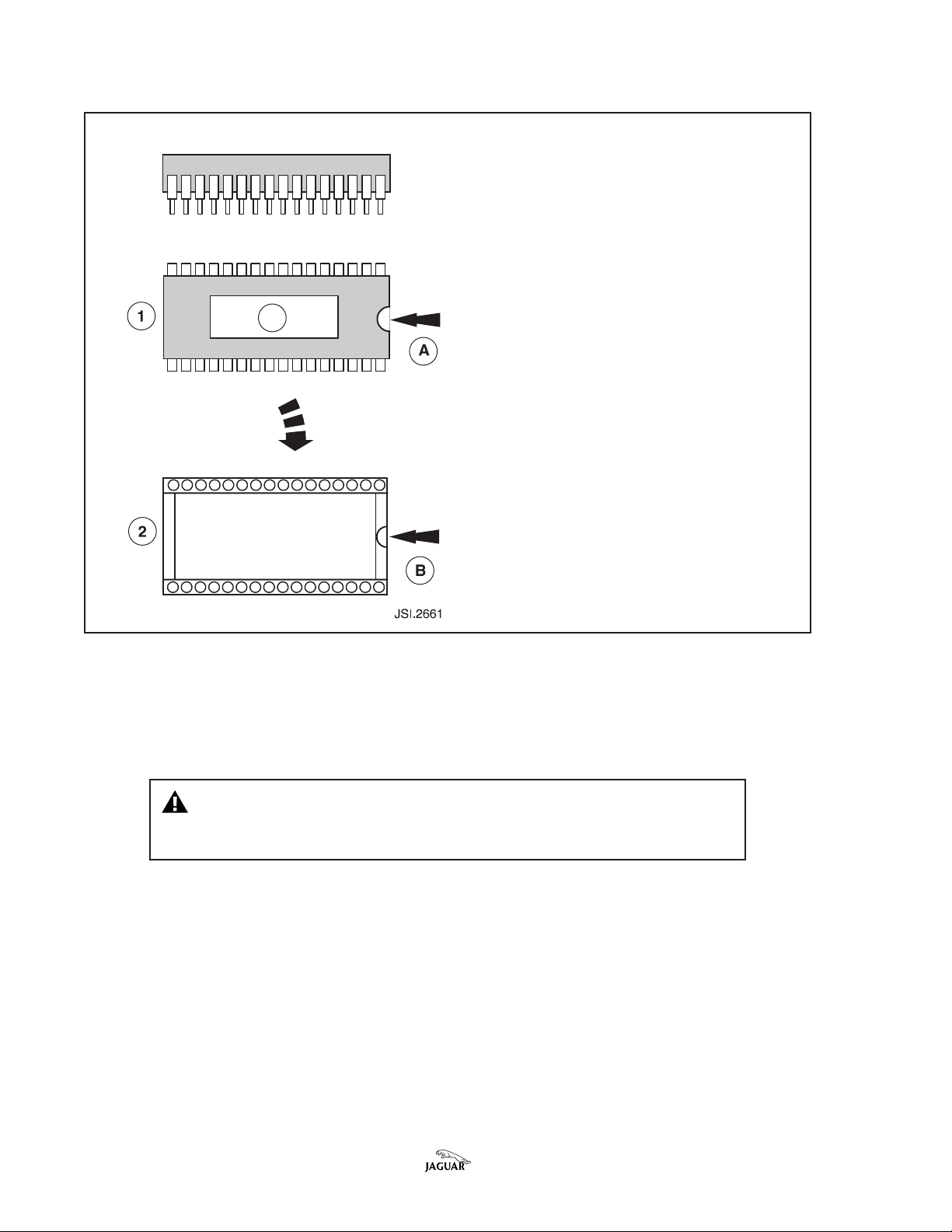

EXAMPLE OF CHIP REMOEXAMPLE OF CHIP REMO

EXAMPLE OF CHIP REMO

EXAMPLE OF CHIP REMOEXAMPLE OF CHIP REMO

VV

V

VV

AL AL

AL

AL AL

TT

OOLOOL

T

OOL

TT

OOLOOL

ILLUSTRATION 3

8. Remove the PROM microchips from the printed circuit board using a suitable

proprietary removal/reinstallation tool (Illustrations 3 & 4).

USE OF USE OF

USE OF

USE OF USE OF

TYPICAL CHIP REMOTYPICAL CHIP REMO

TYPICAL CHIP REMO

TYPICAL CHIP REMOTYPICAL CHIP REMO

VV

AL AL

TT

OOLOOL

V

AL

T

OOL

VV

AL AL

TT

OOLOOL

ILLUSTRATION 4

Bulletin Number 17-12 Amended 08/02 Date of issue 11/0 1 Page 7 of 16

MICROCHIP ORIENMICROCHIP ORIEN

MICROCHIP ORIEN

MICROCHIP ORIENMICROCHIP ORIEN

TT

T

TT

AA

TIONTION

A

TION

AA

TIONTION

1 – O1 – O

VERHEAD VERHEAD

1 – O

VERHEAD

1 – O1 – O

VERHEAD VERHEAD

2 – O2 – O

VERHEAD VERHEAD

2 – O

VERHEAD

2 – O2 – O

VERHEAD VERHEAD

CIRCUIT BOCIRCUIT BO

CIRCUIT BO

CIRCUIT BOCIRCUIT BO

3 – IDEN3 – IDEN

3 – IDEN

3

3 – IDEN3 – IDEN

A – ‘HALF MOON’ CUTA – ‘HALF MOON’ CUT

A – ‘HALF MOON’ CUT

A – ‘HALF MOON’ CUTA – ‘HALF MOON’ CUT

B – ‘HALF MOON’ CUTB – ‘HALF MOON’ CUT

B – ‘HALF MOON’ CUT

B – ‘HALF MOON’ CUTB – ‘HALF MOON’ CUT

VIEW OF MICROCHIPVIEW OF MICROCHIP

VIEW OF MICROCHIP

VIEW OF MICROCHIPVIEW OF MICROCHIP

VIEW OF SOCKET ON PRINVIEW OF SOCKET ON PRIN

VIEW OF SOCKET ON PRIN

VIEW OF SOCKET ON PRINVIEW OF SOCKET ON PRIN

ARDARD

ARD

ARDARD

TIFICATIFICA

TION OF MICROCHIPTION OF MICROCHIP

TIFICA

TION OF MICROCHIP

TIFICATIFICA

TION OF MICROCHIPTION OF MICROCHIP

-OUT ON MICROCHIP-OUT ON MICROCHIP

-OUT ON MICROCHIP

-OUT ON MICROCHIP-OUT ON MICROCHIP

-OUT ON SOCKET-OUT ON SOCKET

-OUT ON SOCKET

-OUT ON SOCKET-OUT ON SOCKET

TEDTED

TED

TEDTED

ILLUSTRATION 5

9. When inserting the replacement PROM microchips, identify the ‘half moon’

cutouts in both the microchip and the socket on the printed circuit board

(Illustration 5).

Caution:Caution:

Caution: Correct orientation is mandatory. The cutouts in

Caution:Caution:

both items must be aligned as the microc hip is inserted into the

socket.

10. The removed microchips should be set on one side, to be returned to Jaguar.

11. Identify and install the replacement 28-pin and 32-pin microchips from the

modification kit to the appropriate sockets.

Page 8 of 16 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

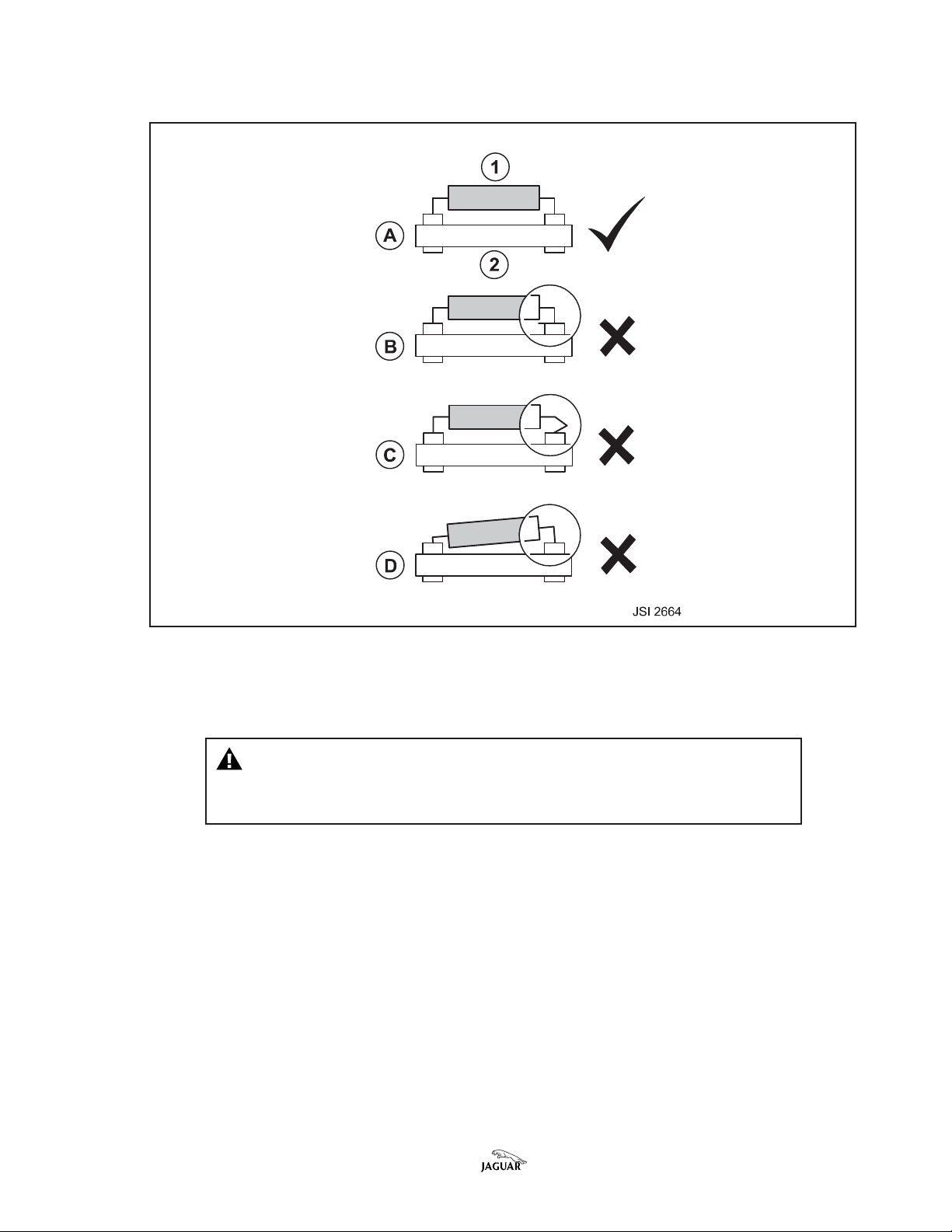

MICROCHIP MICROCHIP

MICROCHIP

MICROCHIP MICROCHIP

ALIGNMENALIGNMEN

ALIGNMEN

ALIGNMENALIGNMEN

TT

T

TT

ILLUSTRATION 6

12. Use great care to achieve condition ‘1’ in Illustration 6. The microchip must lie

parallel to the printed circuit board, with all pins fully engaged into their

corresponding locations in the socket.

Caution:Caution:

Caution: Permanent damage to the microchip is likely in

Caution:Caution:

conditions B or C. Malfunctions will occur with partial

engagement, as in condition D.

13. Reinstall the original covers over the replacement PROM microchips.

14. Carefully fold the printed circuit board back to its original location on the

casing of the ECM, ensuring that the connector is correctly aligned to its

location in the casing. Install and tighten the seven securing screws. Torque

setting: 2.25–2.82 Nm (20–25 lb in).

15. Reinstall the ECM cover on the case, aligning the marks made at step 3 of this

workshop procedure, prior to removal of the cover. Install and tighten the

four securing screws. Torque setting: 2.25–2.82 Nm (20–25 lb in).

Bulletin Number 17-12 Amended 08/02 Date of issue 11/0 1 Page 9 of 16

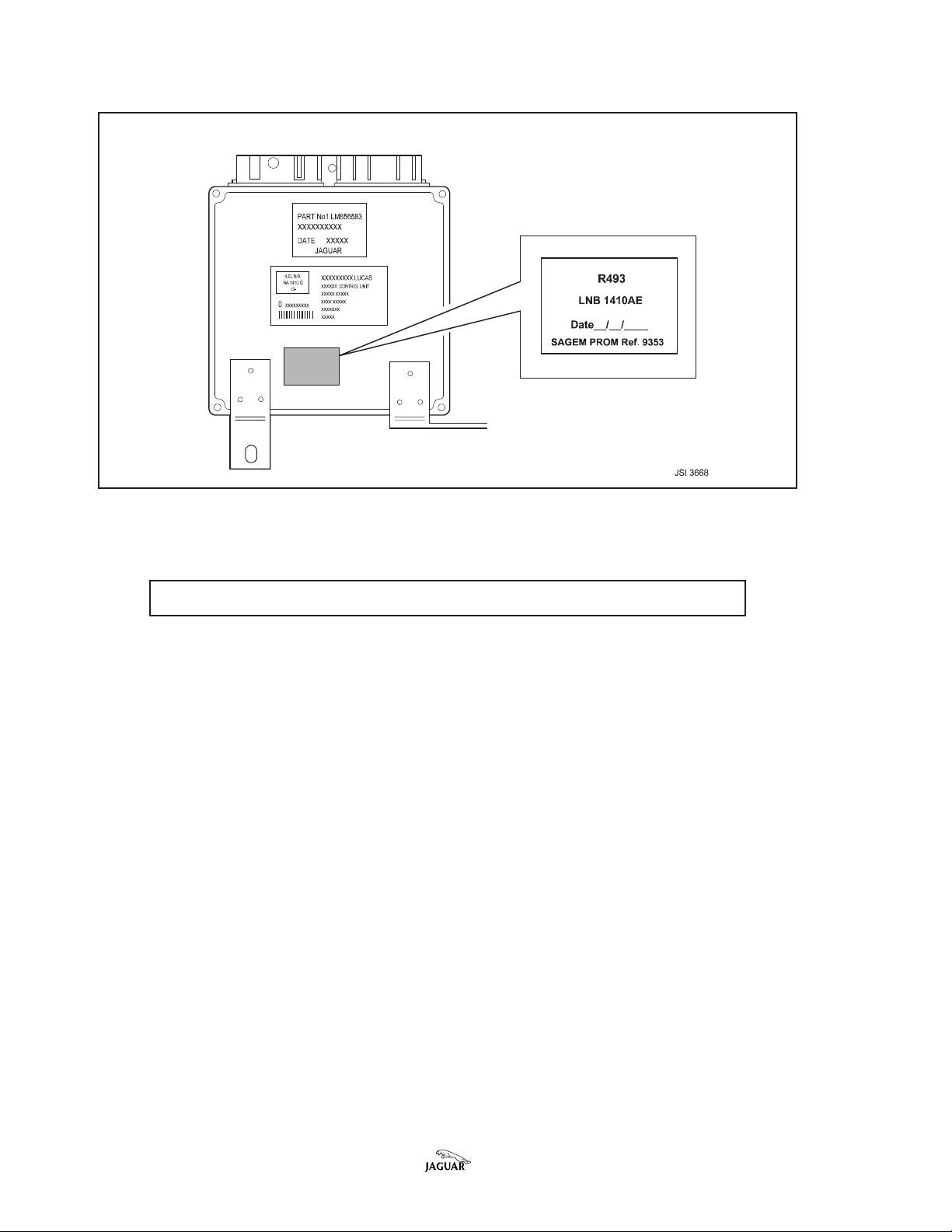

POSITION OF NEW PECUS LABELPOSITION OF NEW PECUS LABEL

POSITION OF NEW PECUS LABEL

POSITION OF NEW PECUS LABELPOSITION OF NEW PECUS LABEL

ILLUSTRATION 7

16. Apply the PECUS label from the modification kit to the cover of the ECM. The

new label must not obscure any existing label on the unit (Illustration 7).

Note:Note:

Note: Use this label for T493 also.

Note:Note:

17. Reinstall the ECM in the vehicle, by a reversal of the process used for its

removal.

18. Continue with the procedure for replacing the EGR valve.

Page 10 of 16 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

EE

GR GR

VV

ALAL

E

EE

GR

GR GR

VE HARNESSVE HARNESS

V

AL

VE HARNESS

VV

ALAL

VE HARNESSVE HARNESS

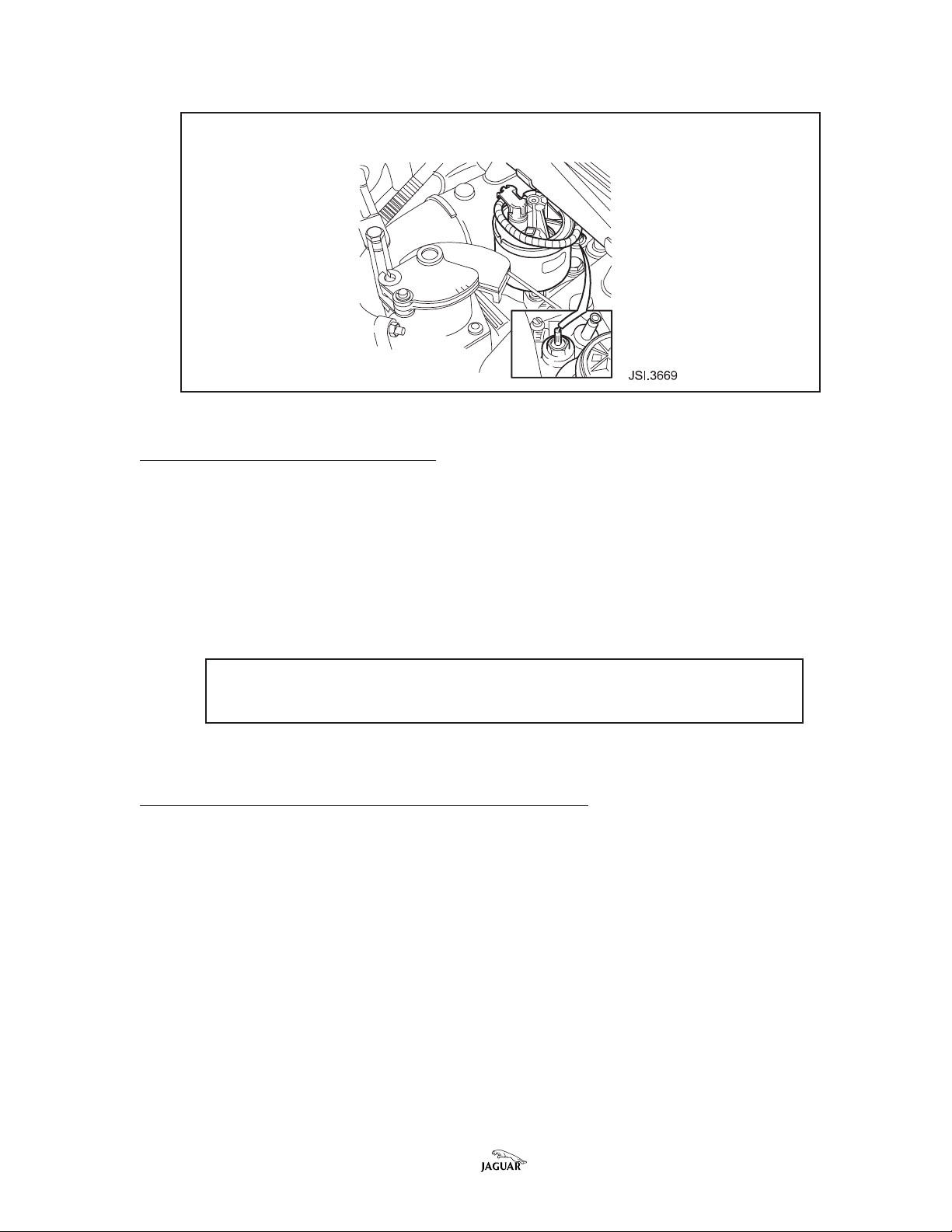

ILLUSTRATION 8

ISSUE 2 - REPLACING EGR VALVE

1. Open the hood and place covers over the fenders.

2. Disconnect the EGR valve harness connector (Illustration 8).

3. Remove the EGR valve securing bolts.

4. Remove the EGR valve and valve gasket.

5. Clean the valve mating faces.

6. To reinstall the new EGR valve and gasket, reverse the EGR valve removal

process.

Note:Note:

Note: Care must be taken not to damage the EGR valve securing

Note:Note:

bolts. Torque figure: 23–27 Nm (17–20 lb ft).

7. Continue with the procedure for replacing the throttle spring.

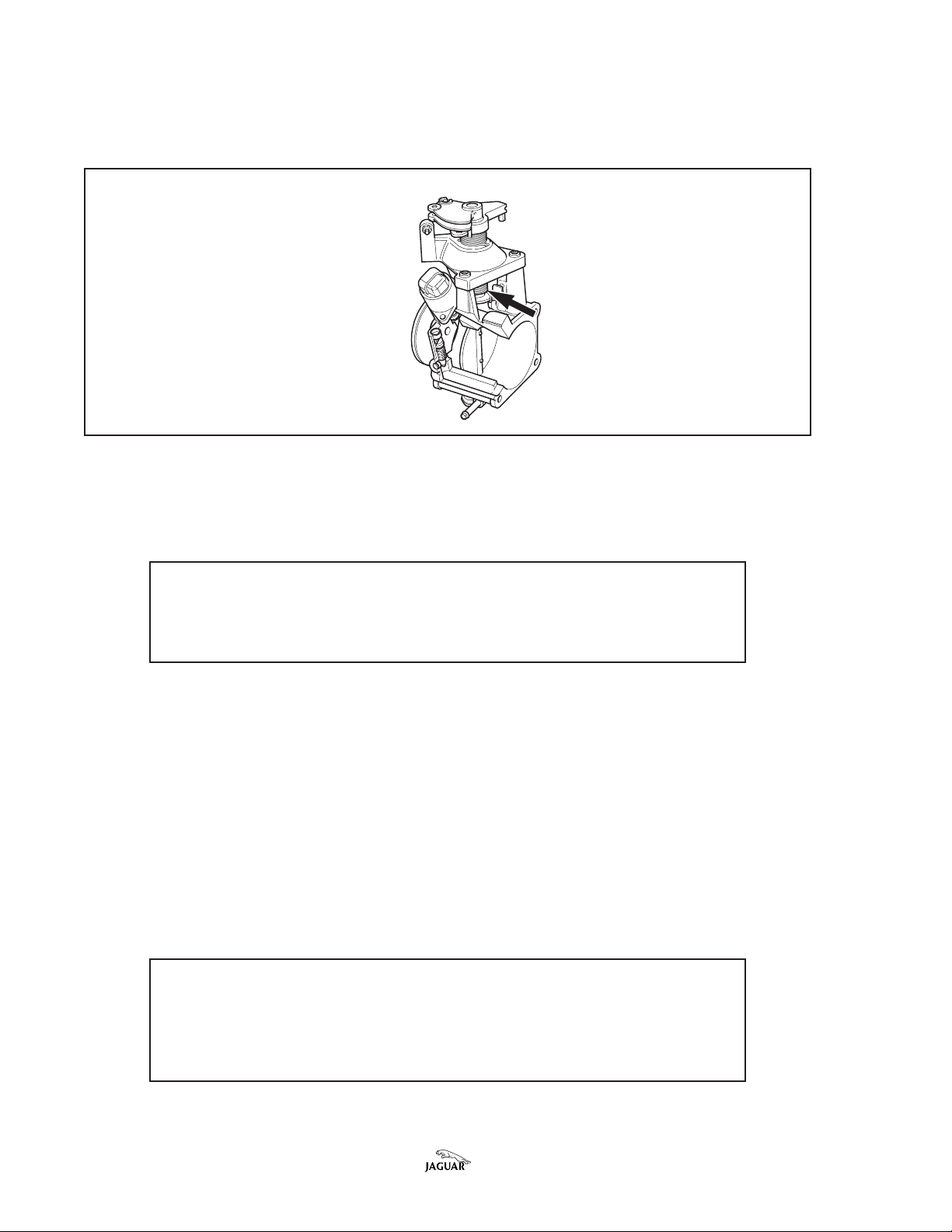

ISSUE 3 - REPLACING THROTTLE RETURN SPRING

1. Disconnect the inner accelerator cable from the throttle assembly.

2. Remove the cruise control linkage pin and circlip.

3. After removing the three Torx head screws that retain the throttle assembly

cap to the pedestal, carefully remove the cap sub-assembly. Note the position

of the straight extension of the throttle return spring.

Bulletin Number 17-12 Amended 08/02 Date of issue 11/0 1 Page 11 of 16

4. Unhook the throttle torsion spring (Illustration 9) from the throttle shaft

actuator and then remove the spring and the sleeve from the shaft.

THROTHRO

TTLE SPRINGTTLE SPRING

THRO

TTLE SPRING

THROTHRO

TTLE SPRINGTTLE SPRING

ILLUSTRATION 9

5. Remove the sleeve from the spring and discard the spring.

6. Insert the sleeve into the replacement spring. Install the sleeve and spring on

the throttle shaf t and hook the spring on to the actuator.

Note:Note:

Note: The throttle return spring must be tensioned, (pre-loaded)

Note:Note:

by rotating the straight extension one full turn countercloc kwise

until it can be installed in the same position as the original

spring.

7. Carefully reinstall the cap to the throttle assembly noting the lever location,

and install and tighten the screws.

8. Reconnect the cruise control linkage.

9. Reconnect the accelerator cable to the throttle assembly.

10. Check the operation of the throttle assembly.

11. Remove fender covers, reconnect the battery, reinstall the battery cover, and

close the lid of the luggage compartment. Reset the vehicle clock and

customer preferences.

12. Using the WDS, perform the oxygen sensors orientation test. (Select set-up

and configuration, engine and transmission, oxygen sensor orientation.)

13. Using the WDS, perform the throttle potentiometer adaptation test.

Note:Note:

Note: During the throttle pot adaptation test por tion of the engine

Note:Note:

set-up procedure, the WDS will ask if a new throttle position

sensor has been installed. Answer this question with YES even

though the existing sensor is being reused. This action will allow

the WDS to reset a larger set of parameters.

14. Check for the presence of any erroneous diagnostic trouble codes (DTCs). If

DTCs are present, they should be recorded, and then cleared.

Page 12 of 1 6 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

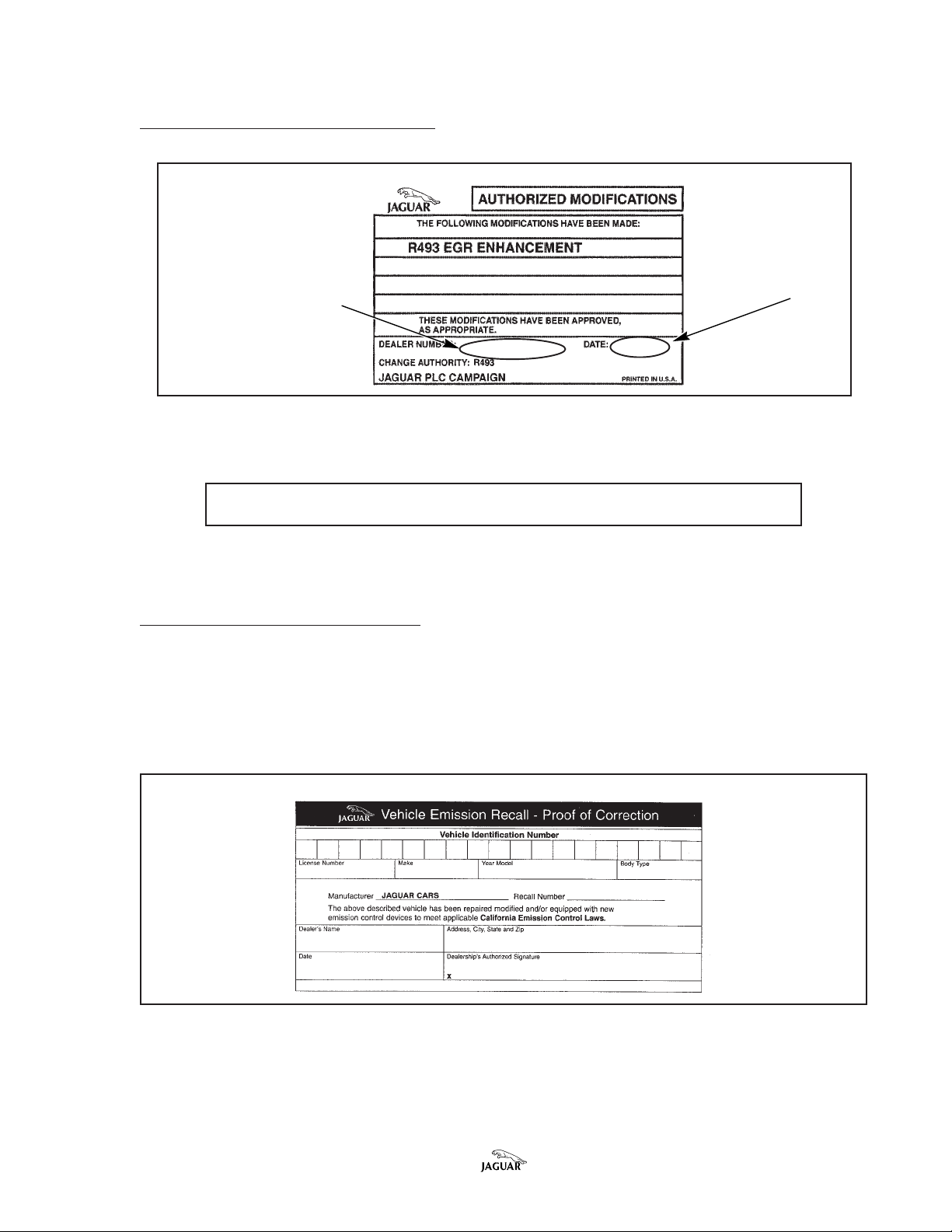

APPLYING MODIFICATION LABEL

MODIFICAMODIFICA

MODIFICA

MODIFICAMODIFICA

WRITE IN DEALER NUMBERWRITE IN DEALER NUMBER

WRITE IN DEALER NUMBER

WRITE IN DEALER NUMBERWRITE IN DEALER NUMBER

TION LABEL (ALL TION LABEL (ALL

TION LABEL (ALL

TION LABEL (ALL TION LABEL (ALL

VEHICLES INCLUDING CA. VEHICLES INCLUDING CA.

VEHICLES INCLUDING CA.

VEHICLES INCLUDING CA. VEHICLES INCLUDING CA.

AND MA.)AND MA.)

AND MA.)

AND MA.)AND MA.)

WRITE IN DWRITE IN D

WRITE IN D

WRITE IN DWRITE IN D

AA

TETE

A

TE

AA

TETE

ILLUSTRA TION 10

Note:Note:

Note: Use this label for T493 also.

Note:Note:

Enter the dealer number and date on the authorized modification label and apply

the label (Illustration 10, part no. R 493 STK) next to the left hood hinge.

PROOF OF CORRECTION FORM

California and Massachusetts Dealers (and any other states where required): Fill

out and place the salmon colored “Vehicle Emission Recall - Proof of Correction”

form (Illustration 11, par t no. S CAL RCL) in the vehicle glove compartment.

PROOF OF CORRECTION FORM (CALIFORNIA AND MASSACHUSETTS)

ILLUSTRATION 1 1

Bulletin Number 17-12 Amended 08/02 Date of issue 11/01 Page 13 of 16

ADDITIONAL INITIATIVES

The following are diagnostic procedures that may be followed should a drivability

concern still be apparent after the recall action has been completed. The

completion of any subsequent repairs are subject to normal New Car Warranty or

Select Edition Warranty, or customer pay authorization as appropriate.

BSTfoetaD

eussi

45-21dednemA

89/21

11-7189/21elttorhT

55-8110/20niatsybwolB

eltiTsmotpmySledoMnoitcA

sgulpkrapSgulprettohotegnahC69-5991

SJX

dlocnehwtuhsskcitselttorhT69/5991

gnikcits

nodesolc

enignedloc

nialecropnonoitarolocsiD69-5991

krapsno

sgulp

SJX

SJX

ecivreS

gulptnemecalper

esacknarcyfidoM

metsysrehtaerb

elttorhtnaelcdna

egnahctonoD

anorocrofsgulp

.niatsegrahcsid

Page 14 of 16 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

PP

ARAR

TS INFORMATS INFORMA

P

AR

TS INFORMA

PP

ARAR

TS INFORMATS INFORMA

TION:TION:

TION:

TION:TION:

The appropriate modification kit for the 1995 MY only (LNC 1411BB) initially will be

allocated to each dealer based on size and volume to ensure an even distribution

and full coverage. After the initial allocation, parts should be ordered from Jaguar

Parts Operations following normal procedures. All other parts required should be

ordered through Jaguar Parts Operations following the normal process.

ELCIHEVEGNARNIVNOITACIFIDOM

SJXYM59136222-577491BB1141CNLBB1141CNL

SJXYM69546622-236222AF1141CNL1JD0141EHL0639

TRAPTIK

BB1141CNLBB1141CNL1 LA0141EHLLA0141EHL

BB1141CNL

YTQMCESETADPUTIK

TRAPSIHTOT

REBMUN

LA0141EHLLA0141EHL2639

LA0141EHL

MORP

.ONDI

All of the PROM kits include 2 PROMs and a revised ‘PECUS’ label to be applied to

the ECM after completing the modification.

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

EGR valve - XJS VIN 1 94775 – 195695 EGR valve LHE 1 550BA 1

EGR valve - XJS VIN 1 95696 – 226645 LHE 1550AC 1

EGR valve g asket C2A 1231 1

EGR valve bolt FS 1 08251J As required

Throttle return spring NBB 3131AB 1

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

QTYQTY

QTY

QTYQTY

To obtain R493 Authorized Modification Labels from the Product Legislation and

Compliance Department, refer to Administration Bulletin 6-94 (USA) or 6-16/02

(Canada) titled “Availability of Service Action and Recall Authorized Modification

Labels/stickers.”

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

R493 Modification Label R 493 STK 1

CA & MA only:

Proof of Correction Form S CAL RCL 1

Bulletin Number 17-12 Amended 08/02 Date of issue 11/01 Page 15 of 16

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

QTYQTY

QTY

QTYQTY

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TION:TION:

TION:

TION:TION:

Warranty claims should be submit ted quoting the information found in the table

below. This will result in payment of the stated time and, where applicable parts/

miscellaneous expense codes as listed.

Drive in/drive out may only be claimed when the vehicle has been brought in for

this action alone to be undertaken.

Please use option code of X and

also enteralso enter

also enter the SRO (s) and parts details on the

also enteralso enter

claim applicable to the repair completed.

RR

ecall ecall

ecall

ecall ecall

T493 - 1T493 - 1

T493 - 1

T493 - 1T493 - 1

R

RR

REPLACEMENT OF PROMS IN ECM

VV

ehicleehicle

V

ehicle

VV

ehicleehicle

XJS 4.0 VIN Range:

194775 - 222631 Replace PROMS within ECM 18.91.18 0.7 LNC 1411BB PROM Kit 1

EGR VALVE & GASKET REPLACEMENT

XJS 4.0 VIN Range:

194775 - 195695 Replace EGR valve & gasket 17.45.01 0.2 LHE 1550BA EGR valve 1

995 MY XJS 4.0L995 MY XJS 4.0L

995 MY XJS 4.0L

995 MY XJS 4.0L995 MY XJS 4.0L

RR

epairepair

R

epair

RR

epairepair

SROSRO

SRO

SROSRO

TT

T

TT

imeime

ime

imeime

PP

arar

t Numbert Number

P

ar

t Number

PP

arar

t Numbert Number

C2A 1231 Gasket 1

FS 108251J Set screw As Req.

DescriptionDescription

Description

DescriptionDescription

QTYQTY

QTY

QTYQTY

THROTTLE RETURN SPRING REPLACEMENT

XJS 4.0 VIN Range

194775 - 226645 Replace throttle return spring 19.91.46 0.2 NBB 3131AB Throttle return

spring 1

DRIVE IN/DRIVE OUT

ALL Drive in/drive out 10.10.10 0 .1

RR

ecall R493 - 1ecall R493 - 1

R

ecall R493 - 1

RR

ecall R493 - 1ecall R493 - 1

REPLACEMENT OF PROMS IN ECM

VV

ehicleehicle

V

ehicle

VV

ehicleehicle

XJS 4.0 VIN Range:

222632 - 226645 Replace PROMS within ECM 18.91.18 0.7 LNC 1411FA PROM Kit 1

EGR VALVE & GASKET REPLACEMENT

XJS 4.0 VIN Range:

195696 - 226645 Replace EGR valve & gasket 17.45.01 0.2 LHE 1550AC EGR valve 1

THROTTLE RETURN SPRING REPLA CEMENT

XJS 4.0 VIN Range

194775 - 226645 Replace throttle return spring 19.91.46 0.2 NBB 3131AB Throttle return

996 MY XJS 4.0L996 MY XJS 4.0L

996 MY XJS 4.0L

996 MY XJS 4.0L996 MY XJS 4.0L

RR

epairepair

R

epair

RR

epairepair

SROSRO

SRO

SROSRO

TT

T

TT

imeime

ime

imeime

PP

arar

t Numbert Number

P

ar

t Number

PP

arar

t Numbert Number

C2A 1231 Gasket 1

FS 108251J Set Screw As Req.

DescriptionDescription

Description

DescriptionDescription

spring 1

QTYQTY

QTY

QTYQTY

DRIVE IN/DRIVE OUT

ALL Drive in/drive out 10.10.10 0 .1

Page 16 of 1 6 Date of issue 11/01 Bulletin Number 17-12 Amended 08/02

DATE

10/95Sedan Range

18-04

SERVICE

Security System – Rear Door False Alarm –

Repair Information

TECHNICAL BULLETIN

MODEL

1995 MY

Sedan Range

VIN

720001-735432

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

Sedan Range vehicles within the above VIN range may experience a security

system false alarm that is recorded in the last alarm data as a door instrusion. On

some vehicles, the side of the actuator connector facing the rear door lock

actuator was incorrectly molded. This may increase the possibility of water

entering the connector, which may trigger the vehicle security system

intermittently.

ACTION:ACTION:

ACTION:

ACTION:ACTION:

In case of a customer complaint of a security system false alarm on a Sedan

Range vehicle within the above VIN range, proceed as follows:

1. Inspect the rear door lock actuator on the affected doors for signs of water

entry.

2. If corrosion is found, clean the connector and seal the connector with Jaguar

electrical contact grease, part no. JLM 11472.

3. If the corrosion is too extensive, the door harness and/or door lock actuator

should be replaced as necessary. The replacement parts are the latest design.

PP

ARAR

TS INFORMATS INFORMA

P

AR

TS INFORMA

PP

ARAR

TS INFORMATS INFORMA

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Jaguar electrical grease JLM 11472 *

Right rear door latch/actuator assembly GNA 2550BD 1

Left rear door latch/actuator assembly GNA 2551BD 1

Right rear door harness LNA 3190CF 1

Left rear door harness LNA 3190FE 1

*= Claim no more than 25% of container cost per vehicle.

TION:TION:

TION:

TION:TION:

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

QTYQTY

QTY

QTYQTY

Date of issue 10/95 Bulletin Number 18-04 Page 1 of 2

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

FF

AA

ULUL

F

A

UL

FF

AA

ULUL

CODECODE

CODE

CODECODE

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TT

T

TT

R.O.R.O.

R.O.

R.O.R.O.

NUMBERNUMBER

NUMBER

NUMBERNUMBER

TION:TION:

TION:

TION:TION:

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

RB BD MB 86.25.47 Left rear door lock actuator - replace 1.00 hrs.

(with diagnostic time)

RB BD MB 86.25.47.09 Left rear door lock actuator - replace 0.65 hrs.

(without diagnostic time)

RB BF MB 86.25.47 Right rear door lock actuator - replace 1.00 hrs.

(with diagnostic time)

RB BF MB 86.25.47.09 Right rear door lock actuator - replace 0.65 hrs.

(without diagnostic time)

LJ GK PS 86.70.47 Replace left rear door harness 1.15 hrs.

(with diagnostic time)

LJ GK PS 86.70.47.09 Replace left rear door harness 0.80 hrs.

(without diagnostic time)

LJ HK PS 86.70.47 Replace right rear door harness 1.15 hrs.

(with diagnostic time)

LJ HK PS 86.70.47.09 Replace right rear door harness 0.80 hrs.

(without diagnostic time)

O

OO

OO

WW

ANCEANCE

W

ANCE

WW

ANCEANCE

Page 2 of 2 Bulletin Number 18-04 Date of issue 10/95

DATE

10/95Sedan Range

18-05

SERVICE

Security System – Panic Alarm –

Diagnostic Procedure –

Service Action S635

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

The Panic Alarm may not operate on some 1995 MY Sedan Range vehicle in the

above VIN range. The absence of the Panic Alarm may result from either a

transmitter problem or an Security Locking Control Module, (SLCM) problem or a

combination of both.

ACTION:ACTION:

ACTION:

ACTION:ACTION:

All vehicles in the above VIN range should be inspected, regardless whether in

dealer stock or in service. Check customer vehicles at the next service opportunity

or in response to a customer complaint as described below.

SECURITY SYSTEM PANIC ALARM OPERATION

NOTE:NOTE:

NOTE: Remote transmitters without any identification mark (113

NOTE:NOTE:

type) must be replaced with the later 101 type. The 101 type can

be identified by a pink paint spot on the blue tags supplied with

transmitters and all new vehicles. If the blue identification tag is

not available, check the oscillator identification mark (101 or 113)

on the printed circuit board in the transmitter.

TECHNICAL BULLETIN

MODEL

1995 MY

Sedan Range

VIN

720001 - 739235

1. Remove the ignition key from the ignition switch and ensure that the vehicle

doors are closed.

2. Check the operation of the Panic Alarm by pressing either button on the

transmitter for at least 3 seconds and then releasing it.

NOTE:NOTE:

NOTE: Perform the Panic Alarm test outside of shop area, if

NOTE:NOTE:

possible, due to the noise level.

3. Repeat the operation using the other transmitter button.

4. The Panic Alarm will sound for five times the normal full alarm period.

5. Insert the ignition key and turn to position I or II and back to 0 to cancel the

Panic Alarm.

NOTE:NOTE:

NOTE: When checking the Panic Alarm on vehicles equipped

NOTE:NOTE:

with the battery transit relay, the checking procedure described

above must be carried out within 30 seconds of the initial

removal of the ignition key.

6. Remove the key and begin checking the second transmitter.

Date of issue 10/95 Bulletin Number 18-05 Page 1 of 5

7. If the second transmitter needs to be checked after the 30 second period has

elapsed, the ignition should first be switched on and off as described in step

5.

CHECKING THE REPLACEMENT TRANSMITTER

1. A maximum of five transmitters can be programmed for one system.

2. Remove the ignition key from the ignition switch and ensure that the vehicle

doors and trunk are closed.

3. Check the operation of the Panic Alarm by pressing first one and then the

other button as described above.

4. If the Panic Alarm functions, no further action is necessary.

5. If the Panic Alarm does not function, and the system is equipped with the 101

type remote transmitter, (pink spot), DO NOT attempt to restore the Panic

Alarm, install a new SLCM. (Refer to “Replacing the SLCM”).

6. When the SLCM has been replaced, check the operation of the Panic Alarm as

described above.

REPLACING THE SLCM

SECURITY LOCKING CONTROL MODULESECURITY LOCKING CONTROL MODULE

SECURITY LOCKING CONTROL MODULE

SECURITY LOCKING CONTROL MODULESECURITY LOCKING CONTROL MODULE

MOUNTING STUDSMOUNTING STUDS

MOUNTING STUDS

MOUNTING STUDSMOUNTING STUDS

JSI-2525

1. Disconnect the vehicle battery.

2. Remove the luggage compartment carpet, front liner, seal retainer and the

side liner.

3. Loosen and remove the nuts retaining the SLCM, Illustration 1.

4. Withdraw the SLCM mounting studs from the mounting holes, (arrows,

Illustration 1) in the body support bracket.

5. Disconnect the SLCM from the vehicle harness, noting the position of the

connectors.

Page 2 of 5 Bulletin Number 18-05 Date of issue 10/95

6. Connect the harness connectors to the new SLCM in the same order as they

were on the original module.

7. Insert the SLCM mounting studs through the holes in the support bracket and

install nuts.

8. Reconnect battery and install trunk trim.

PROGRAMMING THE HAND TRANSMITTER.

Use the PDU to reprogram the security system RF handset transmitters. The

following method can be used to manually reprogram handset transmitters:

NOTE:NOTE:

NOTE: All RF handset transmitters belonging to the vehicle

NOTE:NOTE:

being serviced must be available. If the learning process is

carried out without having all the transmitters present, all

previous transmitter codes will be overwritten, rendering the

missing transmitters inoperable.

1. Open the trunk lid and driver’s door.

2. Turn the ignition switch to the ON or II position.

3. Rock the valet switch located in the center console storage compartment

(Illustration 2) 5 times. A single confirmation chirp and flash of the

headlamps indicate that the security system has entered the learning mode.

NOTE:NOTE:

NOTE: If difficulty is experienced entering the learning mode,

NOTE:NOTE:

check that the valet switch is functioning properly.

VV

ALET SWITCHALET SWITCH

V

ALET SWITCH

VV

ALET SWITCHALET SWITCH

JWX-163

ILLUSTRATION 2

Date of issue 10/95 Bulletin Number 18-05 Page 3 of 5

4. Press the arm/lock (larger) button of the first transmitter. This transmitter will

be linked to position 1 of the seat/column/mirror memory. A tone will confirm

that the transmitter code was accepted. If no transmitter buttons are pushed,

the SLCM will also time out after 15 seconds of inactivity, indicated by two

chirps.

5. Rock the valet switch once. Two short chirps will signal that the system is

prepared to accept the second transmitter.

6. Press the arm/lock button of the second transmitter. This transmitter will be

linked to the position 2 of the seat/column/mirror memory. A tone will

confirm that the transmitter code was accepted.

7. Rock the valet switch once. Three short chirps will signal that the system is

prepared to accept the third transmitter.

8. Press the arm/lock button of the third transmitter. A tone will confirm that the

transmitter code was accepted. This transmitter and any others will not be

linked to a position in the seat/column/mirror memory.

9. The process of pressing the valet switch and waiting for the number of chirps

equivalent to the transmitter number can be repeated for a fourth and fifth

transmitter. The valet switch can be pressed to cycle through the unneeded

transmitter programming sequences. The SLCM will also time out after 15

seconds of inactivity, indicated by two chirps. This will save the transmitter

codes entered up to this point.

10. Turn the ignition switch off, remove the key, and close the doors and trunk lid.

11. Check for proper system operation including the recall of seat, steering wheel

and mirror memory positions 1 and 2 from the handset transmitter.

WW

ARRANARRAN

W

ARRAN

WW

ARRANARRAN

TY INFORMATY INFORMA

TY INFORMA

TY INFORMATY INFORMA

TION:TION:

TION:

TION:TION:

Service Action S635

VEHICLEVEHICLE

VEHICLE

VEHICLEVEHICLE

Sedan Range 1995 MY HA Check, replace and reprogram 0.15 hrs.

VIN 727000 - 739235 new transmitters when

Model codes 2310, 2311, performed at PDI or in

2313, 2314, 2512 conjunction with another repair

Sedan Range 1995 MY HB Check, replace and reprogram 0.30 hrs.

VIN 727000 - 739235 new transmitters

Model codes 2310, 2311, - only repair performed

2313, 2314, 2512 - with drive in/out time

SUMMARSUMMAR

SUMMAR

SUMMARSUMMAR

CODECODE

CODE

CODECODE

YY

DESCRIPTIONDESCRIPTION

Y

DESCRIPTION

YY

DESCRIPTIONDESCRIPTION

(no drive in/out time)

TIMETIME

TIME

TIMETIME

ALLALL

ALL

ALLALL

OO

O

OO

WW

ANCEANCE

W

ANCE

WW

ANCEANCE

Page 4 of 5 Bulletin Number 18-05 Date of issue 10/95

Sedan Range 1995 MY HC Check, replace and reprogram 0.60 hrs.

VIN 727000 - 739235 new transmitters and replace

Model codes 2310, 2311, SLCM when performed at PDI or

2313, 2314, 2512 in conjunction with another repair

(no drive in/out time)

Sedan Range 1995 MY HD Check, replace and reprogram 0.75 hrs.

VIN 727000 - 739235 new transmitters and replace

Model codes 2310, 2311, SLCM - only repair performed

2313, 2314, 2512 - with drive in/out time

CLAIM SUBMISSION PROCEDURE:

Warranty summary codes have been assigned to this service action in order to

simplify claim submission. The dealership will be reimbursed the parts and labor

time allowance as indicated.

DCS DEALERS

Submit claims using the appropriate summary code for the vehicle model and

work performed. Follow standard campaign submission procedures.

NON-DCS DEALERS

Submit claims on the Recall Campaign Summary form W-25. Enter the appropriate summary code for the vehicle model and work performed in the Repair Code

column. Do not use the W-1 warranty claim form.

Date of issue 10/95 Bulletin Number 18-05 Page 5 of 5

DATE

10/95Sedan Range

18-06

SERVICE

Security System – Handset Transmitter –

Manual Programming

ISSUE:ISSUE:

ISSUE:

ISSUE:ISSUE:

The Security System RF handset transmitters can be programmed manually in

case a PDU is not immediately available.

ACTION:ACTION:

ACTION:

ACTION:ACTION:

Use the following method to manually reprogram security system RF handset

transmitters:

TECHNICAL BULLETIN

MODEL

Sedan Range

VIN

1995-96 MY

720001-ON

NOTE:NOTE:

NOTE: All RF handset transmitters belonging to the vehicle

NOTE:NOTE:

being serviced must be available. If the learning process is

carried out without having all the transmitters present, all

previous transmitter codes will be overwritten, rendering the

missing transmitters inoperable.

1. Open the trunk lid and driver’s door.

2. Turn the ignition switch to the ON or II position.

Date of issue 10/95 Bulletin Number 18-06 Page 1 of 3

VV

ALET SWITCHALET SWITCH

V

ALET SWITCH

VV

ALET SWITCHALET SWITCH

JWX-163

ILLUSTRATION 1

3. Rock the valet switch located in the center console storage compartment

(Illustration 1) 5 times. A single confirmation chirp and flash of the

headlamps indicate that the Security Locking Control Module (SLCM) has

entered the learning mode.

NOTE:NOTE:

NOTE: If difficulty is experienced entering the learning mode,