Page 1

Chromasit

Instructions for Use

SR

Page 2

2

Table of Contents

3 SR Chromasit

4 Composition

5 Range and description of products

5 SR Chromasit Opaquer

5 SR Chromasit Intensive Oqaquer

6 SR Chromasit Opaquer Liquid

7 SR Chromasit Dentin

7 SR Chromasit Incisal

8 SR Chromasit Creative Dentin

8 SR Chromasit Creative Incisal

9 SR Chromasit Color

9 SR Chromasit Intensive

10 Bonding systems and accessories

10 SR Link

10 SR Chroma Link

10 SR Spectrasit Liquid

10 SR Chromasit Fluid

11 Retention Adhesive

11 Micro- and Macroretention

11 Separating Fluid

12 Shade selection

13 Processing instructions

13 Fabricating the model

13 Designing the framework / Contouring

14 Preparing the framework

16 Conditioning the metal surfaces with SR Link or SR Chroma Link

17 Applying the opaquer

19 Layering diagram

20 Layering technique

21 Possibilities of customizing SR Chromasit with SR Chromasit Color and SR Chromasit Intensive

22 Preparing the restoration for polymerization

22 Finishing

24 Processing instructions for fully veneered restorations

26 Cleaning

26 Repairs

26 Warnings

27 SR Chromasit – Materials combination table

Page 3

3

Chromasit

SR

SR Chromasit is a pressure/heat-curing micro-

filled veneering material. It features excellent

physical properties and provides true-tonature shade effects. The material therefore

facilitates the fabrication of lifelike composite

veneers.

The consistencies of the various ready-to-use

SR Chromasit veneering materials are

coordinated and compatible with each other.

As a result, SR Chromasit Dentin, Incisal and

the various special compounds can be

layered without intermediate polymerization.

The combination of the SR Chromasit

veneering material with the SR Link or

SR Chroma Link bonding system produces

long-lasting high-quality results.

Indication

– metal-supported crowns and bridges

– fully veneered restorations up to the

second premolar

– metal-supported implant-borne

superstructures

– veneers in combination dentures

– long-term temporaries in combination with

Vectris

Contraindication

– occlusal veneers on molars

– layer thicknesses of less than 1.5 mm in

the occlusal region

– alloys containing more than 50% silver

and/or copper

– alloys containing more than 90% gold,

palladium and platinum

– non-precious metal alloys or titanium with-

out mechanical retention

– bruxism

Important restrictions on

application

If the following advice is not followed, the

success of SR Chromasit restorations may be

jeopardized:

– Do not apply the material in layers thinner

than the stipulated minimum layer

thickness.

– If the polymerization unit is contaminated

(eg lime build-up), the polymerization

temperature may fall below the required

minimum temperature (115–120 °C /

239–248 °F). If the required temperature is

not reached, incompletely polymerized

veneers, which are prone to the formation

of accrection and plaque, may result.

– If used inappropriately, ultrasonic cleaning

fluids may dissolve the resin surfaces

because of their high degree of acidity.

– It is advisable to use a special jet medium

(Al

2O3

) with a grit size of 100 microns at

2 bar pressure for blasting purposes.

– The use of a jet medium with a lower grit

size may result in veneering material

chipping off.

Side effects

Systemic side effects have not been reported

to date. Allergic reactions may occur in rare

cases. Do not use SR Chromasit restorations

in patients with a suspected or known allergy

to any of the material’s ingredients.

Page 4

4

Composition

– SR Chromasit Dentin, Creative Dentin

and Opaque Dentin

Ingredients: The monomer matrix consists

of urethane dimethacrylate and deca-

methylene dimethacrylate (34 wt%). The

fillers are highly dispersed silicon dioxide

and copolymers (65 wt%).

Additionally, the material contains

stabilizers, catalysts and pigments

(1 wt%). The total content of inorganic

fillers is 30 wt%, or 13.8 vol%. The

particle size ranges between 5 and 20 nm.

– SR Chromasit Incisal, Creative Incisal

and Transparent

Ingredients: The monomer matrix consists

of urethane dimethacrylate and deca-

methylene dimethacrylate (35 wt%). The

fillers are highly dispersed silicon dioxide

and copolymers (64 wt%).

Additionally, the material contains

stabilizers, catalysts, and pigments

(1 wt%). The total content of inorganic

fillers is 30 wt%, or 13.7 vol%. The

particle size ranges between 5 and 20 nm.

– SR Chromasit Color and Intensive

Ingredients: dimethacrylate

(61.5–63.5 wt%), fillers (33.5–35.5 wt%).

Additional ingredients: stabilizers, catalysts

and pigments (1–4 wt%).

– SR Chromasit Opaquer

Ingredients: copolymers, aluminium oxide,

titanium dioxide, barium sulphate and zinc

oxide (98.5 wt%).

Additional ingredients are catalysts and

pigments (1.5 wt%).

– SR Spectra Opaquer Pink

Ingredients: polymethyl methacrylate and

titanium dioxide (97.5 wt%)

Additional ingredients: catalysts and

pigments (2.5 wt%).

– SR Chromasit Intensive Opaquer

Ingredients: polymethyl methacrylate,

aluminium oxide, titanium dioxide, barium

sulphate and zinc oxide (> 97 wt%).

Additional ingredients: catalysts and

pigments (1–3 wt%).

– SR Chromasit Opaquer Liquid

Ingredients: methyl methacrylate and

urethane dimethacrylate (100 wt%).

– SR Chroma Link

Ingredients: methyl methacrylate

(> 98 wt%)

Additional ingredients: acid ester and

alcohol (< 2 wt%).

Storage

– Storage temperature: 12–28 °C

(54–82 °F)

– Keep packages in use at room

temperature (18–25 °C / 65–77 °F).

– Store SR Chromasit Fluid and SR Link in

the refrigerator (2–8 °C / 36–46 °F).

Once opened, Chromasit Fluid remains

usable for six months, if stored in a

refrigerator. Possible crystal formations

can be dissolved by warming the

material up to room temperature.

– Protect SR Chromasit Fluid from

humidity.

– SR Chromasit Fluid may exhibit a slightly

yellowish tinge after some time.

However, this does not affect the

quality of the Fluid or the veneer.

– Protect the material against direct

sunlight.

– Do not use the material after the expiry

date.

– Keep the materials out of the reach of

children.

– SR Chromasit Fluid

Ingredients: copolymers and benzoyl

peroxide dissolved in diethyl ketone.

– SR Link

Ingredients: bisphenol A-polyethoxy

dimethacrylate, hydrophobic

dimethacrylate, hydrogen phosphate,

solvent and benzoyl peroxide.

– SR Spectrasit Liquid

Ingredients: urethane dimethacrylate and

decamethylene dimethacrylate

(> 99 wt%), catalyst (< 1 wt%).

– SR Spectrasit Gel

Ingredients: glycerine, highly dispersed

silicon dioxide and aluminium oxide.

– Separating Fluid

Ingredients: sodium alginate, sodium

tetraborate, glycerine and pigments in an

aqueous solution.

– Retention Adhesive

Ingredients: copolymers, resin and

softener (30 wt%) dissolved in acetone

(70 wt%).

– Micro- and Macroretention

Ingredients: copolymer (99.5 wt%) and

titanium oxide (0.5 wt%).

– microretention beads: 200–300 microns

– macroretention beads: 400–600 microns

Page 5

5

Range and description of products

SR Chromasit Opaquer

The heat-curing SR Chromasit Opaquer

reacts with metal surfaces that have been

conditioned with SR Chroma Link or SR Link.

It masks the metal framework in a toothcoloured shade.

Delivery form

– SR Chromasit Opaquer, 5 g

Colour designations: 011, 012, 014, 015, 016, 023, 024

SR Chromasit Intensive Opaquer

These intensive shades are coordinated with

the SR Chromasit Opaquer and are used to

customize the shade of the opaquer.

Delivery form

– SR Chromasit Intensive Opaquer, 5 g

Shades: 01 white, 02 light yellow, 03 yellow, 04 brown,

05 pink, 06 violet, 07 grey

Page 6

6

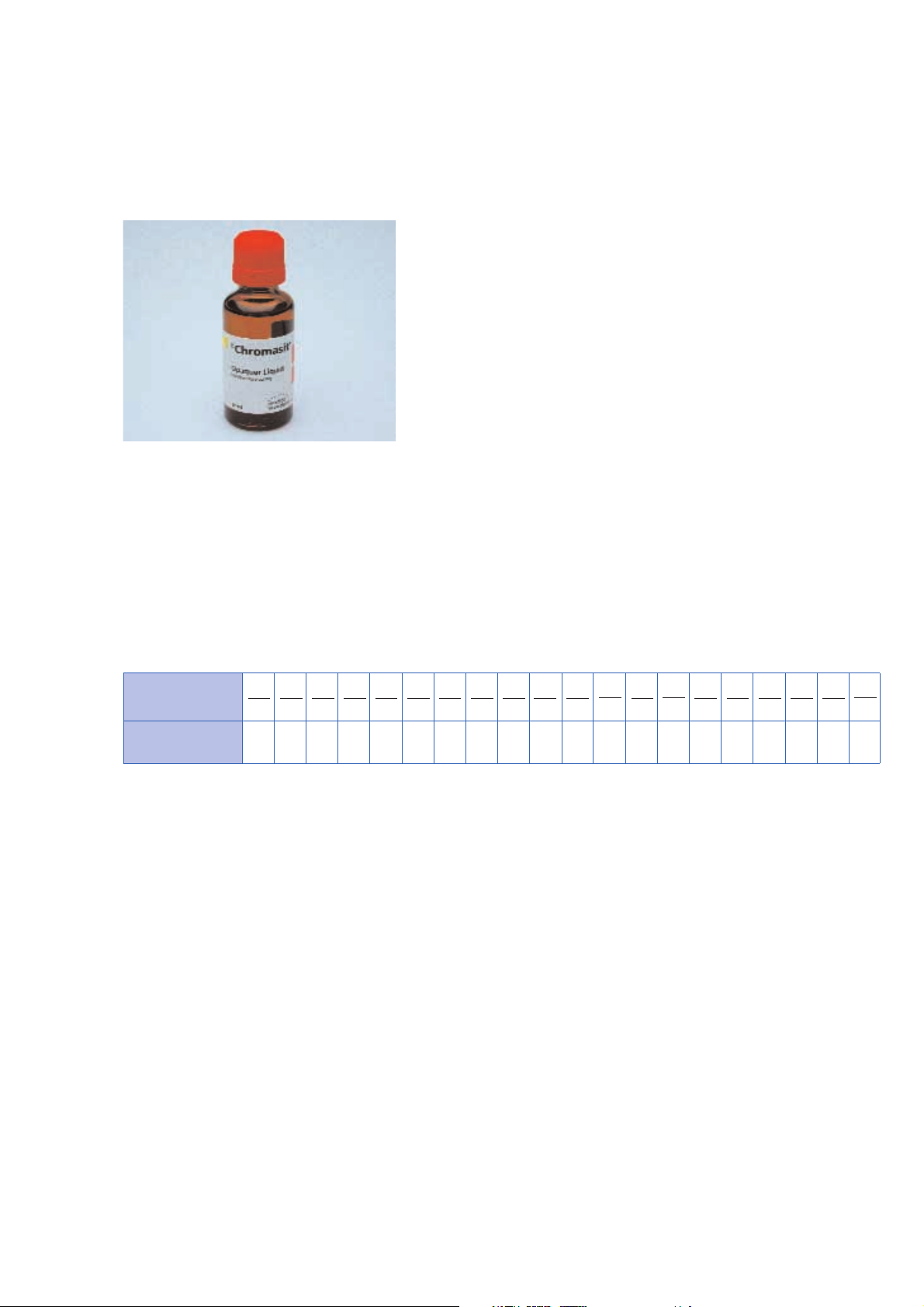

SR Chromasit Opaquer Liquid

This opaquer liquid is used for mixing the

SR Chromasit Opaquer.

Delivery form

– SR Chromasit Opaquer Liquid, 30 ml and 100 ml

Opaquer combination table

Chromascop

SR Chromasit

Opaquer O...

110

01

11

120

1A

11

130

2A

16

140

1C

14

210

2B

15

220

1D

15

230

1E

15

240

2C

12

310

3A

14

320

5B

24

330

2E

14

340

3E

23

410

4A

23

420

6B

14

430

4B

14

440

6C

16

510

6D

23

520

4C

23

530

3C

23

540

4D

12

Page 7

7

SR Chromasit Dentin

These Dentin materials are shaded according

to the Chromascop shade guide and are

compatible with the SR Chromasit Opaquer.

Additionally, they can be ideally combined

with the resin teeth from Ivoclar Vivadent.

Delivery form

– SR Chromasit Dentin, 10 g or 3 x 10 g

Shades: 110, 120, 130, 140, 210, 220, 230, 240, 310,

320, 330, 340, 410, 420, 430, 440, 510, 520, 530, 540

SR Chromasit Incisal

The shade of these incisal materials has been

matched to the Chromascop shade guide,

the SR Vivodent shade guide as well as the

natural incisal structure.

Delivery form

– SR Chromasit Incisal, 10 g or 3 x 10 g

Colour gradation: S1, S2, S3, S4, S5

Dentin/Incisal combination table

Dentin D

Incisal S

110

01

1

120

1A

1

130

2A

1

140

1C

1

210

2B

1

220

1D

2

230

1E

2

240

2C

2

310

3A

2

320

5B

3

330

2E

2

340

3E

1

410

4A

4

420

6B

5

430

4B

5

440

6C

3

510

6D

3

520

4C

3

530

3C

3

540

4D

5

Page 8

8

SR Chromasit Creative Dentin

These ready-mixed, intensely coloured

Dentin materials allow technicians to

incorporate special effects into their veneers.

Delivery form

– SR Chromasit Creative Dentin, 5 g

Shades: CD 21 vanilla-white; CD 22 yellow-orange;

CD 23 orange-brown; CD 24 dark-brown

SR Chromasit Creative Incisal

These ready-mixed, intensely coloured Incisal

materials round off the range of Creative

Dentin materials.

Delivery form

– SR Chromasit Creative Incisal, 5 g

Shades: CS 21 dove-blue; CS 22 transparent-pink;

CS 23 transparent-orange

Page 9

9

SR Chromasit Color

These colour materials are based on the

same materials as SR Chromasit.

SR Chromasit Color is used to customize the

shade of polymerized Chromasit veneers.

Delivery form

– SR Chromasit Color, 2 g

Shades: D12 red-beige; D13 yellow-beige; D14 brownbeige; D15 grey-beige; M1 ivory; M3 honey-yellow;

M4 light-brown; M5 dark-brown; S22 blue-transparent

SR Chromasit Intensive

The Intensive materials are based on the

same materials as SR Chromasit.

SR Chromasit Intensive is used for colouring

or customizing the shade of the

pressure/heat-curing Chromasit materials.

Delivery form

– SR Chromasit Intensive, 2 g

Shades: 0 clear; 1 white; 2 pink; 3 blue; 4 anthracite;

6 light-brown; 7 red-brown; 8 olive-brown; 9 dark-brown

Page 10

10

SR Link

SR Link is a fast, reliable and

easy-to-use bonding system,

consisting of a metal-active,

a resin-active and a

hydrophobic component.

Delivery form

– SR Link, 5 ml

SR Spectrasit Liquid

The light-curing Spectrasit

Liquid is used for wetting

polymerized SR Spectrasit

and SR Chromasit veneers in

case they need to be

modified.

Delivery form

– SR Spectrasit Liquid, 5 ml

SR Chromasit Fluid

Chromasit Fluid prevents the

formation of an inhibition

layer during the polymerization of Chromasit. The fluid

is applied to the

SR Chromasit veneer before

each polymerization cycle

and must be completely

removed after polymerization.

Delivery form

– SR Chromasit Fluid, 3 ml or 4 x 3 ml

SR Chroma Link

The metal-active component

of SR Chroma Link reacts

with the metal oxide on the

metal surface, thereby

creating the appropriate

conditions for an optimum

bond.

Delivery form

– SR Chroma Link, 2.5 g

Bonding systems and accessories

Page 11

11

Retention Adhesive

This retention varnish is

used to secure micro- or

macroretention beads. If

space is limited, microretention beads are used

and if sufficient space is

available, macroretention

beads are used.

Delivery form

– Retention Adhesive, 20 ml

Micro- and Macroretention

Retention beads are

available in two different

sizes: macroretention and

microretention beads. They

are used according to the

space available.

– microretention beads

200–300 microns

– macroretention beads

400–600 microns

Delivery form

– Microretention, 15 g

– Macroretention, 15 g

Separating Fluid

This alginate-based

separating fluid is used for

isolating composite from

plaster.

Delivery form

– Separating Fluid, 30 ml

Page 12

12

Shade selection

The Chromascop shade

guide represents the shade

standard for Ivoclar Vivadent

products. With its logically

arranged shades, the

Chromascop shade guide

permits quick and highly

accurate shade matching.

The 20 shades are divided

into 5 consistently arranged,

detachable shade groups.

After determining the basic

shade group, the correct

shade within that shade

group is selected. The strict

omission of superfluous

effects (eg cervicals,

transparent areas,

pronounced discoloration

of the incisal and dentin

areas, as well as surface

characterization) greatly

facilitates determining the

appropriate shade.

– SR Chromasit,

SR Spectrasit, SR Ivocron

– SR Antaris / SR Postaris

tooth lines

– IPS d.SIGN

– IPS Empress / IPS Empress 2

– Tetric Ceram

restorative materials

Page 13

13

Fabricating the model

Fabricate a stone model with detachable segments according

to the impression.

Fabricating the framework / Contouring

Fabricate a wax framework on the model according to the

requirements of the case in question. The following measures

are indispensable to achieve a long-lasting bond between the

framework and veneer: accurate contouring of the margins,

application of retention wires to the pontics and appropriate

application of micro- and macroretention (eg retention

splinters) on the areas to be veneered.

Prepare a cervical metal margin if possible, or prepare a

chamfer. Flatten out the incisal edge into a chamfer, if

possible. Provide sufficient protection of the incisal edge.

Contouring the pontics

Processing instructions

Make sure to provide sufficient protection of the incisal

edge.

Adequate retention is particular important in the case of fully veneered restorations.

Anatomical modellation with sufficient protection of the incisal edge on the palatal/lingual surface

Use a wax wire to bring the pontics to the same

level.

Page 14

14

Preparing the framework

After divesting, finish and adjust the metal surfaces to be

veneered as usual.

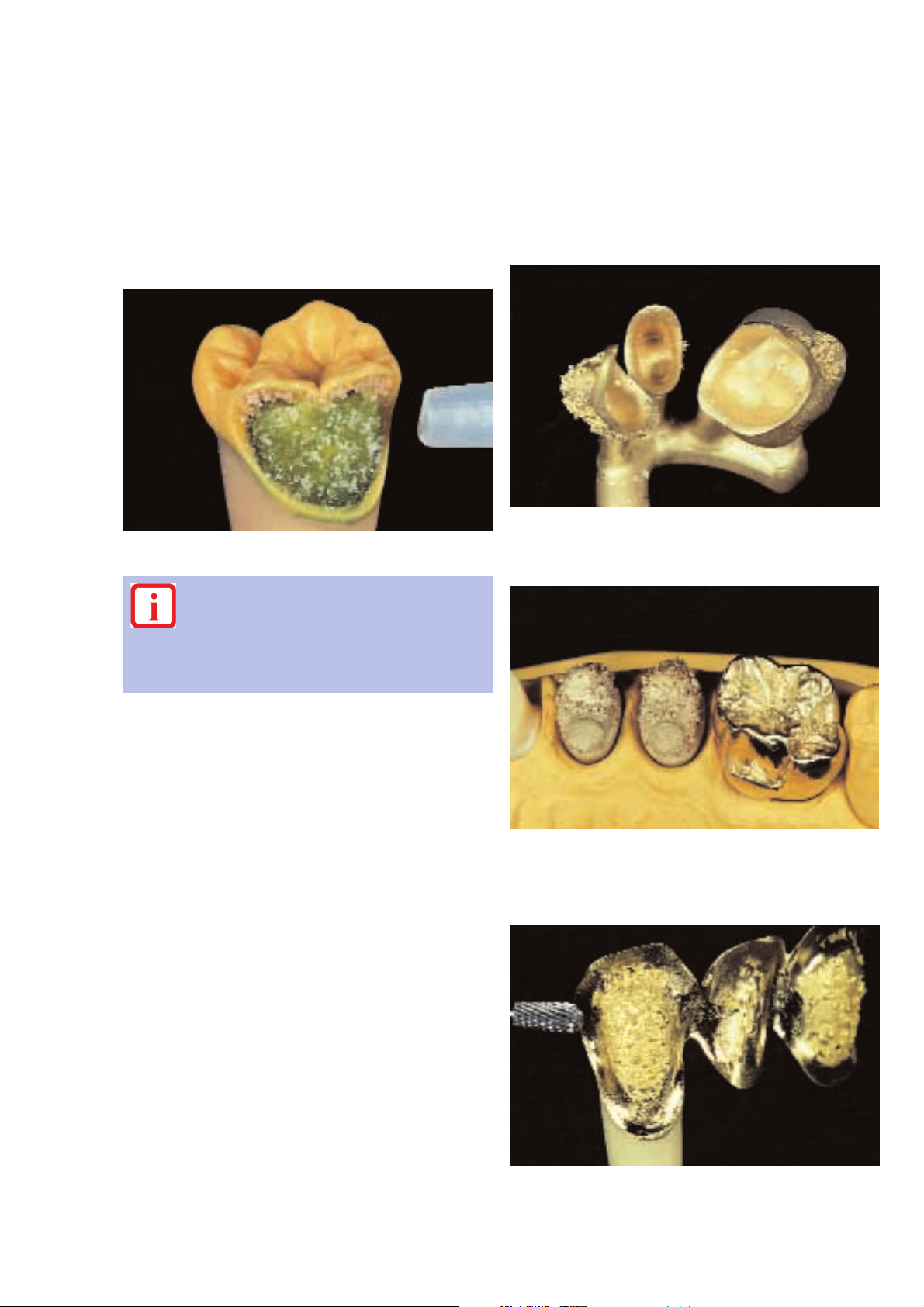

Framework after casting and sandblasting.

Appropriate application of retention beads is essential to ensure a favourable mechanical bond.

Fitting the copings.

Finishing the framework, particularly the marginal areas.

The retention beads should neither be too close

together nor should they be too wide apart – the

retentive effect would be lost in both cases. If the

Retention Adhesive is not applied appropriately, the retention beads may become submerged and lose their retentive

effect.

Designing frameworks with pontics

It is advisable to bring large pontics (eg upper centrals,

molars) to the same level as the neighbouring crowns by

applying a wax wire in a targeted fashion. This measure

helps to create a harmonious shade effect in bridges which

involve various layer thicknesses.

Before the sprues are attached, apply a thin layer of

Retention Adhesive onto the veneering surface (‘veneering

window’) of the wax model. Let the solvent evaporate for

approximately 30 seconds. Then, carefully apply the retention

beads onto the surface where required.

Page 15

15

Sandblast the metal framework with aluminium oxide or with

Ivoclar Vivadent Special Jet Medium.

If SR Link is used as the bonding system, remove blasting

residue only by tapping it off or by applying oil-free

compressed air.

If SR Chroma Link is used as the bonding system, the framework may be steam-cleaned. Subsequently, dry with

compressed oil-free air.

The surface to be veneered must be clean to produce a bond

at a molecular level. Even invisible traces of dirt may

compromise the bond between the framework and veneer.

Consequently, all traces of dirt and grease must be

thoroughly removed.

Do not touch cleaned surfaces!

The jet pressure is chosen according to the grit size

of the jet medium. We recommend using aluminium

oxide, Type 100 microns, at 2 bar pressure to sand-

blast the framework. The use of a lower grit size

and/or jet pressure may result in the material

chipping off.

After having been fitted to the model, the metal framework is finished.

After having been fitted to the model and completed, the metal framework is sandblasted with aluminium

oxide.

Completed framework fitted on the model.

Use only metals that are resistant to corrosion and

oral conditions.Alloys which have a high silver or

copper content are prone to corrosion in the oral

cavity and we therefore advise against using them, particularly if they contain more than 50% silver or copper. Alloys

that have a precious metal content of more than 90%

develop only a limited amount of bonding oxides. They

must therefore not be used.

Please take the alloy manufacturer’s information about the

alloy’s resistance to the conditions in the oral cavity into

account. That information has to be considered to produce a

long-lasting, reliable restoration.

Metal framework after sandblasting and cleaning.

Page 16

16

Conditioning the metal surfaces with

SR Link or SR Chroma Link

Version 1: SR Link

Application of SR Link

After the framework has been sandblasted (Al

2O3

/

100 microns/2 bar) and cleaned of blasting residue by

tapping it off, SR Link is applied. Apply SR Link with a clean

disposable brush and allow it to react for 3 minutes.

Do not apply SR Link on alloys containing more

than 50% silver and/or copper or on alloys

containing more than 90% gold, palladium or

platinum.

Non-precious metal and titanium alloys require mechanical

retention to provide a long-lasting bond.

Mechanical retention is generally advantageous to

improving the bond between the framework and veneer.

Application of SR Chroma Link

After you have sandblasted (Al

2O3

/100 microns/2 bar) the

framework and cleaned it of blasting residue by tapping it

off, apply a thin coat of SR Chroma Link on the blasted

metal surface. Subsequently, leave to evaporate for 3 to

4 minutes. The opaquer is applied immediately after the

evaporation time.

If SR Chroma Link is used, retention beads must be

applied onto all types of metal frameworks

(precious metal, non-precious metal, or titanium).

Apply a thin coat of SR Chroma Link, using a disposable brush.

Version 2: SR Chroma Link

Apply SR Link.

Page 17

17

Apply a thin coat of opaquer (wash).

Apply the second opaquer layer, covering the entire metal surface.

Completely opaqued surface.

Leave the opaquer to dry for a few seconds.

Applying the opaquer

Mix SR Chromasit Opaquer with SR Chromasit Opaquer

Liquid to a thick-flowing mixture, using a brush. Cover the

mixture and leave it to swell for approximately 2 minutes.

Then, apply the first coat of opaquer without masking the

framework completely (wash). Make sure to apply opaquer

to all retention areas.

After that, apply another layer of opaquer. This time, the

metal surface should be entirely covered with opaquer. If

necessary, thin the consistency of the opaquer by adding

SR Chromasit Opaquer Liquid.

Mix the opaquer to a thick-flowing mixture, cover

the mixture and leave it to swell for 2 minutes.

To ensure a smooth transition between the metal and

veneering resin, let the opaquer thin out at the metal

margins.

If a smooth surface is required, the opaquer can be

smoothed by applying a vibrating motion for a short time.

Check all critical areas for thorough polymerization, using a

probe.

Page 18

18

Processing procedure for pontics

Step 1:

Sandblast the completed framework with aluminium oxide,

clean with steam (only if you are using SR Chroma Link) and

dry with oil-free compressed air.

Step 2:

Apply SR Chroma Link or SR Link and allow to dry

(SR Chroma Link: 3 to 4 minutes; SR Link: 3 minutes).

After the drying time has elapsed, apply a thin coating of

SR Chromasit Opaquer to the pontic and build up with

SR Chromasit Dentin until the pontic is at the same level as

the abutment crowns.

Step 3:

Next, apply a masking layer of opaquer to the veneering

areas of the abutment crowns as well as to the pontic,

which has been built up with Dentin. Then, polymerize the

object in the Ivomat (with water) at 120 °C (248 °F) and

6 bar pressure for 5 minutes.

Step 4:

Continue with the veneering procedure.

After having left the opaquer to swell, apply it to the

veneering area and polymerize another time at 120 °C

(248 °F) and 6 bar pressure for 5 minutes.

Polymerizing the opaquer

After applying the opaquer, polymerize the material in the

Ivomat (with water) at 120 °C (248 °F) and 6 bar pressure

for 5 minutes.

The opaqued surface must be free of water. If not, a

separation layer between the opaquer and resin forms. To

prevent such a separation layer from occurring, carefully dry

the opaqued surface with compressed oil-free air before

veneering.

Characterizing the opaquer

Depending on the customary techniques of the technician,

the shade of the standard opaquer can be modified by

adding SR Chromasit Intensive Opaquer. For this purpose, a

small quantity of SR Chromasit Intensive Opaquer is added

to the standard opaquer powder during the mixing procedure. Alternatively, mix SR Chromasit Intensive Opaquer with

SR Chromasit Opaquer Liquid and apply the mixture to the

polymerized standard opaquer.

Polymerization parameters for the opaquer

Pressure

6 bar

Time

5 minutes

Temperature

120 °C (248 °F)

Page 19

19

Chromascop layering diagram

PE layering diagram

Layering diagram

Page 20

If desired, the dentin can be built up and poly-

merized so that mamelons and details can be shaped more easily and more selectively. The entire

surface should in any case be ground, blasted with Al

2O3

,

cleaned and wetted with SR Spectrasit Liquid before finishing the restoration with the Incisal Materials.

The SR Chromasit Materials can be protected from dirt by

means of the orange cover of the working pad.

Use the modelling instruments recommended by Ivoclar

Vivadent for layering.

Application of cervical characterizations

20

Layering technique

Isolating

Before building up the veneer, isolate all contact surfaces

with the wet plaster model, using Separating Fluid. Remove

excess with oil-free compressed air.

The SR Chromasit materials can be applied either according

to the layering diagram to produce the Chromascop shades

or individually. Make sure to build up the pontic areas

adequately.

SR Chromaist Creative Dentin is applied to achieve special

effects such as characterization of cervicals or proximal areas.

The Dentin and Incisal materials can be layered without

intermediate polymerization.

The Dentin and Incisal Materials can be layered without intermediate polymerization.

Page 21

21

SR Chromasit Color or SR Chromasit Intensive can also be

used to apply individual characterizations. These materials

can be applied directly to the restoration, using a brush.

Alternatively, they are first mixed with SR Chromasit Dentin

or Incisal and then applied.

Possibilities of customizing SR Chromasit with SR Chromasit Color and SR Chromasit

Intensive during layering

Characterizations are applied to the proximal area (here: Creative Incisal CS21 dove-blue)

Creative Dentin or Dentin which has been modified with SR Chromasit Color is used to create mamelons….

…which are subsequently covered with Incisal or Creative Incisal Material.

Creative Dentin dove-blue or SR Chromasit Color is applied to accentuate the proximal incisal edge.

Fully layered veneer

After applying the characterizations, complete the veneer

according to the layering diagram, using the SR Chromasit

Incisal materials. The contours created in the dentin are

retained owing to the softer consistency of the Incisal

material.

Avoid trapping air when mixing the shades.

Page 22

22

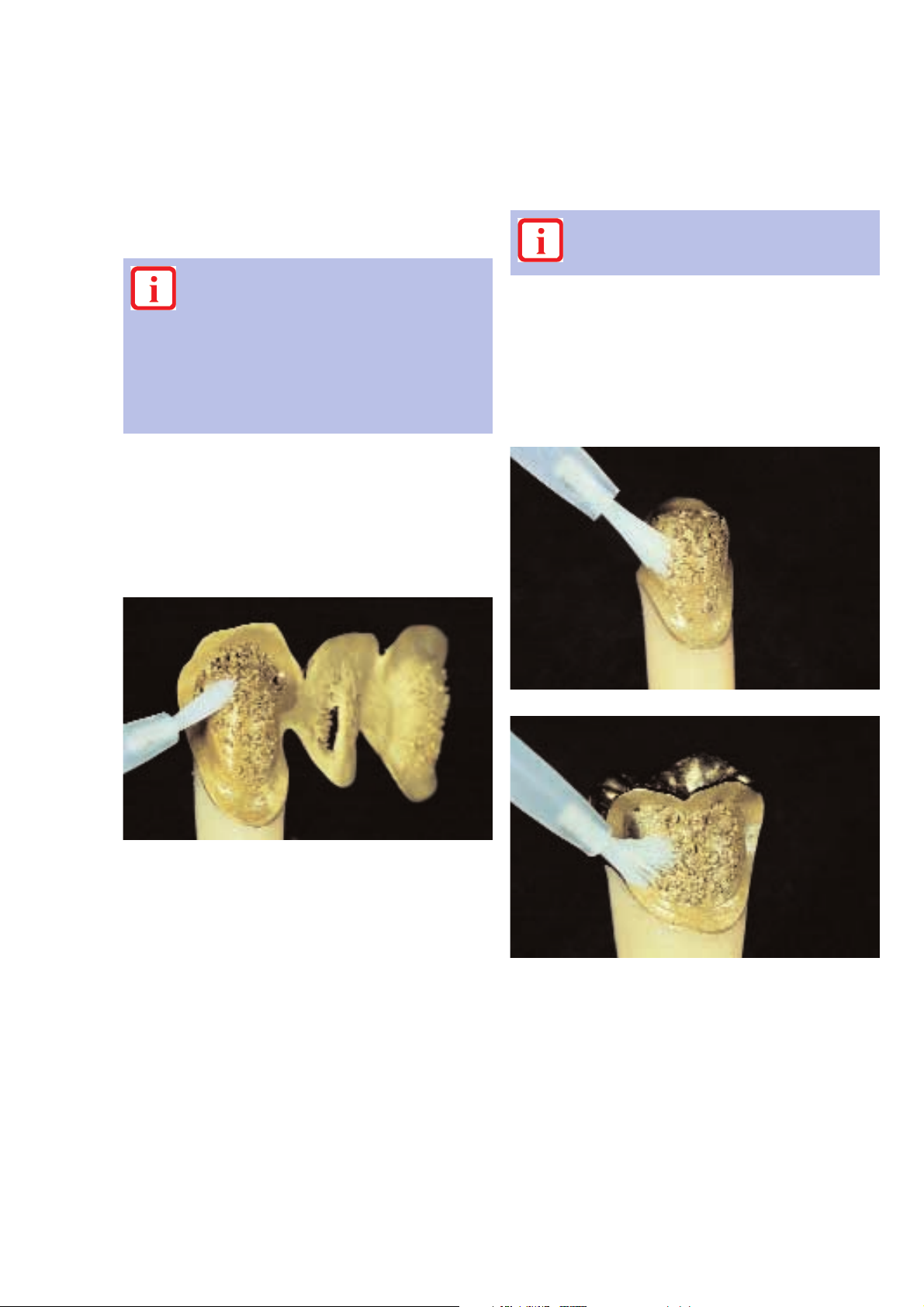

…and coat the fully modelled veneer with SR Chromasit Fluid.

Finish the contact points and interdental spaces,…

…surface characterizations,…

… and proximal surfaces.

Remove the fully layered restoration from the model…

Peparing the restoration for

polymerization

Remove the fully layered restoration from the model and add

Incisal material to the contact points. Make sure that the

material is fully adapted in the marginal areas, ie at the

transition between the metal and veneer.

When fabricating a bridge, separate the individual veneers

using a thin implement.

SR Chromasit Fluid forms a separation layer and

should therefore only be applied to surfaces. It

should not be used as a wetting agent to make

shape adjustments with SR Chromasit.

After polymerization, thoroughly remove SR Chromasit Fluid.

Polymerizing the veneer

Polymerize the veneer in the Ivomat (with water) at 120 °C

(148 °F) and 6 bar pressure for 7 minutes.

Finishing

Finish shape and contact points using appropriate grinding

instruments. Make sure to completely remove SR Chromasit

Fluid from the surfaces of the veneer.

Do not use coarse-grained diamonds, coarse burs or similar

instruments, as it is difficult to produce a sufficiently smooth

surface with this type of instruments.

Polymerization parameters for the Dentin/Incisal

materials

Pressure

6 bar

Time

7 minutes

Temperature

120 °C (148 °F)

Page 23

Final polishing

Carefully polish the restoration to a high gloss using a leather

buffer and Ivoclar Vivadent universal polishing paste.

Microscopic projections on finished veneering

surfaces easily pick up deposits. Finishing and

polishing should therefore be performed very

carefully.

Pay particular attention to crown margins, interdental

spaces and surfaces in contact with gingival tissue.

23

Finish the surfaces and then use a soft rubber polisher to

eliminate rough projections. Next, prepolish the restoration

with a goat’s hair brush and Ivoclar universal polishing paste.

Polishing

Prepolishing

As a rule, polishing should only be performed by means of a

handpiece rather than a polishing lathe. This is the only way

possible to polish all parts of the veneer – and in particular

the interdental spaces – properly.

Finish surfaces and then utilize a soft rubber polisher…

… and prepolish with a goat’s hair brush and Ivoclar Vivadent universal polishing paste.

Polish the restoration to a high gloss, using a leather buffer…

… and Ivoclar Vivadent universal polishing paste.

Completed restoration from labial

Page 24

24

Contraindication

– occlusal veneers on molars

– layer thickness of less than 1.5 mm

Important notes

– If the layer thickness of the crown and the pontic are sig-

nificantly different in the labial region, the shade effect

may be compromised because of the inherent properties

of translucent materials.

– In order as not to compromise the shade effect, the opa-

qued pontic can be characterized with SR Chromasit

Intensive Opaquer and/or built up with SR Chromasit

Creative or SR Chromasit Dentin, which has been modified with SR Chromasit Intensive, so that approximately

the same layer thickness is used on the entire bridge.

After that, the Dentin and Incisal materials are applied as

usual.

– There must be sufficient space between the metal frame-

work and the antagonist (1.5 mm) so that the layering

material can be applied in the required thickness

(1.5 mm). Thinner thicknesses may result in the

material chipping off.

– If the space available is less than 1.5 mm, an occlusal

metal surface should be preferred.

– After completing the restoration, make appropriate grin-

ding adjustments in the articulator, paying particular

attention to the centric and masticatory movements to

prevent inappropriate stresses from occurring.

First, apply the Dentin material to the cervical region…

Apply a coat of SR Chromasit Fluid to the veneering surface and then polymerize.

… after that, contour the labial and lingual aspects and add Incisal material.

Processing instructions for fully

veneered restorations

Preparing the framework

The occlusal space between the metal framework and the

antagonist should be at least 1.5 mm in order to provide

sufficient space for the veneering material. In addition, the

minimum thickness of the metal (0.3 mm) has to be taken

into account.

Condition the framework and apply the bonding system and

opaquer as described on page 17.

Layering technique

Separate plaster surfaces using Separating Fluid. Next, apply

Dentin material, first to the cervical area and after that,

adapt the material in the labial and lingual areas and finally,

adapt the material on the occlusal surface, according to the

layering diagram. Remove the fully layered restoration from

the model and add Incisal material to the contact areas.

Page 25

25

We would like to thank Mr. T. Michel, Schorndorf/Germany, for the clinical pictures.

Page 26

26

Warnings

– SR Chromasit has been designed for use in dentistry.

– Avoid contact of the skin or eyes with uncured material

(pastes). Prolonged or repeated contact of the skin with

uncured material may cause a slight sensitizing reaction

and lead to a sensitization against methacrylate.

– SR Chroma Link, SR Link, SR Chromasit Fluid, SR Opaquer

Liquid and Retention Adhesive contain methyl methacrylate

and solvent. These liquids are easily flammable and irritant.

Keep away from sources of ignition. Do not smoke. Do not

breathe in vapours. Avoid contact with the skin and eyes.

Unpolymerized liquids irritate the eyes, respiratory system

and skin. Sensitization through skin contact is possible.

– Please observe danger signs on the individual primary

packagings and labels.

Cleaning

– Do not clean removable dentures with alkaline or similar

cleaning agents, as they severely corrode the surfaces and

the bonding layer.

– The use of a toothbrush and toothpaste is the best and

simplest way of cleaning removable dentures. If performed

regularly, this cleaning method effectively helps to prevent

the formation of deposits.

Repairs

Repairs in the laboratory

– The veneer to be repaired should be ground with a tung-

sten carbide bur or sandblasted at reduced jet pressure of

1 bar with aluminium oxide, 100 microns, or Ivoclar

Vivadent Special Jet Medium. Next, steam-clean and dry

with oil-free compressed air.

– Then, apply SR Spectrasit Liquid and allow to evaporate.

– Apply the light-curing SR Spectrasit to the prepared

surface.

– Next, apply Spectrasit Gel and polymerize the veneer in the

Spectramat for 5 minutes.

– Then, finish and polish the veneer as described above.

Repairs by the dentist

– The Ceramic Repair Set from Ivoclar Vivadent offers

dentists a comprehensive range of materials and

accessories to repair composite and ceramic restorations.

– Please refer to the Instructions for Use of the

corresponding materials for detailed information.

Page 27

27

Chromasit

Materials combination table

SR

Chromascop

Opaquer

Intensive Opaquer

Dentin

Creative Dentin

Incisal

Creative Incisal

SR Chromasit Intensive

110

01

11

110

01

1

120

1A

11

120

1A

1

130

2A

16

130

2A

1

140

1C

14

140

1C

1

210

2B

15

210

2B

1

220

1D

15

220

1D

2

230

1E

15

230

1E

2

240

2C

12

240

2C

2

310

3A

14

310

3A

2

320

5B

24

320

5B

3

330

2E

14

330

2E

2

340

3E

23

340

3E

1

410

4A

23

410

4A

4

420

6B

14

420

6B

5

430

4B

14

430

4B

5

440

6C

16

440

6C

3

510

6D

23

510

6D

3

520

4C

23

520

4C

3

530

3C

23

530

3C

3

540

4D

12

540

4D

5

21 vanilla-white; 22 yellow-orange; 23 orange-brown; 24 dark-brown

21 dove-blue; 22 transparent--pink; 23 transparent-orange

0 clear; 1 white, 2 pink; 3 blue; 4 anthracite; 6 light-brown; 7 red-brown; 8 olive-brown; 9 dark-brown

1 white, 2 light-yellow, 3 yellow, 4 brown, 5 pink, 6 violet, 7 grey

Page 28

Ivoclar Vivadent AG

Bendererstrasse 2

FL-9494 Schaan

Liechtenstein

Tel. +423 / 235 35 35

Fax +423 / 235 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P.O. Box 367

Noble Park,Vic. 3174

Australia

Tel. 03 / 97959599

Ivoclar Vivadent Ltda.

Rua Maestro João Gomes de

Araújo 50; Salas 92/94

Sao Paulo, CEP 02332-020

Brasil

Tel. +55 11 69 59 89 77 /

69 71 17 50

Ivoclar Vivadent Marketing

Ltd.

Calle 134 No. 13-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 33 99

Ivoclar Vivadent S.A.

B.P. 118

F-74410 Saint-Jorioz

France

Tel. 04.50.88.64.00

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Tel. +49 (0) 79 61 / 8 89-0

Fax: +49 (0) 79 61 / 63 26

Ivoclar Vivadent UK Limited

Meridian South

Leicester

LE3 2WY

Great Britain

Tel. 116 / 265 40 55

Ivoclar Vivadent s.r.l.

Via dell’Industria 16

I-39025 Naturno (BZ)

Italy

Tel. 0473 / 67 01 11

Ivoclar Vivadent S.A. de C.V.

Av. Mazatlán No. 61, Piso 2

Col. Condesa

06170 México, D.F.

Mexico

Tel. +52 (55) 5553-0038

Fax +52 (55) 5553-1426

Ivoclar Vivadent Ltd

12 Omega St, Albany

PO Box 5243 Wellesley St

Auckland, New Zealand

Tel. 09 / 914-9999

Ivoclar Vivadent

Polska Sp. z.o.o.

PL-01-501 Warszawa

ul. Jana Pawla II 78

Poland

Tel. 635 54 96 / 635 54 97

Ivoclar Vivadent S.A.

c/Valderribas 82

E-28007 Madrid

Spain

Tel. 91 / 513 10 08

Ivoclar Vivadent AB

Dalvägen 16

S-169 56 Solna

Sweden

Tel. 08 / 514 93 930

Fax 08 / 514 93 940

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA

Tel. (800) 533-6825

Ivoclar Vivadent, Inc.

23 Hannover Drive

St. Catharines, Ont. L2W 1A3

Canada

Tel. (800) 263-8182

Ivoclar Vivadent – worldwide

Date information prepared: 02/2002

These materials have been developed solely for use

in dentistry. Processing should be carried out strictly

according to the Instructions for Use. Liability cannot

be accepted for damages resulting from failure to

observe the Instructions or the stipulated area of

application. The user is responsible for testing the

materials for their suitability and use for any purpose

not explicitly stated in the Instructions. Descriptions

and data constitute no warranty of attributes and

are not binding.

Printed in Liechtenstein

© Ivoclar Vivadent AG, Schaan / Liechtenstein

564136/0702/e/0.5/BVD

Loading...

Loading...