Page 1

COMPOSITES

SR Adoro

®

C&B

SR

®

Adoro

Instructions for Use

Page 2

Table of Contents

4

5

Product

Information

12

SR Adoro – The Composite Veneering System

Product Information

Material

Uses

Composition

Working Times

Curing Depths

The Product System

SR Accessories

Shade Determination

Practical Procedure for Framework-Free Restorations (Inlays/Onlays)

Preparation Guidelines and Minimum Layer Thicknesses

Layering Diagram for Inlays / Onlays

SR Adoro Step by Step

Sealing the Die

Starting Situation

Applying the Liner

Removing the Inhibition Layer

Layering

Polymerization / Tempering

Finishing / Polishing

Preparing for Cementation

Practical Procedure

24

31

Practical Procedure for Framework-Free Restorations (Anterior Crowns)

Preparation Guidelines and Minimum Layer Thicknesses

SR Adoro Step by Step

Starting Situation

Sealing the Die and Adjoining Parts of the Model

Applying the Liner

Removing the Inhibition Layer

Anterior Tooth Layering

Final Polymerization / Tempering

Finishing / Polishing

Preparing for Cementation

Practical Procedure for Fixed Metal-Supported Restorations

Framework Design

SR Adoro Step by Step

Starting Situation / Framework Fabrication

Casting and Finishing

Conditioning of the Framework

Layering Diagram

Opaquer Layer

Cervical, Dentin and Incisal Layering

Final Polymerization / Tempering

Finishing / Polishing

57

Practical Procedure for Framework-Supported Combination Dentures

Procedure for Combination Dentures

Shade Matching of SR Adoro to Denture Teeth

Masking of Model Cast Retentions with Gingiva Opaquer

2

Page 3

63

Practical Procedure for Fixed ZrO2-Supported Restorations

Framework Design

SR Adoro Step by Step

Starting Situation / Layer Thickness / Framework Design

Framework Preparation / Conditioning

Applying the Liner

Layering Diagram for A–D and Chromascop Shades

Dentin / Incisal Layering

Final Polymerization / Tempering

Finishing / Polishing

Practical Procedure

General

71

76

Information

Practical Procedure for Restorations with Gingiva Components

Framework Design

SR Adoro Step by Step

Example of a Possible Individual Layering Diagram

Final Polymerization / Tempering

Finishing / Polishing

General Information

Cementation

Polymerization / Tempering Parameters

Subsequent Adjustments

Materials Combination Table

Questions and Answers

3

Page 4

SR

Adoro

®

The Composite Veneering System

In view of the versatile application possibilities of veneering composites, we have made it our objective

to develop a universally applicable material system that not only offers a wide variety of design options

for experienced specialists but also constitutes an optimum and economic alternative for first-time users

and all-rounders.

The main thrust of development work on SR Adoro was towards designing a material that offers

optimal physical properties, excellent esthetics, convenient handling properties and ample flexibility.

Particular emphasis was also placed on coordinating the individual components of the SR Adoro system

with each other, as well as with other Ivoclar Vivadent systems (IPS d.SIGN® or IPS InLine®).

Ivoclar Vivadent, who fostered the idea of integrated systems many years ago, has complemented its

product range by introducing SR Adoro. A coordinated range of products encompassing alloys,

ceramics, denture teeth, equipment, cements and composite veneering materials enables dental technicians to fabricate fixed, removable and combination dentures.

At the same time, the range of possible framework materials was extended with SR Adoro. Zirconium

oxide frameworks are an attractive alternative to conventional metal frameworks that may be optimally

veneered with SR Adoro. Furthermore, SR Adoro is ideally suitable if "pink esthetics" is an issue. With

the use of SR Adoro Gingiva materials, it is possible to complete the soft tissue components easily and

efficiently with composite.

The well-balanced assortment – coordinated with the Chromascop and A–D shade guides – and the

various additional assortments, enable users the highly esthetic reconstruction of lost tooth structure

with SR Adoro.

Your possibilities with the SR Adoro system:

Framework-free

Metal-supported ZrO2-supported

SR Adoro Materials

SR Adoro Gingiva

4

Page 5

SR

Adoro

®

Product Information

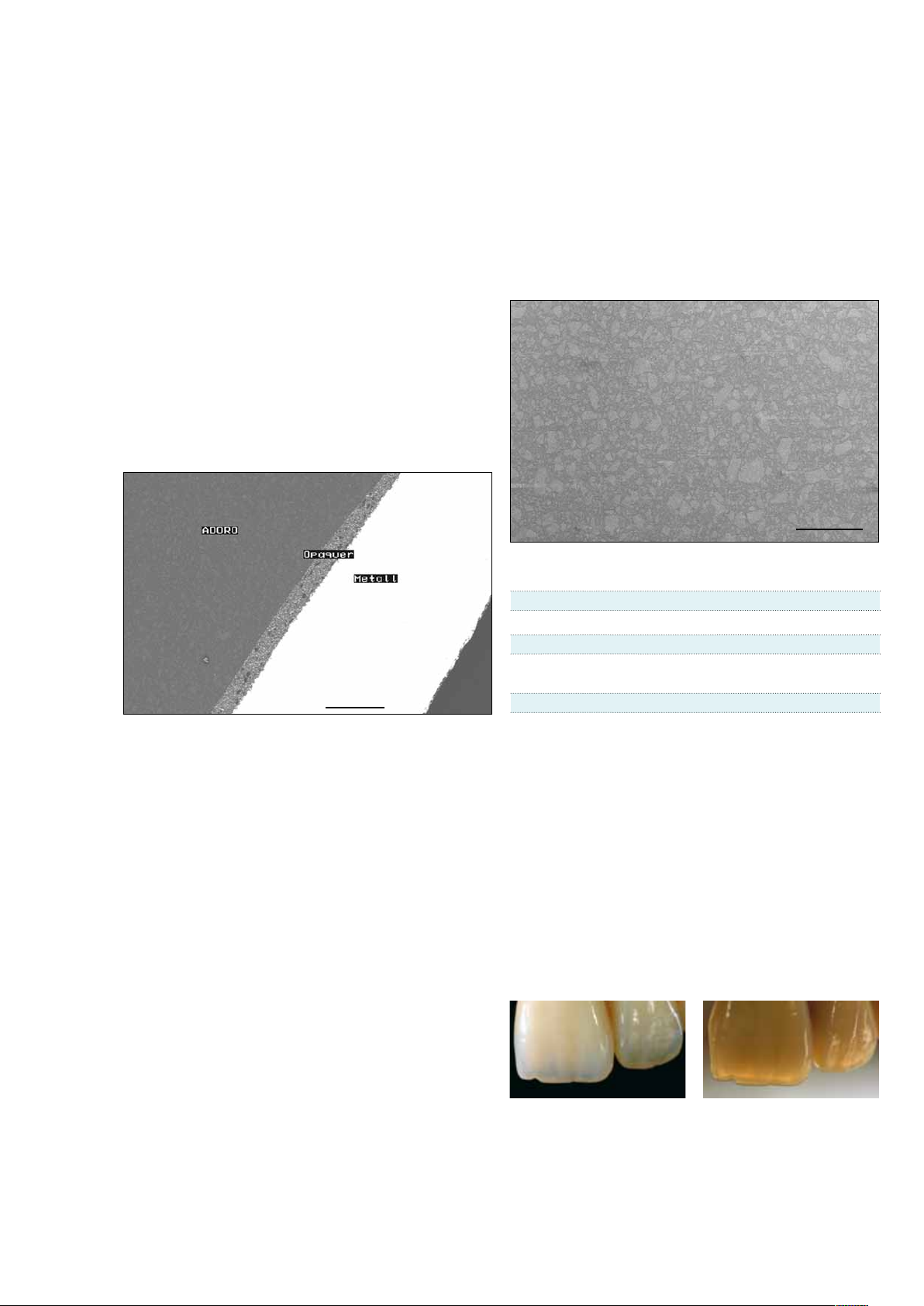

Material

This composite is a tried-and-tested veneering system that offers

several advantages over hybrid composite materials with regard to

wear, handling, plaque resistance and surface gloss. This can be

attributed to the high proportion of inorganic fillers in the nanoscale range. Furthermore, the matrix is based on a urethane dimethacrylate (UDMA), which is distinguished for its toughness, which is

higher than that of its predecessors or the frequently used BisGMA.

In order to achieve a non-sticky, homogeneous consistency and a

low-shrinkage system, a special prepolymer was developed, which,

in turn, is based on nanofillers and the new UDMA. The result is a

virtually homogeneous material, which may well be called a microfilled composite.

500 µm

Physical properties of SR Adoro

The inorganic microfillers together with an innovative matrix impart

homogeneous structure to the material. The coordinated ratio

between these two components provides the best physical

properties and promotes a high resistance against discolouration,

plaque accumulation and wear.

200 µm

SR Adoro SR Adoro

Dentin Incisal

Flexural strength [MPa]* 130 ± 10 120 ± 10

Vickers hardness [MPa] 490 ± 10 480 ± 10

Water absorption [µg /mm3]* 17 ± 1 17 ± 1

Wear (W illitec chewing simulator) –

Volume abrasion

Modulus of elasticity [MPa] 7000 ± 500 7000 ± 500

<0.1 mm

3

*according to ISO 10477

Esthetic properties of SR Adoro

Highly esthetic results can be achieved even if a straightforward,

basic layering procedure is used. Even the basic SR Adoro material

exhibits an opalescent effect, which equals that of the natural

tooth. Aspects such as brightness and chroma and/or opacity and

translucency were taken into consideration for the colouration of

SR Adoro. These characteristics are apparent in the individual components and endow the material with its highly esthetic properties.

5

Page 6

Uses

Indications

Fixed Denture Prosthetics

Metal-supported

– Veneering of metal-supported restorations with the application

of SR Adoro Thermo Guard

– Veneering of combination dentures (e.g. telescope veneers) with

the application of SR Adoro Thermo Guard

– Veneering of partially removable implant superstructures with the

application of SR Adoro Thermo Guard

– Veneering of Gingiva components in partially removable implant

superstructures with the application of SR Adoro Thermo Guard

– Fabrication of long-term temporaries with the application of

SR Adoro Thermo Guard

– Masking of model cast frameworks with SR Adoro Opaquer pink

Zirconium oxide-supported

– Veneering of ZrO

– Characterization and veneering of frameworks and implant

superstructures made of yttrium oxide, partially stabilized,

sintered or HIP zirconium oxide in a CTE range of

10.5–11.0 x 10-6 K-1 (100–500 °C).

Metal-free

– Inlays / onlays / veneers

– Anterior crowns

– Long-term temporaries with Everest C-Temp Blanks (KaVo) with a

maximum wear period of 12 months

Removable Denture Prosthetics

– Surface characterizations with SR Adoro Stains of Ivoclar Vivadent

resin teeth (PMMA) with subsequent veneering with SR Adoro

layering materials

– Shape and shade adjustments of Ivoclar Vivadent resin teeth

(PMMA) with SR Adoro layering materials in combination with

SR Composiv

-supported restorations

2

Contraindications

– Veneering of metal-supported restorations without the applica-

tion of SR Adoro Thermo Guard

– Posterior crowns without framework support (ZrO

or alloys)

2

– Quadrant restorations without sufficient support by the residual

dentition

– Veneering of long-span, multi-unit, metal-supported bridges

(horseshoe) without sufficient support by the residual dentition

– Conventional cementation of fixed, metal-free restorations

– Framework-free long-term temporaries with a wear period of

more than 12 months

– Patients with occlusal dysfunctions and/or parafunctions, such as

bruxism, etc.

– Patients with inadequate oral hygiene

– Any clinical applications that are not described as an indication by

the manufacturer

– Removal of SR Adoro veneers and reuse of the zirconium oxide

framework

– Veneering of zirconium oxide frameworks without the application

of SR Adoro Liners

General notes

As is generally known, composites have to meet different demands

due to country-specific uses.

Composite veneering materials show specific characteristics and

properties and their performance and durability can therefore not

be compared with that of other C&B materials.

The composite restorations may require clinical repair over time,

depending on the situation and the individual case. The restorations

can be repaired by means of microfilled composites, as described in

the section on "Subsequent Adjustments" on page 79.

6

Page 7

Composition

– SR Adoro layering materials

(Cervical, Dentin, Deep Dentin, Incisal, Transpa, Impulse and

Gingiva materials)

Dimethacrylate (17–19 wt.%); copolymer and silicon dioxide

(82–83 wt.%). Additional contents are catalysts, stabilizers and

pigments (<1 wt%).

The total content of inorganic fillers is 64–65 wt.%/46–47 vol.%.

Particle size 10-100 nm.

– SR Adoro Liner

Dimethacrylate (48 wt.%); barium glass filler and silicon dioxide

(51 wt.%). Additional contents are catalysts, stabilizers and

pigments (<1 wt%).

– SR Adoro Opaquer

Dimethacrylate (> 55 wt.%); inorganic fillers (43 wt.%).

Additional contents are catalysts, stabilizers and pigments

(< 2.5 wt%).

– SR Adoro Stains

Dimethacrylate (47–48 wt.%); copolymer and silicon dioxide

(49–50 wt.%).

Additional contents are catalysts, stabilizers and pigments

(2–3 wt%).

– SR Adoro Add-On

Dimethacrylate (16–17 wt.%); copolymer and silicon dioxide

(82–83 wt.%). Additional contents are catalysts, stabilizers and

pigments (<1 wt%).

– SR Model Separator

Polyglycol, polyethylene glycol in a water/alcohol solution.

– SR Link

Dimethacrylate, phosphate ester, solvent and benzoyl peroxide.

– SR Gel

Glycerine, silicon dioxide and aluminium oxide.

Warning

SR Adoro is intended for dental-lab use only. Contact of unpolymerized material (pastes) with the skin or eyes must be prevented.

Skin contact of unpolymerized material may have a slight irritating

effect and may lead to a sensitization against methacrylates.

Many commercial medical gloves do not provide protection

against the sensitizing effect of methacrylates. Do not inhale

grinding dust. The safety notes on the individual primary packages

and labels have to be observed.

General note

Failure to observe the stipulated contraindications and processing

instructions may lead to clinical failure.

Side effects

There are no known side effects to date. In individual cases

allergic reactions may occur. If a patient is known to be allergic to

any of the ingredients, SR Adoro must not be used.

Storage instructions

– Store SR Link in the refrigerator (2–8 °C/36– 46 °F).

– Store SR Adoro layering materials and SR Adoro Thermo Guard

at 12–28°C/54–82 °F.

– Close syringes immediately after usage (exposure to light causes

premature polymerization).

– Reseal SR Adoro Thermo Guard immediately after use

(exposure to light causes premature polymerization).

– Protect the materials from direct sunlight.

– Do not use the products after the indicated expiration date.

– Keep material out of children’s reach.

How to clean SR Adoro restorations

Incorrect use of the ultrasound cleaning liquid may dissolve the

composite surface due to the high aggressiveness of the liquids.

Therefore, alkaline cleaners with a pH value higher than 8 should

not be used.

– SR Adoro Thermo Guard

Diethylene glycol, water, inorganic fillers, synthetic fibres.

– SR Retention Adhesive

Copolymer, resin and softener (30 wt.%) dissolved in acetone

(70 wt.%).

– SR Micro Retention Beads 200–300 microns

– SR Macro Retention Beads 400– 600 microns

Copolymer (99.5 wt.%) and titanium dioxide (0.5 wt.%).

– SR Composiv

Dimethacrylate; silicon dioxide (16–17 wt.%) Additional contents

are catalysts, stabilizers and pigments (<2.5 wt.%).

– Universal Polishing Paste

Emulsion of aluminium oxide, ammonium oleate, petroleum

distillate and water.

7

Page 8

Working Times

SR Adoro materials are sensitive to light. The working time depends

on the layer thickness, shading and the prevailing light conditions.

Light shades react more quickly than do dark ones. The times listed

below represent mean values at a light intensity of 3000 lux, which

corresponds to the light encountered in a well-lit working space.

Bear the maximum time limit in minds, when extruding the material

from the syringe.

SR Adoro

SR Adoro Liner

SR Adoro Opaquer

SR Adoro Intensive Opaquer

SR Adoro Stains

low viscosityhigh viscosity

SR Adoro Cervical

SR Adoro Deep Dentin

SR Adoro Dentin

SR Adoro Incisal / Transpa

SR Adoro Add-On

SR Adoro Impulse

SR Adoro Gingiva

Time

2–25 min

4–25 min

The Product System

Compatibility with Ivoclar Vivadent equipment

The high-performance Lumamat

developed for the fabrication of high-quality composite restorations.

The object holder of the furnace ensures that the SR Adoro restorations are appropriately positioned for optimum polymerization /

tempering so that they can develop their physical properties to the

full. The sensor-controlled Quick can be used for fast precuring

processes. It can also be used for the intermediate polymerization of

other light-curing veneering materials.

Compatibility with Ivoclar Vivadent alloys

All metal-supported restorations involve the veneering of a previously fabricated metal framework. Ivoclar Vivadent offers customers

a wide range of different high-quality alloys, which are purposedesigned for their specific field of application. The selection includes

high gold, reduced-gold and base metal alloys. The SR Link bonding

system provides a sound bond between the metal and composite.

®

100 light furnace was especially

Curing Depths

Given the material's sensitivity to light, the curing depth of

SR Adoro (i.e. precuring with Quick initial light unit) depends on the

shade and, above all, the layer thickness applied. Light and translucent shades cure more readily, as light can penetrate them more

easily than it does darker and more opaque shades. The curing

depths listed below represent values achieved with the Lumamat

100/ Targis Power Upgrade with a precuring step of 20 seconds

using the Quick initial light unit. It is paramount to bear these values

in mind when layering the individual materials.

SR Adoro

SR Adoro Opaquer

SR Adoro Stains

SR Adoro Pastes

(final polyme rization with pr ior prec uring for 20 seconds with the Quic k)

(depending on the shade)

Curing depth in mm

max. 0.05

0.2 – 0.8

1.0 – 2.0

If you use other alloys, please contact the corresponding manufacturer to make sure that the alloy used is compatible with SR Link

and its components.

Alloys

High Gold Content

Academy Gold

®

Harmony

PF

Academy Gold XH

Reduced Gold

Harmony® X-Hard

®

XL-X

Maxigold

®

Midigold® 50

Magenta

Minigold

®

Harmony® 3

Universal Alloys

BioUniversal PdF

Au

77.2

72.0

70.7

68.3

62.8

59.5

50.0

50.0

40.0

3.5

71.1

Pt

< 1.0

3.6

3.6

2.9

–

–

–

–

–

–

9.2

Pd

–

–

–

3.6

3.9

2.7

3.5

6.5

4.0

25.9

–

Ag

12.7

13.7

13.7

13.8

16.1

26.3

35.0

21.0

47.0

50.8

11.7

Co Ni Cr Mon

Base Metal

IPS d.SIGN® 30

®

®

CC

NC

Colado

Colado

4all

60.2

59.0

–

–

–

–

65.1

61.4

30.1

25.5

20.2

25.7

Values in percent (%)

< 1.0

5.5

1.8

11.0

*The range of available alloys may vary

from country to country

8

Page 9

Compatibility with Ivoclar Vivadent tooth lines

Especially in partial and removable denture prosthetics, the compatibility between denture teeth and composite veneering material

plays a particularly essential role. For this reason, we paid particular

attention to developing a material that

is capable of reproducing the shade

of the Ivoclar Vivadent denture

teeth.

Compatibility with IPS d.SIGN

®

and IPS InLine

®

The shade concept of SR Adoro, the IPS InLine System, as well as

IPS e.max Ceram follows that of IPS d.SIGN. This means that there is

an Opaquer, Dentin, Deep Dentin and matching Incisal materials for

each tooth shade. The shading of the Impulse, Gingiva, and Stains

materials follows that of the IPS d.SIGN, IPS InLine and IPS e.max

Ceram materials so that the additional materials that are independent

of any shade system permit a similarly esthetic appearance.

This allows users to work more efficiently.

Consequently, the processing of

combined restorations is easier and faster

and shade adaptation to existing ceramic

restorations is more efficient.

SR® Accessories

SR Link, 5 ml

SR Link is a metal /ZrO

provides a covalent bond between the metal and

ZrO

frameworks and SR Adoro. SR Link is an easy-

2

to-use and, above all, tried-and-tested bonding system that can be used in conjunction with a wide

selection of alloys and ZrO2 frameworks. The bonding system is suitable for use on frameworks made of

– alloys that contain less than 90% gold, palladium and platinum

– alloys that contain less than 50% copper and/or silver

– base metal alloys

– titanium alloys

– ZrO

2

SR Link must not be used on electroformed (Galvano) frameworks,

as the reactivity of the components partaking in the chemical reaction decreases with increasing contents of precious metal (Galvano,

99.9% fine gold). Consequently, not enough metal-phosphate

bonds are formed.

SR Gel, 30 ml

SR Gel is a glycerine-based masking gel that is impervious to

oxygen. The gel is applied to the restoration before polymerization /

tempering to minimize the formation of an inhibition layer on the

surface of the veneering composite. Consequently, the gel

ensures complete curing of the restoration surface.

/composite bonding agent that

2

SR Adoro Gingiva concept

The shades of SR Adoro Gingiva are coordinated with those of the

Ivoclar Vivadent Gingiva concept of the IPS InLine, IPS d.SIGN and

IPS e.max systems. In this way, the shade design of true-to-nature

gingiva components, particularly in conjunction with implant superstructures, is possible according to the same method with all

veneering systems.

Compatibility with Ivoclar

Vivadent cementation systems

Choose an adequate cementation option from the Ivoclar Vivadent

range. Suitable luting composites or cements are available for both

the adhesive cementation of framework-free restorations and the

conventional cementation framework-supported restorations.

Framework-free restorations:

– Variolink

®

Veneer

– Variolink® II

– Multilink® Automix

Metal- / zirconium oxide-supported

restorations:

– Multilink® Automix

– SpeedCEM

®

– Vivaglass® CEM

SR Adoro Thermo Guard, 175 g

SR Adoro Thermo Guard is a diethylene glycol- and water-based

paste. The paste, which is applied to all exposed metal parts,

provides a thermally absorbing

(cooling) effect, thereby minimizing the

internal tension at the interface

between metal and SR Adoro. As a

result, SR Adoro Thermo Guard helps

reduce the risk of hairline cracks.

SR Model Separator, 10 ml

The SR Model Separator is suitable for separating working dies during the fabrication of metal-free restorations

and adjoining stone surfaces during composite veneering.

SR Retention Adhesive, 20 ml

This adhesive varnish is utilized to affix micro- and

macroretention beads to the restoration surfaces after

contouring.

9

Page 10

SR Micro Retention Beads, 15 ml

SR Macro Retention Beads, 15 ml

Two different sizes of retention beads are available,

depending on space conditions.

– Micro retention beads: 200–300 microns

– Macro retention beads: 400 –600 microns

SR Mixing Pad, small

SR Mixing Plate, small

The SR mixing pad and SR mixing plate are used for different

materials. The pad is mainly used to process liquid materials so that

time-consuming cleaning of the plate can be avoided.

By contrast, the plate is used to mix the

composite components. The light-protective

cover of the plate extends the working time

of the materials.

SR Modelling Instruments

A (yellow), B (red), C (blue)

The classic Ivoclar Vivadent modelling instruments for composite

materials, which are provided in a new, user-friendly design, facilitate the adaptation and contouring of composite materials. They are

available with 6 different tips and

can be used for a variety of

applications.

Universal Holder

Used to handle disposable brushes and

sponges and thereby help to facilitate the

working procedures in the dental laboratory.

Disposable Brushes, 50x

The disposable brushes are particularly

suitable for the application of liquid

materials, such as SR Model Separator,

SR Link, and SR Adoro Opaquer.

Disposable Sponges, 50x

The disposable sponges have been

modified to fit into the universal holder.

They are used to remove the inhibition

layer after polymerization of the

Opaquer and Liner.

Cannulas, 10x

These applications can be attached to Liner,

Opaquer and Stains syringes. They help

achieve more accurate dosing and cleaner

application procedures as the extrusion

pressure can be controlled.

Universal Polishing Paste, 100 ml

The SR Universal polishing paste enables quick and efficient

polishing of composite and metal restorations to a high gloss.

The paste is particularly suitable for prepolishing and principal

polishing of SR Adoro veneers.

SR Composiv, 2.5 g

This ivory-coloured bonding paste is the ideal light-curing microfilled

composite to optimize the bond of various resins and composite

materials. The paste is mainly applied

to promote the bond between Ivoclar

Vivadent denture teeth and the

SR Adoro veneering material.

Cannula Caps, 20x

The cannula caps prevent the material from

drying out or polymerizing prematurely while

it is is in the cannula and provide protection

against contamination.

10

Page 11

Shade Determination

After tooth cleaning, the tooth shade of the non-prepared tooth

and/or the adjacent teeth is determined with the help of a shade

guide. Individual characteristics have to be considered when

determining the tooth shade. If a crown preparation is

planned, for example, the cervical shade should also be

determined. In order to achieve the best possible true-tonature results, shade determination should be carried out at

daylight. Furthermore, the patient should not wear clothes of

intensive colours and/or lipstick.

SR Adoro – Individualized shade determination

It goes without saying that the materials shade guides are an integral part of the SR Adoro product concept. The dentin shade tabs

feature a textured surface and anatomical shape for light refraction

purposes. The other shade tabs are slightly wedge-shaped to take

account of the translucency of the individual materials. All shade

tabs feature a smooth, i.e. untextured, reverse side to assist users in

comparing the shades against the prepared tooth and coloured

cements and adhesives. The smooth side of the shade tabs may be

individually ground to determine the layering. The individual shade

tabs are made of ceramic for reasons of shade stability. They are

fired of specially coloured ceramic materials to ensure that they

comply with the individual SR Adoro materials. As the materials

shade guides have been modelled on the IPS d.SIGN and IPS InLine

system shade guides, the sample holders of the SR Adoro shade

guides are coloured light grey to distinguish them from the shade

guides of other materials.

11

Page 12

SR

Adoro® – Practical Procedure

for Framework-Free Restorations

(Inlays/Onlays)

Preparation Guidelines and Minimum Layer Thicknesses

As framework-free SR Adoro restorations are placed using an adhesive cementation method, a toothconserving and defect-oriented preparation technique can be used.

Inlays

Provide a preparation depth of at least 1.5 mm in the fissure area (central fissure). The isthmus width

should be at least 1.5 mm. The walls of the box should be slightly flared. Round out internal line angles

to enable accurate fit of the inlay. Avoid preparation margins in functional or abrasion surfaces. Avoid

proximal contacts areas. Do not prepare slice-cuts or feather edges.

1.5

1.5

Onlays

Allow for a preparation of at least 1.5 mm in the area of the fissures, an isthmus width of at least

1.5 mm and provide 1.5 mm space in the area of the cusps. The shoulder may be prepared with a

chamfer (10°–30°) to improve the esthetic appearance of the transition between the composite and the

tooth. Onlays are indicated if the preparation margin is less than approximately 0.5 mm away from the

cusp tip, or if the enamel is severely undermined.

1.5

1.5

1.5

>90°

60°–80°

10°-30°

12

Page 13

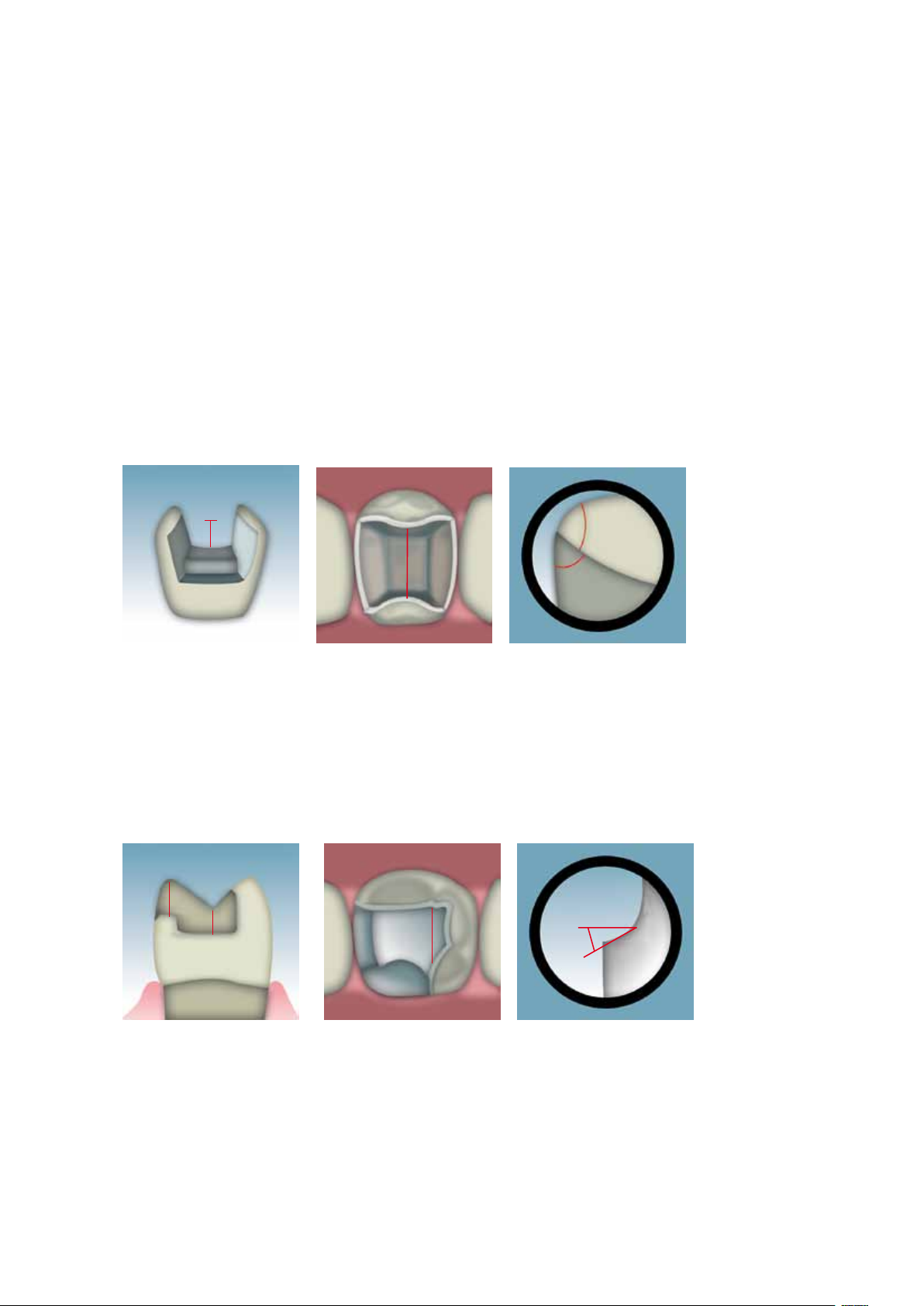

Layering Diagram for Inlays/Onlays

Inlay layering

Practical Procedure for Framework-Free Restorations (Inlays/Onlays)

Onlay layering

Apply the liner up to the margin

13

Liner

Dentin

Incisal

Page 14

SR Adoro Step by Step

Starting Situation

Fabricate a master model or a model with detachable segments according to the impression in the usual manner. Expose

and mark the preparation margin. Block out undercuts with blocking out wax or block out resin to ensure that the

restoration can be removed after the polymerization process without damaging the die. Basically, the application of a

sealer is recommended to harden the surface and to protect the stone die. However, the sealer layer must not result in

any changes of the dimensions of the stone die. It is not mandatory to utilize a spacer, as two coats of SR Model

Separator will be applied. If you use a spacer, check as to whether it is compatible with SR Model Separator.

Fabrication of a working model with removable segments. The die is coated with sealer.

Sealing the Dies and Adjoining Parts of the Model

SR Model Separator is applied in two thin coats. Apply the first coat generously and make sure that all areas of the cavity

are well covered. Watch out for sharp edges in particular. Allow the layer to react for 3 minutes. After the reaction time,

apply a second layer in a thin coat, invert the model, and allow to dry for 3 minutes. Additionally, apply SR Model

Separator to adjoining model surfaces that may come into contact with SR Adoro (including counterbite), allow to react

for a short time, and then disperse excess material with oil-free compressed air.

Apply first coat of SR Model Separator generously, watch out for sharp edges, and allow to react for 3 minutes.

Apply second layer of SR Model Separator in a thin coating and allow to dry for 3 minutes in an upside down position.

14

Page 15

Liner Application

Procedure for

non-discoloured cavities

– Apply Liner clear to the cavity

walls and the cavity floor (dentin

area) for an optimum chameleon

effect.

– Apply Liner incisal in the margin-

al areas (course of natural enamel) to achieve a harmonious transition between the shade of the

restoration and natural tooth

structure without grey lines.

Procedure for

slightly discoloured cavities

– Mask dark areas using a liner in

an appropriate shade (050-500).

– Coat the remaining portions of

the cavity, except the marginal

areas, with Liner clear.

– Apply Liner incisal in the marginal

areas (course of natural enamel)

to achieve a harmonious transition

between the shade of the restoration and natural tooth structure

without grey lines.

Procedure for

severely discoloured cavities

– Mask the entire cavity, except the

marginal areas, using a liner in a

corresponding shade (050–500).

– Apply Liner incisal in the marginal

areas (course of natural enamel)

to achieve a harmonious transition between the shade of the

restoration and natural tooth

structure without grey lines.

Practical Procedure for Framework-Free Restorations (Inlays/Onlays)

Liner clear

1st Liner layer– 050–500, clear

Extrude the desired amount of the ready-to-use Liner paste from the syringe and spread it out slightly on the mixing pad

using a disposable brush.

First, apply the Liner to the cavity walls and cavity floor in a thin coat and precure each segment for 20 seconds using a

Quick curing light. Make sure to fully cover all areas, as the Liner provides an essential bonding surface to the luting composite. Do not cover marginal areas at this stage (course of natural enamel).

Liner incisal

Liner 050–500

Fully cover the cavity walls and cavity floor with the first Liner coat.

15

Page 16

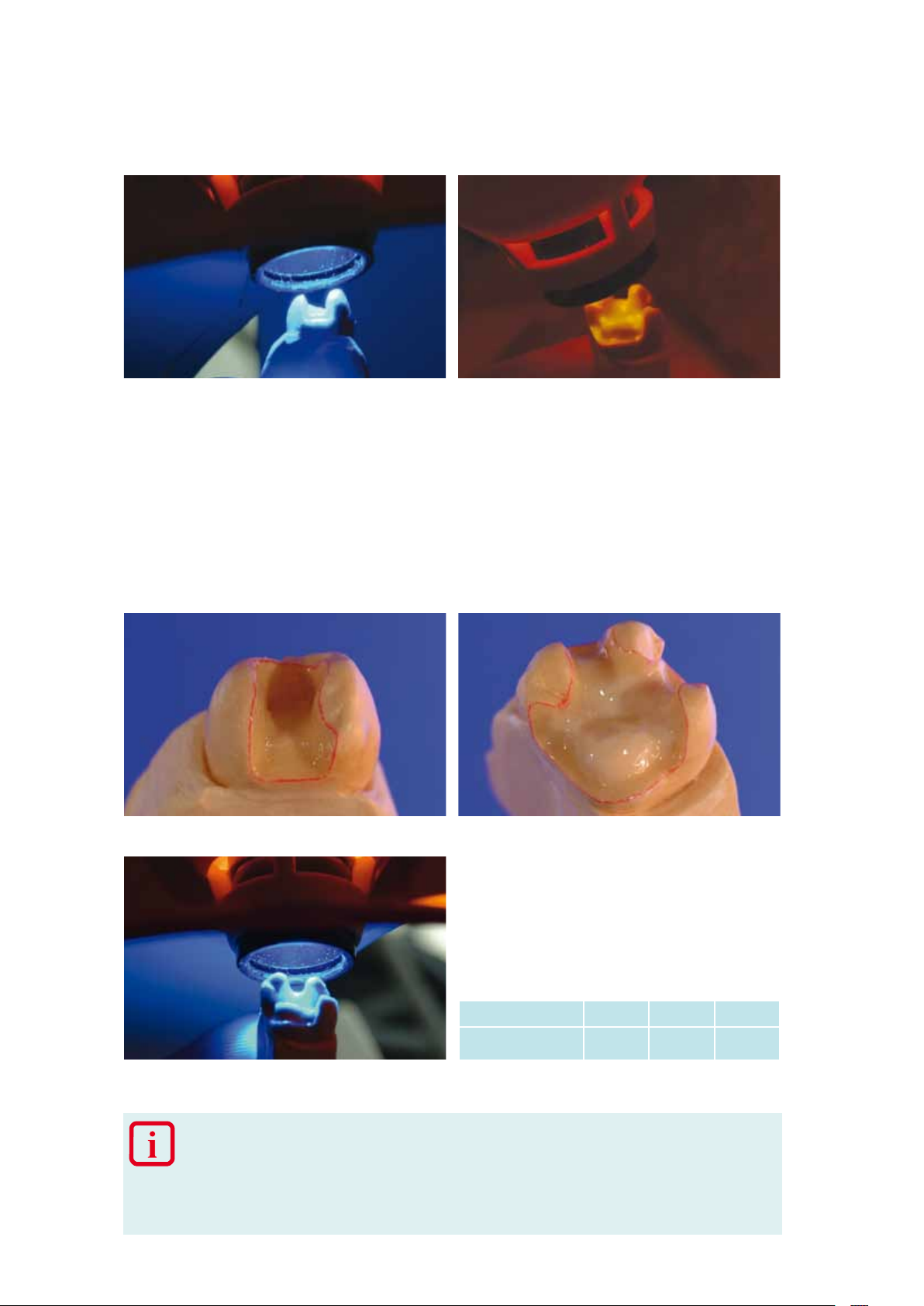

Precure each segment for 20 seconds using a Quick curing light.

2nd Liner layer– incisal

After the application of the first Liner layer, apply Liner incisal in the marginal areas so that all cavity surfaces are coated

with Liner. Apply Liner incisal up to the preparation margin in order to ensure a reliable bond between the preparation

margins and the luting composite. This measure helps to reduce premature discolouration between the restoration

margins and tooth structure.

Apply Liner incisal in the marginal areas, i.e. along the course of the natural enamel ...

Polymerizing the Liner Apparatus Time Program

Precuring time per

segment

... and precure each segment for 20 seconds.

Quick 20 s –

– The entire inner surface of the restoration has to be covered with SR Adoro Liner. The layer

thickness should be at least 150 microns. Thin out the Liner towards the preparation margin.

– Do not detach hardened SR Adoro Liner from the die, as the layer may become deformed or

break in the process.

– If desired, the translucency of the Liners 050-500 may be increased by using Liner clear or Liner

incisal.

16

Page 17

Removing the Inhibition Layer

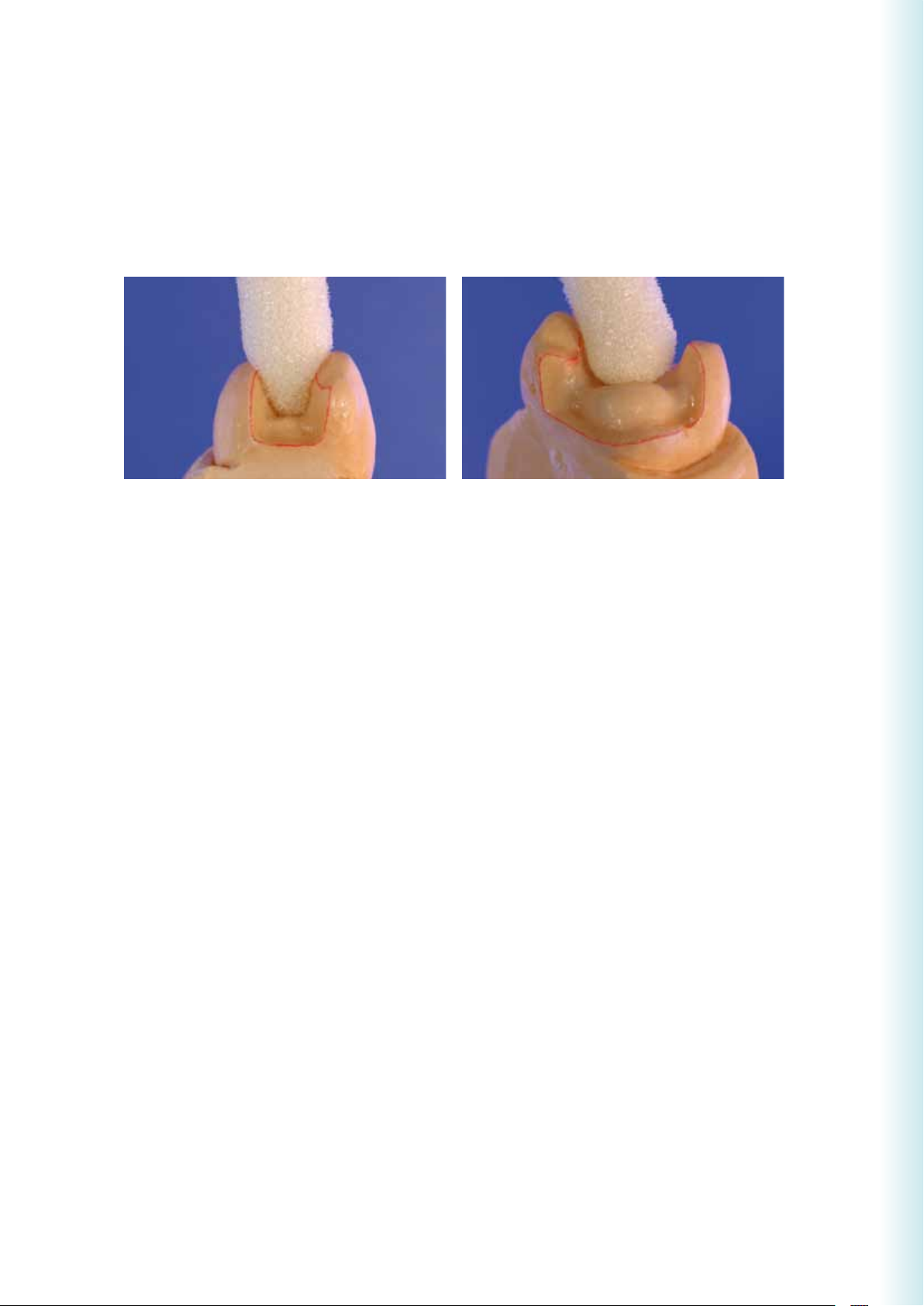

Thoroughly remove the resulting inhibition layer using a disposable sponge (do not use a solvent); make sure that the

Liner surfaces are free of residue and exhibit a mat finish.

Thoroughly remove the inhibition layer with clean disposable sponges.

Practical Procedure for Framework-Free Restorations (Inlays/Onlays)

17

Page 18

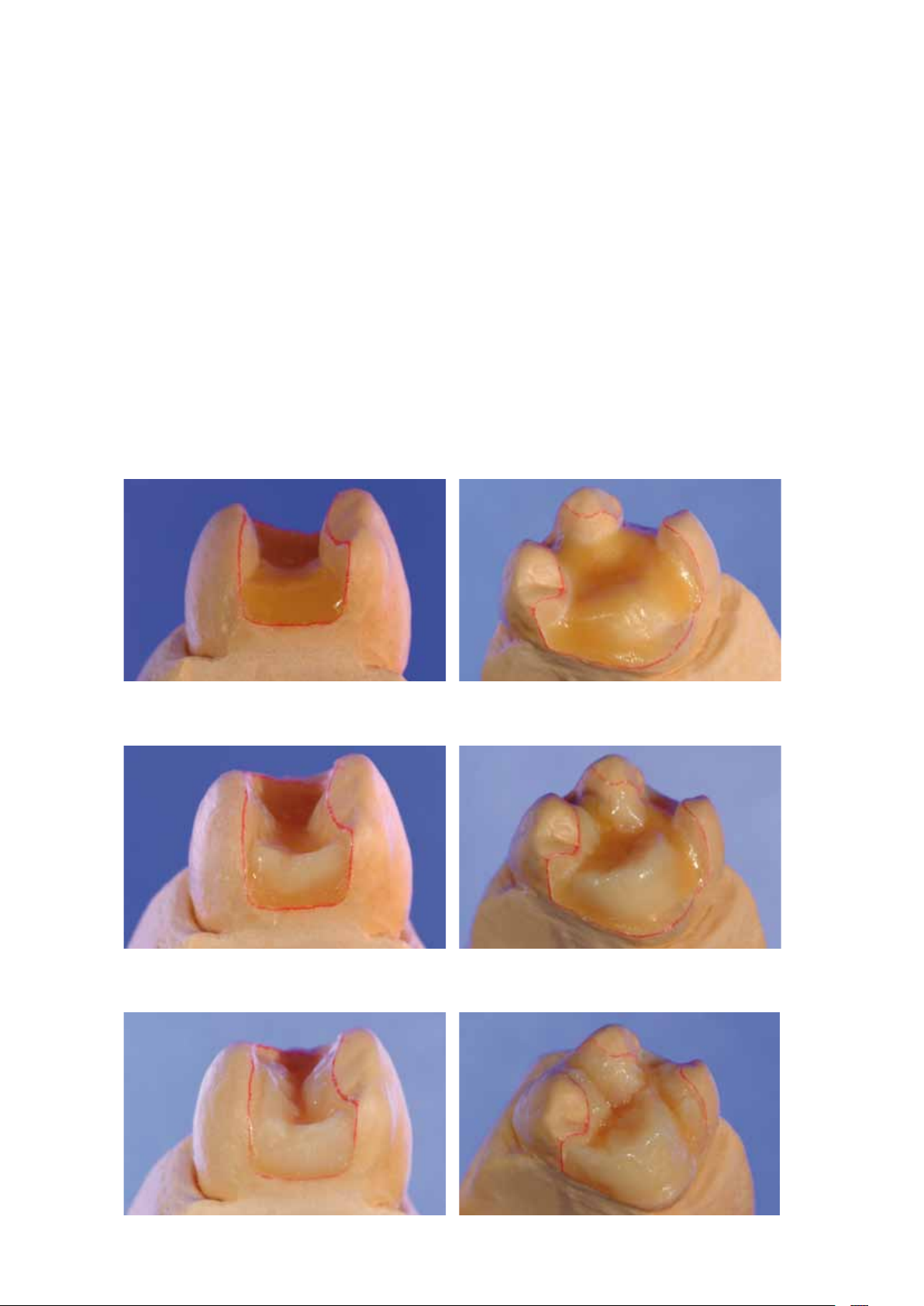

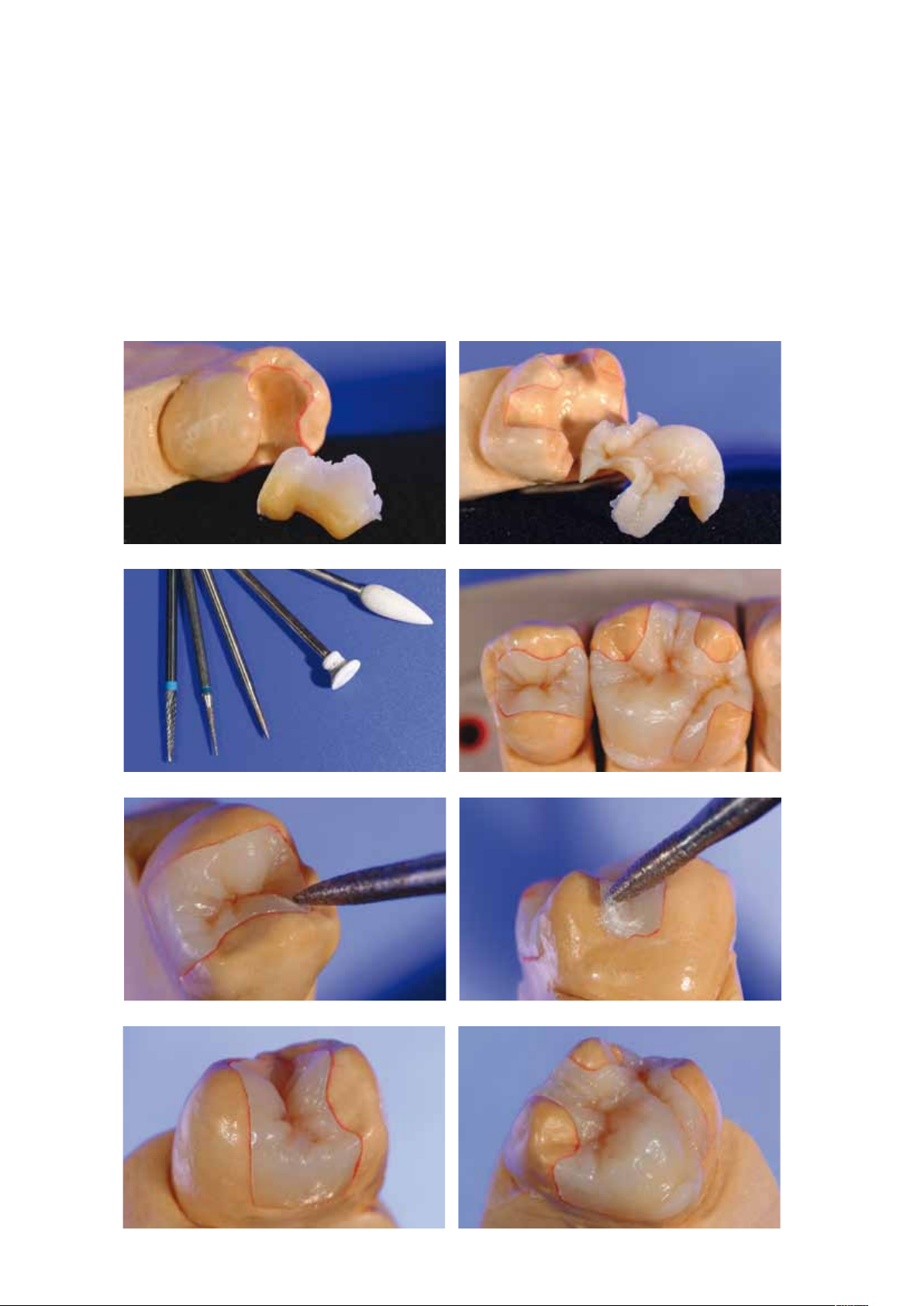

Inlay / Onlay Layering

Adapt the first layer firmly (press into place) to ensure an effective bond between the Liner and composite and precure

each segment for 20 seconds using a Quick curing light. The shade effect in the interdental area and cavity may be

increased by means of Occlusal Dentin orange. Slightly emphasize the marginal ridges and cusps with Deep Dentin.

Subsequently, begin the process of building up the cavity with Dentin materials. Make sure to provide adequate space for

the subsequent application of Incisal and Transpa materials. The translucency of the restoration may be increased by

means of coloured Transpa materials, such as Transpa orange-grey and Transpa brown-grey. Layer SR Adoro layering

materials step by step and precure each individual layer. After building up and precuring the dental plateau, apply

characterizations with SR Adoro Stains and precure for 20 seconds. Next, complete the restoration using Incisal and

Transpa materials. The cusp tips and triangular ridges may be supplemented with a fine layer of Opal Effect 3 and 4.

Adapt firmly and create smooth, rounded transitions between the layers using SR modelling instruments and synthetic

brushes.

Increase the shade effect in the interdental and cavity area with Occlusal Dentin ...

... and slightly emphasize the marginal ridges and cusps with Deep Dentin.

Build up a plateau using various Dentin materials ....

18

Page 19

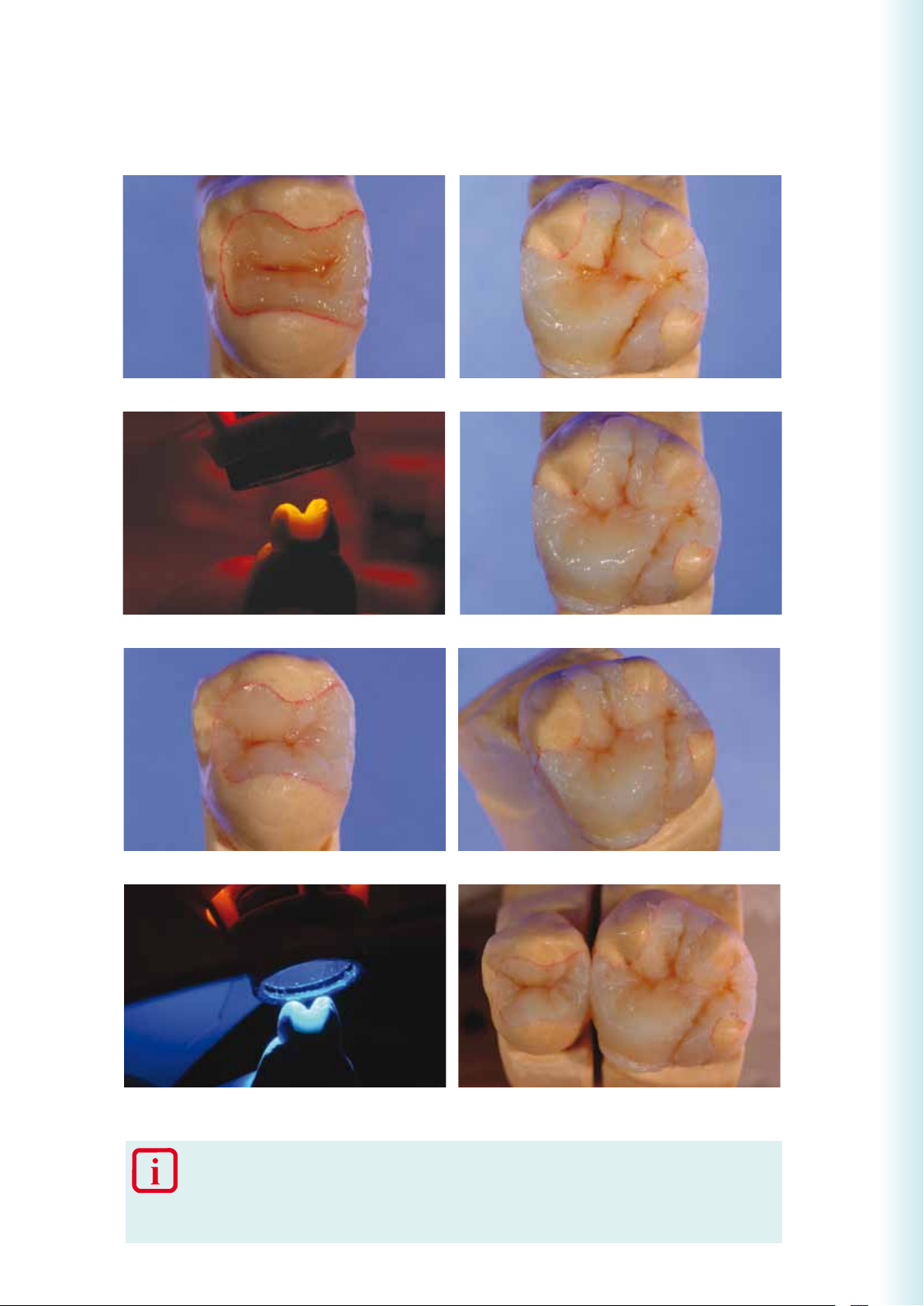

... and apply characterizations using SR Adoro Stains.

Precure with the Quick curing light and apply Incisal and ...

Practical Procedure for Framework-Free Restorations (Inlays/Onlays)

... Transpa materials to cover the characterizations and create a true-to-nature occlusal morphology.

Complete the procedure by precuring each segment for 20 seconds using the Quick curing light.

– It is essential to observe the stipulated curing depth and maximum layer thickness of the

individual materials during the layering procedure.

– If the maximum layer thickness is exceeded, break up large portions into several increments and

precure each increment for 20 seconds.

– SR Adoro Stains have to be coated with layering material (e.g. Incisal, Transpa).

19

Page 20

Polymerization / Tempering

Preparing for polymerization / tempering

After the layering procedure has been completed, all layers must be precured. To make sure that this is the case precure

each segment for 20 seconds using a Quick curing light. Next, apply SR Gel on the entire veneering surface ensuring that

all areas are fully covered and the layer is not too thick.

If necessary, precure one more time and apply a fully covering but not inappropriately thick coat of SR Gel.

General notes on polymerization / tempering

After the application of SR Gel, mount the restoration on the object holder and place it in the Lumamat 100 or Targis

Power Upgrade furnace in the correct position. The following points must be observed for polymerization / tempering:

– 2 programs (P1 and P3) are available for polymerizing / tempering SR Adoro restorations with and without model.

– Framework-supported SR Adoro restorations are permanently polymerized / tempered without model dies and without

model using Program P3.

– Framework-free SR Adoro restorations are permanently polymerized / tempered on the model dies without model base.

If up to 3 restorations are permanently polymerized /tempered together, Program P3 has to be used. For the

permanent polymerization / tempering of more than 3 framework-free SR Adoro restorations, Program P1 is used.

– If SR Adoro restorations are to be permanently polymerized on the model using Program P1 (e.g. bridges), all removable

model components (pontic rests, neighbouring teeth) have to be removed from the working model. The remaining

weight of the working model must not exceed 400 g.

Lumamat 100 /

Targis Power Upgrade

Program 1

Program 3

Framework-supported Framework-free

– 4 or more inlays, onlays and/or

Metal

– Crowns and multi-unit bridges

with applied SR Adoro Thermo

Guard

Zirconium oxide

– Crowns and multi-unit bridges

without applied SR Adoro Thermo

Guard

20

crowns on dies

– up to 3 inlays, onlays and/or

crowns on dies

Page 21

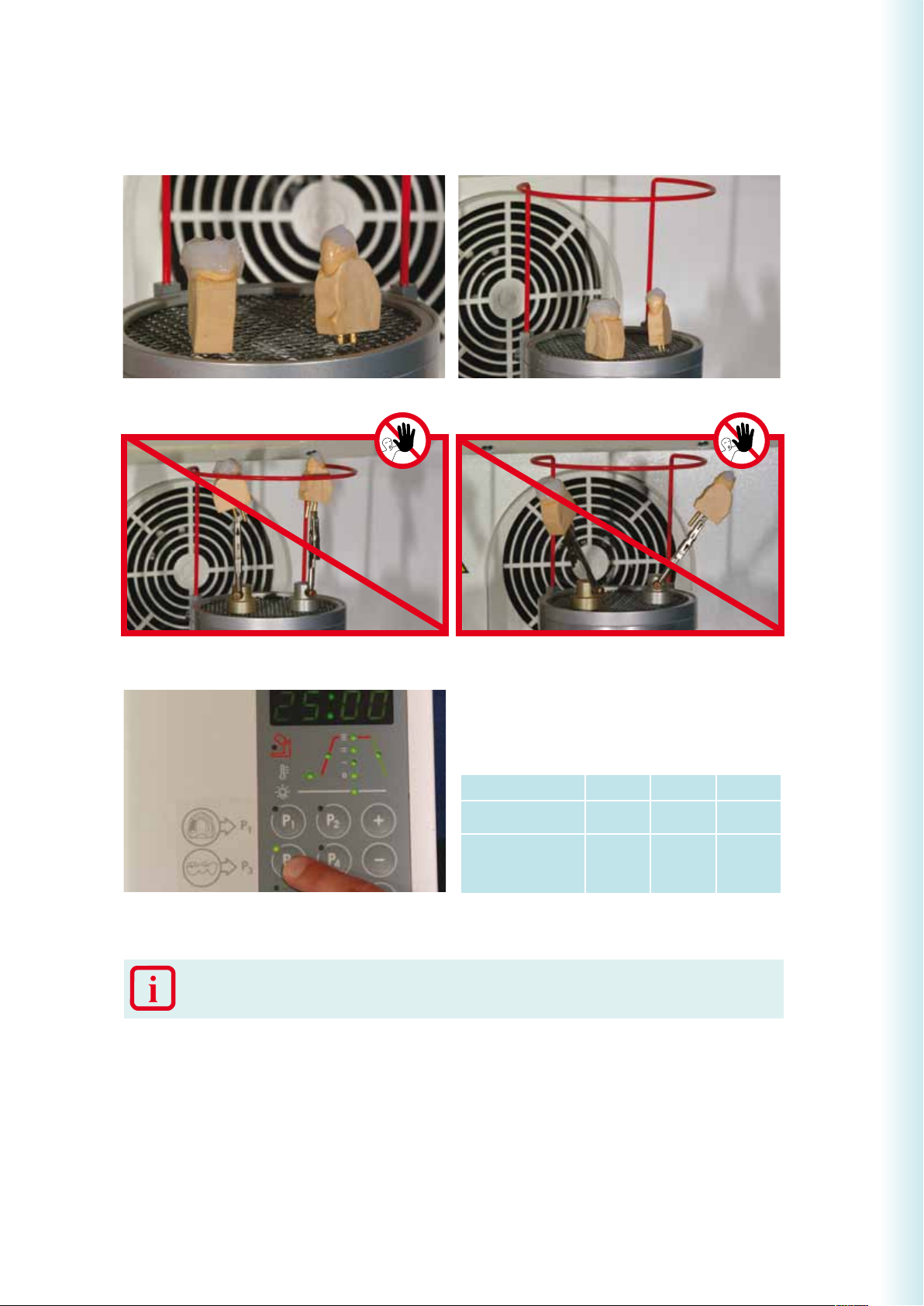

... select Program 3 and start.

Mount the dies on the object holder and position correctly.

Make sure that the restorations are not located outside the marked polymerization/tempering zone ...

Inlays/onlays Apparatus Time Program

Precuring time per

segment

Final polymerization /

tempering

Quick 20 s

Lumamat

100/ Targis

Power

Upgrade

Practical Procedure for Framework-Free Restorations (Inlays/Onlays)

–

25 min 3

– Calibrate the furnace on a regular basis by means of the L 100 test set. Observe the corresponding

manufacturer's instructions.

21

Page 22

Finishing / Polishing

Finishing

After completion of the polymerization / tempering procedure, completely remove SR Gel from the restoration using

running water and/or a steamer. Carefully remove the restoration from the die while it is still warm. If the restoration is

removed at a later stage, it is advisable to warm up the stone die by means of water vapour. Finish the restoration with

cross-cut tungsten carbide burs and fine diamonds. It is advisable to use low speed and light pressure. Make sure to

rework the entire restoration to remove the inhibition layer of approximately 30 microns from all surfaces. Carefully taper

the margins of the restoration, lightly grind the margins, and adjust proximal and occlusal contact points. Subsequently,

recreate a lifelike tooth shape and surface structure.

Remove SR Gel and carefully lift the restorations off the die.

Finish the surface with cross-cut burs and remove the inhibition layer.

Lightly grind the margins using fine diamonds and tungsten carbide burs ...

... and re-create a true-to-nature surface structure.

22

Page 23

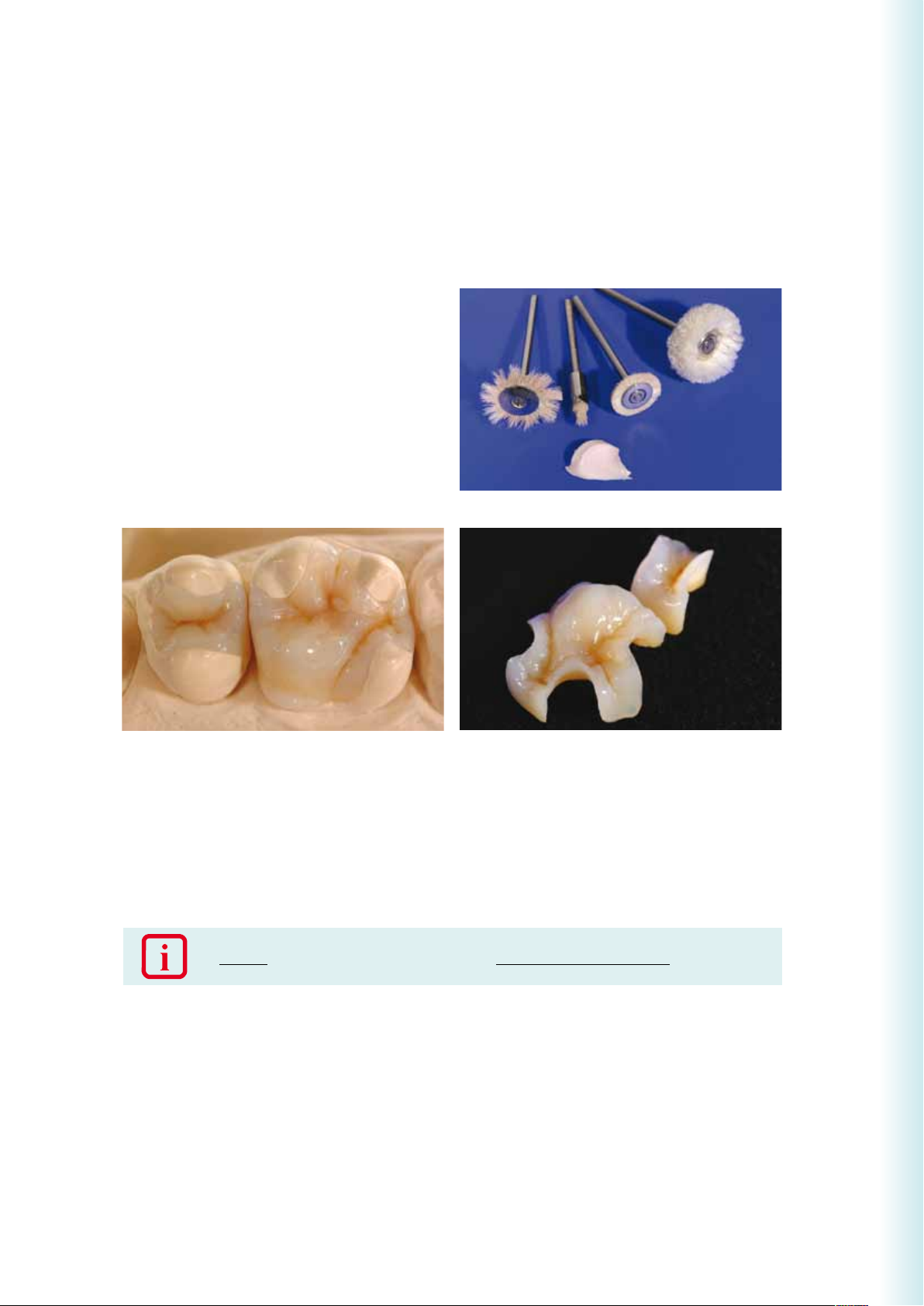

Polishing

Prepolishing

Carefully smooth out the ridges on the occlusal surface and proximal surfaces with rubber polishers and silicone polishing

wheels. Pay particular attention to the margins in order to avoid rendering them too short.

High-gloss polishing

The restorations are polished to a high gloss using cotton or

leather buffing wheels, as well as the Universal Polishing

Paste. Use low speed and slight pressure for high-gloss

polishing. Adjust the pressure at the handpiece, not with

the polishing motor.

In order to optimally polish the occlusal surfaces, we

recommend modifying the goat hair brushes to become starshaped so that only the desired areas can be polished due to

the smaller size of the brush.

Depending on the type of high gloss desired, leather buffing

wheels can be used to achieve a high shine, while cotton

buffers are used to achieve a lesser degree of lustre.

Practical Procedure for Metal-Free Restorations (Inlays/Onlays)

SR Adoro inlay and onlay polished to a high gloss

Preparing for Cementation

It is essential to cement SR Adoro restorations using an adhesive cementation technique.

In order to achieve a chemical bond with the luting composite, the cavity side of the restoration has to be carefully blasted

with Al

the contact surfaces are again roughened with a 25 micron finishing diamond. Finally, the surfaces are silanized (e.g. with

Monobond® Plus) to enable a chemical bond.

at 1 bar (15 psi) pressure in the laboratory. Following the try-in in the dental office and subsequent cleaning,

2O3

23

Page 24

SR

Adoro® – Practical Procedure

for Framework-Free Restorations

(Anterior Crowns)

Preparation Guidelines and Minimum

Layer Thicknesses

Veneer

If possible, the preparation should be entirely located in the enamel.

Either design a classical preparation with oro-incisal, chamfer-type

embrasure of the incisal edge, or a simple incisal reduction without

embrasure of the incisal edge. Avoid incisal preparation margins in

functional or abrasion surfaces. The minimum preparation thickness

is approx. 0.6–1.0 mm depending on the preparation technique

selected. Dissolution of the proximal contacts is not required.

Discoloured teeth may require more preparation. The extent of the

incisal reduction depends on the desired translucency. The more

translucent the incisal edge of the intended veneer is to appear, the

more pronounced the reduction should be.

0.6

0.7

1.0

10°-30°

Anterior crown

Evenly reduce the anatomical shape and observe the stipulated

minimum thickness. Prepare a circular shoulder with rounded inner

edges or a pronounced chamfer of at least 0.8 mm. In the anterior

region, reduce the labial and/or palatal / lingual surfaces by at least

1.0 mm. Reduce the incisal crown third by at least 1.5 mm. Design

transitions in such a way that no angles or edges are present.

0.8

≥1

1.5

≥ 1

0.8

10°-30°

24

Page 25

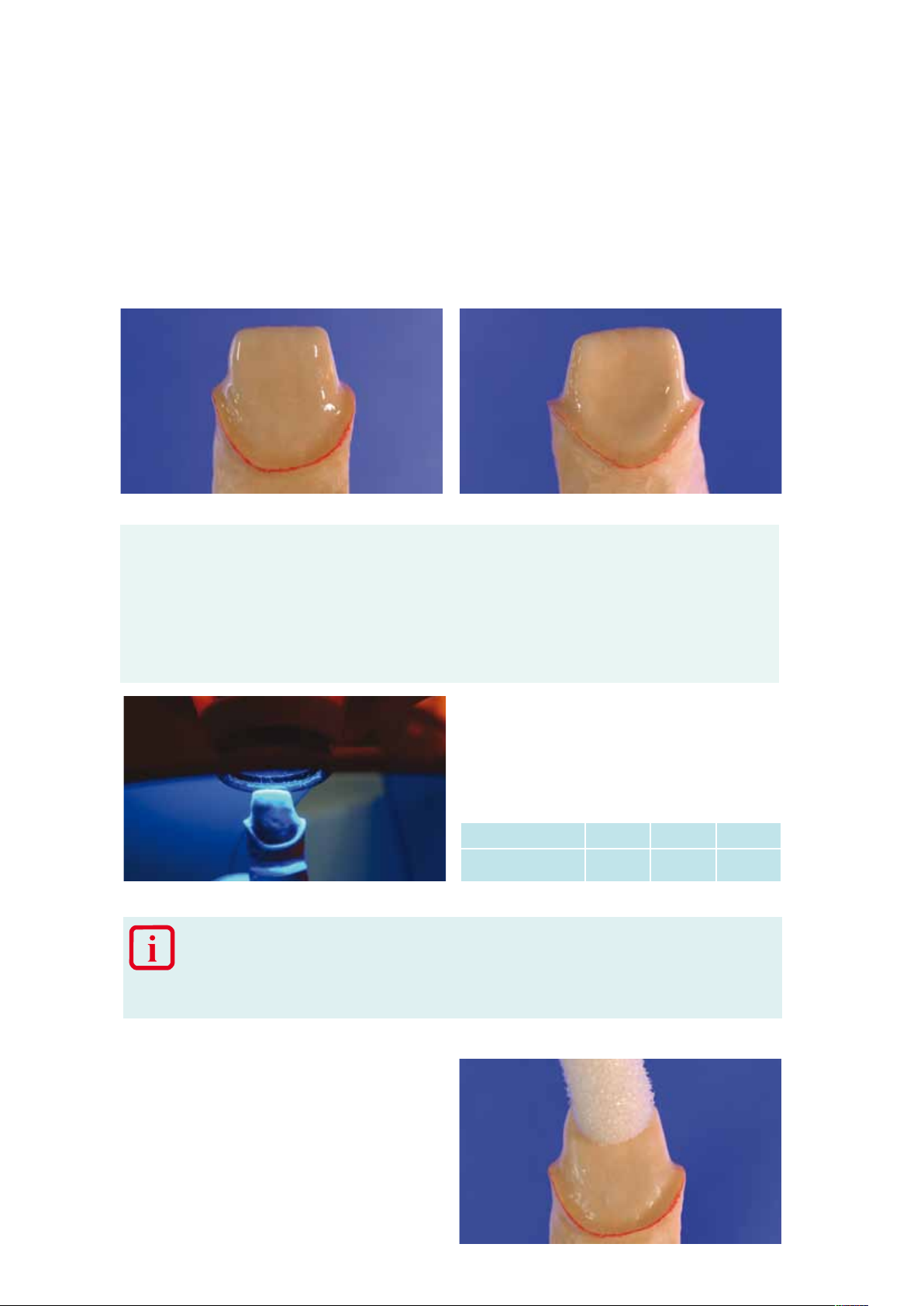

SR Adoro Step by Step

Starting Situation

Fabricate a master model or a model with detachable segments according to the impression in the usual manner. Expose

and mark the preparation margin. Block out undercuts with blocking out wax or block out resin to ensure that the

restoration can be removed after the polymerization / tempering process without damaging the die. Basically, the application of a sealer is recommended to harden the surface and to protect the stone die. However, the sealer layer must not

result in any changes of the dimensions of the stone die. It is not mandatory to utilize a spacer, as two coats of SR Model

Separator will be applied. If you use a spacer, check as to whether it is compatible with SR Model Separator.

A master model is used as the working model. Fabrication of a working model with removable segments. The die is coated with sealer.

Practical Procedure for Framework-Free Restorations (Anterior Crowns)

Sealing the Die and Adjoining Parts of the Model

SR Model Separator is applied in two coats. Apply the first coat generously and make sure that all areas of the die are well

covered. Watch out for sharp edges (incisal edges) in particular. Allow the layer to react for 3 minutes. After the reaction

time, apply a second layer in a thin coat, invert the model, and allow to dry for 3 minutes. Additionally, apply SR Model

Separator to adjoining model surfaces (including counterbite), allow to react for a short time, and then disperse excess

material with oil-free compressed air.

Apply first coat of SR Model Separator generously, pay special attention to the incisal edges,

and allow to react for 3 minutes.

Apply second layer of SR Model Separator in a thin coating and allow to dry for 3 minutes in

an upside down position.

Isolate adjoining model parts, as well as neighbouring teeth and counterbite.

25

Page 26

Liner Application

Extrude the desired amount of the ready-to-use Liner paste from the syringe and spread it out slightly on the mixing pad

using a disposable brush.

First, apply the Liner thinly on the die surfaces. Make sure to fully cover all areas, as the Liner provides an essential

bonding surface to the luting composite. The Liner layer must be at least 150 microns thick and has to be precured for

20 seconds per segment using the Quick.

Apply the Liner on the entire die surface; observe a minimum layer thickness of 150 microns.

TIP

– Liner incisal may be applied to the marginal area to facilitate the transmission of light in the cervical area. This

measure provides a harmonious transition between the gingiva and the restoration.

Procedure for non-vital dies

– Mask the entire die with Liner 050 to block out the dark colour of the underlying tooth stratum and, at the same

time, to attain an adequate degree of brightness.

– Additionally, Stains white or Stains crackliner may be applied locally to the Liner surface to further increase the

degree of brightness.

Liner Apparatus Time Program

Precuring time per

segment

Precure each segment for 20 seconds using a Quick curing light.

Quick 20 s –

– The entire die surface has to be covered with an SR Adoro Liner layer of at least 150 microns. Thin out the

Liner towards the preparation margin.

– Do not detach hardened SR Adoro Liner from the die, as the Liner coping may become deformed or break in

the process.

– If desired, the translucency of the Liners 050-500 may be increased by using Liner clear or Liner incisal.

Removing the Inhibition Layer

Thoroughly remove the resulting inhibition layer using a

disposable sponge (do not use a solvent); make sure that

the Liner surfaces are free of residue. Make sure that the

Liner shows a mat surface.

26

Page 27

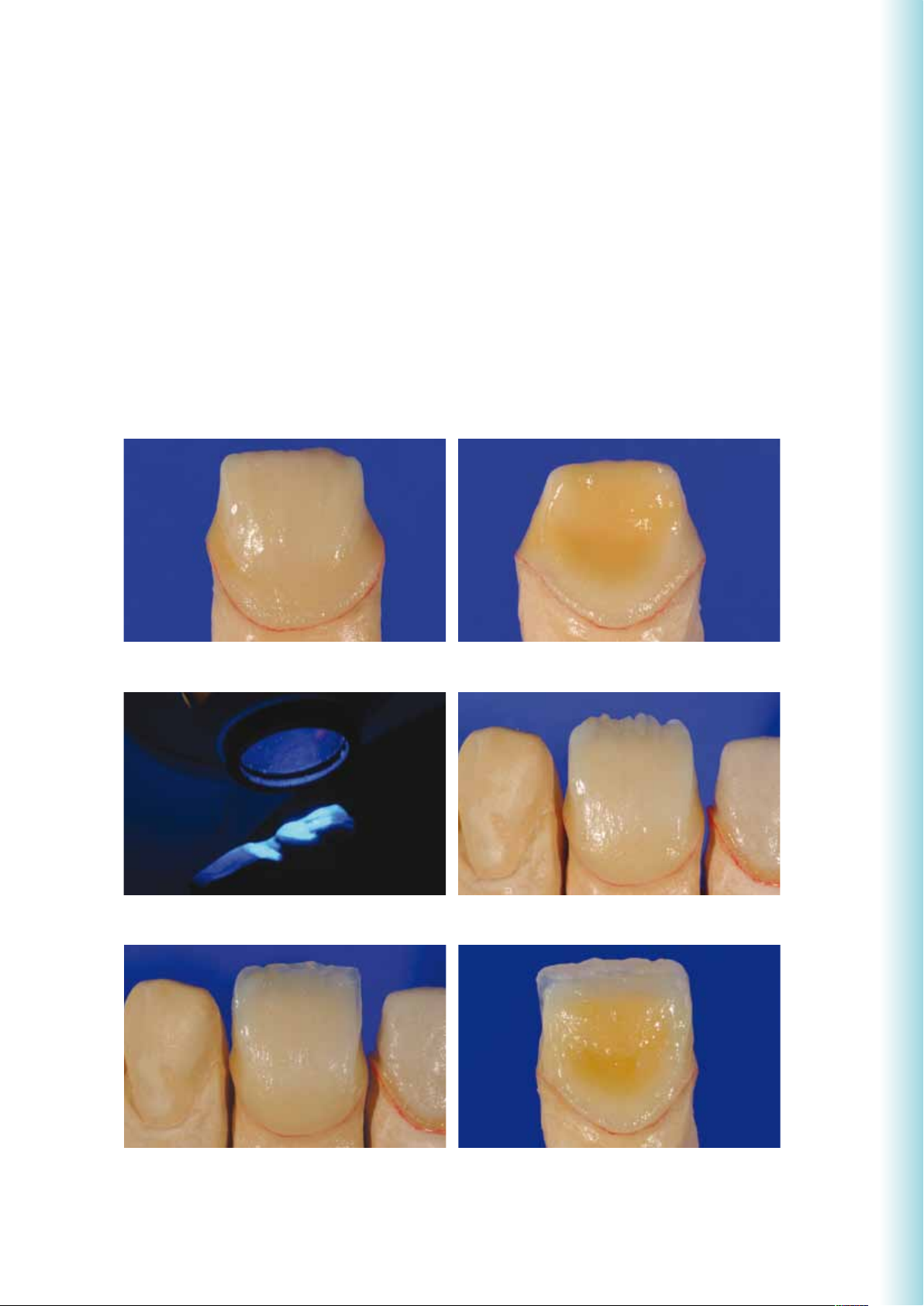

Anterior Tooth Layering

Adapt the first layer firmly (press into place) to ensure an effective bond between the Liner and composite and precure

each segment for 20 seconds using a Quick curing light. The shade effect in the interdental area and palatal fossa may be

increased by means of Stains orange or Occlusal Dentin orange. Build up the labial surface using various Dentin materials.

Reproduce areas of higher brightness with Opal Effect 3 (cervical) and Inter Incisal white-blue (incisal). Apply the appropriate Transpa materials to the dentin core. Build up and precure the incisal extension using Opal Effect materials (OE 1

and OE 2). Mimic mamelons using Mamelon materials and Stains and precure. Next, complete the restoration step by

step using Incisal and Transpa materials. Build up the palatal ridges using Dentin materials. The triangular ridges may be

coated with a fine layer of Opal Effect 3 and 4. Adapt firmly and create smooth, rounded transitions between the layers

using SR Modelling Instruments and synthetic brushes.

Practical Procedure for Framework-Free Restorations (Anterior Crowns)

Complete marginal areas with Deep Dentin and Dentin; enhance the shade effect in the palatal region by means of Stains and Occlusal Dentin ...

... and precure for 20 seconds using the Quick curing light. Complete the dentin core with Transpa materials ...

and build up the incisal area using Opal Effect 1.

27

Page 28

Reproduce mamelons using Mamelon materials and Stains and precure. Contour the tooth shape using Incisal materials.

Mimic enamel cracks between the lateral segmentation ...

... using Stains crackliner. Complete the labial and ...

... palatal tooth shape using Incisal and Transpa materials and precure for 20 seconds, using the Quick curing light.

– It is essential to observe the stipulated curing depth and maximum layer thickness of the individual

materials during the layering procedure.

– If the maximum layer thickness is exceeded, break up large portions into several increments and precure

each increment for 20 seconds.

28

Page 29

Final Polymerization / Tempering

Preparing for polymerization / tempering

After the layering procedure has been completed,

all layers must be precured. Apply SR Gel on the

entire veneering surface ensuring that all areas are

fully covered and the layer is not too thick. Make

sure that all areas are covered and mount the

restoration with the die on the object holder.

Apply a fully covering but not inappropriately thick

coat of SR Gel to the restoration ...

... and mount it on the object holder.

General notes on polymerization / tempering

After the application of SR Gel, mount the restoration on the object holder and place it in the Lumamat 100 or Targis

Power Upgrade furnace in the correct position. The following points must be observed for polymerization / tempering:

– 2 programs (P1 and P3) are available for polymerizing / tempering SR Adoro restorations with and without model.

– Framework-supported SR Adoro restorations are permanently polymerized / tempered without model dies and without

model using Program P3.

– Framework-free SR Adoro restorations are permanently polymerized / tempered on the model dies without model base.

If up to 3 restorations are permanently polymerized / tempered together, Program P3 has to be used. For the

permanent polymerization / tempering of more than 3 framework-free SR Adoro restorations, Program P1 is used.

– If SR Adoro restorations are to be permanently polymerized on the model using Program P1 (e.g. bridges), all removable

model components (pontic rests, neighbouring teeth) have to be removed from the working model. The remaining

weight of the working model must not exceed 400 g.

Lumamat 100 /

Framework-supported Framework-free

Targis Power Upgrade

– 4 or more inlays, onlays and/or

Program 1

Program 3

Metal

– Crowns and multi-unit bridges

with applied SR Adoro Thermo

crowns on dies

– up to 3 inlays, onlays and/or

crowns on dies

Guard

Zirconium oxide

– Crowns and multi-unit bridges

without applied SR Adoro Thermo

Guard

Practical Procedure for Framework-Free Restorations (Anterior Crowns)

Anterior Crown Apparatus Time Program

Precuring time per

segment

Final polymerization /

tempering

Call up Program 3 and start.

Quick 20 s

Lumamat

100 /Targis

Power

Upgrade

– Calibrate the furnace on a regular basis by means of the L 100 test set. Observe the corresponding

manufacturer's instructions.

29

–

25 min 3

Page 30

Finishing and Polishing

Finishing

After completion of the polymerization / tempering procedure, completely remove SR Gel from the restoration using

running water and/or a steamer. Carefully remove the restoration from the die while it is still warm. If the restoration is

removed at a later stage, it is advisable to warm up the stone die by means of water vapour. Finish the restoration with

cross-cut tungsten carbide burs and fine diamonds. It is advisable to use low speed and light pressure. Make sure to

rework the entire restoration to remove the inhibition layer of approximately 30 microns from all surfaces. Carefully taper

the margins of the restoration, lightly grind the margins, and adjust proximal and occlusal contact points. After that,

create a lifelike surface structure, such as incremental lines and convex /concave areas.

Prepolishing

Smooth out the surface (convex areas) of the natural structures, as well as the marginal ridges with rubber polishers and

silicone polishing wheels so that they exhibit an extra lustre after high-gloss polishing.

High-gloss polishing

The restorations are polished to a high gloss using cotton or

leather buffing wheels, as well as the Universal Polishing

Paste. Use low speed and slight pressure for high-gloss

polishing. Adjust the pressure at the handpiece, not with

the polishing motor. In order to optimally polish the

distinctive areas (palatal fossa), we recommend modifying the

goat hair brush to become star-shaped so that only the

desired areas can be polished due to the smaller size of the

brush. Depending on the type of high gloss desired, leather

buffing wheels can be used to achieve a high shine, while

cotton buffers are used to achieve a lesser degree of lustre.

SR Adoro anterior crown polished to a high gloss.

– Microroughness on the finished veneering surface is conductive to plaque accumulation. Therefore, polish

carefully.

– Pay particular attention to crown margins, proximal areas and palatal surfaces.

Preparing for Cementation

It is essential to cement framework-free SR Adoro restorations using an adhesive cementation technique.

In order to achieve a chemical bond with the luting composite, the cavity side of the restoration has to be carefully blasted

with Al

the contact surfaces are again roughened with a 25 micron finishing diamond. Finally, the surfaces are silanized (e.g. with

Monobond Plus) to enable a chemical bond.

at 1 bar (15 psi) pressure in the laboratory. Following the try-in in the dental office and subsequent cleaning,

2O3

30

Page 31

SR

Adoro® – Practical Procedure

for Fixed, Metal-Supported Restorations

Framework Design

The following points must be observed for the design of frameworks for composite veneers:

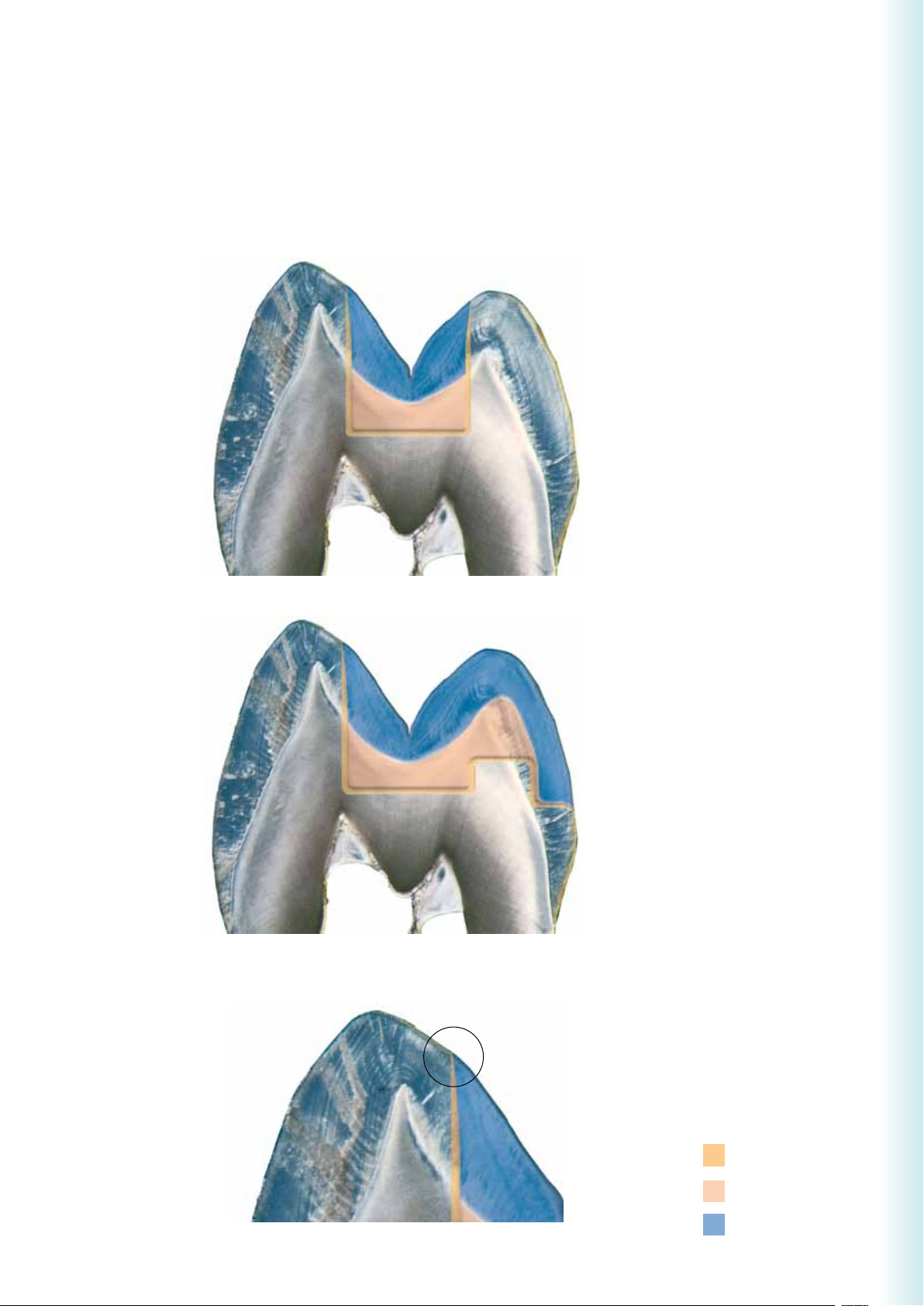

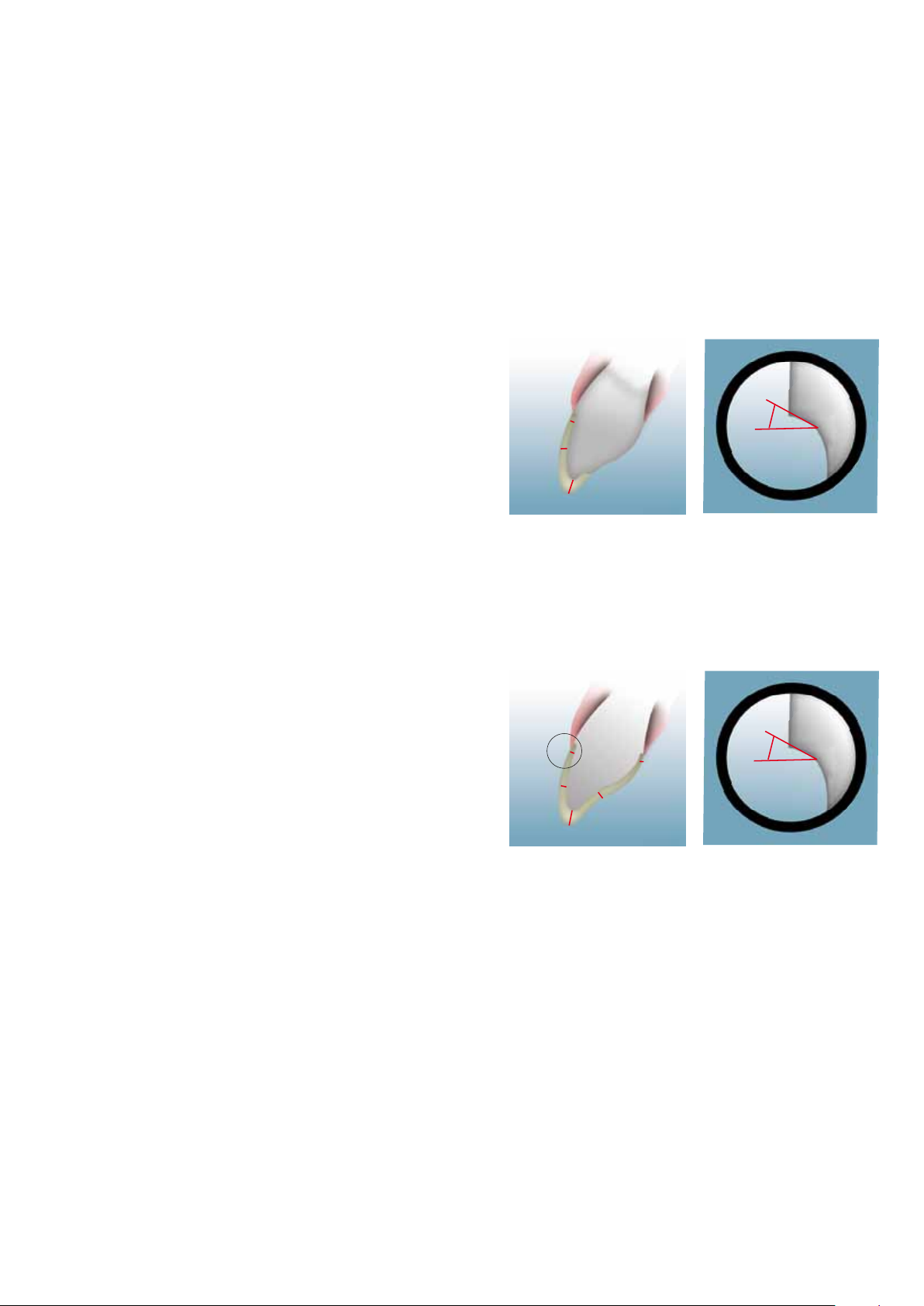

1. Framework design for full-coverage veneers (ideal space conditions)

With full-coverage veneers, the framework has to reflect the shape of the tooth in a reduced form. Design the framework

in such a way that it supports the cusps resulting in a virtually even layer thickness of the veneering composite in the

cusp-fissure area. In this way, the masticatory forces occurring during functional chewing are exerted on the framework

rather than on the veneering composite. In case of unfavourable preparations, the missing tooth structure has to be compensated by the design of the framework and not the veneering composite. Furthermore, an even layer thickness

facilitates the creation of a harmonious shade effect while full-coverage veneering provides a maximum level of esthetic

beauty and function. All areas of the framework should be smooth and rounded to prevent delamination and cracking.

Angles and edges should be rounded out already in the wax-up and not in the metal in order to avoid undermining the

minimum framework thickness. The thickness of the metal framework for single crowns must not be less than 0.3 mm

and 0.5 mm for bridge abutments after finishing (see diagram).

Anterior crowns

Practical Procedure for Fixed Metal-Supported Restorations

Premolar crowns

Molar crowns

31

Page 32

2. Framework design for partial veneers (limited space conditions)

A different framework design is required for partial veneers (e.g. telescope and conus crowns). As the space in the occlusal,

palatal and lingual area in particular tends to be limited in many cases, this area of the restoration must be designed in

the metal in such a way that cracks or delamination cannot occur because of too thin layer thicknesses of the veneering

composite. In this design, the transition between the metal framework and the veneering composite should be clearly

defined and it should incorporate a right angle finish line. The transition areas between the metal framework and the

veneering composite must not be located in the contact point areas, nor on surfaces involved in masticatory functions. A

chamfer or wraparound technique is required in partial veneer preparations to provide adequate support for the veneer.

Observe the palatal area in upper canines (canine guidance) and the occlusal area in posterior teeth. To obtain a balance

between esthetic and functional properties, it is advisable to reduce the medial corner of the occlusal surface in upper

posterior teeth in particular to attain a harmonious esthetic appearance, especially when the buccal corridor is exposed.

The thickness of the metal framework for single crowns must not be less than 0.3 mm and 0.5 mm for bridge abutments

after finishing (see diagram).

For further information, please refer to the Instructions for Use of the corresponding alloy.

Anterior crowns

Premolar crowns

Molar crowns

32

Page 33

3. Design of bridge pontics

Bridge pontics are designed taking esthetic and functional aspects as well as oral hygiene into consideration. The area of

the pontic that contacts the alveolar ridge should be made entirely of metal (polished to a high gloss) or composite. The

transition between the metal and composite should always be located in an area where efficient oral hygiene is ensured.

If adequate space is available, the contact area is made of composite. In order to ensure adequate stability between the

bridge pontic and bridge abutment, a palatal and/or lingual scallop is recommended.

If space is limited, the contact area is made of metal burnished to a high gloss. The palatal and/or lingual areas are made

of metal to ensure adequate stability. To prevent shrinkage cavities from forming in extensive pontics, it is advisable to

hollow out the pontic. A wax wire is placed in the hollowed space (ample space available) and formed in such a way that

it is level with the abutment teeth. This measure provides additional retention and helps achieve an even colour effect in

the bridge pontic and abutment.

Ideal space available Limited space available

Practical Procedure for Fixed Metal-Supported Restorations

33

Page 34

4. Interface between metal and composite

The interface between the metal framework and the veneering composite must be clearly defined; incorporate a right

angle finish line and use a chamfer or wraparound technique. The transition areas between the metal framework and the

veneering composite must not be located in the contact point areas, nor on surfaces involved in masticatory functions.

Furthermore, make sure that the interface in the marginal area does not come into contact with the gingiva, particularly if

a tapered crown margin is used (e.g. no metal margin). In this way, irritation of the gingiva can be prevented. The interface in the interdental area should be designed in such a way that cleaning of these difficult-to-access areas is possible.

5. Correct application of retention beads

It is generally advisable to apply retention beads to provide mechanical retention in addition to the chemical bond with

SR Link. If space is limited, it may not always be possible to apply retention beads or they may only be applied in certain

areas. Therefore, retention beads can be applied locally to the bonding surfaces without compromising the space available or the esthetic appearance of the restoration in particular. The retention adhesive should be applied in as thin a

coating as possible so that the retention beads are not completely immersed in adhesive and enough surface area for

mechanical retention is provided. After casting, the retention beads may be reduced by half of their size (equator) to preserve a sufficiently large retentive area.

Retention Adhesive (schematic)

34

Page 35

SR Adoro Step by Step

Starting Situation / Framework Fabrication

Starting situation

Fabricate a master model or a model with detachable segments according to the impression in the usual manner. Expose

and mark the preparation margin. Basically, the application of a sealer is recommended to harden the surface and to

protect the stone die. However, the sealer layer must not result in any changes of the dimensions of the stone die. Next,

a spacer may be applied depending on the respective working habit.

Fabrication of a working model with removable segments and with the sealer and spacer applied.

Framework design

There are two types of frameworks, i.e. frameworks for full-coverage veneers (ideal space) and frameworks for partial

veneers (limited space). Basically, it is advisable to design a full wax-up and then fabricate a silicone key to check the

space conditions during contouring. When fabricating the frameworks, make sure that the minimum wall thickness after

finishing is 0.3 mm for single crowns and 0.5 mm for bridge abutments. These dimensions are the prerequisite for a stable

metal framework and a durable bond between the metal and composite. If the stipulated framework and connector

dimensions are not obser ved, delamination and cracking may occur.

Practical Procedure for Fixed Metal-Supported Restorations

Full contouring of the anatomical tooth shape ...

... and fabrication of a silicone key for checking.

35

Page 36

Wax-up

On the following pages, two versions of framework design are shown stage by stage up to and including the application

of the opaquer (ideal and limited space). The framework introduced in version A will be veneered and completed.

The framework reflects the reduced anatomical tooth shape (see page 32 for tooth shape-supporting contouring). As a

result, the composite can be applied in an even layer and will consequently be appropriately supported. The requirements

of the different alloys have to be taken into account.

Full-coverage veneer (ideal space)

Reducing the framework on the labial ...

Version A:

Version B:

Partial veneer (limited space)

Reducing the framework only on

the labial side.

... and palatal side.

Checking the labial side using the silicone key. Shaping the wax wire in such a way

On the palatal side, the fully anatomical

shape of the framework is maintained.

that it is level with the abutments.

If the metal framework is too small, the veneering composite is not adequately supported, which may lead to

cracks, delamination and esthetically compromised results.

36

Page 37

Casting and Finishing

After having cast the framework (e.g. with Academy Gold XH), carefully divest, sandblast / pickle and fit it on the model.

After separating, the metal framework is finished using tungsten carbide burs. If softer alloys are used, it is recommended

to work with limited pressure. A correct marginal design is paramount to attaining a reliable composite-metal bond. If

possible, create a tapered chamfer or wraparound design in the cervical area.

Version A:

Full-coverage veneer (ideal space)

Version B:

Partial veneer (limited space)

Practical Procedure for Fixed Metal-Supported Restorations

Carefully divest, sandblast or pickle ...

... and fit to the model.

Using a tungsten carbide bur, create a tapered cervical margin,

preferably by using a wraparound technique or a chamfer preparation.

Polish metal portions not to be veneered to a high gloss.

37

Page 38

Conditioning of the Framework

Conditioning with SR Link

After finishing, carefully blast the framework with aluminium oxide (Al

Instructions for Use of the corresponding alloy). Sandblasting improves the mechanical bond. It roughens and thus substantially increases the surface of the object. After blasting, remove blasting medium residue by tapping off and not by

cleaning with steam or an air gun. Apply SR Link immediately after having tapped off the residue. Use a clean

disposable brush to apply SR Link and allow to react for 3 minutes. Do not "soak" metal surface in SR Link.

Carefully blast the framework with Al2O3 , 80–100 microns at max. 2 bar (29 psi) pressure.

), 80–100 microns at 2 bar (29 psi) pressure (see

2O3

After blasting, do neither clean with steam, nor with an air gun ...

... but instead tap off residue with an instrument.

38

Page 39

Version A:

Full-coverage veneer (ideal space)

Version B:

Partial veneer (limited space)

Practical Procedure for Fixed Metal-Supported Restorations

Blasted and conditioned bridge on the model.

SR Link is applied immediately after the blasting procedure using a disposable brush.

Allow SR Link to react on the conditioned bridges for 3 minutes.

– When using SR Link, do NOT clean the framework with steam or with an air gun after blasting.

– Do not touch clean surfaces.

– Do not use SR Link in conjunction with alloys that contain more than 50% silver and/or copper or alloys

with more than 90 % gold, palladium and platinum.

39

Page 40

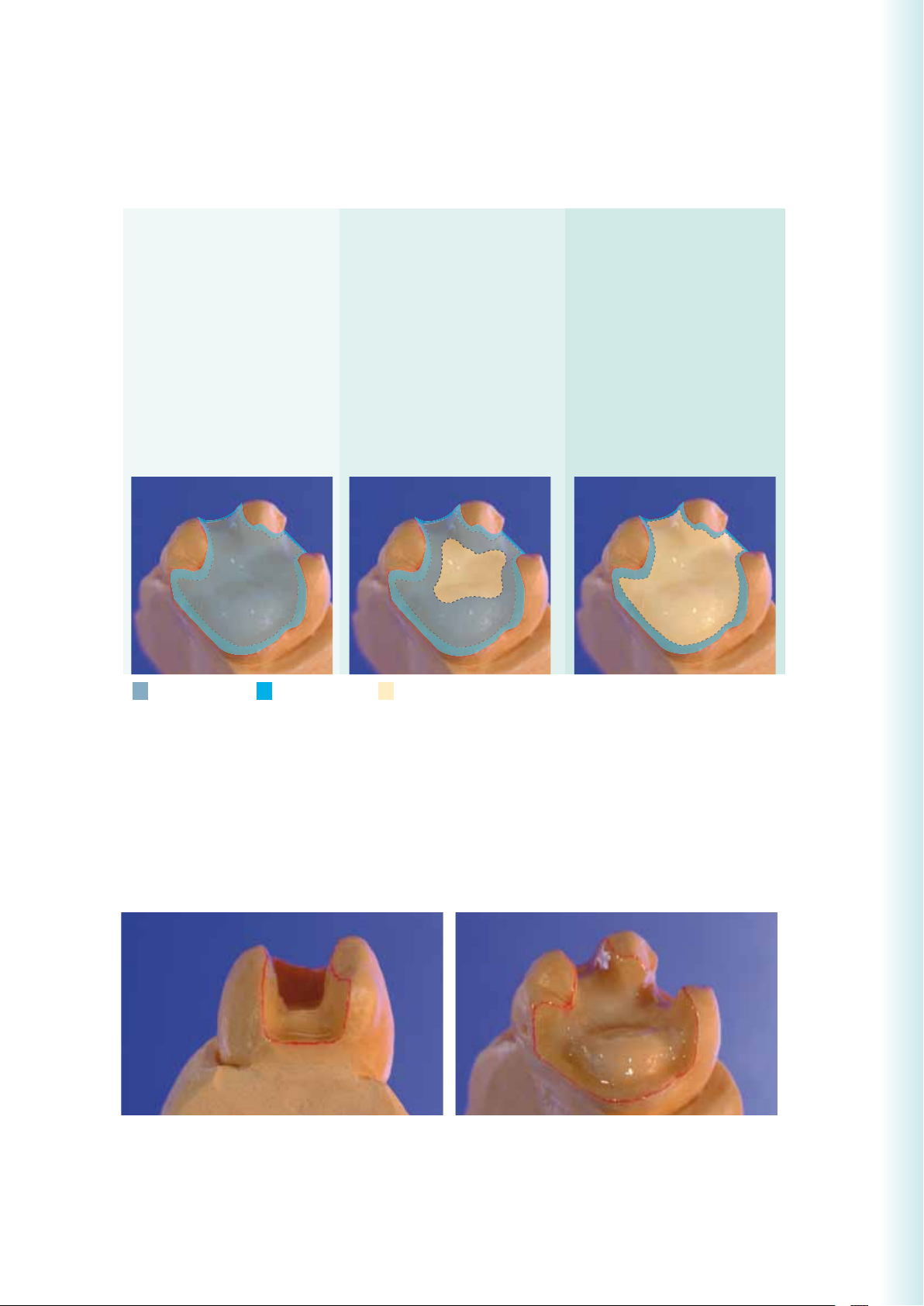

Layering Diagram

for crowns and bridges

Chromascop – ideal space conditions Chromascop – limited space conditions

With the Chromascop layering, the incisal

area extends to the centre of the tooth.

The indications on the right are reference

values.

Framework

Opaquer

Deep Dentin

Cervical

Incisal

Dentin

Cervical

Incisal

Incisal

Incisal

40

Ideal space

conditions

0.3 mm

0.1 mm

–

–

1.2 mm

0.7 mm

0.5 mm

Limited space

conditions

0.3 mm

0.1 mm

0.3 mm

0.1 mm

0.6 mm

0.3 mm

0.4 mm

Page 41

A–D – ideal space conditions

A–D – limited space conditions

Practical Procedure for Fixed Metal-Supported Restorations

With the A–D layering, the incisal area

extends to the centre of the cervical third.

The indications on the right are reference

values.

Framework

Opaquer

Deep Dentin

Cervical

Incisal

Dentin

Cervical

Incisal

Incisal

Cervical

Incisal

41

Ideal space

conditions

0.3 mm

0.1 mm

–

–

0.9 mm

0.7 mm

0.2 mm

0.5 mm

Limited space

conditions

0.3 mm

0.1 mm

0.3 mm

0.1 mm

0.5 mm

0.3 mm

0.1 mm

0.4 mm

Page 42

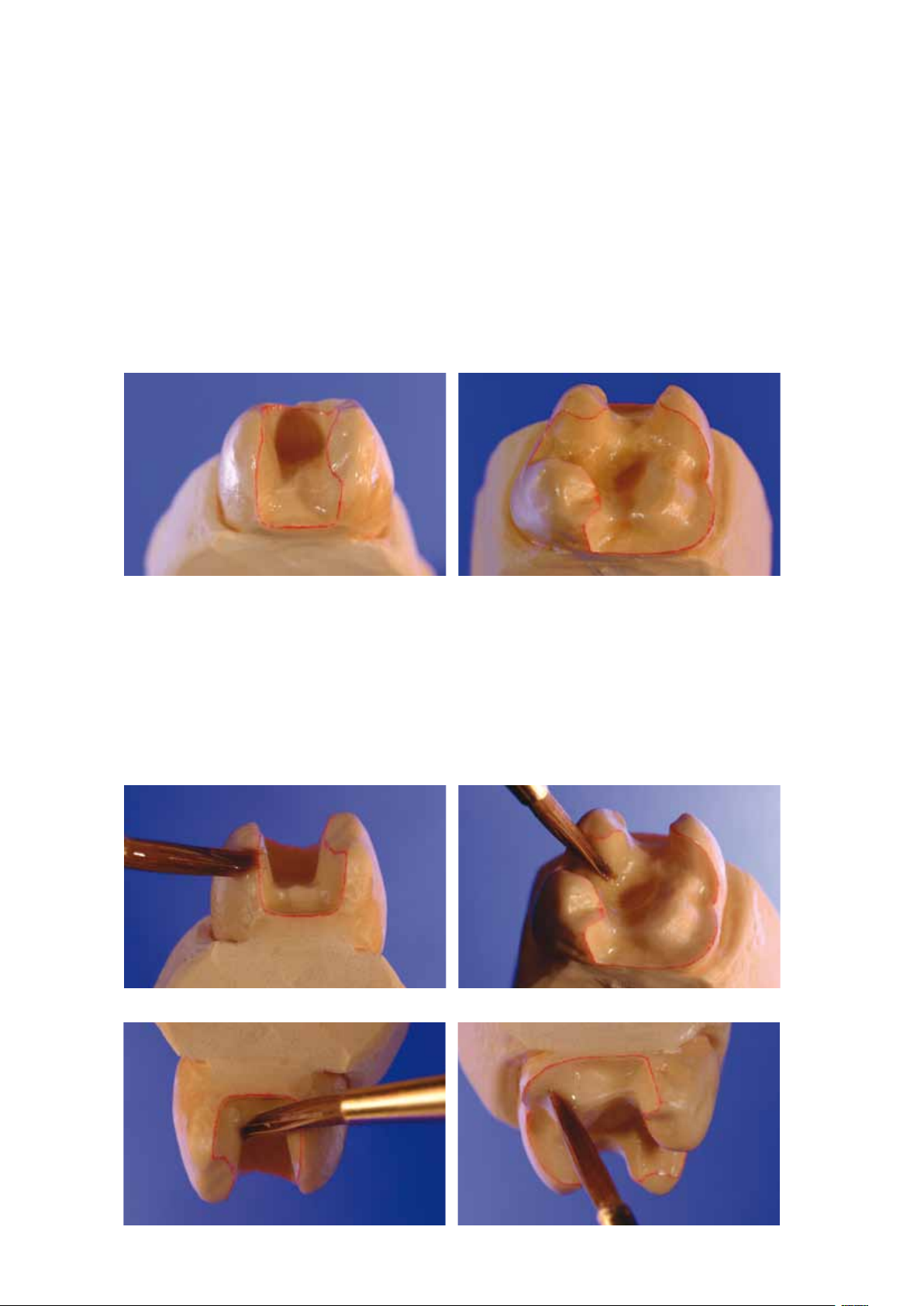

Application of the Opaquer

1st opaquer layer (wash)

Extrude the desired amount of the ready-to-use opaquer paste from the syringe and spread it out slightly on the mixing

pad using a brush. Apply the first opaquer layer (wash) thinly using a brush. Make sure to thoroughly smooth out any

roughness and the retention beads (micro- and macroretention beads) on the metal surface, since the wash layer

represents the most important bond between the metal and the composite. Subsequently, precure the wash for

20 seconds per segment using the Quick.

Version A:

Full-coverage veneer (ideal space)

Apply the first opaquer layer (wash) thinly using a brush ...

Version B:

Partial veneer (limited space)

... and level / fill retentions and any roughness.

1st opaquer layer Apparatus Time Program

Precuring time per

segmen t

42

Quick 20 s –

Page 43

2nd opaquer layer and building up the bridge pontic

Apply the second opaquer layer in such a way that the metal framework, and particularly the retention beads, are entirely

covered with opaquer, i.e. as much as required and as little as possible. After that, precure the opaquer for 20 seconds

per segment using the the Quick and then directly polymerize it in the Lumamat 100 or Targis Power Upgrade (Program

2, 11 minutes). Four Intensive Opaquers are available for the individualization of the opaquer layer. The degree of brightness can be heightened by applying Intensive Opaquer white.

Procedure for the bridge pontic

Apply the second opaquer layer in such a way that the framework is completely covered and precure each segment for

20 seconds. Next, build up the hollowed out space on the bridge pontic to the level of the abutment teeth using Transpa

clear and precure for 40 seconds using the Quick curing light. Then, apply a layer of opaquer directly on the inhibition

layer of Transpa clear and precure for 20 seonds. Polymerize immediately in the Lumamat 1000 or Targis Power Upgrade

using Program 2.

Practical Procedure for Fixed Metal-Supported Restorations

Version A:

Full-coverage veneer (ideal space)

Apply the second opaquer layer in such a way that it entirely covers the retention beads, ... Apply the second opaquer layer ...

Partial veneer (limited space)

Version B:

... individualize using Intensive Opaquer ... ... build up the bridge pontic with Transpa clear,

... and precure each segment for 20 seconds.

43

check against the silicone key, precure

... and completely cover with opaquer.

for 40 seconds ...

Page 44

Polymerizing the Opaquer

Place the restoration without the model on the object holder.

– To obtain a smooth transition between the

metal and composite, thin out the opaquer

at the metal margin.

– If a smooth surface is preferred, lightly tap

top of the surface with a spatula.

– Check opaquer for complete polymerization

in critical areas, using a probe.

Polymerize the restoration without the model using Program 2.

Opaquer Apparatus Time Program

Precuring time per

segment

Conduct final

polymerization

Quick 20 s

Lumamat

100 /Targis

Power

Upgrade

–

11 min 2

44

Page 45

Cervical, Dentin and Incisal Layering

Sealing the model

Before building up the Dentin and Incisal materials, all parts

of the model that may come into contact with SR Adoro are

sealed. This step helps to prevent the composite from

sticking to the model. Use SR Model Separator to seal

adjoining parts of the model (e.g. stone die and pontic rests).

Apply SR Model Separator in a thin layer, allow to react for a

short time, and remove excess with oil-free compressed air.

Removing the inhibition layer

Thoroughly remove the resulting inhibition layer using a

disposable sponge (do not use a solvent); make sure that the

opaquer surfaces are free of residue. Make sure that the

Opaquer shows a mat-shiny surface.

Practical Procedure for Fixed Metal-Supported Restorations

Tip

Characterizing the opaquer

After the inhibited layer has been removed, you may individualize sections of the opaquer surface with SR Adoro

Stains. It is advisable to apply a thin layer of Stains in the marginal and interdental area, particularly if space is limited, to

enhance the in-depth shade effect. Subsequently, precure SR Adoro Stains for 20 seconds using the Quick.

Charac terization Apparatus Time Program

Precuring time per

segment

Quick 20 s –

45

Page 46

Tips for layering

Before layering, avoid mixing and overlapping the pastes to prevent air from

being trapped. Do not mix high- and low-viscosity materials with each

other.

It is advisable to apply Deep Dentin of the next brighter shade or highly opaque

pastes, e.g. Mamelon light, to the pontic rest to ensure adquate shade stability. After

that, layer these areas using Cervical, Deep Dentin and/or Dentin materials.

It is recommended to build up the veneer segment-by-segment (tooth-by-tooth) and

separate from each other and then to precure. Finally, the individual veneers are

joined.

Opal Effect pastes provide a true-to-nature opalescent effect in the incisal third. Opal

Effect 1 is applied to the cut-back dentin as extension of the dentin core and then

precured. Opal Effect 5 is suitable to create secondary dentin.

Use the shaded Transpa materials to complete and enhance the vitality in the incisal

area. Transpa blue is suitable for the mesial and distal aspects.

Use Mamelon materials to create a lifelike shade effect in the incisal third. They are

applied on the completed incisal area. Create smooth transitions. Avoid edges, since

they may look like stubs after polymerization and the mamelons may appear too

pronounced.

46

Page 47

Dentin / Incisal layering

The layering procedure of the individual SR Adoro pastes is carried out in accordance with the layering diagram (shade

guide layering).

Adapt the first layer firmly (press into place) to ensure an effective bond between the composite and the opaquer surface

and precure each segment for 20 seconds using a Quick curing light. Cervical or Deep Dentin material may be applied in

a half-moon shape to cervical areas, pontics and crown margins that are thinning towards the metal. Adapt firmly and

create smooth, rounded transitions between the layers (Cervical – Dentin – Mamelon – Incisal) using SR modelling

instruments or synthetic brushes.

Stabilize the pontic area with Deep Dentin and apply Cervical material in a half-moon shape in the cervical area.

After that, build up the dentin layers step by step and precure each segment for 20 seconds. The shade effect in the

interdental area may be enhanced by means of chromatic materials, such as Occlusal Dentin orange. Design the dentin

core in such a way that the mamelon shape remains outlined. Make sure to provide adequate space for the subsequent

application of the Incisal and Transpa materials. The mamelons can be individually designed with either Mamelon material

or SR Adoro Stains. After that, the restoration is completed layer by layer using Incisal and Transpa materials. The coordinated consistency of the material ensures that modelled contours are maintained and enables easy layering. The Incisal

materials are coordinated with the Dentin materials so that delicate transitions can be designed. Subsequently, precure

each segment for 20 seconds using the Quick.

Practical Procedure for Fixed Metal-Supported Restorations

Apply the first layer on the Opaquer firmly, build up step by step, and precure.

– It is essential to observe the stipulated curing depth and maximum layer thickness of the individual

materials during the layering procedure.

– If the maximum layer thickness is exceeded, break up large portions into several increments and precure

each increment for 20 seconds.

47

Page 48

Labial layering

Increase the shade effect in the interdental area with Occlusal Dentin ...

... complete the dentin core up to the mamelon structure ...

... by precuring with the Quick. Build up the incisal surface with incisal materials ...

... and complete with Opal Effect 1. Add Mamelon materials.

48

Page 49

Complete the labial surfaces with alternate layers ...

... of Incisal materials up to the canine.

Practical Procedure for Fixed Metal-Supported Restorations

Precure the individual layers with the Quick. Finally, complete the incisal edge ...

... using Incisal Edge material and precure.

49

Page 50

Palatal layering

Line the palatal fossa with Occlusal Dentin. Complete the pontic and marginal ridges with Dentin material.

Build up the marginal ridges and the tuberculum with Incisal and Transpa materials and slightly coat with Opal Effect 3 and 4.

Final Polymerization / Tempering

Preparing for final polymerization / tempering

It is imperative to observe the following steps when preparing metal-supported SR Adoro restorations for final

polymerization / tempering:

Step 1 – Applying SR Gel

After the layering procedure has been completed, all layers must be precured. To make sure that this is the case precure

each segment for 20 seconds using a Quick curing light. Apply SR Gel on the entire veneering surface ensuring that all

areas are fully covered and the layer is not too thick to prevent the formation of an inhibited layer.

If necessary, precure one more time and apply a fully covering but not inappropriately thick coat of SR Gel.

50

Page 51

Step 2 – Applying SR Adoro Thermo Guard

Once SR Gel has been applied, cover all exposed metal parts with SR Adoro Thermo Guard.

Open SR Adoro Thermo Guard syringes only immediately before use to prevent admission of air. Quickly start by filling