Page 1

®

Empress

IPS

CAD

Instructions for Use

chairside

Page 2

Table of Contents

IPS Empress® CAD – Product Information 4

Material

Uses

Composition

Block concept

Product overview for CEREC

Preparation guidelines and minimum thicknesses

IPS Empress® CAD – Overview of the Treatment Procedure 13

Overview of the treatment procedure

Shade determination

Intra-oral imaging

Milling

Staining and veneering

Procedure

Overview of the Treatment

Ceramic firing

Etching and silanating

Cementation

Polishing

CAD Restorations

®

Fabrication of IPS Empress

IPS Empress® CAD – Inlays / Onlays – polished 20

Preparation

Finishing

Polishing

IPS Empress® CAD – Inlays / Onlays – stained / glazed 24

Finishing and preparing for stain and glaze firing

2-in-1 technique and stain and glaze firing in one step

Corrective firing

IPS Empress® CAD – Veneers / Crowns – stained / glazed 27

Finishing

Preparing for staining

Stain and characterization firing

Glaze firing

Corrective firing

IPS Empress® CAD – Veneers / Anterior Crowns – cut-back and layered 32

Application of the IPS Empress Esthetic Veneer materials

Cut-back technique

Preparing for veneering

Wash firing

Incisal / Transparent firing

Finishing and preparing for stain and glaze firing

Stain and glaze firing

Corrective firing

IPS Empress® CAD – General Information 41

Preparing for cementation

Firing parameters

Combination table

2

Page 3

®

IPS

Empress

Nearly 20 years ago, IPS Empress revolutionized the processing of ceramic and thanks to the many advantages of the

leucite- reinforced glass-ceramic, such as esthetics, IPS Empress has been established as the "benchmark". More than

33 million restorations fabricated of IPS Empress throughout the world and the use of "IPS Empress" as a synonym for

all-ceramics speak for the durable life-like appearance, the ongoing success, and the high quality standard of the material.

In addition to the tried-and-tested PRESS technology, the CAD/CAM technology has also developed in the area of allceramics. In order to supply the "benchmark" for this technology as well, the IPS Empress System comprises products for

both processing technologies. You will be able to benefit from roughly 20 years of clinical experience and convincing

esthetics, irrespective of whether the restorations were fabricated with the PRESS or CAD/CAM technique.

IPS Empress Esthetic is available for the PRESS technology, while IPS Empress CAD is used in the CAD/CAM

techno logy. Both products consist of the highly esthetic, leucite-reinforced glass-ceramic that has been clinically tried-

and-tested for many years. The two ceramics are characterized by excellent strength values and outstanding esthetic

appearance. They may thus be used for the fabrication of full-contour single-tooth restorations, such as inlays, onlays,

veneers, and crowns.

Both products may subsequently be stained and/or glazed using IPS Empress Universal Shade / Stains / Glaze, or

individually veneered using the IPS Empress Esthetic Veneer layering ceramic.

– the Original

In this way, the IPS Empress System will remain synonymous for highly esthetic, full-contour all-ceramic restorations,

irrespective of the processing technology.

PRESS

Technology

Empress

IPS

®

CAD/CAM

Technology

Empress CAD

IPS

Esthetic

Empress

IPS

®

Esthetic Veneer

Empress

IPS

®

Universal Shade / Stains

3

Page 4

Empress® CAD

IPS

Product Information

Material

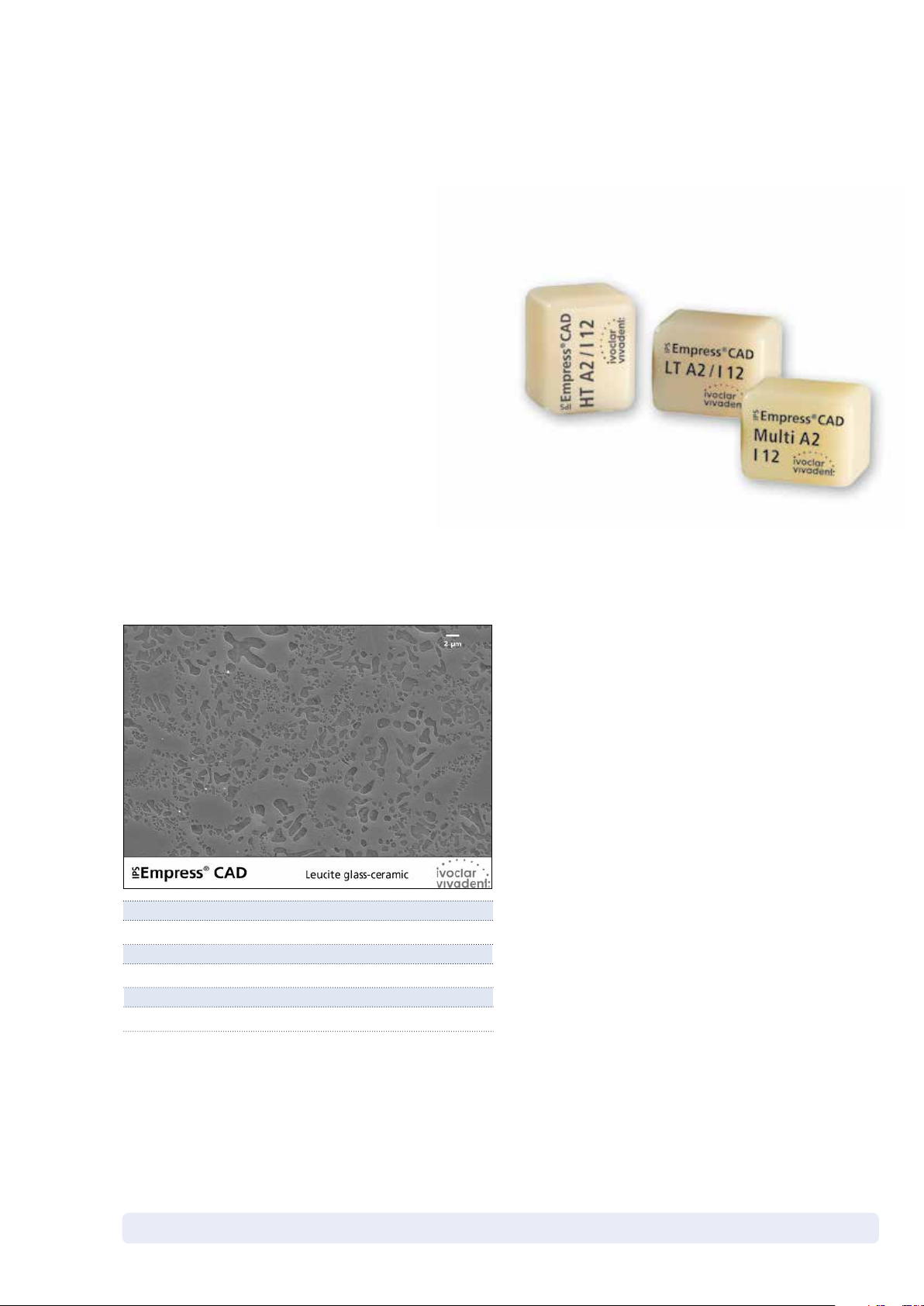

IPS Empress CAD is used for the fabrication of highly esthetic,

full-contour single-tooth restorations by means of the CAD/CAM

technology.

IPS Empress CAD blocks are made of a leucite-reinforced glassceramic which consists of a glass and a crystal phase. Leucite crystals

of few microns evenly grow in a multi-stage process directly from the

amorphous glass phase. During the fabrication of the blocks, the

semi-finished product in powder form is pressed to blocks in a fully

automated procedure, which enables a maximum of homogeneity.

Given the difference in the coefficients of thermal expansion (CTE)

between the glass phase and the crystal phase (leucite), cooling after

sintering produces compressive stress in the glass phase. This

mechanism results in an increase in strength and enables IPS Empress

CAD to achieve a flexural strength of 160 MPa. This type of material

has been successful as well as proven for almost 20 years. The milled

restorations feature excellent accuracy of fit and a homogeneous

surface structure. Subsequently, the restorations may be stained

using IPS Empress Universal and/or individually veneered using IPS

Empress Esthetic Veneer.

CTE (100–400 °C) [10-6 /K] 16.6

CTE (100–500 °C) [10-6 /K] 17.5

Flexural strength (biaxial) [MPa]* 160

Fracture toughness [MPa m

Vickers hardness [MPa] 6200

Chem. resistance [µg/cm2]* 25

Classification: Ceramic Materials Type II / Class 2a

*according to ISO 6872

More information about the authorized CAD/CAM systems is available on the Internet from www.ivoclarvivadent.com.

4

0.5

] 1.3

Page 5

Uses

Indications

IPS Empress CAD blocks can be used for the following adhesively cemented restorations. Depending on

the type and size of the restoration, the respective HT (High Translucency), LT (Low Translucency), or

Multi Block is recommended. IPS Empress CAD restorations may be cemented and either polished,

stained / glazed, or veneered.

HT Blocks

(High Translucency)

Higher translucency and

chameleon effect

Low brightness value

– Inlays

– Onlays

– Veneers

– Anterior and posterior crowns

– Partial crowns

– Veneers

LT Blocks

(Low Translucency)

Lower translucency and

chameleon effect

Higher brightness value

Multi Blocks

True-to-nature transition of

shade, translucency,

and fluorescence

– Anterior and posterior crowns

– Partial crowns

– Veneers

For further processing of IPS Empress CAD restorations, users have the following options:

– esthetic staining and glazing of full-contour restorations using IPS Empress Universal Shade, Stains,

and Glaze Pastes

– esthetic veneering in the incisal third of reduced restorations (veneers and anterior crowns) using

IPS Empress Esthetic Veneer materials.

Contraindications

– Bridge constructions

– Conventional cementation

− Very deep sub-gingival preparations

− Patients with severely reduced residual dentition

– Parafunctions

– Fully (circularly) veneered anterior and posterior crowns using IPS Empress Esthetic Veneer

– Any other use not listed in the indications for IPS Empress CAD

Important processing restrictions

Failure to observe the following restrictions may compromise the success

achieved with IPS Empress CAD:

– The required minimum thicknesses for IPS Empress CAD restorations must be observed.

– The maximum layer thickness of IPS Empress Esthetic Veneers layering materials must not be exceeded.

– IPS Empress CAD restorations must not be stained using materials other than IPS Empress Universal

Shade, Stains, and Glaze.

– Powder materials must not be mixed with paste materials.

– The blocks must not be milled in a non-authorized CAD/CAM system.

Side effects

If patients are known to be allergic to any of the ingredients of IPS Empress CAD, the material should

not be used.

5

Page 6

Composition

– IPS Empress CAD Blocks

Components: SiO2

Additional contents: Al2O3, K2O, Na2O, CaO, and other oxides, pigments

– IPS Empress Esthetic Veneer

Components: SiO2

Additional components: Al2O3, K2O, Na2O, CaO, oxides and pigments

– IPS Empress Universal Shade, Stains and Glaze Paste

Components: Oxides, glycerine, butandiol

– IPS Empress Esthetic Veneer Build-Up Liquid

Components: Water, butandiol and chloride

– IPS Empress Universal Glaze and Stain Liquid

Components: Butandiol

– IPS Contrast Spray Chairside

Components: Pigment suspension in ethanol; the propellant is a fluoridated hydrocarbon

– IPS Natural Die Material

Components: Polyester urethane dimethacrylate, paraffin oil, SiO2 and copolymers

– IPS Natural Die Material Separator

Components: Wax dissolved in hexane

– IPS Ceramic Etching Gel

Components: Hydrofluoric acid

Warning

– Butandiol is irritating – avoid contact with skin and eyes and do not inhale the vapours.

– Hexane is highly flammable and detrimental to health. Avoid contact with skin and eyes. Do not

inhale the vapours and keep away from sources of ignition.

– Do not inhale ceramic grinding dust during processing – use suction equipment and a face mask.

– Etching gel contains hydrofluoric acid. Avoid contact with skin, eyes, and clothing at any time, since

the material is highly toxic and corrosive. The etching gel is intended for professional use only and

must not be applied intra-orally (in the oral cavity).

6

Page 7

Block concept

IPS Empress CAD Blocks

The shading and translucency control of the IPS Empress CAD Blocks is based on the well-known translucency concept. The

system is built on the A-D, Chromascop, and Bleach BL shade guides.

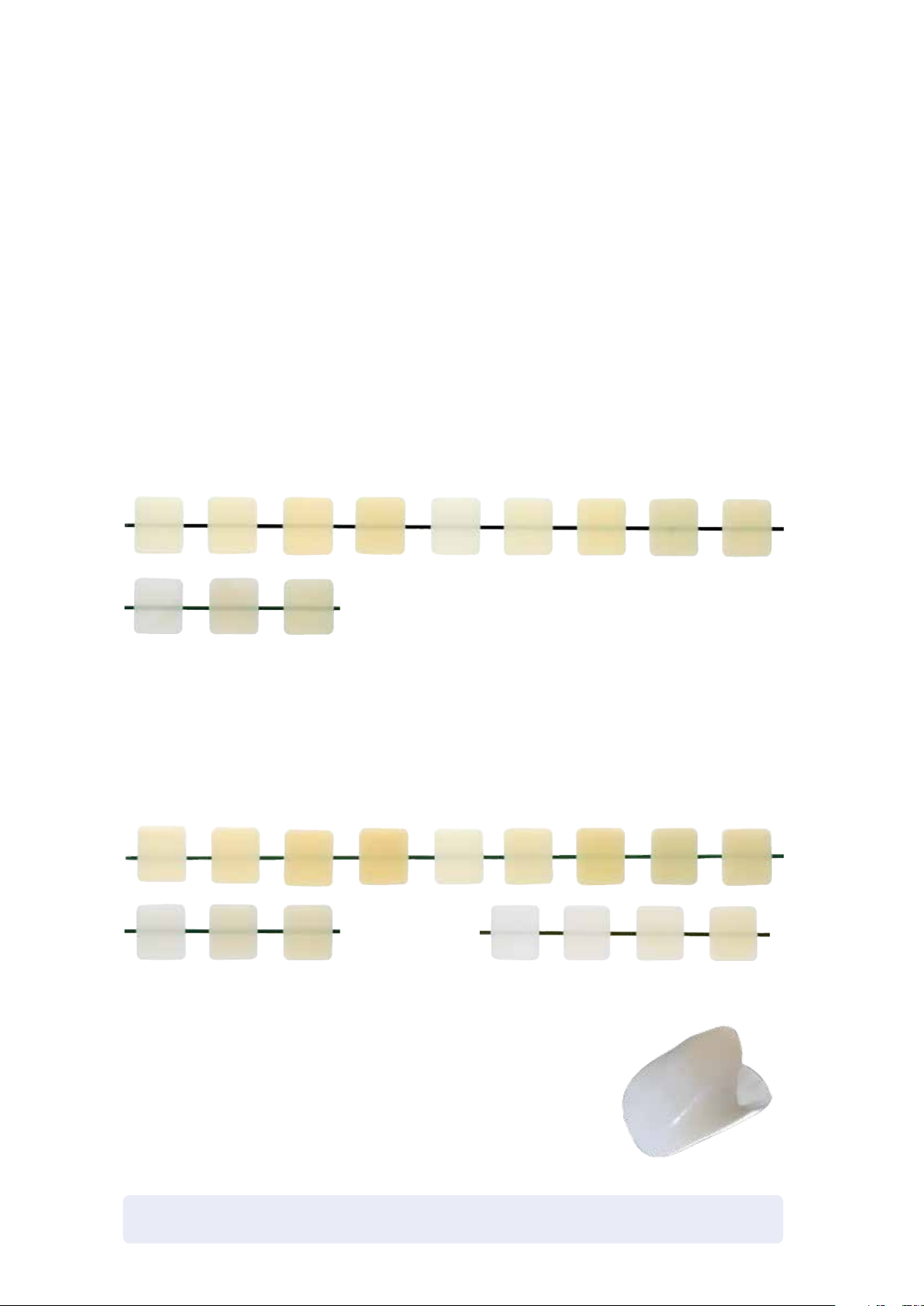

The IPS Empress CAD Blocks are available in two degrees of translucency and as a polychromatic block. The blocks are

precisely coordinated with the respective indications and thus enable excellent shade match with the corresponding shade

guide. Depending on the indication, the blocks provide a true-to-nature chameleon effect, life-like brightness value, or a

natural shade transition.

IPS Empress CAD HT (High Translucency)

These blocks are available in the 9 most popular A–D shades, 3 Chromascop shades, and 4 sizes. Given their high

translucency, HT blocks are ideally suitable for the fabrication of smaller restorations (e.g. inlays and onlays). Restorations

made of HT blocks impress users with their true-to-nature chameleon effect and outstanding adaptation to the residual

tooth structure. The blocks demonstrate life-like fluorescence in order to permit optimum integration into the natural

residual tooth structure under different light conditions.

A–D

Chromascop

IPS Empress CAD LT (Low Translucency)

These blocks are available in the 9 most popular A–D shades, 3 Chromascop shades, 4 Bleach BL shades, and 4 sizes. Given

their high brightness value compared to the HT blocks, the LT blocks are ideal for the fabrication of larger restorations (e.g.

anterior and posterior crowns). Restorations made of LT blocks impress users with their true-to-nature brightness value and

chroma, which prevents a greying of the incorporated restorations. The blocks demonstrate a life-like fluorescence in order

to enable optimum integration into the natural environment, even under varying light conditions. Restorations made of LT

blocks are also ideally suitable for the cut-back technique.

A–D

Chromascop Bleach BL

IPS Empress CAD Multi

These blocks are available in the 5 most popular A–D shades and 3 sizes. Given the

natural shade gradient from the dentin to the incisal areas, restorations made of

IPS Empress CAD Multi Blocks demonstrate a maximum of esthetics and naturalness.

The true-to-nature opacity and translucency gradient enables a multitude of esthetic

possibilities. The IPS Empress CAD Multi Block features a transition of fluorescence very

similar to that of natural teeth, which results in excellent integration into the residual

dentition. Given the innovative combination of true-to-nature transition of shade,

translucency, and fluorescence, highly esthetic restorations are fabricated in an easy way.

The available product range may vary from country to country and is also dependent on the CAD/CAM

system used.

7

Page 8

HT

High Translucency

LT

Low Translucency

Multi

V 12

I 8

I 10

I 12

C 14

Overview of blocks – shades and sizes*

IPS Empress CAD Blocks are available in the following shades and sizes as a Refill of 5 blocks.

A–D

A2

A1

A3

A3.5 B1 B2 B3 C2 D3

C 14 L

HT

High Translucency

LT

Low Translucency

Multi

V 12

I 8

I 10

I 12

C 14

Chromascop Bleach BL

200

100

300

BL1 BL2 BL3 BL4

C 14 L

8

*The available product range may vary from country to country and may depend on the CAD/CAM system used.

Page 9

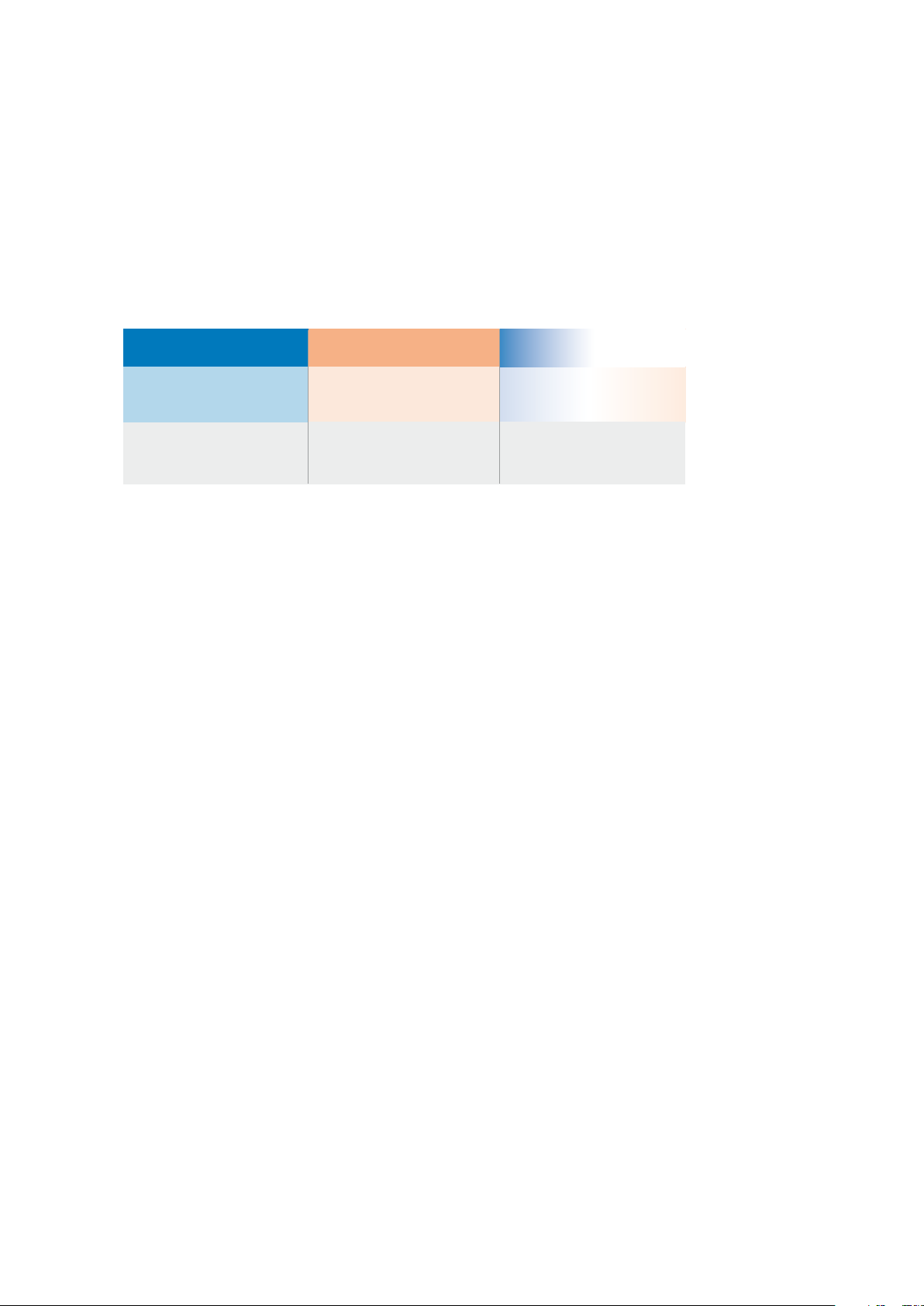

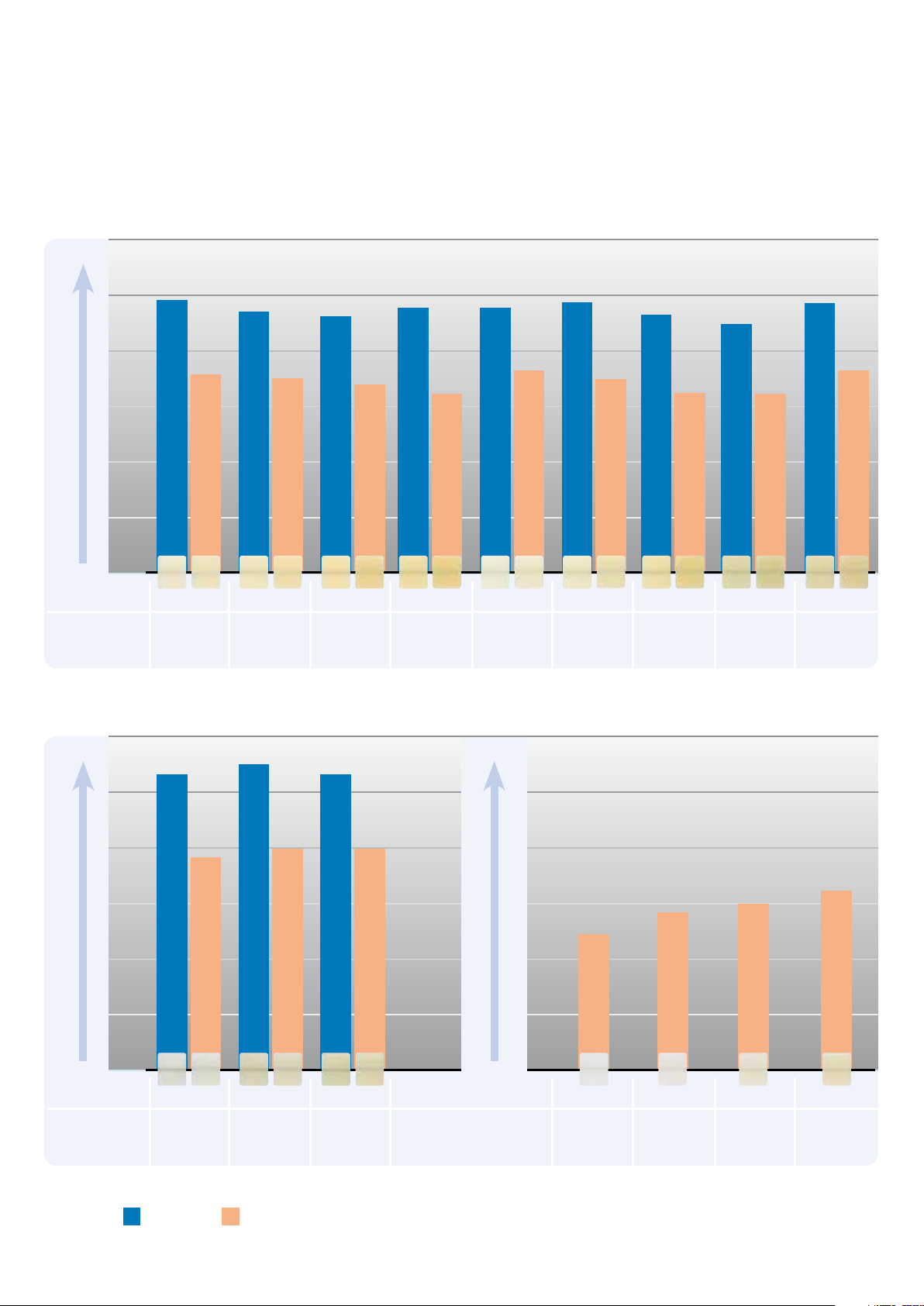

Translucency

Opacity

Overview of blocks – translucency

A–D Shades

Translucency

Opacity

A1 A2 A3 A3.5 B1 B2 B3 C2 D3

Chromascop

100 200 300

HT Block LT Block

Bleach BL

BL1 BL2 BL3 BL4

9

Page 10

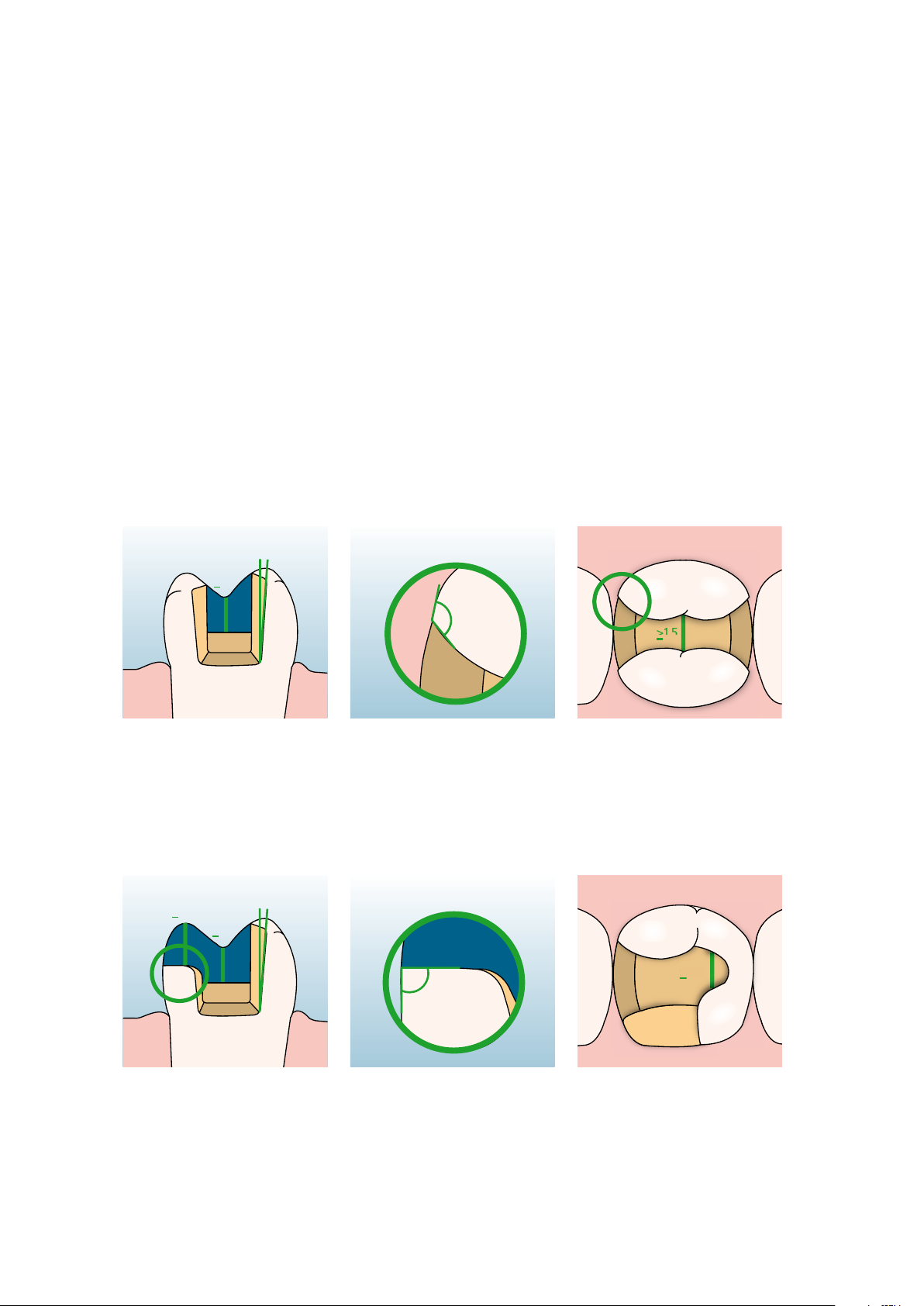

Preparation guidelines and minimum thicknesses

100-120°

>1.5>1.

5

>1.5>1.

5

5

>1.5

4°

100-120°

>1.5>1.

5

90°

>1.5

>1.

5

100-120°

>1.5>1.

5

>1.5

>1.

5

>1.5>1.

5

5

Successful results can only be achieved with IPS Empress CAD if the preparation guidelines and layer thicknesses are strictly

observed. The following minimum thicknesses are required for IPS Empress CAD restorations.

Inlays and onlays

It is absolutely necessary that you take the static and dynamic antagonist contacts into consideration. Do not locate the

preparation margins on centric antagonist contacts.

Observe a preparation depth of at least 1.5 mm and an isthmus width of at least 1.5 mm in the fissure area. Prepare the

proximal box with slightly diverging walls and observe an angle of 100–120° between the proximal cavity walls and the

prospective proximal inlay surfaces. For inlays with pronounced convex cavity walls without adequate support by the

proximal shoulder, avoid marginal ridge contacts. Round out internal edges in order to prevent stress concentration within

the ceramic material. Eliminate the proximal contacts on all sides. Do not prepare slice-cuts or feather edges.

4°

>1.5

100-120°

>1.5>1.

Observe at least 2 mm of space in the cusp areas. Ensure that the shoulder does not show any inclinations, i.e. it must

show a 90° angle to the residual tooth structure. Onlays are indicated if the preparation margin is less than approximately

0.5 mm away from the cusp tip, or if the enamel is severely undermined.

>2.0

4°

>1.5

90°

>1.5

>1.

10

Page 11

2.0

> 0.6

> 0.7

>1.0

>1.0

1.5

1.5

>1.0

1.5

2.0 2.0

1.5

>1.0

>1.0

1.5

>1.5

4°

100-120°

>1.5>1.

5

>1.5

>2.0

90°

>1.5

4°

>1.

5

1.0

> 0.6

> 0.7

>1.0

1.5

2.0 2.0

1.5

>1.0

>1.0

1.5

100-120°

>1.5>1.

5

90°

>1.5

>1.

5

1.5

2.0 2.0

1.5

>1.0

>1.0

1.5

>1.5>1.

5

>1.5

>1.

5

1.5

2.0 2.0

1.5

>1.0

>1.0

1.5

>1.5

4°

100-120°

>1.5>1.

5

>1.5

>2.0

90°

>1.5

4°

>1.

5

1.5

2.0 2.0

1.5

>1.0

>1.0

1.5

100-120°

>1.5>1.

5

90°

>1.5

>1.

5

>1.5>1.

5

>1.5

>1.

5

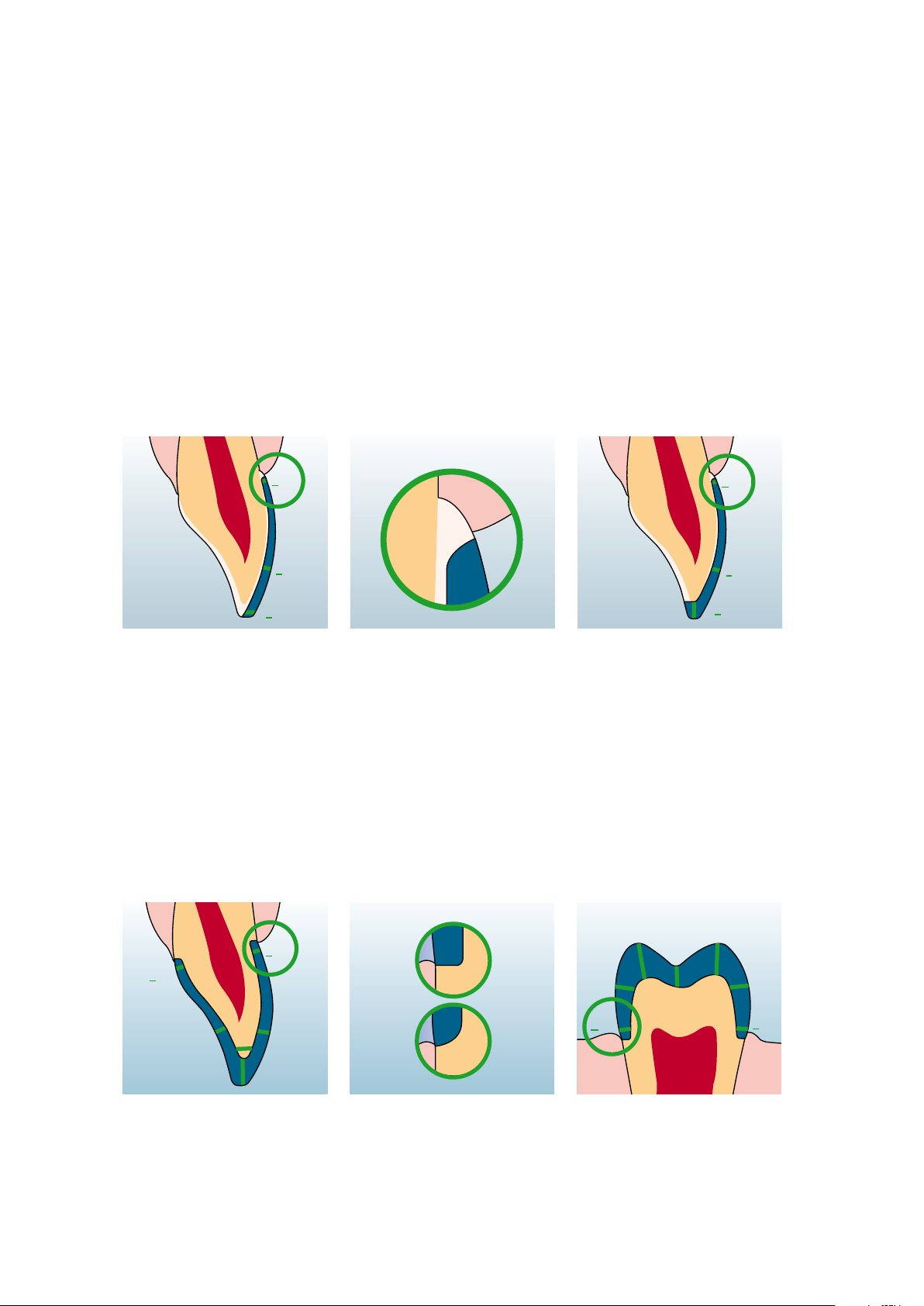

Veneers

If possible, the preparation should be entirely located in the enamel. Do not locate the incisal preparation margins in the

area of the abrasion surfaces or dynamic occlusal surfaces. You can achieve a controlled enamel reduction by preparing

orientation grooves using a depth marker. You are not required to eliminate the proximal contacts.

For preparations without embrasure of the incisal edge (only labial reduction), observe a preparation depth of at least

0.6 mm in the cervical area and of at least 0.7 mm in the labial area.

For preparations with oro-incisal embrasure of the incisal edge (labial / incisal reduction), observe a preparation

depth of at least 0.6 mm in the cervical area and of at least 0.7 mm in the labial area. Reduce the incisal edge by 1.0 mm.

The extent of the incisal reduction depends on the desired translucency of the incisal area to be built up. The more

transparent the incisal edge of the intended veneer, the more pronounced the reduction should be. Discoloured teeth

may require more preparation.

> 0.6

>0.7

>0.7

> 0.6

> 0.7

>1.0

Anterior and posterior crowns

Reduce the anatomical shape evenly while observing the given minimum thicknesses. Prepare a circumferential shoulder

with rounded inner edges or a chamfer. Observe a width of the circular shoulder/chamfer of at least 1 mm. Reduce the

crown third – incisal and/or occlusal – by 2 mm. For anterior crowns, reduce the labial and/or palatal / lingual part of the

tooth by at least 1.5 mm. Ensure that the incisal edge of the preparation is at least 1.0 mm (milling tool geometry) in order

>1.0

1.5

1.0

>1.0

1.5

2.0

to permit optimum milling of the incisal area during CAD/CAM processing.

2.0 2.0

1.5

1.5

>1.0

1.5

>1.0

11

Page 12

Empress® CAD

IPS

Overview of the Treatment Procedure

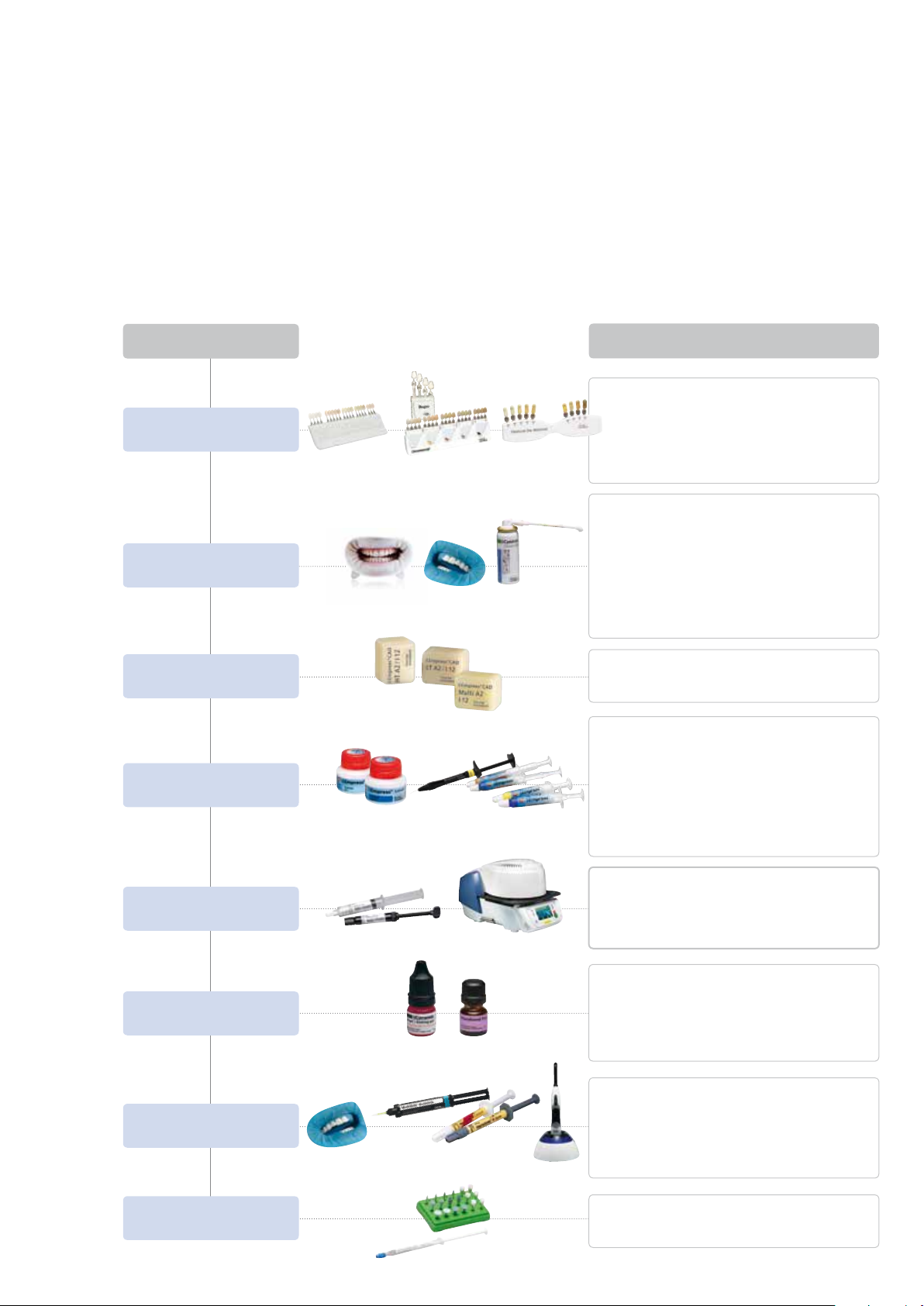

In addition to IPS Empress CAD Blocks, coordinated products are available for the entire chairside treatment procedure. Products coordinated

with each other and the individual working steps increase the processing comfort and the overall quality of the restoration. This enables the

fabrication of highly esthetic and durable IPS Empress CAD restorations with a maximum of efficiency and cost effectiveness.

For information on the CAD/CAM processing, please refer to the respective Instructions for Use and the manuals of the respective CAD/CAM

system. The instructions of the manufacturer must be observed.

Treatment Pocedure

Shade Determination

Intra-Oral Imaging

Milling

Staining and Veneering

Ivoclar Vivadent Products

Tooth Shade A–D, Chromascop and Bleach BL

Determination Shade Guide

Die Shade IPS

Determination To determine the shade of the

OptraGate

Provides easy access to an enlarged treatment area by circular retraction of lips and cheeks

OptraDam®

Anatomically shaped, 3-dimensional rubber dam

IPS® Contrast Spray Chairside

Enables optimum imaging through detailed definition of

the edges

IPS Empress® CAD Bocks

Leucite-reinforced ceramic blocks for the CAD/CAM

technology

IPS Empress Direct® Color

Light-curing composite stains for internal characterizations

IPS Empress

Opalescent ceramic materials for individual, esthetic

adjustments

IPS Empress

Stains in paste form for an individualized surface design

®

To determine the tooth shade of the

non-prepared tooth

®

Natural Die Material

prepared tooth

®

Esthetic Veneer

®

Universal Shade / Stains, Glaze

IPS® Object Fix Putty / Flow

Auxiliary firing paste to support all-ceramic restorations

Ceramic Firing

Etching and Silanating

Cementation

Polishing

12

Programat

The ceramic furnace for optimum firing results

IPS® Ceramic Etching Gel

For the fabrication of retentive bonding surfaces on

all-ceramic restorations

Monobond

Produces silanated bonding surfaces on etched all-ceramic

restorations

OptraDam®

Anatomically shaped, 3-dimensional rubber dam

Variolink

Proven adhesive cementation systems

Bluephase

The cordless high-performance LED light for all indications

OptraFine

High-performance, chairside diamond polishing system for

ceramic materials

®

CS2

®

Plus

®

II, Variolink® Veneer, Multilink® Automix

®

Page 13

Shade determination

The correct tooth shade is the basis for a restoration with a life-like appearance. After tooth cleaning, the tooth shade of

the non-prepared tooth and/or the adjacent teeth is determined. Individual characteristics have to be taken into consideration when determining the tooth shade. If a crown preparation is planned, for example, the cervical shade should also be

determined. In order to achieve true-to-nature results, shade determination should be carried out at daylight. Furthermore,

the patient should not wear clothes of intensive colours and/or lipstick. Basically, it has to be kept in mind that the final

shade of the restoration is the result of the following individual shades:

– the shade of the preparation;

– the shade of the ceramic block;

– the shade of the layering ceramic;

– the shade of the cementation material.

CAD – Overview of the Treatment Procedure

®

IPS Empress

IPS Natural Die Material

In order to facilitate the reproduction of the tooth shade, the shade of

the prepared tooth can be determined with the help of the IPS Natural

Die Material shade guide. This facilitates the fabrication of the allceramic restoration and the individual characteristics of the preparation may also be taken into consideration. By fabricating a working

die made of IPS Natural Die Materials in the respective shade of the

preparation, the shade and brightness value of the IPS Empress CAD

restorations may be checked during the individual fabrication steps.

13

Page 14

Intra-oral imaging

To prepare for the optical imaging, OptraGate® is placed to facilitate access to the

treatment field. OptraGate is a clinical auxiliary device that retracts lips and cheeks

during dental treatment. It enables a full view of the treatment field, facilitates the

accessibility, and improves the moisture control in the oral cavity.

The IPS® Contrast Spray Chairside is used to achieve optimum recordings for

CAD/CAM restorations. The IPS Contrast Spray Chairside balances out the

different optical properties of the natural tooth (dentin and enamel) and

thus permits optimum impressions using a camera. With the atomizing

nozzle, an optimum covering layer with a detailed representation of the

edges is achieved easily and efficiently with only a short spray discharge.

Angled atomizing heads are available for the spray.

Milling

In order to mill the restoration, IPS Empress CAD Blocks are selected in accordance

with the corresponding clinical situation. The clinical situation not only determines

the selection of the block in the required shade and translucency, but also the size

of the block used. Once the desired block has been selected, it is mounted in the

CAM unit and the restoration is milled.

Several options are available to finish and complete the restorations. Please refer

to the Chapter "Fabrication of IPS Empress CAD Restorations" for detailed

descriptions of the individual working steps of the various processing methods.

14

Page 15

Staining and veneering

There are three different techniques for staining, characterizing, and veneering

IPS Empress CAD.

Internal characterization

IPS Empress

®

Direct Color are light-curing composite stains for individual characteri-

zation. They are ideally suitable for internal characterizations (cementation side) of

IPS Empress CAD restorations (e.g. veneers). After etching (60 seconds with

IPS Ceramic Etching Gel) and silanating (Monobond Plus), the stains are applied.

Subsequently, the stains are polymerized with a curing light of the Bluephase family.

No further ceramic firing cycles must be conducted after the "internal

characterization" with IPS Empress Direct.

External characterization*

IPS Empress

®

Universal Shade / Stains are ceramic stains for individualized

characterizations. Among other things, they are ideal for external staining and

characterization of IPS Empress CAD restorations.

The dentin stains are available in 9 A-D and 15 Chromascop shades.

For individualized characterizations, 14 intensive stains are available. To reproduce

the incisal area, there are 2 Incisal Shades, which provide the incisal third with optical

translucency and an in-depth effect. For the final glaze firing of the IPS Empress CAD

restorations, a smooth and fine-grained glazing paste is available.

Cut-back technique*

IPS Empress

®

Esthetic Veneer ceramic materials are leucite-reinforced layering

materials for the cut-back technique. In this technique, full-contour IPS Empress CAD

restorations (veneers and anterior crowns) are reduced in the incisal third to a

dentin-mamelon structure and subsequently completed using materials in paste and

powder form in order to design a true-to-nature and esthetic incisal third.

CAD – Overview of the treatment process

®

IPS Empress

The IPS Empress Veneer Kit comprises a selection of the most popular wash pastes and

layering materials required for the cut-back technique of IPS Empress restorations

(Esthetic and CAD). With the wash pastes, an excellent and homogeneous bond with

the reduced restoration is achieved. The layering materials feature incisal-like fluorescence and true-to-nature opalescence. Additional wash pastes and layering materials

available as Refills are indicated on the material shade guide supplied with the Kit.

* Please refer to the Combination Tables for the available shades and materials.

15

Page 16

Ceramic firing

IPS Empress CAD restorations are generally fired on a honey-comb firing tray. For that

purpose, the restorations are placed either on a firing pillow or metal pins. As an alternative and to better secure the restorations on the metal pins, IPS® Object Fix Putty /

Flow auxiliary firing paste can be used.

Ceramic firing is conducted in the Programat® CS2 ceramic furnace. The furnace

impresses with its economic efficiency and easy operating concept. The furnace is

supplied from the factory with preset programs for IPS Empress and IPS e.max.

Etching and silanating

Conditioning of the ceramic surface in preparation for the adhesive cementation is

critical for generating a sound bond between the cementation material and the allceramic restoration.

Generally, glass-ceramics are etched using IPS® Ceramic Etching Gel.

Etching produces retentive bonding surfaces, which increases the

bond between the luting composite and the all-ceramic restoration.

IPS Ceramic Etching Gel is exclusively intended for extra-oral use

and must not be applied in the oral cavity.

Subsequent silanating of the bonding surface using Monobond® Plus results in a

sound bond between the etched all-ceramic material and the luting composite. The

bonding silane is thus an important contributor to the bonding strength between the

IPS Empress CAD restoration and the tooth structure.

16

Page 17

Cementation

To prepare for the adhesive cementation, a dry operating field, must be established,

preferably using a rubber dam.

The OptraDam® is a convenient, 3-dimensional rubber dam, which can be quickly and

easily inserted thanks to its anatomical shape and the integrated frame. Given its high

flexibility and new functional concept, the OptraDam is very comfortable for patients

even for longer treatment procedures. The gentle, circular retraction of lips and cheeks

enables substantially facilitated access to an enlarged treatment field with simultaneous

isolation.

Total Etch

Total Etch is used for the preparation of adhesive cementation with Variolink. It is an

enamel etching and dentin conditioning gel used during the adhesive cementation of

all-ceramic restorations.

For the adhesive cementation of IPS Empress CAD restorations, you may choose

between tried-and-tested luting composites from Ivoclar Vivadent. Adhesive cementation achieves an excellent bond between the preparation and the restoration.

CAD – Overview of the treatment process

®

IPS Empress

Veneers

Inlays

Onlays

Partial crowns

Anterior and posterior crowns

®

Variolink

(Variolink II, Variolink Veneer)

(Multilink Automix)

Multilink

–

®

Variolink® II

The dual-curing luting composite Variolink II has been used for more than 10 years

and in over 20 million restorations. It is the world's leading highly

esthetic material concept.

Numerous awards as the best product in the category of adhesive luting

composites and excellent results from clinical long-term studies are

testimony to this success.

Variolink

®

Veneer

Variolink Veneer is a purely light-curing luting composite in seven "Value"

shades for the adhesive cementation of translucent all-ceramic restorations

with a layer thickness of < 2.0 mm (veneers, inlays, onlays).

17

Page 18

Multilink® Automix

The universal, self-curing (with light-curing option) luting composite Multilink

Automix offers a broad range of indications and produces very high adhesive

strength on all material surfaces. Together with the self-etching Primer, which is

applied as a simple preliminary layer on enamel and dentin, Multilink Automix is

processed quickly and efficiently.

Bluephase

LED lights of the Bluephase® family are used for the polymerization of light-curing

and dual-curing adhesive composites.

The high light intensity achieved with the Bluephase curing light permits comparatively

short polymerization times with simultaneous good polymerization depth.

®

Polishing

OptraFine, the specially developed, high performance chairside diamond polishing

system for ceramic materials combines the highest efficiency with outstanding polishing results. With regard to both low surface roughness and outstanding esthetic gloss,

OptraFine leaves nothing left to be desired. In contrast to other ceramic polishers,

OptraFine is autoclavable and therefore reusable.

OptraFine is available in the shapes "flame", "cup", and "disc".

Polishing is carried out in three steps:

– Finishing/smoothing out of the surfaces using the Finisher F

– Polishing using the Polisher P

– Polishing to a high gloss using the high-gloss brush and diamond

polishing paste HP

18

Page 19

Empress® CAD

IPS

Inlays / Onlays – polished

IPS Empress CAD restorations are ideally suited to restore small defects with an all-ceramic material, as well as to replace

less esthetic restorations. Given the true-to-nature chameleon effect, IPS Empress CAD restorations beautifully blend in

with the residual tooth structure. In this processing technique, the restoration is polished and incorporated immediately

after milling in the CAD/CAM system. In the process, the surface lustre is achieved by manual polishing. Therefore, this

processing method is very efficient and leads to esthetic results in a quick and easy fashion.

For information on the CAD/CAM processing, please refer to the respective Instructions for Use and the

manuals of the respective CAD/CAM system. The instructions of the manufacturer must be observed.

The available product range may vary from country to country and may depend on the CAD/CAM system used.

Finishing

For finishing and adjusting glass-ceramics, appropriate grinding instruments are indispensable. If the wrong grinding instruments are used, marginal chipping and local overheating may occur.

CAD Restoration – Inlays / Onlays – polished

®

Fabrication of an IPS Empress

The following procedure is recommended for finishing IPS Empress CAD restorations:

– Use only suitable, fine-grained (grain size < 60 µm), ceramic-bonded grinding instruments or diamonds at a speed of up

to 20,000 rpm and little pressure.

– Carefully finish the restoration margins using rubber and silicone polishers (speed: < 10,000 rpm).

– Avoid overheating of the glass-ceramic.

– Smooth out the attachment point of the holder and take the proximal contact points into account.

– Carry out individual shape adjustments, if required.

– Try in the restoration and adjust the occlusion / articulation, if necessary.

– Polish proximal areas and large surfaces extra-orally prior to cementation.

The attachment point of the holder is smoothed out, while the proximal contact points are taken into account. Proximal areas and larger surfaces are polished extra-orally.

19

Page 20

Adhesive cementation

Preparation of the IPS Empress CAD restoration

To condition it for placement, etch the IPS Empress CAD restoration for 60 seconds using IPS Ceramic Etching Gel and

clean it under running water. Subsequently, silanize the bonding surface of the restoration using Monobond Plus. Observe

the corresponding safety instructions.

The IPS Empress CAD restoration is etched using the IPS Ceramic Etching Gel. The IPS Empress CAD restoration is silanized using Monobond Plus.

Conditioning the preparation

You may choose between tried-and-tested luting composites from Ivoclar Vivadent for the adhesive cementation. In the

documented case, Variolink II / Syntac were used.

– To condition the preparation for adhesive cementation with Variolink II / Variolink Veneer, Total Etch is used. Total Etch is

an enamel etching (30 seconds of etching) and dentin conditioning material (10–15 seconds of etching).

– To condition the preparation for adhesive cementation with Multilink Automix, Multilink Primer A/B is used.

The restoration is positioned and excess material is removed. For polymerization, the restoration margin is covered with glycerine gel and the restoration is

polymerized from all sides.

20

Page 21

Polishing

After the restoration has been adhesively cemented, the occlusion / articulation is adjusted with fine diamonds.

Subsequently, the restoration is manually polished in three easy steps. In order to achieve a life-like surface gloss, follow the

instructions below:

– For polishing, we recommend the high-performance, chairside diamond polishing system OptraFine.

– Always pay attention to the contact points and margins during polishing.

– Use the corresponding speed and little pressure to avoid heat development.

– Polish proximal areas and large surfaces extra-orally prior to cementation.

Step 1: Finish/smooth out the surfaces (e.g. proximal areas) using the Finisher F (speed: max. 15,000 rpm, water cooling).

This polisher smoothes out the milling grooves of the approx. 60 µm diamond of the CAD/CAM milling unit.

Step 2: Polish the restoration using the Polisher P (speed: max 15,000 rpm, water cooling).

Step 3: Polish the restoration to a high gloss using the high-gloss brush and diamond polishing paste HP (speed: max.

15,000 rpm).

CAD Restoration – Inlays / Onlays – polished

®

Fabrication of an IPS Empress

The occlusion / articulation is adjusted with fine diamonds. The surfaces are finished /smoothed out using the Finisher F (light blue).

The restoration is polished with Polisher P (dark blue).

The restoration is polished to a high gloss using the high-gloss brush and the diamond

polishing paste HP.

Polished IPS Empress CAD restoration

21

Page 22

Empress® CAD

IPS

Inlays / Onlays – stained / glazed

The 2-in-1 technique is suitable for efficient glazing and staining of inlays and onlays. In this technique, the glaze and stain

firing is conducted in one single step. Even though this technique does not permit as many shade adjustments as a

separate stain firing, the possible adjustments are entirely sufficient for the size of the restoration. If more intensive and

extensive shade adjustments are desired, we recommend conducting a separate stain and characterization firing (as

described in the following chapter).

For information on the CAD/CAM processing, please refer to the respective Instructions for Use and the

manuals of the respective CAD/CAM system. The instructions of the manufacturer must be observed.

Finishing and preparing for stain and glaze firing

For finishing and adjusting glass-ceramics, appropriate grinding instruments

are indispensable. If the wrong grinding instruments are used, marginal

chipping and local overheating may occur. The following procedure is

recommended for finishing IPS Empress CAD restorations:

– Use only suitable, fine-grained (grain size < 60 µm), ceramic-bonded

grinding instruments or diamonds at a speed of up to 20,000 rpm and

little pressure.

– Avoid overheating of the glass-ceramic.

– Smooth out the attachment point of the holder and take the proximal

contact points into account.

– Carry out individual shape adjustments, if required.

The attachment point of the holder is smoothed out, while the proximal

contact points are taken into account.

Before the stain and glaze firing, the restoration must be free of dirt and

grease. Avoid any contamination after cleaning. The following working

procedure should be observed:

– Before staining, blast the restoration with Al

(caution: abrasive) and clean it under running water or with a steam jet.

– Certain blasting devices require different settings for the intended blasting

procedure.

2-in-1 technique – Stain and glaze firing with IPS Empress Universal

Once the restoration has been cleaned, the stains and glazing material is applied in two steps. First, the glazing paste is

applied, followed by the Stains, which are applied on the unfired glaze layer.

The following working procedure should be observed:

Step 1 – Application of the glazing material:

– Extrude IPS Empress Universal Glaze Paste from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid. Do not excessively dilute

the material, since this may render the glazing procedure difficult to control.

– Apply the glazing material on the entire outer surfaces of the restoration.

– The glazing material must not come into contact with the inner aspects of the restoration.

– Avoid pooling and excessively thick glazing material layers.

– Excessively thin glazing material layers result in an unsatisfactory gloss.

at 0.5 bar pressure

2O3

The restoration is cleaned before staining.

22

Page 23

The glazing material is evenly applied on the entire outer surfaces of the restoration.

Step 2 – Application of Shade / Stains:

– Extrude IPS Empress Universal Shade or Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

– Apply the mixed Shade material directly into the unfired glazing material layer.

– Intensify the corresponding dentin shade in the cervical and occlusal areas using IPS Empress Universal Shade.

– To imitate the incisal area and translucency in the incisal third, use IPS Empress Universal Shade Incisal.

– Apply individualized effects and characterizations on cusps and in fissures using the Stains materials. Only apply the

Stains once staining with the Shade materials has been completed.

– Apply the Stains thinly and in a controlled manner on the unfired glazing material layer using a brush.

CAD Restorations – Inlays / Onlays – stained / glazed

®

Fabrication of IPS Empress

Mixed Shades are applied directly into the unfired glazing material layer. The corresponding

dentin shade is intensified in the cervical and occlusal areas and IPS Empress Universal Shade

Incisal is used to imitate the incisal areas.

Individualized effects and characterizations are applied on cusps and in fissures using the

Stains materials.

After glazing and staining, the glaze and stain firing is conducted in a compatible ceramic furnace (e.g. Programat CS2).

The following points should be observed when placing the restoration in the furnace and setting the firing parameters:

– Support inlays and onlays with a firing pillow and place them on the

honey-comb firing tray.

– As an alternative to the firing pillow, a small amount of IPS Object Fix

Putty / Flow may also be used.

– Restorations supported with a firing pillow on the honey-comb tray are

exposed to less heat due to their lower position in the firing chamber. In

order to achieve a true-to-nature gloss nonetheless, it is recommended

to extend the holding time from 1 minute to 2 minutes.

– Make sure that the firing pillow is regularly replaced in order to prevent

contamination.

The objects are placed on the honey-comb firing tray and the firing

program is started.

23

Page 24

Firing parameters for the stain and glaze firing (note the temperature control)

IPS Empress CAD with

IPS Empress Universal

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

H

min.

V

°C / °F

1

Stain and glaze firing 403 6:00 100 790 1:00 – 2:00 – –

B = Stand-by temperature °C / °F

S = Closing time/min.

= Temperature increase rate °C/min. / °F/min.

t

Optional

T = Firing temperature °C / °F

H= Holding time/min.

Completed IPS Empress CAD restoration, stained and glazed in one step

= Vacuum-on temperature °C / °F

V

1

= Vacuum-off temperature °C / °F

V

2

Subsequent adjustments

After completion, additional adjustments (e.g. contact points) may become necessary. For that purpose,

IPS Empress Add-On 770 °C / 1418 °F is available.

V

°C / °F

2

Procedure:

– Before the adjustment, clean the restoration thoroughly from dirt and grease using a steam jet.

– Mix IPS Empress Add-On 770 °C / 1418 °F with IPS Empress Esthetic Veneer Build-Up Liquid to a workable consistency.

Make sure that the add-on material and liquid are evenly mixed so that an optimum firing result can be achieved.

– Apply the mixed add-on material on the cleaned, desired areas using a brush and slightly blot them with an absorbent

cloth.

– Position the adjusted restoration on the firing tray and fire it in the ceramic furnace.

– After firing, manually polish the supplemented areas to a high gloss.

Firing parameters for the corrective firing

IPS Empress CAD with

IPS Empress Add-On 770 °C / 1418 °F

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

H

min.

V

°C / °F

1

Corrective firing 403 04:00 60 770 02:00 450 769

B = Stand-by temperature °C / °F

S = Closing time/min.

= Temperature increase rate °C/min. / °F/min.

t

T = Firing temperature °C / °F

H= Holding time/min.

= Vacuum-on temperature °C / °F

V

1

= Vacuum-off temperature °C / °F

V

2

V

°C / °F

2

24

Page 25

Empress® CAD

IPS

Veneers / Crowns – stained / glazed

If more intensive and excessive shade adjustments are desired, we recommend conducting them in several working steps.

To reproduce the tooth shade easily and reliably, an individual control die may be fabricated using the IPS Natural Die

Material. The IPS Empress Universal Shade and Stains are then applied in a first step and separately fired. The shade result

can be checked after firing. If required, the shade of the restoration may be intensified and adjusted to the individual

patient case by repeated application of the materials. Once the desired shade has been achieved and the individualized

characterizations completed, the glaze firing is conducted.

For information on the CAD/CAM processing, please refer to the respective Instructions for Use and the

manuals of the respective CAD/CAM system. The instructions of the manufacturer must be observed.

Finishing

For finishing and adjusting glass-ceramics, appropriate grinding instruments are indispensable. If the wrong grinding

instruments are used, marginal chipping and local overheating may occur.

The following procedure is recommended for finishing IPS Empress CAD restorations:

– Use only suitable, fine-grained (grain size < 60 µm), ceramic-bonded grinding instruments or diamonds at a speed of up

to 20,000 rpm and little pressure.

– Carefully finish the restoration margins using rubber and silicone polishers

(speed: < 10,000 rpm).

– Avoid overheating of the glass-ceramic.

– Smooth out the attachment point of the holder and take the proximal

contact points into account.

– Carry out individual shape adjustments, if required.

– Design the surface structure somewhat more pronounced, if necessary,

since it will be toned down by the glazing procedure.

Individual shape adjustments and a true-to-nature surface structure are

designed.

CAD Restorations – Veneers / Crowns – stained / glazed

®

Fabrication of IPS Empress

Optional

Die fabrication with IPS Natural Die Material

The light-curing IPS Natural Die Material simulates the shade of the prepared tooth. Fabricate a control die of the selected

shade. This control die supports the optimum shade adaptation of the restoration to reproduce the given oral situation.

– Coat the inner surfaces of the ceramic restorations with IPS Natural Die Material Separator and allow it to react for a

short time.

– Apply the IPS Natural Die Material in the corresponding shade to the

restoration and/or inner aspects of the restoration using the

IPS Condenser and adapt it so that the entire inner aspect is coated

and filled.

– Completely fill the restoration cavity and insert an IPS Die Holder into

the material and adapt excess material around the holder. Make sure

that the Die Material is well adapted to the restoration margins and

that no gaps are present.

– Polymerize the IPS Natural Die Material die with a commercial poly-

merization light for 60 seconds.

– After polymerization, finish and smooth the die, if required.

The control die made of IPS Natural Die Material is the optimum basis

for a true-to-nature all-ceramic restoration.

25

Page 26

Preparing for staining

Before the stain and glaze firing, the restorations must be free of dirt and

grease. Avoid any contamination after cleaning.

The following working procedure should be observed:

– Before staining, blast the restoration with Al

at 0.5 bar pressure

2O3

(caution: abrasive) and clean it under running water or with a steam jet.

– Certain blasting devices require different settings for the intended blasting

procedure.

The restoration is cleaned with a steam jet before staining.

Stain and characterization firing with IPS Empress Universal Shade and Stains

After the restoration has been cleaned, the stain and characterization firing is conducted.

The following working procedure should be observed:

– Extrude IPS Empress Universal Shade and Stains from the syringe and mix thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal Glaze and Stain Liquid.

– For better wetting of the stains, a small quantity of IPS Empress Universal Glaze and Stain Liquid may be slightly rubbed

into the surface.

– Apply the mixed Shade material directly onto the surface.

– Intensify the corresponding dentin shade in the cervical and central crown thirds using IPS Empress Universal Shade.

– Refrain from applying excessively thick or thin material layers.

– You can achieve more intensive shades by repeating the staining and firing procedures, rather than by applying thicker

layers.

– To imitate the incisal area and translucency in the incisal third, use IPS Empress Universal Shade Incisal.

– Design individualized affects and characterizations using the Stains material.

– Apply the Stains thinly and in a controlled manner using a brush.

The dentin body is intensified using IPS Empress Universal Shade.

Individualized effects and characterizations are designed using IPS Empress Universal Stains.

26

The incisal area is imitated using IPS Empress Universal Shade Incisal.

Page 27

After staining, the stain and characterization firing is conducted in a

compatible ceramic furnace (e.g. Programat CS2). The following points

should be observed when placing the restoration in the furnace and setting

the firing parameters:

– Place veneers as well as anterior and posterior crowns on metal pins and

position them on the honey-comb firing tray.

– To better secure the restoration on the metal pins (particularly with

veneers), a small amount of IPS Object Fix Putty / Flow may also be used.

The objects are placed on the honey-comb firing tray and the firing pro-

gram is started.

CAD Restorations – Veneers / Crowns – stained / glazed

®

Firing parameters for the stain and characterization firing

IPS Empress CAD with

IPS Empress Universal

B

°C / °F

(note the temperature control)

S

min.t°C/min. / °F/min.T°C / °F

H

min.

V

°C / °F

1

Stain and glaze firing 403 6:00 100 790 01:00 – –

B = Stand-by temperature °C / °F

S = Closing time/min.

= Temperature increase rate °C/min. / °F/min.

t

T = Firing temperature °C / °F

H= Holding time/min.

= Vacuum-on temperature °C / °F

V

1

= Vacuum-off temperature °C / °F

V

2

Optional

Shade check

To check the tooth shade after the first stain and characterization firing,

proceed as follows:

– Wet the inner aspects of the restoration with IPS Empress Universal Glaze

and Stain Liquid using a brush.

– Place the restoration on the individual control die, wet the surface and

check the tooth shade, as well as the individualized effects.

– If required, perform the necessary adjustments and fire the restoration

again using the same firing parameters.

Shade check. If necessary, the shade intensity can be increased by

additional staining.

V

°C / °F

2

Fabrication of IPS Empress

27

Page 28

Glaze firing with IPS Empress Universal Glazing Paste

Once the desired shade has been achieved and the individualized characterizations completed, the glaze firing is conducted.

The following working procedure should be observed:

– Extrude IPS Empress Universal Glaze Paste from the syringe and mix

thoroughly.

– Thin the material to the desired consistency using IPS Empress Universal

Glaze and Stain Liquid. Do not excessively dilute the material, since this

may render the glazing procedure difficult to control.

– Apply the glazing material evenly on the entire outer surfaces of the

restoration.

– The glazing material must not come into contact with the inner aspects

of the restoration.

– Avoid pooling and excessively thick glazing material layers.

The glazing material is applied evenly on the entire outer surfaces of

the restoration.

– Excessively thin glazing material layers result in an unsatisfactory gloss.

– The objects are positioned on the honey-comb firing tray same as for

the previous firing procedure.

– The glaze firing is conducted in a compatible ceramic furnace (e.g.

Programat CS2).

– If the gloss is unsatisfactory after the first glaze firing, further glaze

firing procedures may be conducted using the same firing parameters.

The objects are placed on the honey-comb firing tray and the firing

program is started.

Glaze firing with IPS Empress Universal Glaze Spray

IPS Empress Universal Glaze Spray is used as an alternative to IPS Empress Universal Glaze Paste for the glazing of

IPS Empress CAD restorations.

– Shake the spray can well immediately before use until the mixing ball in the container is moving freely (approximately

20 seconds).

– Hold the IPS Empress CAD restoration by its inner aspect using tweezers.

– Hold the spray can as upright as possible during spraying.

– Spray the restoration from all sides to coat the characterized restoration

10 cm

with an even layer. Shake the spray can well between individual bursts.

– Wait briefly until the glaze layer is dry and has assumed a whitish col-

our. Subsequently, apply a second layer of Glaze Spray. If Glaze Spray

accidentally reaches the inner aspects of the restoration, remove it with

a dry brush.

– Place the IPS Empress CAD restoration on a honey-combed firing tray for the (stain and) glaze firing and fire it according

to the firing parameters of the respective Instructions for Use.

– Should renewed application of the spray be necessary after firing, spray the restoration in the same manner again and

fire it using the same firing parameters.

Firing parameters for the glaze firing (note the temperature control)

IPS Empress CAD with

IPS Empress Universal

Glaze firing 403 6:00 100 790 1:00 – 2:00 – –

B = Stand-by temperature °C / °F

S = Closing time/min.

= Temperature increase rate °C/min. / °F/min.

t

28

T = Firing temperature °C / °F

H= Holding time/min.

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

= Vacuum-on temperature °C / °F

V

1

= Vacuum-off temperature °C / °F

V

2

H

min.

V

°C / °F

1

V

°C / °F

2

Page 29

Stained and glazed IPS Empress CAD crown and veneer

Optional

Subsequent adjustments

After completion, additional adjustments (e.g. contact points) may become necessary. For that purpose,

IPS Empress Add-On 770 °C / 1418 °F is available.

Procedure:

– Before the adjustment, clean the restoration thoroughly from dirt and grease using a steam jet.

– Mix IPS Empress Add-On 770 °C / 1418 °F with IPS Empress Esthetic Veneer Build-Up Liquid to a workable consistency.

Make sure that the add-on material and liquid are evenly mixed so that an optimum firing result can be achieved.

– Apply the mixed add-on material on the cleaned, desired areas using a brush and slightly blot them with an absorbent

cloth.

– Position the adjusted restoration on the firing tray and fire it in the ceramic furnace.

– After firing, manually polish the supplemented areas to a high gloss.

CAD Restorations – Veneers / Crowns – stained / glazed

®

Fabrication of IPS Empress

Firing parameters for the corrective firing

IPS Empress CAD with

IPS Empress Add-On 770 °C / 1418 °F

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

H

min.

Corrective firing 403 04:00 60 770 02:00 450 769

B = Stand-by temperature °C / °F

S = Closing time/min.

= Temperature increase rate °C/min. / °F/min.

t

T = Firing temperature °C / °F

H= Holding time/min.

= Vacuum-on temperature °C / °F

V

1

= Vacuum-off temperature °C / °F

V

2

V

°C / °F

1

V

°C / °F

2

29

Page 30

Empress® CAD

Instructions for Use

labsi de

Empress

®

CAD

IPS

Empress

®

System

IPS

IPS

Veneers / Anterior Crowns –

cut-back and layered

In order to individualize restorations in the incisal area so that they correspond with their natural model, the

IPS Empress CAD restoration is additionally veneered using opalescent IPS Empress Esthetic Veneer ceramic

materials.

The cut-back technique is very efficient if the full-contour anterior crown or the veneer is first designed

according to the definite final shape. After that, the incisal third is reduced and subsequently provided with

an individualized esthetic veneer.

For a detailed description of the materials used and the individual working steps, please refer to the

Instructions for Use of IPS Empress CAD labside.

After the CAM process, the fitted IPS Empress CAD

restoration is partially reduced using suitable grinding

instruments. Excess pressure and overheating is

prevented. No extreme mamelon structures are milled.

The wash firing is performed using the IPS Empress

Esthetic Veneer Wash Pastes.

The anatomical shape of the reduced areas is

completed using IPS Empress Esthetic Veneer materials.

30

Page 31

The tooth shape is completed with the second firing,

performed according to the firing parameters.

The restoration is finished with diamond grinding

instruments and a true-to-nature shape and surface

structure is designed. Finally, glaze firing is conducted

using IPS Empress Universal Glaze.

CAD Restorations – Veneers / Anterior Crowns – cut-back and layered

®

Fabrication of IPS Empress

IPS Empress CAD cut-back and layered – the ideal

combination for highly esthetic CAD/CAM-fabricated

restorations

31

Page 32

Empress® CAD

IPS

General Information

Preparing for cementation

Conditioning of the ceramic surface in preparation for cementation is critical for generating a sound bond between the

cementation material and the all-ceramic restoration. The following working procedure should be observed:

– Leucite-reinforced glass-ceramics are generally etched with IPS Ceramic Etching Gel and subsequently silanized with

Monobond Plus.

IPS Empress® CAD

Indication

Cementation method

Etching

Conditioning / silanating

Cementation system

The conventional cementation and blasting of completed IPS Empress CAD restorations is contraindicated!

Veneers, inlays, onlays, partial crowns, anterior and posterior crowns

Adhesive cementation

60 s with IPS Ceramic Etching Gel

60 s with Monobond® Plus

Variolink® II, Variolink® Veneer, Multilink® Automix

32

Page 33

Firing parameters

Firing process for leucite-reinforced glass-ceramic restorations

– Always use the honey-comb firing tray to fire the restorations.

– Support inlays, onlays, and partial crowns with a firing pillow and place them on the honey-comb firing tray.

– Place veneers as well as anterior and posterior crowns on metal pins and position them on the honey-comb firing tray.

– As an alternative to the firing pillow and to better secure the restoration on the metal pins (particularly with veneers), a

small amount of IPS Object Fix Putty / Flow may also be used. The inner aspects do not have to be completely covered.

– Observe the firing temperatures at all times. An increase in the firing temperature results in severe vitrification between

the framework and the veneering ceramic, which may lead to cracks later.

– Reducing the firing temperature will result in an underfired ceramic, which is very brittle and thus susceptible to

delamination.

– Depending on the working habits, the glaze and stain firing procedures may also be conducted with a temperature

increase rate of 60 °C / 108 °F per minute.

– If a vacuum pump is available, the stain and glaze firing procedures may also be carried out with a vacuum in place.

– Restorations supported with a firing pillow on the honey-comb tray are exposed to less heat due to their lower position

in the firing chamber. In order to achieve a true-to-nature gloss nonetheless, it is recommended to extend the holding

time from 1 minute to 2 minutes.

– The parameters specified in these Instructions for Use are coordinated with the Ivoclar Vivadent ceramic furnaces

(tolerance range ± 10 °C / 18 °F).

– If a non-Ivoclar Vivadent furnace is used, temperature corrections may be necessary.

CAD – General Information

®

IPS Empress

– The indicated firing parameters represent standard values applicable to the current ceramic furnaces from Ivoclar

Vivadent. The indicated temperatures also apply to furnaces of older generations, e.g. P20, P90, P95, P80, P100, P200.

However, the temperatures may deviate by ± 10 °C / 18 °F, depending on the age of the heating muffle.

– If a non-Ivoclar Vivadent furnace is used, temperature corrections may be necessary.

– Regional differences in the power supply or the operation of several electronic devices by means of the same circuit may

render adjustments of the temperatures necessary.

33

Page 34

IPS Empress CAD stained with IPS Empress Universal

IPS Empress CAD with IPS Empress Universal

2-in-1 technique

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

H

min.

V

°C / °F

1

Stain and glaze firing 403 6:00 100 790 1:00 – 2:00 – –

Corrective firing

IPS Empress Add-On 770 °C / 1418 °F

IPS Empress CAD with

IPS Empress Universal

403 04:00 60 770 02:00 450 769

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

H

min.

V

°C / °F

1

Stain and glaze firing 403 6:00 100 790 01:00 – –

Glaze firing 403 06:00 100 790 1:00 – 2:00 – –

Corrective firing

IPS Empress Add-On 770 °C / 1418 °F

403 04:00 60 770 02:00 450 769

IPS Empress CAD veneered with IPS Empress Esthetic Veneer

IPS Empress CAD with

IPS Empress Esthetic Veneer

Cut-back and veneered

B

°C / °F

S

min.t°C/min. / °F/min.T°C / °F

H

min.

V

°C / °F

1

V

°C / °F

V

°C / °F

V

°C / °F

2

2

2

Wash firing 403 04:00 60 840 02:00 450 839

1. Incisal / Transpa firing 403 04:00 60 830 02:00 450 829

2. Incisal / Transpa firing 403 04:00 60 830 02:00 450 829

Stain and characterization firing 403 06:00 100 790 01:00 450 789

Glaze firing 403 6:00 100 790 1:00 – 2:00 450 789

Corrective firing

IPS Empress Add-On 770 °C / 1418 °F

B = Stand-by temperature °C / °F

S =Closing time/min.

= Temperature increase rate °C/min.

t

T = Firing temperature °C / °F

H = Holding time/min.

403 04:00 60 770 02:00 450 769

= Vacuum-on temperature °C / °F

V

1

= Vacuum-off temperature °C / °F

V

2

34

Page 35

Combination Tables

CAD – General Information

®

IPS Empress

A1 A2 A3 A3.5 A3.5 B1 B2 B3 B3 B1 C2 C2 C2 C2 D3 D3

ND 2 ND 2 ND 3 ND 4 ND 8 ND 2 ND 2 ND 5 ND 5 ND 2 ND 7 ND 7 ND 7 ND 7 ND 2 ND 3

neutral

low value, high value

MM I-s, MM y-o, MM r-o

copper, orange, sky blue, basic yellow, basic red

HT LT MT MT HT LT LT LT MT MT MT MT MT MT MT MT

T neutral, T blue

110/A1, 210/A3

I white, I grey, I orange, I edge, I yellow, I orange-pink

Brightener

A1 A2/A3/A3.5 A4 B1 B2/B3/B4 C1/C2 C3/C4 D2/D3 D4

A-O

white, mahogany, khaki, orange, grey, vanilla, crackliner, olive, yellow, black, maroon, basic red, basic blue, basic yellow

I1 I1 I1 I2 I2 I1 I1 I1 I1 I2 I2 I2 I2 I2 I2 I2

Materials Combination Table

The combinations listed are standard combinations. The A–D and Chromascop shades that are not available as blocks may be achieved using the following procedure:

– Selection of the closest block shade.

A–D A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4

– Staining and intensifying of the dentin shade using IPS Empress Universal Shade and Shade Incisal.

IPS Empress CAD Blocks

IPS Natural Die Material

IPS Empress Esthetic Veneer

Wash Paste

IPS Empress Esthetic Veneer

Wash Paste Value

IPS Empress Esthetic Veneer

Wash Paste Mamelon

IPS Empress Esthetic Veneer

Wash Paste Modifier

IPS Empress Esthetic Veneer

Incisal Opal

IPS Empress Esthetic Veneer

Transpa

IPS Empress Esthetic Veneer

Incisal

IPS Empress Esthetic Veneer

Incisal Chroma Modifier

IPS Empress Esthetic Veneer

Brightener

IPS Empress Universal

Shade

IPS Empress Universal

Shade Incisal

IPS Empress Universal

Stains

IPS Empress Add-On

770 °C / 1418 °F

35

Page 36

100 200 300 200 300

ND 2 ND 2 ND 2 ND 2 ND 3 ND 3 ND 4 ND 4 ND 5 ND 5 ND 5 ND 5 ND 7 ND 7 ND 7 ND 7 ND 8 ND 8 ND 8 ND 8

neutral

low value, high value

MM I-s, MM y-o, MM r-o

copper, orange, sky blue, basic yellow, basic red

HT LT LT LT MT MT MT MT LT MT MT MT MT MT MT MT MT MT MT MT

T neutral, T blue

110/A1, 210/A3

I white, I grey, I orange, I edge, I yellow, I orange-pink

Brightener

110/120 130 140/210 220/230 240 310 320 330 340 410/420 430/440 510 520 530 540

A-O

white, mahogany, khaki, orange, grey, vanilla, crackliner, olive, yellow, black, maroon, basic red, basic blue, basic yellow

I1 I1 I1 I1 I1 I1 I1 I2 I1 I1 I2 I2 I2 I2 I2 I2 I2 I2 I2 I2

Chromascop 110 120 130 140 210 220 230 240 310 320 330 340 410 420 430 440 510 520 530 540

IPS Empress CAD Blocks

IPS Natural Die Material

IPS Empress Esthetic Veneer

Wash Paste

IPS Empress Esthetic Veneer

Wash Paste Value

IPS Empress Esthetic Veneer

Wash Paste Mamelon

IPS Empress Esthetic Veneer

Wash Paste Modifier

IPS Empress Esthetic Veneer

Incisal Opal

IPS Empress Esthetic Veneer

Transpa

IPS Empress Esthetic Veneer

Incisal

IPS Empress Esthetic Veneer

Incisal Chroma Modifier

IPS Empress Esthetic Veneer

Brightener

IPS Empress Universal

Shade

IPS Empress Universal

Shade Incisal

IPS Empress Universal

Stains

IPS Empress Add-On

770 °C / 1418 °F

36

Page 37

Bleach BL BL1 BL2 BL3 BL4

IPS Empress CAD Blocks

BL1 BL2 BL3 BL4

CAD – General Information

®

IPS Natural Die Material

IPS Empress Esthetic Veneer

Wash Paste

IPS Empress Esthetic Veneer

Wash Paste Value

IPS Empress Esthetic Veneer

Wash Paste Mamelon

IPS Empress Esthetic Veneer

Wash Paste Modifier

IPS Empress Esthetic Veneer

Incisal Opal

IPS Empress Esthetic Veneer

Transpa

IPS Empress Esthetic Veneer

Incisal

IPS Empress Esthetic Veneer

Incisal Chroma Modifier

IPS Empress Esthetic Veneer

Brightener

IPS Empress Universal

Shade

IPS Empress Universal

Shade Incisal

IPS Empress Universal

Stains

IPS Empress Add-On

770 °C / 1418 °F

ND 1 ND 1 ND 1 ND 1

neutral

low value, high value

MM I-s, MM y-o, MM r-o

copper, orange, sky blue, basic yellow, basic red

LT LT LT LT

T neutral, T blue

I white, I grey, I orange, I edge, I yellow, I orange-pink

110/A1, 210/A3

Brightener

I1 I1 I1 I1

white, mahogany, khaki, orange, grey, vanilla, crackliner, olive,

yellow, black, maroon, basic red, basic blue, basic yellow

A-O

IPS Empress

37

Page 38

Page 39

Page 40

Ivoclar Vivadent – worldwide

Ivoclar Vivadent AG

Bendererstrasse 2

9494 Schaan

Liechtenstein

Tel. +423 235 35 35

Fax +423 235 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P.O. Box 367

Noble Park, Vic. 3174

Australia

Tel. +61 3 9795 9599

Fax +61 3 9795 9645

www.ivoclarvivadent.com.au

Ivoclar Vivadent Ltda.

Alameda Caiapós, 723

Centro Empresarial Tamboré

CEP 06460-110 Barueri – SP

Brazil

Tel. +55 11 2424 7400

Fax +55 11 3466 0840

www.ivoclarvivadent.com.br

Ivoclar Vivadent Inc.

1-6600 Dixie Road

Mississauga, Ontario

L5T 2Y2

Canada

Tel. +1 905 670 8499

Fax +1 905 670 3102

www.ivoclarvivadent.us

Ivoclar Vivadent Shanghai

Trading Co., Ltd.

2/F Building 1, 881 Wuding Road,

Jing An District

200040 Shanghai

China

Tel. +86 21 6032 1657

Fax +86 21 6176 0968

www.ivoclarvivadent.com

Ivoclar Vivadent Marketing Ltd.

Calle 134 No. 7-B-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 3399

Fax +57 1 633 1663

www.ivoclarvivadent.co

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

France

Tel. +33 4 50 88 64 00

Fax +33 4 50 68 91 52

www.ivoclarvivadent.fr

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Germany

Tel. +49 7961 889 0

Fax +49 7961 6326

www.ivoclarvivadent.de

Wieland Dental + Technik

GmbH & Co. KG

Schwenninger Strasse 13

D-75179 Pforzheim

Germany

Tel. +49 7231 3705 0

Fax +49 7231 3579 59

www.wieland-dental.com

Ivoclar Vivadent Marketing (India)

Pvt. Ltd.

503/504 Raheja Plaza

15 B Shah Industrial Estate

Veera Desai Road, Andheri (West)

Mumbai, 400 053

India

Tel. +91 22 2673 0302

Fax +91 22 2673 0301

www.ivoclarvivadent.in

Ivoclar Vivadent s.r.l.

Via Isonzo 67/69

40033 Casalecchio di Reno (BO)

Italy

Tel. +39 051 6113555

Fax +39 051 6113565

www.ivoclarvivadent.it

Ivoclar Vivadent K.K.

1-28-24-4F Hongo

Bunkyo-ku

Tokyo 113-0033

Japan

Tel. +81 3 6903 3535

Fax +81 3 5844 3657

www.ivoclarvivadent.jp

Ivoclar Vivadent Ltd.

12F W-Tower, 1303-37

Seocho-dong, Seocho-gu,

Seoul 137-855

Republic of Korea

Tel. +82 2 536 0714

Fax +82 2 596 0155

www.ivoclarvivadent.co.kr

Ivoclar Vivadent S.A. de C.V.

Av. Insurgentes Sur No. 863.

Piso 14, Col. Napoles

03810 México, D.F.

México

Tel. +52 55 5062 1000

Fax +52 55 5062 1029

www.ivoclarvivadent.com.mx

Ivoclar Vivadent BV

De Fruittuinen 32

2132 NZ Hoofddorp

Netherlands

Tel. +31 23 529 3791

Fax +31 23 555 4504

www.ivoclarvivadent.com

Ivoclar Vivadent Ltd.

12 Omega St, Rosedale

PO Box 303011 North Harbour

Auckland 0751

New Zealand

Tel. +64 9 914 9999

Fax +64 9 914 9990

www.ivoclarvivadent.co.nz

Ivoclar Vivadent Polska Sp. z o.o.

Al. Jana Pawla II 78

00-175 Warszawa

Poland

Tel. +48 22 635 5496

Fax +48 22 635 5469

www.ivoclarvivadent.pl

Ivoclar Vivadent Marketing Ltd.

Prospekt Andropova 18 korp. 6/

office 10-06

115432 Moscow

Russia

Tel. +7 499 418 0300

Fax +7 499 418 0310

www.ivoclarvivadent.ru

Ivoclar Vivadent Marketing Ltd.

Qlaya Main St.

Siricon Building No.14, 2

Office No. 204

nd

Floor

P.O. Box 300146

Riyadh 11372

Saudi Arabia

Tel. +966 11 293 8345

Fax +966 11 293 8344

www.ivoclarvivadent.com

Ivoclar Vivadent S.L.U.

C/ Ribera del Loira nº 46, 5ª planta

28042 Madrid

Spain

Tel. + 34 913 757 820

Fax + 34 913 757 838

www.ivoclarvivadent.es

Ivoclar Vivadent AB

Dalvägen 14

S-169 56 Solna

Sweden

Tel. +46 8 514 939 30

Fax +46 8 514 939 40

www.ivoclarvivadent.se

Ivoclar Vivadent Liaison Office

: Tesvikiye Mahallesi

Sakayik Sokak

Nisantas’ Plaza No:38/2

Kat:5 Daire:24

34021 Sisli – Istanbul

Turkey

Tel. +90 212 343 0802

Fax +90 212 343 0842

www.ivoclarvivadent.com

Ivoclar Vivadent Limited

Ground Floor Compass Building

Feldspar Close

Warrens Business Park

Enderby

Leicester LE19 4SE

United Kingdom

Tel. +44 116 284 7880

Fax +44 116 284 7881

www.ivoclarvivadent.co.uk

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA

Tel. +1 800 533 6825

Fax +1 716 691 2285

www.ivoclarvivadent.us

Manufacturer:

Ivoclar Vivadent AG, 9494 Schaan/Liechtenstein

www.ivoclarvivadent.com

Date information prepared: 2014-01/Rev. 0

These materials have been developed solely for use in dentistry. Processing should be carried out strictly

according to the Instructions for Use. Liability cannot be accepted for damages resulting from failure to

observe the Instructions or the stipulated area of application. The user is responsible for testing the materials

for their suitability and use for any purpose not explicitly stated in the Instructions. Descriptions and data constitute no warranty of attributes and are not binding.

Printed in Liechtenstein.

© Ivoclar Vivadent AG, Schaan / Liechtenstein

667043/en

Loading...

Loading...