Page 1

<<11..0

-

-

0

0

RRe

OOtthheer

r

Ivoclar Vivadent Worldwide

Headquarters

Liechtenstein

Ivoclar Vivadent AG

Bendererstrasse 2

FL-9494 Schaan

Tel. +423 235 35 35

Fax +423 235 33 60

www.ivoclarvivadent.com

Manufacturer

USA

Ivoclar Vivadent Inc.

175 Pineview Drive

Amherst, NY 14228

Tel. +1 800 533 6825

Fax +1 716 691 2285

www.ivoclarvivadent.us

Australia

Ivoclar Vivadent Pty. Ltd.

1 - 5 Overseas Drive

P.O. Box 367

Noble Park, Vic. 3174

Tel. +61 3 979 595 99

Fax +61 3 979 596 45

www.ivoclarvivadent.com.au

Austria

Ivoclar Vivadent GmbH

Bremschlstr. 16

Postfach 223

A-6706 Bürs

Tel. +43 5552 624 49

Fax +43 5552 675 15

www.ivoclarvivadent.com

ISO 13485

Quality Management System Certified

Made in U.S.A. unless

otherwise indicated

❑ Made in Canada

(fabrique au Canada)

r

e

-

-

<<11..0

-

-

RRu

IIr

a

u

Brazil

Ivoclar Vivadent Ltda.

Rua Geraldo Flausino Gomes,

o

78 - 6.

andar Cjs. 61/62

Bairro: Brooklin Novo

CEP: 04575-060 - São Paulo - SP

Tel. +55 (11) 3466 0800

Fax +55 (11) 3466 0840

www.ivoclarvivadent.com.br

Canada

Ivoclar Vivadent Inc.

2785 Skymark Avenue, Unit 1

Mississauga, Ontario L4W4Y3

Tel. +1 905 238 5700

Fax +1 905 238 5711

www.ivoclarvivadent.ca

China

Ivoclar Vivadent Marketing Ltd.

Rm 603 Kuen Yang

International Business Plaza

No. 798 Zhao Jia Bang Road

Shanghai 200030

Tel. +86 21 5456 0776

Fax +86 21 6445 1561

www.ivoclarvivadent.com

Colombia

Ivoclar Vivadent Marketing Ltd.

Calle 134 No. 7-B-83, Of. 520

Bogotá

Tel. +57 1 627 33 99

Fax +57 1 633 16 63

www.ivoclarvivadent.com

France

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

Tel. +33 450 88 64 00

Fax +33 450 68 91 52

www.ivoclarvivadent.fr

Germany

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Tel. +49 (0) 79 61 / 8 89-0

Fax +49 (0) 79 61 / 63 26

www.ivoclarvivadent.de

www.ivoclarvivadent.com

Caution: US Federal Law

restricts this device to

sale by or on the order

of a licensed dentist.

22674

0120

s

pan bridges, PFM crowns, implant superstructures, partial dentures.

Recommended for onlays, 3/4 crowns, telescope crowns, conus crowns, posts, short and long

Indications

5522..2

<<11..0

2266..0

1177..1

-

22..7

-

<<11..0

7

-

0

IIn

GGa

n

SSn

ZZn

n

n

0

1

-

AAg

CCu

g

u

2

0

AAu

PPt

PPd

u

t

d

Composition

For sale in Japan only

Instructions for Use

White, gold-based dental metal ceramic casting alloy, Type 4

ESPRIT

India

Ivoclar Vivadent Marketing Ltd

503/504 Raheja Plaza

15 B Shah Industrial Estate

Veera Desai Road, Andheri (West)

Mumbai, 400 053

Tel. +91 (22) 2673 0302

Fax +91 (22) 2673 0301

www.ivoclarvivadent.com

Italy

Ivoclar Vivadent s.r.l. & C. s.a.s

Via Gustav Flora 32

I-39025 Naturno (BZ)

Tel. +39 0473 67 01 11

Fax +39 0473 66 77 80

www.ivoclarvivadent.it

Japan

Ivoclar Vivadent K.K.

1-28-24-4F Hongo

Bunkyo-ku, Tokyo 113-0033

Tel. +81 3 6903 3535

Fax +81 3 5844 3657

www.ivoclarvivadent.co.jp

Mexico

Ivoclar Vivadent S.A. de C.V.

Av. Mazatlan No. 61, Piso 2

Col. Condesa

06170 México City, D.F.

Tel. +52 (55) 50 62 10 00

Fax +52 (55) 50 62 10 29

www.ivoclarvivadent.com.mx

New Zealand

Ivoclar Vivadent Ltd

12 Omega St, Albany

PO Box 5243 Wellesley St

Auckland

Tel. +64 9 630 52 06

Fax +64 9 914 99 90

www.ivoclarvivadent.co.nz

Poland

Ivoclar Vivadent Sp. z.o.o.

ul. Jana Pawla II 78

PL-00175 Warszawa

Tel. +48 22 635 54 96

Fax +48 22 635 54 69

www.ivoclarvivadent.pl

Rev. Date 2/09

Rev. 1

Russia

Ivoclar Vivadent Marketing Ltd.

Derbenevskaja Nabereshnaya

11, Geb. W

115114 Moscow

Tel. +7 495 913 66 19

Fax +7 495 913 66 15

www.ivoclarvivadent.ru

Singapore

Ivoclar Vivadent Marketing Ltd.

171 Chin Swee Road

#02-01 San Centre

Singapore 169877

Tel. +65 6535 6775

Fax +65 6535 4991

Spain

Ivoclar Vivadent S.A.

c/ Emilio Muñoz No15

E-28037 Madrid

Tel. +34 913 75 78 20

Fax +34 913 75 78 38

www.ivoclarvivadent.com

Sweden

Ivoclar Vivadent AB

Dalvägen 14

S-169 56 Solna

Tel. +46 (0) 8 514 93 930

Fax +46 (0) 8 514 93 940

www.ivoclarvivadent.se

Turkey

Ivoclar Vivadent Liaison Office

Ahi Evran Caddesi no 1

Polaris Is Merkezi Kat: 7

80670 Maslak

Istanbul

Tel. +90 536 577 12 62

UK

Ivoclar Vivadent UK Limited

Ground Floor Compass Building

Feldspar Close

Warrens Business Park

Enderby

Leicester LE19 4SE England

Tel. +44 116 284 78 80

Fax +44 116 284 78 81

www.ivoclarvivadent.co.uk

N

E

●

●

ODELLATION

M

D

esign the framework in a reduced anatomic shape taking the planned veneer into consideration.

Single crowns require a thickness of minimum 0.3 mm;abutment crowns thickness a minimum of

0

.5 mm. Make sure the framework demonstrates adequate stability of shape.Avoid sharp angles.

D

esign the connector areas to be adequate for the position and alloy being used. To increase the

strength of a bridge in a cantilever situation, maximize the height of the connector.

SPRUING

P

rovide the modeled bridge framework or coping with sprues of a suitable size. Use the direct or

indirect technique being sure that the reservoir is positioned in the heat center. The connection

sprues between the reservoir and the coping should be 2.5-3.0 mm in length and width.

NVESTMENT

I

Weigh the wax pattern including the sprue to determine the quantity of the alloy to be used. (See

wax conversion sheet/formula: weightx density = gr.of alloy). Use investment following themanufacturer`s instruction.

BURN-OUT

The suggested burnout temperature: 750-820C/1380-1510F

MELTING AND CASTING

Use a separate carbon/ceramic crucible for each alloy and preheat the crucible (ceramic) in the

burnout furnace. Used and new alloys must be in a ratio of 1:1. Depending on the type of casting machine, follow the manufacturers instructions for use. If you use Ivoclar Vivadent Magic

Wand, set propaneto 0.35 bar/5 psi and oxygen to0.7 bar/10 psi pressure.Keep the alloy in the

reducing atmosphere of the flame between the inner and outer cones. Do not use flux. After

casting bench cool to room temperature.

Casting Temperature: 1285-1345C/2345-2455F

METAL PREPARATION

Carefully divest and clean the object withAL2O3. Do not use a hammer for divesting the object to

p

revent deformation. Finish the framework with carbide burs or with ceramic-bonded grinding

instruments.Avoid inhalation of dust during grinding!

XIDATION

O

Blast surface with 50-100 micron AL2O3at max. 4.5 bar/65 psi pressure before oxidation.

Subsequently, clean with ultrasonic or steam. Place the object on the firing tray and provide adequate support. Place the tray in a porcelain furnace set at a low temperature of 650C/1200F and

increase the furnace temperature to 950C/1740F without vacuum with 5 min. hold time at top

temperature.

HEAT TREATMENT

Hardening: 600C/1110F for 30 minutes; air cool.

SOLDERS AND FLUXES

Design t he sold ering patty as l ittle a s possible and p reheat it in th e furnace at app roximately 600C/ 1112F. The soldering gap should be the same thickness as the soldering strip.Allow

the object to cool slowly after soldering.

Pre-Solder: Special High Fusing White Ceramic Solder, High-Fusing Bondal Flux

Post-Solder: Low Fusing White Gold Solder, Bondal Flux

Laser weld material: Laser Ceramic White

POLISHING

After glazing removeoxide and flux residueand finish/polish the framework with rubber finishers/

polishers.

INDICATIONS

Recommended for onlays, 3/4 crowns,telescope crowns, conus crowns, posts, short and long span

bridges, PFM crowns,implant superstructures,partial dentures.

CONTRAINDICATIONS

For patients with known allergy/sensitivity to any major or minorconstituents of this alloy, consultation with a physician is recommended.

SIDE EFFECTS

In individual cases, sensitivity or allergies to components of this alloy may occur.

INTERACTIONS

Galvanic effects may occur between different alloys in the same oralenvironment.

For additional information look into the alloy property chart.

RECOMMENDATIONS

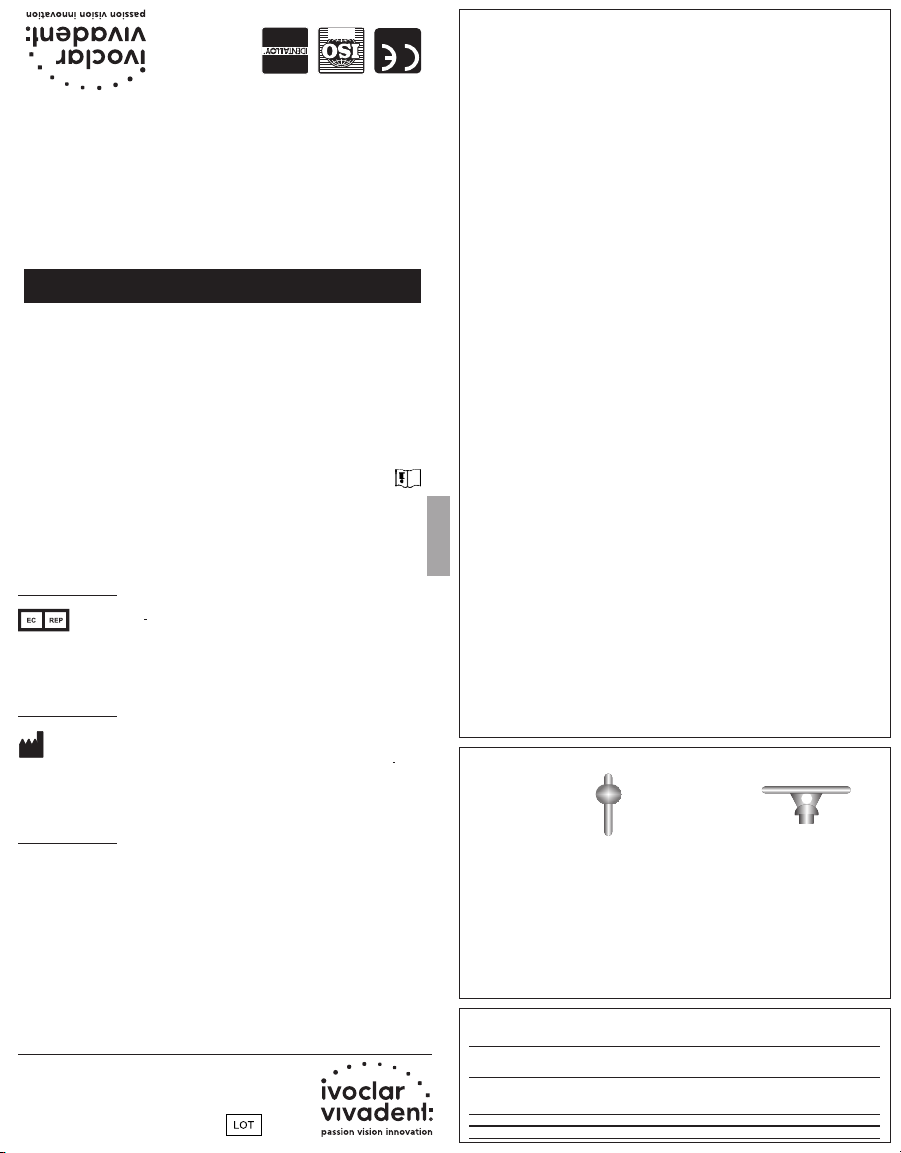

DIRECT: INDIRECT:

single crowns, multiple units

inlays and onlays and multiple

INSTRUCTIONS:

1.Select a sprue with a reservoir equal to or larger than the thickest cross-section of the restoration.

2.Maintain the reservoir(s) within the heat center of the investment; keep the restoration(s)

approximately 5 mm from the end of the investment and no closer than 5 mm from the sides.

3.Make sure that the sprue is connected to the thickest part of the restoration.

4.The connection between the sprue and the restoration should be flared (“trumpet” configura-

tion); eliminating turbulence of the alloy (causing investment erosion) and facilitating an undisturbed flow of alloy during casting and solidification.

5.Maintain proper alloy weight in order to eliminate the negative effect of a too large button dur-

ing solidification. The rule of thumb for proper alloy weight determination is: total wax weight

x specific gravity of the alloy = proper alloy weight.

SUGGESTIONS:

1.Thickness and design of wax pattern: follow your manufacturers instructions.

2.Use chill-vents when casting heavy and/or large restorations.

Proof Stress (0.2% Offset) MPa 400 505 530

Vickers Hardness 180 230* 255

Elongation (%) 18.0 20.0 19.0

Modulus of Elasticity (psi/MPa) 17,1 00,000/118,000

Density (g/cm

Melting Range 1185-1230C/2165-2245F

Casting Temperature 1285-1345C/2345-2455F

*Noritake Ceramic

INSTRUCTIONS FOR USE

SPRUING METHOD

single crowns

PHYSICAL PROPERTIES

3

) 13.8

CTE 25-500C 14.0 CTE 20-600C 14.2

As Cast Porcelain Fired Oven Hardened

Loading...

Loading...