IVECO STRALIS AT, STRALIS AD REPAIR MANUAL

STRALIS AT/AD

REPAIR MANUAL

MECHANICAL

ELECTRIC

ELECTRONIC

STRALIS AT/AD

REPAIR MANUAL

This publication describes the characteristics, the data, the

correct methodology of the repairs that can be made on each

individual component of the vehicle.

By complying with the instructions supplied and using the

specific tools it is possible to perform any repair intervention

correctly, within the specifiedtime frames, while protecting the

technicians against incidents.

Before starting any repair work, make sure that all accident

prevention devices are ready at hand.

Check and wear the protective personal equipment provided

for by the safety standards: goggles, helmet, gloves, shoes.

Check the efficiency of all processing, lifting and transport tools

before using them.

The data contained in this publication might fail to reflect the

latest changes which the Manufacturer may introduce at any

time, for technical or sales purposes, or to meet the

requirements of local legislation.

Copy, even partial, of text and drawings is forbidden.

Publication Edited by:

IVECO S.p.A.

T.C.O. - B.U. Customer Service

Lungo Stura Lazio, 15/19

10156 Torino (Italy)

Printed 603.93.141 -1

st

Ed. 2003

Produced by:

B.U. TECHNICAL PUBLISHING

C.so Svizzera, 185

10149 Torino (Italy)

SPECIAL REMARKS

The workshop manuals for mechanical parts have been divided into Sections, each of which has a number and its relevant contents

are indicated in the General Specifications. Each section features a main Unit (e.g. engine, gears etc.).

The subjects usually dealt with in each section are:

Technical data table, Driving torques, Equipment, Diagnostic, Removal and Fitting in place, Repair operations.

Where possible, the same sequence of procedures has been followed for easy reference.

Diagrams and symbols have been widely used to give a clearer and more immediate illustration of the subject being dealt with, (see

next page) instead of giving descriptions of some operations or procedures.

Example

∅

Ø 1 = h ousing for connecting rod small end bush

1

Tighten to torque

Ø 2 = h ousing for connecting rod bearings

Tighten to torque +

α

angular value

∅2

Furthermore, within each section, every heading or sub-heading concerning the operations to be carried out is preceded by a six

digit number. This number is the Product Code that is to be found in the repair operation described in the REPAIR TIMES CHARTS

and in the FAULT CODES.

For quick reference the indication of how to read this code is described below (see the Repair time charts also).

Product Code:

50

PRODUCT UNIT SUB-ASSEMBLY

COMPONENT

Example:

Product 50 = Frame;

Product 52 = Axles;

Product 53 = Gears etc.

Unit Code:

PRODUCT UNIT SUB-ASSEMBLY

01

COMPONENT

Figures three and four identify the ASSEMBLY within the PRODUCT

Example:

Product 50 = Frame;

Unit 01 = Chassis;

Unit 02 = Bumpers etc .

Sub-assembly Code:

PRODUCT UNIT SUB-ASSEMBLY

40

COMPONENT

Example:

Product 50 = Frame;

Unit 01 = Chassis;

Sub-assembly 40 = Chassis cross members etc.

Print 603.93.141 Base - January 2003

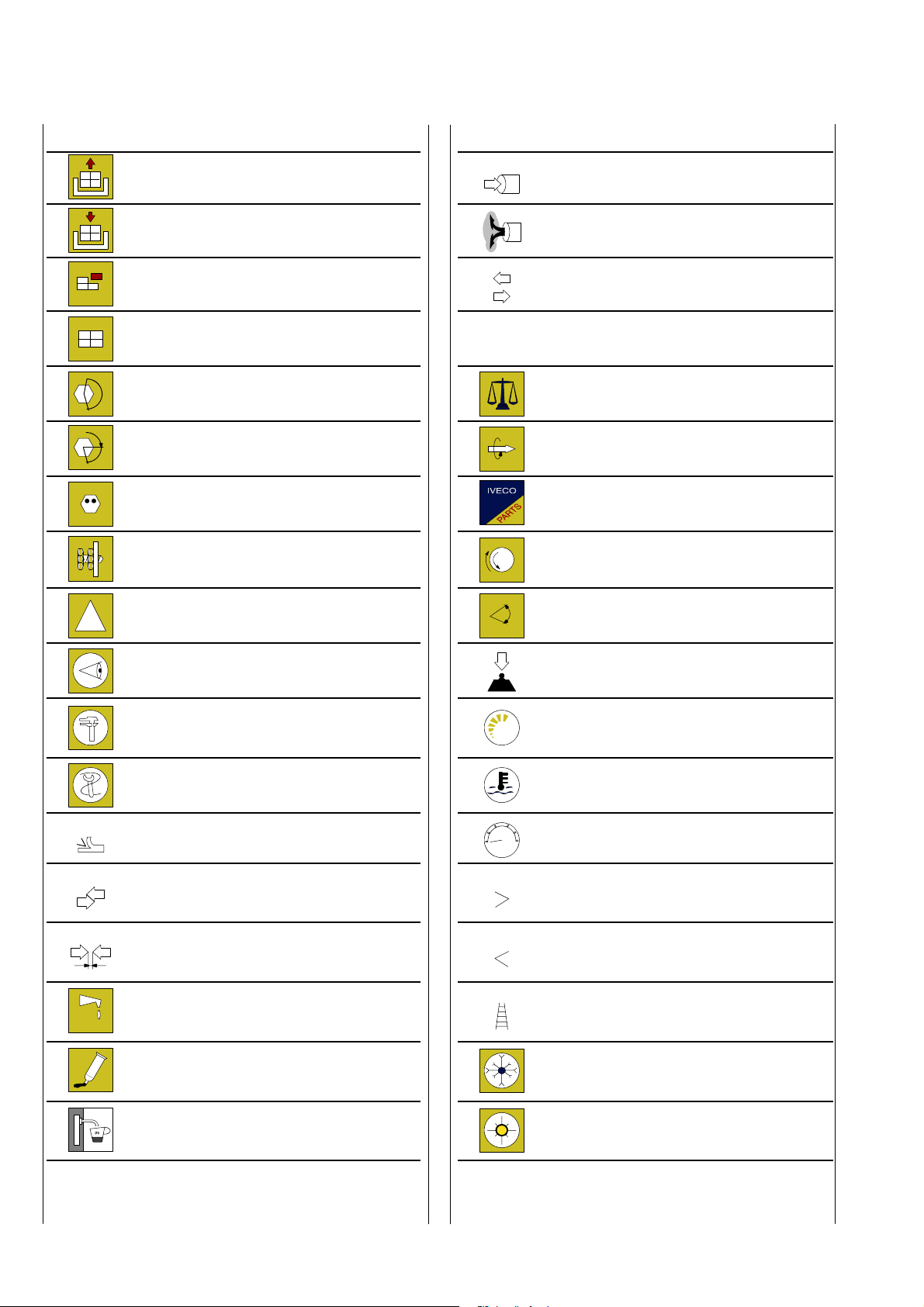

Graphs and symbols

Removal

Disconnection

Refitting

Connection

Removal

Disassembly

Fitting in place

Assembly

Tighten to torque

α

!

Tighten to torque + angle value Rolling torque

Press or caulk

Regulation

Adjustment

Warning

Note

ρ

Intake

Exhaust

Operation

Compression ratio

Tolerance

Weight difference

Replacement

Original spare parts

Rotation

Angle

Angular value

Visual inspection

Fitting position check

Measurement

Value to find

Check

Equipment Temperature

Surface for machining

Machine finish

Interference

Strained assembly

Thickness

Clearance

Lubrication

Damp

Grease

Sealant

Adhesive

Air bleeding

bar

Preload

Number of revolutions

Pressure

Oversized

Higher than….

Maximum, peak

Undersized

Less than….

Minimum

Selection

Classes

Oversizing

Temperature < 0°

Cold

Winter

Temperature > 0°

Hot

Summer

Base - January 2003 Print 603.93.141

Print603.43.671/A

STRALIS AT/AD

Print 603.93.141 — 1stedition

Base — January 2003

UPDATE DATA

Section Description Page Revision date

Print 603.93.141 Base - January 2003

Base - January 2003 Print 603.93.141

INDEX OF SECTIONS

Section

General information

Engine 2

Clutch 3

Gearbox 4

Hydraulic retarder 5

Propeller shafts 6

Rear axles 7

Front axle 8

1

Front and rear suspensions 9

Wheels and tyres 10

Steering system 11

Pneumatic system - brakes 12

Bodywork and chassis frame 13

Maintenance 14

Print 603.93.141 Base - January 2003

Base - January 2003 Print 603.93.141

SECTION 1

General

VEHICLE IDENTIFICATION DATA 3..........

- Vehicle identification plate 4................

- Production identification plate 4.............

COMPOSITION OF MODELS 5..............

P.I.C. NUMBER CODING 9..................

REPLENISHING FLUIDS 13...................

1STRALIS AT/AD GENERAL

Page

Print 603.93.141 Base - January 2003

2

GENERAL

STRALIS AT/AD

Base - January 2003 Print 603.93.141

Print603.43.671

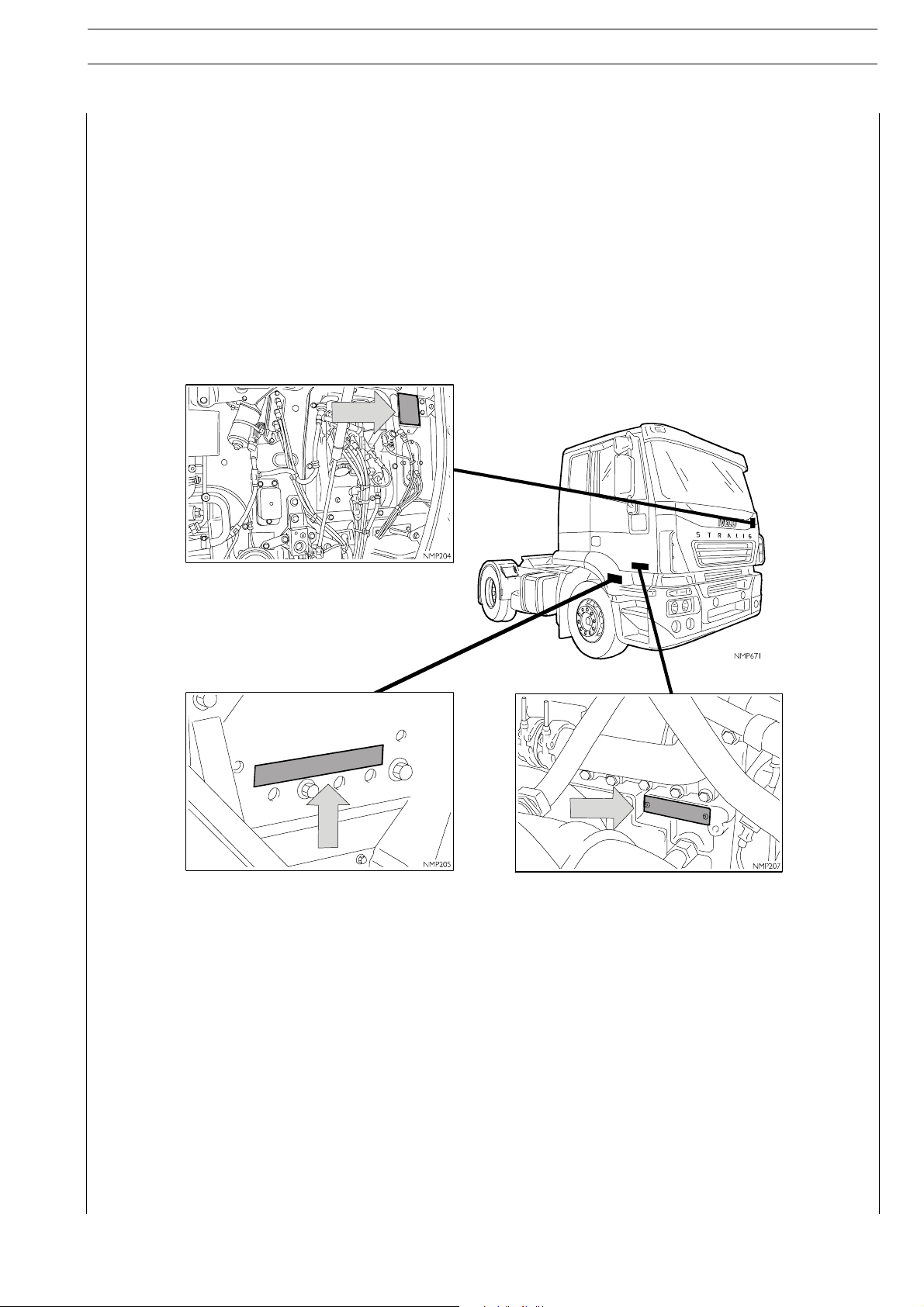

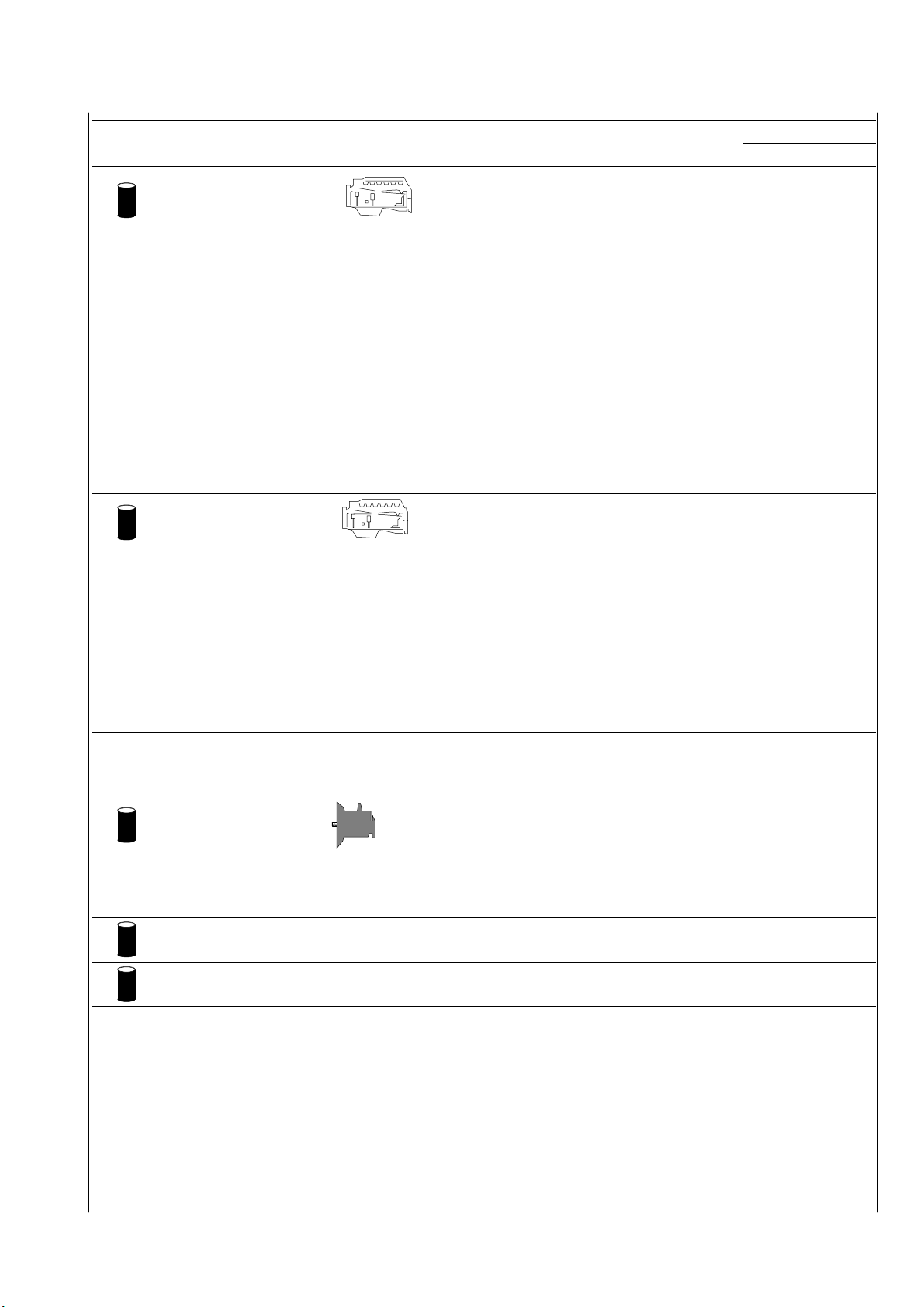

VEHICLE IDENTIFICATION DATA

The type and number of engine, type and

number of chassis and manufacturer’s plate

comprise the vehicle identification data.

3STRALIS AT/AD GENERAL

Manufacturer’s

plate

To identify the vehicle in accordance with the

E.E.C. directive

(under the front radiator cowling).

Chassis frame

Punching (front on right side member of

chassis frame).

Engine

Plate on the left rear side of the crankcase

Print 603.93.141 Base - January 2003

4

GENERAL

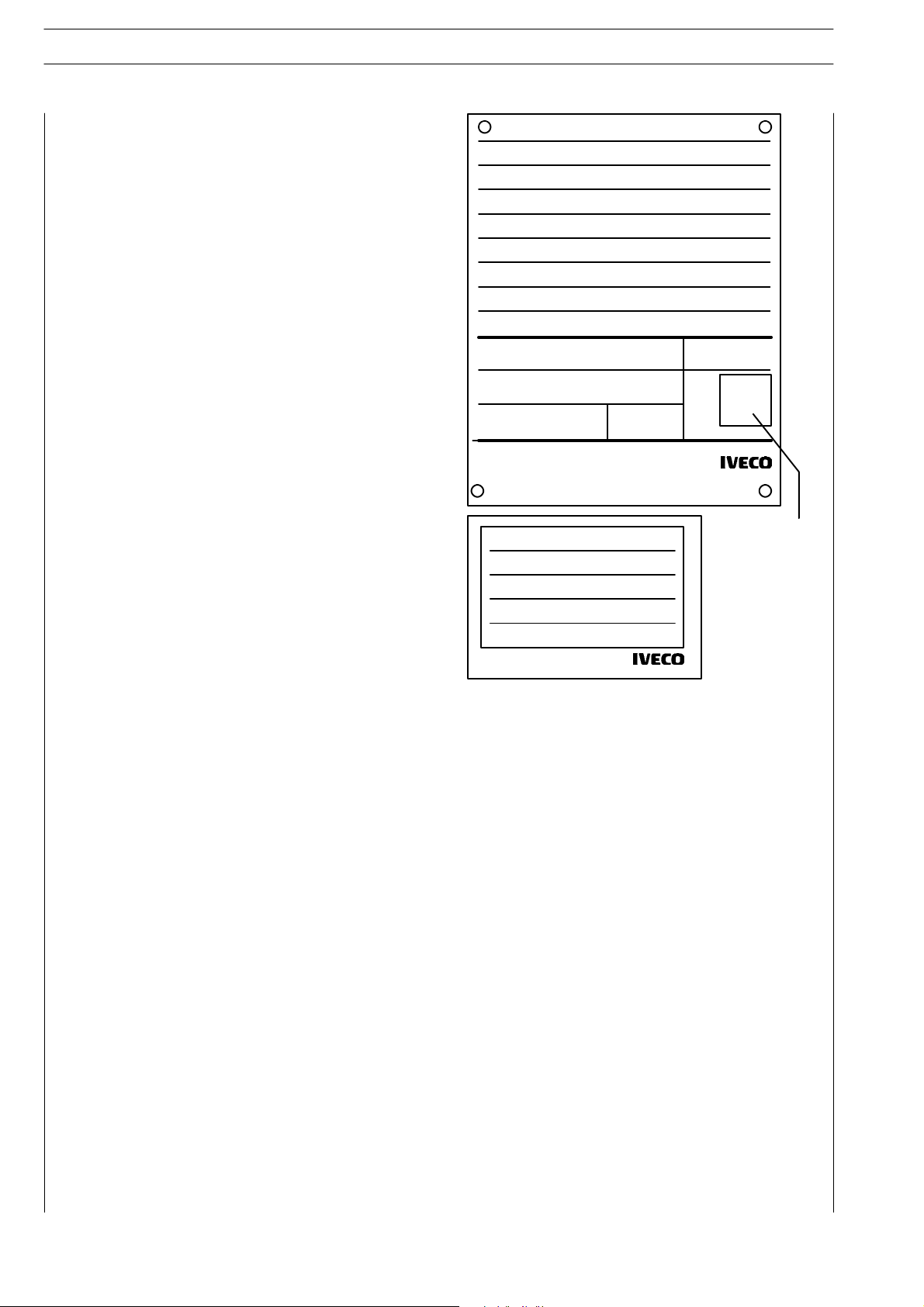

Vehicle Identification Plate

STRALIS AT/AD

Plate legend

a) Type-approval number marking (if applicable).

b) Vehicle identification code number (V.I.N.).

c) Total tractor weight.

d) Total weight of tractor + trailer (if applicable).

e) Permissible weight limit on 1st axle.

f) Permissible weight limit on 2nd axle (if applicable).

g) Permissible weight limit on 3rd axle.

h) Permissible weight limit on 4th axle (if applicable).

i) Specific identification of type.

l) Wheelbase in mm.

m) Engine type.

n) Engine power.

o) No. of axles.

p) Place of manufacture.

Production identification plate

This plate shows the P.I.C. (production identification code

number), which is needed when referring to the spare

parts catalogue (electronic and/or microfiche catalogue).

The P.I.C. is also given on the vehicle warranty card.

Note: When consulting the catalogues, use only the first

8 digits of the product identification code number.

a)

b)

c)

d)

e)

f)

g)

h)

i)

l)

m)

p)

IVECO MAGIRUS AG

1234-

Type

Wheelbase

Engine type

Made in

Unit No

Part No

Serial No

P.I.C. No

Made in Germany-Iveco Magirus AG

Engine power KW

n)

Noof axles

Corrected

absorption

value

Kg

Kg

Kg

Kg

Kg

Kg

o)

Permissible

grade of

smoke

9843 8247

Base - January 2003 Print 603.93.141

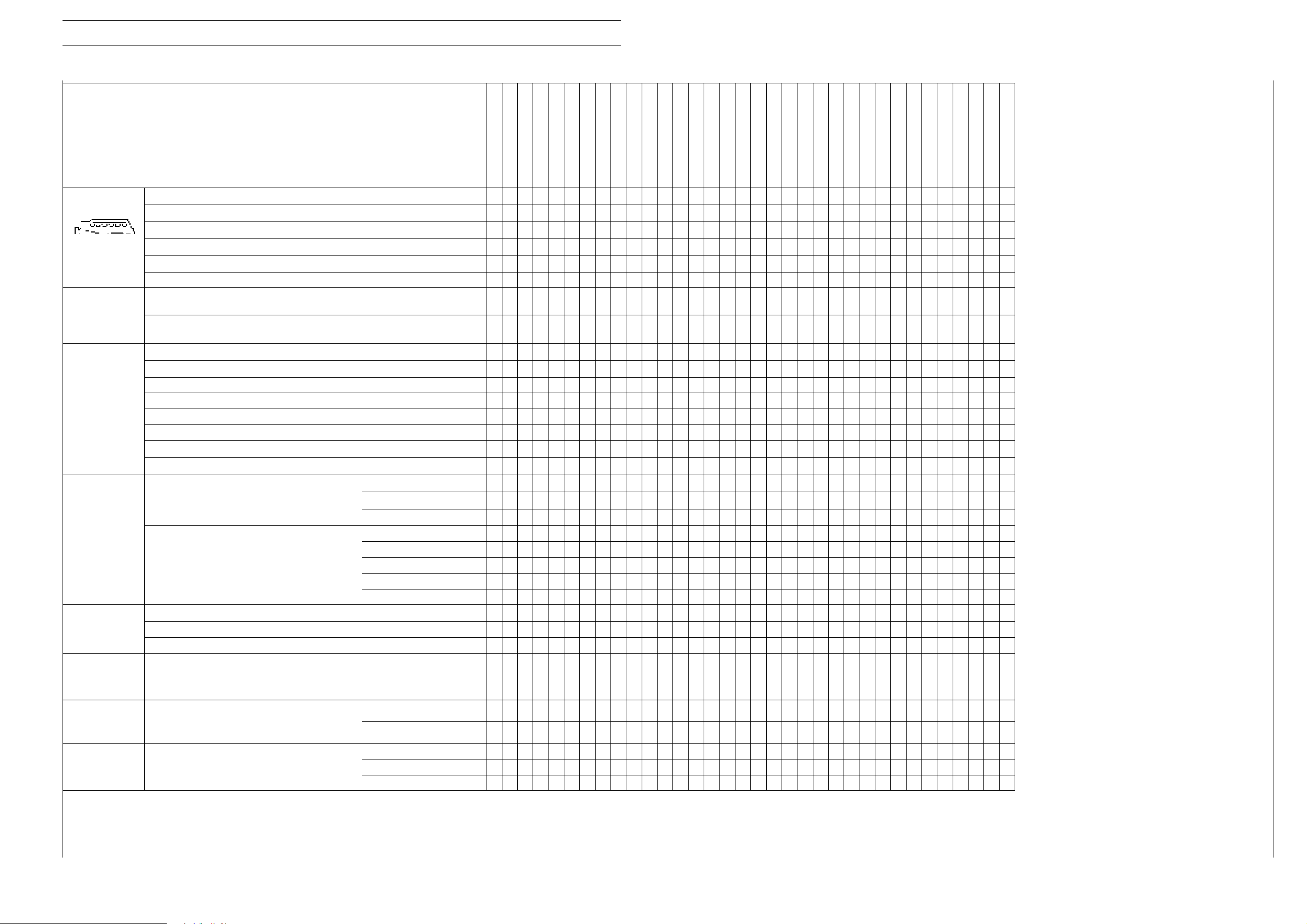

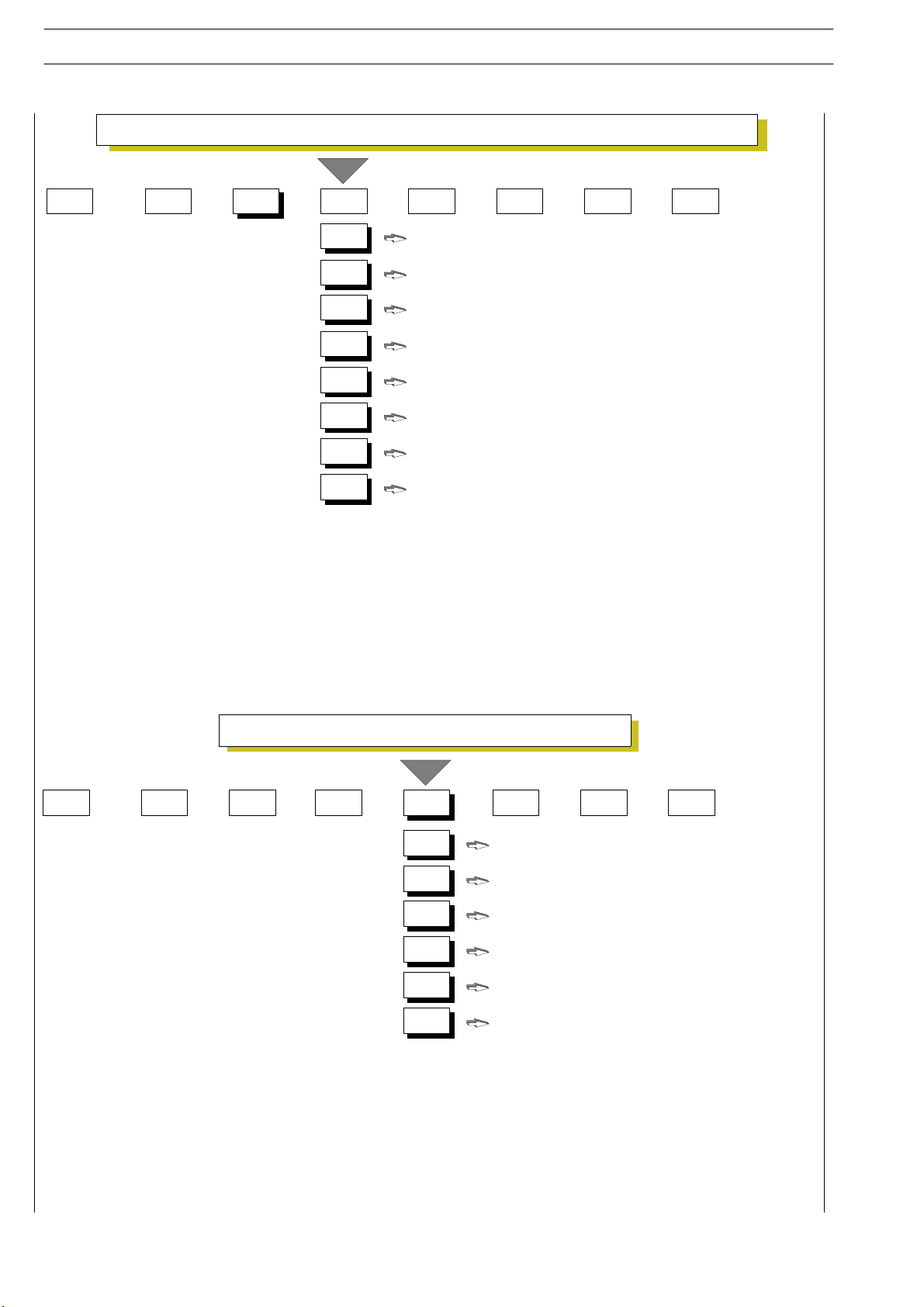

COMPOSITION OF MODELS

5STRALIS AT/AD GENERAL

ASSEMBLIES

CHASSIS CABS - 4x2 MODELS

AD 190 S 27

AT 190 S 27

AD 190 S 27/P

AT 190 S 27/P

AD 190 S 27/FP-D

AT 190 S 27/FP-D

AD 190 S 30

AD 190 S 30/P

AD 190 S 31

AT 190 S S31

AD 190 S 31/P

AT 190 S 31/P

AD 190 S 31/FP-D

AT 190 S 31/FP-D

AD 190 S 35

AT 190 S 35

AD 190 S 35/P

AT 190 S 35/P

AD 190 S 35/FP-D

AT 190 S 35/FP-D

AD 190 S 40

AT 190 S 40

AD 190 S 40/P

AT 190 S 40/P

AD 190 S 40/FP-D

AT 190 S 40/FP-D

AT 190 S 40/FP-CT

AD 190 S 43

AT 190 S 43

AD 190 S 43/P

AT 190 S 43/P

AD 190 S 43/FP-D

AT 190 S 43/FP-D

F2BE0681F (270 CV)

F2BE0681E (300 CV)

F2BE0681B (310 CV)

f f f

fff

f

f

f

f f f f f

F2BE0681A (350 CV) f f f f f f

F3AE0681B (400 CV) f f f f f f f

F3AE0681D (430 CV) f f f f f f f

Single disc 16” f f f f f f f f f f f f f f f f f f f f

Single disc 17” f f f f f f f f f f f f f f

ZF 9 S 109 D.D. f f f f f f f f f f f f

ZF 16 S 151 D.D. f f f f f f

ZF 16 S 181 O.D.

ZF 16 S 181 D.D. f f f f f f f f f f f f f f

ZF 16 S 221 O.D.

EuroTronic Automated 12 AS 2301 O.D.

EuroTronic Automated 12 AS 2301 D.D. f f f f f f f f f f f f f f f f f f f f f f

Allison MD 3060 P - MD 3066 P f f f f

FRONT AXLE: 5876/4 (F 8021)

5876/5 (F 8021) F F F F F F F F F F F F F F

⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗

⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗

F

F F F F F F F F F

5886/5 (F 9021) f f f f f f f f f f

ADDED AXLE:

Steering central 5876/4 (F 8021)

Rigid rear 55080/D1 (N 8071) *

Rigid rear 56082/D1 (N 9171) *

Steering rear 57080/D1 (N 8072) *

MERITOR MS 13-175/T - MS 13-175/D

f f f f f f f f f f f

f f f f f f f f f f f f f f f f f f f f f f f

MERITOR RT 160/1

451391 HR

ZF 8098

FRONT MECHANICAL Front

f f f f f f f f f f f

j

j j

j

j j

j

j j j j j j f j j j j j j j j

f f f f f f f f f f f f f f f f f f f f f f f

Rear j j j j j j j j j j j

T=4x2tractor

TX = 6x2 C tractor (central added axle cannot

be lifted)

TY = 6x2 P tractor (rear added axle can be

lifted)

AT 190 S 43/FP-CT

TN = 6x2 vehicles with mechanical rear

suspensions and raisable rigid rear added

axle

TZ = 6x4 tractor (bogie rear axle)

P = 4x2 — 6x2P — 6x2C vehicles with air

suspension on rear axle and 6x2P vehicles

with rigid rear axle that can be lifted with

single wheels

PT = 6x2P vehicles with air suspension on rear

axle and rigid rear added axle that can be

lifted with twin wheels

PS = 6x2P vehicles with air suspension on rear

axle and on steering rear added axle that

can be lifted with single wheels

FP = 4x2 — 6x4 — 6x2P — 6x2C vehicles with

front and rear air suspensions

FS = 6x2P vehicles with front and rear air

suspensions, steering rear added axle can

be lifted with single wheels

4x2 = Vehicles with two axles with rear driving

axle

6x2P = Vehicleswith three axles with rear driving

axle and rear added third axle that can be

lifted

6x2C = Vehicleswith three axles with rear driving

axle and central added third axle that

cannot be lifted

6x4 = Vehicles with three axles with two rear

driving axles (in tandem)

CM = Movable Boxes

LT = Tractor with lowered chassis frame

CT = Chassis cab with lowered chassis frame

RR = Rough Roads

D=Distribution

HR = Hub Reduction

AT = Active Time

AD = Active Day

PNEUMATIC Front

Rear

f f f f f f f f f f f f

f f f f f f f f f f f f f f f f f f f f f f f

Added axle

⊗ = With brake calliper assembly at 57° without parking brake j = With parabolic leaf springs

F = With brake calliper assembly at 0° with parking brake * = TI with drum brakes

Z = With longitudinal and transversal bars

Print 603.93.141 Base - January 2003

6

GENERAL

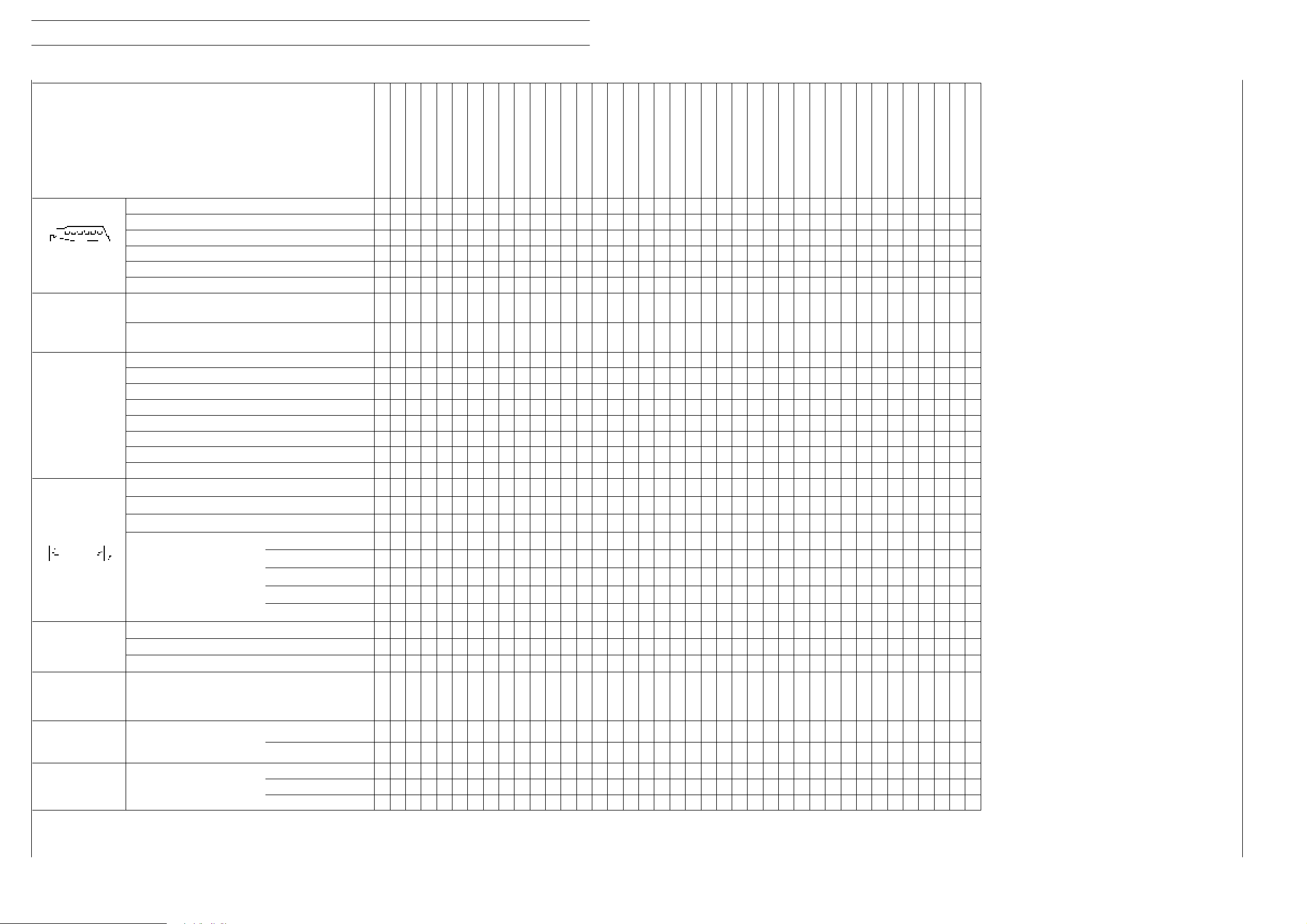

COMPOSITION OF MODELS

STRALIS AT/AD

ASSEMBLIES

CHASSIS CABS - 6x2 P MODELS

AD 260 S 27Y/P

AT 260 S 27Y/PS

AT 260 S 27Y/P

AD 260 S 27Y/PS

AD 260 S 27Y/FP-D

AT 260 S 27Y/FS-D

AT 260 S 27Y/FP-D

AD 260 S 27Y/FS-D

AT 260 S 30Y/FS-D

AD 260 S 31Y/P

AD 260 S 31Y/PS

AT 260 S 31Y/PS

AD 260 S 31Y/FP-D

AT 260 S 31Y/FP-D

AD 260 S 31Y/FS-D

AT 260 S 31Y/FS-D

AD 260 S 35Y/P

AD 260 S 30Y/PS

AT 260 S 30Y/PS

AT 260 S 31Y/P

AT 260 S 35Y/P

AD 260 S 35Y/FP-D

AD 260 S 35Y/PS

AT 260 S 35Y/PS

AT 260 S 35Y/FP-D

AD 260 S 35Y/FS-D

AT 260 S 35Y/FS-D

AD 260 S 27Y/PT

AT 260 S 27Y/PT

AD 260 S 27Y/TN

AT 260 S 31Y/PT

AT 260 S 27Y/TN

AD 260 S 31Y/PT

AD 260 S 31Y/TN

AT 260 S 31Y/TN

AD 260 S 35Y/PT

AT 260 S 35Y/PT

AD 260 S 35Y/TN

F2BE0681F (270 CV) f f f f f f f f f f f f

F2AE0681E (300 CV) f f f

F2BE0681B (310 CV) f f f f f f f f f f f f

F2BE0681A (350 CV) f f f f f f f f f f f f

F3AE0681B (400 CV)

F3AE0681D (430 CV)

Single disc 16” f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f

Single disc 17”

ZF 9S 109 D.D. f f f f f f f f f f f f f f f f f f f f f f f f f

ZF 16S 151 O.D. f f f f f f f f f f f f

ZF 16S 181 O.D.

ZF 16S 181 D.D.

ZF 16S 221 D.D.

EuroTronic Automated 12 AS 2301 D.D.

EuroTronic Automated 12 AS 2301 O.D. f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f

Allison MD 3060 P - MD 3066 P f f f f f f f f f f f

FRONT AXLE: 5876/4 (F 8021) ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗

5876/5 (F 8021) F F F F F F F F F F F F F F F F F F F F F F F F F F F F F F F

5886/5 (F 9021) f f f f f f f f

ADDED AXLE:

Steering central 5876/2 (F 8021)

Rigid rear 55080/D1 (N 8071) * f f f f f f f f f f f f

Rigid rear 56082/D1 (N 9171) * f f f f f f f f f f f f

Steering rear 57080/D1 (N 8072) * f f f f f f f f f f f f f f f

MERITOR MS 13-175/T - MS 13-175/D f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f

MERITOR RT 160/1

451391 HR

ZF 8098 f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f

T=4x2tractor

TX = 6x2 C tractor (central added axle cannot

be lifted)

TY = 6x2 P tractor (rear added axle can be lifted)

TN = 6x2 vehicles with mechanical rear

AT 260 S 35Y/TN

suspensions and raisable rigid rear added

axle

TZ = 6x4 tractor (bogie rear axle)

P = 4x2 — 6x2P — 6x2C vehicles with air

suspension on rear axle and 6x2P vehicles

with rigid rear axle that can be lifted with

single wheels

PT = 6x2P vehicles with air suspension on rear

axle and rigid rear added axle that can be

lifted with twin wheels

PS = 6x2P vehicles with air suspension on rear

axle and on steering rear added axle that

can be lifted with single wheels

FP = 4x2 — 6x4 — 6x2P — 6x2C vehicles with

front and rear air suspensions

FS = 6x2P vehicles with front and rear air

suspensions, steering rear added axle can

be lifted with single wheels

4x2 = Vehicles with two axles with rear driving

axle

6x2P = Vehicles with three axles with rear driving

axle and rear added third axle that can be

lifted

6x2C = Vehicles with three axles with rear driving

axle and central added third axle that

cannot be lifted

6x4 = Vehicles with three axles with two rear

driving axles (in tandem)

CM = Movable Boxes

HM = Heavy Mission

LT = Tractor with lowered chassis frame

CT = Chassis cab with lowered chassis frame

RR = Rough Roads

D=Distribution

AT = Active Time

AD = Active Day

FRONT MECHANICAL Front j j j j j j j j j j j j j j j j j j j j j j j j j j

Rear j j j j j j

PNEUMATIC Front f f f f f f f f f f f f f

Rear f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f

Added axle f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f f

⊗ = With brake calliper assembly at 57° without parking brake j = With parabolic leaf springs

F = With brake calliper assembly at 0° with parking brake * = TI with drum brakes

Z = With longitudinal and transversal bars

Base - January 2003 Print 603.93.141

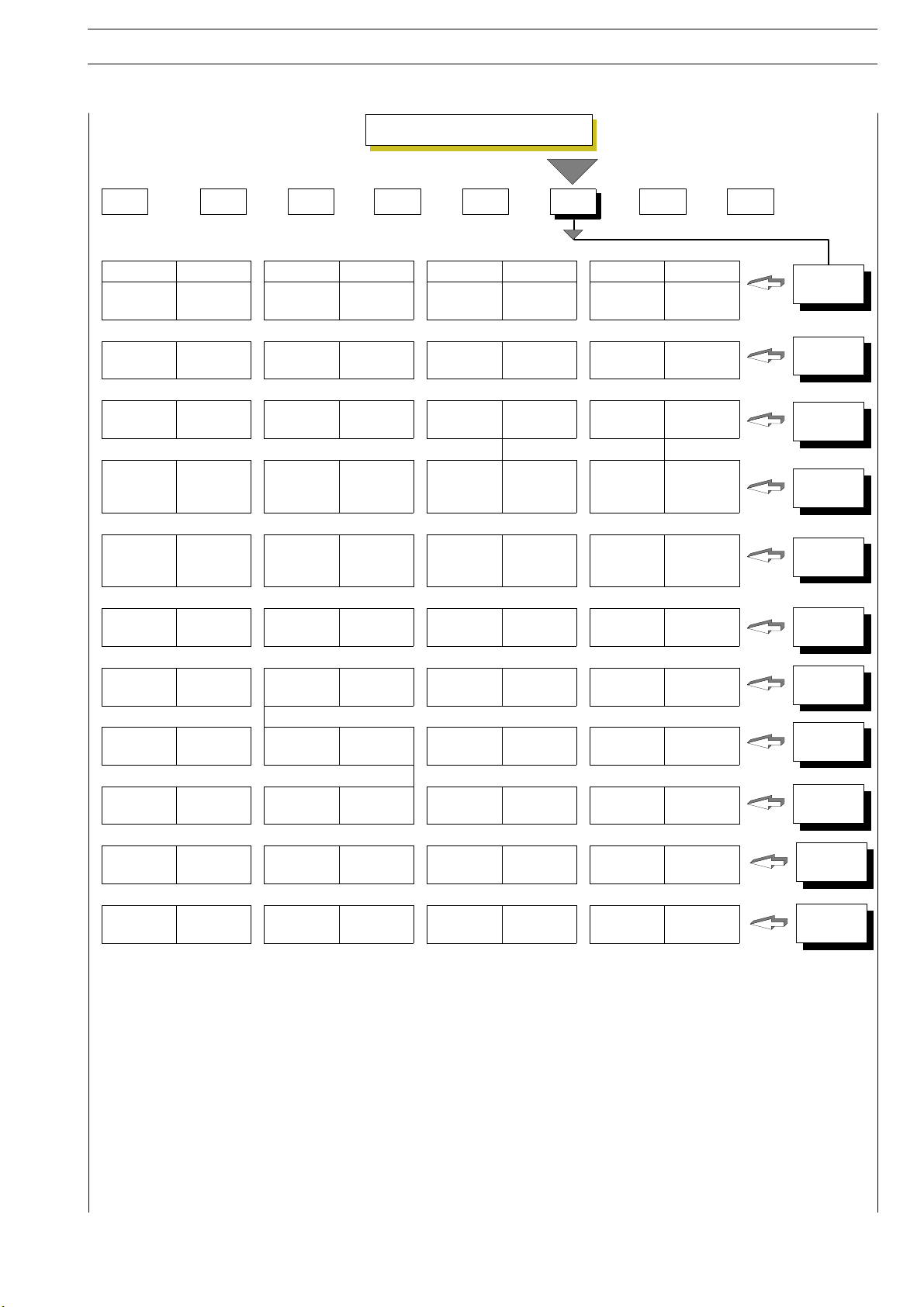

COMPOSITION OF MODELS

7STRALIS AT/AD GENERAL

ASSEMBLIES

CHASSIS CABS - 6x2 P MODELS

AD 260 S 40Y/P

AT 260 S 40Y/PS

AT 260 S 40Y/P

AD 260 S 40Y/PS

AD 260 S 40Y/FP-D

AT 260 S 40Y/FS-D

AT 260 S 40Y/FP-D

AD 260 S 40Y/FS-D

AD 260 S 40Y/FS-CM

AT 260 S 40Y/FS-CM

AD 260 S 43Y/P

AD 260 S 43Y/PS

AT 260 S 43Y/PS

AD 260 S 43Y/FP-D

AT 260 S 43Y/FP-D

AD 260 S 43Y/FS-D

AT 260 S 43Y/FS-D

AD 260 S 43Y/FS-CM

AT 260 S 43Y/P

AT 260 S 43Y/FS-CM

AD 260 S 40Y/TN

AD 260 S 40Y/PT

AT 260 S 40Y/PT

AT 260 S 40Y/TN

AD 260 S 43Y/PT

AT 260 S 43Y/PT

AD 260 S 43Y/TN

F2BE0681F (270 CV)

F2AE0681E (300 CV)

F2BE0681B (310 CV)

F2BE0681A (350 CV)

F3AE0681B (400 CV) f f f f f f f f f f f f f f

F3AE0681D (430 CV) f f f f f f f f f f f f f f

Single disc 16”

Single disc 17” f f f f f f f f f f f f f f f f f f f f f f f f f f f f

ZF 9S 109 D.D.

ZF 16S 151 O.D.

ZF 16S 181 O.D.

ZF 16S 181 D.D. f f f f f f f f f f f f f f f f f f f f f f f f f f f f

ZF 16S 221 D.D.

EuroTronic Automated 12 AS 2301 D.D.

EuroTronic Automated 12 AS 2301 O.D. f f f f f f f f f f f f f f f f f f f f f f f f

Allison MD 3060 P - MD 3066 P

FRONT AXLE: 5876/4 (F 8021) ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗

5876/5 (F 8021) F F F F F F F F F F F F F F F F F F F F F F

5886/5 (F 9021) f f f f f f

ADDED AXLE:

Steering central 5876/4 (F 8021)

Rigid rear 55080/D1 (N 8071) * f f f f f f

Rigid rear 56082/D1 (N 9171) * f f f f f f f f

Steering rear 57080/D1 (N 8072) * f f f f f f f f f f f f f f

MERITOR MS 13-175/T - MS 13-175/D f f f f f f f f f f f f f f f f f f f f f f

MERITOR RT 160/1

451391 HR

ZF 8098 f f f f f f f f f f f f f f f f f f f f f f f f f f f f

T=4x2tractor

TX = 6x2 C tractor (central added axle cannot

be lifted)

TY = 6x2 P tractor (rear added axle can be lifted)

TN = 6x2 vehicles with mechanical rear

AT 260 S 43Y/TN

suspensions and raisable rigid rear added

axle

TZ = 6x4 tractor (bogie rear axle)

P = 4x2 — 6x2P — 6x2C vehicles with air

suspension on rear axle and 6x2P vehicles

with rigid rear axle that can be lifted with

single wheels

PT = 6x2P vehicles with air suspension on rear

axle and rigid rear added axle that can be

lifted with twin wheels

PS = 6x2P vehicles with air suspension on rear

axle and on steering rear added axle that

can be lifted with single wheels

FP = 4x2 — 6x4 — 6x2P — 6x2C vehicles with

front and rear air suspensions

FS = 6x2P vehicles with front and rear air

suspensions, steering rear added axle can

be lifted with single wheels

4x2 = Vehicles with two axles with rear driving

axle

6x2P = Vehicles with three axles with rear driving

axle and rear added third axle that can be

lifted

6x2C = Vehicles with three axles with rear driving

axle and central added third axle that

cannot be lifted

6x4 = Vehicles with three axles with two rear

driving axles (in tandem)

CM = Movable Boxes

LT = Tractor with lowered chassis frame

CT = Chassis cab with lowered chassis frame

RR = Rough Roads

D=Distribution

HR = Hub Reduction

AT = Active Time

AD = Active Day

FRONT MECHANICA0L Front j j j j j j j j j j j j j j j j

Rear j j j j

PNEUMATIC Front j j j j Z Z j j j j Z Z

Rear f f f f f f f f f f f f f f f f f f f f f f f f

Added axle f f f f f f f f f f f f f f f f f f f f f f f f

⊗ = With brake calliper assembly at 57° without parking brake j = With parabolic leaf springs

F = With brake calliper assembly at 0° with parking brake * = TI with drum brakes

Z = With longitudinal and transversal bars

Print 603.93.141 Base - January 2003

8

TRACTORSMODEL

S

GENERAL

COMPOSITION OF MODELS

STRALIS AT/AD

ASSEMBLIES

TRACTORS - MODELS

AD 440 S 31T/P

AT 440 S 35T/P

AT 440 S 31T/P

AD 440 S 35T/P

AD 440 S 35T/P-HR

AT 440 S 35T/P-HR

AT 440 S 40T/P

AD 440 S 40T/P

4x2 6x2 C 6x4

AD 440 S 40T/P-HR

AD 440 S 40T/P-RR

AT 440 S 40T/P-RR

AT 440 S 40T/P-HR

AT 440 S 40T/FP-CT

AT 440 S 40T/FP-LT

AD 440 S 43T/P

AT 440 S 43T/P

AD 440 S 43T/P-RR

AT 440 S 43T/P-RR

AD 440 S 43T/P-HR

AT 440 S 43T/P-HR

AT 440 S 43T/FP-CT

AT 440 S 43T/FP-LT

AD 440 S 40TX/P

AT 440 S 40TX/P

AD 440 S 43TX/P

AT 440 S 43TXP

F2BE0681F (270 CV)

F2AE0681E (300 CV)

F2BE0681B (310 CV) f f

F2BE0681A (350 CV) f f f f

F3AE0681B (400 CV) f f f f f f f f f f

F3AE0681D (430 CV) f f f f f f f f f f f

Single disc 16”

Single disc 17” f f f f f f f f f f f f f f f f f f f f f f f f f f f

ZF 9S 109 D.D.

ZF 16S 151 O.D. f f f f f f

ZF 16S 181 O.D. f f f f f f f f

ZF 16S 181 D.D. f f f f f f f f f f f f

ZF 16S 221 D.D. f

EuroTronic Automated 12 AS 2301 D.D. f f f f

EuroTronic Automated 12 AS 2301 O.D. f f f f f f f f f f f f f f f f f f f f

Allison MD 3060 P - MD 3066 P

FRONT AXLE: 5876/4 (F 8021) ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗ ⊗

5876/5 (F 8021) F F F F F F F F F F F F F F F F F F F F F F F F F F F

5886/5 (F 9021)

ADDED AXLE:

Steering central 5876/4 (F 8021) f f f f

Rigid rear 55080/D1 (N 8071) *

Rigid rear 56082/D1 (N 9171) *

Steering rear 57080/D1 (N 8072) *

MERITOR MS 13-175/T - MS 13-175/D f f f f f f f f f f f f f f f f f f f f f f

MERITOR RT 160/1 f

451391 HR f f f f

ZF 8098 f f f f f f f f f f f f f f f f f f f f f f f f f f f

FRONT MECHANICAL Front j j j j j j j j j j j j j j j j j j j j j j j

Rear j

T=4x2tractor

TX = 6x2 C tractor (central added axle cannot

be lifted)

TY = 6x2 P tractor (rear added axle can be lifted)

TN = 6x2 vehicles with mechanical rear

suspensions and raisable rigid rear added

axle

AT 440 S 43TZ/P

TZ = 6x4 tractor (bogie rear axle)

P = 4x2 — 6x2P — 6x2C vehicles with air

suspension on rear axle and 6x2P vehicles

with rigid rear axle that can be lifted with

single wheels

PT = 6x2P vehicles with air suspension on rear

axle and rigid rear added axle that can be

lifted with twin wheels

PS = 6x2P vehicles with air suspension on rear

axle and on steering rear added axle that

can be lifted with single wheels

FP = 4x2 — 6x4 — 6x2P — 6x2C vehicles with

front and rear air suspensions

FS = 6x2P vehicles with front and rear air

suspensions, steering rear added axle can

be lifted with single wheels

4x2 = Vehicles with two axles with rear driving

axle

6x2P = Vehicles with three axles with rear driving

axle and rear added third axle that can be

lifted

6x2C = Vehicles with three axles with rear driving

axle and central added third axle that

cannot be lifted

6x4 = Vehicles with three axles with two rear

driving axles (in tandem)

CM = Movable Boxes

HM = Heavy Mission

LT = Tractor with lowered chassis frame

CT = Chassis cab with lowered chassis frame

RR = Rough Roads

D=Distribution

AT = Active Time

AD = Active Day

PNEUMATIC Front f f f f

Rear f f f f f f f f f f f f f f f f f f f f f f f f f f f

Added axle

⊗ = With brake calliper assembly at 57° without parking brake j = With parabolic leaf springs

F = With brake calliper assembly at 0° with parking brake * = TI with drum brakes

Z = With longitudinal and transversal bars

Base - January 2003 Print 603.93.141

P.I.C. NUMBER CODING

CAB LIVEABILITY

AAB CDBCA

9STRALIS AT/AD GENERAL

M

M

N

= Stralis AD (Active Day)

= Stralis AT (Active Time)

TO TAL WEI GH T O N G RO UN D - AXL ES CONFIGURATION

AAB CDBC

A

C

D

E

F

G

H

K

=4x2;18-20ton.

=4x2T;19-20ton.

=6x2C;26ton.

=6x2P;26ton.

=6x2P;26ton.

=4x2T;19-20ton.

J

=6x2C;26ton.

=6x4;26ton.

ENGINE

ABCDBCA

L

M

N

=4x2P;19-20ton.

=6x2P;26ton.

=6x2P;26ton.

A

H

L

K

P

Q

R

E 270

E 400

E 430

E 310

E 300

E 352

Print 603.93.141 Base - January 2003

10

GENERAL

SUSPENSION TYPE - REAR AXLE TYPE - TYPE OF ADDITIONAL AXLE

STRALIS AT/AD

ABCDBCA

A

A

B

C

E

E

F

G

H

* = Suspensions with 5886/D front axle

TWIN = Twin rear wheels

CENT = Middleaxle(6x2Cvehicles)

SING = Added axle with rear single wheels

STER = Added axle with rear steering single wheels

HR = Double reduction rear axle

SR = Simple reduction rear axle

Mechanical - SR - TWIN

Pneumatic - SR - CENT/SING/TWIN

-SR-CENT/SING

Pneumatic - HR (Tractor 4x2)

Pneumatic - HR - SR - STER (Chassis cab 6x2P)

-SR-STER

(*) - SR - SING

(*) - SR - STER

VERSION COMBINATION - USE

AA CDCA B

Cartran = Car transport

LOW T R = Lowered tractor

STD = Standard use

GRAV = Heavy duty use

B

1

2

H

M

N

T

= Chassis cab - STD

=Tractor-STD

=Tractor-GRAV

= Cartran - STD -Tractor

= Cartran - STD - Chassis cab

= LOW TR - STD

Base - January 2003 Print 603.93.141

WHEELBASE

CAA CDBA B

VERSION WHEELBASE VERSION WHEELBASE VERSION WHEELBASE VERSION WHEELBASE

T6x2C 3800 T4x2 3650 6x2P 3120 T6x4 2800

11STRALIS AT/AD GENERAL

1

T6x4 3200

6x2P

C4x2

C4x2 6300 6x2P 6050

3805

T4x2

C6x2C

C4x2

C6x2C

6x2P

C4x2

C6x2

6x2P

C4x2

6x2P

C4x2

6x2P

C4x2

6x2P

3800

4200

4500

4800

5100

5700

2

3

4

5

6

7

8

9

C4x2 5500

C4x2 6300

Print 603.93.141 Base - January 2003

L

M

12

Mechanical

L

L

LeftRight

GENERAL

GEARBOX - BRAKES COMBINATION

AA DBCA B C

STRALIS AT/AD

GEARBOX

Mechanical

A

ISON Disc Drum

EuroTronic 12 A S 2301 Disc Disc

EuroTronic 12 A S 2301 Disc Drum

NO YES

Disc Disc

Disc Drum

BRAKES

CAB - DRIVE - BRAKES COMBINATION

A

B

D

E

F

AABCA B C D

DRIVE

1

A

Base - January 2003 Print 603.93.141

REPLENISHING FLUIDS

t

y

g

UraniaLD5

A

1

13STRALIS AT/AD GENERAL

LUBRICANTS RECOMMENDED BY IVECO

Urania FE 5W30

Urania LD5

Urania Turbo LD

Urania FE 5W30

Urania LD5

Urania Turbo LD

Tutela Truck FE-Gear

Tutela ZC 90

* Quantity 1stfilling

(1)

(1)

1

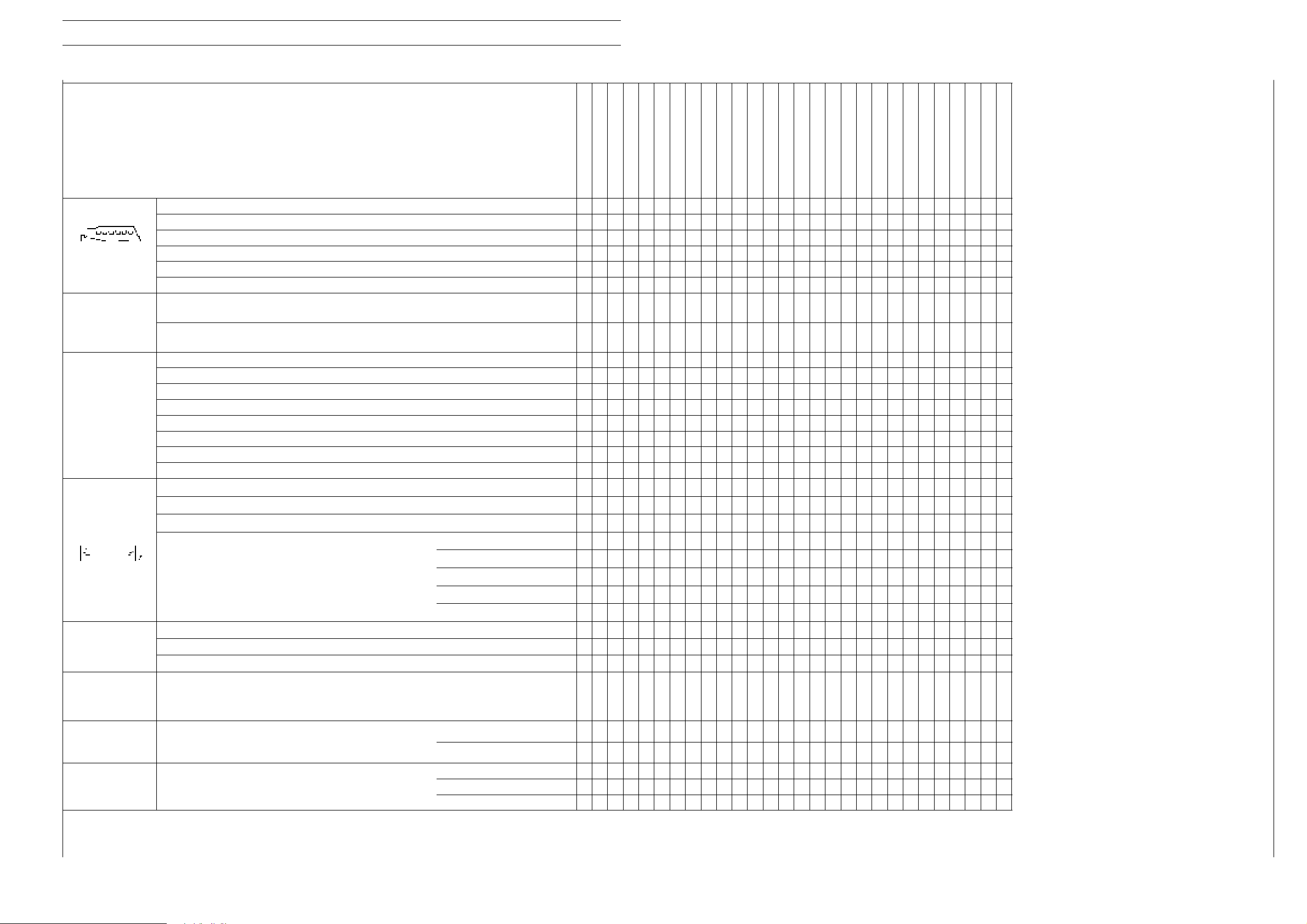

PARTS TO BE FILLED UP Quanti

Litres

Engine F2B

Total capacity for first filling

Capacity:

- engine sump min level

- engine sump max level

- quantity in circulation that

does not flow back to the engine sump

- quantity contained in the cartridge filter (which has to be

added to the cartridge filter refill)

Engine F3A

st

Total capacity 1

filling

Capacity:

- engine sump at minimum level

- engine sump at maximum level

- quantity in c irculation that does not return to sump

- quantity contained in cartridge filter (to

add when changing the cartridge filter)

Gearbox

ZF 9 S 109 *

ZF 16 S 151 *

ZF 16 S 151 + Intarder *

ZF 16 S 181 *

ZF 16 S 181 + Intarder*

ZF 16 S 221 *

ZF 16 S 221 + Intarder*

EuroTronic automated 12 AS 2301*

EuroTronic automated 12 AS 2301* + intarder

28 25,2

12.5

23

5

2.5

30 29.8

17

25

7

2.5

8

11

18.5

13

21.5

13

21.5

12

23

K

11,2

21

4.5

2.3

15.3

22.5

6.3

2.3

7.2

10

16.65

12

19.35

12

19.35

11

21

Tutela GI/

TutelaTruckFE-Gear

Tutela ZC 90

Allison MD 3060 P - MD 3066 P 18 16

Power take off (Multipower) 2.5

(1) IVECO recommends using these oils for reasons of fuel economy. IVECO provides new vehicles already with these types of

lubricants. Also suited for cold climates (minimum temperature down to -30ºC)

These quantities are not decisive. An exact check must be made by verifying the levels

Print 603.93.141 Base - January 2003

14

LUBRICANTSRECOMMENDEDBYIVEC

OPA

g

A

g

v

GENERAL

REPLENISHING FLUIDS

STRALIS AT/AD

Tutela Truck FE-Axle

Tutela W140/M-DA

Tutela W90/M-DA

Tutela Truck

FE-Axle

(2)

TutelaW140/M-D

Tutela W90/M-DA

Tutela GI/A

Tutela TRUCK

DOT SPECIAL

RTS FOR REPLENISHING

Front hubs (single)

FRONT AXLE 5876/4-/5 (F8021)

(2)

3

3

FRONT AXLE 5886/5

ADDED AXLE::

Steering central 5876/4 (F 8021)

Rigid rear 55080/D1 (N 8071)

Rigid rear 56082/D1 (N 9171)

Steering rear 57080/DI (N 8072)

Bridge Meritor MS 13-175/T - MS 13-175/D:

V (mechanical suspension)

V (pneumatic suspension)

Bridge 451391 HR

Rear axle Meritor in tandem RT 160E/1

- middle

-rear

Power steering

*Excludin

ehicleswith steeringrear axle

** For vehicles with steering rear axle only

Clutch circuit

(excluding vehicles with Euro Tronic gearbox)

Litres k

0.35

0.35

0.35

0.35

0.35

0.35

18.5

17

16

18.5

16.5

0.32

0.32

0.32

0.32

0.32

0.32

16.5

15.5

14.5

16.6

14.8

2.7*

13.5**

0.5 0.45

2.4

12

Quantity

Cooling system

µ23.4

µ27

µ39.6

µ57.6

Water+Paraflu

11

Engine F2B Total capacity*

Engine F2B with Intarder Total capacity*

Engine F3A Total capacity*

Engine F3A with Intarder Total capacity*

µ34

µ50

µ38

µ58

*=Protective anti -freeze

(concentration 50% freezing point —35°C)

Tutela LHM

Cab tilting system 0.6 0.54

(2) Only on axles with disc brakes, IVECO recommends using these oils for reasons of fuel economy. IVECO provides new vehicles

already with these types of lubricants. Also suited for cold climates (minimum temperature down to -30ºC)

(3) Specific for cold climates

These quantities are not decisive. An exact check must be made by verifying the levels

Base - January 2003 Print 603.93.141

International lubricant designation FL products

Engine oil

Meets the specifications:

ACEA E4 with a totally synthetic base SAE 50W 30

ACEA E5 with a mineral base SAE 15W 40

ACEA E3 with a mineral base SAE 15W 40

URANIA FE 5W30

Urania LD5

Urania Turbo LD

Oil for differential gear and wheel hubs

Meets the specifications:

API GL5, MT-1 with a totally synthetic base SAE 75W 90

API GL5 with a mineral base SAE 85W 140

API GL5 with a mineral base SAE 80W 90

Tutela Truck FE-Axle

Tutela W140/M-DA

Tutela W90/M-DA

Oil for mechanical gearboxes

Containing non-EP anti-wear additives

Meets the specifications:

API GL4 with a totally synthetic base SAE 75W 85

API GL3 with a mineral base SAE 80W 90

Tutela Truck FE-Gear

Tutela ZC90

Oil for power steering and hydrostatic transmissions

A.T.F. DEXRON II D

Grease for general greasing

based on lithium soaps, N.L.G.I. consistency no. 2

Specific grease for bearings and wheel hubs

based on lithium soaps, N.L.G.I. consistency no. 3

Tutela GI/A

Tutela MR 2

Tutela MR 3

Clutch drive fluid

Conforming to N.H.T.S.A. standards 116, ISO 4925, Std. SAEJ 1703,

Tutela TRUCK DOT SPECIAL

IVECO STANDARD 18-1820

Mineral oil for hydraulic circuits

In compliance with IVECO STANDARD 18-1823

Windscreen washer fluid, mixture of spirit, water and surfactants

CUNA NC 956-11

Tutela LHM

Tutela PROFESSIONAL SC 35

Grease for central lubrication systems based on lithium soaps,

with synthetic base, N.L.G.I. no. 2.

Tutela COMAR 2

Working temperatures: from —30°C to +140°C

Concentrated protective fluid for radiators

based on ethylene glycol containing corrosion inhibitors, conforming to the

Paraflu

11

standard: IVECO-STANDARD 18-1830

15STRALIS AT/AD GENERAL

Print 603.93.141 Base - January 2003

16

Print603.43.671

GENERAL

STRALIS AT/AD

Base - January 2003 Print 603.93.141

STRALIS AT/AD

ENGINE 1

SECTION 2

Engine

Page

- F2B Engine 3............................

- F3A Engine 113...........................

- Hidrocar pressure take-off on timing system

(P.T.O. - Optional) 223.....................

Print 603.93.141 Base - January 2003

2

ENGINE

TRALIS AT/AD

S

Base - January 2003 Print 603.93.141

STRALIS AT/AD

ENGINE F2B 3

Print603.43.671

F2B Engine

Page

VIEWS OF THE ENGINE 8..................

GENERAL CHARACTERISTICS 13.............

ASSEMBLY CLEARANCE DATA 16............

TIGHTENING TORQUES 22.................

TOOLS 28................................

DISMANTLING THE ENGINE ON THE BENCH 40

REPAIR OPERATIONS 47....................

CYLINDER BLOCK 47.......................

- Checks and measurements 47...............

CYLINDER LINERS 48.......................

- Fitting and checking protrusion 49............

- Removal 49.............................

- Replacing cylinder liners 49..................

CRANKSHAFT 50..........................

- Measuring main journals and crank pins 51......

PRELIMINARY MEASUREMENT OF MAIN AND BIG

END BEARING SHELL SELECTION DATA 52..

- Replacing the timing control gear and

the oi l pump 59..........................

- Checking main journal installation clearance 59...

- Checking crankshaft end float 60.............

PISTON-CONNECTING ROD ASSEMBLY 61....

- Removal 61.............................

- Measuring the diameter of the pistons 62.......

- Conditions for correct gudgeon pin-piston

coupling 62..............................

- Piston rings 63...........................

CONNECTING ROD 64.....................

- Checking connecting rod alignment 65.........

Print 603.93.141 Base - January 2003

4

ENGINE F2B

TRALIS AT/AD

S

- Mounting the connecting rod-piston assembly 65.

- Mounting the piston rings 65.................

- Fitting the connecting rod-piston assembly into

the piston liners 66........................

- Piston protrusion check 66..................

- Checking assembly clearance of big end pins 67..

CYLINDER HEAD 67........................

- Valve removal 67..........................

- Checking the planarity of the head on

the cylinder block 67.......................

VALVE 67.................................

- Removing deposits and checking the valves 67...

VALVE GUIDES 68..........................

- Replacing of valve guides 69.................

Page

Page

- Fitting the connecting rod-piston assembly into

the cylinder liners 80.......................

ENGINE FLYWHEEL 83......................

- Fitting engine flywheel 83...................

- Fitting camshaft 84.........................

- Fitting pump-injectors 85....................

- Fitting rocker-arm shaft assembly 85...........

- Camshaft timing 86........................

- Phonic wheel timing 88.....................

- Intake and exhaust rocker play adjustment and

pre-loading of rockers controlling pump injectors. 89

ENGINE COMPLETION 90..................

LUBRICATION 93..........................

- Replacing - Reaming the valve seats 69.........

REPLACING INJECTOR HOLDER CASES 69.....

- Removal 69..............................

- Checking protrusion of injectors 71............

TIMING GEAR 72...........................

- Checking cam lift and pin alignment 72.........

- Camshaft 73.............................

- Bushes 73...............................

- Replacing camshaft bushes using

beater 99360487 74.......................

- Removal 74..............................

- Assembly 74.............................

VALVE SPRINGS 75.........................

- Fitting the valves and oil seal ring 75...........

- Oil pump 95.............................

- Overpressure valve 95.....................

- Oil pressure control valve 96................

- Heat exchanger 96........................

- By-pass valve 97..........................

- Thermostatic valve 97......................

- Engine oil filters 97........................

COOLING 99..............................

- Description 99............................

- Operation 99............................

- Water pump 101..........................

- Thermostat 101...........................

- Electromagnetic coupling 101.................

ROCKER SHAFT 76.........................

- Rocker 76...............................

- Shaft 76.................................

TURBOCHARGER 102.......................

TURBOCHARGING 102......................

TURBO COMPRESSOR HOLSET HX 40V 104.....

ASSEMBLING THE ENGINE ON THE BENCH 77.

- Actuator 107..............................

DIAGRAM SHOWING THE UNDERBLOCK FIXING

SCREWS TIGHTENING ORDER 79..........

Base - January 2003 Print 603.93.141

- Solenoid valve for VGT control 107............

STRALIS AT/AD

FUEL FEED 108.............................

- Replacing injectors-pump 109.................

- Injector-pump 109..........................

- Fuel pump 109............................

- Injector Phases 110.........................

ENGINE F2B 5

Page

Print 603.93.141 Base - January 2003

Loading...

Loading...