Page 1

Intel740™ Graphics Accelerator

Design Guide

August 1998

Order Number: 290619-003

Page 2

Information in this document is provided in connection with Intel products. No license, express or implied, by estoppel or otherwise, to any intellectual

property rights is granted by this document. Except as provided in Intel's Terms and Conditions of Sale for such products, Intel assumes no liability

whatsoever, and Intel disclaims any express or implied warranty, relating to sale and/or use of Intel products including liability or warranties relating to

fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property right. Intel products are not

intended for use in medical, life saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

The Intel740™ graphics accelerator may contain design defects or errors known as errata which may cause the products to deviate from published

specifications.

2

I

C is a two-wire communications bus/protocol developed by Philips. SMBus is a subset of the I2C bus/protocol and was developed by Intel.

Implementations of the I

North American Philips Corporation.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by:

Copyright © Intel Corporation, 1998

*Third-party brands and names are the property of their respective owners.

Such errata are not covered by Intel’s warranty.

2

C bus/protocol or the SMBus bus/protocol may require licenses from various entities, including Philips Electronics N.V. and

calling 1-800-548-4725 or

by visiting Intel's website at http://www.intel.com.

Current characterized errata are available upon request.

Intel740™ Graphics Accelerator Design Guide

Page 3

Contents

1 Introduction................................................................................................................1-1

1.1 About This Design Guide..............................................................................1-1

1.2 References....................................................................................................1-2

2 Addin Card Design.....................................................................................................2-1

2.1 Introduction ...................................................................................................2-1

2.1.1 Design Features...............................................................................2-2

2.1.1.1 Intel740™ Graphics Accelerator.....................................2-2

2.1.2 BT829B - Video Decoder .................................................................2-3

2.1.2.1 BT869 - TV Encoder.......................................................2-3

2.1.3 Terminology .....................................................................................2-3

2.1.3.1 Power Sources ...............................................................2-3

2.1.3.2 Fences............................................................................2-4

2.1.3.3 Stitching..........................................................................2-4

2.2 Layout and Routing Guidelines.....................................................................2-5

2.2.1 Placement........................................................................................2-5

2.2.2 Board Description ............................................................................2-6

2.2.3 BGA Component..............................................................................2-8

2.2.3.1 Layout Requirements......................................................2-8

2.2.3.2 Ground Connections.......................................................2-9

2.2.3.3 Power Connections.........................................................2-9

2.2.3.4 Decoupling....................................................................2-10

2.2.3.5 General Signal Routing.................................................2-11

2.2.4 Voltage Regulator ..........................................................................2-11

2.2.5 Bt829 Video Decoder.....................................................................2-11

2.2.5.1 Ground Planes..............................................................2-12

2.2.5.2 Power Planes................................................................2-12

2.2.5.3 Passive Components and Signal Routing ....................2-12

2.2.6 Bt869 Video Encoder.....................................................................2-12

2.2.6.1 Ground Planes..............................................................2-12

2.2.6.2 Power Planes................................................................2-13

2.2.6.3 Passive Components and Signal Routing ....................2-13

2.2.6.4 AGP Layout and Routing Guidelines............................2-13

2.2.6.5 Intel740™ Graphics Accelerator Memory

Layout and Routing Guidelines.....................................2-14

2.2.6.6 Intel740™ Graphics Accelerator Memory

Configurations...............................................................2-17

2.2.6.7 TV Out Interface ...........................................................2-20

2.2.6.8 Analog Signals....................................................... .......2-20

2.2.7 UL and FCC Considerations..........................................................2-20

2.3 Addin Card Schematics ..............................................................................2-21

Intel740™ Graphics Accelerator Design Guide

iii

Page 4

3 3 Device AGP MotherBoard Design ....................... ....... ...... ...... ....... ...... ....... ............3-1

3.1 Introduction......... ....... ...... ....... ...... ....... ...... ....... ...... ...... ....... .........................3-1

3.1.1 Overview....................................... ....... ...... ...... ....... ...... ....... ...... ......3-1

3.1.2 About This Chapter..........................................................................3-2

3.1.3 Block Diagram .................................................................................3-2

3.1.4 Implementation Issues.....................................................................3-3

3.1.4.1 Disabling A Master Device .............................................3-3

3.1.4.2 Low Power Logic Implementation...................................3-4

3.1.4.3 GPO27# and GPO28# Signal Duration..........................3-5

3.1.5 State Diagrams................................................................................3-5

3.1.5.1 Signal Quality and Timing Issues ...................................3-6

3.1.5.2 Strobe Edge Quality Issues............................................3-7

3.1.5.3 Clock Issues ...................................................................3-7

3.1.6 Design Recommendations...............................................................3-9

3.1.6.1 Voltage Definitions..........................................................3-9

3.1.6.2 General Design Recommendation .................................3-9

3.2 3 Device AGP Motherboard Layout and Routing Guidelines........................3-9

3.2.1 BGA Quadrant Assignment ...........................................................3-10

3.2.2 Board Description ..........................................................................3-12

3.2.3 3-point AGP Design Guidelines.....................................................3-12

3.2.3.1 Layout and Routing ............................................ ...... ....3-12

3.2.3.2 Data and strobe definitions...........................................3-13

3.2.3.3 Assumptions for Board Design Guidelines...................3-14

3.2.3.4 Add-in Card guideline assumptions:.............................3-14

3.2.3.5 Motherboard Guideline Assumptions ...........................3-14

3.2.3.6 3-Load AGP Topology..................................................3-16

3.2.3.7 Overall Solution Space.................................................3-16

3.2.4 Intel740™ Graphics Accelerator Memory Layout and

Routing Guidelines ....................... ....... ...... ....................................3 -18

3.2.4.1 3 Device AGP Intel740™ Graphics Accelerator

Memory Configurations ................................................3-21

3.3 3 Device AGP Motherboard Reference Design Schematics ......................3-22

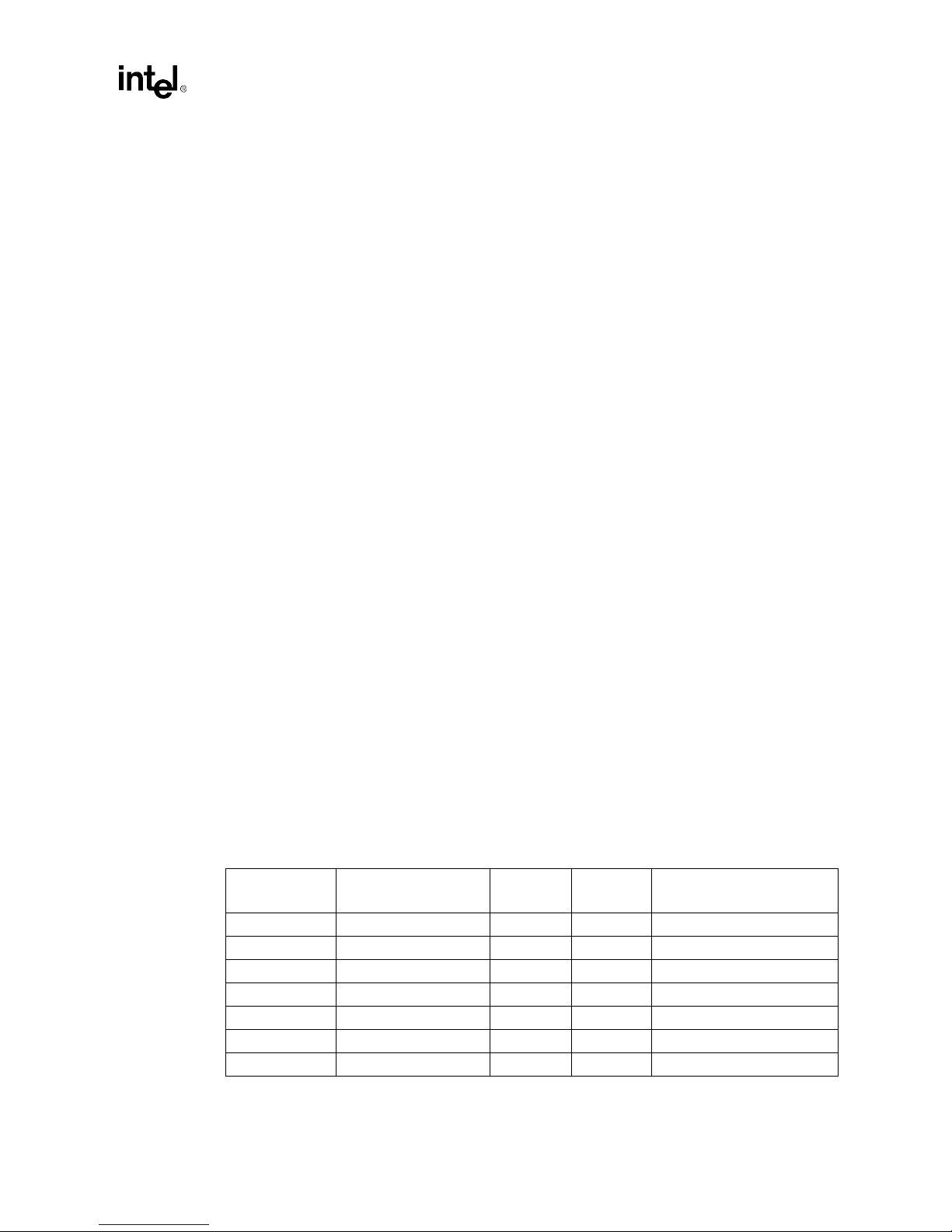

4 Thermal Considerations.............................................................................................4-1

5 Mechanical Information..............................................................................................5-1

5.1 Board Dimensions ........................................................................................5-1

5.2 Fan/Heatsink Hole Pattern............................................................................5-1

5.3 VMI Header Placement.............................. ....... ...... ...... ....... ...... ....... ...... ......5-2

5.4 50 Pin Video Connector................................................................................5-3

5.5 Bracket..........................................................................................................5-4

5.6 NLX Considerations................................... ....... ...... ...... ....... ...... ...................5-5

6 Third Party Vendors...................................................................................................6-1

6.1 Voltage Regulator.........................................................................................6-1

6.2 50 Pin Connector..........................................................................................6-1

6.3 Fan/Heatsink.................................................................................................6-1

6.4 Flash Components........................................................................................6-1

6.5 Video Encoders/Decode rs ...................................... ...... ....... .........................6-1

6.6 DVD Daughter Cards....................................................................................6-2

6.7 TV Tuner.......................................................................................................6-2

A Application Notes

B Reference Information

iv

Intel740™ Graphics Accelerator Design Guide

Page 5

Figures

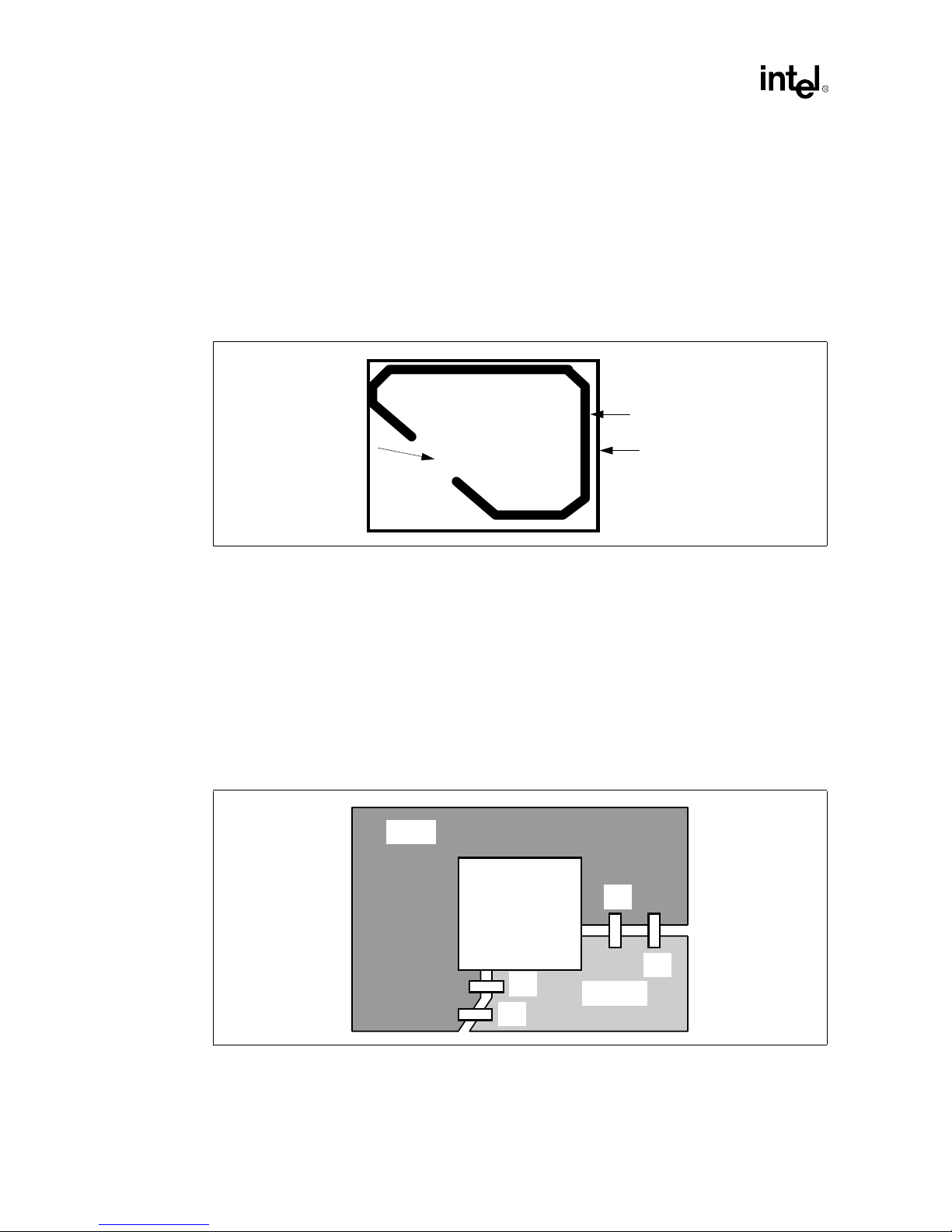

2-1 Example of Power Plane Separation ("fencing")...........................................2-4

2-2 Example of Power Plane Stitching................................................................2-4

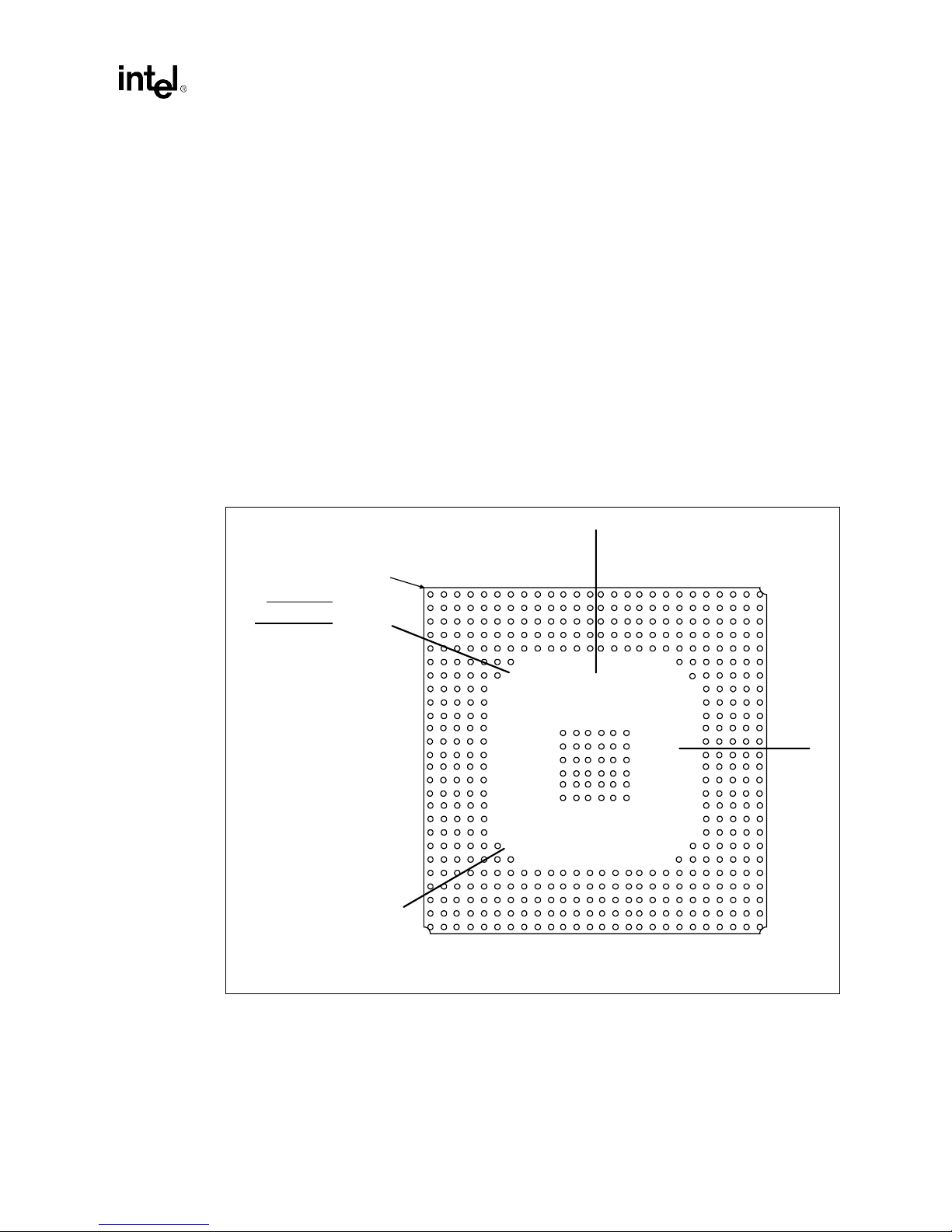

2-3 Major Signal Sections...................................................................................2-5

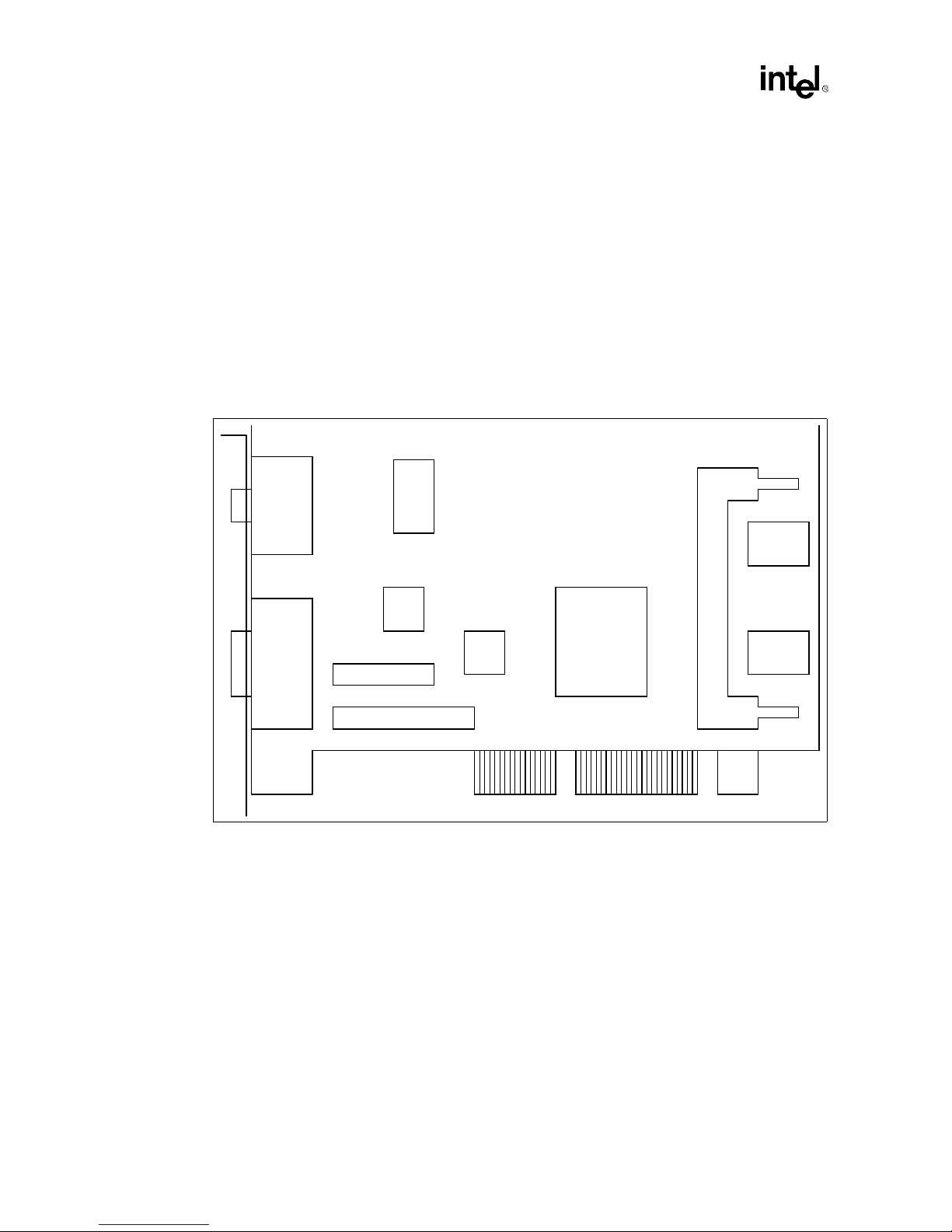

2-4 Example ATX Layout....................................................................................2-6

2-5 Four Layer Board Stack-up...........................................................................2-7

2-6 Metal Defined land dimensions.....................................................................2-8

2-7 BGA Trace....................................................................................................2-8

2-8 Dogbone Via Pattern.....................................................................................2-9

2-9 Suggested VCC Planes for the Intel740™ Graphics Accelerator...............2-10

2-10 Intel740™ Graphics Accelerator Decoupling..............................................2-10

2-11 Intel740™ Graphics Accelerator BGA Routing Example............................2-11

2-12 Layout Dimensions (MA[11:0])....................................................................2-15

2-13 Layout Dimensions (MD[63:0], DQM[7:0])..................................................2-15

2-14 Layout Dimensions (WEA#, SRASA#, SCASA#, CSA1#, CSB0#).............2-15

2-15 Layout Dimensions (WEB#, SRASB#, SCASB#, CSA0#)..........................2-16

2-16 Memory Layout Dimensions (TCLK0).........................................................2-16

2-17 Memory Layout Dimensions (TCLK1).........................................................2-16

2-18 Memory Layout Dimensions (RCLK and OCLK to RCLK)..........................2-17

2-19 2/4 MB Local Memory Connection (64-bit data path) .................................2-17

2-20 4/8 MB Local Memory Connection (64-bit data path) .................................2-18

2-21 8 MB Local Memory Connection (64-bit data path) ....................................2-19

2-22 Layout Dimensions, Digital TV Bus.............................................................2-20

2-23 512Kx32 and 256Kx32 Pinout Compatibility...............................................2-24

2-24 1M X 16 Pinout Compatibility.....................................................................2-24

3-1 Pentium

®

II Processor / Intel® 440BX AGPset/Intel 740 Graphics

Accelerator System Block Diagram ..............................................................3-3

3-2 The Schematic Diagram for GPO27#, PCIRST# (System Reset),

RESET#, ROMA16 Signals ..........................................................................3-4

3-3 The Schematic Diagram for the WEB#, SCASB#, SRASB#,

CS0B#, CS1B# and TEST............................................................................3-5

3-4 Intel740™ Graphics Controller (On Board Device) Remains in

Low Power Mode ..........................................................................................3-6

3-5 Intel740™ Graphics Controller (On Board Device) State Diagram...............3-6

3-6 Point-to-Point Topology ................................................................................3-8

3-7 Major Signal Sections.................................................................................3-10

3-8 Example ATX Placement for a UP Pentium

®

Intel

440BX AGPset / Intel 740 Graphics Accelerator Design ..................3-11

®

II Processor /

3-9 Four Layer Board Stack-up.........................................................................3-12

3-10 Point-to-Point Topology ..............................................................................3-15

3-11 3 Device Data Load Topology.....................................................................3-16

3-12 3 Device Strobe Load Topology..................................................................3-16

3-13 3 Device Data Load Topology (Solution 1 is Shown)..................................3-17

3-14 3 Device Strobe Load Topology (Solution 1 is shown) ...............................3-17

3-15 Clock Topology and Matching.....................................................................3-17

3-16 Layout Dimensions (MA[11:0])....................................................................3-19

3-17 Layout Dimensions (MD[63:0], DQM[7:0])..................................................3-19

3-18 Layout Dimensions (WEA#, SRASA#, SCASA#, CSA0#)..........................3-20

3-19 Memory Layout Dimensions (TCLK1).........................................................3-20

3-20 Memory Layout Dimensions (RCLK and OCLK to RCLK)..........................3-21

Intel740™ Graphics Accelerator Design Guide

v

Page 6

3-21 2/4 MB Local Memory Connection (64-bit data path) .................................3-21

3-22 512Kx32 and 256Kx32 Pinout Compatibility...............................................3-26

3-23 1M X 16 Pinout Compatibility.....................................................................3-26

5-1 Mounting Hole Locations (Fan/Heatsink Assembly).....................................5-1

5-2 VMI Header Placement........................ ...... ....... ...................................... ......5-2

5-3 DVD Daughter Card Dimensions (ATX and NLX)—Top Side ......................5-2

5-4 50 Pin Video Connector Schematic..............................................................5-3

5-5 Recommended Bracket Placement ..............................................................5-4

5-6 Recommended Bracket Cutout.....................................................................5-4

vi

Intel740™ Graphics Accelerator Design Guide

Page 7

Tables

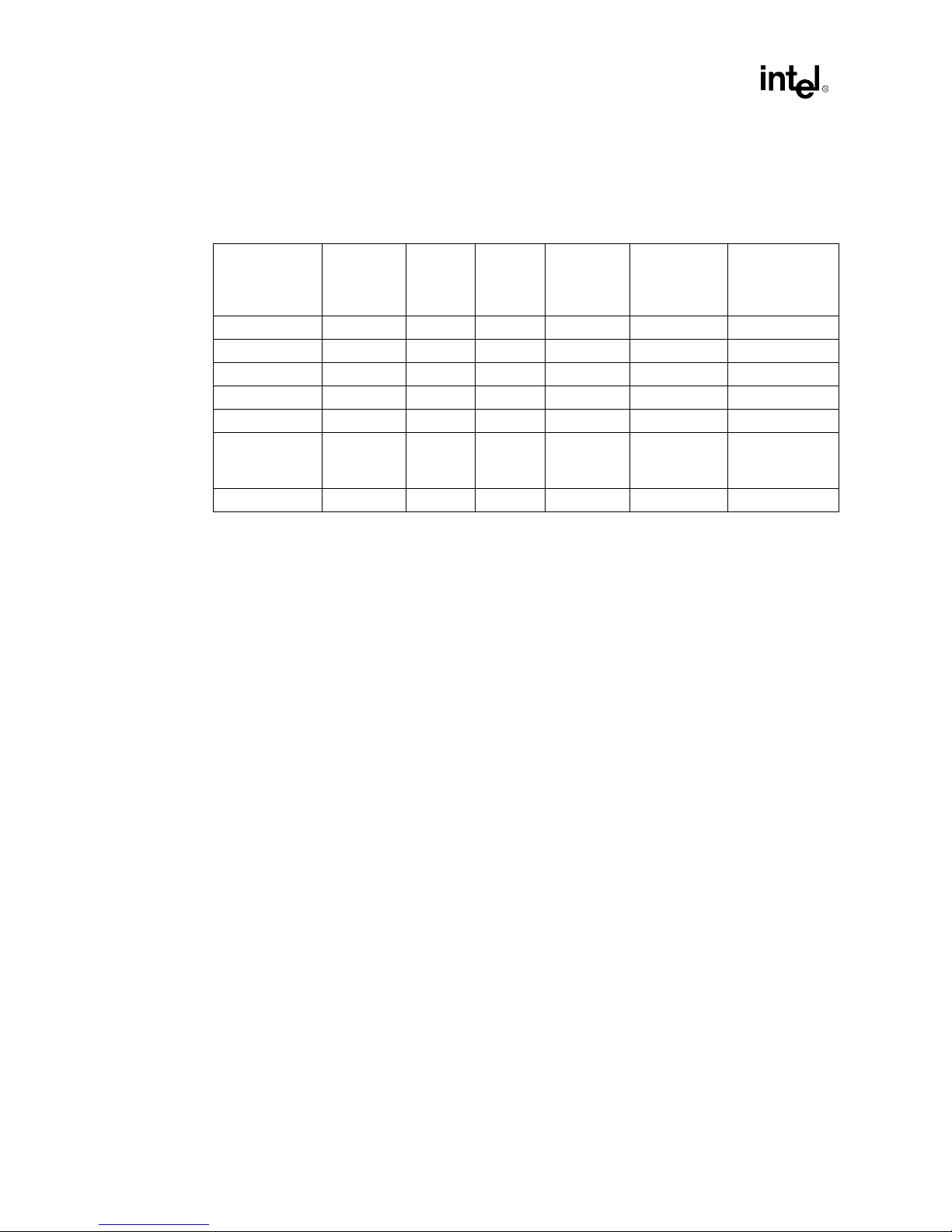

2-1 Mix and Match Options For Intel740™ Graphics Accelerator Card..............2-2

2-2 Intel740™ Graphics Accelerator Power Supplies.........................................2-3

2-3 Bt829B GND and AGND Pins.....................................................................2-12

2-4 Bt829B VCC and AVCC Pins......................................................................2-12

2-5 Bt869 Digital and Analog Power Pins .........................................................2-13

2-6 AGP Signal Lengths....................................................................................2-13

2-7 Strobes and Corresponding Signal Groups ................................................2-13

2-8 Supported Memory Options (Other Memory Options Are

Not Supported)............................................................................................2-14

2-9 Memory Layout Restrictions (See Figure 2-12 and Figure 2-13)................2-14

2-10 Memory Layout Restrictions (See Figure 2-14 and Figure 2-15)................2-15

2-11 Memory Layout Restrictions (See Figure 2-16 and Figure 2-17)................2-16

2-12 TV Out/ROMA Trace Lengths (See Figure 2-22)........................................2-20

2-13 GPIO Functions ................................................... ...... ....... ..........................2-21

3-1 State of Signals to be Driven After System Reset but at Least

One Clock Prior to Asserting TEST ..............................................................3-4

3-2 Signal Duration of the GPO Signals from PIIX4............................................3-5

3-3 Data and Associated Strobe.......................................................................3-13

3-4 Data Signal and Strobe Guideline Assumptions.........................................3-14

3-5 Control and Clock Signal Guideline Assumptions.......................................3-14

3-6 Data signal and strobe requirements..........................................................3-14

3-7 Control Signal Line Length Requirements ..................................................3-15

3-8 Strobe and Data Segment Solution Space .................................................3-16

3-9 Clock Segment Solution Space ..................................................................3-18

3-10 Supported Memory Options (Other Memory Options Are

Not Supported)............................................................................................3-18

3-11 Memory Layout Restrictions (See Figure 3-16 and Figure 3-17)................3-19

3-12 Memory Layout Restrictions (See Table 3-16 and Table 3-17) ...................3-19

3-14 Memory Layout Restrictions (See Figure 3-19) ..........................................3-20

3-13 Memory Layout Restrictions (See Figure 3-19) ..........................................3-20

4-1 Thermal Design Considerations Chart.............................. ...... ....... ...... ....... ..4-1

Intel740™ Graphics Accelerator Design Guide

vii

Page 8

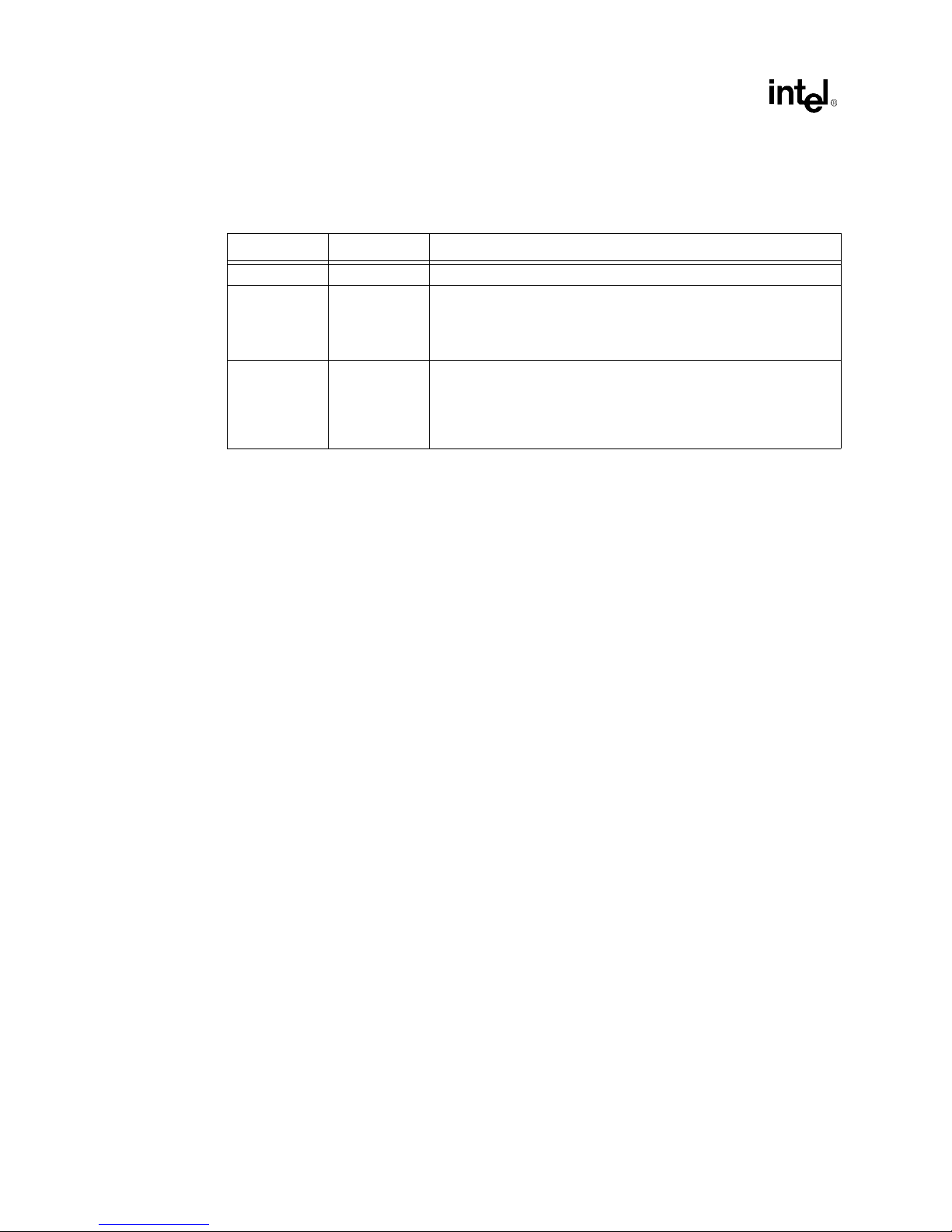

Revision History

Date Revision Description

2/98 -001 Initial Release.

Part 2: Added Figure 2-2; added “Note” verbiage in 2.14.

4/98 -002

7/98 -003

Part 3: Added verbiage to 3.3.5; Modified Figures

3-14, 3-15, 3-16, 3-19; Modified Table 3-10.

Part 5: Modified Figure 5-6.

Restructured document and added a motherboard design:

Chapter 2 contains the Addin Card design. This chapter combines

revision 2 Chapters 1, 2, 3, and Appendix A. Only re-organizaiton; the

information is the same.

Chapter 2 adds the motherboard design.

viii

Intel740™ Graphics Accelerator Design Guide

Page 9

Introduction

1

Page 10

Page 11

Introduction

Introduction

This document provides a complete package of design information for the Intel740™ Graphics

Accelerator. There are two design discussed:

•

ATX Addin Card Design (Chapter 2 provides design considerations, layout and routing

guidelines, and schematic diagrams)

•

Motherboard Design (Chapter 3 pro vides design consid erations, layo ut and routi ng guideline s,

and schematic diagrams)

The purpose of the reference design is to provide a comprehensive design encompassing every

Intel740™ graphics accelerator interface. The designer of another board may then modify this

design as needed since the basic hook-up will remain the same.

For the latest Intel740™ graphics accelerator information, please visit Intel’s website at:

http://developer.intel.com/design/graphics/740.htm

1.1 About This Design Guide

This design guide is intended for hardware designers who are experienced with PC architectures

and board design. The design guide assumes that the designer has a working knowledge of the

vocabulary and practices of PC hardware design.

•

This chapter introduces the designer to the organization and purpose of this design guide and

provides a list of references and related document s.

•

Chapter 2, "Addin Card Design"—This chapter provides a detailed set of Intel740™ graphics

accelerator design information for ATX and NLX graphics cards. The basis of the design

information is a reference ATX card design. Schematics for the reference design are provided

at the end of the chapter.

•

Chapter 3, "3 Device AGP Motherboard Design "—This chapter provides design guidelines for

developing a motherboar d based on the Pen tium II

Intel740™ graphics accelerator. The main focus of this chapter is the guidelines for

developing a 3-point AGP solution with the Intel740 graphics accelerator and provides a

detailed set of design information for a 3-point AGP reference design (DS1P/440BX/I740).

Schematics for the reference design are provided at the end of the chapter.

•

Chapter 4, "Thermal Considerations"—This chapter introduces the topic of thermal

considerations. See Application Note 653 in Appendix A for a comprehensive description of

thermal considerations.

•

Chapter 5, "Mechanical Information"— This chapter provides mechanical information on Fan/

Heatsink, VMI Header Placement, Video Connector, brackets, and NLX considerations.

•

Chapter 6, "Third Party Vendor Information"— This section includes information regarding

various third-party vendors who provide products to support the Intel 440BX AGPset and the

Intel740 graphics accelerator.

•

Appendix A, "Application Notes"—This appendix contains Application Note 653, Thermal

Design Considerations. The application note provides a comprehensive guide to thermal

design

•

Appendix B, "Reference Information"—This appendix provides reference information for

designing with the Intel740 graphics accelerator. The appendix contains information on

®

processor, Intel® 440BX AGPset, and the

1

Intel740™ Graphics Accelerator Design Guide

1-1

Page 12

Introduction

SDRAM/SGRAM Graphics SO-DIMM Modules. The appendix also contains information on

PC SGRAM specifications.

1.2 References

•

Intel740™ Graphics Accelerator Datasheet: Contact your field sales representative (Literature

order #290618) or visit the Intel740™ Graphics Accelerator WEB page at:

http://developer.intel.com/design/graphics/740.htm

•

Accelerated Graphics Port Interface Specification Rev 1.0: Contact www.agpforum.com

•

Bt829A/Bt827A/Bt825A VideoStreamII Decoders Oct. 1996: Contact Rockwell*

Semiconductor

•

Bt868/869 Flicker-Free Video Encoder with UltrascaleTM Technology: Contact Rockwell*

Semiconductor

•

VMI 1.4 Interface Specification: Contact SGS Thompson Microelectronics

•

PC ’98: Contact www.microsoft.com/hwdev

•

PC SGRAM Specification: See Appendix B

•

SO-DIMM Module Specification: See Appendix B

•

Intel740™ Graphics Accelerator Application Note 653 - Thermal Design Considerations: See

Appendix A

•

Intel 440BX AGPset Design Guide. Contact your field sales representative (Literature order

#290634). or visit the 440BX AGPSet WEB page at:

http://developer.intel.com/design/pcisets/designex/290634.htm

1-2

Intel740™ Graphics Accelerator Design Guide

Page 13

Intel740™ Graphics

Accelerator Addin

Card Design

2

Page 14

Page 15

Addin Card Design

Addin Card Design

This chapter provides a complete package of design information for the Intel740™ graphics

accelerator. Usage of the Intel740™ graphics accelerator on an ATX and NLX graphics card is

discussed. The basis of this document is a reference ATX card.

2.1 Introduction

The reference design card described in this document contains the following features.

•

ATX Fo rm Factor

•

Memory

— 100 MHz SDRAM or SGRAM

— SO-DIMM Memory Upgrade Socket

— 2,4 MB Solder-Down Option

•

BIOS

— Support for Flash or ROM

— Capable of Supporting up to 256KB

•

Monitor

— Hardware Support for DDC 2B

•

Video

—Capture

— Bi-Directional VMI Video Port for DVD Hardware

— CCIR 601 8/16-bit Video Capture Port

— NTSC, PAL, and SECAM Inputs Accepted

— Intercast Capable

— Video-Conferencing Capable

— Output

— NTSC or PAL TV Output

— Flicker Free TV Output

— Overscan Compensation

— 50-Pin Video Connector

— S-Video In/Out

— Composite In/Out

—TV Tuner

•

I2C Programmability

2

Intel740™ Graphics Accelerator Design Guide

2-1

Page 16

Addin Card Design

Table 2-1 lists the various functions capable of being supported by the reference card design. This

table describes which component is necessary for a specific feature. For hookup information, the

Intel740™ Graphics A ccelerator

corresponding schematic page should be referenced.

Table 2-1. Mix and Match Options For Intel740™ Graphics Accelerator Card

Component/

Functionality

2D/3D X

Video Capture X X

TV Out X X

DVD (HW) X X

2 MB X (1) 256K x 64 (2) 256K x 32

4 MB X

8 MB X (1) 1M x 64 (4) 1M x 16

Intel740™

Graphics

Accelerator

Page 3

BT829

Page 5

2.1.1 Design Features

2.1.1.1 Int el7 40™ Graphi cs Ac ce lerator

The Intel740™ graphics accelerator is the main component of the graphics reference design. This

component delivers high performance 3D/2D graph ics and video capabilities. Each of the

interfaces are described below.

•

Accelerated Graphics Port (AGP) Interface. The AGP interface is a new interface designed

for 3D graphics. This interface provides increased bandwidth over PCI, side band addressing,

and AGP memory 3D texture storage. For a more complete description of the AGP interface

refer to the Intel740™ Graphics Accelerator Datasheet and AGP Specification.

•

Local Memory Interface. The memory interface on the Intel740™ graphics accelerator can

operate at speeds up to 100 MHz. An SDRAM interface supports SGRAM and SDRAM to be

used for different memory densities.

•

VMI Interface. A bi-directional VMI like port is incorporated into the Int el740™ graphics

accelerator providing a mechanism for affordable DVD. Video capture is also supported using

the video port pins.

•

TV Out Interface. Intel has worked with Rockwell* (Brooktree*) to design an interface

capable of supporting a high quality TV out chip. This interface allows the Intel740™ graphics

accelerator to output on a monitor, TV, or both.

•

BIOS Interface. The Intel740™ graphics accelerator supports a FLASH or ROM BIOS. Up

to 256Kx8 can be supported.

•

GPIO Interface. Nine GPIO signals exist on the Intel740™ graphics accelerator. GPIO[8:0]

allow for power management, DDC, I

•

DAC Interface. An integrated DAC provides display resolutions up to 1600x 12 00.

2

BT869

Page 6

DVD Chip/

Daughter

Card

Page 7

SO-DIMM

Module

Page 11

(1) 512K x 64

or

(2) 256K x 64

Memory

Components

Page 12

(2) 512K x 64

or

(4) 256K x 32

C, thermal fault sensing, and other general features.

2-2

Intel740™ Graphics Accelerator Design Guide

Page 17

2.1.2 BT829B - Video Decoder

The Bt829B is a video capture processor used to convert analog video data into CCIR 601 digital

video data. This chip contains the following capabilities.

•

Analog Inputs. The Bt829B con tain s four composite video inp uts al on g wi th o ne chroma and

one luma input for s-video.

•

I2C Interface. Control of the Bt829B is accomplished though the use of an I2C interface. All

of the chip’s registers are programmed using this interface as is the selection of the analog

input source to use in generating digital video data.

•

Video Port. The Bt829B contains a video port capable of out p ut tin g 8 or 1 6 bi t dat a. The data

format is YUV 4:2:2 with HSYNC, VSYNC, and PIXEL CLOCK as control signals.

2.1.2.1 BT869 - TV Encoder

The Bt869 provides high quality TV out. This component contains the following interfaces:

•

Input Port. The Bt869 is capable of receiving data in two formats. The format used by this

reference design for receiving data is through the 24 bit digital port accepting data on both

edges of the reference clock. This mode of operation is documented in the Intel740™

Graphics Accelerator Datasheet. The second method for capturing data is through the use of

the VMI protocol. This interface is documented in the VMI 1.4 Interface Specification.

•

Flicker Filter Output. The output of the Bt869 is a very high quality flicker filtered output.

This is due to a 5 tap internal filter. Output can be displayed in interlaced, non-interlaced,

PAL, or NTSC formats. Macrovision7 output is also supported in the Bt869 component. The

Bt869 is capable of displaying composite or S-Video data.

•

I2C Interface. Control of the Bt869 is achieved through the I2C port.

Addin Card Design

2.1.3 Terminology

2.1.3.1 Power Sources

The card is supplied with four voltages through the edge connector. Other voltages are derived onboard. Thus, the Power Layer of the board must be divided into several distinct planes. Table 2-2

lists the various power elements on the Intel740™ graphics accelerator reference design. Each of

the voltage sources are supplied by a plane except for 12 volts, which is supplied by a 25 mil trace.

Table 2-2. Intel740™ Graphics Accelerator Power Supplies

Schematic

Symbol

VDDQ3 3.3V AGP Supply +3.3V 8.0A Edge connector

VCC3 3.3V Logic Supply +3.3V 6.0A Edge connector

VCC 5V Logic Supply +5.0V 2.0A Edge connector

+12V 12V Supply +12V 1.0A Edge connector

VCC2 2.7V Core Supply +2.7V 3.0A VCC3, via Voltage Regulator

3VAA_BT869 3.3V Analog Supply +3.3V < 1.0A VCC3, via Ferrite Bead

AVCC 5V Analog Supply +5.0V < 1.0A VCC, via “fence”

Description Voltage

Max

Current

Source

Intel740™ Graphics Accelerator Design Guide

2-3

Page 18

Addin Card Design

2.1.3.2 Fences

A “fence” is a line routed out of the plane such that a given area is isolated from the rest of the

plane except at a single point of contact, conceptually the “gate” in the fence. A fence will

minimize noise originating from digital signaling onto the analog signals. This provides higher

quality video for both the Bt829B and Bt869. An example of a fenced power plane is shown in

Figure 2-1. The heavy black line is the routed area. The width of the gate or opening can be up to

75% of the length of the IC in question. The widt h of the routed fence should conform to the

separation routing between power planes (i.e., 25 mils minimum).

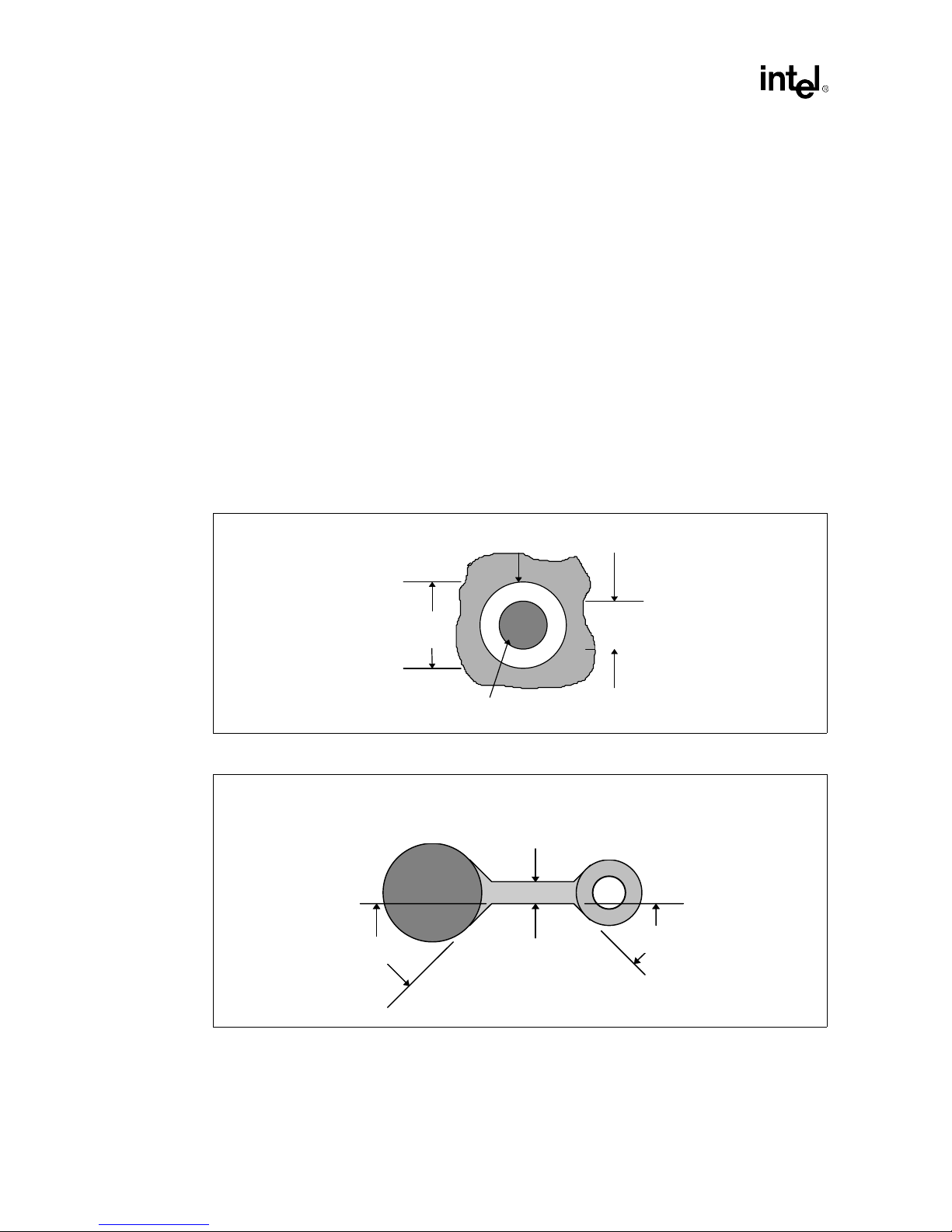

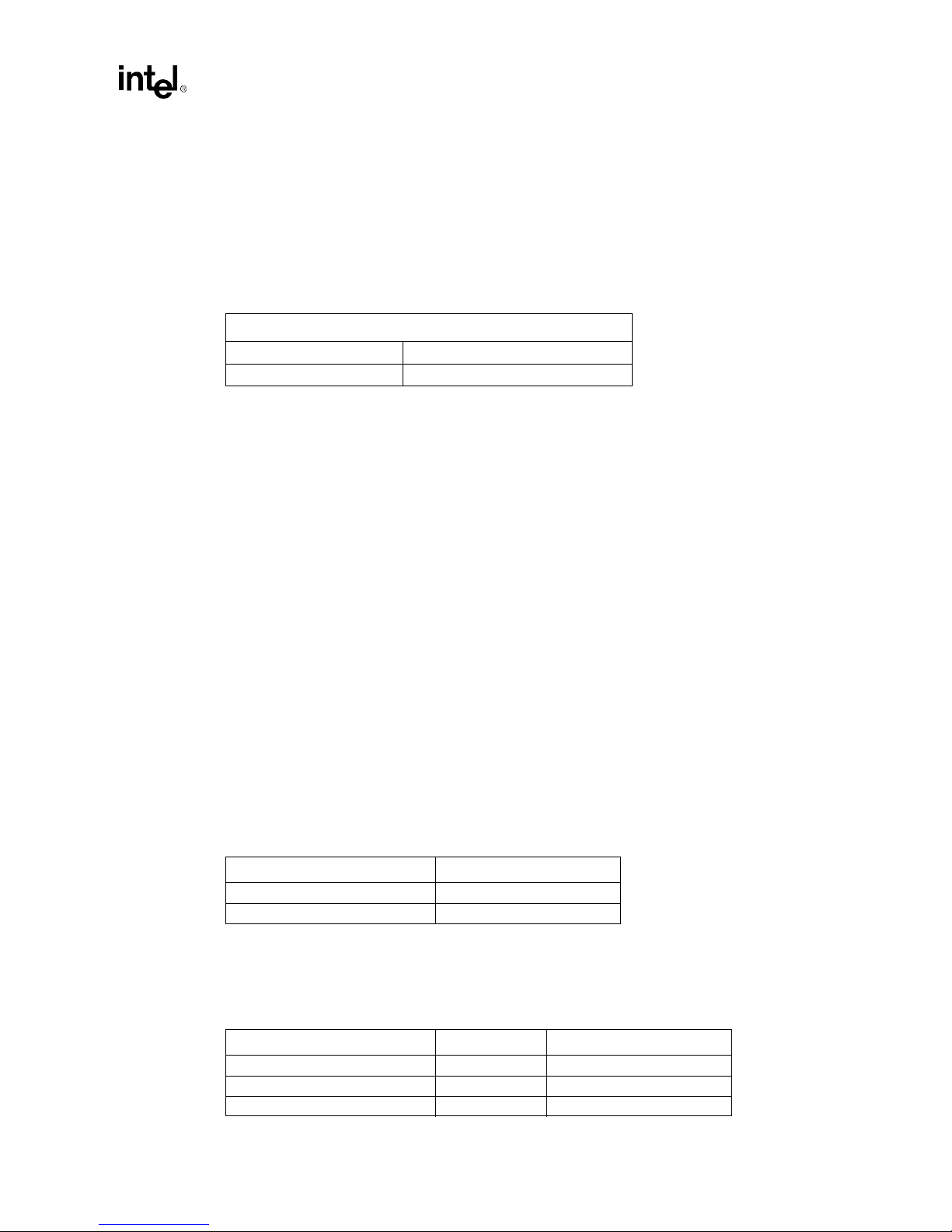

Figure 2-1. Example of Power Plane Separation ("fencing")

“gate”

Plane

(e.g. VCC)

2.1.3.3 Stitching

Power plane “stitching” is required between the VCC3 and VDDQ3 planes. Stitching two isolated

planes together with capacitors allows a current return path for high frequency signals which pass

over split power planes. This helps to eliminate EMI. The six 0.1 µF capacitors coupling VCC3 to

VDDQ3 should be spaced evenly if possible. Note the VDDQ3 plane is only near the AGP

connector . An example of sti tchi ng is s hown in Figure 2-2. This figure illustrates the power planes

and, therefore, does not show signal traces between capacitors. The general rule for power plane

stitching is to have a capacitor placed between every four signals crossing the two planes. As an

example, there should be a capacitor, four signals, a capacitor, another four signals, and so forth

ending with a capacitor.

Figure 2-2. Example of Power Plane Stitching

VCC3

Fenced area

(e.g. AVCC)

Routed “fence”

Overlying Chip

2-4

cap

IC

cap

cap

VDDQ3

cap

Intel740™ Graphics Accelerator Design Guide

Page 19

2.2 Layout and Routing Guidelines

This chapter describes layout and routing recommendations to insure a robust design. These

guidelines should be followed as closely as possible. Any deviations from the guidelines listed here

should be simulated to insure adequate margin is still main tained in the design.

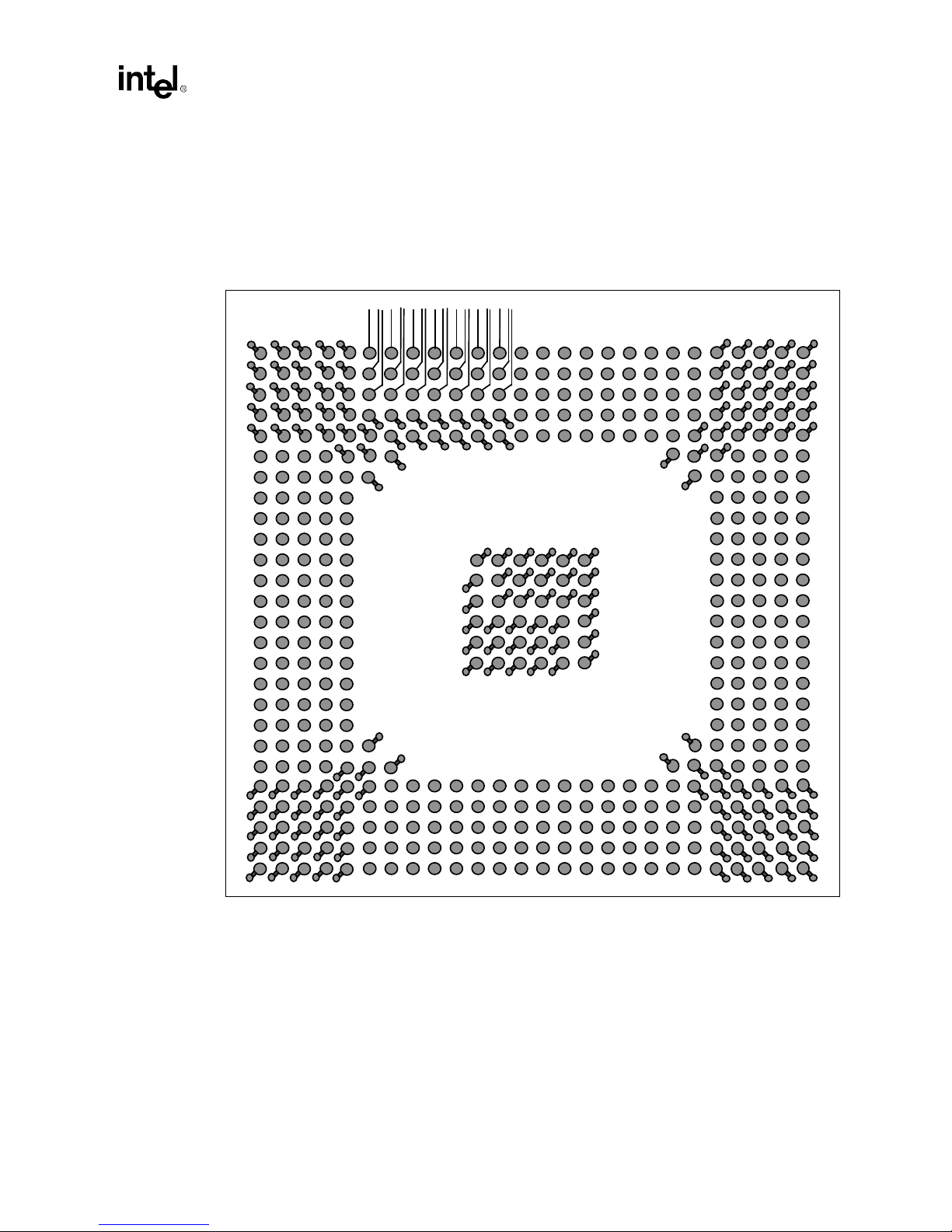

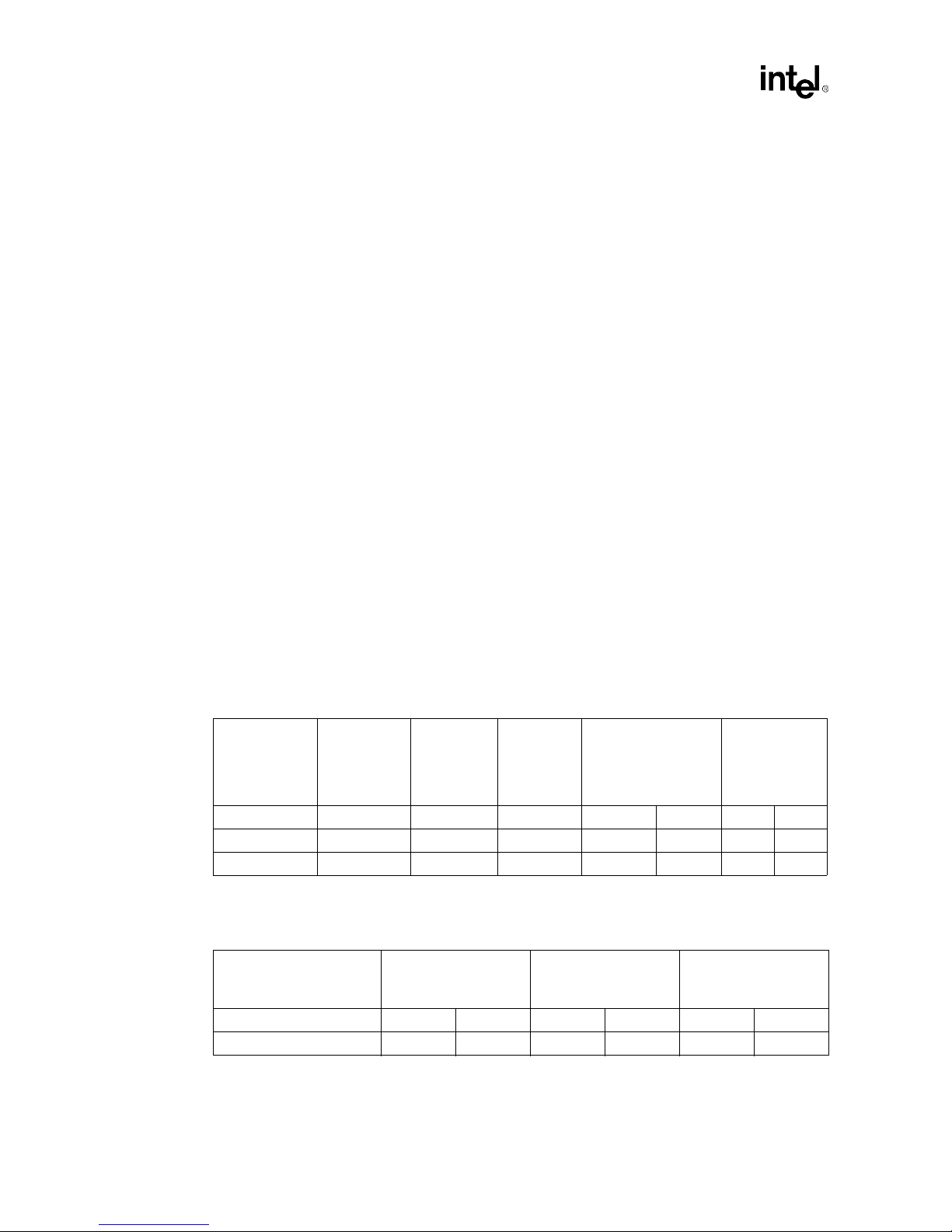

2.2.1 Placement

The ball connections on the Intel740™ graphics accelerator have b een assigned to simplify routing

and keep board fabrication costs down by enabling a 4-layer design. Figure 2-3 shows the four

signal quadrants of the Intel740 graphics accelerator. Component placement should be done with

this general flow in mind. This will simplify routin g and minimize the number of signals which

must cross. The individual signals within the respective groups have also been optimized to be

routed using only 2 PCB layers.

A complete list of signals and ball assignments can be found in the Intel740™ Graphics

Accelerator Datasheet.

Figure 2-3. Major Signal Sections

Addin Card Design

Intel740

Top View

Quadrant

Pin #1 Corner

A.G.P.

BIOS/Flicker

Quadrant

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

Local Memory

VMI Port

Quadrant

Quadrant

Intel740™ Graphics Accelerator Design Guide

2-5

Page 20

Addin Card Design

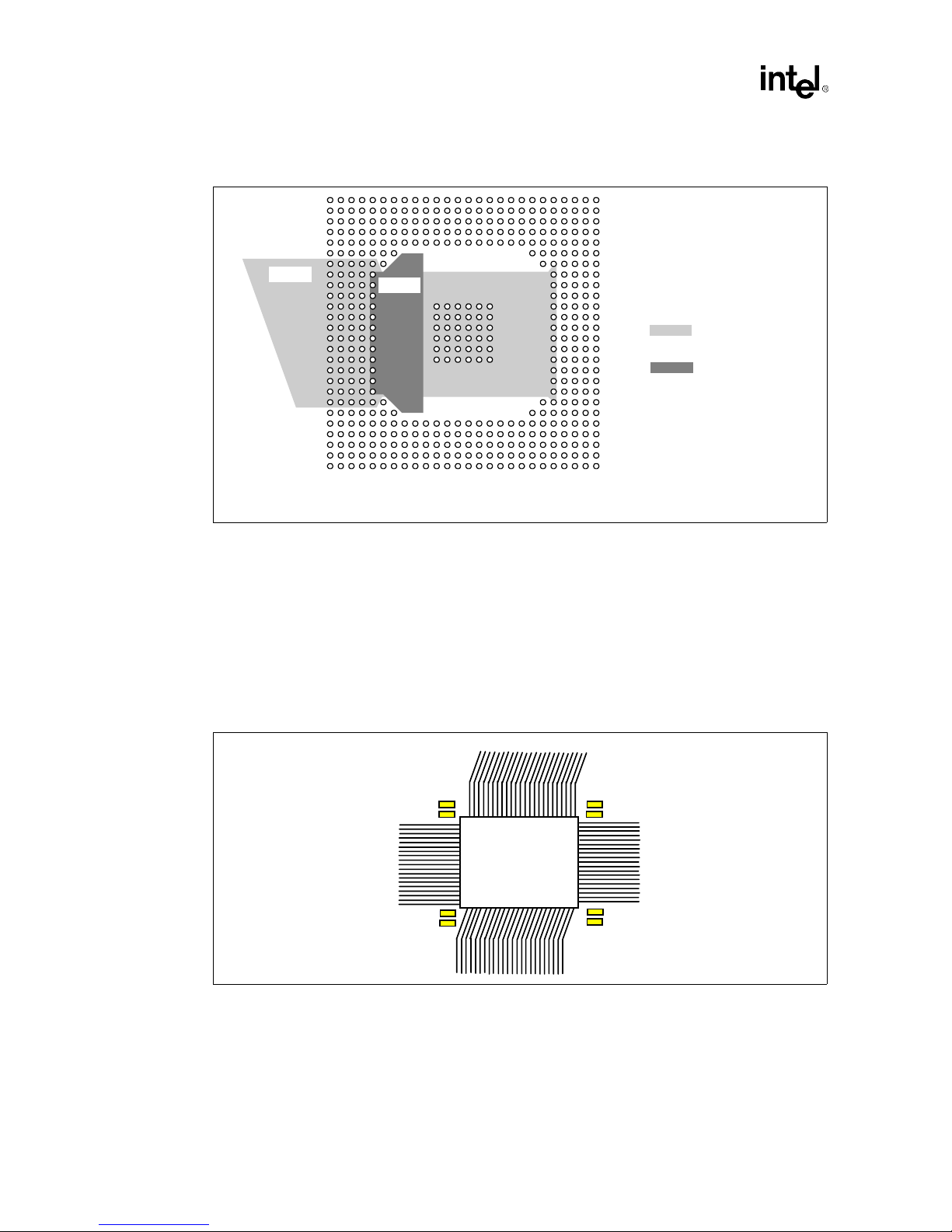

An example of the proposed component placement for an ATX form factor design is shown in

Figure 2-4. This is the placement used on the reference card. For NLX placement issues, refer to

Section 5.6, “NLX Considerations” on page 5-5.

ATX Form Factor:

•

The example placement (Figure 2-4) shows the Bt829B, Bt869, SO-DIMM Module, Intel740

graphics accelerator, VMI Port connections along with a 50 pin video connector.

•

The trace length limitation between critical connections will be addressed later in this

document.

•

Figure 2-4 is for reference only. The choice of size of memory, whether to have an SO-DIMM

connector, what video components to place on the board, and which video connectors to have

on the bracket will have to be evaluated by the board designer.

Figure 2-4. Example ATX Layout

VGA

Connector

Bt869

50 Pin

Connector

VMI Port

Connectors

2.2.2 Board Description

Bt829B

28F010

Flash

BIOS

Intel740™

Intel740

Chip

SO-DIMM

Connector

Memory

Memory

Even with the following recommendations, it is important to simulate your design.

A 4-layer stack-up arrangement is recommended. T he stack-up of the bo ard is shown in Figure 2-5.

The impedance of all the signal layers are to be between 50 and 80 ohms. Lower trace impedance

will slow signal edge rates, over & undershoot, and have less cross-talk than higher trace

impedance. Higher trace impedance will create faster edge rates and decrease signal flight times.

Prepreg is FR-4 material.

2-6

Intel740™ Graphics Accelerator Design Guide

Page 21

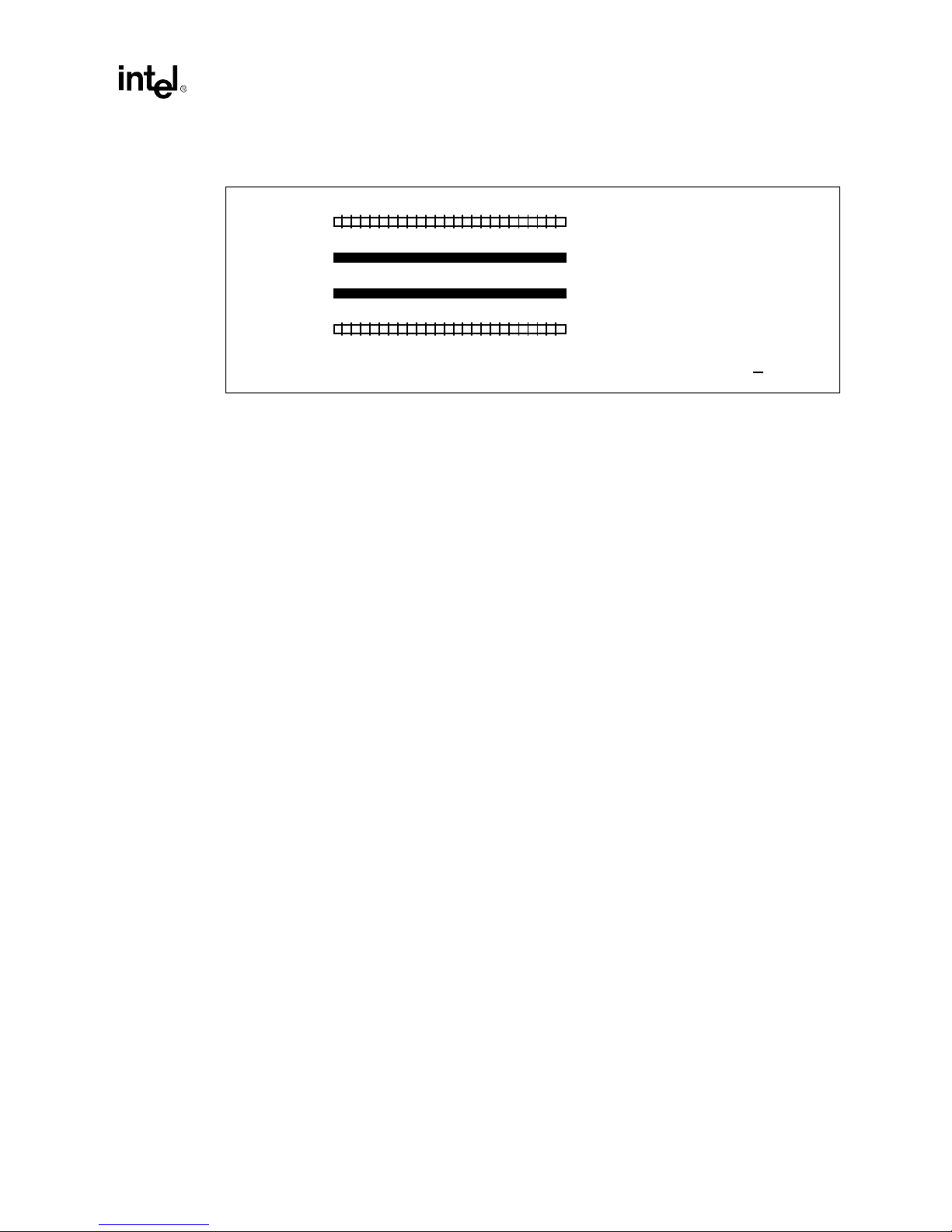

Figure 2-5. Four Layer Board Stack-up

Addin Card Design

Z = 65 ohms

Z = 65 ohms

Note: Top and bottom routing layers specify 1/2 oz. cu. However, by the time the board is plated, the

traces will end up with about 1 oz. cu. Please check with your fabrication vendor on the exact value

and insure that any signal simulation accounts for this.

Note: Thicker core helps reduce board warpage issues, while thinner prepreg reduces trace impedance.

Additional guidelines on board buildup, placement and layout include:

•

All layers should be cut back from the substrate outer edge by 0.050”. A 0.025”-wide strip

should be added to all signal and power layers around the outer edge and tied to the ground

plane.

•

All power and ground traces between vias and pads for all components should be at least as

wide as the component power or ground pad itself.

•

Through-hole vias, unless otherwise noted, are 10 mil drill, 25 mil diameter pad. Via capping

is required. All vias on the secondary side should be covered with solder mask. All vias on the

primary side are to be encroached with solder mask and anti-pad unless board dryness has

been guaranteed.

•

T o minimize solder wicking with the BGA, the component side solder mask should be applied

prior to tinning the copper. There should be no surface mount over bare copper (S.M.O.B.C.).

•

The solder mask must cover the trace between the via and pad.

•

The board impedance (Z) should be between 50 and 80 ohms (65 ohms ±20%).

•

FR-4 material should be used for the board fabrication.

•

The ground plane should not be split on the ground plane layer. If a signal must be routed for a

short distance on a power plane, then it should be routed on a VCC plane, not the ground

plane.

•

Keep vias for decoupling capacitors as close to the capacitor pads as possible.

•

Keep isolated power planes as close as possible to each other. This will minimize impedance

mismatch at the split.

•

All decoupling capacitors should be tied to the ground plane by a trace at least as wide as the

via ring to the plane.

6 mils

50 mils

6 mils

PREPREG

CORE

PREPREG

Primary Signal Layer (1/2 oz. cu.)

Ground Plane (1 oz. cu.)

Power Plane (1 oz. cu)

Secondary Signal Layer (1/2 oz. cu)

Total board width = 62 + .6 mils

Intel740™ Graphics Accelerator Design Guide

2-7

Page 22

Addin Card Design

2.2.3 BGA Component

2.2.3.1 Layout Requirements

The following layout requirements should be followed when routing the 468 MBGA package.

•

All non-ground BGA lands should be Metal Defined (MD) lands with the following nominal

dimensions (see Figure 2-6).

— Metal pad: 20 (6/6 routing) / 24 mils (5/5 routing)

— Solder mask opening: 24 mil (20 mil pad) / 27 mils (24 mil pad)

•

Any trace connected to a MBGA land or PTH via in the MBGA land grid array should be

teardropped. The teardrop should leave the trace at a 45° angle and intersect the via

tangentially (see Figure 2-7).

•

The minimum distance between the gold finger edg e of the card and the center of the first row

of MBGA lands should be 525 mils, and 480 mils from the end of the start of the bevel.

•

All BGA ground vias should use 16 mil drill with no thermal reliefs.

Figure 2-6. Metal Defined land dimensions

Figure 2-7. BGA Trace

(.024”)

.027”

BGA Lan d

45°

Solder Mask Ope nin g

(.020”)

.024”

Metal Pad

Cover Trace with Solder M ask

PTH Via

45°

.010” min

Recommended to be as

wide as via

2-8

Intel740™ Graphics Accelerator Design Guide

Page 23

2.2.3.2 Ground Connections

Addin Card Design

All lands in the four corners and center are V

connect to an adjacent via which passes through to the solder side of the board, one via per ball,

with a trace as wide as the via. Heat will dissipate through these vias to the GND plane as well as to

the air on the solder side.

Figure 2-8. Dogbone Via Pattern

(GND). Thermal analysis requires that each Vss ball

ss

2.2.3.3 Power Connections

The VCC2 plane should be as wide as practical for high current-carrying capacity. Because of the

interspersing of VCC2 and VCC3 pins on the Intel740™ graphics accelerator, a polygon will be

needed on one of the signal layers to extend the VCC3 plane to the isolated VCC3 pins

(Figure 2-9). The VCC2 polygon is a separate plane on the VCC Layer; the darker VCC3 polygon

is a power flood on the solder side and connects to the VCC3 plane on the VCC Layer through vias.

Intel740™ Graphics Accelerator Design Guide

2-9

Page 24

Addin Card Design

p

p

p

p

p

Gr

Figure 2-9. Suggested VCC Planes for the Intel740™ Graphics Accelerator

VCC2

VCC3

2.2.3.4 Decoupling

Decoupling capacitors should ideally be placed as close as possible to the Intel740 graphics

accelerator. This means that the best decou

underneath the com

underneath the com

accelerator

the ca

ackage. At least a 0.1 µF and 0.01 µF are recommended for each corner. By placing

acitors in this location all of the traces can “break-out” from the BGA package on all four

sides.

Figure 2-10. Intel740™ Graphics Accelerator Decoupling

onent. If a single sided board is required and capacitors cannot be placed

onent then decoupling is recommended at the corners o f the I ntel740 graphics

VCC2 on VCC Layer

VCC3 on Secondary Side

Signal Layer

vcc_pl.vsd

ling will occur if the capacitors are placed directly

2-10

0.1uF

0.01uF

0.1uF

0.01uF

0.1uF

0.01uF

Intel740

Graphics

Accelerator

(468 BGA)

0.1uF

0.01uF

Intel740™ Graphics Accelerator Design Guide

Page 25

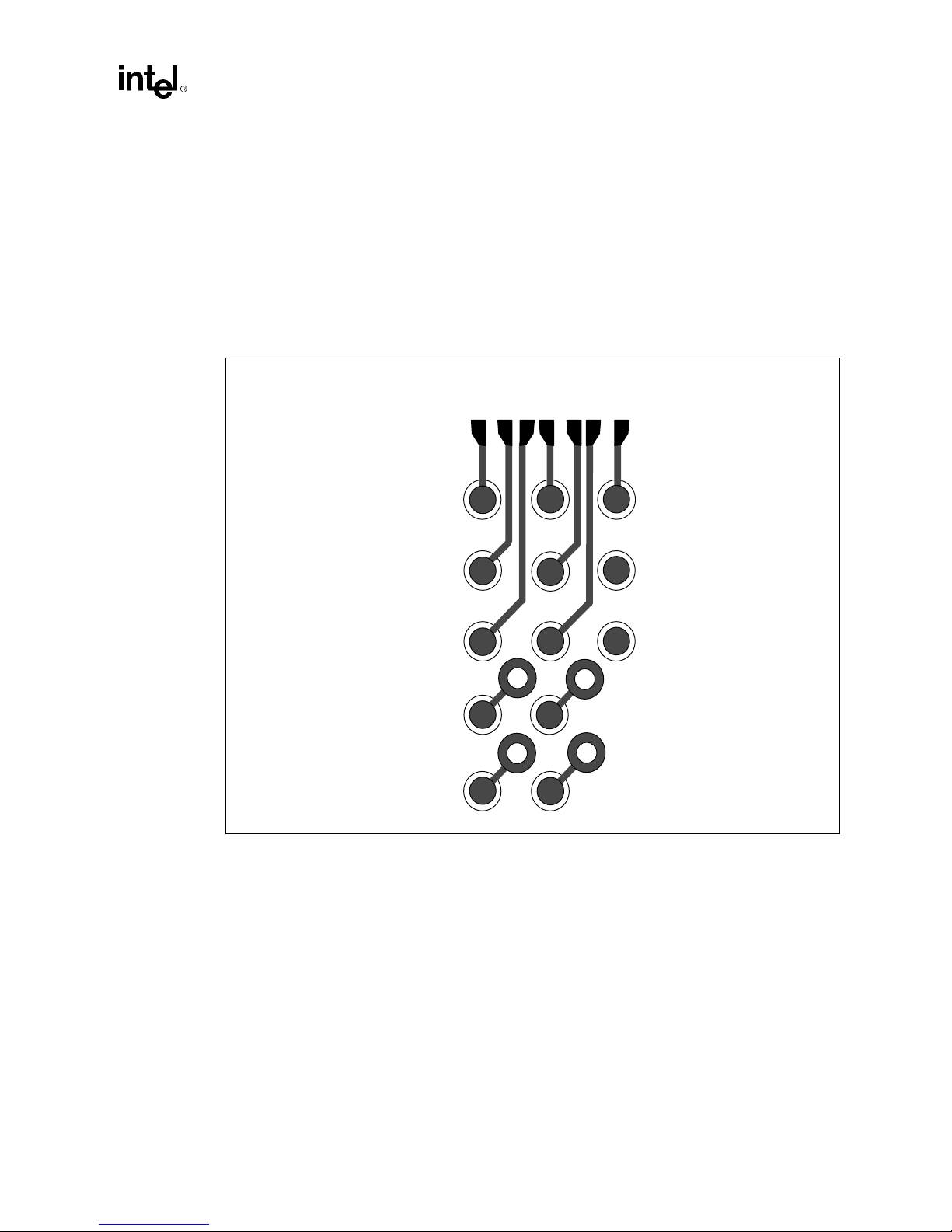

2.2.3.5 General Sign al Routing

Figure 2-11 depicts general escape of traces from the five rows of BGA ball pads. The first three

ball rows can be routed on the primary layer. The last two must be routed through vias to the

secondary layer. Underneath the BGA, trace routing should be 5 on 5 or 6 on 6. Once the traces

have left the BGA, however, routing should expand to 5 o n 10 or 6 on 12. The ratio should be kept

as 1:2.

The signals AD _STB_A, AD_STB_B and SB_STB sh ould have a spacing of 1:4 to other signals.

Using this extra spacing between these specific signals will help to keep crosstalk to a minimum.

Addin Card Design

Figure 2-11.

Intel740™ Graphics Accelerator BGA Routing Exampl

COMPONENT SIDE ROUTING FOR 5 ROWS OF BALL PADS

R1

R2

R3

R4

e

2.2.4 Voltage Regulator

The physical tab (used as a built in heatsink) on the MOSFET package is the drain pin, and will

need a tab-shaped pad to solder to.

Note: The resistor/capacitor network between the COMP pin (pin 5) and the GND pin (pin 3) of the

LT1575 should be connected directly to the GND pin of the device rather than tied to the ground

plane.

2.2.5 Bt829 Video Decoder

Note: Rockwell* Semiconductor should be contacted for up to date layout recommendations.

Intel740™ Graphics Accelerator Design Guide

R5

2-11

Page 26

Addin Card Design

2.2.5.1 Ground Planes

The Bt829B and associated circuitry have two ground planes, GND and ANALOG_GND

(AGND). These are electrically the same plane but should be separated by a fence, as described in

Section 2.1.3.2, “Fences” on page 2-4. The schematic illustrates which pins attach to which plane

as does Table 2-3. The opening in the fence should be under the Bt829B and be up to 75% of the

IC’s width. The AGND plane is the isolated or subset plane, hence GND is the return path for

current. The AGND plane should be as small as possible.

Table 2-3. Bt829B GND and AGND Pins

GND 11, 21, 31, 33, 39, 77, 81, 90, 93, 95, 100

AGND 42, 47, 54, 56, 58, 61, 66, 71, 75

2.2.5.2 Power Planes

The Bt829 and associated circuitry have three power planes, VCC3, VCC and AVCC. The latter

two are digital and analog +5V, respectively. As above, these are electrically the same plane but

separated by a fence. This fence and the AVCC plane should parallel the AGND fence and plane

closely, with the opening in about the same location.

Bt829 Ground Pins

Table 2-4. Bt829B VCC and AVCC Pins

Bt829B 5V Pins

VCC 10, 38, 76, 88, 96

AVCC 40, 44, 48, 60, 65, 72

2.2.5.3 Passive Components and Signal Routing

All passive components should be placed as near to the Bt829B as possible. These parts include:

the 0.1µF and 0.01 µF bypass capacitors, the 10µF capacitors, the 75 ohm terminating resistors, an d

the crystal oscillator circuitry.

Note: There must be NO digital signals routed under or above the analog power and ground planes

(AVCC and AGND).

The filter circuits on the four video input signals (TUNER, SV_LUM, SV_CHR, CV_IN) need to

be located near the 50-pin connector. Note that other designs not using a 50 pin video connector

should have the filter circuits placed as close as possible to the input connectors. The analog traces

should not be routed such that they parallel other analog signals at a close spacing for a long length.

Wherever analog signals run in parallel, separated by less than 15 mils for longer than 250 mils,

run a ground line between them of approximately 12 mils width.

2.2.6 Bt869 Video Encoder

Note: Rockwell Semiconductor should be contacted for up to date layout recommendations.

2.2.6.1 Ground Planes

Only one ground plane is recommended for the Bt869. This ground plane should be formed as a

fence underneath the Bt869.

2-12

Intel740™ Graphics Accelerator Design Guide

Page 27

2.2.6.2 Power Planes

The Bt869 and associated circuitry have two power planes, VCC3 and 3VAA_BT869. The

3VAA_BT869 plane is a separate cutout, joined to VCC3 by a ferrite bead. The device should

reside entirely above the 3VAA_BT869 plane, as there are no VCC3 connections to the device. So

long as the 3VAA_BT869 plane underlies all the analog components, it should be as small as

possible.

Table 2-5. Bt869 Digital and Analog Power Pins

Bt869 3V Pins

3VAA_BT869 (Analog) 69, 71, 73, 80

3VAA_BT869 (Digital) 19, 20, 30, 40, 46, 47, 57, 60, 61

2.2.6.3 Passive Components and Signal Routing

All passive components should be placed as close to the Bt869 device as possible. These devices

consist of: the 0.1µF and 0.01µF bypass capacitors, the 10µF capacitors, the crystal oscillator

circuitry , and the 0.1 µF capacitors and 75 ohm resistors at the VREF, VBIAS and FSADJUST pins

as well as the protection diodes.

Addin Card Design

Note: There must be NO digital signals routed under or above the analog power and ground planes

(3VAA_BT869 and AGND).

The filter circuits on the three video output signals (TVOUT_Y, TVOUT_C, TVOUT_CVBS)

must be very near the 50-pin connector or other output connecto rs. Long leng ths of closely spaced

parallel analog signals should be avoided. Wherever analog signals run in parallel, separated by

less than 15 mils for longer than 250 mils, run a ground line between the video input traces of

approximately 12 mils width.

2.2.6.4 AGP Layout and Routing Guidelines

This section describes the group of signals that runs between the Intel740 graphics accelerator

AGP Interface and the AGP edge connector. For the definition of AGP functionality (protocols,

rules and signaling mechanisms, as well as th e platform level aspects of AGP functionality), refer

to the latest AGP Interface Specification. This document focuses onl y on specif ic Inte l740 grap hics

accelerator recommendations for the AGP interface. The gen eral len gth requir ements are shown in

Table 2-6.

Table 2-6. AGP Signal Lengths

Group Recommendation

All

CLK 2.6” ± 0.4”

Mismatch between strobe and data traces must be less than 0.5”. Thus the trace length for signals

within a group must be within ±0.5” of the corresponding strobe’s trace length, as indicated in

Table 2-7.

≤

3.0”

Table 2-7. Strobes and Corresponding Signal Groups

Group Strobe Recommendation

AD[31:16], C/BE[3:2]# AD_STB_B L

AD[15:0], C/BE[1:0]# AD_STB_A L

SBA[7:0] SB_STB L

Intel740™ Graphics Accelerator Design Guide

AD_STB_B

AD_STB_A

± 0.5”

SB_STB

± 0.5”

± 0.5”

2-13

Page 28

Addin Card Design

For example, AD29 and AD_STB_B must not be mismatched by more than 0.5”. No such

comparison, however, should be enforced between AD29 and AD30, or AD29 and C/BE2#, etc.

Note: AGP strobes must be separated by 2X no rmal signal spacing ( i.e., if no rmal spacing is 5/ 10 or 6/12,

the strobe signals must be separated from other traces by 20 or 24 mils, respectively).

2.2.6.5 Intel740™ Graphics Accelerator Memory Layout and Routing

Guidelines

The Intel740 graphics accelerator integrates a memory controller which supports a 64-bit memory

data interface. SGRAM can be used in addition to SDRAM if it is configured to perform as an

SDRAM. The Intel740 graphics accelerator generates the Row Address Strobe (SRAS[A:B]#),

Chip Selects (CS0[A:B]#, CS1[A:B]#), Column Address Strobe (SCAS[A:B]#), Byte Enables

(DQM[0:7]#), Write Enables (WE[A:B]#), and Memory Addresses (MA). The memory controller

interface is fully configurable through a set of control registers.

Eleven memory address signals (MAx[10:0]) allow the Intel740™ graphics accelerator to support

a variety of commercially available SO-DIMMs and components. Two SRAS# lines permit two

64-bit wide rows of SDRAM. All write operations must be one Quadword (QWord). The Intel740

graphics accelerator supports memory up to 100 MHz.

Rules for populating a Intel740 graphics accelerator Memory:

•

Memory can be populated using either an SO-DIMM or components.

•

SDRAM and SGRAM components and/or SO-DIMMs can be mixed.

•

The DRAM Timing register, which provides the DRAM speed grade control for the entire

memory array, must be programmed to use the timings of the slowest memories installed.

Possible DRAM and system options supported by the Intel740 graphics accelerator are shown in

Table 2-8.

Table 2-8. Supported Memory Options (Other Memory Options Are Not Supported)

SDRAM/

SGRAM

Technology

8 Mbit 256K 32 Asymmetric 10 8 2MB 4MB

16Mbit 512K 32 Asymmetric 11 8 4MB 8MB

16Mbit 1M 16 Asymmetric 12 8 8MB 8MB

SDRAM/

SGRAM

Density

SDRAM/

SGRAM

Width

Addressing Address Size

Row Column Min Max

There are several groups of signals within the memory bus with layout restrictions.

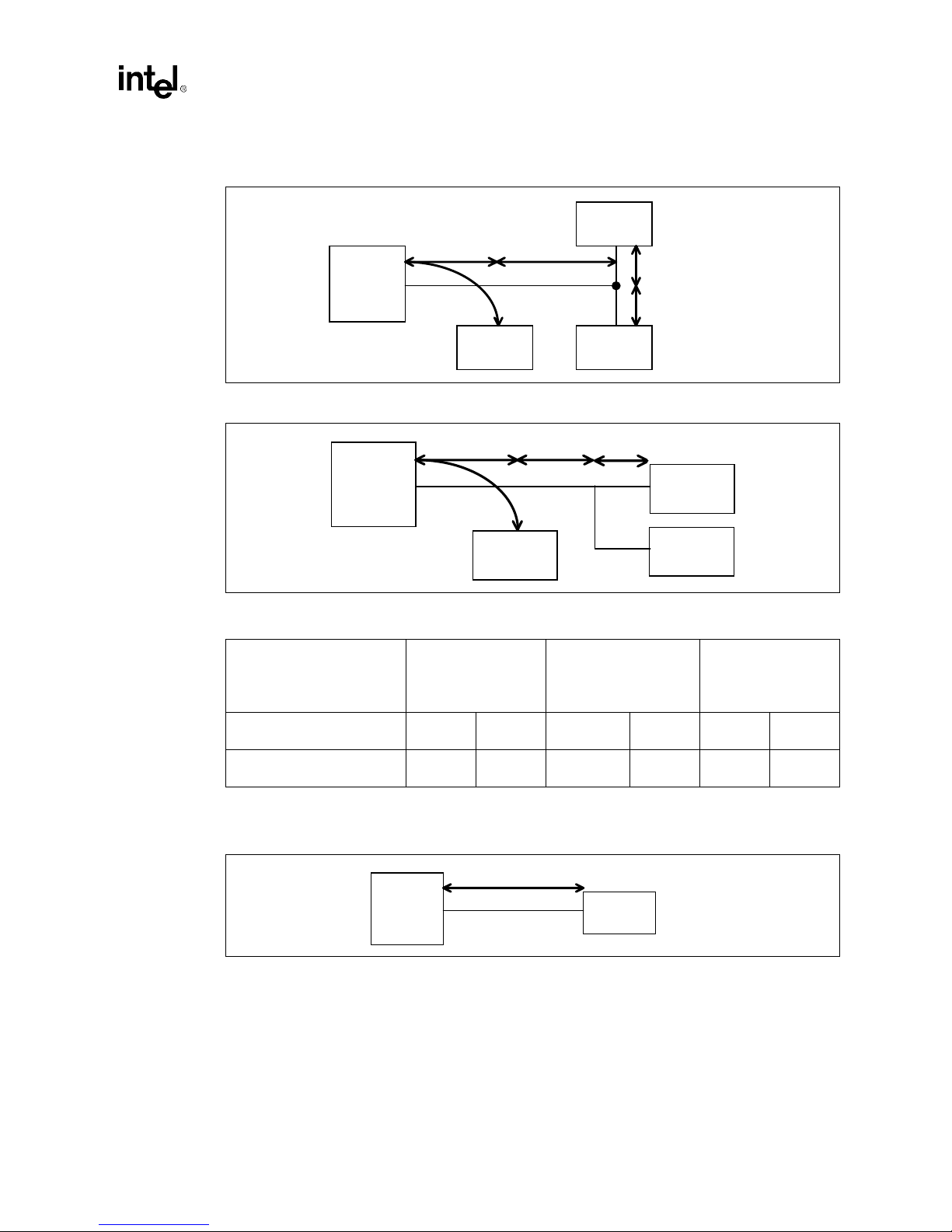

Table 2-9. Memory Layout Restrictions (See Figure 2-12 and Figure 2-13)

Signal Intel740™ to SO-DIMM SO-DIMM SGRAM Stub SGRAM Stub

Min Max Min Max Min Max

MA[11:0] n/a 4.0” 0.25” 0.9” 0.25" 0.6”

MD[63:0], DQM[7:0] n/a 3.0” 0.25” 0.9” 0.25" 0.4”

Local Memory

Size

2-14

Intel740™ Graphics Accelerator Design Guide

Page 29

Figure 2-12. Layout Dimensions (MA[11:0])

Intel740™

Intel740

Chip

4.0”

Addin Card Design

SGRAM

0.25” - 0.9”

0.25” - 0.6”

0.25” - 0.6”

SO-DIMM

SGRAM

Figure 2-13. Layout Dimensions (MD[63:0], DQM[7:0])

Intel740™

Intel740

Chip

3.0”

0.9”

0.4”

SGRAM

0.4”

SO-DIMM

SGRAM

Table 2-10. Memory Layout Restrictions (See Figure 2-14 and Figure 2-15)

Signal

WEA#, SRASA#, SCASA#,

CSA1#, CSB0#

WEB#, SRASB#, SCASB#,

CSA0#

Intel740™ to

SO-DIMM

Min Max Min Max Min Max

n/a 4.0” n/a n/a

n/a 4.0” 0.25” 0.9” 0.25” 0.6”

SO-DIMM to SGRAM

Stub

SGRAM Stub

Figure 2-14. Layout Dimensions (WEA#, SRASA#, SCASA#, CSA1#, CSB0#)

Intel740™ Graphics Accelerator Design Guide

Intel740™

Intel740

Chip

2.0” - 4.00”

SO-DIMM

2-15

Page 30

Addin Card Design

Figure 2-15. Layout Dimensions (WEB#, SRASB#, SCASB#, CSA0#)

SGRAM

2.0” - 4.0”

Intel740

Intel740

Chip

™

0.25” - 0.9”

SGRAM

0.25” - 0.6”

0.25” - 0.6”

Table 2-11. Memory Layout Restrictions (See Figure 2-16 and Figure 2-17)

Signal

TCLK0 0.6” 2.4” ±0.25” n/a n/a n/a

TCLK1 0.6” 2.4” ±0.25” 1.0” 0.4” 0.6”

Intel740™ to

Resistor

Resistor to

SO-DIMM

Figure 2-16. Memory Layout Dimensions (TCLK0)

0.6”

Intel740™

Intel740

Chip

0

Figure 2-17. Memory Layout Dimensions (TCLK1)

0.6”

Ω

SO-DIMM to

SGRAM Stub

2.4” +/- 0.25”

2.4” +/- 0.25”

SGRAM Stub

Min Max

SO-DIMM

Connector

Intel740™

Intel740

Chip

2-16

SO-DIMM

Connector

0

Ω

Intel740™ Graphics Accelerator Design Guide

Page 31

Addin Card Design

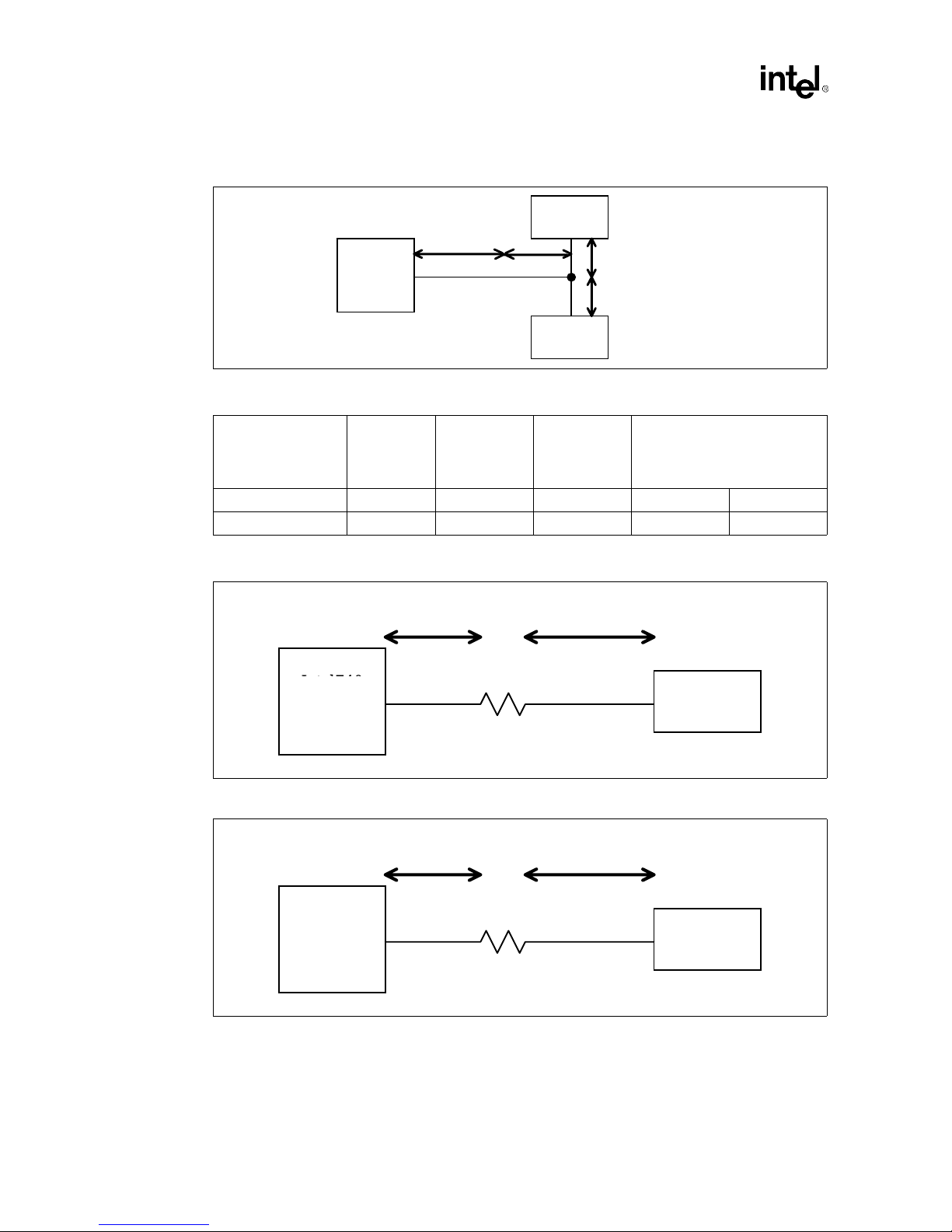

Signal Intel740™ to Resistor

OCLK to Resistor 2.75” ±0.25

RCLK0, RCLK1 3.0” ±0.25”

Note: It is important to match clock lengths. For example, if the length from OCLK to Resistor is 1.03,

then the length from Resistor to RCLK should be 3.03.

Figure 2-18. Memory Layout Dimensions (RCLK and OCLK to RCLK)

Intel740™

Intel740

2.75” +/- 0.25

Chip

OCLK

Ω

3.0” +/- 0.25”

33

RCLK0

3.0” +/- 0.25”

RCLK1

2.2.6.6 Intel740™ Graphics Accelerator Memory Configurations

In the following discussion the term row refers to a set of memory devices that are simultaneously

selected by an SRAS and the CS# signal.

Configuration #1: In this configuration, the minimum amount of memory (2MB) is supported.

Note that, the same copy of all control signals goes to each component.

Figure 2-19. 2/4 MB Local Memory Connection (64-bit data path)

33

Ω

Intel740™ Graphics Accelerator Design Guide

Intel740

MD[63:0]

CSx[A:B]# DQM[3:0] DQM[7:4] RCLKx OCLK

CS0A#

MD[31:0]

CS0A#

MD[63:32]

Intel740™ Chip

256K/512K X 32

256K/512K X 32

MA[11:0]

WEA#

SRASA#

SCASA#

TCLKA

WEA#

SRASA#

SCASA#

TCLKA

2-17

Page 32

Addin Card Design

Configuration #2: Two rows of memory are supported in this configuration. If 256Kx32

components are used 4MB of memory is obtainable, if 512Kx32 is used, then 8MB is supported.

Note that both rows of memory receive different copies of each control signal, for loading reasons.

Figure 2-20. 4/8 MB Local Memory Connection (64-bit data path)

Intel740™ Chip

Intel740

MD[63:0]

CSx[A:B]# DQM[3:0] DQM[7:4] RCLKx OCLK

MA[11:0]

MD[31:0]

MD[63:32]

MD[31:0]

MD[63:32]

CS0A#

CS0A#

CS1A#

CS1A#

256K/512K X 32

256K/512K X 32

256K/512K X 32

256K/512K X 32

WEA#

SRASA#

SCASA#

TCLKA

WEA#

SRASA#

SCASA#

TCLKA

WEB#

SRASB#

SCASB#

TCLKB

WEB#

SRASB#

SCASB#

TCLKB

2-18

Intel740™ Graphics Accelerator Design Guide

Page 33

Configuration #3: One row of memory is supported in this configuration using 1Mx16 SDRAMs.

Only the maximum allowable amount of memory (8MB) is supported in this configuration. Note

that each copied signal is sent to only two components.

Figure 2-21. 8 MB Local Memory Connection (64-bit data path)

Intel740™ Chip

MD[63:0]

Addin Card Design

Intel740

MA[11:0]

CSx[A:B]# RCLKx OCLK

CS0A#

MD[15:0]

CS0B#

MD[31:16]

CS0A#

MD[47:32]

CS0B#

MD[63:48]

DQM[1:0]

DQM[3:2]

DQM[5:4]

1M X 16

1M X 16

1M X 16

1M X 16

DQM[7:6]

WEA#

SRASA#

SCASA#

TCLKA

WEB#

SRASB#

SCASB#

TCLKB

WEA#

SRASA#

SCASA#

TCLKA

WEB#

SRASB#

SCASB#

TCLKB

Intel740™ Graphics Accelerator Design Guide

2-19

Page 34

Addin Card Design

2.2.6.7 TV Out Interface

The TV out bus is the group of s ignals that carry dig itized display da ta from the Intel740

graphics accelerator to the Bt869 flicker filter TV-out component. This interface is shared with

the BIOS interface. Table 2-12 gives the maximum trace lengths between components.

Table 2-12. TV Out/ROMA Trace Lengths (See Figure 2-22)

Signal

ROMA[17:0] 0.0” 3.5” 0.0” 1.5” 0.0” 4.0”

Intel740™ to BIOS

Stub

Min Max Min Max Min Max

Figure 2-22. Layout Dimensions, Digital TV Bus

Intel740™

Intel740

Chip

0.0” - 3.5”

BIOS ROM

2.2.6.8 Analog Signals

It is recommended that all analog signal traces be 75Ω ±5%. It is important that these traces not

violate the 5x10 mil spacing for the 65Ω traces. Analog traces include the DAC R, G, B traces, all

of the inputs to the Bt829B component and outputs from the Bt869 component.

2.2.7 UL and FCC Considerations

BIOS Stub BIOS to Bt869

0.0” - 4.0”

Bt869

0.0” - 1.5”

2-20

Certain precautions should be taken in the design of the of a graphics card to ensure passing safety

and EMI tests. These precautions are listed below.

•

When a signal can be hot plugged, clamping diodes should be used to limit voltage spikes.

•

When a voltage leaves the card, a fuse should be placed in the path to protect from a short

circuit.

•

Sockets, Fans and Brackets should be grounded.

•

Separate Power Planes of the same voltage should be stitched together.

Intel740™ Graphics Accelerator Design Guide

Page 35

2.3 Addin Card Schematics

This section describes the Intel740™ Graphics Accelerator Reference Design Schematics. Please

read this section carefully to observe all design recommendations and requirements.

The description of each schematic page is named by the logic block shown on that page.

Cover Sheet (Schematic Page 1)

The Cover Shee t shows the schem atic page titles, page numbers, dis claimers and power pins.

Block Diagram (Schematic Page 2)

This page shows a block diagram overview of the Intel740 AGP card design. Schematic page

numbers for each of the major schematic components are shown.

Intel740™ Graphics Accelerator (Schematic Pages 3,4)

This page shows all of the connections to the Intel740 graphics accelerator. Each Intel740 graphics

accelerator interface is hooked up in this reference design. Beginning in the upper left hand corner

of the page, the video capture port is shown. Internally, the input pins are pulled down. These pins

contain a strapping option for subsystem ID. In this case the reference design has an ID of 0100h.

Bits that should be a “1” may be pulled up using a 2K pull-up resistor. If the graphics design will

not have video, the only concern is pu lling the bus up to the correct value for the subsys tem ID.

The video control signals may be left unconnected. The BIOS interface multiplexes the BIOS,

vendor ID, and flicker filter TV encoder. The ROMA lines are internally pulled down and may be

pulled up using a 2K pull-up resistor. The video host port connects directly to the VMI header. The

section labeled AGP interface connects directly to the AGP connector. The memory interfaces

connect to an SO-DIMM connector and memory components. Each of the 9 GPIOs serve a

different function in the reference design. Table 2-13 lists the function assigned to the GPIOs.

Addin Card Design

Table 2-13. GPIO Functions

GPIO FUNCTION

GPIO0 I

GPIO1 I

GPIO2 DDC Data

GPIO3 DDC Clock

GPIO4 Fan Fail

GPIO5 Extra For DVD Control

GPIO6 VP[15:0] Bus Isolation Control

GPIO7 Extra For DVD Control

GPIO8 Power Down

Decoupling for the Intel740 graphics accelerator is shown along the bottom of the schematic page.

2

C Data

2

C Clock

Intel740™ Graphics Accelerator Design Guide

2-21

Page 36

Addin Card Design

Voltage Regulator (Schematic Page 5)

This page shows the circuitry to convert from 3.3 Volts to 2.7 Volts. The regulator used in the

reference design does not need any heat sink for the FET. As shown, the FET will be dissipating

slightly over 1 watt. If a different voltage regulator solution will be used, calculations will be

needed to determine the need for a heatsink. Resistors R50, R44, R42, and R43 are only for the

reference card design. These resistors allow different voltage combinations for core and internal

Intel740 graphics accelerator PLLs. The table at the top of the page describes the voltage

configurations. Core decoupling is shown at the bottom of the page and should be placed close to

the Intel740 graphics accelerator.

Bt829B (Sch ematic Page 6 )

The Bt829B component contains analog inputs which require special routing requirements detailed

in Section 2.2.5, “Bt829 Video Decoder” on page 2-11. If these analog inputs are not used, then

they should be tied to ground as is MUX3 in the reference design. The I2CCS pin is pulled low in

the reference design to select an I

connecting other I

Note: Care must be taken to ensure that no two devices use the same address.

The QCLK output of the Bt829B obviates the need for connection to the VRDY input on the

Intel740 graphics accelerator as this clock “ANDs” the ACTIVE and CLK outputs of the Bt829B

together. The reference design is designed to support NTSC, PAL and SECAM. If only NTSC is

desired, the circuitry including Y1 can be removed and XT1I should be tied high or low with

XT1O left floating. If only PAL mode of operation is desired, XT1I should be tied high or low with

XT1O floating and Y2 should be replaced with Y1. Decoupling for the component is shown at the

bottom of the page.

2

2

C devices like the Bt869.

C address of 88h and 89h. This selection becomes important if

Bt869 (Schematic Page 7)

The Bt869 power supply is generated from the VCC3 supply. Decoupling for this supply is shown

at the top of the page. The componen t contains a 24-bit data port. The In tel740 gr aphics acceler ator

connects only to 12 of these bits. The functionality of this interface is described in the Intel740

Graphics Accelerator Datasheet. The slave input is tied to ground to place this chip in m aster mode.

If the digital port were to be used as a VMI port, the component should be placed in slave mode.

This page contains the only jumper in the design. This jumper selects which mode (PAL or NTSC)

the Bt869 will operate in. The PC ’98 specification recommends this jumper for designs where a

TV may be the only output display. The ALTADDR pin is pulled high so that the device responds

to an address of 8Ah. This address keeps this device from conflicting with the Bt829B’s I

2

C

address. Note that ROMA17 is wired to the CLKI pin while ROMA14 is connected to the CLKO

pin. ROMA17 is also called CLKOUT and ROMA14 is called CLKIN. The Intel740’s graphics

accelerator CLKOUT pin corresponds to the Bt869’s CLKI pin while the CLKIN pin corresponds

to the CLKO pin on the Bt869. The DAC lines have special routing requirements detailed in

section. These DAC lines allow the component to output S-Video and composite video.

VMI Video Connectors (Schematic Page 8)

The VMI video connectors are used for the attachment of a DVD daughter card or video capture

card. The capture port is connected to the 26 pin header while the bi-directional host port is

connected to the 40 pin header. The reference design uses a 2A fuse for the 3.3 volt supply to the

40 pin header. The 2A fuse is allowed for the 5 volt supply and 1A is allowed for the 12 volt

supply . GPIO5 an d GPIO7 com e to the h eader for added DVD daughter card functionality control.

GPIO8 is used for power down operation on the card. The I

2

C connections on the 26 pin header are

3.3 volt signals. Mechanical dimensions for the placement of the connectors is shown in

Section 5.3, “VMI Header Placement” on page 5-2.

2-22

Intel740™ Graphics Accelerator Design Guide

Page 37

Addin Card Design

AGP Card Edge (Schematic Page 9)

This page details the connections of AGP. All power is derived from this connector. Using the rule

of 1A per pin, the 12 volt supply is capable of supplying 1A, the 5 Volt supply is capable of

supplying 2A and the 3.3 Volt supply is capable of supplying 8A.

VGA Connector

(Schematic Page 10)

The VGA connector provides the RGB output to a monitor. BIOS and hardware provide support

for plug-and-play capability.

2

DDC/I

This page details the 3.3 volt/5 volt signal conversion as well as the DDC/I

C (Schematic Page 11)

2

C connections. To

perform the voltage translation, quick switches are used. The quick switches at the top of the page

serve a second function of isolating the VMI port from the Intel740 graphics accelerator. GPIO6

can tri-state this bus to preclude the possibility of contention between something connected to the

VMI header and the Bt829B.

SO-DIMM Connector (Schematic Page 12)

The SO-DIMM connector shows a fairly straight forward connection to the Intel740 graphics

accelerator memory signals. Note that the primary CS0 connection is tied to the Intel740 graphics

accelerator CSA1# signal. The CSB0# signal is connected to CS1 on the connector. The reference

design has the first row of memory down on the graphics card. The second row of memory is

assumed to be placed in the SO-DIMM connector.

Note: It is important not to have the memory on the graphics card and memory on the SO-DIMM

connector connected to the same row.

SGRAMS (Schematic Page 13)

The SGRAMs shown on this page are labeled as 512Kx32. The schematic pinout is actually

capable of supporting either the 512Kx32 or 256Kx32 SGRAMs. This dual-support connection is

achieved through the following method. The 512Kx32 Jedec standard defines AP on pin 51 which

is address 9. BS is on pin 29 and is also labeled as address 10. Addres s 8 is on pin 30. The Int el740

contains the AP on its address 8 pin and BS on address 9 pin. Since the 256Kx32 has AP with

graphics accelerator address 8 and on pin 51 along with BS with address 9 on pin 29 and a no

connect on pin 30, either the 512K or the 256K SGRAMs are capable of being supported in the

same design (see Figure 2-23).

Note: It is important to disable the special features of SGRAM. This will make the SGRAM operate as an

SDRAM, thus making it compatible with the Intel740 graphics accelerator.

Intel740™ Graphics Accelerator Design Guide

2-23

Page 38

Addin Card Design

Figure 2-23. 512Kx32 and 256Kx32 Pinout Compatibility

Intel740™

Intel740

Chip

A8/AP

A9/BS

A10

A7

.

.

A0

Intel740™

Chip

Intel740

A8/AP

A9/BS

A10

A7

.

.

A0

Figure 2-24. 1M X 16 Pinout Compatibility

Pin 51

Pin 29

Pin 30

Pin 51

Pin 29

Pin 30

A9/AP

A10/BS

A8

A7

.

.

A0

A8/AP

A9/BS

NC

A7

.

.

A0

512Kx32

SGRAM

Jedec

Standard

256Kx32

SGRAM

Jedec

Standard

2-24

Intel740™

Chip

A11/BS

A10/AP

A9

A8

.

.

.

A1

A0

A11

A10

A9

A8

A1

A0

Intel740™ Graphics Accelerator Design Guide

.

.

.

1M X 16

SDRAM

Page 39

Addin Card Design

Video Connector (Schematic Page 14)

This page shows a specially designed solution to the problem of too many connectors and not

enough board space. This 50 pin connector allows external hookup for a tuner , S-V ideo in, S-V ideo

Out, composite video in, and composite video out. The input connections feed to the Bt829B

component while the out connections come from the Bt869. Individual designs may or may not

have all possible connectors and, therefore, may not need this type of solution.

BIOS/FAN (Schematic Page 15)

This page shows the connections to the flash BIOS and fan power. The BIOS used in this design is

a PLCC socket for early debug capabilities. To use less board space a TSOP package may be the

preferred component. Since the selected part is a 5 volt part, the data lines are isolated from the

Intel740 graphics accelerator by a level shifter.

Note: The Intel740 graphics accelerator does not require a fan for AGP compliant systems. These

design features have been added for ease of use if the customer determines a fan is required. Refer

to the Thermal Application Note and software to determine the correct thermal solution.

The fan powerdown control is done through the use of a FET. Normal operation of the fan is

allowed by the 4.7 KΩ pull-up resistor (R26). If powerdown is desired, the GPIO8 pin will turn the

FET off. Pin 3 of the fan header allows the fan to signal the I ntel740 graphics accelerator that it has

failed.

Intel740™ Graphics Accelerator Design Guide

2-25

Page 40

Addin Card Design

2-26

Intel740™ Graphics Accelerator Design Guide

Page 41

A

A

B

B

C

C

D

D

E

E

4 4

3 3

2 2

1 1

INTEL740(TM) GRAPHICS ACCELERATOR FULL FEATURED REFERENCE CARD

TITLE

P.1

P.2

P.3

P.4

P.5

P.6

P.7

P.8

P.9

P.10

P.11

P.12

P.13

P.14

P.15

P.16

P.17

PAGE

COVER SHEET

BLOCK DIAGRAM

INTEL740(TM) GRAPHICS ACCELERATOR (A)

INTEL740(TM) GRAPHICS ACCELERATOR (B)

VOLTAGE REGULATOR

BT829B VIDEO DECODER

BT869 VIDEO ENCODER

VMI VIDEO CONNECTOR

AGP CONNECTOR

VGA CONNECTOR

VMI/DDC/I2C/FANFAIL LEVEL SHIFTER

SO-DIMM

SGRAM

VIDEO CONNECTORS

BIOS/FAN CONNECTOR

REVISION HISTORY

+12V = 12V ANALOG UNLESS OTHERWISE SPECIFIED

VCC = 5V DIGITAL UNLESS OTHERWISE SPECIFIED

VCC3 = 3.3V DIGITAL UNLESS OTHERWISE SPECIFIED

VDDQ = 3.3V AGP POWER SUPPLY

VCC_CORE = VOLTAGE SUPPLIED TO THE INTEL740 CHIP CORE

GND = DIGITAL GND

VCC

VCC3

VDD

THIS SPECIFICATION IS PROVEDED AS IS WITH NO WARRANTIES

WHATSOVER, INCLUDING ANY WARRANTY OF MERCHANTABILITY, FITNESS

FOR ANY PARTICULAR PURPOSE, OR ANY WARRANTY OTHERWISE ARISING

OUT OF PROPOSAL, SPECIFICATION OR SAMPLE.

NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO

ANY INTELLECTUAL PRPERTY RIGHTS IS GRANED HEREIN.

INTEL DISCLAIMS ALL LIABILITY, INCLUDING LIABILITY FOR

INFRINGEMENT OF ANY PROPRIETARY RIGHTS, RELATING TO USE OF

INFORMATION IN THIS SPECIFICATION. INTEL DOES NOT WARRANT

OR REPRESENT THAT SUCH USE WILL NOT INFRINGE SUCH RIGHTS.

I2C IS A TWO-WIRE COMMUNICATIONS BUS/PROTOCOL DEVELOPED BY

PHILIPS. SMBUS IS A SUBSET OF THE I2C BUS/PROTOCOL AND WAS

DEVELOPED BY INTEL. IMPLEMENTATIONS OF THE I2C BUS/PROTOCAL

OR THE SMBUS BUS/PROTOCOL MAY REQUIRE LICENSES FROM VARIOUS

ENTITIES, INCLUDING PHILIPS ELECTRONICS N.V. AND NORTH

AMERICAN PHILIPS CORPORATION.

*THIRD-PARTY BRANDS AND NAMES ARE THE PROPERTY OF THEIR

RESPECTIVE OWNERS.

COPYRIGHT * INTEL CORPORATION 1997

+12V

Intel740(TM) Graphics Accelerator Reference Card

2.1

Cover Sheet

C

1 16Thursday, April 09, 1998

Title

Size Document Number Rev

Date: Sheet of

Page 42

A

A

B

B

C

C

D

D

E

E

4 4

3 3

2 2

1 1

VIDEO CONNECTORS

p. 14

VIDEO

DECODER

p. 6

VMI CONNECTOR

p. 8

VOLTAGE REGULATOR

p. 5

SO-DIMM

p. 12

A.G.P. CONNECTOR

p. 9

VGA/DDC

CONNECTOR

p. 10

TV TUNER

CONNECTOR

p. 14

VIDEO

ENCODER

INTEL740(TM)

Graphics Accelerator

p. 3, 4

p. 7

p. 13

GRAPHICS

MEMORY

FLASH

p. 15

BIOS

CNTL

ADDR

DATA

ADDR/DATAA

ADDR/DATA

CNTL

AGP SIDEBAND

Intel740(TM) Graphics Accelerator Reference Card

2.1

Block Diagram

B

2 16Thursday, April 09, 1998

Title

Size Document Number Rev

Date: Sheet of

Page 43

A

A

B

B

C

C

D

D

E

E

4 4

3 3

2 2

1 1

INTEL740 (A)

VENDOR ID IS 0X8086

NOTE:

----THIS I.D. NEEDS TO

REFLECT BOARD VENDOR

SUBSYSTEM ID IS 0X100

1%

1%

1%

USE TANTALUM CAPACITORS FOR 10 AND 22UF

Intel740(TM) Graphics Accelerator Reference Card

2.1

Intel740(TM) Graphics Accelerator(A)

C

3 16Thursday, April 09, 1998

Title

Size Document Number Rev

Date: Sheet of

TP_03J26

SBA7

SBA1

ROMA7

ROMA2

TP_03L24

AD21

3VVP14

AD30

AD22

AD12

ROMA13

ROMA5

3VVP2

ROMA0

SBA4

AD2

ROMA11

3VROMD4

3VROMD2

3VROMD0

AD26

AD17

AD6

ROMA14

ROMA9

3VVP3

AD31

AD5

AD3

3VVP7

3VVP4

3VVP0

3VROMD1

ST1

SBA6

AD23

AD4

IREFSET#

SBA0

AD28

AD13

3VVP11

ROMA15

AD1

ROMA8

ROMA1

ST0

AD27

AD25

AD19

ROMA10

ROMA6

VMIHA3

AD20

AD8

ROMA16

SBA5

SBA3

3VVP12

ROMA4

ROMA3

VMIHA0

AD9

AD7

3VVP9

3VVP5

VMIHA4

VMIHA2

TP_03L23

3VVP15

AD10

AD15

3VVP8

AD14

ST2

AGPREF

3VROMD5

AD29

ROMA17

3VROMD3

AD24

AD18

3VVP10

ROMA12

VMIHA1

SBA2

AD11

3VVP13

AD16

3VVP6

AD0

3VROMD7

3VROMD6

3VVP1

VCC3

VCC3

VDDQ

VCC_CORE VCC3 VDDQ VCC3

VCC3

VDDQ

VDDQ

VCC3

VCC3

R22

2K

R472KR522KR512KR55

2K

C127

.01UF

R60

182

R59

267

R24

562

AGP INTERFACE

VIDEO CAPTURE